Page 1

User’s Manual

Laser Bar Code Reader

96M11884

BL-700 Series

Page 2

Introduction

Symbols

This instruction manual describes the operation and function of the BL-700. Read

this manual carefully to ensure safe use and maximum performance from your BL-

700. The BL-700 series uses a semiconductor laser as light source. Before using

the product, see "Safety Precautions on Laser Product" on page 1 to learn the safe

and correct method of using the BL-700 series.

The following symbols alert you to important messages. Be sure to read these

messages carefully.

WARNING

CAUTION

Note:

Failure to follow instruction may lead to injury. (electric

shock, burn, etc.)

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

Safety Information for BL-700 Series

General Precautions

• Do not use this product for the purpose to protect a human body or a part of

human body.

• This product is not intended for use as explosion-proof product. Do not use this

product in a hazardous location and/or potentially explosive atmosphere.

• At startup and during operation, be sure to monitor the functions and

performance of the BL-700.

• We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the BL-700 or use it in any way other than described in

the specifications.

• When the BL-700 is used in combination with other instruments, functions and

performance may be degraded, depending on operating conditions and the

surrounding environment.

i

Page 3

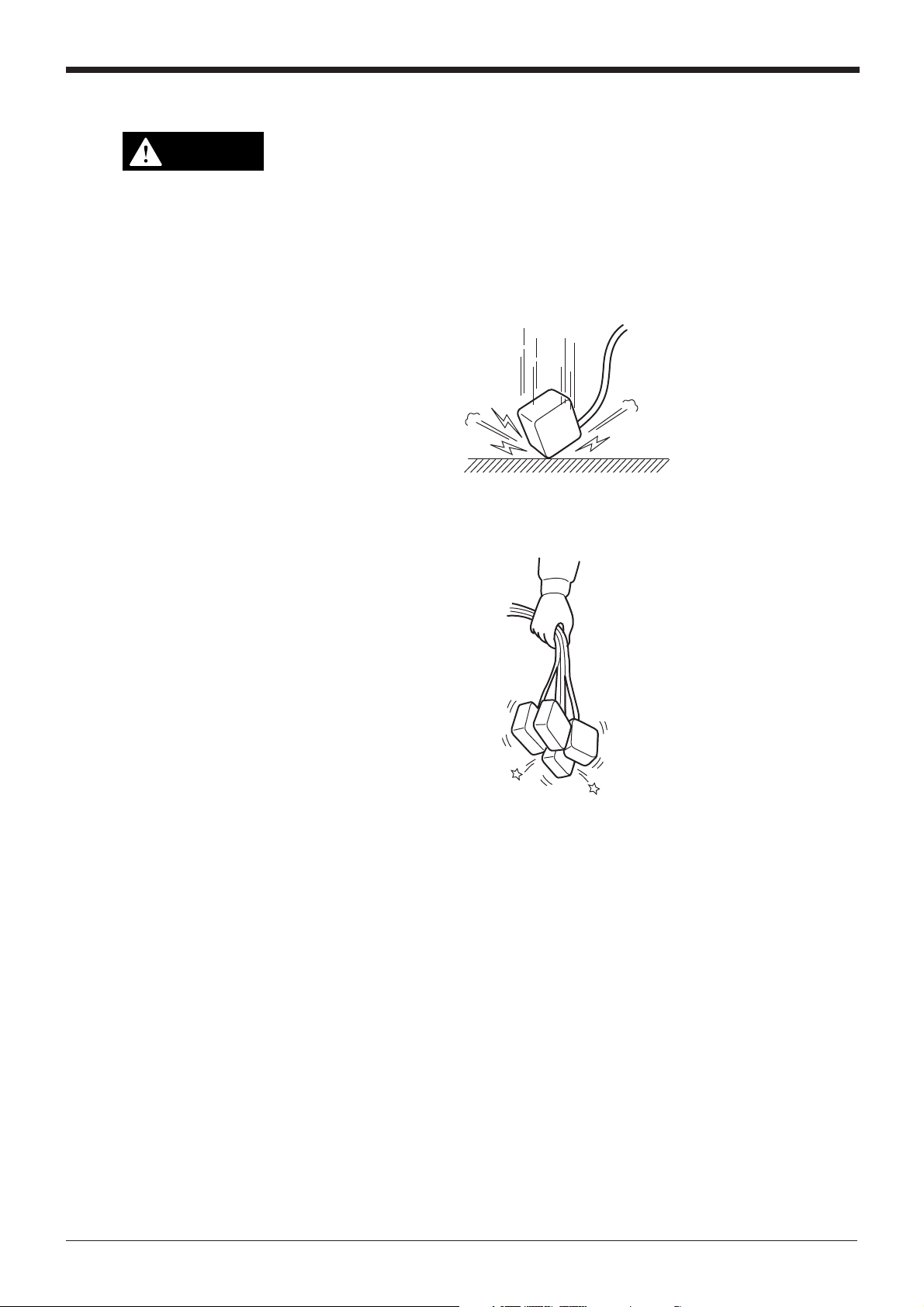

Warnings and Cautions Specific to the BL-700

• The BL-700 uses a 5 VDC power supply. Using a different voltage level

CAUTION

may damage the unit.

When using the KEYENCE power supply unit BL-U1, BL-U2, N-42 or N-48,

select the voltage level which can be supplied by the power supply unit. If

a nonconforming power supply is connected, the BL-700 may be damaged.

• The BL-700 is a precision instrument. If the unit is dropped or shocked, it

may be damaged. Take due consideration when transporting or installing

the unit.

Incorrect

• Do not hold the cables when carrying the units. The units may hit each

other and become damaged.

Incorrect

• Before installing the BL-700, read “2.4 Installation” of this manual carefully to

select a suitable installation site.

• You cannot perform any operation for 5 seconds after turning ON the BL-700.

During this time, the motor rotation stabilizes. Wait for a while after turning ON

the BL-700, then start reading or another operation.

• At shipment, the protective seals are affixed to the transmitter and receiver to

avoid fingerprints when mounting the unit. Be sure to remove the seals before

use.

• Do not allow water, oil or dust to adhere to the transmitter and receiver. Adhesion of these materials may cause a reading error. If the surface is contaminated, gently wipe it with a soft cloth moistened with alcohol.

96M11884

ii

Page 4

Package Contents List

The package contains the following components. Be sure to check the package

contents against the checklist before use.

■ BL-700 package

• BL-700 unit ................................................................................................ 1

• Mounting bracket ......................................................................................1

• Mounting screw ......................................................................................... 2

• Insulating spacer ....................................................................................... 4

• Washer ...................................................................................................... 4

• Laser warning label (Japanese/English/German) ............................... 1 set

■ BL-U1 package

• BL-U1 unit .................................................................................................1

■ BL-U2 package

• BL-U2 unit .................................................................................................1

• D-sub 9-pin connector, connector case .................................................... 1

• Instruction manual ..................................................................................... 1

■ N-42 package

• N-42 unit ...................................................................................................1

• Instruction manual ..................................................................................... 1

■ Setup software, user’s manual (BL-H1WE)

• Setup software (3.5-inch, 1.44 MB) ..........................................................1

• User’s manual (this manual) ..................................................................... 1

iii

Page 5

BL Series Lineup

■ Laser bar code reader

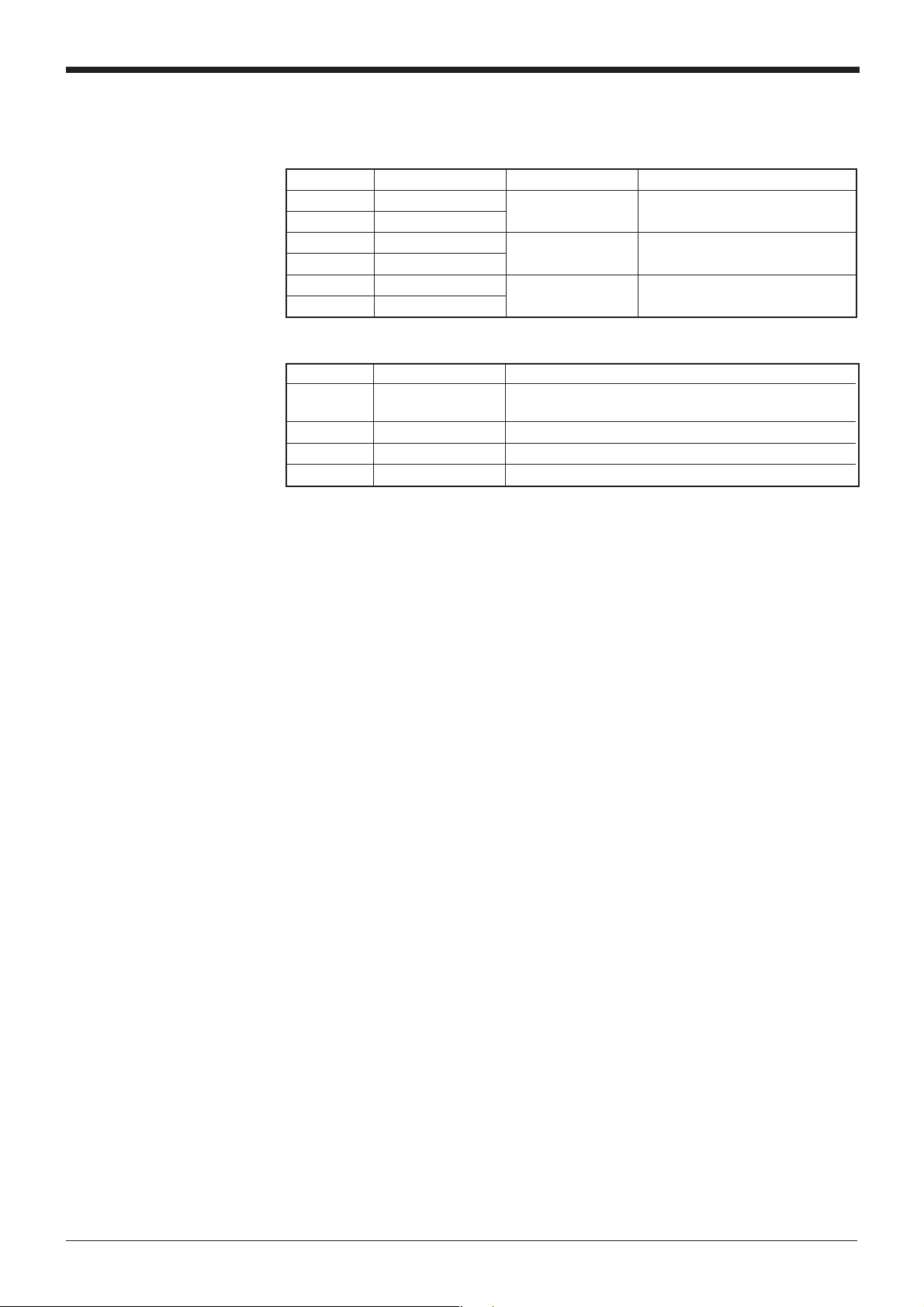

Model Scanning method Readable bar width Reading distance

BL-700 Single 0.15 to 1.0 mm 160 to 370 mm

BL-701 Raster (When narrow width is 0.5 mm)

BL-740 Single 0.25 to 2.0 mm 150 to 750 mm

BL-741 Raster (When narrow width is 1.0 mm)

BL-780 Single 0.32 to 2.0 mm 200 to 1200 mm

BL-781 Raster (When narrow width is 2.0 mm)

■ Power supply

Model Supply voltage Interface

BL-U1 100 to 240 VAC RS-232C, RS-422A, RS-485 multi-drop

* Select one of these.

BL-U2 24 VDC RS-232C

N-42 24 VDC RS-422A

N-48 24 VDC RS-485 multi-drop

■ Other options

• N-400: Multi-drop controller

Used as the master unit when multi-drop linking with the BL series.

• BL-P2E: Handheld programmer specially designed for the BL series.

Used when changing the BL-series or N-400 settings.

• OP-22149 : D-sub 25-pin (male) — D-sub 25-pin (male) RS-232C cross cable

Connects the BL-U1 to the PC (use with OP-25057).

• OP-25057 : D-sub 25-pin — D-sub 9-pin conversion connector

Used in conjunction with OP-22149 when connecting the BL-U1 to

the DOS PC.

• OP-27937: D-sub 9-pin — D-sub 9-pin RS-232C cross cable

Connects the BL-U2 to the DOS PC.

iv

Page 6

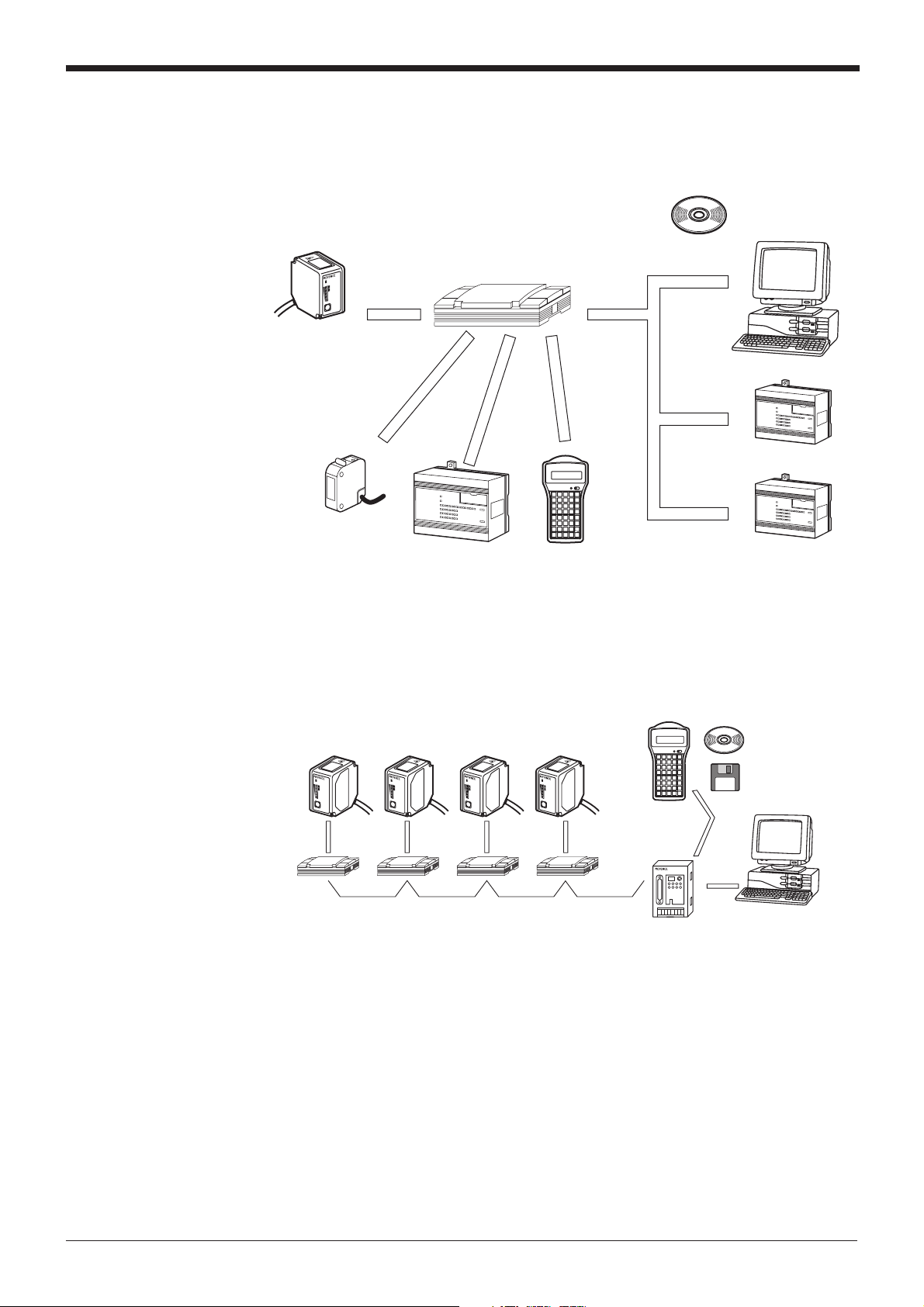

System Configuration

■ When using RS-232C or RS-422A

BL-700

LASER ON

STB

TEST

Timing sensor

OK/NG

TIMING

BL-700

Trigger input

BL-U1, BL-U2, N-42

Power supply unit

OK/NG

output

PLC etc. Handheld

programmer BL-P2E

Setup software

for BL series

(BL-H1WE)

Windows version

Serial

communication

RS-232C

RS-422A

Serial

communication

PLC (RS-232C/422A unit)

PLC link

IBM PC/AT

or compatible

PLC (Link unit)

* Use the BL setup software or the handheld programmer BL-P1E to set the BL

series.

Handheld programmer

BL-P2E

BL setup software

BL-700

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

Windows version

N-400 setup software

Windows version

PC

Multi-drop

controller N-400

Power supply unit

BL-U1, N-48

RS-485

RS-232C

■ When using the RS-485 multi-drop link

* Use the N-400 setup software or handheld programmer BL-P2E to set the multi-

drop controller N-400.

* For system configuration for the multi-drop link, see the “N-400 User’s Manual”.

Also, for connection and operation of the multi-drop link controller, see the “N400 User’s Manual”. The BL-700 User’s Manual does not cover these subjects.

v

Page 7

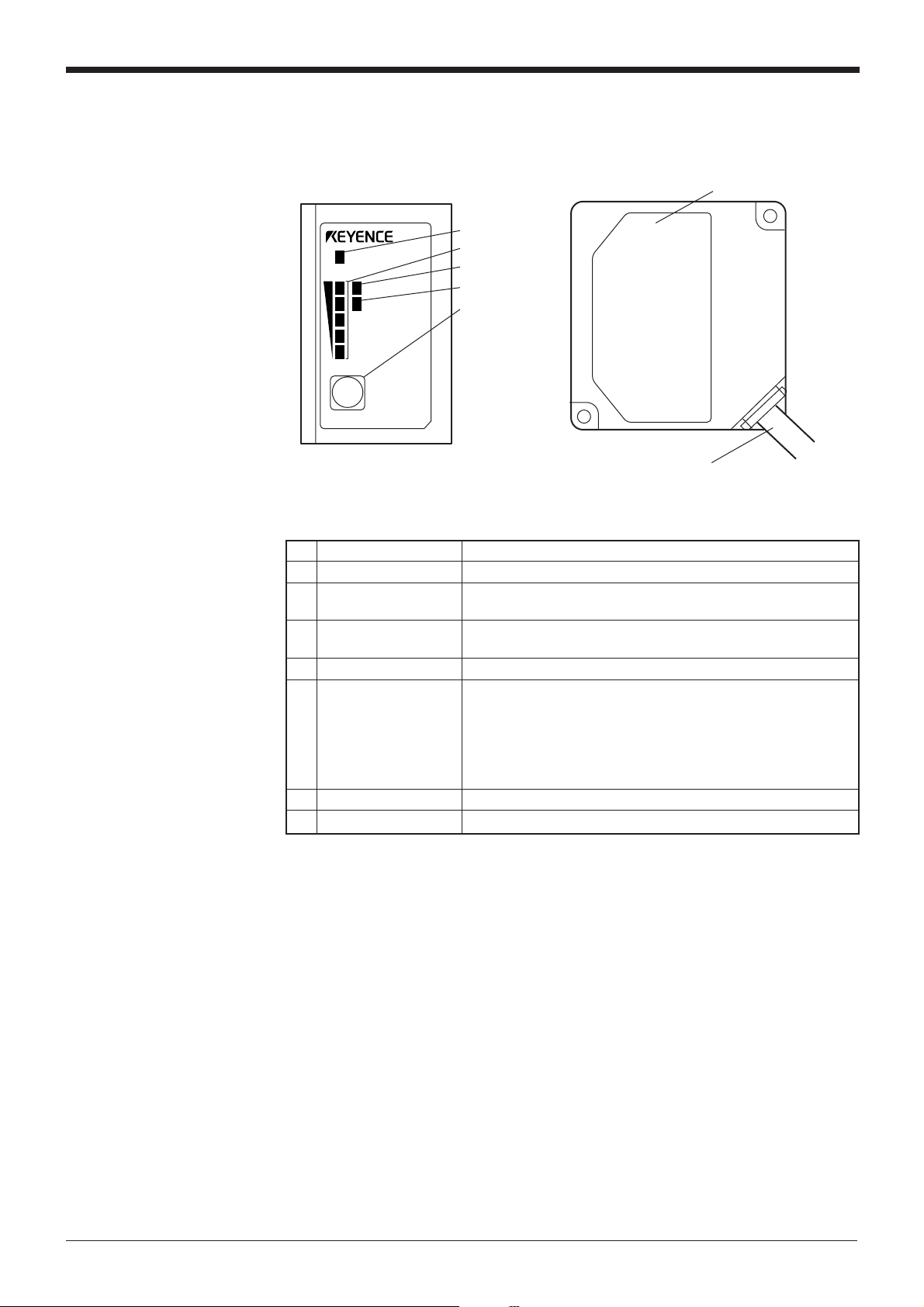

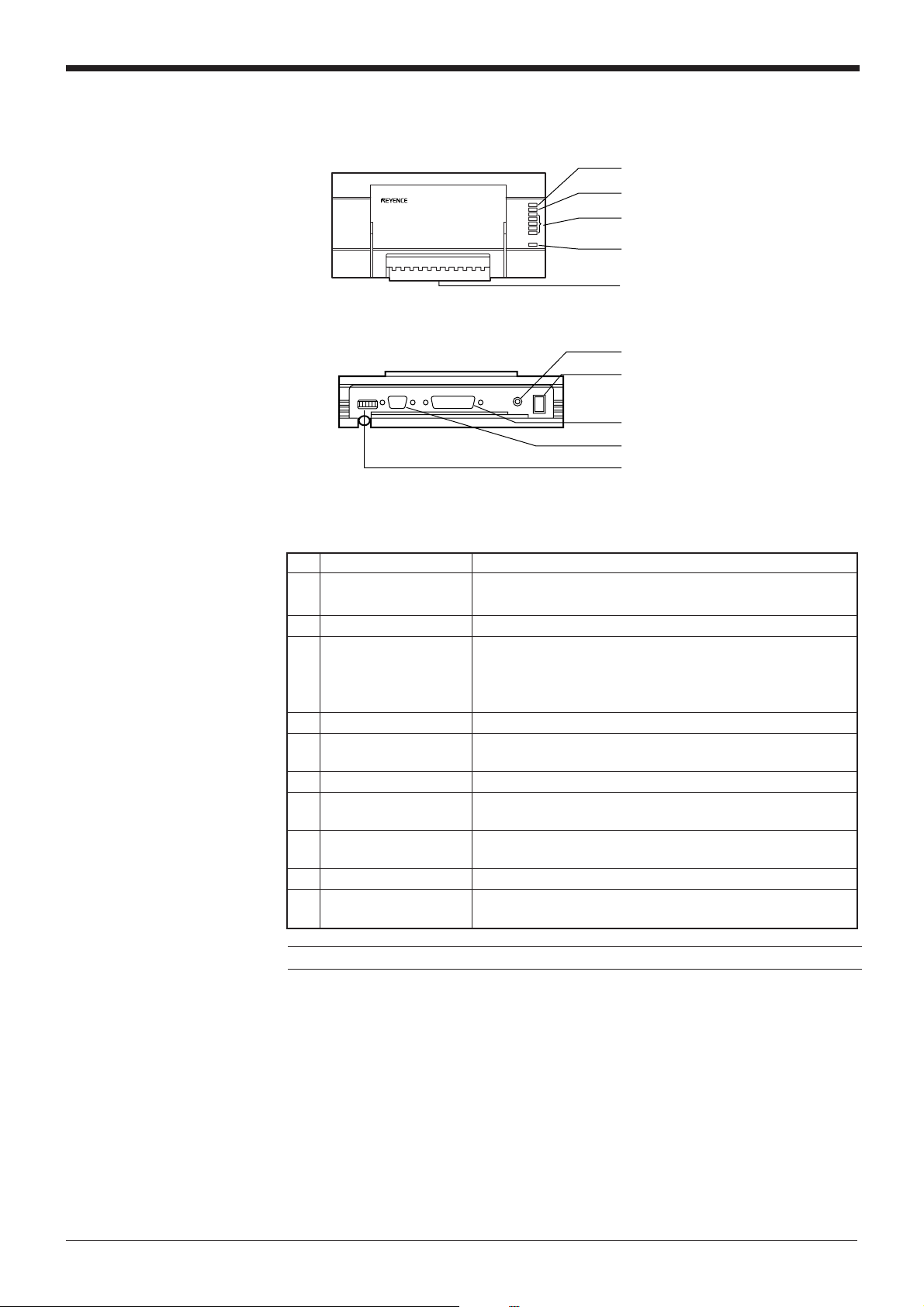

Parts and Functions

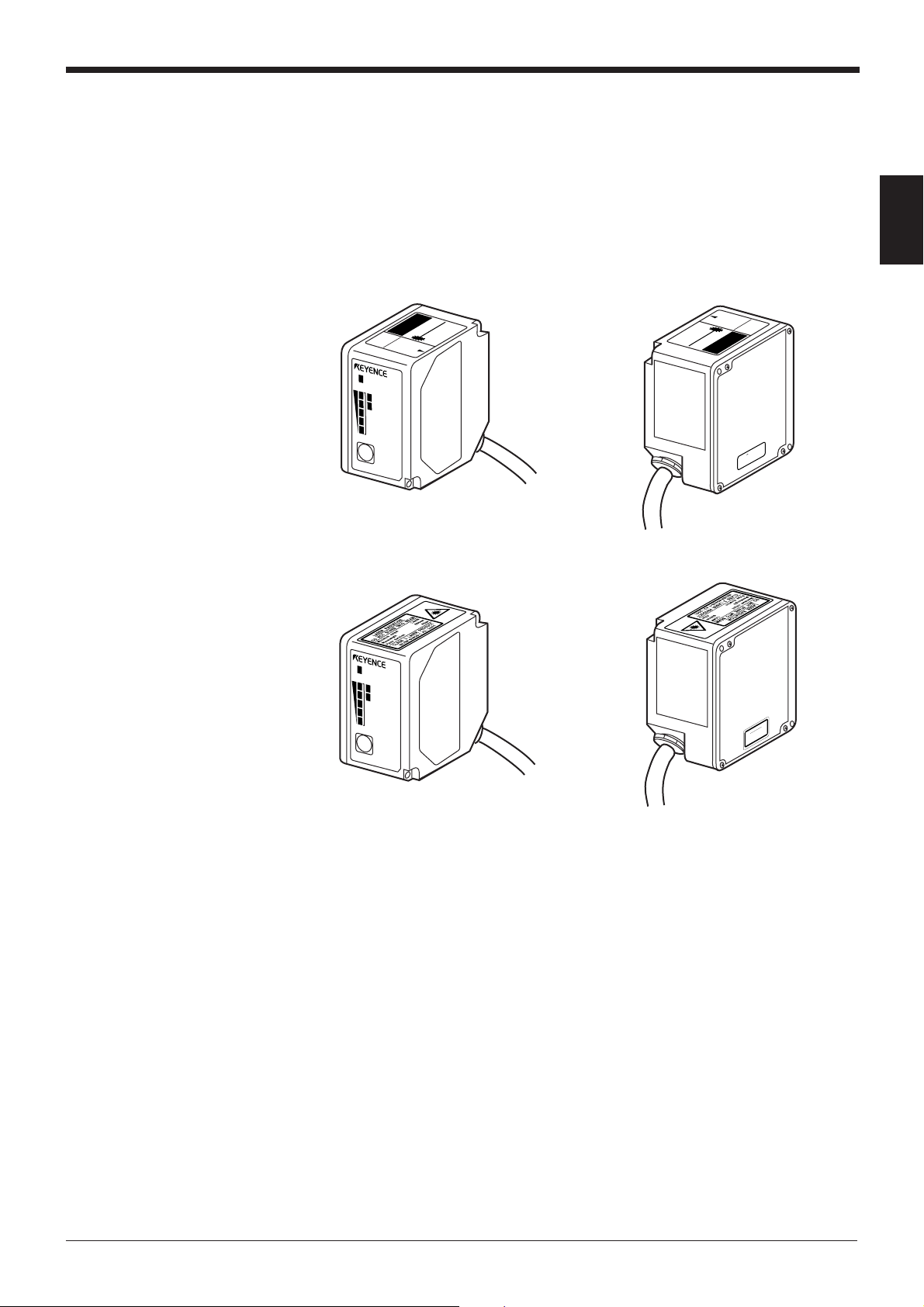

BL-700

No. Name Function

1 LASER ON LED Lit when laser beams are emitted.

2 STABILITY LED Displays the reading stability and the BL-700 operating status.

3 OK/NG LED • When OK output is ON: The green LED lights.

4 TIMING LED Lit when trigger input is ON.

5 TEST SWITCH This switch allows the following operations:

6 Transmitter/receiver Window to emit laser beams and receive reflected lights.

7 Cable Cable length is 1.8 m.

STB

TEST

LASER ON

OK/NG

TIMING

BL-700

6Transmitter/receiver

1LASER ON LED

2STABILITY LED

3OK/NG LED

4TIMING LED

5TEST switch

7 Cable

➮

See P. 64 to P. 65

• When NG output is ON: The red LED lights.

• Start the test mode.

• Pressing the switch once reads the bar code once.

• Sets the communication protocol to the initial values when

sending the settings.

• Reset the error status.

➮

See P.75

➮

See P.45

vi

Page 8

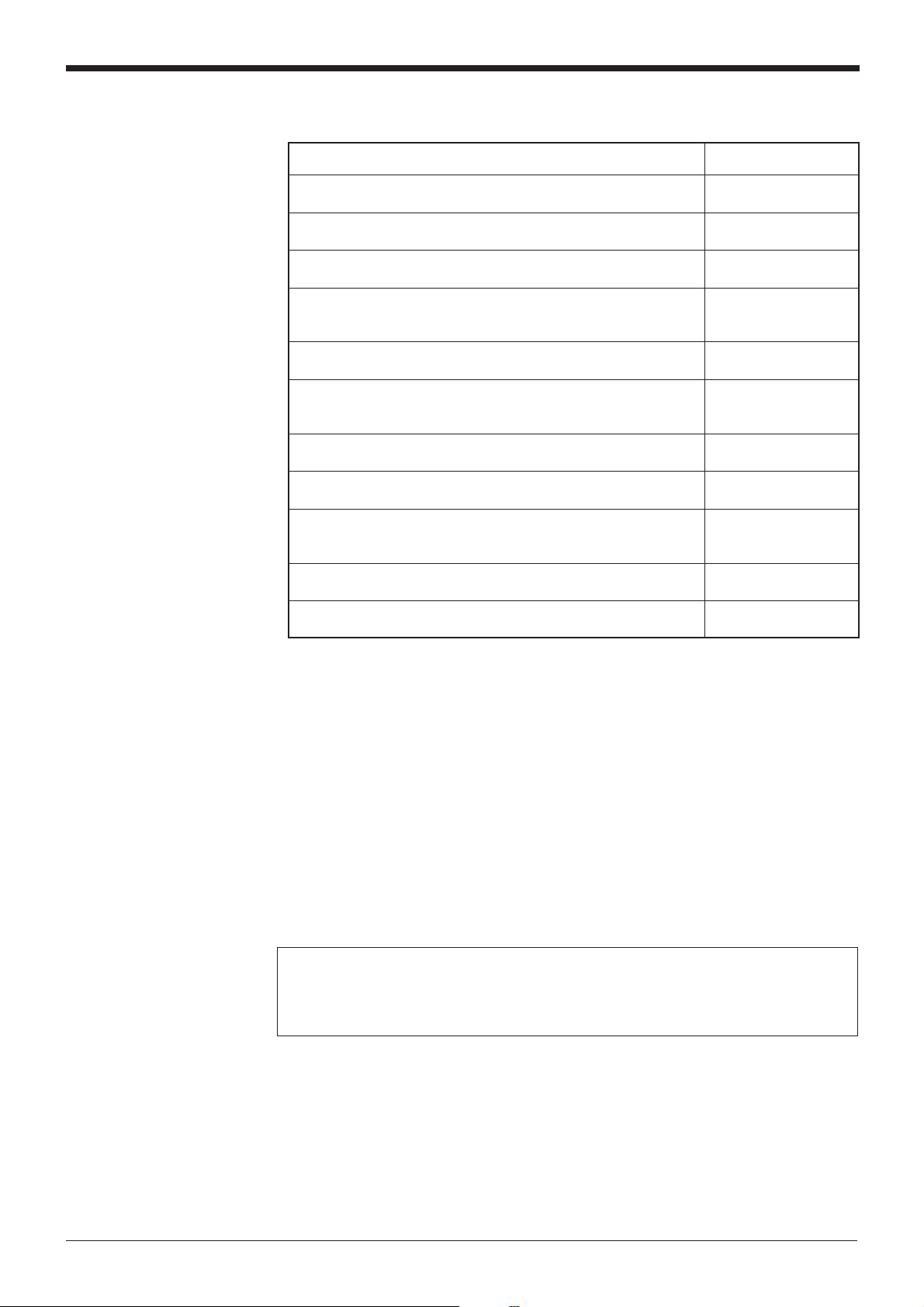

BL-U1

1 OK/NG LED

2 TIMING LED

3 Communication status indicator

LEDs

4 POWER LED

5 I/O terminal block

6 Power switch

7 Power supply cable (2 m)

8 RS-232C port

9 READER port

0 DIP switches

No. Name Function

1 OK/NG LED • When OK output is ON: The green LED lights.

• When NG output is ON: The red LED lights.

2 TIMING LED Lit when trigger input is ON.

3 • Allows you to monitor the communication status of the

Communication status

indicator LEDs

RS-232C port.

• The SD, RD, RS and CS indicators are provided in this

order from the top.

4 POWER LED Lit when power is ON.

5 I/O terminal block Includes the trigger input terminal, OK/NG output terminals,

RS-422A terminal and RS-485 terminal.

6 Power switch Turns the power ON/OFF.

Power supply cable

7 Use a 100 to 240 VAC (50/60 Hz) power supply.

(2 m)

8 RS-232C port Connect a personal computer to this port. This port is

unused in multi-drop link mode.

9 READER port Connect the BL series to this port.

0 DIP switches Switches the communication port, and turns the terminator

ON/OFF.

Note: This product does not comply with EC directives.

vii

Page 9

BL-U2

1 READER port

2 TRIGGER input

terminals

3 OK/NG output

terminals

POWER

BL-U2

4 Power supply

terminals

READER

SD

RD

RS-232C

7 RS-232C port

5 POWER LED

6 Communication

status indicator LEDs

No. Name Function

1 READER port Connects to a BL series bar code reader.

2 TRIGGER Connect to a sensor for input terminals

trigger input.

3 OK/NG output terminals Output OK/NG signals.

4 Power supply terminals Connect to a 24 VDC power supply.

5 POWER LED Turns on when the power is on.

6 Communication status Indicate the communication status of the RS-232C.

indicator LEDs

7 RS-232C port Connects to a personal computer, etc.

N-42

1 READER port

2 TRIGGER input

terminals

3 OK/NG output

terminals

4 Power supply terminals

READER

POWER SD RD

ON

OFF

7 POWER LED

6 Communication

status indicator

LEDs

5 Terminator switch

No. Name Function

1 READER port Connects to a BL series or RS-232C equipment.

2 TRIGGER input terminals Connect to a sensor for trigger input.

3 OK/NG output terminals Output OK/NG signals.

4 Power supply/ interface The 24 VDC power supply terminal and communi-

terminal block cation interface (RS-422A or RS-485) terminal are

provided.

5 Terminator switch Turns ON/OFF the terminator resistor: 100 ).

6 Communication status Indicates the RS-422A or RS-485 communication

status.

7 POWER LED Lights when the power is turned ON

viii

Page 10

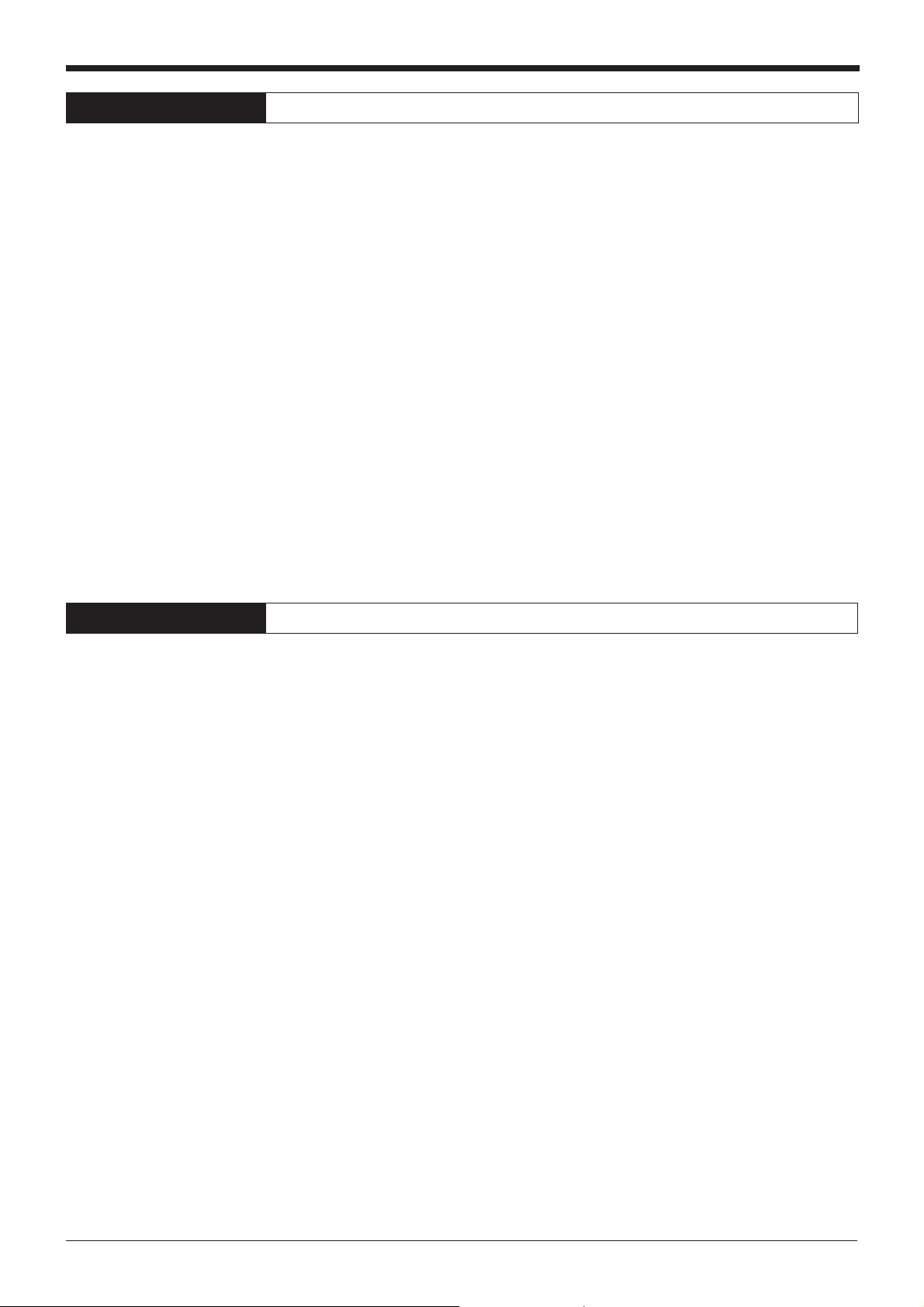

Using the Manual

Purpose Reference page

Turn on the trigger timing or wire the RS-232C cable. P.6 to 24

Mount the bar code reader. P.25 to 29

Perform the simple read test. P.40

Check the test mode reading rate or readout count on the P.81

PC screen.

Change the BL-700 settings using the setup software. P.51 –

Change the BL-700 settings through the handheld programmer See the BL-P2E

BL-P2E. User’s Manual.

Communicate with a PC. P.105 –

Control the BL-700 with the PLC link. P.121 –

Use the BL-700 with the multi-drop link. See the N-400

User’s Manual.

Notice

Troubleshooting P.136

PLC link communication setup. P.118

* This manual uses the expression “BL-700” for the BL-700/701/740/741/780/781

unless otherwise specified.

• No part of this instruction manual may be reprinted or reproduced without the

prior written permission of KEYENCE CORPORATION.

• KEYENCE assumes no responsibility for the contents of this manual. No liability

is assumed for damages resulting from a program created by customers.

• The contents of this manual are subject to change without notice.

• “MS”, “Windows” and “Windows95” are registered trademarks of Microsoft,

U.S.A.

• Other company names and product names are registered or nonregistered

trademarks of respective companies.

ix

Page 11

Contents

Chapter 1 Safety Precautions on Laser Product

Chapter 2 Connection and Installation

1.1 Classification .......................................................................................... 2

1.2 Warning Labels ...................................................................................... 2

1.3 Label Location ........................................................................................ 3

1.4 Safety Consideration ............................................................................. 4

1.5 Safety Measures Provided with the BL-700 Series .............................4

2.1 BL-700 connections ...............................................................................6

2.1.1 Connector pin assignment ........................................................................6

2.1.2 Power supply connections ........................................................................6

2.1.3 Wiring I/O .................................................................................................. 7

2.1.4 RS-232C connection................................................................................. 7

2.2 Connecting BL-U1 and wiring ............................................................... 8

2.2.1 Connecting the power supply.................................................................... 8

2.2.2 Connecting the BL-700 .............................................................................8

2.2.3 Setting BL-U1 DIP switches...................................................................... 9

2.2.4 Terminals of I/O terminal block and wiring.............................................. 10

2.2.5 Connecting RS-232C .............................................................................. 11

2.2.6 Wiring the RS-422A ................................................................................14

2.3 Wiring the KEYENCE power supply unit BL-U2/N-42 .......................16

2.3.1 Connecting the power supply.................................................................. 16

2.3.2 Connecting the BL-700 to BL-U2/N-42 ...................................................16

2.3.3 Terminals of I/O terminal block and connections .................................... 17

2.3.4 Terminal .................................................................................................. 18

2.3.5 Connecting RS-232C (BL-U2) ................................................................ 18

2.3.6 Connecting the N-42 to RS-422A ........................................................... 21

2.4 Installation ............................................................................................ 23

2.4.1 Operating environment precautions........................................................ 23

2.4.2 Installing the BL-700 Series .................................................................... 25

2.4.3 Installing the BL-U1................................................................................. 27

2.4.4 Installing the BL-U2, N-42....................................................................... 27

x

Page 12

Chapter 3 Functions for Reading Operation

3.1 Read Operation .................................................................................... 30

3.1.1 Scanning method .................................................................................... 30

3.1.2 Data-send mode ..................................................................................... 32

3.2 Read Modes ..........................................................................................33

3.2.1 Single label read mode ...........................................................................33

3.2.2 Multi-label read mode 1 (Multi 1) ............................................................ 33

3.2.3 Multi-label read mode 2 (Multi 2) ............................................................ 34

3.2.4 Multi-label read mode 3 (Multi 3) ............................................................ 35

3.3 Label Orientation Mode........................................................................... 37

3.4 Test Mode ............................................................................................. 38

3.4.1 Reading rate check mode ....................................................................... 38

3.4.2 Tact check mode..................................................................................... 39

3.4.3 Online test mode..................................................................................... 41

3.5 STABILITY LEDs .................................................................................. 42

3.6 Preset Function (Compare with:) .......................................................44

3.6.1 What is the preset function? ................................................................... 44

3.6.2 Wildcard Symbols (“!” and “?”) ...............................................................45

3.7 Additional Information ......................................................................... 46

3.8 Max. Code Length (Designated Digit ) Output Function .................. 48

Chapter 4 Setup Software

4.1 Installing the Setup Software .............................................................. 50

4.1.1 Installing setup software ......................................................................... 50

4.1.2 Installation procedure.............................................................................. 50

4. 2 Setup Software Operating Procedure ................................................ 52

4.2.1 Operating procedure ............................................................................... 52

4.2.2 Description on each setup screen........................................................... 53

4.2.3 Outline of operation................................................................................. 54

4.3 Details of Setup ....................................................................................56

4.3.1 Setup procedure ..................................................................................... 56

4.3.2 Reading/Saving/Printing File................................................................... 69

4.4 Sending/Receiving Settings ................................................................ 73

4.5 Using Monitor .......................................................................................77

4.6 List of Error Messages ........................................................................ 80

4.7 Example of Printing from the Setup Software ................................... 81

xi

Page 13

Chapter 5 Serial Communication

5.1 Serial Communication ......................................................................... 84

5.2 Details on Data Communication .........................................................85

5.3 Command Communication ................................................................. 88

5.3.1 Setup of Direct Control Commands ........................................................88

5.3.2 Details on Parameter Setting Commands............................................... 92

Chapter 6 PLC Link

6.1 PLC Link .............................................................................................104

6.1.1 List of PLCs used for PLC link ..............................................................104

6.1.2 Devices used for PLC link..................................................................... 105

6.2 Setting the BL-700 and PLC ..............................................................106

6.2.1 Setting the BL-700 series...................................................................... 106

6.2.2 Setting the PLC..................................................................................... 106

6.3 Device Assignment ............................................................................ 109

6.4 PLC Link Error .................................................................................... 116

6.5 Communication Time ........................................................................117

Appendices

Appendix A Specifications .......................................................................120

Appendix A.1 Specifications .......................................................................... 120

Appendix A.2 Reading range characteristics (Typical) .................................. 122

Appendix A.3 Angular characteristics (Typical) ............................................. 125

Appendix B. BL-U1 Specifications ............................................................ 126

Appendix C. BL-U2, N-42 Specifications .................................................. 127

Appendix D. Dimensions ........................................................................... 128

Appendix E. Example Program for Serial Communication .................... 131

Appendix F. Sample Program for the PLC Link ...................................... 132

Appendix G. Troubleshooting ................................................................... 135

Appendix H. CODE93 Specifications ........................................................ 137

Appendix I. CODE128 Specifications ...................................................... 138

Appendix J. Checksum Calculation Method ........................................... 139

Appendix K. ASCII Code Table .................................................................. 141

Appendix L. Setup Parameter List ............................................................ 142

Appendix M. Default Setting List ............................................................... 145

Chapter 7 Warranty

Warranty ..................................................................................................147

xii

Page 14

xiii

Page 15

Chapter 1

Safety Precautions on Laser Product

1.1 Classification ........................................................................ 2

1.2 Warning Labels ..................................................................... 2

1.3 Label Location ...................................................................... 3

1.4 Safety Consideration ............................................................ 4

1.5 Safety Measures Provided with the BL-700 Series ............ 4

Page 16

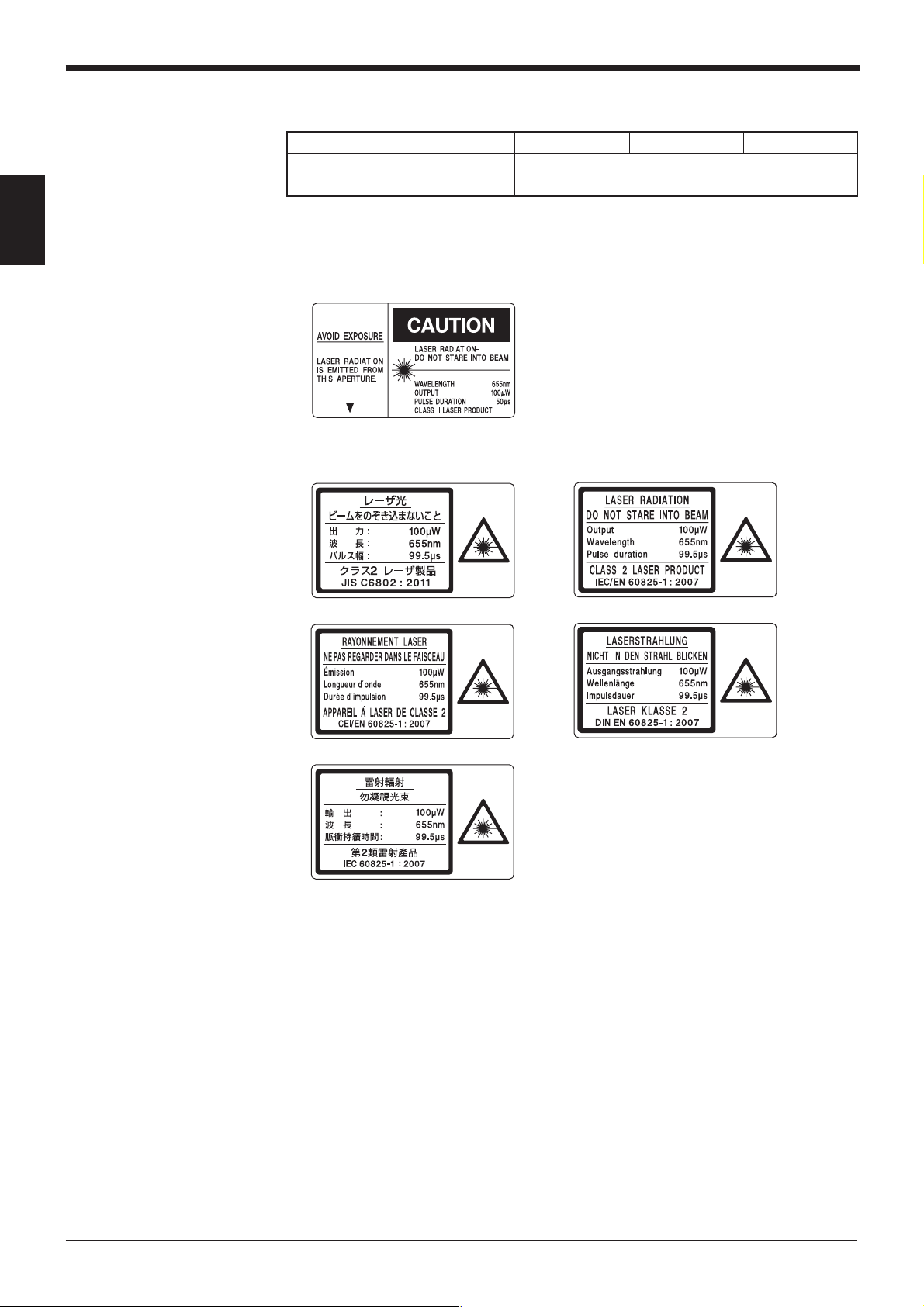

Chapter 1 Safety Precautions on Laser Product

1.1 Classification

Model BL-700/701 BL-740/741 BL-780/781

FDA(CDRH) Part 1040.10 Class II Laser Product

EN60825-1 Class 2 Laser Product

1

1.2 Warning Labels

■ FDA(CDRH)

■ IEC

Japanese English

French German

Chinese (Traditional)

2

Page 17

1.3 Labels Location

CAUTION LASER RADIATION

WHEN OP

EN.

DO NOT

STARE INTO BEAM.

LASER RADIATION-

DO NOT STARE INTO BEAM

SEMICONDUCTOR LASER 650nm

MAXIMUM OUTPUT 1.4mW

PULSED RADIATION 91

µm

CLASS II LASER PRODUCT

CAUTION

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

Laser radiation when

open. D

o not stare

into beam

.

A FDA(CDRH) warning label is affixed to the product.

When using this product in the countries and/or regions other than U.S., use the

IEC warning/explanatory label in the package of this product. In this case, it can be

affixed on the FDA (CDRH) warning label, which has already been affixed to this

product.

■ FDA(CDRH)

Chapter 1 Safety Precautions on Laser Product

1

■ IEC

STB

STB

TEST

LASER ON

TEST

LASER ON

OK/NG

TIMING

OK/NG

TIMING

AVOID EXPOSURE

LASER RADIATION

BL-700

BL-700

CAUTION

LASER RADIATION-

DO NOT STARE INTO BEAM

IS EMITTED FROM

THIS APERTURE.

CTOR LASER 650nm

UTPUT 1.4mW

SEMICONDU

MAXIMUM O

PULSED RADIATION 91

CLASS II LASER PRODUCT

µm

3

Page 18

Chapter 1 Safety Precautions on Laser Product

1.4 Safety Consideration

WARNING

1

Use of controls or adjustment or the performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Precautions on Class II/2 Laser Product

• Do not stare into the beam.

• Do not direct the beam at people or into areas where people might be present.

• Be careful of the path of the laser beam. If there is a possibility that the operator

may be exposed to the specular or diffuse reflections, block the beam by

installing a protective enclosure.

• Install the products so that the path of the laser beam is not as the same height

as that of human eye.

• Do not disassemble this product. Laser emission from this product is not automatically stopped when it is disassembled.

1.5 Safety Measures Provided with the BL-700 Series

The BL-700 Series is provided with the following safety measures. Make sure

these measures function correctly before operating.

• Laser emission caution LED (LASER ON LED)

During laser emission, the LASER ON LED illuminates. The LED ON status can be

checked through the laser protective glasses.

• Laser forced OFF command

Sending the laser forced OFF command (LOCK, see P.92) to the BL-700 can

inhibit emission of laser beams. When working near the laser transmitter, be sure

to use the laser forced OFF command to avoid looking into the laser beams.

When this command is selected, the bottom STABILITY LED flashes.

4

Page 19

Chapter 2

Connection and Installation

2.1 BL-700 connections .............................................................. 6

2.1.1 Connector pin assignment .......................................................6

2.1.2 Power supply connections .......................................................6

2.1.3 Wiring I/O ................................................................................. 7

2.1.4 RS-232C connection ................................................................ 7

2.2 Connecting BL-U1 and wiring ............................................. 8

2.2.1 Connecting the power supply .................................................. 8

2.2.2 Connecting the BL-700 ............................................................8

2.2.3 Setting BL-U1 DIP switches..................................................... 9

2.2.4 Terminals of I/O terminal block and wiring............................. 10

2.2.5 Connecting RS-232C ............................................................. 11

2.2.6 Wiring the RS-422A ...............................................................14

2.3 Wiring the KEYENCE power supply unit BL-U2/N-42 ...... 16

2.3.1 Connecting the power supply ................................................ 16

2.3.2 Connecting the BL-700 to BL-U2/N-42 ..................................16

2.3.3 Terminals of I/O terminal block and connections ................... 17

2.3.4 Terminal ................................................................................. 18

2.3.5 Connecting RS-232C (BL-U2) ............................................... 18

2.3.6 Connecting the N-42 to RS-422A .......................................... 21

2.4 Installation ........................................................................... 23

2.4.1 Operating environment precautions....................................... 23

2.4.2 Installing the BL-700 Series ................................................... 25

2.4.3 Installing the BL-U1 ............................................................... 27

2.4.4 Installing the BL-U2, N-42...................................................... 27

Page 20

Chapter 2 Connection and Installation

2.1 BL-700 Connections

This section describes connections when a KEYENCE power supply unit is not

used.

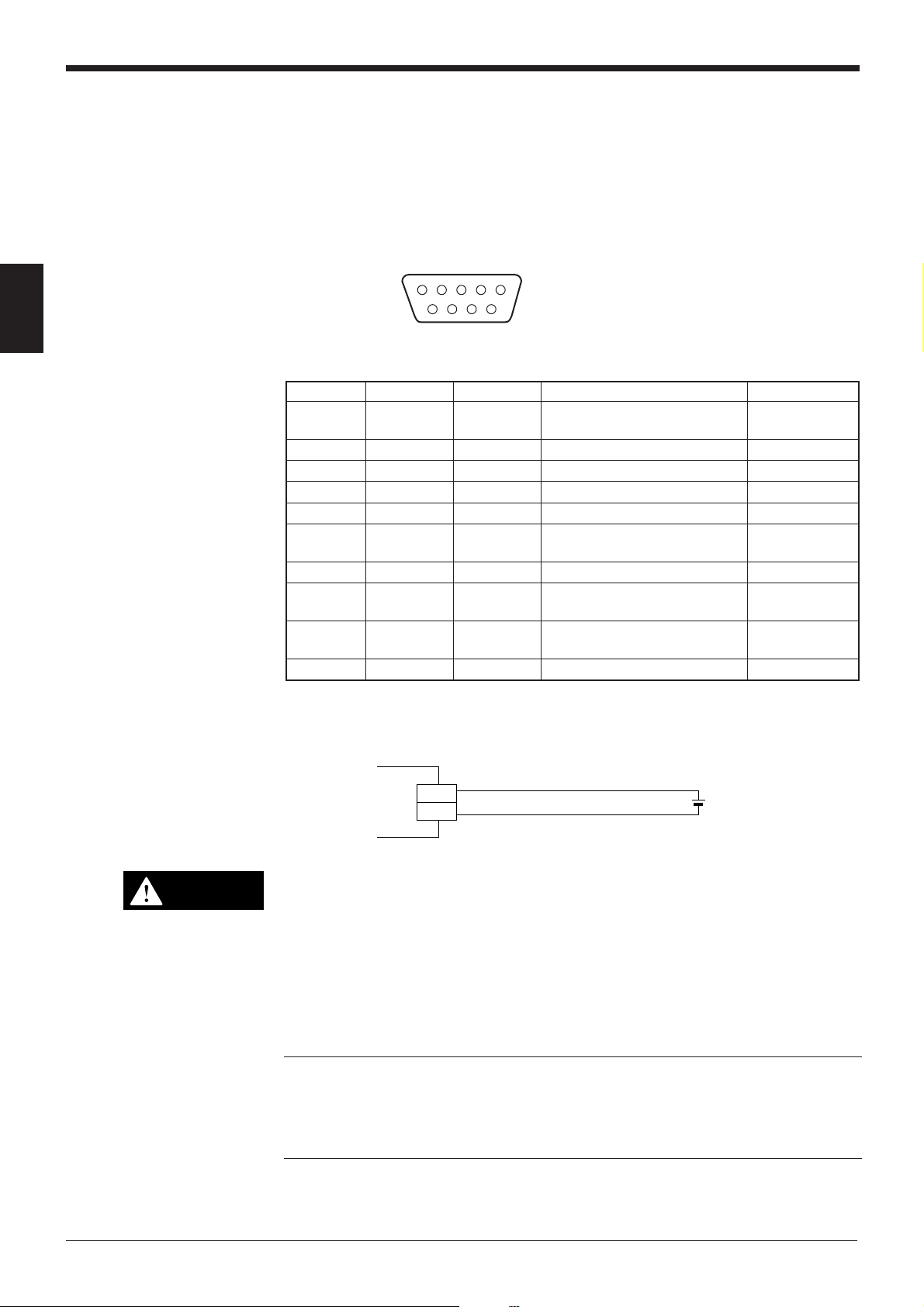

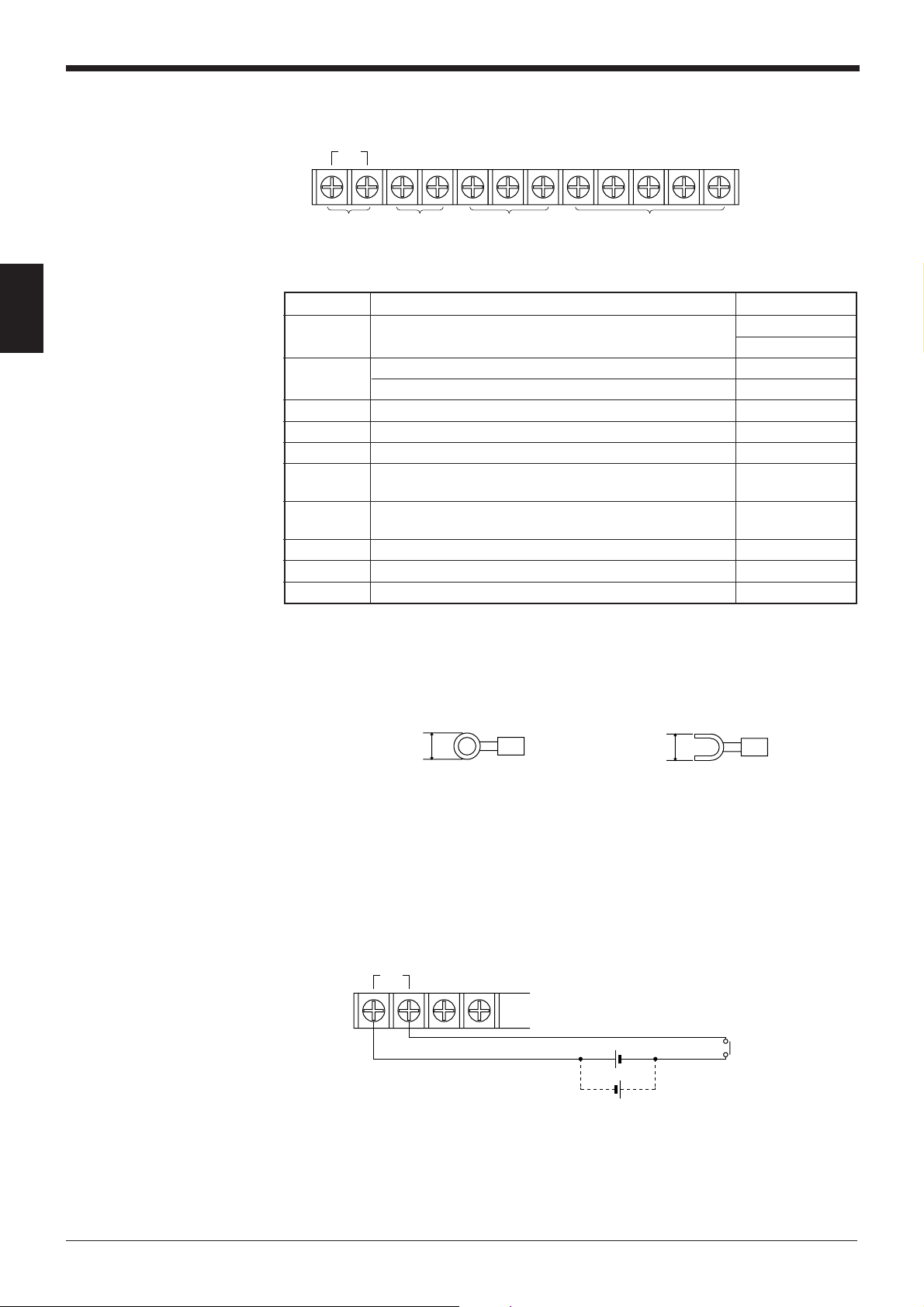

2.1.1 Connector pin assignment

The BL-700 connector has the following pin assignment.

2

Pin No. Cable color Symbol Description Signal direction

Connector Shield FG Frame ground —

12 3 45

D-sub 9-pin (female)

DTE specification (defined as terminal)

#4-40 screw (male)

6789

case

1 Yellow TIM Trigger input Input

2 Brown RD (RXD) Receives RS-232C data Input

3 Purple SD (TXD) Sends RS-232C data Output

4 White OK OK output Output

5 Black GND (SG) Ground (common ground for —

respective signals)

6 Gray NG NG output Output

7 Pink RS (RTS) Request to send RS-232C data Output

(always ON)

8 Blue CS (CTS) Enable to send data through Input

RS-232C

9 Red +5 V +5 V DC power supply Input

2.1.2 Power supply connections

BL-700

+5V

GND

• Be sure to match the polarities of the power supply when soldering the

CAUTION

connections. Reversing the polarities will damage the unit.

• Make sure that the power supply provides a stable 5 VDC ± 5%. If the

power supply does not function in the above range, it can damage the unit.

• Do not extend the power cable. A long power cable can cause a voltage

drop, preventing the BL-700 from starting properly.

Note: • Use the power supply that provides Class 2 output defined in NFPA 70

(NEC: National Electrical Code) when using this product as an UL certified

product.

• Use the Limited Power Source defined in UL/IEC60950-1 to comply with UL/

IEC60950-1.

9

5

+

5 VDC

6

Page 21

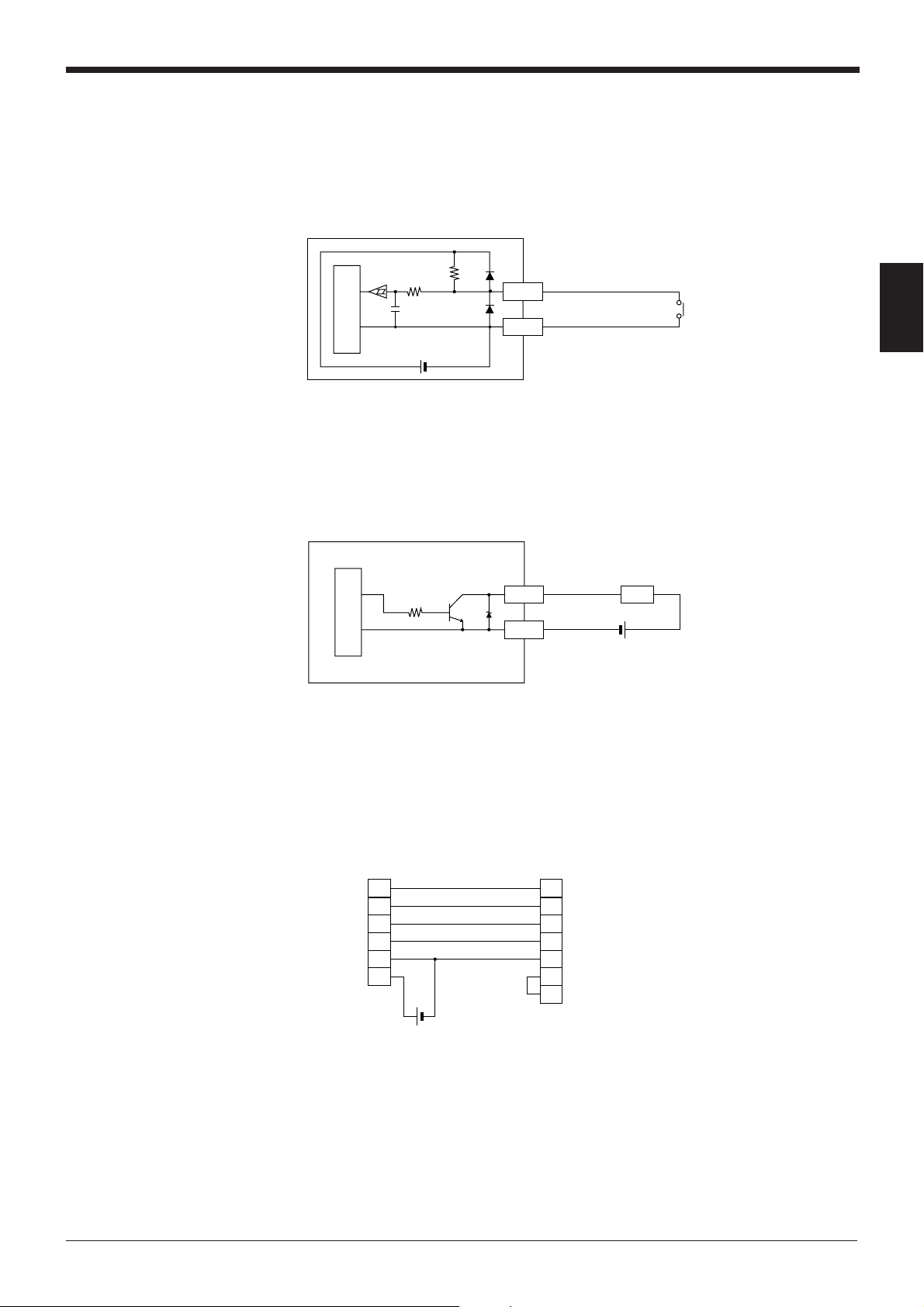

2.1.3 Wiring I/O

Chapter 2 Connection and Installation

■ Trigger input

The trigger input is used to signal the BL-700 to start reading (start laser emission).

The trigger input is a non-voltage input (TTL input is also available with negative

logic).

BL-700

4.7

10 kΩ

Internal circuit

5 VDC

kΩ

TIM

GND

1

5

Contact or

solid-state

■ OK/NG output

This output signals whether the readout data is the same as the preset data. When

no preset data has been entered, the signal indicates bar code read status. It is an

NPN open-collector output.

➮

See P. 44

BL-700

2

2.1.4 RS-232C connection

Wire the RS-232C as indicated below when connecting the BL-700 to a PC.

■ Connecting the computer with 25-pin

D-sub 9-pin (male)

# 4-40 screw

Internal circuit

BL-700

2

SD

3

CS

8

RS

7

GND

5

+5V

9

10 kΩ

OK/NG

4/6

5

GND

* Rated load: 24 VDC

(30 mA) max.

PC

2

3

4

5

7

6

20

D-sub 25-pin (male)

M2.6 screw

Load

+

SDRD

RD

RS

CS

SG

DR

ER

7

Page 22

Chapter 2 Connection and Installation

2.2 Connecting BL-U1 and Wiring

Note: This product does not comply with EC directives.

To use the BL-U1 AC power supply, connect it as described below.

2.2.1 Connecting the power supply

Plug the BL-U1 power cable into an outlet.

2

CAUTION

Use a power supply with 100 to 240 VAC ± 10% (50/60 Hz).

FG line

2.2.2 Connecting the BL-700

Connect the BL-700 to the READER port of the BL-U1.

The BL-U1 READER port pin assignment is as described below.

■ BL-U1 READER port pin assignment

12 3 45

Pin No. Symbol Function Signal direction

1 TIM Trigger input Output

2 RD (RXD) Receives RS-232C data. Output

3 SD (TXD) Sends RS-232C data. Input

4OKOK Input

5 GND (SG) Ground (Common ground for respective —

6NGNG Input

7 RS (RTS) Ready to send RS-232C data. Input

8 CS (CTS) Request to send RS-232C data. Output

9 +5 V +5 V power supply Output

6789

D-sub 9-pin (male)

DCE specification (defined as terminal)

#4-40 screw (female)

signal)

(Control method can be selected with the DIP

switches.)

➮

See p. 9.

8

Note: Do not extend a power cable. A long power cable can cause a voltage drop,

preventing the BL-700 from starting properly.

Note: This product does not comply with EC directives.

Page 23

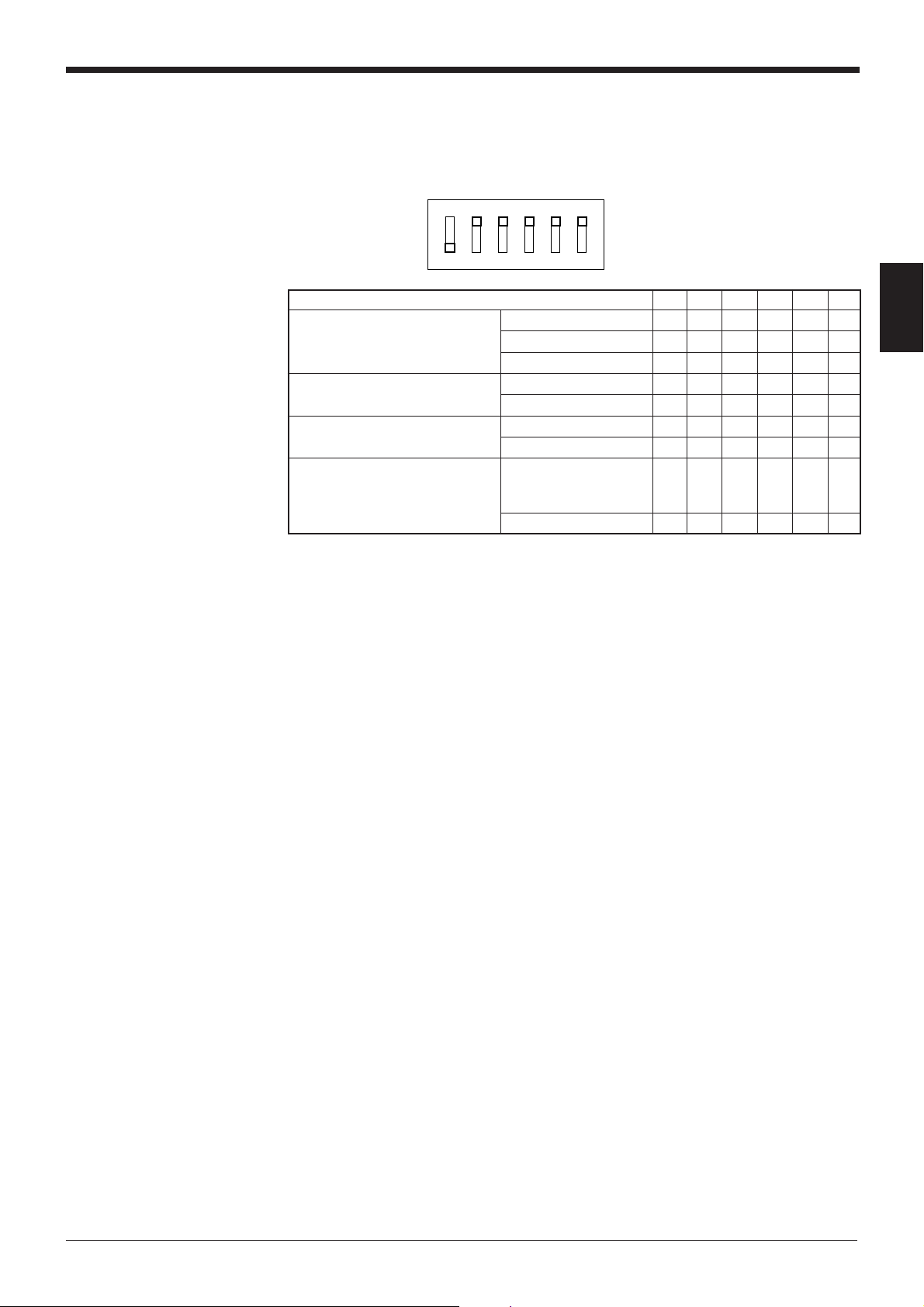

2.2.3 Setting BL-U1 DIP switches

Change the DIP switch settings depending on the selected interface and trigger

input method.

OFF

ON

123456

Chapter 2 Connection and Installation

* The figure on the left shows the

default settings.

DIP Switch No. 1 2 3 4 5 6

Interface selection RS-232C ON OFF OFF

RS-422A OFF ON OFF

RS-485 multidrop OFF OFF ON

RS-422A terminator OFF OFF

(Termination resistance: 100 ) ON ON

RS-485 terminator OFF OFF

(Termination resistance: 100 ) ON ON

Selection of READER port ON or OFF according

CS control method to the RS-232C port OFF

CS signal status.

Normally ON ON

2

9

Page 24

Chapter 2 Connection and Installation

2.2.4 Terminals of I/O terminal block and wiring

TIM +12V OUT– COM OK NG SDA SDB SG RDA RDB

2

Trigger

input

Symbol Description Signal direction

TIM Trigger input Input

+12 V OUT- + terminal of power supply for sensor (12 VDC, 300 mA) Output

COM Common terminal for OK/NG output —

OK OK output Output

NG NG output Output

SDA + terminal for RS-422A data transmission/ Output,

SDB – terminal for RS-422A data transmission/ Output,

SG Signal ground —

RDA + terminal for RS-422A data reception Input

RDB – terminal for RS-422A data reception Input

Power supply

for sensors

(12 VDC, 300 mA)

– terminal of power supply for sensor (0 V) Output

RS-485 + terminal Input/Output

RS-485 - terminal Input/Output

OK/NG output RS-422A/RS-485

Input

* Viewed from the left of the terminal block

• M3.0 screws are used for the terminal block.

• Use the following crimp terminals for connections.

6.0 mm or

less

Round-shape

6.0 mm or

less

Fork-shape

■ Connecting trigger input

The trigger input allows the BL-700 series to start reading bar codes (turn on the

laser beam).

The trigger input is turned ON when 8.5 to 30 VDC input is activated between the

trigger input terminals.

The BL-U1 power supply for the sensor can be used as the input power supply.

TIM +12V OUT–

+

+

8.5 to 30 VDC

Contact or

solid-state

10

Page 25

Chapter 2 Connection and Installation

■ Connecting OK/NG output

The OK/NG output is used to differentiate between acceptable and unacceptable

results based on the comparison with the preset data, and to indicate whether or

not the BL-700 series successfully read bar codes.

➮

See P.44.

The OK/NG output is an open-collector output.

COM OK NG

*Rated load: 30 V max. (100 mA)

Load

Load

+

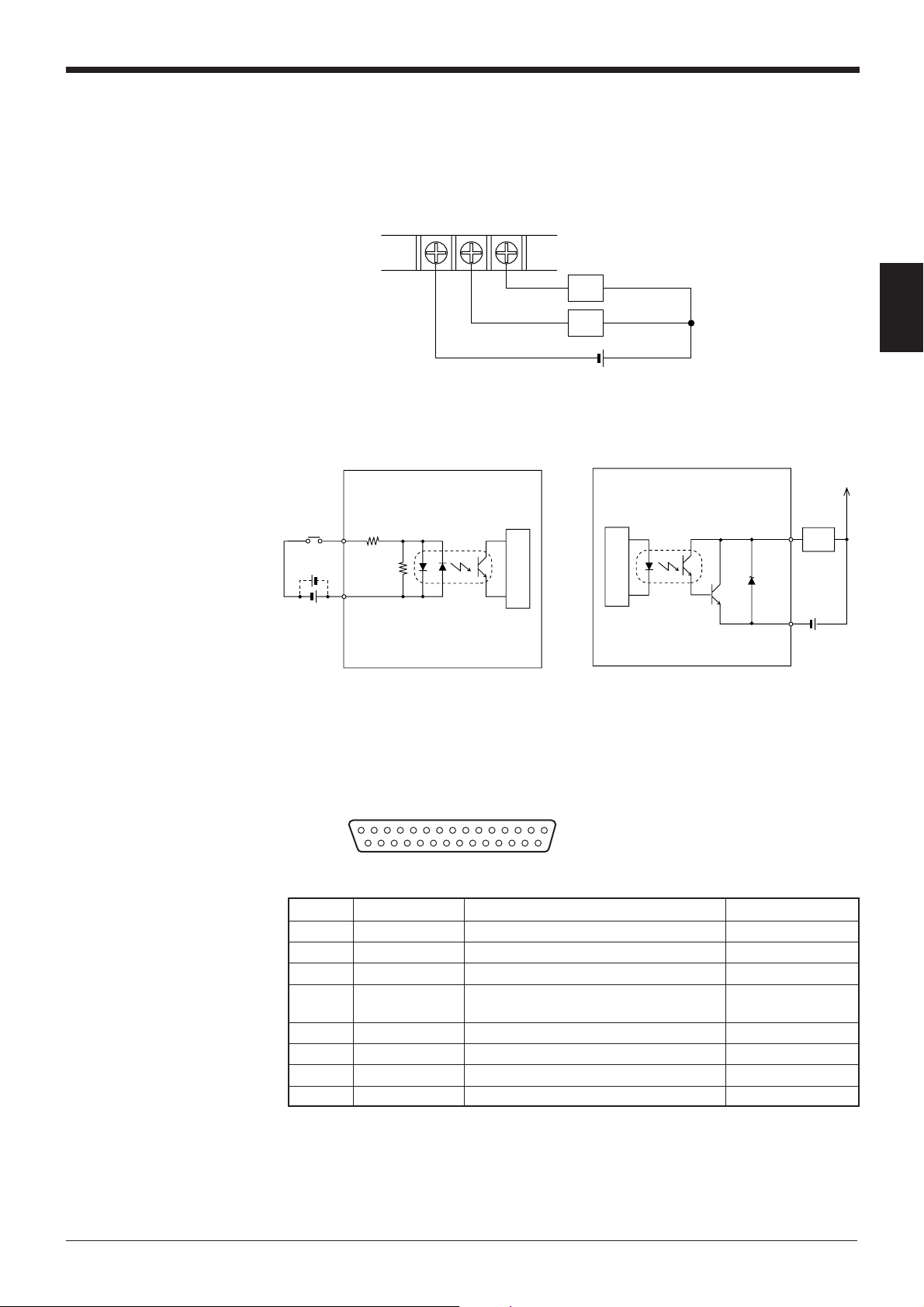

■ I/O circuit diagram

• Input circuit diagram • Output circuit diagram

2

2.2.5 Connecting RS-232C

Pin assignment

Pin No. Symbol Function Signal direction

1FG Frame ground —

2 SD (TXD) Sends RS-232C data Output

3 RD (RXD) Receives RS-232C data Input

4 RS (RTS) Ready to send RS-232C data Output

5 CS (CTS) Request to send RS-232C data Input

6 DR (DSR) Connected to pin No. 20 inside. Input

7 GND (SG) Signal ground —

20 ER (DTR) Connected to pin No. 6 inside. Output

3.3 kΩ

2.4

TIM

kΩ

13 1

25 14

(always ON)

Internal circuit

OK/NG

Internal circuit

COM

D-sub 25-pin (female)

DCE specification (defined as terminal)

M2.6 screw (female)

Load

+

11

Page 26

Chapter 2 Connection and Installation

OP-96369

BL-U1*

OP-96368 (2.5 m)

KV-10, 16, 24

KV-40, 80

KV-300*

Wiring the RS-232C cable

2

■ Connecting a PC

25-pin serial port 9-pin serial port

PC

2

SD

3

RD

4

RS

CS

5

DR

6

ER

20

SG

7

D-sub 25-pin (male)

M2.6 screw

BL-U1

FGFG

11

2

SD

3

RD

4

RS

CS

5

DR

6

ER

20

SG

7

D-sub 25-pin (male)

M2.6 screw

Connector case

PC

RD

SD

ER

SG

DR

RS

CS

CD

D-sub 9-pin (female)

#4-40 screw

BL-U1

1

FG

2

3

4

5

6

7

8

D-sub 25-pin (male)

M2.6 screw

SD

2

RD

3

4

RS

5

CS

6

DR

7

SG

8

ER

201

* KEYENCE option OP-22149 (1.5 m)

or commercially available cross cable

can be used.

* KEYENCE option OP-22149 (1.5 m)

and OP-25057 (conversion connector) can be used.

■ Connecting KV series/Handheld programmer port

Use the optional cable manufactured by KEYENCE.

Note: KV-300 and BL-U1 are not available in Europe.

■ Connecting KV-L2*

Port 1 Port 2

SD

RD

RS

CS

DR

ER

SG

KV-L2

2

3

4

5

6

20

7

BL-U1*

11

2

3

4

5

6

20

7

FGFG

SD

RD

RS

CS

DR

ER

SG

SD

RD

SG

KZ-L2

3

5

BL-U1*

1

2

3

4

5

6

20

71

FG

SD

RD

RS

CS

DR

ER

SG

12

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

* KEYENCE option OP-22149 (1.5 m) or

commercially available cross cable can be

used.

Terminal block

D-sub 25-pin (male)

M2.6 screw

Page 27

■ Connecting MELSEC-A series

Connection with AJ71C24,

AL71C24-S■■,

A0J2-C214-S1,

AJ71UC24

Chapter 2 Connection and Installation

Connection with A1SJ71(U)C24-R2/PRF,

A2CCPUC24,

A2CCPUC24-PRF

Link unit

2

SD

3

RD

4

RS

CS

5

DR

6

SG

7

CD

ER

20

D-sub 25-pin (male)

M2.6 screw

BL-U1*

FGFG

11

2

SD

3

RD

4

RS

CS

5

DR

6

SG

7

88

ER

20

D-sub 25-pin (male)

M2.6 screw

■ SYSMAC-C series

Connection with C-200H-LK201(-V1),

C-500-LK203,

C-500-LK201-V1,

C120-LK201-V1

Link unit

SD

RD

RS

CS

SG

2

3

4

5

7

BL-U1*

11

2

3

4

5

7

FGFG

SD

RD

RS

CS

SG

Link unit

2

RD

3

SD

4

ER

SG

5

DR

6

RS

7

CS

CD

1

D-sub 9-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

Connection with C-20H,

C-28H,

C-40H,

C-60H

PLC

2

SD

3

RD

4

RS

CS

5

SG

7

BL-U1*

1–

2

3

4

5

6

7

88

20

BL-U1*

11

2

3

4

5

7

FGConnector case

SD

RD

RS

CS

DR

SG

ER

FGFG

SD

RD

RS

CS

SG

2

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (male)

M2.6 screw

* KEYENCE option OP-22149 (1.5 m) or

commercially available cross cable can be

used.

Note: KV-L2 and BL-U1 are not available in Europe.

Connection with C-200HS(CPU21/23/31/33),

CQM1(CPU21/41/42/43/44),

C-200HE(CPU42),

C200HG(CPU43/63),

C200HX(CPU44/64),

C200HW-COM02/COM04/COM05/COM06

PLC

2

SD

3

RD

4

RS

CS

5

SG

9

D-sub 9-pin (male)

M2.6 screw

BL-U1*

FGFG

11

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

13

Page 28

Chapter 2 Connection and Installation

2

■ SYSMAC-CV series

Connection with CV500-LK201

(Port 1)

Link unit

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

* KEYENCE option OP-22149 (1.5 m) or

commercially available cross cable can be

used.

BL-U1*

FGFG

11

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

Note: BL-U1 is not available in Europe.

Connection with CV500-LK201 (Port 2),

CV500,

CV1000,

CVM1

PLC

2

SD

3

RD

4

RS

CS

5

SG

9

D-sub 9-pin (male)

M2.6 screw

BL-U1*

FGFG

11

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

2.2.6 Wiring the RS-422A

Wire the RS-422A as indicated below.

■ Connecting a general RS-422A unit

Use the same wiring when connecting the BL-U1 to the BL-U1*.

• Turn ON the terminators (BL-U1/external unit terminal resistance: 100 ).

➮

• The cable can be extended to within 1.2 km.

■ Connecting KV-L2*

Connecting the unit to RS-422A port 2

See P.35

External unit

.

BL-U1*

SG

RD + (RDA)

RD – (RDB)

SD + (SDA)

SD – (SDB)

Link Unit

SG

RDB

RDA

SDB

SDA

Twisted pair cable

Twisted pair cable

BL-U1*

SG

SDA

SDB

RDA

RDB

BL-U1*

SG

SDA

SDB

RDA

RDB

14

Page 29

■ Connecting the MELSEC-A series

SDA

SG

BL-U1*

SDB

RDA

RDB

8RDB

RDA

SDB

SDA

6

2

1

9

SG

D-sub 9-pin (male)

M2.6 screw

Twisted pair cable

Communication

board

Connecting with AJ71C24,

AJ71C24-S■■,

AJ71UC24,

A0J2-C214-S1,

A1SJ71(U)C24-R4

Chapter 2 Connection and Installation

Link unit

SG

RDA

RDB

SDA

SDB

Twisted pair cable

BL-U1*

SG

SDA

SDB

RDA

RDB

Note: BL-U1 and KV-L2 are not available in Europe.

■ Connecting SYSMAC-C series

Connecting with C200H-LK202 (-V1), Connecting with C200HW-COM03/

C500-LK201-V1, COM06

C500-LK203,

C120-LK202-V1

Link unit

SG

3

1RDB

6

RDA

5

SDB

SDA

9

FG

7

D-sub 9-pin (male)

M2.6 screw

Twisted pair cable

BL-U1*

SG

SDA

SDB

RDA

RDB

2

■ Connecting SYSMAC-CV series

Connecting with CV-500-LK201,

CV500,

CV1000,

CVM1

PLC

SG

9

8RDB

6

RDA

2

SDB

SDA

1

RS

4

CS

5

D-sub 9-pin (male)

M2.6 screw

Twisted pair cable

BL-U1*

SG

SDA

SDB

RDA

RDB

Note: BL-U1 is not available in Europe.

15

Page 30

Chapter 2 Connection and Installation

2.3 Wiring the KEYENCE Power Supply Unit BL-U2/N-42

To use the BL-U2/N-42, connect as indicated below.

2.3.1 Connecting the power supply

Connect BL-U2/N-42 to a 24 VDC power supply.

BL-U2 N-42

24V DC IN

2

CAUTION

+–

24 VDC

+

Make sure that the power supply provides 24 VDC. If the power supply output

is not 24 VDC, it can damage the unit.

Note: If the power supply is UL rated, it must provide Class 2 output.

2.3.2 Connecting the BL-700 to BL-U2/N-42

Connect the BL-700 to the READER port of the BL-U2/N-42.

READER

POWER SD RD

N.C. N.C. N.C.

24V DC IN

+–

24 VDC

+

16

■ READER port pin assignment

12 3 45

6789

Pin No. Symbol Function Signal direction

1 TIM Trigger input Output

2 RD (RXD) Receives RS-232C data Output

3 SD (TXD) Sends RS-232C data Input

4OK OK signal Input

5 GND (SG) Ground (Common ground for respective signal) —

6NG NG signal Input

7 RS (RTS) Ready to send RS-232C data Input

8 CS (CTS) Request to send RS-232C data Output

9 +5 V 5 V power supply output Output

D-sub 9-pin (male)

DCE specification (defined as terminal)

#4-40 screw (female)

Note: Do not extend a power cable. A long power cable can cause a voltage drop,

preventing the BL-700 from starting properly.

Page 31

Chapter 2 Connection and Installation

2.3.3 Terminals of I/O terminal block and connections

TIM

COM

OK OG

COM

Symbol Description Signal direction

TIM Trigger input Input

COM Common terminal for trigger input Input

OK OK output Output

NG NG output Output

COM Common terminal for output Output

■ Connecting trigger input

The trigger input allows the BL-700 to start reading bar codes (turn on the laser

beam).

To turn ON the trigger input, supply 15 to 26 VDC between the trigger input terminals.

* Viewed from the left of the unit

2

TIM

COM

OK

TIM

+

+

+

15 to 26 VDC

+

COM

■ Connecting OK/NG output

The OK/NG output indicates the result of the comparison with preset data, or

indicates whether reading is successful or not.

OK

NG COM

+

Internal circuit

Load

Internal circuit

Load

Load

* Rated load: 30 V max. (100 mA)

+

17

Page 32

Chapter 2 Connection and Installation

2.3.4 Terminal

A solderless contact pin, as shown below, is available for connection.

2

2.3.5 Connecting RS-232C (BL-U2)

Pin assignment

Pin No. Symbol Description Signal direction

2 RD (RXD) Receive data Input

3 SD (TXD) Send data Output

4 ER (DTR) Connected to pin No.6 inside. Output

5SG Signal ground —

6 DR (DSR) Connected to pin No.4 inside. Input

7 RS (RTS) Request to send data (always ON) Output

8 CS (CTS) Enable to send data Input

* One connector is provided.

2.0 mm

max.

6 mm min

12 3 45

6789

5 mm max.

D-sub 9-pin (male)

DTE specification (defined as terminal)

#4-40 screw

Wiring the RS-232C cable

■ Connecting a PC

25-pin serial port 9-pin serial port

PC

1

FG

SD

2

RD

3

4

RS

5

CS

6

DR

20

ER

7

SG

D-sub 25-pin (male)

M2.6 screw

BL-U2

Connector case

RD

2

SD

3

7

RS

8

CS

4

ER

6

DR

5

SG

D-sub 9-pin (female)

#4-40 screw

* KEYENCE option OP-22149 (1.5 m)

or OP-25057 (conversion connector)

can be used.

Connector case

PC

RD

2

SD

3

7

RS

8

CS

4

ER

6

DR

5

SG

D-sub 9-pin (female)

#4-40 screw

* KEYENCE option cable OP-27937 (1.5

m) can be used.

BL-U2

Connector case

RD

2

SD

3

7

RS

8

CS

4

ER

6

DR

5

SG

D-sub 9-pin (female)

#4-40 screw

18

Page 33

Chapter 2 Connection and Installation

OP-96369 OP-25057

BL-U2

OP-96368 (2.5 m)

KV-10, 16, 24

KV-40, 80

KV-300*

POWER

SD

RD

BL-U2

RS-232C

READER

■ Connecting KV series/Handheld programmer port

Use the optional cable manufactured by KEYENCE.

■ Connecting KV-L2*

Port 1 Port 2

FG

SD

RD

RS

CS

DR

ER

SG

KV-L2*

1

2

3

4

5

6

20

7

BL-U2

2

3

7

8

4

6

5

Connector case

RD

SD

RS

CS

ER

DR

SG

SD

RD

SG

KV-L2*

3

5

BL-U1*

2

3

7

8

4

6

51

2

Connector case

RD

SD

RS

CS

ER

DR

SG

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (female)

#4-40 screw

Terminal block

* KEYENCE option OP-22149 (1.5 m) or the

OP-25057 (conversion connector) can be

used.

Note: KV-300, KV-L2 and BL-U1 are not available in Europe.

■ Connecting MELSEC-A series

Connection with AJ71C24,

Connection with A1SJ71(U)C24-R2/PRF,

AL71C24-S■■,

A0J2-C214S1,

AJ71UC24

Link unit

FG

SD

RD

RS

CS

DR

SG

CD

ER

BL-U2

1

2

3

4

5

6

20

Connector case

2

RD

3

SD

7

RS

CS

8

ER

4

SG

57

68

DR

Link unit

RD

SD

RS

CS

ER

DR

SG

CD

2

3

7

8

4

1

D-sub 9-pin (female)

#4-40 screw

A2CCPUC24,

A2CCPUC24-PRF

BL-U2

Connector caseConnector case

2

RD

3

SD

7

RS

CS

8

ER

4

DR

66

55

SG

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (female)

#4-40 screw

D-sub 9-pin (male)

M2.6 screw

D-sub 9-pin (female)

#4-40 screw

19

Page 34

Chapter 2 Connection and Installation

2

■ SYSMAC-C series

Connection with C-200H-LK201(-V1),

C-500-LK203,

C-500-LK201-V1,

C120-LK201-V1

Link unit

FG

1

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

* KEYENCE option OP-22149 (1.5 m) or the

OP-25057 (conversion connector) can be

used.

BL-U2

Connector case

2

RD

3

SD

7

RS

CS

8

SG

5

D-sub 9-pin (female)

#4-40 screw

■ SYSMAC-C series

Connection with C-200HS(CPU21/23/31/33),

CQM1(CPU21/41/42/43/44),

C-200HE(CPU42),

C200HG(CPU43/63),

C200HX(CPU44/64),

C200HW-COM02/COM04/COM05/COM06

Connection with C-20H,

C-28H,

C-40H,

C-60H

PLC

FG

1

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 9-pin (male)

M2.6 screw

BL-U2

2

3

7

8

5

D-sub 9-pin (female)

#4-40 screw

Connector case

RD

SD

RS

CS

SG

PLC

FG

1

2

SD

3

RD

4

RS

CS

5

SG

9

D-sub 9-pin (male)

M2.6 screw

BL-U2

Connector case

2

RD

3

SD

7

RS

CS

8

SG

5

D-sub 9-pin (female)

#4-40 screw

■ SYSMAC-CV series

Connection with CV500-LK201 Connection with CV500-LK201

(Port 1) (Port 2),

CV500,

CV1000,

CVM1

Link unit

FG

SD

RD

RS

CS

SG

FG

SD

RD

RS

CS

SG

PLC

1

2

3

4

5

9

BL-U2

1

2

3

4

5

7

Connector case

2

RD

3

SD

7

RS

CS

8

SG

5

BL-U2

Connector case

2

RD

3

SD

7

RS

CS

8

SG

5

20

D-sub 25-pin (male)

M2.6 screw

D-sub 9-pin (female)

#4-40 screw

* KEYENCE option OP-22149 (1.5 m) or the

OP-25057 (conversion connector) can be

used.

D-sub 9-pin (male)

M2.6 screw

D-sub 9-pin (female)

#4-40 screw

Page 35

2.3.6 Connecting the N-42 to RS-422A

RS-422 terminal block assignment

Code Description Signal direction

SG Ground —

SD+ Sends data to + terminal. Output

SD- Sends data to - terminal. Output

RD+ Receives data from + terminal. Input

RD- Receives data from - terminal. Input

Connecting external equipment

■ Connecting N-42 to external unit

Use the same wiring when connecting the N-42 to the N-42.

Chapter 2 Connection and Installation

RS-422

SG SD+ RD+SD– RD–

2

External unit

(N-42)

SG

RD +

RD –

SD +

SD –

Twisted pair cable

N-42

SG

SD +

SD –

RD +

RD –

• Turn ON the terminators (BL-U1/external unit terminal resistance: 100 ).

➮

See P. viii.

• The cable can be extended to within 1.2 km.

■ Connecting KV-L2*

Connecting the unit to RS-422A port 2

Link unit

SG

RDB

RDA

SDB

SDA

Twisted pair cable

BL-U1*

SG

SD+

SD–

RD+

RD–

■ Connecting the MELSEC-A series

Connecting with AJ71C24,

AJ71C24-S■■,

AJ71UC24,

A0J2-C214-S1,

A1SJ71(U)C24-R4

Link unit Twisted pair cable

SG

RDA

RDB

SDA

SDB

BL-U1*

SG

SD+

SD–

RD+

RD–

21

Page 36

Chapter 2 Connection and Installation

■ Connecting SYSMAC-C series

Connecting with C200H-LK202 (-V1), Connecting with C200HW-COM03/

C500-LK201-V1, COM06

C500-LK203,

C120-LK202-V1

2

Link unit Twisted pair cable

SG

3

1RDB

6

RDA

5

SDB

SDA

9

FG

7

D-sub 9-pin (male)

M2.6 screw

N-48

SG

SD+

SD–

RD+

RD–

■ Connecting SYSMAC-CV series

Connecting with CV-500-LK201,

CV500,

CV1000,

CVM1

PLC Twisted pair cable

SG

9

8RDB

6

RDA

2

SDB

SDA

1

RS

4

CS

5

D-sub 9-pin (male)

M2.6 screw

Communication

board

SG

9

8RDB

6

RDA

2

SDB

SDA

1

D-sub 9-pin (male)

M2.6 screw

N-42

SG

SD+

SD–

RD+

RD–

N-48Twisted pair cable

SG

SD+

SD–

RD+

RD–

Note: BL-U1 and KV-L2 are not available in Europe.

22

Page 37

2.4 Installation

2.4.1 Operating environment precautions

Ambient environments

This unit is a precision instrument and you must take care in choosing the operating environment. Do not install the unit in place as shown below:

• The unit is exposed to direct sunlight, or the ambient temperature may fall

below 0°C (32°F) or exceed 40°C (104°F) (Power supply: 0 to 50°C (32 to

122°F));

• The relative humidity may exceed the range of 35 to 85%, or condensation may

occur due to rapid temperature changes;

• Corrosive gas or inflammable gas is present, or a high level of dust, salt, iron

particles or soot is present;

• The unit is subject to vibration or impact;

• Water, oil or chemicals may splash the unit;

•A strong magnetic field or electric field is generated.

Chapter 2 Connection and Installation

2

In-panel installation

Hints on correct use

• The ambient illumination intensity exceeds the range defined in the specification

in P.120.

To mount the power supply unit BL-U1, BL-U2 or N-42, carefully observe the

following instructions.

• Provide enough ventilation space.

• If the ambient temperature may fall below 0°C (32°F) or exceed 50°C (122°F),

provide a fan or air conditioner.

• Do not mount this unit in a panel where a high voltage device is installed.

• Place this unit as far away from power lines as possible.

Note: The BL-700 conforms to the protective structure defined in IP-65 (excluding

the power supply unit connected). Although installation environments subject to

dust and water will not affect the BL-700, adhesion of dust or water drops to the

transmitter/receiver may disable readout of bar codes.

• Trigger (TIM) input

Set the trigger input to be long enough to allow the laser beam to cover the entire

bar code.

If the trigger input needs to be on for only a short period of time, select one-shot

mode.

• Influence from mirror surface

If a mirror surface (metallic surface) is near the bar code and the laser beam

reflects off the mirror, the BL-700 may cause a read error. Protect the unit from the

influence of a mirror surface by covering the surface or changing the bar code label

position.

23

Page 38

Chapter 2 Connection and Installation

• Bar code pitch

Do not place several bar codes in the field of the laser beam, unless you are in

multi-label read mode (Multi 3).

STB

TEST

LASER ON

OK/NG

TIMING

BL-700

2

If you use multi-label read mode (multi 3), the BL-700 can simultaneously read 2 to

4 bar codes in the field of the laser beam.

• Influence from photoelectric sensor

When using a photoelectric sensor to control trigger, block the sensor beam so it

does not enter the BL-700 optical pickup.

The beam from the photoelectric sensor can interfere with the BL-700, deteriorating

reading performance. If this case, reposition the photoelectric sensor.

Object

STB

TEST

LASER ON

OK/NG

TIMING

BL-700

Optical pickup

Bar code

Light source

• Interference between the BL-700 units

When two BL-700 units are placed adjacent to each other with only a small separation, the mutual laser beams result in interference and will cause a readout error.

To avoid interference, place the units as far apart as possible.

24

• When a bar code is stained or partially missing

Use a raster scan reader (BL-701/741/781) when a bar code is stained or partially

missing. This raster scan readers scan several portions of the bar code. Normal

portions of the bar code, even with stained or missing portions, can be read by the

BL-700.

Page 39

2.4.2 Installing the BL-700 series

Installation method

Use the mounting holes on the side panel to install the unit.

■ Installation with no mounting bracket

Chapter 2 Connection and Installation

M3 nuts

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

M3 screws

• Select screws of the proper length by checking the thickness of the plate used

for mounting. (The screws provided are for use with the mounting bracket.)

• For the mounting hole diameter, see P.127.

■ Using the supplied mounting brackets

Vertical scanning

M4 screws

Washer (accessory)

Insulating spacer

(accessory)

M3 screws

(accessory)

2

Horizontal scanning

M4 screws

Washer (accessory)

BL-700

TEST

TIMING

OK/NG

STB

LASER ON

Insulating spacer

(accessory)

M3 screws

(accessory)

• Use the set screw to secure the mounting bracket to the unit.

• For the mounting hole diameter, see P.127.

• When the insulating spacer is mounted, it can reduce the influence of noise

from the mounting bracket.

25

Page 40

Chapter 2 Connection and Installation

Mounting angle and mounting distance

Reading distance

Panel surface

2

10°

Set the angle and reading distance by referring to the read range characteristics

and angle characteristics described on P.122 to P.124.

The allowable reading distance and angle may vary depending on the narrow bar

width of the bar code, the bar code size, and the readability of the bar code. Set

these parameters after performing a test read of the required bar code using the

unit.

Note: Do not set the unit at an angle at which the laser beam is perpendicular to

the surface of the bar code. The beam will be fully reflected into the reader, making

correct reading impossible (

Incorrect

➮

See P.124

).

* Reading distance = 230 mm (BL-700/701)

380 mm (BL-740/741)

500 mm (BL-780/781)

10°

Tips

The reading check test mode allows you to set the optimal reading position.

➮

To use the test mode, see P. 38.

26

Page 41

2.4.3 Installing the BL-U1*

There are 2 methods for installing the BL-U1:

■ When installing the BL-U1 directly

Pull out the 4 screw slots on the rear panel and screw them to the base.

■ When installing the BL-U1 to the DIN rail

1. Hook the BL-U1 to the DIN rail groove from its top. Push the BL-U1 bottom

against the DIN rail until you hear a click.

Chapter 2 Connection and Installation

4 - ø5

98

2

150

2. Check that the DIN rail mounting notch is shaped like notch A below. If not,

push the BL-U1 further.

3. To remove the BL-U1 from the DIN rail, pull out the notch until its shape turns

from Fig. B to Fig. A. Then, disengage the BL-U1 from the DIN rail.

4. When you want to reinstall the BL-U1 to the DIN rail, return the notch from that

of Fig. A to Fig. B.

Note: BL-U1 is not available in Europe.

2.4.4 Installing the BL-U2, N-42

Install the BL-U2 or N-42 using the mounting hole.

AB

POWER

BL-U2

READER

SD

RD

RS-232C

2 - ø4.5 mm

43.2 mm

63.2 mm

* The BL-U2 is 21 mm thick and the N-42 is 26 mm thick.

27

Page 42

Chapter 2 Connection and Installation

2

28

Page 43

Chapter 3

Functions for Reading Operation

3.1 Read Operation ................................................................... 30

3.1.1 Scanning method ................................................................... 30

3.1.2 Data-send mode .................................................................... 32

3.2 Read Modes ......................................................................... 33

3.2.1 Single label read mode ..........................................................33

3.2.2 Multi-label read mode 1 (Multi 1) ........................................... 33

3.2.3 Multi-label read mode 2 (Multi 2) ........................................... 34

3.2.4 Multi-label read mode 3 (Multi 3) ........................................... 35

3.3 Label Orientation Mode ...................................................... 37

3.4 Test Mode ............................................................................ 38

3.4.1 Reading rate check mode ...................................................... 38

3.4.2 Tact check mode ................................................................... 39

3.4.3 Online test mode.................................................................... 41

3.5 STABILITY LEDs ................................................................. 42

3.6 Preset Function (Compare with:) ...................................... 44

3.6.1 What is the preset function? .................................................. 44

3.6.2 Wildcard Symbols (“!” and “?”) .............................................. 45

3.7 Additional Information .......................................................46

3.8 Max. Code Length (Designated Digit )

Output Function .................................................................. 48

Page 44

Chapter 3 Functions for Reading Operation

3.1 Read Operation

3.1.1 Scanning method

3

There are two methods for triggering the BL-700 to read bar codes; the “Level

signal” method and the “One-shot signal” method. The example given for these two

methods uses the “single label read mode” (

➮

see P.33

), which reads one bar code

while trigger input turns on once, and uses the “after read” as the data-send mode

(

➮

see P.32

).

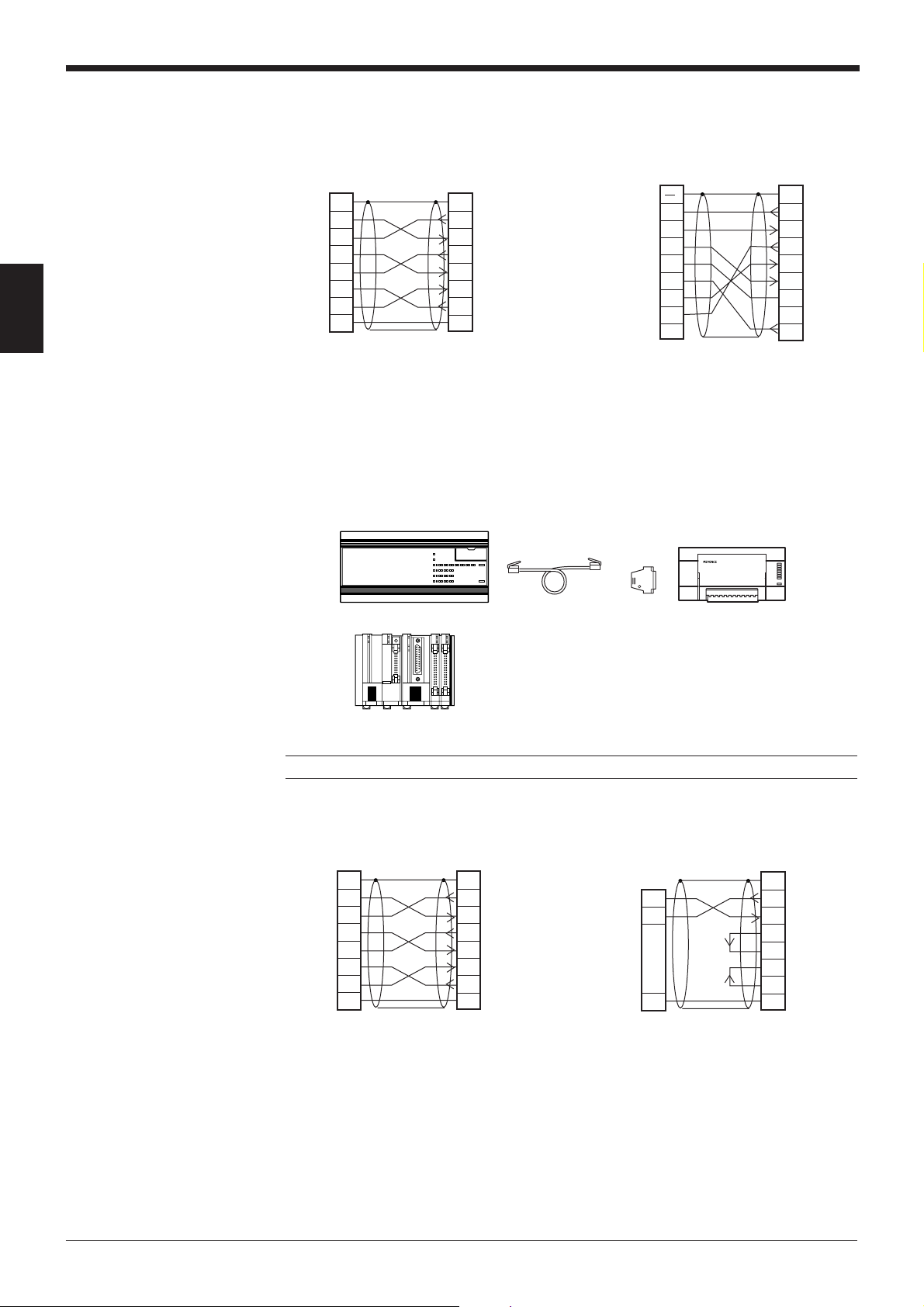

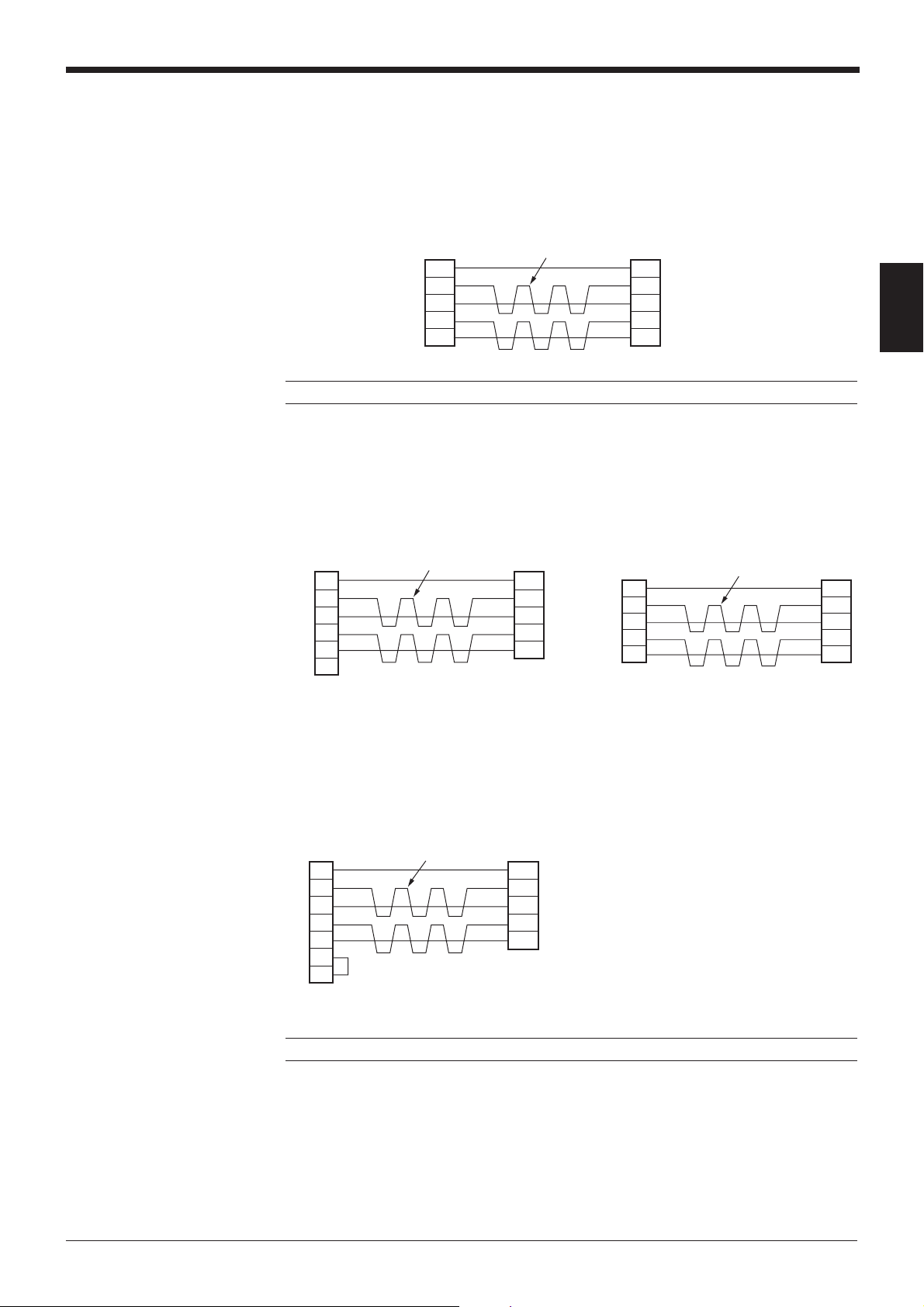

■ Level signal trigger

When the trigger input turns on, laser emission begins and the unit begins reading.

The laser turns off after reaching the specified decode count. Then, the unit sends

the readout data.

Trigger input

Bar code

<Succeed to read> <Fail to read>

*1

Laser beams

Communication time

OK/NG output OK/NG NG

*2

*3

*4

*5

*1. Set trigger input so that it stays on long enough for the laser beam to cover the

entire bar code.

*2. After the trigger input exceeds the preset input time, the laser begins to emit.

➮

See note on the next page.

*3. The communication time can be obtained from the following expression:

Data bits + (1: If parity is used) + Start/stop bit

Baud rate

(Code length of data to be

X

sent + Header/number of

characters in delimiter)

*4. The length of time that the OK/NG output is on can be changed to between 10

ms and 2.55 s.

*5. The OK/NG output turns on 5 ms after the data has been read (or trigger input

turns off in case of reading failure).

30

Note: 5 seconds after the power switch turns on or an UNLOCK command (

P.90

) is sent, the unit will not start reading a bar code by turning on the trigger

input.

➮

see

Page 45

Chapter 3 Functions for Reading Operation

■ One-shot signal trigger

The unit detects the rising edge of the trigger input and starts reading bar codes for

the preset input time. The laser beam turns off after reaching the specified decode

count and the unit sends the readout data.

The remaining actions are the same as those for level signal trigger.

Tips

Trigger input

Bar code

Laser beams

Communication time

OK/NG output

<Succeed to read> <Fail to read>

*1

Preset input time

OK/NG

Preset input time

NG

1. After the trigger input exceeds the preset input times, the laser begins to emit.

Trigger input minimum ON time:

4 ms (when the trigger input value is 2 ms)

13 ms (when the trigger input value is 10 ms)

• The BL-700 can read up to 4 types of bar codes without changing the bar code type

setting (➮ see P.61).

• For general operation, see “Level signal trigger”

Choose “One-shot signal trigger” when the trigger input signal is very short or you

want to set the input time.

3

• To use a one-shot trigger signal instead of trigger input, gently press the TEST switch

once (for less than 3 seconds) (➮ see P.vi).

NOTE: The BL-700 has a built-in AGC (auto gain control) circuit. It requires a

maximum of 3 scans (4.3 ms) to adjust gain. The BL-700 generates a maximum of

4.3 ms delay until starting to read the data after the laser beam turns ON.

31

Page 46

Chapter 3 Functions for Reading Operation

3.1.2 Data-send mode

3

In the single label read mode only, you can select from the two data send modes

(OK/NG output on trigger) described below: In the multi-label read mode, you can

only select the “send after reading” mode.

• Send after read

The unit outputs the communication and OK/NG signals after a successful read

(trigger output turns on as many times as the preset decode count). This is the

same operation as in the time chart described in “3.1.1 Scanning method”. Normally, this is the method you should use.

• Send at trigger input

The unit outputs the communication and OK/NG signal when the trigger input turns

off (or the preset input time has passed if one-shot signal trigger is selected).

Trigger input

Bar code

Laser beams

Communication time

OK/NG output

<Succeed to read>

OK/NG

<Fail to read>

NG

32

Page 47

3.2 Read Modes

p

The BL-700 provides 4 types of read modes.

3.2.1 Single label read mode

This mode allows the unit to read one bar code during one trigger input signal. The

operation and timing chart are described on page 30 to 32.

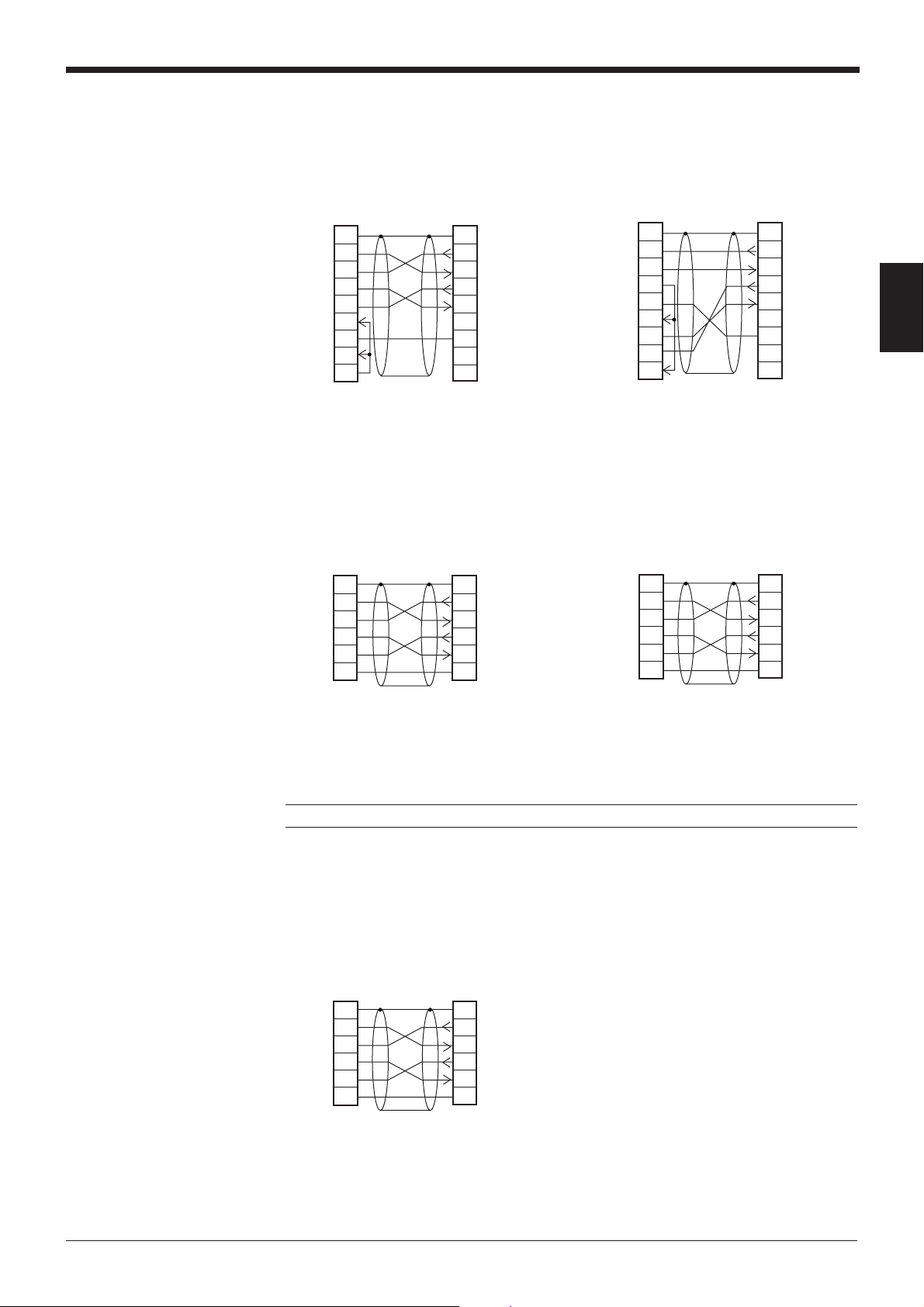

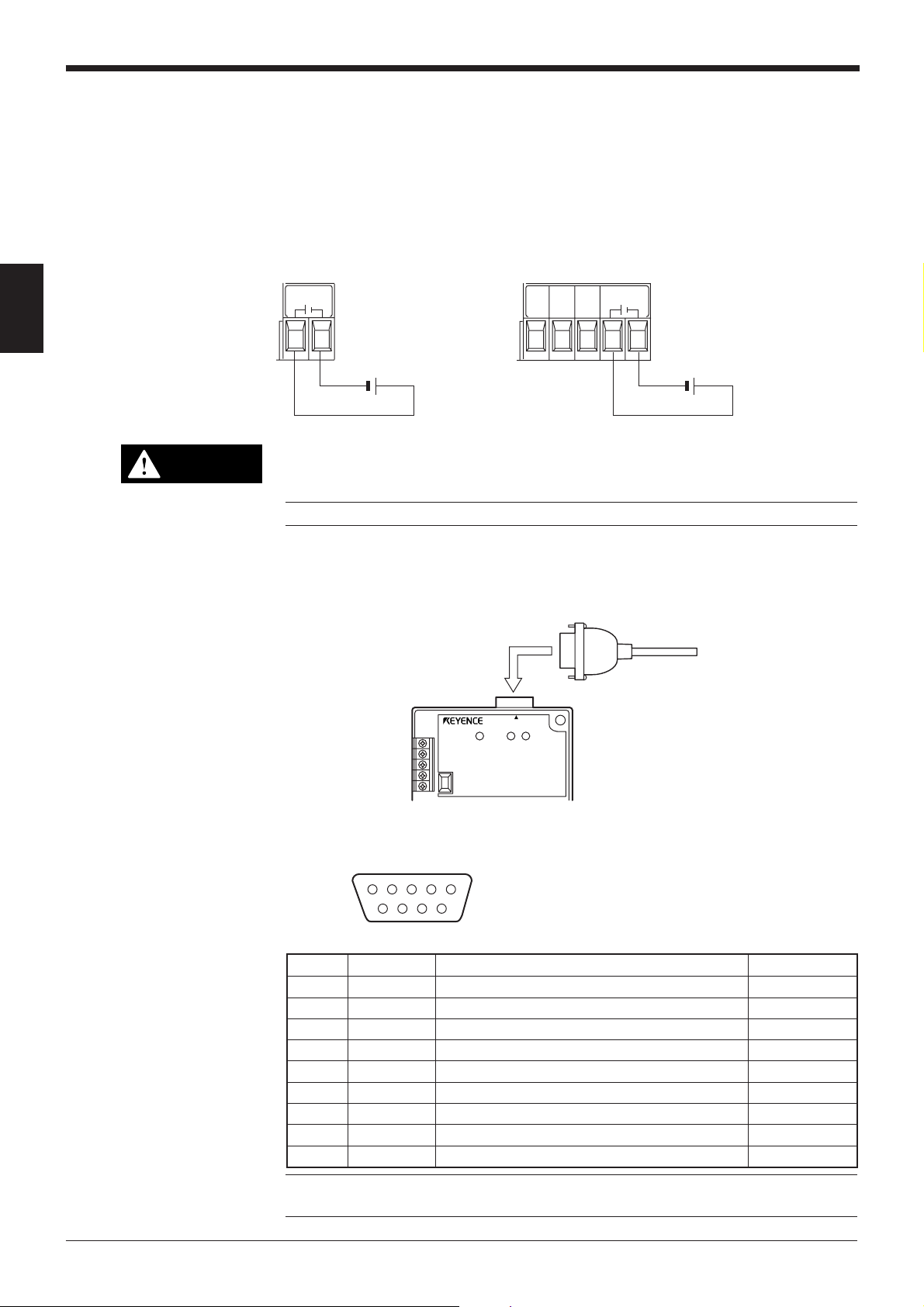

3.2.2 Multi-label read mode 1 (Multi 1)

This mode allows the unit to read several bar codes printed on one label as shown

below during one trigger input signal. The unit outputs the readout data sequentially.

Chapter 3 Functions for Reading Operation

LASER ON

STB

OK/NG

TIMING

TEST

BL-700

3

Multi-label read mode 1 operation

Trigger input

Bar code

Laser beams

Communication time

OK/NG out

• In the multi-label read mode 1, the unit reads several bar codes continuously,

and outputs them sequentially as it reads while laser beam remains on and

trigger input turns on after bar codes have been read (or during the preset input

time if one-shot signal trigger is selected).

• To prevent the unit from reading the same bar code twice, the time for one bar

code to pass across the laser beam’s field and read, plus the repeat reading

time must be set (100 ms to 25.5 s). During the repeat reading time, the unit

cannot read the same bar code repeatedly, but can read different bar codes.

•A reading error is issued only when the unit cannot read any bar code while the

trigger input is on.

<Succeed to read> <Fail to read>

Repeat reading time

OK

ut

OK OK OK

NG

• For OK/NG output, “OK” turns on every time the unit reads a bar code and “NG”

turns on if the unit fails to read a bar code. (Comparison to the preset data is not

performed.)

33

Page 48

Chapter 3 Functions for Reading Operation

3.2.3 Multi-label read mode 2 (Multi 2)

As with multi 1 mode, this mode allows the unit to read several bar codes continuously while the trigger input is on. (The number of bar codes that can be read

depends on the buffer capacity. See P.86.) The difference between the two modes

is that multi 2 mode sends all the readout data at one time after the trigger input

turns off.

Multi-label read mode 2 operation

<Succeed to read> <Fail to read>

Trigger input

Bar code

12345

Laser beams

Repeat reading

time

3

Reading data format

Communication time

OK/NG output

12345

OK

NG

• Multi 2 mode allows the unit to read several bar codes while the trigger input is

on (or during the preset input time if one-shot signal trigger is selected) and

sends all the readout data at one time after the trigger input turns off (or after

the preset input time is expired if one-shot signal trigger is selected).

• To prevent the unit from reading the same bar code twice, the time for one bar

code to pass across the laser beam’s field and read, plus the repeat reading

time must be set (100 ms to 25.5 s). During the repeat reading time, the unit

cannot read the same bar code repeatedly, but can read different bar codes.

•A reading error is issued only when the unit cannot read any bar code while the

trigger input is on.

• For OK/NG output, after trigger input turns off, “OK” turns on if the unit reads at

least one bar code and “NG” turns on if the unit fails to read a bar code. (Comparison to the preset data is not performed.)

34

Header 1st data

, , , ,

2nd data 3rd data 4th data Delimiter•••••••

• Each data packet is separated by a comma (, : 2CH) (intermediate delimiter).

• The unit sends as many data packets the number of bar codes read.

➮

See P.87 for “header string” and “delimeter”.

Page 49

3.2.4 Multi-label read mode 3 (Multi 3)

OK

Trigger input

Bar Code

Laser beams

Communication time

OK/NG output

Code 1 Code 2 Code 3 Code 4

Code 1

Code 2

Code 3

Code 4

NG

Header

Data read

from Code

1

Data read

from Code

2

Data read

from Code

3

Data read

from Code

4

, , ,Delimiter

As described in multi-label read modes 1 and 2, this mode also allows the unit to

read several bar codes (up to 4 codes) while the trigger input is on.

The unit sends the readout data at one time according to a specified sequence

after the trigger input turns off. When up to 4 codes are in the laser beam’s field,

the unit can simultaneously reads all of them.

Operation of multi-label read mode 3

This mode allows the unit to continuously read each one of 4 bar code types “Code

1”, “Code 2”, “Code 3”, and “Code 4” as specified in the “code setup” of the setup

software (

bar codes (each of 3 types). If 2 types are specified, the unit reads 2 bar codes.

The following time chart is given.

➮

see P.61

). If 3 types are specified in the “code setup”, the unit reads 3

Chapter 3 Functions for Reading Operation

3

Reading data format

* The above example chart is with all 4 codes specified in the “code setup” of the

setup software.

• The bar code reading sequence is not fixed.

• The unit communicates the readout data in the order of Code 1 to Code 4. After

the trigger input turns off, the unit sends all the data at one time.

• For OK/NG output, “OK” turns on if the unit reads all the specified Codes 1 to 4

and “NG” turns on if the unit fails to read at least one bar code. (Comparison to

the preset data is not performed.)

• Each data packet is separated by a comma (, : 2CH) (intermediate delimiter).

• If an read error occurs on any one of Codes 1 to 4, or the corresponding bar

code does not exist, “ERROR” (➮

see P.87 for the reading error codes

), instead