VHF FM TRANSCEIVER

TK-7150

SERVICE MANUAL

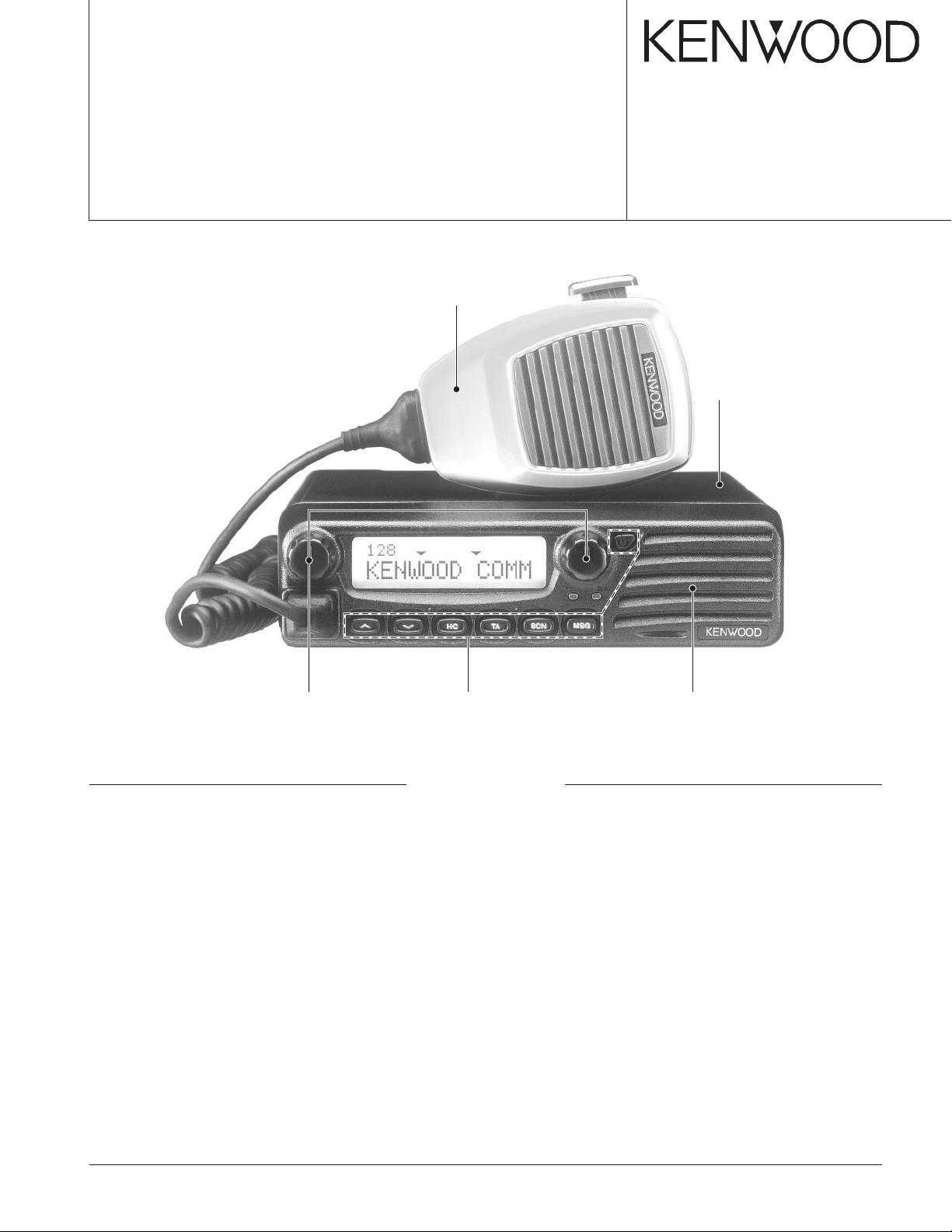

Microphone

(T91-0621-15)

© 2002-10 PRINTED IN JAPAN

B51-8633-00 (N) 843

Cabinet

(A01-2185-12)

Knob

(K29-9221-03) x 2

Key top

(K29-9222-02)

CONTENTS

GENERAL .................................................. 2

SYSTEM SET-UP ...................................... 3

OPERATING FEATURES .......................... 4

REALIGNMENT ......................................... 5

INSTALLATION ......................................... 7

CIRCUIT DESCRIPTION .......................... 12

SEMICONDUCTOR DATA ...................... 16

COMPONENTS DESCRIPTION .............. 20

PARTS LIST ............................................. 22

EXPLODED VIEW.................................... 32

PACKING ................................................. 33

Panel assy

(A62-1037-03)

ADJUSTMENT ........................................ 34

PC BOARD

DISPLAY UNIT (X54-3400-10) ............ 45

TX-RX UNIT (X57-6570-10) ................ 49

SCHEMATIC DIAGRAM.......................... 55

BLOCK DIAGRAM ................................... 63

WIRING.................................................... 65

TERMINAL FUNCTION ........................... 66

OPTIONS ................................................. 68

SPECIFICATIONS .................................... 69

TK-7150

GENERAL

INTRODUCTION

SCOPE OF THIS MANUAL

This manual is intended for use by experienced technicians familiar with similar types of commercial grade communications equipment. It contains all required service information for the equipment and is current as of this publication

data. Changes which may occur after publication are covered

by either Service Bulletins or Manual Revisions. These are

issued as required.

ORDERING REPLACEMENT PARTS

When ordering replacement parts or equipment information, the full part identification number should be included.

This applies to all parts : components, kits, and chassis. If the

part number is not known, include the chassis or kit number

of which it is a part, and a sufficient description of the required component for proper identification.

PERSONNEL SAFETY

The following precautions are recommended for personnel safety :

•DONOT transmit if someone is within two feet (0.6

meter) of the antenna.

•DONOT transmit until all RF connectors are verified se-

cure and any open connectors are properly terminated.

• SHUT OFF and DO NOT operate this equipment near

electrical blasting caps or in an explosive atmosphere.

• All equipment should be properly grounded before power-

up for safe operation.

• This equipment should be serviced by a qualified techni-

cians only.

PRE-INSTALLATION CONSIDERNATIONS

1. UNPACKING

Unpack the radio from its shipping container and check for

accessory items. If any item is missing, please contact

KENWOOD immediately.

2. LICENSING REQUIREMENTS

Federal regulations require a station license for each radio

installation (mobile or base) be obtained by the equipment

owner. The licensee is responsible for ensuring transmitter

power, frequency, and deviation are within the limits permitted by the station license.

Transmitter adjustments may be performed only by a licensed technician holding an FCC first, second or general

class commercial radiotelephone operator’s license. There is

no license required to install or operate the radio.

3. PRE-INSTALLATION CHECKOUT

3-1. Introduction

Each radio is adjusted and tested before shipment. However, it is recommended that receiver and transmitter operation be checked for proper operation before installation.

3-2. Testing

The radio should be tested complete with all cabling and

accessories as they will be connected in the final installation.

Transmitter frequency, deviation, and power output should

be checked, as should receiver sensitivity, squelch operation,

and audio output. QT equipment operation should be verified.

4. PLANNING THE INSTALLATION

4-1. General

Inspect the vehicle and determine how and where the radio antenna and accessories will be mounted.

Plan cable runs for protection against pinching or crushing

wiring, and radio installation to prevent overheating.

4-2. Antenna

The favored location for an antenna is in the center of a

large, flat conductive area, usually at the roof center. The

trunk lid is preferred, bond the trunk lid and vehicle chassis

using ground straps to ensure the lid is at chassis ground.

4-3. Radio

The universal mount bracket allows the radio to be

mounted in a variety of ways. Be sure the mounting surface

is adequate to support the radio’s weight. Allow sufficient

space around the radio for air cooling. Position the radio

close enough to the vehicle operator to permit easy access to

the controls when driving.

4-4. DC Power and wiring

1. This radio may be installed in negative ground electrical

systems only. Reverse polarity will cause the cable fuse

to blow. Check the vehicle ground polarity before installa-

tion to prevent wasted time and effort.

2. Connect the positive power lead directly to the vehicle

battery positive terminal. Connecting the Positive lead to

any other positive voltage source in the vehicle is not rec-

ommended.

CAUTION

If DC power is to be controlled by the vehicle ignition switch,

a switching relay should be used to switch the positive power

lead. The vehicle ignition switch then controls DC to the relay

coil.

3. Connect the ground lead directly to the battery negative

terminal.

4. The cable provided with the radio is sufficient to handle

the maximum radio current demand. If the cable must be

extended, be sure the additional wire is sufficient for the

current to be carried and length of the added lead.

5. INSTALLATION PLANNING – CONTROL STATIONS

5-1. Antenna system

Control station. The antenna system selection depends

on many factors and is beyond the scope of this manual.

Your KENWOOD dealer can help you select an antenna system that will best serve your particular needs.

2

GENERAL / SYSTEM SET-UP

TK-7150

5-2. Radio location

Select a convenient location for your control station radio

which is as close as practical to the antenna cable entry point.

Secondly, use your system’s power supply (which supplies

the voltage and current required for your system). Make sure

sufficient air can flow around the radio and power supply to

allow adequate cooling.

SYSTEM SET-UP

Merchandise received

License and frequency

allocated by FCC

YES

YES

Frequency range

136~174MHz

Control cable KCT-22

M : 8 feet

M2 : 17 feet

M3 : 25 feet

Supplied key label

Choose the type of transceiver

Are you using

the remote kit?

NO

Are you using

the key label?

NO

SERVICE

This radio is designed for easy servicing. Refer to the

schematic diagrams, printed circuit board views, and alignment procedures contained in this manual.

RF power

50W

See page 8.

KRK-9

See page 7.

Type

TK-7150 K

Are you using

the voice scrambler/

ANI?

NO

Are you using

the ignition sense

cable?

NO

Transceiver programming

Are you using

the external speaker?

NO

DC power cable

Supplied cable or

KCT-23 M : 10 feet

KCT-23 M3 : 23 feet

Are you using

the keypad microphone?

NO

Are you using

the noise-canceling micro-

phone?

NO

Supplied microphone

YES

YES

YES

YES

YES

Modified of control unit

See page 5.

A personal computer (IBM PC or compatible), programming interface (KPG-46),

and programming software (KPG-79D) are required for programming.

External speaker KES-5

DC power supply KPS-10A

See page 9.

See page 7.

KCT-18

See page 7.

KMC-28A

KMC-27A

Desk top microphone KMC-9C

Delivery

3

TK-7150

OPERATING FEATURES

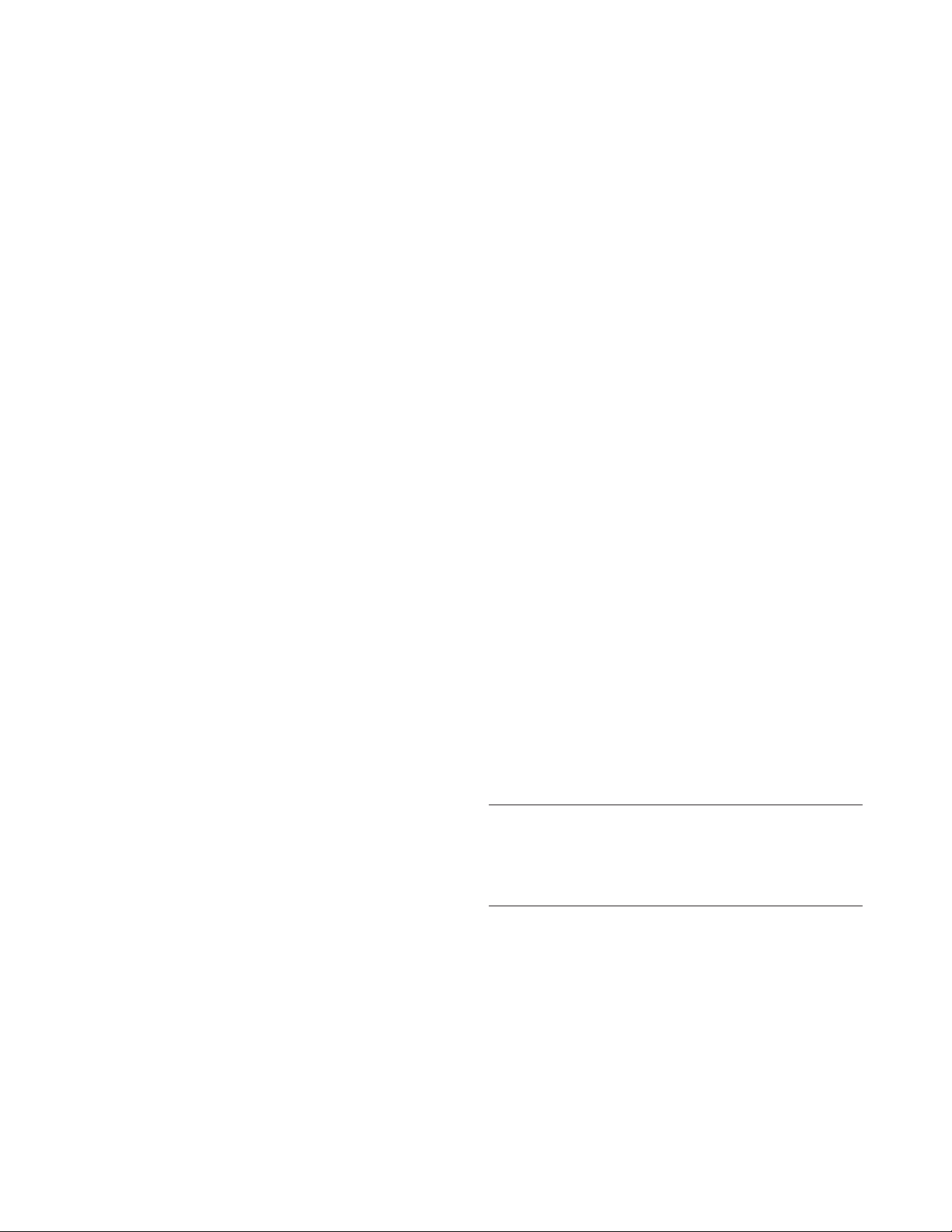

1. Controls and Functions

1-1. Front Panel

qwer

u

y

1-2. Microphone

!3

q Volume Control

Rotate to adjust the volume level. Clockwise increases

the volume and counterclockwise decreases the volume.

w Display

(See right.)

e Selector

Rotate to select a Zone or CH/GID (channel/group ID).

Clockwise increases the Zone / CH/GID and counterclockwise decreases the Zone / CH/GID. The default setting is

CH/GID Up/Down.

r (Power) switch

Press to switch the transceiver ON. Press and hold for

approximately 1 second to switch the transceiver OFF.

t Microphone Jack

Insert the microphone plug into this jack.

y PF1 Key

Press this key to activate its programmable auxiliary function. The default setting is Zone Up.

u PF2 Key

Press this key to activate its programmable auxiliary function. The default setting is Zone Down.

i PF3 Key

Press this key to activate its programmable auxiliary function. The default setting is None.

o PF4 Key

Press this key to activate its programmable auxiliary function. The default setting is None.

!0 PF5 Key

Press this key to activate its programmable auxiliary function. The default setting is None.

!1 PF6 Key

Press this key to activate its programmable auxiliary function. The default setting is None.

!2 TX / BUSY LEDs

The TX LED lights red while transmitting. In Conventional

Groups, the BUSY LED lights green while receiving.

4

!0t

oi!1 !2

!3 PTT switch

To transmit, press and hold this switch, then speak into

the microphone. Release to receive.

1-3. Display

CALL

Indicator Description

Displays the zone, group ID, and channel

numbers. Also displays various functions

which have been programmed by your dealer.

CALL

MON

(left side) the scan list.

SCN

SP

OP

(right side) ID is added to the scan list.

A

B

OS

Appears when the squelch opens during a

2-Tone or DTMF call.

Appears when the key programmed as

Monitor is pressed.

Appears when the selected Zone is added to

Appears when you are using Scan mode.

Appears when you are using an external

speaker.

Appears when the optional scrambler board

is installed and activated.

Appears when the selected Channel/Group

Appears when the auxiliary A function is

activated.

Appears when the auxiliary B function is

activated.

Appears when Operator Selectable Tone is

activated.

Appears when a FleetSync message is

stored in the transceiver memory. Appears

and blinks when a new message is received.

Displays the zone, group ID, and channel

numbers. Your dealer can program the zone,

group ID, and channel names with up to 12

characters, in place of numbers.

SCN SP OP OSABMON

1-4. Rear Panel

Power input

connector

Antenna

connector

6-pin connector

(for accessories)

25-pin connector

(for accessories)

REALIGNMENT

1. Modes 3. Panel Test Mode

User mode

[PF3]

Panel test mode

[PF1]+Power on

PC mode

Firmware programming mode

Clone mode

[PF6]+Power on

Firmware version

information

[PF3]+Power on

Mode Function

User mode For normal use.

Panel test mode Used by the dealer to check the funda-

Panel tuning mode Used by the dealer to tune the radio.

PC mode Used for communication between the

FPU data program- Used to read and write frequency data and

ming mode other features to and from the radio.

PC test mode Used to check the radio using the PC.

Firmware program- Used when changing the main program of

ming mode the flash memory.

Clone mode Used to transfer programming data from

Firmware version Used to confirm the internal firmware

information version.

Panel tuning mode

FPU data programming mode

PC test mode

[PF5]

Checksum

display mode

[PF4]

ment characteristics.

radio and PC (IBM compatible).

This feature is included in the FPU.

See panel tuning.

one radio to another.

PC tuning mode

2. How to Enter Each Mode

Mode Operation

User mode Power ON

Panel test mode [PF1]+Power ON

Panel tuning mode [Panel test mode]+[PF3]

PC mode Received commands from PC

Firmware programming mode

Checksum display mode

Clone mode [PF6]+Power ON

Firmware version information

[PF2]+Power ON

[Firmware programming mode]+[PF5]

[PF3]+Power ON (one second)

Setting method refer to “ADJUSTMENT”.

4. Panel Tuning Mode

Setting method refer to “ADJUSTMENT”.

5. PC Mode

5-1. Preface

The transceiver is programmed by using a personal computer, programming interface (KPG-46) and programming

software (KPG-79D).

The programming software can be used with an IBM PC

or compatible. Figure 1 shows the setup of an IBM PC for

programming.

5-2. Connection Procedure

1. Connect the transceiver to the personal computer with

the interface cable.

2. When the Power switch on, user mode can be entered

immediately. When PC sends command the radio enter

PC mode, and “PROGRAM” is displayed on the LCD.

When data transmitting from transceiver, the red LED is

blinking.

When data receiving to transceiver, the green LED is blink-

ing.

5-3. KPG-46 Description

(PC programming interface cable : Option)

The KPG-46 is required to interface the transceiver to the

computer. It has a circuit in its D-subconnector (25-pin) case

that converts the RS-232C logic level to the TTL level.

The KPG-46 connects the modular microphone jack of the

transceiver to the computers RS-232C serial port.

5-4. Programming Software Description

The KPG-79D programming disk is supplied in 3-1/2” disk

format. The software on this disk allows a user to program

the transceiver radio via programming interface cable (KPG-

46).

KPG-79D

TK-7150

IBM PC

KPG-46 or

KPG-46 +

Tuning cable

(E30-3383-05)

Fig. 1

TK-7150

5

TK-7150

REALIGNMENT

5-5. Programming With IBM PC

If data is transferred to the transceiver from an IBM PC

with the KPG-79D, the destination data (basic radio information) for each set can be modified. Normally, it is not necessary to modify the destination data because their values are

determined automatically when the frequency range (frequency type) is set.

The values should be modified only if necessary.

Data can be programmed into the flash memory in RS232C format via the modular microphone jack.

KPG-79D instruction manual parts No. : B62-1588-XX.

6. Firmware Programming Mode

6-1. Preface

The TK-7150 uses flash memory to allow it to be easily

upgraded when new features are released in the future.

6-2. Connection Procedure

Connect the TK-7150 to the personal computer (IBM PC or

compatible) with the interface cable (KPG-46). (Connection is

the same as in the PC mode.)

Note :

You can only program firmware from the 8-pin microphone connector on the front panel. Using the 25-pin logic

interface on the rear panel will not work.

6-3. Programming

1. Start up the programming software (Fpro. exe).

2. Set the communications speed (normally, 57600 bps) and

communications port in the configuration item.

3. Set the firmware to be updated by file name item.

4. Turn ON the transceiver while pressing and holding the

[PF2] key. The transceiver enters Firmware programming

mode and “PROG 57600”. If Firmware programming

mode is inhibited by the FPU, the transceiver enters User

mode instead.

If the transceiver receives the firmware data from a PC,

“PG” appears on the display.

5. Check the connection between the TK-7150 and the per-

sonal computer, and make sure that the TK-7150 is in the

program mode.

6. Press write button in the window. A window opens on

the display to indicate progress of writing.

7. If writing ends successfully, the TX LED on the TK-7150

lights.

8. If you want to continue programming other TK-7150, re-

peat steps 3 to 6.

Note :

This mode cannot entered if the firmware programming

mode is set to disable in the programming software (KPG79D).

6-4. Function

Each time you press the [PF4] key, the data transfer rate

alters (19200 / 38400 / 57600 bps).

Note :

Normally, write in the high-speed mode (57600 bps).

6

Firmware checksum display

PROG 57600

[PF4]

PROG 19200

[PF4]

PROG 38400

[PF4]

PROG 57600

[PF5]

SUM=[

****

[PF4]

]

Fig. 2

7. Clone Mode

Programming data can be transferred from one radio to

another by connecting them via their modular microphone

jacks. The operation is as follows (the transmit radio is the

master and the receive radio is a slave).

1. Turn the master TK-7150 power ON with the [PF6] key

held down. The TK-7150 displays “CLONE”.

If Firmware programming mode is inhibited by the FPU,

the transceiver enters User mode instead.

2. Power on the slave TK-7150.

3. Connect the cloning cable (No. E30-3382-05) to the modu-

lar microphone jacks on the master and slave.

4. Press the [PF6] key on the master while the master dis-

plays “CLONE”. The data of the master is sent to the

slave. While the slave is receiving the data, “PROGRAM”

is displayed. When cloning of data is completed, the mas-

ter displays “END”, and the slave automatically operates

in the User mode. The slave can then be operated by the

same program as the master.

5. The other slave can be continuously cloned. When the

[PF6] key on the master is pressed while the master dis-

plays “END”, the master displays “CLONE”. Carry out

the operation in steps 2 to 4.

6. To end cloning, first you must remove the cloning cable,

then switch both master and slave TK-7150s off.

Note :

Only the same models can be cloned together.

Cloning cable

(E30-3382-05)

Fig. 3

8. Firmware Version Information

This is a mode to confirm the internal firmware version.

1. Turn the transceiver ON while pressing the [PF3] key.

The firmware version will appear on the LCD.

When you release the [PF3] key, the transceiver automati-

cally enters User mode.

INSTALLATION

Cut

Tie wrap

Protective cover

4

5

Short plug

Black lead

Black/White lead

Speaker cable (to KES-5)

TK-7150

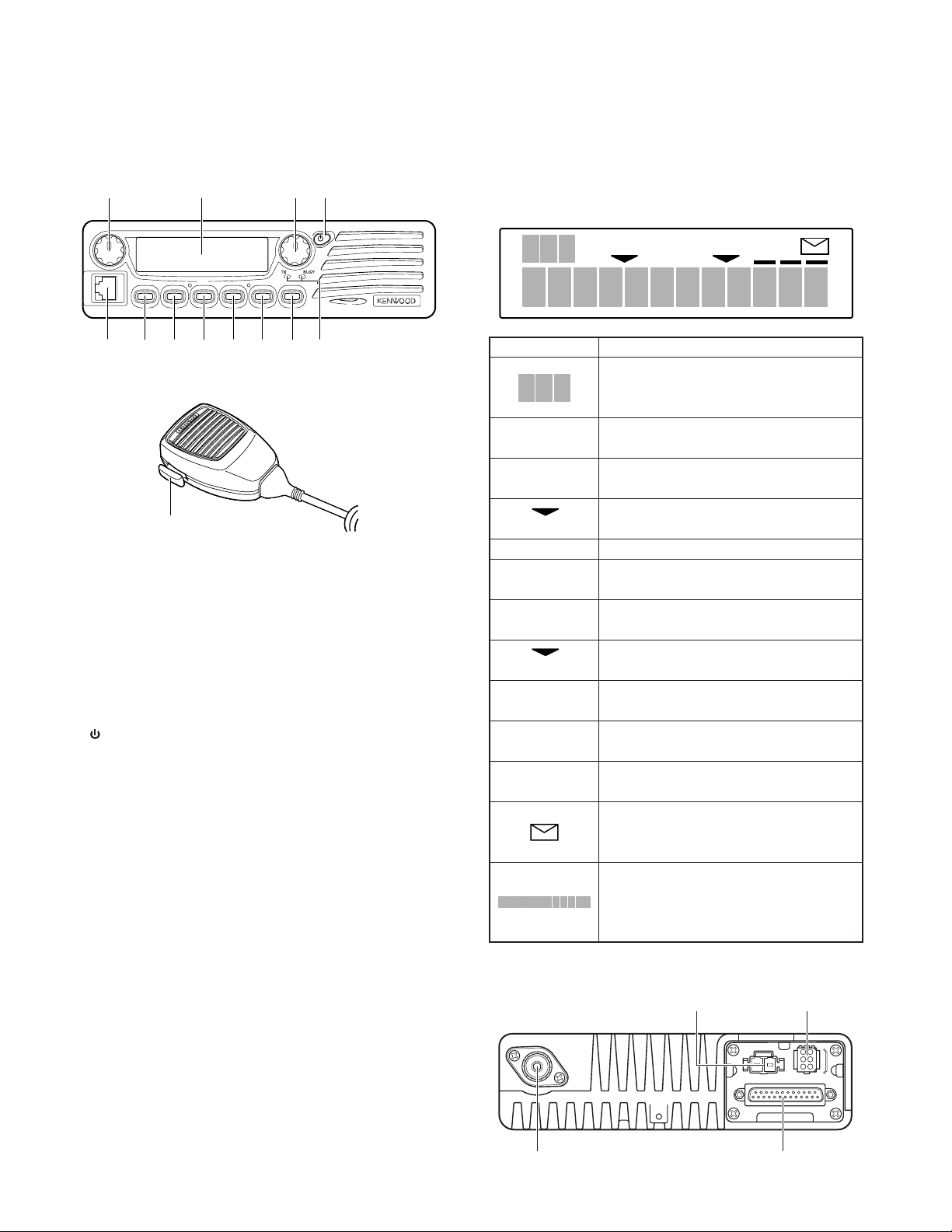

1. Installing Name Plate

Punch out the name plate card. Then insert the plates

onto the relative function keys.

You can reconfigure the name plates at any time.

Punch out the

name plate cards

Name plates for

the function keys

Squeeze and

insert the plates

Name plates

Side view of the key

Fig. 1

2. Ignition Sense Cable (KCT-18)

The KCT-18 is an optional cable to use the following func-

tions;

2-1. Ignition Function

The ignition function allows you to turn the transceiver’s

power on and off with the ignition key of your car. When you

are driving with the ignition key on, the horn alert function is

disabled.

2-2. Timed Power Off Function

The timed power off function turns the transceiver’s

power off the time specified with the programming software

(KPG-79D) after the ignition key is turned off. When you are

driving with the ignition key on, the horn alert function is disabled.

The ignition sense function and the timed power off function can be used at the same time.

2-3. Modification

1. Remove the short plug from the accessory connector (6

pins) on the rear of the transceiver.

2. Cut off the end of the protective cover (accessory), insert

the KCT-18 into the protective cover, and insert it into pin

1 (IGN) of the short plug.

3. Install the short plug and protective cover on the connec-

tor on the rear of the transceiver, then clamp the bottom

of the protective cover with the supplied tie wrap.

Short plug

3. External Speaker (KES-5)

The external speaker output from the accessory connector

(6 pin) on the rear of the transceiver is 13W/4Ω. Use the KES-5.

3-1. Connection for the KES-5 with the TK-7150

■ When taking the AF output from the accessory

connector (6-pin) on the rear of the radio

The following tools are required for changing the connector.

• Extracting tool

The following extracting tool is recommended;

Molex inc. Order No. : J5800-002 (W05-0878-00)

1. Remove the connector with jumper from the external

speaker connector on the rear panel of the radio (Fig. 3-1).

Note : Save the jumper, which is required when the radio

is used without the external speaker.

2. Remove the terminals with the jumper from the connec-

tor housing holes number 5 and 6 using the extracting

tool.

Removing the jumper lead (Fig. 3-2)

1) Insert the extracting tool (J5800-002) into the connec-

tor while pushing the jumper lead in the direction of (a).

2) Push the extracting tool into collapse the barbs of the

crimp terminal.

3) Pull out the lead while continuing to push the extracting

tool in the direction (b).

3. Cut off the end of the protection cover, insert the KES-5

speaker cable into the protective cover.

4. Reinsert the terminal with the black and white stripe lead

into hole number 5, and the terminal with the black lead

into hole number 4 (Fig. 3-3).

5. Install the plug and protective cover on the accessory con-

nector on the rear of the transceiver, then clamp the bottom of the protective cover with the supplied tie wrap.

Square-type plug

(E37-1031-05)

Extracting tool

(J5800-002)

Crimp terminal

Fig. 3-1

Fig. 3-2

(a)

(b)

Jumper

lead

Barbs

Crimp terminal

(E23-0613-05)

6

3

4

1

KCT-18

Protective cover

Fig. 2

Tie wrap

Cut

Fig. 3-3

7

TK-7150

Main panel

CN703

4. Use as Public Address Speaker

1. Remove the short plug from the 6-pin accessory connector on the rear of the radio. (Remove the jumpers as described in Section 3-1.)

2. Cut off the end of the protective cover, insert the speaker

cable into the protective cover, and insert it into pins 2 and

3.

3. Install the plug and protective cover on the accessory connector on the rear of the transceiver, then clamp the bottom of the protective cover with the supplied tie wrap.

4. If you remove jumper shorting pins 5 and 6, the 20W PA

(public address) voice signal is output from pins 2 and 3.

(Only when the PA or SP switch is on.)

5. If you use the radio with pins 5 and 6 shorted, the internal

speaker is available.

Notes :

•Relation ship between accessory connector (6-pins) connection and speaker output.

• When pins 5 and 6 are shorted; The internal speaker is

used.

• When pins 5 and 6 are open and output is from pins 2 and

3; The 20W external speaker is used.

Short plug

INSTALLATION

Rubber seal

Ground wire

KCT-22

Fig. 5-1

CN902

Display unit

3

Black lead

2

Black/White lead

Protective cover

Tie wrap

Cut

Speaker cable

Fig. 4

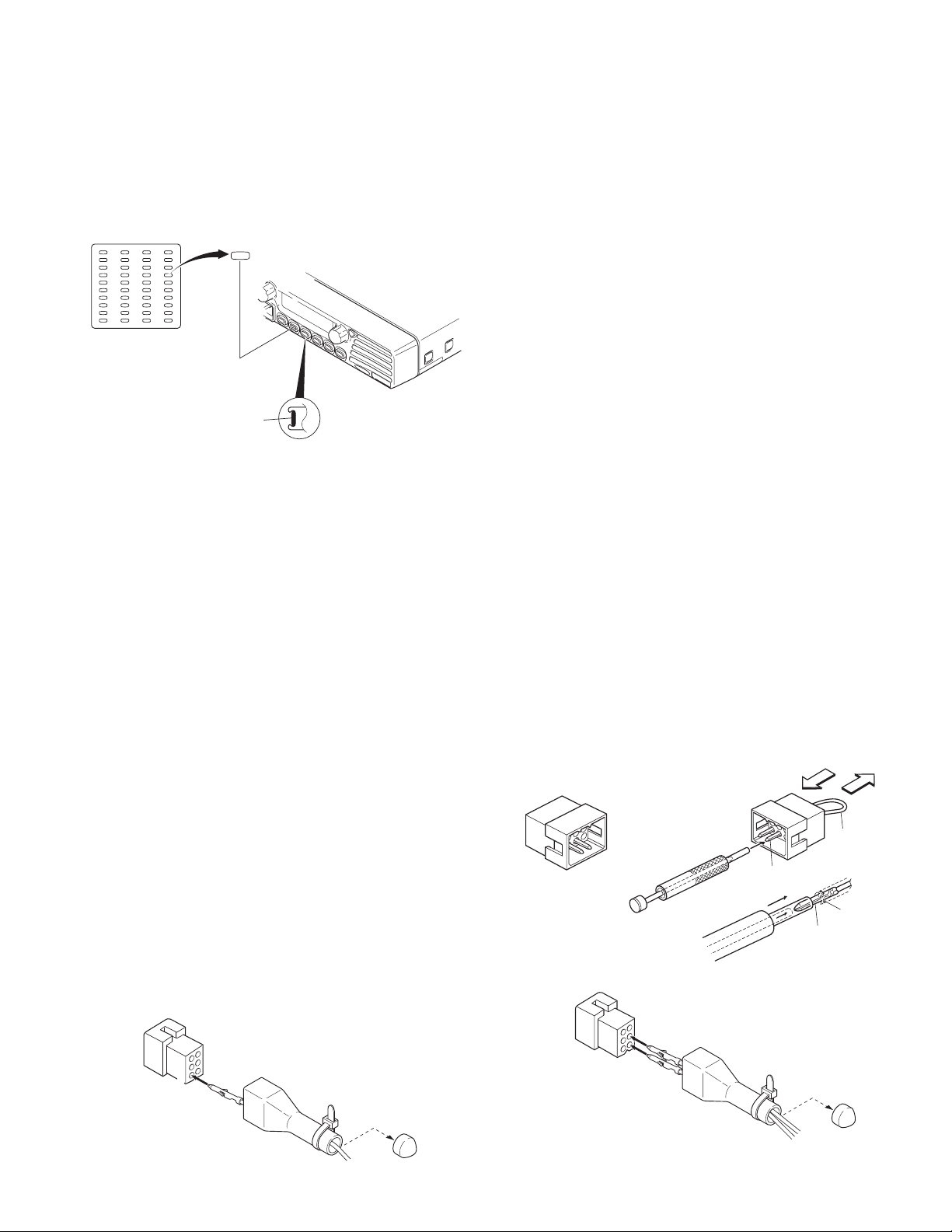

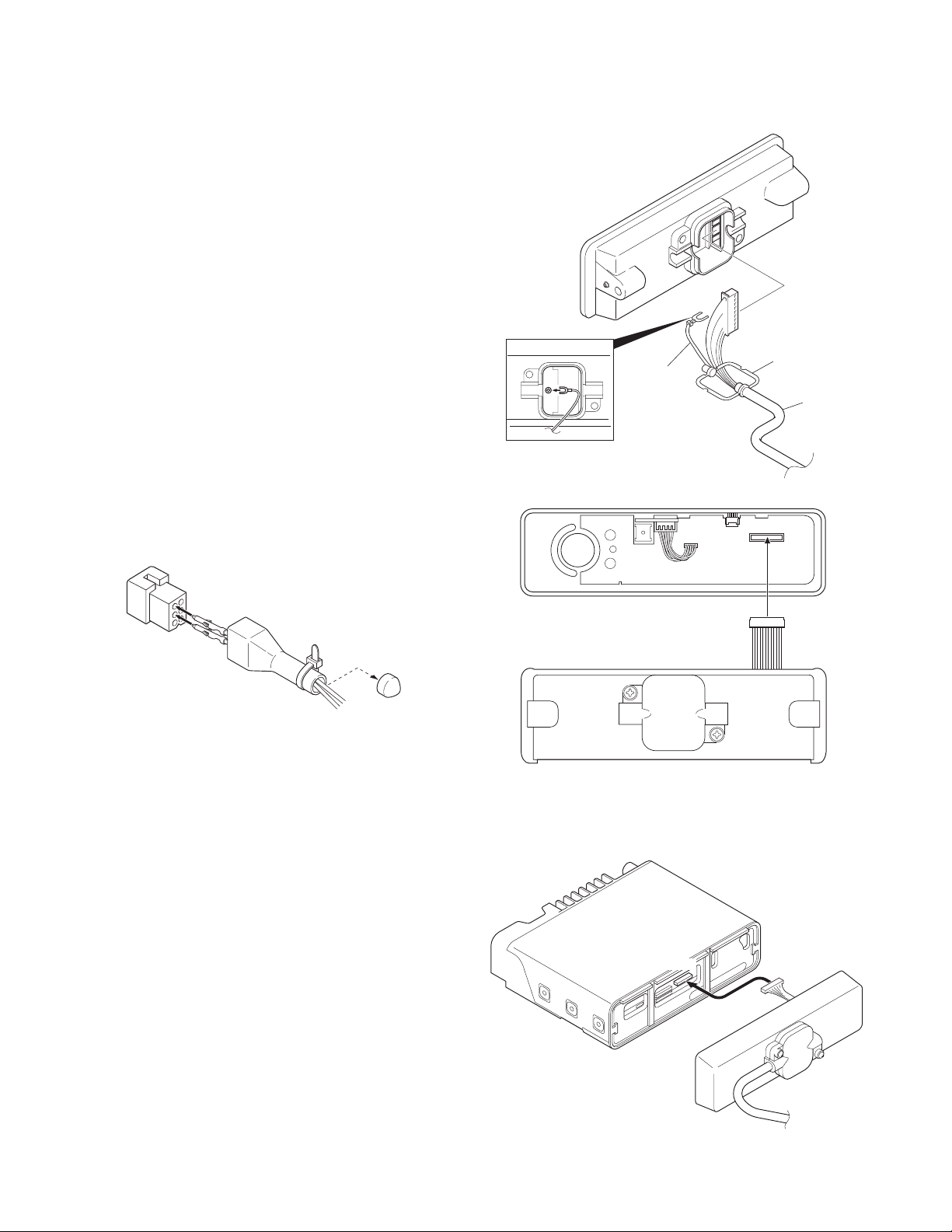

5. Single Control Head Remote Kit (KRK-9)

and Control Cable (KCT-22)

1. Lift the tab on the bottom of the transceiver, then pull the

panel away from the transceiver.

2. Remove the connector that binds the display unit to the

TX-RX unit.

3. As shown in Figure 5-1, make sure that the rubber seal is

placed above the cable, then plug the 11-pin connector

into the front panel PCB assembly.

4. Also, affix the ground wire to the front panel chassis, as

shown in Figure 5-1, with the supplied screw.

5. Choose the remote wire position (right side or left side),

then place the seal within the guide rail. Attach and secure the cover using the 2 binding screws.

6. Plug the 12-pin connector (from the rear panel) to the

CN902 socket on the display PCB, as shown in Figure 5-2.

7. Push and secure the panel into the chassis so that the 6

tabs on the top and bottom are securely fixed.

8. Plug the connector from the main panel into the CN703

socket (Figure 5-3).

9. Push and secure the main panel so that the 6 tabs on the

top and bottom of the panel are securely fixed.

8

Rear panel

Fig. 5-2

Fig. 5-3

INSTALLATION

TK-7150

6. Optional Board

6-1. Voice Scrambler Board Connection

■ Modification

1. Remove the cabinet and shielding cover from the trans-

ceiver.

2. Remove the panel.

3. Delete R798 and R866 on the TX-RX unit.

■ Connection

The functions of pins of CN701 on the foil side of the TX-

RX unit are shown in the figure.

Join the CN701 connector to the voice scrambler board via

the E37-0808-05 connector cable.

Note : You must setup the FPU.

The Voice Scrambler Board is connected subsequent

to the de-emphasis circuit.

CN701

TXI (MIC signal input)

TXO (MIC signal output)

RXI (Audio signal input)

AC (Scrambler control signal output)

BC1 (Scrambler code signal output 1)

BC2 (Scrambler code signal output 2)

BC3 (Scrambler code signal output 3)

BC4 (Scrambler code signal output 4)

NC (Non connection)

NC (Non connection)

RXO (Audio signal output)

PTOS (TX signal output)

8C (8V output)

E (Ground)

1

14

Voice

scrambler

6-2. ANI Board Connection

■ Modification

1. Remove the cabinet and shielding cover from the transceiver.

2. Remove the panel.

■ Connection

Join the CN700 connector to the ANI board via the E37-

0808-05 connector cable.

When the ANI board QE-2 is used, you must also use the

E37-1075-05 connector.

Note : You must setup the FPU.

1

14

ANI board

CN700

BUSY (Busy signal output)

EMG (Emergency signal output)

KEY (TX control signal input)

AUX (Emergency signal input)

INH (MIC mute signal input)

STON (Side tone input)

TCNT (Speaker mute signal input)

DATA (Data signal input)

E (Ground)

8C (8V output)

PTOA (PTT signal output)

DETO (Detected signal output)

NC (Non connection)

NC (Non connection)

Fig. 6-3 Component side of the TX-RX unit

Fig. 6-1 Foil side of the TX-RX unit

TX-RX UNIT

Component side

R866

R798

6-3. Example for Wire Connection

■ Picture (Scrambler board and ANI board)

Top view

Fig. 6-2

Front view

9

TK-7150

INSTALLATION

7.

Wiring of the Cable for Installing the

Built-in Type GPS Unit or Other PC Board

1. Loosen the 2 screws ( 1 ) to remove the D-sub 25-pin

connector.

2. Looses the 4 screws ( 2 ) to remove the Hardware fixture.

3. Remove the CN704 connector with the 6-pin lead wire.

4. Take out the Hardware fixture.

5. Cut the packing as shown in the illustratation.

7. Tighten the 4 screws to attach the Hardware fixture.

8. Tighten the 2 screws to fix attach D-sub 25-pin connector.

2

1

1

Packing

Cut out

Hareware

fixture

2

2

2

Packing

8. Horn Alert Function

The HR1 and HR2 pin of the accessory connector (25-pin)

on the rear of the transceiver is a relay and maximum current

is 1A.

8-1. Modification

1. Remove the cabinet and shielding cover from the trans-

ceiver.

2. Remove the panel.

3. Remove the short plug from the 6-pin accessory connec-

tor on the rear of the transceiver.

4. Delete R754 on the TX-RX unit.

Default Modification

R754 Enable Disable

State

HR1

HR2

HR1

HR2

R754

Cable of GPS unit

or other board

Cable styling

Fig. 7-1

TX-RX UNIT

Component side

Fig. 8

Fig. 7-2

10

Fig. 7-3

INSTALLATION

TK-7150

9. Special Instructions for Replacing the

Final Amplifier Q5

To replace the Final Amp Q5, ensure to follow the instruc-

tions given below:

9-1. C89 and C90 Positions

1. Ensure to solder C89 and C90 to securely contact Q5.

Note : The TX power may vary depending on the position

of C89 and C90.

9-2. Soldering

1. Ensure to solder C89 and C90 with the earth spring legs as

illustrated in Fig. 9-3.

Note : Use excessive solder to make it thicker than the

the electrodes of the chip.

2. Solder the terminals until the electrodes of the chip are

fully covered. (Refer to Fig. 9-1.)

Note : Use excessive solder to make it thicker than the

the electrodes of the chip. (Refer to Fig. 9-2.)

3. To solder the source side of C90 (FET Q5 source side),

solder the earth springs until they are fully covered. (Refer

to Fig. 9-4.)

C89,C90

C89,C90

The C89 and C90 must

contact securely the

Top view

Q5

C90

Side view

Solder Solder

Metal plate Metal plate

Solder

C90

PCB

Q5 package

C89

C89

ElectrodeConnect with solder

Fig. 9-3

NG

C89,C90

NG

Fig. 9-1

Fig. 9-2

OK

C89,C90

OK

The C89 and C90 must

contact securely

the Q5 package

C89

Q5

C90

OK

Top view

Fig. 9-4

11

TK-7150

CIRCUIT DESCRIPTION

1. Outline

The TK-7150 is a VHF/FM transceiver designed to operate

in the frequency range of 136 to 174MHz. Transmission output power is 50 watts. The maximum channel capacity is

128.

The unit consists of receiver, transmitter, phase-locked

loop (PLL) frequency synthesizer, and control circuits.

2. Receiver Circuit

The receiver is double conversion superheterodyne, designed to operate in the frequency range of 136MHz to

174MHz.

The receiver circuit consists of the following : 2-1 frontend circuit, 2-2 first mixer, 2-3 IF amplifier circuit, 2-4 audio

amplifier circuit, and 2-5 squelch circuit.

2-1. Front-end Circuit

The front-end circuit consists of former BPF (D209), RF

amplifier Q213, and latter BPF (D208 and D207). The BPF

covers frequency ranges 136 to 174MHz.

The latter BPF (D208 and D207) attenuates the unwanted

signals, and sends only the necessary signal to the first

mixer.

TX-RX UNIT (X57-657)

44.85MHz

IF AMP

Q207

IF AMP

Q206

SW

MCF (Wide)

XF201

MCF (Narrow)

XF202

D206D205

SW

2-2. First Mixer

The signal from the BPF is heterodyned with the first local

oscillator signal from the PLL frequency synthesizer circuit at

the first mixer DBM (Q209, Q210, Q211 and Q212) to become a 44.85MHz first intermediate frequency (IF) signal.

The first IF signal is fed through two monolithic crystal filters

(XF201; Wide, XF202; Narrow) to further remove spurious

signals.

2-3. IF Amplifier

The first IF signal is amplified by Q207 and Q206, and then

enters IC201 (FM system IC). The signal is heterodyned

again with a second local oscillator signal (44.395MHz) with

in IC201 to become a 455kHz second IF signal. The second

IF signal is fed through a 455kHz ceramic filters (CF201 and

CF203; Wide, CF202 and CF204; Narrow) to further eliminate

unwanted signal, and the quadrature detection circuit FM-detects the signal to produce a base-band signal and output it

from pin 9.

RX ANT

1st MIX DBM

Q209~212

BPF

D207,208

RF AMP

Q213

BPF

D209

RSSI

DET

SQL

W/N

Q205

SW

W/N

NOISE DET

D202

DET

IC714

AINR AOUTR

AMP

IC712 (A/2)

ASQ

RSSI

44.850MHz

FM SYSTEM IC : IC201

QUD

NOISE

AMP

Q204

SW

D203

W/N

DEO

IC713

CODEC

IC701

CPU

W/N

CF201,203

(Wide)

CF202,204

(Narrow)

455kHz

LPF

IC716 (A/2)

RXO RXI AFO

X201

44.395MHz

SW

D204

W/N

IC724 IC722

SW

Fig. 1 Receiver circuit

LPF

IC718

DAC

RF AMP

Q208

AMP

Buff AMP

Q513,515

RX

+44.85MHz

f

Q711 IC717

SW

MUTE

INT. SP

Q509

RX VCO

IC720

AF

AMP

12

CIRCUIT DESCRIPTION

TK-7150

2-4. Audio Amplifier

The recovered audio signal obtained from IC201 is amplified and anti-aliasing filtered by IC712 (A/2), inputted to the

AINR terminal of CODEC IC (IC713), and audio processed by

DSP (IC710). The processed audio signal from AOUTR terminal of IC713 is amplified and filtered by IC716 (A/2) to a sufficient level. The audio signal goes to an electronic volume

(IC718) and then it passes through the amplifier (IC722), to

the input of multiplexer IC (IC717), and is amplified to drive a

loudspeaker by an audio power amplifier (IC720). The audio

output can be provided to external 4Ω speaker through the 6pin ACC connector “ES1, ES2” on the rear panel. Q711 is a

mute switch.

2-5. Squelch Circuit

The output signal from IC201 enters FM IC again, then

passed through a band-pass filter.

The noise component output from IC201 is amplified by

Q204 and rectified by D202 to produce a DC Voltage corresponding to the noise level. The DC voltage is sent to the

analog port of the CPU (IC701).

IC201 outputs a DC voltage (RSSI) corresponding to the

input of the IF amplifier.

3. Transmitter Circuit

The transmitter circuit consists of the following circuits : 31 microphone circuit, 3-2 modulation level adjustment circuit,

3-3 driver and final power amplifier circuit, and 3-4 automatic

power control circuit.

3-1. Microphone Circuit

The signal from the microphone passes through the mute

switch (Q901) and is then routed to the Display unit (X54-340)

and TX-RX unit (X57-657). The signal then passes through

the AGC circuit to avoid signal distortion.

This circuit consists of IC714, D711, D712, Q707, and

Q708. The AGC is operated by controlling the + and – side

levels of amplitude using the current obtained by positive and

negative detection of the amplified audio signal.

The audio signal is amplified by IC712 (B/2), input to the

AINL terminal of CODEC IC (IC713), and audio processed by

DSP (IC710). The processed audio signal from the AOUTL

terminal of IC713 is amplified and filtered by IC716 (B/2), and

amplified by the summing amplifier IC719 (B/2).

3-2. Modulation Level Adjustment Circuit

The output of the summing amplifier IC719 (B/2) is passed

to an electronic volume (IC718) for maximum deviation adjustment before being applied to a varactor diode in the voltage controlled oscillator VCO.

3-3. Driver and Final Power Amplifier Circuit

The transmit signal is generated by the TX VCO (Q507),

amplified by Q513 and Q 515. This amplified signal is amplified by Q1, Q2, Q4, and Q5. And this signal is passed to the

FINAL stage. The RF power amplifier consists of MOS FET

transistor.

DISPLAY UNIT

(X54-340) TX-RX UNIT (X57-657)

IC714

(A/2)

MO

MB

VR700

SW

D-SUB

MI2

16.8MHz

IC717

Q507

TX VCO

VCXO

X501

AMP

DET

D711,712

Q513

Buff

AMP

Q901

SW

J901

MIC jack

MIC

TXI

IC712

(B/2)

AMP

AINL

Q707,708

ATT

TXO

Fig. 2 Microphone circuit

Q515

Buff

AMP

Q1

Drive

AMP

Q2

Drive

AMP

PC

IC2

(A/2)

CODEC

Q4

Drive

AMP

REF

AMP

DC

AMP

IC

D-SUB

Vcont

IC2

(B/2)

AOUTL

DI

Q5

Final

AMP

VR1

Power adj.

IC716

(B/2)

LPF

SW

IC717

D3

SW

D5 D6

IC719

(B/2)

AMP

DET DET

IC718IC713

DAC

ANT

IC715

(B/2)

DC

AMP

MO

MB

Fig. 3 Drive and final amplifier circuit

13

TK-7150

CIRCUIT DESCRIPTION

3-4. Automatic Power Control, Circuit and Transmitter

The automatic power control (APC) circuit stabilizes the

transmitter output power at a predetermined level, and consists of forward/reflected power detector circuits. The forward/reflected power detector circuits detects forward RF

power and reflected RF power to DC voltage, and consists of

a C coupling type detection circuit, RF detector D5/D6, and

DC amplifier IC2 (A/2).

The voltage comparator (IC2 B/2) compares the voltage

obtained by the above detected voltage with a reference voltage, set using the microprocessor and IC718 and IC715.

An APC voltage proportional to the difference between

the sensed voltage and the reference voltage appears at the

output of IC2. This output voltage controls the gate voltage

for the drive amplifier Q4 and final amplifier Q5, which keeps

the transmitter output power constant.

4. PLL Frequency Synthesizer

The transmit signal and the receive first L.O. signal are

generated by the PLL digital frequency synthesizer. The frequency synthesizer consists of a transmitter voltage controlled oscillator (TX VCO; Q507), a receiver voltage controlled oscillator (RX VCO; Q509), a buffer amplifier (Q513

and Q515), an RF amplifier (Q516), a low-pass filter (Q501,

Q503 and Q504), a PLL IC (IC501), and TX VCO/RX VCO

switches (Q510 and Q512).

In the transmit signal mode, an operating frequency programming data is sent to IC501, from the CPU (IC701), to set

the programmable counter within IC501. Q512 is turned on

to activate the TX VCO and the output signal of the TX VCO is

amplified by Q513 and Q516.

The signal is then divided down in frequency, at the programmable counter in IC501, to 5.0kHz or 6.25kHz, 7.5kHz

which is compared in phase with a 5.0kHz or 6.25kHz, 7.5kHz

reference signal, derived from 16.8MHz VCXO (X501) and a

MO

STR

12CL

LPF

Q501

Q503

Q504

Q507

Q509

IC501

8CL 8CL 8C 8T

Q513 Q515

TX VCO

SW

SWSW

RX VCO

PLL IC

CP

DT

IC701

CPU

Q512

Q510Q514

8CL

5C

EP

BUFF

AMP

Q516

AMP

LPF

Q518 Q519

SW SW

UL

BUFF

AMP

5C

D513

D514

SW

8R

X501

16.8MHz

VCXO 5C

MB

TX

RX

1/3360 or a 1/2688, 1/2240 fixed counter in IC501, at the

phase comparator in IC501. The VCXO operates at 16.8MHz

and its frequency stability is maintained within 2.5ppm (temperature range of –30 to +60 degrees).

The phase comparator output signal is fed into a low-pass

filter (Q501, Q503 and Q504) before being applied tot the TX

vco as a frequency control voltage. This low-pass filter’s

power is supplied by the DC/DC converter (Q502, Q505,

Q506, Q508, and Q511). If an unlock condition occurs in the

phase locked loop, this condition is detected by Q518 and

Q519. This cause the transmitter 8V supply cut off, resulting

in the prevention of an unauthorized transmission.

The transmitter modulation signals (processed Mic. audio

and sub-audible signalling) are applied to the TX VCO for frequency modulation.

In the receive mode, the VCO is substituted with Q509

(RX VCO) and it generates the receiver first local oscillator

signal according to the data sent from the CPU (IC701). The

basic operation of the synthesizer remains the same.

5. Control Circuit

The control circuit mainly consists of CPU, memory circuit, DSP circuit, and power supply circuit.

5-1. CPU

The CPU (IC701) controls the flash ROM (IC705), the DSP

(IC710), the receiver circuit, the transmitter circuit, the control circuit, and the display circuit and transfers data to or

from an external device.

5-2. Memory Circuit

IC705 has a flash ROM with a capacity of 4M bits that

contains the control program for the CPU, the signal processing program for DSP and data such as channels and operating

features.

This program can be easily written from an external devices. Data such as the operating status are programmed

into the EEPROM (IC704).

IC705IC704

EEPROM

IC103

Reset IC

X700

12.288MHz

Q700

BEAT

SHIFT

IC711

IC701

CPU

SW

Interface IC

INV

DSP

CODEC IC IC713

Flash ROM

IC703

232C driver

IC718

D/A IC

IC700/702

Shift register IC

IC706~709

IC710

14

Fig. 4 PLL circuit

Fig. 5 Control circuit

CIRCUIT DESCRIPTION

TK-7150

5-3. DSP Circuit

The DSP circuit filters transmit/receive audio signal and

encode/decode signalling (QT, DQT, MSK, DTMF, 2-Tone,

LTR ID). This circuit consists of IC710, IC706, IC707, IC708,

IC709 and IC713.

The receive audio signal is converted from analog to digital

by IC713 with a sampling frequency of 19.2kHz. The digitized

audio signal is sent to DSP (IC710) to process the signalling

signal and audio signal. The processed digital audio signal is

fed to CODEC (IC713), converted from digital to analog, and

the analog signal is output from pin 16 (AOUTR).

The transmit audio signal coming from IC714 (A/2) is amplified by IC712 (B/2), fed to pin 3 (AINL) of CODEC (IC713),

and converted from analog to digital at a sampling frequency

of 19.2kHz. The digitized transmit audio signal is AGC-processed, pre-emphasized and filtered at 300Hz to 3kHz by

DSP (IC710), and the resulting signal is feed back to CODEC

(IC713), and converted from digital to analog, and the analog

signal is output from pin 15 (AOUTL).

IC706, IC707, IC708 and IC709 are interface IC between

the CPU operated at 5.0V and the DSP operated at 3.3V.

5-4. Power Supply Circuit

The voltage is always applied from +B. D103 protects

IC102 (DFF) against overvoltage.

Pulses from power switch are input to the IC102 clock line

and the CPU (IC701). These clock pulses reverse the output

High (radio : turn off) → Low (radio : turn on), do not reverse

the output Low → High. The CPU (IC701) output the pulse to

IC102 set line to reverse the output Low → High.

IGN is input to the IC102 reset line and the CPU (IC701).

When the IC102 reset voltage rise, the output goes Low (ra-

dio : turn on). When IGN falls, the CPU (IC701) output the

pulse to IC102 set line to reverse the output Low → High

after the programmed time expire (Timed power off function).

If 24V is supplied to the radio by mistake, Q102 turns on,

Q101 turns off, the power is forced to be turned off.

This circuit consists of IC104 (8V), IC105 (5V), IC106

(3.3V), IC108 (3.3V) and IC107 (1.8V).

6. Display Circuit

The display unit consists of CPU (IC904), LCD assembly,

LED, and other components.

Channels are changed by the rotary switch (S1). The up/

down signals from the rotary switch enter the CPU (IC904),

and converted to a serial data signal, and are sent to the CPU

(IC701) in the TX-RX unit. The on/off signals of keys other

than the power switch, and the PTT and HOOK signals, are

converted to serial data and sent to the CPU (IC701) in the

TX-RX unit.

Data is displayed on the 12 digits and 3 digits dot matrix

alphanumeric display.

7. RS-232C Circuit

The RS-232C circuit connects the RS-232C serial port of a

personal computer directly to this model to perform FPU operation (Read and Write). The FPU operation can also be performed by connecting a programming cable (KPG-46) to the

local microphone on the front panel. The 232C driver IC

(IC703) changes the TTL-232C level. The firmware can only

be rewritten with the local microphone on the front panel.

+B

R112

D103

AVR

D104

SW

Q109,110

SW

D105

SW

D109

AVR

IGN PSW

IC102

DFF

Q112,113

SW

IC701

CPU

Q710

SW

D106SWD102

Q111

SW

Q108

SW

Q713

SW

Fig. 6 Power supply circuit

SW

Q102

SW

Q103

SW

Q101

SW

SB

LCD

PTT

D915

RX LED

D912

TX LED

Q903

SW

SB

D910

D909D908

SW

Key back lamp

HK

SW

Q907

SW

Q906

D907

REF

D911D913D914

SWQ904

IC904

CPU

Q908

Q902

SW

X901

12MHz

5V

RST

PF1

DM

MIC

1

Rotary SW

AVR

IC901

PF2 PF3 PF4 PF5 PF6

AF VR

SB

HK

PTT

J901

BEAT SHIFT

POWER

SW

E

ME

8LC

8

PSW

SB

RST

IRS

ES2

MIC

INT SP

Fig. 7 Display circuit

15

TK-7150

SEMICONDUCTOR DATA

1. CPU : 30620M8A-5H1GP (TX-RX Unit IC701)

1-1. Pin Function

Pin No. Name I/O Function

1 I/O Go to port check mode

L : Port check mode, H : User mode

2WNOWide/Narrow H : Narrow, L : Wide

3 8RC O 8R Control H : 8R on, L : 8R off

4 INTx O INT Request to DSP L : INT request

5 STR O VCO TX/RX H : TX VCO, L : RX VCO

6 BYTE +5V

7 CNVss GND

8 8TC O 8T Control H : 8T on, L : 8T off

9 SFT O Beat Shift H : SFT on, L : SFT off

10 RESET CPU Reset

11 Xout 12.288MHz

12 Vss GND

13 Xin 12.288MHz

14 Vcc +5V

15 NMI I Not Used

16 IGN I Ignition Sense

H : IGN. Sense off, L : IGN. Sense on

17 PSI I Power Down Det L : Power down det

18 LD O D/A Converter LD

19 CP O PLL IC Clock

20 EP O PLL IC Enable

21

22 DT O Common Data

23 CK O Common Clock

24 SOE O Shift Register 1 OE

25 STB1 O Shift Register 1 Strobe

26 AI4 I AUX Input No.4 H : Inactive, L : Active

27 RXD2 I Head Comm (RXD)

28 TXD2 O Head Comm (TXD)

29 TXD1 O Acc com2 (TXD)

30 RXD1 I Acc com2 (RXD)

31 AI3 I AUX Input No.3 H : Inactive, L : Active

32 AI2 I AUX Input No.2 H : Inactive, L : Active

33 TXD0 O Acc com1 (TXD)

34 RXD0 I Acc com1 (RXD)

35 AI1 I AUX Input No.1 H : Inactive, L : Active

36 O Not Used

37 RDY I Hardware BUS Wait Control

38 ALE O Cannot Use (Address Latch)

CONTROL

O Connect Codec TX Out to speaker line

H : Connect, L : Disconnect

Pin No. Name I/O Function

39 HOLD I Cannot Use (BUS Hold)

40 HLDA O Cannot Use (BUS Hold Status)

41 BCLK O Cannot Use (Sys Clock Output)

42 RD O Flash ROM : RD, DSP : HDS1

43 BHE O Cannot Use (BUS High Enable)

44 WR O Flash ROM : WR, DSP : HDS2

45 SBC O SB Control H : SBC off, L : SBC on

46 AM O

47 HCS O DSP HCS

48 CS0 O Flash CS

49~59 A19~A9 O Cannot Use (Flash ROM Address BUS)

60 Vcc +5V

61 A8 O Cannot Use (Flash ROM Address BUS)

62 Vss GND

63~70 A7~A0 O Cannot Use (Flash ROM Address BUS)

71 PTO O Scrambler TX/RX Control H : RX, L : TX

72 PSW I

73 Inty I INT Request from DSP L : INT request

74 RS O DSP Reset H : DSP reset

75 SCL O EEPROM Clock

76 SDA I/O EEPROM Data

77 KEY I

78 STB2 O Shift Register 2 Strobe

79~86 D7~D0 Cannot Use (Flash ROM Data BUS)

87 PDET I Power Det Level

88 CDET I Power Current Det Level

89 TEMP1 I Power Temp1 Level

90 TEMP2 I Power Temp2 Level

91 ASQ I Analog Squelch Level

92 RSSI I RSSI Level

93 UL I Unlock Level

94 Avss GND

95 I Not Used

96 Vref +5V

97 Avcc +5V

98 AUX I Emergency Channel Request from ANI

99 INH I Audio Inhibit from ANI board

100 TCNT I Tone Control from ANI board

Audio Mute H : SP mute, L : SP unmute

Pow. Switch Det H : Inactive, L : Active

TX Request from ANI board L : TX request

board L : Channel request

H : SP unmute, L : SP mute

L : Board tone output request

16

SEMICONDUCTOR DATA

TK-7150

2. Shift Register 1 : BU4094BCFV (TX-RX Unit IC702)

2-1. Pin Function

Pin No. Port Name

1

STROBE

2

SERIAL IN

3 CLOCK CLK I

4Q1 MI2 O External Mic Mute

5Q2DIOExternal Data Line Mute

6Q3SPOFront SP/EXT SP Change

7Q4 HRO

8 VSS VSS GND

9QsQsONo Connect

10 Qs’ Qs’ O No Connect

11 Q8 AO4 O AUX Output No.4

12 Q7 AO3 O AUX Output No.3

13 Q6 AO2 O AUX Output No.2

14 Q5 AO1 O AUX Output No.1

15 OUTPUT SOE I From CPU SOE (Pin No.24)

ENABLE L → Inactive, H → Active

16 VDD VDD +5V

Name I/O Function

STB1 I From CPU STB1 (Pin No.25)

DATA I

From CPU Common Data (Pin No.22)

From CPU Common Clock (Pin No.23)

L : Mute, H : Unmute

L : Mute, H : Unmute

L : Front SP, H : External SP

Horn Alert L : Relay off, H : Relay on

H : AUX Out No.4 on, L : AUX Out No.4 off

H : AUX Out No.3 on, L : AUX Out No.3 off

H : AUX Out No.2 on, L : AUX Out No.2 off

H : AUX Out No.1 on, L : AUX Out No.1 off

3. Shift Register 2 : BU4094BCFV (TX-RX Unit IC700)

3-1. Pin Function

Pin No. Port Name

1 STROBE STB2 I From CPU STB1 (Pin No.21)

2

SERIAL IN

3 CLOCK CLK I

4Q1 BC1 O Scrambler Code 1 (For SCR)

5Q2 BC2 O Scrambler Code 2 (For SCR)

6Q3 BC3 O Scrambler Code 3 (For SCR)

7Q4 BC4 O Scrambler Code 4 (For SCR)

8 VSS VSS GND

Name I/O Function

DATA I

From CPU Common Data (Pin No.22)

From CPU Common Clock (Pin No.23)

L : SCR Code1 off, H : SCR Code1 on

L : SCR Code2 off, H : SCR Code2 on

L : SCR Code3 off, H : SCR Code3 on

L : SCR Code4 off, H : SCR Code4 on

Pin No. Port Name

9QsQsONo Connect

10 Qs’ Qs’ O No Connect

11 Q8 AC O Scrambler ON/OFF (For SCR)

12 Q7 BUSY O Channel Busy (For ANI)

13 Q6 EMG O Emergency ON/OFF (For ANI)

14 Q5 PTO O PTT Output (For ANI)

15 OUTPUT SOE GND

16 VDD VDD +5V

4. D/A Converter : M62364FP (TX-RX Unit IC718)

4-1. Pin Function

Pin No.

1 Vin1 I AF Volume First IN

2 Vout1 O AF Volume First OUT

3 Vout2 O AF Volume Second OUT

4 Vin2 I AF Volume Second IN (From DAC Pin No.2)

5 VDD +5V

6LDOFrom CPU LD(Pin No.18)

7CKOFrom CPU Common Clock (Pin No.23)

8DTOFrom CPU Common Data (Pin No.22)

9 Vin3 I GND

10 Vout3 O Tune Varicap

11 Vout4 O Side Tone Out

12 Vin4 I Side Tone (From Option Board)

13 Vin5 I

14 Vout5 O Max Deviation

15 Vout6 O

16 Vin6 I DQT Balance

17 Do O Open

18 VDAref I

19 Reset I +5V

20 GND GND

21 Vin7 I +5V

22 Vout7 O Frequency Adjust

23 Vout8 O Auto Power Control

24 Vin8 I +5V

Name I/O Function

L : Scrambler on, H : Scrambler off

L : Busy, H : Not Busy

L : Emergency on, H : Emergency off

L : PTT on, H : PTT off

ENABLE

Name I/O Function

17

TK-7150

SEMICONDUCTOR DATA

5. Display CPU : 30622M4A-443GP (Display Unit IC904)

5-1. Pin Function

Pin No. Name I/O Function

1 DISP O LCD Display ON/OFF L : On, H : Off

2~5 O Not used

6 BYTE GND

7 CNVss GND

8ONot used

9 SFT O Beat Shift L : Shift off, H : Shift on

10 RESET CPU Reset

11 Xout 12.0MHz

12 Vss GND

13 Xin 12.0MHz

14 Vcc +5V

15 NMI I Not used

16~19 O Not used

20 MIC O Mic Mute L : Mute, H : Unmute

21,22 O Not used

23 DM I/O Mic Keypad Data

24 O Not used

25 BLC O

26 O Not used

27 RXD2 I Body Comm (RXD)

28 TXD2 O Body Comm (TXD)

29 TXD1 O PC Comm (TXD)/connect to PTT

30 RXD1 I Open (RXD)

31 I Not used

32 O Not used

33 TXD0 O Open (TXD)

34 RXD0 I PC Comm (RXD)/connect to HOOK

35 HOOK I HOOK/connect to RXD0

36 PTT I PTT/connect to TXD1

37 O Not used

38 BCK1 O PF Key Backlight Control L : Off, H : On

39 PF1 I PF1 Key Input

40 PF2 I PF2 Key Input

Mic Keypad Backlight Control L : Off, H : On

Pin No. Name I/O Function

41 PF3 I PF3 Key Input

42 PF4 I PF4 Key Input

43 PF5 I PF5 Key Input

44 PF6 I PF6 Key Input

45~49 O Not used

50 BCK2 PF Key Backlight Control L : Off, H : On

51 TP3 I Head Check Mode L : Head check mode,

H : Not go to head check mode

52~56 O Not used

57 BUSY O BUSY LED L : Off, H : On

58 TX O TX LED L : Off, H : On

59 O Not used

60 Vcc +5V

61 O Not used

62 Vss GND

63~66 O Not used

67 RSW4 I Rotary SW4

68 RSW3 I Rotary SW3

69 RSW2 I Rotary SW2

70 RSW1 I Rotary SW1

71~81 O Not used

82 LEDK O LCD Back Light Control L : Off, H : On

83 DO O LCD Data Output

84 DI I LCD Data Input

85 CL O LCD Clock

86 CE O LCD CS

87~92 O Not used

93 VOL I Audio Volume Input

94 AVss GND

95 O Not used

96 AVref +5V

97 AVcc +5V

98~100 O Not used

18

SEMICONDUCTOR DATA

6. DSP : 320VC5402PGE (TX-RX Unit IC710)

6-1. Pin Function

Pin No. Name I/O Function

1,2,12,15,

35~38,

71~74,80,

90,110,126,

143,144

6,58,69,81, HD0~HD7 I/O HPI data bus

95,120,124,

135

5,7~11,105,

107~109,

131~134,

136~141,

13 HAS I HPI address strobe (Pull up)

17 HCS I HPI chip select

18 HR/W I HPI read/write

19 READY I Data ready (Pull up)

20 PS O Not used (No connect)

21 DS O Not used (No connect)

22 IS O Not used (No connect)

23 R/W O Not used (No connect)

24 MSTRB O Not used (No connect)

25 IOSTRB O Not used (No connect)

26 MSC O Not used (No connect)

27 XF O CODEC control

28 HOLDA - Not used (No connect)

29 IAQ - Not used (No connect)

30 HOLD I Hold (Pull up)

31 BIO I Serial data synchronize input

32 MP/MC I Not used (Pull down)

39 HCNTL0 I HPI control 0

41 BCLKR0 I

42 BCLKR1 -

43 BFSR0 I Frame sync. for receiver output

44 BFSR1 I Not used (No connect)

45 BDR0 I Serial data receive input

46 HCNTL1 I HPI control 1

47 BDR1 - Not used (No connect)

48 BCLKX0 I

49 BCLKX1 O Not used (No connect)

51

NC1~NC18

A0~A19 O Not used (No connect)

HINT/TOUT1

- Not used (No connect)

(H : power down, L : active)

Receive clock output (SCLK : 614.4kHz)

Master clock output (MCLK : 4.9152MHz)

(LRCK : 19.2kHz)

Transmit clock input (SCLK : 614.4kHz)

O Interrupt for Host CPU/Boot mode

select (Pull up)

TK-7150

Pin No. Name I/O Function

53 BFSX0 I Frame sync.for transmitter input

(LRCK : 19.2kHz)

54 BFSX1 I Not used (No connect)

55 HRDY - Not used (No connect)

59 BDX0 O Serial data transmit output

60 BDX1 - Not used (No connect)

61 IACK - Not used (No connect)

62 HBIL I Byte identification (HPI)

63 NMI I Not used (Pull up)

64 INT0 I Command interrupt from Host CPU

65 INT1 I Not used (Pull up)

66 INT2 I Boot mode select (Pull up)

67 INT3 I Not used (Pull up)

77 CLKMD1 I Clock mode select (Pull down)

78 CLKMD2 I Clock mode select (Pull up)

79 CLKMD3 I Clock mode select (Pull down)

82 TOUT0 - Not used (No connect)

83 EMU0 I/O Emulator 0 (to JTAG connector)

84

85 TDO O

86 TDI I Test data input (to JTAG connector)

87 TRST I Test reset (to JTAG connector)

88 TCK I Test clock (to JTAG connector)

89 TMS I

92 HPIENA I Not used (Pull up)

94 CLKOUT O Not used (No connect)

96 X1 - 12.288MHz (System clock)

97 X2/CLKIN - 12.288MHz (System clock)

98 RS I DSP reset input

99~104, D0~D15 - Not used (No connect)

113~119,

121~123

127 HDS1 I HPI data strobe1 (Pull up)

129 HDS2 I HPI data strobe2 (Pull down)

3,14,34,40, Vss - GND

50,57,70,

76,93,106,

111,128

4,33,56, DVDD - VDD for I/O pins (+3.3V)

75,112,130

16,52,68, CVDD - VDD for core CPU (+1.8V)

91,125,142

EMU1/OFF

I/O Emulator 1 (to JTAG connector)

Test data output (to JTAG connector)

Test mode select (to JTAG connector)

19

TK-7150

COMPONENTS DESCRIPTION

1. Display Unit (X54-3400-10)

Ref. No. Part Name Description

IC901 IC Voltage regulator

IC902 IC Voltage detector

IC904 IC CPU

Q901 FET MIC switch

Q902 FET DC switch

Q903 Transistor Current driver

Q904~908 Transistor DC switch

Q909,910 Transistor Inverter

Q911 Transistor DC switch

D902~906 Diode Surge protector

D907 Zener diode Voltage reference

D908~911 LED Key backlight

D912 LED TX light

D913,914 LED Key backlight

D915 LED RX light

D916 Zener diode Surge protector

D917 Varistor Current protector

D918 Zener diode Surge protector

2. TX-RX Unit (X57-6570-10)

Ref. No. Part Name Description

IC1 IC Not used

IC2 IC DC amplifier

IC101 IC Voltage detector

IC102 IC D flip-flop

IC103 IC Voltage detector

IC104~108 IC Voltage regulator

IC201 IC FM IF system

IC202 IC Multiplexer

IC501 IC PLL

IC700 IC Shift register

IC701 IC CPU

IC702 IC Shift register

IC703 IC RS232C transceiver

IC704 IC EEPROM

IC705 IC Flash ROM

IC706 IC Bus transceiver

IC707~709 IC OR gate

IC710 IC DSP

Ref. No. Part Name Description

IC711 IC Inverter

IC712 IC AF amplifier

IC713 IC CODEC

IC714 IC MIC amplifier/AGC

IC715 IC Buffer amplifier

IC716 IC Anti-aliasing filter

IC717 IC Multiplexer

IC718 IC D/A converter

IC719 IC AF amplifier

IC720 IC Audio power amplifier

IC721 IC DC amplifier

IC722 IC AF amplifier

IC723 IC Voltage regulator

IC724 IC Multiplexer

IC725 IC Voltage detector

Q1,2 Transistor RF amplifier

Q4 FET Drive amplifier

Q5 FET Final amplifier

Q101 Transistor DC switch

Q102 Transistor Switch

Q103 FET DC switch

Q104~113 Transistor DC switch

Q201~203 Transistor W/N switch

Q204 Transistor Noise amplifier

Q205 Transistor W/N switch

Q206 Transistor IF amplifier

Q207 Transistor Pre IF amplifier

Q208 Transistor RF amplifier

Q209~212 FET Mixer

Q213 Transistor RF amplifier

Q501 Transistor Active filter

Q502 FET Oscillator

Q503,504 Transistor Active filter

Q505,506 Transistor DC switch

Q507 FET TX oscillator

Q508 Transistor AVR

Q509 FET RX oscillator

Q510 Transistor TX/RX switch

Q511 Transistor Ripple filter

Q512 Transistor TX/RX switch

20

COMPONENTS DESCRIPTION

TK-7150

Ref. No. Part Name Description

Q513 Transistor Buffer amplifier

Q514 Transistor Inverter

Q515 Transistor Buffer amplifier

Q516 Transistor Amplifier

Q517 Transistor Ripple filter

Q518~520 Transistor DC switch

Q521 Transistor Inverter

Q700 FET DC switch

Q701~706 Transistor DC switch

Q707,708 Transistor MIC gain switch

Q709 Transistor Inverter

Q710,711 Transistor DC switch

Q712,713 FET DC switch

Q714 Transistor DC switch

Q716 Transistor DC switch

Q719,720 Transistor DC switch

D1 Zener diode Surge protector

D2 Zener diode Voltage protection

D3,4 Diode ANT switch

D5,6 Diode RF detector

D7 Diode Temperature compensation

D11 Diode Surge protector

D101 Diode Protection of reverse connection

D102,103 Zener diode Voltage reference

Ref. No. Part Name Description

D104~106 Diode DC switch

D108 Diode Surge protector

D109 Zener diode Voltage reference

D201 Diode DC switch

D202 Diode Noise detection

D203~206 Diode Wide/Narrow switch

D207~209 Varicap BPF tuning

D501~508 Varicap Frequency control

D509,510 Diode Voltage doubler

D511 Varicap Modulator

D512 Zener diode Voltage reference

D513,514 Diode RF switch

D515 Diode DC switch

D700~703 Diode Surge protector

D704 Diode Voltage reduction

D705~709 Diode Surge protector

D710 Zener diode Surge protector

D711,712 Diode AF detector

D714 Diode DC switch

D715 Zener diode Surge protector

D785~790 Zener diode Surge protector

D791 Varistor Current protector

D793 Varistor Current protector

D794 Diode Delay

21

TK-7150

TERMINAL FUNCTION

1. Display Unit (X54-3400-10) (A/2)

Pin No.

Name Description

CN901 (To remote speaker)

1 IRS BTL output for remote speaker output.

2 ES2 BTL output for remote speaker output.

CN902 (To TX-RX unit)

1ME MIC ground.

2 MIC MIC signal output.

3E Ground.

4 RESET Reset signal input.

5 TXD Serial data input.

6 RXD Serial data output.

7E Ground.

8 PSW Power switch control signal output.

9SB Power input after power switch (13.6V±15%).

10 IRS BTL input for remote speaker output.

11 ES2 BTL input for remote speaker output.

CN905 (To LCD assy)

1E Ground.

2 VCC 5V.

3CE Enable output for LCD driver.

4CL Clock output for LCD driver.

5DI Data output for LCD driver.

6DO Not used.

7 DISP Display control signal output. “L” : Display off

8 LEDA Power output for LCD backlight.

9 LEDK Ground for LCD backlight. “L” : Backlight on

10 NC Non connection.

CN906 (To Display unit B/2 : CH SW)

1E Ground.

2P4 SW position signal input 4.

3P3 SW position signal input 3.

4P2 SW position signal input 2.

5P1 SW position signal input 1.

J901 (MIC jack)

1DM Serial data input for keypad MIC.

2 MIC MIC signal input.

3 PTT PTT signal input. “L” : TX, “OPEN” : RX

Serial data output.

4SB Power output after power switch (13.6V±15%).

Pin No.

Name Description

5HK

6ME MIC ground.

7E Ground.

8 BLC

Hook signal input. “L” : On hook, “H” : Off hook

Serial data input.

MIC backlight control signal output. “H” : On, “L” : Off

2. Display Unit (X54-3400-10) (B/2)

Pin No.

Name Description

W1 (To Display unit A/2)

1P1 SW position signal output 1.

2P2 SW position signal output 2.

3P3 SW position signal output 3.

4P4 SW position signal output 4.

5E Ground.

3. TX-RX Unit (X57-6570-10)

Pin No.

Name Description

CN700 (To ANI board)

1 BUSY

2 EMG Emergency signal output.

3 KEY TX control signal input.

4 AUX Emergency signal input.

5 INH MIC mute signal input. “L” : Mute

6 STON Side tone input.

7 TCNT Speaker mute signal input. “L” : Unmute

8 DATA Data signal input.

9E Ground.

10 8C

TX sens signal output

Conventional “H” : Not TX, “L” : TX

LTR “H” : Not Link complete, “L” : Link complete

“L” : Emergency function is operated,

“H” : Emergency function is not operated

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

Active low with 47kΩ pull-up to 5V

L ≤ 0.8V, H ≥ 2.5V

Active low with 47kΩ pull-up to 5V

L ≤ 0.8V, H ≥ 2.5V

Active low with 47kΩ pull-up to 5V

L ≤ 0.8V, H ≥ 2.5V

L ≤ 0.8V, H ≥ 2.5V

8V. (CN700 No.10 + CN701 No.13 = 100mA Max.)

66

TERMINAL FUNCTION

TK-7150

Pin No.

Name Description

11 PTOA PTT signal output. “L” : PTT on, “H” : PTT off

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

12 DETO Detected signal output. DC coupled. Zo ≤ 100Ω

Wide : 0.8Vp-p typ., Narrow : 0.7Vp-p typ.

(Standard modulation)

13 NC Non connection.

14 NC Non connection.

CN701 (To voice scrambler)

1 TXI

2 TXO MIC signal output (Capacitor-coupled). Zo = 1kΩ

3 RXI

4AC

5 BC1 Scrambler code signal output 1.

6 BC2 Scrambler code signal output 2.

7 BC3 Scrambler code signal output 3.

8 BC4 Scrambler code signal output 4.

9NC Non connection.

10 NC Non connection.

11 RXO Audio signal output. DC coupled. Zo ≤ 100Ω

12 PTOS TX signal output. “L” : TX, “H” : Not TX

13 8C

14 E Ground.

MIC signal input (Capacitor-coupled). Zin = 100kΩ

Wide : 85mVp-p typ., Narrow : 85mVp-p typ.

(Standard modulation)

Audio signal input (Capacitor-coupled). Zin = 27kΩ

Wide : 1.3Vp-p typ., Narrow : 1.1Vp-p typ.

(Standard modulation)

Scrambler control signal output. “L” : On, “H” : Off

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

Wide : 1.3Vp-p typ., Narrow : 1.1Vp-p typ.

(Standard modulation)

L ≤ 0.05V, H ≥ 4.6V/30kΩ load

8V. (CN700 No.10 + CN701 No.13 = 100mA Max.)

CN703 (To Display unit A/2)

1ME MIC ground.

2 MIC MIC signal input.

3E Ground.

4 RESET Reset signal output.

5 TXD Serial data output.

Pin No.

Name Description

6 RXD Serial data input.

7E Ground.

8 PSW Power switch control signal input.

9SB Power output after power switch (13.6V±15%).

10 IRS BTL output for remote speaker output.

11 ES2 BTL output for remote speaker output.

CN704 (To ACC 6-pin connector)

1 IRS Remote speaker switch.

2 ES1 BTL output for external speaker A.

3 ES2 BTL output for external speaker A.

4 OS1 BTL output for external speaker B (PA).

5 OS2 BTL output for external speaker B (PA).

6 IGN Ignition sense input.

J700 (ACC 25-pin)

1NC Non connection.

2 RXD2 * Serial data input 2. RS-232C level. Input voltage

range = ± 30V max. L ≤ 0.4V, H ≥ 2.4V. Zi ≥ 5kΩ

3 TXD2 * Serial data output 2. RS-232C level.

L ≤ –5V, H ≥ 5V/3kΩ load. Zo ≤ 2kΩ

4 AO3 Auxiliary output 3 (Programmable). Active low

open collector (100mA max.) (Default none).

L ≤ 0.3V

5DI Data signal input (Capacitor-coupled). Z ≥ 10kΩ

6 MI2

7E Ground.

8 AO2 Auxiliary output 2 (Programmable). Active low

9 TXD3 ** Serial data output 3.

10 RXD3 ** Serial data input 3.

11 E Ground.

12 AI4 Auxiliary input 4 (Programmable). Active low

13 AI2 Auxiliary input 2 (Programmable). Active low

External MIC input (Capacitor-coupled). Z = 600Ω

with 10kΩ pull-up to 5V (100mA max.) (Default

none). L ≤ 0.3V, H ≥ 4.8V

L ≤ 0.7V, H ≥ 4.2V/25kΩ load. Zo ≤ 1kΩ

Input voltage range = +5/0 max. L ≤ 0.8V, H ≥ 4.2V.

with 47kΩ pull-up to 5V (Default none).

L ≤ 0.8V, H ≥ 2.5V

with 47kΩ pull-up to 5V (Default none).

L ≤ 0.8V, H ≥ 2.5V

67

TK-7150

TERMINAL FUNCTION / OPTIONS

Pin No.

Name Description

14 SB Power output after power switch. 13.6V± 15%,

1.1A max. at 25°C, 0.8A max. at 60°C

15 TXS TX sense signal output. Active high with 10kΩ

pull-up to 5V. L ≤ 0.3V, H ≥ 4.8V

16 HR1 Horn alert signal output 1. 1A max.

17 AFO Filtered audio output (DC coupled). Zo ≤1kΩ

PA : MIC signal output. 0.65Vp-p typ. (1kHz/5mV input)

RX : RX low level output. Wide : 1.3Vp-p typ.,

Narrow : 1.1Vp-p typ. (Standard modulation)

18 E Ground.

19 DEO Detected signal output (Capacitor-coupled).

20 AO1 Auxiliary output 1 (Programmable). Active low

with 10kΩ pull-up to 5V (100mA max.) (Default

none). L ≤ 0.3V, H ≥ 4.8V

21 AI1 Auxiliary input 1 (Programmable). Active low

with 47kΩ pull-up to 5V (Default none).

L ≤ 0.8V, H ≥ 2.5V

22 AO4 Auxiliary output 4 (Programmable). Active low

open collector (100mA max.) (Default none).

L ≤ 0.3V

23 HR2

24 AI3 Auxiliary input 3 (Programmable). Active low

25 ME MIC ground.

Horn alert signal output 2. 1A max. (Default ground)

with 47kΩ pull-up to 5V (Default none).

L ≤ 0.8V, H ≥ 2.5V

1. KES-5 (External Speaker)

1-1. External View

1-2. Parts List

New

Ref. No.

parts

✽ A62-1050-08 Panel assy

✽ A82-0050-08 Rear panel

✽ B43-1142-08 Badge Panel

✽ E30-3479-08 Speaker cable

✽ G13-1923-08 Cushion SP front

✽ G53-1553-08 Packing Rear panel

✽ J29-0699-08 Bracket

✽ N08-0551-08 Dressed screw Bracket

✽ N99-2031-08 Screw set Acc

✽ T07-0741-08 Speaker

Parts No.

Description

✽ : New parts

2. KRK-9 (Single Control Head Remote Kit)

1-1. External View

16

1514

17

* and ** : Pair

4. ACC 6-pin Connector

Pin No.

68

Name Description

1 IGN Ignition sense input.

2 OS2 BTL output for external speaker B (PA).

3 OS1 BTL output for external speaker B (PA).

4 ES2 BTL output for external speaker A.

5 ES1 BTL output for external speaker A.

6 RS1 Remote speaker switch.

1918

20

24232221

25

13121110987654321

1-2. Parts List

New

Ref. No.

parts

6

3

2

5

1

4

Parts No. Description

✽ A62-1039-02 Panel Body

✽ A82-0049-02 Rear panel Head

✽ E37-1008-05 Lead wire with connector 11P

✽ F07-1865-03 Mold cover For cable

✽ G02-0895-04 Earth spring Cable GND

✽ G53-1552-03 Packing Rear panel

✽ J21-8447-04 Hardware fixture Panel

✽ J29-0698-03 Bracket Acc

✽ N08-0550-04 Dressed screw Acc

N87-3008-45 Brazier head taptite screw Panel

✽ N99-2032-05 Screw set Acc

✽ : New parts

TK-7150

KENWOOD CORPORATION

2967-3, Ishikawa-machi, Hachioji-shi, Tokyo 192-8525, Japan

KENWOOD U.S.A. CORPORATION

P. O. BOX 22745, 2201 East Dominguez Street, Long Beach, CA 90801-5745, U.S.A.

KENWOOD ELECTRONICS CANADA INC.

6070 Kestrel Road, Mississauga, Ontario, Canada L5T 1S8

KENWOOD ELECTRONICS DEUTSCHLAND GMBH

Rembrücker Str. 15, 63150 Heusenstamm, Germany

KENWOOD ELECTRONICS BELGIUM N.V.

Leuvensesteenweg 248 J, 1800 Vilvoorde, Belgium

KENWOOD ELECTRONICS FRANCE S.A.

13, Boulevard Ney, 75018 Paris, France

KENWOOD ELECTRONICS U.K. LIMITED

KENWOOD House, Dwight Road, Watford, Herts., WD18 9EB United Kingdom

KENWOOD ELECTRONICS EUROPE B.V.

Amsterdamseweg 37, 1422 AC Uithoorn, The Netherlands

KENWOOD ELECTRONICS ITALIA S.p.A.

Via G. Sirtori, 7/9 20129 Milano, Italy

KENWOOD IBERICA S.A.

Bolivia, 239-08020 Barcelona, Spain

KENWOOD ELECTRONICS AUSTRALIA PTY. LTD.

(A.C.N. 001 499 074)

16 Giffnock Avenue, Centrecourt Estate, North Ryde, N.S.W. 2113 Australia

KENWOOD ELECTRONICS (HONG KONG) LTD.

Unit 3712-3724, Level 37, Tower one Metroplaza, 223 Hing Fong Road, Kwai Fong, N.T., Hong Kong

KENWOOD ELECTRONICS TECHNOLOGIES(S) PTE LTD.

Sales Marketing Division

1 Ang Mo Kio Street 63, Singapore 569110

Loading...

Loading...