Kenwood KM2901T Service Manual

MICROWAVE OVEN

KM2901T

SERVICE

Manual

MICROWAVE OVEN CONTENTS

plated

meal

auto weight

defrost

soup

hot

drink

min.

1min.

10sec.

hr.

10min.

power clock

KM2901T

0.1kg

0.1 kg

start

1min.+

stop

cancel

1. Precaution

2. Specifications

3. Operating Instructions

4. Disassembly and Reassembly

5. Alignment and Adjustments

6. Troubleshooting

7. Exploded Views and Parts List

8. PCB Diagrams

9. Schematic Diagrams

KENWOOD

1. Precaution

1-1 Safety precautions ( )

1-1

1. All repairs should be done in accordance

with the procedures described in this

manual. This product complies with

Federal Performance Standard 21 CFR

Subchapter J (DHHS).

2. Microwave emission check should be

performed to prior to servicing if the oven is

operative.

3. If the oven operates with the door open :

Instruct the user not to operate the oven and

contact the manufacturer and the center for

devices and radiological health immediatly.

4. Notify the Central Service Center if the

microwave leakage exceeds 5 mW/cm

2

5. Check all grounds.

6. Do not power the MWO from a "2-prong"

AC cord. Be sure that all of the built-in

protective devices are replaced. Restore any

missing protective shields.

7. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control

knobs and compartment covers.

8. Make sure that there are no cabinet openings

through which people--particularly

children--might insert objects and contact

dangerous voltages. Examples: Lamp hole,

ventilation slots.

9. Inform the manufacturer of any oven found

to have emmission in excess of 5 mW/cm2,

Make repairs to bring the unit into

compliance at no cost to owner and try to

determine cause.

Instruct owner not to use oven until it has

been brought into compliance.

CENTRAL SERVICE CENTER

10. Service technicians should remove their

watches while repairing an MWO.

11. To avoid any possible radiation hazard,

replace parts in accordance with the wiring

diagram. Also, use only the exact

replacements for the following parts:

Primary and secondary interlock switches,

interlock monitor switch.

12. If the fuse is blown by the Interlock Monitor

Switch: Replace all of the following at the

same time: Primary and secondary switches,

as well as the Interlock Monitor Switch. The

correct adjustment of these switches is

described elsewhere in this manual. Make

sure that the fuse has the correct rating for

the particular model being repaired.

13. Design Alteration Warning:

Use exact replacement parts only, i.e.,

only those that are specified in the

drawings and parts lists of this manual.

This is especially important for the

Interlock switches, described above.

Never alter or add to the mechanical or

electrical design of the MWO. Any design

changes or additions will void the

manufacturer's warranty.10.Always unplug

the unit's AC power cord from the AC

power source before attempting to

remove or reinstall any component or

assembly.

14. Never defeat any of the B+ voltage

interlocks. Do not apply AC power to the

unit (or any of its assemblies) unless all

solid-state heat sinks are correctly installed.

15. Some semiconductor ("solid state") devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs). Examples include

integrated circuits and field-effect

transistors.

Immediately before handling any

semiconductor components or assemblies,

drain the electrostatic charge from your

body by touching a known earth ground.

16. Always connect a test instrument's ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument's ground lead last.

Follow these special safety precautions. Although the microwave oven is completely safe during ordinary

use, repair work can be extremely hazardous due to possible exposure to microwave radiation, as well as

potentially lethal high voltages and currents.

17. When checking the continuity of the witches

or transformer, always make sure that the

power is OFF, and one of the lead wires is

disconnected.

18. Components that are critical for safety are

indicated in the circuit diagram by

shading, or .

19. Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications. A

replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

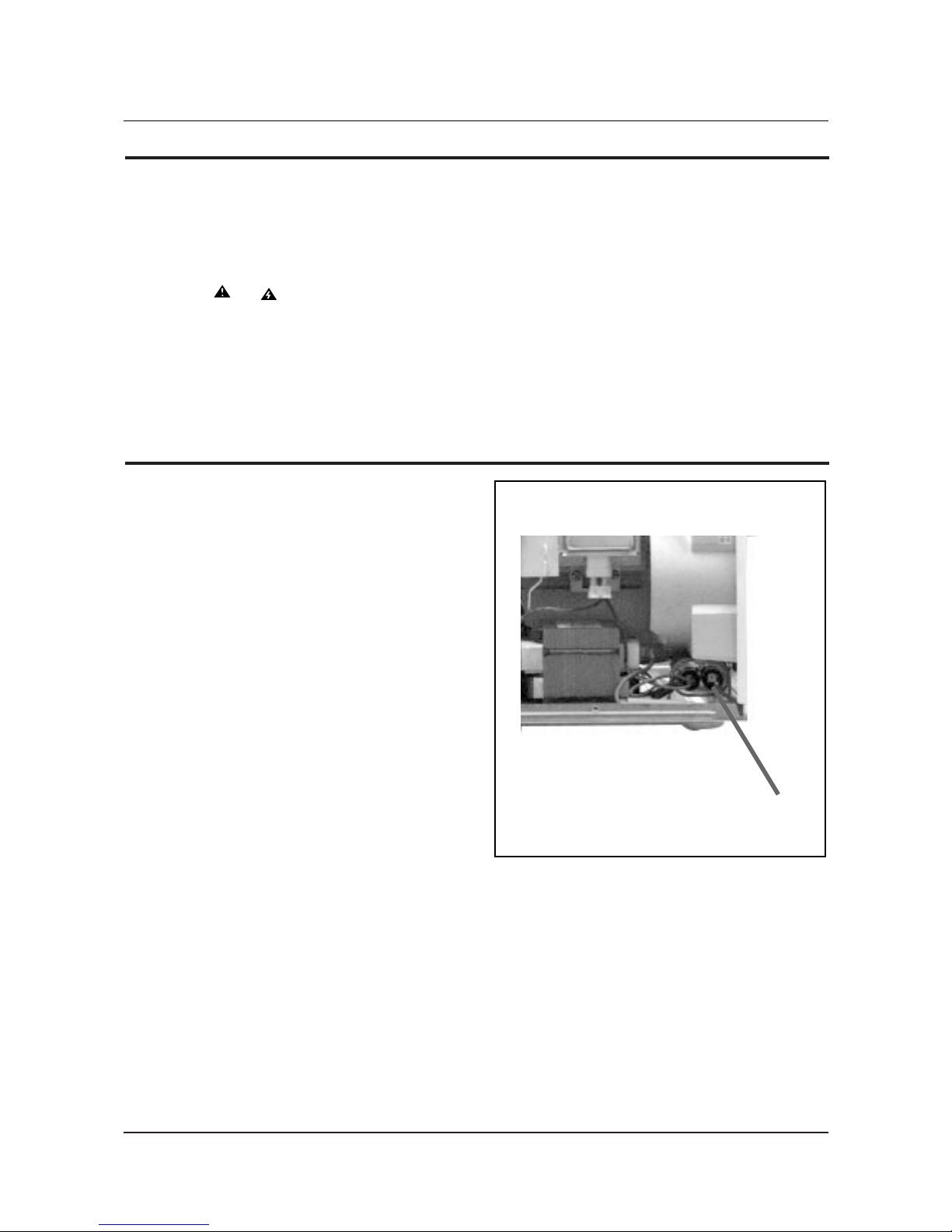

1. High Voltage Warning

Do not attempt to measureany of the high

voltages--this includes the filament voltage

of the magnetron. High voltage is present

during any cook cycle.

Before touching any components or wiring,

always unplug the oven and discharge the

high voltage capacitor (See Figure 1-1)

2. The high-voltage capacitor remains charged

about 30 seconds after disconnection. Short

the negative terminal of the high-voltage

capacitor to to the oven chassis. (Use a

screwdriver.)

3. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

1-2

Pretaution

1-2 Special Servicing Precautions (Continued)

1-3 Special High Voltage Precautions

Fig. 1-1. Discharging the High Voltage Capacitor

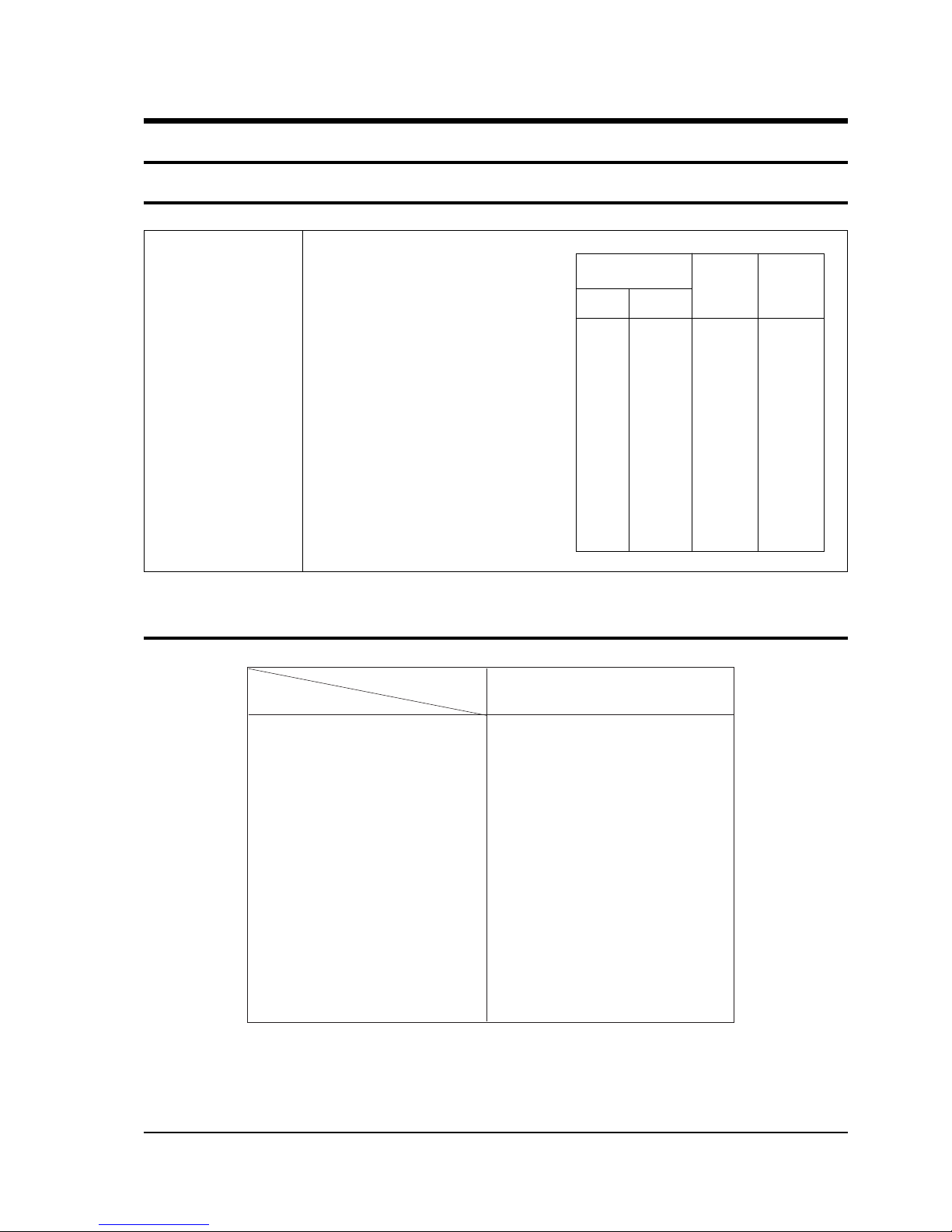

2. Specifications

2-1 Table of Specifications

2-1

TIMER 99 MINUTES 90 SECONDS

POWER SOURCE 230V 50Hz, AC

POWER CONSUMPTION MICROWAVE : 1,300W

OUTPUT POWER FROM 80 TO 800W (10 LEVEL POWER)

(IEC-705 TEST PROCEDURE)

OPERATING FREQUENCY 2,450MHz

MAGNETRON OM75SH(31)

COOLING METHOD COOLING FAN MOTOR

OUTSIDE DIMENSIONS 489(W) x 275(H) x 356(D)

POWER LEVEL

% KM2901T

10% 80W 4 sec 26 sec

20% 160W 7 sec 23 sec

30% 240W 10 sec 20 sec

40% 320W 13 sec 17 sec

50% 400W 16 sec 14 sec

60% 480W 19 sec 11 sec

70% 560W 22 sec 8 sec

80% 640W 25 sec 5 sec

90% 720W 28 sec 2 sec

100% 800W 30 sec 0 sec

ON TIME OFF TIME

2-2 Comparison Chart

MODEL

FEATURE

MORE/LESS −

AUTO COOK/DISH −

AUTO DEFROST O

TIME COOK O

POWER LEVEL O

INSTANT COOK O

MEMORY −

BOOST O

CHILD LOCK −

CLOCK O

GRILL −

COMBI −

KM2901T

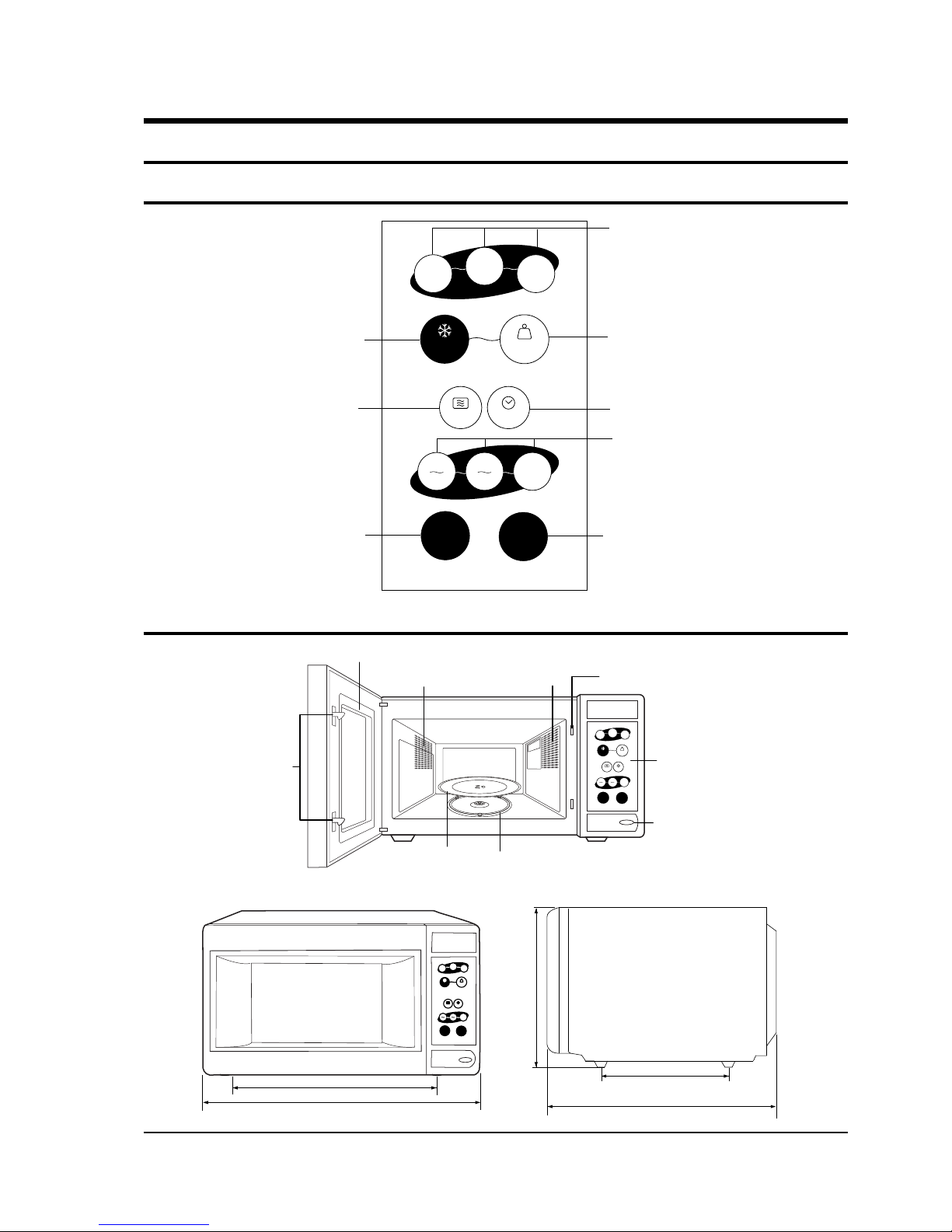

Auto Deforst Button

Power Level Selection Button

Cancel Button

Standard Boost Button

Timer Setting Button

Clock Setting Button

Weight EnteringButton

Instant Cook Button

plated

meal

auto weight

defrost

soup

hot

drink

min.

1min.

10sec.

hr.

10min.

power clock

KM2901T

0.1kg

0.1 kg

start

1min.+

stop

cancel

3. Operating Instructions

3-1 Control Panel

3-1

3-2 Features & External Views

Door

Ventilation Holes

Light

Safety Interlock Holes

Open Door Push Button

Guide Roller

Glass Plate

Door Latches

plated

meal

auto weight

defrost

soup

hot

drink

min.

1min.

10sec.

hr.

10min.

power clock

KM2901T

0.1kg

0.1 kg

start

1min.+

stop

cancel

Control Panel

489mm

357mm

275mm

200mm

356mm

plated

meal

auto weight

defrost

soup

hot

drink

min.

1min.

10sec.

hr.

10min.

power clock

KM2901T

0.1kg

0.1 kg

start

1min.+

stop

cancel

4. Disassembly and Reassembly

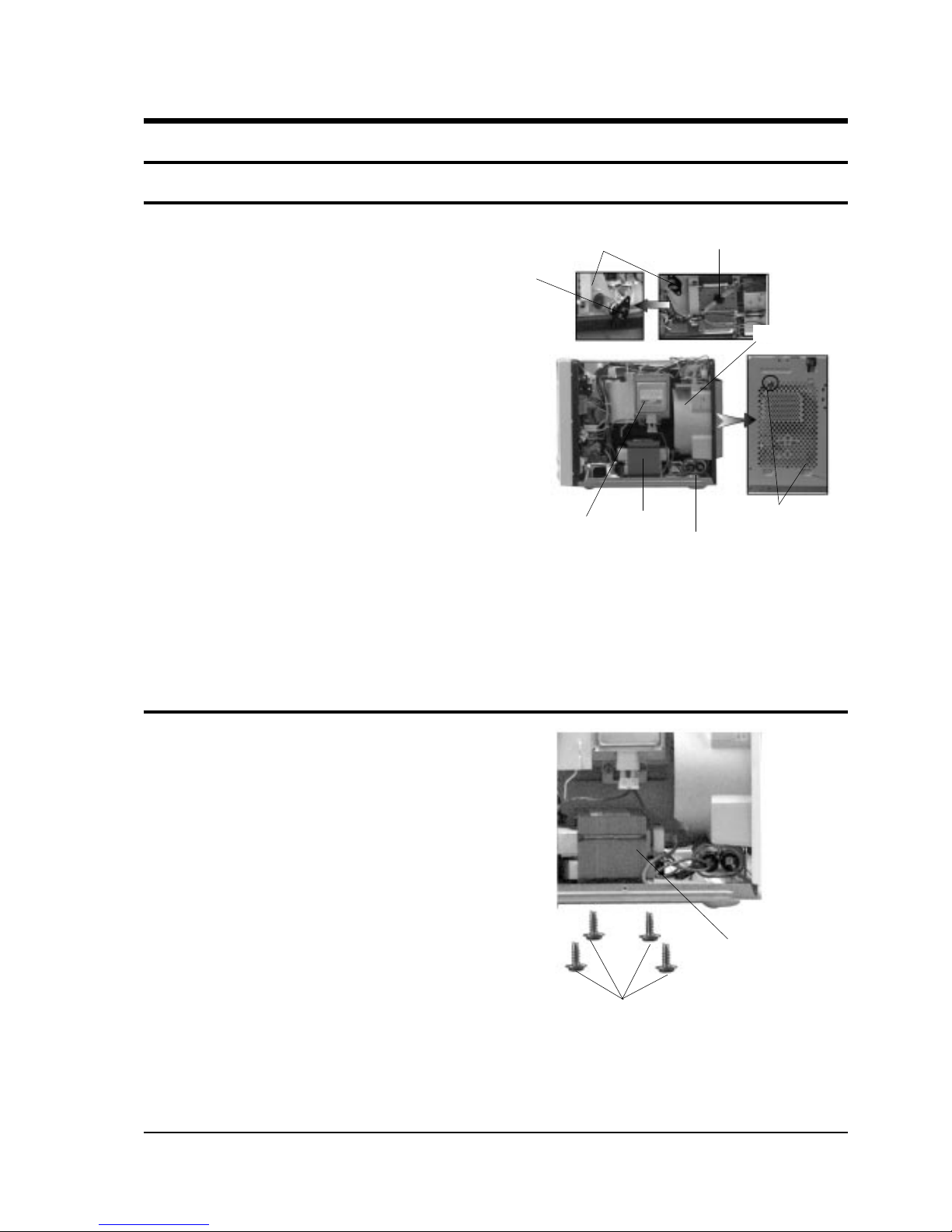

4-1 Replacement of Magnetron, Motor Assembly and Lamp

4-1

Remove the magnetron including the shield case,

permanent magnet, choke coils and capacitors (all

of which are contained in one assembly).

1. Disconnect all lead wires from the magnetron

and lamp.

2. Remove a screw securing the magnetron

supporter.

3. Remove the magnetron supporter.

4. Remove the air cover.

5. Remove screws securing the magnetron to the

wave guide.

6. Take out the magnetron very carefully.

7. Remove screws from the back panel.

8. Take out the fan motor.

9. Remove the oven lamp by rotating to pull out

from hole of air cover.

NOTE1: When removing the magnetron, make

sure that its antenna does not hit any

adjacent parts, or it may be damaged.

NOTE2: When replacing the magnetron, be sure

to remount the magnetron gasket in

the correct position and make sure the

gasket is in good condition.

1. Discharge the high voltage capacitor.

2. Disconnect all the leads.

3. Remove the mounting bolts.

4. Reconnect the leads correctly and firmly.

4-2 Replacement of High Voltage Transformer

Lamp

Magnetron

H. V. Trans

H. V. Capacitor

Screw

Thermo S/WCover Air

Fan Motor

H. V. Trans

Screws

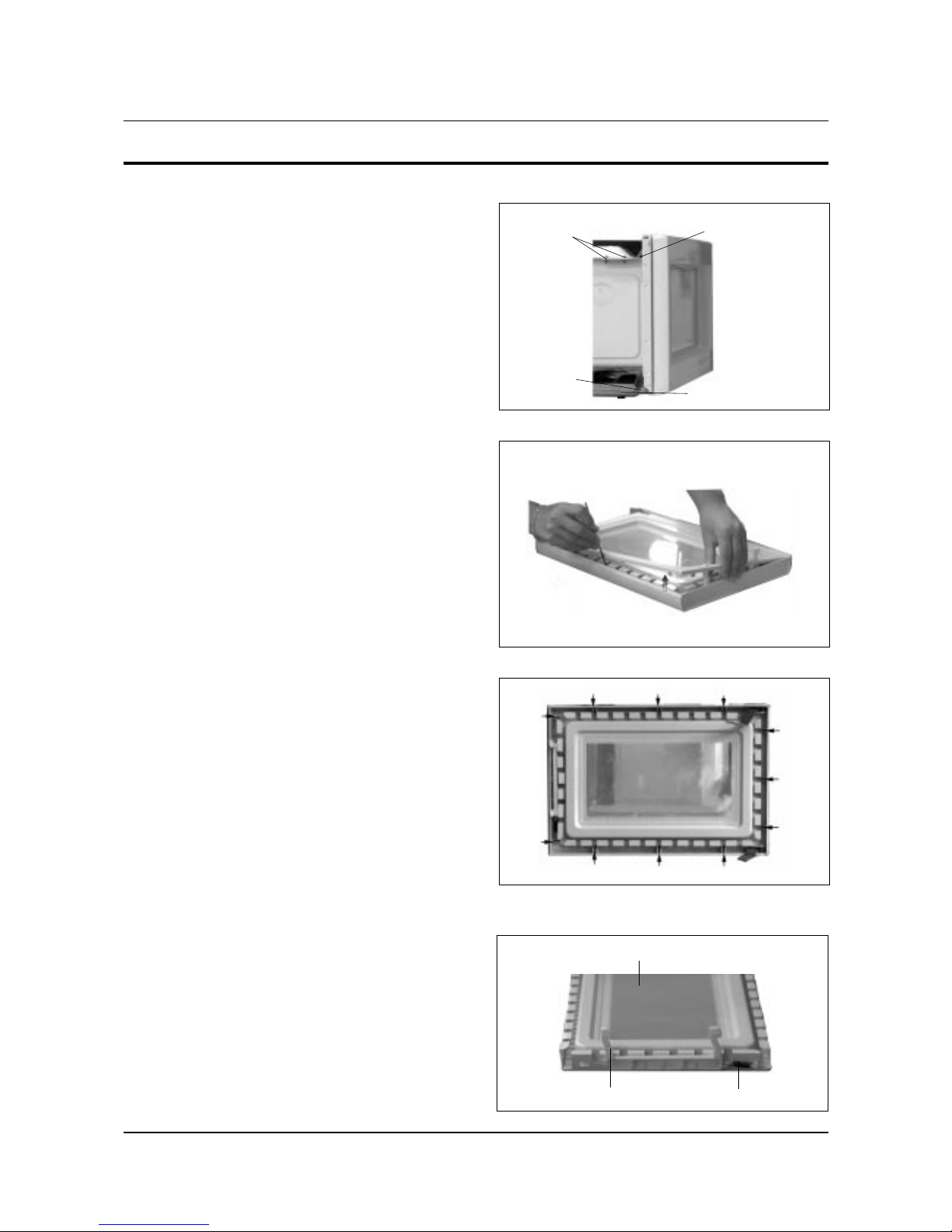

4-3 Replacement of Door Assembly

4-3-1 Removal of Door Assembly

4-2

Remove hex bolts securing the upper hinge and

lower hinge. Then remove the door assembly.

Insert flat screwdriver into the gap between Door

"E" and Door "C" to remove Door "C". Be careful

when handling Door "C" because it is fragile.

Following the procedure as shown in the figure,

insert and bend a thin metal plate between Door

"E" and Door "A" until you hear the 'tick' sound.

1. Insertion depth of the thin metal plate should be

0.5mm or less.

4-3-4 Removal of Key Door & Spring

Remove pin hinge from Door "E"

Detach spring from Door "E" and key door.

4-3-2 Removal of Door "C"

4-3-3 Removal of Door "E"

Disassembly and Reassembly

Upper Hinge

Lower Hinge

Screws

Screws

Key Door Spring

Door "E"

Loading...

Loading...