Page 1

CD AUTO CHANGER

KDC-C719/C719Y

KDC-C719/G4

SERVICE MANUAL

REVISED

© 2006-5 PRINTED IN JAPAN

B53-0418-00 (N) 960

Model

KDC-C719 (E type)

KDC-C719 (K,M type)

KDC-C719/G4 (M type)

Serial Number

U0400251~

60400351~

67400651~

Cord with plug

(E30-4291-15)

Service jig

For initial position setting

When transporting these models, always attach CAUTION

CARD and STEPPED SCREW (for transportation).

COMPACT DISC AUTO CHANGER KDC-C719

NEW ANTI VIBRATION MECHANISM DISC NAME PRESET

COMPACT

CD-R/RW

DIGITAL AUDIO

Tray

(J99-0614-01)

TEXT

Holder assy

(J19-5146-02)

DISC

10

Parts No.

W05-0635-00

5m

Bracket (L)

(J19-5018-03)

Products for European market comply with the

Bracket (R)

(J19-5019-03)

RoHS

Directive.

Screw set

(N99-1784-05)

This product uses Lead Free solder.

Page 2

KDC-C719/C719Y

KDC-C719/G4

(X92)

PICKUP

ASSY (X16-339)

PD

C

DA

B

EF

FO COIL

TR COIL

SPINDLE

M

SLED

M

LOE SW

LIM SW

ELEVATOR

M

(X32)

7

Q1

SD5V

8

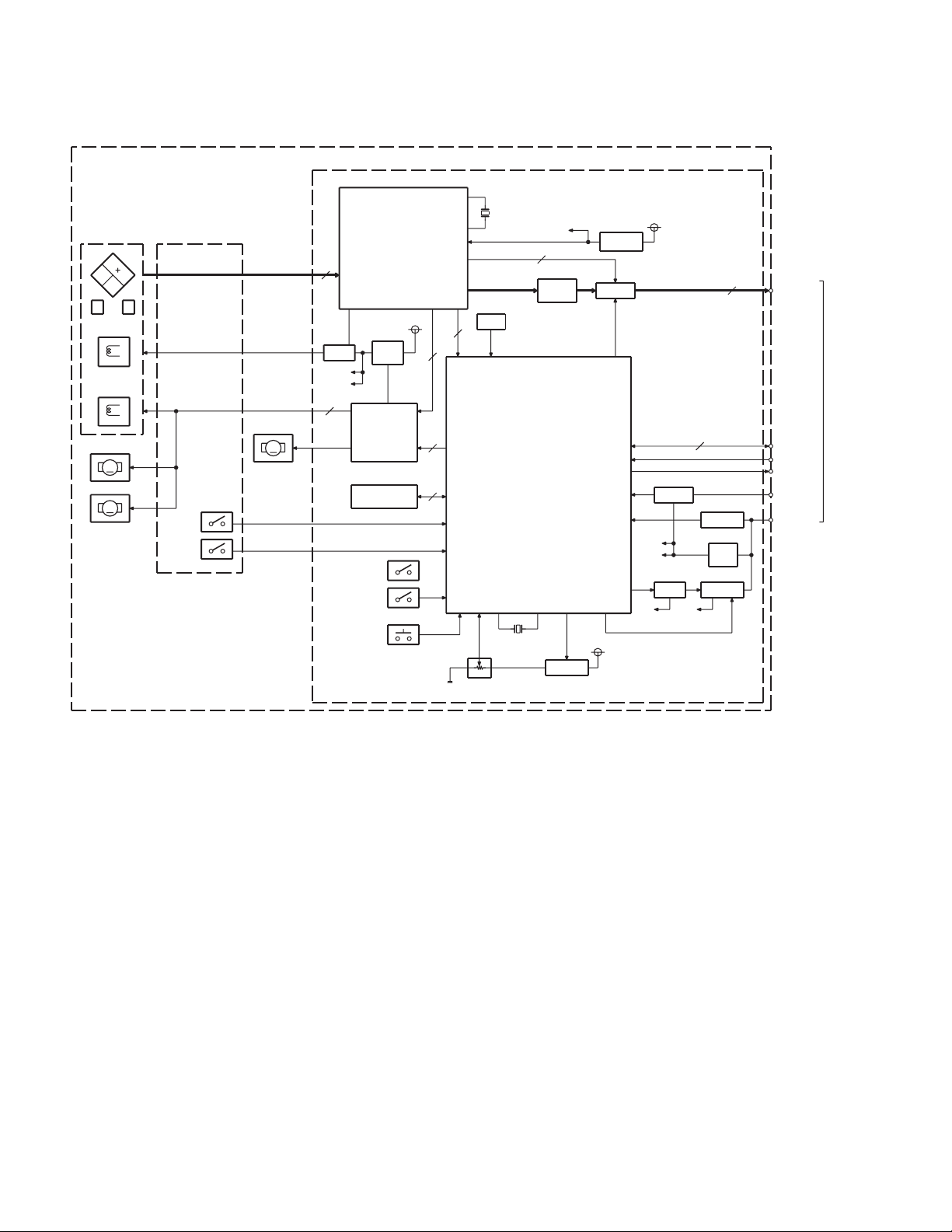

BLOCK DIAGRAM

IC1

X1

16.93MHz

HOT

SYSTEM u-COM

12.5MHz

L.P.S.

APC

SA5V

IC5

BTL &

DC MOTOR

DRIVER

IC8

MG SW

ARM SW

EJ SW

RF AMP &

SERVO DSP &

TEXT DECODER &

D/A CONVERTER &

SCF

S8V

Q9

SA5V

AVR

E2PROM

S1

S3

S2

4

5

2

13

S8V

Q6-8

M5V1

IC4

5VREG

MUTE

IC7

M5V2

7V/8V

M5V1

5

IC9

RESET

Q20

BU. DET

Q21,22

5V

AVR

Q10 Q15,16

P-ON

8V AVR

S8V

3

AUDIO

OUT

5L I/F

CH-CON

CH-MUTE

CH-RST

BU14V

to

X16-338

DA5V

2

Q4,5

0bit

MUTE

X2

Q12

AVREF0

2

Page 3

KDC-C719/C719Y

KDC-C719/G4

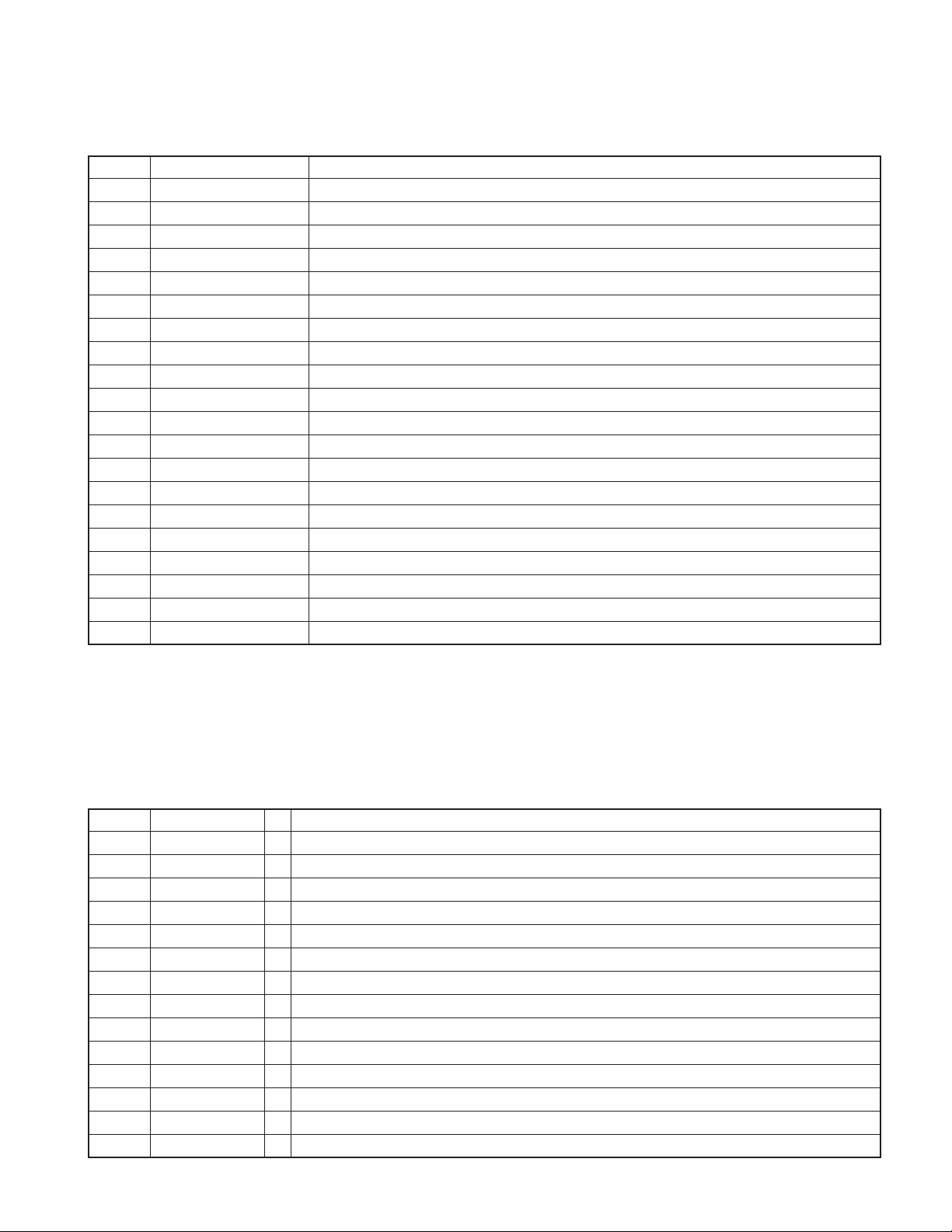

COMPONENTS DESCRIPTION

● CD PLAYER UNIT (X32-5810-00)

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 DSP Servo control

IC4 A5V regulator Power supply for 5V audio

IC5 Driver Driving spindle motor, loading/eject operation, elevation operation, driving pick-up ACT

IC7 µ-com Servo control, LX_BUS communication control

IC8 Memory IC ELV operation parameter, Store servo coefficient

IC9 Reset IC

Q1 Current AMP Adjust the current to be applied to the laser

Q4~8 AMUTE SW AMUTE

Q9 SW SA5V

Q10 PON SW PON

Q11 CH RESET SW CH RESET

Q13 CH control SW

Q14 CH MUTE SW CH MUTE

Q16 SW8V

Q17,18 8V SW

Q19 8V/7V SW 8V/7V switching

Q20 BU5V detection SW BU5V detection

Q21,22 BU5V Supply power to IC7

Q30 Anti-scratch measure

Q31 SW Switching loading, eject, and spindle

MICROCOMPUTER’S TERMINAL DESCRIPTION

● SYSTEM MICROCOMPUTER: 784214YGC132A/784217YGC106A (X32: IC7)

Pin No. Pin Name I/O Application

1 NOR/RW O Disc detection result

2 /TSTB O TEXT data strobe signal

3 P_CON O Power supply control signal for video CH

4 FOK I Focus-ON status signal input

5 /XTALEN O Servo IC oscillation stop signal

6 RST O Servo IC reset terminal

7 SA0 O Servo IC communication address setting

8 SSTB O Servo IC communication strobe

9 VDD Positive power supply voltage connection terminal

10 X2 Oscillator connection terminal 2

11 X1 I Oscillator connection terminal 1

12 VSS GND electric potential connection

13 XT2 Sub clock connection terminal 2

14 XT1 I Sub clock connection terminal 1

3

Page 4

KDC-C719/C719Y

KDC-C719/G4

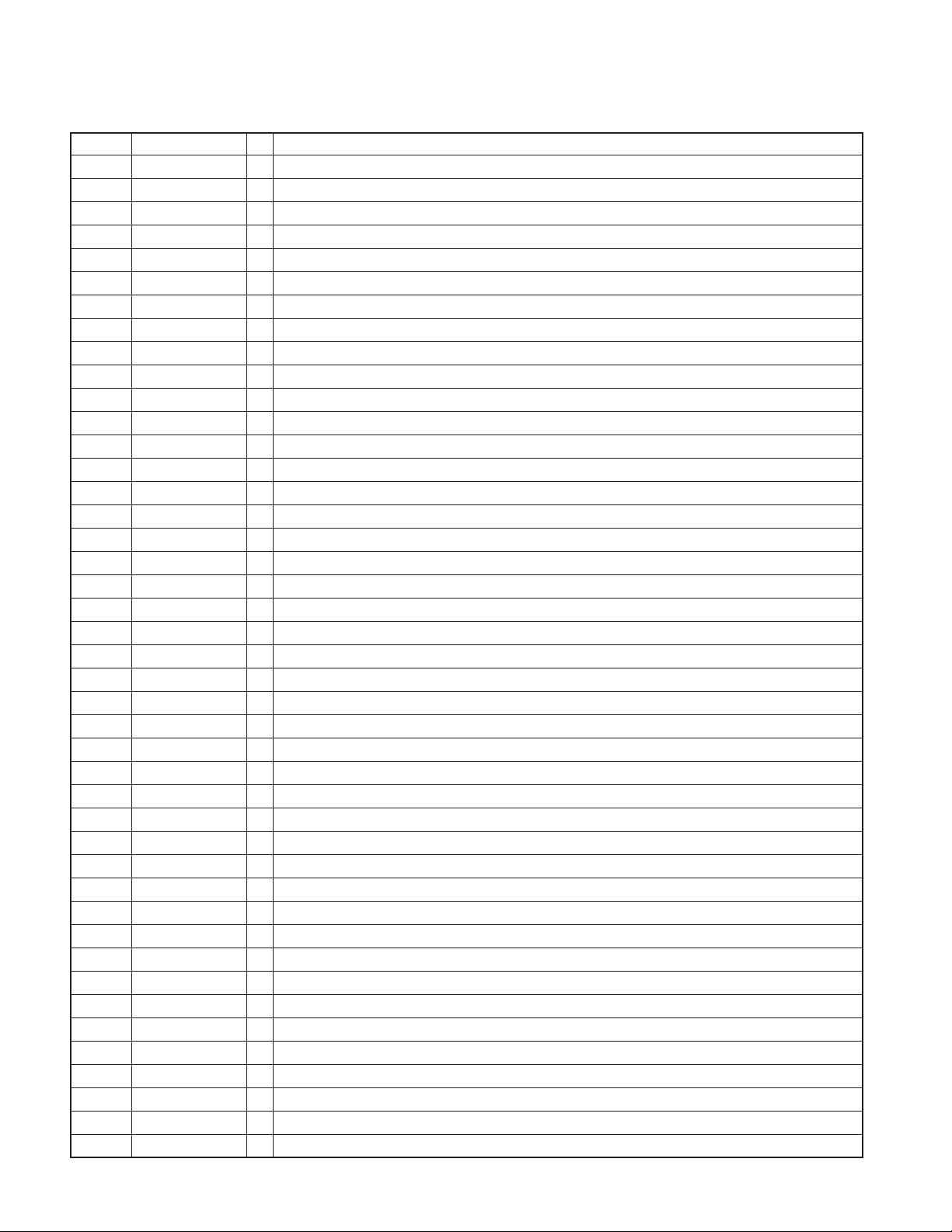

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Application

15 RESET I Reset

16 FOGUP I Focus gain up terminal

17 MGSW I Magazine switch

18 EJSW I Eject switch

19 COMMSW I 5 line communication new/old switch

20 PACK I TEXT data PACK synch signal

21 CHCON I Changer control input from H/U

22 BUDET I BU power supply detection terminal

23 AVDD A/D converter analog power supply terminal

24 AVREF0 I A/D converter reference voltage input

25 HOT I Temperature rise detection

26 LPS I MD deck up/down position detection

27 LOESW I Loading completion switch

28 LIMSW I Limit switch

29 TOFF I Tracking off mode

30 ADJSEL I Servo auto-adjustment ON/OFF

31 TBANK I Tracking bank switching terminal

32 SIM2 I Model detection terminal

33 AVSS A/D converter standard GND terminal

34 LPSCO O A/D converter reference power supply control

35 AMUTE O Audio mute

36 AVREF1 D/A converter reference power supply

37 SDI I Servo IC communication serial data input

38 SDO O Servo IC communication serial data output

39 SCK O Servo IC communication serial clock output

40 DATAH I Data input from H/U

41 DATAC O Data output from the changer

42 HCLK I/O Communication clock input from H/U

43 REQC O Request of communication with H/U

44 CHMUTE O Audio mute output to H/U

45 TSI I TEXT data input

46 TSO O TEXT data output

47 /TSCK O TEXT clock output

48~71 NC O Not used

72 VSS GND electric potential connection terminal

73,74 NC O Not used

75 PUOK O Pick-up type detection terminal (for production)

76 ELVADJ I MD deck up/down position adjustment mode

77~80 NC O Not used

81 VDD Positive power supply voltage connection terminal

82 PUSEL I Pick-up type detection

83 REQH I Request of communication from H/U

84 SP/LO+ O Spindle/loading control terminal +

4

Page 5

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Application

85 SP/LO- O Spindle/loading control terminal 86 ELV+ O MD up/down control terminal +

87 ELV- O MD up/down control terminal 88 SIM1 I Standard stack CH destination port

89 SEARCH O Search/play switching port

90 TEST1 I Mechanism duration mode

91 TEST2 I Mechanism duration mode

92 8V/7V O Driver IC for mechanism operation power supply voltage control

93 EEPWR I EEPROM writing mode

94 TEST/VPP I Flash ROM program mode

95 SRVSEL I Servo operation mode (no mechanism operation)

96 SLNSA I Sled blind zone ON/OFF terminal

97 SDA I/O EEPROM data input/output

98 SCL O EEPROM clock output

99 PON O PON output

100 ARMSW I Arm switch

KDC-C719/C719Y

KDC-C719/G4

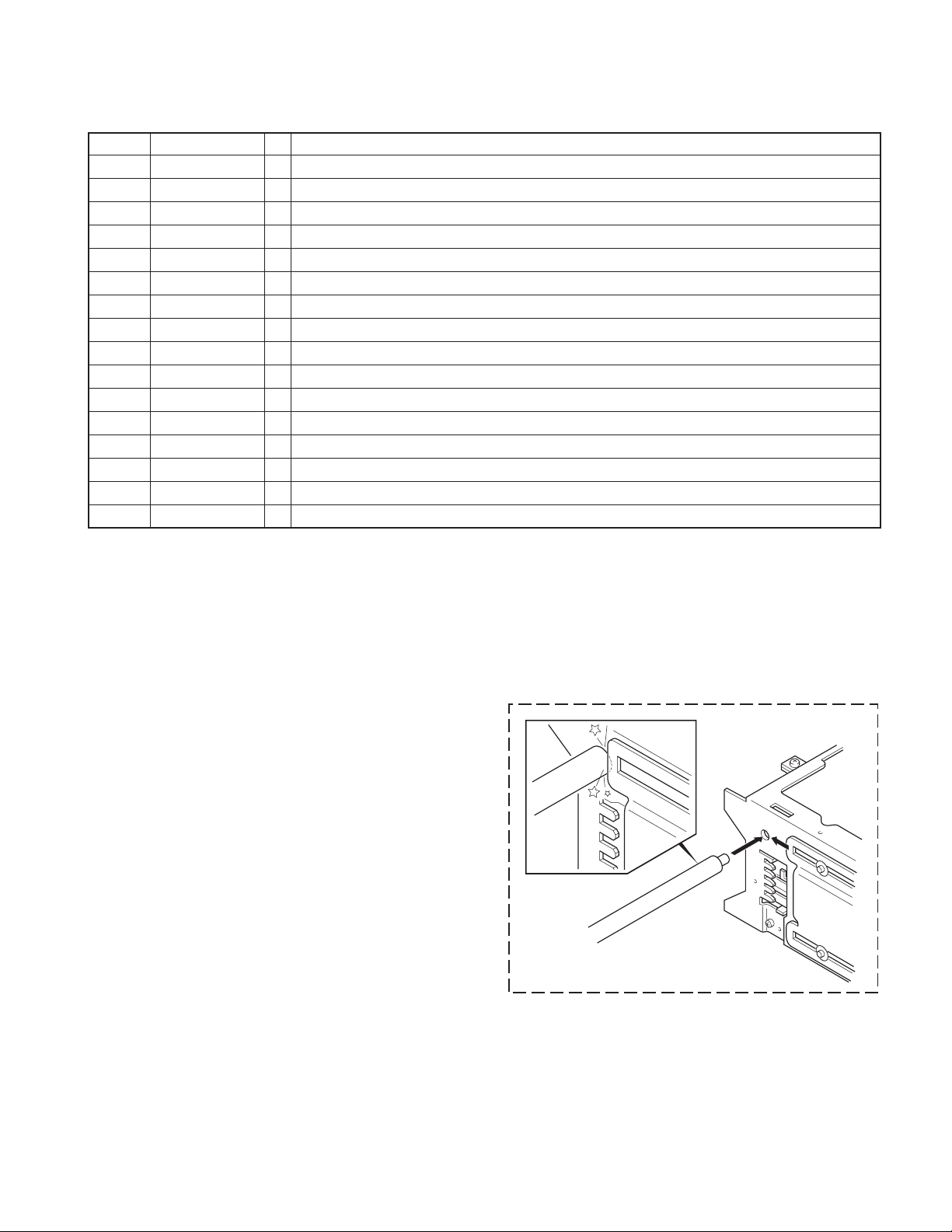

ADJUSTMENT

● L.P.S. initial position adjustment procedure

1. Connect the changer to the HEAD UNIT (H/U).

2. While holding the magazine eject button of the changer,

press the reset button of the H/U.

3. After about 3 seconds, release the magazine eject button.

4. Press the SRC button of the H/U to enter the CD-CH mode,

and the H/U's display section indicates “E-88”.

5. Move the mechanism deck to around the 1st stage b y pressing the DISC- or DISC+ button.

6. Insert the adjustment tool (W05-0635-00) into the tool hole

on the changer mechanism.

7. Then press the DISC+ button to move the mechanism dec k

until the mechanism's slider hits the adjustment tool.

8. When the motor locks (stops), press the REPEAT key of

the H/U.

When the REPEAT key is pressed, the mechanism moves

automatically to the 1st stage and the initial position adjustment completes. (The data is written in the EEPROM at

this time.)

W05-0635-00

● Caution : Note on IC8 (EEPROM)

Be sure to use the W05-1306-00 when replacing the

EEPROM. IC8 stores the digital ser vo data of the pickup

servo.

Therefore, if the EEPROM does not store servo data, ERROR76 (E-76) will indicate the H/U’ s display section at the

moment CD is played.

5

Page 6

A B C D E

KDC-C719/C719Y

KDC-C719/G4

1

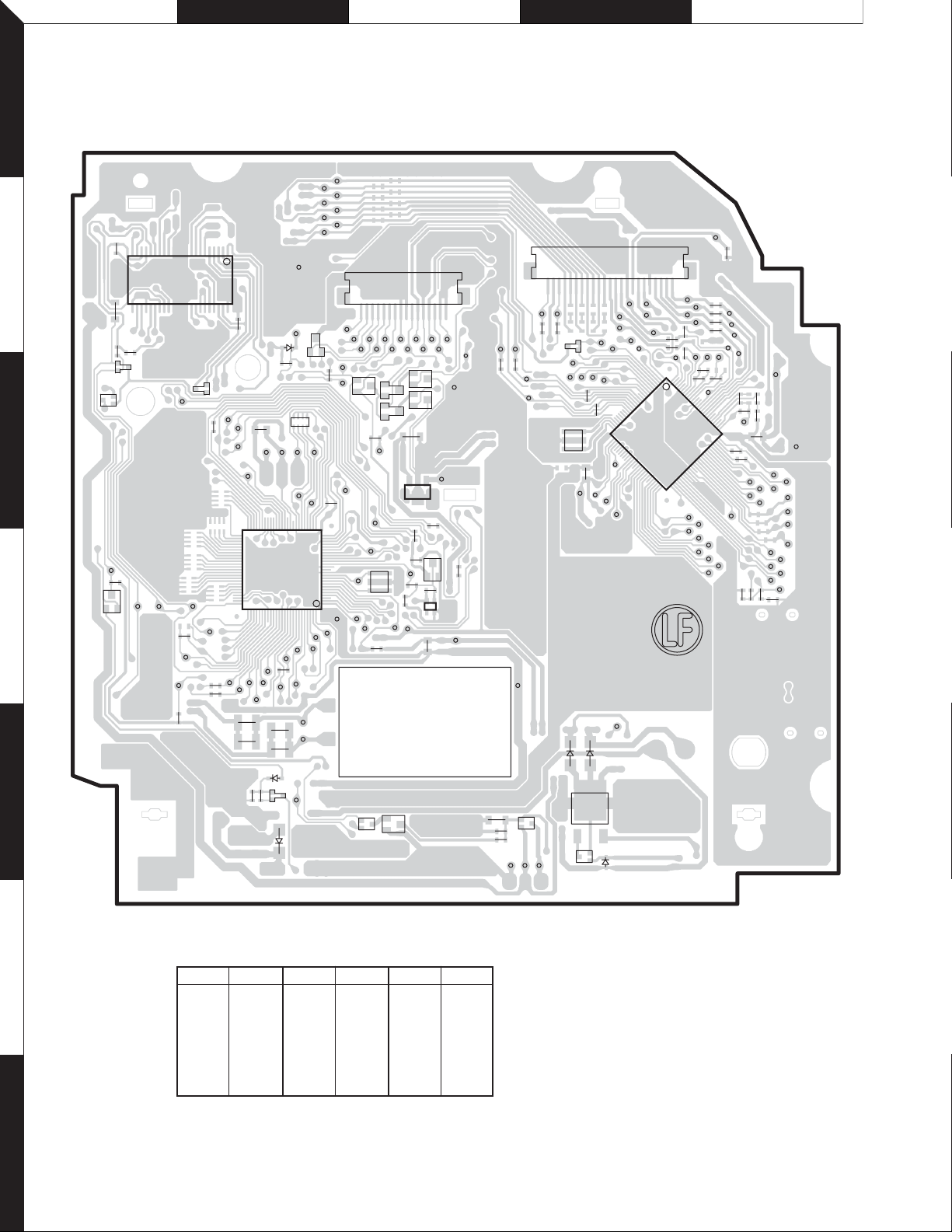

PC BOARD (COMPONENT SIDE VIEW)

CD PLAYER UNIT X32-5810-00 (J76-0139-11)

F+

T+

T-

F-

SP-

SP+

SL-

SL+

D24

SPLO-

R123

R122

/TSCK

R105

RMK

119

R162

C71

TSO

AVR0 LPS

TSI

GND

SI

50 26

51

IC7

75

76 100

SRVSEL

VPP

TS2

(ELV+)

SIM1

EEP

TS1

SRH

(ELV-)

R856

R854

R857

R855

D7

C61

R77

D11

D3

R102

D12

SGND

(QH)

CP3

TBANK

R505

SLNSA

ELV-

ELV+

8/7V

D15

TOFF

SCL

SDA

R502

ADJSEL

C70

25

1

PON

GND

AM

(DH)

NC

QH

HOT

16

QC

Q8

X1

N/RW

/TSTB

Q18

CCLK

EB

CRST

PACK

BE

DC

R99

CON

R506

DH

D21

D22

X2

VDD

Q17

CN1

L-CH

R78

R54

R-CH

R53

GND

B14V

LIMSW

ROUT

LOUT

Q16

BE

8V

23

LOESW

R73

R72

D16

/RST

RFOK

A0

/STB

S

/SCK

C15

X1

C17

EMPH

SD5V

D9

D10

SI

C16

26

FLAG

ARMSW

E

TX

F

HOLD

VC

IOP-

LD

PD

IOP+

R7

PN

1

IC1

502551

Q21

EBEB

Q22

BASE

D8

CN2

R

L

(CM)

C52

RST

R507

C68

CCON

IGO

IC4

R97

C69

5V

AGND

EB EB

R106

2

C72

CRST

Q6

Q7

EB

1

43

B14V

AMUTE

AGND

DAVDD

R206

Q11

R96

IC9

AVDD

C63

R79

GND

CM

EB

2

R69

IC5

20 38 1

R68

R70

R67

D23

COMMSW

BE

Q31

3

BDET

R76

EJSW

EB

4

Q20

SPLO+

R127

PSL

ELVADJ

R133

5

R5

(LD)

C1D2

100

1

C2D1

A

B

C2D3

PLCK

C3

TE2

C4

LOCK

C5

C

D

TE0

C2D2

(E)

C1D1

VR

R11

R12

R13

R14

FE0

R59

C6

MIRR

R4

(F)

76

75

ATEST

RFCK

(A)

(C)

C9

DAC3

DAC1

(B)

(D)

C7

RF0

C10

DAC2

R87

C11

DAC0

TSTB

PACK

R84

R16

TSI

SA5V

C8

C19

AGC

EFM

R851

GND

ASY

MD

SD

TD

FD

/TSCK

TS

MGSW

C851

6

X32-5810-00

Ref. No. Address

IC1 3D

IC4 3C

IC5 2B

IC7 4B

IC9 4C

Q6 3C

Ref. No. Address

Q7 3C

Q8 3C

Q11 4C

Q16 5D

Q17 5C

Q18 5C

Ref. No. Address

Q20 4A

Q21 5D

Q22 5D

Q31 3A

7

Refer to the schematic diagram for the values of resistors and capacitors.

6

Page 7

JIHGF

KDC-C719/C719Y

KDC-C719/G4

PC BOARD (FOIL SIDE VIEW)

CD PLAYER UNIT X32-5810-00 (J76-0139-11)

C46

C24

R93

R61

R205

R60

C48

C49

R57 R58

C47

C300

C301

C853

R853

S3

R85

D1

Q30

BE

R120

C23

R15

C205

C13

R19

C12

R18

C204

C200

CP16

S1

C75

C201

R20

C206

R9

C2

C202

R10

Q1

EB

R8

C14

C203

L2

R82

CP9

C34

Q13

R95

C85

R100

BE

R81

BE

Q10

EB

1

R25

BE

R71

C55

R26

R161

R17

BE

R101

Q14

R121

R107

D4

R83

R108

R75

R74

R98

IC8

58

R153

R154

R148

TH1

R149

14

R150

C67

CP17

R155

VR1

R156

CP1

R503

Q5

EB

Q4

R80

R110

R111

R22

R190

C56

R21

C21

R852

Q9

C192

R191

R114

R86

C852

S2

2

3

4

C62

R124

C60

C59

D14

Q32

BE

Q19

D5

E

B

X32-5810-00

Ref. No. Address

IC8 4H

Q1 2G

Q4 3H

Q5 3H

Q9 2J

Ref. No. Address

Q10 4H

Q13 3H

Q14 2H

Q19 5H

Q30 2F

Refer to the schematic diagram for the values of resistors and capacitors.

C640

5

C64

6

7

7

Page 8

K L M N O

KDC-C719/C719Y

KDC-C719/G4

1

PC BOARD (COMPONENT SIDE VIEW)

SUB-CIRCUIT UNIT X16-3380-00 (J76-0144-12)

2

13

1211

9

10

8

56

7

1

3

4

2

2

J1

1

16

15

CN1

PC BOARD (FOIL SIDE VIEW)

3

SUB-CIRCUIT UNIT X16-3380-00 (J76-0144-12)

CH-RST

CH-MUTE

CH-CON

CH-CLK

L-CH

R-CH

BU14V

DATAH

AGND

REQC

DATAC

REQH

GND

4

SUB-CIRCUIT UNIT X16-3390-00 (J76-0145-11)

CN1

1

LIMSW

5

R1

R2

6

MGND

SL+

CN2

23

1

16

SP-

SP+

BLACK

RED

SL-

SW1

LOESW

SW2

7

Refer to the schematic diagram for the values of resistors and capacitors.

8

Page 9

A B C D E

D2

KDC-C719/C719Y

KDC-C719/G4

1

2

3

4

5

6

BU14V

CH-CON

CH MUTE

A GND

CH RST

DATAC

DATAH

CH CLK

(OUTSIDE VIEW)

2SB1565

DTA124EK

DTA143EK

DTC114YUA

DTC124EK

DTC343TK

2SB1295-E

(X16-3380-00)

J1

REQH

1

GND

2

3

4

5

6

7

R ch

8

REQC

9

10

11

L ch

12

13

J1

3

2

4

7

6

8

11

10

12

13

(E56-0865-05)

TP2

1

2

3BU+14V

4

1

5 CH MUTE

5

6A GND

9

8

9

10

11

12 L ch

2SC4081

DTA124EUA

DTA143EUA

DTC124EUA

DAN202K

DAN202U

TP14

TP3

TP7

TP8

TP6

TP12

TP4

TP5

TP11

TP10

TP13

TP9

TP1

REQH

GND

CH CON

CH RST7

R ch

REQC

DATAC

DATAH

CH CLK13

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CN1

CH RST

A GND

CH CON

CH MUTE

CH-CLK

LPS

VR1

BU14V

BU14V

Rch

Lch

GND

GND

DATAH

DATAC

REQC

REQH

NC

10K

CN2

(X32-5810-0x)

2.2

C71

B14V

1

2

CRST

3

R

4

AGND

5

L

6

CCON

7

GND

8

GND

9

CM

10

DH

11

DC

12

CCLK

13

QC

14

QH

15

NC

16

C640

1

R100

1K

AVREF0

LPS

GND

+

220u16

Q20,21

Q18

R503

44

40

41

42

43

83

14.4V

D11

BU 5V

AVR

Q17

2

3

0

7

AGND

D12

1

Q21

+

C64

22K

R124

220u16

4.7

C60

Q17,18

SVR 8V

SW

8/7V

BU DET

DETECT

Q22

D8

R79

3.3K

R61

100

C49

680P

C48

680P

R60

100

R77

18K

0.1

C61

A. MUTE

DRIVE

C59

100u16

D5

BASE

Q19

Q6,7

R57

R58

D7

D10

D9

+

C75(X92-)

(X92-)

7/8V

SW

A. MUTE

10u50

22K

22K

10u50

Q20

Q8

0.047F5.5

Q32

Q16

2

LOUT

Lch

C47

R54

680

R53

680

5V

AVDD

4.7

R78

ROUT

5V AVR

IC4

IN

AVDD

C62

100K

GND

AGND

DAVDD

OUT

8VB14V

100u16

Lch

48

49

Rch

DAVDD

5.0V

10

C34

0V

5V

2.2

2.2

C72

C85

8V

+

6

C70

100P

1

83

+

D21

Q6

D22

Q7

C46

+

Rch

AM

7.0V

C52

+

SRV 8V

AVR

D14

4.7

C63

DAVDD

CRST

R97

3

Q13

7

CH CON

SW

R76

27

28

CP3 100K

R105

1K

R106

1K

D4

100K

R502

R148

100

R149

100

TODF

ADJSEL

TBANK

0

100K

R98

10K

5.0V

5.0V

5.0V

5.0V

0V

SI

(DH)

AVDD

35

37

R111

100K

38

39

R107

100

40

R108

41

42

R99

HOT

TH1

0V

25

26

LPS

27

LOESW

28

LIMSW

29

TOFF

30

ADJSEL

31

TBANK

32

SIM2

33

AVSS

34

LPSCO

35

AMUTE

36

AVREF1

37

SDI

38

SDO

39

SCK

40

DATAH

41

DATAC

42

HCLK

3.9K

0.1

C69

100K

20

R95

100K

BDET

CON

PACK

0V

0V

5.0V

5.0V

5.0V

24

23

HOT

AVDD

AVREF0

0V

0V

22

BUDET

21

CH-CON

20

PACK

D15

R150

1K

0V

43

R121

44

Q14

10K

45

R110

100K

46

47

(CM)

5.0V

CH MUTE

SW

TSI

TSO

TSCK

5.0V

43

REQC

44

CHMUTE

45

TSI

0V

0V

46

TSO

47

TSCK

48

A0

49

A1

50

A2

D0

A3

51

A4A6A7

52

53

D1

A5

565558

54

57

7

2SB1202-E

DAP202K

DAP202U

DA204U

5V

AVDD

8V

VCC

X32-5810-00 (1/3), X16-3380-00 (1/1)

9

Page 10

F G H I J

0V

V

O1

I3-

A6

BUDET

SD

64

13

SP

KDC-C719/C719Y

KDC-C719/G4

R97

3.9K

CON

5.0V

21

CH-CON

A7

0.1

C69

R95

PACK

D0

565558

57

20

10K

100K

R114

COMMSW

0V

5.0V

201918

PACK

D3

D1

D2

60

59

RESET

SW

18

0V

5.0V

17

EJSW

COMMSW

(X32-5810-0x)

D4

D5

61

62

Q11

16

R507

RST

17

0V

5.0V

MGSW

RESET

FOGUP

∗

IC7

SYSTEM u-COM

UNIT

No.

784217YGC106A

0-00

784214YGC132A

0-01

A8

D7

D6

636665

64

L+

56

0V

R190

22K

19

201718

L-

DGND4

TSTB

57

TSTB

CP16

1K

2

R69

30K

AI1

680P

C192

C16

0.1

R-

58

8V

R+

TEST0

59

ATEST

SD5V

16

21

2.5V

R191

5.0V

DAVDD2

TEST1

60

0V

2.5V2.1V2.1V

I1

I2

22

2.5V

12K

DAVDD

Lch

16

L OUT

ATEST

61

I2-

C300

AGND

C301

15

DAGND2

2.5V0V

2.5V

2.5V

AGND1

62

L2

600

7.0V

151413

VCC1

I2+

I3

23

24

2.5V

2.5V

22

0.1

FD

63

TDFDSD

62

SP+

R21

12K

C21

680P

SER

5V

14

REGC

TD

64

12K

R26

63

SP+

3.3V

3.3V

O1-

25

2.5V

18K

R22

2 2

5V

MGSW

R84

17

2

TSTB

0V

2

1

TSTB

NOR/RW

ARMSW

PON

SDA

SLNSA

SRVSEL

TEST/VPP

EEPWR

TEST2

TEST1

SEARCH

SIM1

ELV-

ELV+

SPLO-

SPLO+

REQH

PUSEL

VDD

ASTB

WAIT

ELVADJ

N/RW

SCL

8/7

WR

RD

18

ARMSW

6

1K

4.7K

47K

R87

0.1

C851

EJSW

R83

1K

4.7K

R852 R851

47K

R86

0.1

C852

4.7K

R853

47K

R85

0.1

C853

1K

R82

R155

100

5

5.0V

R156

6

5.0V

0V

100

7

R153

4.7K

5.0V

8

R154

4.7K

5.0V

100

5.0V

99

SCL

5.0V

98

97

0V

96

SLNSA

95

SRVSEL

EEP

94

93

92

91

90

89

SRH

88

87

86

85

84

5.0V

83

5.0V

82

5.0V

81

80

79

78

77

5.0V

76

ELVADJ

5V

AVDD

8V

VCC

C67

0.1

PON

SDA

TS1 TS2

87

86

85

84

PSL

R133

100K

CP1

100K

R505

0

VPP

CP17

100K

SIM1

3 3

(QH)

D3

100K

R102

R127

10K

VDD

R506

0

RESET IC

IC9

IN

3

0V

4

C68

0.1

0

12.500MHz

0V

0V

14

131615

12

XT1

XT2

VSS

IC7

A10

A11

A9

68

67

5.0V

2

R96

OUT

1

X2

X1

9

10

11

X1

X2

5.0V

A13

A12

69

100K

5.0V

VDD

4

5

7

8

1K

CP9

0V

0V

0V

0V

0V

7

643

5

8

VDD

A14

70

RST

SAO

FOK

SSTB

A15

VSS

71

72

0V

P-CON

XTALEN

0V

0V

0V

A17

A16

RAMOK

73

75

74

RMK

R101

1K

SDA

SCL

WP

VCC

E2PROM

IC8

GND

R80

1K

S1

MG

SW

S2

EJ

SW

S3

ARM

SW

0V

4

3

A2

2

A1

1

A0

Q10

R81

10K

P-ON

5V

5V

VCC

VDD

VDD

48,49

6

C203

0.1

6

C201

6

0.1

0bit

MUTE

16

R10

100K

SD5V

C14

0.1

24

XTAL

TSO

53

0V

TSCK

TSO

45

2.5V

23

22

XTAL

16.934MHz

5V

0V

5V

0V

0V

TSI

54

TSI

46

R68

120K

191817

BI1-

BI1+

20

2.5V

63

62

64

XVDD

55

5.0V

AI1+

9.1K

5.0V

21

TSCK

47

R71

0V

X1

16.934MHz

25

XGND

26

5.0V

DVDD1

27

EMPH

EMPH

28

FLAG

FLAG

29

DIN

30

DOUT

31

SCKIN

32

SCKO

33

LRCKIN

34

LRCK

35

HOLD

HOLD

36

TX

TX

37

0V

R20

100K

0V

48

49

R9

1K

6

LOCK

RFCK

PLCK

Q4

Q5

MIRR

C1D1

C1D2

C2D3

3.4V

5.0V

65

C17

C2D1

C2D2

0V

2.2

38

39

40

41

42

43

44

45

46

47

48

49

50

C200

MOTOR

DRIVER

DGND2

C16M

LIMIT

DVDD2

LOCK

RFCK

MIRR

PLCK

DGND3

C1D1

C1D2

C2D1

0V

C2D2

0V

C2D3

DVDD3

51

5.0V

0.1

IC5

PACK

52

PACK

20

SD5V

8V

VCC

X32-5810-00 (2/3)

10

Page 11

ONMLK

I2+

AGND

D

KDC-C719/C719Y

KDC-C719/G4

1

D

4

VCC

R11 5.1K

R12 5.1K

R13 5.1K

R14 5.1K

R4

220

R5

47K

R7

47K

F+

T+

TF-

SPSP+

SLSL+

LOESW

R72

100

LIMSW

R73

100

22K

R75

AMUTE

Q30

ECCENTRIC

DISC SW

R854

3 1/2W

R855

3 1/2W

R856

3 1/2W

R857

3 1/2W

PD

VR

VC

F

E

ELV+

ELV-

A

C

B

D

R120

620K

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

A

C

B

D

F

E

4

6

27

R74

2.2K

28

35

0.1

C202

5

C300

C301

151413

DAGND2

2.5V

2.5V

.5V

62

L2

600

7.0V

151413

VCC1

I3

24

2.5V

C15

22

Rch

0V

0.1

12

REGC

R OUT

DAGND

IC1

SERVO IC

0.1V

0V

MD

SD

TD

FD

65

63

64

TDFDSD

MD

12K

R26

R25

636265

64

SP-

SP+

SP+ SP- T- T+

3.3V

3.3V

O1-

O1+

I3-

I3+

25

262728

R21

2.5V

2.5V

12K

C21

680P

18K

R22

SERVO

5V

0.1

2.5V

1K

R206

SISOSCK

5.0V

0V

5.0V

0V

978

10

11

VDD

XTALEN

DAVDD1

DAC2

DAC1

DAC0

666768

69

DAC1

DAC2

DAC0

11K

0.1

C204

T-

T+

0V

3.3V

3.3V

12

11

O2-

O2+

RIN

ROUT

0V

6.2V

5.0V

C55

10

Q9

7

8

393738

STBAORST

0V

6

SI

SO

AO

STB

SCK

5.0V

5V

0V

AVDD1

DAC3

EFM

71

70

R18

R19

10K

33K

DAC3

EFM

0.01

C12

C13

4

F+

3.3V

9

O3-

VOUT

I1SW

31

30

7.0V

2.5V

Q31

10K

R17

30K

R70

4.7

C56

R205

345

3.3V

8

2.8V5.0V

72

0.01

VIN

SW

D16

RST

ASY

F-

O3+

1K

ASY

3.2V

1.8V

C11

32

C24

RFOK

5.0V

C3T

73

6800P

SL- SL+F-F+

2.5V

VIN

I4+

333435

SP/LOD+

SA5V

4

1000P

220K

2

RFOK

2.5V

2.5V

RFI

74

C10

2200P

SL-

3.3V

3.3V

76543

O4-

I4-

R93

2.5V

REFOUT

2.5V

AGCO

75

AGCO

SL+

O4+

I4

R161

R67

120K

0V

1

DGND1

AVDD3

AGND3

TEC

TEO

FEO

AVDD2

AGND2

EQ2

RFO

AGCI

0V

LO+

D24

16K

TE2

TE-

FE-

RF-

EQ1

D23

6

APC

IOP-

R8

10

C2

10

100

5.0V

PN

0V

99

PN

5.0V

98

LD

0V

97

PD

0V

96

C4

95

1500P

94

93

R59

92

270K

91

C6

90

100P

2.5V

89

5.0V

88

2.5V

87

E

2.6V

86

F

85

(C)

D

84

(A)

B

83

(D)

C

(B)

82

A

0V

81

2.3V

80

79

78

C7

77

C9

76

0.22

3.2V

1.8V

1K

7.0V

0V

R123

2

LO-

VCC2

5.0V

4.3V

MT1

36

4.7K

R162

SP/LOD-

85

84

LDIOP+

Q1

D1

C206

R15

100K

(LD)

TE2

TE0

C5

22P

FE0

(E)

E

(F)

C3

F

470P

C

5

A

D

B

R16

5.6K

4P

RF0

GND

SA5V

3

87

86

ELVD-ELVD+

1K

R122

1

REV

FWD

MT2

SGND

38

37

0V

5.0V

SGND

5

0.1

SA5V

C8

15P

C23

4.7

C205

0.1

C19

2.2

KDC-C719/C719Y, KDC-C719/G4

(X16-3390-00)

CN1

CN1

A

1

C

B

D

GND

LD

PD

VR

VC

VCC

F

E

F+

T+

T-

FSP-

SP+

SL-

SL+

LOESW

MGND

LIMSW

TP1

1

TP2

2

TP3

3

TP4

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

TP13

TP14

TP15

TP16

TP17

TP18

TP19

TP20

TP21

TP22

TP23

TP5

TP6

TP7

TP8

TP9

TP10

TP11

TP12

R2

0

R1

0

S1

S2

CN2

1

VCC

2

VC

3

GND

4

LD

5

VR

6

PD

7

C+D

8

F

9

B

10

A

11

E

12

GND

13

F+

14

T+

15

T-

16

F-

LOE SW LIM SW

(X92- )

ELEVATOR

M2

MM

SLED

(X32- )

IC1 : UPD63711AGC-A

IC4 : KIA78L05F-P

IC5 : LA6576-E

IC7 :

IC8 : W05-1306-00

IC9 : S-80830CNNB-G

Q1 : 2SB0970

Q4,8 : DTA124EK

Q5 : DTA124EUA

Q6,7 : DTC343TK

Q9,21 : 2SB1202-E

Q10 : 2SB1295-E

Q11,20 : DTC124EK

Q13,18,19,31 : DTC124EUA

Q14 : DTA143EUA

M

Q16,22 : 2SC4081

D1,15 : DAP202K

D3,4,7 : UDZS5.6B

D5 : MAZS0750M

D8 : MAZS0620M

D9,10 : M1F60-5063

D11 : 1SR154-400

D12 : DA204U

D14 : MAZS0910M

D16 : DAP202U

D21,22 : DAN202K

D23,24 : DAN202U

(X92- )

Q32

M4

∗

DTA143EK:Q17

DTC114YUAQ30 :

2SB1565(E,F):

M1

SPINDLE

SIGNAL LINE

GND LINE

B LINE

CAUTION : For continued safety, replace safety

critical components only with manufacturer’s

recommended parts (refer to parts list).

Indicates safety critical components. To reduce the risk of electric shock, leakage-current

or resistance measurements shall be carried

out (exposed parts are acceptably insulated

from the supply circuit) before the appliance is

returned to the customer.

• DC voltages are as measured with a high

impedance voltmeter. Values may vary

slightly due to variations between individual

instruments or/and units.

X32-5810-00 (3/3), X16-3390-00 (1/1)

DPU1

OPTICAL

PICKUP

2

3

4

5

6

7

11

Page 12

KDC-C719/C719Y

KDC-C719/G4

A

B

C

D

E

F

G

H

J

K

L

1

M

N

φ2x3.5

φ2x2.5(BLK)

φ2x5

φ1.7x1.5(BLK)

φ2x6

M1.7x3

M1.7x2.2

φ2x3.5

WASHER

WASHER

WASHER

WASHER

φ2x3(BLK)

φ3.8

φ4

φ3.8

φ3.5

: N09-4126-15

: N09-6392-05

: N86-2005-48

: N09-4189-15

: N09-6155-15

: N09-6390-05

: N39-1722-48

: N09-6108-15

: N19-2105-14

: N19-2058-04

: N19-2080-14

: N19-2028-04

: N09-6391-05

EXPLODED VIEW (CD MECHANISM)

BA

70

52

H

H

7

H

H

H

21

20

L

54

L

H

L

L

18

L

H

x2

H

47

D

61

59

D

63

12

74

55

2

5

68

22

75

13

29

L

3

2

H

K

11

31

K

30

48

H

23

14

M

A

6

17

A

A

M3

40

(X32-)

27

15

19

x2

50

51

36

K

35

K

C75

H

781

H

772

62

Q32

H

C

C

H

H

3

B

76

53

16

34

J

32

37

K

H

49

4

N

x2

FC1

FC2

56

33

73

F

J

39

J

J

25

57

E

26

M2

N

N

69

E

28

x2

24

38

M1

772

(X16-)

780

FPC1

E

58

46

1

G

x2

A

PU1

FPC1

E

x2

FC1

12

Parts with the exploded numbers larger than 700 are not supplied.

Page 13

226

x10

223

215

EXPLODED VIEW (UNIT)

213

214

KDC-C719/C719Y

KDC-C719/G4

DC

203

1

221

M4x17.3

A

φ2x4

B

φ2.6x6 (BLK)

C

2

222

:

N09-6414-05

:

N89-2004-48

:

N89-2606-43

229

227

206

214

BLACK

SILVER

214

214

213

ME1

212

C

C

207

C

3

A

204

205

Parts with the exploded numbers larger than 700 are not supplied.

732

B

731

B

(X16-3380-00)

C

201

C

C

212

211

A

A

13

Page 14

KDC-C719/C719Y

KDC-C719/G4

PARTS LIST

✽ New parts

Parts without Parts No. are not supplied.

Les articles non mentionnes dans le Parts No. ne sont pas fournis.

Teile ohne Parts No. werden nicht geliefert.

A

Ref. No.

N

d

d

Parts No. Description

e

w

KDC-C719/C719Y_C719/G4

201 3D✽A10-5277-01 CHASSIS

201 3D✽A10-5277-01 CHASSIS M3

201 3D

203 1D A01-2881-01 METALLIC CABINET

203 1D A01-2881-01 METALLIC CABINET M3

203 1D

204 3C A21-4047-12 DRESSING PANEL

204 3C A21-4047-12 DRESSING PANEL M3

204 3C A21-4082-02 DRESSING PANEL K1

205 3C A21-4048-12 DRESSING PANEL

✽

A10-5278-01 CHASSIS K1

✽

A01-2882-01 METALLIC CABINET K1

Desti-

nation

M1E2E3

M1E2E3

M1E2E3

M1E2E3

A

Ref. No.

A3D

B2D

C3DN89-2606-43

ME1 2D✽X92-5310-00

N

d

d

Parts No. Description

e

w

✽

N09-6414-05 STEPPED SCREW

✽

N89-2004-48

BINDING HEAD TAPTITE SCREW

BINDING HEAD TAPTITE SCREW

MECHANISM ASSY (CHM-1400W)

SUB-CIRCUIT UNIT (X16-3380-00)

CN1 E41-2245-05 FLAT CABLE CONNECTOR

J1 E56-0865-05 CYLINDRICAL RECEPTACLE

SUB-CIRCUIT UNIT (X16-3390-00) in X92

✽

CN1

CN2 E41-2612-05 FLAT CABLE CONNECTOR

E41-2514-05 FLAT CABLE CONNECTOR

Desti-

nation

205 3C A21-4048-12 DRESSING PANEL M3

205 3C A21-4083-02 DRESSING PANEL K1

206 2C A22-2997-02 SUB PANEL

207 3C A64-2896-01 PANEL K1

207 3C A64-2897-01 PANEL

207 3C A64-2897-01 PANEL M3

- B46-0100-50 WARRANTY CARD

- B46-0182-14 ID CARD E2E3

- B46-0682-00 WARRANTY CARD E2E3

- B58-1236-04 CAUTION CARD

- B58-1411-04 CAUTION CARD E2E3

- B58-1947-00 CAUTION CARD E2E3

- B64-2346-00

- B64-2350-00

-

- B64-2355-00

- B64-2356-00

211 3D B58-1275-04 CAUTION CARD

212 3D D10-4515-03 ARM

213 1C

214 1C D39-0242-05 DAMPER

215 1C E30-4291-15 CORD WITH PLUG

- H02-0827-03 INNER CARTON CASE

- H10-4729-02

- H13-1706-04 CARTON BOARD

- H25-0337-04

- H25-1111-04

- H25-1111-04

- H25-1115-04 PROTECTION BAG K1

-

-

- H54-2598-04 ITEM CARTON CASE E2

221 1C J19-5018-03 BRACKET (L)

222 1C J19-5019-03 BRACKET (R)

223 1C J19-5146-02

226 1C J99-0614-01 TRAY

✽

B64-2351-10 INSTRUCTION MANUAL (ARA) M1M3

✽

B64-2365-10

✽

D10-4516-14 LEVER

✽

H54-2592-14 ITEM CARTON CASE K1E3

✽

H54-2595-14 ITEM CARTON CASE M1M3

INSTRU.MANUAL (ENG,FRE,SPA,POR)

INSTRUCTION MANUAL (ENG,T-CHI)

INSTRUCTION MANUAL (ENG,RUS,POL

INSTRUCTION MANUAL (CZE,HUN,CRO

INSTRUCTION MANUAL (GER,DUT,ITA

POLYSTYRENE FOAMED FIXTURE

PROTECTION BAG (180X300X0.03)

PROTECTION BAG (280X450X0.03)

PROTECTION BAG (280X450X0.03)

HOLDER ASSY (DISC MAGAZINE)

M1E2E3

K1M1M3

K1E3

M1M3

E2

E2

E3

M1E2E3

M3

R1,2 RK73EB2E000JX CHIP R 0.0 J 1/4W

S1,2 S74-0811-05 MICRO SWITCH

CD PLAYER UNIT (X32-5810-00) in X92

C2 CK73EB1A106K CHIP C 10UF K

C3 CC73GCH1H471J CHIP C 470PF J

C4 CK73GB1H152K CHIP C 1500PF K

C5 CC73GCH1H220J CHIP C 22PF J

C6 CC73GCH1H101J CHIP C 100PF J

C7 CC73GCH1H040C CHIP C 4.0PF C

C8 CC73GCH1H150J CHIP C 15PF J

C9 CK73GB1C224K CHIP C 0.22UF K

C10 CK73GB1H222K CHIP C 2200PF K

C11 CK73GB1H682K CHIP C 6800PF K

C12,13 CK73GB1H103K CHIP C 0.010UF K

C14-16 CK73GB1H104K CHIP C 0.10UF K

C17 CK73FB1A225K CHIP C 2.2UF K

C19 CK73FB1A225K CHIP C 2.2UF K

C21 CC73GCH1H681J CHIP C 680PF J

C23 CK73EB1A475K CHIP C 4.7UF K

C24 CK73GB1H102K CHIP C 1000PF K

C34 CK73EB1A106K CHIP C 10UF K

C46,47 CE32BJ1H100M CHIP EL 10UF 50WV

C48,49 CC73GCH1H681J CHIP C 680PF J

C52 CK73EB1A475K CHIP C 4.7UF K

C55 CK73EB1A106K CHIP C 10UF K

C56 CK73EB1A475K CHIP C 4.7UF K

C59 CE32BJ1C101M CHIP EL 100UF 16WV

C60 CK73EB1A475K CHIP C 4.7UF K

C61 CK73GB1H104K CHIP C 0.10UF K

C62 CE32BJ1C101M CHIP EL 100UF 16WV

C63 CK73EB1A475K CHIP C 4.7UF K

C64 CE32BM1C221M CHIP EL 220UF 16WV

C67-69 CK73GB1H104K CHIP C 0.10UF K

C70 CC73GCH1H101J CHIP C 100PF J

C71,72 CK73FB1A225K CHIP C 2.2UF K

C85 CK73FB1A225K CHIP C 2.2UF K

C192 CC73GCH1H681J CHIP C 680PF J

C200-206 CK73GB1H104K CHIP C 0.10UF K

227 2C K24-4055-04 PUSH KNOB

229 1C

14

✽

N99-1784-05 SCREW SET

E2 : KDC-C719Y E3 : KDC-C719 (Europe)

K1 : KDC-C719 (North America)

M1 : KDC-C719 M3 : KDC-C719/G4 (Other Areas)

C300 CK73EB0J226K CHIP C 22UF K

C301 CK73GB1H104K CHIP C 0.10UF K

C640 CE32BM1C221M CHIP EL 220UF 16WV

C851-853 CK73GB1H104K CHIP C 0.10UF K

Indicates safety critical components.

Page 15

PARTS LIST

CD PLAYER UNIT (X32-5810-00) in X92

A

Ref. No.

CN1

CN2

L2 L92-0322-05 CHIP FERRITE

X1 L78-0596-05 RESONATOR

X2 L78-0568-05 RESONATOR

CP1 RK74GB1J104J CHIP-COM 100K J 1/16W

CP3 RK74GB1J104J CHIP-COM 100K J 1/16W

CP9 RK74GA1J102J CHIP-COM 1.0K J 1/16W

CP16 RK74GB1J102J CHIP-COM 1.0K J 1/16W

CP17 RK74GB1J104J CHIP-COM 100K J 1/16W

R4 RK73GB2A221J CHIP R 220 J 1/10W

R5 RK73GB2A473J CHIP R 47K J 1/10W

R7 RK73GB2A473J CHIP R 47K J 1/10W

R8 RK73EB2E100J CHIP R 10 J 1/4W

R9 RK73GB2A102J CHIP R 1.0K J 1/10W

R10 RK73GB2A104J CHIP R 100K J 1/10W

R11-14 RK73GB2A512J CHIP R 5.1K J 1/10W

R15 RK73GB2A104J CHIP R 100K J 1/10W

R16 RK73GB2A562J CHIP R 5.6K J 1/10W

R17 RK73EB2E103J CHIP R 10K J 1/4W

R18 RK73GB2A103J CHIP R 10K J 1/10W

R19 RK73GB2A333J CHIP R 33K J 1/10W

R20 RK73GB2A104J CHIP R 100K J 1/10W

R21 RK73GB2A123J CHIP R 12K J 1/10W

R22 RK73GB2A183J CHIP R 18K J 1/10W

R25 RK73GB2A113J CHIP R 11K J 1/10W

R26 RK73EB2E123J CHIP R 12K J 1/4W

R53,54 RK73GB2A681J CHIP R 680 J 1/10W

R57,58 RK73GB2A223J CHIP R 22K J 1/10W

R59 RK73GB2A274J CHIP R 270K J 1/10W

R60,61 RK73EB2E101J CHIP R 100 J 1/4W

R67 RK73GB2A124J CHIP R 120K J 1/10W

R68 RK73EB2E124J CHIP R 120K J 1/4W

R69,70 RK73GB2A303J CHIP R 30K J 1/10W

R71 RK73GB2A912J CHIP R 9.1K J 1/10W

R72,73 RK73GB2A101J CHIP R 100 J 1/10W

R74,75 RK73GB2A222J CHIP R 2.2K J 1/10W

R76 RK73GB2A104J CHIP R 100K J 1/10W

R77 RK73GB2A183J CHIP R 18K J 1/10W

R78 RK73GB2A104J CHIP R 100K J 1/10W

R79 RK73GB2A332J CHIP R 3.3K J 1/10W

R80 RK73GB2A102J CHIP R 1.0K J 1/10W

R81 RK73GB2A103J CHIP R 10K J 1/10W

R82-84 RK73GB2A102J CHIP R 1.0K J 1/10W

R85-87 RK73GB2A473J CHIP R 47K J 1/10W

R93 RK73GB2A224J CHIP R 220K J 1/10W

R95,96 RK73GB2A104J CHIP R 100K J 1/10W

R97 RK73GB2A392J CHIP R 3.9K J 1/10W

R98 RK73GB2A103J CHIP R 10K J 1/10W

R99 RK73GB2A104J CHIP R 100K J 1/10W

R100,101 RK73GB2A102J CHIP R 1.0K J 1/10W

R102 RK73GB2A104J CHIP R 100K J 1/10W

R105,106 RK73GB2A102J CHIP R 1.0K J 1/10W

R107 RK73GB2A101J CHIP R 100 J 1/10W

E2 : KDC-C719Y E3 : KDC-C719 (Europe)

K1 : KDC-C719 (North America)

M1 : KDC-C719 M3 : KDC-C719/G4 (Other Areas)

N

d

d

Parts No. Description

e

w

✽

E41-2179-05 FLAT CABLE CONNECTOR

✽

E41-2173-05 FLAT CABLE CONNECTOR

Desti-

nation

KDC-C719/C719Y

KDC-C719/G4

A

Ref. No.

R108 RK73GB2A104J CHIP R 100K J 1/10W

R110,111 RK73GB2A104J CHIP R 100K J 1/10W

R114 RK73GB2A103J CHIP R 10K J 1/10W

R120 RK73GB2A624J CHIP R 620K J 1/10W

R121 RK73GB2A103J CHIP R 10K J 1/10W

R122,123 RK73GB2A102J CHIP R 1.0K J 1/10W

R124 RK73GB2A223J CHIP R 22K J 1/10W

R127 RK73GB2A103J CHIP R 10K J 1/10W

R133 RK73GB2A104J CHIP R 100K J 1/10W

R148,149 RK73GB2A101J CHIP R 100 J 1/10W

R150 RK73GB2A102J CHIP R 1.0K J 1/10W

R153,154 RK73GB2A472J CHIP R 4.7K J 1/10W

R155,156 RK73GB2A101J CHIP R 100 J 1/10W

R161 RK73GB2A163J CHIP R 16K J 1/10W

R162 RK73GB2A472J CHIP R 4.7K J 1/10W

R190 RK73GB2A223J CHIP R 22K J 1/10W

R191 RK73GB2A123J CHIP R 12K J 1/10W

R205 RK73EB2E102J CHIP R 1.0K J 1/4W

R206 RK73GB2A102J CHIP R 1.0K J 1/10W

R502 RK73GB2A000JX CHIP R 0.0 J 1/10W

R503 RK73EB2E000JX CHIP R 0.0 J 1/4W

R505-507 RK73GB2A000JX CHIP R 0.0 J 1/10W

R851-853 RK73GB2A472J CHIP R 4.7K J 1/10W

R854-857

S1 S68-0823-05 PUSH SWITCH

S2 S70-0838-05 TACT SWITCH

S3 S68-0823-05 PUSH SWITCH

D1 DAP202K DIODE

D3,4 UDZS5.6B ZENER DIODE

D5

D7 UDZS5.6B ZENER DIODE

D8

D9,10 D1F60-5063 DIODE

D11 1SR154-400 DIODE

D12 DA204U DIODE

D14 MAZS0910M ZENER DIODE

D15 DAP202K DIODE

D16 DAP202U DIODE

D21,22 DAN202K DIODE

D23,24 DAN202U DIODE

IC1 UPD63711AGC-A MOS-IC

IC4

IC5

IC7

IC8 W05-1306-00 ROM IC

IC9 S-80830CNNB-G MOS-IC

Q1 2SB0970 TRANSISTOR

Q4 DTA124EK DIGITAL TRANSISTOR

Q5 DTA124EUA DIGITAL TRANSISTOR

Q6,7 DTC343TK DIGIT AL TRANSIST OR

Q8 DTA124EK DIGITAL TRANSISTOR

Q9

Q10 2SB1295-E TRANSISTOR

Q11 DTC124EK DIGIT AL TRANSIST OR

N

d

d

Parts No. Description

e

w

✽

RK73PB2H3R0J CHIP R 3.0 J 1/2W

✽

MAZS0750M ZENER DIODE

✽

MAZS0620M ZENER DIODE

✽

KIA78L05F-P ANALOGUE IC

✽

LA6576-E ANALOGUE IC

✽

784217YGC106A MICROCONTROLLER IC

✽

2SB1202-E TRANSISTOR

Indicates safety critical components.

Desti-

nation

15

Page 16

KDC-C719/C719Y

KDC-C719/G4

CD PLAYER UNIT (X32-5810-00) in X92

A

Ref. No.

Q13 DTC124EUA DIGITAL TRANSISTOR

Q14 DTA143EUA DIGITAL TRANSIST OR

Q16 2SC4081 TRANSISTOR

Q17 DTA143EK DIGITAL TRANSISTOR

Q18,19 DTC124EUA DIGITAL TRANSIST OR

N

d

d

Parts No. Description

e

w

PARTS LIST

Desti-

nation

Ref. No.

46 2B

47 1B G01-3037-04 EXTENSION SPRING

48 2B G01-3038-04 TORSION COIL SPRING

49 3A G01-3039-04 COMPRESSION SPRING

50 3A G01-3040-04 EXTENSION SPRING

A

d

d

N

Parts No. Description

e

w

✽

G01-3036-14 TORSION COIL SPRING

Desti-

nation

Q20 DTC124EK DIGIT AL TRANSIST OR

Q21

Q22 2SC4081 TRANSISTOR

Q30 DTC114YUA DIGITAL TRANSISTOR

Q31 DTC124EUA DIGITAL TRANSISTOR

TH1

✽

2SB1202-E TRANSISTOR

✽

NCP18WB333J0S THERMISTOR 33K

MECHANISM ASSY (X92-5310-00) (CHM-1400W)

12B

22B

32BA10-4751-13 CHASSIS CALKING ASSY

43A

52A

62A

71A

C75 3A C90-5647-05 ELECTRO 0.047F 5.5WV

11 2B D10-4546-03 ARM

12 2A

13 2B

14 2B

15 3A

16 2A

17 2A

18 1B

19 3A

20 1B

21 1B D10-4547-03 LEVER

22 2B

23 2B

24 3B D13-2185-04 GEAR

25 3B D13-2186-04 GEAR

26 3B D13-2187-04 GEAR

27 3A D13-2188-04 WORM

28 2B D13-2092-04 GEAR

29 2B

30 2B D13-2095-04 GEAR

31 2B D13-2096-04 GEAR

32 3A D13-2099-04 GEAR

33 3A D13-2100-04 GEAR

34 3A D13-2101-04 GEAR

35 3A D13-2102-04 GEAR

✽

A10-4745-23 CHASSIS ASSY

✽

A10-4748-32 CHASSIS CALKING ASSY

✽

A10-4754-14 CHASSIS CALKING ASSY

✽

A10-4757-42 CHASSIS CALKING ASSY

✽

A10-4759-12 CHASSIS

✽

A10-4760-12 CHASSIS CALKING ASSY

✽

D10-4527-13 SLIDER

✽

D10-4528-13 ARM

✽

D10-4529-13 ARM

✽

D10-4531-14 LEVER ASSY

✽

D10-4533-13 LEVER

✽

D10-4534-24 SLIDER ASSY

✽

D10-4536-23 SLIDER

✽

D10-4537-14 SLIDER ASSY

✽

D10-4540-23 ARM

✽

D12-0630-12 CAM

✽

D12-0631-12 CAM

✽

D13-2093-14 GEAR ASSY

51 3A G01-3041-04 EXTENSION SPRING

52 1B G01-3042-04 TORSION COIL SPRING

53 2A G01-3043-04 TORSION COIL SPRING

54 1B G01-3044-04 EXTENSION SPRING

55 2A G01-3045-04 EXTENSION SPRING

56 2A G01-3046-04 EXTENSION SPRING

57 3B G02-1374-04 FLAT SPRING

58 3B G02-1375-03 FLAT SPRING

59 2B G02-1376-03 FLAT SPRING

61 2B G02-1378-14 FLAT SPRING

✽

62 3A

63 2A G10-1045-14 FELT

68 2B J11-0637-03 CLAMPER

69 3B

70 1B

73 2B J90-0759-03 GUIDE

74 2A J90-0992-03 RAIL

75 2B J90-0990-03 GUIDE

FPC1 3B J86-0027-05 FPC (LEAD FREE)

A2A

B3A

C3A

D2B

E3BN09-6155-15

F2B

G3B

H3AN09-6108-15 TAPTITE SCREW (M2X3.5)

J3AN19-2105-14 FLAT W ASHER

K3AN19-2058-04 FLAT W ASHER

L1BN19-2080-14 FLAT WASHER

M2BN19-2028-04 FLA T WASHER

N3A

76 3A✽R33-0207-35

M1 3B✽T42-1337-04 DC MOTOR

M2, 3 3A

Q32 3A 2SB1565(E,F) TRANSISTOR

PU1 3B X93-2010-01 OPTICAL PICKUP ASSY

G02-1380-14 FLAT SPRING

✽

J21-9592-14 MOUNTING HARDWARE

✽

J21-9595-13 MOUNTING HARDWARE

✽

N09-4126-15 TAPTITE SCREW (2X3.5,CT)

✽

N09-6392-05 TAPTITE SCREW (S2X2.5 NI)

✽

N86-2005-48

✽

N09-4189-15 TAPTITE SCREW (1.7X1.5 ST)

✽

N09-6390-05 MACHINE SCREW (M1.7X3)

✽

N39-1722-48 PAN HEAD MACHINE SCREW

✽

N09-6391-05

✽

T42-1063-15 DC MOTOR

BINDING HEAD TAPTITE SCREW

SEMS (TAPTITE SCREW) (PT 2X6)

TAPTITE SCREW (S2X3 BLACK-NI)

SLIDE TYPE V ARIABLE RESISTOR

36 3A D13-2103-04 GEAR

37 3A D13-2104-14 GEAR

38 3B D19-0636-04 LEAD SCREW

39 3A D19-0637-04 CLUTCH ASSY

40 3A D39-0225-05 DAMPER

FC1 3A E39-0172-15 FLAT CABLE

FC2 3A E39-0173-35 FLAT CABLE

E2 : KDC-C719Y E3 : KDC-C719 (Europe)

K1 : KDC-C719 (North America)

M1 : KDC-C719 M3 : KDC-C719/G4 (Other Areas)

16

Indicates safety critical components.

Page 17

PARTS LIST

CAPACITORS

C C 4 5 T H 1 H 2 2 0 J

1234 56

1 = Type ... ceramic, electrolytic, etc. 4 = Voltage rating

2 = Shape ... round, square, etc. 5 = Value

3 = Temp. coefficient 6 = Tolerance

• Temperature coefficient

1st Word C L P R S T U

Color* Black Red Orange Yellow Green Blue Violet

ppm/°C0–80 –150 –220 –330 –470 –750

CC45

Color*

2nd Word G H J K L

ppm/°C ±30 ±60 ±120 ±250 ±500

Example : CC45TH = –470±60ppm/°C

• Capacitor value

010 = 1pF 2 2 0 = 22pF

100 = 10pF

101 = 100pF Multiplier

102 = 1000pF = 0.001µF 2nd number

103 = 0.01µF 1st number

KDC-C719/C719Y

KDC-C719/G4

• Tolerance (More than 10pF)

Code C D G J K M X Z P No code

(%) ±0.25 ±0.5 ±2 ±5 ±10 ±20 +40 +80 +100 More than 10µF : –10~+50

–20 –20 –0 Less than 4.7µF : –10~+75

• Voltage rating

2nd word

1st word

0 1.0 1.25 1.6 2.0 2.5 3.15 4.0 5.0 6.3 8.0 –

11012.5 16 20 25 31.5 40 50 63 80 35

2 100 125 160 200 250 315 400 500 630 800 –

3 1000 1250 1600 2000 2500 2150 4000 5000 6300 8000 –

• Chip capacitors

(EX) C C 7 3 F S L 1 H 0 0 0 J Refer to the table above.

12345 67 1 = Type

(Chip) (CH, RH, UJ, SL) 2 = Shape

(EX) C K 7 3 F F 1 H 0 0 0 Z 4 = Temp. coefficient

12345 67 5 = Voltage rating

(Chip) (B, F) 6 = Value

ABCDEFGHJKV

3 = Dimension

7 = Tolerance

RESISTORS

• Chip resistor (Carbon)

(EX) R D 7 3 E B 2 B 0 0 0 J

12345 67

(Chip) (B, F)

• Carbon resistor (Normal type)

(EX) R D 1 4 B B 2 C 0 0 0 J

12345 67

1 = Type 5 = Rating wattage

2 = Shape 6 = Value

3 = Dimension 7 = Tolerance

4 = Temp. coefficient

(Less than 10pF)

Code B C D F G

(pF) ±0.1 ±0.25 ±0.5 ±1 ±2

• Dimension

L

T

W

Chip capacitor

Code L W T

Empty 5.6±0.5 5.0±0.5 Less than 2.0

A 4.5±0.5 3.2±0.4 Less than 2.0

B 4.5±0.5 2.0±0.3 Less than 2.0

C 4.5±0.5 1.25±0.2 Less than 1.25

D 3.2±0.4 2.5±0.3 Less than 1.5

E 3.2±0.2 1.6±0.2 Less than 1.25

F 2.0±0.3 1.25±0.2 Less than 1.25

G 1.6±0.2 0.8±0.2 Less than 1.0

H 1.0±0.05 0.5±0.05 0.5±0.05

Chip resistor

Code L W T

E 3.2±0.2 1.6±0.2 1.0

F 2.0±0.3 1.25±0.2 1.0

G 1.6±0.2 0.8±0.2 0.5±0.1

H 1.0±0.05 0.5±0.05 0.35±0.05

• Rating wattage

Code Wattage Code Wattage Code Wattage

1J 1/16W 2C 1/6W 3A 1W

2A 1/10W 2E 1/4W 3D 2W

2B 1/8W 2H 1/2W

17

Page 18

KDC-C719/C719Y

KDC-C719/G4

Disc section

Laser diode ........................................................................................................... GaAlAs (λ=780nm)

Digital filter ..................................................................................................... 8 Times Over Sampling

D/A Converter ................................................................................................................................1Bit

Spindle speed ....................................................................................................... 500~200rpm (CLV)

Wow & Flutter.................................................................................................Below Measurable Limit

Frequency response ............................................................................................. 5Hz~20kHz (±1dB)

Total harmonic distortion .............................................................................................. 0.005% (1kHz)

S/N ratio .................................................................................................................................... 100dB

Dynamic range ............................................................................................................................ 94dB

Channel separation ..................................................................................................................... 96dB

General

Operating voltage........................................................................................................14.4V (11~16V)

Current consumption.................................................................................................................... 0.8A

Installation Size (W x H x D) .............................. 250 x 80 x 176 mm (9-13/16 x 3-1/8 x 6-13/16 inch)

Weight ........................................................................................................................... 2.0kg (4.4 lbs)

SPECIFICATIONS

KENWOOD follows a policy of contin uous advancements in development.

For this reason specifications may be changed without notice.

DANGER:

Please do not look the laser beam directly during repair or operation check.

Loading...

Loading...