Kenwood KDC-C715Y Service Manual

CD AUTO CHANGER

KDC-C715/Y

SERVICE MANUAL

KDC-C715/Y

© 1999-12 PRINTED IN JAPAN

B51-7553-00 (N) 3444

When transporting this model, always attach CAUTION

CARD and STEPPED SCREW (for transportation).

CAUTION CARD : B58-1275-04

STEPPED SCREW : N09-4186-25

Dressing Panel

(A21-3536-12)

Holder Assy (Magazine)

(J19-4676-52)

Dressing Panel

(A21-3539-12)

Service jig Parts No.

For initial position setting W05-0635-00

Panel

(A64-1992-01)

COMPACT DISC AUTO CHANGER KDC-C715

NEW ANTI VIBRATION MECHANISM DISC NAME PRESET

COMPACT

DIGITAL AUDIO

TEXT

DISC

10

Bracket (L)

(J19-4710-13)

Bracket (R)

(J19-4711-13)

Blind Plate

(F19-1303-04)

Screw Set

K/E T ype:

(N99-1645-15)

M T ype:

(N99-1628-15)

Adhessive Tape

(J69-0506-04)

Mounting Hardware Assy

(J21-7775-04)

M T ype Only

Cord With Plug

(E30-4138-05)

The MECHANISM OPERATION DESCRIPTION is the same as model KDC-C710.

Please refer to the service manual of model KDC-C710 (B51-7104-00).

KDC-C715/Y

M5V1

LIM SW

L.P.S.

S4 COMM SW

S2 EJ SW

S3 ARM SW

12.5MHz

AVREF0

X2

SPINDLE

PD

PICKUP ASSY

(X13-973)

(X32-466)

(X13-900)

SLED

LOE SW

TR COIL

FO COIL

E

D

B

AC

MOTOR

DRIVER

BTL & DC

ELEVATOR

EEPROM

S-24C01B

HOT

TEXT DECODER &

APC

SD5V

Q1

S8V

LA6556

Q9

UPD784214GC-062-8EU

SYSTEM u-COM

IC7

IC1

RF AMP & SERVO DSP &

16.93MHz

X1

P ON

Q10

7V/9V

M5V1

M5V2

RESET

IC9

Q15,16

8V AVR

Q20

Q21,22

BU.DET

5V AVR

BU14V

DA5V

MUTE

5VREG

S8V

CH CON

CH RST

CH MUTE

5L I/F

AUDIO OUT

T0

IC8

7

4

5

8

2

5

Q6-8

IC4

IC5

AVR

S5V

13

IC11

LC3564ST-70

S-RAM

24

2

S8V

Q12

S1 MG SW

3

HEAD

UNIT

M

MM

SA5V

UPD63711GC

D/A CONVERTER & SCF

OBIT

MUTE

Q4,5

F

BLOCK DIAGRAM

2

KDC-C715/Y

MICROCOMPUTER’S TERMINAL DESCRIPTION

UPD784214GC (X32-4660-00, IC7)

Pin No

1 TOUT O Test output

2 TSTB O Text data strobe signal

3 - O NC.

4 FOK I H: Focusing OK. L:Focusing NG.

5 X OFF O H: Servo IC oscillation OFF.

6 RST O L: Servo IC reset.

7 AO O H: Parameter setting. L: Address register setting.

8 STB O L: Data latch.

9 VDD Power supply connection.

10 X2 - Oscillator.

11 X1 I Oscillator.

12 VSS I GND.

13 XT2 - NC.

14 XT1 GND.

15 RESET I L:Reset.

16 BSY

17 MGSW I H:Holder IN. L:Holder OUT.

18 EJSW I H:Eject.

19 COMMSW I H:New. L:Old.

20 PACK I Text data pack sync signal.

21 CHCON I Changer control.

22 BUDET I B-U detection.

23 AVDD I A/D converter power supply.

24 AVREF I A/D converter reference voltage.

25 HOT I High temperature detection.

26 LPS I Position detection.

27 LOESW I L:Loading completed.

28 LIMSW I L:PU limit switch ON.

29 TOFF I Tracking off mode.

30 ADJSEL I H:Service adjustment OFF. L:Servo adjustment ON.

31 TBANK I H:Gain UP. L:Normal.

32 SIM3

33 AVSS GND.

34 LPSCO O A/D converter power supply. H:OFF.

35 AMUTE O L:Muting ON.

36 AVREF1 A/D converter power supply.

37 SDI I Servo data input.

38 SDO O Servo data output.

39 SCK O Servo clock output.

40 DATAH I Data input from H/U.

Name I/O Processing, Operation

3

KDC-C715/Y

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No

41 DATAC O Data output to H/U.

42 HCLK I/O H:Clock input. L:Clock output.

43 REQC O Communication request to H/U.

44 CHMUTE O L:Muting ON.

45 TSO O Text data output.

46 TSI I Text data input.

47 TSCK O Text clock output.

48Å`55

A0Å`7 O S-RAM address setting.

56Å`63

D0Å`7 I/O S-RAM data input/output.

64Å`68

A8Å`12 O S-RAM address setting.

69Å`71

A13Å`15 O S-RAM enable control.

72 VSS GND.

73,74 A16,17 O S-RAM enable control.

75 RAMOK O H:OK.

76 ELVADJ I L:Adjustment mode.

77 RD O S-RAM read control.

78 WR O S-RAM write control.

79 WAIT I Wait during S-RAM access.

80 ASTB O NC.

81 VDD Power supply connection.

82 RAMTEST I H:S-RAM check mode.

83 REQH I Communication request from H/U.

84 SP/LO+ O Spindle/Loading+ control.

85 SP/LO- O Spindle/Loading- control.

86 ELV+ O Mechanism UP/DOWN control.

87 ELV- O Mechamism UP/DOWN control.

88 SIM1 I L:Text. H:No text.

89 SEARCH O H:Play. L:Search.

90,91 TEST1,2 I L:Normal. H:Test.

92 8V/7V O H:7V. L:8V(Servo power supply).

93 SLG I H:+3dB. L:0dB(Sled gain).

94 TEST/VPP I L:Flash ROM program mode OFF.

95 SRVSEL I H:Servo mode.

96 SLNSA I L:Sled non-sensible area ON.

97 SDA I/O EEPROM data input/output.

98 SCL O EEPROM clock output.

99 PON O L:Power ON.

100 ARMSW I H:Arm switch ON.

Name I/O Processing, Operation

4

ADJUSTMENT

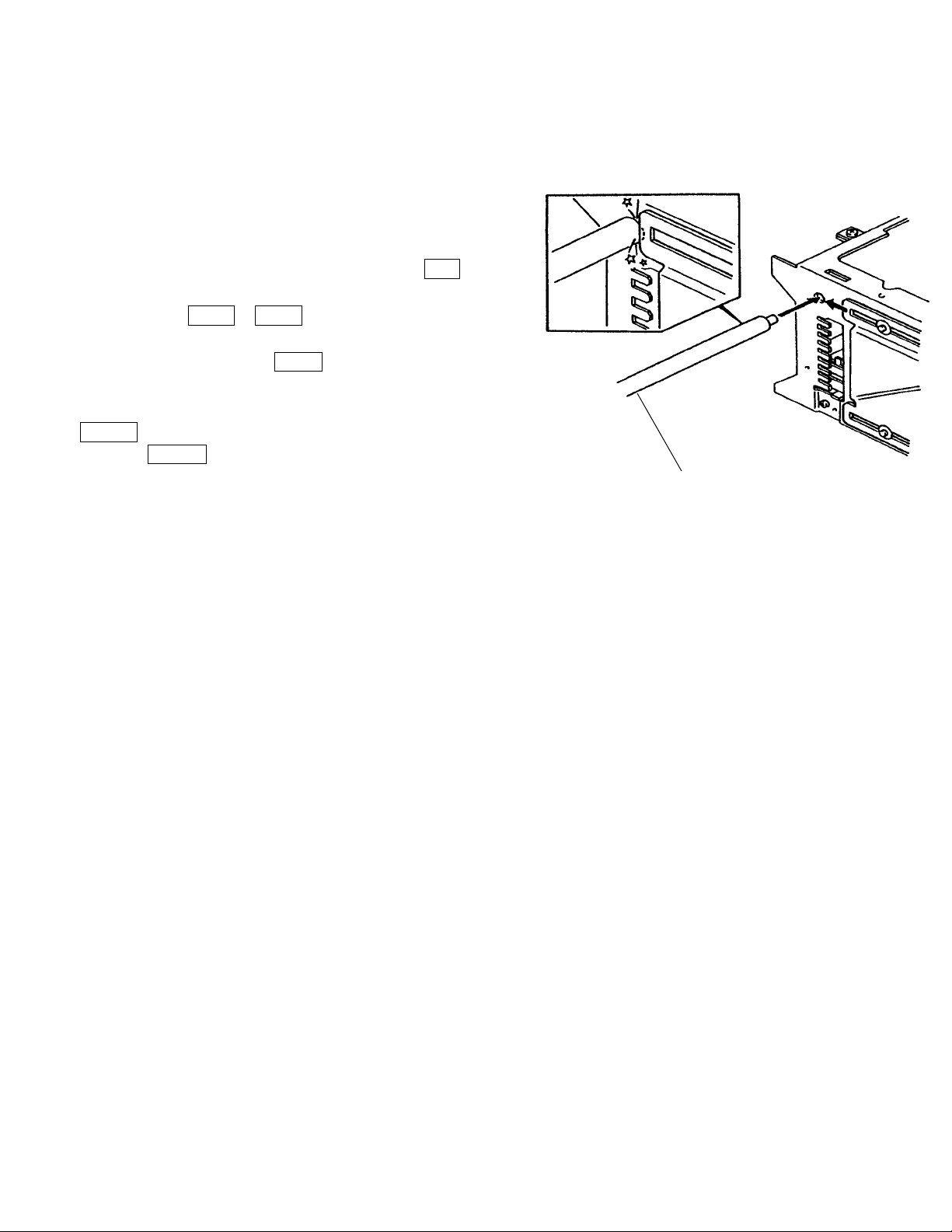

LPS initial position adjustment procedure

Connect the changer to the H/U. While holding the magazine eject button of the changer, press the reset button of

the H/U and, in about 1 second, release the magazine eject

button. Press the CD button of the H/U to enter the E-88

mode. Move the mechanism deck to around the 1st stage

by pressing the DISC- or DISC+ button.

Insert the adjustment tool into the tool hole on the changer

mechanism. Then press the DISC+ button to move the

mechanism deck until the mechanism's slider hits the

adjustment tool. When the motor locks(stops) press the

REPEAT key of the H/U.

When the REPEAT key is pressed, the mechanism moves

automatically to the 1st stage and the initial position adjustment completes. (The data is written in the E2PROM

at this time.)

KDC-C715/Y

(W05-0635-01)

5

Loading...

Loading...