Kenwood KDC-152, KDC-153, KDC-153S Service Manual

SERVICE MANUAL

CD RECEIVER

WA001<Rev.001>201110SERVICE MANUALB53-0892-00

KDC-152, KDC-153, KDC-153S

Tuner setting adjustment after replacing E2PROM

After replacing E2PROM (IC771 on ELECTRIC UNIT), tuner setting adjustment is needed.

The adjustment is that to perform the "TUNER Setting Adjustment Mode" in the TEST MODE.

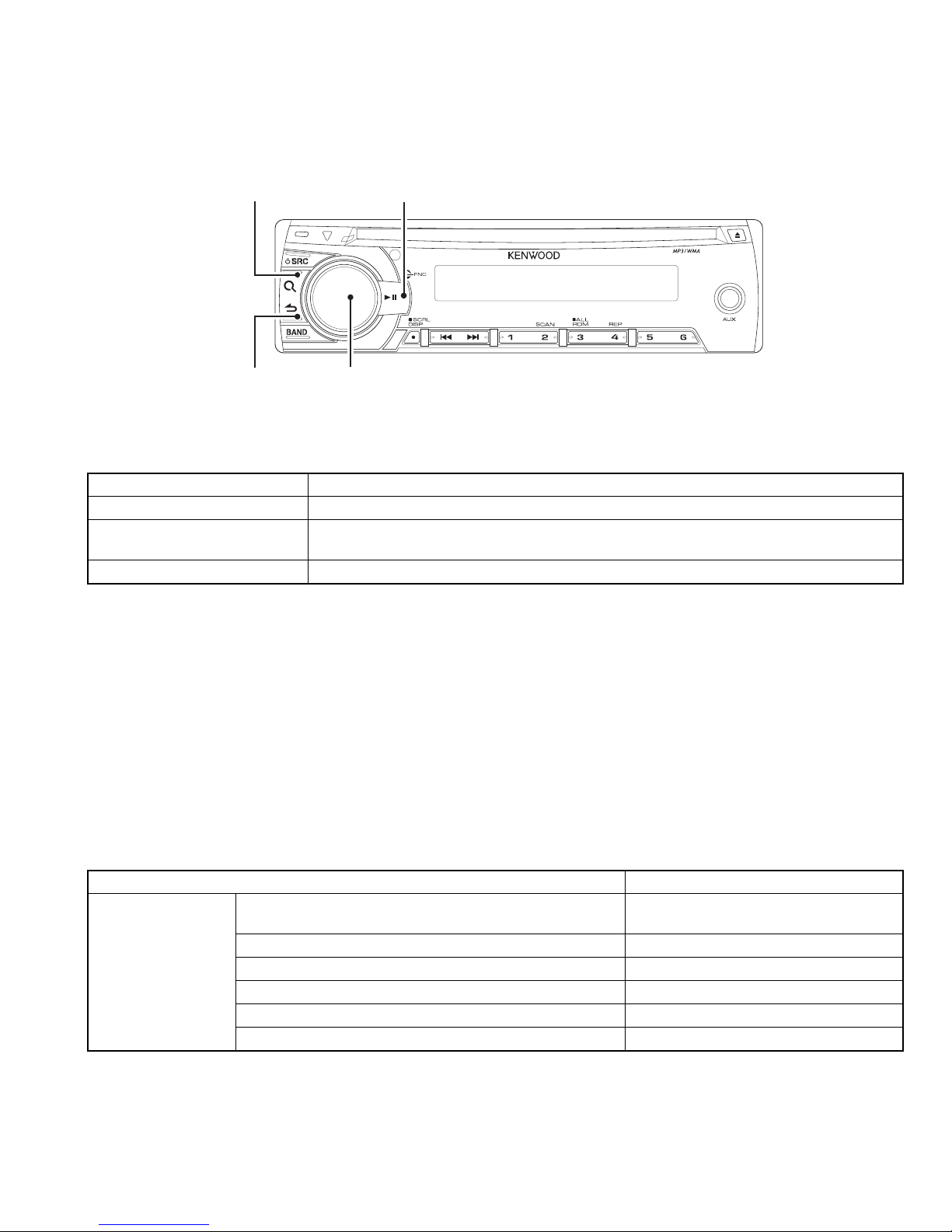

Illustration is KDC-152

M. sleeve assy

(GE34826-001A)

Tap screw (2x8)

(QYSPSF2008MA)

DC cord

(QAM1335-001)

Screw set

(GE40536-001A)

KDC-152

Trim plate

(GE20274-001A)

Hook

(GE40578-001A) x2

TDF SPARE-PANEL

MAIN UNIT NAME TDF PARTS No. TDF NAME

KDC-152

KDC-153

KDC-153S

Remocon unit (RC-405)

(QAL1303-001)

Y33-3350-13

Y33-3370-27

Y33-3370-28

TDF-1215D

TDF-153

TDF-153S

COPYRIGHT © 2011 JVC KENWOOD Corporation

B53-0892-00

COPYRIGHT © 2011 JVC KENWOOD Corporation

This product uses Lead Free solder.

This product complies with the RoHS directive for the European market.

PbF

No.WA001<Rev.001>

2011/10

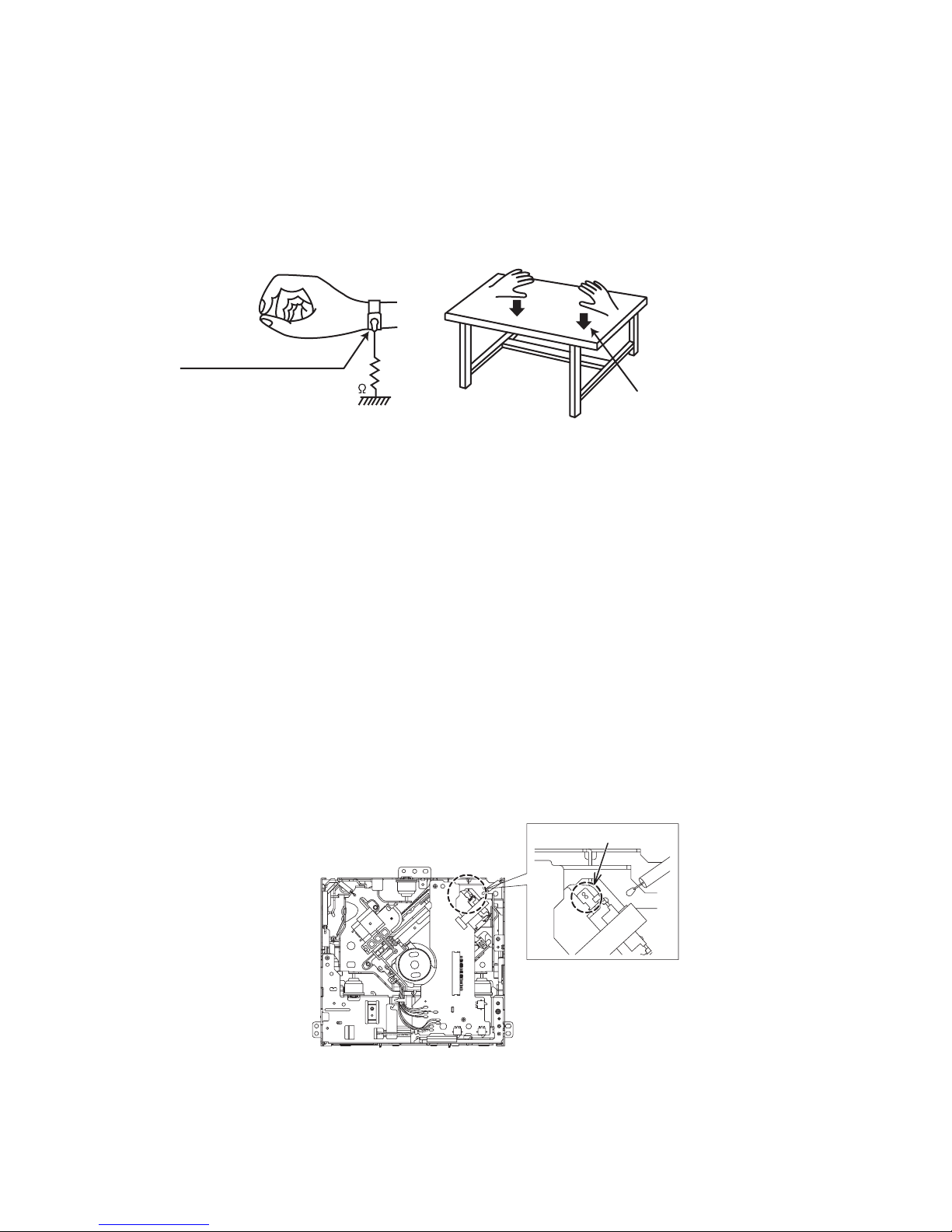

SPECIFICATION

Model for destination "K" (KDC-152)

FM tuner section

Frequency range (200 kHz space) 87.9 MHz - 107.9 MHz

Usable sensitivity (S/N= 26 dB) 11.2 dBf (1.0 µV/75 Ω)

Quieting sensitivity (DIN S/N = 46 dB) 19.2 dBf (2.5 µV/75 Ω)

Frequency response (± 3 dB) 30 Hz - 15 kHz

Signal-to-Noise ratio (MONO) 63 dB

Stereo separation (1 kHz) 40 dB

AM tuner section

Frequency range (10 kHz space) 530 kHz - 1 700 kHz

Usable sensitivity (S/N= 20 dB) 31 dBµ (36 µV)

CD player section

Laser diode GaAIAs

Digital filter (D/A) 8 Times Over Sampling

D/A converter 24 Bit

Spindle speed 500 rpm - 200 rpm (CLV)

Wow & Flutter Below Measurable Limit

Frequency response (± 1 dB) 20 Hz - 20 kHz

Total harmonic distortion (1 kHz) 0.01%

Signal-to-Noise ratio (1 kHz) 105 dB

Dynamic range 90 dB

MP3 decode Compliant with MPEG-1/2 Audio Layer-3

WMA decode Compliant with Windows Media Audio

Audio section

Maximum output power 50 W × 4

Full bandwidth power (at less than 1 % THD)

Speaker impedance 4 Ω - 8 Ω

Tone action Bass 100 Hz ± 8 dB

Middle 1 kHz ± 8 dB

Treble 10 kHz ± 8 dB

Preout level / load (CD) 2 000 mV/10 kΩ

Preout impedance ≤ 600 Ω

Auxiliary input section

Frequency response (± 3 dB)

Input maximum voltage 1 200 mV

Input impedance 10 kΩ

General

Operating voltage (11 V - 16 V allowable) 14.4 V

Maximum current consumption 10 A

Installation size (W × H × D) 182 mm × 53 mm × 158 mm (7-3/16" × 2-1/16" × 6-1/4")

Weight 2.9 lbs (1.3 kg)

22 W × 4

20 Hz - 20 kHz

Subject to change without notice.

(No.WA001<Rev.001>)2/18

SPECIFICATION

Models for destination "M" (KDC-153, KDC-153S)

FM tuner section

Frequency range (200 kHz space) 87.9 MHz - 107.9 MHz

Frequency range (50 kHz space) 87.5 MHz - 108.0 MHz

Usable sensitivity (S/N= 26 dB) 11.2 dBf (1.0 µV/75 Ω)

Quieting sensitivity (DIN S/N = 46 dB) 19.2 dBf (2.5 µV/75 Ω)

Frequency response (± 3 dB) 30 Hz - 15 kHz

Signal-to-Noise ratio (MONO) 63 dB

Stereo separation (1 kHz) 40 dB

AM tuner section

Frequency range Band 1 (MW) 530 kHz - 1 700 kHz (10 kHz space)

531 kHz - 1 611 kHz (9 kHz space)

Band 2 (SW1) 2 940 kHz - 7 735 kHz (5 kHz space)

Band 3 (SW2)

Usable sensitivity (S/N= 20 dB) MW: 31 dBµ (36 µV)

CD player section

Laser diode GaAIAs

Digital filter (D/A) 8 Times Over Sampling

D/A converter 24 Bit

Spindle speed 500 rpm - 200 rpm (CLV)

Wow & Flutter Below Measurable Limit

Frequency response (± 1 dB) 20 Hz - 20 kHz

Total harmonic distortion (1 kHz) 0.01%

Signal-to-Noise ratio (1 kHz) 105 dB

Dynamic range 90 dB

Audio section

Maximum output power 50 W × 4

Full bandwidth power (at less than 1 % THD)

Speaker impedance 4 Ω - 8 Ω

Tone action Bass 100 Hz ± 8 dB

Middle 1 kHz ± 8 dB

Treble 10 kHz ± 8 dB

Preout level / load (CD) 2 000 mV/10 kΩ

Preout impedance ≤ 600 Ω

Auxiliary input section

Frequency response (± 3 dB)

Input maximum voltage 1 200 mV

Input impedance 10 kΩ

General

Operating voltage (11 V - 16 V allowable) 14.4 V

Maximum current consumption 10 A

Installation size (W × H × D) 182 mm × 53 mm × 158 mm

Weight 1.3 kg

9 500 kHz - 10 135 kHz /11 580 kHz - 18 135 kHz (5 kHz space)

SW: 32 dBµ (40 µV)

22 W × 4

20 Hz - 20 kHz

Subject to change without notice.

(No.WA001<Rev.001>)3/18

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

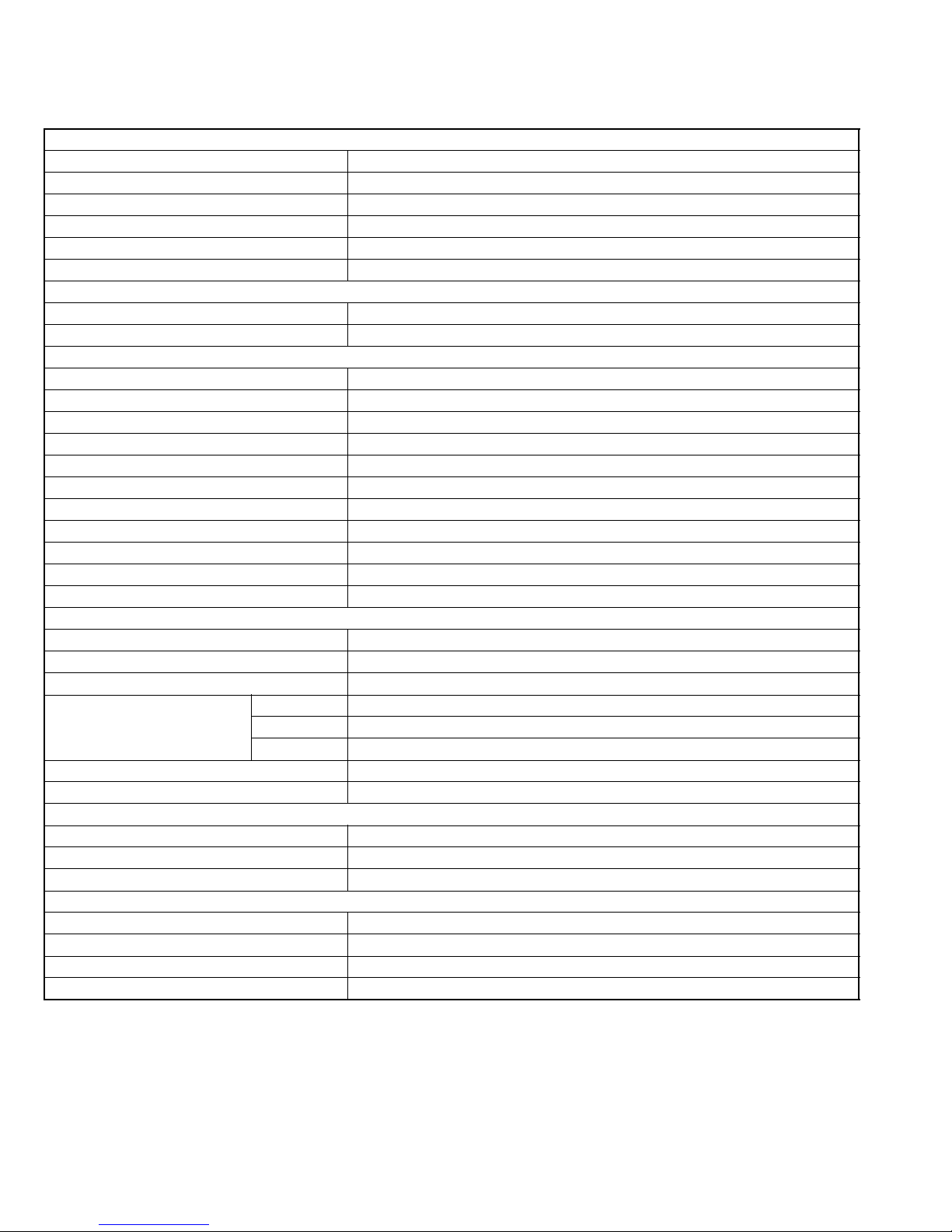

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.WA001<Rev.001>)4/18

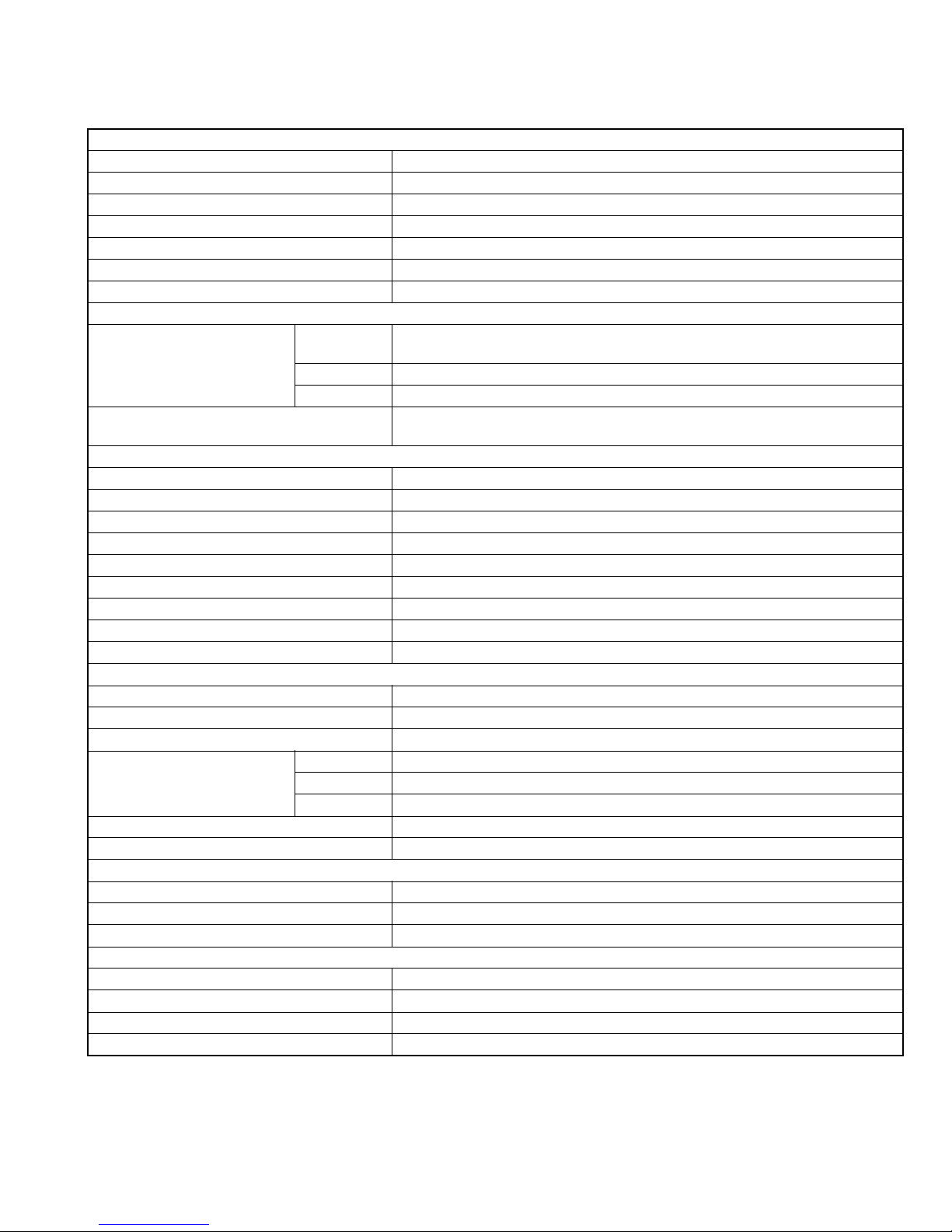

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connector on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

SOLDER

(No.WA001<Rev.001>)5/18

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 2

(No.WA001<Rev.001>)6/18

SECTION 3

DISASSEMBLY

3.1 Main body (Used model: KDC-152)

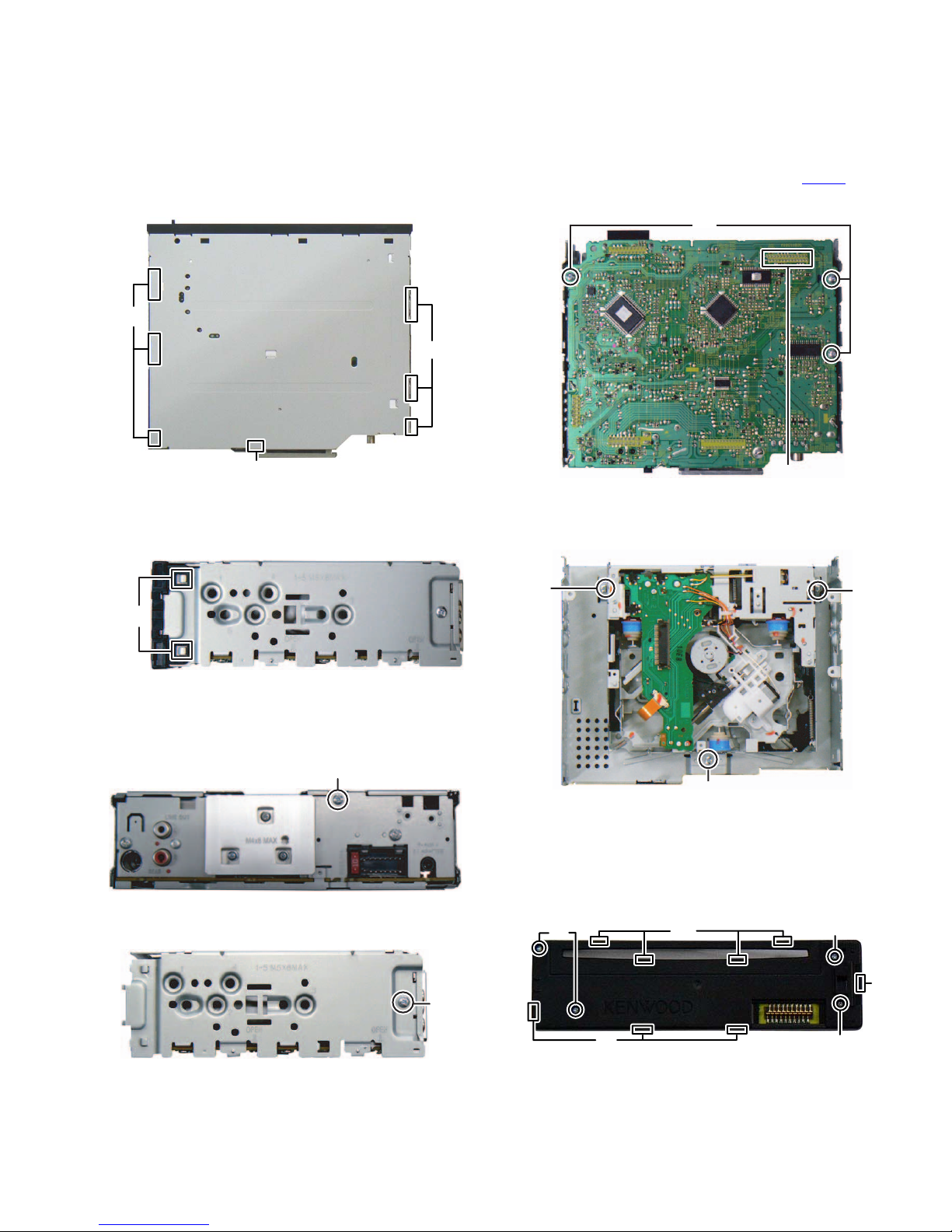

3.1.1 Removing the Bottom chassis (See Fig.1)

(1) Disengage the 7 hooks a engaging the Bottom chassis.

(2) Slide the Bottom chassis backward to remove it.

hook a

hook a

hook a

Fig.1

3.1.2 Removing the Front chassis (See Fig.2)

(1) Disengage the 4 hooks b engaging both sides of the Front

chassis.

hook b

(3) Remove the 3 screws C attaching the Electric unit. (See

Fig.5)

(4) Disconnect the board to board connector CN502

ing the Electric unit and the CD mechanism. (See Fig.5)

connect-

C

CN502

Fig.5

3.1.4 Removing the CD mechanism (See Fig.6)

(1) Remove the 3 screws J attaching the CD mechanism.

D

D

Fig.2

3.1.3 Removing the Electric unit (See Fig.3, 4 and 5)

(1) Remove the 1 screws A attaching the Rear bracket. (See

Fig.3)

A

Fig.3

(2) Remove the 2 screws B attaching both sides of the Top

chassis. (See Fig.4)

B

Fig.4

D

Fig.6

3.1.5 Removing the Switch unit (See Fig.7)

(1) Remove the Volume knob.

(2) Remove the 4 screws E attaching the Rear cover.

(3) Disengage the 8 hooks c engaging the Rear cover.

E

c

c

Fig.7

E

c

E

(No.WA001<Rev.001>)7/18

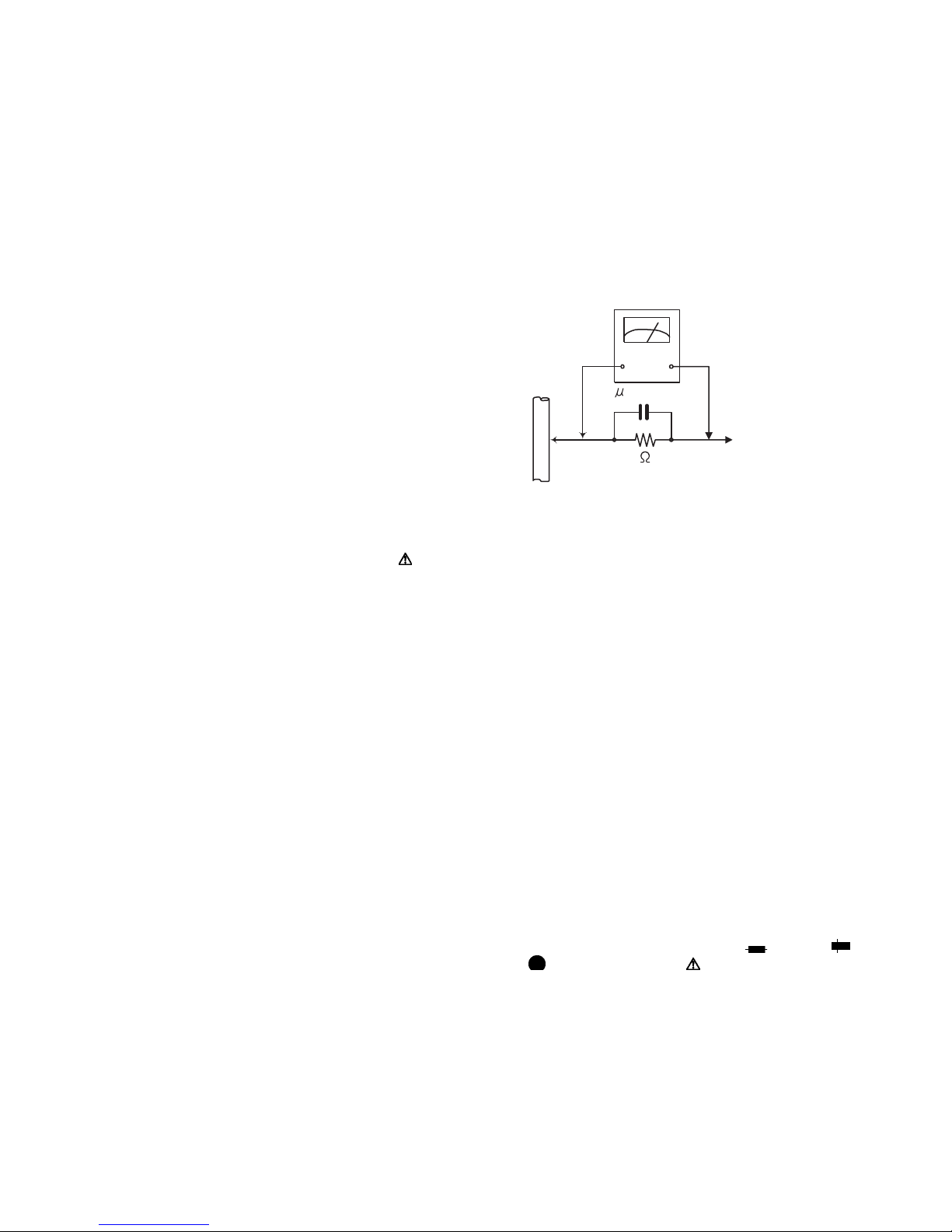

3.2 CD mechanism assembly section

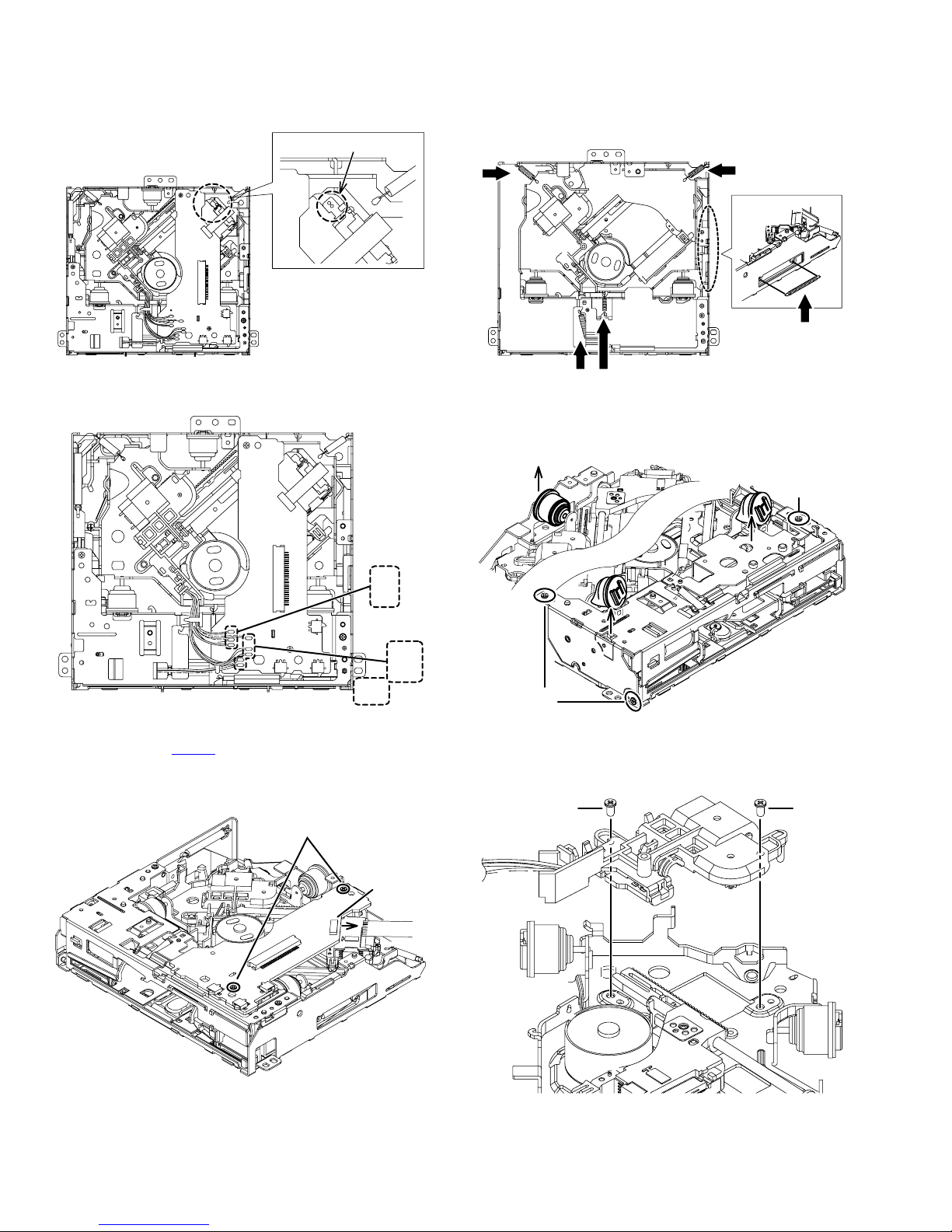

3.2.1 Removing the Mecha control board

(1) Solder the short land on the pickup. (See Fig. 1)

SOLDER

3.2.2 Removing the Traverse mechanism (See Fig.4, 5)

(1) Remove the five springs from the traverse mechanism.

(See Fig.4)

Fig.1

(2) Remove the eight wires from the Mecha control board.

(See Fig.2)

BLACK

RED

WHITE

YELLOW

ORANGE

ORANGE

WHITE

YELLOW

Fig.2

(3) Disconnect the flexible wire from the pickup connected to

the connector CN102

on the Mecha control board. (See

Fig.3)

(4) Remove the two screws A attaching the Mecha control

board. (See Fig.3)

A

Fig.4

(2) Remove the three screws B attaching the bottom frame as-

sembly. (See Fig.5)

(3) Remove the three dumpers from the bottom frame assem-

bly. (See Fig.5)

B

B

Fig.5

3.2.3 Removing the Pickup (See Fig.6, 7)

(1) Remove the two screws C attaching the feed bracket as-

sembly. (See Fig.6)

CC

Fig.3

CN102

Fig.6

(No.WA001<Rev.001>)8/18

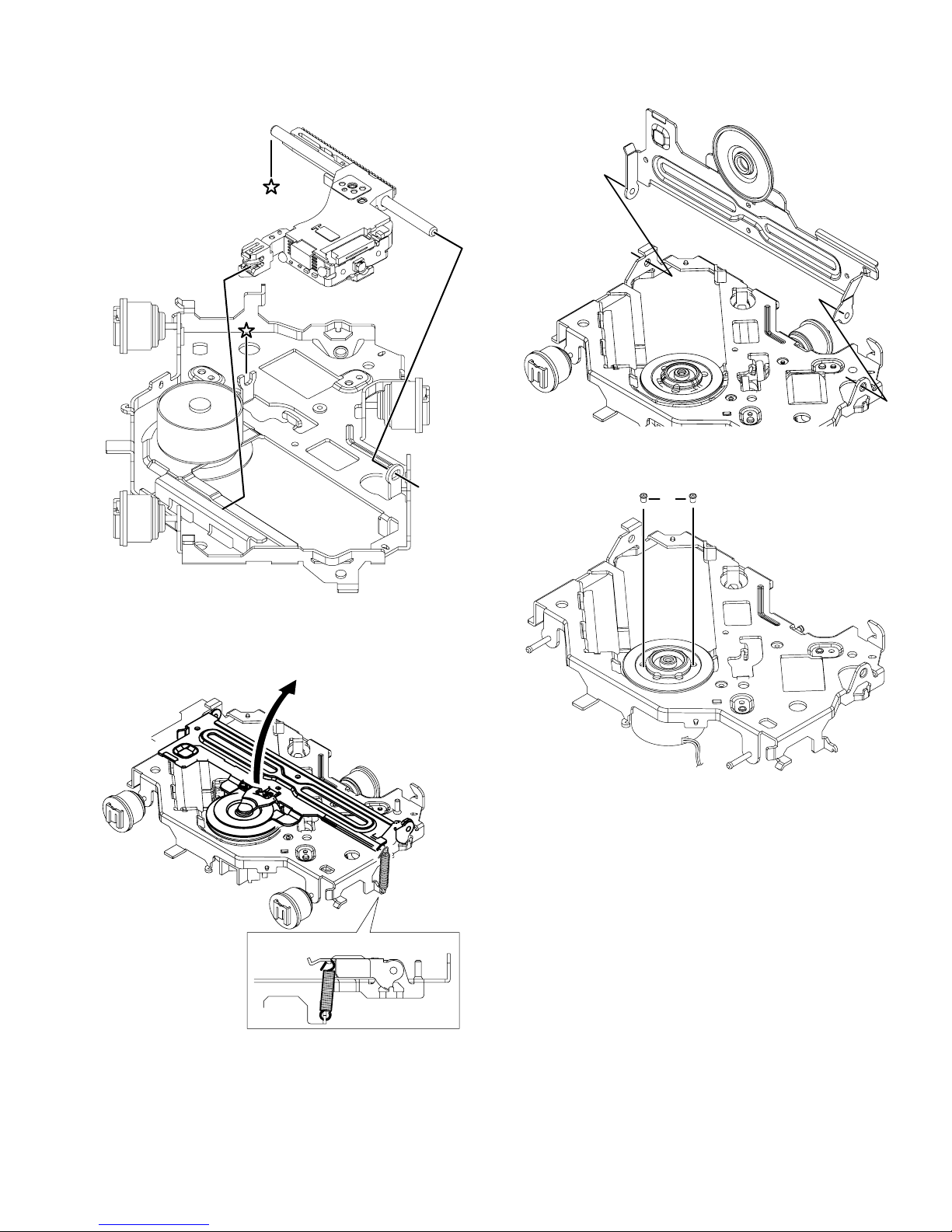

(2) Remove the shaft from the TM base. (See Fig.7)

(3) Disengage the hook on the pickup from the TM base. (See

Fig.7)

shaft

(2) Remove the HC CL. base from the holes on the TM base.

(See Fig.9)

Fig.9

(3) Remove the two screws D attaching the spindle motor.

(See Fig.10)

D

Fig.7

3.2.4 Removing the Spindle motor (See Fig.8. 9)

(1) Remove the HC CL. Spring from the HC CL. base and the

TM base, and then lift up the HC CL. base. (See Fig.8)

HC CL. spring

[ SIDE VIEW ]

Fig.8

Fig.10

(No.WA001<Rev.001>)9/18

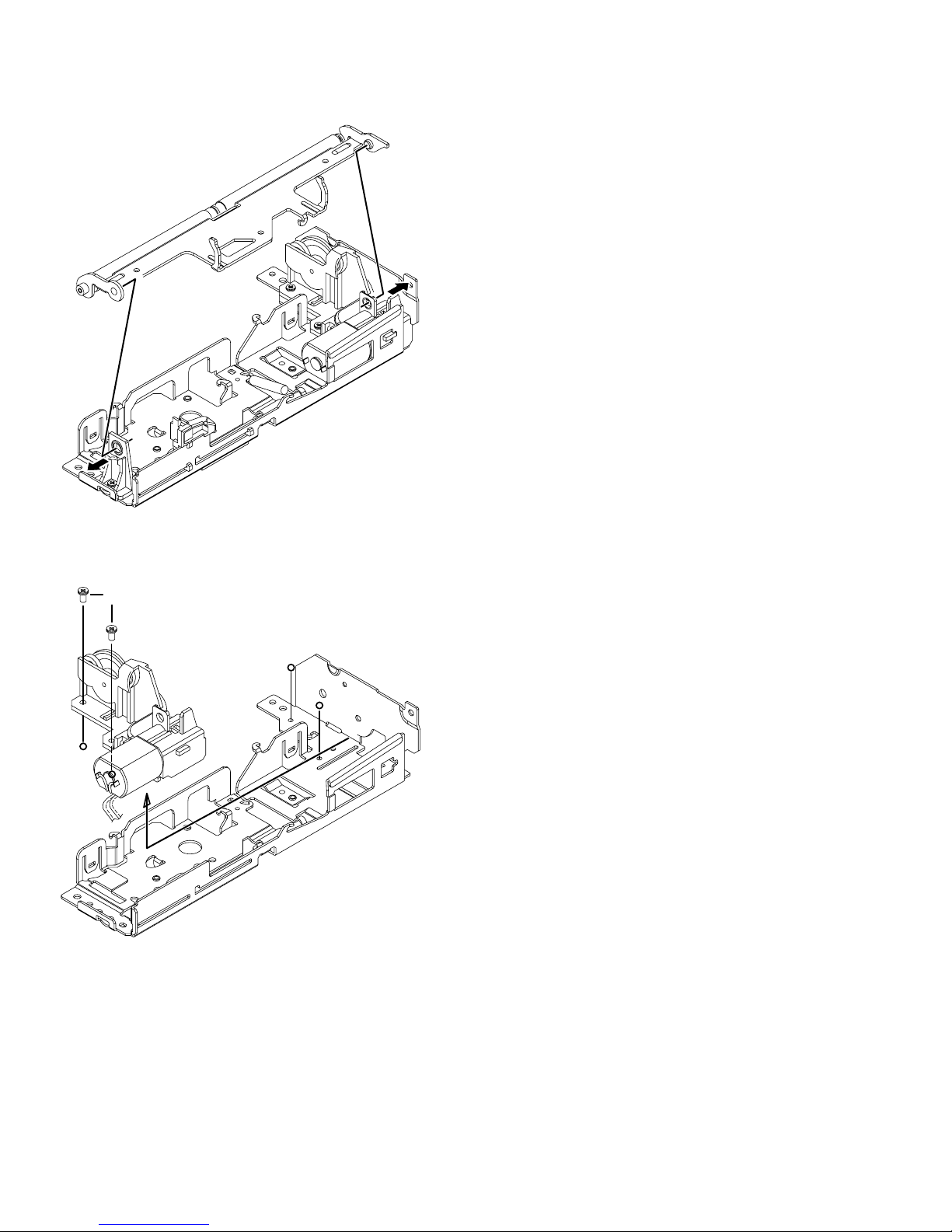

3.2.5 Removing the Loading motor

(1) Remove the roller arm assembly from the bottom frame as-

sembly. (See Fig.11)

Fig.11

(2) Remove the two screws E attaching the loading motor as-

sembly, and then remove the loading motor assembly in

the direction of the arrow. (See Fig.12)

E

Fig.12

(No.WA001<Rev.001>)10/18

4.1 TEST MODE

4.1.1 Panel

SEARCH

SECTION 4

ADJUSTMENT

ACCENT

KDC-152

RETURN

A symbol "" in the key column indicates that the key should be pressed and held for 1 second or longer.

4.1.2 How to enter each Test Mode

Test Mode name Operation

Production Test Mode Press and hold [1] key and [3] key and reset.

Service Test Mode

DC Error Information Mode Press and hold [3] key and [6] key and reset.

∗Transition to Test Mode shall be available during DC Error detection.

4.1.3 How to release each Test Mode

• Reset

• Momentary voltage drop

• ACC OFF

• POWER OFF

• Panel Detach

4.1.4 Production Test Mode

Press and hold [1] key and [3] key and reset.

VOL

In the STANDBY source, while pressing and holding [2] key, press [6] key for 7 seconds.

(Starting to press [2] key and [6] key at the same time can not be entered into the mode)

zDefault status immediately after the mode activation

It shall be same as normal RST start in other settings than the following.

Period to prohibit TEL/LINE MUTE immediately after activation

(normally 10seconds)

Mecha Initialize Action Prohibited

Difference in action

Write-in to E2PROM when detecting a DC error Prohibited

Demo Mode ON/OFF Setting Menu Prohibited

Power supply during ACC OFF (Back Up On) MUTE terminal turns OFF after 2 seconds

BEEP sound Beep with short-pressing in any functions

Details

1 second

(No.WA001<Rev.001>)11/18

Volume 30 (-10dB)

BASS BOOST OFF

EQ NATURAL

Various setting value

Fader/Balance Center

DEMO Mode Setting OFF

AUX Setting ON

NAVI MUTE Setting for Japan Detecting function valid (ATT)

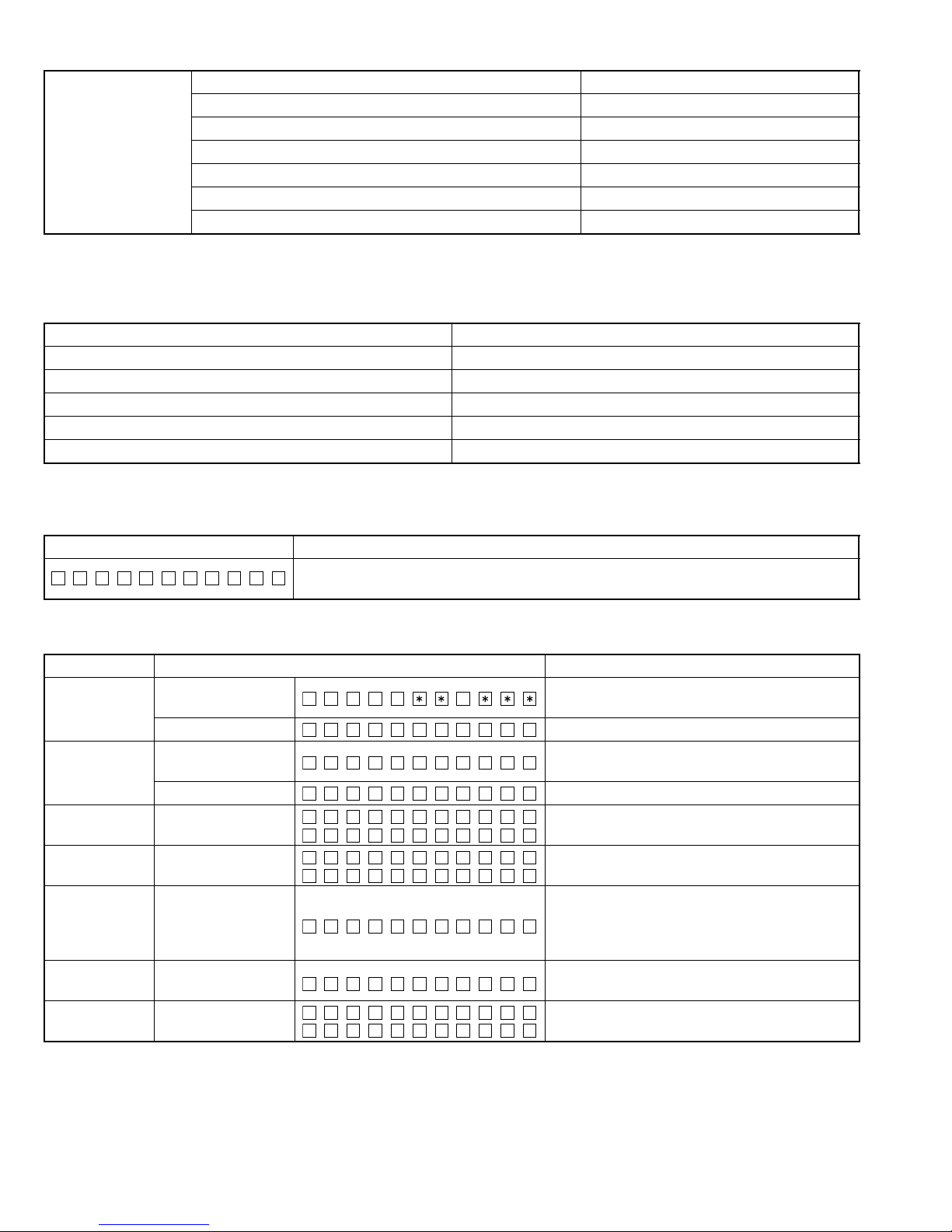

zMode structure

Some Test Modes change according to the current source.

The following table shows the current source in Set and the related test mode status.

Model source Test mode

POWER OFF -

Standby STANDBY Test Mode

TUNER UNER Test Mode

CD CD Test Mode

AUX -

zMode content

Syscom shall display the following information after entering this mode. The operation shown below shall be workable.

Display content Details

PRO T TES

The display is released when another operation is executed.

The display will blink if sub clock is not functioning.

zSTANDBY Test Mode Specification

Operation Display content Details

1 (Toggle)

Syscom version

display

Y–SS

Syscom version (Refer to Syscom Version Table)

All lights ON All lights ON (Switch with other display)

Serial No. display (8-digit)

∗Display as it is in hex

2 (Toggle)

Serial No. display

SN 00000000

All lights ON All lights ON (Switch with other display)

3 (Toggle) All lights ON/OFF All lights ON/OFF with toggle

5 (Toggle) Preout switch Switch Preout with toggle

SWP R R REEA

SWP R S –EUBW

All lights ON → All lights OFF → odd terminal and

6

FL display short

check

even terminal of the largest grid ON alternatively

every 125ms → odd terminal ON → even terminal

ON → (repeat continuously)

SOURCE

transition

RETURN

(Toggle)

Mode release Return to Normal mode

All lights ON/OFF All lights ON/OFF with toggle

(No.WA001<Rev.001>)12/18

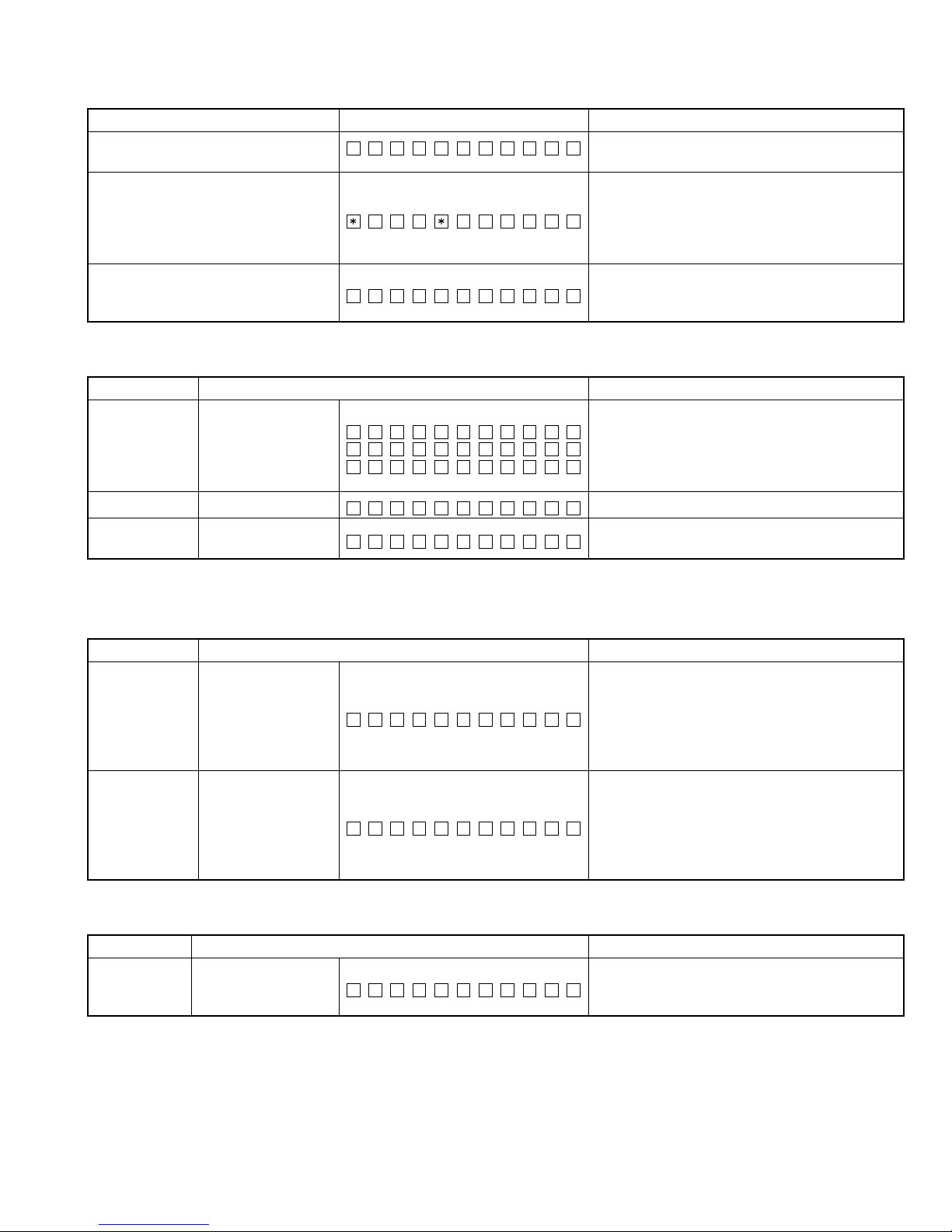

zTuner Test Mode Specification

The following display shall be indicated according to the TUNER status.

Status Display content Details

TUNER IC Normal Error

TUN CON NG

Communication to TUNER IC not available (indicated unless the mode is in Clock Display Mode).

For models that TUNER adjustment is necessary

but not done (adjustment value: 0x00 or 0xFF), the

Adjustment not implemented

ERR A A979

following TUNER Test Mode functions are valid

(“∗ERR∗”display is continuing).

Display “∗ERR∗“ blinks with 250ms interval.

Turn OFF P-CON forcibly if PS=RDS TEST is re-

RDS Specified data reception

DRS STTE

ceived.

P-CON recovers with Power OFF/ON.

Operations

Operation Display content Details

S meter value xx: Current S meter value

Determination result

OK: Within S meter voltage spec

NG: Out of S meter voltage spec

SEARCH

S meter voltage judgment display

MS– T x:xORK

MS– T x:xNRG

MS– T x:x–R–

- - : No LEVEL OFFSET adjustment

ACCENT

BAND

TUNER IC display Display TUNER IC version

BAND switch

operation

TAOM DSR

MF1–3 799AA

Execute Band Switch as shown in the following table every time Band key is pressed in each type.

TUNER Setting Adjustment Mode

1. Operation

Operation Display content Details

Shift to TUNER setting mode after switching to

98.3MHz

DISP

Shift to TUNER

setting mode

SG setting values

Frequency: 98.3MHz, Modulation frequency:

1kHz, Modulation mode: MONO, Modulation:

OFF, Deviation: 40kHz, ANT input level: 34dBpV

Select TUNER adjustment method (AUTO) using

BAND key.

BAND

(Toggle)

AUTO Adjustment

Mode

SA– –xxxLx

S-xx: Current S meter value (Hex)

L-xx: Level offset value (Hex)

∗

In case that the level offset value is not adjusted

(0xFF or 0x00), display "- -".

2. Operation in AUTO Adjustment Mode

Operation Display content Details

Start adjustment (Start Auto adjustment, and tran-

VOL PUSH Adjustment start

SA– –xxxLx

sit to Success/Failure display depending on the

adjustment result)

(No.WA001<Rev.001>)13/18

Loading...

Loading...