Kenwood DNX-6980, DNX-6480-BT, DNX-6040-EX, DNX-5580-BT, DNX-5380-M Service Manual

...

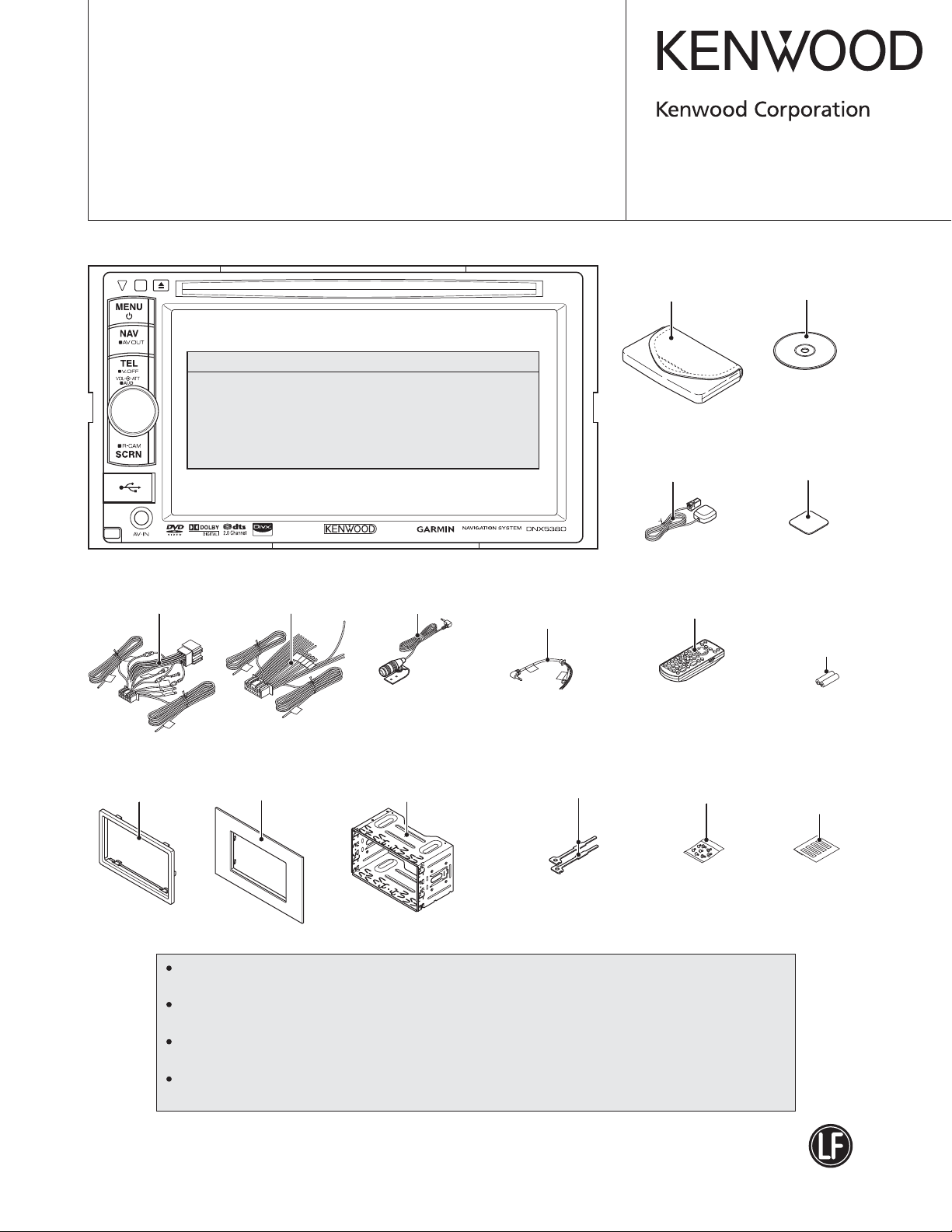

MONITOR WITH DVD RECEIVER NAVIGATION SYSTEM

DNX4280BT/5180/5280BT

/5380/5380M/5380BT

/5580BT/6040EX/6180

/6480BT/6980

SERVICE MANUAL

Illustrations is DNX5380M

TDF SPARE-PANEL

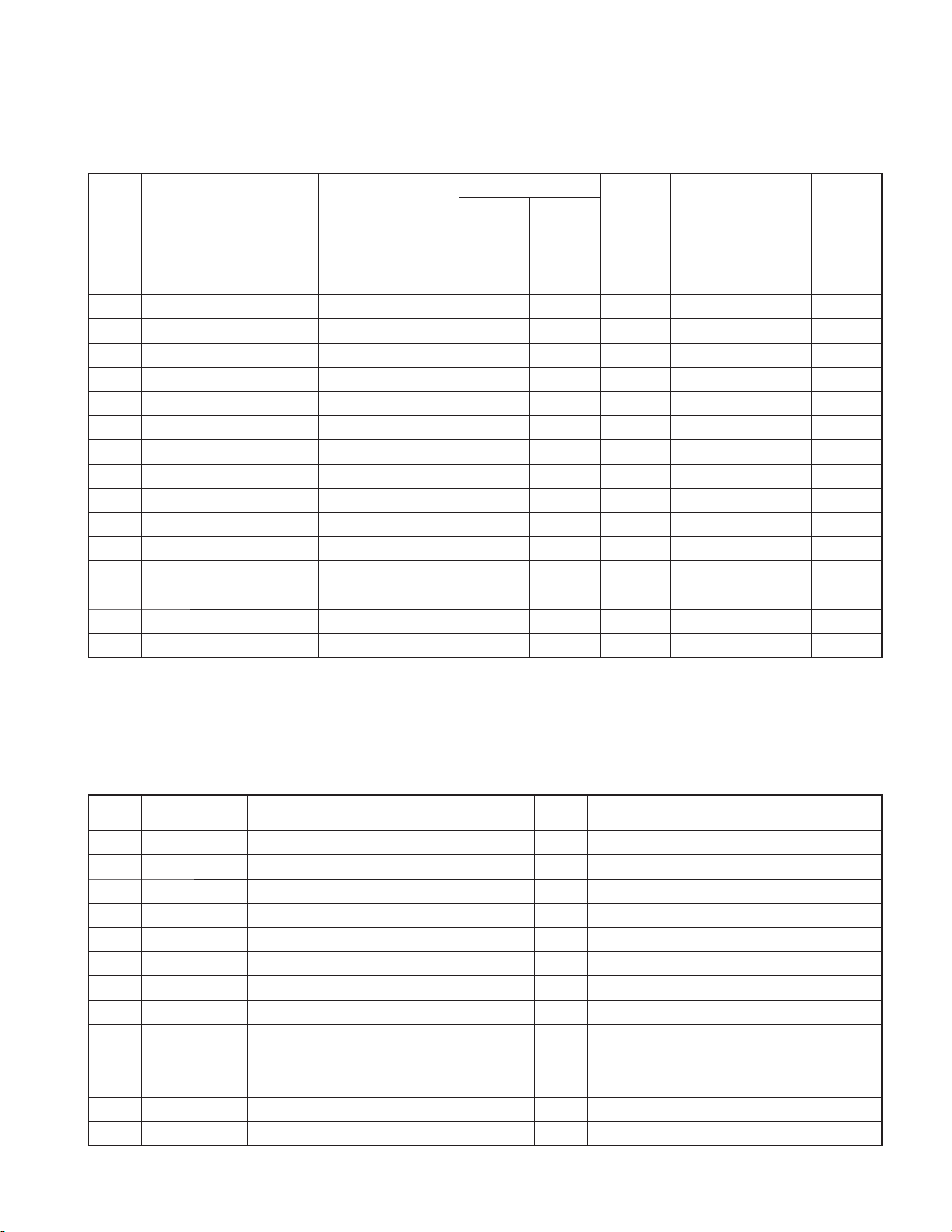

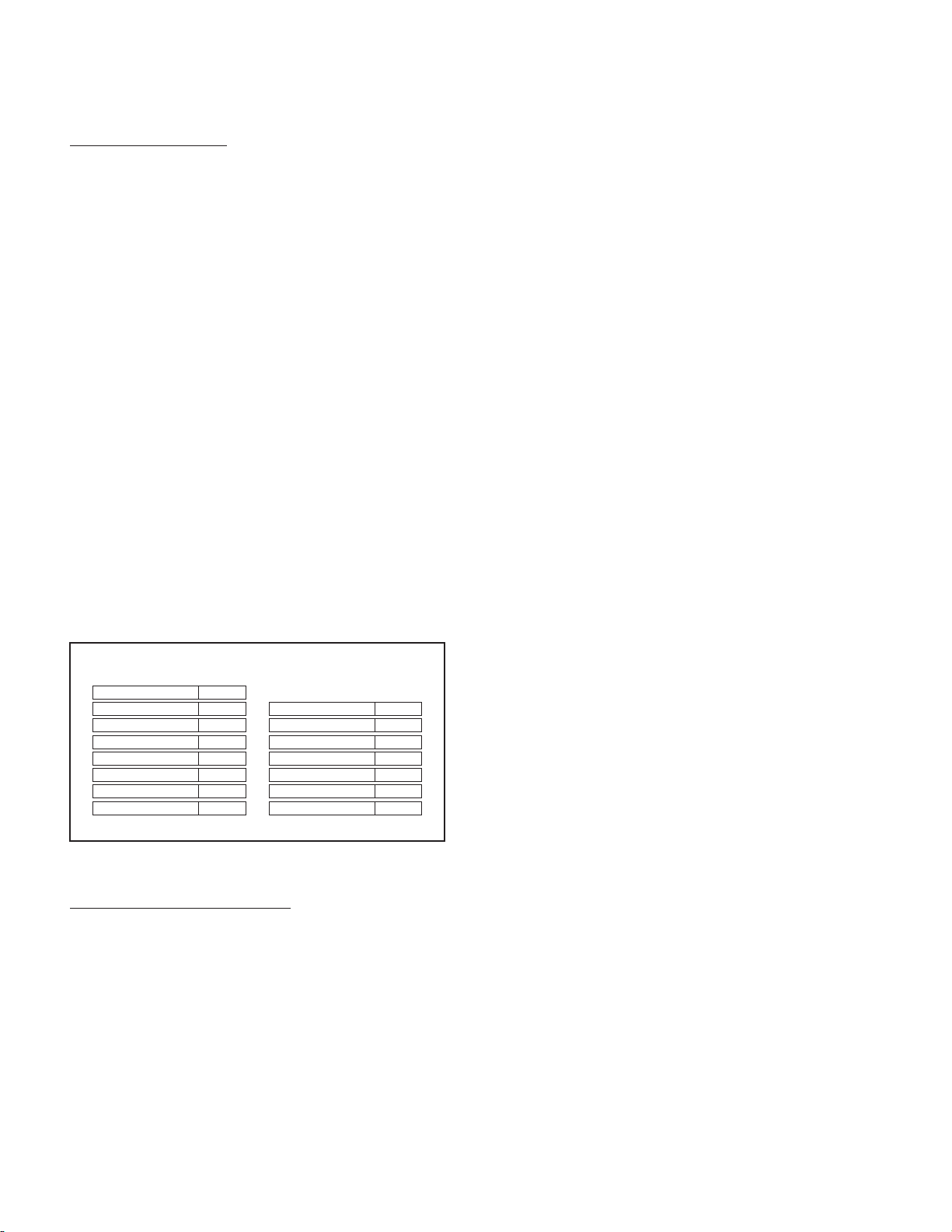

MODEL TDF PANEL No. TDF NAME

DNX5280BT Y33-3452-70 TDF-N5280

DNX5380 Y33-3450-21 TDF-N5380

DNX5380M Y33-3450-21 TDF-N5380

DNX5380BT Y33-3450-71 TDF-N5380

DNX5580BT Y33-3453-81 TDF-N5580

© 2011-3 PRINTED IN JA PAN

B53-0849-00 (N) 303

Carrying case *

(W01-2010-05)

Antenna module

(GPS ANT)

(W02-5304-05)

Compact disc

(W01-2005-05)

Mounting hardware

(GPS plate)

(J22-0964-04)

DC cord *

(E30-6796-15)

Escutcheon *

(B07-3165-02)

DC cord

(E30-6881-25)

Escutcheon

(B07-3172-12)

The IC261 in the ELECTRIC UNIT (X34-695x-xx) are not replaceable components.

When these ICs are defective, replace the whole ELECTRIC UNIT (X34-695x-xx).

The IC3 and IC100 in the VIDEO UNIT (X35-514x-xx) are not replaceable components.

When these ICs are defective, replace the whole VIDEO UNIT (X35-514x-xx) .

The IC103,402, 403, 500 and IC501 in the DIGITAL I/O UNIT (X88-2080-xx) are not replaceable

components. When these ICs are defective, replace the whole DIGITAL I/O UNIT (X88-2080-xx).

The IC5 in the DVD unit (X37-1300-00) are not replaceable components.

When these ICs are defective, replace the whole DVD mechanism assembly (X92-6640-00).

*

*

Microphone *

(W01-1768-15)

(3m)

Mounting hardware assy

(J22-0657-03)

Accessories

(Remocon cable)

(W01-2004-05)

Lever *

*

(D10-7012-04) x2

Remote controller assy

*

(A70-2107-05)

RC-DV331

Screw set

(N99-1779-15)

*

*

Size AAA battery

(Not supplied)

Adhesive doublecoated tape

(H30-0595-04)

*

* It uses it by some models. Refer to the parts list.

This product uses Lead Free solder.

This product complies with the

PbF

RoHS directive for the European market.

2

J1

BU

ACC

P-CON

ANT-CON

ILLUMI

PARKING

REVERSE

REMO

SPEED

FRONT SP L/R

REAR SP L/R

FAN

J571

J302

J301

PRE OUT

FRONT L/R

REAR L/R

SUB WOOFER

L/R

CENTER

J405

AV

IN/OUT

J401

STE

REMO

J400

BT

MIC

J403

GPS

ANT

J402

TV I/F

DC

KAB I/F

PRE OUT

J501

iPod AV

J531

AV IN

W201

FM/AM

ANT

(X15-154) (A/3)

REAR

CAMERA

AVOUT

GPS

MODULE

12MHz

16.368MHz

POWER

(X34-695)

IC2

POWER

SUPPLY IC

CAR I/F

IC1

POWER

IC

CN596

2pin

5V PRE

(EXCELON)

2V PRE

(ENTRY)

AV OUT

CN200

CN101

IC406

DVD

R.CAM

VIDEO

SEL

OUTPUT

iPodTVSOC

AV IN

CN201

40pin 70pin

CN102

MUTE

IC261

TMC

DECODER

ANT

DISTRIBUTOR

X2

DVD

27MHz

MECHA

CN402 CN400

50pin

IC205

SYSTEM

u-COM

ISO

70pin40pin

IC301

E-VOL

MUX

AC IN

SPPRE

OUTPUT SEL

A201

FM/AM

F/E

X1

10.25MHz

IC231

RDS

DECODER

MUX

ISO

INPUT SEL

ISO

X231

4.332MHz

BLUETOOTH

14pinAV(50pin)

14pin

IC401

AUDIO

SEL

OUTPUT

MAIN

SUB

DVD

USB/SD

NAVI

X200

32.768kHz

X201

12MHz

IC204

E2PROM

(1k)

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

SD

SLOT

14pin

J406

CN405

CN404

CN403

IC405

AUDIO

DAC

IC404

AUDIO

DAC

CN202

SYNC

RGB/YCbCr

CVBS

(R-CAMERA)

CN205

SYSCOM

8pin5pin

REWRITE

CN207

BT

TV

KAB

AV IN

iPod

TUNER

MASTER

REWRITE

CN410

(X15- ) (C/3) (X88-208)

CN408

J408

MICRO

14pin

14pin

SD

SLOT

50pin

70pin70pin

CN200 J201

J200

70pin

DSI

LED

CN201 CN2

4pin

4pin

CN702

50pin70pin

CN700

24pin

24pin

X100

12MHz

IC714

VIDEO

DECODER

X700

32MHz

SOC R/G/B, DVD Y/Cr/Cb

SOC SYNC

(X17- ) (A/2)(X17-213) (B/2)

J2J1CN1

24pin24pin

70pin

4pin

IC103

TELECHIPS CVBS

IC704

VIDEO

DAC

CN401

70pin

CN600 CN400

USB HS

5pin

W700

IC402

SDRAM

128Mbit (x8)

IC403

SDRAM

128Mbit (x8)

DIGITAL MEDIA

PROCESSOR

IC705

IC500

SDRAM

128Mbit (x8)

IC501

SDRAM

128Mbit (x8)

IC706

NAND FLASH

2Gbit (x16)

LCD HS,LCD VS

IC707

IC202

PANEL

u-COM

IC402

SERISL

FLASH

IC406

MASTER

X400

12MHz

4pin 60pin 10pin 24pin

X200

IC3

for LED

BACK LIGHT

CN1 CN700

12MHz

IC203

iPod

CP

POWER

CN920

VOL+

VOL-

24pin

J901

J900

USB

4pin

SLOT

AUX

VOL+

VOL-

(X35-514)

24pin

KEY

SW

KEY

SW

KEY

ILLUMI

KEY

ILLUMI

(X16-706)

IC920

REMO

(X16-716)

IC900

REMO

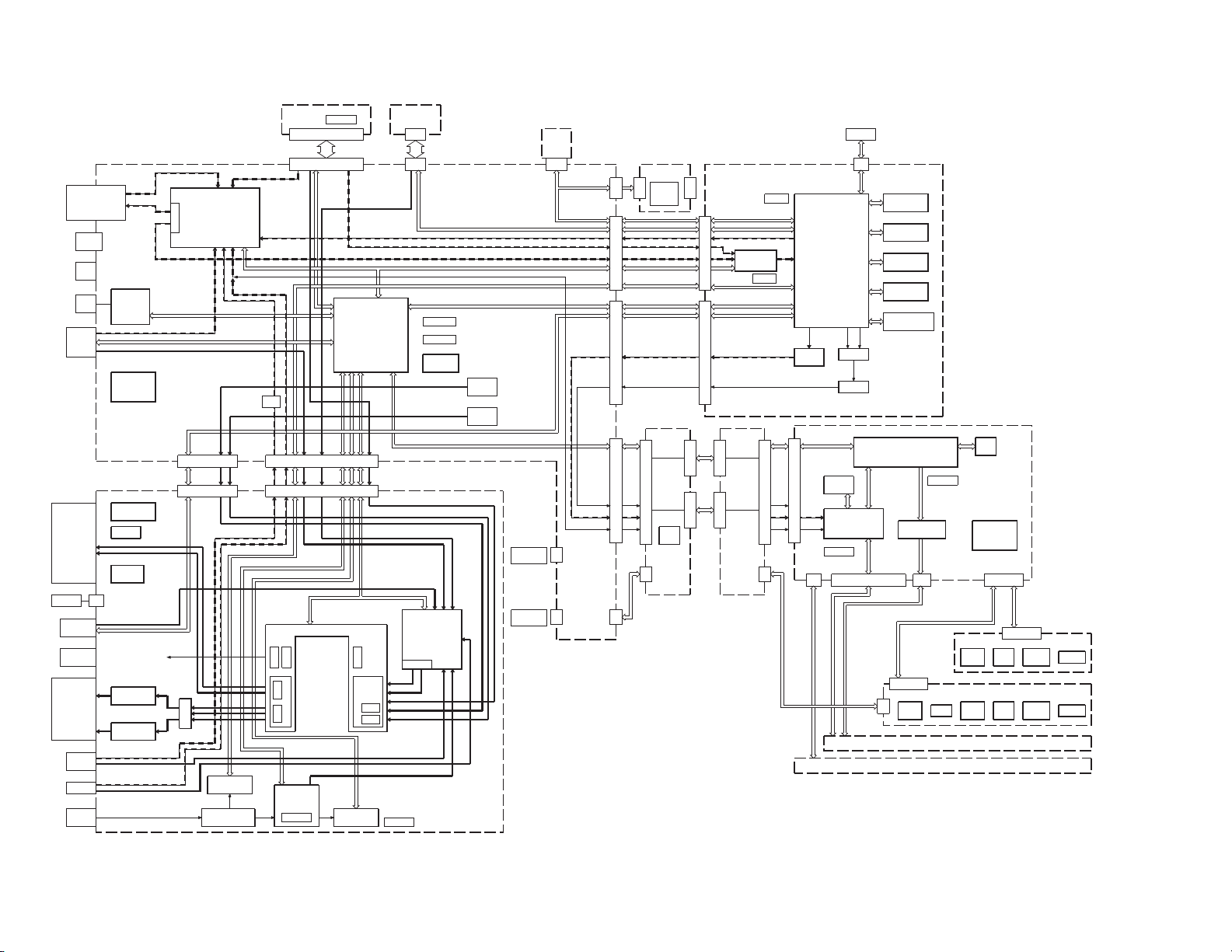

BLOCK DIAGRAM

LCD PANEL CPT WVGA

TOUCH PANEL

BLOCK DIAGRAM

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

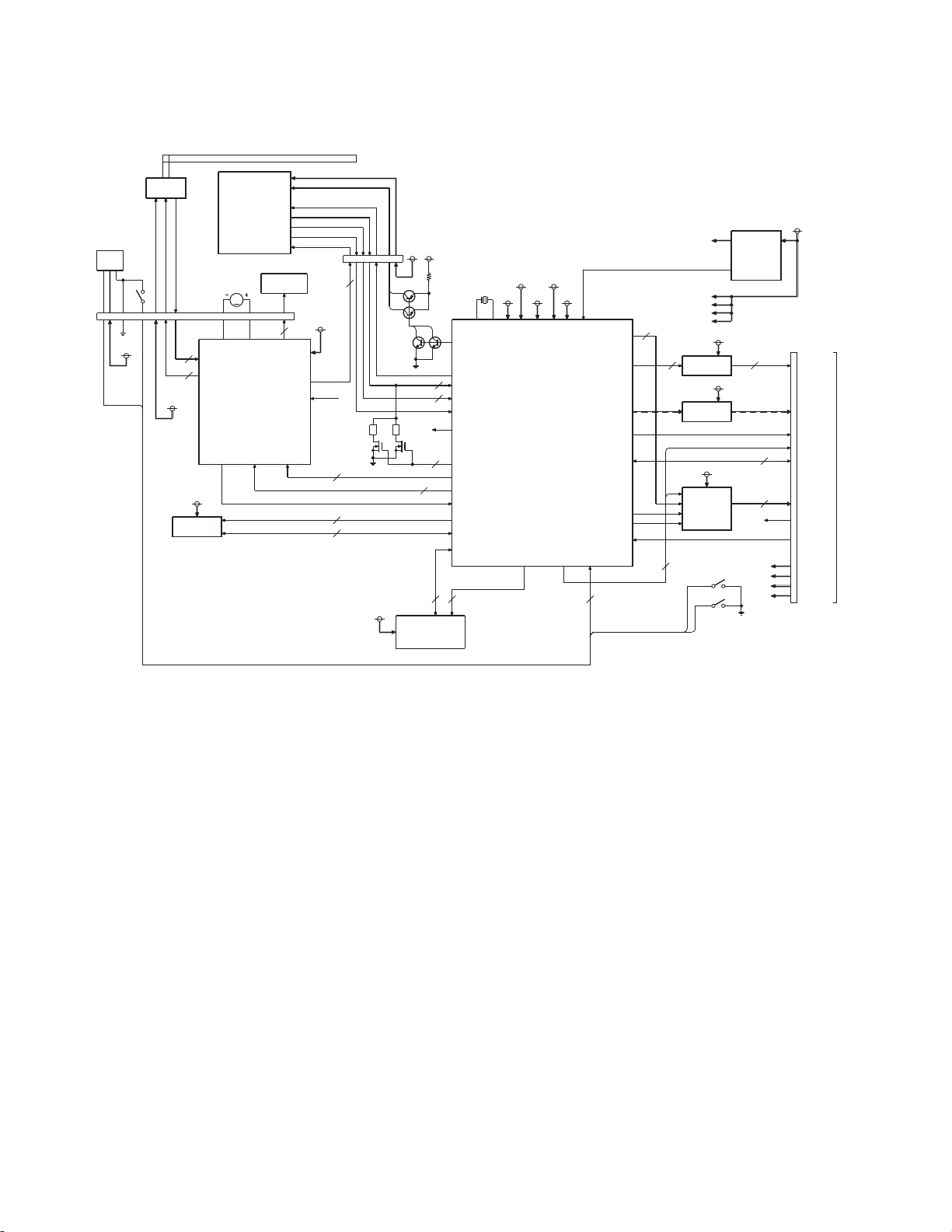

DVS-870xW BLOCK DIAGRAM (X37-1300)

SPINDLE

MOTOR

DISC

OPTICAL PICKUP

HALL

IC

HALL SENSOR

IC10

3

H1H,H1L,HB

3

A1,A2,A3

D3.3V

IC54

SDRAM

128M

LO/EJ

DC MOTOR

M

FO6,RO6

MOTOR &

ACTUATOR

DRIVER

FG

D3.3V

SW EJEND

LIM-SW

HALL BIAS

U,V,W COIL

P5V

2 PHASE

STEPPING

SPIN,IN2-6

PDIC VCC,HFM

DVD LD/CD LD

VREFH

IMON/VR DVD/VR CD

PDIC I/V OUT

THERMISTER

FO+/-,TR+/-

CN3

28pin

4

FO5,RO5

FO4,RO4

FO2,RO2

FO3,RO3

VREF,EC

STBY

MUTE

CN1

30pin

VHALF

3

NC

3.3V

A5V

V5V

P5V

3.3V

CN6

50pin

Y/G

Pb/B

Pr/R

VIDEO

SPDIF

AMUTE

2

2

AOUTL

AOUTR

IFSEL

RESET

to

VIDEO

CONTROL

UNIT

IC59

LX VIN

V5V

V5V

A3.3V

PLL3.3V

V3.3V

D1.2VD3.3V

4

Q12,13

27MHz

IC1

P5V

Q10,11

Q14,15

2

21

16

IC5

D3.3V

FLASH

ROM

32M

LPC01/LPC02

VREFH

2

LPC1/LPC2

9

A,B,C,D,E,F,

FE1,FE2,RF

TEMP(AD1)

VHALF

2

TRCCLK,EXTRG1

DQM3,P12

6

DRV1,DRV2,DRV3,DRV4

PWM0,PWM1

FG,P5

NWE,NCAS,NRAS,NCSM,MCK0

BA0-1,MA0-11,DQM0-1

MDQ0-15

EXADT0-15

24

16

A0-20

DQ0-15

W, G, E

DVN

F/E + B/E + MCU

EXADR16-19

NEXWE

NEXCE

P15(ADR20)

NEXOE

EXADT0-15

DRV5

SRCK,LRCK

NRST

DT,CK,CS

DAC0-3OUT

DAC4OUT

IECOUT

P1,P2 SDA,SCL

ADOUT3

DACCK

RESET

P3

P11P6P4

P14

4

D1.2V

SW REG

VDOUT

D3.3V

A3.3V

PLL3.3V

V3.3V

5

3

IC64

Q34-36

RGB AMP

IC65

Q33

V5V

V5V

VIDEO AMP

A5V

IC61

RSTN

L

AUDIO

R

DAC

2

SW LOST

SW LOEND

3

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

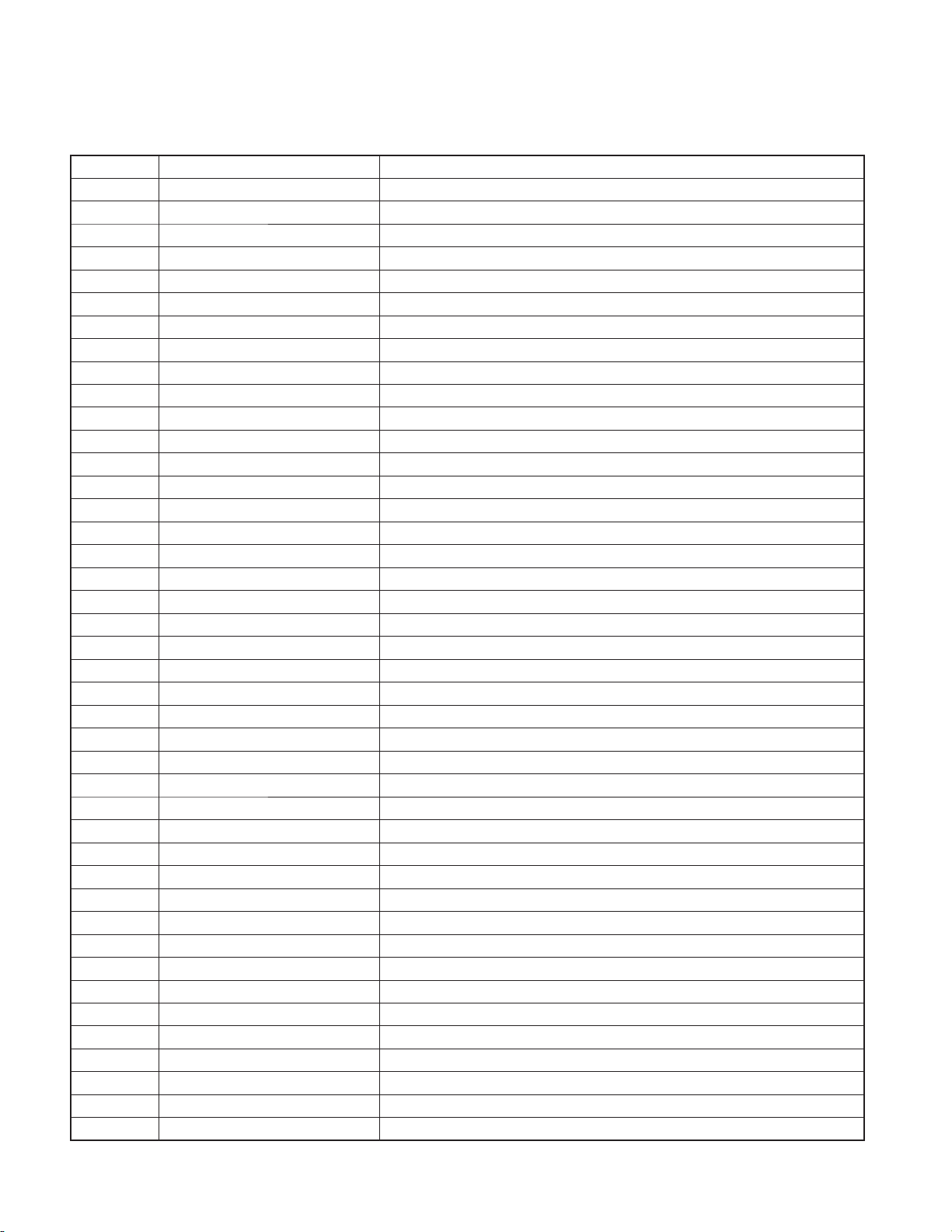

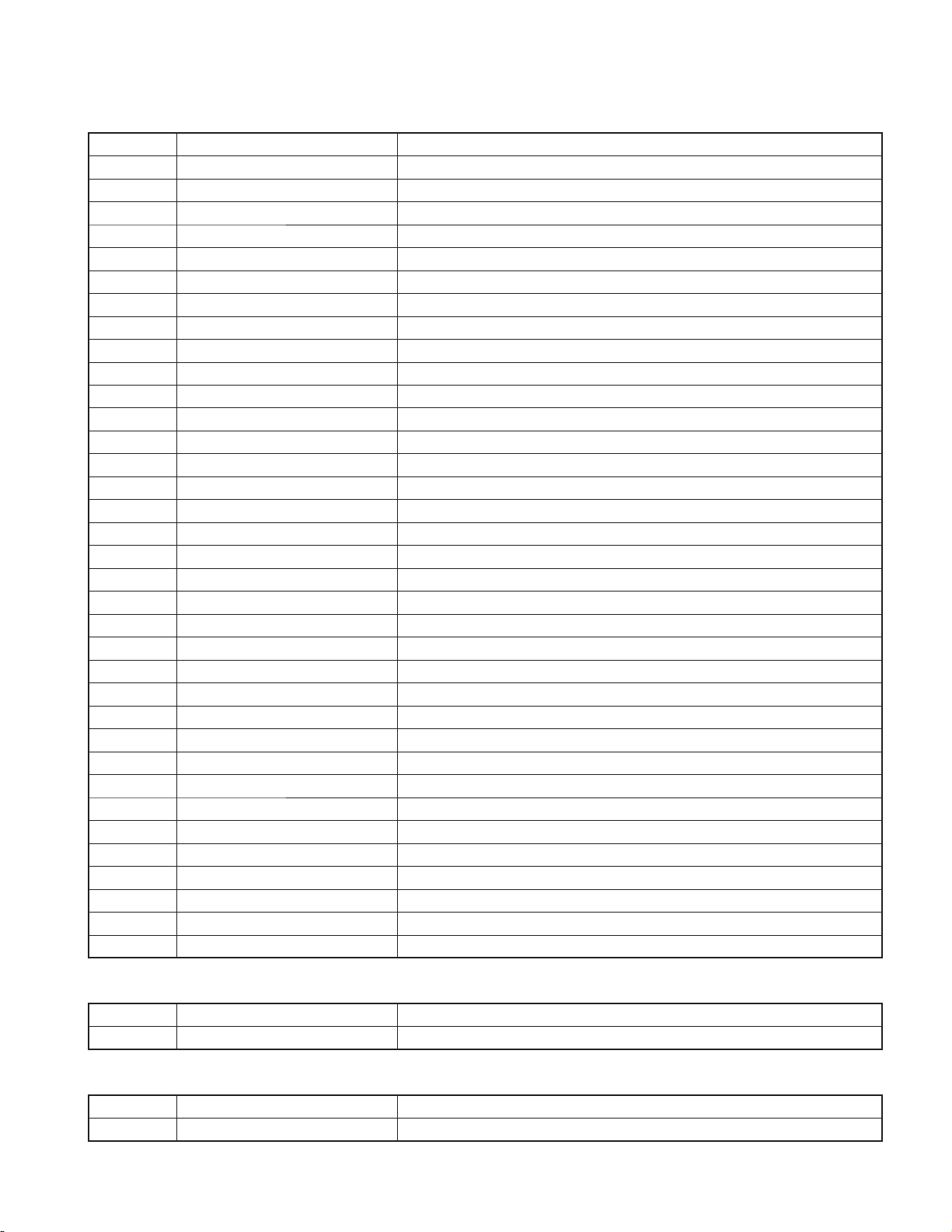

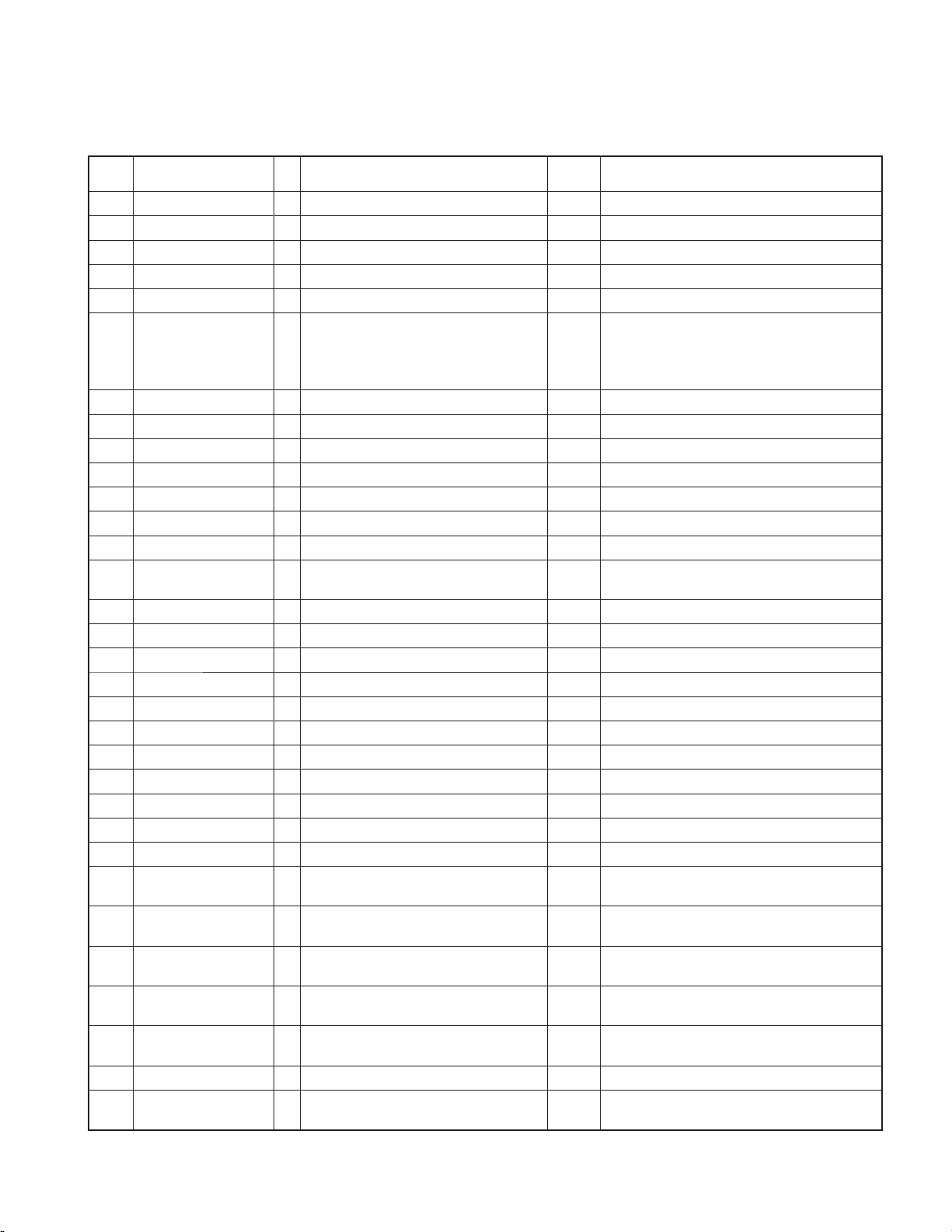

COMPONENTS DESCRIPTION

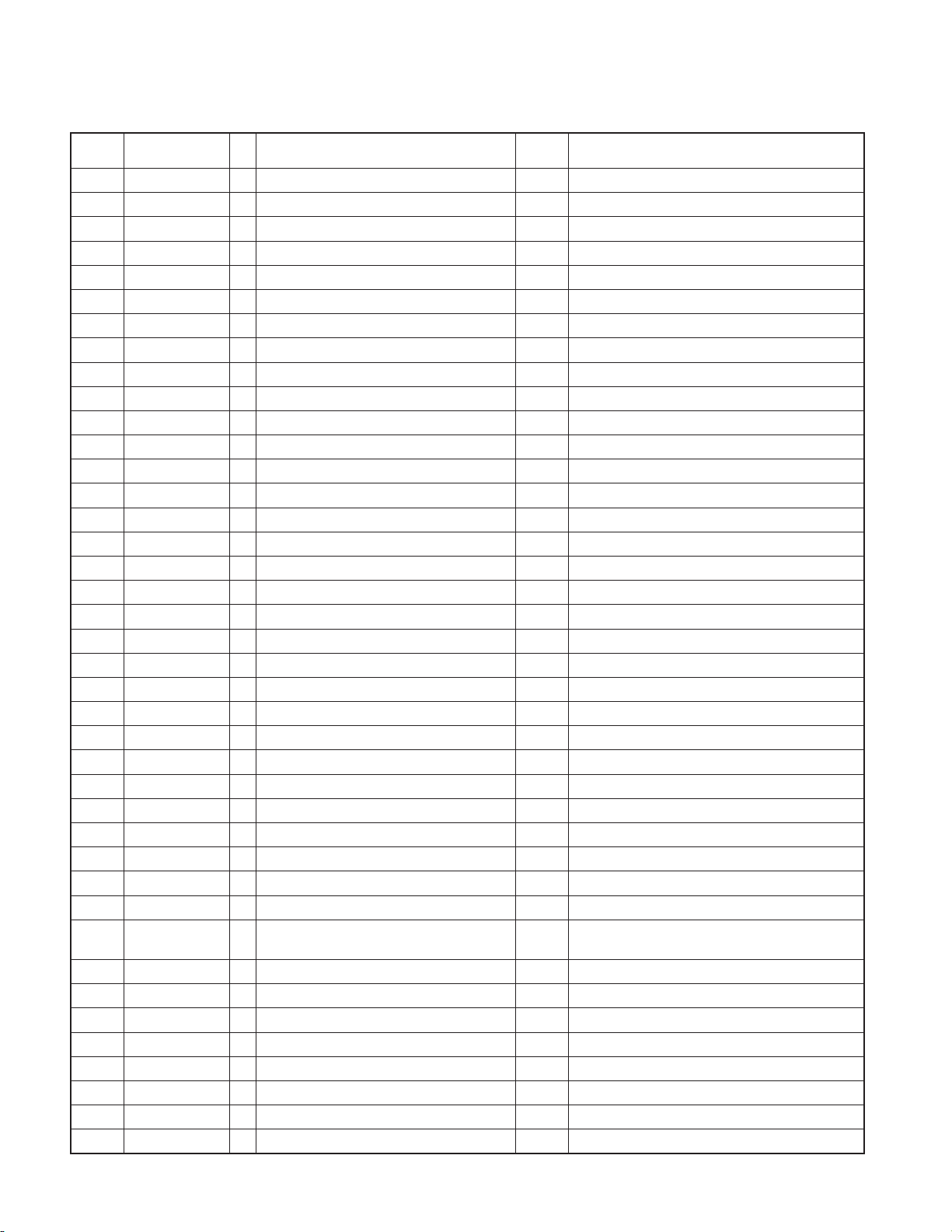

VIDEO CONTROL UNIT (X15-154x-xx)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 DCDC controller IC 6.5V/1.5V DCDC converter

IC2 DCDC converter IC D5V/V5V/V5V_DVD DCDC converter

IC3 DCDC converter IC BU3.3V DCDC converter

IC4 Regulator BU1.8V Regulator IC

IC5 Regulator SW1.8V Regulator IC

IC6 Regulator D1.2V Regulator IC

IC7 Regulator NAND3.3V Regulator IC

IC8 Regulator SW1.8V_DA Regulator IC

IC9 Regulator P5V/FAN5V Regulator IC

IC200 Analogue IC VIDEO ISO, AMP for iPod

IC201 Regulator BU3.3V_SYS Regulator IC

IC202 AND Logic IC TV_SDATA Buffer

IC203 Voltage detect IC Reset signal generate at 3.0V

IC204 EEPROM EEPROM 1Kb

IC205 MCU IC System control IC

IC206 AND Logic IC Video Mute control

IC207 Analogue IC VIDEO ISO, AMP for AVIN

IC400 OP-AMP X 2 For BT Audio LPF

IC401 Regulator BT3.3V Regulator IC

IC402 Regulator A5V Regulator IC

IC403 Regulator USB5V Regulator IC

IC404 Audio DA convertor Audio DAC for NAVI voice

IC405 Audio DA convertor Audio DAC for USB audio

IC406 Video SW 8IN 5OUT Composite signal selector

IC408 Voltage detect IC USB5V over current detect

IC409 3state Buffer x2 IC BT control signal buffer

IC410 EXOR Logic IC BT control signal buffer

Q1~3 SW SW14V control

Q4 LOAD SW FET SW14V ON/OFF

Q5 BU voltage detect (Hi-side) BU_DET signal control

Q6,7 SW BU_DET signal control

Q8 BU voltage detect (Low-side) BU_DET signal control

Q9~13 SW BU_DET signal control

Q14,15 SW DET_MUTE signal generation

Q16 SW IC3 Forced PWM control

Q17 FET DCDC SW FET D1.5V

Q18 FET DCDC SW FET 6.5V

Q19 LOAD SW G3.3V ON/OFF

Q20 SW Q19 control

Q21 LOAD SW D3.3V ON/OFF

Q22 SW Q21 control

Q23 LOAD SW D3.3V_DVD ON/OFF

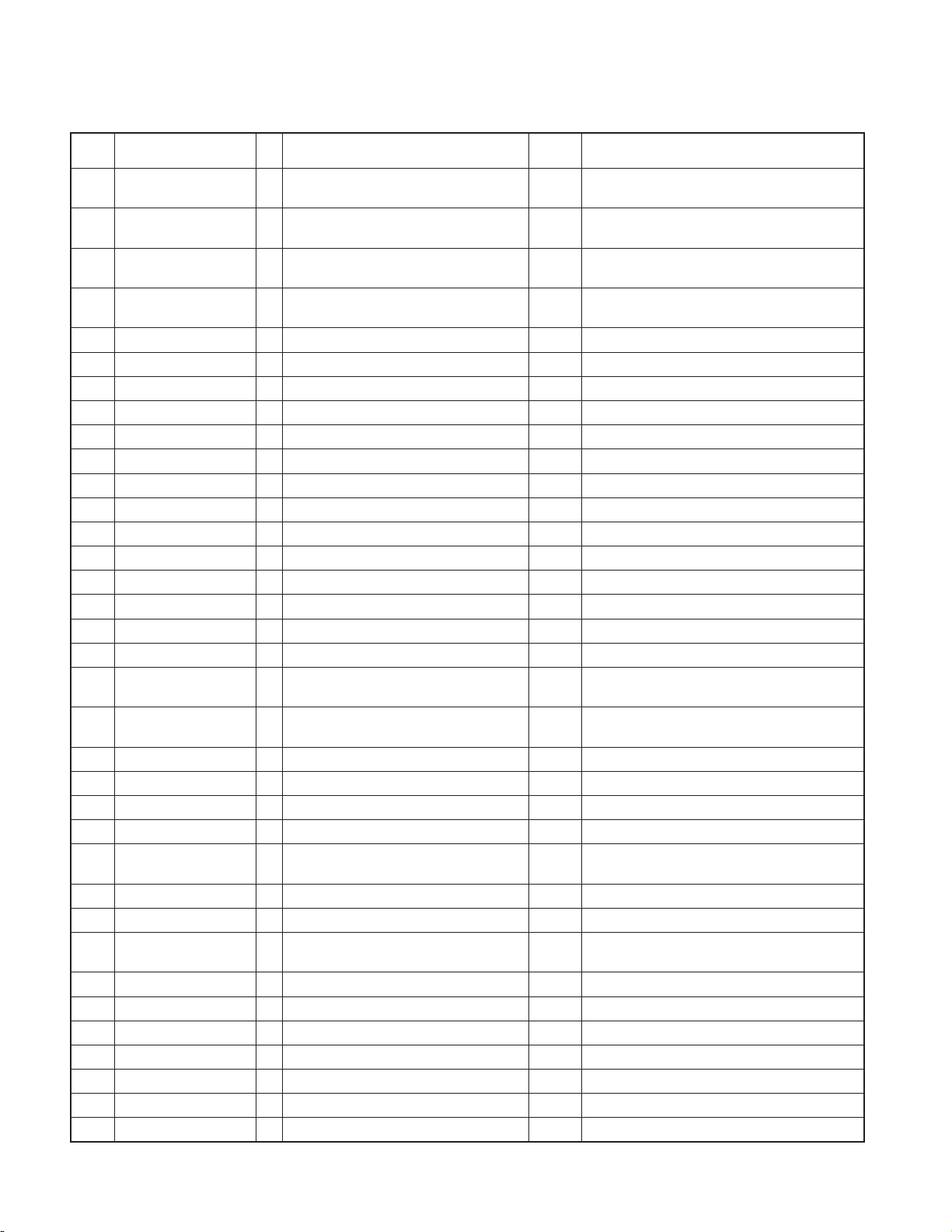

4

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

COMPONENTS DESCRIPTION

Ref. No. Application / Function Operation / Condition / Compatibility

Q24 SW Q23 control

Q27 LOAD SW SW5V_X35 ON/OFF

Q28 SW SW5V_X35 control

Q29 LOAD SW D5V_X35 ON/OFF

Q30 SW Q29 control

Q31 LOAD SW BL_14V_X35 ON/OFF

Q32 SW BL_14V_X35 control

Q33 SW IC3 DCDC output voltage control

Q34 SW IC4 VIN 2.6V or 2.1V control

Q35 SW Q34 control

Q36 SW Q35 control

Q37,38 SW BL_14V_X35 control

Q39,40 SW SW5V_X35 control

Q200 LOAD SW BU3.3V_X35 ON/OFF

Q201 LOAD SW SI ON/OFF

Q202 SW Reset signal control sw by KEY_RESET

Q203 SW TV_RESET signal generation

Q205 SW KAB detect

Q208 SW KEY_RESET detect

Q209 SW KAB_RX invert

Q210 SW KAB_RX 5V→3.3V

Q211 LOAD SW BU5V for pull up ON/OFF

Q212 SW Q211 control

Q403 SW BT_BOOT control

Q423 SW AV OUT AR Mute

Q424 SW AV OUT audio Mute control

Q426 SW AV OUT AL Mute

Q427 SW BT_BOOT control

Q436 SW Q437 control

Q437 LOAD SW SD3.3V ON/OFF

Q438 SW DVD audio Mute control

Q439 SW DVD audio AR Mute ON/OFF

Q440 SW DVD audio AL Mute ON/OFF

Q442,443 SW Q446 control

Q446 SW STEREMO KEY pull up resistor control

SWITCH UNIT (X16-7060-10)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC920 Remote control module Remote control sensor

SWITCH UNIT (X16-716x-xx)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC900 Remote control module Remote control sensor

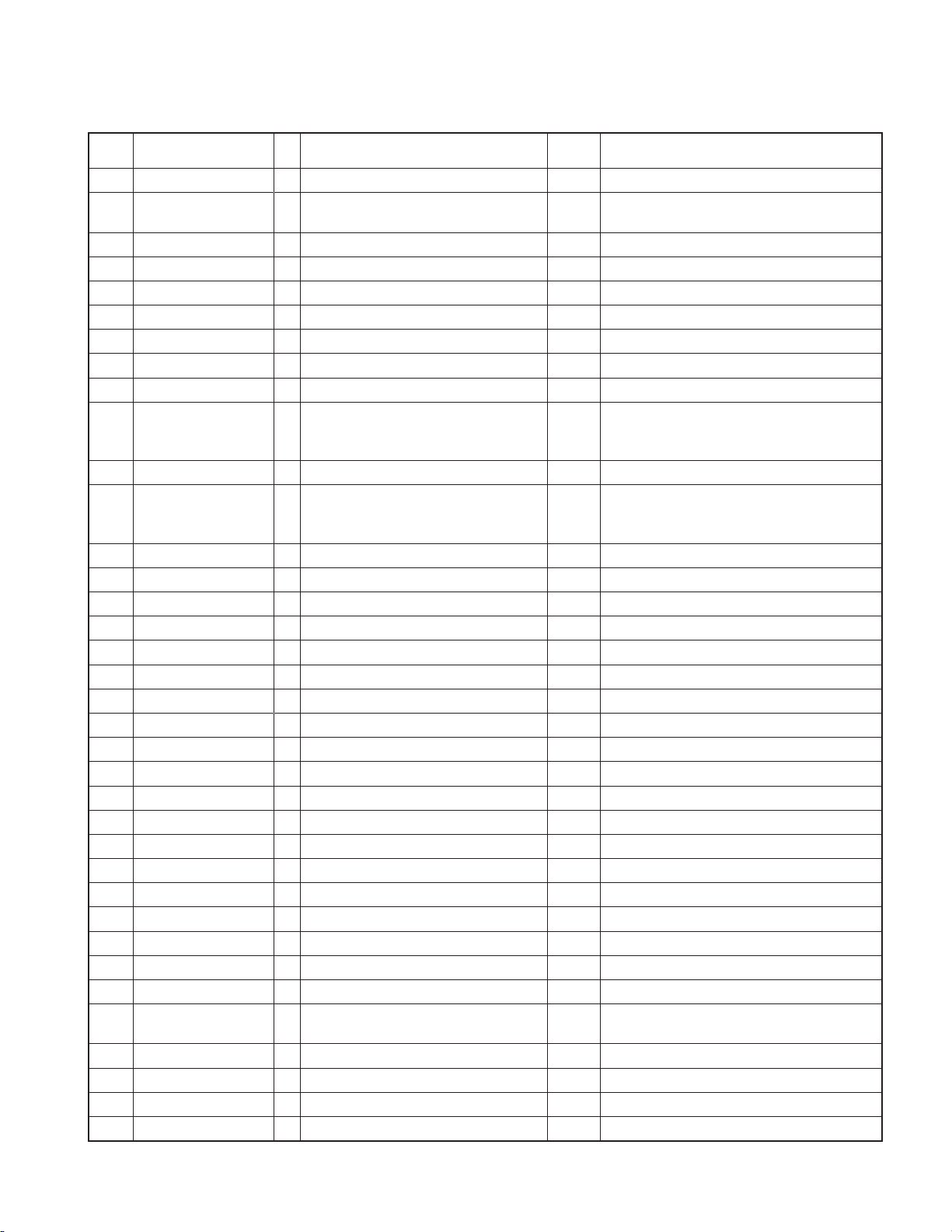

5

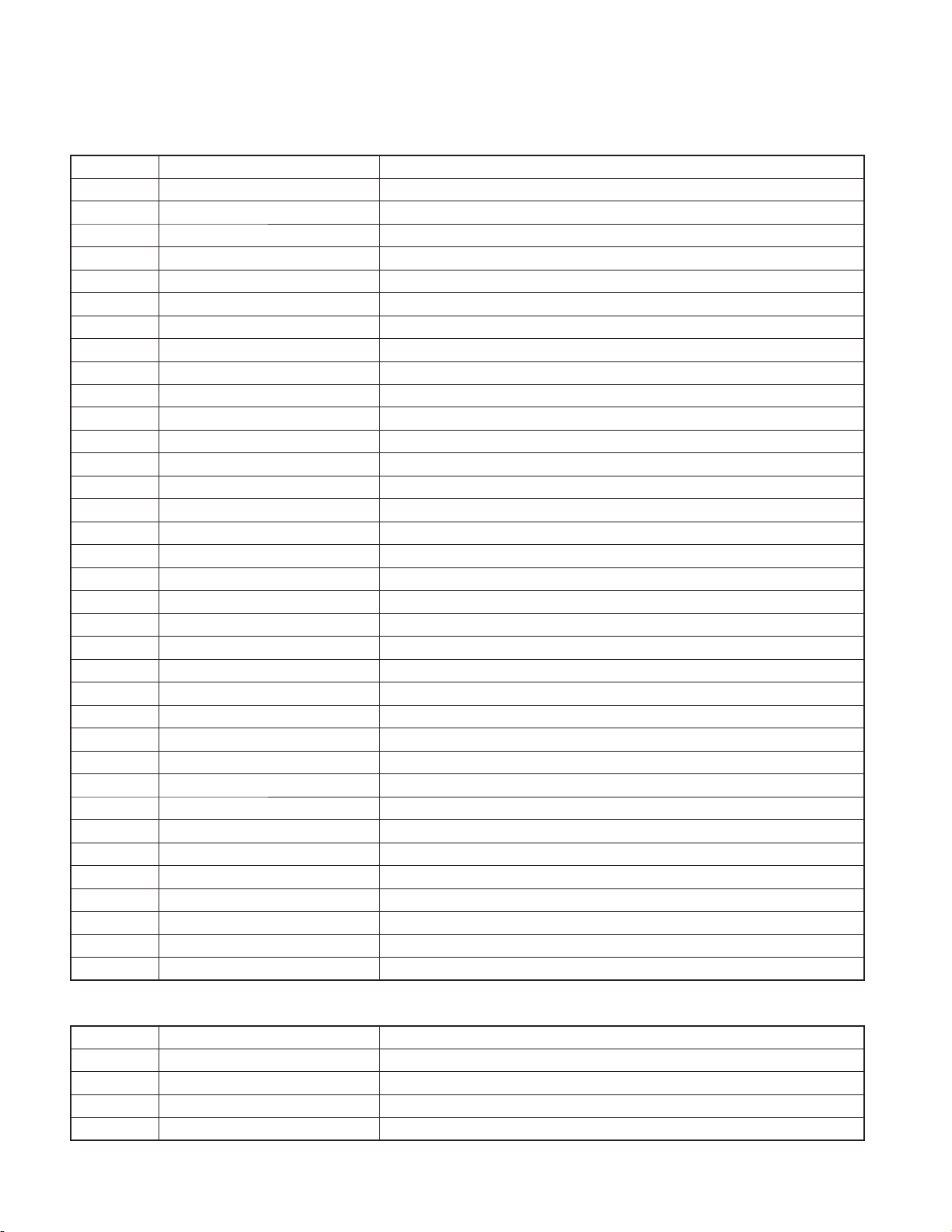

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

COMPONENTS DESCRIPTION

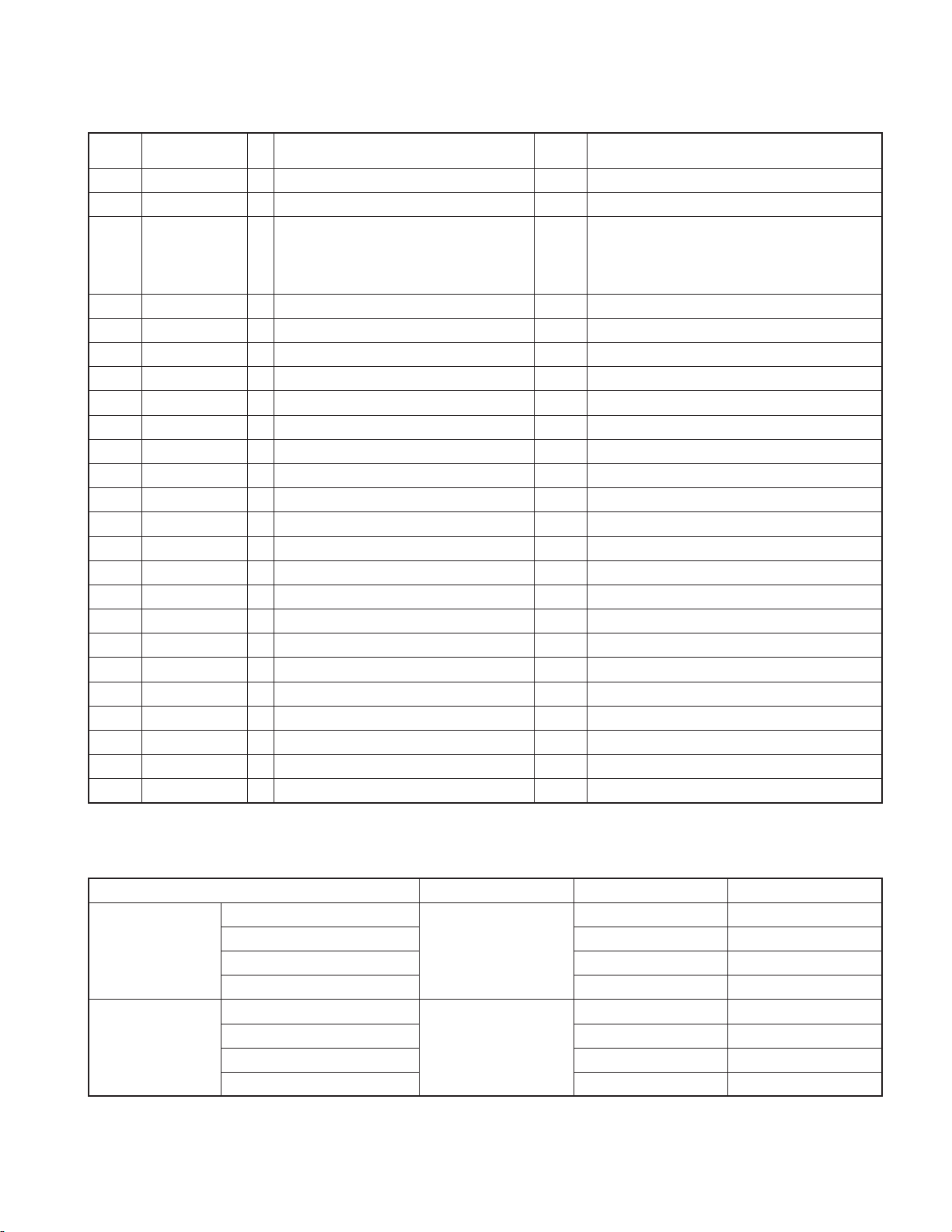

ELECTRIC UNIT (X34-695x-xx)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 Power IC Power AMP

IC2 Multi channel Voltage Regulator ILM8V, CD8V, A8.5V, SW5V, BU5V Power Supply

IC4 3-terminal Regulator TMC3.3V Power Supply

IC71 Voltage Converter +9V, -9V Power Supply

IC231 RDS Decoder IC RDS Signal Processing etc

IC261 FM & RDS Receiver Tuner for TMC

IC301 Electoric Vol IC Audio Vol Control, Audio Signal Select

IC371,381,391

IC401 Audio selector IC Audio Signal Select

IC571 AND (*4) logic IC KAB signal level shift

Q71,72 +9V, -9V Power Supply control

Q73 +9V, -9V Power Supply

Q74,75 +9V, -9V Power Supply control

Q76 -9V Power Supply

Q77,78 +9V, -9V Power Supply control

Q79 +9V Power Supply

Q80 +9V, -9V Power Supply control

Q111 Reverse Detect

Q121 Parking Detect

Q131 Illumi Detect

Q151 ACC Detect

Q201 AM+B Power Supply

Q202 AM+B Power Supply control

Q241 ANT Distributer

Q341 Preout FL mute

Q342 Preout FR mute

Q343,344 Preout mute drive

Q351 Preout RL mute

Q352 Preout RR mute

Q361 Preout SWL mute

Q362 Preout SWR mute

Q363,364 Preout mute drive

Q573,574 KAB_TX short protection

Q575 KAB+B Power Supply control

Q576 KAB+B Power Supply

OP amp 5V Pre out AMP

VIDEO UNIT (X35-514x-xx)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 Logic Waveform shaping

IC2 Logic AND

IC3 DCDC controller LCD Backlight power supply

IC4 Logic AND

6

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

COMPONENTS DESCRIPTION

Ref. No. Application / Function Operation / Condition / Compatibility

IC5 Logic OR

IC6 LDO 3.3V Regulator

IC100 DCDC controller LCD power supply, Variable LED power supply

IC101 LDO 3.3V Regulator

IC200 Logic Panel μCOM terminal protection

IC201 Voltage detect IC Reset signal generate at 4.4V

IC202 MCU IC Panel system control IC

IC203 iPod Authentication Coprocessor iPod Authentication

IC204 LDO 3.3V Regulator

IC400 OP Amp VCOM AMP

IC401 LDO 1.8V Regulator

IC402 F ROM Mstar FIRMWARE ROM

IC403 Logic AND

IC404 LDO 3.3V Regulator

IC405 LDO 1.8V Regulator

IC406 LCD Controller Croma γ T/C Scaller

IC407 Logic AND

IC700 Logic Inverter

Q1,2 SW Soft start for Input power supply for LCD Backlight

Q4~6 SW Input power supply detection

Q7 SW FET DCDC SW FET (LCD Backlight)

Q100~103 SW Soft Start for +18V

Q104~107 SW Soft Start for +9.2V

Q108~110 SW Soft Start for -6V

Q113,114 SW Soft Start for -6V

Q115~117 SW Soft Start for +9.2V

Q200 SW Reset signal control for Panel μCOM

Q203 SW Reset signal control for Panel μCOM

Q204~207 SW Soft Start for Panel μCOM power supply

Q208 SW Reset signal control for Panel μCOM

Q209 SW BL_PDET signal control for Panel μCOM

Q212~218 SW Soft Start for Panel μCOM power supply

Q219 SW RCAM_INT signal control for Panel μCOM

Q220 SW Soft Start for Panel μCOM power supply

Q221,222 SW Reset signal control for Panel μCOM

Q400~403 SW Soft Start for LCD controller power supply

Q404,405 Buffer Buffer for temperature property absorption

Q600~605 SW Control for touch panel

Q700 LED B lighting LED B Constant current circuit

Q701 LED G lighting LED G Constant current circuit

Q702 LED R lighting LED R Constant current circuit

Q703 SW KEY LED signal control

Q705 SW ILL_R signal control

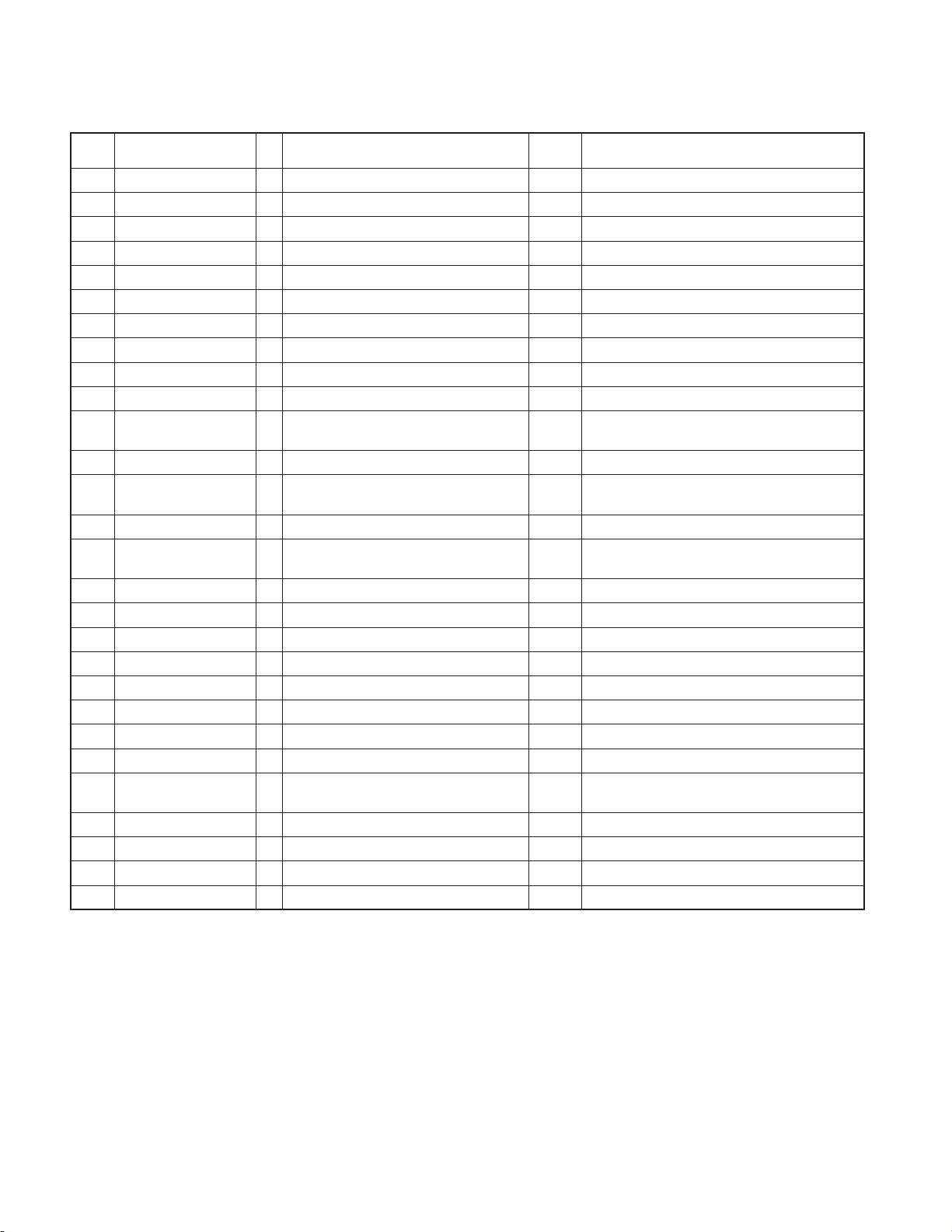

7

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

COMPONENTS DESCRIPTION

Ref. No. Application / Function Operation / Condition / Compatibility

Q706 SW SI_SYS signal control

Q708 LED R lighting LED R Constant current circuit

Q709 LED G lighting LED G Constant current circuit

Q710 LED B lighting LED B Constant current circuit

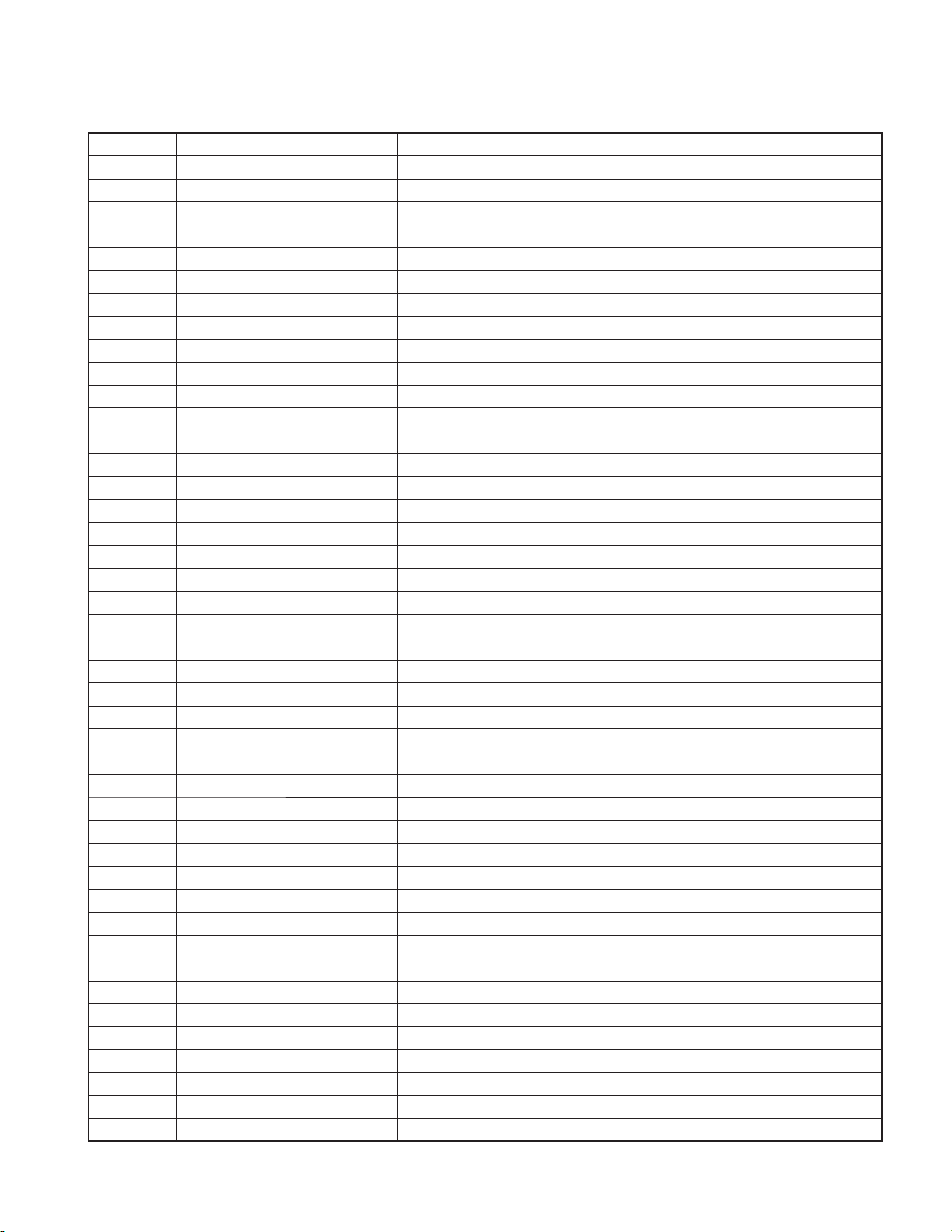

DIGITAL I/O UNIT (X88-2080-xx)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC103 SoC IC Processor for Digital Media

IC402,403 1Gbx8 DDR2 memory For SoC memory

IC500,501 1Gbx8 DDR2 memory For SoC memory

IC704 Video DA convertor SoC RGB signal DA converte

IC705 EXOR Logic IC SoC Video Sync signal generate

IC706 SLC NAND 256MB SoC program memory

IC707 Invertor Logic IC For SoC Video Sync

IC708 Regulator For V1.8V Regulator from D3.3V

IC714 Video Decoder IN Analog Composite and RGB video/ OUT Digital Video (BT656)

DVD UNIT (X37-1300-00)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 1 chip LSI for DVD player RF signal processing/ servo processing/ decode processing/ AV decode processing

IC5 FLASH ROM F/W retaining (nonvolatile) for 1 chip LSI

IC10 Driver IC Fo coil/ Tr coil/ SP motor/ SLD motor/ LO-EJ motor drive

IC54 SDRAM Data retaining (volatile) for 1 chip LSI

IC59 1 output switching REG 3.3V→1.2V

IC61 Audio DAC DA converter for 2ch analog audio output

Q1 Resistance built-in transistor LO_MUTE control

Q2 Resistance built-in transistor For FG signal

Q4 Resistance built-in transistor DRMUTE control

Q10 Preceding transistor for APC Laser diode luminescence amount control for CD

Q11 Preceding transistor for APC Laser diode luminescence amount control for DVD

Q12 Latter transistor for APC Laser diode luminescence amount control for CD

Q13 Latter transistor for APC Laser diode luminescence amount control for DVD

Q14 MOS-FET Laser diode ON/OFF control for CD

Q15 MOS-FET Laser diode ON/OFF control for DVD

Q33 Transistor for CVBS output Emitter follower for composite video output

Q34 Transistor for Pb output Emitter follower for component/ RGB video output

Q35 Transistor for Y output Emitter follower for component/ RGB video output

Q36 Transistor for Pr output Emitter follower for component/ RGB video output

8

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

MICROCOMPUTER’S TERMINAL DESCRIPTION

SYSTEM MICROCONTROLLER (X15 : IC205)

●

Pin No.

1 VREF

2 AVCC

3 TV_SC_DATA I Data input from TV μ-com

4 TV_MC_DATA O Data output to TV μ-com

5 TV_BP_CLK O Communication clock with TV μ-com

6 SI (DSI) O SI (DSI) control

7 LV5680P O LV5680P control

8 R_DATA I “DATA” input from RDS decoder

9 WREMO I Remote controller input

10 R_QUAL I “QUAL” input from RDS decoder

11 TV_MC_REQ O Request to TV μ-com

12 TV_SC_CON O Request to start-up TV μ-com

13 BYTE I External data bus width switching input In single chip mode: Connected to VSS

14 CNVSS I Processor mode switching terminal

15 XCIN Sub-clock oscillation circuit input 32.768kHz (crystal oscillator)

16 XCOUT Sub-clock oscillation circuit output 32.768kHz (crystal oscillator)

17 RESET Reset input L: Reset, H: Reset clear

18 XOUT Main clock oscillation circuit output 12MHz (crystal oscillator)

19 VSS

20 XIN Main clock oscillation circuit input 12MHz (crystal oscillator)

21 VCC1

22 NMI

23 TV_SC_REQ I Request from TV μ-com

24 R_CLK I Clock input from RDS decoder

25 PANEL_DET I PANEL detach / attach detection H: Detach, L: Attach

26 R_AFS_H I/O

27

27

27

27

28

29

Pin Name I/O Application

Time constant switching when F/E noise

is detected

EVOL_SCL/ASEL_SCL/

E2PROM_SCL/DSP_SCL

EVOL_SCL/ASEL_SCL/

E2PROM_SCL/DSP_SCL

EVOL_SCL/ASEL_SCL/

E2PROM_SCL/DSP_SCL

EVOL_SCL/ASEL_SCL/

E2PROM_SCL/DSP_SCL

TUN_IFC

EVOL_SDA/ASEL_SDA/

E2PROM_SDA/DSP_SDA

O Communication clock with E-VOL

O Communication clock with AV selector

Communication clock with EEP

O

(External memory)

O Communication clock with simplifi ed DSP

I F/E IFC input H: Station found, L: Station not found

I/O Communication data with E-VOL

Truth value

table

Processing / Operation / Description

H: Off (at power-off), L: On (at power-on (in nor-

mal operation) Duty50%),

Intermittent operation (2S interval, L width

100ms): Blinking (at ACC off)

In microprocessor mode: Connected to VCC1

In single chip mode: Connected to VSS

9

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

29

29

29

30 STEREMO_SW O Selection of STEREMO pull up resistance

31 POWER_PWM O Frequency control in X15_DC-DC_IC Duty50%

32 PARKING I Parking detection H: Parking is detected, L: During running

33 BEEP O BEEP PWM output

34 TUN_SCL I/O Communication clock with tuner

35 TUN_SDA I/O Communication data with tuner

36 CAM_TX O Communication with optional camera

37 VCC1

38 CAM_RX I Communication with optional camera

39 VSS

40 WRT_SCLK I In standard serial I/O mode: VCC1

41 BUSY O BUSY signal output terminal Used to re-write FLASH

42 TS_SDA I/O Communication data with electrostatic key

43 TS_SCL I/O

44 PGOOD I Power supply error detection H: Normal, L: Error

45

46 TV_JUDGE I

47 NC

48 EVOL_MUTE0 O E-VOL front mute L: ON, H: OFF

49 EVOL_MUTE1 O E-VOL rear mute L: ON, H: OFF

50 EVOL_MUTE2 O E-VOL SW mute L: ON, H: OFF

51 EVOL_MUTEC O

52 EPM I In standard serial I/O mode: VSS

53 PRE_MUTE_SW O Preout mute (For sub-woofer)

54 DSP_RST O

55 SIR_DET I Sirius connection detection H: Detected

56 SIR_PON O Sirius power supply ON/OFF H: ON

57 REVERSE I Reverse detection L: Detected, H: Normal

58 ILLUMI I Illumi detection L: ON (detected), H: OFF (not detected)

59,60 NC

61 CE I In standard serial I/O mode: VCC2

62 BL_ENA O Backlight ON/OFF control H: ON, L: OFF

Pin Name I/O Application

EVOL_SDA/ASEL_SDA/

E2PROM_SDA/DSP_SDA

EVOL_SDA/ASEL_SDA/

E2PROM_SDA/DSP_SDA

EVOL_SDA/ASEL_SDA/

E2PROM_SDA/DSP_SDA

EVOL_MUTEB/

AVOUT_MUTE

I/O Communication data with AVSEL

Communication data with EEP

I/O

(External memory)

I/O Communication data with simplifi ed DSP

Communication clock with electrostatic key

O E-VOL_AVOUT mute

Determination of whether TV_BOX is a

new one or old one

Mute exclusively for AF,

time constant=0.5mS, DSP input mute

Power supply control & RESET terminal

for DSP, DSP Power Down

Truth value

table

Processing / Operation / Description

H: 460Ω Toyota, Daihatsu, Nissan, Mazda,

Honda, Subaru, L: 4.7kΩ Mitsubishi

H: Old

L: New (For K and M destinations, Hi fi xed)

L: ON, H: OFF

L: Reset, H: Reset clear

10

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

63 AM+B O AM power ON/OFF control H: ON, L: OFF

64 P_START2 O

65 DVS_SDA I/O

66 DVS_SCL I/O

67 ATA_RST O DVD mechanism reset L: Reset, H: Reset clear

68 NC

69 EJECT I EJECT at OFF L: Depression of KEY is detected

70 SRC I SRC at OFF L: Depression of KEY is detected

71 SYS_VMUTE O

72 I2C_RELEASE I Used when writing the data in PSoC

73 P_RESET# O Reset request to peripheral circuits L: Reset, H: Reset clear

74 AVIN2_SW O

75 CAM_INT O Camera interruption setting on/off H: Switch to rear view camera screen

76 TS_RST O Touch sensor reset H: Reset, L: Cancel reset

77 EJECT_ILLUMI_ON O ON/OFF of DISC slot illumi H: ON, L: OFF

78 TILT_SPEED O Tilt mechanism power supply switching

79 TMOTOR_M O Tilt control of tilt mechanism

80 TMOTOR_P O Tilt control of tilt mechanism

81 SYS_SREQ O Request to Telechips

82 RST_MD O Activation request to Telechips H: Activation request

83 TCC_DOWN O Shutdown request to Telechips L: Shutdown request

84 TCC_STATUS I Telechips status indication H: Normal, L: Error

85 VCC2

86 P_START O ON/OFF control in X15_DC-DC H: Start, L: Stop

87 VSS

88,89 NC

90 ACC_DET I ACC detection H: ACC reduce voltage is detected, L: Normal

91 BU_DET I Backup power supply detection H: Backup reduce voltage is detected, L: Normal

92 PRE_MUTE_FR O Preout mute (For front and rear) H: ON, L: OFF

93 (GPS_RST#) O Reserve (GPS reset output) L: Reset, H: Reset clear

94,95 NC

96 TS_DET I

97 SYS_MREQ I Request from Telechips

98 SW_A I Panel release key detection

99 (Moni _RST) O Reserve (Moni ucom Reset) L: Reset, H: Reset clear

100 SYS_SDATA O Communication data to Telechips

Pin Name I/O Application

ON/OFF control in X15_DC-DC

(For D1_5V OFF)

Communication data with DVD mechanism

Communication clock with DVD mechanism

Video MUTE terminal (Power supply system)

Turn on/off the video isolation circuit when

using iPod dedicated video input is used

as AVIN2

Interruption request from electrostatic

touch key

Truth value

table

H: Mute OFF, L: Mute ON

Processing / Operation / Description

H: Start, L: Stop

L: Normal, H: When writing the data in PSoC

(Stop controlling entire I2C and switch TS_RST

terminal to input within 1s)

H: When AVIN2 is selected

L: When iPod is selected

H: Detected

11

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

101 SYS_MDATA I Communication data from Telechips

102 SYS_CLK I Communication clock from Telechips

103 TYPE_EXCELON I eXcelon

104 TYPE0 I Type2 destination detection

105 TYPE2 I For destination setting

106 TYPE_OEM I DOP

107 TYPE_M/E I Mid/Entry

108 TYPE_TDF I TDF/Fix

109 TYPE_BT I BT included or not

110 SW14V O SW14V ON/OFF H: ON, L: OFF

111 BU3_3_SW O

112 X35P_ON O X35 power supply control for TDF model H: ON, L: OFF

113 RELAY_DET1 I

114 RELAY_SW1 O Relay q control H: Relay ON, L: Relay OFF

115 RELAY_DET2 I

116 GPS_PON O GPS_ON/OFF control H: ON, L: OFF

117 RELAY_SW2 O Relay w control H: Relay ON, L: Relay OFF

118 PWIC_STBY O Power IC standby control H: ON, L: OFF

119 PWIC_MUTE O Power IC audio mute control H: OFF, L: ON

120 PWIC_DC_DET I DC offset detection in SP output When DC offset is detected: LOW

121 TILT_POSI I Panel mechanism tilt detection

122 TUN_SMET I S-meter input

123 R_NOISE I FM noise input

124 LINE_MUTE I LINE-MUTE input detection

125 STEREMO_KEY1 I Steering remote control KEY1 input

126 STEREMO_KEY2 I Steering remote control KEY2 input

127 AVSS

128 P_ON O SW power supply ON/OFF control H: ON, L: OFF

Pin Name I/O Application

Reduction of current consumption while

OFF

Relay q output error detection

(Short circuit, over current)

Relay w output error detection

(Short circuit, over current)

Truth value

table

q

q

q

q

q

q

q

Processing / Operation / Description

H: eXcelon

H: Mid, L: Entry

H: TDF, L: FIX

H: With BT, L: Without BT

H: ON 3.3V, L: OFF 2.7V

At RELAY_SW1 Hi

L: Normal, H: Error (At SW1 Low: Hi)

At RELAY_SW2 Hi

L: Normal, H: Error (At SW2 Low: Hi)

Normal: 1.6V, TEL MUTE: 1V or less,

NAVI MUTE: 2.5V or more

12

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

MICROCOMPUTER’S TERMINAL DESCRIPTION

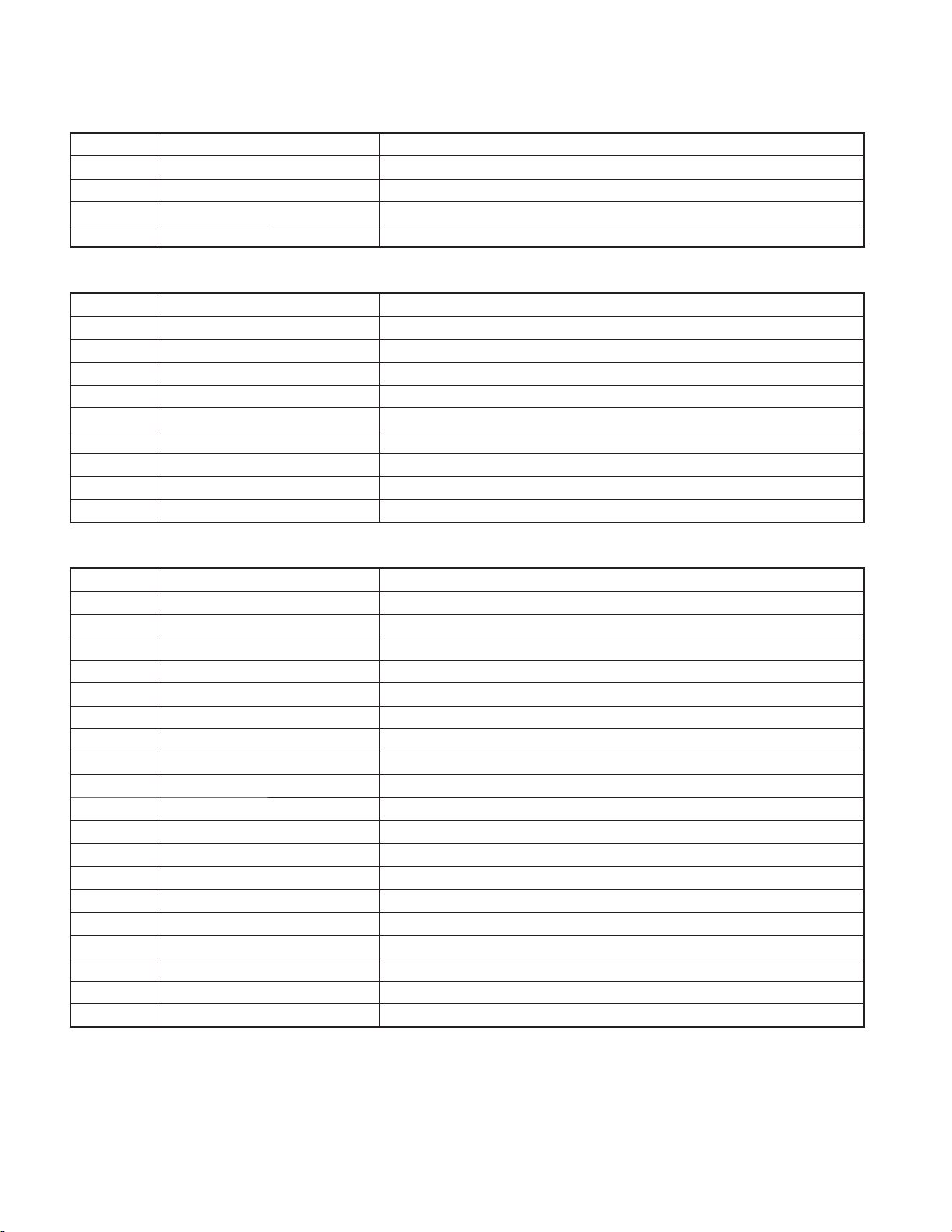

Truth value table

Destination setting

q

MODEL Destination TYPE_M/E TYPE2

0-10 DNX6980 K (eXcelon) 0 0 10k None 1 1 0 0

DNX6180 K 0 0 10k None 1 0 0 0

0-11

DNX6040EX K2 0 1 10k None 1 0 0 0

3-21 DNX5480BT R 0 0 None 10k 1 0 0 0

2-71 DNX5280BT E 0 0 2k 10k 1 0 1 0

3-81 DNX5580BT Q 0 0 5.1k 10k 1 0 1 0

0-71 DNX5380BT X 0 0 51k 10k 1 0 1 0

0-12 DNX5180 K 0 0 10k None 0 0 0 0

0-21 DNX5380 M 0 0 10k 10k 0 0 1 0

0-22 DNX5380M M2 0 1 10k 10k 0 0 1 0

3-01 DNX5380 V 0 0 20k 10k 0 0 1 0

2-72 DNX4280BT E 0 0 2k 10k 1 0 0 0

0-10 DNX7180 K 1 0 10k None 1 0 0 0

2-71 DNX7280BT E 1 0 2k 10k 1 0 1 0

0-21 DNX7380BT M 1 0 10k 10k 1 0 1 0

0-22 DNX7380BTM M2 1 1 10k 10k 1 0 1 0

0-71 DNX7380BT X 1 0 51k 10k 1 0 1 0

3-21 DNX7480BT R 1 0 None 10k 1 0 1 0

TYPE0

DOWN UP

TYPE_BT

TYPE_EX-

CELON

TYPE_TDF TYPE_OEM

PANEL MICROCONTROLLER (X35 : IC202)

●

Pin No.

1,2 NC -

3 R_VOL- - Rotary encoder Vol_DOWN sheet: Rotary SW

4 R_VOL+ - Rotary encoder Vol_UP sheet: Rotary SW

5 REMO I Remote controller control

6 BYTE I Bus width selection: Not used (Fixed to VSS)

7 CNVSS I Boost mode selection Vcc+RESET: Hi, fl ash writing-in

8,9 NC -

10 RESET I Reset terminal

11 XOUT O Crystal CLK_OUT

12 VSS -

13 XIN I Crystal CLK_IN 12.000MHz

14 VCC1 -

15 NMI I

Pin Name I/O Application

Truth value

table

Processing / Operation / Description

13

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

16~19 NC -

20 BL_SYNC O Sync signal

21 NC -

22 BL_PWM O Backlight luminance control

23 BL_ENA O Backlight on / off control Hi: ON

24 NC -

25 BL_SW O For LED driver F.R. frequency switching

26~28 NC -

29 FLASH_DO O For writing data in FLASH

30 FLASH_DI I For writing data in FLASH

31 FLASH_CLK I For writing data in FLASH

32 BUSY O

33~38 NC -

39 EPM I For writing data in FLASH While writing: Lo

40~43 NC -

44 CE I While writing: Hi

45 PANEL_SDATA O SoC communication data output

46 PANEL_MDATA I SoC communication data input

47 PANEL_MCLK I SoC communication clock input

48~50 NC -

51 PON_VD5.0V O VD5V SS circuit control Hi: ON

52 RCAM_INT I RCAM interruption at start-up Lo: Set RCAM, MST to RCAM

53 NC -

54~56 TYPE0~TYPE2 I Destination setting

57~59 NC -

60 VCC2 -

61 NC -

62 VSS -

63 NC -

64 PANEL_SREQ O SoC communication request

65 PANEL_MREQ I SoC communication request

66 BL_PDET I

67 CP_RESET O IC control for IPOD authentication RESET Lo: RESET

68 CP_SDA I/O IC control for IPOD authentication I2C DATA

69 CP_SCL I/O IC control for IPOD authentication I2C CLK

70 NC -

71 MST_RESET O MST7912 RESET Lo: RESET

72 MST_WAIT I MST7912 communication Wait Lo: MST_I2C command transmission stop

73 PANEL_VMUTE O LCD display VMUTE control Lo: VMUTE

74 NTSC/PAL I RCAM NTSC / PAL determination Hi: NTSC, Lo: PAL

Pin Name I/O Application

Backlight power supply power reduction

detection

Truth value

table

q

Processing / Operation / Description

sheet: Type

Hi: BL_ENA can be set to Hi, Lo: Power supply

power reduction detection → BL_ENA: Lo

14

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

75 MST_SDA I/O MSTAR_SI2C_data 100k Other restrictions apply

76 MST_SCL O MSTAR_SI2C_clock 100k Other restrictions apply

77 MST_WP I/O MST7912 external fl ash WRITE protection

78,79 NC -

80 SRC I At PON only Hi: ON

81 EJECT I At PON only Hi: ON

82,83 NC -

84 IPOD_AVIN (NC) -

85 ILL_R O Blinking Test_Mode: Blinking, Hi: ON

86 KEY I KEY for Entry

87 Y1 O For touch panel control

88 Y0 O For touch panel control

89 X1 O For touch panel control

90 X0 O For touch panel control

91 YDATA_D I For touch panel control

92 XDATA_D I For touch panel control

93 YDATA_U I For touch panel control

94 AVSS -

95 XDATA_U I For touch panel control

96 VREF -

97 AVCC -

98 PULL_UP_ON O For touch panel control

99 TP_PRESS O For touch panel control

100 NC -

Pin Name I/O Application

Truth value

table

Processing / Operation / Description

In normal operation: Input

Hi: MST_I2C command transmission stop

When writing-in adjustment value: Output

Hi: WRITE protection cancel

Truth value table

Destination setting (54pin: Type0, 55pin: Type1, 56pin: Type2)

q

Destination TYPE2 TYPE1 TYPE0

K (eXcelon)/K/K2/R/ER (FIX)

DNX4/5/6 (Entry)

DNX7 (Mid)

E/Q (TDF) 0 1

M/M2/V/X (TDF/Swichable) 1 0

Not used 1 1

K (eXcelon)/K/K2/R/ER (FIX)

E/Q/M/M2/V/X (TDF) 0 1

Not used 1 0

Not used 1 1

00

0

00

1

15

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

TEST MODE

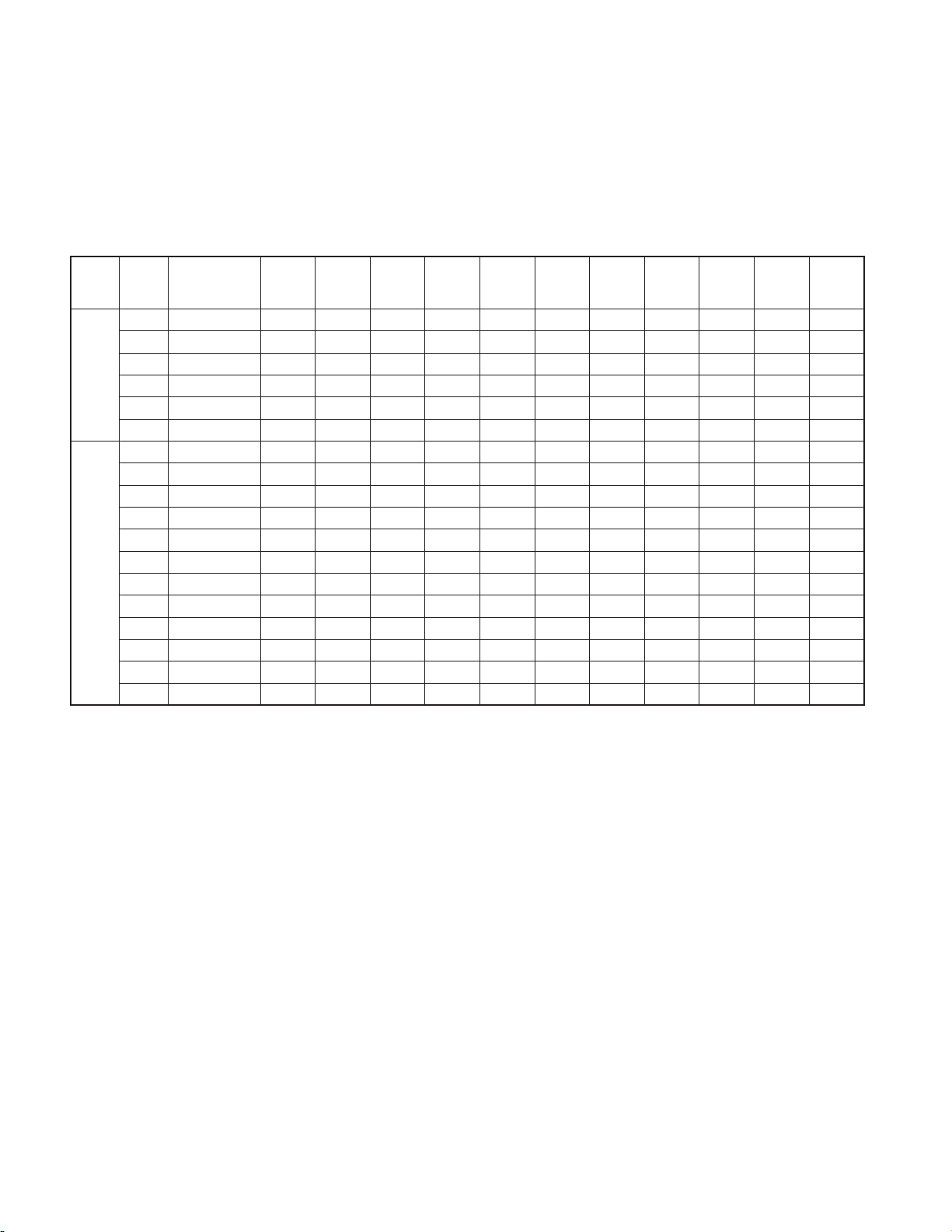

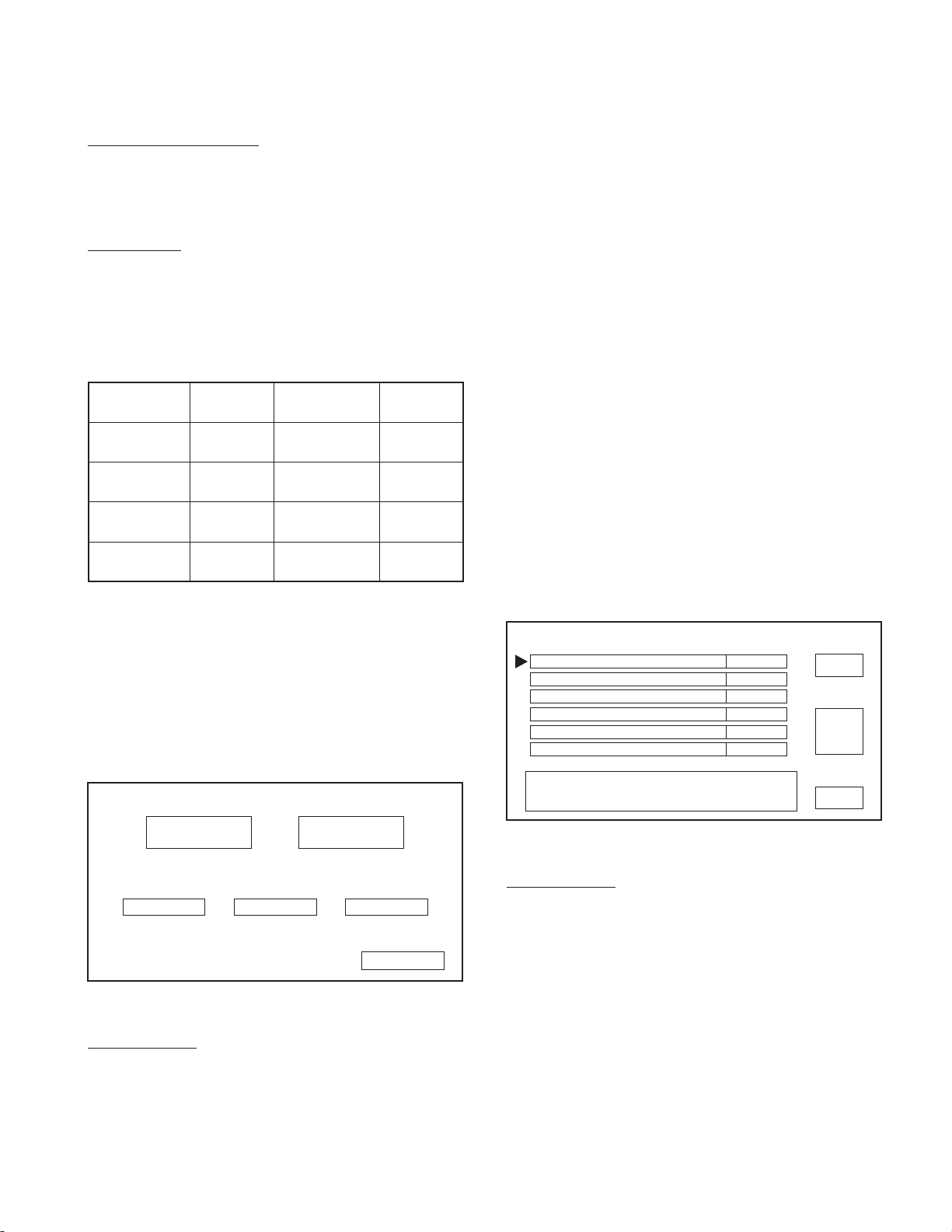

1 General information

1.1 Purpose

The purpose of this document is to define the items re-

quired for the test mode used at the manufacturing process

and service stations for 11 Visual Mid / Entry model.

Model

type

DNX

(Mid)

DNX

(Entry)

Destination

Model Name

K DNX7180

R DNX7480BT

E DNX7280BT

M DNX7380BT

M2 DNX7380BTM

X DNX7380BT

K DNX6980

K DNX6180

K2 DNX6040EX

R DNX6480BT

E DNX5280BT

Q DNX5580BT

X DNX5380BT

ER DNX4280BT

K DNX5180

M DNX5380

M2 DNX5380M

V DNX5380

Panel

mecha-

Attachable/

detachable

nism

c°ccc°cc°cc

c°cccc°c°°c

cccccccc°cc

cccccc°cccc

cccccc°cc°c

cccccc°cc°c

°°c°°°c°°cc

°°c°°°c°°c°

°°c°°°c°°c°

°°c°°c°°°°c

°cc°°cc°°cc

°cc°°c°°°cc

°cc°°c°°c°c

°°c°°c°°°c°

°°°°°°c°°°°

°c°°°cc°ccc

°c°°°cc°c°c

°c°°°cc°c°c

panel

BT

Built-in

Ext SW

Table 1.2.1 Model List of 11 Visual Mid/Entry model

1.2 Scope of application

This document is applied for the models described in Table

1.2.1. (This document also describes the presence or ab-

sence of the functions related to the Test mode.)

Electro-

static

touch

DivX KAB I/F DSP

Steering

Remote

TMC

Tuner

SD Slot

1.3 Outline

This section describes the Test mode of the 11 Visual Mid/

Entry model regarding the display specifi cations, the speci-

fi cations of the operation with the key remote controller, and

the details of its behavior.

2 Test Mode specifi cation

2.1 Operations

The system can be transferred to the Test mode with the

following two approaches:

Regardless of the ON/OFF status of security, the system

can be transferred to the Test mode with one of the follow-

ing operations.

Start the system by pressing [Reset] key while pressing

q

the following keys.

Mid : [MENU] + [ATT]

Entry : [Eject] + [SCRN]

Input [2] → [] → [3] with the remote controller (SW:

w

AUD) into the standby source.

16

While in the test mode, fl ash ILLUMI of the EJECT port in 1

sec intervals regardless of the panel position (only Mid).

In the Test mode, the LED for SI fl ickers at regular intervals.

Panel: Flash (all models)

Sub panel: Turn off when panel is attached. Flash when

panel is detached. (Only for attachable/de-

tachable model)

When starting in the Test mode, the illumi is turned ON in

white.

Turn the system OFF in 30 minutes when it is started in the

Test mode.

Continue the test mode by ACC OFF/ON. Clear the test

mode by Reset.

2.2 Specifi cation of screens

This section describes the Test mode functions available

in each screen. (The screen layout may differ from the real

system.)

TEST MODE

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

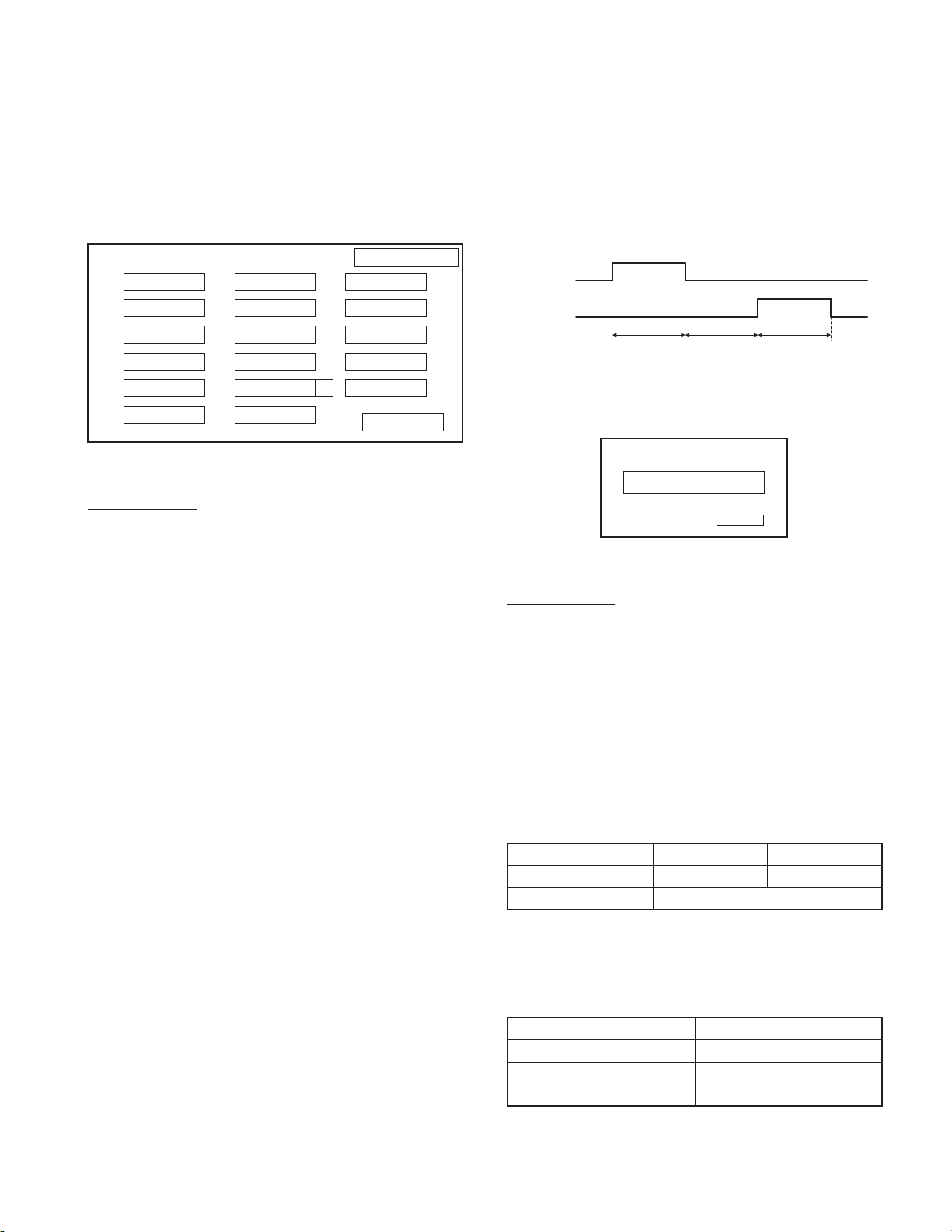

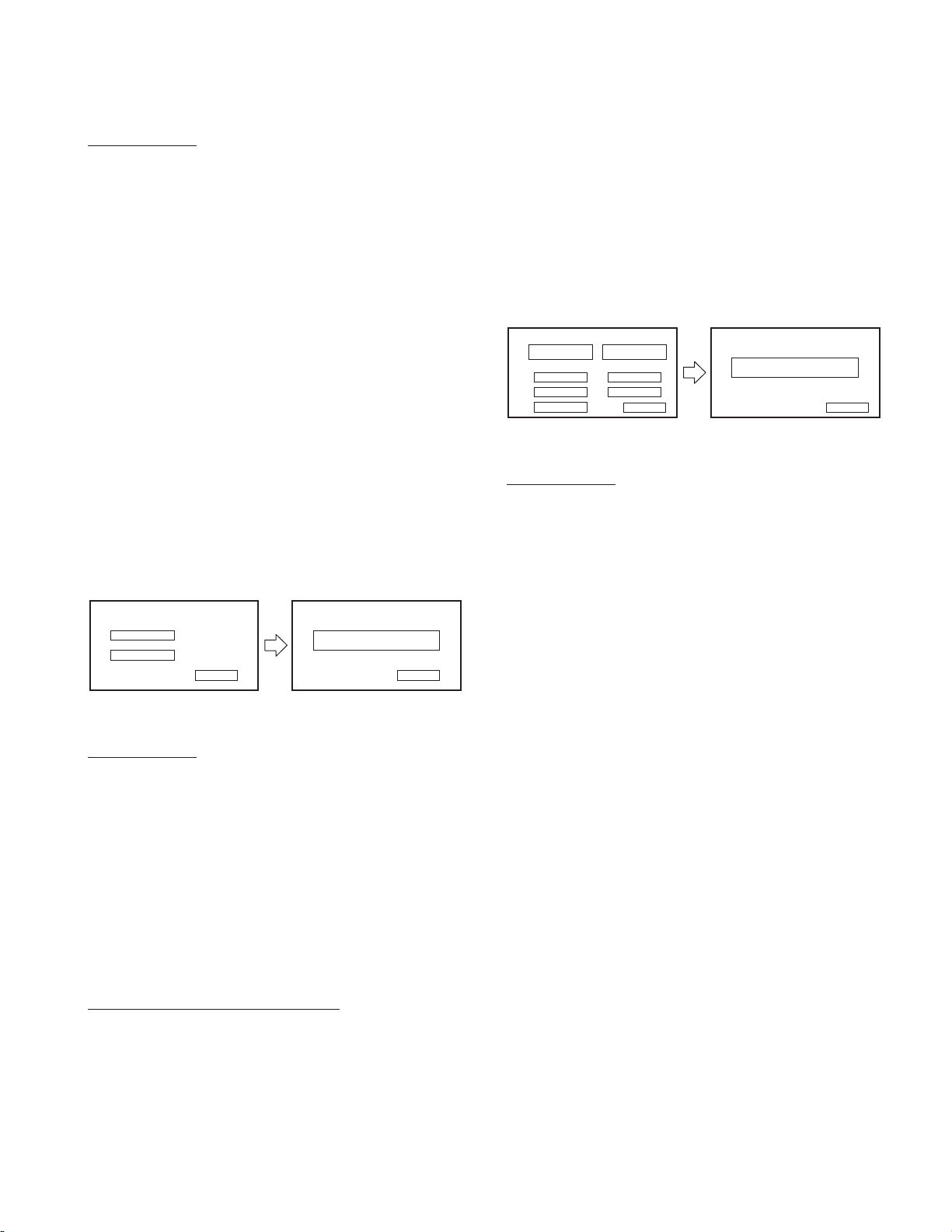

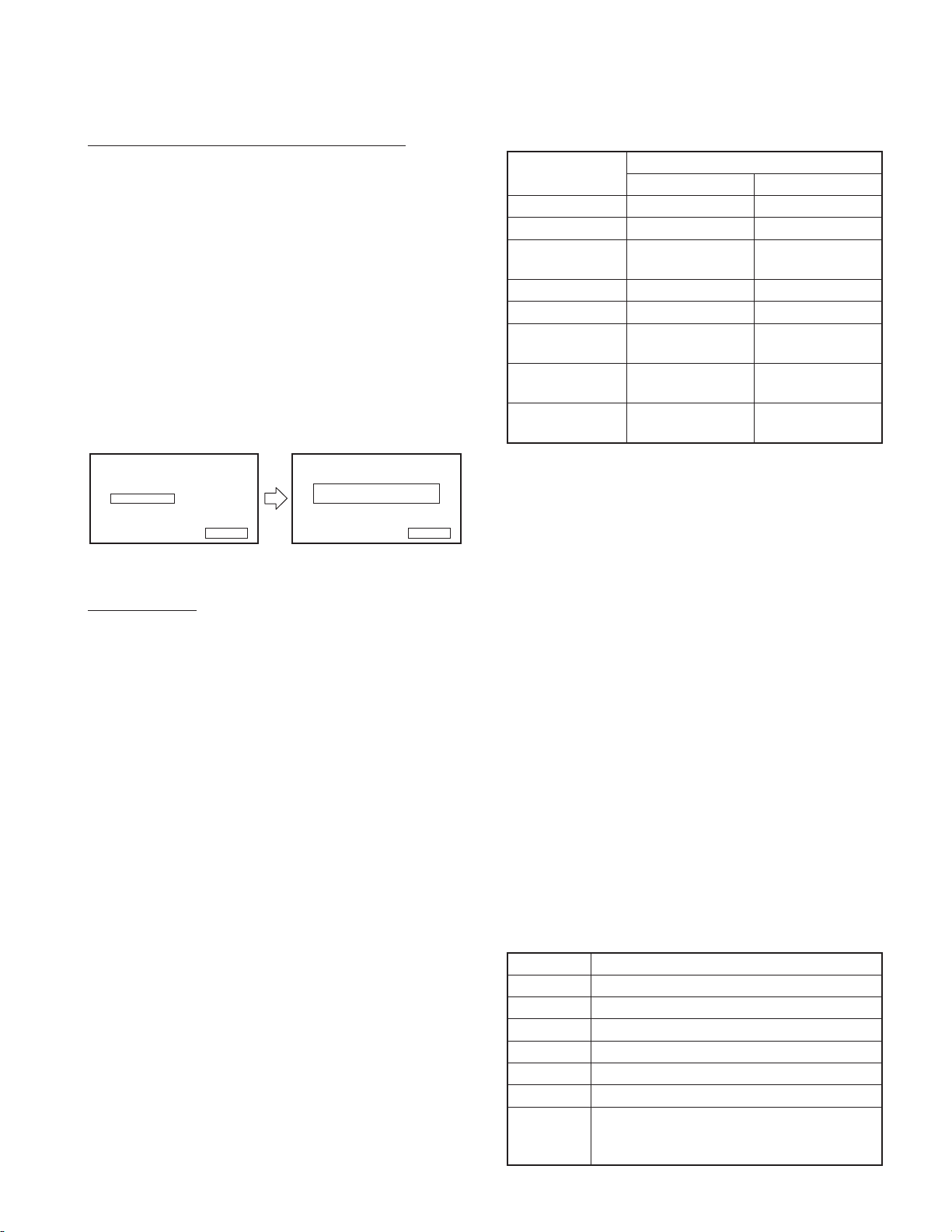

2.2.1 Test Mode Main screen

The Test Mode Main screen is displayed after transferring to

the test mode.

Contents of the display shown in the Test Mode Main

screen are described in Figure 2.2.1.

Test Mode Main

Information

Service

Ext SW

For FCT

Navigation

Direct Select

Figure 2.2.1 Test Mode Main screen

Key Specifi cation

Information : Transfer to Information screen.

Service : Transfer to Service screen.

Ext SW * : Start Ext SW test.

For FCT * : Switch 2ZONE and BASS settings.

Navigation : Transfer to Navigation Test screen.

This key is displayed in red when starting up

the Navigation.

Direct Select

: Transfer to Top Menu screen of the product

mode.

Touch : Transfer to Touch Adjust screen.

Illumi * : Transfer to llumi Adjust screen.

iPod : Transfer to iPod screen.

Tilt Mecha * : Transfer to Tilt Mecha Adjustment screen.

Steering Remote *

: Transfer to Steering Remote test screen. (start

Steering Remote test)

LCD : Transfer to the LCD Adjustment screen.

Bluetooth * : Transfer to Bluetooth screen.

This key turns red after the completion of Flash

memory initialization in Bluetooth Module.

SW-Touch * : Transfer to SW-Touch Confi rmation screen.

Development

: Transfer to Development screen.

Rear Camera *

: Start CMOS-300 communication line test.

Note: ID setting for the CMOS-300 shall be “1”.

Return : Transfer to product mode screen.

*: Item for which key becomes disabled depending on the

model.

Touch

Illumi

iPod

Tilt Mecha

LCD Backlight 1

Steering Remote

DRAM OK

LCD

Bluethooth

SW-Touch

Development

Rear Camera

Return

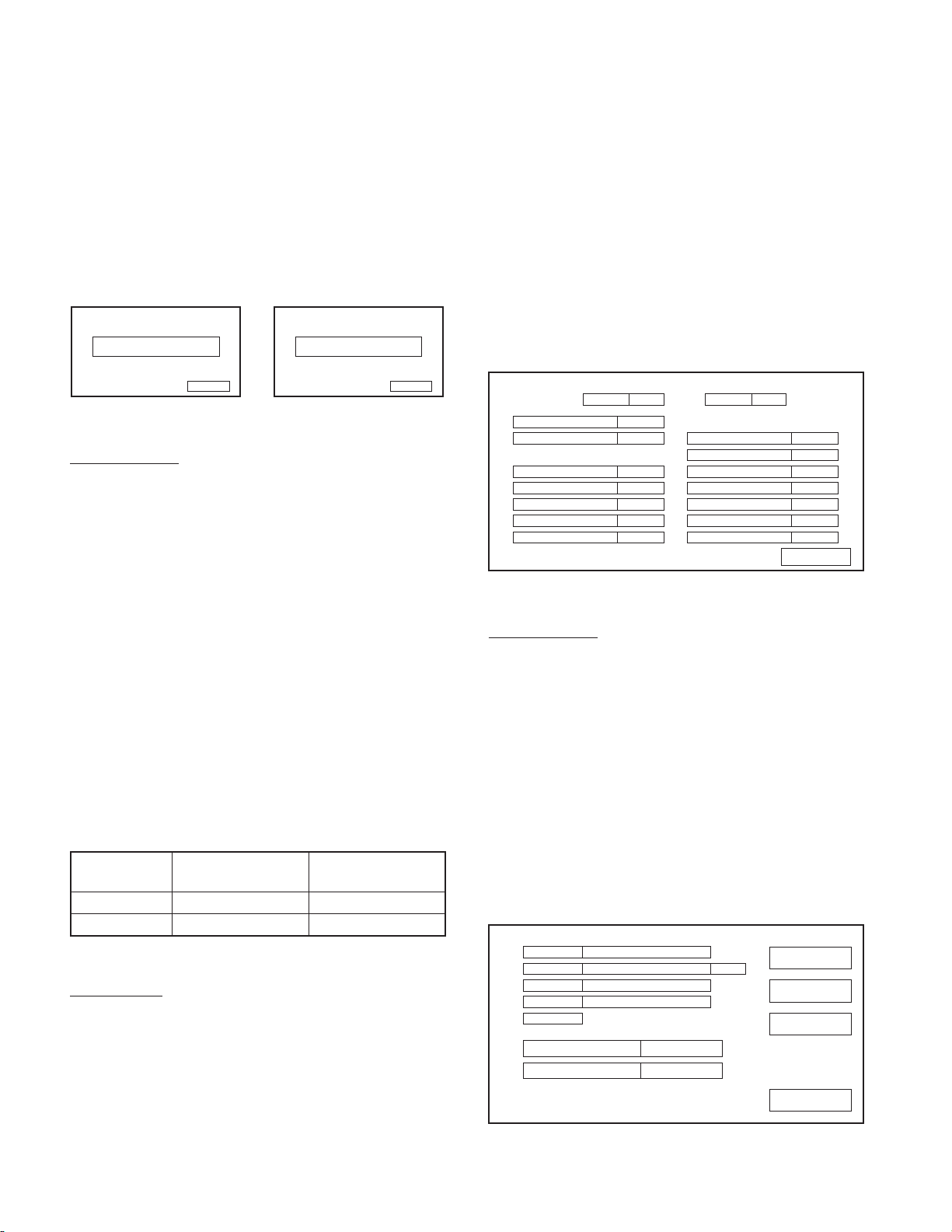

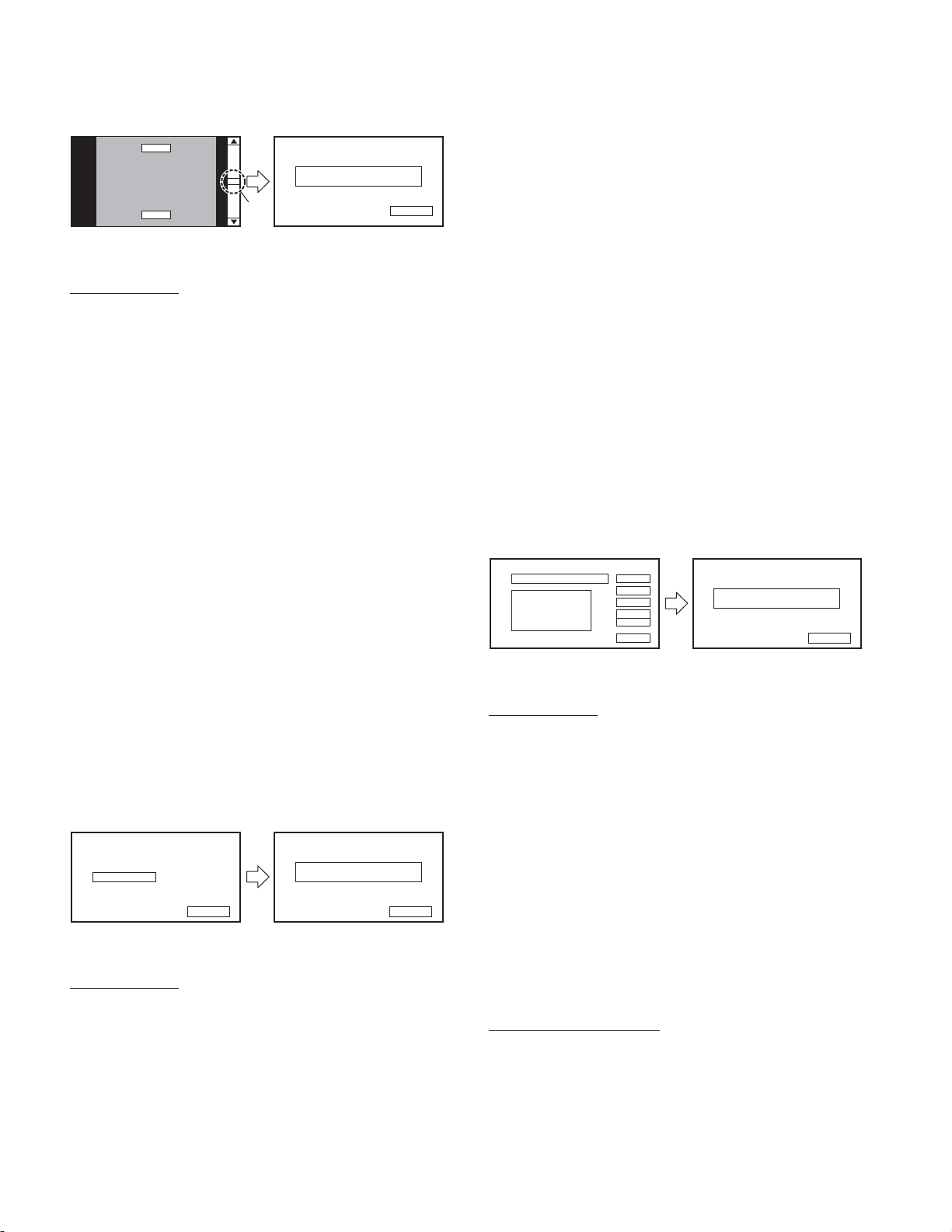

2.2.1.1 Ext SW test

When [Ext SW] key is pressed, Ext SW1/ Ext SW2 terminals

are controlled as shown in fi gure 2.2.1.1-A.

This test is disabled for the models with “X” listed in the Ext

SW column of Table 1.2.1.

Ext SW1

Ext SW2

1sec 400msec 1sec

Figure 2.2.1.1-A Output Waveform for Ext SW Test

If over current is detected, output from the terminal is termi-

nated and transfer to Error screen shown in Figure 2.2.1.1-B.

Ext SW

ERROR

Return

Figure 2.2.1.1-B Ext SW Error screen

Key Specifi cation

Return : Transfer to Test Mode Main screen.

2.2.1.2 For FCT

Switch the setting for 2ZONE and BASS as shown below

every time [For FCT] key is pressed.

2ZONE ON/ ALL FLAT → 2ZONE OFF/ BASS ON → 2ZONE

OFF/ ALL FLAT → 2ZONE ON/ ALL FLAT → · · ·

This test is disabled for the models with “°” listed in the

DSP column of Table 1.2.1.

Set the setting when the BASS ON as in Table 2.2.1.2-A.

DSP BASS frequency Level

Model with Simple DSP 250Hz +8dB

Model without DSP This function is not necessary

Table 2.2.1.2-A Setting when BASS ON

Switch the color of [For FCT] key as in Table 2.2.1.2-B so

current status is visible.

Status [For FCT] key color

2ZONE ON/ ALL FLAT Red

2ZONE OFF/ BASS ON Green

2ZONE OFF/ ALL FLAT Same as other key

Table 2.2.1.2-B [For FCT] key color for each status

17

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

TEST MODE

2.2.1.3 CMOS-300 communication line test

Start the communication with CMOS-300 by pressing [Rear

Camera] key.

When the communication is successful, “OK” is displayed,

and if it has failed, “NG” is displayed (refer to the Figure

2.2.1.3).

This test is disabled for the models with “°” listed in the

Ext SW column of Table 1.2.1.

Rear Camera

Figure 2.2.1.3

OK

Return

CMOS-300 communication line test result screen

Rear Camera

NG

Return

Key Specifi cation

Return : Transfer to Test Mode Main screen.

2.2.1.4 Direct Select

It will transfer to Top Menu screen of product mode while

continuing in the test mode when [Direct Select] key is

pressed.

The following operation is transferred to Test Mode Main

screen while displaying the GUI screen of the product

mode.

• Press the [MENU] key in the panel ([MENU] key at the bot-

tom left of the screen will operate as normal even during

the test mode)

• Press Tenkey4 on the remote controller

2.2.1.5 DRAM Check

Display the DRAM Check result at the top right of the Test

Mode Main screen. (For details about the DRAM Check re-

sult, refer to the Table 2.2.1.4)

DRAM Check

result

OK DRAM OK No specifi cation

NG DRAM NG Red

Table 2.2.1.4 DRAM Check result display

Check method

Transfer to the test mode. (At this time, “DRAM NG”

q

is displayed at the top right of the screen, but ignore it

here)

Perform ACC OFF/ON.

w

Test Mode Main screen is displayed. Display at this time

e

is the result of DRAM check.

Displayed character

string

Background color of

the character string

2.2.1.6

LCD Backlight automatic adjustment value display

Display the current LCD Backlight automatic adjustment

value close to the [LCD Backlight] key.

Make the display region red when the automatic adjustment

value is not between 2 and 8.

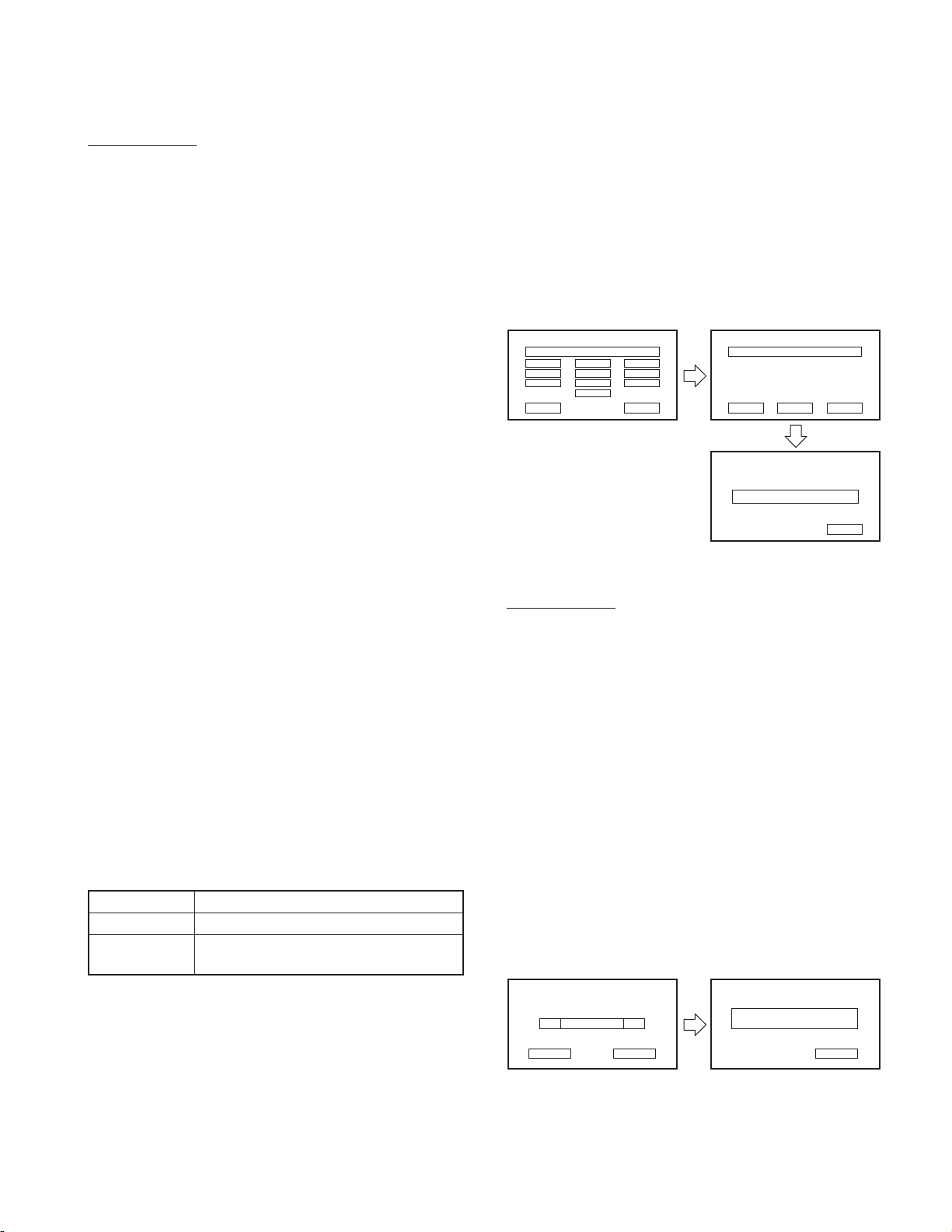

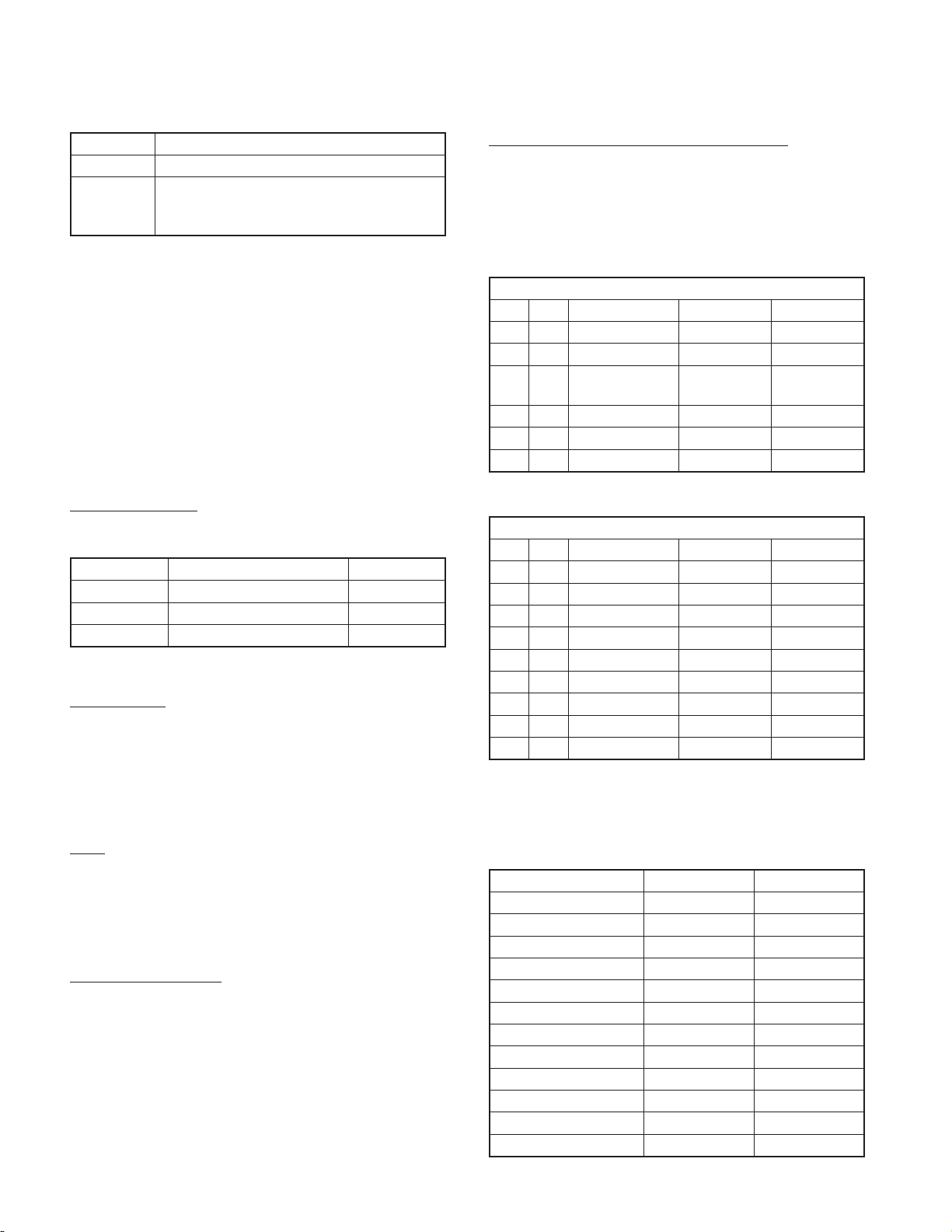

2.2.2 Information screen

This screen is to display such information as version num-

ber and other conditions.

The contents displayed on the Information screen are

shown in Figure 2.2.2.

Information

DNX

Application Processor

System μ-com

M-Star

DVS87xx F/E

DVS87xx B/E

macrovision

Serial

Type

∗

V∗.∗.

V∗.

∗∗∗

V

∗∗

V∗∗.

∗∗

V∗∗.

∗∗

V1.01

∗∗∗∗∗∗∗∗

∗

Figure 2.2.2 Information screen

Key Specifi cation

Return : Transfer to Test Mode Main screen.

Hide “Capacitance Detection IC” for the models with “°”

listed in the Electrostatic touch column of Table 1.2.1.

Hide “BT Module” and “PIN Code” for the models with “°”

listed in the BT built-in column of Table 1.2.1.

Hide “DivX Codec Version” for the models with “°” listed in

the DivX column of Table 1.2.1.

2.2.3 Service screen

This screen is to show a variety of service information.

The contents displayed on the Service screen are shown in

Figure 2.2.3.

Span

Panel μ-com

Capacitance Detection IC

BT Module

PIN Code

Region

DivX Codec Version

DC Offset

∗

V∗.

∗∗∗

V∗.

∗∗∗

V∗.∗.

∗∗∗∗

∗

V1.00

None

Return

∗

Service

Init

Init

Init

Init

Start

■

DivX Registration Code Clear

DC Offset Clear

Power ON

DVD-Video

Monitor Open

Disc Eject

∗∗∗

∗∗∗

∗∗∗

minutes

minutes

times

∗∗∗

times

∗∗∗∗

None

Disp

Serial

Tuner Mute Level

DVS8700 Adjust

Return

18

Figure 2.2.3 Service screen

TEST MODE

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

Key Specifi cation

Init : Select the item to initialize. (selection will be can-

celled by pressing it again)

Start : Initialize the information of the item selected by

■

pressing [Init] key.

Disp : Display switching of the disc play back time.

DVD-Video → CD → VCD → Media Disc →

DVD Video

→

· · ·

Serial : Transfer to the Serial No. Writing-in screen.

Tuner Mute Level

: Transfer to Tuner Mute Level Adjustment screen.

DVS8700 Adjust

: Transfer to DVS8700 Adjustment screen.

DivX Registration Code Clear

: Clear DivX Registration Code.

Note:

Eject the disc before performing this operation.

DC Offset Clear

: Clear the DC Offset information stored in the non-

volatile memory.

Return : Transfer to Test Mode Main screen.

2.2.3.1 DivX Registration Code

Since the Registration Code cannot be displayed constantly

after the model is made to be compatible with Ver3.0, the

following status of the DivX is displayed instead.

• Activate

• Deactivate

• None (In factory default condition or when the code is

cleared)

Hide this item for the models with “°” listed in the DivX col-

umn of Table 1.2.1.

2.2.3.2 DC Offset

Display DC Offset detection information (for details of dis-

play, refer to the Table 2.2.3.2).

Details of display DC Offset detection status

None DC Offset not detected

Detect (x)

Table 2.2.3.2 Display regarding DC Offset

DC Offset detected (x = 0 to 3: Number of

capacitor leak detection)

2.2.3.4 Power on log

Display if the unit was powered on or not.

Details of display are as following.

Power Detected: Has power on log.

No Detection: Does not have power on log.

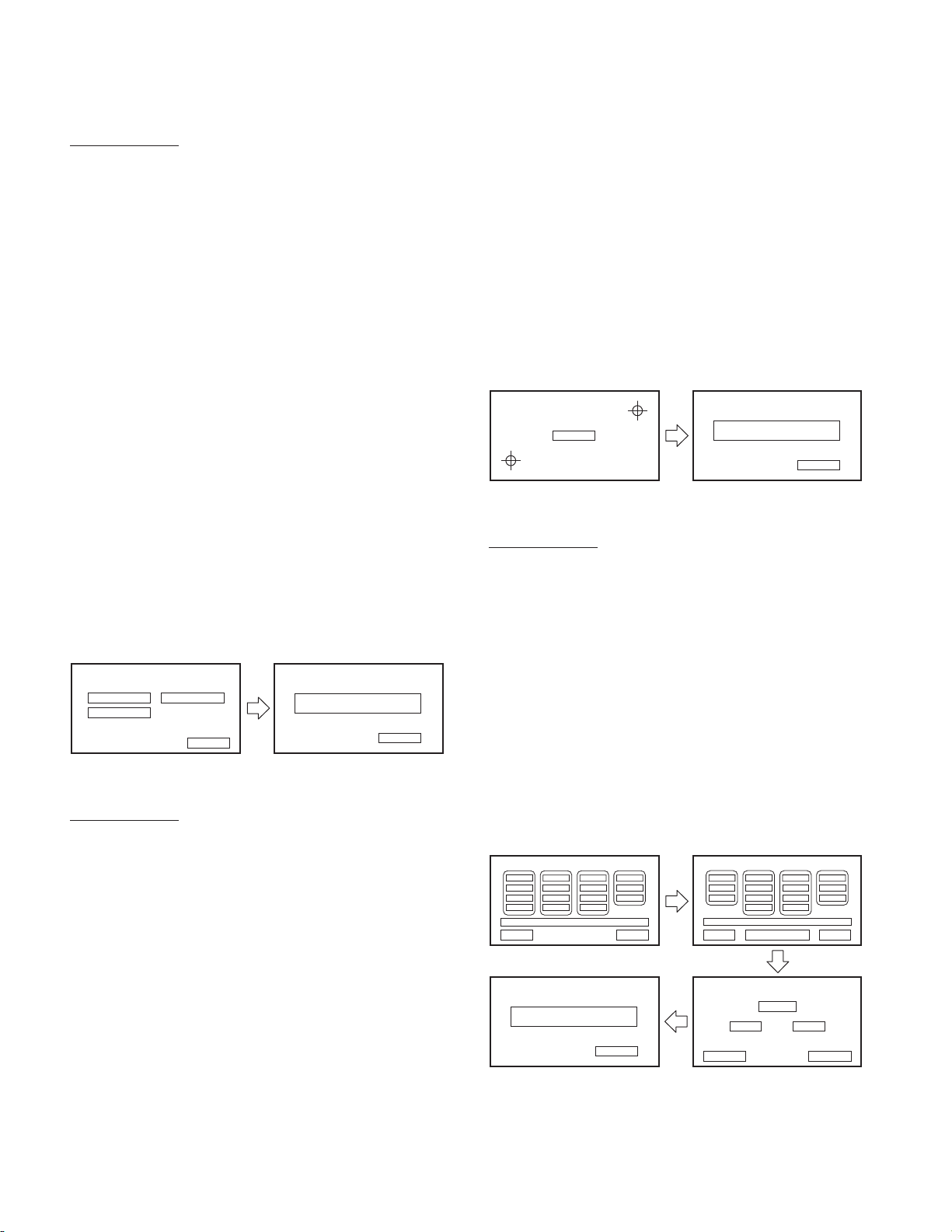

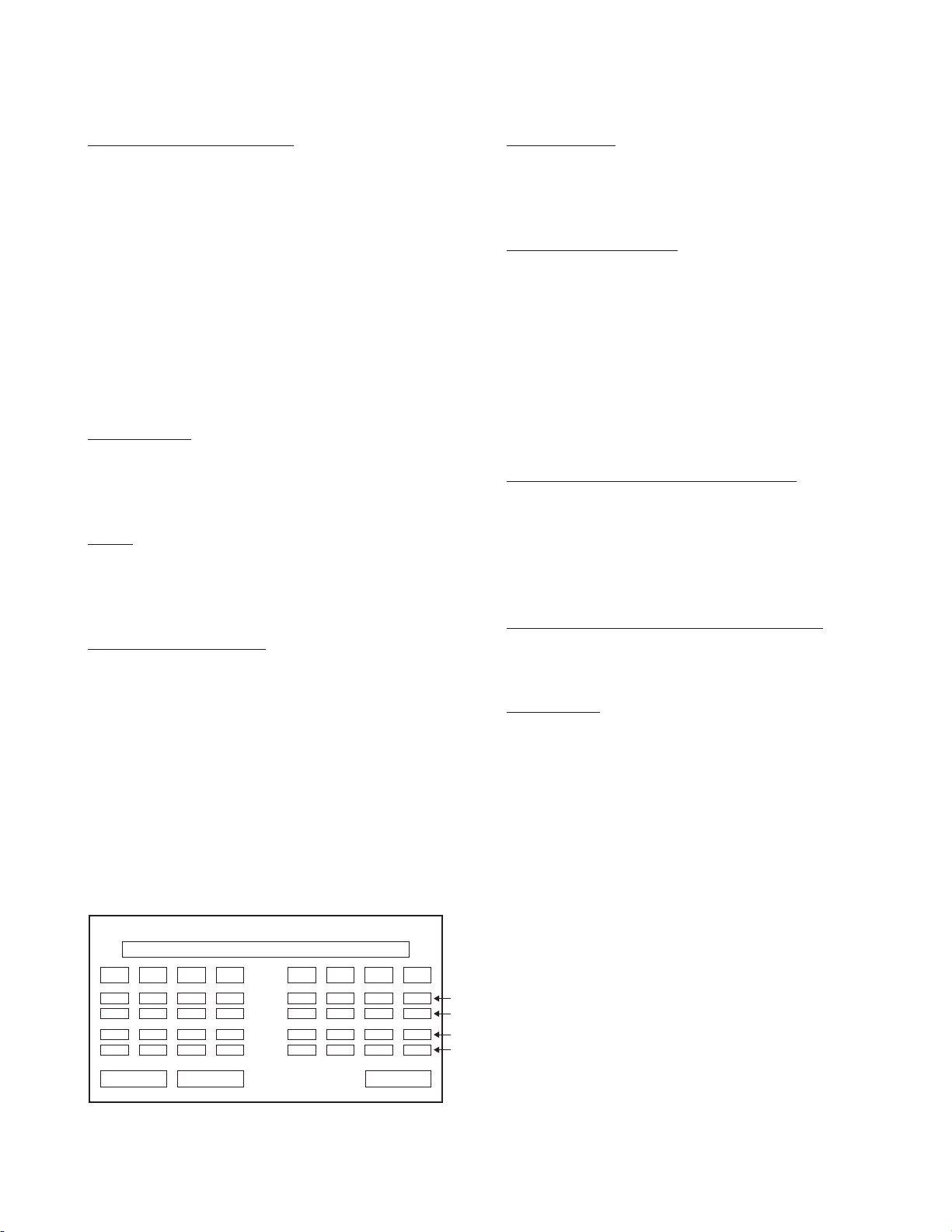

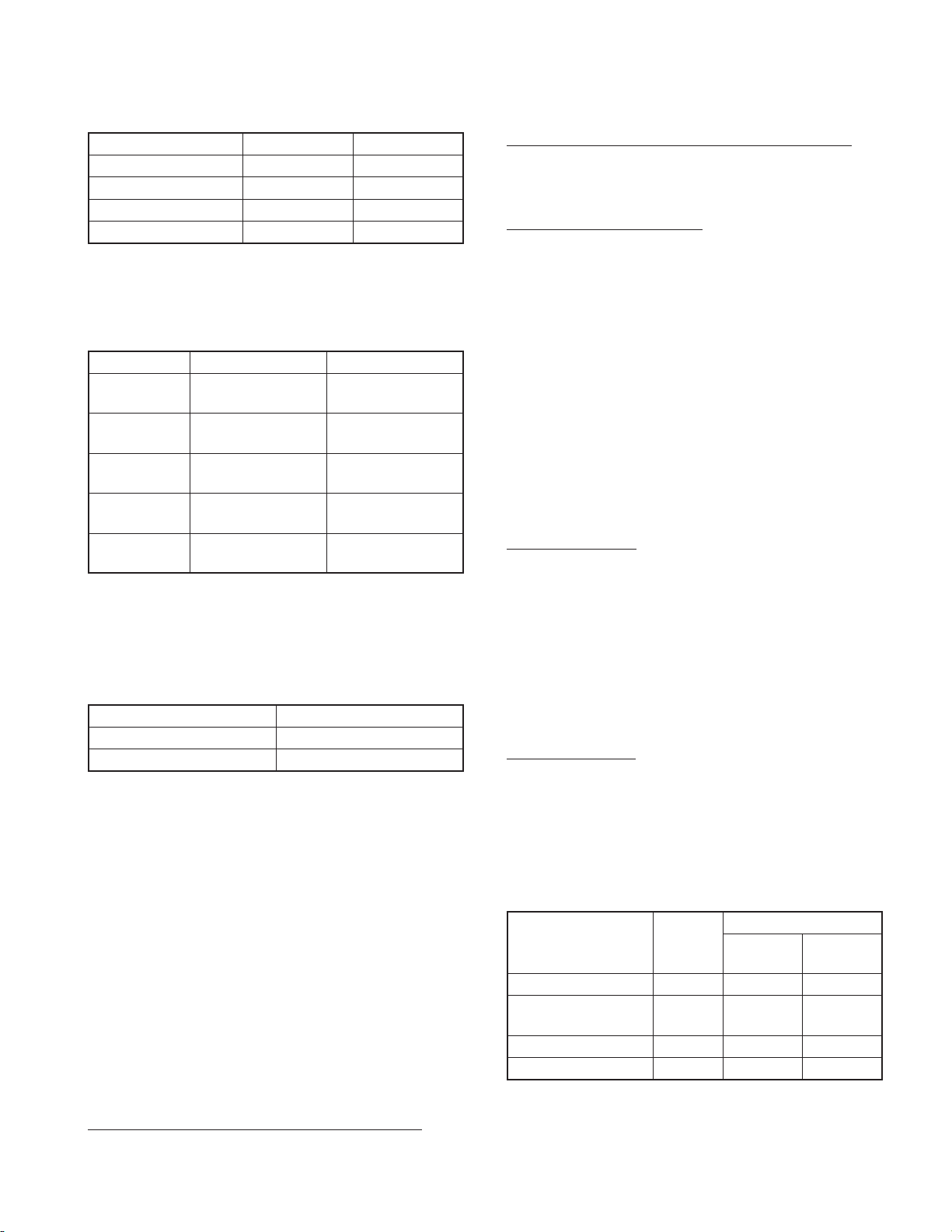

2.2.3.5 Serial No. Entry screen

Enter the serial number of each set from this screen.

The Serial No. Entry screen is shown in Figure 2.2.3.5.

Serial Number Input

– – – – – – – –

1

4

7

Clear Cancel

2

5

8

0

3

6

9

Serial Number Input

X X X X X X X X

Clear Enter Cancel

Serial Number Input

Write OK/NG

Return

Figure 2.2.3.5 Serial No. Entry screen

Key Specifi cation

0~9 : 10key used to enter the serial number.

Clear : Clear the serial number being input.

Cancel : Transfer to Service screen.

Enter : Start entering the serial number.

Return : Transfer to Service screen.

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

When “Write NG” is displayed after pressing the [Enter]

∗

key, enter the Test mode again to start from the beginning.

2.2.3.6 Tuner Mute Level Adjustment screen

Perform adjustment of the Mute Level memorized in the

nonvolatile memory of Tuner F/E.

The Tuner Mute Level screen is shown in Figure 2.2.3.6.

Tuner Mute Level Tuner Mute Level

2.2.3.3 Service Information

Power ON time, Disc play back time, Monitor Open count,

and Disc Eject count are displayed.

Display fi xed characters “Monitor mecha don’t exist” in the

number of Monitor Open for the models with “°” listed in

the Panel mechanism column of Table 1.2.1.

DW

Write Cancel

■

UP∗∗∗∗

Write OK/NG

Return

Figure 2.2.3.6 Tuner Mute Level Adjustment screen

19

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

TEST MODE

Key Specifi cation

UP : Mute Level Up

DW : Mute Level Down

Write : Write to the nonvolatile memory.

■

Cancel : Transfer to Service screen.

Return : Transfer to Service screen.

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

When adjusting the Tuner Mute Level, perform with the

∗

following condition.

Set the frequency before transferring to the Tuner Mute

Level adjustment screen. (Even after completing adjust-

ment, the frequency remains the same.)

Audio Source : Tuner

LOUD : OFF

Volume : Step30

Frequency : Default value of the set

2.2.3.7 DVS8700 Adjustment screen

This is to display DVS-8700 Servo Adjustment screen.

The DVS8700 Adjustment screen is displayed in Figure

2.2.3.7.

DVS8700 Adjust DVS8700 Adjust

Offset Cancel

Focus Height

Figure 2.2.3.7 DVS-8700 Adjustment screen

Key Specifi cation

Offset Cancel

: Start the Offset Cancel Adjustment.

Note: Active only when there is no disc and not

Inner Limit : Start the Inner Limit Adjustment.

Note: Active only when there is no disc and not

Focus Height

: Start the Focus Height Adjustment.

Note: Active only when there is disc, not ad-

Cancel : Transfer to Service screen.

Return : Transfer to the DVS8700 Adjustment screen.

Inner Limit

Cancel

Adjust OK/NG

adjusting.

adjusting.

justing, and mechanism power off.

(left screen in Figure 2.2.3.7)

Return

Background color will be blue when “Adjust OK” is dis-

∗

played.

Background color will be red when “Adjust NG” is dis-

∗

played.

2.2.4 Touch Adjust screen

Fine-tune the variations of touch feeling in of each set.

Touch 2 markers one by one, and the adjustment is com-

pleted when the “Write OK” is shown on the screen.

If the “Write NG” is shown, transfer to the Test mode again

to re-start the adjustment from the fi rst step.

The Touch Adjustment screen is shown in Figure 2.2.4.

Touch Adjust Touch Adjust

1-point

being input

Cancel

2-point

being input

Write OK/NG

Return

Figure 2.2.4 Touch Adjust screen

Key Specifi cation

Cancel : Transfer to Test Mode Main screen.

Return : Transfer to Test Mode Main screen.

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

2.2.5 Illumi Adjust screen

This screen is used to adjust the white color of the key il-

lumi.

This test is not performed for the models with “°” listed in

the Electrostatic touch column of Table 1.2.1.

The Illumi Adjustment screen is displayed in Figure 2.2.5.

Illumination Adjust Illumination Adjust

Table9

Table3

Table5

Table10

Table10

Table8

Table4

Table2

Table2

Cancel

Illumination Adjust Illumination Adjust

Table1

Write OK /NG

Table4

Table6

Table2

Return

Table7

Table6

Table8

Next

Figure 2.2.5 Illumi Adjustment screen

Step1

Step1

Step1

Step2

Step3

Step4

Step1

Step2

Step3

Up

Next

Step2

Step2

Step3

Step3

Step4

Step0

RGB compensation value

Cancel Next

Adjustment value

Down

Cancel

20

TEST MODE

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

Key Specifi cation

Next : Transfer to the next Adjustment screen.

Cancel : Transfer to the previous Adjustment screen.

(Transfer to the Test Mode Main screen while

displaying the top left screen of Figure 2.2.5)

Table1~10 : Selection of table for key illumi.

Step0~4 : Fine tuning.

Down/Up : Right and Left Adjustment.

Return : Transfer to Test Mode Main screen.

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

2.2.6 iPod screen

Check communication for iPod authentication.

The iPod Authentication Chip Confirmation screen is dis-

played in Figure 2.2.6.

Switch to video connected to the iPod video line by press-

ing the [iPod V-Play] key. (Switching to iPod video can be

performed regardless of connection with the iPod.)

iPod iPod Check

iPod Check

iPod V-Play

Cancel

Figure 2.2.6 iPod screen

Key Specifi cation

iPod Check : Start the verification operation check of the

iPod verifi cation chip.

iPod V-Play : Transfer to iPod video screen.

Cancel : Transfer to Test Mode Main screen.

Return : Transfer to iPod screen. (left of Figure 2.2.6)

iPod OK/NG

Return

Select the fi rst fi le (start play back)

e

Transfer to Test Mode Main screen by pressing the [MENU]

hard key from the iPod video screen.

2.2.7 LCD Adjustment screen

This screen is used to perform adjustment of LCD.

The displayed contents of the LCD Adjustment screen is

displayed in Figure 2.2.7.

LCD Adjust LCD Adjust

All Auto Flicker

W.B. Au to

DVD W.B. Auto

Video W.B. Aut o

AGC Auto

HPOSI Auto

Return

Figure 2.2.7 LCD Adjustment screen

Key Specifi cation

All Auto : Start Auto Adjustment. (The following fi ve

Auto adjustments are executed continu-

ously)

W.B. Auto : Start the W.B. Auto adjustment.

AGC Auto : Start the AGC Auto adjustment.

DVD W.B. Auto : Start the DVD W.B. Auto adjustment.

HPOSI Auto : Start the HPOSI Auto adjustment.

Video W.B. Auto : Start the Video W.B. Auto adjustment.

Flicker : Transfer to the Flicker Adjustment screen.

Return : Transfer to Test Mode Main screen.

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

Set the DVD wallpaper to color bar with this adjustment

screen.

Write OK /NG

Return

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

[iPod V-Play] key operation specifi cation

A key to play back the Video contents in the iPod with 1 op-

eration.

Following sequence of operation is performed by pressing

the [iPod V-Play] key.

Turn ON the [Video] key in the iPod Source Control

q

screen

Select “Movie” in the Video contents List screen

w

10 model was adjusting the W.B. adjustment and HPOSI

adjustment with the Navigation video, but 11 model will not

perform W.B. adjustment or HPOSI adjustment with the

Navigation video.

2.2.7.1 Flicker Adjustment screen

This screen is used to perform adjustment of the Flicker.

Transfer to this screen also when Tenkey0 on the remote

controller is pressed.

The displayed contents of the Flicker Adjustment screen are

displayed in Figure 2.2.7.1.

21

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

TEST MODE

Register

value

Cancel

OK

Initial

position

: Center

Flicker Adjust

Write OK/NG

Return

Figure 2.2.7.1 Flicker Adjustment screen

Key Specifi cation

Scroll bar : Flicker Adjustment. (The topmost part is MIN

and the lowermost part is MAX.)

Touching an arbitrary part sets a preset value

according to the places.

Cancel : Transfer to the LCD Adjustment screen.

OK : Start the Writing-in operation in the nonvolatile

memory.

Return : Transfer to the LCD Adjustment screen.

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

With the 10 model, fl icker adjustment screen (left of the Fig-

ure 2.2.7.1) was drawn by the M-STAR, but it will be drawn

by the Application Processor (Telechips) for the 11 model.

2.2.8 Tilt Mecha Adjustment screen

This screen is used to perform adjustment of the Panel

Mecha.

The Tilt Mecha Adjustment screen is displayed in Figure

2.2.8.

This adjustment is not performed for the models with “°”

listed in the Panel mechanism column of Table 1.2.1.

Tilt Mecha Adjust Tilt Mecha Adjust

Mecha Adjust

Cancel

Figure 2.2.8 Tilt Mecha Adjustment screen

Key Specifi cation

Mecha Adjust : Start the panel mechanism adjustment.

Cancel : Transfer to Test Mode Main screen.

Return : Transfer to Test Mode Main screen.

Background color will be blue when “Write OK” is dis-

∗

played.

Background color will be red when “Write NG” is dis-

∗

played.

Write OK/NG

Return

NG is displayed in any one of the following conditions: (It

is not written to the nonvolatile memory when NG is dis-

played)

• Failed to write to the nonvolatile memory

• When acquired value of voltage is 0.268V or more during

Open

• When acquired value of voltage is less than 4.160V or

more than 4.376V during Close

In the case of NG, check that the mechanism position ad-

justment jig is properly mounted and restart from the begin-

ning by re-entering the test mode.

2.2.9 Bluetooth screen

Perform check of the communication with the Parrot Mod-

ule, LOOPBACK test (check of the audio line), RF test, and

initialization of the flash memory. Figure 2.2.9 shows the

Bluetooth screen.

This test is not performed for the models with “°” listed in

the BT built-in column of Table 1.2.1.

Bluetooth Parrot Check

Status Displayed Section

Search result display area

Key Specifi cation

Parrot : Start the communication check with the Parrot

Module (notify the result in the Parrot Check

screen)

Loopback : Initiate the LOOPBACK test.

Search (Cancel)

: Initiate the peripheral device search.

Device search is force-quit when this key is

pressed while searching peripheral devices.

Clear : Initialize the fl ash memory and to set “0000” in

PIN Code.

Return : Transfer to previous screen. (Transfer to Test

Mode Main screen while displaying the left

screen of Figure 2.2.9)

Status display specifi cation

Loopback Testing... : The LOOPBACK test is running.

Searching… : Searching peripheral devices.

Search End : End peripheral device search.

Parrot

Loopback

Search

Clear conditions

Clear

Return

Parrot OK/NG

Figure 2.2.9 Bluetooth screen

Return

22

TEST MODE

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

Clear status display specifi cation

Clearing... : Performing initialization of the flash memory

and overwriting the PIN Code setting value.

Clear OK : Initialization of the fl ash memory and overwrit-

ing of the PIN Code setting value have been

successfully completed.

Clear NG : Initialization of the fl ash memory and overwrit-

ing the PIN Code setting value have failed.

Background color will be blue when “Parrot OK” is dis-

∗

played.

Background color will be red when “Parrot NG” is dis-

∗

played.

Audio line check

LOOPBACK test is started when the [Loopback] key is

pressed and “Loopback Testing…” is displayed on the sta-

tus display area.

RF test

Press the [Search] key and check that the peripheral Blue-

tooth devices are searched in the search result display area.

End the search operation when 1 device is detected.

Initialization of fl ash memory

Flash memory is initialized and setting value of PIN Code is

set to “0000” when the [Clear] key is pressed.

It is completed when “Clear OK” is displayed.

If “Clear NG” is displayed, perform from the beginning by

re-entering the test mode.

2.2.10 SW-Touch check screen

Determine the sensitivity of the electrostatic touch key.

The content of SW-Touch check screen is shown in Figure

2.2.10.

This test is not performed for the models with “°” listed in

the Electrostatic touch column of Table 1.2.1.

SW-Touch

Status Displayed Section

Key1

Key2

Key3

Key4

OK

OK

OK

∗∗∗

OK

∗∗∗

∗∗∗

OK

∗∗∗

∗∗∗

OK

∗∗∗

OK

∗∗∗

OK

∗∗∗

Signal

Figure 2.2.10 SW-Touch check screen

Noise

Signal

Key5

OK

∗∗∗

OK

∗∗∗

: Noise result

:

: Noise value

@

Key6

OK

∗∗∗

OK

∗∗∗

Key7

Key8

OK

∗∗∗

∗∗∗

OK

∗∗∗

∗∗∗

ReturnNoise

: Signal result

.

: Signal_ave value

;

OK

OK

:

@

.

;

Key Specifi cation

Noise : Start the Noise test.

Signal : Start the Signal test.

Return : Transfer to Test Mode Main screen.

Status display specifi cation

Push Noise Button

: Display once the preparation of Noise test is completed.

Wait (Please do not touch key.)

: Display during the Noise test. (Do not touch the electro-

static touch key during the test)

Please set JIG & Push Signal button

Display once the preparation of Signal test is completed.

:

Wait : Display during the Signal test.

End : Display once the Signal test is completed.

Noise result/ Signal result display specifi cation

OK : Display when the test result is OK. Background of dis-

play area is blue at this point.

NG : Display when the test result is NG. Background of dis-

play area is red at this point.

: Display until the test result is obtained.

∗∗

Noise value/ Signal_ave value display specifi cation

: Display each value at the end of the test. Display “

∗∗∗

∗∗∗

until the test result is obtained.

Test procedure

• When the [SW-Touch] key in the Test Mode Main screen

is pressed, it will transfer to the SW-Touch check screen

and move the panel to the EJECT position at the same

time.

• Once it is ready for the Noise check, “Push Noise Button”

is displayed in the status display.

• After the [Noise] key is pressed, data of 3000 samples for

the time each Key is not pressed is acquired, and Noise

value = Count Data_Max – Count Data_Min are calculated

for each Key.

“Wait (Please do not touch key.)” is displayed in the sta-

tus display area during the test.

• “OK” is displayed in the Noise result display area for each

Key when the Noise value is 25 or less. “NG” is displayed

in the Noise result display area for each Key when the

Noise value is larger than 25.

• “Please set JIG & Push Signal button” is displayed in the

status display area at the time calculation results are ob-

tained.

• Once “Please set JIG & Push Signal button” is displayed

in the status display area, tester will move the dummy fi n-

ger close to each Key.

”

23

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

TEST MODE

• After pressing the [Signal] key, acquire 100 samples of the

data for each Key, and calculate its average (Signal_ave).

“Wait” is displayed in the status display area during the

test.

• Display “OK” in the Signal result display area for each Key

if the Signal_ave/ Noise≥7.

• Display “NG” in the Signal result display area for each

Key if the Signal_ave/ Noise<7.

Display “End” in the status display area once all the re-

sults for each Key are displayed.

• Make it so that re-test of the Key that was NG as a result

of the Signal test is possible.

The following is the procedure for the re-test.

q Touch the electrostatic touch key to re-test. (Simulta-

neous re-test is possible when there are multiple elec-

trostatic touch keys to re-test.)

w Press [Signal] key. This will start the re-test of the Key

that was NG with the previous Signal test (sampling

numbers, calculation method of values, criteria for

determining OK/NG for the re-test will be same as nor-

mal.)

“Wait” is displayed in the status display area, “∗∗” in

the Signal result display area, and “

” in Signal_ave

∗∗∗

value display area during the re-test.

e “End” is displayed in the status display area and test

result is displayed in the Signal result display area once

the re-test is completed.

• It will transfer to Test Mode Main screen and the panel

is moved to the default position when the [Return] key is

pressed.

2.2.11 Development screen

This is a screen to display the table for multiple key press-

ing specifi cation. Also, make this screen possible to start

from bmp_View.exe.

Figure 2.2.11-A shows the display with the Development

screen (list contents of Table 2.3.2).

Development

Operation

Test Mode ON

Span Changing

Clear DC Offset/Service/Memory/other

Demo Mode ON

Demo Mode OFF

RDS Field Test Mode ON

Opening Screen Customize

Bluetooth Certification Mode ON

Key (Mid)

MENU + ATT + Reset

Eject + NAV + Reset

MENU + AUD+ Reset

Eject + AUD + Reset

MENU + Reset

Eject + Volume Down + Reset

MENU + Volume Down + Reset

NAV + AUD + Reset

Key (Entry)

Eject + SCRN + Reset

Eject + ATT + Reset

MENU + ATT + Reset

MENU + SCRN + Reset

MENU + Reset

Eject + TEL + Reset

MENU + TEL + Reset

Eject + NAV + Reset

ReturnSteering Remotebmp_View.exe

Key Specifi cation

bmp_View.exe

: Startup bmp_View.exe.

Connect the USB memory containing bmp_View.exe.

Steering Remote

: Transfer to steering remote controller screen.

Display this key as inactive for the models with “°”

listed in the Steering Remote column of Table 1.2.1.

Return : Transfer to Test Mode Main screen.

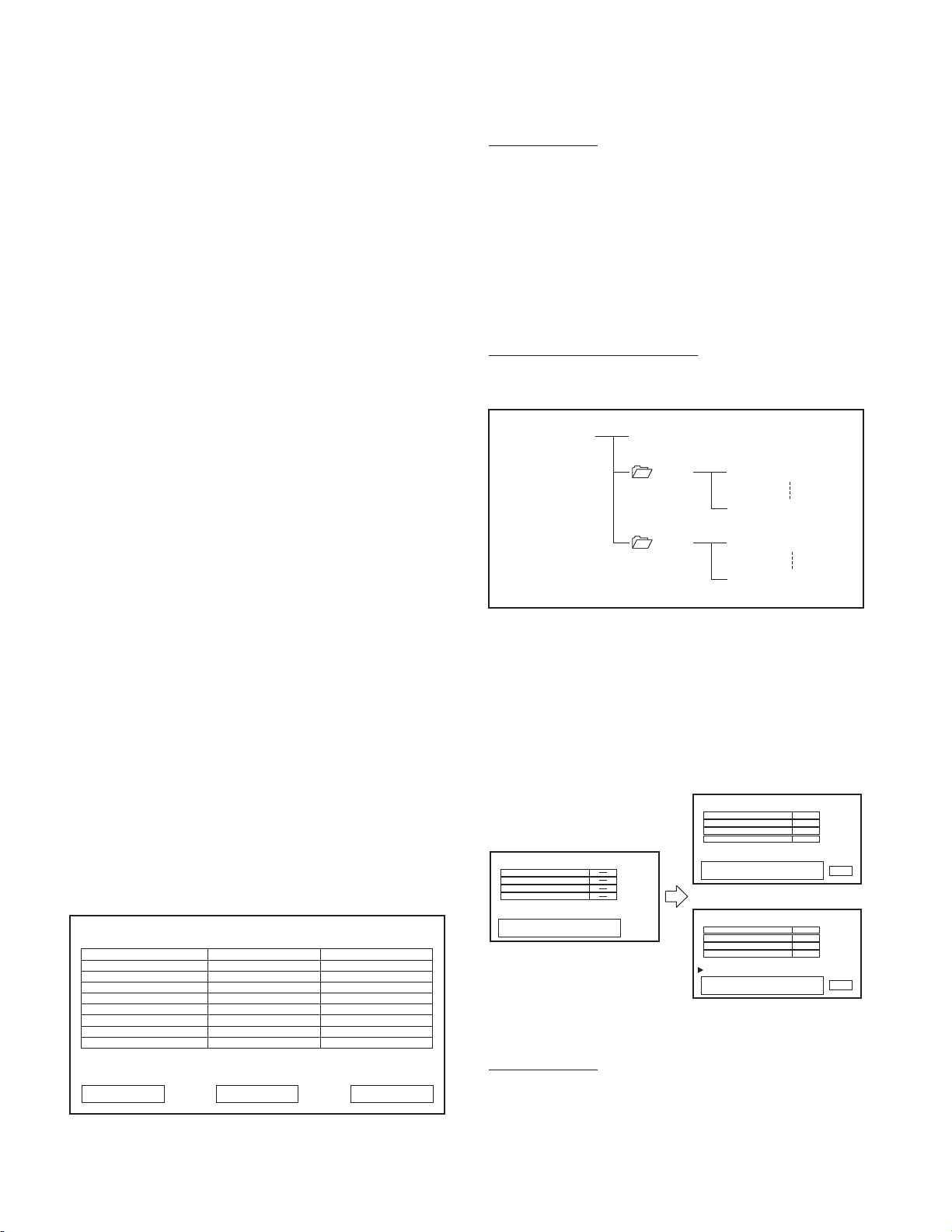

USB memory folder/ fi le structure

Figure 2.2.11-B shows the folder/ fi le structure of the USB

memory containing bmp_View.exe.

USB Memory

Bmp View.exe

/

720

800

aaaaa1.bmp

/

aaaaaM.bmp

/

bbbbb1.bmp

/

bbbbbN.bmp

/

Figure 2.2.11-B USB memory folder/ fi le structure

2.2.12 Steering Remote test screen

Perform the test for Steering Remote.

Figure 2.2.12 shows the display contents of the Steering

Remote test screen.

This test is not performed for the models with “°” listed in

the Steering Remote column of Table 1.2.1.

Steering Remote Test

Steremo Key 1 (Pull up 4.7kΩ)OK

Steremo Key 2 (Pull up 4.7kΩ)

Steremo Key 1 (Pull up 460Ω)

Steremo Key 2 (Pull up 460Ω)

Steering Remote Test

Steremo Key 1 (Pull up 4.7kΩ)

Steremo Key 2 (Pull up 4.7kΩ)

Steremo Key 1 (Pull up 460Ω)

Steremo Key 2 (Pull up 460Ω)

Testing...

Result : OK

Steering Remote Test

Steremo Key 1 (Pull up 4.7kΩ)

Steremo Key 2 (Pull up 4.7kΩ)

Steremo Key 1 (Pull up 460Ω)

Steremo Key 2 (Pull up 460Ω)

Result : NG

Figure 2.2.12 Steering Remote test screen

Key Specifi cation

Return : Transfer to Test Mode Main screen.

All items OK

More than 1 NG

OK

OK

OK

Return

OK

NG

OK

OK

Return

24

Figure 2.2.11-A Development screen

TEST MODE

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

Result display specifi cation

– – – : Test not performed or testing.

OK : Test result OK.

NG : Test result NG.

Test procedure

Connect the test jig while displaying the Test Mode Main

q

screen.

Press the [Steering Remote] key in the Test Mode Main

w

screen. Then, it will transfer screens to the left fi gure of

the Figure 2.2.12, and the Steering Remote test is start-

ed. For determining criteria, refer to the Table 2.2.12.

Test item

Steremo Key1

(Pull up 4.7kΩ)

Steremo Key2

(Pull up 4.7kΩ)

Steremo Key1

(Pull up 460Ω)

Steremo Key2

(Pull up 460Ω)

Pull Up resis-

tance value

4.7kΩ STEREMO_KEY1 1.1~1.4V

4.7kΩ STEREMO_KEY2 1.1~1.4V

460Ω STEREMO_KEY1 3.7~4.0V

460Ω STEREMO_KEY2 3.7~4.0V

Input terminal

Consider OK

input voltage

Table 2.2.12 Steering Remote determining criteria

GPS Reception

: Transfer to GPS Reception screen.

This key is displayed inactive until the Navigation

is started up.

Information

: Transfer to Navi Information screen.

This key is displayed inactive until the Navigation

is started up.

TMC : Transfer to TMC screen.

Unit ID : Transfer to Unit ID screen.

This key is displayed inactive until the Navigation

is started up.

However, this key will be hidden in the release ver-

sion. (Vx.x.0)

Return : Transfer to Test Mode Main screen.

2.2.13.1 Auto Test screen

Perform multiple Navigation test automatically (require tes-

ter input for some part).

Start the test at the same time it transfers to Auto Test

screen.

Figure 2.2.13.1 shows the display contents of the Auto Test

screen.

Once all the test items are completed, screen is trans-

e

ferred according to the result.

2.2.13 Navigation Test screen

Perform test for Navigation.

Figure 2.2.13 shows the display contents of the Navigation

Test screen.

Navigation Test

GPS ReceptionAuto

Information TMC Unit ID

Return

Figure 2.2.13 Navigation Test screen

Key Specifi cation

Auto : Transfer to Auto Test screen.

This key is displayed inactive until the Navigation

is started up.

Navigation Auto Test

1. Navi Voice Test

2. Memory Card Test

3. TMC Test

4. GPS 3D Fix Test

5. Unit ID & Unlock Code

6. Initialize

Message display area

Figure 2.2.13.1 Auto Test screen

Key Specifi cation

Next : Start next test.

Stop : Stop testing.

Return : Transfer to Navigation Test screen.

The above 3 keys will change their display/hide status de-

pending on the test status.

Background color will be blue when all the tests are “OK”.

∗

Background color will be red if there is even 1 item that is

“NG” within the tests.

Result

Result

Result

Result

Result

Result

Stop

Next

Return

25

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

TEST MODE

Result display specifi cation

– : Test not performed.

Progress : Testing.

Pass : Test result OK.

NG : Test result NG.

Details of each test

1. Navi Voice Test

Start: Set the audio selector to Navi audio interrupt sta-

tus, and request 1kHz sine wave output to Garmin.

End: Cancel the Navi audio interrupt status for the audio

selector, and request stop of sine wave output to

Garmin.

2. Memory Card Test

Insert the SD card and perform writing of a fi le/reading of

a fi le/comparison of the written fi le and the read fi le/delet-

ing of the written fi le.

3. TMC Test

Receive the RDS broadcasting station, and check that the

PS of that broadcasting station is “KENWOOD”.

4. GPS 3D Fix

Determine by the GPS information currently receiving and

display the result.

5. Unit ID & Unlock Code

Copy the Unit ID, Unlock Code, and GMA in the uSD to

the NAND memory.

6. Initialize

Transmit initialization command to the Garmin.

2.2.13.2 GPS Reception screen

Start the test at the same time it transfers to GPS Reception

screen.

Figure 2.2.13.2 shows the display contents of the GPS Re-

ception screen.

GPS Reception

1. GPS Reception

progress

GPS Reception

1. GPS Reception

Result

NG : Test result NG.

Background color will be red at this time, and “Result:

NG” is displayed on the message display unit.

Details of test

Determine by the GPS information currently receiving and

display the result.

2.2.13.3 Navi Information screen

Figure 2.2.13.3 shows the display contents of the Navi In-

formation screen.

Navi Information

Navigation S/W

Base Map

Detail Map

Junction View

Figure 2.2.13.3 Navi Information screen

Key Specifi cation

Return : Transfer to Navigation Test screen.

2.2.13.4 TMC screen

Perform the operation check of the TMC Tuner.

Figure 2.2.13.4 shows the display contents of the TMC

screen.

AVN4.1/5.1 System Software

0380

WW Autoroute DEM Basemap

0300

CN North America NT 2010

2010

2010

CN North America NT 2010

Return

TMC Tuner

DW

PS PS information

∗∗∗.∗

MHz

UP

Testing... (CN value)

Message display area (CN value)

Figure 2.2.13.2 GPS Reception screen

Key Specifi cation

Return : Transfer to Navigation Test screen.

Result display specifi cation

pass : Test result OK.

Background color will be blue at this time, and “Re-

sult: OK” is displayed on the message display unit.

26

Return

87.9MHz

RDS SYNC Not SYNC or SYNC

98.1MHz 107.9MHz

Figure 2.2.13.4 TMC screen

Key Specifi cation

UP/DW : TMC Tuner [Seek Up / Down] key.

Return : Transfer to Navigation Test screen.

MHz :

∗∗∗

Key to select the frequency written on the key top.

Return

TEST MODE

DNX4280BT/5180/5280BT/5380/5380M

/5380BT/5580BT/6040EX/6180/6480BT/6980

PS automatic determination when selecting station

Select a station and receive the PS.

q

Turn off the P_ANT and P_CON terminals if the received

w

PS is “RDS_TEST” or “KENWOOD_” (_: Space).

2.2.13.5 Unit ID screen

Copy the Unit ID, Unlock Code, and GMA in the uSD to the

NAND memory.

Prohibit transfer to the Unit ID screen in the release version

(Vx.x.0).

This screen is a screen for designing purposes, so copy

the Unit ID, Unlock Code, and GMA unconditionally to the

NAND memory.

Figure 2.2.13.5 shows the display contents of the Unit ID

screen.

Unit ID Unit ID

Copy

Cancel

Write OK/NG

Return

Figure 2.2.13.5 Unit ID screen

Key Specifi cation

Copy : Start copying Unit ID, Unlock Code, and GMA.

Cancel : Transfer to Navigation Test screen.

Return : Transfer to Navigation Test screen.

2.3 Functional specifi cation

This section describes the test mode specifi cation in each

function.

2.3.1 Display

During the test mode, other than the screen described in

2.2, it is possible to transfer to the screen displayed nor-

mally, such as Source Control screen, Audio Control screen,

Setup screen, etc.

(Press [Direct Select] key in the Test Mode Main screen to

transfer)

Do not perform Touch cursor display on the 11 Visual Mid/

Entry model.

2.3.2 Key

Even in the Test mode, the specifi cations of the hard key

shall be the same as while in normal operation. (Except for

[MENU] key)

For your reference, the multiple pressing specifi cations of

the key are described in Table 2.3.2.

(For original documents of multiple key pressing specifi ca-

tion, refer to the “11 Function specifi cation_hard key”)

Operation

Test Mode ON MENU + ATT + Reset

Span switching Eject + NAV + Reset Eject + ATT + Reset

DC Offset/ Service/

Memory Other Clear

Retailer mode: ON Eject + AUD + Reset

Retailer mode: OFF MENU + Reset MENU + Reset

RDS test drive

mode ON

Opening screen

customization

Bluetooth authenti-

cation mode ON

Table 2.3.2

Due to the restriction of the electrostatic touch sensor IC

∗

MENU + AUD + Reset

Eject + Volume Down

MENU + Volume Down

NAV + AUD + Reset Eject + NAV + Reset

(for reference) Multiple pressing key specifi cations

Multiple press key

Mid Entry

Eject + SCRN + Reset

MENU + ATT + Reset

MENU + SCRN + Reset

+ Reset

+ Reset

Eject + TEL + Reset

MENU + TEL + Reset

(PSoC), perform multiple press + Reset operation as de-