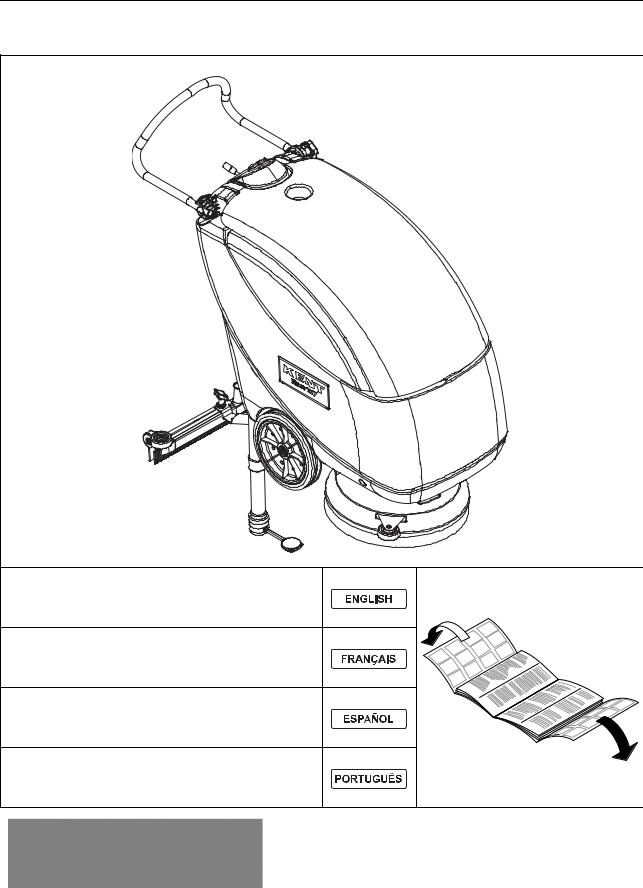

Kent Euroclean Razor SV17 Instruction Manual

Razor SV17

INSTRUCTIONS FOR USE |

KENT model: |

908 7112 020 |

INSTRUCTIONS D’UTILISATION |

Modèle KENT: |

908 7112 020 |

INSTRUCCIONES DE USO |

Modelo KENT: |

908 7112 020 |

INSTRUÇÕES DE USO |

Modelo KENT: |

908 7112 020 |

909 6309 000(1)2006-01 |

B |

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

4 |

|

|

|

|

|

6 |

|

|

|

1 |

5 |

|

|

|

|

|

|

S311238 |

C |

|

|

|

|

|

|

31 |

6 |

|

19 |

2 |

|

|

|

|

|

|

30 |

|

|

|

|

|

32 |

|

|

|

|

17 |

|

|

|

|

16 |

|

|

|

|

3 |

28 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

29 |

|

|

|

21 |

27 |

|

|

|

|

26 |

|

|

|

|

|

|

|

|

|

18 |

|

|

25 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

5a |

22 |

|

|

|

|

|

|

|

|

|

|

5b |

12 |

|

|

|

|

|

|

|

24 |

|

|

4 |

7 |

|

23 |

10 |

9 |

15 |

||

|

|

|

|

|

|

|

|

|

13 |

11 |

|

|

|

8 |

15 |

|

|

|

|

14 |

|

||

|

|

|

|

|

|

|

|

|

|

|

13 |

23a |

|

|

|

23b |

14 |

|

|

|

|

||

|

|

|

|

|

S311239 |

|

|

|

|

|

909 6309 000(1)2006-01 |

D |

|

|

|

|

|

|

S311240 |

E |

|

|

4 |

|

|

|

3 |

|

|

|

1 |

|

|

|

2 |

|

|

|

6 |

5 |

9 |

|

1 |

1 2 |

7 |

||

|

|

|

6 |

|

|

|

S311226 |

F |

|

|

|

|

|

|

7 |

|

|

|

9 |

|

|

|

10 |

|

|

|

S311227 |

INSTRUCTIONS FOR USE |

|

INTRODUCTION ................................................................................................................................... |

2 |

MANUAL PURPOSE AND CONTENTS ........................................................................................................... |

2 |

TARGET ........................................................................................................................................................... |

2 |

HOW TO KEEP THIS MANUAL ....................................................................................................................... |

2 |

IDENTIFICATION DATA ................................................................................................................................... |

2 |

OTHER REFERENCE MANUALS .................................................................................................................... |

2 |

SPARE PARTS AND MAINTENANCE ............................................................................................................. |

2 |

CHANGES AND IMPROVEMENTS ................................................................................................................. |

2 |

SAFETY ................................................................................................................................................. |

3 |

SYMBOLS ......................................................................................................................................................... |

3 |

GENERAL INSTRUCTIONS ............................................................................................................................. |

3 |

UNPACKING ......................................................................................................................................... |

4 |

MACHINE DESCRIPTION ..................................................................................................................... |

5 |

OPERATION CAPABILITIES ............................................................................................................................ |

5 |

CONVENTIONS ................................................................................................................................................ |

5 |

DESCRIPTION ................................................................................................................................................. |

5 |

TECHNICAL DATA ........................................................................................................................................... |

6 |

ELECTRICAL FUSES ....................................................................................................................................... |

6 |

ACCESSORIES/OPTIONS ............................................................................................................................... |

6 |

USE ........................................................................................................................................................ |

7 |

BATTERY CHECK/SETTING ON A NEW MACHINE ...................................................................................... |

7 |

(WET OR GEL) BATTERY SETTING, INSTALLATION AND CHARGING ...................................................... |

7 |

BEFORE START-UP ........................................................................................................................................ |

8 |

MACHINE START AND STOP ......................................................................................................................... |

8 |

MACHINE OPERATION (SCRUBBING/DRYING) ........................................................................................... |

9 |

MACHINE TRANSPORT/PARKING ................................................................................................................. |

9 |

TANK EMPTYING ............................................................................................................................................. |

9 |

AFTER USING THE MACHINE ...................................................................................................................... |

10 |

RECOVERY WATER TANK REMOVAL ......................................................................................................... |

10 |

MACHINE LONG INACTIVITY ....................................................................................................................... |

10 |

FIRST PERIOD OF USE ................................................................................................................................ |

10 |

MAINTENANCE .................................................................................................................................. |

10 |

SCHEDULED MAINTENANCE TABLE .......................................................................................................... |

11 |

SQUEEGEE CLEANING ................................................................................................................................ |

11 |

SQUEEGEE BLADE CHECK AND REPLACEMENT ..................................................................................... |

11 |

BRUSH CLEANING ........................................................................................................................................ |

12 |

TANK AND VACUUM GRID CLEANING ........................................................................................................ |

12 |

SOLUTION FILTER CLEANING ..................................................................................................................... |

12 |

MACHINE SPEED ADJUSTMENT ................................................................................................................. |

12 |

CHARGING THE BATTERIES ....................................................................................................................... |

13 |

FUSE CHECK/REPLACEMENT ..................................................................................................................... |

13 |

TROUBLESHOOTING ........................................................................................................................ |

14 |

SCRAPPING ........................................................................................................................................ |

14 |

Razor SV17 — 909 6309 000(1)2006-01 |

1 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

INTRODUCTION

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the customer with all necessary information to use the machine properly in a safe an autonomous way. It contains information about technical data, operation, machine inactivity, maintenance, spare parts and safety conditions.

Before carrying out any procedure on the machine, the operators and qualified technicians must read this Manual carefully. Contact an authorized KENT Service Center in case of doubts concerning the interpretation of the instructions and for any further information.

TARGET

This Manual is intended for operators and technicians qualified to perform the machine maintenance.

The operators must not carry out operations reserved for qualified technicians. KENT will not be answerable for damages coming from the non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Instructions for Use Manual must be kept near the machine, inside an adequate case, away from liquids and other substances that can cause damage to it.

IDENTIFICATION DATA

The machine serial number and model are shown on the label and can be read from the outside (1, Fig. C).

The machine model year is shown after the Date Code on the serial plate (A06 means January 2006).

This information is useful when requiring machine spare parts. Use the following table to write down the machine identification data for any further reference.

MACHINE model ...........................................................

MACHINE serial number ...............................................

OTHER REFERENCE MANUALS

–Electronic Battery Charger Manual (if equipped), which is to be considered as integral part of this Manual.

–Spare Parts List, supplied with the machine.

–Service Manual (that can be consulted at KENT Service Centers).

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures must be carried out by qualified personnel or by KENT Service Centers. Only original spare parts and accessories must be used.

Call KENT for service or to order spare parts and accessories, specifying the machine model and serial number.

CHANGES AND IMPROVEMENTS

KENT constantly improves its products and reserves the right to make changes and improvements at its discretion without being obliged to apply such benefits to the machines previously sold.

Any change and/or addition of accessories must be approved and performed by KENT.

2 |

Razor SV17 — 909 6309 000(1)2006-01 |

INSTRUCTIONS FOR USE

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary precautions to safeguard people and property. The operator's cooperation is essential in order to prevent injury. No accident prevention program is effective without the total cooperation of the person responsible for the machine operation. Most of the accidents that may occur in a factory, while working or moving around, are caused by failure to comply with the simplest rules for exercising prudence. A careful and prudent operator is the best guarantee against accidents and is essential for successful completion of any prevention program.

SYMBOLS

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people.

CAUTION!

It indicates a caution or a remark related to important or useful functions. Pay particular attention to the paragraphs marked by this symbol.

NOTE

It indicates the necessity to refer to the Instructions for Use Manual before performing any operation.

GENERAL INSTRUCTIONS

Specific warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

–Disconnect the batteries before performing any maintenance/repair procedure.

–This machine must be used by properly trained and authorized personnel only. Children or disabled people cannot use this machine.

–When using lead (WET) batteries, keep sparks, flames and smoking materials away from the batteries. During the normal operation explosive gases are released.

–Do not wear jewels when working near electrical components.

–Do not operate the machine near toxic, dangerous, inflammable and/or explosive powders, liquids or vapours.

–When using lead (WET) batteries, battery charging produces highly explosive hydrogen gas. During battery charging, remove the recovery water tank and perform this operation in well-ventilated areas and away from naked flames.

WARNING!

–Carefully read all the instructions before carrying out any maintenance/repair procedure.

–Before connecting the battery charger to the electrical mains, be sure that frequency and voltage indicated in the related Manual correspond to the mains voltage.

–To reduce the risk of fire, electric shock, or injury, do not leave the machine unattended when it is plugged in. Unplug the machine from the outlet when not in use and before servicing.

–To avoid electric shock, do not expose to rain. Store the machine indoors.

–Do not allow to be used as a toy. Close attention is necessary when used near children.

–Use only as described in this Manual. Use only KENT's recommended accessories.

–Do not use with damaged power supply cable or plug. If the machine is not working as it should, has been damaged, left outdoors or dropped into water, return it to the Service Center.

–If the supply cable or the plug is worn or damaged, it needs to be replaced at the Service Center.

–Do not pull or carry the machine by the supply cable; never use the power supply cable as a handle. Do not close a door on the supply cable, or pull the supply cable around sharp edges or corners. Do not run the machine on the supply cable. Keep the supply cable away from heated surfaces.

–When using lead (WET) batteries, don't smoke while charging the batteries.

–Take all necessary precautions to prevent hair, jewels and loose dresses from being caught by the machine moving and vacuuming devices.

–Do not work under the lifted machine without supporting it with safety stands.

Razor SV17 — 909 6309 000(1)2006-01 |

3 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

–Do not leave the machine unattended without being sure that the machine cannot move independently.

–Do not use the machine on slopes with a gradient exceeding the specifications.

–Do not wash the machine with direct or pressurized water jets, or with corrosive substances.

–Do not use the machine in particularly dusty areas.

–While using this machine, take care not to cause damage to people.

–Do not put any can containing fluids on the machine.

–The storage temperature must be between +32°F and +104°F (0°C and +40°C).

–The machine operating temperature must be between +32°F and +104°F (0°C and +40°C).

–The humidity must be between 30% and 95%.

–Always protect the machine against the sun, rain and bad weather, both under operation and inactivity condition.

–Do not use the machine as a means of transport.

–Do not allow the brush to operate while the machine is stationary to avoid damaging the floor.

–In case of fire, possibly use a powder fire extinguisher, not a water one.

–Do not bump into shelves or scaffoldings, particularly where there is a risk of falling objects.

–Do not tamper with the machine safety guards and follow the ordinary maintenance instructions scrupulously.

–Do not remove or modify the plates affixed to the machine.

–In case of machine malfunctions, ensure that these are not caused by a lack of maintenance. Otherwise, request assistance from the authorized personnel or from an authorized Service Center.

–If parts must be replaced, require ORIGINAL spare parts from a Dealer or Authorized Retailer.

–To ensure the proper and safe operation of the machine, have the scheduled maintenance, detailed in the relevant chapter of this Manual, performed by the authorized personnel or an authorized Service Center.

–The machine must be disposed of properly, because of the presence of toxic-harmful materials (batteries, etc.), which are subject to standards that require disposal in special centers (see Scrapping chapter).

–If the machine is used according to the instructions, the

vibrations do not cause dangerous situations. The machine vibration level is less than 98.42 in/s2 (2.5 m/s2) (98/37/EEC - EN 1033/1995).

–Do not allow any object to enter into the openings. Do not use the machine if the openings are clogged. Always keep the openings free from dust, hairs and any other foreign material which could reduce the air flow.

–This machine cannot be used on roads or public streets.

–Pay attention during the machine transfers when temperature is below freezing point. The water in the recovery tank or in the hoses could freeze and seriously damage the machine.

–Use only brushes and pads supplied with the machine or specified in this Manual. Using other brushes or pads could reduce safety.

–When lead (WET) batteries are installed on the machine, do not tilt the machine more than 30° from the horizontal plane to prevent the highly corrosive acid from leaking out of the batteries. If the machine must be tilted to perform any maintenance operation, remove the batteries.

UNPACKING

To unpack the machine carefully follow the instructions on the packing.

When the machine is delivered, check that the packing and the machine were not damaged during transportation. In case of visible damages, keep the packing and have it checked by the Carrier that delivered it. Call the Carrier immediately to fill in a damage claim.

Please check that the following items have been supplied with the machine:

1.Technical documents:

–Scrubber-dryer Instructions for Use Manual

–Electronic battery charger manual (if equipped).

–Scrubber-dryer Spare Parts List

2.No.1 40A lamellar fuse

3.No.2 battery panels

4.(Only for machine supplied without batteries)

–No.1 battery jump cable

–No.4 battery terminal caps

4 |

Razor SV17 — 909 6309 000(1)2006-01 |

INSTRUCTIONS FOR USE

MACHINE DESCRIPTION

OPERATION CAPABILITIES

This scrubber-dryer is used to clean (scrubbing and drying) smooth and solid floors, in civil or industrial environment, under safe operation conditions by a qualified operator. The scrubber-dryer cannot be used for moquette and carpet cleaning.

CONVENTIONS

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to say with the hands on the handlebar (2, Fig. C).

DESCRIPTION

Control panel (See Fig. B)

1.Control panel

2.Charged battery warning light (green)

3.Semi-discharged battery warning light (yellow)

4.Discharged battery warning light (red)

5.Brush/pad switch

6.Vacuum switch

Exterior rear view (See Fig. C)

1.Serial number plate/technical data

2.Handlebar

3.Handlebar inclination adjusting knob

4.Solution flow control lever

5a. Solution flow control lever ECO position (water "economy" usage, for a washing autonomy of 70-80 minutes).

5b. Maximum solution flow

5.Recovery water tank cover

6.Rear support wheel for transport/parking

7.Central wheels on fixed axle

8.Brush/pad

9.Brush/pad cover

10.Squeegee

11.Squeegee fixing handwheels

12.Front squeegee blade

13.Rear squeegee blade

14.Squeegee blade fixing springs

15.Recovery water drain hose

16.Recovery water drain hose bracket

17.Solution drain valve

18.Squeegee lifting/lowering lever

19.Solution filter

20.Battery charger-electrical mains connecting cable (optional)

21.Squeegee vacuum hose

22.Transport/parking device

23a. Transport/parking device activated

23b. Transport/parking device deactivated

23.Transport/parking device positioning pin

24.Electrical component box

25.Battery charger (optional)

26.Battery charger warning lights (optional)

27.Battery installation diagram

28.Battery connector (models without on-board battery charger)

29.Brush/pad support (activated)

30.Recovery water tank

31.Solution tank

Under-tank front view (See Fig. J)

1.Recovery water tank cover (open)

2.Recovery water tank cover gasket

3.Brush/pad support (activated)

4.Recovery water tank

5.Solution tank

6.Vacuum grid with automatic shut-off float

7.Recovery water drain hole

8.Vacuum system motor

9.Brush/pad motor

10.Batteries

11.Battery installation diagram

12.Cover with brush/pad-holder coupling pin

13.Machine speed adjusting screw

14.Brush

15.Pad-holder

16.Pad

17.Screw

18.Compensation hole

19.Cover stand (applied)

Razor SV17 — 909 6309 000(1)2006-01 |

5 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

TECHNICAL DATA

General |

Values |

|

Cleaning width |

17.0 in (430 mm) |

|

|

|

|

Machine width (without squeegee) |

22.4 in (570 mm) |

|

|

|

|

Minimum machine length with adjustable |

36.6 in (930 mm) |

|

handlebar |

||

|

||

|

|

|

Minimum machine height with adjustable |

40.2/44.7 in |

|

handlebar |

(1,020/1,135 mm) |

|

|

|

|

Squeegee width |

28.3 in (720 mm) |

|

|

|

|

Machine weight (with batteries, battery |

233.70 lbs (106 Kg) |

|

charger and brush) |

||

|

||

|

|

|

Central (fixed axle) wheel diameter |

9.8 in (250 mm) |

|

|

|

|

Brush/pad diameter |

17.0 in (430 mm) |

|

|

|

|

Wheel pressure on the ground |

<0.5 N/mm2 |

|

Brush/pad pressure on the ground (with full |

50,6 lbs (23 Kg) |

|

tank) |

||

|

||

|

|

|

Battery compartment size (length x width x |

13.8 x 13.8 x 10.2 in |

|

height) |

(350 x 350 x 260 mm) |

|

|

|

|

|

|

|

Performance |

Values |

|

Vacuum |

41.5 in H2O |

|

(1,055 mm H2O) |

||

|

||

Sound pressure level |

67 dB (A) |

|

|

|

|

Vacuum system motor power |

330 W |

|

|

|

|

Brush/pad motor power |

520 W |

|

|

|

|

Battery voltage |

24 V |

|

|

|

|

Standard batteries |

12 V, 50 Ah |

|

|

|

|

Clean water tank capacity |

8 gal (31 liters) |

|

|

|

|

Recovery water tank capacity |

7.9 gal (30 liters) |

|

|

|

Wiring diagram (See Fig. L)

CH1: |

Battery charger |

C1: |

Battery charger connector |

EB1: |

Electronic board (CF BA430) |

EB2: |

Electronic board led (CF BALED) |

ES1: |

Brush/pad switch |

ES2: |

Vacuum switch |

ES3: |

Battery charger relay |

EV1: |

Water solenoid valve |

F1: |

Brush fuse (40A) |

F2: |

Vacuum fuse (40A) |

F3: |

Solenoid valve and electronic board fuse (5A) |

IS1: |

Negative insulator |

M1: |

Brush/pad motor |

M2: |

Vacuum system motor |

SW1: |

Brush/pad switch |

SW2: |

Vacuum switch |

Colour code

BK: Black

BU: Blue

BN: Brown

GN: Green

GY: Grey

OG: Orange

PK: Pink

RD: Red

VT: Violet

WH: White

YE: Yellow

ELECTRICAL FUSES

The following fuses are located under the cover (1, Fig. I):

–Brush (40A): (2, Fig. I)

–Vacuum (40A): (3, Fig. I)

–Solenoid valve and electronic board (5A): (4, Fig. I)

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be equipped with the following accessories/options, according the machine specific use:

–Brushes/pads of different materials;

–Electronic battery charger.

For further information concerning the above-mentioned optional accessories, contact an authorized Retailer.

6 |

Razor SV17 — 909 6309 000(1)2006-01 |

INSTRUCTIONS FOR USE

USE

WARNING!

On some points of the machine there are some adhesive plates indicating:

–DANGER

–WARNING

–CAUTION

–NOTE

While reading this Manual, the operator must pay particular attention to the symbols shown on the plates.

Do not cover these plates for any reason and immediately replace them if damaged.

BATTERY CHECK/SETTING ON A NEW MACHINE

WARNING!

The electric components of this machine can be seriously damaged if batteries are either installed or connected improperly. The batteries must be installed by qualified personnel only.

Check the batteries for damage before installation.

Handle the batteries with great care.

Install the battery terminal caps supplied with the machine.

The machine requires two 12V batteries, connected according to the diagram (28, Fig. C).

The machine can be supplied in one of the following modes:

a)GEL batteries already installed and ready to be used.

–Start the machine by pressing the brush/pad and vacuum switches (5 and 6, Fig. B). If the green warning light (2, Fig. B) turns on, the batteries are charged.

If the yellow or red warning light (3 or 4, Fig. B) turns on, it is necessary to charge the batteries before using the machine (see the procedure in the Maintenance chapter).

(b)Without battery

–Buy appropriate batteries [See the Technical Data paragraph and the diagram (28, Fig. C)].

For the battery choice and installation, apply to qualified battery retailers.

–Perform setting for (WET) or (GEL) batteries, then install the batteries on the machine and charge them, according to the procedure shown in the next paragraph.

(WET OR GEL) BATTERY SETTING, INSTALLATION AND CHARGING

The electronic board of the machine is to be set according to the type of batteries chosen, lead (WET) or gel (GEL). Proceed as follows:

Machine setting

1.Ensure that the battery connector (29, Fig. C), if equipped, is disconnected.

2.The machine factory setting is for GEL batteries; if this setting corresponds to the type of batteries bought, go to step 6. Otherwise, carry out steps 3, 4 and 5 too.

3.Remove the screws (5, Fig. I) and carefully pull out the electrical component box cover (1).

4.Turn the microswitch (6, Fig. I) to WET position.

WARNING!

Do not move the adjacent switch (7, Fig. I).

5.Reinstall the electrical component box cover (1, Fig. I) and tighten the screws (5).

Battery installation

6.Disconnect the vacuum hose (22, Fig. C) from the squeegee (11).

7.Disconnect the recovery water drain hose (16, Fig. C) from the bracket (17).

8.Open the cover (6, Fig. C) and apply the cover stand (19, Fig. J).

9.Grasp the recovery water tank (1, Fig. H) in the area (2) and slightly raise it.

10.Disconnect the vacuum hose (3) from the tank, then remove the tank (1) with the hoses (4) and (5).

11.Install the batteries on the machine according to the diagram (28, Fig. C).

12.Reinstall the tank (1, Fig. H) by carrying out steps 6 to 10 in the reverse order.

Battery charging

13.Charge the batteries (see the relevant procedure in the Maintenance chapter).

Razor SV17 — 909 6309 000(1)2006-01 |

7 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

BEFORE START-UP

Squeegee installation

1.Install the squeegee (11, Fig. C) and fix it by means of the handwheels (12), then connect the vacuum hose (22) to the squeegee.

Solution tank filling

2.Fill the solution tank (5, Fig. J) with a solution suitable for the work to be carried out.

Do not fill the solution tank completely, leave few inches from the edge.

Always follow the dilution instructions on the label of the chemical product used to prepare the solution.

The solution temperature must not exceed 104°F (40°C).

CAUTION!

Use only low-foam and non-flammable liquid detergents, intended for automatic scrubber applications.

NOTE

Use either the brush (14, Fig. J) or the pad-holder (15) according to the type of floor to be cleaned.

Brush or pad-holder installation

3.Insert the positioning pin (24, Fig. C) and deactivate the transport/parking device (23b).

4.Lift the brush/pad cover (10, Fig. C) by prying the handlebar (2).

5.Place the brush (14, Fig. J) or the pad-holder (15) under the cover.

6.Lower the cover (10, Fig. C) by means of the handlebar

(2).

7.Hook the brush/pad-holder by pressing the brush/pad switch (5, Fig. B) for a few seconds.

If the hooking operation is difficult, manually rotate the brush/pad-holder counter-clockwise (Fig. K).

Adjustments

8.Using the knob (3, Fig. C), adjust the handlebar (2) to the most comfortable position.

MACHINE START AND STOP

Machine start

1.Prepare the machine according to the procedure shown in the previous paragraph.

2.Lower the squeegee (11, Fig. C) by means of the lever (19).

3.Turn the solution flow control lever (4, Fig. C) to one of the following positions, according to the type of cleaning to be carried out:

–ECO system: When the lever (4) is in the “ECO” position (5a), the machine works in a special condition of programmed water "economy" usage; as the water flow is set and constant, the machine can work with a washing autonomy of 70-80 minutes [0.08 gal/min (0.3 liters/min) average].

–Variable system: When the lever is turned to the left (variable flow), it is possible to increase the capacity up to 0.26 gal/min (1 liter/min).

During machine operation, it is not possible to close completely the water flow to the brushes.

4.While keeping one hand on the handlebar (2, Fig. C), start the machine by turning the brush/pad switch and the vacuum switch (5 and 6, Fig. B) to "I".

NOTE

If the green warning light (2, Fig. B) turns on, the machine is ready to be used.

If the yellow or red warning light (3 or 4, Fig. B) turns on, it is necessary to charge the batteries (see the procedure in the Maintenance chapter).

Machine stop

5.Turn the brush/pad switch and the vacuum switch (5 and 6, Fig. B) to “0”.

6.Lift the squeegee by means of the lever (19, Fig. C).

7.Insert the positioning pin (24, Fig. C) and lift the brush/pad by activating the transport/parking device (23a).

8 |

Razor SV17 — 909 6309 000(1)2006-01 |

INSTRUCTIONS FOR USE

MACHINE OPERATION (SCRUBBING/DRYING)

1.Start the machine according to the procedure shown in the previous paragraph.

2.While keeping both hands on the handlebar (2, Fig. C), move the machine and start scrubbing/drying the floor.

CAUTION!

To avoid damaging the floor surface:

–Do not use the brush/pad without the solution.

–When the machine is stopped, stop the brush/pad by pressing the switch (5, Fig. B).

CAUTION!

Before lifting the brush/pad, stop its rotation by pressing the switch (5, Fig. B).

3.If necessary, adjust the solution flow sent to the brushes by turning the lever (4, Fig. C).

Battery discharge during operation

4.Until the green warning light (2, Fig. B) stays on, the batteries allow the machine to operate normally.

When the green warning light (2) turns off and the yellow

(3) and red (4) warning lights turn on in sequence, it is necessary to charge the batteries.

CAUTION!

Do not use the machine with discharged batteries, to avoid damaging the batteries and reducing their life.

Machine speed adjustment

5.The machine speed varies according to the type of floor to be cleaned and the choice of using the brush or the pad.

If necessary, it is possible to adjust the machine speed by following the relevant procedure in the Maintenance chapter.

MACHINE TRANSPORT/PARKING

To transport/park the machine, proceed as follows.

1.Turn the brush/pad switch and the vacuum switch (5 and 6, Fig. B) to “0”.

2.Lift the squeegee by means of the lever (19, Fig. C).

3.Grasp the handlebar (2, Fig. C) and slightly lower it until the rear wheel (7, Fig. C) comes into contact with the floor (Fig. D). While holding the machine in this position, push it to the transport/parking area.

4.After finishing the work, in order not to drag the brush/pad on the floor and leave wet marks, remove the brush/pad from the deck by using the release device (for the procedure, see the After Using The Machine paragraph), then place it on the support (3, Fig. J).

TANK EMPTYING

An automatic float shut-off system (6, Fig. J) stops the vacuum system when the recovery water tank (4) is full. The vacuum system deactivation is signalled by a sudden increase in the vacuum system motor noise frequency. When the recovery water tank (4, Fig. J) is full, empty it according to the following procedure.

Recovery water tank emptying

1.Stop the machine by pressing the brush/pad and vacuum switches (5 and 6, Fig. B).

2.Lift the squeegee by means of the lever (19, Fig. C).

3.Drive the machine to the appointed disposal area.

4.Insert the positioning pin (24, Fig. C) and lift the brush/pad by activating the transport/parking device (23a).

5.Empty the recovery water tank by means of the drain hose (16, Fig. C).

Then, rinse the tank with clean water.

Solution tank emptying

6.Carry out steps 1 to 4.

7.Empty the solution tank by means of the drain valve (18, Fig. C).

Then, rinse the tank with clean water.

Razor SV17 — 909 6309 000(1)2006-01 |

9 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

AFTER USING THE MACHINE

After scrubbing-drying, before leaving the machine:

1.Disconnect the brush/pad-holder as follows:

– Lift the brush/pad, turn the brush/pad switch (5, Fig. B) to “I” and, after a few seconds, to “0”, thus releasing the brush/pad-holder.

2.Empty the tanks (4 and 5, Fig. J) according to the procedure shown in the previous paragraph.

3.Perform the daily maintenance operations (see the Maintenance chapter).

4.Store the machine in a clean and dry place, with the brush/pad and the squeegee lifted or removed.

RECOVERY WATER TANK REMOVAL

To check or charge the lead (WET) batteries, or to perform other operations, it may be necessary to remove the recovery water tank (1, Fig. H) according to the following procedure.

1.Empty the recovery water tank (4, Fig. J) according to the procedure shown in the relevant paragraph.

2.Drive the machine on a level ground.

3.Make sure that the switches (5 and 6, Fig. B) are turned to "0".

4.Disconnect the vacuum hose (22, Fig. C) from the squeegee (11).

5.Disconnect the recovery water drain hose (16, Fig. C) from the bracket (17).

6.Open the cover (6, Fig. C) and apply the cover stand (19, Fig. J).

7.Grasp the recovery water tank (1, Fig. H) in the area (2) and slightly raise it.

8.Disconnect the vacuum hose (3, Fig. H) from the tank, then remove the tank (1) with the hoses (4) and (5).

MACHINE LONG INACTIVITY

If the machine is not going to be used for more than 30 days, proceed as follows:

1.Perform the operations described in the After Using The Machine paragraph.

2.Remove the recovery water tank (1, Fig. H) according to the procedure shown in the previous paragraph, then disconnect the battery negative terminals (10, Fig. J).

3.Reinstall the recovery water tank (1, Fig. H).

4.Store the machine in a clean and dry place.

FIRST PERIOD OF USE

After the first period of use (first 8 hours) it is necessary to check the fixing and connecting parts of the machine for proper tightening. Check the visible parts for integrity and leakage.

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance. The following chart provides the scheduled maintenance. The intervals shown may vary according to particular working conditions, which are to be defined by the person in charge of the maintenance.

WARNING!

Maintenance operations must be carried out with the machine switched off and the batteries/battery charger cable disconnected. Moreover, carefully read all the instructions in the Safety chapter.

All scheduled or extraordinary maintenance operations must be performed by qualified personnel, or by an authorized Service Center.

This Manual describes only the easiest and most common maintenance procedures.

NOTE

For other maintenance procedures contained in the scheduled maintenance table, see the specific Service Manual that can be consulted at any Service Center.

10 |

Razor SV17 — 909 6309 000(1)2006-01 |

INSTRUCTIONS FOR USE

SCHEDULED MAINTENANCE TABLE

|

Daily or after |

|

Every six |

|

|

Operation |

using the |

Weekly |

Yearly |

||

months |

|||||

|

machine |

|

|

||

|

|

|

|

||

|

|

|

|

|

|

Squeegee cleaning |

|

|

|

|

|

Brush cleaning |

|

|

|

|

|

Tank and vacuum grid cleaning |

|

|

|

|

|

Squeegee blade check and replacement |

|

|

|

|

|

Solution filter cleaning |

|

|

|

|

|

Battery charger |

|

|

|

|

|

WET battery fluid level check |

|

|

|

|

|

Screw and nut tightening check |

|

|

(1) |

|

|

Brush motor carbon brush check or replacement |

|

|

|

(2) |

|

Vacuum system motor carbon brush check or replacement |

|

|

|

(2) |

|

|

|

|

|

|

(1): And after the first 8 working hours

(2): This maintenance operation must be performed by KENT authorized Service Center.

SQUEEGEE CLEANING

NOTE

The squeegee must be clean and its blades must be in good conditions in order to get a good drying.

CAUTION!

It is advisable to use protective gloves when cleaning the squeegee because there may be cutting debris.

1.Drive the machine on a level ground.

2.Make sure that the switches (5 and 6, Fig. B) are turned to "0".

3.Lower the squeegee by means of the lever (19, Fig. C).

4.Disconnect the vacuum hose (22, Fig. C) from the squeegee.

5.Loosen the handwheels (12, Fig. C) and remove the squeegee (11).

6.Wash and clean the squeegee. In particular, clean the compartments (1, Fig. E) and the vacuum hole (2) from dirt and debris.

7.Check the front blade (3, Fig. E) and the rear blade (4) for integrity, cuts and tears; otherwise replace them (according to the procedure shown in the next paragraph).

8.Assemble in the reverse order of disassembly.

SQUEEGEE BLADE CHECK AND REPLACEMENT

1.Clean the squeegee according to the procedure shown in the previous paragraph.

2.Check that the edges of the front (5, Fig. E) and rear blades (12) lay down on the same level, along all their length; otherwise adjust their height according to the following procedure:

–Remove the fixing springs (6) and adjust the front blade (3) and the rear blade (4).

–Reinstall the fixing springs on the properly adjusted front and rear blades.

3.Check the front blade (3, Fig. E) and the rear blade (4) for integrity, cuts and tears; otherwise replace them according to the following procedure. Check that the front corner (9) of the rear blade is not worn; otherwise, overturn the blade to replace the worn corner with the other one (7), provided that it is not worn. If the other corner is worn too, replace the blade according to the following procedure:

–Remove the fixing springs (6) and replace (or overturn) the rear blade (4).

–Reinstall the fixing springs on the properly adjusted front and rear blades.

4.Reinstall the squeegee (11, Fig. C) and screw down the handwheels (12).

5.Connect the vacuum hose (22, Fig. C) to the squeegee (11).

Razor SV17 — 909 6309 000(1)2006-01 |

11 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

BRUSH CLEANING

NOTE

It is advisable to use protective gloves when cleaning the brush because there may be cutting debris.

1.Remove the brush from the machine, according to the procedure shown in the Use chapter.

2.Clean and wash the brush with water and detergent.

3.Check the brush bristles for integrity and wear; if necessary, replace the brush.

TANK AND VACUUM GRID CLEANING

1.Drive the machine to the appointed disposal area.

2.Make sure that the switches (5 and 6, Fig. B) are turned to "0".

3.Lift the cover (1, Fig. J) and apply the cover stand (19, Fig. J), then clean and wash the cover, the tanks (4 and

5) and the vacuum grid (6) with clean water.

Drain the water from the tanks by means of the drain hose (16, Fig. C) and valve (18).

4.If necessary, release the retainers (2, Fig. F), open the vacuum grid (1), remove the float (3), then carefully clean and reinstall them.

5.Check the cover gasket (7, Fig. F) of the recovery water tank for integrity.

NOTE

The gasket (7, Fig. F) creates vacuum in the tank, which is necessary for vacuuming the recovery water.

If necessary, replace the gasket (7) after removing it from its housing (8).

When reassembling the new gasket, install the joint (9) in the central area, as shown in the figure.

6.Check the gasket (7, Fig. F) bearing surface (10) for integrity and sealing capabilities.

7.Check the compensation hole (33, Fig. C) for clogging.

NOTE

The hole (33, Fig. C) compensates the air in the cover interspaces, thus allowing the creation of vacuum in the recovery water tank.

8.Remove the cover stand (19, Fig. J) and close the recovery water tank cover (1).

SOLUTION FILTER CLEANING

1.Empty the solution tank (5, Fig. J) according to the procedure shown in the relevant paragraph.

2.Drive the machine on a level ground.

3.Make sure that the switches (5 and 6, Fig. B) are turned to "0".

4.Remove the transparent cover (1, Fig. G) and the filter strainer (2); clean and reinstall them on the support (3).

NOTE

Properly install the filter strainer (2, Fig. G) in the housing (4) of the support (3).

MACHINE SPEED ADJUSTMENT

NOTE

The machine speed depends on the floor type and on the choice of using brush or pad.

The machine speed can be adjusted according to the following procedure.

1.Remove the recovery water tank as shown in the Use chapter.

2.Adjust the machine speed by means of the screw (13, Fig. J); according to the following procedure:

–Loosen the screw (17, Fig. J) on the right side of the machine, by turning it counter-clockwise;

–Turn the adjusting screw (13, Fig. J) counter-clockwise to increase the machine speed;

–Turn the adjusting screw (13, Fig. J) clockwise to decrease the machine speed;

–After adjusting, tighten the screw (17, Fig. J).

3.Install the recovery water tank as shown in the Use chapter.

4.With the machine ready to operate, carry out hands-on tests of the machine and, if other adjustments are necessary, repeat steps 1 to 4.

12 |

Razor SV17 — 909 6309 000(1)2006-01 |

INSTRUCTIONS FOR USE

CHARGING THE BATTERIES

NOTE

Charge the batteries when the warning light (3 or 4, Fig. B) turns on, or when finishing cleaning.

Keeping the batteries charged make them last longer.

CAUTION!

When the batteries are discharged, charge them as soon as possible, as that condition makes them last shorter.

Check for battery charge at least once a week.

WARNING!

When using lead (WET) batteries, charging the batteries produces highly explosive hydrogen gas. Charge the batteries in well-ventilated areas and away from naked flames.

Do not smoke while charging the batteries. Do not reinstall the recovery water tank until the battery charging cycle is over.

WARNING!

When using lead (WET) batteries, be extremely careful while charging the batteries as there may be battery fluid leakages. The battery fluid is corrosive. If it comes in contact with the skin or eyes, rinse thoroughly with water and consult a physician.

CAUTION!

Batteries must be charged indoors, in a dry environment (damp free).

1.For lead (WET) batteries only: Remove the recovery water tank as shown in the Use chapter.

2.Drive the machine indoors, in a dry environment (damp free), to charge the batteries.

3.For lead (WET) batteries only:

–Check the level of electrolyte inside the batteries; if necessary, top up through the caps.

–Leave all the battery caps open for next charging.

–If necessary, clean the upper surface of the batteries.

4.Charge the batteries according to the following procedure.

5.Connect the battery charger cable (21, Fig. C) to the electrical mains (the mains voltage and frequency must be the same as the battery charger corresponding values: see the Battery Charger Manual).

NOTE

When the battery charger is connected to the electrical mains, all machine functions are automatically cut off.

The green warning light (27, Fig. C) flashes when the battery charger is charging the batteries.

6.When the green warning light (27, Fig. C) stays on, the battery charging cycle is over.

7.When the battery charging cycle is over, disconnect the battery charger cable (21, Fig. C) from the electrical mains and wind it round its housing on the machine.

8.For lead (WET) batteries only:

–Reinstall the recovery water tank as shown in the Use chapter.

–Check the level of electrolyte inside the batteries; if necessary, top up through the caps.

–Close all the battery caps;

–If necessary, clean the upper surface of the batteries.

9.Now the machine is ready to be used.

NOTE

For further information about the operation of the battery charger (26, Fig. C), see the relevant Manual.

FUSE CHECK/REPLACEMENT

1.For machines without battery charger only

Disconnect the battery connector (29, Fig. C).

2.For machines with battery charger only

Remove the recovery water tank as shown in the Use chapter.

3.For machines with battery charger only

Disconnect the negative battery terminals (10, Fig. J).

4.Remove the screws (5, Fig. I) and pull out the electrical component box cover (1).

5.Check/replace the following fuses:

–Brush (40A) (2, Fig. I)

–Vacuum (40A) (3, Fig. I)

–Solenoid valve and electronic board (5A) (4 Fig. I).

6.Assemble in the reverse order of disassembly.

Razor SV17 — 909 6309 000(1)2006-01 |

13 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

TROUBLESHOOTING

TROUBLE |

REMEDY |

|

|

|

|

No motor ignition; no warning |

Disconnected battery terminals |

|

|

||

light on |

Completely discharged batteries |

|

|

||

|

|

|

No vacuum system motor |

Blown fuse |

|

ignition |

||

|

||

|

|

|

|

Recovery water tank full |

|

|

|

|

|

Clogged vacuum grid or stuck |

|

|

closed float |

|

|

|

|

|

Vacuum hose disconnected from |

|

Insufficient dirty water |

the squeegee or faulty |

|

vacuuming |

|

|

Dirty squeegee, or worn or |

||

|

||

|

damaged squeegee blades |

|

|

|

|

|

Improperly closed recovery water |

|

|

tank cover; worn gasket or clogged |

|

|

compensation hole |

|

|

|

|

|

Dirty solution filter |

|

Insufficient solution flow to the |

|

|

|

||

brush/pad |

Dirty recovery water tank (clogged |

|

|

drain hole) |

|

|

|

|

|

Debris under the squeegee blades |

|

Squeegee-related marks |

|

|

Worn, chipped or torn squeegee |

||

|

||

|

blades |

|

|

|

For further information refer to the Service Manual, available at any KENT Service Center.

SCRAPPING

Have the machine scrapped by a qualified scrapper. Before scrapping the machine, remove the following components:

–Batteries

–Brushes

–Plastic hoses and components

–Electrical and electronic components

CAUTION!

Removed components must be disposed of according to the law in force.

14 |

Razor SV17 — 909 6309 000(1)2006-01 |

INSTRUCTIONS D'UTILISATION |

|

INTRODUCTION ................................................................................................................................... |

2 |

BUT ET CONTENU DU MANUEL .................................................................................................................... |

2 |

DESTINATAIRES ............................................................................................................................................. |

2 |

CONSERVATION DU MANUEL ....................................................................................................................... |

2 |

DONNEES D'IDENTIFICATION ....................................................................................................................... |

2 |

AUTRES MANUELS DE REFERENCE ............................................................................................................ |

2 |

PIECES DE RECHANGE ET ENTRETIEN ...................................................................................................... |

2 |

MODIFICATIONS ET AMELIORATIONS ......................................................................................................... |

2 |

SECURITE ............................................................................................................................................. |

3 |

SYMBOLES ...................................................................................................................................................... |

3 |

INSTRUCTIONS GENERALES ........................................................................................................................ |

3 |

DEBALLAGE ......................................................................................................................................... |

4 |

DESCRIPTION DE LA MACHINE ......................................................................................................... |

5 |

CAPACITES OPERATIONNELLES .................................................................................................................. |

5 |

CONVENTIONS ................................................................................................................................................ |

5 |

DESCRIPTION ................................................................................................................................................. |

5 |

CARACTERISTIQUES TECHNIQUES ............................................................................................................. |

6 |

PROTECTIONS ELECTRIQUES ...................................................................................................................... |

6 |

ACCESSOIRES/OPTIONS ............................................................................................................................... |

6 |

UTILISATION ........................................................................................................................................ |

7 |

CONTROLE/PREPARATION DE LA BATTERIE SUR UNE MACHINE NEUVE ............................................. |

7 |

ETABLISSEMENT (WET OU GEL), INSTALLATION ET CHARGE DE LA BATTERIE ................................... |

7 |

AVANT LA MISE EN MARCHE ........................................................................................................................ |

8 |

MISE EN MARCHE ET ARRET DE LA MACHINE ........................................................................................... |

8 |

MACHINE AU TRAVAIL (LAVAGE/SECHAGE) ............................................................................................... |

9 |

TRANSPORT/STATIONNEMENT DE LA MACHINE ....................................................................................... |

9 |

VIDANGE DES RESERVOIRS ......................................................................................................................... |

9 |

APRES L'UTILISATION DE LA MACHINE ..................................................................................................... |

10 |

DEPOSE DU RESERVOIR DE L'EAU DE RECUPERATION ........................................................................ |

10 |

INACTIVITE PROLONGEE DE LA MACHINE ............................................................................................... |

10 |

PREMIERE PERIODE D'UTILISATION .......................................................................................................... |

10 |

ENTRETIEN ......................................................................................................................................... |

10 |

PROGRAMME D'ENTRETIEN ....................................................................................................................... |

11 |

NETTOYAGE DE L'EMBOUCHURE .............................................................................................................. |

11 |

CONTROLE ET REMPLACEMENT DES LAMELLES EN CAOUTCHOUC DE L'EMBOUCHURE ............... |

11 |

NETTOYAGE DE LA BROSSE ...................................................................................................................... |

12 |

NETTOYAGE DES RESERVOIRS ET DE LA GRILLE D'ASPIRATION ........................................................ |

12 |

NETTOYAGE DU FILTRE DE SOLUTION ..................................................................................................... |

12 |

REGLAGE DE LA VITESSE D'AVANCE DE LA MACHINE ........................................................................... |

12 |

CHARGE DES BATTERIES ........................................................................................................................... |

13 |

CONTROLE/REMPLACEMENT DES FUSIBLES .......................................................................................... |

13 |

DEPISTAGE DES PANNES ................................................................................................................ |

14 |

MISE EN DECHARGE ......................................................................................................................... |

14 |

Razor SV17 — 909 6309 000(1)2006-01 |

1 |

INSTRUCTIONS D'UTILISATION

INSTRUCTIONS D'UTILISATION

INTRODUCTION

BUT ET CONTENU DU MANUEL

Ce manuel se propose de fournir au client toutes les informations nécessaires afin qu’il puisse utiliser la machine correctement et la gérer de la manière la plus autonome et sûre. Il comprend des informations relatives à l’aspect technique, le fonctionnement, l’arrêt de la machine, l’entretien, les pièces de rechange et la sécurité.

Avant d’effectuer toute opération sur la machine, les opérateurs et les techniciens chargés de l'entretien doivent lire attentivement les instructions contenues dans ce texte. En cas de doutes sur la correcte interprétation des instructions, contacter un Service après-vente qualifié KENT pour avoir plus de renseignements.

DESTINATAIRES

Ce manuel s’adresse à l’opérateur aussi bien qu’aux techniciens préposés à l’entretien de la machine.

Les opérateurs ne doivent pas exécuter les opérations réservées aux techniciens qualifiés. KENT ne répond pas des dommages dus à l'inobservance de cette interdiction.

CONSERVATION DU MANUEL

Les Instructions d'utilisation doivent être gardées près de la machine, dans une enveloppe spéciale et, surtout, loin de liquides et de tout ce qui pourrait en compromettre l’état de lisibilité.

DONNEES D'IDENTIFICATION

Le numéro de série et le modèle de votre machine sont indiqués sur la plaque lisible de l'extérieur (1, Fig. C). L'année de fabrication de votre machine est indiquée après le code de la date sur le numéro de série de la machine (A06 signifie janvier 2006).

Ces informations sont nécessaires lors de la commande des pièces de rechange de la machine. Utiliser l'espace ci-dessous pour y noter les données d'identification de la machine pour toute référence future.

Modèle de la MACHINE ................................................

Numéro de série de la MACHINE ..................................

AUTRES MANUELS DE REFERENCE

–Manuel d'utilisation du chargeur de batterie électronique, si livré avec la machine, qui constitue une partie intégrante de ce manuel.

–Catalogue des pièces de rechange (livré avec la machine).

–Manuel d’entretien (consultable auprès des Services après-vente KENT).

PIECES DE RECHANGE ET ENTRETIEN

Pour toute nécessité relative à l’utilisation, l’entretien et, le cas échéant, les réparations, il faut s’adresser au personnel qualifié ou directement aux Services après-vente KENT, et il ne faut utiliser que des pièces de rechange et accessoires originaux.

Pour l’assistance ou la commande de pièces de rechange et accessoires, contacter KENT en spécifiant toujours le modèle et le numéro de série.

MODIFICATIONS ET AMELIORATIONS

Notre entreprise vise à un constant perfectionnement de ses produits et se réserve le droit d’effectuer des modifications et des améliorations, lorsqu’elles sont nécessaires, sans l’obligation de modifier les machines précédemment vendues.

Il est entendu que toute modification et/ou addition d’accessoires doit toujours être approuvée et réalisée par KENT.

2 |

Razor SV17 — 909 6309 000(1)2006-01 |

Loading...

Loading...