Kent Euroclean Blue 32 Instruction Manual

Blue 32

INSTRUCTIONS FOR USE |

KENT model: 908 4106 010 |

MODE D’EMPLOI ET D’ENTRETIEN |

Modèle KENT: 908 4106 010 |

INSTRUCCIONES DE USO |

Modelo KENT: 908 4106 010 |

INSTRUÇÕES DE USO |

Modelo KENT: 908 4106 010 |

146 2301 000(1)2005-03 |

B

C

2 |

9 |

3 |

4 |

5 |

D |

E |

|

|

9

9

9

8

7 |

1 |

|

6 |

||

9 |

S310027 |

S310028 |

F |

G |

S310025

S310029 |

S310030 |

H |

I |

S310081 |

S310032 |

J |

K |

S310080 |

S310082 |

S310034 |

|

Blue 32 – 146 2301 000(1)2005-03

INSTRUCTIONS FOR USE |

|

INTRODUCTION....................................................................................................................... |

2 |

PURPOSE AND CONTENTS OF THIS MANUAL............................................................................................. |

2 |

IDENTIFICATION DATA.................................................................................................................................... |

2 |

OTHER REFERENCE MANUALS..................................................................................................................... |

2 |

SPARE PARTS AND MAINTENANCE .............................................................................................................. |

2 |

MODIFICATIONS AND IMPROVEMENTS........................................................................................................ |

2 |

SAFETY - ACCIDENT PREVENTION ...................................................................................... |

2 |

SYMBOLS.......................................................................................................................................................... |

2 |

GENERAL SAFETY INSTRUCTIONS............................................................................................................... |

3 |

UNPACKING............................................................................................................................. |

3 |

MACHINE DESCRIPTION ........................................................................................................ |

4 |

SWEEPER OPERATION CAPABILITIES.......................................................................................................... |

4 |

TECHNICAL DATA ............................................................................................................................................ |

4 |

ELECTRICAL PROTECTIONS.......................................................................................................................... |

5 |

ACCESSORIES / OPTIONS.............................................................................................................................. |

5 |

MACHINE USE ......................................................................................................................... |

5 |

BATTERY CHECK/INSTALLATION ON A NEW MACHINE ............................................................................. |

5 |

BATTERY INSTALLATION AND BATTERY TYPE SETTING (WET OR GEL)................................................. |

6 |

BEFORE START-UP ......................................................................................................................................... |

6 |

STARTING AND STOPPING THE MACHINE................................................................................................... |

6 |

MACHINE OPERATION .................................................................................................................................... |

7 |

EMPTYING THE HOPPER................................................................................................................................ |

7 |

AFTER MACHINE USE ..................................................................................................................................... |

7 |

PUSHING THE MACHINE................................................................................................................................. |

7 |

MACHINE STORAGE........................................................................................................................................ |

7 |

MAINTENANCE........................................................................................................................ |

8 |

SCHEDULED MAINTENANCE TABLE ............................................................................................................. |

8 |

MAIN BROOM HEIGHT CHECK ....................................................................................................................... |

9 |

MAIN BROOM REPLACEMENT ....................................................................................................................... |

9 |

SIDE BROOM HEIGHT ADJUSTMENT .......................................................................................................... |

10 |

SIDE BROOM REPLACEMENT ...................................................................................................................... |

10 |

DUST FILTER CLEANING AND INTEGRITY CHECK .................................................................................... |

10 |

SKIRT HEIGHT AND OPERATION CHECK ................................................................................................... |

11 |

BATTERY CHARGING .................................................................................................................................... |

11 |

SAFETY FUNCTIONS AND TROUBLESHOOTING .............................................................. |

12 |

HOOD SAFETY SWITCH ................................................................................................................................ |

12 |

TROUBLESHOOTING............................................................................................................ |

12 |

SCRAPPING ........................................................................................................................... |

12 |

Blue 32 – 146 2301 000(1)2005-03 |

1 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

INTRODUCTION |

MODIFICATIONS AND IMPROVEMENTS |

PURPOSE AND CONTENTS OF THIS MANUAL

The purpose of this manual is to provide the Customer with all necessary information to use the machine properly in a safe way. It contains information about technical characteristics, operation, machine storage, maintenance, spare parts and safety conditions.

This manual is intended for Operators and Technicians qualified for performing the machine maintenance. Before carrying out any procedure on the machine, the Operators and Qualified Technicians must read this manual carefully. Contact the Manufacturer in case of doubts regarding the interpretation of the instructions and for any further information.

IDENTIFICATION DATA

The Machine Model and Serial Number are marked on the nameplate that is located under the hood. (20, Fig. U). The machine production year is shown after the Date Code on the serial plate. (A04 means January 2004) This information is useful when machine and engine replacement parts are required. Use the following table to write down the machine identification data for any future reference.

MACHINE Model..........................................................

MACHINE Serial Number.............................................

OTHER REFERENCE MANUALS

–Electronic Battery Charger Manual, also provided, is

to be considered an integral part of this manual. The following manuals are also available:

–Service Manual (that can be consulted at any Kent Service Center)

–Parts List, supplied with the machine

Our Company constantly improves its products and reserves the right to make changes and improvements at its discretion without being obliged to apply such benefits to the machines that were previously sold.

Any modifications and/or the addition of accessories must be approved and performed by the Manufacturer.

SAFETY - ACCIDENT PREVENTION

The following symbols indicate potentially dangerous situations. Always carefully read this information and take the necessary precautions to protect people and property. No accident prevention program is effective without the total cooperation of the person responsible for the machine operation. Most of the accidents that may occur in a factory, while working or transporting the machine, are caused by the failure to comply with the most simple prudence rules. A careful and prudent user is the best guarantee against accidents and is a prerequisite to carry out any accident prevention program.

SYMBOLS

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or property.

CONSULTATION

Consult the instruction booklet before performing any operation.

SPARE PARTS AND MAINTENANCE

All extraordinary maintenance and repairs must be carried out by qualified personnel or by Kent Service Centers. Only original spare parts and accessories should be used. Call Kent for service or to order spare parts and accessories. Specify the machine Model and Serial Number when discussing your machine.

2 |

Blue 32 – 146 2301 000(1)2005-03 |

INSTRUCTIONS FOR USE

GENERAL SAFETY INSTRUCTIONS

Specific warnings and cautions to inform you about potential exposure to bodily harm and machine damage are listed below.

DANGER!

–To perform maintenance/repair procedures turn the machine ignition key to the OFF position and disconnect the battery.

–This machine must be used by qualified and authorized personnel only. Children or disabled people cannot use this machine.

–Keep the battery far from sparks, flames and smoke. Explosive gases are vented during normal operation.

–Do not wear jewelry when working near electrical components.

–Do not work under the lifted machine if it is not securely supported.

–Do not operate the machine near dangerous, flammable and/or explosive powders, liquids or vapors.

–Battery charging produces explosive hydrogen gas. Keep the hood open during battery charging and perform the operation only in well-ventilated areas and far from open flames.

–When wet (lead-acid) batteries are mounted on this machine, do not tilt the machine more than 30° from its horizontal position. Doing so could cause the highly corrosive acid to leak out of the batteries. When it is necessary to tilt the machine for maintenance, remove the batteries.

WARNING!

–Carefully read all maintenance/repair instructions before carrying out any maintenance/repair procedure.

–Take all necessary precautions to prevent hair, jewelry and loose clothing from being caught in moving parts.

–Do not smoke during battery charging.

–Do not leave the machine unattended with the ignition key inserted and the parking brake deactivated, if equipped,.

–Do not use the machine on surfaces with a gradient greater than 2%.

–Do not wash the machine with pressurized water, or with corrosive substances. Do not use compressed air to clean this type of machine.

–Do not use the machine in extremely dusty areas.

–During the use of this machine take care not to endanger other people.

–Storage temperature must be within +32°F - +104°F (0°C - +40°C).

–The machine working temperature must be within +32°F - +104°F (0°C - +40°C).

–Humidity range should be within 30% and 95%.

–Do not use the machine as a transport vehicle.

–Do not allow the brooms to operate while the machine is stationary to avoid damaging the floor.

–In case of fire, use a powder extinguisher. Do not use water.

–Do not bump into shelves or scaffolding where there is a risk of falling objects.

–Adjust the operating speed according to the floor conditions.

–Do not tamper with the machine safety guards; follow the ordinary maintenance instructions scrupulously.

–Do not remove or modify the plates affixed on the machine.

–In case of machine malfunctions ensure that these are not caused by a lack of maintenance. Otherwise, request assistance from the authorized personnel or a Service Center.

–If parts must be replaced, request ORIGINAL spare parts from a dealer or Authorized Retailer.

–To ensure proper machine operation and safety conditions, the authorized personnel or Service Center must carry out the Scheduled Maintenance detailed in the related chapter of this Manual.

–The machine must be disposed of properly, at the end of its cycle of life, because of the presence of toxic-harmful materials (battery acid, oil, etc.), which are subject to standards that require disposal in special centers (see chapter “Scrapping”).

–If the machine is used according to the instructions, it

will not produce dangerous levels of vibration. The machine vibration level is below 2.5 m/s2.

UNPACKING

When the machine is delivered, check that the carton and the machine were not damaged during shipping. If damage is evident, keep the packing materials and have it checked by the Parcel Service that delivered it. Call the Parcel Service immediately to fill out a request for a compensation for damages.

Please check that the following items have been supplied with the machine:

1.Technical documents: Sweeper Instruction for Use Electronic Battery Charger Manual, Parts List

2.Side broom fuse (1)

3.Spare battery cables, terminal boots

4.Electronics fuse (1)

Blue 32 – 146 2301 000(1)2005-03 |

3 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

MACHINE DESCRIPTION

SWEEPER OPERATION CAPABILITIES

The Sweeper is designed and constructed to sweep non-hazardous dust or light debris on smooth and solid floors, light carpeting, in civil or industrial environments, under safe operating conditions by a trained Operator.

Note:

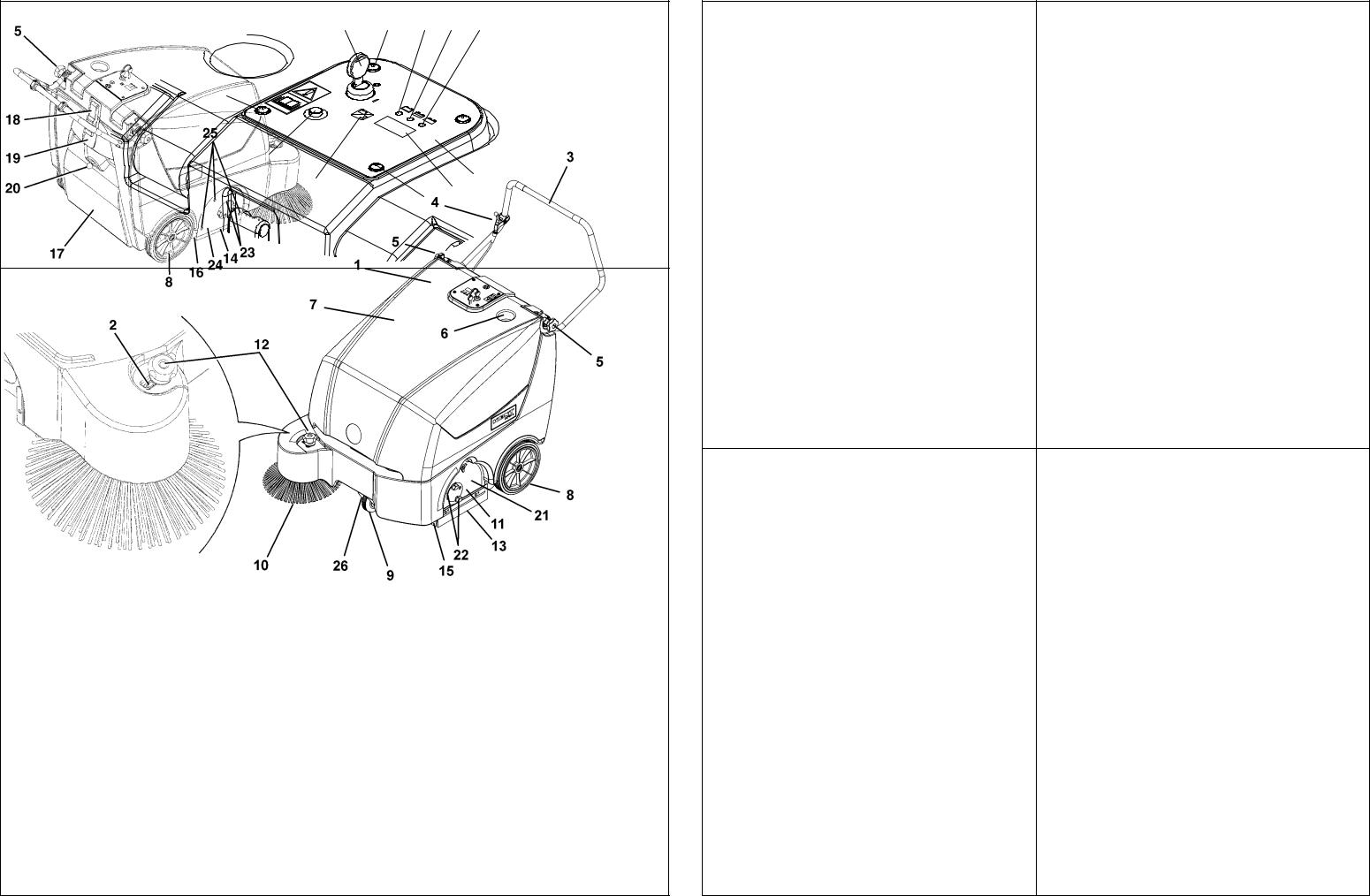

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, with the hands on the handlebar (3, Fig. C).

Control panel

(See Fig. B)

1.Control panel

2.Ignition key

3.Discharged battery warning light

4.Semi-discharged battery warning light

5.Charged battery warning light

6.Display

7.Display selection button: hour counter/ hour and minutes counter / battery voltage (V),

8.Filter shaker push-button (optional)

9.Panel fastening screws

Exterior general overview

(See Fig. C)

1.Serial number plate / technical data

2.Side broom latch

3.Handlebar

4.Drive lever

5.Knobs to adjust the handlebar inclination

6.Can holder

7.Hood

8.Rear wheels

9.Pivoting front wheel

10.Side broom

11.Main broom

12.Side broom lifting and adjusting knob

13.Left side skirt

14.Right side skirt

15.Front skirt

16.Rear skirt

17.Hopper

18.Hopper latch

19.Hopper handle

20.Manual filter-shaker handle

21.Main broom access door

22.Left main broom height adjuster

23.Right adjuster of the main broom height

24.Main broom right door

25.Main broom right door fastening screws

26.Brake pedal on front wheel (optional)

Under hood

6.Circuit breaker

7.Side broom motor fuse

8.Battery caps (Lead-acid battery)

9.Lead (WET) or gel (GEL) battery selector switch (positioned on the electronic battery charger)

10.Battery connection diagram

11.Charged battery warning light

12.Main broom belt

13.Drive belt

14.Drive pulley for main broom

15.Drive pulley for rear wheels

16.Fan

17.Main electric motor

18.Signal circuit fuse

19.Hood opening switch

20.Serial number plate / technical data

21.Grounding chain

TECHNICAL DATA

Dimensions |

Values |

Cleaning width |

|

(without side broom) |

600 mm (23.62 in) |

Cleaning width |

|

(with side broom) |

791 mm (31.14 in) |

Machine length |

1070 mm (42.18 in) |

Machine width, |

|

(without side broom) |

773 mm (30.43 in) |

Height when the |

|

handlebar is lowered |

836 mm (32.91 in) |

Minimum height from ground |

40 mm (1.6 in) |

Handlebar height |

926.46 mm (36.50 in) |

Main broom size |

ø 245 x 600 mm |

|

(9.65x23.62 in) |

Side broom size |

ø 347 mm (13.7 in) |

Max speed |

4.4 Km/h (2.7 mph) |

Maximum slope |

2% |

Hopper capacity |

50 l (1.7 ft3) |

Machine total weight |

|

(without battery) |

99.82 Kg (220.1 lb) |

Front wheel, steering |

ø 125/37.5-50 mm |

|

(4.92/1.48-1.97 in) |

Rear wheels, driving |

ø 250 x 50 mm |

|

(ø9.84x1.97 in) |

Electric motor |

600W (0.8 hp) |

Weighted sound pressure |

|

level (LpA) |

64 dB(A) |

Batteries

-Lead, with acid electrolyte (WET)

-Gel, hermetic (GEL)

The machine setting performed at the factory is for lead – acid (WET) batteries.

Battery voltage

Usable battery capacity Battery compartment size

(See Fig. U)

1.Hood (open position)

2.Batteries

3.Battery connector

4.Electronic battery charger

5.Battery charger power cord

Dust control and filter

Paper dust filter 5-10 µm Electric filter-shaker (optional) Vacuum in main broom compartment

4 |

Blue 32 |

INSTRUCTIONS FOR USE

Diagram

Wiring diagram. See Figure V.

CH1 |

Battery charger |

CN1 |

Battery connector |

CN2 |

Charger connector |

EB1 |

Electronic Board |

ES1 |

Electromagnetic switch |

F1 |

Circuit breaker 70A |

F2 |

Side broom fuse 15A |

F3 |

Signal fuse 10A |

M1 |

Main motor |

M2 |

Side broom motor |

M3 |

Shaker motor |

R1 |

Shaker relay |

SW1 |

Key switch |

SW2 |

Hood safety switch |

SW3 |

Skaker switch (optional) |

Color code |

|

BK |

Black |

BU |

Blue |

BN |

Brown |

GN |

Green |

GY |

Grey |

OG |

Orange |

PK |

Pink |

RD |

Red |

VT |

Violet |

WH |

White |

YE |

Yellow |

ELECTRICAL PROTECTIONS

Circuit breaker: |

6, Fig. U |

Side broom fuse: |

7, Fig. U |

Signal circuit fuse |

18, Fig. U |

ACCESSORIES / OPTIONS

In addiction to the standard components, the machine can be equipped with the following accessories/ options, according to the specific machine use:

1.Gel batteries

2.Main and side broom with harder and softer bristles

3.Antistatic polyester or polyester BIA C dust filter

4.Electric filter shaker

5.Front wheel with brake pedal

6.Different skirt types

7.Front skirt lifting lever

For further information concerning the optional accessories, contact an authorized retailer.

MACHINE USE

WARNING!

On the machine there are some decals indicating:

-DANGER

-WARNING

-CAUTION

-CONSULTATION

Using this Manual, the operator must learn the meaning of these symbols.

Do not cover these decals for any reason and in case of damage, replace them immediately.

BATTERY CHECK/INSTALLATION ON A NEW MACHINE

NOTE:

Battery charger must be connected to the batteries for machine to function.

The machine needs a 12 V battery or two 6 V batteries connected according to the diagram (10, Fig. U).

The machine can be equipped in one of the following ways:

a.A lead or gel battery installed on the machine and ready to be used.

b.A lead battery installed on the machine but without electrolyte.

c.Without a battery.

According to these conditions, follow the instructions as described below.

a.Lead or gel battery installed on the machine and

ready to be used.

1.Open the hood (7, Fig. C) and check that the battery is connected to the machine using the appropriate connector (3, Fig. U).

2.Lower the hood and check that it is closed correctly (the hood must be as shown in Fig. C).

3.Insert the ignition key (2, Fig. B) in the control panel and turn it to the “I” position (without pulling the lever 4, Fig. C).

If the green warning light (5, Fig. B) turns on, the battery is charged and ready to be used. Otherwise the battery needs to be charged (refer to

the procedure in the Maintenance chapter).

b.Lead battery installed on the machine but without liquid electrolyte

1.Open the machine hood (7, Fig. C).

2.Remove the battery caps (8, Fig. U).

Blue 32 – 146 2301 000(1)2005-03 |

5 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

WARNING!

Please pay strict attention when working with sulfuric acid, as it is corrosive. If it comes in contact with the skin or the eyes, wash thoroughly with water and consult a physician.

Battery has to be filled in a properly ventilated area. Use protective gloves

3.Fill up each battery cell with sulfuric acid for batteries (density from 1.27 to 1.29 Kg at 25°C) in accordance with the instructions specified in the Battery Use and Maintenance Manual.

The correct quantity of sulfuric acid is indicated in the Battery Use and Maintenance Manual.

4.Let the battery rest and fill with sulfuric acid in accordance with the instructions specified in the Battery Use and Maintenance Manual.

5.Proceed with charging the batteries (refer to the procedure in the Maintenance chapter).

c.Battery not supplied

1.Buy an appropriate battery (See Technical Characteristics paragraph and the diagram 10, Fig. U).

Consult qualified battery retailers to choose and install the battery.

2.Proceed with machine and battery charger setting according to the chosen battery type (lead-acid or gel).

3.Proceed with charging the batteries.

BATTERY INSTALLATION AND BATTERY TYPE SETTING (WET OR GEL)

NOTE:

Battery charger must be connected to the batteries for machine to function.

According to the battery type (lead – acid or gel) chosen, perform the setting of the electronic board of the machine and the battery charger following the instructions as indicated below:

Machine setting (electronic board)

1.Turn the ignition key (2, Fig. B) to “0” position.

2.Open the hood (7, Fig. C).

3.The machine setting performed at the factory is for lead – acid (WET) batteries. If the setting corresponds to the chosen battery, go to the following paragraph, otherwise perform the following operations:

4.Disconnect the battery connector (3, Fig. U).

5.Remove the screws (9, Fig. B) and remove the control panel (1, Fig. B) with care.

6.Install the jumper wire (1, Fig. T) on the “WET” connectors (2, Fig. T) for lead batteries or on the “GEL” connectors (3, Fig. T) for gel batteries.

7.Reinstall the control panel and tighten the screws (9, Fig. B).

8.Reconnect the battery connector (3, Fig. U).

9.Close the hood (7, Fig. C).

Battery charger setting

1.Turn the key (2, Fig. B) to the “0” position; open the hood (7, Fig. C) and switch the selector (9, Fig. U) to (WET) for lead – acid batteries or to (GEL) for gel batteries.

2.Install the battery on the machine according to the diagram (10, Fig. U).

3.Proceed with charging the batteries (see the procedure in the Maintenance chapter).

BEFORE START-UP

WARNING!

Ensure that the hopper (17, Fig. C) is correctly closed before starting up the machine.

STARTING AND STOPPING THE MACHINE

At every start-up

1.Insert the ignition key (2, Fig. B) in the control panel; turn it to the “I” position [without pulling the lever (4, Fig. C)], then check that the green warning light (5, Fig. B) turns on.

2.If the warning light becomes yellow or red (3 or 4, Fig. B) turn the ignition key to “0” position and remove it. Proceed with recharging the batteries (see the procedure in the Maintenance chapter).

Starting the machine

1.Adjust the handlebar (3, Fig. C) by means of the knobs (5), to reach a comfortable position.

2.Lower the side broom (10, Fig. C), disengage the handle (12) from its latch (2) and lower the knob (without turning it).

NOTE:

the side broom (10, Fig. C) can be lowered also when it is running.

3.Turn the ignition key (2, Fig. B) to the “I” position without pulling the drive lever (4, Fig. C).

4.Check that the green warning light (5, Fig. B) (charged battery) turns on. If the warning light becomes yellow or red (3 or 4, Fig. B), turn the ignition key to the “0” position and then proceed with recharging the battery. (See related chapter).

5.Pull the drive lever (4, Fig. C) with care until the machine starts to move.

The speed is proportional to the pressure applied to the drive lever (4, Fig. C).

6 |

Blue 32 – 146 2301 000(1)2005-03 |

INSTRUCTIONS FOR USE

Stopping the machine |

EMPTYING THE HOPPER |

To stop the machine, release the drive lever (4, Fig. C) completely and pull back on handle bar.

To stop the brooms from rotating, turn the key (2, Fig. B) to “0” position.

To lift the side broom (10, Fig. C), lift the knob (12, Fig. C) (without turning it) and align the latch with the slot in the plastic chassis. Rotate the knob (12) forward to engage the latch (2).

MACHINE OPERATION

1.Release the drive lever to stop the machine.

2.Turn the ignition key (2, Fig. B) to the “0” position.

3.Disengage the hopper latch (18, Fig. C) by pulling the bottom outward.

4.Using the hopper handle (19, Fig. C) remove the hopper (17, Fig. C) from the machine and empty it.

5.Return the hopper to its normal operating position and engage the hopper latch (18, Fig. C).

6.The machine is ready to start sweeping again.

1.Avoid stopping for a long time with the machine in the same position and the brooms still rotating: this could create unwanted marks on the floor.

2.To pick-up large debris, could be lifted the front skirt by pulling the option lever; keep in mind that during this operation the dust control of the machine will decrease.

3.For proper machine operation, the dust filter must be as clean as possible. To clean the filter while sweeping proceeds as follows according to the type of filter-shaker installed:

a)Manual filter - shaker: turn the ignition key in the “0” position, then pull the handle (20, Fig. C) outward until the end of the stroke is reached and then release it: the return spring strikes the dust filter frame and shakes it.

Repeat this operation several times. Turn the ignition key in the “I” position to continue working.

b)Electric filter-shaker (optional) press and hold the filter-shaker button (8, Fig. B) for a few seconds.

NOTE:

Repeat the operation at least every ten minutes while working (according to the dust conditions)

NOTE:

During this operation the electric motors and all machine functions are automatically stopped.

NOTE:

When the hopper and/or filter are full the machine can not collect more dust and debris.

CAUTION!

To avoid damaging the dust filter do not sweep wet floors or ground.

AFTER MACHINE USE

When finished working:

1.Clean the filter using the manual filter shaker (20, Fig. C) or the electric filter-shaker, if equipped, by pressing the filter shaker button (8, Fig. B).

2.Empty the hopper (17, Fig. C) (see previous paragraph).

3.Lift the side broom by lifting the knob (12, Fig. C).

4.Remove the ignition key (2, Fig. B) from the machine.

5.Ensure that the machine cannot move independently.

6.Activate the optional brake pedal (26, Fig. C).

PUSHING THE MACHINE

The machine can be moved my pushing it both with the ignition key (2, Fig. B) in the “0” and in the “I” positions.

MACHINE STORAGE

If you foresee that the machine will not be used for more than 30 days, proceed as follows:

–Move the machine to a suitable indoor storage area.

–Disconnect the battery connector (3, Fig. U).

–Lift the machine so that the skirts, the main broom and the wheels do not touch the ground.

–Disconnect the positive battery terminal (+) from the positive battery (+) pole.

.

The hopper (17, Fig. C) should be emptied after each working period and whenever it is full.

Blue 32 – 146 2301 000(1)2005-03 |

7 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

MAINTENANCE

The proper and safe machine operation is guaranteed by careful and regular maintenance.

The following table sums up the scheduled maintenance for the machine. The indicated periods can be subjected to variations according to working conditions. These variations must be defined by the person in charge of the maintenance.

WARNING!

Maintenance operations are to be carried out with the machine off, the ignition key removed and (if required) the battery disconnected.

Moreover, carefully read the instructions in the Safety chapter.

All periodic or extraordinary maintenance operations must be performed by skilled personnel, or by an authorized service center.

This manual describes only the easiest and most common maintenance procedures.

NOTE:

For other maintenance procedures, see the specific “Service Manual” that can be consulted at the Kent Service Center.

SCHEDULED MAINTENANCE TABLE

Maintenance operation |

On delivery |

Every 10 |

Every 50 |

Every 100 |

Every 200 |

Every 400 |

|

hours |

hours |

hours |

hours |

hours |

|||

|

|

||||||

Battery liquid level check |

z |

z (1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive belt visual inspection: main broom |

z |

|

|

z (*) |

|

|

|

drive |

|

|

|

|

|||

|

|

|

|

|

|

||

Skirt height and operation check |

z |

|

z |

|

|

|

|

|

|

|

|

|

|

|

|

Side and main broom height check |

|

z |

|

|

|

|

|

|

|

|

|

|

|

|

|

Dust filter cleaning and integrity check |

|

z (1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Electric filter-shaker (optional) operation |

|

|

z (*) |

|

|

|

|

check |

|

|

|

|

|

||

|

|

|

|

|

|

||

Nut and screw tightening check |

|

|

|

z (*) |

|

|

|

|

|

|

|

|

|

|

|

Drive belt tensioner adjustment |

|

|

z (*) |

|

|

|

|

|

|

|

|

|

|

|

|

Drive belt replacement: main broom drive |

|

|

|

|

z (*) |

|

|

|

|

|

|

|

|

|

|

Main electric motor carbon brushes check |

|

|

|

|

|

z (*) |

|

or replacement |

|

|

|

|

|

||

|

|

|

|

|

|

||

Hood opening switch operation check |

|

|

z (*) |

|

|

|

(*): For the related procedure see “Service Manual”. (1): Or before each start.

8 |

Blue 32 – 146 2301 000(1)2005-03 |

INSTRUCTIONS FOR USE

MAIN BROOM HEIGHT CHECK |

MAIN BROOM REPLACEMENT |

NOTE:

Brooms with harder or softer bristles are available. This procedure is applicable for all types of brooms.

1.Check the correct main broom height from the ground (not carpet), proceeding as follows:

a.With the machine on level ground, keep the machine stationary and allow the main broom to rotate for several seconds.

b.Stop the main broom and move the machine.

c.Check that the main broom pattern (1, Fig. D), proper width, is from 2 to 4 cm(0.8-1.6 in) on the type of surface where the machine will be used.

d.If the pattern (1, Fig. D) is different, it is necessary to adjust the broom height, proceeding as described in step 2.

2.With the machine on level ground, activate the brake pedal (26, Fig. C) (if equipped), or block the wheels

3.Turn the ignition key (2, Fig. B) to the “0” position.

4.Loosen the knobs (1, Fig. E) on both side of the machine.

5.Using the knobs (1, fig. E) on both sides of the machine, rotate the broom height adjuster indicator

(2) as necessary and then retighten the knobs (1).

NOTE:

The indicator (2) does not have to be at the same position on both sides of the machine; the maximum difference allowed is 2 notches to obtain a correct broom pattern (1, Fig. D) from 2 to 4 cm (0.8 – 1.6 in) as described in step 1.

6.Perform step 1 again to check the proper adjustment of the main broom height from ground.

7.When the broom becomes too worn, adjustment is no longer possible. Replace the broom following the instructions in the following chapter.

CAUTION!

A main broom pattern in excess of 4 cm (1.6 in) compromise the normal function of the machine and can overheat the electrical components, drastically reducing their life. Pay particular attention when checking the main broom height (broom pattern) and never operate the machine outside the specifications listed above.

CAUTION!

It is advisable to use protective gloves when replacing the main or side broom because there can be potentially harmful debris between the bristles.

NOTE:

Brooms with harder or softer bristles are available. This procedure is applicable to each type of broom.

1.With the machine on level ground activate the brake (26, Fig. C) (if equipped) or block the wheels.

2.Turn the ignition key (2, Fig. B) to the “0” position.

3.Loosen the knobs (1, Fig. E) on both sides of the machine.

4.Move the broom height adjuster indicators (2, Fig. E) until the broom reaches the maximum distance from the ground. Retighten the knobs (1).

5.Open the cover (7, Fig. C).

6.On the left side of the machine, remove the knob (3, Fig. E).

7.Remove the broom cover (1, Fig. F) by rotating the top of the cover outward and lifting upward to disengage the retainers (2).

8.Remove the broom (1, Fig. G) by sliding it out slowly.

9.Check that both broom hubs (4, Fig. R) are free of dirt and foreign materials (cords, rope, etc.) accidentally rolled up.

10.The new broom must be installed with the curve of the bristle rows (1, Fig. H) as shown in figure (top view).

11.Slide the new broom into the broom housing and align the main broom hub (1, Fig. I) with the drive hub (4, Fig. R).

12.Reinstall the broom cover (1, Fig. F) by engaging the retainers (2) and aligning the plastic broom core with the broom hub and pushing the top of the door inward.

13.Retighten the knob (3, Fig. E).

14.Carry out the Main Broom Height Adjustment as described in the previous paragraph.

Blue 32 – 146 2301 000(1)2005-03 |

9 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

SIDE BROOM HEIGHT ADJUSTMENT |

DUST FILTER CLEANING AND INTEGRITY |

||

|

NOTE: |

CHECK |

|

|

|

|

|

|

Brooms with harder or softer bristles are |

|

NOTE: |

|

available. This procedure is applicable to |

|

Besides the standard paper filter, optional |

|

each type of broom. |

|

polyester filters are available. The following |

1. |

Check the correct height of the side broom from the |

|

procedure is applicable to each type of filter. |

|

|

||

|

ground, by proceeding as follows: |

1. |

With the machine on level ground, activate the brake |

2. |

With the machine on level ground, lower the side |

|

pedal (26, Fig. C) (if present), or block the wheels. |

|

broom by disengaging the side broom latch (2, Fig. |

2. |

Turn the ignition key (2, Fig. B) to the “0” position. |

|

C). |

3. |

Disengage the hopper latch (18, Fig. C). |

3. |

Keep the machine stationary and allow the side |

4. |

Using the handle (19, Fig. C) remove the hopper (17, |

|

broom to rotate for a few seconds. |

|

Fig. C) from the machine. |

4. |

Stop the side broom and move the machine. |

5. |

Rotate the filter clamp (1, Fig. L) upward |

5. |

Check that the side broom pattern is as shown in |

|

(approximately 90°) and let the top of the filter frame |

|

figure J. If it is different, adjust the broom height as |

|

(2) rotate outward. |

|

described in the following step. |

6. |

Pull the dust filter (3, Fig. L) upward to remove it. |

6. |

Rotate the knob (12, Fig. C) clockwise or |

7. |

In a well-ventilated, outdoor area, clean the filter by |

|

counter-clockwise to adjust the broom height from |

|

gently tapping the side of the filter (1, Fig. M), |

|

the ground. |

|

opposite to the wire screen (2) on the ground. |

7. |

Perform steps from 1 to 5 again to check the proper |

8. |

Finish cleaning the filter by using compressed air (3, |

|

adjustment of the side broom height from the ground. |

|

Fig. M) of max. 6 bars (87 psi), blowing only from the |

8. |

When the broom becomes too worn, adjustment is |

|

side protected by the wire screen (2, Fig. M). |

|

no longer possible. Replace the broom following the |

|

According to the type of filter, take care of the |

|

instructions in the following paragraph. |

|

following cautions: |

SIDE BROOM REPLACEMENT |

|

– Paper filter (standard): do not use water or |

|

|

detergents to clean it; the filter can be damaged. |

||

|

NOTE: |

|

– Polyester filter (optional): to clean it, follow the |

|

|

instructions mentioned in number 7 above. For |

|

|

Brooms with harder or softer bristles are |

|

|

|

|

better cleaning, wash the filter with water and |

|

|

available. This procedure is applicable to |

|

|

|

|

non-foaming detergents. This type of washing will |

|

|

each type of brooms. |

|

|

|

|

clean the filter better, but it reduces the life of the |

|

|

|

|

|

|

CAUTION! |

|

filter. The use of inadequate detergents can |

|

It is advisable to use protective gloves when |

|

damage the filter. Check the filtering medium body |

|

replacing the main or side broom because |

|

for cuts or holes. |

|

there can be potentially harmful debris |

9. |

If necessary clean the filter compartment rubber seal |

|

between the bristles. |

|

(4, Fig. L) along its perimeter and check its integrity. |

1. |

With the machine on level ground, activate the brake |

|

If necessary replace it. |

10. |

Install in the reverse order of removal. |

||

|

(26, Fig. C) (if equipped) or block the wheels. |

|

NOTE: |

2. |

Turn the ignition key (2, Fig. B) to the “0” position. |

|

|

3. |

Slide your hand under the side broom and press the |

|

Reinstall the filter with the wire screen (2, |

|

two tabs (1, Fig. K) inward and then push the broom |

|

Fig. M) facing the front part of the machine |

|

(2, Fig. K) downward to disengage it from the four |

|

(toward the fan (16, Fig. U)). |

pins (3, Fig. K) on the side broom hub.

4.Install the new broom on the machine by aligning it on the pins (3, Fig. K) and then pressing it onto the two tabs (1, Fig. K).

5.Carry out the Side Broom Height Adjustment as described in the previous paragraph.

10 |

Blue 32 – 146 2301 000(1)2005-03 |

INSTRUCTIONS FOR USE

SKIRT HEIGHT AND OPERATION CHECK BATTERY CHARGING

1.With the machine on level and adequate ground to check the skirt height, activate the brake pedal (26, Fig. C) (if present), or block the wheels.

2.Turn the ignition key (2, Fig. B) to the “0” position.

Side skirt check

3.Check the side skirt (13 and 14, Fig C) integrity. Replace the skirts when they have cuts (1, Fig N) larger than 20 mm (0.75 in) or cracks (2) larger than 10 mm (0.5 in) (see the “Service Manual” for Skirt Replacement).

4.Check that the side skirt (13 and 14, Fig. C) height from the ground is within 0 – 3 mm (0 – 0.1in) (see figure O). If necessary adjust the skirt height, proceeding as follows:

Left skirt:

a.Open the hood (7, Fig. C), loosen the knob (3, Fig. E) and remove the main broom access door (1, Fig. F), lifting upward to disengage the retainers (2).

b.Adjust the skirt (3, Fig. F) height by loosening the two screws and using its slots (4, Fig. F).

c.Install in the reverse order of removal.

Right skirt:

a.Remove the Main Broom, as described in the related chapter.

b.Remove the belt (12, Fig. U) from the pulley (14, Fig. U); to facilitate the operation, rotate the pulley (14, Fig. U) by rotating the fan (16, Fig. U).

c.Remove the screws (25, Fig. C) and the right cover (24, Fig. C) together with the belt (12, Fig. U).

d.On the machine, adjust the skirt (1, Fig. S) height by loosening the two screws (2, Fig. S) and using its slots.

e.Install in the reverse order of removal.

Front and rear skirt check

WARNING!

Battery charging produces explosive hydrogen gas. Charge the batteries only in a well-ventilated area and far from open flames or sparks.

Do not smoke during battery charging.

Keep the hood open while recharging the battery.

WARNING!

Pay attention during battery recharging because there can be battery liquid leakage. The battery liquid is corrosive. If it comes in contact with the skin or eyes rinse thoroughly with water and consult a physician.

1.Drive the machine on level ground and activate the brake pedal (26, Fig. C) (if present), or block the wheels.

2.Turn the ignition key (2, Fig. B) to the “0” position.

3.Open the hood (7, Fig. C).

4.Only for lead-acid batteries, check the correct level of electrolyte inside the battery; if necessary, fill through the caps (8, Fig. U) to the required level.

5.Leave the caps (8) open for the next recharging.

6.Clean (if necessary) the upper surface of the battery.

7.Connect the battery charger electrical cable (5, Fig. U) to the electrical supply (the system voltage and frequency must be compatible with the battery charger: see the Battery Charger Manual).

8.When the green warning light (11, Fig. U) turns on, the battery is charged.

NOTE:

For further information about the battery charger (4, Fig. U) see the related Manual.

5.Remove the main broom, as described in the related paragraph.

6.Check the front and rear skirts (15 and 16 Fig. C) for integrity.

7.Replace the skirts when they have cuts (1, Fig N) larger than 20 mm (0.8 in) or cracks (2) larger than 10 mm (0.4 in) (see the “Service Manual” for Skirt Replacement).

8.Verify that:

–the front skirt (1, Fig. P) drags lightly on the ground (like in Figure P) and that it raised off the ground.

–the rear skirt (1, Fig. O) must have an height from ground from 0 up to 3 mm (0.1 in) (like in Fig. O).

9.If necessary, adjust the skirt height by loosening the four screws and using its slots (3, Fig. R).

10.Pulling on the front skirt lifting lever (optional), verify that the front skirt (1, Fig. Q) rotates upward approximately 90° (like in Figure Q). Release, the lever and verify that the skirt returns to its initial vertical position and does not remain slightly elevated. If necessary, see the installation instructions for assembling, adjusting or replacing the skirt lifting cable.

11.Install in the reverse order of removal.

9.Disconnect the battery charger electrical cable (5, Fig. U) from the electrical supply and put it back into its housing in the machine.

10.Reassemble the battery caps (8, Fig. U)

11.Close the hood (1, Fig. U); the machine is ready to be used.

NOTE:

When the battery charger is connected to the electrical supply, all machine functions are automatically shut off.

Blue 32 – 146 2301 000(1)2005-03 |

11 |

INSTRUCTIONS FOR USE

INSTRUCTIONS FOR USE

SAFETY FUNCTIONS AND

TROUBLESHOOTING

HOOD SAFETY SWITCH

It is activated when the machine hood is lifted up: it stops all machine functions.

In the case where the machine starts even when the hood is open, contact an authorized Service Center or Retailer for Service.

TROUBLESHOOTING

TROUBLE |

SOLUTION |

|

|

|

|

|

Check that the connector 3, Fig. U |

|

|

is properly connected. |

|

|

Check that the hood is properly |

|

|

closed. |

|

When the key is in the “I” |

Check the circuit breaker (6, Fig. |

|

U). |

||

position, the machine does not |

|

|

Check the Electronic circuit fuse |

||

start. |

||

|

(18, Fig. U) integrity |

|

|

Check that the battery charger is |

|

|

properly connected to the batteries |

|

|

and/or the battery charger is not |

|

|

plugged in to recharge the |

|

|

batteries. |

|

The side broom does not |

Check the side broom fuse (7, Fig. |

|

operate |

U) integrity |

|

The machine operates only |

Re-charge the battery. If the |

|

when stationary, otherwise the |

problem persists, replace the |

|

red warning light turns on. |

battery. |

|

|

Check if the main broom pattern is |

|

|

not wider than 4 cm (1.57 in) |

|

The circuit breaker (6, Fig. U) |

Check that the machine is not |

|

trips frequently. |

working on slopes higher than 2% |

|

|

Check if debris is not blocking the |

|

|

main broom rotation |

|

The battery run time is low. |

Install a battery with greater |

|

capacity. (Min. 140Ah) |

||

|

SCRAPPING

Have the machine scrapped by a qualified dismantler. Before scrapping the machine, remove the following components:

1.Battery

2.Polyester dust filter

3.Main and side brooms.

4.Circuit board

CAUTION!

The removed components must be disposed of properly and according to all applicable laws.

NOTE:

As your machine has a battery charger installed, the machine can not operate if the charger is not on board. In case of battery charger malfunction, contact an Authorized Service Center.

For further information consult the Service Manual at any Kent Service Center.

12 |

Blue 32 – 146 2301 000(1)2005-03 |

MODE D’EMPLOI ET D’ENTRETIEN |

|

INTRODUCTION....................................................................................................................... |

2 |

BUT ET CONTENU DU MANUEL ..................................................................................................................... |

2 |

DONNEES D’IDENTIFICATION ........................................................................................................................ |

2 |

AUTRES MANUELS DE REFERENCE............................................................................................................. |

2 |

PIECES DE RECHANGE ET ENTRETIEN ....................................................................................................... |

2 |

MODIFICATIONS ET AMELIORATIONS .......................................................................................................... |

2 |

SECURITE - PREVENTION DES ACCIDENTS ....................................................................... |

2 |

SYMBOLES UTILISES ...................................................................................................................................... |

2 |

INSTRUCTIONS GENERALES ......................................................................................................................... |

3 |

DEBALLAGE ............................................................................................................................ |

3 |

DESCRIPTION DE LA MACHINE ............................................................................................ |

4 |

CAPACITES OPERATIONNELLES BALAYEUSE ............................................................................................ |

4 |

CARACTERISTIQUES TECHNIQUES.............................................................................................................. |

4 |

PROTECTIONS ELECTRIQUES....................................................................................................................... |

5 |

ACCESSOIRES/OPTIONS................................................................................................................................ |

5 |

UTILISATION............................................................................................................................ |

5 |

CONTROLE / PREPARATION DE LA BATTERIE SUR UNE MACHINE NOUVELLE ..................................... |

5 |

INSTALLATION DE LA BATTERIE ET ETABLISSEMENT DU TYPE DE BATTERIE (WET OU GEL)............ |

6 |

AVANT LA MISE EN MARCHE ......................................................................................................................... |

6 |

MISE EN MARCHE ET ARRET DE LA MACHINE............................................................................................ |

6 |

MACHINE AU TRAVAIL .................................................................................................................................... |

7 |

DECHARGEMENT DU CONTENEUR DECHETS ............................................................................................ |

7 |

APRES L'UTILISATION DE LA MACHINE ........................................................................................................ |

7 |

MOUVEMENT DE LA MACHINE PAR POUSSEE............................................................................................ |

7 |

INACTIVITE PROLONGEE DE LA MACHINE .................................................................................................. |

7 |

ENTRETIEN .............................................................................................................................. |

8 |

PLAN D'ENTRETIEN PROGRAMME ................................................................................................................ |

8 |

CONTROLE HAUTEUR BROSSE CENTRALE ................................................................................................ |

9 |

REMPLACEMENT BROSSE CENTRALE......................................................................................................... |

9 |

REGLAGE HAUTEUR BROSSE LATERALE.................................................................................................. |

10 |

REMPLACEMENT BROSSE LATERALE........................................................................................................ |

10 |

NETTOYAGE FILTRE POUSSIERES ET CONTROLE INTEGRITE .............................................................. |

10 |

CONTROLE HAUTEUR ET FONCTIONNEMENT VOLETS........................................................................... |

11 |

CHARGEMENT DE LA BATTERIE ................................................................................................................. |

11 |

FONCTIONS DE SECURITE ET DEPISTAGE DES PANNES .............................................. |

12 |

INTERRUPTEUR DE SECURITE OUVERTURE COFFRE ............................................................................ |

12 |

DEPISTAGE DES PANNES ................................................................................................... |

12 |

MISE A LA FERRAILLE ......................................................................................................... |

12 |

Blue 32 – 146 2301 000(1)2005-03 |

1 |

MODE D’EMPLOI ET D’ENTRETIEN

MODE D’EMPLOI ET D’ENTRETIEN

INTRODUCTION

BUT ET CONTENU DU MANUEL

Ce manuel se propose de fournir au Client toutes les informations nécessaires afin qu’il puisse utiliser la machine correctement et la gérer dans la manière la plus sûre. Il comprend des informations relatives à l’Aspect Technique, le Fonctionnement, le Stockage de la Machine, l’Entretien, les Pièces de Rechange et les Conditions de Sécurité.

Ce Manuel s'adresse aux Opérateur aussi bien qu'aux Techniciens préposés à l'Entretien de la machine. Avant d’effectuer toute opération sur la Machine, les Opérateurs et les Techniciens Qualifiés doivent lire

attentivement les instructions contenues dans ce texte. En cas de doutes sur la correcte interprétation des instructions, contacter le Fabricant pour avoir plus de renseignements.

DONNEES D’IDENTIFICATION

Le Numéro de Série et le Modèle de Votre Machine sont indiqués sur le marquage situé sous le coffre de la machine. (20, Fig. U).

L’année de fabrication de Votre machine est indiquée après le code de la date sur le numéro de série de la machine. (A04 signifie janvier 2004)

Ces informations sont nécessaires lors de la commande des pièces de rechange pour la machine et le moteur. Utiliser l'espace ci-dessous pour noter les données d'identification de Votre machine pour une référence future.

.

.......................................................Modèle MACHINE |

: |

|

|

Numéro de série MACHINE ......................................... |

|

|

|

MODIFICATIONS ET AMELIORATIONS

Notre entreprise vise à un constant perfectionnement de nos produits et se réserve le droit d’effectuer des modifications et des améliorations, si nécessaires, sans l’obligation de sa part de modifier les machines déjà vendues.

Il est entendu que toute modification et/ou addition d’accessoires doit toujours être approuvée et réalisée par le Fabricant.

SECURITE - PREVENTION DES ACCIDENTS

Kent utilise la symbologie suivante pour signaler les conditions de danger potentielles. Lire toujours ces informations avec attention et prendre les précautions nécessaires pour protéger les personnes et les choses. Aucun programme de prévention des accidents du travail ne peut résulter efficace sans la totale collaboration de la personne directement responsable du fonctionnement de la machine. La plupart des accidents qui peuvent survenir dans une entreprise, pendant le travail ou les déplacements, sont dus à l’inobservance des plus simples règles de prudence. Un utilisateur attentif et prudent est la meilleure garantie contre les accidents du travail et se révèle indispensable pour compléter n’importe quel programme de prévention.

SYMBOLES UTILISES

DANGER !

Indique un danger qui comporte des risques, même la mort, pour l’Utilisateur.

ATTENTION !

Il est utilisé pour avertir de l'exposition à un risque d'accident aux personnes.

AUTRES MANUELS DE REFERENCE

-Le Manuel du chargeur de batterie électronique, qui

est en dotation, doit être considéré comme une partie intégrante de ce manuel.

En outre les suivants manuels sont disponibles:

-Manuel d’entretien consultable chez les Services Après-vente Kent

-Catalogue des pièces de rechange, équipé avec la machine.

AVERTISSEMENT !

Indique un avertissement ou une remarque sur des fonctions clé ou utiles. Prêter la plus grande attention aux segments de texte marqués par ce symbole.

CONSULTATION

Le Manuel doit être consulté avant toute opération.

PIECES DE RECHANGE ET ENTRETIEN

Pour toute nécessité concernant l’utilisation, l’entretien extraordinaire et les réparations, si nécessaires, il faut s’adresser au personnel qualifié ou directement aux Centres de Service Après-vente Kent et il ne faut utiliser que des pièces de rechange et accessoires originaux. Pour l’assistance ou la commande de pièces de rechange et accessoires, contacter l'organisation Kent en spécifiant toujours le Modèle et le Numéro de série.

2 |

Blue 32 – 146 2301 000(1)2005-03 |

Loading...

Loading...