Page 1

www.tek.com/keithley

Model 2182/2182A Nanovoltmeter

User’s Manual

2182A-900-01 Rev. B / May 2017

Page 2

WARRANTY

Keithley Instruments warrants this product to be free from defects in material and workmanship for a

period of one (1) year from date of shipment.

Keithley Instruments warrants the following items for 90 days from the date of shipment: probes,

cables, software, rechargeable batteries, diskettes, and documentation.

During the warranty period, Keithley Instruments will, at its option, either repa

proves to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instrument

return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are

warranted for the balance of the original warranty period, or at least 90 days.

s headquarters in Cleveland, Ohio. You will be given prompt assistance and

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley

Instruments’ express written consent, or misuse of any product or part. This warranty also does not

apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems

arising from normal wear or failure to follow instructions.

ir or replace any product that

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRE

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE THE BUYER’S SOLE AND

EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING

OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE, EVEN IF KEITHLEY

INSTRUMENTS HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH

DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COST

OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-800-KEITHLEY (1-800-935-5595) • www.tek.com/keithley

SSED OR IMPLIED,

3/07

Page 3

Model 2182 and 2182A Nanovoltmeter

User’

This User’s Manual supports both the Models 2182 and 2182A:

References to the Model 2182 apply to both the Models 2182 and 2182A.

References to the Model 2182/2182A apply to the Model 2182 with firmaware version A10

or higher, and the Model 2182A with firmware version C01 or higher.

References to the Model 2182A applies to the Model 2182A with firmware version C01 or

higher.

s Manual

©2017, Keithley Instruments

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing, June 2004

Document Number: 2182A-900-01 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Level letter increases alphabetically as the manual undergoes

subsequent updates. Addenda, which are released between Revisions, contain important change

information that the user should incorporate immediately into the manual. Addenda are

numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each new

Revision includes a revised copy of this print history page.

Revision A (Document Number 2182A-900-01) ............................................................. June 2004

Revision B (Document Number 2182A-900-01) ............................................................. May 2017

All Keithley product names are trademarks or registered trademarks of Keithley Instruments.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation.

Although some instruments and accessories would normally be used with non-hazardous voltages, there are

situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance

information carefully before using the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring

that the equipment is operated within its specifications and operating limits, and for ensuring that operators are

adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper

use of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example,

setting the line voltage or replacing consumable materials. Maintenance procedures are described in the user

documentation. The procedures explicitly state if the operator may perform them. Otherwise, they should be

performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly

trained service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I

and Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC

60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly

connected to mains voltage or to voltage sources with high transient over-voltages. Measurement Category II

connections require protection for high transient over-voltages often associated with local AC mains connections.

Assume all measurement, control, and data I/O connections are for connection to Category I sources unless

otherwise marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks

or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage

levels greater than 30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous

voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that

operators are prevented access and/or insulated from every connection point. In some cases, connections must be

exposed to potential human contact. Product operators in these circumstances must be trained to protect

themselves from the risk of electric shock. If the circuit is capable of operating at or above 1000 volts, no conductive

part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedancelimited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards,

install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power recep tacle.

Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate

main input power disconnect device must be provided in close proximity to the equipment and within easy reach of

the operator.

11/07

Page 6

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the

!

circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before:

connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal changes,

such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of

withstanding the voltage being measured.

The instrument and accessories must be used in accordance with specifications and operating instructions, or the

safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and

operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation

requires the use of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user shoul d refer to the operating instructions located in the

documentation.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined

effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these

voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp

must be properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death.

Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such

damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection f rom elect ric shoc k and fi re, replacement components in mains circuits - including the power

transformer, test leads, and input jacks - must be purchased from Keithley Instruments. Standard fuses with

applicable national safety approvals may be used if the rating and type are the same. Other components that are

not safety-related may be purchased from other suppliers as long as they are equivalent to the original component

(note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and

functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley

Instruments office for information.

T o clean an instrument, use a damp cloth or mild, water-based cleaner . Clean the exterior of the instrument only . Do

not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist

of a circuit board with no case or chassis (e.g., data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

Page 7

Table of Contents

1 Getting Started

General information

Warranty information ....................................................................................... 1-3

Contact information ......................................................................................... 1-3

Safety symbols and terms ................................................................................ 1-3

Inspection ......................................................................................................... 1-3

Options and accessories ................................................................................... 1-4

Nanovoltmeter features ........................................................................................... 1-6

Front and rear panel familiarization ........................................................................ 1-7

Front panel summary ....................................................................................... 1-7

Rear panel summary ...................................................................................... 1-11

Cleaning input connectors ..................................................................................... 1-13

Power-Up .............................................................................................................. 1-14

Line power connection ................................................................................... 1-14

Setting line voltage and replacing fuse .......................................................... 1-15

Power-up sequence ........................................................................................ 1-15

Line frequency ............................................................................................... 1-16

Display .................................................................................................................. 1-16

Status and error messages .............................................................................. 1-16

Default settings ..................................................................................................... 1-16

................................................................................................ 1-3

2 Voltage and Temperature Measurements

Measurement overview

Voltage measurements ..................................................................................... 2-3

Temperature measurements ............................................................................. 2-3

Performance considerations .................................................................................... 2-5

Warm-up .......................................................................................................... 2-5

ACAL (calibration) .......................................................................................... 2-5

Autozeroing modes .......................................................................................... 2-6

LSYNC (line cycle synchronization) ............................................................... 2-8

Pumpout current (low charge injection mode) ................................................. 2-9

SCPI programming - ACAL, Front Autozero, Autozero, LSYNC, and

Low Charge Injection .................................................................................. 2-10

Connections ........................................................................................................... 2-12

Connection techniques ................................................................................... 2-12

Voltage only connections ............................................................................... 2-14

Temperature only connections ....................................................................... 2-15

Voltage and temperature connections ............................................................ 2-16

Cleaning test circuit connectors ..................................................................... 2-17

........................................................................................... 2-3

Page 8

Temperature configuration

Measuring voltage and temperature ..................................................................... 2-19

SCPI programming - voltage and temperature measurements ...................... 2-20

Low-level considerations ...................................................................................... 2-22

Thermal EMFs ............................................................................................... 2-22

Noise .............................................................................................................. 2-22

Applications .......................................................................................................... 2-23

Low-resistance measurements ....................................................................... 2-23

Standard cell comparisons ............................................................................. 2-26

Heated Zener Reference and Josephson Junction Array comparisons .......... 2-27

................................................................................... 2-18

3 Range, Digits, Rate, and Filter

Range ......................................................................................................................

Maximum readings .......................................................................................... 3-3

Manual ranging ............................................................................................... 3-3

Autoranging ..................................................................................................... 3-4

SCPI programming - range ............................................................................. 3-4

Digits ...................................................................................................................... 3-5

SCPI programming - digits ............................................................................. 3-5

Rate ......................................................................................................................... 3-6

SCPI programming - rate ................................................................................ 3-7

Filter ....................................................................................................................... 3-8

Analog filter .................................................................................................... 3-8

Digital filter ..................................................................................................... 3-8

SCPI programming - filter ............................................................................. 3-12

4 Relative, mX+b, and Percent (%)

Relative ...................................................................................................................

REL Key .......................................................................................................... 4-3

SCPI programming - relative ......................................................................... 4-4

mX+b and percent (%) ........................................................................................... 4-6

mX+b ............................................................................................................... 4-6

Percent (%) ...................................................................................................... 4-7

SCPI programming - mX+b and percent ......................................................... 4-8

5 Ratio and Delta

3-3

4-3

Ratio .......................................................................................................................

Basic procedure ............................................................................................... 5-2

Filter, Rel, and Ranging considerations .......................................................... 5-4

Delta ....................................................................................................................... 5-6

Selecting Delta ................................................................................................ 5-9

Delta measurement procedure using a SourceMeter ....................................... 5-9

Filter considerations ...................................................................................... 5-15

5-2

Page 9

SCPI programming - ratio and delta

Programming examples ................................................................................. 5-16

Applications .......................................................................................................... 5-18

Testing superconductor materials .................................................................. 5-19

6 Buffer

..................................................................... 5-16

Buffer operations

Store ................................................................................................................. 6-2

Recall ............................................................................................................... 6-3

Buffer statistics ................................................................................................ 6-4

SCPI programming - buffer .................................................................................... 6-5

Programming example ..................................................................................... 6-6

7 Triggering

Trigger model

Idle ................................................................................................................... 7-3

Control source and event detection .................................................................. 7-4

Delay ................................................................................................................ 7-4

Device action ................................................................................................... 7-5

Output trigger ................................................................................................... 7-5

Reading hold (autosettle) ........................................................................................ 7-6

Hold example ................................................................................................... 7-6

External triggering .................................................................................................. 7-7

External trigger ................................................................................................ 7-8

Voltmeter complete .......................................................................................... 7-8

External triggering example ............................................................................. 7-9

External triggering with BNC connections .................................................... 7-12

SCPI programming - triggering ............................................................................ 7-13

Trigger model (remote operation) .................................................................. 7-13

Trigger model operation ................................................................................ 7-15

Triggering commands .................................................................................... 7-16

Programming example ................................................................................... 7-17

..................................................................................................... 6-2

.......................................................................................................... 7-3

8 Limits

Limit operations

Setting limit values .......................................................................................... 8-4

Enabling limits ................................................................................................. 8-4

SCPI programming - limits ..................................................................................... 8-5

Application .............................................................................................................. 8-7

Sorting resistors ............................................................................................... 8-7

...................................................................................................... 8-3

Page 10

9 Stepping and Scanning

10

Step/Scan overview

Internal Stepping/Scanning (Channels 1 and 2) .............................................. 9-3

External Stepping/Scanning ............................................................................ 9-3

Front panel trigger models ...................................................................................... 9-4

Internal scanning ............................................................................................. 9-4

Other Stepping/Scanning operations ............................................................... 9-6

Stepping/Scanning controls .................................................................................... 9-6

Step/Scan configuration .................................................................................. 9-7

Stepping/Scanning examples .................................................................................. 9-8

Internal scanning ............................................................................................. 9-8

Internal stepping .............................................................................................. 9-9

External scanning .......................................................................................... 9-10

SCPI programming - stepping and scanning ........................................................ 9-12

Programming example .................................................................................. 9-13

Application — I-V curves using internal scan ..................................................... 9-14

SCAN for IV curves [Measure V, sweep I, constant H (magnetic field)

or T (temperature)] ..................................................................................... 9-14

................................................................................................ 9-3

Analog Output

Overview ..............................................................................................................

Operation .............................................................................................................. 10-5

Analog output connections ............................................................................ 10-5

Configure and control analog output ............................................................. 10-5

Analog output rel ........................................................................................... 10-5

SCPI programming - analog output ...................................................................... 10-6

Programming example .................................................................................. 10-6

10-3

11

Remote Operation

Selecting and configuring an interface

Interfaces ....................................................................................................... 11-3

Languages ...................................................................................................... 11-3

Interface selection and configuration procedures .......................................... 11-4

GPIB operation and reference .............................................................................. 11-6

GPIB bus standards ....................................................................................... 11-6

GPIB bus connections ................................................................................... 11-6

Primary address selection .............................................................................. 11-8

QuickBASIC programming ........................................................................... 11-8

General bus commands ................................................................................. 11-9

Front panel GPIB operation ........................................................................ 11-12

Status structure ............................................................................................ 11-13

Programming syntax ................................................................................... 11-21

................................................................. 11-3

Page 11

RS-232 interface reference

Sending and receiving data .......................................................................... 11-27

Baud rate, flow control and terminator ........................................................ 11-27

RS-232 connections ..................................................................................... 11-29

Error messages ............................................................................................. 11-30

.................................................................................. 11-27

12

13

Common Commands

*CLS — Clear Status Clear status registers and error queue

*ESE <NRf> – Event Enable Program the standard event enable register ... 12-4

*ESE? – Event Enable Query Read the standard event register .................... 12-4

*ESR? – Event Status Register Query Read register and clear it .................. 12-6

*IDN? – Identification Query Read the identification code .......................... 12-7

*OPC – Operation Complete Set the OPC bit in the standard

event register after all pending commands are complete ............................ 12-8

*OPC? – Operation Complete Query Place a “1” in the output

queue after all pending operations are completed ..................................... 12-10

*RCL – Recall Return to setup stored in memory ....................................... 12-11

*RST – Reset Return 2182 to *RST defaults .............................................. 12-12

*SAV – Save Save present setup in memory ............................................... 12-12

*SRE <NRf> – Service Request Enable Program service request

enable register ........................................................................................... 12-12

*SRE? – Service Request Enable Query Read service request

enable register ........................................................................................... 12-12

*STB? – Status Byte Query Read status byte register ................................. 12-14

*TRG – Trigger Send bus trigger to 2182 ................................................... 12-15

*TST?– Self-Test Query Run self test and read result ................................ 12-15

*WAI – Wait-to-Continue Prevent execution of commands until

previous commands are completed ........................................................... 12-16

........................ 12-3

SCPI Signal Oriented Measurement Commands

14

:CONFigure:<function> .................................................................................

:FETCh? ......................................................................................................... 13-3

:READ? .......................................................................................................... 13-3

:MEASure:<function>? ................................................................................. 13-4

SCPI Reference Tables

13-2

Page 12

15

Additional SCPI Commands

DISPlay subsystem

:TEXT commands ......................................................................................... 15-3

FORMat subsystem .............................................................................................. 15-4

:DATA command .......................................................................................... 15-4

:BORDer command ....................................................................................... 15-6

:ELEMents command .................................................................................... 15-6

STATus subsystem ............................................................................................... 15-7

[:EVENt]? command .................................................................................... 15-7

:ENABle command ..................................................................................... 15-11

:CONDition? command ............................................................................... 15-13

:PRESet command ....................................................................................... 15-14

:QUEue commands ..................................................................................... 15-14

:SYSTem subsystem ........................................................................................... 15-16

:PRESet command ....................................................................................... 15-16

Performance commands .............................................................................. 15-16

:BEEPer command ...................................................................................... 15-18

:KCLick command ...................................................................................... 15-18

:POSetup <name> command ...................................................................... 15-18

:VERSion? command .................................................................................. 15-19

:ERRor? command ...................................................................................... 15-19

:CLEar command ........................................................................................ 15-19

:KEY <NRf> command ............................................................................. 15-20

A Specifications

............................................................................................... 15-3

B Status and Error Messages

C Measurement Considerations

Measurement considerations

Thermoelectric potentials ................................................................................ C-2

Thermoelectric generation ............................................................................... C-3

Source resistance noise .................................................................................... C-4

Magnetic fields ................................................................................................ C-6

Radio frequency interference .......................................................................... C-6

Ground loops ................................................................................................... C-6

Shielding .......................................................................................................... C-8

Meter loading .................................................................................................. C-9

.................................................................................. C-2

Page 13

D Model 182 Emulation Commands

E Example Programs

Program examples

Changing function and range .......................................................................... E-2

One-shot triggering ......................................................................................... E-4

Generating SRQ on buffer full ........................................................................ E-5

Storing readings in buffer ............................................................................... E-6

Taking readings using the :READ? command ................................................ E-7

Controlling the Model 2182 via the RS-232 COM2 port ............................... E-8

.................................................................................................. E-2

F IEEE-488 Bus Overview

Introduction .............................................................................................................

Bus description ........................................................................................................ F-2

Bus lines .................................................................................................................. F-4

Data lines ......................................................................................................... F-4

Bus management lines ..................................................................................... F-4

Handshake lines ............................................................................................... F-5

Bus commands ........................................................................................................ F-6

Uniline commands ........................................................................................... F-7

Universal multiline commands ........................................................................ F-8

Addressed multiline commands ....................................................................... F-9

Address commands .......................................................................................... F-9

Unaddress commands ...................................................................................... F-9

Common commands ...................................................................................... F-10

SCPI commands ............................................................................................. F-10

Command codes ............................................................................................. F-10

Typical command sequences ......................................................................... F-11

IEEE command groups .................................................................................. F-12

Interface function codes ........................................................................................ F-13

F-2

G IEEE-488 and SCPI Conformance Information

Introduction ............................................................................................................

H Measurement Queries

:FETCh? .................................................................................................................

What it does .................................................................................................... H-2

Limitations ...................................................................................................... H-2

Where appropriate ........................................................................................... H-2

:READ? .................................................................................................................. H-2

What it does .................................................................................................... H-2

Limitations ...................................................................................................... H-3

When appropriate ............................................................................................ H-3

G-2

H-2

Page 14

:MEASure[:<function>]? ......................................................................................

What it does .................................................................................................... H-3

Limitations ..................................................................................................... H-3

When appropriate ........................................................................................... H-3

[:SENSe[1]]:DATA:FRESh? ................................................................................ H-4

What it does .................................................................................................... H-4

Limitations ..................................................................................................... H-4

When appropriate ........................................................................................... H-4

[:SENSe[1]]:DATA[:LATest]? ............................................................................. H-4

What it does .................................................................................................... H-4

Limitations ..................................................................................................... H-4

When appropriate ........................................................................................... H-4

Examples ............................................................................................................... H-5

One-shot reading, DC volts, no trigger, fastest rate ....................................... H-5

One-shot reading, DC volts, bus trigger, auto ranging ................................... H-5

One-shot reading, external trigger, auto delay enabled .................................. H-5

H-3

I Delta, Pulse Delta, and Dif

Overview .................................................................................................................

Keithley instrumentation requirements ............................................................ I-2

Operation overview .......................................................................................... I-3

Test system configurations ...................................................................................... I-5

Delta measurement process ..................................................................................... I-6

Pulse Delta process .................................................................................................. I-9

Pulse Delta measurements ................................................................................ I-9

Pulse Delta outputs ......................................................................................... I-11

Differential Conductance process .......................................................................... I-14

Differential Conductance calculations ........................................................... I-16

ferential Conductance

I-2

Page 15

List of Illustrations

1 Getting Started

Figure 1-1

Figure 1-2 Model 2182 rear panel ...................................................................................... 1-11

Figure 1-3 Power module ................................................................................................... 1-14

Model 2182 front panel ....................................................................................... 1-7

2 Voltage and Temperature Measurements

Figure 2-1

Figure 2-2 Model 2107 input cable .................................................................................... 2-13

Figure 2-3 LEMO connector - terminal identification ....................................................... 2-13

Figure 2-4 Connections - single channel voltage ............................................................... 2-14

Figure 2-5 Connections - dual channel voltage .................................................................. 2-15

Figure 2-6 Connections - temperature (internal reference) ................................................ 2-15

Figure 2-7 Connections - temperature (simulated reference) ............................................. 2-16

Figure 2-8 Connections - voltage and temperature (internal reference) ............................. 2-16

Figure 2-9 Connections - voltage and temperature (simulated reference) ......................... 2-17

Figure 2-10 4-Wire low-resistance measurement technique ................................................ 2-23

Figure 2-11 Measuring switch contact resistance ................................................................. 2-24

Figure 2-12 Measuring switch contact resistance and temperature ...................................... 2-25

Figure 2-13 Standard cell comparison measurements .......................................................... 2-26

Figure 2-14 Heated Zener characterization .......................................................................... 2-27

Line cycle synchronization ................................................................................. 2-8

3 Range, Digits, Rate, and Filter

Figure 3-1

Figure 3-2 Moving and repeating filters ............................................................................. 3-10

Speed vs. noise characteristics ............................................................................ 3-6

5 Ratio and Delta

Figure 5-1

Figure 5-2 Delta measurement using bipolar source ............................................................ 5-8

Figure 5-3 Delta measurement connections ....................................................................... 5-11

Figure 5-4 Triggering timing diagram ................................................................................ 5-14

Figure 5-5 Calibrating 1:10 divider .................................................................................... 5-18

Figure 5-6 Test circuit—Fixed I (Vary H) ......................................................................... 5-20

Figure 5-7 H-V Curve (Fixed I) ......................................................................................... 5-21

Figure 5-8 SourceMeter output—2-point custom sweep ................................................... 5-21

Figure 5-9 I-V Curve (Fixed H) ......................................................................................... 5-22

Figure 5-10 Test circuit—Fixed H (Vary I) ......................................................................... 5-23

Figure 5-11 SourceMeter output—30-point custom sweep ................................................. 5-25

Figure 5-12 Trigger link connections using two Model 2182s ............................................ 5-26

Test circuit using constant current source ........................................................... 5-7

Page 16

6 Buffer

Figure 6-1

Buffer locations .................................................................................................. 6-3

7 Triggering

Figure 7-1

Figure 7-2 Device action ...................................................................................................... 7-5

Figure 7-3 Rear panel pinout ............................................................................................... 7-7

Figure 7-4 Trigger link input pulse specifications (EXT TRIG) ......................................... 7-8

Figure 7-5 Trigger link output pulse specifications (VMC) ................................................ 7-8

Figure 7-6 DUT test system ................................................................................................. 7-9

Figure 7-7 Trigger link connections .................................................................................... 7-9

Figure 7-8 Operation model for triggering example .......................................................... 7-10

Figure 7-9 DIN to BNC trigger cable ................................................................................ 7-12

Figure 7-10 Trigger model (remote operation) .................................................................... 7-13

Front panel trigger model (without Stepping/Scanning) .................................... 7-3

8 Limits

Figure 8-1

Figure 8-2 Setup to test 10Ω resistors

Figure 8-3 Limits to sort 10Ω resistors (1%, 5%, and >5%) ............................................... 8-8

Default limits ...................................................................................................... 8-3

.................................................................................. 8-7

9 Stepping and Scanning

Figure 9-1

Figure 9-2 Front panel triggering (other step/scan operations) ........................................... 9-5

Figure 9-3 External scanning example with Model 7001 .................................................. 9-11

Figure 9-4 Waveform to be programmed into Model 2400 ............................................... 9-14

Figure 9-5 Setup of Model 2182 and Model 2400 ............................................................. 9-15

Front panel triggering (internal scanning) .......................................................... 9-5

11

Figure 11-1

Figure 11-2 IEEE-488 connections ...................................................................................... 11-7

Figure 11-3 IEEE-488 connector location ........................................................................... 11-7

Figure 11-4 Model 2182 status model structure ................................................................ 11-14

Figure 11-5 Standard event status ...................................................................................... 11-16

Figure 11-6 Operation event status .................................................................................... 11-16

Figure 11-7 Measurement event status .............................................................................. 11-17

Figure 11-8 Questionable event status ............................................................................... 11-17

Figure 11-9 Status byte and service request ...................................................................... 11-19

Figure 11-10 RS-232 interface connector ............................................................................ 11-29

Remote Operation

IEEE-488 connector ......................................................................................... 11-6

Page 17

12

Common Commands

Figure 12-1

Figure 12-2 Standard event status register ........................................................................... 12-7

Figure 12-3 Service request enable register ....................................................................... 12-13

Figure 12-4 Status byte register .......................................................................................... 12-15

15

Figure 15-1

Figure 15-2 IEE754 single precision data format (32 data bits) ........................................... 15-5

Figure 15-3 IEEE754 double precision data format (64 data bits) ....................................... 15-5

Figure 15-4 Measurement event register .............................................................................. 15-8

Figure 15-5 Questionable event register ............................................................................... 15-9

Figure 15-6 Operation event register .................................................................................. 15-10

Figure 15-7 Measurement event enable register ................................................................. 15-12

Figure 15-8 Questionable event enable register ................................................................. 15-12

Figure 15-9 Operation event enable register ...................................................................... 15-13

Figure 15-10 Key-press codes .............................................................................................. 15-21

Standard event enable register .......................................................................... 12-5

Additional SCPI Commands

ASCII data format ............................................................................................. 15-4

C Measurement Considerations

Figure C-1

Figure C-2 Power line ground loops .................................................................................... C-7

Figure C-3 Eliminating ground loops .................................................................................. C-7

Figure C-4 Shielding example .............................................................................................. C-8

Figure C-5 Meter loading ..................................................................................................... C-9

Thermal EMF generation ................................................................................... C-3

F IEEE-488 Bus Overview

Figure F-1

Figure F-2 IEEE-488 handshake sequence ........................................................................... F-5

Figure F-3 Command codes .................................................................................................. F-8

I Delta, Pulse Delta and Dif

Figure I-1

Figure I-2 Test system configurations .................................................................................. I-5

Figure I-3 Delta measurement technique ............................................................................. I-6

Figure I-4 Pulse Delta 3-point measurement technique ....................................................... I-9

Figure I-5 Pulse timing ...................................................................................................... I-12

Figure I-6 Pulse sweep output examples ........................................................................... I-13

Figure I-7 Differential Conductance measurement process ............................................... I-15

IEEE-488 bus configuration ................................................................................ F-3

ferential Conductance

Delta, Pulse Delta, and Differential Conductance measurements ...................... I-4

Page 18

Page 19

List of T

1 Getting Started

ables

Table 1-1

Table 1-2 Factory defaults ................................................................................................. 1-17

Fuse ratings ....................................................................................................... 1-15

2 Voltage and Temperature Measurements

Table 2-1

Table 2-2 SCPI commands - ACAL, Front Autozero, Autozero, LSYNC, and

Table 2-3 SCPI commands - voltage and temperature measurements .............................. 2-20

Measurement channels ........................................................................................ 2-3

Low Charge Injection .................................................................................. 2-10

3 Range, Digits, Rate, and Filter

Table 3-1

Table 3-2 SPCI commands - digits ..................................................................................... 3-5

Table 3-3 SCPI commands - rate ........................................................................................ 3-7

Table 3-4 SCPI commands - filter ..................................................................................... 3-12

SPCI commands - range ..................................................................................... 3-4

4 Relative, mX+b, and Percent (%)

Table 4-1

Table 4-2 SCPI commands - mX+b and percent ................................................................ 4-8

SCPI commands - relative .................................................................................. 4-4

5 Ratio and Delta

Table 5-1

SCPI commands - ratio and delta ..................................................................... 5-16

6 Buffer

Table 6-1

SCPI commands - buffer ..................................................................................... 6-5

7 Triggering

Table 7-1

Table 7-2 SCPI commands - triggering ............................................................................. 7-16

Auto delay times ................................................................................................. 7-4

8 Limits

Table 8-1

SCPI commands - limits ..................................................................................... 8-5

9 Stepping and Scanning

Table 9-1

SCPI commands - stepping and scanning ......................................................... 9-12

Page 20

10

Analog Output

Table 10-1

Table 10-2 SCPI commands - analog output ...................................................................... 10-6

11

Table 11-1

Table 11-2 RS-232 connector pinout ................................................................................ 11-29

Table 11-3 PC serial port pinout ....................................................................................... 11-30

12

Table 12-1

13

Table 13-1

14

Table 14-1

Table 14-2 CALibration command summary (user accessible) ......................................... 14-4

Table 14-3 DISPlay command summary ............................................................................ 14-5

Table 14-4 FORMat command summary ........................................................................... 14-5

Table 14-5 OUTPut command summary ............................................................................ 14-6

Table 14-6 ROUTe command summary ............................................................................ 14-6

Table 14-7 SENSe command summary .............................................................................. 14-7

Table 14-8 STATus command summary .......................................................................... 14-11

Table 14-9 SYSTem command summary ........................................................................ 14-12

Table 14-10 TRACe command summary ........................................................................... 14-12

Table 14-11 Trigger command summary ........................................................................... 14-13

Table 14-12 UNIT command summary .............................................................................. 14-14

Analog output examples* ................................................................................. 10-3

Remote Operation

General bus commands and associated statements .......................................... 11-9

Common Commands

IEEE-488.2 common commands and queries .................................................. 12-2

SCPI Signal Oriented Measurement Commands

Signal oriented measurement command summary .......................................... 13-2

SCPI Reference Tables

CALCulate command summary ....................................................................... 14-3

B Status and Error Messages

Table B-1

Status and error messages .................................................................................. B-2

C Measurement Considerations

Table C-1

Material thermoelectric coefficients ................................................................... C-2

D Model 182 Emulation Commands

Table D-1

Model 182 device-dependent command summary ............................................ D-2

Page 21

F IEEE-488 Bus Overview

Table F-1

Table F-2 Hexadecimal and decimal command codes ...................................................... F-10

Table F-3 Typical addressed bus sequence ........................................................................ F-11

Table F-4 Typical addressed common command sequence .............................................. F-11

Table F-5 IEEE command groups ..................................................................................... F-12

Table F-6 Model 2182 interface function codes ................................................................ F-13

IEEE-488 bus command summary ..................................................................... F-7

G IEEE-488 and SCPI Conformance Information

Table G-1

Table G-2 Coupled commands ........................................................................................... G-3

IEEE-488 documentation requirements ............................................................. G-2

Page 22

Page 23

Getting

Started

Getting

1

Started

Page 24

1-2

Getting Started

NOTE This User’s Manual supports both the Models 2182 and 2182A:

References to the Model 2182 apply to both the Models 2182 and 2182A.

References to the Model 2182/2182A apply to the Model 2182 with firmaware version A10 or higher, and the Model 2182A with firmware version C01 or higher.

References to the Model 2182A applies to the Model 2182A with firmware version

C01 or higher.

• General information — Covers general information that includes warranty

information, contact information, safety symbols and terms, inspection, and a

vailable

options and accessories.

• Nanovoltmeter features — Summarizes the features of the Model 2182.

• Front and rear panel familiarization — Summarizes the controls and connectors of

the instrument.

• Cleaning input connector terminals — Explains ho

w to clean the contacts of the input

LEMO connectors.

• Power

-Up — Covers line power connection, line voltage setting, fuse replacement, and

the power-up sequence.

• Display — Provides information about the display of the Model 2182.

• Default settings — Co

vers the two instrument setup configurations available to the user;

user defined or factory default.

Page 25

General information

Warranty information

Warranty information is located at the front of this manual. Should your Model 2182 require

warranty service, contact the Keithley representative or authorized repair facility in your area for

further information. When returning the instrument for repair, be sure to fill out and include the

service form at the back of this manual to provide the repair facility with the necessary

information.

Contact information

Worldwide phone numbers are listed at the front of this manual. If you have any questions,

please contact your local Keithley representative or call one of our Application Engineers at

1-800-348-3735 (U.S. and Canada only).

Safety symbols and terms

The following symbols and terms may be found on the instrument or used in this manual:

!

The symbol on an instrument indicates that the user should refer to the operating

instructions located in the manual.

The symbol on an instrument shows that high voltage may be present on the terminal(s).

Use standard safety precautions to avoid personal contact with these voltages.

Getting Started

1-3

The WARNING heading used in this manual explains dangers that might result in personal

injury or death.

indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the

instrument. Such damage may in

Inspection

The Model 2182 was carefully inspected electrically and mechanically before shipment.

After unpacking all items from the shipping carton, check for any obvious signs of physical

damage that may have occurred during transit. (There may be a protective film over the display

lens, which can be removed). Report any damage to the shipping agent immediately. Save the

original packing carton for possible future shipment. The following items are included with

every Model 2182 order:

Always read the associated information very carefully before performing the

validate the warranty.

• Model 2182 Nanovoltmeter with line cord.

• Model 2107-4 Input Cable.

•Four alligator clips that attach to the copper lugs of the Model 2107 Input Cable.

• DeoxIt copper cleaning solution.

• Accessories as ordered.

• Certificate of calibration.

• Model 2182 User’s Manual (P/N 2182-900-00).

• Model 2182 Service Manual (P/N 2182-902-00).

• Manual Addenda (pertains to any improvements or changes concerning the instrument

or manual.

Page 26

1-4

Getting Started

If an additional manual is required, order the appropriate manual package. The manual

packages include a manual and any pertinent addenda.

Options and accessories

The following options and accessories are available from Keithley for use with the

Model 2182.

Cables, connectors, and adapters

Models 2107-4 and 2107-30 Input Cable — Connect the Model 2182 Nanovoltmeter to

DUT using one of these input cables. The input cable is terminated with a LEMO connector (for

connection to the Model 2182) on one end and four copper spade lugs (for connection to DUT)

on the other. The Model 2107-4 (which is a supplied accessory to the Model 2182) is 1.2m (4 ft)

in length and the Model 2107-30 is 9m (30 ft) in length. Also included are four copper alligator

clips that attach to the copper lugs of the cable, and DeoxIt copper cleaning solution.

Model 2182-KIT Low Thermal Connector — Consists of a lo

and strain relief. Includes all the connector parts required to build a custom input cable for the

Model 2182 Nanovoltmeter.

Model 2187-4 Input Cable — Low-thermal input cable for the Model 2182/2182A. Terminated with a LEMO connector on one end and four banana plugs on the other

(1.2m) in length.

Model 2188 Low-Thermal Calibration Shorting Plug — This input shorting plug is

required to calibrate the Model 2182 Nano

Models 7007-1 and 7007-2 Shielded GPIB Cables — Connect the Model 2182 to the GPIB

bus using shielded cables and connectors to reduce electromagnetic interference (EMI).

Model 7007-1 is 1m long; the Model 7007-2 is 2m long.

Model 7009-5 Shielded RS-232 Cable — 1.5m (5 ft) RS-232 cable terminated with a male

DB-9 connector on one end and a female DB-9 connector on the other end. It is wired as a

straight through (not null modem) cable.

Models 8501-1 and 8501-2 Trigger Link Cables — Connect the Model 2182 to other

instruments with

1 is 1m long; the Model 8501-2 is 2m long.

Model 8502 Trigger Link Adapter — Lets you connect an

the Model 2182 to instruments that use the standard BNC trigger connectors.

Model 8503 DIN to BNC Trigger Cable — Lets you connect Trigger Link lines one

(V

oltmeter Complete) and two (External Trigger) of the Model 2182 to instruments that use

BNC trigger connectors. The Model 8503 is 1m long.

Trigger Link connectors (e.g., Model 7001 Switch System). The Model 8501-

voltmeter.

w-thermal LEMO connector

. The cable is 4 ft

The

y of the six Trigger Link lines of

Silver solder

2182-325A — Use this Keithley part number to order a 20-foot length of silver solder. Also

included is an MSDS sheet listing the solder chemical contents.

Page 27

Getting Started

Rack mount kits

Model 4288-1 Single Fixed Rack Mount Kit — Mounts a single Model 2182 in a standard

19-inch rack.

1-5

Model 4288-2 Side-by-Side Rack Mount Kit — Mounts tw

486, 487, 2000, 2001, 2002, 2010, 2182, 2400, 2410, 2420, 6517, 7001) side-by-side in a

standard 19-inch rack.

Model 4288-4 Side-by-Side Rack Mount Kit — Mounts a Model 2182 and a 5.25-inch

instrument (Models 195A, 196, 220, 224, 230, 263, 595, 614, 617, 705, 740, 775, etc.)

side-by-side in a standard 19-inch rack.

o instruments (Models 182, 428,

Carrying case

Model 1050 Padded Carrying Case — A carrying case for a Model 2182. Includes handles

and shoulder strap.

Page 28

1-6

Getting Started

Nanovoltmeter features

The Model 2182 is a 71⁄2-digit high-performance digital nanovoltmeter. It has two input

channels to measure voltage and temperature. The measurement capabilities of the Model 2182

are explained in Section 2 of this manual (see “Measurement overview”).

Features of the Model 2182 Nanovoltmeter include:

• Ratio — Provides comparison readings between two voltage inputs. Ratio performs

V1/V2.

• Delta — Provides average difference of Channel 1 inputs. Delta performs

(V1t1–V1t2)/2.

• Enhanced Delta, Pulse Delta, and Differential Conductance — The following tests

can be performed when using a Model 2182/2182A with a Model 6220 or 6221 Current

Source:

— Delta - Uses a square w

the effects of thermal EMFs.

— Pulse Delta (6221 and 2182A only) - Provides a pulse output and a 3-point (or

2-point) measurement algorithm for testing of temperature sensiti

Test (DUT).

— Differential Conductance - Uses a dif

average algorithm to perform differential measurements.

• mX+b and Percent — These calculations provide mathematical manipulation of

readings.

• Relative — Null offsets or establish baseline values.

• Buffer — Store up to 1024 readings in the internal buffer.

• Limits — Set high and low reading limits to test devices.

• Internal Scanning — Scan the two input channels of the Model 2182.

• External Scanning — Scan the channels or matrix points of K

switching cards.

• Setup Storage — Two instrument setups (user and factory defaults) can be saved and

recalled.

• Analog Output —

1V analog output.

• Remote Interface — The Model 2182 can be controlled using the IEEE-488 interface

(GPIB) or the RS-

• GPIB Programming Language — When using the GPIB, the instrument can be

programmed using the SCPI or Model 182 (DDCs) programming language.

• Closed-cover Calibration — The Model 2182 can be calibrated from either the front

panel or the GPIB.

With analog output gain set to one, a full range input will result in a

232 interface.

ave output and a 3-point measurement algorithm to cancel

ve Device Under

ferential current output and a 3-point moving

eithley Model 7001/7002

Page 29

Front and rear panel familiarization

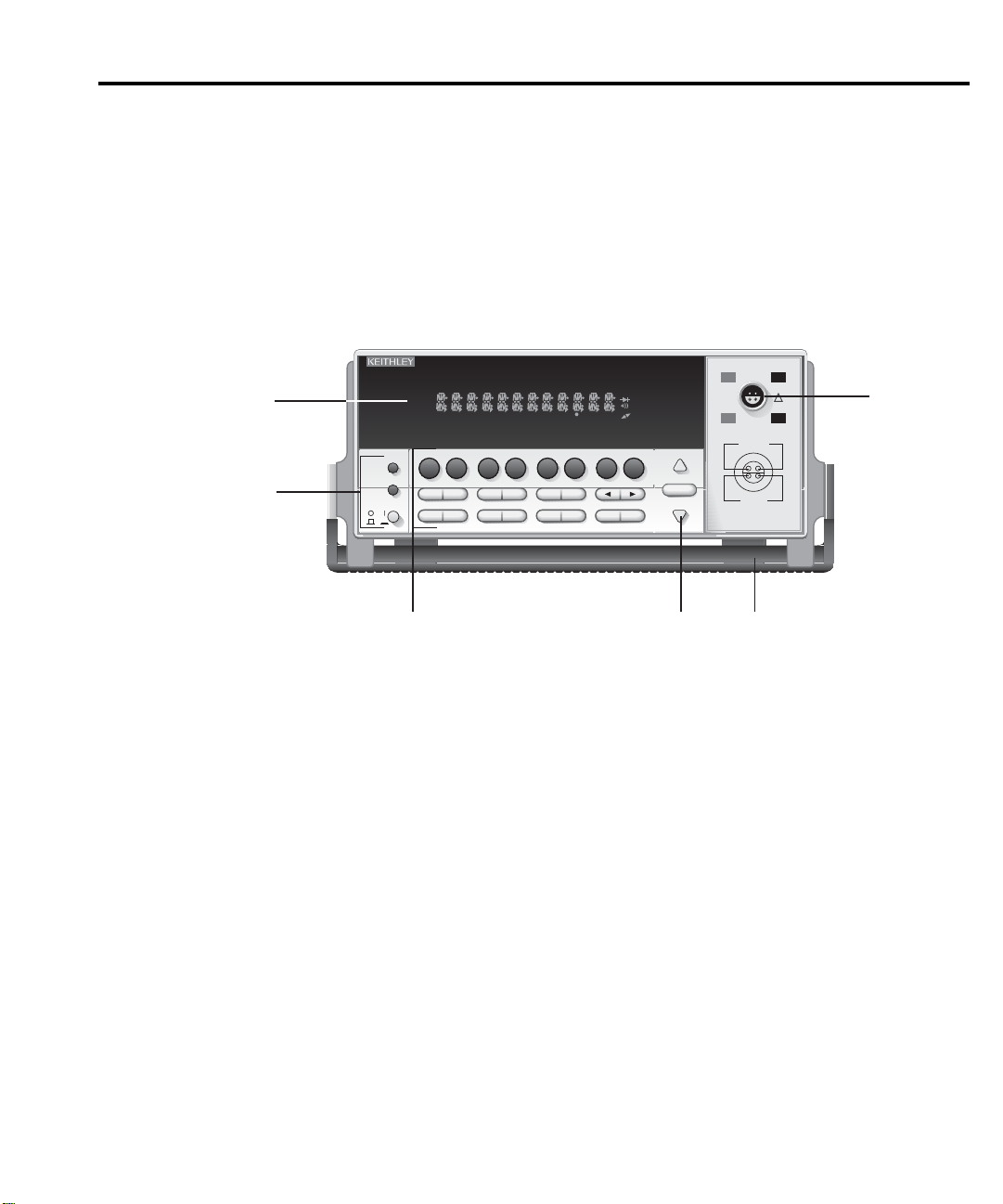

Front panel summary

The front panel of the Model 2182 is shown in Figure 1-1. This figure includes important

abbreviated information that should be reviewed before operating the instrument.

Figure 1-1

Model 2182 front panel

SCAN

CH1REM

STEP CH2 CH3 CH4 CH5 CH6 CH7 CH8 CH9 CH10

TALK

LSTN

4

1

POWER

SRQ

SHIFT

TIMER

HOLD TRIG FAST MED SLOW AUTO ERR

%

MX+B

SHIFT

DCV1

DCV2

HOLD

DELAY

LOCAL

EX TRIG

TRIG

CONFIG HALT

STEP SCAN

V1-V

2

L

ACAL

1/V2

V

BUFFER

STORE

RECALL

SETUP

SAVE RESTR

REL FILT

SYNC

TYPE

OUTPUT

FILT REL

LIMITS

ON/OFFVALUE

RS232

GPIB

DIGITS RATE

MATH

REAR

4W

BUFFER

STAT

2182 NANOVOLTMETER

A

OUT

TCOUPL

TEMP

TEMP

1

CAL TEST

EXIT ENTER

Getting Started

CHANNEL 1

LO

HI

!

HI

LO

CHANNEL 2

120V MAX

2

RANGE

AUTO

RANGE

12V MAX

CAT I

350V PEAK ANY

TERMINAL TO CHASSIS

1-7

5

236

NOTE Most keys provide a dual function or operation. The nomenclature on a key indicates

its unshifted function/oper

ation, which is selected by pressing the key. Nomenclature

(in blue) above a key indicates its shifted function. A shifted function is selected by

pressing the SHIFT key and then the function/operation key.

1 Special keys and power switch

SHIFT Use to select a shifted function or operation.

LOCAL Cancels GPIB remote mode.

POWER Power switch. In position turns 2182 on (1), out position turns it off (0).

Page 30

1-8

Getting Started

2 Function and operation keys

Top Row

Un-shifted

DCV1 Selects Channel 1 voltage measurement function.

DCV2 Selects Channel 2 voltage measurement function.

V1/V2 Selects Ratio (Channel 1 voltage reading / Channel 2 voltage reading).

ACAL Selects automatic gain calibration.

FILT Enables/disables filter for selected measurement function.

REL Enables/disables relative for selected measurement function.

TEMP1 Selects Channel 1 temperature measurement function.

TEMP2 Selects Channel 2 temperature measurement function.

Shifted

MX+B Multiplies a scale factor (M) to the reading (X) and then adds an offset (B).

% Calculates percent deviation from a specified reference.

V1-V2 Selects Delta; (V1t1 – V1t2)/2.

LSYNC Enables/disables line cycle synchronization. When enabled, noise induced

by the power line is reduced at the expense of speed.

TYPE Select filter (analog and/or digital) and configure digital filter (window,

count and type).

OUTPUT Enables/disables relative for Analog Output.

A

OUT

Enables/disables Analog Output.

TCOUPL Configure temperature measurement (units, junction type, thermocouple

type, sensor type).

Middle Row

Un-shifted

EX-TRIG Selects external triggering (front panel, bus or trigger link) as trigger

source.

TRIG Triggers a measurement from the front panel.

STORE Sets reading count for buffer and enables buffer.

RECALL Displays stored readings (including maximum, minimum, peak-to-peak,

average, and standard deviation). The and range keys scroll through

the b

uffer, and the and key toggles between reading number and

reading.

VALUE

Set the upper and lower limits for limit testing.

ON/OFF Enables/disables limit testing, and selects beeper mode for limit testing.

and Controls cursor position for making selections or editing values.

Shifted

DELAY Sets user delay between trigger and measurement.

HOLD Holds reading when the specified number of samples is within the selected

tolerance.

Page 31

Getting Started

Bottom Row

Un-shifted

STEP Steps through channels; sends a trigger after each channel.

SCAN Scans through channels; sends a trigger after last channel.

SAVE Saves present configuration for power-on user default.

RESTR Restores factory or user default configuration.

DIGITS Changes number of digits of reading resolution.

RATE Changes reading rate; number of power line cycles (PLC).

EXIT Cancels selection, moves back to measurement display.

ENTER Accepts selection, moves to next choice or back to measurement display.

Shifted

CONFIG Configures a scan (type, timer, channel count, and reading count).

HALT Turns off step/scan operation.

GPIB Enables/disables GPIB, sets address, and selects language.

RS232 Enables/disables RS-232 interface, selects baud rate, flow control, and

terminator.

CAL Accesses calibration.

TEST Tests display annunciators and front panel keys.

1-9

3 Range keys

Selects the next higher voltage measurement range.

Selects the next lower voltage measurement range.

AUTO Enables/disables autorange.

Page 32

1-10

Getting Started

4 Display annunciators

* (asterisk) Readings being stored in buffer.

↔ (more) Indicates additional selections are available.

))

(speaker) Beeper on for limit testing.

)

AUTO Autorange enabled.

BUFFER Recalling readings stored in buffer.

CH1 Channel 1 input displayed.

CH2 Channel 2 input displayed.

CH1 and CH2 Ratio (V1/V2) reading displayed.

ERR Questionable reading, or invalid cal step.

FAST Fast (0.1 PLC) reading rate selected.

FILT Filter enabled.

HOLD Instrument in hold mode.

LSTN Instrument addressed to listen over GPIB.

MATH mX+b or Percent (%) calculation enabled.

MED Medium (1 PLC) reading rate selected.

REAR Indicates that Analog Output is on.

REL Relative enabled for present measurement function.

REM Instrument in GPIB remote mode.

SCAN Scan mode selected.

SHIFT Accessing a shifted key.

SLOW Slow (5 PLC) reading rate selected.