Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

KBWT SERIES

These Installation and Operation Instructions

Cover Models KBWT-16, 26, 110, 112, 210

SAFETY WARNING, ON PAGE 7, MUST BE READ AND UNDERSTOOD BEFORE PROCEEDING!

1 DESCRIPTION

Thank you for purchasing the KBWT Series Pulse Width Modulated (PWM) Adjustable Speed DC Drive.

KB Electronics, Inc. is committed to providing total customer satisfaction by providing quality products that are

easy to install and operate.

Several models are available that provide the user a choice of input voltage and output current. The drives are

designed to operate Permanent Magnet (PM) DC motors rated 0.75 HP (0.5 kW) thru 2.2 HP (1.7 kW) continuous

duty and 1.5 HP (1.1 kW) thru 4.0 HP (3.0 kW) intermittent duty.

The drive provides excellent dynamic response to load variation. The efficient PWM waveform produces an

almost pure DC current to the motor (form factor < 1.05), which has several advantages over a conventional SCR

control. PWM significantly lowers audible motor noise and provides longer brush life. It also produces less motor

heating, allowing a smaller and less costly motor to be used for most applications. Another advantage of PWM is

higher output voltage, which provides increased output speed. In addition, pulse-by-pulse current sensing

provides short circuit protection and prevents control damage due to shorted motors.

A unique feature of the drive is its active bridge, which provides a substantial reduction in AC line surge current

each time the control is turned on. This prevents nuisance tripping of the circuit breaker and allows the control to

be turned on or off rapidly without damage to critical components. The drive also contains a built-in safety circuit

that will shut down the control if the main power transistor short circuits. This prevents high-speed runaway,

a potential problem with competitors’ controls.

The drive utilizes heat-spreader construction. This system provides an enhanced thermal path that eliminates

overtemperature cycles which cause premature failure of the power transistor. Other features of the drive are

Timed Current Limit (TCL) motor burnout protection (I x t), which will shut the control down if the motor is

overloaded for a predetermined time and the Potentiometer Safety Circuit™ (PSM), which prevents the control

from starting when the AC line is applied unless the signal input is reset to zero. Diagnostic LEDs for Power On

(PWR) and Overload (OL) indication are also provided. The drive contains barrier terminal blocks as standard or

quick-connect terminals for OEM applications. A 5 kΩ Main Speed Potentiometer (supplied), an isolated analog

input signal (0 – 5 Volts DC), or an isolated Pulse Width Modulated (PWM) signal from a microprocessor can be

used to control motor speed.

STANDARD FEATURES

• Short Circuit Protection: Pulse-by-pulse current sensing provides short circuit protection and prevents control

damage due to shorted motors.

• Timed Current Limit (TCL): Electronic Motor Burnout Protection (I x t) will trip the drive if an overload condition

persists for a predetermined time of 3 seconds (factory setting), 5 seconds, or 10 seconds.

• Status Indicator LEDs: Power On (PWR) and Overload (OL).

• Active Bridge: Provides controlled AC line inrush current limiting.

• Power Transistor Short Circuit Runaway Protection: Will shut down the control if the main power transistor

short circuits.

• Heat-Spreader: Eliminates overtemperature cycles which cause premature failure of the power transistor.

• Adjustable Trimpots: Current Limit (CL), IR Compensation (IR), Maximum Speed (MAX), Minimum Speed

(MIN), Acceleration (ACCEL), and Deceleration (DECEL).

• Potentiometer Safety Circuit: Prevents startup with the AC line unless the signal input is set to zero.

• Barrier Terminal Blocks: Facilitate wiring of the AC Line input, motor armature, motor field (shunt wound

motors only), and signal inputs.

• Quick-Connect Terminals: Used to connect an Inhibit switch or contact.

• Armature Fuse: Models KBWT-16, 26 contain a 10 Amp fuse, Models KBWT-110, 210 contain a 15 Amp fuse,

and Model KBWT-112 contains a 20 Amp fuse.

KBWT Series Installation and Operation Instructions (A40130) – Rev. B00 – 5/29/2013

RoHS

Page 1 of 7

Page 2

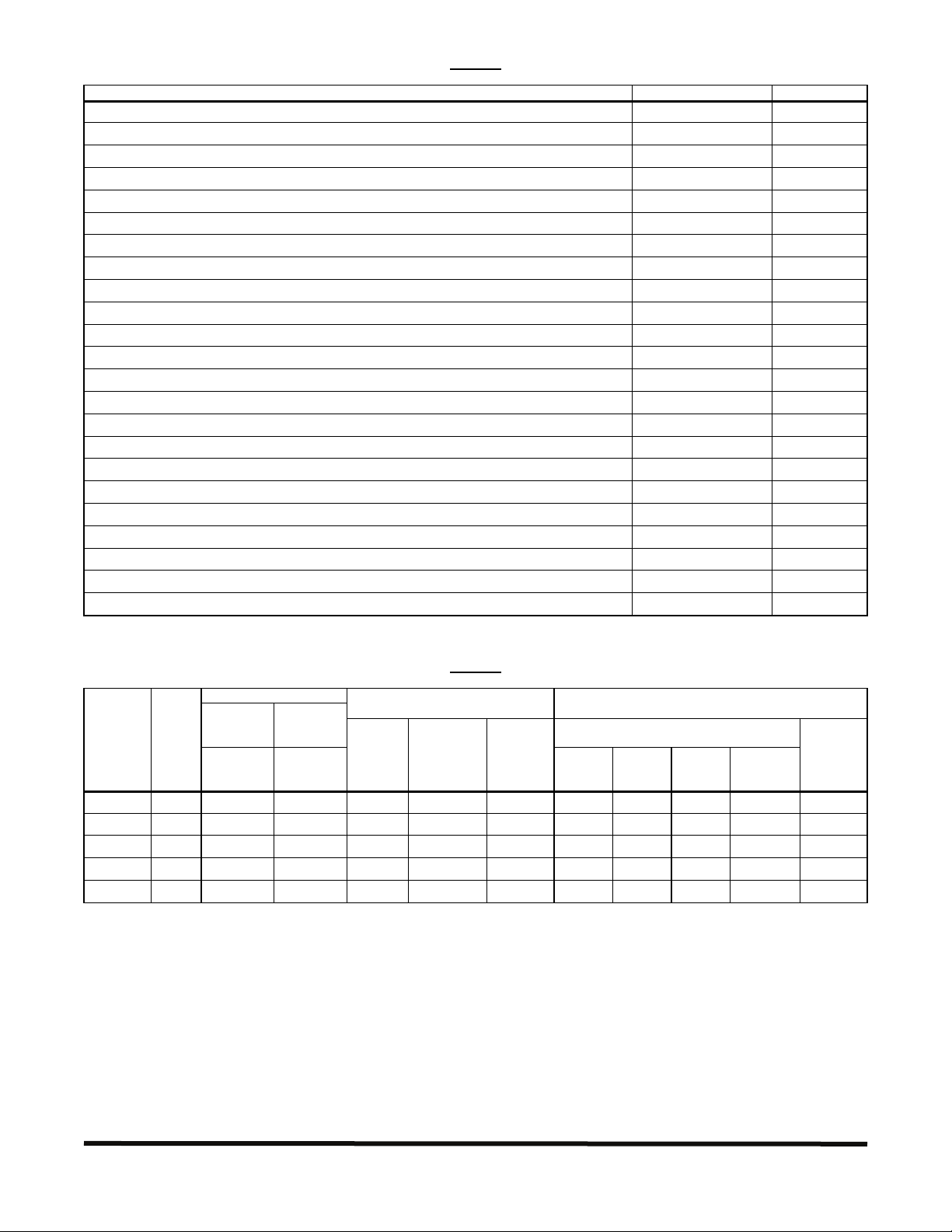

GENERAL PERFORMANCE SPECIFICATIONS

Description Specification Factory Setting

Models KBWT-16, 110, 112 AC Line Input Operating Range (Volts AC, 50/60 Hz) 115 (± 15%) ──

Models KBWT-26, 210 AC Line Input Operating Range (Volts AC, 50/60 Hz) 208 (-15%) / 230 (+15%) ──

Speed Range (Ratio) 50:1 ──

Field Voltage for Models KBWT-16, 110, 112 (for Shunt Wound Motors Only) (Volts DC) 100 / 50 ──

Field Voltage for Models KBWT-26, 210 (for Shunt Wound Motors Only) (Volts DC) 200 / 100 ──

Operating Frequency (kHz) >16 ──

Form Factor (RMS/AVG Amps) <1.05 ──

AC Line Load Regulation (% Base Speed) 0.5 ──

Load Regulation (% Base Speed) 1* ──

Analog Input Voltage (Voltage Following) (Volts DC) 0 – 5 ──

Voltage Following Linearity (% Base Speed) ±5 ──

Main Speed Potentiometer (5 Watts) 5 kΩ ──

Fixed Timed Current Limit (I X t) (Seconds) 3, 5, 10 3

Current Limit (CL) Trimpot Range (% Full Load) 0 – 200 150

IR Compensation (IR) Trimpot Range at Full Load (Models KBWT-16, 26) (Volts DC) 0 – 15 6

IR Compensation (IR) Trimpot Range at Full Load (Models KBWT-110, 112, 210) (Volts DC) 0 – 15 3

Maximum Speed (MAX) Trimpot Range (% Base Speed) 50 – 100 100

Minimum Speed (MIN) Trimpot Range (% Base Speed) 0 – 30 0

Acceleration (ACCEL) Trimpot Range (Seconds) 0.2 – 12 2

Deceleration (DECEL) Trimpot Range (Seconds) 0.2 – 12 2

Operating Temperature Range (°C / °F) 0 – 40 / 32 – 104 ──

Operating Humidity Range (% Relative, Non-Condensing) 0 – 95 ──

Storage Temperature (°C / °F) -25 – +85 / -13 – +185 ──

*Based on a motor having linear IR compensation characteristics.

Maximum Horsepower

Continuous

Duty

Model No. Part No.

KBWT-16 8614 0.75 (0.5) 1.5 (1.1) 115 10 15 6.0 90 6.0 130 10.0

KBWT-26 8615 1.5 (1.1) 3.0 (2.0) 208/230 10 15 6.0 180 6.0 200 10.0

KBET-110 8603 1.2 (0.9) 2.0 (1.5) 115 15 20 10.0 90 8.5 130 15.0

KBWT-112 8612 1.5 (1.1) 2.5 (1.9) 115 18 25 12.0 90 10.5 130 20.0

KBWT-210 8610 2.2 (1.7) 4.0 (3.0) 208/230 15 20 10.0 180 8.5 200 15.0

HP (kW) HP (kW)

Intermittent

Duty

(1 Minute) Continuous Duty Rating

Volts AC

(50/60 Hz)

TABLE 1

TABLE 2

ELECTRICAL RATINGS

AC Line Input Output

Maximum

Current

(Amps RMS)

Fuse or

Circuit

Breaker

Rating

(Amps AC)

Amps DC Volts DC Amps DC Volts DC

Armature

Fuse

(Amps DC)

WARNING! This drive has been factory Hi-Pot tested. If you choose to perform another Hi-Pot test on the

drive, there is a risk that the drive can be damaged. Contact our Sales Department.

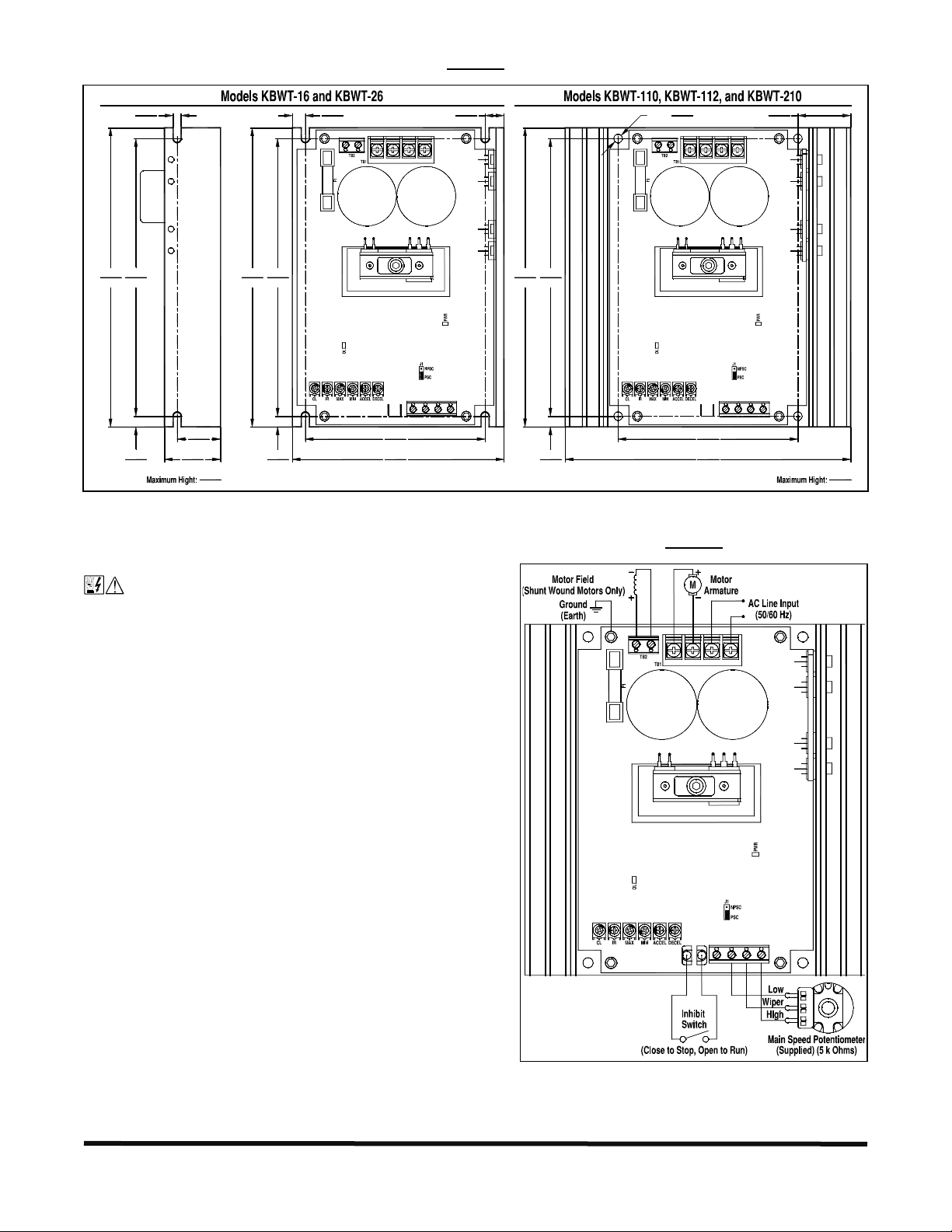

2 MOUNTING INSTRUCTIONS

The drive should be mounted on a flat surface and located in an area where it will not be exposed to

contaminants such as water, metal chips, solvents, or excessive vibration. When mounting the drive in an

enclosure, the enclosure should be large enough to allow proper heat dissipation so that the ambient temperature

does not exceed 40 °C (104 °F) at full rating. See Figure 1, on page 3.

KBWT Series Installation and Operation Instructions (A40130) – Rev. B00 – 5/29/2013

Page 2 of 7

Page 3

MECHANICAL SPECIFICATIONS (INCH / mm)

FIGURE 1

7.00

178

6X Ø

6.50

165

0.25

6.35

0.19

4.83

1.125

28.6

1.325

33.7

2.00

50.8

7.00

178

0.305

7.75

F+ F− A+ A− L1 L2

6.50

165

I1I2

4.25

108

0.25

2X

6.35

5.00

127

V+ P1 P2 P3

TB3

0.445

11.3

7.00

178

6.50

165

0.25

2X

6.35

0.20

4X Ø

5.08

F+ F− A+ A− L1 L2

I1I2

4.25

108

6.75

171

V+ P1 P2 P3

1.25

2X

31.8

TB3

3.25

82.6

3 ELECTRICAL CONNECTIONS

See Figure 2 for the connections to the drive.

GENERAL CONNECTION DIAGRAM AND DRIVE LAYOUT

FIGURE 2

WARNING! HIGH VOLTAGE! The Safety Warning,

on page 7, must be read and understood before using

the drive. Disconnect the main power before making

F+ F− A+ A− L1 L2

connections to the drive. To avoid electric shock, be

sure to properly ground the drive.

3.1 AC Line Input and Ground: Connect the AC line input

to TB1 Terminals L1 and L2. Connect the chassis to earth

ground. Be sure the AC Line voltage corresponds to the drive

voltage rating, as shown in Table 2, on page 2.

3.2 AC Line Input Fusing: The drive does not contain AC

Line fuses. Most electrical codes require that each

ungrounded conductor contain circuit protection. Do not fuse

neutral or ground connections. It is recommended to install a

fuse (Littelfuse 326, Buss ABC, or equivalent) or a circuit

breaker (Square D QOU or equivalent) in series with each

ungrounded conductor. For the recommended fuse or circuit

breaker rating, see Table 2, on page 2.

3.3 Motor Armature: Connect the motor armature to TB1

I1I2

TB3

V+ P1 P2 P3

Terminals A+ and A-. Be sure the motor voltage corresponds

to the drive output voltage rating, as shown in Table 2, on

page 2.

3.4 Armature Fuse: Models KBWT-16, 26 contain a 10 Amp fuse, Models KBWT-110, 210 contain a 15 Amp

fuse, and Model KBWT-112 contains a 20 Amp fuse. The fuse should be rated 1.5 times the full load rating of

the motor. See Table 2, on page 2.

KBWT Series Installation and Operation Instructions (A40130) – Rev. B00 – 5/29/2013

Page 3 of 7

Page 4

3.5 Motor Field (Shunt Wound Motors Only): Connect the motor field as described in Sections 3.5.1 and 3.5.2.

A

r

FIGURE 3

FULL VOLTAGE FIELD

F+ F− A+ A− L1 L2

TABLE 3

FIELD CONNECTION (SHUNT WOUND MOTORS ONLY)

Model

KBWT-16, 110, 112 115 0 – 90

KBWT-26, 210 208/230

*Step-down operation.

AC Line

Input Voltage

(Volts AC)

Armature

Voltage

(Volts DC)

0 – 180 200 F+ and F-

0 – 90* 100 F+ and L1

Field Voltage

(Volts DC) Terminals

100 F+ and F-

50 F+ and L1

FIGURE 4

HALF VOLTAGE FIELD

F+ F− A+ A− L1 L2

M

Notes: 1. Do not use field terminals for any purpose other than to power the field of a shunt wound motor. 2. Do

not connect motor armature to the field terminals. 3. Shunt wound motors may be damaged if the field remains

energized without armature rotation for an extended period of time.

3.5.1 Full Voltage Field: For 90 Volt DC motors with 100 Volt DC field and 180 Volt DC motors with 200 Volt DC

field. Connect the field positive (+) lead to TB2 Terminal F+ and the field negative lead (-) to TB2 Terminal F-, as

shown in Figure 3 and Table 3, above.

3.5.2 Half Voltage Field: For 90 Volt DC motors with 50 Volt DC field and 180 Volt DC motors with 100 Volt DC

field. Connect the field positive lead (+) to TB2 Terminal F+ and the field negative lead (-) to TB1 Terminal L1, as

shown in Figure 4 and Table 3, above.

3.6 Inhibit Switch or Contact: The drive can be electronically stopped and started with

an Inhibit switch or contact connected to TB3 Terminals I1 and I2. When the switch or

FIGURE 5

INHIBIT

contact is closed, the drive motor will coast to stop. When the switch or contact is opened,

the motor will run at the Main Speed Potentiometer or signal input setting. See Figure 5.

I1I2

3.7 Signal Input: The drive can be operated with a 5 kΩ Main Speed Potentiometer

(supplied), an isolated 0 – 5 Volt DC analog signal, or an isolated Pulse Width Modulated

(PWM) signal from a microprocessor.

Note: If an isolated signal is not available, an optional signal isolator must be installed (KBSI-240D

(Part No. 9431) or equivalent).

3.7.1 Main Speed Potentiometer:

Connect the potentiometer low side

to Terminal P1, the wiper to

Terminal P2, and the high side to

Terminal P3. See Figure 6.

3.7.2 Voltage Following Signal:

An isolated 0 – 5 Volt DC analog

voltage signal can be used to

control motor speed. Connect the

isolated voltage signal positive (+)

lead to Terminal P2 and the

negative (-) to Terminal P1. See

Figure 7.

3.7.3 Microprocessor Signal:

n isolated PWM signal from a

microprocessor can be used to

control motor speed. The

output frequency should be 200

Hz or higher and should be

derived from an optocouple

with a transistor or operational

amplifier signal output. See

Figure 8.

MAIN SPEED POTENTIOMETER

FIGURE 6

TB3

V+ P1 P2 P3

FIGURE 7

VOLTAGE FOLLOWING SIGNAL INPUT

TB3

V+ P1 P2 P3

+

FIGURE 8

MICROPROCESSOR SIGNAL INPUT

TB3

V+ P1 P2 P3

KBWT Series Installation and Operation Instructions (A40130) – Rev. B00 – 5/29/2013

Page 4 of 7

Page 5

4 SELECTABLE JUMPER J1

The drive contains a Potentiometer Safety Circuit (PSC). When power is applied to

the drive the signal input must first be set to zero: the Main Speed Potentiometer

must be set fully counterclockwise, or the analog signal must be set to 0 Volts DC,

FIGURE 9

JUMPER JI SETTINGS

Jumper J1 Set to

"PSC" Position

(Factory setting)

Jumper J1 Set to

"NPSC" Position

or the PWM signal must be set to 0 Volts DC. Then increase the signal to the

desired setting to control motor speed.

Jumper J1 is factory set to the "PSC" position, to enable the Potentiometer Safety Circuit. To disable the

Potentiometer Safety Circuit, set Jumper J1 to the "NPSC" position. See Figure 9. See Figure 2, on page 3, for

the location of Jumper J1.

5 DIAGNOSTIC INDICATORS

Two diagnostic LEDs are provided to indicate the drive's operational status. See Figure 2, on page 3, for the

location of the LEDs.

5.1 Power ON (PWR): The PWR LED will illuminate green when AC line is applied to the drive.

5.2 Overload (OL): When the motor is loaded to the Current Limit (CL) set point (established by the CL Trimpot

setting), the OL LED will illuminate red. If the drive is allowed to stay in CL and then "times out" in Timed Current

Limit (TCL), the OL LED will remain illuminated until the drive is restarted (either by an On/Off AC Line Switch or

with the Inhibit Switch). If the OL LED remains illuminated during normal drive operation, a fault condition may

exist. On cyclical loads, it may be normal for the CL LED to momentarily flash.

6 ADJUSTABLE TRIMPOTS

The drive contains trimpots which have been factory set for most applications. Figure 2, on page 3, illustrates the

location of the trimpots and their approximate factory settings. Some applications may require readjustment of the

trimpots in order to tailor the drive for a specific requirement. See Figures 10 – 15, for the trimpot ranges.

WARNING! If possible, do not adjust trimpots with the main power applied. If adjustments are

made with the main power applied, an isolated adjustment tool must be used and safety glasses must be

worn. High voltage exists in this control. Electrocution can result if caution is not exercised. The Safety

Warning, on page 7, must be read and understood before proceeding.

FIGURE 10

CL TRIMPOT

RANGE

(% FULL LOAD)

150

2000

FIGURE 11

IR TRIMPOT

RANGE

(VOLTS DC)

3, 6

150

FIGURE 12

MAX TRIMPOT

RANGE

(% BASE SPEED)

50

100

FIGURE 13

MIN TRIMPOT

RANGE

(% BASE SPEED)

300

FIGURE 14

ACCEL TRIMPOT

RANGE

(SECONDS)

2

120.2

FIGURE 15

DECEL TRIMPOT

RANGE

(SECONDS)

2

120.2

6.1 Current Limit Trimpot (CL): The CL Trimpot sets the current limit (overload), which limits the maximum

current (torque) to the motor. The CL also limits the AC line inrush current to a safe level during startup. The CL

Trimpot is factory set to 1.5 times the full load rating of the drive. To increase the current limit, rotate the CL

Trimpot clockwise (do not exceed 2 times motor current rating (maximum clockwise position)). To decrease

the current limit, rotate the CL Trimpot counterclockwise. See Figure 10, above.

Note: On cyclical loads, it may be normal for the CL LED to momentarily flash.

KBWT Series Installation and Operation Instructions (A40130) – Rev. B00 – 5/29/2013

Page 5 of 7

Page 6

To Recalibrate the CL Trimpot:

1 Disconnect the AC power and wire a DC ammeter in series with either motor armature lead.

Note: If only an AC ammeter is available, wire it in series with either AC line input lead.

2 Set the Main Speed Potentiometer to approximately 30 – 50 % clockwise position.

3 Set the CL Trimpot fully counterclockwise. The CL LED will illuminate red.

4 Lock the motor shaft (be sure the CL Trimpot is set fully counterclockwise).

5 Apply power and rotate the CL Trimpot clockwise until the desired current reading is observed on the DC

ammeter. Factory Current Limit setting is 1.5 times the full load rating of the motor (with a DC ammeter wired

in series with the motor armature). If using an AC ammeter wired in the AC line input, the factory Current Limit

setting will read 0.75 times the full load rating of the motor. Do not exceed 2 times motor current rating

(maximum clockwise position).

Note: Steps 4 and 5 must be completed within 3 seconds or the Timed Current Limit (TCL) will trip the drive. If the

drive trips in TCL the drive must be restarted (either with the On/Off AC Line Switch or the Inhibit Switch).

Warning! Do not leave motor shaft locked for more than 2 – 3 seconds or motor damage may result.

6.2 IR Compensation Trimpot (IR): The IR Trimpot sets the amount of compensating voltage required to keep

the motor speed constant under changing loads. If the load does not vary substantially, the IR Trimpot may be set

to a minimum level (approximately 1/4 of full clockwise rotation). The IR Trimpot is factory set to provide 6 Volts of

compensation for Models KBWT-16, 26 and 3 Volts of compensation for Models KBWT-110, 112, 210.

To increase the amount of compensating voltage, rotate the IR Trimpot clockwise. To decrease the amount of

compensating voltage, rotate the IR Trimpot counterclockwise. See Figure 11, on page 5.

Note: Excessive IR Compensation will cause the motor to become unstable, which causes cogging.

To Recalibrate the IR Trimpot:

1 Set the IR Trimpot to approximately 25 % rotation.

2 Run the motor unloaded at approximately 1/3 speed and record the RPMs.

3 Run the motor with the maximum load and adjust the IR Trimpot so that the motor speed under load equals

the unloaded speed recorded in step 2.

4 Remove the load and recheck the RPMs.

5 If the unloaded RPM has changed, repeat steps 2 – 4 for more exact regulation. The control is now

compensated to provide minimal speed change due to changing loads.

6.3 Maximum Speed Trimpot (MAX): The MAX Trimpot sets the maximum speed of the motor when the Main

Speed Potentiometer is set fully clockwise. The MAX Trimpot is factory set to 100% of base motor speed.

To increase the maximum speed, rotate the MAX Trimpot clockwise. To decrease the maximum speed, rotate the

MAX Trimpot counterclockwise. See Figure 12, on page 5.

Caution! Do not set the maximum speed above the rated motor RPM since unstable motor operation may occur.

6.4 Minimum Speed Trimpot (MIN): The MIN Trimpot sets the minimum speed of the motor when the Main

Speed Potentiometer is set fully counterclockwise. The MIN Trimpot is factory set to 0% of base motor speed.

To increase the minimum speed, rotate the MIN Trimpot clockwise. To decrease the minimum speed, rotate the

MIN Trimpot counterclockwise. See Figure 13, on page 5.

6.5 Acceleration Trimpot (ACCEL): The ACCEL Trimpot is provided to allow for a smooth start over an

adjustable time period each time the AC power is applied or the Main Speed Potentiometer is adjusted to a higher

speed. The ACCEL Trimpot is factory set to 2 seconds, which is the amount of time it will take for the motor to

accelerate from zero speed to full speed. To increase the acceleration time, rotate the ACCEL Trimpot clockwise.

To decrease the acceleration time, rotate the ACCEL Trimpot counterclockwise. See Figure 14, on page 5.

KBWT Series Installation and Operation Instructions (A40130) – Rev. B00 – 5/29/2013

Page 6 of 7

Page 7

6.6 Deceleration Trimpot (DECEL): The DECEL Trimpot controls the amount of ramp-down time when the

Main Speed Potentiometer is adjusted to a lower speed. The DECEL Trimpot is factory set to 2 seconds, which is

the amount of time it will take for the motor to decelerate from full speed to zero speed. To increase the

deceleration time, rotate the DECEL Trimpot clockwise. To decrease the acceleration time, rotate the DECEL

Trimpot counterclockwise. See Figure 15, on page 5.

Note: The deceleration time cannot be made less than the natural coast time of the motor and actual load.

7 OPERATION

WARNING! The Safety Warning, on page 1, must be read and understood before attempting to

operate this drive or severe injury or electrocution can result.

After the drive has been set up properly and wiring has been completed, the start-up procedure can begin. If the

AC power has been properly connected to the drive, the PWR LED should illuminate green. Before starting, be

sure that the Main speed Potentiometer is in the minimum position (fully counterclockwise). To start the drive,

rotate the potentiometer clockwise. The motor should begin to rotate.

Note: If the motor rotates in the incorrect direction, it will be necessary to disconnect the main AC power and

reverse the armature leads.

SAFETY WARNING! – PLEASE READ CAREFULLY!

This product must be installed and serviced by a qualified technician, electrician, or electrical maintenance

person familiar with its operation and the hazards involved. Proper installation, which includes electrical

connections, fusing or other current protection, and grounding, can reduce the chance of electrical shocks,

and/or fires, in this product or products used with this product, such as electric motors, switches, coils, solenoids,

and/or relays. Do not use this drive in an explosion-proof application. Eye protection must be worn and insulated

adjustment tools must be used when working with drive under power. This product is constructed of materials

(plastics, metals, carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding, and filtering

of this product can reduce the emission of radio frequency interference (RFI) which may adversely affect

sensitive electronic equipment. It is the responsibility of the equipment manufacturer and individual installer to

supply this Safety Warning to the ultimate end user of this product. (SW 8/2012)

The drive contains electronic Start/Stop circuits, which can be used to start and stop the drive. However, these

circuits are never to be used as safety disconnects since they are not fail-safe. Use only the AC Line for this

purpose.

Be sure to read and follow all instructions carefully. Fire and/or electrocution can result due to improper use of this

product.

This product complies with all CE directives pertinent at the time of manufacture. Contact our Sales

Department for Declaration of Conformity. Installation of a CE approved RFI filter (KBRF-200A (Part No. 9945),

or equivalent) is required. Additional shielded motor cable and/or shielded AC Line cables may be required along

with a signal isolator (KBSI-240D (Part No. 9431) or equivalent).

KBWT Series Installation and Operation Instructions (A40130) – Rev. B00 – 5/29/2013

Page 7 of 7

Loading...

Loading...