Page 1

ASSEMBLY INSTRUCTIONS

for :

PRO-II KS

Parts: 0111-0 & 0113-0

®

11_1.1

(916) 638-8703

• 11253- G Trade Center Drive • Rancho Cordova, CA 95742 •

(800) 343-7486

Page 2

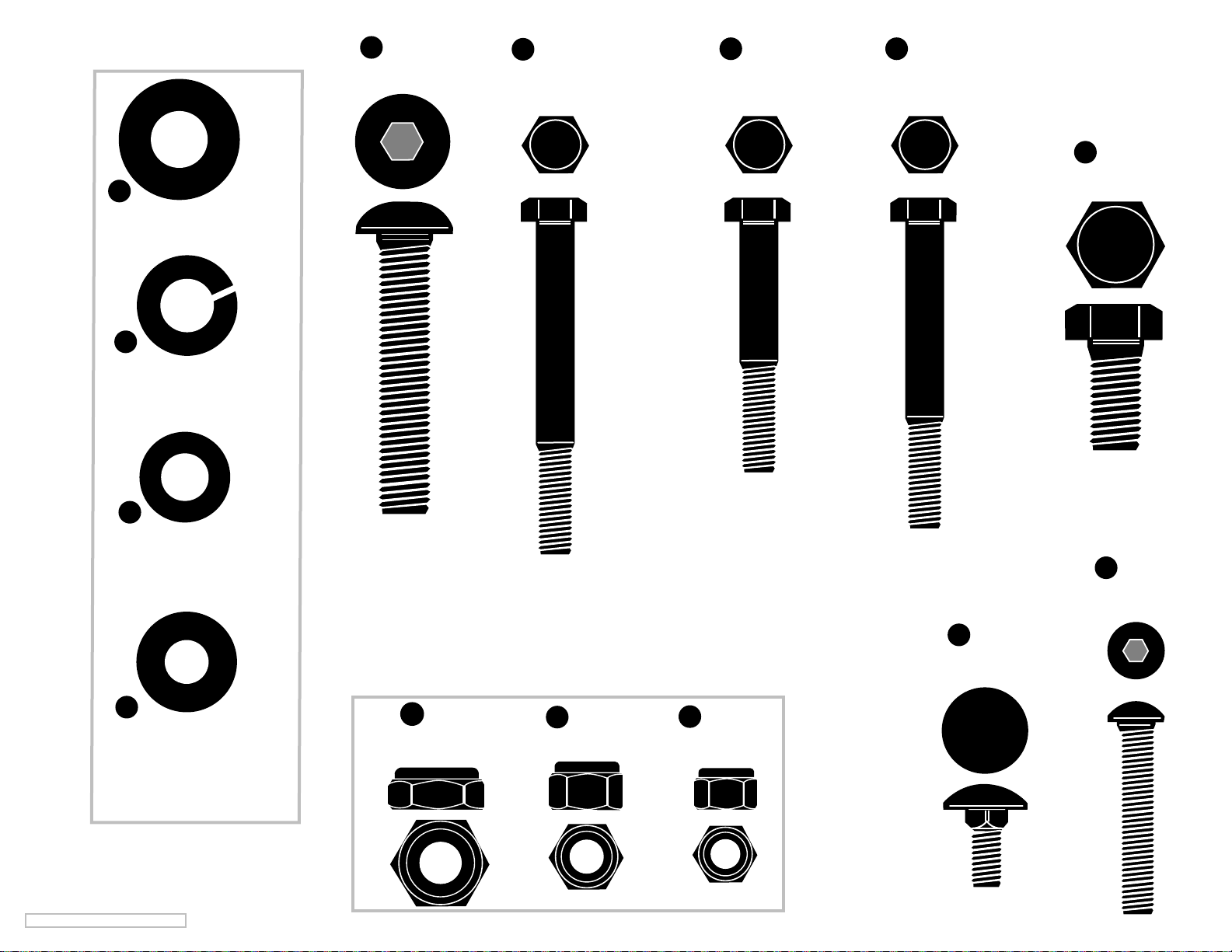

H

(11 ea.)

1/2" SAE Flat Washer

O

(9 ea.) 1/2" Lock Washer

G

(2 ea.)

1/2" x 2 1/2"

Button Head Bolt

F

3/8" x 3"

Hex Bolt

(4 ea.)

(1 ea.)

W

3/8" x 2 1/4"

Hex Bolt

(2 ea.)

Z

3/8" x 2 3/4"

Hex Bolt

PII-"KS"

0111-0 & 0113-0

(8 ea.)

P

1/2" x 1"

Hex Bolt

U

(15 ea.) 3/8" SAE Flat Washer

L

(25 ea.) 5/16" Flat Washer

© 2011 KargoMaster-'KS' _11_1.1

I

(3 ea.)

1/2" Jam Lock Nut

Thin

R

(8 ea.)

3/8" Lock Nut

M

(17 ea.)

5/16" Lock Nut

(8 ea.)

Q

5/16" x 3/4"

Carriage Bolt

(8 ea.)

X

5/16" x 1 3/4"

Button Head Bolt

Page 3

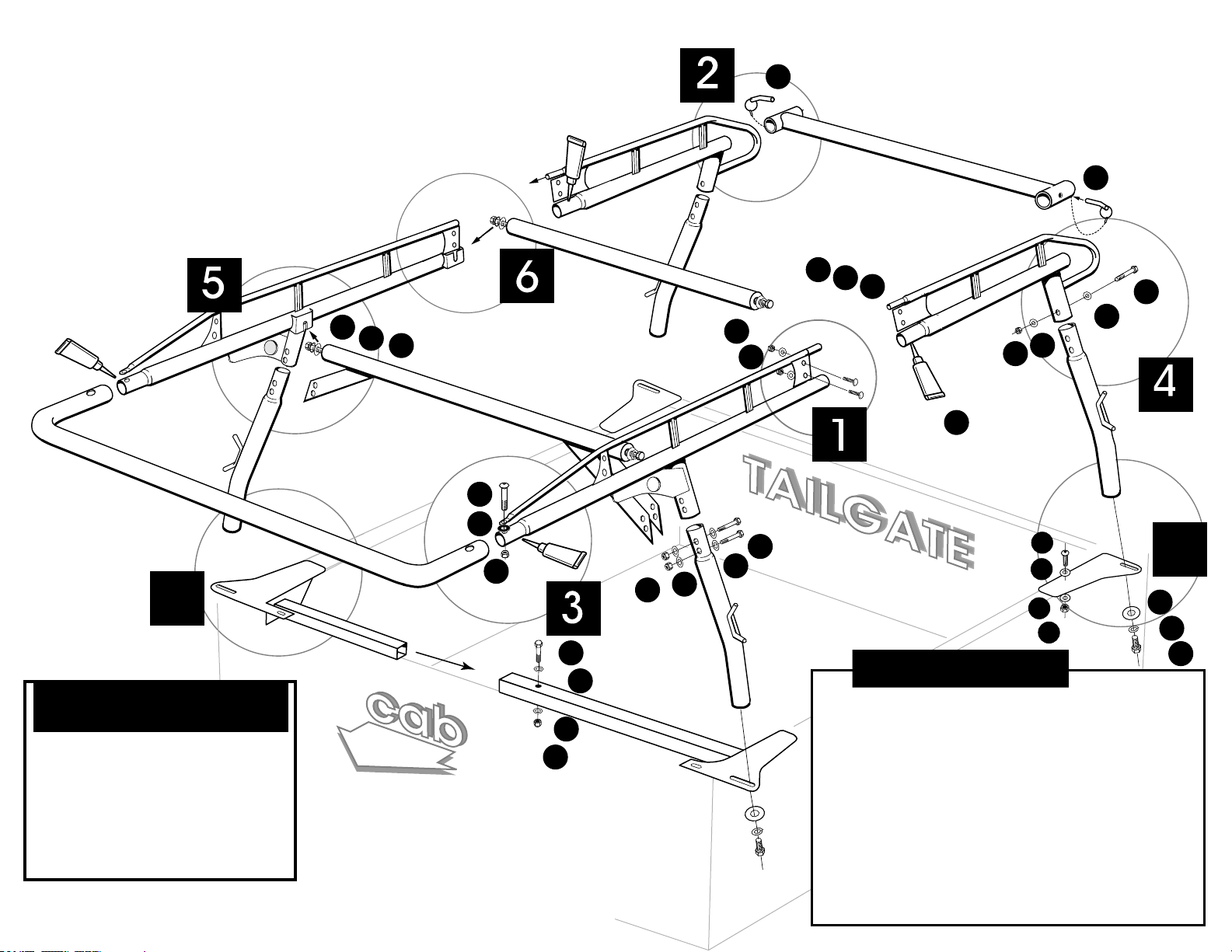

ASSEMBLY INSTRUCTIONS

Read all instructions carefully and

follow each step in proper sequence

for ease and speed in assembling

your KARGO-MASTER RACK. See below

for nuts and bolts diagram.

5

S

i

l

i

c

o

n

e

P

O

H

G

KS

2

J

0111-01 & 0113-0

P

O

O

G

P

O

H

J

Z

U

M

U

L

G

O

O

P

R

4

Q

1

88

8

REQUIRED TOOLS

NOT INCLUDED

• RATCHET WRENCH WITH

1/2", 9/16", & 3/4" SOCKETS

• ADJUSTABLE END WRENCH

• 3/8" DRILL WITH 3/8" DRILL BIT

• CENTER PUNCH AND HAMMER

• 3/4" OPEN END WRENCH

© 2011 KargoMaster-'KS' _11_1.1

Z

G

O

O

P

I

R

3

W

U

U

R

FOR HIGH RISE CAMPER SHELL APPLICATIONS,

YOU'LL NEED TO PURCHASE SEPARATELY

ACCESSORY LEG KIT # :

31520 - MINI

31530 - FULL SIZE

31540 - 99 - F250/F350

U

U

F

X

L

L

M

H

77

7

O

P

CAUTION!

• Too much weight will greatly reduce the stability of your

vehicle. Weight carried on an overhead rack will

significantly increase the vehicle's tendency to

overturn. Kargo Master makes no representation or

warranty as to the amount of weight that can be carried

safely by or without damaging the body of your vehicle.

For guidance, we recommend that you consult the

vehicle manufacturer.

• Do not use your rack with the REAR CROSS BAR

removed. The structural integrity will be affected.

• Secure all payloads properly for safe transportation.

Page 4

KS_

11_1.1

GOOP APPLICATION

Apply a healthy air tight bead of goop

around every swaged joint as shown, to

prevent moisture from leaking into and out

of the joint. If this is not done properly, the

inside surface of the tubes can rust and

rusty water can leak out. Maintain this

joint seal throughout the life of your rack.

STEP 1

#1 = Cover entire swedge joints with GOOP and

join FRONT and REAR side channels together.

Be sure the connecting plates overlap and bolt

together with bolts Q, washers L and lock nuts M.

Swaged joint & holes

Smooth goop at swaged joint & holes

M

L

GOOP

GOOP

P

O

O

G

Q

STEP 2

#1= Slide REAR BAR on to

REAR SIDE BEAMS

#2= Fully insert LOCK PINS

completely to the bend of the pin

D

04

06

J

STEP 3

#1 = Cover entire swedged joint surfaces with GOOP.

Slide FRONT CROSS BAR

#2 = BOLT TOGETHER with TOP (small tube)

& SIDE RAIL (large tube), as shown, using bolt

The allen wrench is included in the package.

A into FRONT SIDE BEAMS 03 & 05.

D

G & nut I.

A

06

D

J

G

GOOP

05

I

Page 5

STEP 4

KS_11_1.1

NOTE: All 4 LEGS are identical with the

exception of PART 0113-0 (FORD SUPER

DUTY), The FRONT legs are bent twice

and the REAR legs are bent only once.

NOTE: FOR HIGH RISE CAMPER SHELLS, UP TO 6" ABOVE

THE CAB , YOU WILL NEED TO PURCHASE SEPARATELY

ACCESSORY EXTENDED LEG KIT # :

31520 - MINI TRUCK

31530 - FULL SIZE TRUCK

31540 - '99 + F250/F350

NOTE: Steps #4 & #5 are more easily completed

with rack turned upside down.

#1= Cover entire swedged joint surfaces with GOOP,

Then insert the swedged end of each leg, rope hooks

facing outward, into the short leg cup.

Repeat this operation for each leg, leaving

LEGS unbolted.

#2= Bolt REAR LEGS (as shown)

FRONT

Leg Cup

GOOP

01

Silicone

GOOP

GOOP

01

01

U

R

Z

01

U

01

STEP 5

#1= At each end of CENTER CROSS BAR ,

start BOLTS & WASHERS. Be sure to include

both flat and lock WASHERS.

Leave loose enough so that

BOLT shaft can be slid into

the FRONT SLOTTED BRACKET

as shown in #3 below.

#2= On one side of rack, slide BOLTS & WASHERS

into

FRONT SLOTTED BRACKET as shown in #3 below.

On the other side of the rack, slide the BOLT &

WASHERS into FRONT SLOTTED BRACKET. Bolt

CENTER CROSS BAR

BRACES and LEG together

(snug only).

Returning to the other side

of the rack, bolt the

CENTER CROSS BAR

BRACES

and LEG together (snug only)

F

B

U

B

44

//

#3= With an open end

3/4" wrench, snug the

CENTER CROSS BAR

B

33

BOLTS on each side of

the rack.

B

R

H

O

P

Page 6

STEP 6

KS_11_1.1

#2= At each end of CROSS BAR

start BOLTS & WASHERS

P

C

H

O

Slide BOLTS & WASHERS into SLOTTED BRACKETS

on the INSIDE CLAMP PLATES , snug with an open end 3/4" wrench (included in this package)

7a

44

//

P

O

H

33

C

C

H

P

O

01

W

U

U

R

(MOUNTING PLATES WILL VARY)

Depending on the make and

model of truck.

STEP 7

The front Mounting Plates have Support Arms. Slide one Arm

into the other and attach this assembly loosely to the front

legs of the rack using bolts P, lock washers O , and flat

washers H. Attach rear Mounting Plates loosely to legs using

bolts P, lock washers O & flat washers H.

Page 7

STEP 8

(MOUNTING PLATES WILL VARY DEPENDING

ON MAKE AND MODEL OF TRUCK)

H

REAR VIEW OF TRUCK

CAMPER SHELL

KS_11

_

1.1

#1 = Remove your camper shell from truck. Note wheather or not there is

a ridge on the bottom of your shell.

O

P

Outside of

Truck Bed

#2 = Position the rack on the truck as far forward as possible, with Mounting Plate tongue over the front bulkhead of the

truck bed. Center the rack left to right on truck bed. Slide the front Mount Plates apart so that they are flush against

opposite sides of the truck bed. Measure the inside dimension of the Mount Plates just above the Support Bar, and the

outside diminsion of the ridges (if any) on the bottom of your shell. It may be necessary to notch this ridge to avoid

interference with the Mount Plates. Or, you may want to notch the ridge front and back so that the Mount Plates can be slid

in towards the center of the truck to minimize overhang.

#3 = With the Mount Plates in their final position, locate and mark two optimal bolt hole locations on the top of each Mount

Plate. The bolts should be located as far apart as possible, with clear access to the bolt and nut underneath the truck's bed

rail. If the inside of your truckbed has a double wall and it is not possible to locate a bolt on the Mounting Plate near the leg,

we recommend using our accessory STAKE POCKET "T" BOLTS to provide an additional attachment point. With the

Front Mount Plates in thier final location, mark the through bolt hole in the inner Support Arm.

#4 = Remove Rack from the truck, and unbolt the Mounting Plates. Punch hole centers in the locations that you have

marked and drill 3/8" holes in the Mount Plates and the inner Support Arm.

#5 = Bolt the Support Arms together using bolt W , Flat washer U, and lock nut R.

#6 = Set the Mount Plates back on the truck, in exactly the same

location that they were before. Make certain that the Mount Plate is

square with the bed rail and dead horizontal. We recommend that you

clamp each foot plate in position before drilling through the truck's bed

rail. CHECK TWICE - DRILL ONCE!

#7 = Apply adhesive foam tape (NOT INCLUDED) to seal the

gaps between the footplates and camper shell along the bed

rail and bulk head. Attach the camper shell to the truck. Place

the rack on the Mount Plates and center. Adjust each rear leg

slightly side to side to ensure that the lock pins in the

removable rear bar slide in and out easily.

Tighten up ALL bolts and...

X

L

THAT'S IT!

You're ready to use and enjoy your

KARGO MASTER TRUCK RACK!

INSIDE BED WALL

X

L

BULKHEAD

L

W

THROUGH

BOLT HOLE

U

R

M

3" 8

3/8"

©2011 KARGO MASTER --KS_11_1.1

Page 8

DON'T OVERLOAD YOUR VEHICLE!

O

V

E

R

T

U

R

N

F

O

R

C

E

LBS.

LBS.

@

@

WEIGHT CARRIED ABOVE THE FLOOR OF THE TRUCK BED (E.G. ON AN OVERHEAD TRUCK RACK)

WILL SIGNIFICANTLY INCREASE THE VEHICLE'S TENDENCY TO OVERTURN. ALWAYS KEEP

HEAVY LOADS EVENLY DISTRIBUTED AND AS LOW AS POSSIBLE. IT IS IMPORTANT TO NOTE THAT

THE KARGO MASTER RACK LOAD BEARING CAPACITY OF 1700 LBS. MAY BE GREATER THAN YOUR

TRUCK'S GAWR OR GVWR CAPACITY, AND IS PROBABLY GREATER THAN THE WEIGHT THAT CAN BE

SAFELY CARRIED OVERHEAD.

100" = X3 lbs.

35" =

x1 lbs.

®

For TECHNICAL SUPPORT Call:

1-800-343-7486

HOURS: Monday- Friday 8:00 A.M. to 4:30 P.M. (PACIFIC)

Loading...

Loading...