Page 1

KMR 1250 BAT

!

1.091-101

1.091-111

www.kaercher.com

5.956-832 A2008274 (04/04)

Page 2

Deutsch

Lesen Sie vor der Inbetriebnahme diese Betriebsanleitung und beachten

Sie besonders die “Sicherheitshinweise”.

1–12

English

13–24

Français

25–36

Italiano

37–48

Nederlands

49–60

Español

61–72

Português

73–84

ЕллзнйкЬ

85–96

Please read these operating instructions before starting and strictly

observe the "Safety Instructions".

Veuillez lire attentivement la présente notice d´instructions avant la mise en

service et respecter en particulier les "Consignes de sécurité".

Leggere queste istruzioni per l´uso prima della messa in esercio facendo

particolarmente "Istruzioni per la sicurezza".

Lees voor de ingebruikneming deze gebruikshandleiding en neem in het

bijzonder de "Veiligheidsvoorschriften" in acht.

Antes de poner en marcha el aparato deberá estudiar atentamente las

"Advertencias y observaciones relativas a la seguridad".

Antes da primeira utilização do aparelho leia este manual de utilização e

tenha em especial atenção a brochura anexa «Conselhos de

segurança».

Рсйн иЭуефе фз ухукехЮ гйб рсюфз цпсЬ уе лейфпхсгЯб,

дйбвЬуфе фйт рбспэует пдзгЯет чейсйумпэ кбй фзсеЯфе

йдйбЯфесб фйт "ХрпдеЯоейт буцблеЯбт".

Dansk

97–108

Norsk

109–120

Svenska

121–132

Suomi

133–144

Polski

145–156

De bedes læse denne driftsvejledning igennem før idrifttagningen i denne

forbindelse skal især "Sikkerhedsforskrifter" overholdes.

Før ibruktaking må bruksanvisningen leses nøye og det må taes hensyn til

"Sikkerhetsregler".

Läs igenom bruksanvisningen före driftstart och uppmärksamma

"Säkerhetsanvisningar" extra noga.

Lue ennen käyttöönottoa tämä käyttöohje huolellisesti läpi ja kiinnitä

erikoista huomiota "Turvallisuusohjeitiin".

Jeszcze przed pierwszym u¿yciem urz¹dzenia przeczytaæ tê Instrukcjê

obs³ugi i Wskazówki bezpieczeñstwa i przestrzegaæ podanych w nich

warunków!

Page 3

English

!

Contents

IMPORTANT INFORMATION ............................... 13

For your safety ........................................................... 13

Risk of explosion when charging the battery ................ 13

Take care when handling the battery! .......................... 13

The sweeper can topple over when travelling or turning

on steep slopes. ......................................................... 13

Risk of sweeper toppling over when negotiating turns

quickly! ...................................................................... 13

Precautions to take when doing repair and

maintenance .............................................................. 13

On behalf of the environment ..................................... 13

General data .............................................................. 14

Precautions to take when transporting the sweeper .... 14

Intended usage .......................................................... 14

Function of the main components ............................... 14

OPERATING CONTROLS .................................... 15

PRIOR TO INITIAL START-UP ............................. 16

Directions for unloading .............................................. 16

Pushing the sweeper by hand .................................... 16

After sweeper has been moved by hand: .................... 16

PRIOR TO EVERY START-UP.............................. 16

STARTING THE SWEEPER ................................. 16

Adjusting the driver’s seat ........................................... 16

Initial driving trials ....................................................... 16

Working with the sweeper .......................................... 17

Braking ...................................................................... 17

Going up slopes ......................................................... 17

Stopping the sweeper and switching off ...................... 17

Cleaning the filter ....................................................... 17

Emptying the waste hopper ........................................ 17

TYPICAL APPLICATIONS .................................... 18

Picking up larger items (sticks, tins, etc.) ..................... 18

Overcoming obstacles ................................................ 18

BATTERY ............................................................. 19

Checking the level of electrolyte in the battery ............. 19

Charging the battery ................................................... 19

MAINTENANCE ................................................... 20

Initial inspection after 8 operating hours ...................... 20

Daily maintenance ...................................................... 20

Maintenance intervals ................................................ 20

Maintenance tasks ..................................................... 20

Checking the hydraulic system ................................... 20

Replacing the sealing skirts ........................................ 20

Replacing the side brush ............................................ 20

Adjusting the sweeping pattern ................................... 21

Replacing the main brush roller .................................. 21

Replacing fuses .......................................................... 22

Replacing the dust filters ............................................ 22

TECHNICAL DATA ............................................... 23

TROUBLESHOOTING.......................................... 24

IMPORTANT INFORMATION

For your safety

Before using the machine for the first time, read these user

instructions and the appended booklet Safety Informa-

tion 5.956-250.

Please note carefully all the information contained in them.

Risk of explosion when charging the battery

When low-maintenance batteries are being charged, explosive gases are given off. Each time the battery is charged

open the cover of the sweeper and make sure there is

sufficient ventilation. Do not smoke and make sure there is

no naked flame. For further information, see chapter

Battery.

Take care when handling the battery!

Observe the information on safety provided by the battery

manufacturer. The right to claim under the warranty exists

only if you are using Kärcher recommended batteries and

battery chargers.

Risk of sweeper toppling over when slope

too great!

The sweeper can topple over when travelling or turning on

steep slopes.

If you are working in the direction of motion, only attempt

slopes of up to 18 % gradient

If you are working across the direction of motion, only

attempt slopes of up to 10 % gradient

Risk of sweeper toppling over when

negotiating turns quickly!

The sweeper can topple over if turns are negotiated quickly.

Make slow turns.

Precautions to take when doing repair and

maintenance

To avoid the sweeper being started unintentionally, proceed

as follows after switching the sweeper off:

Remove starting key

Pull out battery plug connection

On behalf of the environment

Caution! Used batteries are a danger to the environment!

Used batteries do not belong in the household rubbish. See

that they are disposed of in a way that will cause no harm

to the environment.

Caution! Hydraulic fluid is a danger to the environment!

When you change the oil, hand in the used oil at a usedoil collection point or to a disposal firm.

13

Page 4

English

General data

The sweeper is designed for 24 V direct current. It has been

provided with a 24 V trough battery (supplied with the 1.091-

111). In the case of other machines, the battery and its

appropriate charger must be obtained separately.

Your Kärcher dealer will be pleased to advise you.

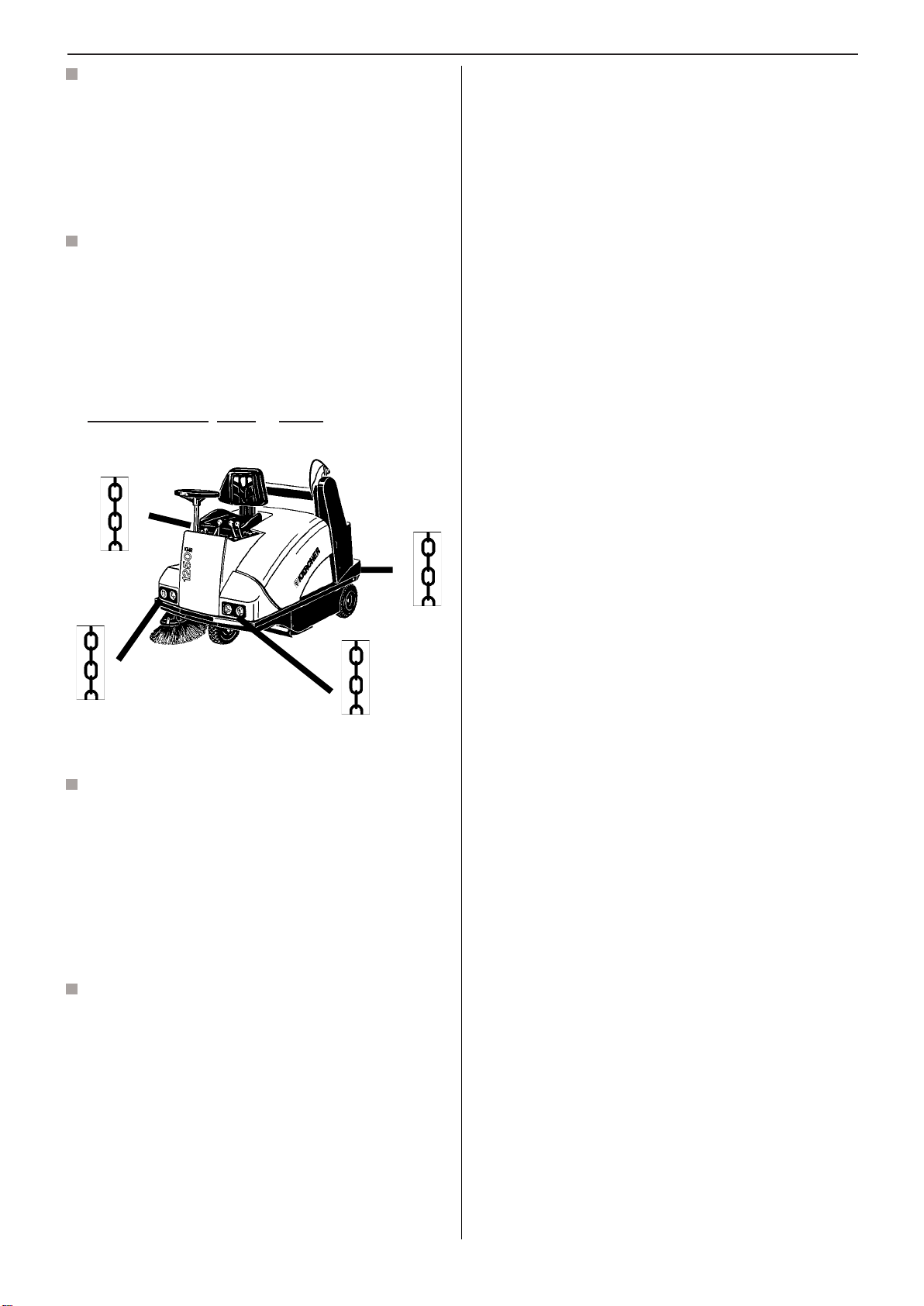

Precautions to take when transporting the

sweeper

If you have to transport the sweeper to another location

see that it is firmly attached. Do not use a fork-lift truck to

load or unload it as the sweeper could sustain damage in

this way.

Lock parking brake

Attach sweeper only in the manner illustrated, using

elasticated straps, ropes or chains

Sweeping mechanism

main brush employing throw-over principle for particu-

larly effective filling of waste hopper

floating main brush roller with adjustable height above

ground

quick-change mechanism for main brush

side brush can be raised and swivels automatically

bulk waste flap for picking up larger items (e.g.

cigarette packs or drink cans)

Filter system

integrated dust extraction on the main roller by means

of radial turbine

2 circular filters with 2 x 3 m2 effective surface area

electric filter cleaner with automatic shaking mecha-

nism

Intended usage

This sweeper

is intended to be used for sweeping outdoor and indoor

surfaces,

corresponds to Usage Category U for dust that is not

injurious to health,

can only be used on public paths and highways if it has

been fitted with the StVZO Accessory Kit.

Function of the main components

Drive unit

driven by an electric motor

continuously-adjustable hydraulic drive to rear wheels

main brush and side brush driven by means of electric

motor

hydraulically controlled emptying of waste hopper

14

Page 5

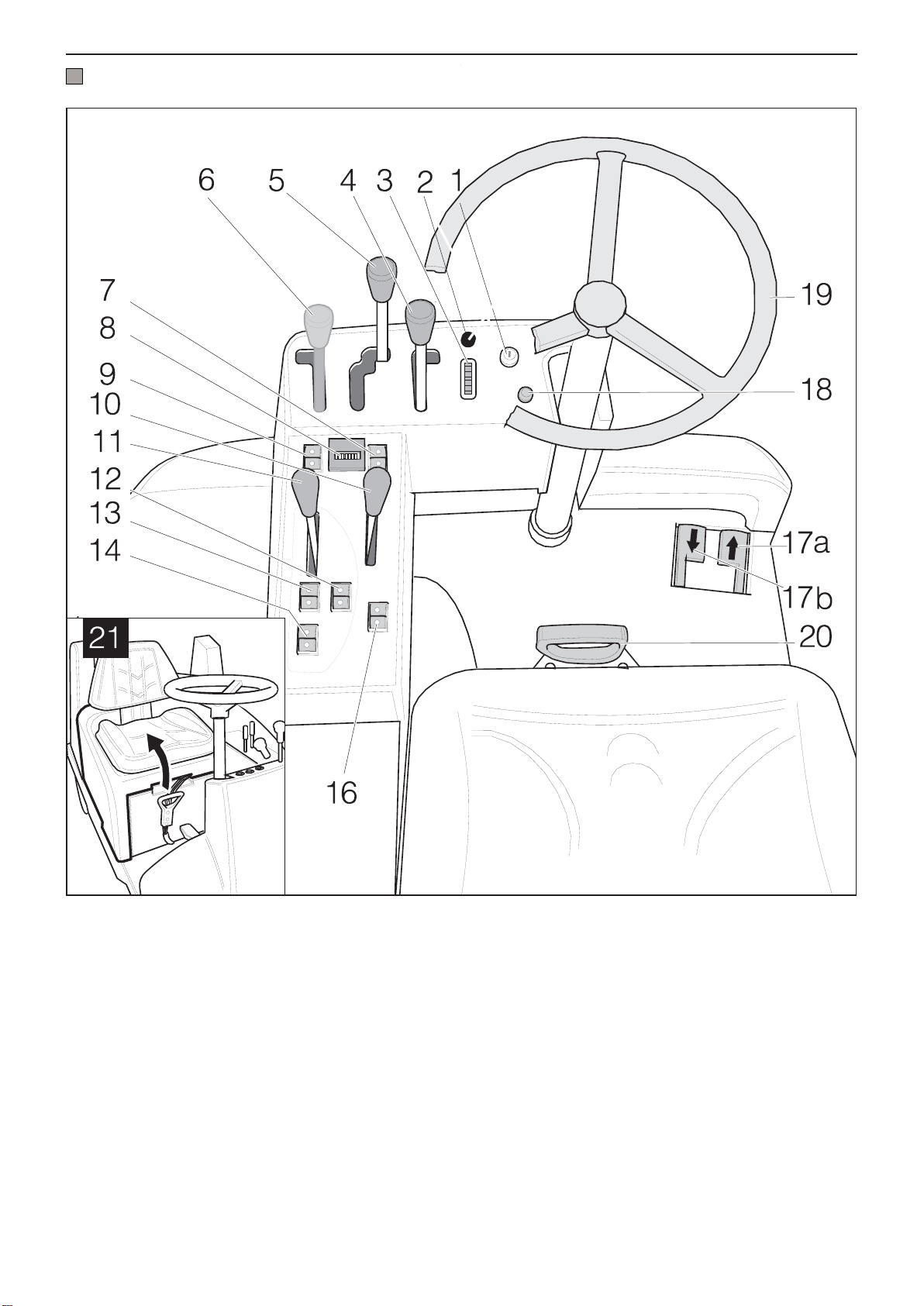

OPERATING CONTROLS

English

1. Ignition lock

2 . Pilot lamp - drive malfunction

3. Battery charge monitoring indicator

4. Raise/lower RH side brush

5. Raise/lower main brush

6. Raise/lower LH side brush (optional)

7. Two-handed operation hydraulics

8. Operating hours counter

9. Lights

10. Bulk waste flap

Function only operative in conjunction with 7 (two-handed operation).

*

11. Parking brake/Driving brake

12. Tip waste hopper *

13. Raise waste hopper *

14. Lower waste hopper *

16. Blower ON/OFF

17a. Drive pedal forwards

17b. Drive pedal backwards

18. Horn

19. Steering wheel

20. Battery plug connection

21. Cover open/close

15

Page 6

English

!

PRIOR TO INITIAL START-UP

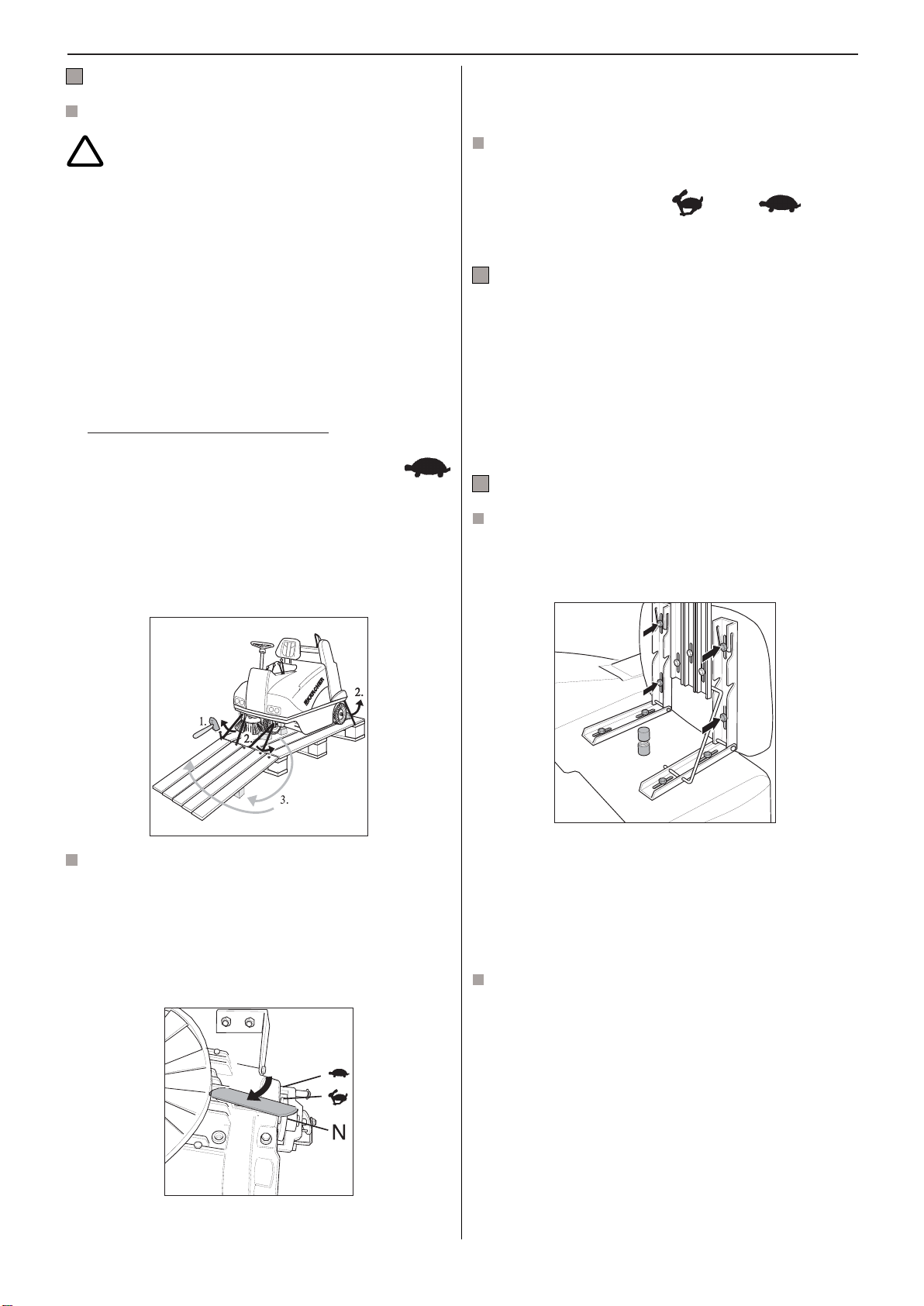

Directions for unloading

Do not use a fork-lift truck for unloading the

sweeper as the sweeper can sustain damage

in this way.

The sweeper has been fastened to a pallet for safe transport.

Proceed as follows for unpacking it:

1. Remove wooden boards from the pallet and nail them to

the abutments of the pallet (front end of the sweeper)

2. Remove strap attachments at the abutment points

3. Knock away the wooden blocks for locking the wheels

and use them for supporting the wooden boards on right

and left

4. Push the sweeper off the pallet over the ramp that has

been created

In sweepers with installed battery (1.091-111) it is

possible to drive down the ramp. To do this, open motor

cover and fold it back. Put gear lever into position

(slow), and close the cover again. Insert battery plug

connection (at drivers seat). Key switch to Position 1

and drive down carefully - see in addition chapter Driving

trials and Stopping the sweeper and switching off.

5. The side brush is tied to the frame for transportation

purposes. Undo the string.

Release the handbrake.

Push the sweeper to the required destination.

After sweeper has been moved by hand:

Apply the handbrake.

Put gear lever into position (fast) or slow, as

otherwise the sweeper cannot be driven.

PRIOR TO EVERY START-UP

Check the hydraulic-fluid level, fill up if necessary (see

chapter Maintenance)

Check main brush roller for strapping or cord that may

have wrapped round it. If so, remove it.

Examine the dust filters, if there is heavy dust accumu-

lation shake them out

Empty waste hopper.

STARTING THE SWEEPER

Adjusting the drivers seat

The drivers seat can be adjusted to suit persons of various

heights by changing the seat position.

Pushing the sweeper by hand

If you wish to move the sweeper without using its own drive:

Open the engine cover.

Fold the cover towards the rear; it will be held in place by

the gas-filled spring.

Put gear lever in direction of motion on to the

symbol N

Unhook the rods for the seat tilting device.

Undo the 4 attachment screws

Move the seat to the desired position.

Tighten the screws and hook the rods back into the tilting

device.

Initial driving trials

Carry out initial driving trials in an area where there is plenty

of free space until you are familiar with the individual

operating controls and their functions.

All indications of direction (right/left, front/rear) are given in

relation to the direction of travel as seen from the drivers

seat.

Sit on the drivers seat.

The sweeper cannot be started until the driver has sat

down (seat contact switch). As soon as driver gets up

from the seat, the safety shut-down comes into force and

the drive control, blower fan and main brush roller drive

are disconnected.

16

Page 7

English

!

!

Make sure that

the LH side brush (if fitted) is still in the raised position,

the RH side brush is still in the raised position,

the main brush is still in the raised position.

Put the starting key into Position 1. The sweeper is

ready to operate.

Important information

The drive mechanism is equipped with an electronic

overload fuse. Overload is indicated by a pilot lamp. In

the event engage the parking brake and release the drive

pedals(approx. 10 min.) until the drive components have

cooled down.

For safety reasons the drive mechanism remains inac-

tive if a drive pedal is engaged before the keyswitch is

turned on.

Working with the sweeper

Lower the main brush and, if required, the side

brush as well .

Main brush roller and side brush switch themselves on

automatically.

Switch the blower fan on in order to sweep without clouds

of dust forming.

Release the parking brake by moving the lever

forwards

Slowly depress the drive pedal, the speed can be

selected smoothly according to the setting.

Depress left pedal, machine moves backwards.

Depress right pedal, machine moves forwards.

Braking

Release the drive pedal and the sweeper will brake

automatically.

Note: The braking effect can be increased by careful

operation of the drive pedal for the opposite direction

and/or by using the parking brake.

Going up slopes

The sweeper can be driven in the fast gear (position )

Recommendation: Clean interior with compressed air.

Wipe over the exterior with a damp cloth but do not use

an aggressive cleaning agent.

Park sweeper in a protected place and stop it from rolling

away.

Pull out battery plug connection.

If the sweeper is shut down for a relatively long period,

charge the battery at approx. two-monthly intervals, see

in addition chapter Maintenance.

Cleaning the filter

Manual cleaning

While the sweeper is operating, the filter should be cleaned

approx. every 1530 minutes (depending on amount of

dust).

Switch off the blower fan. The electric filter cleaner is

operated automatically for approx. 10 seconds.

Switch on the blower fan again.

Emptying the waste hopper

Important information

Injury hazard!

No person or animal should be allowed to remain in the area

traversed by the hopper while it is being emptied.

Danger of being crushed!

Do not reach into the shafts and linkage of the emptying

mechanism.

Do not stand under the raised hopper.

Risk of sweeper toppling over!

If the sweeper is standing on a slope with a gradient of more

than 5 %, it could topple over while the hopper is being

emptied. The hopper should therefore only be emptied when

the gradient at the location where the sweeper is standing

is less than 5 % for the direction in which it is facing.

Stop the sweeper.

Raise the main brush .

Note: Following steps can only be performed with the

sweeper set to two-handed operation.

for slopes up to a gradient of 15 %.

For slopes of gradients between 15 % and 18 %, the

sweeper must be operated in low gear (position ).

Stopping the sweeper and switching off

Release the drive pedal. The sweeper brakes automati-

cally and comes to a halt.

Apply the parking brake .

Make sure the main roller and side brush are raised so

that the bristles are not damaged. (Main brush roller,

side brush and blower fan switch off automatically).

Turn the ignition key to Position 0 and then remove it.

Clean the sweeper inside and outside as required.

Raise the waste hopper, 1 + 2. +

When the hopper has reached the required height drive

backwards towards the discharge container.

17

Page 8

English

!

!

Note: The hopper can only be emptied when the supporting

arms have reached a horizontal position. To avoid the dust

billowing up when the hopper is emptied, the waste hopper

should be lowered as far as possible into the discharge

container.

Tip the waste hopper

1 + 3 +

When you release the button for tipping the waste

hopper, the waste hopper returns to its home position

automatically.

Raise the waste hopper, drive away from the discharge

container and retract the waste hopper.

1 + 4 +

Typical applications

Caution while sweeping!

Do not sweep up packing bands, wires or similar items,

otherwise the sweeping mechanism will be damaged.

Do not sweep any burning/glowing objects.

For cleaning even surfaces

set the lever for the main brush roller to the middle

position (minimum brush wear).

For cleaning uneven surfaces

set the lever for the main brush roller to the lower

position (increased brush wear).

switch on blower fan for dust extraction

for cleaning right up to the edges lower the side brush

.

If you are sweeping up fine dust, use the side brush as

little as possible as it will increase the amount of dust

stirred up by the sweeper.

If the side brush encounters an obstacle, it automatically swivels back inside the outer contours of the

sweeper. Avoid collisions!

To protect the filter from getting damp when sweeping

wet surfaces, switch off the dust extraction

Picking up larger items (sticks, tins, etc.)

Caution!

When the bulk waste flap is open, stones or grit could be

thrown forwards by the main brush. Make sure therefore

that when you open the flap no persons, animals or

property are endangered.

Open the bulk waste flap by hand.

Drive over the items to be picked up, at low speed and

with the bulk waste flap open.

Note: In order to avoid stirring up dust unnecessarily, the

bulk waste flap should be open for short periods only.

Overcoming obstacles

Obstacles up to 2 cm in height can be driven over without

any problems. Before you do so, open the bulk waste flap

and raise the main brush.

Obstacles more than 2 cm in height can be only be driven

over with the aid of a suitable ramp.

18

Page 9

English

Battery

Safety instructions to be noted when handling

batteries are:

Note instructions for use and display

them where they can be easily seen at

the place where the battery is charged.

Work with batteries only after having

had instruction from skilled personnel.

Wear protective glasses and protective

clothing when working with batteries.

Note the accident-prevention

regulations as well as DIN VDE 0510,

VDE 0105 T.1.

No Smoking !

No naked flames, glowing embers or

sparks in the vicinity of the battery as

there is a risk of explosion and fire.

Splashes of acid in the eyes or on the

skin should be rinsed out or washed

away with copious amounts of clean

water, thereafter consult a doctor

without delay. Wash clothes

contaminated with acid in water.

Checking the level of electrolyte in the

battery

Note: Applies only to batteries that are not maintenancefree.

Check regularly the level of electrolyte in batteries filled

with acid. Make sure the battery is fully charged before you

carry out the check.

If required top up each cell with distilled water up to the

mark or until the lead plates are covered by approx.

1 cm of liquid.

Charging the battery

Note: Use only the Kärcher recommended battery charger

6.654-107 for the battery 6.654-112 which is installed.

Bring the sweeper to a halt, remove the starting key

Pull out battery plug connection

Tip seat forwards and open cover

Connect battery cable to the charger

Connect charger to the mains power supply and switch

it on. For the period for charging see the information

supplied by the manufacturer of the battery charger.

It is essential to observe the instructions provided

by the manufacturer of the battery charger!

Risk of explosion and fire! Avoid shortcircuits. Caution! Metal parts of the

battery cells are always live so do not

put any foreign object or tool down on

the battery.

Electrolyte is highly corrosive. Under

normal operating conditions there is

absolutely no contact with the

electrolyte. If the housing is destroyed

the bound electrolyte released is

equally as corrosive as the liquid form.

Return to manufacturer!

Used batteries bearing this symbol are

reusable articles and must be fed back

into the recycling process. Used

batteries which are not fed back into the

recycling process are to be disposed of

as special rubbish in compliance with

the regulations.

19

Page 10

English

!

!

MAINTENANCE

Initial inspection after 8 operating hours

Caution!

For the safe functioning of your sweeper, an initial inspection

must be carried out after 8 hours of operation. You should

have the inspection done by your Kärcher Customer Service.

inspect all bowden cables and adjust where necessary

check that all hydraulic parts are leakproof and function

correctly

check that the handbrake functions

Daily maintenance

Inspect main brush roller for strapping and/or cord, etc.,

which may have wrapped round it. If so remove them.

Check dust filters. If they are heavily contaminated with

dust, shake them out.

Empty waste hopper.

Checking the hydraulic system

Carry out a visual inspection. If there is any loss of fluid

from the hydraulic unit, cylinder or hoses, call Kärcher

Customer Service.

Replacing the sealing skirts

The sealing skirts fulfil an important function. They retain the

partial vacuum in the area round the main brush roller which

is essential so that the sweeper can function properly. They

ensure that sweeping can take place without clouds of dust

being raised.

If the sealing skirts are damaged or worn out, they must be

replaced immediately.

Park the sweeper and switch off the engine.

Remove the retaining screws and detach the sealing

skirts.

Fit new skirts, and align them as follows:

The side skirts should be adjusted so that they clear the

ground by 13 mm. Adjust the rear skirt so that it clears

the ground by 1-5 mm.

Maintenance intervals

Keep to the maintenance schedule given in the Maintenance

booklet (5.950-535) in order to ensure that the sweeper

functions reliably and to maintain your rights under the

guarantee.

The maintenance work required must be carried out by an

authorised specialist workshop.

Maintenance tasks

Risk of injury

Before you work under the waste hopper in its swung-up

position, you must first secure the hopper against dropping

unintentionally by using the swing-out safety bar.

The front skirt cannot be adjusted. Replace the skirt as

soon as you see signs of excessive wear.

Tighten the retaining screws.

Replacing the side brush

Park the sweeper, switch it off and make it secure.

Raise the side brush.

Remove the three hex-socket bolts (SW 5).

Remove ignition key

Pull out battery plug connection

Open cover

Tip seat forwards. Pull cover up by the handle grip

designed for the purpose.

Detach the side brush.

Push the new side brush onto the drive pin.

Tighten the bolts again.

20

Page 11

English

Adjusting the sweeping pattern

Open the unit cover and secure it in place.

–

The sweeping pattern can be altered by turning the

–

central adjusting knob:

To increase size of sweeping pattern: turn adjusting

knob counter-clockwise (towards +).

To reduce size of sweeping pattern: turn adjusting

knob clockwise (towards ).

After any adjustments have been made, check the

–

sweeping pattern.

Drive the sweeper onto a dusty surface and apply the

parking brake.

Lower the main brush (lever set to middle position) and

allow it to brush the floor for several seconds.

Raise the main brush and drive backwards a short

distance with the bulk waste flap open (first release the

parking brake).

The width of the sweeping pattern should be

3050 mm.

Replacing the main brush roller

Park the sweeper and switch off the engine.

–

Lower the brush roller.

–

Open the RH side flap 1 (seen in direction of travel).

–

Undo the retaining bolt on the lower forked head 2 and

–

swivel the push rod towards the rear.

Unscrew the knurled knob 3.

–

Remove the oscillating linkage 4.

–

Open the flap over the end of the brush roller 5 (turn-lock

–

fastener).

Pull out the brush roller 6.

–

Note: The shape of the sweeping pattern should not be

trapezoidal. If it is, call Kärcher Customer Service.

Screw in the knob for adjusting the sweeping pattern as

–

far as it will go (clockwise, towards ).

Fit the new brush roller in reverse order to the removal

–

procedure.

Note: Make sure the bristles point in the right direction see

illustration.

Brush roller seen from above

Direction of travel

Set up the sweeping pattern by turning the adjusting

–

knob see Adjusting the sweeping pattern.

21

Page 12

English

Replacing fuses

Park the sweeper, switch it off and make it secure.

–

Pull out battery plug connection and open the unit

–

cover.

Replace blown fuses with ones with the same rating.

–

Note: If a fuse blows repeatedly, this indicates a fault

somewhere in the electrical system. Please call Kärcher

Customer Service.

Replacing the dust filters

The dust filters should be inspected for damage every 50

operating hours.

A significant build-up of dust at the air outlet from the fan

is a sign of a filter that is not fitted properly or is defective.

Raise the hopper half way 1.

–

Release the catches on the filter box 2.

–

Swivel the filter box forwards and lift it off 3.

–

Replace light unit

Stop the machine and turn it off

Take out the ignition key

Undo 6 screws S on the panel

Remove the panel 1

Unscrew the Phillips screw between the supports of the

lamp holder on the defective headlight

Turn the lens of the defective headlight anti-clockwise

about 1/4 of a turn 2 and take out reflector housing 3

Replace light unit

Insert reflector housing with new light unit in panel again

from below and secure with about 1/4 of a turn clockwise. Make certain it engages properly, the label

HALOGEN on the headlight glass must be able to be

read horizontally 4

Screw in again the screw between the supports, then

secure the panel with the 6 screws.

Open out the handle, pull it outwards and turn it through

–

90º (make sure it engages) 4.

Remove the filter cartridge 5.

–

Insert a new filter cartridge (pins should fit into the

–

holes) 6.

Turn the handle back to its original position and make

–

sure it locks in place.

Mount the filter box and engage the catches.

–

22

Page 13

English

Technical Data

Dimensions and weights:

Length 1.650 mm

Width 1.000 mm

Height 1.270 mm

Weight unladen (ready to operate) 580 kg

Total permissible weight 730 kg

Driving and sweeping performance:

Sweeping path width without side brush 750 mm

Sweeping path width with 1 side brush 1.000 mm

Sweeping path width with 2 side brushes 1.300 mm

Fast gear (Position )

Max. speed 6 km/h

Max. gradient of climb 15 %

Low gear (Position )

Max. speed 4 km/h

Max. gradient of climb 18 %

Surface area performance (theoretical):

Without side brush 4.500 m

With 1 side brush 6.000 m

With 2 side brushes 7.800 m

Waste hopper:

Theoretical volume 100 l

Max. usable volume 80 l

Lift of stroke 1.430 mm

Filter surface area 6 m

Sweeping mechanism:

Main brush roller with rows of bristle in V-formation

Diameter of main brush roller 285 mm

Diameter of side brush 450 mm

2

/h

2

/h

2

/h

2

Drive system:

Mechanical gear drive with differential, operating on the

rear wheels.

Hydraulic fluid:

Class DIN HVLP 51 524/2

46 c St /40 °C

Capacity * 1.5 l

* We recommend BP BARTRAN Hydraulic Fluid.

Protection type: dripping-water protection IPX3

Ambient conditions:

– temperature –5 to +40 °C

– air humidity, not wet with dew 0–90 %

Operating period:

With one battery charging and under favourable

conditions the operating period is 3 hours. It is

dependent on several factors:

– nature of the ground and evenness of the terrain

– maintenance of the unit

– type and wear of the brush roller.

Noise emission

Sound level (EN 60704-1) 74 dB(A)

Guaranteed noise level

(2000/14/EC) 94 dB(A)

Machine vibration

Rated vibration value (ISO 5349)

Upper limb

measurements < 2,5 m/s²

Feet/seating area < 0,5 m/s²

Tyres

Diameter 300 mm

Designation 4.00-4

Lighting

Light unit DIN 49 848

HS3 6 V/2,4 W

Battery:

e.g. HAGEN Favorit 24 V/240 Ah

Your Kärcher Customer Service will be pleased to advise

you about the existing supply.

Motor data:

Drive control motor, AMER MP80 M 24 V/1100 W

Main brush motor, AMER MP80/2 24 V/600 W

Blower motor, AMER MP80/2 24 V/600 W

23

Page 14

English

Troubleshooting

Problem Possible cause Remedy

Sweeper does not move Battery is flat Recharge or replace battery

Warning light flashes Follow the startup sequence

Call Customer Service

Fuse has blown Replace fuse

Free-wheeling mechanism

switched on

The safety cutout triggered Reset the safety cutout

Brushes do not rotate V-belt has snapped Call Customer Service

V-belt too loose Check belt tension and adjust

Main brush or side b rush has been

jammed by packing bands or

similar item

Fuse has blown Replace fuse

Blower fan does not rotate Fan li mit switch is not being

operated

Fuse has blown Replace fuse

See “Pushing the sweeper by

hand”

as required

Remove blockage

Lower waste hopper completely

so that limit switch is operated

Poor sweeping results Brushes are worn down Replace brushes

Waste hopper is full Empty waste hopper

Incorrect sweeping pattern Adjust sweeping pattern

Filter is blocked Clean or replace filter

Dust is stirred up during

sweeping

Lifting mechanism for

emptying hopper does not

work

Worn out seals on sweeper, filter

not fitted properly or defective

Fuse has blown Replace fuse or inform

Defective switch Inform Customer Service

Defective hydraulic unit Inform Customer Service

Replace defective seals; fit filter

correctly or replace it

Customer Service if fuse blows

repeatedly

24

Page 15

KMR 1250 BAT

1.091-101.0

KMR 1250 BAT Package

1.091-111.0

KMR

0

6.414-532.0

6.348-306.0

6.905-986.0

7.312-260.0

7.313-003.0

5

2

1

6.435-319.0

6.435-318.0

KARCHER

6.644-299.0

6.644-246.0

6.644-272.0

6.644-246.0

7.644-013.0

6.682-429.0

5.031-452.0

7.644-017.0

7.644-017.0

7.651-002.0

6.651-382.0

6.654-112.0

6.277-428.0

7.306-500.0

6.654-107.0

6.277-427.0

6.277-435.0

5.190-084.0

5.031-378.0

K

I

N

H

C

E

T

E

D

A

L

<

<

P

M

O

R

C

I

M

>

>

Wa

A

0

3

V

4

2

6.905-982.0

4.038-524.0

5.190-084.0

6.277-427.0

20.03.2000

Page 16

EG-Konformitätserklärung

Hiermit erklären wir, daß die nachfolgend bezeichnete Maschine

aufgrund ihrer Konzipierung und Bauart sowie in der von uns in

Verkehr gebrachten Ausführung den einschlägigen grundlegenden

Sicherheits- und Gesundheitsanforderungen der EG-Richtlinien

entspricht.

Bei einer nicht mit uns abgestimmten Änderung der Maschine verliert

diese Erklärung ihre Gültigkeit.

Produkt: Kehrsaugmaschine Aufsitzgerät

Typ: 1.091-xxx

Einschlägige EG-Richtlinien:

EG-Maschinenrichtlinie (98/37/EG)

EG-Richtlinie Elektromagnetische Verträglichkeit (89/336/EWG),

geändert durch 91/263/EWG, 92/31/EWG, 93/68/EWG

EG-Richtlinie über Geräuschemissionen (2000/14/EU)

Angewandte harmonisierte Normen:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Angewandte nationale Normen: –

Angewandtes Konformitätsbewertungsverfahren: Anhang V

Gemessener Schallleistungspegel: 92 dB(A)

Garantierter Schallleistungspegel: 94 dB(A)

Es ist durch interne Maßnahmen sichergestellt, daß die Seriengeräte

immer den Anforderungen der aktuellen EG-Richtlinien und den

angewandten Normen entsprechen.

Die Unterzeichnenden handeln im Auftrag und mit Vollmacht der

Geschäftsführung.

EU Declaration of Conformity

We hereby declare that the equipment described below conforms to

the relevant fundamental safety and health requirements of the

appropriate EU Directives, both in its basic design and construction as

well as in the version marketed by us.

This declaration will cease to be valid if any modifications are made to

the machine without our express approval.

Product: Sweeping suction machine

Model: 1.091-xxx

Relevant EU Directives:

EU Machinery Directive (98/37/EEC)

EU Directive on Electromagnetic Compatibility (89/336/EEC), amended

by 91/263/EEC, 92/31/EEC, 93/68/EEC

EC directive on noise emissions (2000/14/EU)

Harmonised standards applied:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

National standards applied: –

Applied conformity evaluation procedure: Appendix V

Measured sound power level: 92 dB(A)

Guaranteed sound power level: 94 dB(A)

Appropriate internal measures have been taken to ensure that seriesproduction units conform at all times to the requirements of current EU

Directives and relevant standards.

The signatories are empowered to represent and act on behalf of the

company management.

EU-conformiteitsverklaring

Hiermee verklaren wij dat de hierna vermelde machine op grond van

haar concipiëring en constructie en in de door ons in omloop

gebrachte uitvoering beantwoordt aan de desbetreffende veiligheidsen gezondheidsvoorschriften van de EG-richtlijnen.

Na een wijziging aan de machine die niet in overleg met ons wordt

uitgevoerd, verliest deze verklaring haar geldigheid.

Produkt: Veegzuigmachine

Type: 1.091-xxx

Desbetreffende EG-richtlijn:

EG-machinerichtlijn (98/37/EEG)

EG-richtlijn elektromagnetische verenigbaarheid (89/336/EEG),

gewijzigd door 91/263/EEG, 92/31/EEG en 93/68/EEG

EG-richtlijn geluidsemissies (2000/14/EU)

Toegepaste geharmoniseerde normen:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Toegepaste nationale normen: –

Toegepaste conformiteitswaarderingsmethode: aanhangsel V

Gemeten geluidsvermogenniveau: 92 dB(A)

Gegarandeerd geluidsvermogenniveau: 94 dB(A)

Door interne maatregelen is er voor gezorgd dat de standaard-apparaten

altijd beantwoorden aan de eisen van de actuele richtlijnen en de

toegepaste normen.

De ondergetekenden handelen in opdracht en op volmacht van de

bedrijfsleiding.

Declaración de conformidad de la Unión Europea

Por la presente declaramos los abajo firmantes que la máquina

designada a continuación cumple, tanto por su concepción y clase de

construcción como por la ejecución que hemos puesto en circulación,

las normas fundamentales de seguridad y protección de la salud

formuladas en las directivas comunitarias correspondientes.

La presente declaración pierde su validez en caso de alteraciones en

la máquina efectuadas sin nuestro consentimiento explícito.

Producto: Barredora-aspiradora

Modelo: 1.091-xxx

Directivas comunitarias aplicables:

Directiva comunitaria sobre máquinas (CEE 98/37)

Directiva sobre compatibilidad electromagnética (CEE 89/336),

modificada mediante CEE 91/263, CEE 92/31 y CEE 93/68

Directiva comunitaria sobre emisiones sonoras (UE 2000/14)

Normas armonizadas aplicadas:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Normas nacionales aplicadas: –

Procedimiento de evaluación de la conformidad aplicado: Anexo V

Nivel de potencia acústica medido: 92 dB(A)

Nivel de potencia acústica garantizado: 94 dB(A)

Mediante una serie de medidas internas, queda asegurado que los

aparatos y equipos de serie cumplan siempre las exigencias

formuladas en las directivas comunitarias actuales y en las normas

correspondientes a aplicar.

Los firmantes actúan autorizados y con poder otorgado por la dirección

de la empresa.

Déclaration de conformité européenne

Par la présente, nous déclarons que la machine ci-après répond, de

par sa conception et sa construction ainsi que de par le modèle que

nous avons mis sur le marché, aux exigences de sécurité et d’hygiène

en vigueur de la directive européenne.

En cas de modification de la machine effectuée sans notre accord,

cette déclaration sera caduque.

Produit: Machine de balayage-aspiration

Type: 1.091-xxx

Directives européennes en vigueur:

Directive européenne sur les machines (98/37/CE)

Directive européenne sur la compatibilité électromagnétique (89/336/

CE), modifiée par 91/263/CE, 92/31/CE, 93/68/CE

Directive européenne sur les émissions sonores (2000/14/CE)

Normes harmonisées appliquées:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Normes nationales appliquées: –

Procédure appliquée d’évaluation de la conformité: annexe V

Niveau de puissance sonore mesuré: 92 dB(A)

Niveau de puissance sonore garanti: 94 dB(A)

La conformité permanente des appareils de série avec les exigences

consignées dans les directives actuelles de la CE et avec les normes

appliquées est garantie par des mesures internes.

Les soussignés agissent par ordre et avec les pleins pouvoirs de la

Direction commerciale.

Dichiarazione di conformità CE

Dichiariamo con la presente, che la macchina qui di seguito indicata,

in base alla sua concezione e al tipo di costruzione, e nella versione

da noi introdotta sul mercato, è conforme ai relativi requisiti

fondamentali di sicurezza e di sanità delle direttive della CE.

In caso di modifica apportate alla macchina senza il nostro accordo,

questa dichiarazione perde la sua validità.

Prodotto: Spazzatrice aspiratrice

Tipo: 1.091-xxx

Direttive CE pertinenti:

Direttiva macchine CE (98/37/CEE)

Direttiva compatibilità elettromagnetica CE (89/336/CEE), modificata

dalle 91/263/CEE, 92/31/CEE, 93/68/CEE

Direttiva CEE sulle emissioni acustiche (2000/14/UE)

Norme armonizzate applicate:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Norme nazionali applicate: –

Procedura di valutazione di conformità applicata: Allegato V

Livello di potenza sonora misurato: 92 dB(A)

Livello di potenza sonora garantito: 94 dB(A)

Mediante accorgimenti interni, è stato assicurato che gli apparecchi di

serie siano sempre conformi ai requisiti delle attuali direttive CE e alle

norme applicate.

I firmatari agiscono su incarico e con i poteri dell’Amministrazione.

CE - Declaração de conformidade

Nós declaramos pelo presente instrumento que a máquina abaixo

indicada corresponde, na sua concepção, fabricação bem como no

tipo por nós comercializado, às exigências básicas de segurança e de

saúde da directiva da CE.

Se houver uma modificação na máquina sem o nosso consentimento

prévio, a presente declaração perderá a sua validade.

Produto: Vassoura mecânica

Tipo: 1.091-xxx

Directivas aplicáveis da CE:

Directiva de máquinas CE (98/37/CEE)

Directiva de compatibilidade electromagnética CE (89/336/CEE),

modificada 91/263/CEE, 92/31/CEE, 93/68/CEE

Directiva CE sobre emissões de ruído (2000/14/EU)

Normas harmonizadas aplicadas:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Normas nacionais aplicadas: –

Processo de avaliação de conformidade aplicado: Suplemento V

Nível de potência acústica medido: 92 dB(A)

Nível de potência acústica garantido: 94 dB(A)

Assegura-se, através de medidas internas da empresa, que os

aparelhos de série correspondem sempre às exigências das directivas

actualizadas da CE e às normas aplicadas.

Os abaixo assinados, actuam e representam através de procuração a

gerência.

ДЮлщуз Рйуфьфзфбт ЕК

ЕмеЯт, дзлюнпхме ме фзн рбспэуб, ьфй фп мзчЬнзмб рпх

чбсбкфзсЯжефбй рбсбкЬфщ, льгщ фпх учедйбумпэ кбй фпх фсьрпх

кбфбукехЮт, ьрщт кбй льгщ фзт рбсбллбгЮт рпх дйбфЯиефбй брь мбт

уфзн бгпсЬ, бнфбрпксЯнефбй уфйт учефйкЭт вбуйкЭт брбйфЮуейт

буцблеЯбт кбй хгеЯбт фщн Пдзгйюн ЕК.

Уе ресЯрфщуз бллбгюн уфп мзчЬнзмб чщсЯт рспзгпэменз

ухнненьзуз мбжЯ мбт, рбэей нб йучэей з рбспэуб дЮлщуз.

Рспъьн: Mзчбнйкь уЬсщисп ме бнбссьцзуз

Фэрпт: 1.091-xxx

УчефйкЭт ПдзгЯет ЕК:

ПдзгЯб ЕК учефйкЬ ме фйт мзчбнЭт (98/37/ЕПК)

ПдзгЯб ЕК ресЯ злекфспмбгнзфйкЮт ухмвбфьфзфпт (89/336/ЕПК),

рпх фспрпрпйЮизке ме фзн ПдзгЯб 91/263/ЕПК, 92/31/ЕПК, 93/68/

ЕПК

ПдзгЯб ЕК ресЯ екрпмрюн ипсэвщн (2000/14/EE)

ЕнбсмпнйумЭнб рсьфхрб рпх Эчпхн ецбсмпуиеЯ:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

ЕинйкЬ рсьфхрб рпх Эчпхн ецбсмпуиеЯ:

ЕцбсмпумЭнз дйбдйкбуЯб бойпльгзузт рйуфьфзфбт: РбсЬсфзмб V

МефсзмЭнз уфЬимз бкпхуфйкЮт йучэпт: 92 dB(A)

ЕггхзмЭнз уфЬимз бкпхуфйкЮт йучэпт: 94 dB(A)

Ме лзциЭнфб еущфесйкЬ мЭфсб Эчей еобуцблйуиеЯ, ьфй пй ухукехЭт

уейсЬт кбфбукехЮт бнфбрпксЯнпнфбй рЬнфб уфйт брбйфЮуейт фщн

ерйкбЯсщн пдзгйюн ЕК кбй уфб ецбсмпуиЭнфб рсьфхрб.

Пй хрпгсЬцпнфет енесгпэн ме енфплЮ кбй кбфьрйн еопхуйпдьфзузт

фзт ГенйкЮт Дйеэихнузт.

Page 17

EU-overensstemmelseserklæring

Hermed erklærer vi at nedenstående maskine på grund af sin

udformning og konstruktion i den udførelse, i hvilken den sælges af

os, overholder EU-direktivernes relevante, grundlæggende

sikkerheds- og sundhedsmæssige krav.

Hvis maskinen ændres uden aftale med os, mister denne attest sin

gyldighed.

Produkt: Fejesugemaskine

Type: 1.091-xxx

Relevante EU-direktiver:

EU-maskindirektiv (98/37/EØF)

EU-direktiv om elektromagnetisk kompatibilitet (EMC)(89/336/EØF)

som ændret ved 91/263/EØF, 92/31/EØF og 93/68/EØF

EF-direktiv for støjemissioner (2000/14/EU)

Harmoniserede standarder, der blev anvendt:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Nationale standarder, der blev anvendt: –

Anvendte procedurer for overensstemmelsesvurdering: Bilag V

Målt lydeffektniveau: 92 dB(A)

Garanteret lydeffektniveau: 94 dB(A)

Interne forholdsregler sikrer, at serieapparaterne altid opfylder kravene

fra de aktuelle EU-direktiver og de standarder, der blev anvendt.

Underskriverne handler på forretningsledelsens vegne og med dennes

fuldmagt.

EU-KONFORMITETSERKLÆRING

Vi erklærer herved at maskinen som er beskrevet nedenfor, i

konstruksjon og utførelse tilsvarer markedsførte modell og er i

overensstemmelse med de gjeldende og grunnleggende sikkerhetsog helsekrav i EU-direktivet.

Denne erklæring mister sin gyldighet dersom maskinen endres uten

etter avtale med oss.

Produkt: Selvopptagende feiemaskin

Type: 1.091-xxx

Gjeldende EU-direktiv:

EU-direktiv for maskiner (98/37/EØF)

EU-direktiv for elektromagnetisk toleranse (89/336/EØF), endret ved

91/263/EØF, 92/31/EØF og 93/68/EØF

EU-direktiv vedr. støyutslipp (2000/14/EU)

Anvendte overensstemmende normer:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Anvendte nasjonale normer: –

Anvendte samsvarsvurderinger: Vedlegg V

Målt støynivå: 92 dB(A)

Garantert støynivå: 94 dB(A)

Gjennom interne tiltak er det sikret at serieproduserte maskiner alltid er i

overensstemmelse med kravene i de aktuelle EU-direktiver og anvendte

normer.

Undertegnede handler etter oppdrag og med fullmakt fra ledelsen.

Deklaracja zgodnoci z normami Wspólnoty Europejskiej Niniejszym owiadczamy,

¿e poni¿ej wymieniona maszyna ze wzglêdu na jej koncepcjê i budowê, jak i

wprowadzone przez nas w obieg wykonanie, odpowiada odnonym i

podstawowym wymogom bezpieczeñstwa i zdrowia i poni¿ej wymienionym

wytycznym Wspólnoty Europejskiej.

JeWeli przeprowadzone w maszynie zmiany nie zostan¹ z nami uzgodnione,

owiadczenie to traci na wa¿noci.

Wyrób: zamiatarka mechaniczna / maszyna z siedzeniem

Typ: 1.091-xxx

Odnone wytyczne Wspólnoty Europejskiej

Wytyczna Wspólnoty Europejskiej dotycz¹ca maszyn (98/37/EG)

Wytyczna Wspólnoty Europejskiej dotycz¹ca zgodnoci elektromagnetycz-

nej (89/336/EWG) zmieniona przez 91/263/EWG, 92/31/EWG, 93/68/EWG

Wytyczna Wspólnoty Europejskiej e misja ha³asu (2000/14/EU)

Zastosowane tzw. normy zharmonizowane, tzn. dostosowane do norm

Wspólnoty Europejskiej

DIN EN 60335-1

DIN EN 60335-2-79

DIN EN 55014-2:1997

Zastosowane normy krajowe:

Zastosowana metoda oceny zgodnoci: Za³¹cznik V

Mierzony poziom mocy akustycznej: 92 dB(A)

Gwarantowany poziom mocy akustycznej: 94 dB (A)

Wewnêtrzne zarz¹dzenia w przedsiêbiorstwie gwarantuj¹ dostosowanie

urz¹dzeñn seryjnych do aktualnych wytycznych Wspólnoty Gospodarczej i

stosowanych norm. Sygnatariusze dzia³aj¹ w imieniu i z pe³nomocnictwa dyrekcji

przedêbiorstwa.

Försäkran om överensstämmelse

Härmed försäkrar vi att den enligt nedan angivna maskinen till

konstruktion, byggnadssätt och i av oss levererat utförande motsvarar

tillämpliga baskrav beträffande säkerhet och hälsa enligt EUdirektiven.

Vid ändringar på maskinen som icke avtalats med oss upphör denna

försäkran att gälla.

Produkt: Sopmaskin

Typ: 1.091-xxx

Tillämpliga EU-direktiv:

EG maskindirektiv (98/37/EEG)

EG direktiv för elöverkänslighet (89/336/EEG), ändrat genom 91/263/

EEG, 92/31/EEG, 93/68/EEG

EG-direktiv för buller (2000/14/EU)

Tillämpade harmoniserade normer:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Tillämpade nationella normer: –

Tillämpat värderingsförfarande för överensstämmelse: Bilaga V

Uppmätt ljudeffektnivå: 92 dB(A)

Garanterad ljudeffektnivå: 94 dB(A)

Vi har genom interna åtgärder säkerställt, att serietillverkade maskiner

alltid motsvarar aktuella EU-direktiv och tillämpade normer.

De undertecknade agerar på uppdrag av och med fullmakt av

företagsledningen.

Alfred Kärcher Kommanditgesellschaft. Sitz

Winnenden.

Registergericht: Waiblingen, HRA 169.

Persönlich haftende Gesellschafterin: Kärcher

Reinigungstechnik GmbH.

Sitz Winnenden, 2404 Registergericht Waiblingen, HRB

S. Reiser H. Jenner

Geschäftsführer: Dr. Bernhard Graf, Hartmut Jenner,

Georg Metz

EU-vaatimustenmukaisuusvakuutus

Me vakuutamme, että alla mainittu tuote vastaa suunnittelultaan ja

rakenteeltaan sekä valmistustavaltaan EU-direktiivien asianomaisia

turvallisuus- ja terveysvaatimuksia.

Jos koneeseen tehdään muutoksia, joista ei ole sovittu kanssamme,

tämä vakuutus ei ole enää voimassa.

Tuote: Lakaisuimuri

Tyyppi: 1.091-xxx

Asianomaiset EU-direktiivit:

EU-konedirektiivi (98/37/ETY)

EU-direktiivi sähkömagneettinen yhteensopivuus (89/336/ETY)

muutettu 91/263/ETY, 92/31/ETY, 93/68/ETY

EY-direktiivi melupäästöistä (2000/14/EU)

Sovelletut harmonisoidut normit:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 72

DIN EN 55 014 - 1 : 2000 + A1: 2001

DIN EN 55 014 - 2 : 1997

Sovelletut kansalliset normit: –

Sovellettu vaatimustenmukaisuusmenettely: liite V

Mitattu äänitehotaso: 92 dB(A)

Taattu äänitehotaso: 94 dB(A)

Sisäisin toimenpitein varmistetaan, että sarjatuotantolaitteet vastaavat

aina voimassaolevien EU-direktiivien vaatimuksia ja sovellettuja

normeja.

Allekirjoittaneet toimivat yrityksen johdon toimeksiannosta ja

valtuuttamina.

Alfred Kärcher GmbH & Co. KG

Cleaning Systems

Alfred-Kärcher-Str. 28–40

P.O. Box 160

D-71349 Winnenden

Tel.: ++ 49 71 95 14-0

Fax: ++ 49 71 95 22 12

5.957-544

(04/03)

Loading...

Loading...