Page 1

DVD

SOUND

DVD STB VCR TV

ANALOG/DIGITAL

TAPE

INPUT

BASS+CENTER

SOUND

123

Ð

BASS

TEST

456

BASS BOOST

TREBLE

+

789

EFFECT

Ð

TREBLE

10

RETURN FM MODE

TA/NEWS/INFO

SURROUND

ON/OFF

PTY PTY

ENTER

SURROUND

MODE

PTY

SEARCH

CHANNEL VOLUMETV VOL

TV/VIDEO

VCR

CONTROL

/REW

PLAY

TUNING

DOWN UP

STOP PAUSE

REC

RM-SRXE111R

REMOTE CONTROL

HOME CINEMA CONTROL CENTER

RX-E112RSL/RX-E111RSL

SERVICE MANUAL

HOME CINEMA CONTROL CENTER

RX-E112RSL

RX-E111RSL

AUDIO

VCR

SLEEP TV DIRECT

FM

Ð

REAR-L

Ð

REAR-R

Ð

SUBWOOFER

Ð

0

DVD MENU

DIMMER

FF/

+10

+100

DISPLAY MODE

MUTING

TVSTB

AM

+

+

+

+

RDS

DVD

MENU

STANDBY/ON

PHONES

STANDBY

TV DIRECT

CONTROL

ADJUST

SETTING

MEMORY

HOME CINEMA CONTROL CENTER

DVD STB VCR TV TAPE FM/AM

ANALOG

PL

LCR

SLEEP MODE TA

INFONEWS AUTO MUTING

AUTO

DSP HP

LPCM

SUBWFRLFE

AUTO SR

DOLBY D

LS S RS

DTS

INPUT ATT

DVD STB VCR TV TAPE

STTUNED

RDS

MH

KH

VOL

Z

Z

FM/AM

INPUT

ANALOG/DIGITAL

INPUT ATT

SURROUND

SURROUND

ON/OFF

MODE

B ------------------------ U.K.

E ---- Continental Europe

EN ----- Northern Europe

EV ------- Eastern Europe

MASTER VOLUME

Area suffix

Each difference points

MODEL

RX-E112RSL

RX-E111RSL

Source indication lens color

GRAY SMOKE

CLEAR LIGHT GREEN

Contents

Safety precautions --------------------------------------------------------1- 2

Disassembly method -----------------------------------------------------1- 3

Adjustment method -------------------------------------------------------1- 8

Description of major ICs -------------------------------------------------1- 9~22

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.21085

Apr. 2002

Page 2

RX-E112RSL/RX-E111RSL

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards .

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

RX-E112RSL/RX-E111RSL

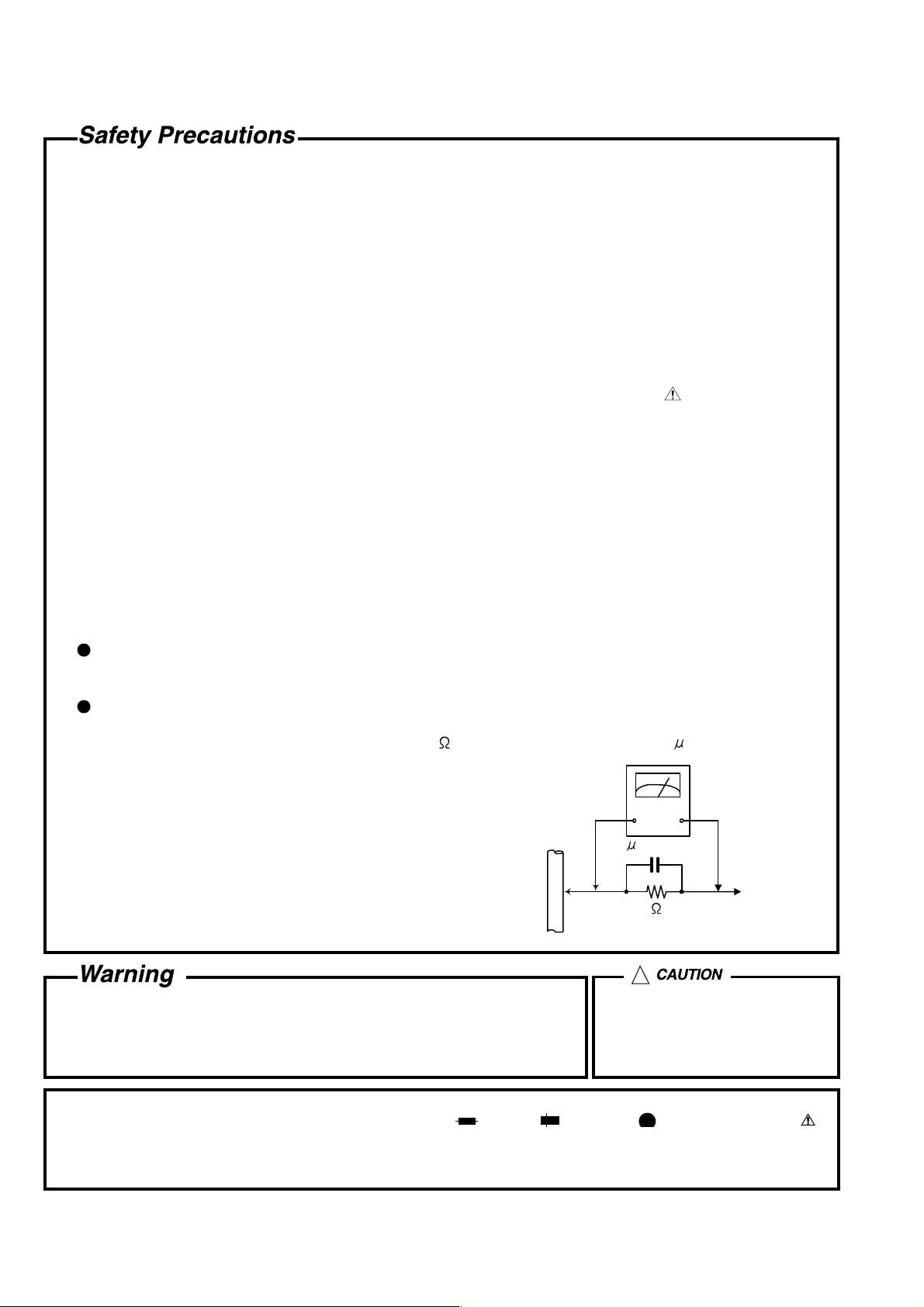

Disassembly method

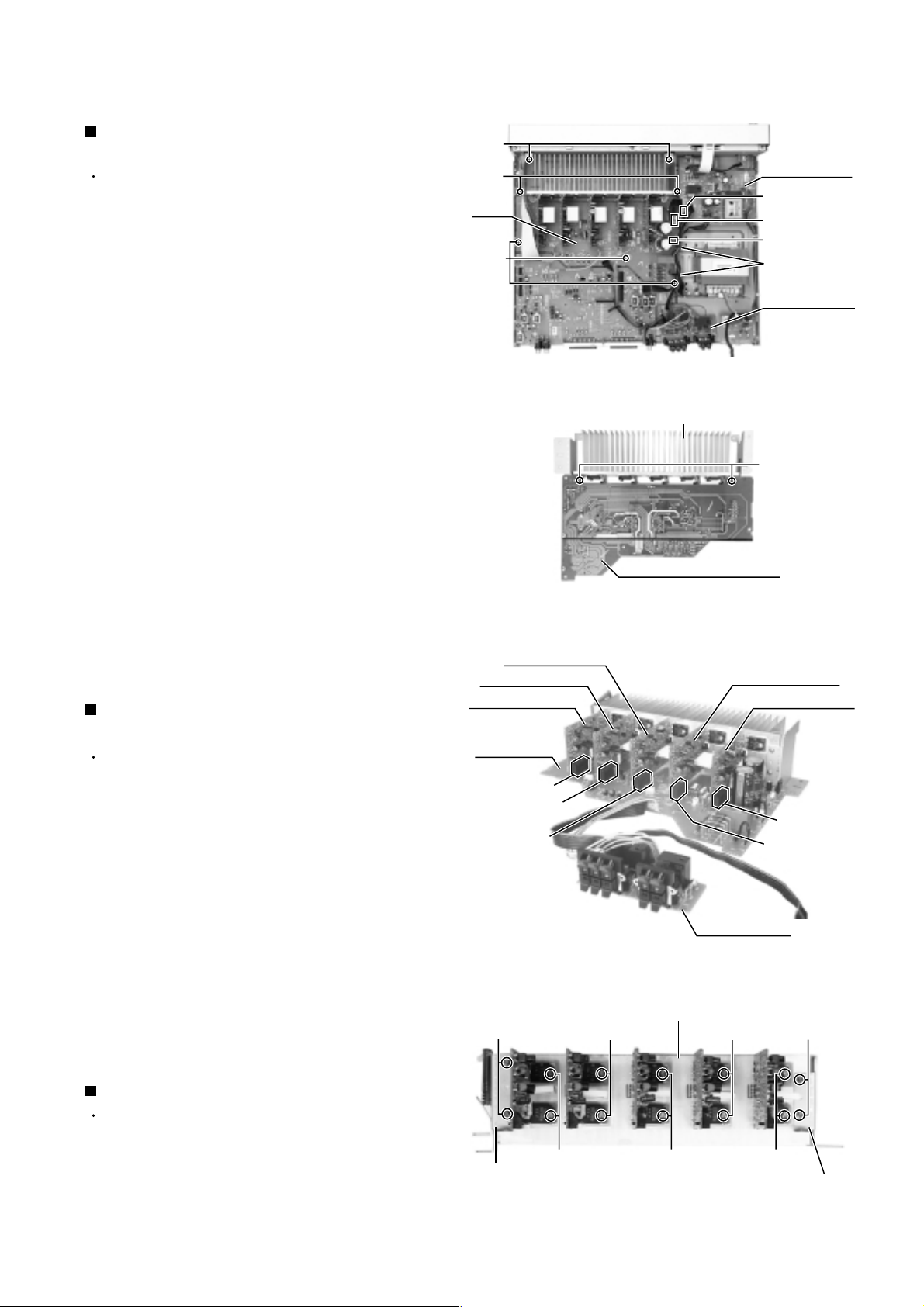

Removing the top cover (See Fig.1)

1.

Remove the four screws A attaching the top cover on

both sides of the body.

2.

Remove the three screws B on the back of the body.

3.

Remove the top cover from behind in the direction of

the arrow while pulling both sides outward.

Removing the front panel assembly

(See Fig.2 and 3)

Prior to performing the following procedure, remove

the top cover.

1.

Cut off the tie band fixing the harness, if needed.

2.

Disconnect the card wire from the connector CN411

on the audio board, CN412 on the input board and

CN204 on the power supply board.

3.

Disconnect the harness form the connector CN209

on the power supply board.

Tie band

Main board

CN411

Audio board

Top cover

A

(both sides)

CN412

B

Fig.1

Front panel assembly

CC

Input board

Fig.2

CN209

D

(attaching the

headphone jack board)

CN204

Power supply

board

4.

Remove the three screws C attaching the front

panel assembly.

5.

Remove the screw D attaching the headphone jack

board.

6.

Remove the four screws E attaching the front panel

assembly on the bottom of the body. Detach the front

panel assembly toward the front.

Removing the rear panel (See Fig.4)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the power cord stopper from the rear panel

by moving it in the direction of the arrow.

2.

Remove the nineteen screws F & G attaching the

each boards to the rear panel.

3.

Remove the four screws H attaching the rear panel

on the back of the body.

Rear panel

F

E

(Bottom side)

Front panel assembly

E

Fig.3

Power cord

stopper

Fig.4

F

GF

HHHH

1-3

Page 4

RX-E112RSL/RX-E111RSL

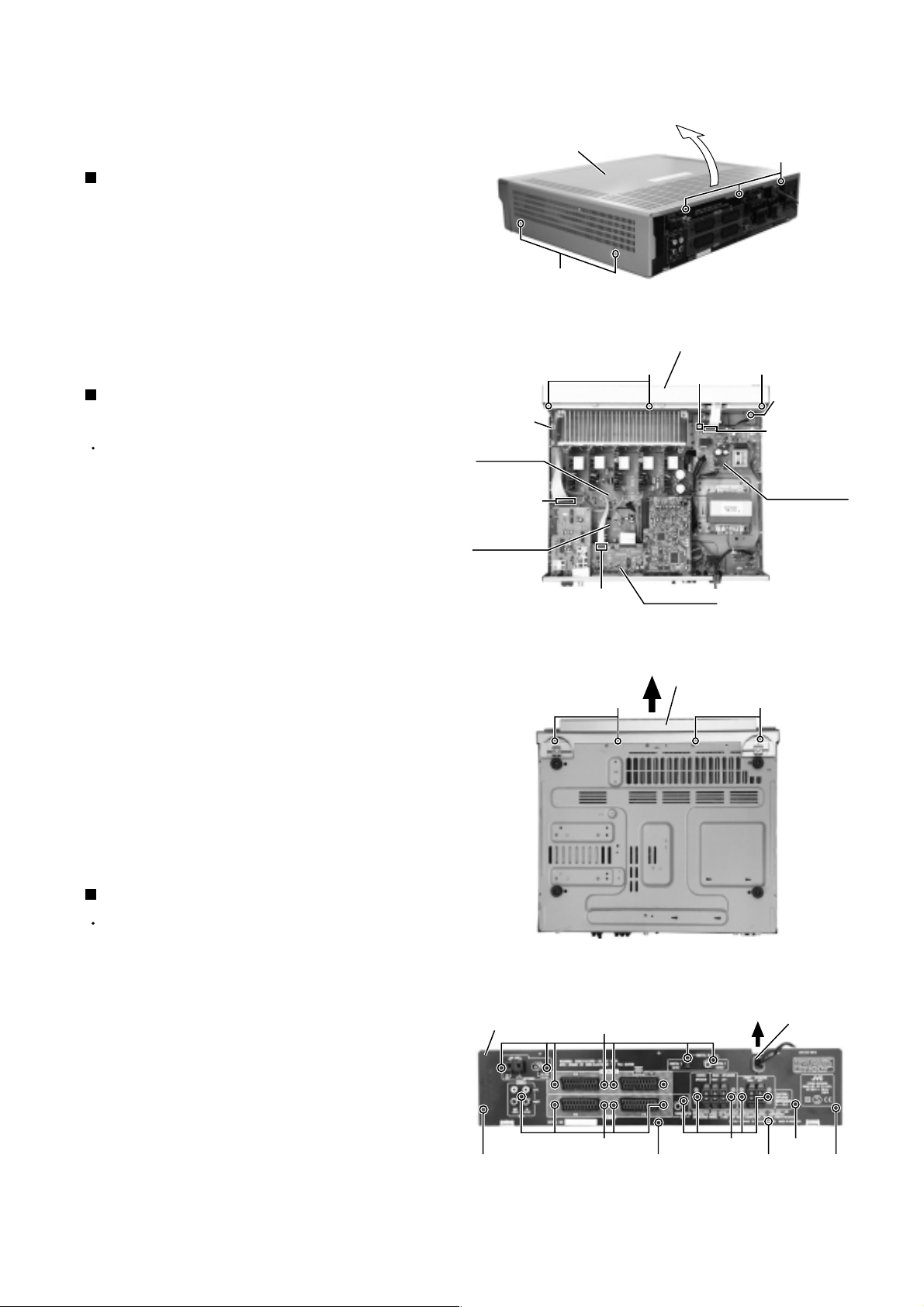

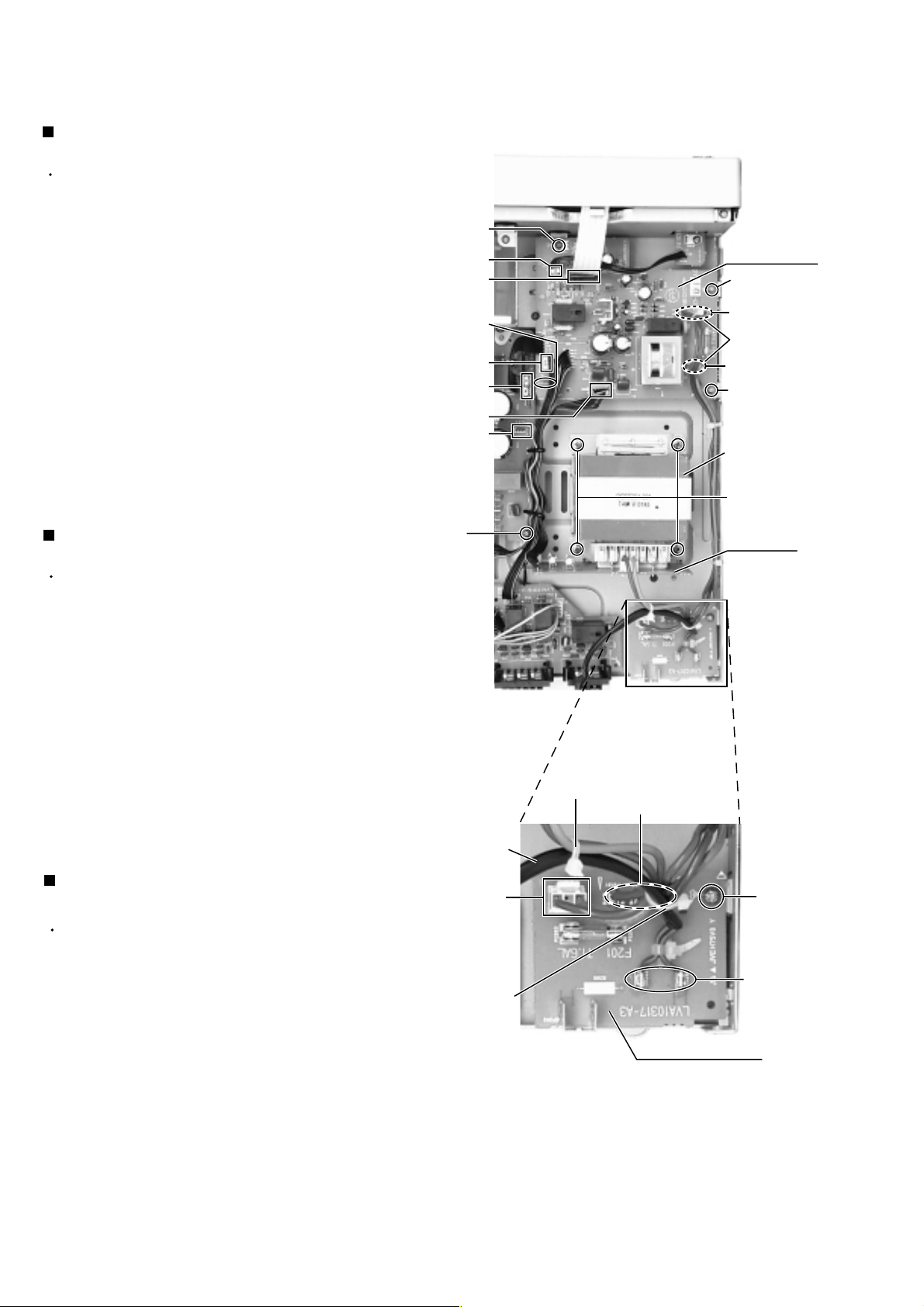

Removing the input board (See Fig.5)

Prior to performing the following procedure, remove

the top cover and rear panel.

1.

Disconnect the card wire from the connector CN412

and CN512 on the input board.

Removing the tuner board

(See Fig.5 and 6)

Prior to performing the following procedure, remove

the top cover and rear panel.

1.

Disconnect the connector CN111 and CN112 on the

tuner board and draw out the tuner board in the

direction of the arrow (see fig.5).

2.

Disconnect the connector CN513 and CN514 on the

relay board (tuner) and draw out the relay board

(tuner) in the direction of the arrow (see fig. 6).

Removing the DSP board (See Fig.5 and 6)

Prior to performing the following procedure, remove

the top cover and rear panel.

1.

Disconnect the connector CN681 on the DSP board

and draw out the DSP board in the direction of the

arrow (see fig.5).

2.

Disconnect the connector CN511 on the relay board

(DSP) and draw out the relay board (DSP) in the

direction of the arrow (see fig.6).

CN112

CN111

Tuner board

Relay board(tuner)

CN412

CN513

CN514

CN512

Fig.5

CN681

DSP board

Input board

Removing the audio board (See Fig.7)

Prior to performing the following procedure, remove

the top cover, rear panel, input board, tuner board,

DSP board and relay boards (tuner & DSP).

Remove the harness band[1] fixing the harness.

1.

Disconnect the card wire from the connector CN411

2.

on the audio board.

Disconnect the harness from the connector CN224

3.

/CN225 on the audio board.

Disconnect the harness from the connector CN515,

4.

CN516 and CN517 on the main board.

Remove the three screws I attaching the audio board.

5.

1-4

CN516

CN515

Main board

CN517

CN411

Audio board

CN511

Relay board(DSP)

Fig.6

I

Harness band[1]

CN224

/CN225

Fig.7

Page 5

RX-E112RSL/RX-E111RSL

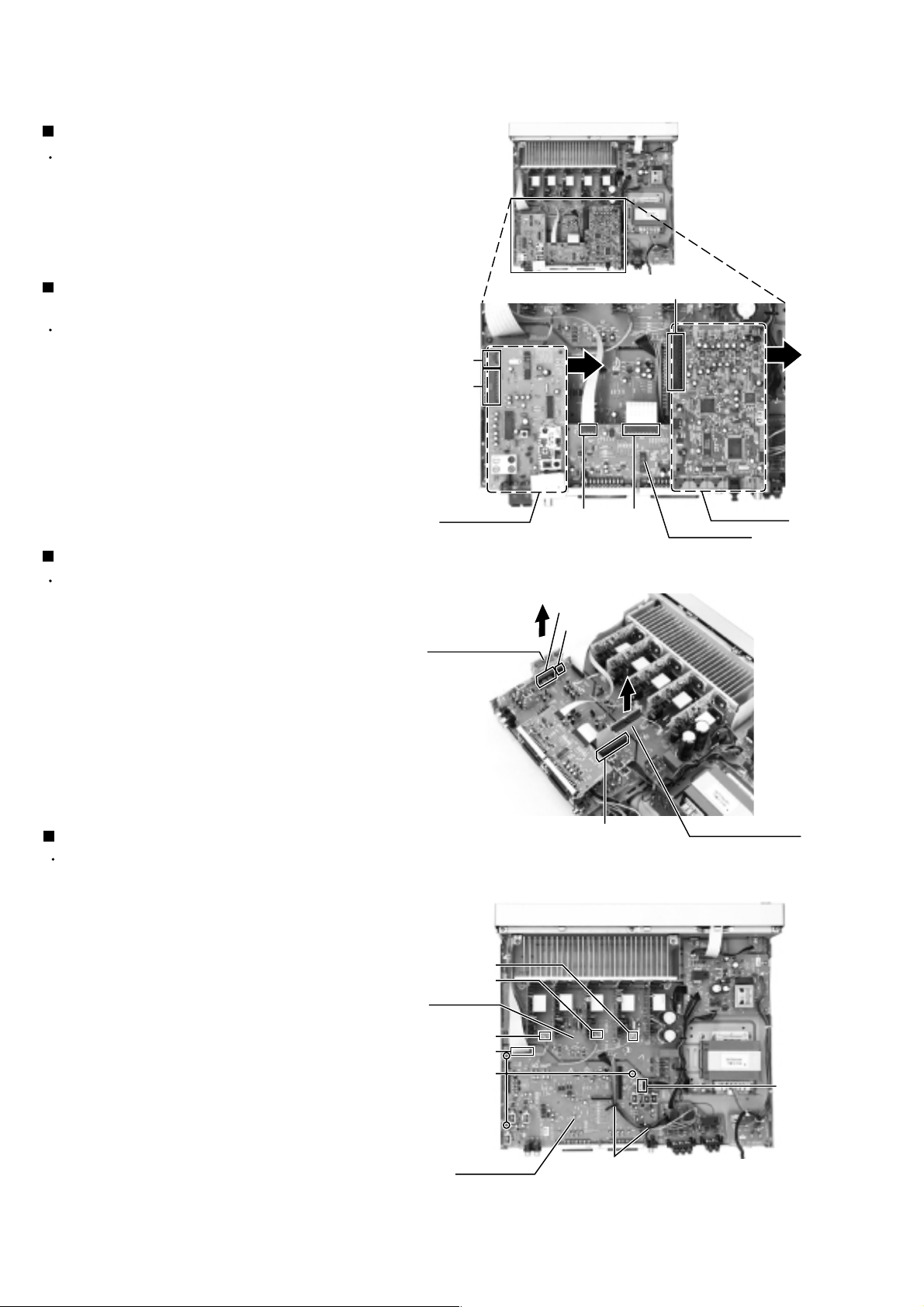

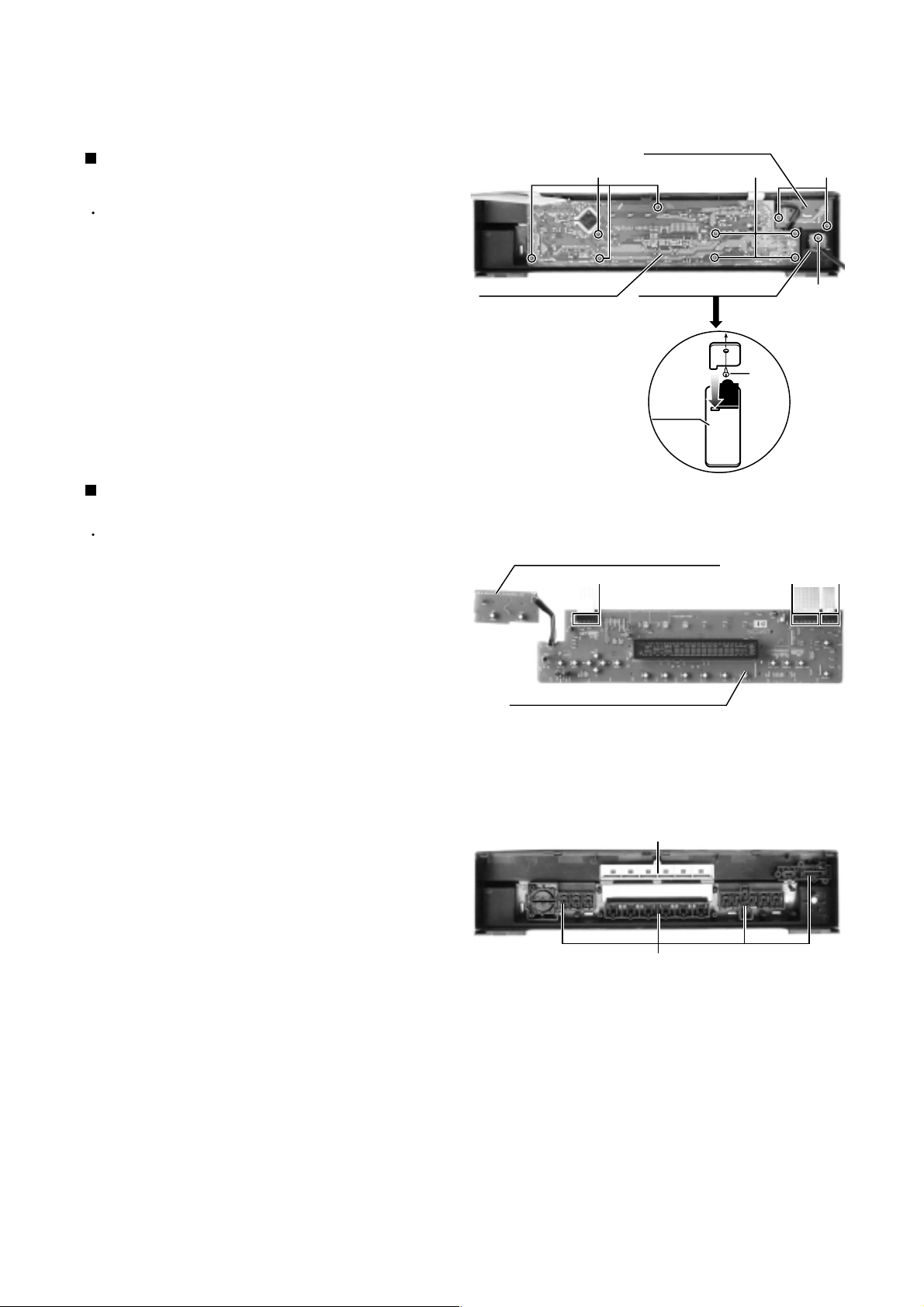

Removing the main board with speaker

board (See Fig.8 to 10)

Prior to performing the following procedure, remove

the top cover, rear panel, input board, DSP board

and relay board (DSP).

1.

Disconnect the harness from the connector CN515,

CN516 and CN517 on the main board (see fig.7).

2.

Remove the harness band[1] (see fig.7) and harness

band[2] fixing the harness.

3.

Disconnect the harness from the connector CN707

on the power supply board .

4.

Disconnect the harness from the connector CN202

and CN226/CN227 on the main board .

5.

Remove the five screws J and two screws K

attaching the main board.

6.

Remove the two screws L attaching the heat sink to

the main board.

7.

Disconnect the connector of each amp. board.

J

K

Main

board

J

CN707

CN226/CN227

CN202

Harness

Speaker board

Fig.8

Heat sink

L

Main board (reverse side)

power supply

board

band[2]

Removing the each amp. board of Cch,

Lch, Rch, SLch and SRch (See Fig.11)

Prior to performing the following procedure, remove

the top cover and main board.

1.

Remove the two screws M attaching the Cch amp.

board and remove the Cch amp. board.

2.

Remove the two screws N attaching the Lch amp.

board and remove the Lch amp. board.

3.

Remove the two screws O attaching the Rch amp.

board and remove the Rch amp. board.

4.

Remove the two screws P attaching the SLch amp.

board and remove the SLch amp. board.

5.

Remove the two screws Q attaching the SRch amp.

board and remove the SRch amp. board.

Rch amp. board

SLch amp. board

SRch amp. board

Main board

CN704

CN703

CN702

R

P

Fig.9

Fig.10

(SLch)

Heat sink

Lch amp. board

Cch amp. board

CN701

Speaker board

N

(Lch)

CN705

R

Removing the Heat sink (See Fig.11)

Prior to performing the following procedure, remove

the top cover, main board and each amp. board.

Remove the four screws R attaching the two

1.

brackets to the heat sink and remove the two

brackets.

Bracket

Q

(SRch)

O

Fig.11

(Rch)

M

(Cch)

Bracket

1-5

Page 6

RX-E112RSL/RX-E111RSL

Removing the power supply board

(See Fig.12)

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the card wire from the connector CN204

on the power supply board.

2.

Disconnect the harness from the connector CN201,

CN209 and CN707 on the power supply board.

3.

Disconnect the harness from the connector CN226

/CN227 on the main board

4.

Remove the three screws S attaching the power

supply board and pull out the power supply board

removing the hook.

5.

Unsolder the three harness connected to the power

supply board (If necessary, cut off the band fixing the

harness on the side of the base chassis).

Removing the power transformer

(See Fig.12 and 13)

Prior to performing the following procedures, remove

the top cover.

S

CN209

CN204

Hook

CN707

CN226

/CN227

CN201

CN202

J

(fixing the

earth wire)

Power supply

board

S

PW201

PW203

Solder

PW202

S

Power

transformer

R

Power

transformer

board

1.

Cut off the tie band.

2.

Disconnect the harness from the connector CN217

on the power/fuse board.

3.

Disconnect the harness from the connector CN201

on the power supply board and CN202 on the main

board.

4.

Remove the one screw J and remove the earth wire.

5.

Remove the four screws R attaching the power

transformer.

Removing the power/fuse board

(See Fig.13)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the screw G attaching the power/fuse board

to the rear panel (see fig. 4).

2.

Disconnect the harness from the connector CN217

on the power/fuse board (If necessary, cut off the

band fixing the harness on the side of the base

chassis).

Power cord

CN217

Tie band

Fig.12

Tie band

Solder

(on the reverse side)

Power/fuse board

Fig.13

U

Solder

3.

Remove the screw U attaching the power/fuse

board.

4.

Unsolder the power cord and other harness

connected to the power/fuse board.

1-6

Page 7

RX-E112RSL/RX-E111RSL

<Front panel assembly>

Removing the system control board with

power switch board (See Fig.1 to 3)

Prior to performing the following procedure, remove

the top cover and front panel assembly.

1.

Remove the two screws A attaching the power

switch board.

2.

Remove the eight screws B attaching the system

control board.

3.

Disconnect the card wire from the connector CN401,

CN402 and CN412 on the system control board.

4.

Remove the switch buttons and indicator esc., if

needed.

Removing the headphone jack board

(See Fig.1)

Prior to performing the following procedure, remove

the top cover and front panel assembly.

1.

Remove the screw C attaching the headphone jack

board to the front panel assembly.

Front panel assembly (inner side)

BBA

System control board

Power switch board (forward side)

Headphone jack board

Power switch board

C

Headphone

jack board

Fig.1

C

CN401CN412 CN402

System control board (forward side)

Fig.2

Front panel assembly (inner side)

Indicator esc.

Switch button

Fig.3

1-7

Page 8

RX-E112RSL/RX-E111RSL

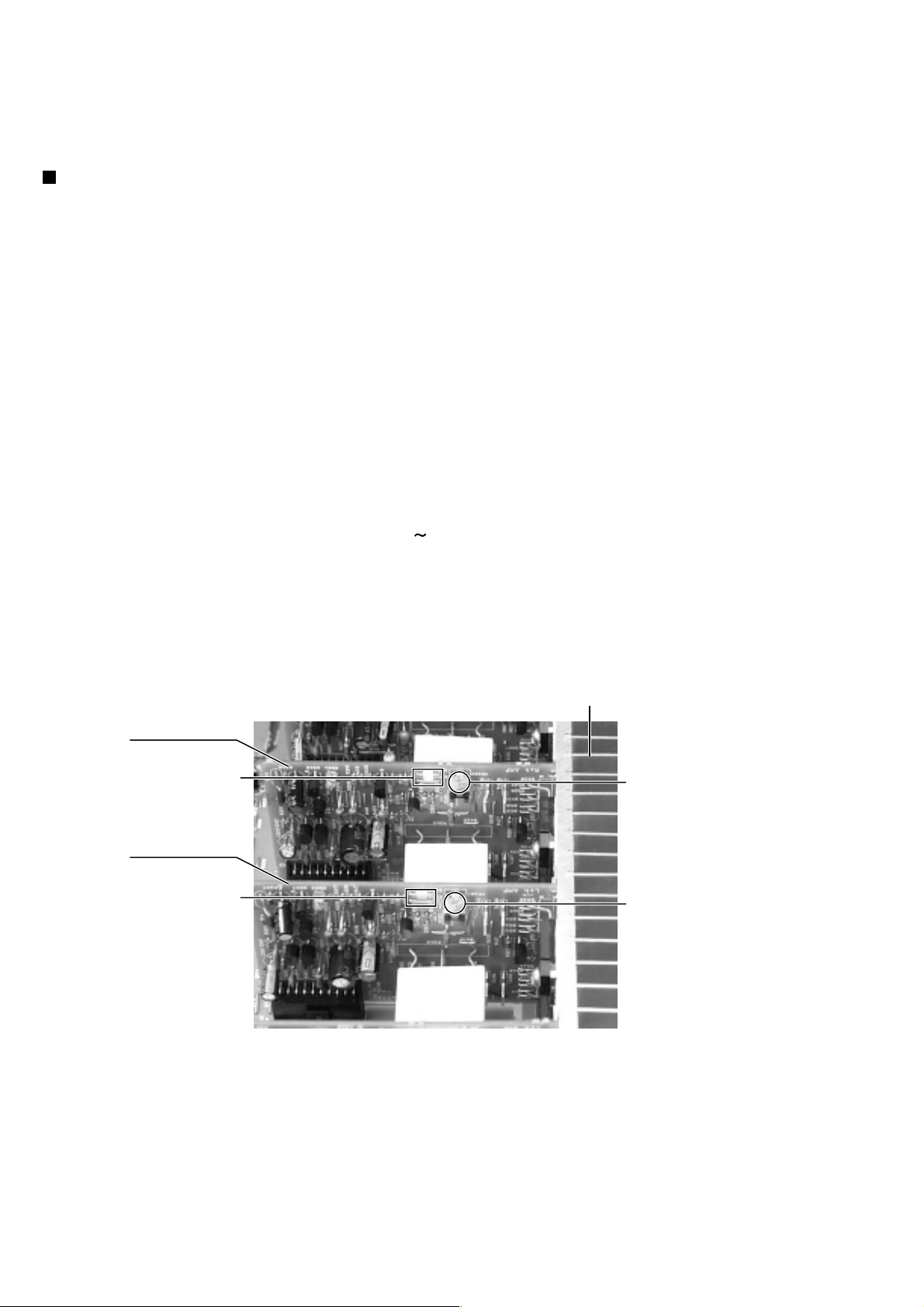

Adjustment method

Power amplifier section

Adjustment of idling current

Measurement terminal B451-B452(Lch) , B453-B454(Rch)

Adjustment volume VR301(Lch) , VR302(Rch)

Attention

This adjustment does not obtain a correct adjustment value immediately after the amplifier is

used (state that an internal temperature has risen).

Please adjust immediately after using the amplifier after turning off the power supply of the

amplifier and falling an internal temperature.

<Adjustment method>

1. Prior to turning the power ON, fully turn the adjusting resistor (VR301(Lch),VR302(Rch)) counterclockwise

direction and connect the DC voltmeter to the measuring terminal(B451-B452(Lch) , B453-B454(Rch)).

2. Set the surround mode OFF.

3. Adjust the resistor so that the measured value becomes 3.2mV immediately after turning the power ON.

4. When the idling current has been stable (about 30 minutes after the power is turned ON),

confirm that the measured value falls within 1.0mV 10mV(2.7mV).

* It is not abnormal though the idling current might not become 0mA even if it is finished to turn variable

resistance (VR301VR302) in the direction of counterclockwise.

Heat sink

Rch amp. board

B453-B454 (Rch)

Lch amp. board

B451-B452 (Lch)

VR302 (Rch)

VR301 (Lch)

1-8

Page 9

Description of major ICs

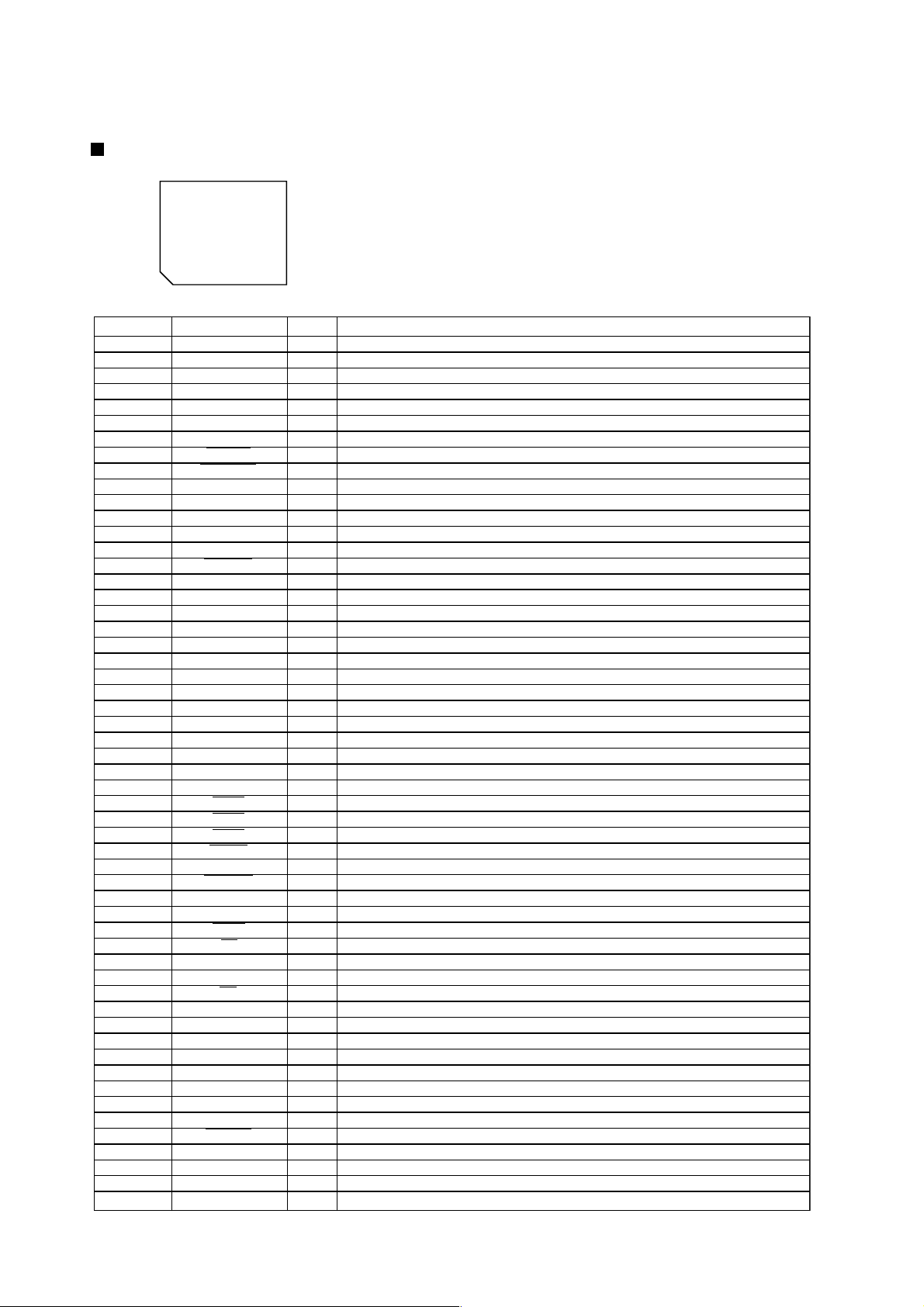

UPD784215AGC (IC671) : Unit CPU

1.Pin layout

75 ~ 51

76

~

50

~

RX-E112RSL/RX-E111RSL

100

2.Pin function

Pin No.

1~8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25~32

33

34,35

36

37,38

39

40

41

42

43

44

45,46

47

48

49

50

51,52

53

54~63

64,65

66

67

68

69,70

71

72

73~80

81

82,83

84

85

86

87

88

89

90~93

94

95~100

1 ~ 25

Symbol

VDD

X2

X1

VSS

XT2

XT1

RESET

AUTODAT A

LOCK

DIGITAL0

FORMAT

CHANNEL

ERR

RSTDET

AVDD

AVREF0

AVSS

AV REF1

RX,TX

DSPCOM

DSPSTS

DSPCLK

DSPRDY

MIDIO_IN/OUT

MICK

MICS

MILP

MIACK

DSPRST

CDTI/CDTO

CCLK

CS

XTS

PD

GND

VDD

ANA/T-TONE

LEF-MIX

S.MUTE

ASW1~4

TEST

26

I/O

O

O

O

I/O

O

O

O

O

O

I/O

O

O

O

O

O

O

O

O

O

Function

-

-

I

-

I

I

I

I

I

I

I

I

I

-

-

-

-

-

-

-

I

I

I

-

-

-

-

-

-

-

-

-

-

-

-

Non connect

Power supply terminal

Connecting the crystal oscillator for system main clock

Connecting the crystal oscillator for system main clock

Connect to GND

Connecting the crystal oscillator for system sub clock

Connecting the crystal oscillator for system sub clock

System reset signal input

Output of DSP to general-purpose port

Output of DSP to general-purpose port

Output of DSP to general-purpose port

Output of DSP to general-purpose port

Output of DSP to general-purpose port

Output of DSP to general-purpose port

Reset signal input

Power supply terminal

Connect to GND

Connect to GND

Connect to GND

Non connect

Power supply terminal

Not use

Non connect

Communication port

Status communication port

Clock input

Ready signal input

Non connect

Interface I/O terminal with microcomputer

Interface I/O terminal with microcomputer of clock signal

Interface I/O terminal with microcomputer of chip select

Interface I/O termonal with microcomputer

Interface I/O termonal with microcomputer

Non connect

Reset signal output of DSP

Non connect

Interface I/O terminal with microcomputer

Interface I/O terminal with microcomputer of clock signal

Interface I/O terminal with microcomputer of chip select

OSC Select

Non connect

Reset signal output

Connect to GND

Non connect

Power supply

Non connect

Test tone control

Control at output destination of LFE channel

Non connect

Mute of the digital out terminal is controlled

Mute of the audio signal is controlled

Non connect

Selection of digital input selector

Test terminal

Non connect

1-9

Page 10

RX-E112RSL/RX-E111RSL

AK4527B (IC601) : A/D,D/A Converter

1.Pin layout

LOOP1

LOOP0/SDA/CDTI

DIF1/SCL/CCLK

DIF0/CSN

P/S

MCLK

DZF1

AVSS

AVDD

VREFH

VCOM

SDOS

I2C

SMUTE

BICK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

4443424140393837363534

1

2

3

4

5

6

7

8

9

10

11

AK4527BVQ

T op View

1213141516171819202122

NC

DZFE

TVDD

DVDD

DVSS

PDN

TSTNCADIF

CAD1

33

32

31

30

29

28

27

26

25

24

23

CAD0

DZF2/OVF

RIN+

RINLIN+

LINROUT1

LOUT1

ROUT2

LOUT2

ROUT3

LOUT3

2. Pin function (1/2)

No.

1

Pin name

SDOS

I/O

I

SDTO Source Select Pin (Note 1)

Function

"L" : Internal ADC output, "H" : DAUX input

2

3

I2C

SMUTE

I

Control Mode Select Pin

"L" : 3-wire Serial, "H" : I

I

Soft Mute Pin (Note 1)

2

C Bus

When this pin goes to "H", soft mute cycle is initialized.

When returning to "L", the output mute releases.

4

5

6

7

8

9

10

11

BICK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

I

Audio Serial Data Clock Pin

I/O

Input Channel Clock Pin

I

DAC1 Audio Serial Data Input Pin

I

DAC2 Audio Serial Data Input Pin

I

DAC3 Audio Serial Data Input Pin

O

Audio Serial Data Output Pin

I

Sub Audio Serial Data Input Pin

I

Double Speed Sampling Mode Pin (Note 1)

"L" : Normal Speed, "H" : Double Speed

12

NC

-

No Connect

No internal bonding.

13

DZEF

I

Zero Input Detect Enable Pin

"L" : mode 7 (disable) at parallel mode,

zero detect mode is selectable by DZFM2-0 bits at serial mode.

"H" : mode 0 (DZF is AND of all six channels)

14

15

16

17

TVDD

DVDD

DVSS

PDN

-

Output Buffer Power supply Pin, 2.7V~5.5V

-

Digital Power Supply Pin, 4.5V~5.5V

-

De-emphasis Pin, 0V

I

Power-Down & Reset Pin

When "L", the AK4527B is powered-do wn and the control registers are reset to def ault

state. If the state of P/S or CAD0-1 changes, then the AK4527B m ust be reset b y PDN.

18

TST

I

Test Pin

This pin should be connected to DVSS.

1-10

Page 11

RX-E112RSL/RX-E111RSL

2. Pin function (2/2)

Pin name

No.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

NC

ADIF

CAD1

CAD0

LOUT3

ROUT3

LOUT2

ROUT2

LOUT1

ROUT1

LINLIN+

RINRIN+

DZF2

OVF

VCOM

VREFH

AVDD

AVSS

DZF1

MCLK

P/S

DIF0

CSN

DIF1

SCL/CCLK

LOOP0

SAD/CDTI

LOOP1

I/O

No Connect

No internal bonding.

Analog Input Format Select Pin

I

"H" : Full-differential input, "L" : Single-ended input

Chip Address 1 Pin

I

Chip Address 0 Pin

I

DAC3 Lch Analog Output Pin

O

DAC3 Rch Analog Output Pin

O

DAC2 Lch Analog Output Pin

O

DAC2 Rch Analog Output Pin

O

DAC1 Lch Analog Output Pin

O

DAC1 Rch Analog Output Pin

O

Lch Analog Negative Input Pin

I

Lch Analog Positive Input Pin

I

Rch Analog Negative Input Pin

I

Rch Analog Positive Input Pin

I

Zero Input Detect 2 Pin (Note 2)

O

When the input data of the group 1 follow total 8192LRCK cycles with "0" input data,

this pin goes to "H".

Analog Input Overflow Detect Pin (Note 3)

O

This pin goes to "H" if the analog input of Lch or Rch is overflows.

Common Voltage Output Pin,AVDD/2

O

Large external capacitor around 2.2uF is used to reduce power-supply noise.

Positive Voltage Reference Input Pin,AVDD

I

Analog Power Supply Pin,4.5V~5.5V

Analog Ground Pin,0V

Zero Input Detect 1 Pin (Note 2)

O

When the input data of the group 1 follow total 8192 LRCK cycles with "0" input data,

this pin goes to "H".

Master Clock Input Pin

I

Parallel / Serial Select Pin

I

"L" : Serial control mode, "H" : Parallel control mode

Audio Data Interface Format 0 Pin in parallel mode

I

Chip select pin in 3-wire serial control mode

I

This pin should be connected to DVDD at I2C bus control mode

Audio Data Interface Format 1 Pin in parallel mode

I

Control Data Clock Pin in serial control mode

I

I2C = "L" : CCLK(3-wire Serial), I2C = "H" : SCL(I2CBus)

Loopback Mode 0 Pin in parallel control mode

I

Enables digital loop-back from ADC to 3 DACs.

Control Data Input Pin in serial control mode

I/O

I2C = "L" : CDTI(3-wire Serial), I2C = "H" : SDA(I2CBus)

Loopback Mode 1 Pin (Note 1)

I

Enable all 3 DAC channels to be input from SDTII.

Function

Notes : 1. SDOS, SMUTE, DFS, and LOOP1 pins are ORed with register data if P/S = "L".

2. The group 1 and 2 can be selected by DZFM2-0 bit if P/S = "L" and DZFME = "L".

3. This pin becomes OVF pin if OVFE bit is set to "1" at serial control mode.

4. All input pins should not be left floating.

1-11

Page 12

RX-E112RSL/RX-E111RSL

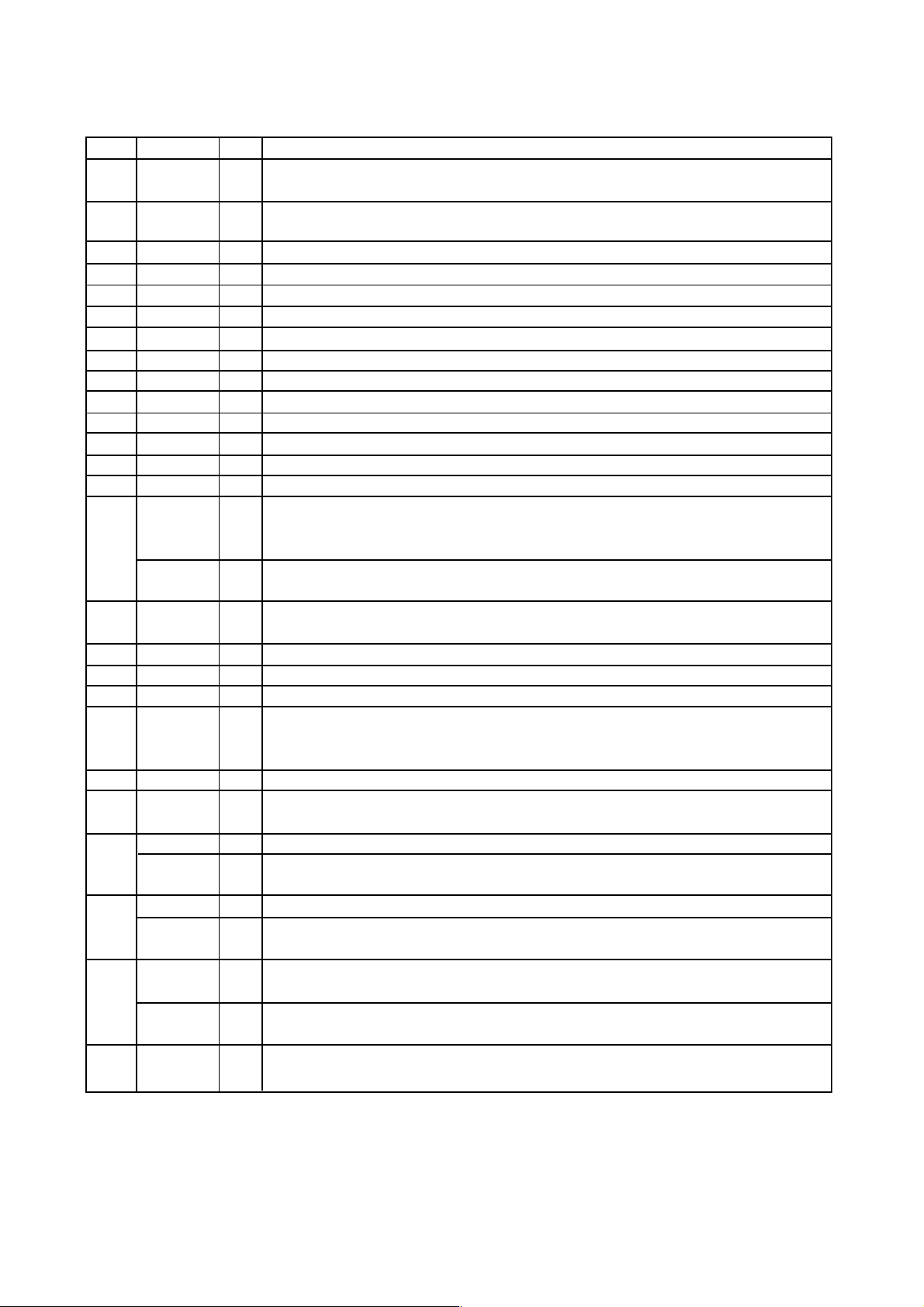

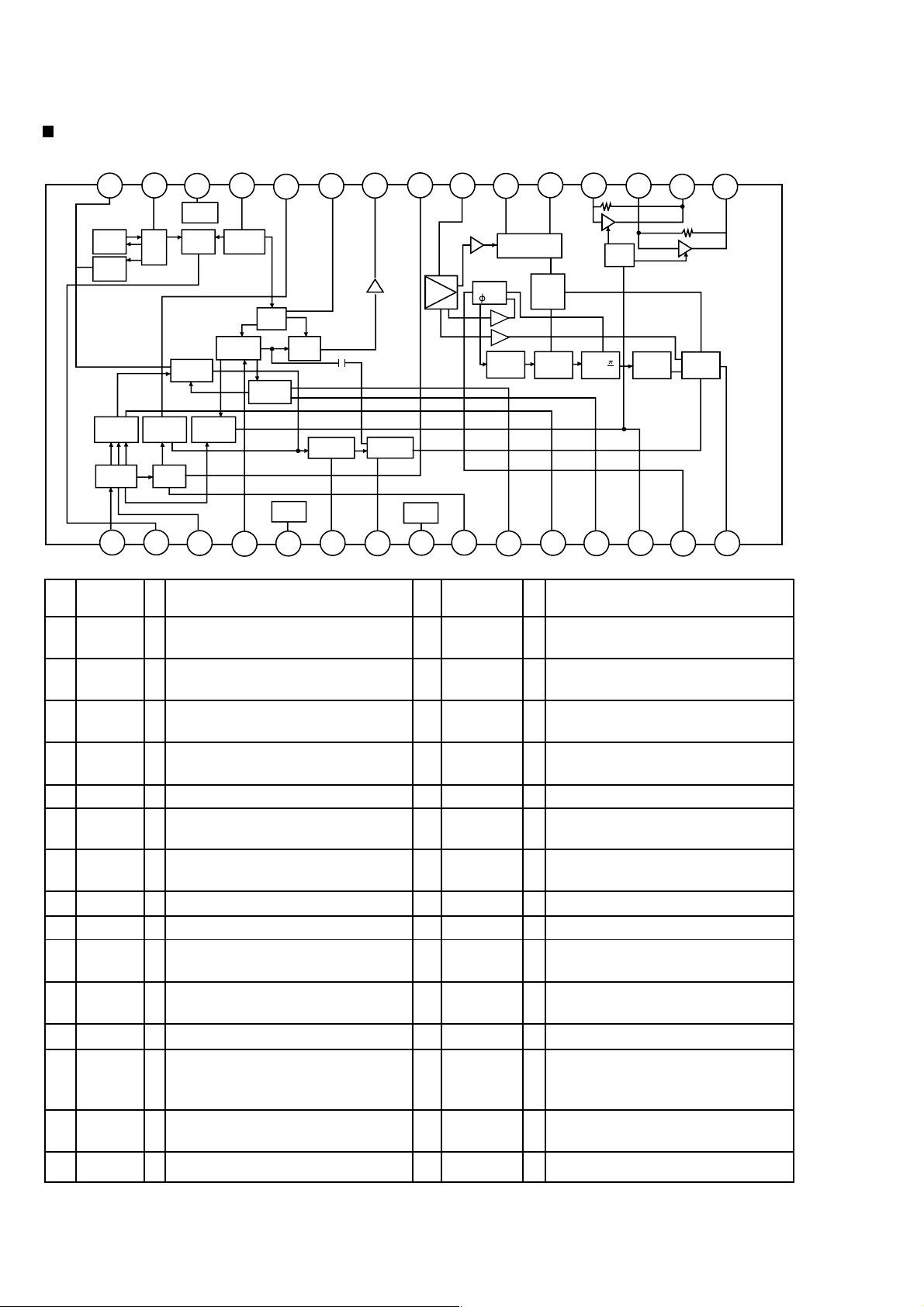

M61501FP (IC501) : Analog sound processor

1. Block diagram

40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25

41

42

43

44

45

46

47

48

49

50

0/6/10dB

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

A

A

SW2

A

B

M

B

M

0/6/10dB

B

M

A

B

B

A

ATT

SLch Vol

Lch Vol

BYPASS

TONE

10/2dB

SW1

0/-6dB

Cch Vol

Bus boost

MCU I/F

0/6/10dB

+

SWch Vol

Bus boost

L+R+C

SRch Vol

0/6/10dB

Rch Vol

BYPASS

TONE

0/6/10dB

SW1

M

A

B

B

A

ATT

0/-6dB

B

A

B

M

0/6/10dB

B

M

SW2

10/2dB

24

23

22

21

20

19

A

18

17

16

15

14

13

A

12

11

10

9

8

7

6

5

4

3

2

1

2. Pin function (1/2)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Symbol

NC

ING1

RECOUT1B

RECOUT1A

SELOUT1

TINA1

TINB1

TCC

TCB1

TCA1

TONEOUT1

SWOUT

AGND

RchAIN

RchBIN

RchOUT

RchBBO

RchBBI

AGND

SRchAIN

SRchBIN

I/O

-

I

O

O

O

I

I

I

I

I

O

O

-

I

I

O

O

I

-

I

I

Function

No connect

G signal input of right side input selector

B through signal output of right side

A through signal output of right side

Signal output after 0/-6dB of right side

Tone A signal input of right side

Tone B signal input of right side

Tone C control of right side

Tone B control of right side

Tone A control of right side

Tone signal output of right side

L+R+C signal output

Analog ground for Rch

A select signal input of Rch

B select signal input of Rch

Signal output of Rch

Bus boost control output of Rch

Bus boost control input of Rch

Analog ground for SRch

A signal input of SRch

B signal input of SRch

1-12

Page 13

RX-E112RSL/RX-E111RSL

2. Pin function (2/2)

Pin No.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Symbol

SRchOUT

AGND

NC

NC

SWchAIN

SWchBIN

SWchOUT

AVSS

DVDD

CLOCK

DATA

LATCH

DGND

AGND

AGND

CchOUT

CchBIN

CchAIN

NC

NC

AGND

SLchOUT

SLchBIN

SLchAIN

AGND

LchBBI

LchBBO

LchOUT

LchBIN

LchAIN

AGND

NC

TONEOUT2

TCA2

TCB2

TCC2

TINB2

TINA2

SELOUT2

RECOUT2A

RECOUT2B

ING2

NC

NC

INF2

INE2

IND2

INC2

INB2

INA2

AVDD

AVDD

INA1

INB1

INC1

IND1

INE1

ING1

NC

I/O

O

-

-

-

O

-

-

-

-

-

O

-

-

-

O

-

O

O

-

-

O

O

O

O

-

-

-

-

-

Function

Signal output of SRch

Analog ground for SWch

No connect

No connect

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

A select signal input of SWch

B select signal input of SWch

Signal output of SWch

Analog power supply

Digital power supply

Digital clock input

Digital data input

Digital latch input

Digital ground

Analog ground

Analog ground

Signal output of Cch

B select signal input of Cch

A select signal input of Cch

No connect

No connect

Analog ground for Cch

Signal output of SLch

B select signal input of SLch

A select signal input of SLch

Analog ground for SLch

Bus boost control input of Lch

bus boost control output of Lch

Signal output of Lch

B select signal input of Lch

A select signal input of Lch

Analog ground for Lch

No connect

Tone signal output of left side

Tone A control of left side

Tone B control of left side

Tone C control of left side

Tone B signal input of left side

Tone A signal input of left side

Signal output after 0/-6dB of left side

A through signal output of left side

B through signal output of left side

G signal input of left side input selector

No connector

No connector

F signal input of left side input selector

E signal input of left side input selector

D signal input of left side input selector

C signal input of left side input selector

B signal input of left side input selector

A signal input of left side input selector

Analog power supply

Analog power supply

A signal input of right side input selector

B signal input of right side input selector

C signal input of right side input selector

D signal input of right side input selector

E signal input of right side input selector

F signal input of right side input selector

No connect

1-13

Page 14

RX-E112RSL/RX-E111RSL

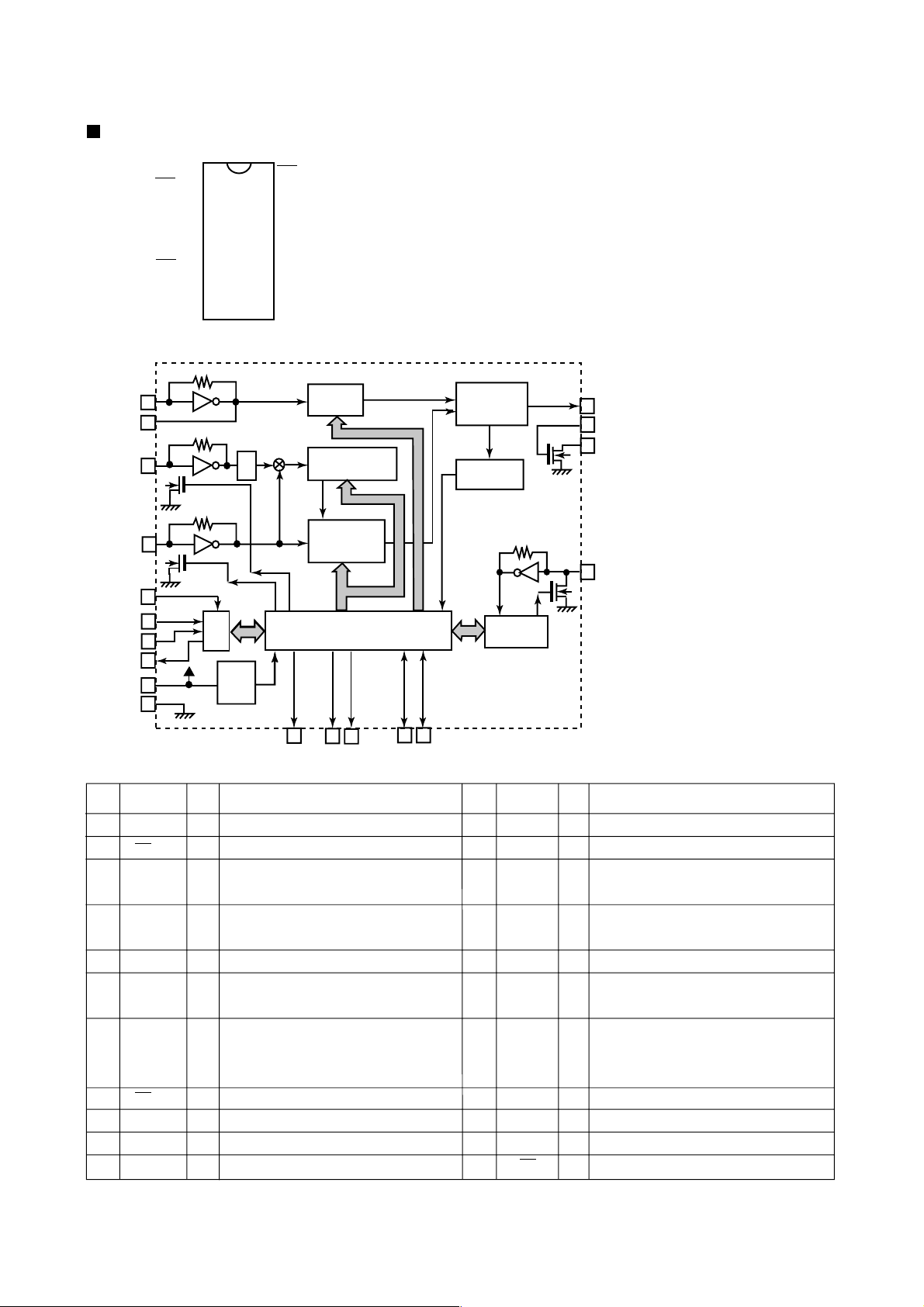

LA1838(IC102) : FM AM IF amp. & detector, FM MPX decoder

1. Block diagram

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

28

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

Function

DET

5

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tuning, this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

TUNING

DRIVE

6

24

STEREO

DRIVE

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

L OUT

17

R OUT

18

19

20

21

22

23

24

25

26

27

28

29

30

L IN

R IN

RO

LO

IF IN

FM OUT

AM DET

AM AGC

AFC

AM RF

REG

AM OSC

OSC BUFFER

21

DECODER

ANIT-BIRDIE

VCO

384KHz

10

20

STEREO

5N

SW

FF

38k

11

I/O

O

Left channel signal output.

O

Right channel signal output.

Input terminal of the left channel post

I

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

14

AMP.

Input terminal of the right channel

I

post AMP.

Mpx Right channel signal output.

O

O

Mpx Left channel signal output.

I

Mpx input terminal

FM detection output.

O

AM detection output.

O

This is an AGC voltage input terminal

I

for AM

I

This is an output terminal of voltage

for FM-AFC.

AM RF signal input.

I

Register value between pin 26 and pin28

O

desides the frequency width of the

input signal.

I

This is a terminal of AM Local

oscillation circuit.

AM Local oscillation Signal output.

O

15

1-14

Page 15

LC72136N (IC121) : PLL frequency synthesizer

1. Pin layout

FM/ST/VCO

2. Block diagram

XT

FM/AM

CE

DI

CLOCK

DO

AM/FM

SDIN

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

RX-E112RSL/RX-E111RSL

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

LW

MW

SDIN

Reference

Driver

Swallow Counter

1/2

C

2B

I/F

Power

on

Reset

Function

I/O

X'tal oscillator connect (75kHz)

I

LOW:FM mode

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

Open state after the power on reset

O

Input/output port

I/O

Input/output port

I/O

Data input/output

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

No.

12

IFCONT

13

14

15

16

17

18

19

LPFOUT

20

21

22

Symbol

IFIN

AMIN

FMIN

VCC

PD

LPFIN

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

I

Output for active lowpassfilter of PLL

O

Connected to GND

X'tal oscillator(75KHz)

I

1-15

Page 16

RX-E112RSL/RX-E111RSL

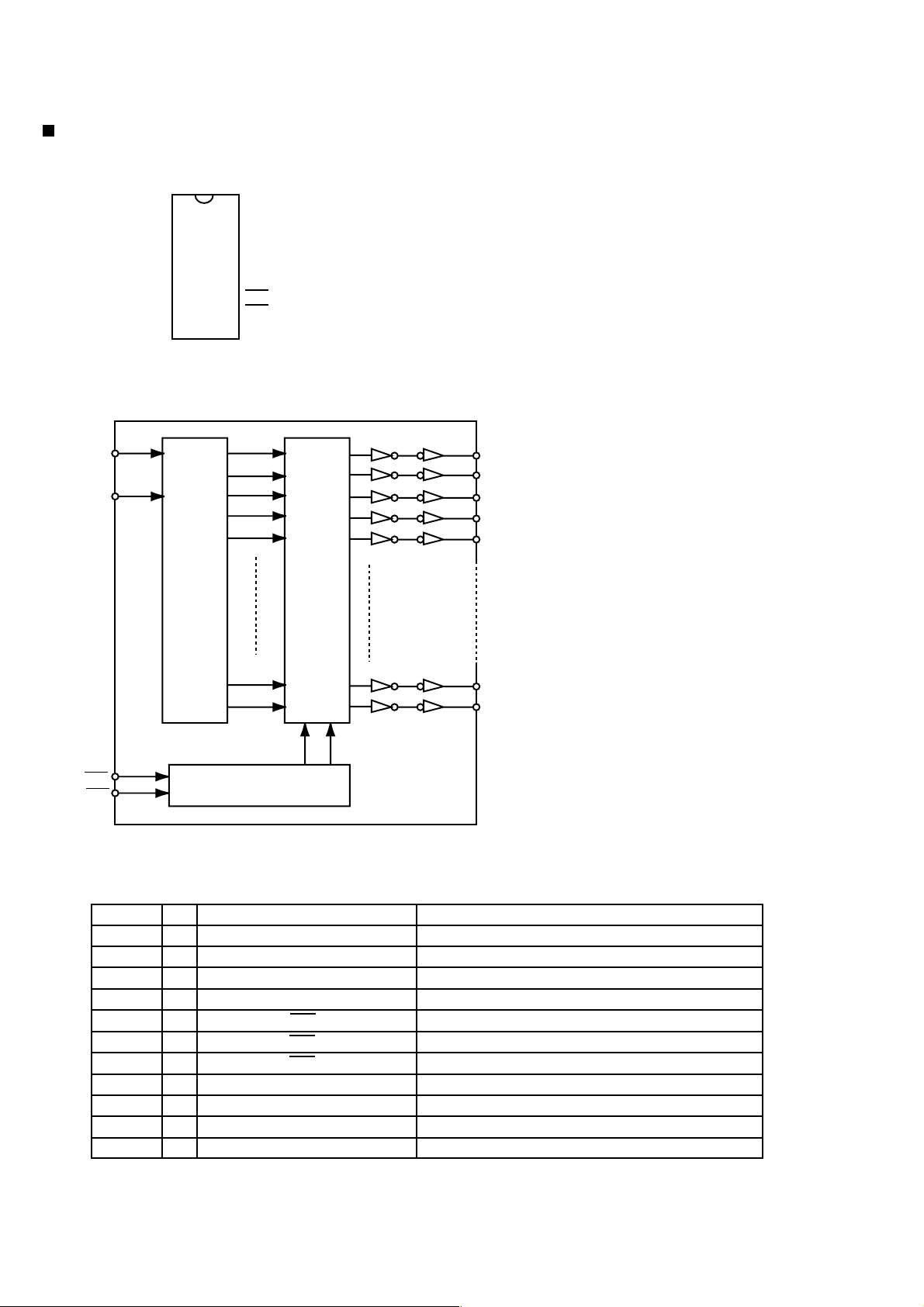

NJU3713 (IC402) : L.E.D. driver

1.Pin layout

P5

2.Block diagram

P6

P7

P8

Vss

P9

P10

p11

P12

1

2

3

4

5

6

7

8

9

18

17

16

15

14

13

12

11

10

VDD

P4

P3

P2

P1

CLR

STB

CLK

DATA

DATA

CLK

STB

CLR

3.Pin function

Shift

resistor

Control Circuit

Latch

circuit

P1

P2

P3

P4

P5

P11

P12

1-16

PIN No.

1~4

5

6~9

10

11

12

13

14

15

16~17

18

I/O

O

O

O

I

I

I

O

O

O

-

Symbol

P5, P6, P7, P8

Vss

P9, P10, P11, P12

DA TA

CLK

STB

CLR

P1

P2

P3, p4,

DD

V

Function

Parallel conversion data output terminal.

Connect to GND.

Parallel conversion data output terminal.

Serial data input terminal.

Clock signal input terminal.

Strobe signal input terminal.

Clear signal input terminal.

Parallel conversion data output terminal.

Parallel conversion data output terminal.

Parallel conversion data output terminal.

Power supply terminal.

Page 17

SAA6588 (IC191) : RDS detector

RX-E112RSL/RX-E111RSL

1. Pin layout

MRO

NC

GND

OSCO

OSCI

VSSD

VDDD

DAVN

SDA

SCL

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

NC

CIN

SCOUT

Vref

MPX

VSSA

VDDA

NC

GND

NC

2. Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

MRO

GND

OSCO

OSCI

VSSD

VDDD

DAVN

SDA

SCL

GND

VDDA

VSSA

MPX

Vref

SCOUT

CIN

NC

NC

NC

NC

FunctionI/OSymbol

Multi-path rectifier output

O

Non connect

Test control input pin

I

Oscillator output

O

Oscillator input

I

Digital ground (0V)

Digital power supply (5V)

Data available output (active LOW)

O

IC-bus serial data I/O

I/O

IC-bus serial clock input

I

Non connect

Connect to ground

Non connect

Analog power supply (5V)

Connect to ground

Multiplex input signal

I

Reference voltage output

O

Band-pass filter output

O

Comparator output

O

Level input

I

3. Block diagram

16

MPX

13

AFIN

LVIN

20

VDDA

14

8th ORDER

BAND-PASS

DETECTOR

POWER

SUPPLY

AND RESET

VSSA

SCOUT

57 kHz

PAUSE

15

18

17

Vref

19

CLOCK

COMPARATOR

MULTI-PATH

DETECTOR

TEST

CONTROL

3

TCON

RDS/RDBS

DEMODULATOR

SIGNAL QUALITY

DETECTOR

OSCILLATOR

AND CLOCK

1

MRO

OSCI OSCO

VDDDCIN

7

DAVN

12

MAD

11

10

8

2

9

PSWN

MPTH

SDA

SCL

RDS/RDBS

DECODER

INTERFACE

REGISTER

IC-BUS SLAVE

TRANSCEIVER

5

4

6

VSSD

1-17

Page 18

RX-E112RSL/RX-E111RSL

L

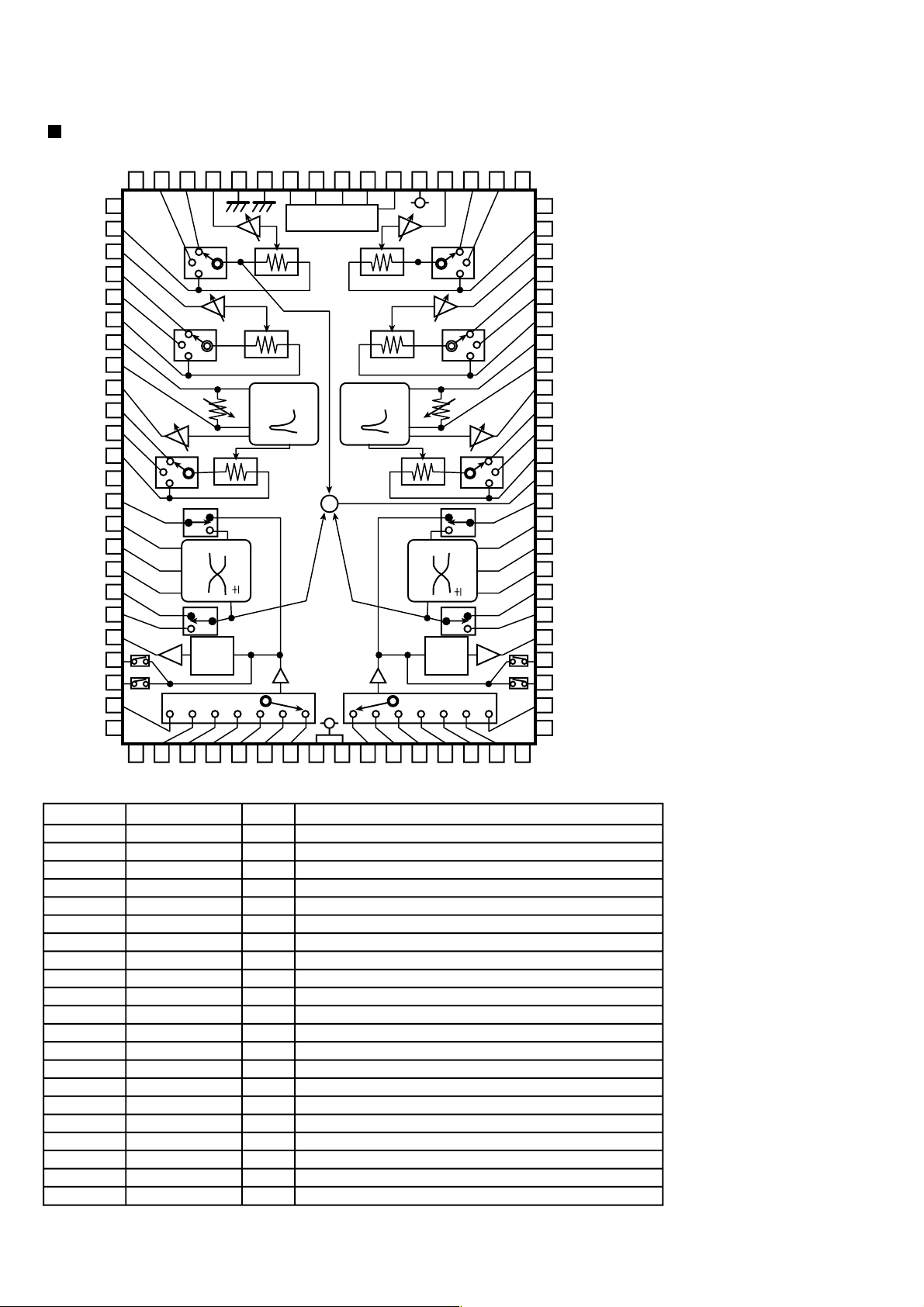

TC9446F-025 (IC631) : Audio digital processor

1. Block diagram

Program

ROM

4k word x3

RAM

128 word

Program

Instruction

control

IRQ

Interrupt

RX

RST

2

4

MCU interface

Audio

Interface

DIR

Timer

SDIn

SDOn

RCK/BCK

LOCK

MIMD

MICS

MILP

MIDIO

MICK

MIACK

40 bit

Instruction

Detector

1 bus

X bus

Y bus

XRAM

4k word

YRAM

4k word

Register

X0, X1, X2

Y0, Y2, Y3

MX

A1

CROM

4k word

MY

MAC ALU

Round/Limiter Round/Limiter

ERAM

4k word

MZ

A0 A2 A3

AX

Address Operater

X pointer

register

AY

x2

Y pointer

register

C pointer

register

Timing

DLL

Bus switch

External SRAM

interface

General output

port

Flag

DIT

17

3

8

8

4

SCKO

SCKI

DLON

LPFO

CE, OE, WR

ADn

IOn

POn

FIn

TXO

2. Pin function

Pin No.

8~11

12

13

14

15

16~19

20

21

22, 23

24

25

26

27, 28

29

30

31

32,33

34

35

36

37

38

39

40

1-18

1

2

3

4

5

6

7

Symbol

RST

MIMD

MICS

MILP

MIDIO

MICK

MIACK

FI0~3

IRQ

VSS

LRCKA

BCKA

SDO0~3

LRCKB

BCKB

SDI0, 1

VDD

LRCKOA

BCKOA

TEST0,1

LRCKOB

BCKOB

TXO

TEST2,3

RX

VSS

TSTSUB0

FCONT

TSTSUB1

TSTSUB2

PDO

I/O

Function

I

Reset signal input terminal

(L:reset H:nomal operation)

I

Mode select input for MCU interface

(L:serial H:IC bus)

I

Chip select input for MCU interface

I

Latch pulse input for MCU interface

I/O

Data I/O for MCU interface

I

Clock input for MCU interface

O

Acknowledge output for MCU interface

I

Flag input 0~3

I

Interrupt input

-

Digital ground

I

LR clock input-A for audio interface

I

Bit clock input-A for audio interface

O

Data output-0~3 for audio interface

I

LR clock input-B for audio interface

I

Bit clock input-B for audio interface

I

Data input-0, 1 for audio interface

-

Digital power supply

O

LR clock output-A for audio interface

O

Bit clock output-A for audio interface

I

Test input-0, 1 (L:test H:nomal operation)

O

LR clock output-B for audio interface

O

Bit clock output-B for audio interface

O

SPDIF output

I

Test input-2, 3 (L:test H:nomal operation)

I

SPDIF input

-

Digital ground

I

Test sub input-0 (L:test H:nomal operation)

O

Frequency control output for VCO circuit

I

Test sub input-1, 2

(L:test H:nomal operation)

O

Phase detect signal output

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54~61

62

63~70

71

72~80

81

82~89

90

91

92

93

94

95

96

97

98, 99

100

Symbol

VDDA

PLON

AMPI

AMPO

CKI

VSSA

CKO

LOCK

VSS

WR

OE

CE

VDD

IO7~0

VSS

AD0~7

VDD

AD8~16

VSS

PO0~7

VDDDL

LPFO

DLON

DLCKS

SCKO

VSSDL

SCKI

VSSX

XO,XI

VDDX

I/O

Function

-

Analog power supply

I

Clock selection input

(L:external clock H:VCO clock)

I

AMP.input for LPF

O

AMP.output for LPF

I

External clock input

-

Analog ground

O

DIR clock output

O

VCO lock output

-

Gigtal ground

O

Writing signal output for extrenal SRAM

O

Enable signal output for external SRAM

O

Chip enable signal output for external SRAM

-

Digital power supply

I/O

Data I/O-7~0 for external SRAM

-

Digital ground

O

Address output-0~7 for external SRAM

-

Digital power supply

O

Address output-8~16 for external SRAM

-

Digital ground

O

General output port-0~7

-

Power supply for DLL circuit

O

LPF output for DLL circuit

I

*

O

ASP clock output

-

Ground for DLL circuit

I

External system clock input

-

Ground for crysoal oscillator

I/O

Crystal oscillator I/O

-

Digital power supply

*

DLCKS pin

DLON pin

L

L

H

H

DLL clock setting

L

SCKI input (DLL circuit OFF)

H

Four times XI clock

L

Three times XI clock

H

Six times XI clock

Page 19

BA033LBSG (IC683) : Standard voltage power supply

1. Block diagram

RX-E112RSL/RX-E111RSL

Vcc 1

CLT 3

GND 2

Standard voltage

Current restriction

circuit

Temperature

protection circuit

5 OUT

4 C

BA15218F (IC503, IC609, IC610, IC650, IC651, IC661, IC690, IC691) : OP amp.

1. Block diagram

EE

1OUT1

2-IN1

1

3+IN1

+

2

4

8

V

CC

OUT2

7

-IN2

6

-

+IN2

5V

+

BA7625 (IC514) : Video selector

1. Block diagram

MONITOR OUT

GND

IN5

GND

IN4

CTL E

IN3

CTL D

1

2

3

4

5

6

7

8

logic

logic

16

15

14

13

12

11

10

11

IN1

CTL A

VOUT 1

CC

V

IN2

CTL B

VOUT 2

CTL C

2. Truth table

A B E MONITOR OUT

LL

HL

LH

H H L IN4

HHH

*

*

*

C D E VOUT1

LL

HL

LH

H H L IN4

HHH

*

*

*

C D E VOUT2

LL

HL

LH

H H L IN4

H H H IN5

*

*

*

IN1

IN2

IN3

IN5

-IN2

IN3

IN5

IN1

-IN3

1-19

Page 20

RX-E112RSL/RX-E111RSL

TC74HC08AF (IC611) : AND gate

1. Pin layout

1A

1B

1Y

2A

2B

2Y

GND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

Vcc

4B

4A

4Y

3B

3A

3Y

TC74HC4072AF (IC612) : OR gate

1. Pin layout

1Y

1A

1B

1C

1D

NC

GND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

Vcc

2Y

2D

2C

2B

2A

NC

2. Truth table

A

L

L

H

H

2. Truth table

A

B

H

X

X

H

X

X

X

X

L

L

X : Don't care

B

L

H

L

H

Y

L

L

L

H

C

D

Y

X

X

H

X

X

H

H

X

H

X

H

H

L

L

L

TC74HC4053A (IC515) : Multiplexer

1. Pin layout

1Y

1-20

0Y

1Z

Z-COM

0Z

INH

V

GND

1

2

3

4

5

6

EE

7

8

16

15

14

13

12

11

10

9

Vcc

Y-COM

X-COM

1X

0X

A

B

C

2. Truth table

CONTROL INPUTS

INHIBIT

L

L

L

L

L

L

L

L

H

X: Don't Care.

C

L

L

L

L

H

H

H

H

X

B

H

H

H

H

"ON" CHANNEL

A

L

L

L

H

L

H

L

L

L

H

L

H

X

X

0X, 0Y, 0Z

1X, 0Y, 0Z

0X, 1Y, 0Z

1X, 1Y, 0Z

0X, 0Y, 1Z

1X, 0Y, 1Z

0X, 1Y, 1Z

1X, 1Y, 1Z

NONE

Page 21

NJM2246M (IC511, IC512, IC513) : Video switch

1. Block diaglam

RX-E112RSL/RX-E111RSL

GND Vout V+ Vin3

8 7 6 5

6dB

AMP.

BIAS

1 2 3 4

Vin1 CTL1 Vin2 CTL2

INPUT CONTROL SIGNAL- OUTPUT SIGNAL

CTL1

L

H

L/ H

CTL2

L

L

H

OUTPUT SIGNAL

Vin1

Vin2

Vin3

TC74HCU04AF (IC621) : Inverter

1. Pin layout

1Y

2A

2Y

3A

3Y

11A

2

3

4

5

6

7

14

13

12

11

10

9

8GND

VCC

6A

6Y

5A

5Y

4A

4Y

TC7SET32FU (IC672) : 2 input or gate

IN B

A

L

H

1

54VCC

Y

H

L

IN A

GND

2

3

OUT Y

1-21

Page 22

RX-E112RSL/RX-E111RSL

W24L010AJ-12 (IC641) : CMOS SRAM

32

NC

A16

A14

A12

A7

A6

A5

A4

A3

A2

A1

A0

I/O1

I/O2

I/O3

Vss

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

VDD

A15

CS2

WE

A13

A8

A9

A11

OE

A10

CS2

I/O8

I/O7

I/O6

I/O5

I/O4

2. Block diagram1. Pin layout

A16

A14

A12

A4

A3

A2

A7

A6

A5

A9

I/O 1

I/O8

WE

R

O

W

D

E

C

O

D

E

R

DATA

CNTRL.

CLK

GEN.

PRECHARGE CKT.CLK GEN.

CORE CELL ARRAY

7024 ROWS

728x8 COLUMN5

I/O CKT

COLUMN DECODER

A15 A13 A8 A1 A0 A11 A10

CS1

CS2

OE

1-22

Page 23

RX-E112RSL/RX-E111RSL

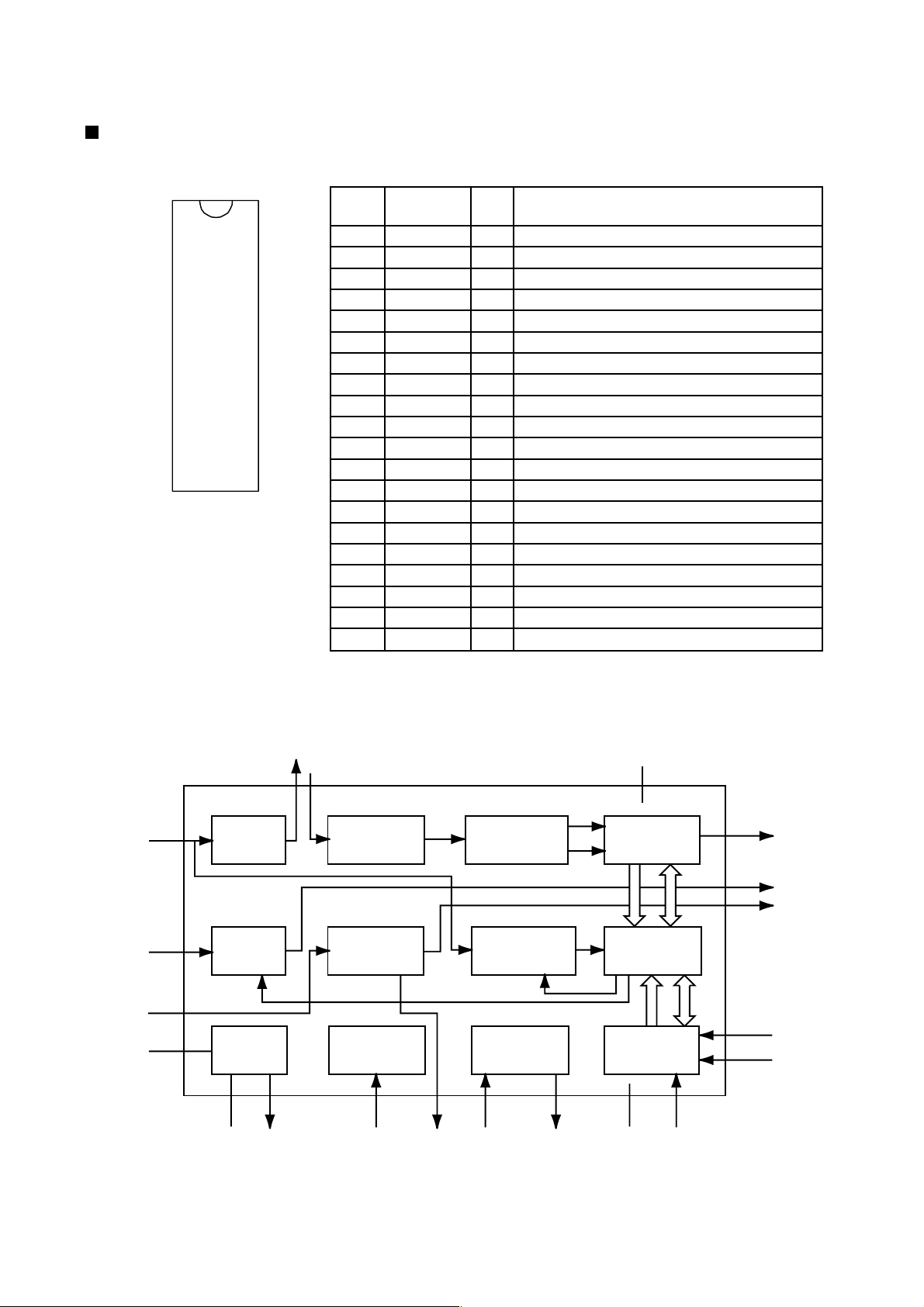

Block diagram

5

4

3

COAXIAL

IN

OPTICAL

IN

2

1

ABCD E F G

IC611

SW

IC611

LVA10321-1

SUBWOOFER

IC611

TV

VCR

DVD

STB

TAPE PLAY

TAPE REC

OUT

DSP

IC631

SDRAM

IC641

J1501 J1502

LVA10318-1

J501

STB R/C,G,B,Y/V,YS IN

STB SLOW IN

STB AUDIO IN

J502

LVA10316-1

IC402

TV AUDIO IN

AUDIO OUT

TV R/C,G,B,Y/V,YS OUT

TV- LINK

Y/V OUT

VCR R/C,G,B,Y/V,YS IN

AUDIO OUT

VCR AUDIO IN

TV SLOW OUT

VCR SLOW IN

DVD R/C,G,B,Y/V,YS IN

DVD AUDIO IN

DVD SLOW IN

TV- LINK

TAPE PLAY

TAPE REC

SUBWOOFER OUT

DSP

CONTROLLER

IC671

DSP COMMAND,DSP CLK, DSP STATUS, DSP READY, DSP RESET

KEY

LVA10318-2

IC511

IC512

IC513

IC514

IC515

CN512

CN502

AUDIO OUT

CN501

CN681

AD/DA CONVERTER

IC601

VOLCLK, VOLDAT A, V OL LA TCH

CN401

SYSTEM CONTROLLER

IC401

FL DISPLAY

DI401

(B)

(G)

(R/C)

(Y/V)

(YS)

S/W

Video 1~4

AUDIO SW

DAVN, SDA, SCK

RY HP, RY LR

RY S, RY C

CN412

CN504

IC501

&

VOLUME

CN503

CN411

CN402

CN214

TUNER L/R

PLL CLK,

PLL DATA, PLLCE

PLL CLK, PLL DATA, PLLCE,

REAR

CENTER

FRONT

AUDIO

AMP.

AM/FM DET

CN111 CN112

CN506CN505 CN507

Lch

LVA10317-4

Rch

LVA10317-5

Cch

LVA10317-8

RLch

LVA10317-6

RRch

LVA10317-7

IC191

IC102

PLL

IC121

Q315

Q317

Q316

Q318

Q915

Q917

Q815

Q817

Q816

Q818

LVA10009

TUNER

RF101

MW RF&OSC

T111

CN517

CN516CN515CN711

CN701CN702CN705CN703CN704

CN712

CN715

CN713

CN714

FM

AM

LVA10316-2

Q207~Q209

CN204

CN721

FW702

FW206

CN721

FW702

CN226

LVA10316-3

RY741

RY743

RY742

FW707

CN707

LVA10317-1

Lch

Rch

TERMINAL

Cch

RLch

RRch

CN204

SPEAKER

FW209

LVA10316-6

2-1

Page 24

RX-E112RSL/RX-E111RSL RX-E112RSL/RX-E111RSL

Standard schematic diagrams

Power supply section

5

FW205

CN204

POWER

RELAY_LR

RELAY_C

RELAY_S

PROTECTOR

HP_SW

Sheet 6/8

4

3

Sheet 4/8

SHEET

NUMBER

1 / 8 POWER SUPPLY

2 / 8 SPEAKER TERMINAL

3 / 8 AUDIO AMP

4 / 8 AUDIO SIGNAL INPUT TERMINAL

5 / 8 VIDEO&AUDIO SIGNAL INPUT TERMINAL

Sheet 2/8

CN212

C225

0.022

11ES2

D219

11ES2

D220

R209

100k

C218

1/50

D217

MTZJ6.2C

C206

0.047

Q205

KTC3200/GL

C207

0.047

R208

10

FW201

CN201

C202

0.1

F202

T2AL

F203

T2AL

R201

8.2

D201

10E2-FD

D203

10E2-FD

C204 C205

2200/35 1000/35

D202

11ES2

C203

0.1

C201

0.1

D204

11ES2

D206

11ES2

D208

11ES2

0.0047/100

CN207

F204

T100mAL

T202

QQT0281-002

C208

R202

10

D207

11ES2

R203

10

D209

11ES2

C209

470/25

PW201

PW203

PW202

C210

0.0047

RY201

QSK0142-001

D210

1SS133

Q203

KTC3203/OY

R204

820

C212

470/16

MTZJ6.2C

CN217

EP202

F201

T1.6AL

PW101

PW103

PW102

Q202

KRC105M

D212

11ES2

POWER

D211

R213

330

2200/6.3

TA201

TA202

C213

EP201

6 / 8 SYSTEM CONTROL & FL DISPLAY

7 / 8 DSP

8 / 8 TUNER

CIRCUIT DESCRIPTION

R211

12

Q211

FW206

S1RELAY

PROTECTOR

2

Sheet 2/8

HP_R

HP_L

1

R217

12

RY202

QSK0109-001

J201

Q212

KRC105M

D222

1SS133

Q210

KRC105M

R216

470

R215

470

CN209

FW209

C232

330p

C231

330p

C233

0.1

EP203

2SD2395/EF

C221 D221

100/25 MTZJ6.2C

R212

6.8k

RELAY_C

KRC105M

2-2

RELAY_LR

RELAY_S

Q207

Q208

KRC105M

Q209

KRC105M

CN707

Sheet 2/8

Parts are safety assurance parts.

When replacing those parts, make

sure to use the specified parts.

SHEET 1/8

HABC DEFG

Page 25

Speaker terminal section

RX-E112RSL/RX-E111RSL

EP701

5

CN715

Sheet 3/8

4

CN711

C706

47/25

R351

R353

10

L301

1

0.047MY

C701

0.1/160

C702

0.1/160

D701

D702

D703

D704

C703

0.1/160

C704 C705

4700/63 4700/63

R701

3.3k

D705

MTZJ22C

C327

0.047MY

C325

Sheet 3/8

R352

R354

101010

C328

CN712

0.047MY

L302

C326

1

0.047MY

Sheet 3/8

3

CN713

Sheet 3/8

CN714

R720

Sheet 3/8

2

CN517

Sheet 4/8

Sheet 4/8

CN516

CN515

R721

4.7k

Q708

KRC109M

D712

1SS133

D713

1SS133

Q710 Q712

KRC109M KRC109M

1SS133

C713

4.7/50

R725 R726

4.7k 4.7k

Sheet 4/8

Q714

D714 D715

KRC109M

R729

1SS133 1SS133

1

22k

C714

R730

4.7/50

15k

3.9k

D711

R722

22k

R723

15k

Q711 Q713

KRC109M KRC109M

R728R727

4.7k4.7k

Q715

KRC109M

C715

4.7/50

CN202

RY701

QSK0082-001

D716

1SS133

R735

12

-30V

HP_R

HP_L

R736

Q716

10

KTA1046/Y

R737

5.6k

C721D717

47/50MTZJ30C

R704

100k

R705

100k

R706

82k

R707

100k

R708

82k

C709 R709

10/50 10k

Q702

KTC3200/GL/

R711

R710

100k

10k

Q703

KTA1268/GL

R712

100k

D710

MTZJ5.1C

C712

4.7/50

R718

R731

22k

R732

15k

10k

R719

47k

R713

10

R714

2.2k

MTZJ8.2C

MTZJ6.8C

Q704

KTC3199/GL/

C710

220/6.3

2SD2395/EF

D709

D721

Q705

Q706

KTC3200/GL/

D707

1SS133

C717

100p

C718

0.1MY

CN227

Sheet 1/8

Sheet 1/8

CN721

FW702

FW707

CN721

FW702

D741

1SS133

R741

12

R742

12

D743

1SS133

RY741

QSK0109-001

R743

12

RY742

QSK0109-001

D742

1SS133

RY743

QSK0109-001

L741

C741

0.45

0.022

C743

R745

4.7

220p

R746

4.7

C744

L742

0.45

L743

0.45

L744

0.45

L745

0.45

220p

C742

0.022

C749

0.022

R747

C751

4.7

220p

R748

4.7

C752

220p

C750

0.022

R749

4.7

C758

220p

C757

0.022

FRONT signal

CENTER signal

REAR signal

C745 C747

220p 0.022

C746 C748

220p 0.022

C753 C755

220p 220p

C754

220p

C756

220p

C760

220p

C759

220p

ST741

ST742

Parts are safety assurance parts.

When replacing those parts, make

sure to use the specified parts.

SHEET 2/8

ABCD E F G

2-3

Page 26

Audio amp section

RX-E112RSL/RX-E111RSL RX-E112RSL/RX-E111RSL

R915

270

R909

100

Q901

2SC2240/L

KTA1268/GL

C907

0.0015

C917

100/16

R963

R913

3k

56k

C911

10p

R965

Q903

68

2SC2240/L

R911

R905

300

18k

C909

100/16

R907

3k

D901

5

1SS133

C905

270p

C901

R901

2.2/50

2.2k

C903

R903

68k

100p

4

R315

0.0015

R312

470

Q304

2SC2240/L

220

C307

R355

2.7k

Q303

2SC2240/L

R365

33

R305

12k

C310

220/16

R366

33

R314

56k

C312C306

10p270p

R356

C316

2.7k

22p

100/16

Q305

KTA1268/GL

C315

22p

C313

0.01MY

C311

10p

Q307

R313

KTC3200/GL

56k

R311

470

R319

220

D303

SLR-342MC

D304

SLR-342MC

R320

220

R318

47k

Q308

KTC3200/GL

C314

0.01MY

Q306

KTA1268/GL

R316

C318

220

100/16

R307

2.7k

R309

100

D301

1SS133

C305

270p

C301

R301

4.7/50

2.2k

3

C303 R303 C309

100p 68k 220/16

2

R302

C302

2.2k

4.7/50

Q301

2SC2240/L

R306R304C304

12K68k100p

Q302

2SC2240/L

D302

1SS133

R310

C308

100

0.0015

R308

2.7k

R921

180

C919

47/63

Q905

C913

C915

0.01MY

33p

R927

10k

2.2k

R955

3.3k

R957

3.3k

C929

R959

47/50

3.3k

R961

3.3k

R923

10

C319

100/63

C317

R317

47k

C320

100/63

R967

Q909

R925

560

R321

10

VR301

1K

R327

1.5k

R325

560

R323

10

R324

10

R326

560

R328

1.5k

VR302

1K

2SD637/QR

D305

1SS133

Q321

Q309

2SD637/QR

Q310

2SD637/QR

Q322

KTA1268/GL

D306

1SS133

R322

10

D905

1SS133

Q921

D907

1SS133

KTA1268/GL

D308

1SS133

KTA1268/GL

Q312

KTC3200/GL

KTA1268/GL

KTC3200/GL

KTA1268/GL

1SS133

R334

10

Q314

R332

10

KTC3200/GL

KTA1268/GL

Q311

Q313

D307

R931

10

Q911

Q913

R933

10

R331

10

R333

10

R336

82

2SD2389LD/OPY

C321

47p

R335

82

R337

82

2SB1559LD/OPY

C323

47p

C324

47P

Q318

2SB1559LD/OPY

R342

180

R338

82

R340

Q316

C322

47P

C921

47p

2SD2389LD/OPY

180

Q915

2SD2389LD/OPY

R939

180

R935

100

R943

R937

0.22

100

R941

180

R945

1k

Q917

2SB1559LD/OPY

C923

47p

B452 B451

Q315

R339

180

R341

180

Q317

R344

0.22

KTA1268/GL

R343

0.22

R345

1k

D309

1SS133

D310

1SS133

R348

R346

15k

1k

Q320

KTA1268/GL

R949

47k

Q919

KTA1268/GL

R951

33

L901

0.45

R953

10

C925

D909

0.047MY

1SS133

C927

R947

0.047MY

18k

R349

47k

Q319

R347

15k

R350

47k

CN705

R821

C819

180

Sheet 2/8

D801

1SS133

C801

R801

2.2/50

2.2k

C805

330p

Q801

2SC2240/L

C803

R803

100p

68k

CN701

47/63

R815

270

Q805

KTA1268/GL

C817

100/16

R807

3k

C807

R809

0.0015

100

R863

3k

Q803

2SC2240/L

R805

18k

R827

10k

C815

33p

C813

0.01MY

R813

56k

C811

8p

R865

82

R811

390

C809

100/16

R867

2.2k

Q821

R855

3.3k

KTA1268/GL

R857

3.3k

C829

47/50

R825

R859

560

3.3k

R861

3.3k

R823

10

2SD637/QR

Q809

D805

1SS133

KTA1268/GL

D807

1SS133

R831

10

Q811

KTC3200/GL

Q813

R833

10

2SD2389LD/OPY

R839

R835

100

R837

100

R841

2SB1559LD/OPY

C821

47p

Q815

180

R843

0.22

180

Q817

C823

47p

R849

12k

Q819

KTA1268/GL

R851

33

L801

0.45

R845

R853

1k

10

C825

D809

0.047MY

1SS133

C827

R847

0.047MY

18k

CN703

Sheet 2/8

Sheet 2/8

R822

180

R816

270

C820

47/63

D802

1SS133

C802

R802

2.2/50

CN702

Sheet 2/8

2.2k

C806

330p

Q802

2SC2240/L

C804

R804

100p

68k

Q806

KTA1268/GL

C816

C818

100/16

C808

0.0015

R864

33p

C814

0.01MY

R808

3k

R810

100

R856

3k

3.3k

R858

3.3k

R814

56k

C812

C830

8p

47/50

R866

R860

82

3.3k

Q804

R812

2SC2240/L

390

R806

18k

R862

3.3k

C810

100/16

R832

C822

47p

10

D806

Q816

1SS133

R868

2SD2389LD/OPY

2.2k

10k

R828

Q812

KTC3200/GL

R840

180

R844

R836

0.22

100

Q822

KTA1268/GL

R838

100

R842

2SD637/QR

180

Q814

KTA1268/GL

Q810

Q818

560

R826

2SB1559LD/OPY

D808

1SS133

R834

C824

10

R824

47p

10

R850

12k

Q820

KTA1268/GL

R852

33

L802

0.45

R854

10

R846

1k

C826

0.047MY

D810

1SS133

C828

0.047MY

R848

18k

CN704

Sheet 2/8

B454 B453

1

FRONT signal

CENTER signal

REAR signal

2-4

Parts are safety assurance parts.

When replacing those parts, make

sure to use the specified parts.

SHEET 3/8

HABC DEFG

Page 27

Audio signal input terminal section

5

J501

R502

470

C502

330p

C501

330p

D511

MTZJ13C

D512

MTZJ13C

D513

MTZJ13C

D514

4

3

MTZJ13C

R510

75

J502

C508

330p

C507

330p

D515

MTZJ13C

D516

MTZJ13C

D517

MTZJ13C

D518

MTZJ13C

R522

75

2

J503

DVD_R

R1612

100k

R1611

100k

R501

DVD_L

470

DVD_B

R504

DVD_SLOW

4.7/50

C503

330

C504

75

R503

4.7/50

330

R506

DVD_G

75

R505

C505

R507

75

4.7/50

DVD_R/C

330

R508

DVD_Ys

R509

75

C506

4.7/50

DVD_V/Y

R511

330

R514

470

STB_R

R1614

100k

R1613

R513

100k

470

STB_L

STB_B

R516

STB_SLOW

330

4.7/50

C509

C510

75

R515

4.7/50

330

R518

STB_G

75

R517

C511

75

R519

4.7/50

STB_R/C

330

R520

STB_Ys

R521

75

C512

4.7/50

330

STB_V/Y

R523

R525

470

C515

220p

R1615

100k

TAPE_L TAPE_R

R527

470

J504

C563

0.1MY

1

DSP signal

SUBWOOFER signal

TUNER signal

ABCD E F G

RX-E112RSL/RX-E111RSL

Sheet 7/8

CN601

CN511

0.0068MY

C527

0.0068MY

C528

IC501

M61501FP

DSP_RESET

C530 C529

22/50 22/50

R584

2.2k

DSP_READY

R1619

100k

R537

R583

10

DSP_COMMAND

DSP_STATUS

10k

L_OUT

R_OUT

C532

0.1MY

100k

R1620

DSP_CLK

0.1MY

C531

R538

CN501

C577

47/16

DSP_SL

0.1MY

C533

C534

10k

DSP_SR

EP502

DSP_C

C538

SW_OUT

560p

VOL_LATCH

VOL_DATA

VOL_CLK

C537

47/10

C536

47/16

DSP_LFE

C556

R579

68

47/16

C555

47/16

R580

68

R585

10

R586

1.8k

Q513

2SD2395/EF

R594

6.8

R588

1.8k

D506D505D504

MTZJ15CMTZJ15CMTZJ7.5C

SL_OUT

SR_OUT

0.1MY

R535

6.2k

R536

6.2k

C535

47/16

C513

C514

2SC3576

330p

C518

330p

Q507

R526

470

C516

220p

R1616

100k

R528

470

R529 R530

1k 1k

2SC3576

Q510 Q512

KTA1271/OY KTA1046/Y

Q516

R532R531

DTA114YKA

10k10k

Q508

D503

R1621

MTZJ7.5C

1k

SW_MUTE

C581

2.2/50

330p

C517

330p

TV audio signal

VCR audio signal

DVD audio signal

10k

C596

C595

C594

C593

C592

C591

R534

DSP_LFE

DSP_C

DSP_SR

DSP_SL

DSP_R

DSP_L

DSP.IN_R

DSP.IN_L

DSP.IN_LDSP.IN_R

C519

R1617

100k

TAPE_LOUT

TUNER_L

TV_L

STB_L

DVD_L

TAPE_L

VCR_L

VCR_R

TAPE_R

DVD_R

STB_R

TV_R

TAPE_ROUT

C522

22/50

R1618

100k

TV_ROUT TV_LOUT

R581

10

R582

2.2k

FRONT signal

CENTER signal

REAR signal

4.7/50

C520

10k

R533

DSP_L

22/50

C521

4.7/50

DSP_R

KTC3203/OY

0.068MY

0.0068MY

C525

0.0068MY

C526

0.068MY

-14V

C523

C524

Q511

Sheet 5/8

VCR_L

VCR_R

TV_ROUT

TV_LOUT

TV_L

TV_R

DVD_SLOW

DVD_B

DVD_G

DVD_R/C

DVD_Ys

DVD_V/Y

R1623

10

C549

4.7/50

C550

4.7/50

C545

4.7/50

R556

R554

1k

27k

R552

100k

IC503

C544

BA15218F( 1/2)

4.7/50

2SD2395/EF

B208

C546

4.7/50

C541

10/50

R545

100k

R546

100k

C542

10/50

R589

Q514

22

R590

6.8k

Q522