Page 1

SERVICE MANUAL

AUDIO/VIDEO CONTROL RECEIVER

MB17220043

RX-7042S

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.MB172

2004/3

Page 2

SPECIFICATION

Amplifier

Output Power

At Stereo

Operation

At Surround

Operation

Audio

Audio Input Sensitivity/

Impedance (1 kHz)

Audio Input

(DIGITAL IN)*

* Corresponding to Linear PCM, Dolby Digital, and DTS (with sampling frequency-32 kHz, 44.1 kHz, 48 kHz).

Audio Output Level SUBWOOFER OUT : 1 V

Recording Output Level VCR OUT, TAPE/CDR OUT : 200 mV

Digital Output Optical DIGITAL OUT Signal wave length : 660 nm

Signal-to-Noise Ratio

('66 IHF/'78 IHF)

Frequency Response (8

Bass Boost +6 dB ±1.0 dB at 100 Hz

Equalization 63 Hz, 250 Hz, 1 kHz, 4 kHz, 16 kHz (±8 dB) (in 2 dB steps)

Video

Video Input Sensitivity/Impedance Composite Video : DVD IN, VCR IN, TV SOUND/DBS IN 1 V(p-p)/75

Video Output Level Composite Video : VCR OUT, MONITOR OUT 1 V(p-p)/75 Ω

Synchronization Negative

Signal-to-Noise Ratio 45 dB

Tuning Range 87.5 MHz to 108.0 MHz

Usable Sensitivity Monaural : 12.8 dBf (1.2

50 dB Quieting Sensitivity Monaural : 16.0 dBf (1.7

Stereo Separation at OUT (REC) 35 dB at 1 kHz

Tuning Range 530 kHz to 1 710 kHz

Power Requirements AC 120V , 60 Hz

Power Consumption 320 W/440 VA (at operation), 2 W (in standby mode)

Dimensions (W

Mass 12.1 kg (26.7 lbs)

Front ch 130 W per channel, min. RMS, driven into 8

Front ch 130 W per channel, min. RMS, driven into 8

Center ch 130 W, min. RMS, driven into 8

Surround ch 130 W per channel, min. RMS, driven into 8

Surround Back ch 130 W, min. RMS, driven into 8

Coaxial DIGITAL 1 (DVD) : 0.5 V(p-p)/75 Ω

Optical DIGITAL 2 (CD), DIGITAL 3 (TV), DIGITAL 4 (CDR) : -21 dBm to -15 dBm (660 nm ±30 nm)

distortion.

Ω at 1 kHz, with no more than 0.8% total harmonic distortion.

Ω at 1 kHz, with no more than 0.8% total harmonic distortion.

DVD IN, VCR IN, TV SOUND/DBS IN : 200 mV/47 k

CD IN, TAPE/CDR IN : 200 mV/47 kΩ

Output level : -21 dBm to -15 dBm

DVD IN, VCR IN, TV SOUND/DBS IN : 87 dB/80 dB

CD IN, TAPE/CDR IN : 87 dB/80 dB

Ω) DVD IN, VCR IN, TV SOUND/DBS IN : 20 Hz to 100 kHz (+1 dB, -3 dB)

CD IN, TAPE/CDR IN : 20 Hz to 100 kHz (+1 dB, -3 dB)

S-video : DVD IN, VCR IN, TV SOUND/DBS IN (Y: luminance) : 1 V(p-p)/75 Ω

Component Video DVD IN, DBS (VCR) IN : DVD IN, DBS (VCR) IN (Y: luminance) : 1 V(p-p)/75 Ω

S-video : VCR OUT, MONITOR OUT (Y: luminance) : 1 V(p-p)/75 Ω

Component Video : MONITOR OUT (Y: luminance) : 1 V(p-p)/75 Ω

FM tuner (IHF)

µV/75 Ω)

µV/75 Ω)

Stereo : 37.5 dBf (20.5

µV/75 Ω)

AM tuner

General

× H × D) 435 mm × 157 mm × 425 mm (17 3/16 in. × 6 3/16 in. × 16 3/4 in.)

Designs & specifications are subject to change without notice.

Ω, 20 Hz to 20 kHz, with no more than 0.08% total harmonic

Ω at 1 kHz, with no more than 0.8% total harmonic distortion.

Ω at 1 kHz, with no more than 0.8% total harmonic distortion.

Ω

(C: chrominance, burst) : 0.286 V(p-p)/75 Ω

(PB/PR) : 0.7 V(p-p)/75 Ω

(C: chrominance, burst) : 0.286 V(p-p)/75 Ω

(PB/PR) : 0.7 V(p-p)/75 Ω

Ω

1-2 (No.MB172)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

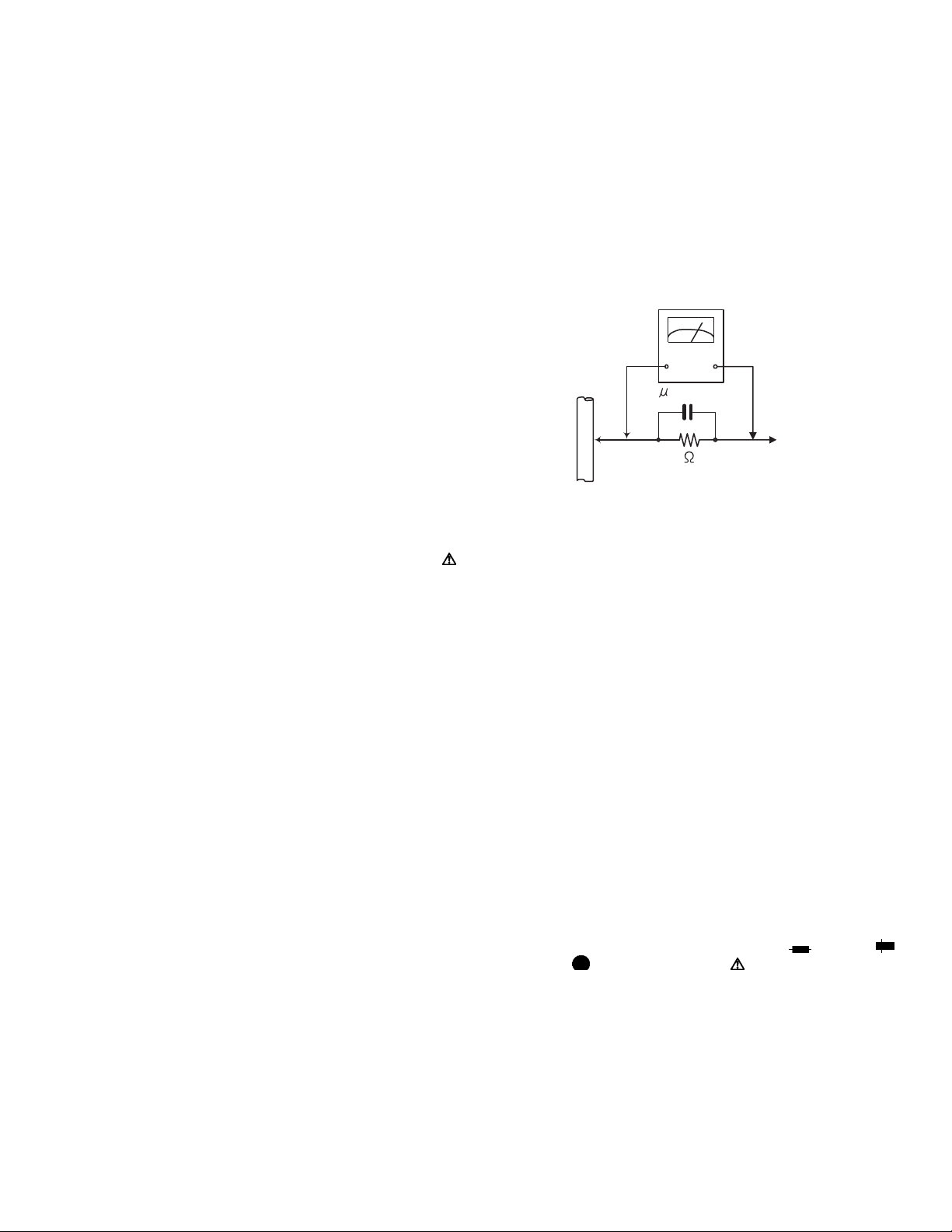

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB172)1-3

Page 4

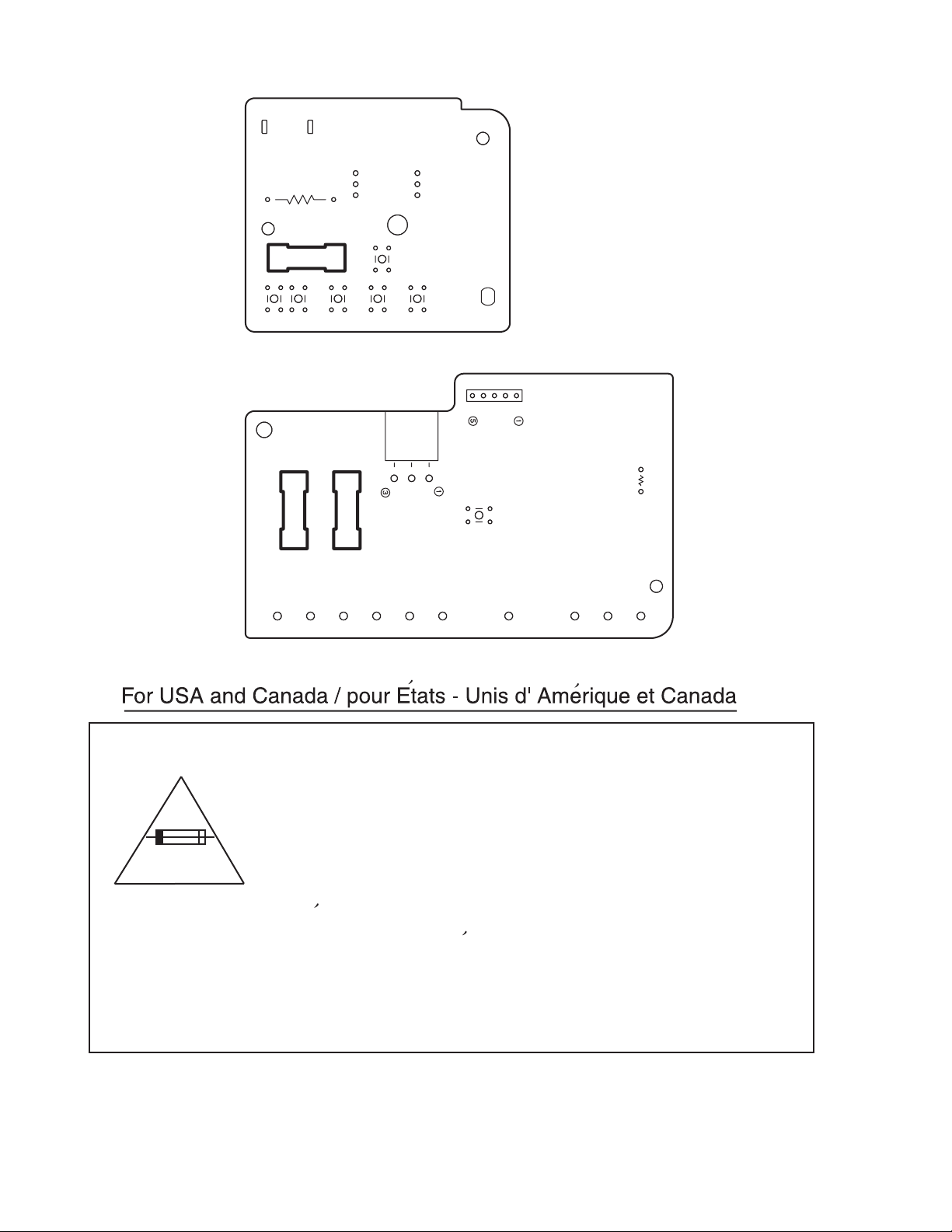

1.5 Importance administering point on the safety

Power / fuse board

F1

6.3A-125V

Power trans 1 board

2A-125V

F61

2A-125V

F62

Caution: For continued protection against risk of

fire, replace only with same type 6.3A/125V for

F1, 2A/125V for F61 and F62.

This symbol specifies type of fast operating fuse.

1-4 (No.MB172)

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F1 comme le meme type

que 6.3A/125V, et 2A/125V pour F61 et F62.

Ce sont des fusibles suretes qui functionnes rapide.

^

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB172)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 Removing the top cover (See Fig.1)

(1) From the right and left sides of the main body, remove the

four screws A attaching the top cover.

(2) From the back side of the main body, remove the three

screws B attaching the top cover.

(3) Remove the top cover in the direction of the arrow 2 while

extending the lower sections of the top cover in the direction of the arrow 1.

3.2 Removing the front panel assembly (See Figs.2 and 3)

• Prior to performing the following procedures, remove the top

cover.

(1) Disconnect the card wire from the connector CN400

micon board. (See Fig.2)

(2) Disconnect the card wire from the connector CN402 on the

power supply board. (See Fig.2)

(3) Remove the tie band and wire protection board fixing the

card wire. (See Fig.2)

(4) Remove the three screws C attaching the front panel as-

sembly. (See Fig.2)

(5) From the bottom side of the main body, remove the four

screws D attaching the front panel assembly. (See Fig.3)

(6) Remove the front panel assembly in the direction of the ar-

row. (See Fig.3)

on the

Top cover

A

Tie band

Wire

protection

board

Card wire

CN400

2

1

Fig.1

Front panel assembly

C

C

CN402

B

A

1

C

Card wire

Power

supply

board

Micon

board

Fig.2

Front panel assembly

DD

Fig.3

1-6 (No.MB172)

Page 7

3.3 Removing the rear panel

r

(See Fig.4)

• Prior to performing the following procedures, remove the top

cover.

(1) From the back side of the main body, remove the strain re-

lief from the rear panel in the direction of the arrow.

(2) Remove the twenty-nine screws E, two screws F and three

screws G attaching the rear panel.

E

G

E

F

E

Strain relief

Rear panel

3.4 Removing the I/O board

(See Fig.5)

• Prior to performing the following procedures, remove the top

cover and rear panel.

(1) Remove the two plastic rivets in the direction of the arrow

from the top side of the main body, remove the stopper

boards in the direction of the arrow.

(2) Remove the tie bands bundling the wires.

(3) Disconnect the wire from the connector CN722

ter board.

(4) Disconnect the wire from the connector CN714

board(L).

(5) Disconnect the wire from the connector CN717 on the sur-

round back board.

(6) Disconnect the wire from the connector CN719

board(R).

(7) Disconnect the wire from the connector CN723

board.

(8) Disconnect the connectors (CN205, CN381, CN501) on

the I/O board in an upward direction.

3.5 Removing the tuner, DSP board, audio board, video board and S-video board (See Fig.6)

• Prior to performing the following procedures, remove the top

cover, rear panel and I/O board.

(1) Disconnect the card wire from the connector CN314

audio board from the top side of the main body, take out the

tuner.

(2) Disconnect the DSP board from the connector CN601

the micon board.

(3) Disconnect the audio board from the connectors (CN101

CN303

) on the micon board.

(4) Disconnect the video board from the connector CN201 on

the micon board.

(5) Disconnect the S-video board from the connector CN241

on the micon board.

on the cen-

on the front

on the front

on the main

on the

on

Front board(R)

,

CN719

Main

board

CN723

Plastic

rivet

CN501

Stopper

board

CN381

CN205

Stopper board

CN314

CN303

CN101

DSP board

CN717

Card wire

GE

Fig.4

Surround board

Front board(L)

Plastic rivet

Fig.5

CN201 CN241

CN714

I/O board

E G

Center board

Tie

band

CN722

Tie

bands

Tune

CN601

Audio board

Video board

Fig.6

Micon board

S-video board

(No.MB172)1-7

Page 8

3.6 Removing the micon board (See Fig.7)

• Prior to performing the following procedures, remove the top

cover, rear panel, I/O board, tuner, DSP board, audio board,

video board and S-video board.

(1) From the top side of the main body, disconnect the card

wire from the connector CN400

(2) Disconnect the relay board from the connectors CN81

the micon board.

(3) Disconnect the parallel wire from the connectors CN931

and CN932 on the micon board.

(4) Disconnect the parallel wire from the connector CN831 on

the main board.

(5) Remove the three screws H attaching the micon board.

(6) Remove the three screws J attaching the transistors

, Q941, Q981) to the chassis base.

(Q931

(7) Loosen the screw K attaching the micon board.

3.7 Removing the speaker board (See Fig.8)

• Prior to performing the following procedures, remove the top

cover and rear panel.

(1) From the top side of the main body, remove the tie band

bundling the wires.

(2) Disconnect the wires from the connectors (CN813

on the main board.

(3) Disconnect the parallel wire from the connectors (CN931

CN932) on the micon board.

(4) Take out the speaker board in the direction of the arrow.

on the micon board.

on

, CN814)

J

CN831

Card wire

Main board

Relay

board

H

CN400

K

H

Chassis

Micon board

Transistors

(Q931,Q941,Q981)

Micon board

,

Main board

CN931

CN932

H

Fig.7

Tie band

base

CN81

CN931

CN932

1-8 (No.MB172)

CN814

CN813

Speaker board

Fig.8

Page 9

3.8 Removing the main board

r

(See Fig.9)

• Prior to performing the following procedures, remove the top

cover.

(1) From the top side of the main body, remove the tie bands

bundling the wires.

(2) Remove the tie band and wire protection board bundling

the card wire.

(3) Disconnect the wire from the connector CN811

er transformer board 1.

(4) Disconnect the relay board from the connectors (CN71

CN81) on the power supply board and micon board.

(5) Disconnect the parallel wires from the connectors (CN831

) on the main board.

CN881

(6) Disconnect the wires from the connectors (CN723, CN813,

) on the main board.

CN814

(7) Disconnect the wire from the connector CN722

ter board.

(8) Disconnect the wire from the connector CN714

board(L).

(9) Disconnect the wire from the connector CN717

round back board.

(10) Disconnect the wire from the connector CN719

board(R).

(11) Remove the screw K, four screws L, two screws M and two

screws N attaching the main board.

(12) Take out the main board.

on the pow-

on the cen-

on the front

on the sur-

on the front

Front board(R)

Surround board

Tie band

CN881

CN717

M

,

,

Wire

protection

board

L

Card wire

N

Main

board

CN723

CN814

CN719

Micon board

CN831

CN813

Front board(L)

Center board

Tie

band

M

N

CN714

Fig.9

L

CN71

CN722

CN811

Power

supply

board

Power

transforme

board 1

Tie bands

Relay

board

K

CN81

3.9 Removing the heat sink (See Figs.10 and 11)

• Prior to performing the following procedures, remove the top

cover and main board.

(1) From the reverse side of the main board, remove the two

screws P attaching the main board to the heat sink. (See

Fig.10)

(2) Disconnect the connectors (CN701

board, remove the main board. (See Fig.10)

(3) Remove the twelve screws Q attaching the heat sink. (See

Fig.11)

-CN706) on the main

P

CN703

Heat sink

Heat sink

CN701

CN704

Fig.10

CN702

Main board

P

CN706

CN705

Q

Q

Fig.11

(No.MB172)1-9

Page 10

3.10 Removing the center board, surround back board, front boards (L/R) and surround boards (L/R)

r

(See Figs.10 and 12)

• Prior to performing the following procedures, remove the top

cover and main board.

(1) From the reverse side of the main board, remove the two

screws P attaching the main board to the heat sink. (See

Fig.10)

(2) Disconnect the connectors (CN701

board, remove the main board. (See Fig.10)

(3) Remove the two screws Q attaching the center board. (See

Fig.12)

(4) Remove the two screws Q attaching the front board(L).

(See Fig.12)

(5) Remove the two screws Q attaching the surround back

board. (See Fig.12)

(6) Remove the two screws Q attaching the front board(R).

(See Fig.12)

(7) Remove the two screws Q attaching the surround board(L).

(See Fig.12)

(8) Remove the two screws Q attaching the surround

board(R). (See Fig.12)

3.11 Removing the power transformer

(See Fig.13)

• Prior to performing the following procedures, remove the top

cover.

(1) From the top side of the main body, remove the tie band

bundling the wires.

(2) Disconnect the wire from the connectors (CN55

on the power transformer board 1.

(3) Remove the solders from the soldered sections a on the

power transformer board 2.

(4) Remove the four screws R attaching the power transform-

er.

to CN706) on the main

, CN811)

Surround board(R)

Tie band

Front board(R)

Front board(L)

Q Q Q Q Q Q

Surround back board

Surround board(L)

Fig.12

CN811 CN55

Center board

Power

transformer

board 1

3.12 Removing the power/fuse board

(See Fig.13)

• Prior to performing the following procedures, remove the top

cover.

(1) From the back and top sides of the main body, remove the

screw S and screw T attaching the power/fuse board.

(2) Remove the solders from the soldered sections b attaching

the power cord.

(3) From the reverse side of the power/fuse board, remove the

solders from the soldered sections c attaching the wires.

Soldered

sections a

Soldered sections c

Power/fuse board

Power

transformer

RR

Power

transforme

board 2

T

Soldered

sections b

Power cord

S

Fig.13

1-10 (No.MB172)

Page 11

3.13 Removing the power supply board

r

(See Fig.14)

• Prior to performing the following procedures, remove the top

cover.

(1) From the top side of the main body, disconnect the parallel

wires from the connector CN55

board 1.

(2) Disconnect the card wire from the connector CN402

power supply board.

(3) Disconnect the relay board from the connector CN71

the power supply board.

(4) Remove the three screws U attaching the power supply

board.

(5) Remove the power supply board from the hook d of the

chassis base bracket in the direction of the arrow, take out

the power supply board.

(6) Turn over the power supply board, remove the solders from

the soldered sections e attaching the wires.

3.14 Removing the headphone jack board

(See Figs.14 and 15)

• Prior to performing the following procedures, remove the top

cover and front panel assembly.

(1) From the top side of the main body, remove the tie bands

attaching the parallel wire. (See Fig.14)

(2) Disconnect the parallel wire from the connector CN881

the main board. (See Fig.14)

(3) From the front side of the main body, remove the nut and

screw V attaching the headphone bracket to the front

bracket. (See Fig.15)

(4) Remove the three screws U attaching the power supply

board. (See Fig.14)

(5) Take out the headphone jack board from the inside of the

chassis base while lifting the power supply board.

on the power transformer

on the

on

on

U

CN71

Tie

bands

CN881

Main board

Relay board

Nut

CN402

Card wire

Power supply board

Headphone

jack board

U

Soldered

sections e

U

CN55

Power

transforme

board 1

Hook d of the chassis base bracket

Fig.14

V

Headphone jack board

3.15 Removing the switch board

(See Fig.16)

• Prior to performing the following procedures, remove the top

cover and front panel assembly.

(1) From the back side of the front panel assembly, remove the

two screws W attaching the switch board.

(2) Take out the switch board, disconnect the wire from the

connector CN432

3.16 Removing the power switch board

(See Fig.16)

• Prior to performing the following procedures, remove the top

cover and front panel assembly.

(1) From the back side of the front panel assembly, remove the

two screws X attaching the power switch board.

(2) Take out the power switch board, disconnect the wire from

the connector CN430

on the switch board.

on the power switch board.

Headphone bracket

W

CN432

Switch board

W

Front bracket

Fig.15

Front panel assembly

CN430

X

Power switch board

Fig.16

(No.MB172)1-11

Page 12

3.17 Removing the front key & system control board

Y

(See Figs.17 to 20)

• Prior to performing the following procedures, remove the top

cover, front panel assembly, switch board and power switch

board.

(1) Pull out the volume and jog knobs from the front side of the

front panel assembly, remove the nut attaching the front

key & system control board. (See Fig.17)

(2) From the back side of the front panel assembly, remove the

eight screws Y attaching the sub panel assembly. (See

Fig.18)

(3) Remove the sub panel assembly while releasing the claws

f in the direction of the arrow. (See Figs.18 and 19)

(4) Release the claws g attaching the front key & system con-

trol board in the direction of the arrow and take out the front

key & system control board. (See Fig.20)

Front panel assembly

Volume knob

Nut

Jog knob

Fig.17

Y

Claws f Claws f

Sub panel assembly

Front key & System control board

Sub panel assembly

Fig.18

Fig.19

Front panel assembly

Front panel assembly

Front panel assembly

1-12 (No.MB172)

Claws g

Fig.20

Page 13

SECTION 4

ADJUSTMENT

4.1 Adjustment method

Tuner section

1. Tuner range

FM 87.5MHz to 108.0MHz

AM 530kHz to 1710kHz

Power amplifier section

Adjustment of idling current

Measurement location B2204

Adjustment part VR787

Attention:

This adjustment does not obtain a correct adjustment value immediately after the amplifier is used (state that an internal temperature has risen). Please adjust immediately after using the amplifier after turning off the power supply of

the amplifier and falling an internal temperature.

<Adjustment method>

(1) Set the volume control to minimum during this adjustment. (No signal & No load)

(2) Set the surround mode OFF.

(3) Turn VR787

and VR788 fully counterclockwise to warm up before adjustment.

If the heat sink is already warm from previous use the correct adjustment can not be made.

(4) For L-ch, connect a DC voltmeter between B2204

(5) 30 minutes later after power on, adjust VR787 for Lch, or VR788 for Rch so that the DC voltmeter value has 1mV to 10mV.

-82205 (Lch), B2213-B2214 (Rch)

(Lch), VR788 (Rch)

and B2205 (Lch) and, connect it between B2213 and B2214 (Rch).

• It is not abnormal though the idling current might not become 0mA even if it is finished to turn variable resistance (VR787

VR788) in the direction of counterclockwise.

VR787 (Lch)

Front amp. board (L)

VR787

B2204

B2205

B2204, B2205 (Lch)

VR788 (Rch)

Front amp. board (R)

VR788

B2213

B2214

,

B2213, B2214 (Rch)

(No.MB172)1-13

Page 14

SECTION 5

TROUBLESHOOTING

5.1 Self-diagnose function

This model incorporates the following self-diagnostic functions.

1. PROTECTOR

• The PROTECTOR IN port detects errors such as speaker overcurrent and DC voltage output errors (Active: L). Immediately after

detection, all relays are switched off and the alarm display as shown below (blinking at intervals of 0.5 sec. ON and 0.5 sec. OFF)

is displayed in the lower part of the FL matrix.

During the alarm display, all other FL and LED segments are turned off.

OVERLOAD

• The overload status can be canceled by switching the power off. When the power is switched on again, the unit is turned on in

the same abnormal status as before. Lower the volume level for 10 steps for protection. (If the previous volume level was between 0 and 9, lower it to 0).

• The detection by the protector is not performed for 4 seconds after power on.

2. Supply voltage error detection

• When the power is switched on, the supply voltage at the A/D input port (pins 2 to 5 and 7) is monitored and, when an error is

detected continuously for 1 second, the unit immediately enters the standby mode.

• When the power is switched on again, the unit is turned on in the same abnormal status as before.

• The supply voltage error detection is not performed for 4 seconds after power on.

• The following table shows the error detection thresholds.

At abnormal state (Low voltage) At normal state At abnormal state (High voltage)

Pin 2

Pin 3

Pin 4

Pin 5

Pin 7

Analog value : 0 - 2.2

Digital value : 000 - 1C0

Analog value : 0 - 2.2

Digital value : 000 - 1C0

Analog value : 0 - 2.2

Digital value : 000 - 1C0

Analog value : 0 - 2.2

Digital value : 000 - 1C0

Analog value : 0 - 2.2

Digital value : 000 - 1C0

Analog value : 2.2 - 2.8

Digital value : 1C1 - 240

Analog value : 2.2 - 2.8

Digital value : 1C1 - 240

Analog value : 2.2 - 2.8

Digital value : 1C1 - 240

Analog value : 2.2 - 2.8

Digital value : 1C1 - 240

Analog value : 2.2 - 2.8

Digital value : 1C1 - 240

Analog value : 2.8 - 5.0

Digital value : 241 - 3FF

Analog value : 2.8 - 5.0

Digital value : 241 - 3FF

Analog value : 2.8 - 5.0

Digital value : 241 - 3FF

Analog value : 2.8 - 5.0

Digital value : 241 - 3FF

Analog value : 2.8 - 5.0

Digital value : 241 - 3FF

1-14 (No.MB172)

Page 15

(No.MB172)1-15

Page 16

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB172)

Printed in Japan

WPC

Loading...

Loading...