Page 1

SERVICE MANUAL

MENU

ENTER

AUDIO/VIDEO CONTROL RECEIVER

RX-7000RBK

Area Suffix

E

Continental Europe

EN

Northern Europe

RX-7000RBK

RX-7000RBK

TV/CATV/DBS

DVD DVD MUILTI CD TAPE/MD

TV/DBS PHONO FM/AM

ANALOG/DIGITAL

VCR

SURROUND

ON/OFF

123

TEST REAR-L

SURROUND

MODE

456

CD-DISC

EFFECT REAR-R

7

/P

89

SOUND

SUBWOOFER

SEA MODE

10

0

RETURN

MENU

SET

EXIT

CHANNEL VOLUMETV VOL

VCR

TV/VIDEO

TAPE/MD

CONTROL

PLAY

/REW

PTY SEARCH

PTY PTY

STOP PAUSE

REC

RM-SRX7000R REMOTE CONTROL

VCR

SLEEP

CENTER

MENU

ENTER

+10

100+FM MODE

AUDIO/

TV/VCR

CATV/DBS

TEXT

DISPLAY

MUTING

FF/

RX-7000R AUDIO/VIDEO CONTROL RECEIVER

STANDBY

STANDBY/ON

PHONES

COMPULINK

Remote

ENHANCEDCOMPULINKCONTROL SYSTEM

SPEAKERS

12

SURROUND ON/OFF

EON

PTY SEARCH

DSP MODE

BALANCE/SURROUND

ADJUST

TA/NEWS/INFO

DISPLAY MODE

SEA MODE

SEA ADJUST

THEATER LIVE CLUB DANCE CLUB HALL PAVILION

INPUT

ANALOG/DIGITAL

FM/AM TUNING TUNER PRESET

TUNER/SEA MEMORY FM MODE

SETTING

SOUND SELECT

INPUT ATT.

BASS BOOST ONE TOUCH OPERATION

SOURCE NAME

DIGITAL

DVD

CD

TV SOUND/DBS PHONO

TAPE/MDVCR

FM

AM

SOURCE SELECTOR

MULTI JOG

–

MASTER VOLUME

+

DIGITAL

Contents

Safety precautions ---------------- 1-2

Disassembly method ------------- 1-3

This service manual is printed on 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

Adjustment method --------------- 1-9

Description of major ICs --------- 1-10

No.20846

1-1

Jul. 2000

Page 2

RX-7000RBK

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical par ts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

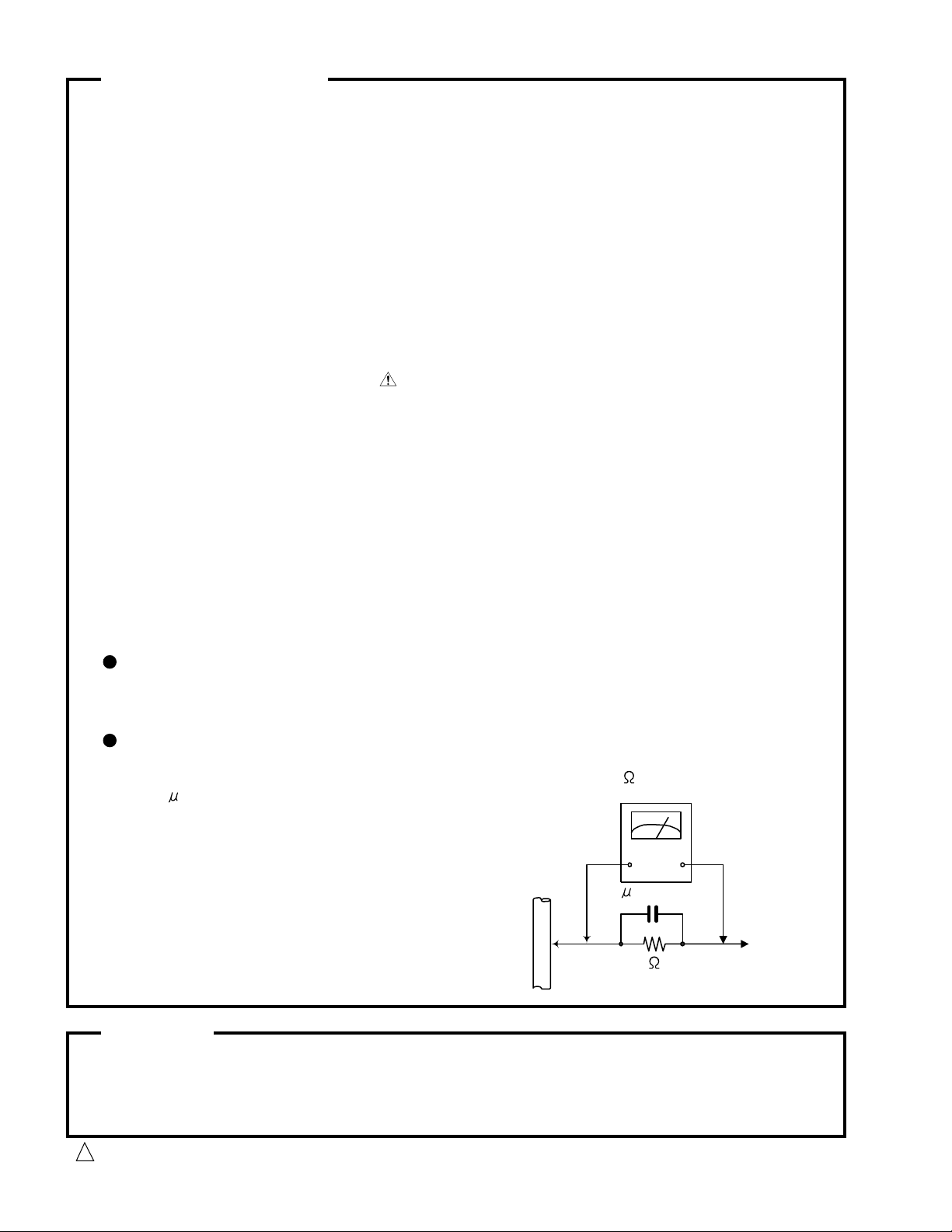

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

Move the resistor connection to eachexposed metal

part, par ticularly any exposed metal part having a

return path to the chassis, and meausre the AC

voltage across the resistor. Now, reverse the plug in

the AC outlet and repeat each measurement. voltage

measured Any must not exceed 0.75 V AC (r.m.s.).

This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

1-2

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

CAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 3

RX-7000RBK

Disassembly method

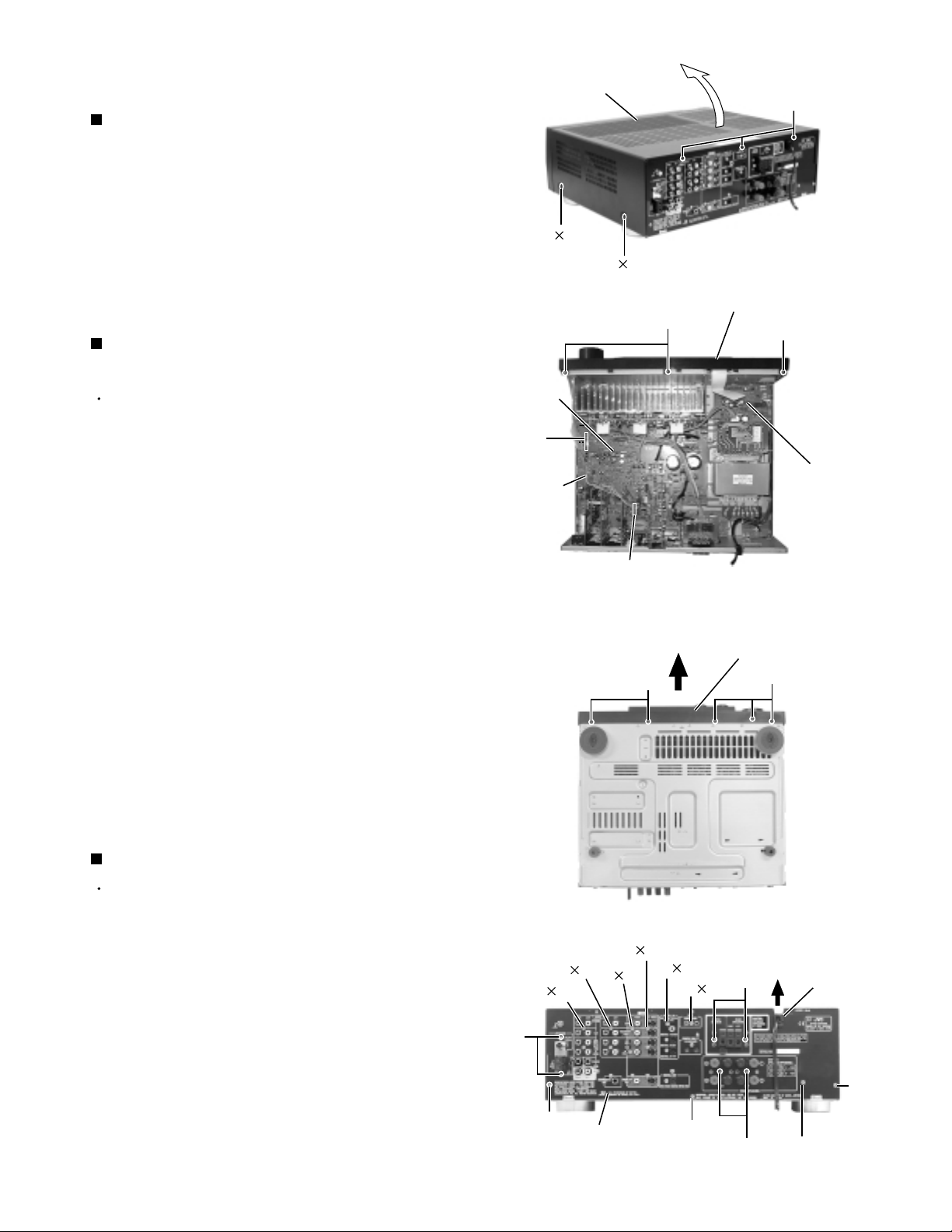

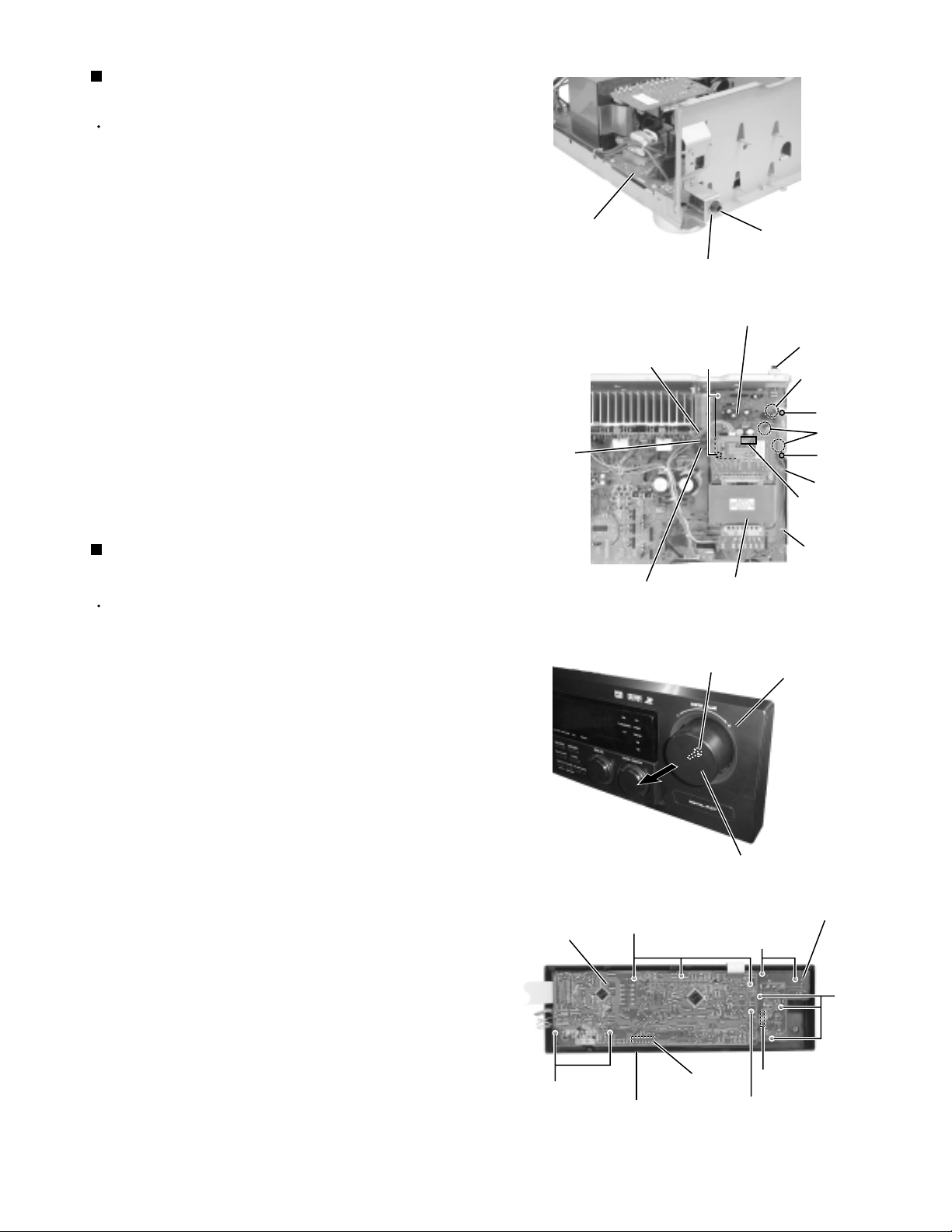

Removing the top cover (See Fig.1)

1.

Remove the four screws A attaching the top cover

on both sides of the body.

2.

Remove the three screws B on the back of the body.

3.

Remove the top cover from behind in the direction of

the arrow while pulling both sides outward.

Removing the front panel assembly

(See Fig.2 and 3)

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the card wire from connector CN400 on

the main board and CN402 on the power supply

board in the front panel assembly.

2.

Cut off the tie band fixing the harness.

A

Main board

CN400

Tie band

Top cover

2

A

B

Fig.1

2

Front panel assembly

C

C

Power supply

board

CN402

3.

Disconnect the harness from connector CN202 on

the video board.

4.

Remove the three screws C attaching the front

panel assembly.

5.

Remove the five screws D attaching the front panel

assembly on the bottom of the body. Detach the front

panel assembly toward the front.

Removing the rear panel (See Fig.4)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the power cord stopper from the rear panel

by moving it in the direction of the arrow.

2.

Remove the twenty-six screws E attaching the each

boards to the rear panel on the back of the body.

3.

Remove the three screws F attaching the rear panel

on the back of the body.

E

E

E

3

3

Video board

CN202

D

E

3

E

E

3

Fig.2

Front panel assembly

Fig.3

5

E

E

2

D

Cord stopper

F

F

Rear panel

Fig.4

F

E

E

1-3

Page 4

RX-7000RBK

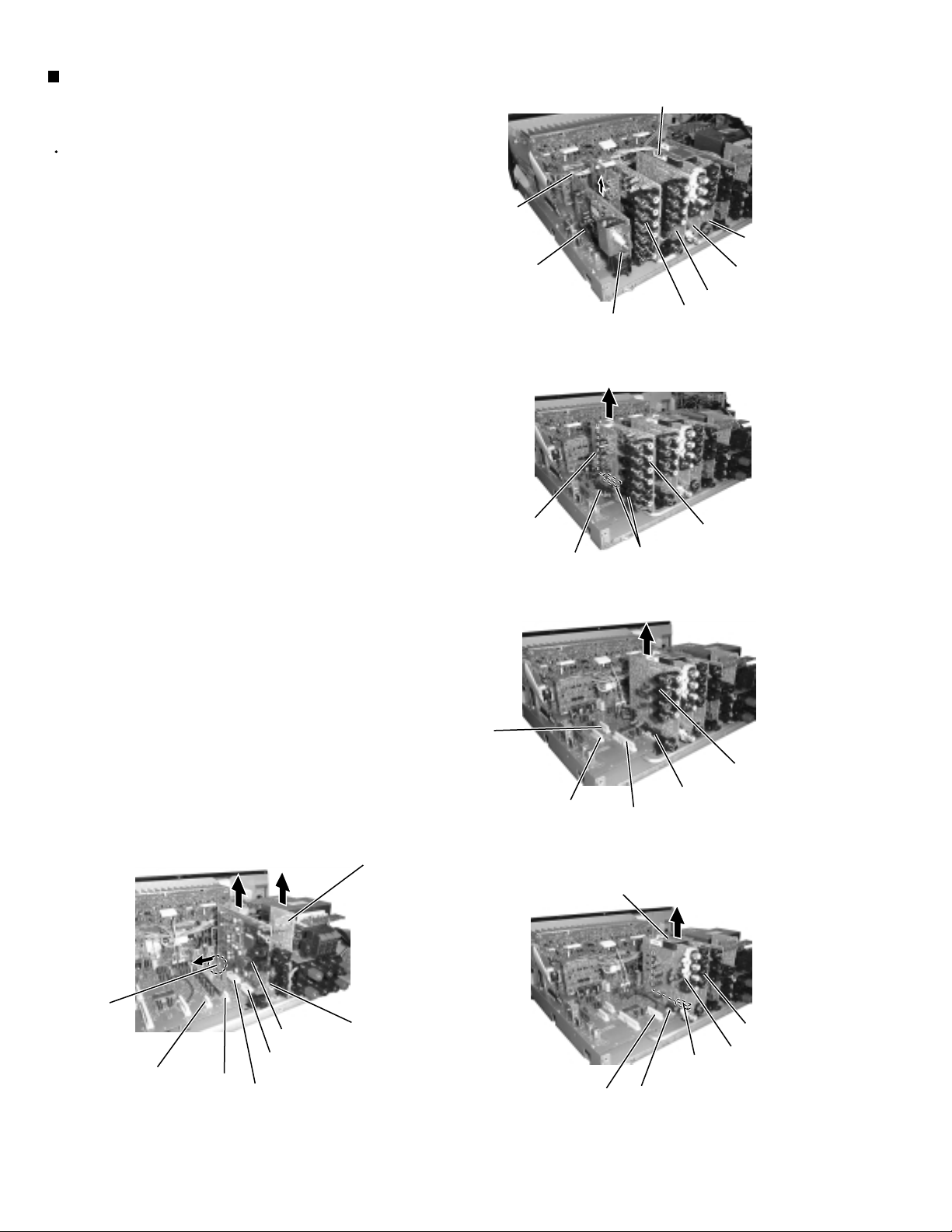

Removing each board connected to the

rear side of the main board

(See Fig.5 to 9)

Prior to performing the following procedure, remove

the top cover and the rear panel.

CN202

1.

Cut off the tie band fixing the harness.

2.

Disconnect the harness from connector CN202 on

the video board.

3.

Disconnect the tuner board from connector CN101,

CN102 on the main board.

4.

Disconnect the SEA board and the audio board from

connector CN452, CN301and CN302 on the main

board.

5.

Disconnect the V-audio board from connector CN303

on the main board.

6.

Disconnect the relay board 4.Then, disconnect the

video board and the S-video board from connector

CN201 and CN241 on the main board.

7.

Disconnect the DSP board from connector CN501

and CN601 on the main board while removing the

DSP board from the bracket fixing the lower part of

the DSP board at the same time.

8.

Disconnect the compulink board from connector

CN255 on the main board.

Tie band

Main board

CN101,CN102

SEA board

Tuner board

Main board

CN452

Audio board

Fig.5

Main board

CN302,CN301

Fig.6

S-video board

Video board

V-audio board

Audio board

Bracket

CN201

CN241

Fig.9

DSP board

Main board

CN601

Main board

CN501

Compulink board

Main board

CN255

CN302

CN452

Relay board 4

CN303

CN301

Fig.7

Main board

CN201

Fig.8

Fig.8

Main board

CN303

Main board

CN241

V-audio board

S-video board

Video board

1-4

Page 5

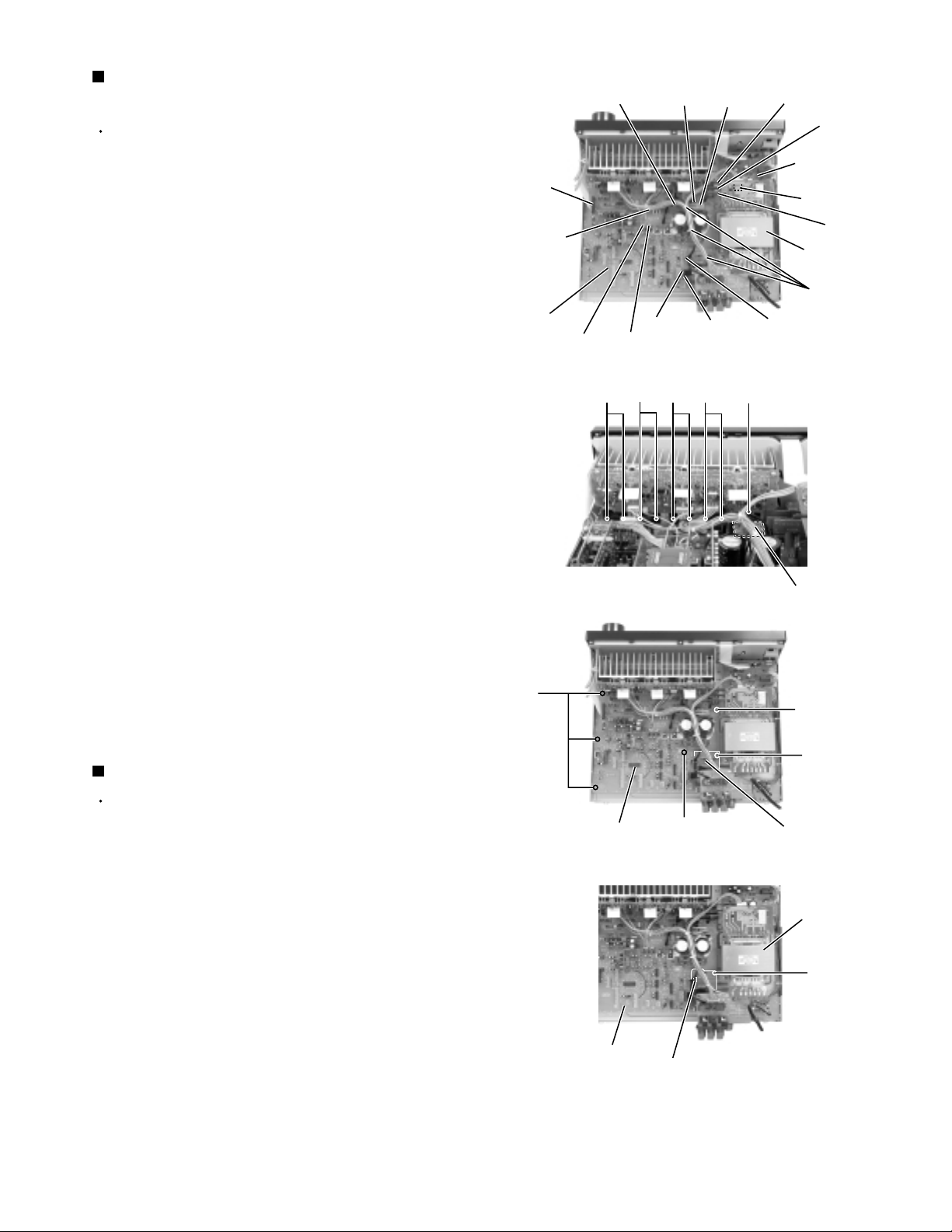

Removing the main board / regulator

board (See Fig.10 to 12)

Prior to performing the following procedure, remove

the top cover and the rear panel.

ATTENTION:

1.

Disconnect the card wire from connector CN400 on

the main board.

2.

Cut off the four tie bands fixing the harnesses.

3.

Disconnect the harness from connector CN811 on

the power transformer board.

4.

Disconnect the relay board 1, 2 and 3 from the main

board and the power supply board.

It is not necessary to remove the

boards connected to the back of the

main board. But to disassemble the

main board and the power supply

board efficiently, remove them.

Main board

CN400

Tie band

Main board

CN901

CN711

CN712

H H H

CN821

CN931

H

CN932

Fig.10

CN704

Relay board 1

Relay board 2

CN961

G

RX-7000RBK

Power supply

board

CN811

Relay

board 3

Power

transformer

Tie band

5.

Disconnect the harness from connector CN704,

CN821, CN901, CN711, CN712, CN931 and CN932,

CN961.

6.

Remove the screw G attaching the regulator board

to the heat sink cover.

7.

Remove the eight screws H attaching the main

board to the heat sink cover.

8.

Remove the five screws I and the screw J attaching

the main board to the chassis base (The resistor

board will come off at the same time).

Removing the resistor board (See Fig.13)

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the harness from connector CN881 on

the resistor board.

2.

Remove the screw J attaching the resistor board.

Fig.11

Regulator board

I

I

J

Main board

I

Fig.12

Resistor board

Power

transformer

Main board

Resistor board

CN881

Fig.13

J

1-5

Page 6

RX-7000RBK

Removing the amplifier board

(See Fig.10 and 14)

Prior to performing the following procedure, remove

the top cover.

1.

Cut off the four tie bands fixing the harnesses.

2.

Disconnect the harnesses from connector CN711,

CN712, CN704 and CN901 on the main board

respectively.

3.

Remove the four screws K and six screws L

attaching the amplifier board.

4.

If necessary, unsolder the harness connected to

connector CN803 and CN952 on the amplifier board.

Removing the power transformer

(See Fig.15)

Prior to performing the following procedures, remove

the top cover.

1.

Unsolder the two harnesses connected to the power

transformer.

2.

Disconnect the harness from connector CN811 and

the harnesses connected to connector CN55 and

CN56 on the power transformer board.

Main board

CN400

Tie band

Main board

CN711

K

Amplifier board

CN901

CN712

CN711

CN821

CN931

Fig.10

L

CN952

Fig.14

CN704

CN932

L

CN803

CN712

Relay board 1

Relay board 2

Power supply

board

CN961

L

Tie band

CN811

Relay

board 3

Power

transformer

Tie band

K

3.

Remove the four screws M attaching the power

transformer.

Removing the power / fuse board

(See Fig.16)

Prior to performing the following procedure, remove

the top cover and the rear panel.

1.

Remove the screw N attaching the power / fuse

board.

2.

Unsolder the power cord and other harnesses

connected to the power / fuse board.

Solder

Fig.15

Power cord

CN55

CN56

CN811

M

Power

transformer

M

Power

transformer

N

Solder

Power / fuse board

1-6

Fig.16

Page 7

Removing the power supply board

(See Fig.17 and 18)

Prior to performing the following procedure, remove

the top cover and the front panel.

1.

Remove the one nut attaching the headphone jack of

the power supply board on the front side of the body.

RX-7000RBK

2.

Disconnect the relay board 1, 2 and 3 from the

power supply board and the main board respectively.

3.

Disconnect the harness connected to connector

CN55 and CN56 on the power transformer board (If

necessary, cut off the two tie bands fixing the

harness on the side of the chassis base).

4.

Remove the four screws O attaching the power

supply board and pull out the power supply board

from the front bracket backward.

5.

Unsolder the three harnesses connected to the

power supply board.

Removing the system control board /

power switch board (See Fig.19 to 20)

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

1.

Pull out the volume knob on the front side of the front

panel and remove the nut attaching the system

control board.

Power supply board

Relay board 2

Relay board 3

Fig.17

Relay board 1

Fig.18

Headphone jack

Nut

Power supply board

Headphone jack

O

Power transformer

Nut

Front panel

Solder

O

Solder

O

Tie band

CN55

CN56

Tie band

2.

Remove the six screws P attaching the system

control board on the back of the front panel and

disconnect the harness from connector CN422 on

the system control board.

3.

Disconnect the harness from connector CN430 on

the power switch board.

4.

Remove the five screws Q attaching the power

switch board.

System control board

P

Front panel assembly

P

Fig.19

Fig.20

Volume knob

CN422

Power switch board

Q

Q

CN430

P

1-7

Page 8

RX-7000RBK

Removing the operation switch board

(See Fig.21 to 23)

Prior to performing the following procedure, remove

the top cover, the front panel assembly and the

system control board.

1.

Remove the six screws R attaching the operation

switch board on the back of the front panel.

2.

On the back of the front panel, release the four joints

by pushing the joint tabs inward. Remove the

operation switch board toward the front.

3.

Pull out the multi jog knob and the source selector

knob.

4.

Remove the two screws S attaching the operation

switch board.

Front panel

R

R

Joint

R

Fig.21

Multi jog knob

Source selector knob

Fig.22

S

Operation switch board

Fig.23

1-8

Page 9

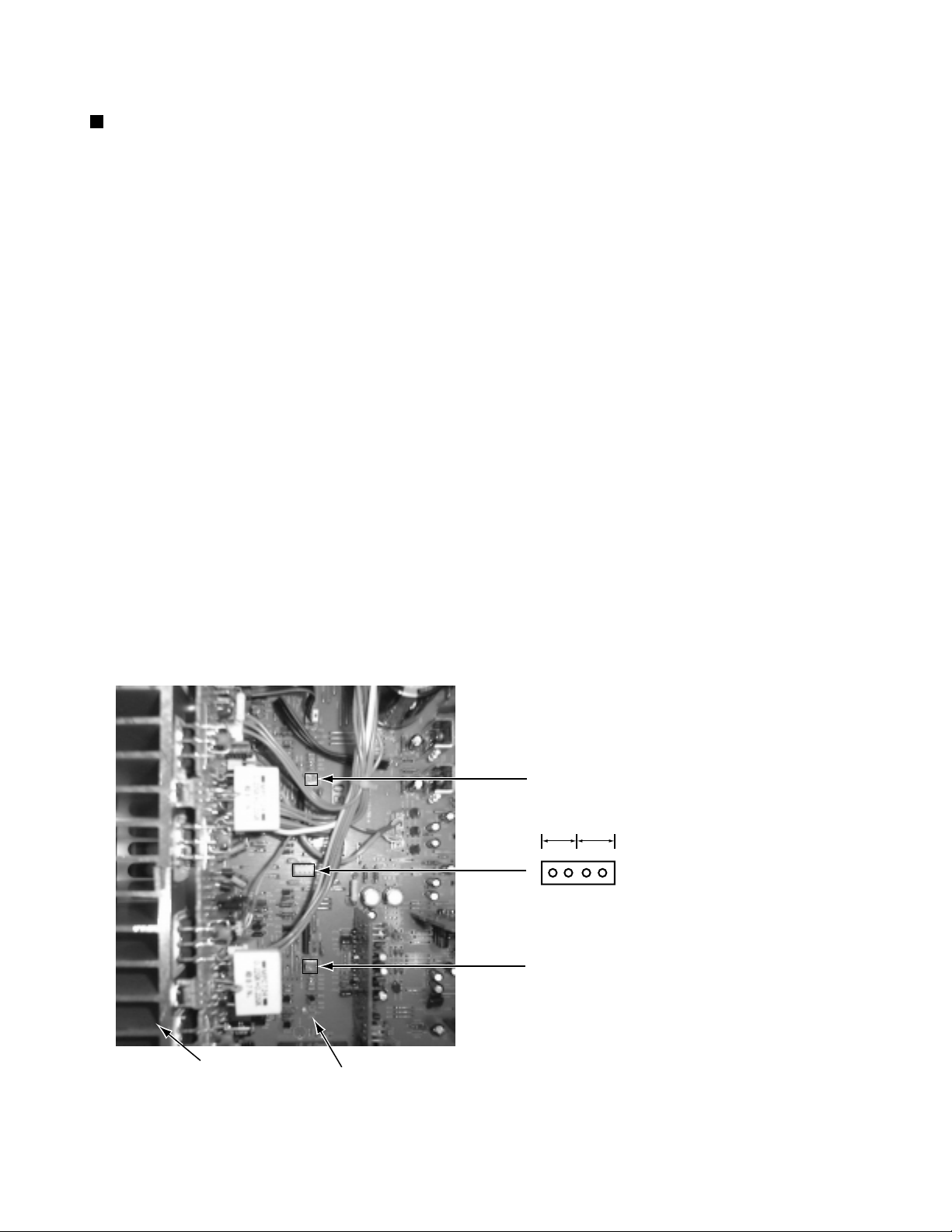

Adjustment method

Power amplifier section

Adjustment of idling current

Measurement location TP781

Adjustment part VR787(Lch) , VR788(Rch)

Attention

This adjustment does not obtain a correct adjustment value immediately after the amplifier is

used (state that an internal temperature has risen).

Please adjust immediately after using the amplifier after turning off the power supply of the

amplifier and falling an internal temperature.

<Adjustment method>

1.Set the volume control to minimum during this adjustment.(No signal & No load)

2.Set the surround mode OFF.

2.Turn VR787 and VR788 fully counterclockwise to warm up before adjustment.

If the heat sink is already warm from previous use the correct adjustment can not be made.

3.For L-ch,connect a DC voltmeter between TP781's pin1 and pin2 (Lch)

And,connect it between pin3 and pin4(Rch).

4.30 minutes later after power on, adjust VR787 for L-ch, or VR788 for R-ch so that the DC voltmeter

value has 1mV~10mV.

RX-7000RBK

* It is not abnormal though the idling current might not become 0mA even if it is finished to turn variable

resistance (VR787,VR788) in the direction of counterclockwise.

VR787 (Lch)

Rch

Lch

4321

TP781

VR788 (Rch)

Heat sink

Main board

1-9

Page 10

RX-7000RBK

Description of major ICs

AK4527 (IC601) : A/D,D/A Converter

1.Pin layout

CDTO

CDTI

CCLKCSPIS

XTO

XTI

AVSS

AVDD

VREFH

VCOM

2.Block diagram

LIN+

LIN-

SDOS

OCKS

MIS

BCLK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

4443424140393837363534

1

2

3

4

5

6

7

8

9

10

11

1213141516171819202122

DEM1

DEM0

MCKO

DVDD

ADC

DVSSPDXTS

HPF

ICKS1

ICKS0

CAD1

Audio

I/F

33

32

31

30

29

28

27

26

25

24

23

CAD0

VREFL

RIN+

RINLIN+

LINROUT1

LOUT1

ROUT2

LOUT2

ROUT3

LOUT3

RIN+

RIN-

LOUT1

ROUT1

LOUT2

ROUT2

LOUT3

ROUT3

HPF

DA TT

DA TT

DA TT

DA TT

DA TT

DA TT

LRCK

BICK

MCLK

SDOUT

SDIN1

SDIN2

SDIN3

LPF

LPF

LPF

LPF

LPF

LPF

ADC

DAC

DAC

DAC

DAC

DAC

DAC

Block Diagram (DIR and AC-3) DSP are external parts)

DAUX

Format

Converter

SDOS

SDTO

SDTI1

SDTI2

SDTI3

1-10

Page 11

RX-7000RBK

3. Pin function (1/2)

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Pin name

SDOS

OCKS

MIS

BICK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

DEM1

DEM0

MCKO

DVDD

DVSS

PD

XTS

ICKS1

ICKS0

CAD1

CAD0

LOUT3

ROUT3

LOUT2

ROUT2

LOUT1

ROUT1

LINLIN+

RINRIN+

I/O

SDTO Source select pin

I

Function

"L" : Internal ADC output, "H" : DAUX input

ORed with serial control register if P/S="L".

MCKO Clock frequency select pin

I

"L" : MCLK, "H" : MCLK/2. ORed with serial control register if P/S= "L".

Connect to GND

I

Audio serial data clock pin

I

Input/Output channel clock pin

I/O

DAC1 Audio serial data input pin

I

DAC2 Audio serial data input pin

I

DAC3 Audio serial data input pin

I

Audio serial data output pin

O

AUX Audio serial data input pin

I

Double speed sampling mode pin

I

"L" : Normal speed, "H" : Double speed, the ADC is powered down.

ORed with serial control register if P/S="L".

De-emphasis pin

I

ORed with serial control register if P/S="L"

De-emphasis Pin

I

ORed with serial control register if P/S="L"

Master clock output pin

O

Digital power supply pin

Digital ground pin

Power-down & Reset pin

I

When "L", the AK4527 is powered-down and the control registers are reset

to default state. If the state of CAD0-1 changes, then the AK4527

must be reset by PDN.

X'tal oscillator Select/Test mode pin

I

"H" : X'tal Oscillator selected

"L" : External clock source selected

Input clock select 1 pin

I

Input clock select 0 pin

I

Chip address pin

I

Used during the serial control mode.

Chip address pin

I

Used during the serial control mode.

Lch #3 analog output pin

O

Rch #3 analog output pin

O

Lch #2 analog output pin

O

Rch #2 analog output pin

O

Lch #2 analog output pin

O

Rch #1 analog output pin

O

Lch analog negative Input Pin

I

Lch analog positive Input Pin

I

Rch analog negative Input Pin

I

Rch analog positive Input Pin

I

AK4527(1/2)

1-11

Page 12

RX-7000RBK

3.Pin function (2/2)

No.

33

34

35

36

37

38

39

Pin Name

VREFL

VCOM

VREFH

AVDD

AVSS

XTI

XTO

MCKI

40

41

P/S

DIF0

CS

42

DIF1

CCLK

43

LOOP0

CDTI

44

LOOP1

CDTO

I/O

I

O

I

-

I

O

I

I

I

I

I

I

I

I

I

O

AK4527(2/2)

Function

Negative voltage reference Input pin, AVSS

Common voltage output pin,AVDD/2

Large external capacitor around 2.2uF is used to reduce power-supply noise

Positive voltage reference input pin,AVDD

Analog power supply pin

Analog ground pin

X'tal input pin

X'tal output pin if XTS="H"

External master clock input pin if XTS="L"

Parallel/Serial select pin

"L" : Serial control mode, "H" : Parallel control mode

Audio data interface format pin in parallel mode

Chip select pin in serial mode

Audio data interface format pin in parallel mode

Control data clock pin in serial mode

Loop back mode pin in parallel mode

Enables digital loop-back from ADC to 3 DACs.

Control data input pin in serial mode

Loop back mode pin in parallel mode

Enable all 3 DAC channels to be input from SDTII.

Control data output pin in serial mode

BA7625 (IC242,IC201) / BA7626 (IC241): Video selector

MONITOR OUT

GND

IN5

GND

IN4

CTL E

IN3

CTL D

1

2

3

4

5

6

7

8

logic

logic

16

15

14

13

12

11

10

11

IN1

CTL A

VOUT 1

CC

V

IN2

CTL B

VOUT 2

CTL C

A B E MONITOR OUT

LL

HL

LH

HHL IN4

HHH IN5

*

*

*

IN1

IN2

IN3

C D E VOUT1

LL

HL

LH

HHL IN4

HHH IN5

*

*

*

-IN2

IN3

C D E VOUT2

LL

HL

LH

HHL IN4

HHH IN5

*

*

*

IN1

--

IN3

1-12

Page 13

BU2092(IC402,IC405):LED Controller

1.Terminal Layout

RX-7000RBK

Vss

DATA

CLOCK

LCK

Q0

Q1

Q2

Q3

Q4

1

2

3

4

5

6

7

8

9

CONTROL

CIRCUIT

12BIT SHIFT RESISTER

12BIT STRAGE RESISTER

OUTPUT BUFFER(OPEN DRAIN)

17

16

15

14

13

12

11

10

18

Vdd

OE

Q11

Q10

Q9

Q8

Q7

Q6

Q5

2.Pin Function

Pin No.

1

2

3

4

5~16

17

18

Symbol

Vss

DATA

CLOCK

LCK

Q0~Q11

OE

Vdd

I/O

I

I

I

O

I

-

Function

Connect to GND

Serial Data input

Shift Clock of Data

Latch Clock of Data

Parallel Data Output

Latch Data L H

OUTPUT ON OFF

Output Enable

Power Supply

1-13

Page 14

RX-7000RBK

LA1838(IC102): FM AM IF AMP&detector, FM MPX Decoder

1. Block Diagram

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin Function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

28

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

Function

DET

5

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tunning,this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

TUNING

DRIVE

6

24

STEREO

DRIVE

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

R OUT

17

L OUT

18

19

20

21

22

23

24

25

26

27

28

29

30

R IN

L IN

RO

LO

IF IN

FM OUT

AM DET

AM AGC

AFC

AM RF

REG

AM OSC

OSC BUFFER

21

DECODER

ANIT-BIRDIE

VCO

384KHz

10

20

STEREO

5N

SW

FF

38k

11

I/O

O

Right channel signal output.

O

Left channel signal output.

Input terminal of the Right channel post

I

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

14

AMP.

Input terminal of the Left channel

I

post AMP.

Mpx Right channel signal output.

O

O

Mpx Left channel signal output.

I

Mpx input terminal

FM detection output.

O

AM detection output.

O

This is an AGC voltage input terminal

I

for AM

I

This is an output terminal of voltage

for FM-AFC.

AM RF signal input.

I

Register value between pin 26 and pin28

O

besides the frequency width of the

input signal.

I

This is a terminal of AM Local

oscillation circuit.

AM Local oscillation Signal output.

O

15

1-14

Page 15

LC72136N (IC121) : PLL Frequency synthesizer

1. Pin layout

FM/AM

CLOCK

FM/ST/VCO

AM/FM

2. Block diagram

XT

CE

DI

DO

SDIN

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

RX-7000RBK

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

LW

MW

SDIN

Reference

Driver

Swallow Counter

1/2

C

2B

I/F

Power

on

Reset

Function

I/O

X'tal oscillator connect (75kHz)

I

LOW:FM mode

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

Open state after the power on reset

O

Input/output port

I/O

Input/output port

I/O

Data input/output

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

Symbol

No.

12

IFCONT

13

14

15

16

17

18

19

LPFOUT

20

21

22

IFIN

AMIN

FMIN

VCC

PD

LPFIN

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

I

Output for active lowpassfilter of PLL

O

Connected to GND

X'tal oscillator(75KHz)

I

1-15

Page 16

RX-7000RBK

LC7522 (IC451) : SEA Control

1.Pin layout 2.Block diagram

1

28

2

27

3

26

4

25

5

24

6

23

7

22

8

21

9

20

10

19

11

18

12

17

13

16

14

15

D1

CLK

TEST1

10

f1

9

f2

8

f3

7

f4

6

f5

5

f6

4

f7

16

17

13

S

4

Control Shift Resistor

3.Pin function

Pin No. Symbol

1

18

14

15

2,27

3,26

VDD

VSS

VEE

VCC

IN 1

IN 2

16 D1 Data input terminal from CPU

17 CLK Clock input terminal from CPU

4~10

f1~f7 Joint terminal of B.P.F.

19~25

11

12

13

TEST1

TEST2

S

28 NC No use

Power Supply terminal for Audio signal +7V(typ)

Power Supply terminal 0V

Power Supply terminal for Audio signal. Single channel use, joint VSS.

Power Supply terminal +5V(typ)

Audio signal Input terminal

IN1 joint opposite input of Operation amp.

IN2 joint inapposite input of Operation amp.

It have Right and Left.

Shumit inverter style

Shumit inverter style

f1~f7 X Right, Left Total 14 terminal

Internal test terminal of IC

It can use open condition

Select terminal for 2 tip use

"1" input, key code 7C3 - VDD joint

"0" input, key code 7C2 - VEE joint

+

–

2IN1

3IN2 27 IN126 IN2

Network

Resistor

Latch Circuit

18

1

Vdd

Vss

14

Vee

Function

Network

Resistor

15

Vcc

+

–

19

f1

20

f2

21

f3

22

f4

23

f5

24

f6

25

f7

12

TEST2

1-16

Page 17

MN101C15FDE (IC401) : System control micon

1. Pin layout

80 61

1

60

RX-7000RBK

20

21 40

2. Pin function

Pin

No

1

2

3

4

5

6

Symbol Symbol

GND

DVD-S/C

VCR1-S/C

VIDEO-S/C

TV-S/C

4/8-IN

7

8

9

10

GND

PROTECT

GND

11

12

13

OSC 12

OSC 11

14

15

16

17

18

19

20

21

22

23

GND

TEXT-OUT

TEXT-IN

MASTER

DSP-COMMAND

DSP-STATUS

DSP-CLK

24

25

26

27

RESET-IN

TUNER-CE

TUNER-CLK

28

TUNER-DATA

29

TUNER-MUTE

30

31

32

33

34

TUNER-IN

STEREO-IN

RDS-ST

M-BUSY

35

36

37

38

39

40

OSD-DATA

OSD-STB

OSD-CLK

VIDEO1

VIDEO2

VDD

VSS

X1

X0

INH

41

Functions Functions

Ground

DVD S/C signal select terminal

VCR1 S/C signal select terminal

VIDEO S/C signal select terminal

TV S/C select terminal

4 ohm / 8 ohm select signal terminal

Ground

Protect

Ground

Power supply

Oscillation terminal

Oscillation terminal

Ground

Ground

No use

Ground

Text signal output terminal

Text signal input terminal

Master signal terminal

DSP control signal terminal

DSP control signal terminal

DSP control signal terminal

No use

Reset signal input terminal

Tuner chip enable

Tuner clock signal terminal

No use

Tuner control signal terminal

Tuner mute signal terminal

Tuner signal input terminal

Stereo signal input terminal

Data start signal for block data to

output serial data.

Busy signal from IC400

Inhibit signal input

OSD data signal input terminal

OSD standby signal terminal

OSD clock signal terminal

VIDEO 1 signal terminal

VIDEO 2 signal terminal

Pin

No

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

VIDEO3

VIDEO4

S.MUTE

RDS-DATA

RDS-CLK

DSP-READY

DSP-RESET

M/CS

M-RESET

M-STATUS

M-COMMAND

M-CLK

SEA-CLK

SEA-DATA

VL/VH

4/8 OUT

SW-DAT A

SW-CLK

VOL-STB

VOL-DAT A

VOL-CLK

SW-STB

FR1-RELAY

FR2-RELAY

CNTR-RELAY

SUR-RELAY

SUB-MUTE

LED-LCK2

C.TONE3

C.TONE2

C.TONE1

LED-LCK1

LED-DATA

LED-CLK

VIDEO 3 signal terminal

VIDEO 4 signal terminal

Source mute control terminal

No use

No use

No use

RDS control signal terminal

No use

RDS control signal clock

DSP control signal clock

DSP reset signal terminal

Control signal from IC400

Reset signal from IC400

Status signal from IC400

Command signal from IC400

Clock signal from IC400

SEA clock signal from terminal

SEA data signal terminal

Connect to power supply board

4 ohm / 8 ohm select signal terminal

Switch data signal terminal

Switch clock signal terminal

Volume strobe signal terminal

Volume data signal terminal

Volume clock signal terminal

Switch strobe signal terminal

No use

No use

Relay 1 signal terminal

Relay 2 signal terminal

Center speaker relay terminal

Surround speaker relay terminal

SUB woofer out mute control

LED latch clock signal terminal

Center tone 3 signal terminal

Center tone 2 signal terminal

Center tone 1 signal terminal

LED latch clock signal terminal

LED data signal terminal

LED clock signal terminal

1-17

Page 18

RX-7000RBK

MB90088PF-131 (IC203) : On screen display controller

1.Terminal layout

YIN

VIN

CIN

AVcc

FSCO

VBLK

Vcc

EXS

XS

HSYNC

VSYNC

EXHSYN

EXVSYN

Vss

2.Block diagram

SIN

SCLK

CS

EXHSYN

EXVSYN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

AVss

27

YOUT

26

VOUT

25

COUT

24

CS

23

SIN

22

SCLK

21

TEST

20

VOC0

19

VOC1

18

VOC2

17

VOB

16

XD

15

EXD

Serial Input

Control

H/V Separate

Each Control, Data

VIN

YIN

CIN

HSYNC

VSYNC

XS

EXS

XD

EXD

NTSC/PAL

Signal OSC

Display Memory

Control

VRAM

4FSC CLK

OSC

Dot CLK

OSC

Each Block

Each Block

Analog SW

Video Signal

OSC

Output

Control

CGROM

VOUT

YOUT

COUT

BOUT

ROUT

GOUT

IOUT

VOC

VOB

1-18

Page 19

3.Pin functions (MB90088PF-131)

pin

Symbol I/O Function

no

YIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

VIN

CIN

AVcc

IOUT

VOC

Vcc

EXS

XS

HSYNC

VSYNC

EXHSYN

EXVSYN

Vss

EXD

XD

VOB

GOUT

ROUT

BOUT

TEST

SCLK

SIN

CS

COUT

VOUT

YOUT

AVss

I

Brightness signal Input terminal for Superinpause indication

I

Composite video signal input terminal for Superinpause indication

Contrast signal input terminal for Superinpause indication

I

-

Analog power supply terminal

O

Color (Brightness) signal output terminal

Character output terminal

O

Power supply terminal

Clock generater outside circuit terminal for color burst

I

O

O

Horizontal signal output terminal

O

Vertical signal output terminal

EXT horizontal signal input terminal

I

EXT vertical signal input terminal

I

GND

Dot clock generater outside circuit signal terminal for indication

I

O

Character & background signal output terminal

O

Color signal (Green, Red, Blue)

O

I

Test signal input terminal

Shift clock input terminal for serial transmission

I

Serial data input terminal

I

Chip select terminal

I

Contrast signal output terminal

O

Composite video signal output terminal

O

O

Brightness signal output terminal

Analog GND terminal

-

RX-7000RBK

NJM2285D (IC202) : Video switch

1.Terminal layout & Block diagram

GND 1 IN 2B

IN 1A

16 15 14 13 12 11 10 9

L

H

Bias Type

Clamp Type

12345678

IN 1B

CTL 1

OUT 1

CTL 2 IN 2A GND 3 IN 3B

V+

HL

GND 2 OUT 2

OUT 3 CLT 3 IN 3A

Clamp Type

H

L

1-19

Page 20

RX-7000RBK

MN173222DG(IC400):FL Display & Operation switch control

1.Pin layout

84 64

1

63

21

22 42

43

2.Key matrix

KEY OUT1

DSP MODE

LOUDNESS

SEA MODE

KEY IN 0

KEY IN 1

KEY IN 2

KEY IN 3

KEY OUT 0

POWER

SURROUND

SPEAKER 1

SPEAKER 2

3.Pin function

Pin No. I/O

1~22

23

24~39

40,41

42,43

44

45

46

47

48

49

50

51

52

53

54

55

56,57

58

Symbol Description

S22~S1

VPP

G15~G1/KO0~5

JOG1,2

JOG3,4

M BUSY

M CLK

M COMMAND

M STATUS

M CS

RM

VCRI

DCSI

DCSO

VCRO

TVD

TVC

JOG5,6

POWER

59

60~63

64~67

68

69

70

71

72

73

KI3~KI0

S36~S33

RST

X1

X2

VSS

OSC2

OSC1

74

75~84

S32~S23

ANALOG/

DIGITAL

KEY OUT 2

SEA ADJUST

FM MODE

LEVEL ADJUST

SOUND SELECT

O

-

O

I

I

O

I/O

I

O

I

I

I

I

O

O

O

O

I

I

O

I

O

I

-

-

-

-

-

-

O

FL Segment control signal

Power supply terminal

FL grid control signal / Key matrix output

Source select JOG1,2

Volume JOG 3,4

BUSY Signal output to IC401

Clock signal to IC401

Command data input from IC401

Status signal output to IC401

Chip select signal input from IC401

Remote control signal input

AV Compu-link VCR input

AV Compu-link DCS input

AV Compu-link DCS output

AV Compu-link VCR output

AV Compu-link TV output

AV Compu-link TV control output

Multi JOG 5,6

Power ON control output

STANDBY LED control H:Lighting

Key matrix input

FL Segment control signal

Reset input

Connect to GND

Non connect

Connect to GND

Oscillation terminal 6MHz

Oscillation terminal 6MHz

Not use

FL Segment control signal

KEY OUT 3 KEY OUT 5

FM/AM TUNING

TUNER PRESET

MEMORY

SETTING

KEY OUT 4

DISPLAY MODE

TA/NEWS/INFO

EON

PTY SEARCH

ONE TOUCH

OPERATION

1-20

Page 21

TC9162AN (IC321): Analog switch

1.Function

Switch to On/Off of S1 to S8 by control of LSI.

2.Terminal Lay out & Block Diagram

TC9162N

VSS

L-S1

S-2

1

2

3

28

27

26

RX-7000RBK

VDD

R-S1

S-2

COM-1

S-3

S-4

COM-2

S-5

S-6

COM-3

S-7

COM-4

GND

4

5

SHIFT

6

7

8

9

10

11

12

13

ST

14

RESISTOR

&

LATCH

SHIFT RESISTOR

SHIFT

RESISTOR

&

LATCH

25

24

23

22

21

20

19

18

17

16

15

COM-1

S-3

S-4

COM-2

S-5

S-6

COM-3

S-7

COM-4

DATA

CK

W24L011AJ-15(IC641):SDRAM

1.Pin layout 2.Block diagram 3.Pin function

A0

A1

A2

A3

CS

I/O1

I/O2

VDD

VSS

I/O3

I/O4

WE

A4

A5

A6

A7

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

A16

A15

A14

A13

OE

I/O8

I/O7

VSS

VDD

I/O6

I/O5

A12

A11

A10

A9

A8

Vdd

Vss

A0

A16

CS

OE

WE

DECODER

CONTROL

CORE

ARRAY

I/O1

DATA I/O

I/O8

Symbol Description

A0~A16

I/O1~I/O8

CS

WE

OE

Vdd

Vss

Address inputs

Data inputs/outputs

Chip select inputs

Write enable input

Output enable input

Power supply

Ground

1-21

Page 22

RX-7000RBK

TC9446F-014(IC631):Digital signal processor for dolby digital

/ DTS audio decode

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8~11

12

13

14

15

16~18

19

20

21

22

23

24

25

26

27,28

29~31

32,33

34

35

36

37

38,39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54~61

62

63~70

71

72~80

81

82~89

90

91

92,93

94

95

96

97

98,99

100

RST

MIMD

MICS

MILP

MIDIO

MICK

MIACK

FI0~3

IRQ

VSS

LRCKA

BCKA

SDO0~2

SD03

LRCKB

BCKB

SDT0

SDT1

VDD

LRCKOA

BCKOA

TEST0,1

LRCKOB,BCKOB,TXO

TEST2,3

RX

VSS

TSTSUB0

FCONT

TSTSUB1,TSTSUB2

PDO

VDDA

PLON

AMPI

AMPO

CKI

VSSA

CKO

LOCK

VSS

WR

OE

CE

VDD

IO7~0

VSS

AD0~7

VDD

AD8~16

VSS

PO0~7

VDDDL

LPFO

DLON,DLCKS

SCKO

VSSDL

SCKI

VSSX

XO,XI

VDDX

Reset signal input terminal (L:reset H:Operation usually)

I

Microcomputer interface mode selection input terminal (L:serial H:IC bus)

I

Microcomputer interface chip select input terminal

I

Microcomputer interface latch pulse input

I

Microcomputer interface data I/O terminal

I/O

Microcomputer interface clock input terminal

I

Microcomputer interface acknowledge output terminal

O

Flag input terminal 0~3

I

Interrupt input terminal

I

Digital ground terminal

Audio interface LR clock input terminal A

I

Audio interface bit clock input terminal A

I

Audio interface data output terminal 0

O

Non connect

Audio interface LR clock input terminal B

I

Audio interface bit clock input terminal B

I

Audio interface data input terminal 0

I

Audio interface data input terminal 1

I

Power supply for digital circuit

Audio interface LR clock output terminal A

O

Audio interface bit clock output terminal A

O

Test input terminal 0/1 (L:test H:operation usually)

I

Non connect

Test input terminal (L:test H:operation usually)

I

SPDIF input terminal

I

Ground terminal for digital circuit

Test sub input terminal 0 (L:test H:operation usually)

I

VCO Frequency control output terminal

O

Test sub input terminal 1,2 (L:test H:operation usually)

I

Phase error signal output terminal

O

Power supply for analog circuit

Clock selection input terminal (L:external clock H:VCO clock)

I

AMP.input terminal for LPF

I

AMP.output terminal for LPF

O

External clock input terminal

I

Ground terminal for analog circuit

DIR Clock output terminal

O

VCO Lock detection output terminal

O

Ground terminal for digital circuit

External SRAM writing signal output terminal

O

External SRAM output enable signal output terminal

O

External SRAM chip enable signal output terminal

O

Power supply terminal for digital circuit

External SRAM data I/O terminal 7~0

I/O

Ground terminal for digital circuit

External SRAM address output terminal 0~7

O

Power supply terminal for digital circuit

External SRAM address output terminal 8~16

O

Ground terminal for digital circuit

General purpose output terminal 0~7

O

Power supply terminal for DLL

LPF output terminal for DLL

O

Refer to the undermentioned table

I

Non connect

Ground terminal for DLL

External system clock input terminal

I

Ground termonal for oscillation circuit

Oscillation I/O terminal

I/O

Power supply terminal for oscillation circuit

-

1-22

DLCKS terminal

L

L

H

H

DLONterminal

L

H

L

H

DLL clock setting

SCKI input (DLL circuit OFF)

Four times XI clock

Three times XI clock

Six times XI clock

Page 23

TC9459F (IC331,IC332,IC333) : Electronic volume control

1.Pin layout

VSS

L-OUT

NC

L-ch

L-IN

L-LD1

L-LD2

L-A-GND

NC

CS1

NC

GND

CK

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

VDD

R-OUT

NC

R-IN

R-LD1

R-LD2

R-A-GND

NC

CS2

NC

STB

DATA

R-ch

2. Block diagram

2

L-OUT

3

NC

L-1N

L-LD1

L-LD2

L-A-GND

NC

CS1

NC

GND

CK

4

5

6

7

8

9

10

11

12

50k /

91 STEP

VR

L-ch 7 to 91

decoder

L-ch data

latch circuit

VSS

1

Shift register (24BIT)

Level shift circuit

VDD

24

Same as L-ch

Circuit

R-ch 7 to 91

decoder

R-ch data

latch circuit

RX-7000RBK

23

R-OUT

22

NC

21

R-IN

20

R-LD1

19

R-LD2

18

R-A-GND

17

NC

16

CS2

15

NC

14

STB

13

DATA

3.Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

Symbol

VSS

L-OUT

NC

NC

L-LD1

L-LD2

L-A-GND

NC

CS1

NC

NC

CK

Function

Negative power supply pin

Volume output pin

No connection

No connection

Loudness tap output pin

Loudness tap output pin

Analog GND pin

No connection

Chip select input pin

No connection

No connection

Data transfer clock input

Pin No.

13

14

15

16

17

18

19

20

21

22

23

24

Symbol

DATA

STB

NC

CS2

NC

R-A-GND

R-LD2

R-LD1

R-IN

NC

R-OUT

VDD

Function

Volume setup serial data input

Data write strobe input

No connection

Chip select input pin

No connection

Analog GND pin

Loudness tap output pin

Loudness tap output pin

Volume input pin

No connection

Volume output pin

Positive power supply pin

1-23

Page 24

RX-7000RBK

UPD784215AGC103(IC671):UNIT CPU

1.Pin layout

75 ~ 51

76

~

50

~

100

1 ~ 25

26

2.Pin function

Pin No. Symbol I/O Function

1~8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25~32

33

34,35

36

37,38

39

40

41

42

43

44

45,46

47

48

49

50

51,52

53

54~63

64,65

66

67

68

69,70

71

72

73~80

81

82

83

84

85

86

87

88

89

90~93

94

95~100

VDD

X2

X1

VSS

XT2

XT1

RESET

AUTODAT A

LOCK

DIGITAL0

FORMAT

CHANNEL

ERR

RSTDET

AVDD

AVREF0

AVSS

RX,TX

DSPCOM

DSPSTS

DSPCLK

DSPRDY

MIDIO_IN/OUT

MICK

MICS

MILP

MIACK

DSPRST

CDTI/CDTO

CCLK

CS

XTS

PD

GND

VDD

3D-ON

3D-ON

ANA/T-TONE

REF-MIX

D.MUTE

S.MUTE

ASW1~4

TEST

Non connect

Power supply terminal

Connecting the crystal oscillator for system main clock

O

Connecting the crystal oscillator for system main clock

I

Connect to GND

Connecting the crystal oscillator for system sub clock

O

Connecting the crystal oscillator for system sub clock

I

System reset signal input

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Reset signal input

I

Power supply terminal

Connect to GND

Connect to GND

Connect to GND

Non connect

Power supply terminal

Not use

Non connect

Communication port from IC401

I

Status communication port to IC401

O

Clock input from IC401

I

Ready signal input from IC401

I

Non connect

Interface I/O terminal with microcomputer

I/O

Interface I/O terminal with microcomputer of clock signal

O

Interface I/O terminal with microcomputer of chip select

O

Interface I/O termonal with microcomputer

O

Interface I/O termonal with microcomputer

O

Non connect

Reset signal output of DSP

O

Non connect

Interface I/O terminal with microcomputer

I/O

Interface I/O terminal with microcomputer of clock signal

O

Interface I/O terminal with microcomputer of chip select

O

OSC Select

O

Non connect

Reset signal output

O

Connect to GND

Non connect

Power supply

Non connect

Switch at output destination of surround channel

O

Test tone control

O

Control at output destination of LFE channel

O

Non connect

Mute of the digital out terminal is controlled

O

Mute of the audio signal is controlled

O

Non connect

Selection of digital input selector

O

Test terminal

Non connect

-

1-24

Page 25

SAA6588 (IC191) : RDS Detector

RX-7000RBK

1.Terminal Layout

MRO

GND

OSCO

OSCI

VSSD

VDDD

DAVN

NC

SDA

SCL

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

NC

CIN

SCOUT

Vref

MPX

VSSA

VDDA

NC

GND

NC

2.Pin Function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

MRO

NC

GND

OSCO

OSCI

VSSD

VDDD

DAVN

SDA

SCL

NC

GND

NC

VDDA

VSSA

MPX

Vref

SCOUT

CIN

NC

FunctionI/OSymbol

O

Multi-path rectifier output

-

Non connect

I

Test control input pin

O

Oscillator output

I

Oscillator input

-

Digital ground (0V)

-

Digital power supply (5V)

O

Data available output (active LOW)

I/O

IC-bus serial data I/O

I

IC-bus serial clock input

-

Non connect

-

Connect to ground

-

Non connect

-

Analog power supply (5V)

-

Connect to ground

I

Multiplex input signal

O

Reference voltage output

O

Band-pass filter output

Comparator output

O

Level input

I

3.Block Diagram

16

MPX

AFIN

LVIN

VDDA

14

BAND-PASS

13

DETECTOR

20

AND RESET

VSSA

SCOUT

57 kHz

8th ORDER

PAUSE

POWER

SUPPLY

15

18

17

Vref

19

CLOCK

COMPARATOR

MULTI-PATH

DETECTOR

TEST

CONTROL

3

TCON

RDS/RDBS

DEMODULATOR

SIGNAL QUALITY

DETECTOR

OSCILLATOR

AND CLOCK

1

MRO

OSCI OSCO

VDDDCIN

7

DAVN

12

MAD

11

10

8

2

9

PSWN

MPTH

SDA

SCL

RDS/RDBS

DECODER

INTERFACE

REGISTER

IC-BUS SLAVE

TRANSCEIVER

5

4

6

VSSD

1-25

Page 26

RX-7000RBK

<<MEMO>>

1-26

Page 27

RX-7000RBK

RX-7000RBK

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK B.U 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

No.20846

Printed in Japan

2000 07(O)

1-27

Loading...

Loading...