Page 1

RX-6010VBK/6012VSL

SERVICE MANUAL

AUDIO/VIDEO CONTROL RECEIVER

RX-6010VBK

TV

SLEEP

VCR

SURROUND

– SUBWOOFER +TEST

1

SURROUND

EFFECT

– CENTER +

MODE

54

5

– REAR•L + – VCR CH +

SOUND

7/P

CD-DISC

TV/VIDEO

– REAR•R +

10

DVD

TV SOUND

VCR

CD

TAPE/CDR

+

+

TV VOL

VOLUME

–

–

£

1

+

TV CH

–

7

RM-SRX6010U

REMOTE CONTROL

A/V CONTROL RECEIVER

AUDIO

5

5

ANALOG/DIGITAL

FM/AM

MUTING

RX-6012VSL

Area Suffix

RX-6010VBK

UJ

RX-6012VSL

UY

US

UP

A

32

6

5

98

MENU

+10

ENTER

8

1

PHONES

STANDBY

STANDBY/ON

FM/AM TUNING

DIGITAL

SURROUND

SURROUND ON/OFF

DSP MODE

FM/AM PRESET FM MODE

DIGITAL

INPUT ATT

SPEAKERS ON/OFF

MEMORY

INPUT DIGITALINPUT ANALOG

AUDIO/VIDEO CONTROL RECEIVER

DVD VCR TV SOUND

CD TAPE/CDR

SOURCE NAME

FM/AM

ADJUST

DOWN UP

MASTER VOLUME

SETTING

CONTROL

U.S.military

Argentina

Singapore

Korea

Australia

DIGITAL

As for RX-6012VSL the body is silver color

Contents

Safety precautions --------------------------------------------------------1-2

Disassembly method -----------------------------------------------------1-3

Adjustment method -------------------------------------------------------1-8

Description of major ICs -------------------------------------------------1-9~22

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No.20988

Jun. 2001

Page 2

RX-6010VBK/ RX-6012VSL

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitr y of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will fur ther

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement par ts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the JC version)

1-2

Page 3

RX-6010VBK/ RX-6012VSL

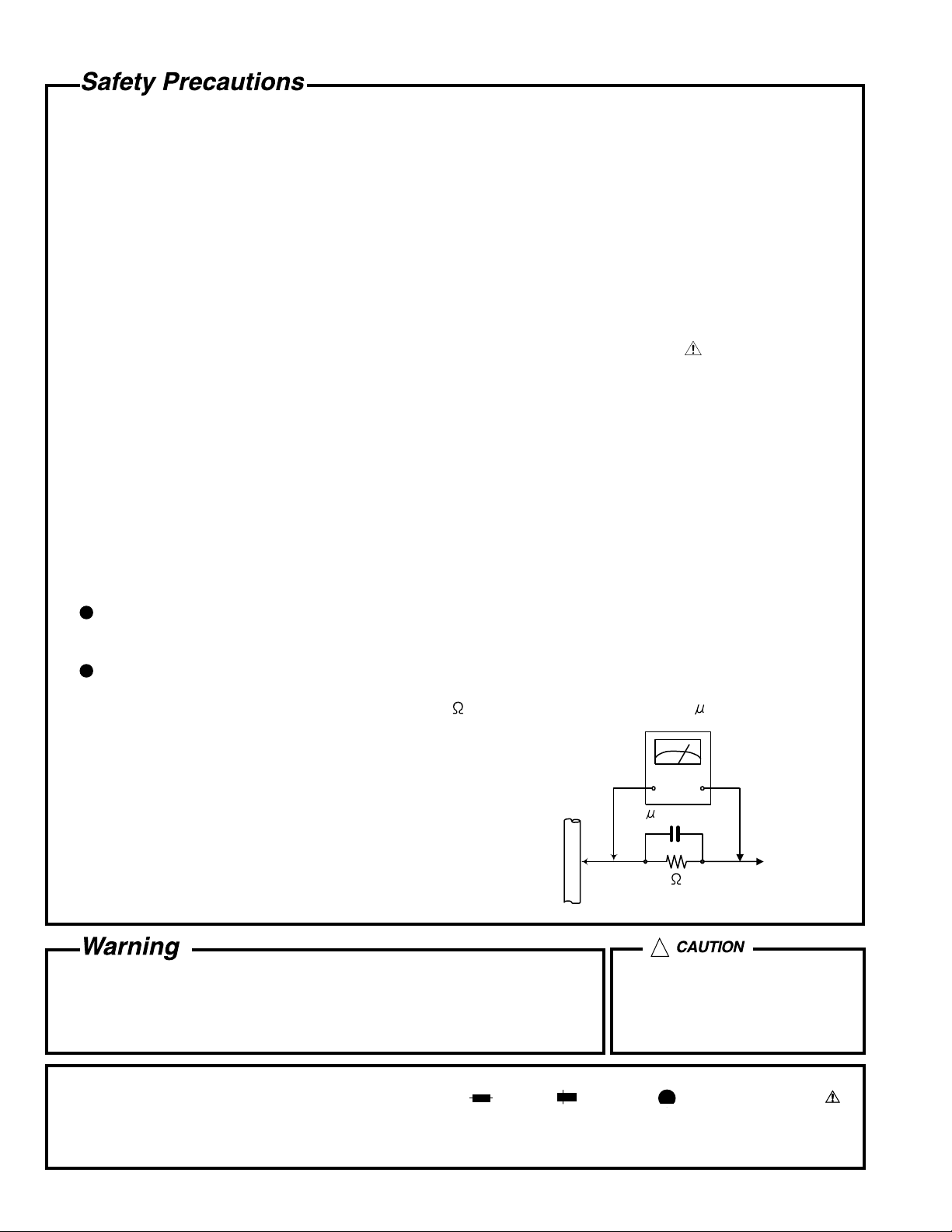

Disassembly method

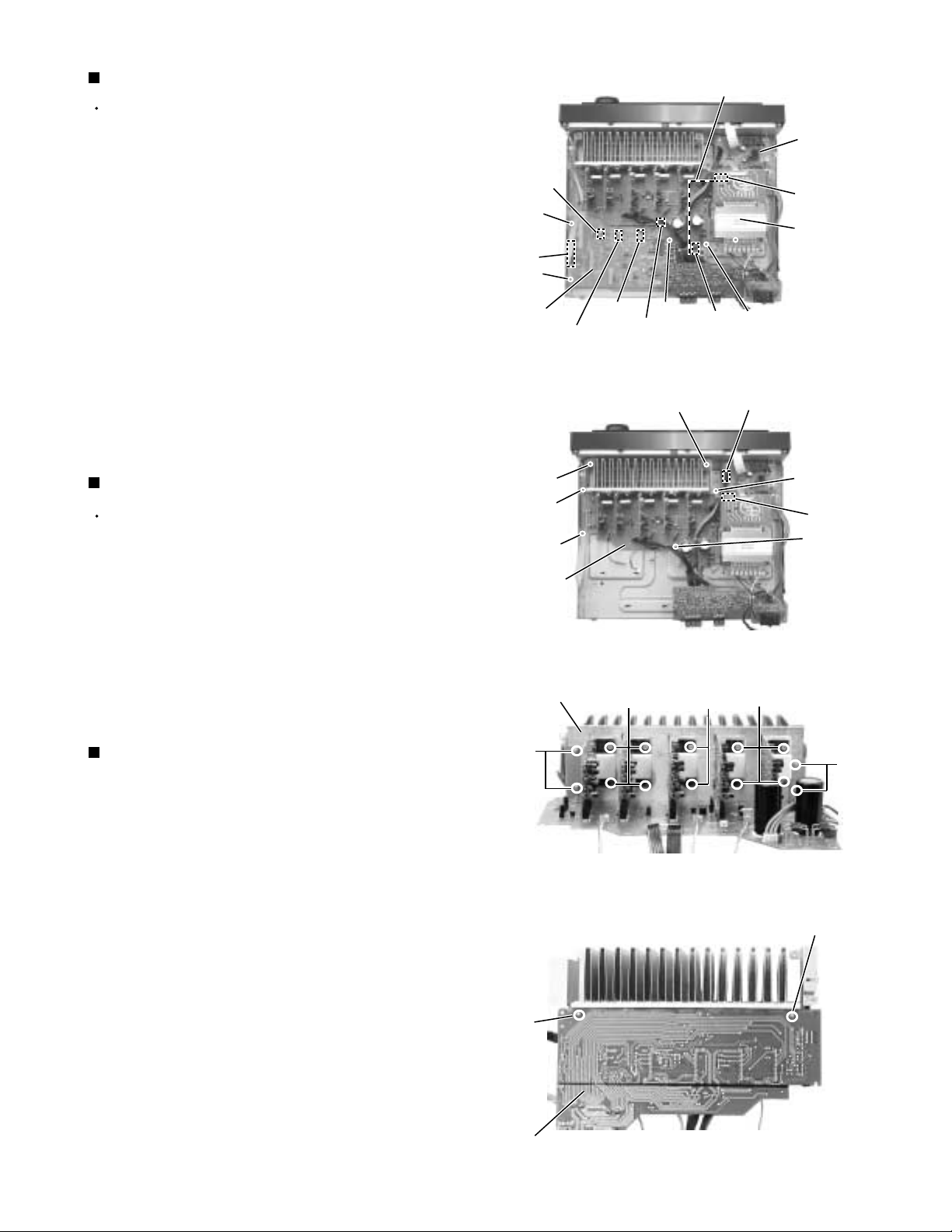

Removing the top cover (See Fig.1)

1.

Remove the four screws A attaching the top cover

on both sides of the body.

2.

Remove the three screws B on the back of the body.

3.

Remove the top cover from behind in the direction of

the arrow while pulling both sides outward.

Removing the front panel assembly

(See Fig.2 and 3)

Prior to performing the following procedure, remove

the top cover.

1.

Disconnect the card wire from connector CN402 on

the audio board and CN201 on the power supply

board in the front panel assembly.

2.

Cut off the tie band fixing the harness.

Tie band

Main

board

CN402

A

Top cover

2

A

2

C

B

Fig.1

Front panel assembly

C

CN201

Power supply

board

3.

Remove the three screws C attaching the front

panel assembly.

4.

Remove the four screws D attaching the front panel

assembly on the bottom of the body. Detach the front

panel assembly toward the front.

Removing the rear panel (See Fig.4)

Prior to performing the following procedure, remove

the top cover.

1.

Remove the power cord stopper from the rear panel

by moving it in the direction of the arrow.

2.

Remove the nineteen screws E attaching the each

boards to the rear panel on the back of the body.

Audio board

E

E

E

E

D

E

Fig.2

Front panel assembly

Fig.3

E

D

Cord stopper

E

3.

Remove the four screws F attaching the rear panel

on the back of the body.

F

Rear panel

F

Fig.4

E

F

F

1-3

Page 4

RX-6010VBK/ RX-6012VSL

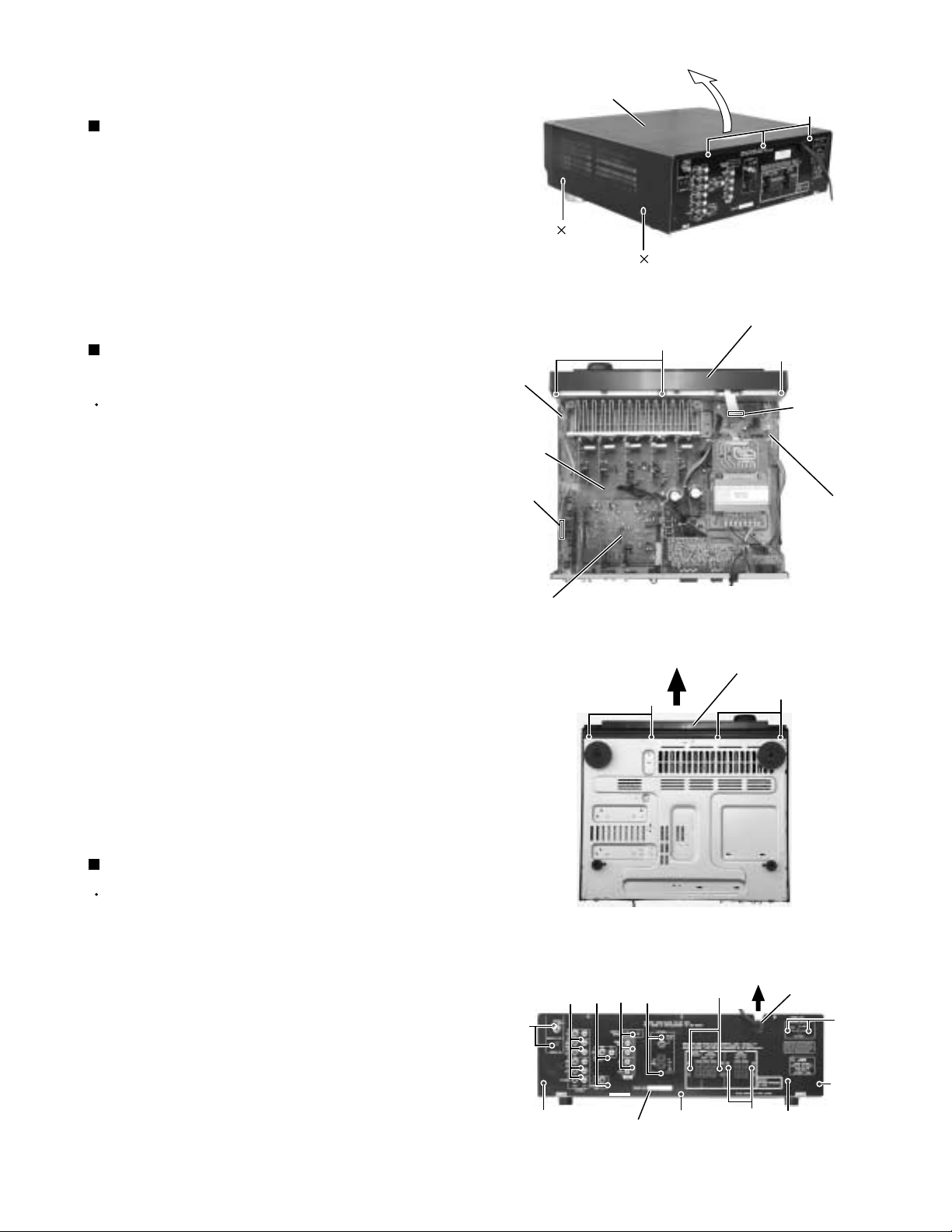

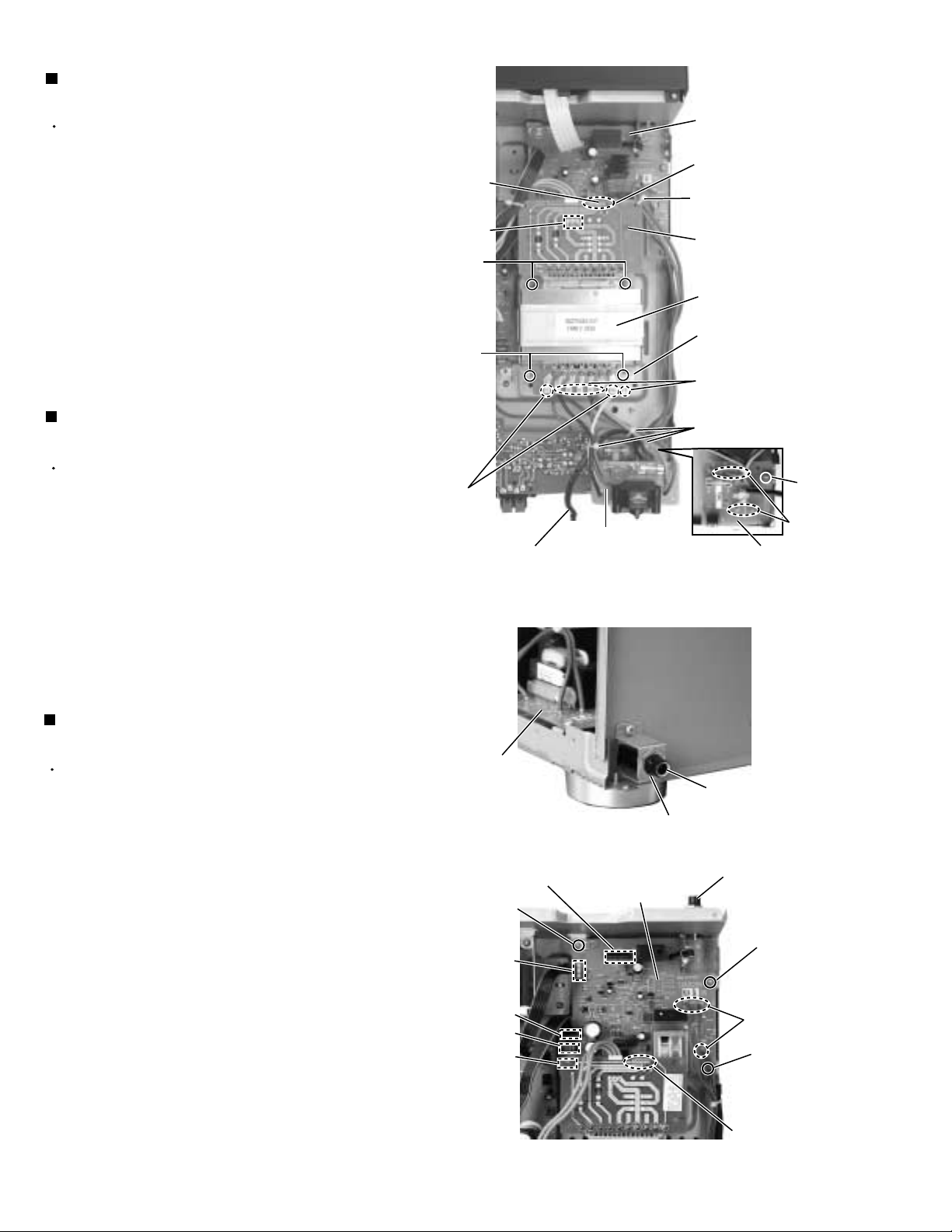

Removing each board connected to the

rear side of the audio board

(See Fig.5 to 8)

Prior to performing the following procedure, remove

the top cover and the rear panel.

1.

Cut off the tie band fixing the harness.

2.

Disconnect the DSP board from connector CN481 on

the audio board.

Audio

board

DSP

board

CN481

Tie band

3.

Disconnect the audio input board, DVD board and

the video board from connector CN421, CN431 and

CN441 on the audio board.

4.

Disconnect the tuner board from connector CN411

on the audio board.

CN421

Audio

input

board

CN431

CN481

DVD

Video

board

board

DSP board

CN441

Fig.5

Fig.6

Tuner

board

CN411

1-4

CN421

CN431

CN441

Fig.8

Tie band

CN411

Tuner

board

Audio

input

board

CN421

DVD

board

CN431

Video

board

CN441

Fig.7

Page 5

RX-6010VBK/ RX-6012VSL

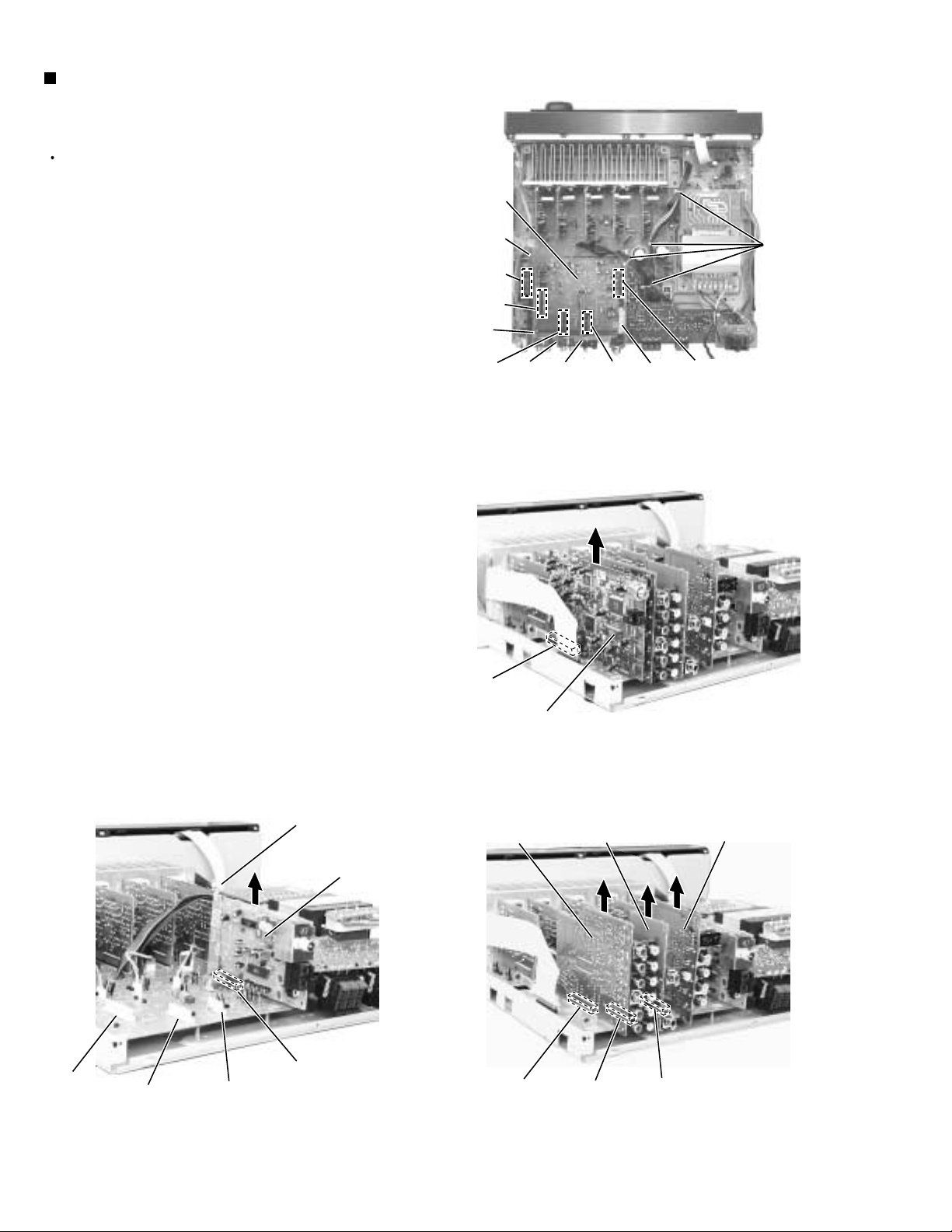

Removing the audio board (See Fig.9)

Prior to performing the following procedure, remove

the top cover and the rear panel.

1.

Disconnect the card wire from connector CN402 on

the audio board.

2.

Disconnect the relay board from the audio board and

the power supply board. (CN291,CN491)

3.

Disconnect the harness from connector CN473,

CN471, CN472, and CN385.

4.

Remove the three screws G attaching the audio

board assembly.

5.

Remove the screw H attaching the audio board

assembly.

Removing the main board (See Fig.10)

Prior to performing the following procedure, remove

the top cover, the rear panel and audio board.

CN473

G

CN402

G

Audio board

CN471

I

J

I

CN472

CN385

G

Fig.9

I

Relay board

CN491

H

CN241

power

supply

board

CN291

Power

transformer

J

CN203

I

1.

Disconnect the harness from connector CN241 and

CN203 on the power supply board respectively.

2.

Remove the four screws I and the two screws J

attaching the main board.

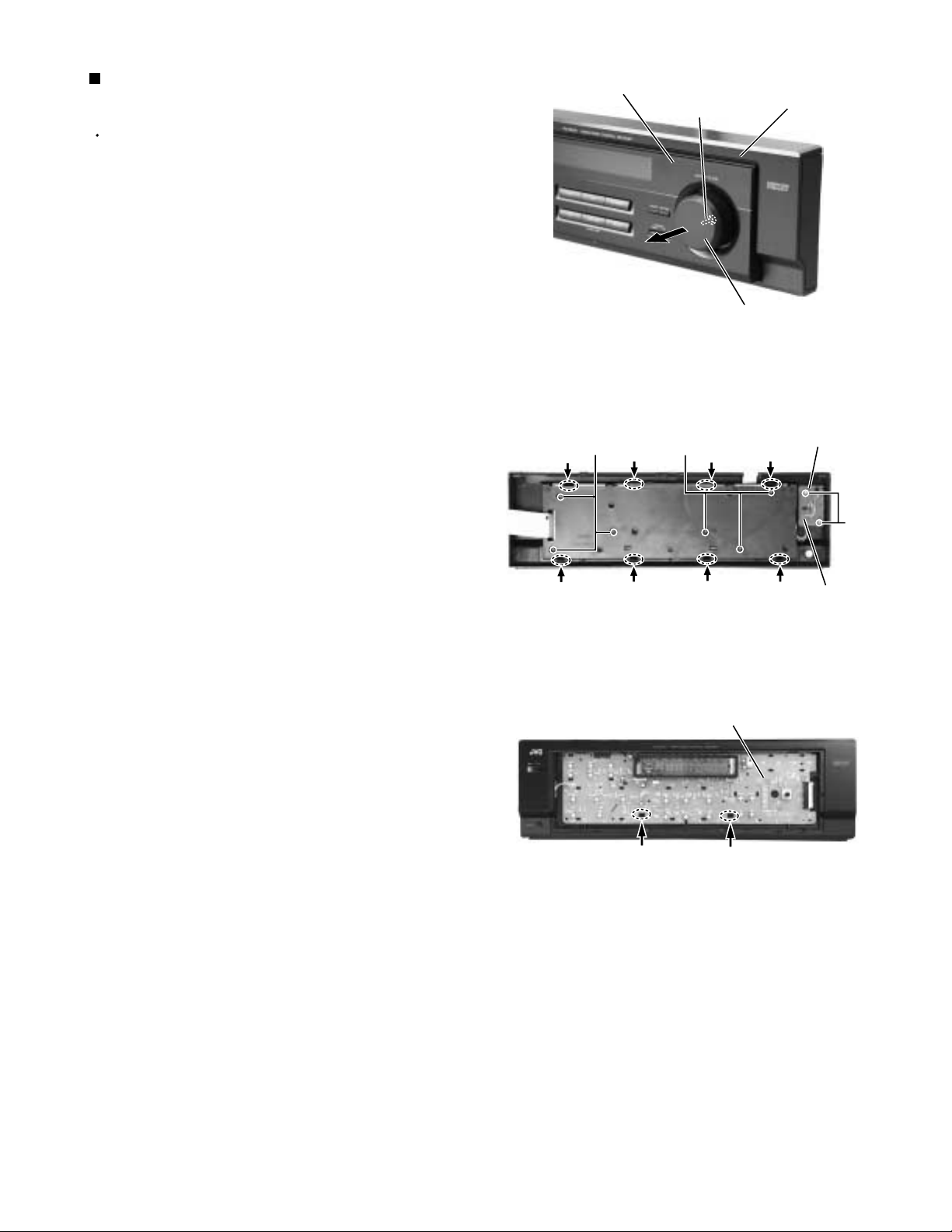

Removing the Heat sink

(See Fig.11 and 12)

1.

Remove the ten screws K and four screws L

attaching the heat sink.

2.

Remove the two screws L' attaching the heat sink

from the rear side of main board.

Main

board

Heat sink

L

K

Fig.10

Fig.11

K

K

L

L'

L'

Main board

rear side

Fig.12

1-5

Page 6

RX-6010VBK/ RX-6012VSL

Removing the power transformer

(See Fig.13)

Prior to performing the following procedures, remove

the top cover.

1.

Cut off the tie band fixing the harness.

2.

Unsolder the two harnesses connected to the power

transformer.

3.

Disconnect the harness from connector CN251 and

unsolder the harnesses connected to FW201 on the

power transformer board.

4.

Remove the four screws M attaching the power

transformer.

Removing the voltage selector board and

the power / fuse board (See Fig.13)

Prior to performing the following procedure, remove

the top cover and the rear panel.

1.

Unsolder the six harnesses connected to the power

transformer board and remove the voltage board.

2.

Remove the screw N attaching the power / fuse

board.

FW201

CN251

M

M

Solder

(from the

power/ fuse

board)

Power cord

Voltage selector

board

Fig.13

Power

supply

board

Solder

Tie band

Power

transformer

board

Power

transformer

Power

transformer board

Solder (from the

voltage selector

board)

Tie band

N

Solder

Power / fuse board

3.

Unsolder the power cord and other harnesses

connected to the power / fuse board.

Removing the power supply board

(See Fig.14 and 15)

Prior to performing the following procedure, remove

the top cover and the front panel.

1.

Remove the one nut attaching the headphone jack of

the power supply board on the front side of the body.

2.

Disconnect the harness connected to connector

CN241,CN201,CN203 and CN291 on the power

transformer board.

Remove the three screws O attaching the power

3.

supply board and pull out the power supply board

from the front bracket backward.

Unsolder the three harnesses connected to the

4.

power supply board.

Power

supply

board

O

CN241

CN203

CN291

Hook

CN201

Fig.14

Power

supply board

Headphone jack

Nut

Headphone jack

O

Solder

O

1-6

Solder

Fig.15

Page 7

RX-6010VBK/ RX-6012VSL

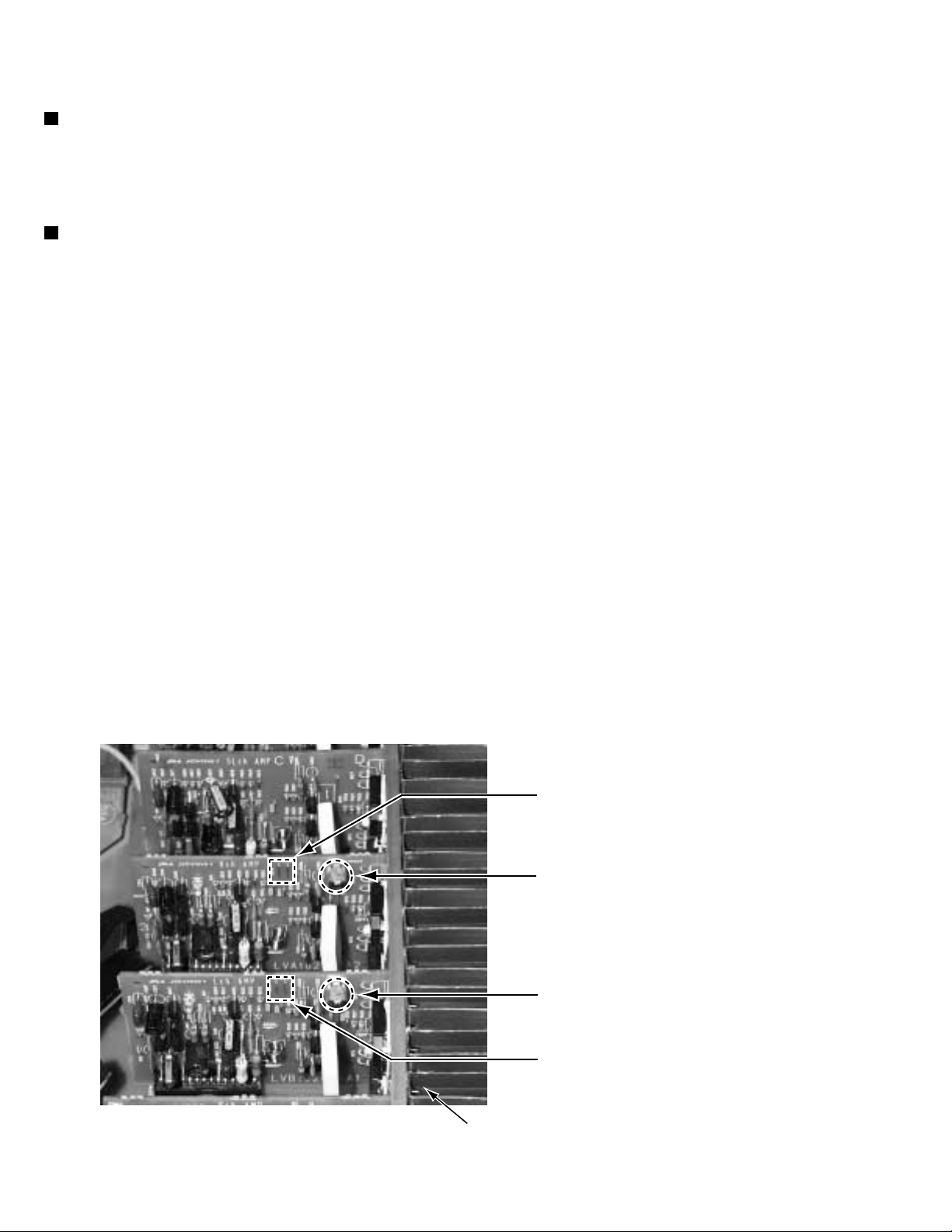

Removing the system control board /

power switch board (See Fig.16 to 18)

Prior to performing the following procedure, remove

the top cover and the front panel assembly.

1.

Pull out the volume knob on the front side of the front

panel and remove the nut attaching the system

control board.

2.

Remove the two screws P attaching the power

switch board.

3.

Disconnect the harness from connector CN714 on

the power switch board.

4.

Remove the six screws Q attaching the system

control board on the back of the front panel.

5.

On the back of the front panel, release the eight

joints by pushing the joint tabs inward.

Remove the operation switch panel toward the front.

6.

Release the two hook attaching the system control

board.

Operation switch panel

Fig.16

Q

Joint

Joint

Q

Nut

Joint

Front panel assembly

Volume knob

Power switch

board

Joint

P

Joint

Joint

Hook

Joint

Fig.17

System control board

Fig.18

Hook

Joint

CN714

1-7

Page 8

RX-6010VBK/ RX-6012VSL

Adjustment method

Tuner section

1.Tuner range

FM 87.5MHz~108.0MHz

AM(MW) 531kHz~1710kHz

Power amplifier section

Adjustment of idling current

Measurement location TP301(Lch) , TP302(Rch)

Adjustment part VR301(Lch) , VR302(Rch)

Attention

This adjustment does not obtain a correct adjustment value immediately after the amplifier is

used (state that an internal temperature has risen).

Please adjust immediately after using the amplifier after turning off the power supply of the

amplifier and falling an internal temperature.

<Adjustment method>

1.Set the volume control to minimum during this adjustment.(No signal & No load)

2.Set the surround mode OFF.

2.Turn VR301 and VR302 fully counterclockwise to warm up before adjustment.

If the heat sink is already warm from previous use the correct adjustment can not be made.

3.For L-ch,connect a DC voltmeter between TP301's B216 and B217 (Lch)

And,connect it between TP302's B218 and B219(Rch).

4.30 minutes later after power on, adjust VR301 for L-ch, or VR302 for R-ch so that the DC voltmeter

value has 1mV~10mV.

* It is not abnormal though the idling current might not become 0mA even if it is finished to turn variable

resistance (VR301,VR302) in the direction of counterclockwise.

TP302(Rch)

VR302 (Rch)

VR301 (Lch)

TP301(Lch)

Heat sink

1-8

Page 9

Description of major ICs

UPD784215AGC103 (IC671) : Unit CPU

1.Pin layout

75 ~ 51

76

~

50

~

RX-6010VBK/ RX-6012VSL

100

1 ~ 25

26

2.Pin function

Pin No. Symbol I/O Function

1~8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25~32

33

34,35

36

37,38

39

40

41

42

43

44

45,46

47

48

49

50

51,52

53

54~63

64,65

66

67

68

69,70

71

72

73~80

81

82

83

84

85

86

87

88

89

90~93

94

95~100

VDD

X2

X1

VSS

XT2

XT1

RESET

AUTODAT A

LOCK

DIGITAL0

FORMAT

CHANNEL

ERR

RSTDET

AVDD

AVREF0

AVSS

AV REF1

RX,TX

DSPCOM

DSPSTS

DSPCLK

DSPRDY

MIDIO_IN/OUT

MICK

MICS

MILP

MIACK

DSPRST

CDTI/CDTO

CCLK

CS

XTS

PD

GND

VDD

3D-ON

3D-ON

ANA/T-TONE

REF-MIX

D.MUTE

S.MUTE

ASW1~4

TEST

Non connect

Power supply terminal

Connecting the crystal oscillator for system main clock

O

Connecting the crystal oscillator for system main clock

I

Connect to GND

Connecting the crystal oscillator for system sub clock

O

Connecting the crystal oscillator for system sub clock

I

System reset signal input

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Output of DSP to general-purpose port

I

Reset signal input

I

Power supply terminal

Connect to GND

Connect to GND

Connect to GND

Non connect

Power supply terminal

Not use

Non connect

Communication port from IC701

I

Status communication port to IC701

O

Clock input from IC701

I

Ready signal input from IC701

I

Non connect

Interface I/O terminal with microcomputer

I/O

Interface I/O terminal with microcomputer of clock signal

O

Interface I/O terminal with microcomputer of chip select

O

Interface I/O terminal with microcomputer

O

Interface I/O terminal with microcomputer

O

Non connect

Reset signal output of DSP

O

Non connect

Interface I/O terminal with microcomputer

I/O

Interface I/O terminal with microcomputer of clock signal

O

Interface I/O terminal with microcomputer of chip select

O

OSC Select

O

Non connect

Reset signal output

O

Connect to GND

Non connect

Power supply

Non connect

Switch at output destination of surround channel

O

Test tone control

O

Control at output destination of LFE channel

O

Non connect

Mute of the digital out terminal is controlled

O

Mute of the audio signal is controlled

O

Non connect

Selection of digital input selector

O

Test terminal

Non connect

-

1-9

Page 10

RX-6010VBK/ RX-6012VSL

AK4527BVQ (IC601) : A/D,D/A Converter

1.Pin layout

LOOP1

LOOP0/SDA/CDTI

DIF1/SCL/CCLK

DIF0/CSN

P/S

MCLK

DZF1

AVSS

AVDD

VREFH

VCOM

SDOS

I2C

SMUTE

BICK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

2. Pin function (1/2)

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Pin name

SDOS

I2C

SMUTE

BICK

LRCK

SDTI1

SDTI2

SDTI3

SDTO

DAUX

DFS

NC

DZEF

TVDD

DVDD

DVSS

PDN

TST

4443424140393837363534

1

2

3

4

5

6

7

8

9

10

11

I/O

I

SDTO Source Select Pin (Note 1)

AK4527BVQ

T op Vie w

1213141516171819202122

NC

DZFE

TVDD

DVDD

DVSS

PDN

TSTNCADIF

Function

CAD1

CAD0

33

32

31

30

29

28

27

26

25

24

23

DZF2/OVF

RIN+

RINLIN+

LINROUT1

LOUT1

ROUT2

LOUT2

ROUT3

LOUT3

"L" : Internal ADC output, "H" : DAUX input

I

Control Mode Select Pin

"L" : 3-wire Serial, "H" : I

I

Soft Mute Pin (Note 1)

2

C Bus

When this pin goes to "H", soft mute cycle is initialized.

When returning to "L", the output mute releases.

I

Audio Serial Data Clock Pin

I/O

Input Channel Clock Pin

I

DAC1 Audio Serial Data Input Pin

I

DAC2 Audio Serial Data Input Pin

I

DAC3 Audio Serial Data Input Pin

O

Audio Serial Data Output Pin

I

Sub Audio Serial Data Input Pin

I

Double Speed Sampling Mode Pin (Note 1)

"L" : Normal Speed, "H" : Double Speed

-

No Connect

No internal bonding.

I

Zero Input Detect Enable Pin

"L" : mode 7 (disable) at parallel mode,

zero detect mode is selectable by DZFM2-0 bits at serial mode.

"H" : mode 0 (DZF is AND of all six channels)

-

Output Buffer Power supply Pin, 2.7V~5.5V

-

Digital Power Supply Pin, 4.5V~5.5V

-

De-emphasis Pin, 0V

I

Power-Down & Reset Pin

When "L", the AK4527B is powered-do wn and the control registers are reset to def ault

state. If the state of P/S or CAD0-1 changes, then the AK4527B m ust be reset b y PDN.

I

Test Pin

This pin should be connected to DVSS.

AK4527(1/2)

1-10

Page 11

RX-6010VBK/ RX-6012VSL

Pin function (2/2)

No.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Pin name

NC

ADIF

CAD1

CAD0

LOUT3

ROUT3

LOUT2

ROUT2

LOUT1

ROUT1

LINLIN+

RINRIN+

DZF2

OVF

34

35

36

37

38

39

40

41

VCOM

VREFH

AVDD

AVSS

DZF1

MCLK

P/S

DIF0

CSN

42

DIF1

SCL/CCLK

43

LOOP0

SAD/CDTI

44

LOOP1

No Connect

I/O

No internal bonding.

-

Function

Analog Input Format Select Pin

"H" : Full-differential input, "L" : Single-ended input

I

Chip Address 1 Pin

Chip Address 0 Pin

I

DAC3 Lch Analog Output Pin

I

DAC3 Rch Analog Output Pin

O

DAC2 Lch Analog Output Pin

O

DAC2 Rch Analog Output Pin

O

DAC1 Lch Analog Output Pin

O

DAC1 Rch Analog Output Pin

O

Lch Analog Negative Input Pin

O

Lch Analog Positive Input Pin

I

Rch Analog Negative Input Pin

I

Rch Analog Positive Input Pin

I

Zero Input Detect 2 Pin (Note 2)

I

When the input data of the group 1 follow total 8192LRCK cycles with "0" input data,

O

this pin goes to "H".

Analog Input Overflow Detect Pin (Note 3)

This pin goes to "H" if the analog input of Lch or Rch is overflows.

O

Common Voltage Output Pin,AVDD/2

Large external capacitor around 2.2uF is used to reduce power-supply noise.

O

Positive Voltage Reference Input Pin,AVDD

Analog Power Supply Pin,4.5V~5.5V

I

Analog Ground Pin,0V

Zero Input Detect 1 Pin (Note 2)

When the input data of the group 1 follow total 8192 LRCK cycles with "0" input data,

O

this pin goes to "H".

Master Clock Input Pin

Parallel / Serial Select Pin

I

"L" : Serial control mode, "H" : Parallel control mode

I

Audio Data Interface Format 0 Pin in parallel mode

Chip select pin in 3-wire serial control mode

I

This pin should be connected to DVDD at I2C bus control mode

I

Audio Data Interface Format 1 Pin in parallel mode

Control Data Clock Pin in serial control mode

I

I2C = "L" : CCLK(3-wire Serial), I2C = "H" : SCL(I2CBus)

I

Loopback Mode 0 Pin in parallel control mode

Enables digital loop-back from ADC to 3 DACs.

I

Control Data Input Pin in serial control mode

I2C = "L" : CDTI(3-wire Serial), I2C = "H" : SDA(I2CBus)

I/O

Loopback Mode 1 Pin (Note 1)

Enable all 3 DAC channels to be input from SDTII.

I

AK4527(1/2)

Notes : 1. SDOS, SMUTE, DFS, and LOOP1 pins are ORed with register data if P/S = "L".

2. The group 1 and 2 can be selected by DZFM2-0 bit if P/S = "L" and DZFME = "L".

3. This pin becomes OVF pin if OVFE bit is set to "1" at serial control mode.

4. All input pins should not be left floating.

1-11

Page 12

RX-6010VBK/ RX-6012VSL

M62446FD(IC428) : 6CH Master volume

1.Block Diagram

OUT4

OUT3

OUT2

OUT1

AVDD

SWIN

GNDS

SRin

SLin

GNDC

Cin

GNDR

Rin

GNDL

Lin

BYPASSR

BYPASSL

LTRE

LBASS3

LBASS2

LBASS1

10

11

12

13

14

15

16

17

18

19

20

21

1

2

3

4

5

6

7

8

9

OUTPUT

PORT

tone

volume

volume

volume

volume

volume

volume

MCU

I/F

tone

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

DVDD

CLK

DATA

LATCH

DGND

AGND

SWout

SRout

SLout

Cout

Rout

Lout

AVSS

CL1

CL2

CR1

CR2

RTRE

RBASS3

RBASS2

RBASS1

1-12

Page 13

2.Pin Function

RX-6010VBK/ RX-6012VSL

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16,17

18

19~21

22

23,24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Symbol I/O Descriptions

SURROUND

BASS BOOST

INPUT-ATT

MUTING

AVDD

SWIN

A.GND

RR IN

RL IN

A.GND

C IN

A.GND

R IN

A.GND

L IN

BYPASSR,L

LTRE

LBASS3~1

CR2

RBASS2,4

RTRE

RBASS1

CR1

CL2

CL1

AVSS

L OUT

R OUT

C OUT

RL OUT

RR OUT

SW OUT

A.GND

D.GND

VOL STB

VOL DATA

VOL CLK

DVDD

O

O

O

O

I

I

I

I

I

I

-

-

-

O

-

-

I

O

I

O

O

O

O

O

O

-

-

I

I

I

-

SURROUND control terminal

BASS BOOST control terminal

Input attenuator control terminal

MUTING control terminal

Analog positive power supply terminal

SUB Woofer volume signal input terminal

Analog ground terminal

R ch volume signal input terminal for rear speaker

L ch volume signal input terminal for rear speaker

Analog ground terminal

Center volume signal input terminal

Analog ground terminal

R ch volume signal input terminal

Analog ground terminal

L ch volume signal input terminal

Non connect

Frequency adjustment terminal tone/treble

Frequency adjustment terminal tone/bass

Tone output terminal

Frequency adjustment terminal tone/bass

Frequency adjustment terminal tone/treble

Frequency adjustment terminal tone/bass

L/R volume input terminal

Tone output terminal

L/R volume input terminal

Analog negative power supply terminal

L ch output

R ch output

Center volume signal output terminal

L ch volume signal output terminal for rear speaker

R ch volume signal output terminal for rear speaker

SUB Woofer volume signal output terminal

Analog ground terminal

Digital ground terminal

Latch input terminal

Volume data input terminal

Clock input terminal for data transfer

Digital power supply terminal

1-13

Page 14

RX-6010VBK/ RX-6012VSL

MN101C35DHK1 (IC701) : System controller

100 76

1

75

Pin function (1/2)

Pin No.

1

TXD/SB00/P00

2

3

4

5

6

7

8

9,10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

RNOUT/TM0I0/P10

28

29

30

31

32

33

34

SENS/IRQ1/P21

35

36

37

38

39

40

25

26 50

Symbol

RXD/SBI0/P01

SBT0/P02

SB01/P03

SBI1/P04

SBT1/P05

BUZZER/P06

VDD

OSC1,2

VSS

XI

X0

MMOD

VREFAN0/PA0

AN1/PA1

AN2/PA2

AN3/PA3

AN4/PA4

AN5/PA5

AN5/PA5

AN5/PA5

VREF+

P07

RST /P27

TM1I0/P11

TM2I0/P12

TM3I0/P13

TM4I0/P14

P15

IRQ0/P20

IRQ2/P22

IRQ3/P23

IRQ4/P24

P25

SB02/P30

SBI2/P31

51

I/O

I

I

I/O

O

O

I

I

-

I/O

I

O

I

I

I

I

I

I

I

I

I

I

I

O

I

O

I

O

I/O

I

I

I

I

I

I

O

I

Function

VOL.JOG IN_1

VOL.JOG IN_2

DATA (PLL)

CLK (PLL)

DE (PLL)

VIDEO S/C DVD

VIDEO S/C VCR

Power supply +5V

OSC (8MHz)

GND

GND

OPEN

GND

GND

KEY INPUT 1 (7KEY)

KEY INPUT 2 (7KEY)

KEY INPUT 3 (7KEY)

KEY INPUT 4 (7KEY)

KEY INPUT 5 (7KEY)

INH IN

CHIP SELECT 1

CHIP SELECT 2

Power supply +5V

VIDEO S/C DBS

RESET INPUT

RDS CLK OUT (RDS)

DCS INPUT

DCS OUTPUT

A VLINK VCR IN

A VLINK VCR OUT

RDS DATA (RDS)

PROTECTOR IN

REMOCON INPUT

TUNED IN (TUNER)

STEREO IN (TUNER)

RDS DAVN (RDS)

SELF CHECK INPUT

COMMAND (DSP)

STATUS (DSP)

1-14

Page 15

Pin function (2/2)

RX-6010VBK/ RX-6012VSL

Pin No.

41

42

43

44

45

46

47

48

49 64

65 80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Symbol

SBT2/P32

P50

P51

P52

P53

P54

DGT17/P67

DGT16/P66

G16 G1

P87 P90

SEG24/PC2

SEG25/PC1

SEG26/PC0

SEG27/PB7

SEG28/PB6

SEG29/PB5

SEG30/PB4

SEG31/PB3

SEG32/PB2

SEG33/PB1

SEG34/PB0

SEG35/PD7

SEG36/PD6

SEG37/PD5

SEG38/PD4

SEG39/PD3

SEG40/PD2

SEG41/PD1

SEG42/PD0

VPP

I/O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Function

CLK (DSP)

READY (DSP)

RESET (DSP)

RELAY S

RELAY C

RELAY L/R 1

RELAY L/R 2

RELAY HEADPHONE

FL GRID SIGNAL CONTROL OUT

FL SEGMENT SIGNAL CONTROL OUT

LED8 SIGNAL CONTROL OUT (FM/AM)

LED7 SIGNAL CONTROL OUT (TV/DBS)

LED6 SIGNAL CONTROL OUT (TAPE/CDR)

LED5 SIGNAL CONTROL OUT (VCR)

LED4 SIGNAL CONTROL OUT (CD)

LED3 SIGNAL CONTROL OUT (DVD)

LED2 SIGNAL CONTROL OUT (PHONO)

LED1 SIGNAL CONTROL OUT (DVD MULTI)

SOUSE MUTE

SUBWOOFER MUTE

TUNER MUTE

POWER ON (STANDBY)

SURROUND

DATA (A.SW)

CLK (A.SW)

STB (A.SW)

LATCH (A.SW)

DATA (VOL)

CLK (VOL)

VPP

1-15

Page 16

RX-6010VBK/ RX-6012VSL

LA1838 (IC102) : FM AM IF amp &detector, FM MPX decoder

1. Block Diagram

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin Function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

28

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

Function

DET

TUNING

DRIVE

5

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tuning, this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

6

24

STEREO

DRIVE

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

L OUT

17

R OUT

18

19

20

21

22

23

24

25

26

27

28

29

30

L IN

R IN

RO

LO

IF IN

FM OUT

AM DET

AM AGC

AFC

AM RF

REG

AM OSC

OSC BUFFER

21

DECODER

ANIT-BIRDIE

VCO

384KHz

10

20

STEREO

5N

SW

FF

38k

11

I/O

O

Left channel signal output.

O

Right channel signal output.

Input terminal of the left channel post

I

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

14

AMP.

Input terminal of the right channel

I

post AMP.

Mpx Right channel signal output.

O

O

Mpx Left channel signal output.

I

Mpx input terminal

FM detection output.

O

AM detection output.

O

This is an AGC voltage input terminal

I

for AM

I

This is an output terminal of voltage

for FM-AFC.

AM RF signal input.

I

Register value between pin 26 and pin28

O

desides the frequency width of the

input signal.

I

This is a terminal of AM Local

oscillation circuit.

AM Local oscillation Signal output.

O

15

1-16

Page 17

LC72136N (IC121) : PLL frequency synthesizer

1. Pin layout

FM/AM

CLOCK

FM/ST/VCO

AM/FM

2. Block diagram

XT

CE

DI

DO

SDIN

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

RX-6010VBK/ RX-6012VSL

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

LW

MW

SDIN

Reference

Driver

Swallow Counter

1/2

C

2

B

I/F

Power

on

Reset

Function

I/O

X'tal oscillator connect (75kHz)

I

LOW:FM mode

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

782

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

Open state after the power on reset

O

Input/output port

I/O

Input/output port

I/O

Data input/output

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

11

13

Pin

Symbol

No.

IFIN

12

IFCONT

13

14

AMIN

15

FMIN

16

VCC

17

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

18

PD

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

19

20

21

22

LPFIN

LPFOUT

GND

XT

I

Output for active lowpassfilter of PLL

O

Connected to GND

X'tal oscillator(75KHz)

I

1-17

Page 18

RX-6010VBK/ RX-6012VSL

TC9162AF (IC423) : Analog switch

VSS

L-S1

L-S2

L-COM1

L-S3

L-S4

L-COM2

L-S5

L-S6

L-COM3

L-S7

L-COM4

ST

GND

L-S1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VDD

R-S1

R-S2

R-COM1

R-S3

R-S4

R-COM2

R-S5

R-S6

R-COM3

R-S7

R-COM4

DATA

CK

VSS

GND VDD

1

14

28

27

R-S1

L-S2

L-COM1

L-S3

L-S4

L-COM2

L-S5

L-S6

L-COM3

L-S7

L-COM4

ST

3

4

5

6

7

8

9

10

11

12

13

LEVEL SHIFTER

LATCH CIRCUIT

LATCH CIRCUIT

LEVEL SHIFTER

26

25

24

23

22

21

20

19

18

17

16

R-S2

R-COM1

R-S3

R-S4

R-COM2

R-S5

R-S6

R-COM3

R-S7

R-COM4

DATA

1-18

SHIFT REGISTER

15

CK

Page 19

RX-6010VBK/ RX-6012VSL

TC9446F-014 (IC631) : Digital signal processor for dolby digital (AC-3)

/ MPEG2 audio decode

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8~11

12

13

14

15

16~18

19

20

21

22

23

24

25

26

27,28

29~31

32,33

34

35

36

37

38,39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54~61

62

63~70

71

72~80

81

82~89

90

91

92,93

94

95

96

97

98,99

100

RST

MIMD

MICS

MILP

MIDIO

MICK

MIACK

FI0~3

IRQ

VSS

LRCKA

BCKA

SDO0~2

SD03

LRCKB

BCKB

SDT0

SDT1

VDD

LRCKOA

BCKOA

TEST0,1

LRCKOB,BCKOB,TXO

TEST2,3

RX

VSS

TSTSUB0

FCONT

TSTSUB1,TSTSUB2

PDO

VDDA

PLON

AMPI

AMPO

CKI

VSSA

CKO

LOCK

VSS

WR

OE

CE

VDD

IO7~0

VSS

AD0~7

VDD

AD8~16

VSS

PO0~7

VDDDL

LPFO

DLON,DLCKS

SCKO

VSSDL

SCKI

VSSX

XO,XI

VDDX

Reset signal input terminal (L:reset H:Operation usually)

I

Microcomputer interface mode selection input terminal (L:serial H:IC bus)

I

Microcomputer interface chip select input terminal

I

Microcomputer interface latch pulse input

I

Microcomputer interface data I/O terminal

I/O

Microcomputer interface clock input terminal

I

Microcomputer interface acknowledge output terminal

O

Flag input terminal 0~3

I

Interrupt input terminal

I

Digital ground terminal

Audio interface LR clock input terminal A

I

Audio interface bit clock input terminal A

I

Audio interface data output terminal 0

O

Non connect

Audio interface LR clock input terminal B

I

Audio interface bit clock input terminal B

I

Audio interface data input terminal 0

I

Audio interface data input terminal 1

I

Power supply for digital circuit

Audio interface LR clock output terminal A

O

Audio interface bit clock output terminal A

O

Test input terminal 0/1 (L:test H:operation usually)

I

Non connect

Test input terminal (L:test H:operation usually)

I

SPDIF input terminal

I

Ground terminal for digital circuit

Test sub input terminal 0 (L:test H:operation usually)

I

VCO Frequency control output terminal

O

Test sub input terminal 1,2 (L:test H:operation usually)

I

Phase error signal output terminal

O

Power supply for analog circuit

Clock selection input terminal (L:external clock H:VCO clock)

I

AMP.input terminal for LPF

I

AMP.output terminal for LPF

O

External clock input terminal

I

Ground terminal for analog circuit

DIR Clock output terminal

O

VCO Lock detection output terminal

O

Ground terminal for digital circuit

External SRAM writing signal output terminal

O

External SRAM output enable signal output terminal

O

External SRAM chip enable signal output terminal

O

Power supply terminal for digital circuit

External SRAM data I/O terminal 7~0

I/O

Ground terminal for digital circuit

External SRAM address output terminal 0~7

O

Power supply terminal for digital circuit

External SRAM address output terminal 8~16

O

Ground terminal for digital circuit

General purpose output terminal 0~7

O

Power supply terminal for DLL

LPF output terminal for DLL

O

Refer to the undermentioned table

I

Non connect

Ground terminal for DLL

External system clock input terminal

I

Ground termonal for oscillation circuit

Oscillation I/O terminal

I/O

Power supply terminal for oscillation circuit

-

DLCKS terminal

L

L

H

H

DLONterminal

L

H

L

H

DLL clock setting

SCKI input (DLL circuit OFF)

Four times XI clock

Three times XI clock

Six times XI clock

1-19

Page 20

RX-6010VBK/ RX-6012VSL

AS7C31025-15 (IC641) : CMOS SRAM

1. Pin layout

32-pin TSOP II

A0

A1

A2

A3

CE

I/O0

I/O1

Vcc

GND

I/O2

I/O3

WE

A4

A5

A6

A7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

AS7C1025

AS7C31025

22

21

20

19

18

17

A16

A15

A14

A13

OE

I/O7

I/O6

GND

Vcc

I/O5

I/O4

S12

A11

A10

A9

A8

2. Block diagram

Vcc

GND

A0

A1

A2

A3

A4

A5

A6

A7

A8

BA15218F (IC427, 609, 610, 650, 651,

661, 690, 691) : Op amp.

Input buffer

512x256x8

Array

(1,048,576)

Row decoder

Column decoder

A9

A10

I/O7

A11

A12

A13

A14

A15

Sense amp

Control

circuit

A16

I/O0

WE

OE

CE

BA15218N (IC403) : Dual ope. amp.

1OUT1

2-IN1

1

3+IN1

+

-

2

EE

4

+

BU4066BCF (IC611) : Switch

1.Terminal Layout

14 13 12 11 10 9 8

8

7

6

5V

V

CC

OUT2

-IN2

+IN2

+

+

1

-

1 2 3 4 5 6 7 8

OUT1 +IN1 +IN1

+IN2 -IN2 OUT2

GND

2

-

2.Block Diagram

VDD

C1

C4

I/O 4

O/I 4

O/I 3

14 13 12 11 10 9 8

Vcc

I/O 3

1-20

1 2 3 4 5 6 7

1 2 3 4 5 6 7

C2

I/O 1

O/I 1

O/I 2

I/O 2

C3

VSS

Page 21

NJM2246D (IC501) : Video switch

GND

8

Vout

7

V+

6

Vin3

5

RX-6010VBK/ RX-6012VSL

6dB

AMP.

BIAS

1

Vin1

2

CTL1

3

Vin2

4

CTL2

PQ3DZ53 (IC681) : Regulator IC

Control input - output signal

CTL 1

L

H

L/H

CTL 2

L

L

H

Output

VIN 1

VIN 2

VIN 3

DC INPUT(Vin)

1

CUSTOM IC

5

GND

RN5RZ33BA (IC683) : Voltage regurator

2

CE

VDD

Vref

5

-

+

Current Limit

3

DC OUTPUT(Vo)

ON/OFF CONTROL(Vc)

2

VOUT

3

GND

1

1-21

Page 22

RX-6010VBK/ RX-6012VSL

TC7SET32FU (IC672) : Z-Input or gate

IN B

IN A

GND

1

2

3

54VCC

OUT Y

TC7SU04FU (IC621, 622) : High speed CMOS inverter

NC

IN A

GND

1

2

3

5

4

VCC

OUT Y

TC9164AN (IC402) : Analog switch

1.Function

Switch to On/Off of S1 to S8 by control of LSI.

2.Terminal Lay out & Block Diagram

TC9164AN

VSS

L-S1

S-2

S-3

S-4

COM-1

S-5

S-6

COM-2

S-7

S-8

COM3

ST

GND

1

2

3

4

SHIFT

5

RESISTOR

6

7

8

9

10

11

12

13

14

&

LATCH

SHIFT RESISTOR

SHIFT

RESISTOR

&

LATCH

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VDD

R-S1

S-2

S-3

S-4

COM-1

S-5

S-6

COM-2

S-7

S-8

COM3

DATA

CK

1-22

Page 23

< MEMO >

RX-6010VBK/RX-6012VSL

1-23

Page 24

RX-6010VBK/6012VSL

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.20988)

200106(V)

Loading...

Loading...