Page 1

SERVICE MANUAL

AUDIO/VIDEO CONTROL RECEIVER

2203820034

RX-5032VSL

MASTER VOLUME

DIMMER

INPUT ATT

TA/NEWS/INFO

DISPLAY MODE

RXÐ6030V

STANDBY

STANDBY/ON

PHONES

DIGITAL

PRO LOGIC

AUDIO/VIDEO CONTROL RECEIVER

INPUT DIGITAL

INPUT ANALOG

Area Suffix

E ----- Continental Europe

EN ----- Northern Europe

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.22038

2003/4

Page 2

SECTION 1

Important Safety Precautions

1.1 Safety Precautions

(1) This d esign of this product co ntains special hardware and

many circuits and components specially for safety purposes.

For continued protection, no changes should be made to the

original design unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations o f the design or circuitry of the p roduct should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, watt age, etc. Replacement parts which have these special safety

characteristics are identified in the Parts List of Service Manual. Electrical components having such feat ures are id en tified by shading on the schematics and by ( ) on the

Parts List in the Service Manual. The use of a substitute replacement which does not have the same safety characteristics as the recommended replacement parts shown in the

Parts List of Service Manual may create shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the origin al lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing)

After reassembling the product, always perform an isolation

check on the exposed metal parts of the product (antenna

terminals, knobs, metal cabinet, screw heads, headphone

jack, control shafts, etc.) to be sure the product is safe to

operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC

voltmeter having, 1,000 ohms per volt or more sensitivity in

the following manner. Connect a 1,500 ohm 10W resistor

paralleled by a 0.15 µF AC-type capacitor between an

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75

V AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the leg al responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components a re replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety.

When replacing them, be sure to use the parts o f the same type

and rating as specified by the manufacturer. (Except the JC version)

1-2 (No.22038)

Page 3

SECTION 2

y

Disassembly method

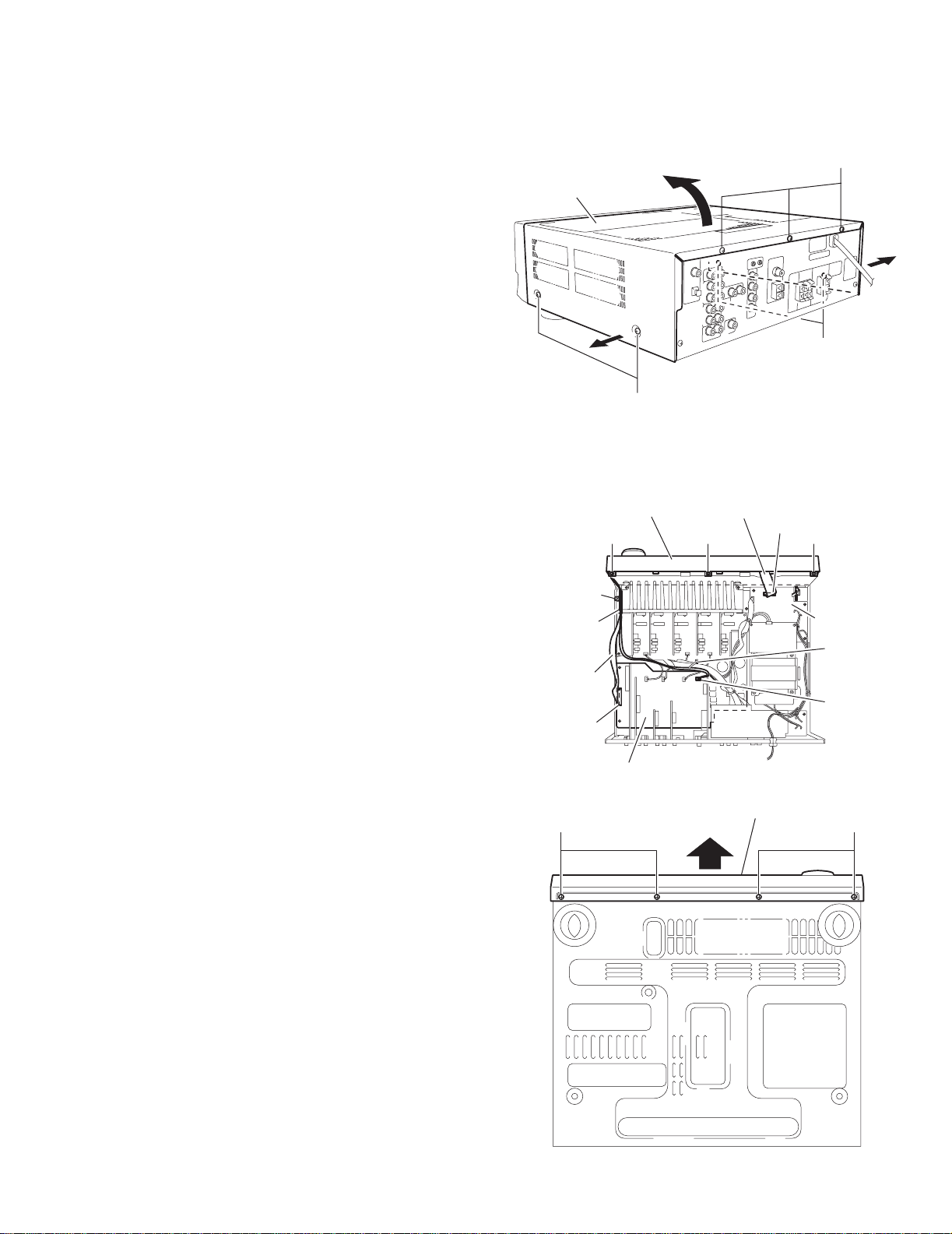

2.1 Removing the top cover

(See Fig.1)

(1) From the righ t and left sid es of the main body, remove the

four screws A attaching the top cover.

(2) From the back side of the main body, remove the three

screws B attaching the top cover.

(3) Remove th e top cover in the direction of the arrow 2 whi le

extending the lower sections of the top cover in the direction of the arrow 1.

Top cover

2

B

1

2.2 Removing the front panel assembly

(See Figs.2 and 3)

• Prior to performing the following procedure, re move the top

cover.

(1) Disconnect the card wire from the connector CN402 on the

audio board. (See Fig.2)

(2) Disconnect the card wire from the connector CN201 on the

power supply board. (See Fig.2)

(3) Remove the tie band and wire protection board fixing the

card wire. (See Fig.2)

(4) Remove the tie band fixing the parallel wires, disconnect

the parallel wire from the connector CN403 on the audio

board. (See Fig.2)

(5) Remove the three screws C attaching the front panel as-

sembly. (See Fig.2)

(6) From the b ottom side of the main body, remove the four

screws D attaching the front panel assembly. (See Fig.3)

(7) Remove the front panel assembly in the direction of the ar-

row. (See Fig.3)

1

A

A

Fig.1

Front panel assembly

C C C

Tie band

Wire protection

board

Card wire

CN402

Audio board

Card wire

CN201

Power suppl

board

Tie band

CN403

Fig.2

Front panel assembly

DD

Fig.3

(No.22038)1-3

Page 4

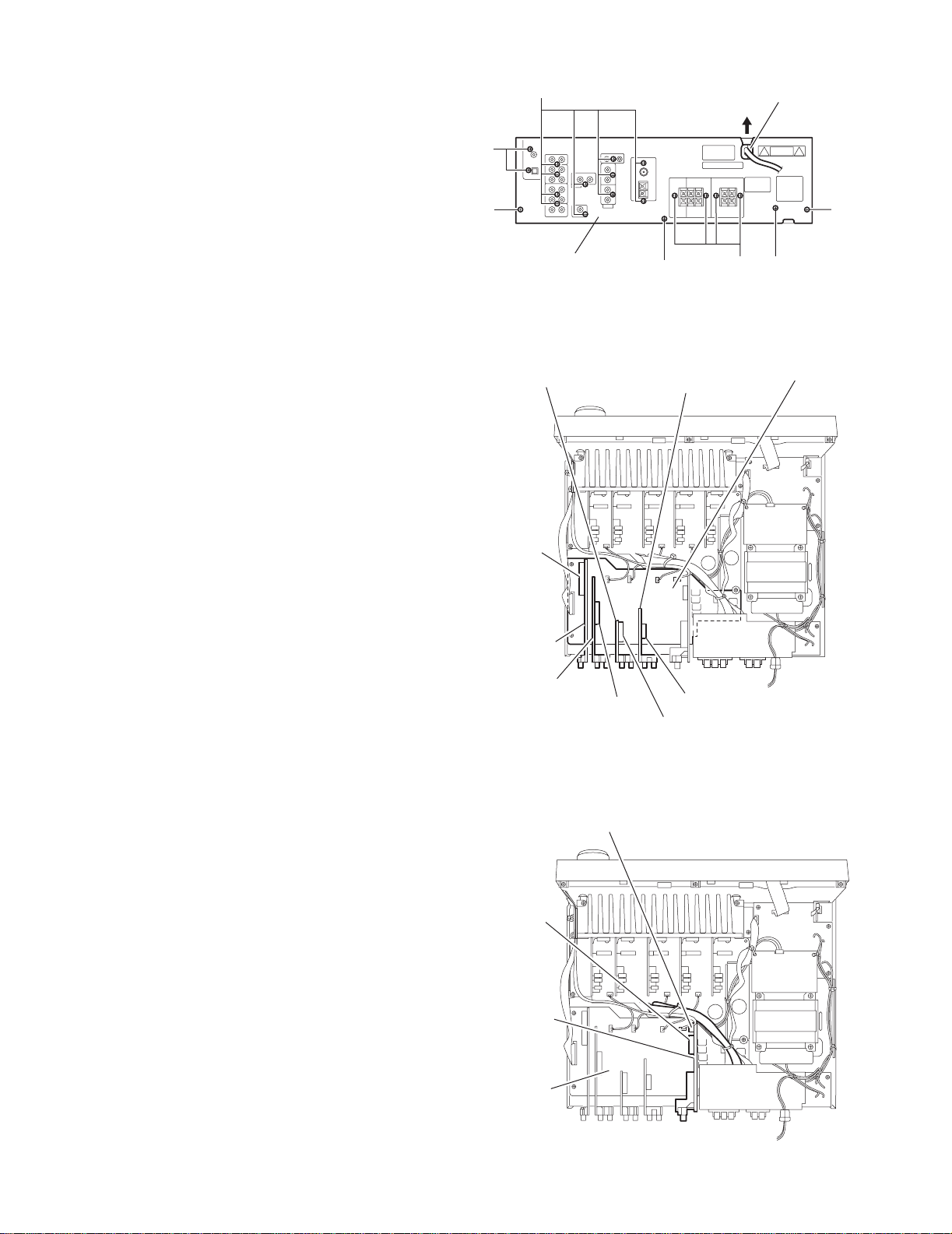

2.3 Removing the rear panel

A

A

(See Fig.4)

• Prior to performing the following procedure, remove the top

cover.

(1) From the back side of the main body, remove the strain re-

lief from the rear panel in the direction of the arrow.

(2) Remove the seventeen screws E and four screws F attach-

ing the rear panel.

E

F

E

Strain relief

F

Rear panel

2.4 Removing the DSP board, audio input board, DVD board and video board

(See Fig.5)

• Prior to performing the following procedure, remove the top

cover and rear panel.

(1) From the top side of the main body, disconnect the DSP

board from the connector CN481 on the audio board.

(2) Disconnect the audio input board from the connector

CN421 on the audio board.

(3) Disco nnect the DVD board from the connector CN431 on

the audio board.

(4) Disco nnect the video bo ard from the connector CN44 1 on

the audio board.

DVD board

CN481

DSP board

udio input board

CN421

Fig.4

Video board

CN441

CN431

Fig.5

EFF

Audio board

2.5 Removing the tuner board

(See Fig.6)

• Prior to performing the following procedure, remove the top

cover and rear panel.

(1) Disconnect the tuner board from the connectors CN411

and CN412 on the audio board.

1-4 (No.22038)

CN412

CN411

Tuner board

udio board

Fig.6

Page 5

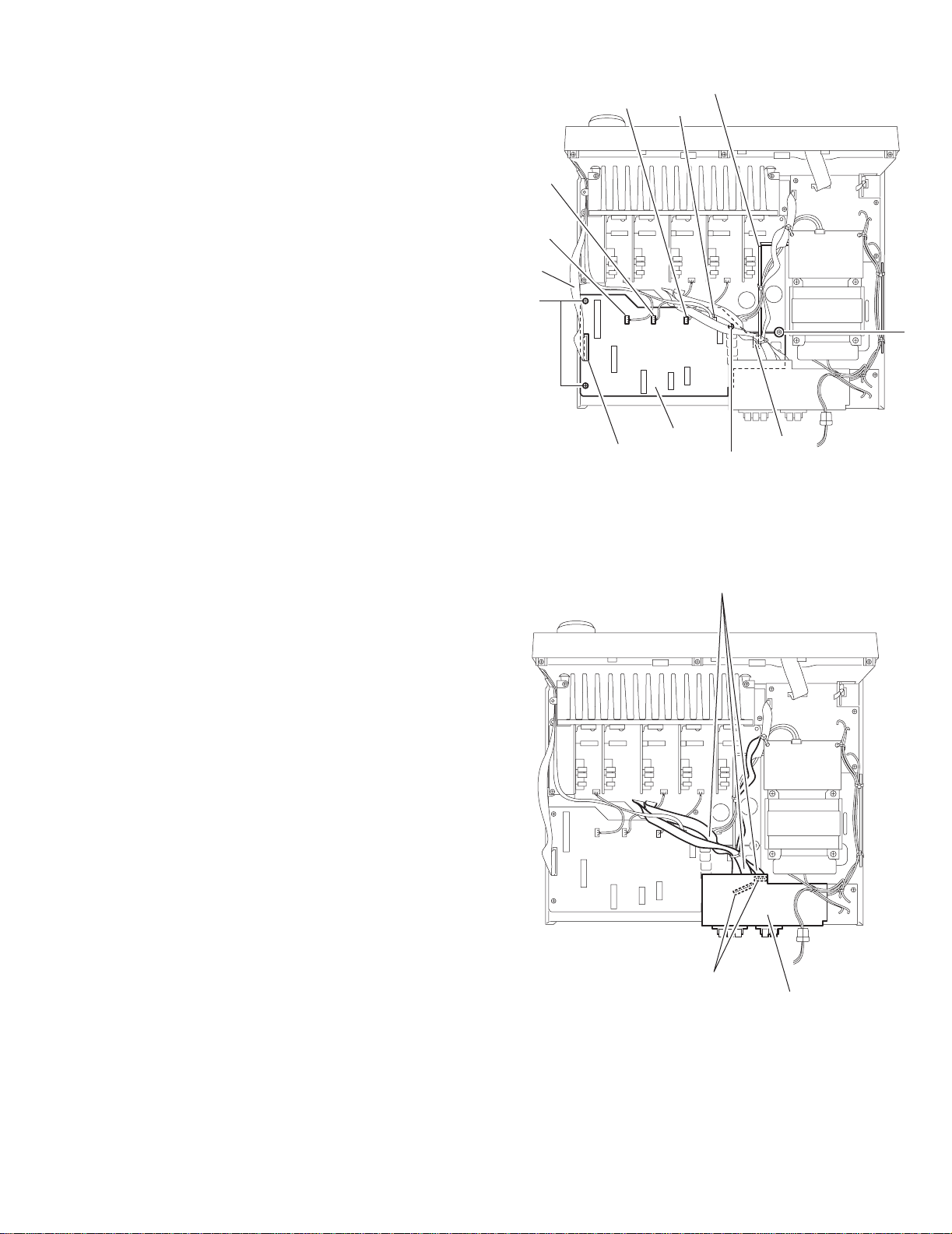

2.6 Removing the audio boar d

(See Fig.7)

• Prior to performing the following procedure, re move the top

cover, rear panel, DSP board, audio input board, DVD board,

video board and tuner board.

(1) From the top side of the main body, disconnect the card

wire from the connector CN402 on the audio board.

(2) Disconnect the parallel wire from the connector CN403.

(3) Disconn ect the relay board from the connector CN4 91 on

the power supply board and audio board.

(4) Disconn ect the wires from the con nectors CN471, CN472

and CN473 on the audio board.

(5) Remove the three screws G attaching the audio board.

(6) Loosen the screw H attaching the audio board.

CN471

CN473

rd wire

G

CN472

Relay board

CN403

2.7 Removing the speaker terminal board

(See Fig.8)

• Prior to performing the following procedure, re move the top

cover and rear panel.

(1) From th e top side of the main body, remove the solders

from the soldered sections a on the speaker terminal

board.

CN402

Audio board

Fig.7

Parallel wires

CN491

G

Soldered sections a

Fig.8

Speaker terminal board

(No.22038)1-5

Page 6

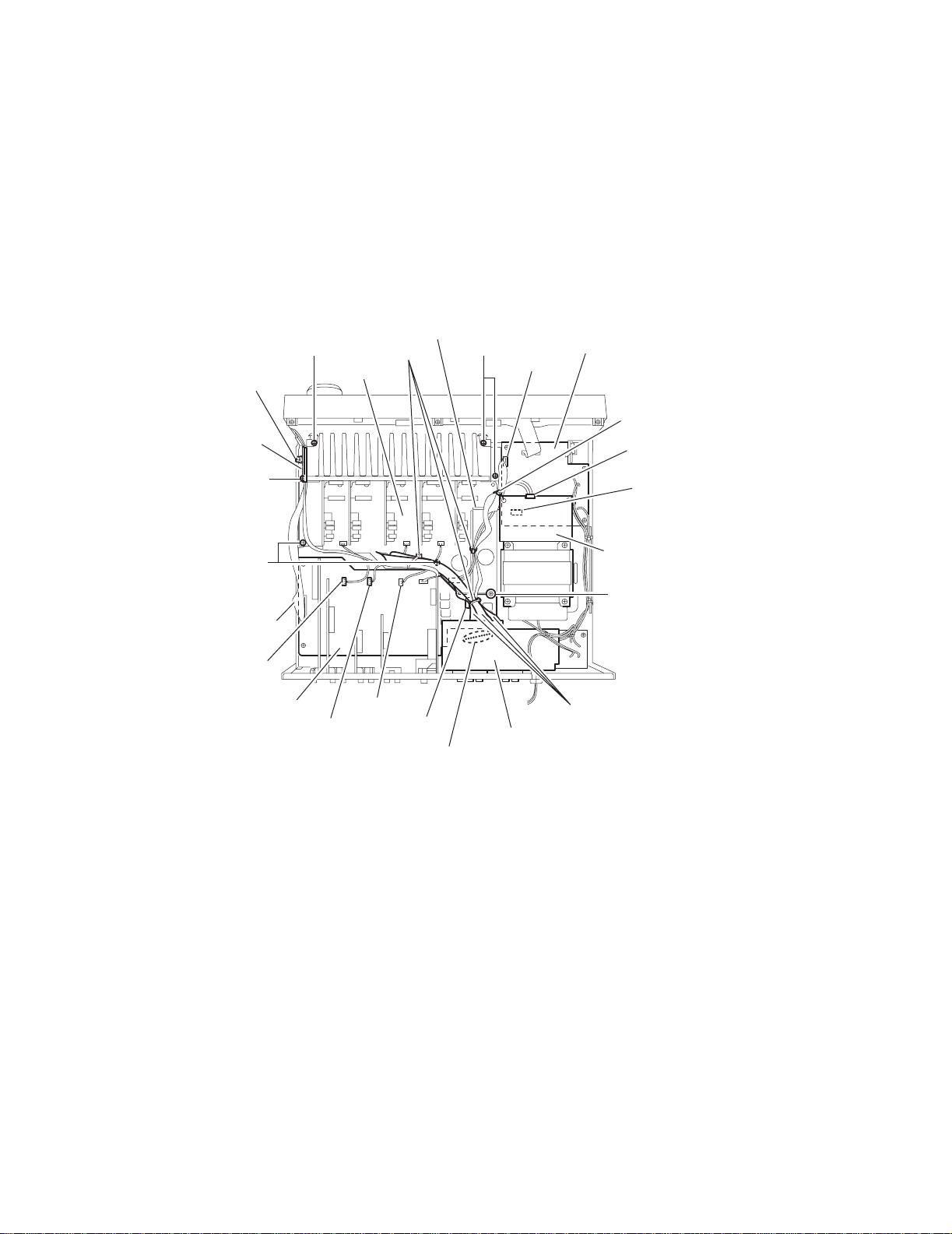

2.8 Removing the main board

r

(See Fig.9)

• Prior to performing the following procedure, remove the top cover.

(1) From the top side of the main body, remove the tie bands fixing the wires.

(2) Remo v e the tie band and wire protection board fixing the card wire.

(3) Remov e the solders from the soldered section b on the speaker terminal board attaching the parallel wires.

(4) Di sco nnect the relay board from the connectors (CN291, CN491) on the power supply board and audio board.

(5) Disco nnect the parallel wire from the connector CN241 on the power supply board.

(6) Disco nnect the wire from the connector CN251 on the power transformer board 1.

(7) Disconnect the wires from the connectors CN471, CN472 and CN473 on the audio board.

(8) Remove the screw H, two screws J and four screws K attaching the main board.

(9) Take out the main board.

Relay board

Power supply board

CN241

Tie band

CN251

Tie band

Wire protection

board

K

Main board

Tie bands

K

K

J

Card wire

CN473

Audio board

CN471

CN472

CN491

Soldered section b

Fig.9

CN291

Power transforme

board 1

H

Parallel wires

Speaker terminal board

1-6 (No.22038)

Page 7

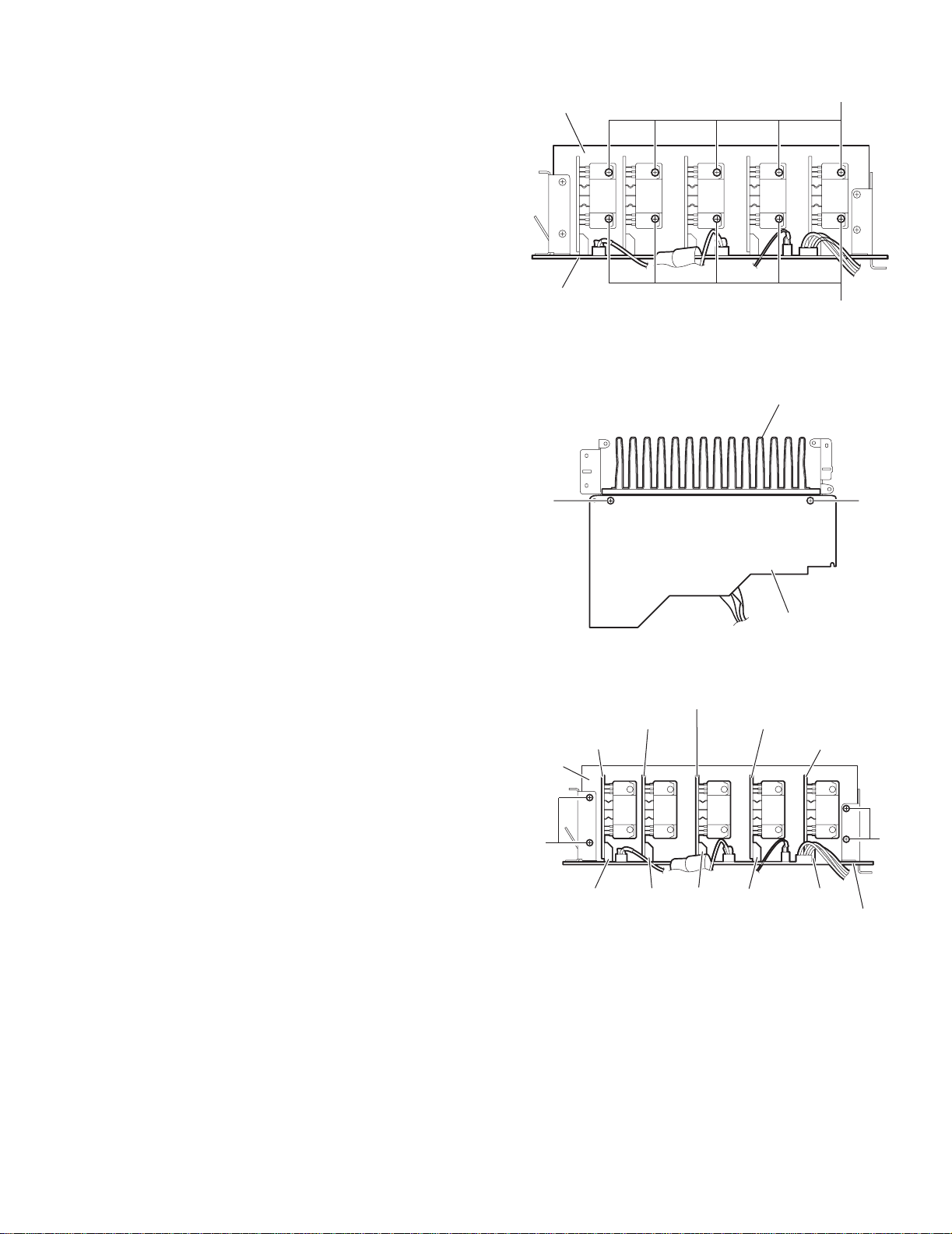

2.9 Removing the heat sink

(See Figs.10 and 11)

• Prior to performing the following procedure, re move the top

cover and main board.

(1) Remove the ten screws L attaching the heat sink. (See

Fig.10)

(2) From the reverse side of the main board, re move the two

screws M attaching the heat sink. (See Fig.11)

2.10Removing the center amp. board, front amp. boards (L /

R) and rear amp. boards (L/R)

(See Figs.10 and 12)

• Prior to performing the following procedure, re move the top

cover and main board.

(1) Remove the ten screws L attaching the heat sink. (See

Fig.10)

(2) Remove the four screws N attachin g the heat sink. (See

Fig.12)

(3) Disconnect the center amp. board from the connector

CN321 on the main board. (See Fig.12)

(4) Disconnect the front amp. board (L) from the connector

CN311 on the main board. (See Fig.12)

(5) Disconn ect the front amp. board (R) from the connector

CN312 on the main board. (See Fig.12)

(6) Disconnect the rear amp. board (L) from the connector

CN331 on the main board. (See Fig.12)

(7) Disconnect the rear amp. board (R) from the connector

CN332 on the main board. (See Fig.12)

Heat sink

Main board

M

L

L

Fig.10

Heat sink

M

Rear amp. board (L)

Rear amp. board (R)

Heat sink

N

CN332 CN331 CN312 CN311 CN321

Main board

Fig.11

Front amp. board (R)

Front amp. board (L)

Center amp. board

N

Main board

Fig.12

(No.22038)1-7

Page 8

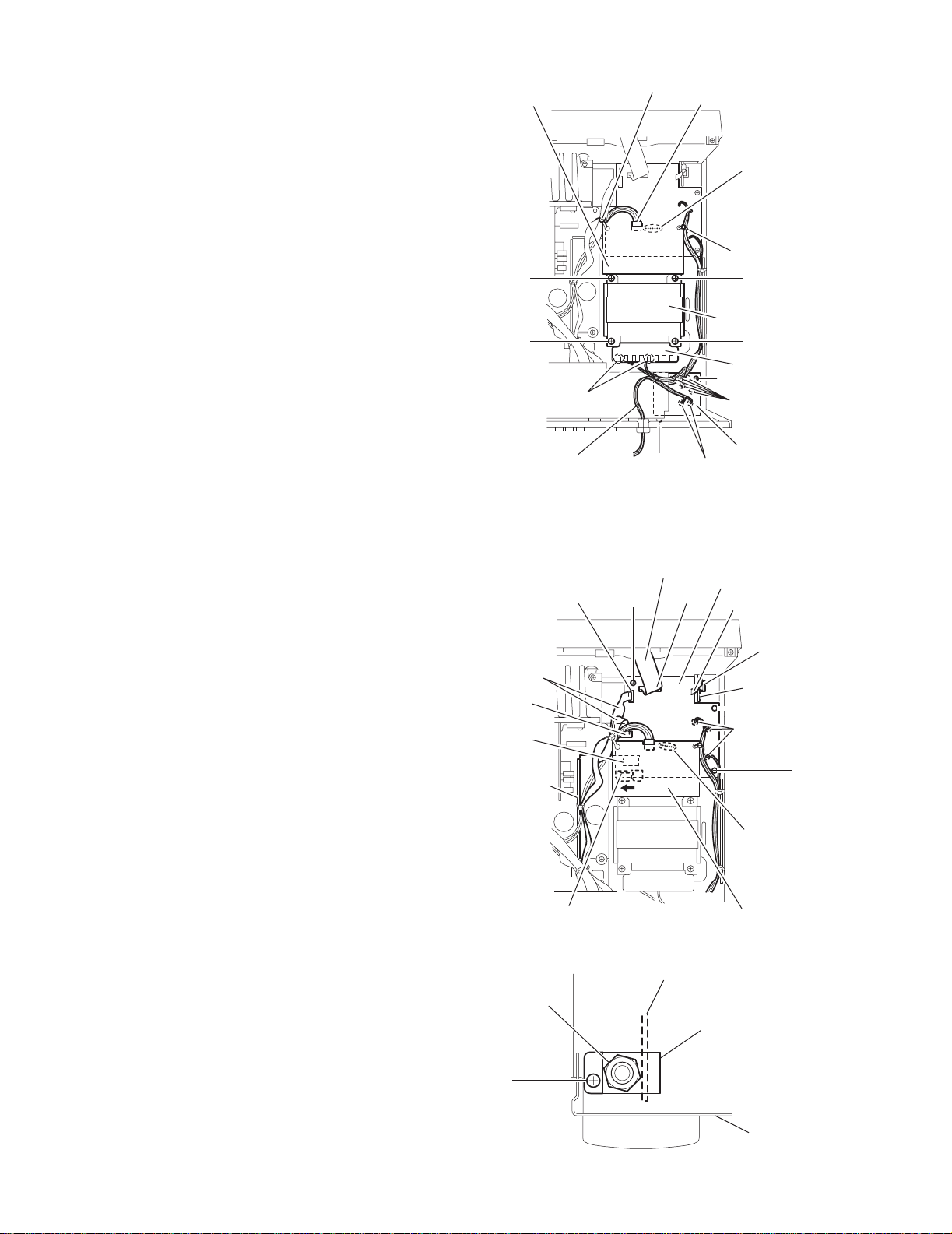

2.11Removing the power transformer

r

(See Fig.13)

• Prior to performing the following procedure, remove the top

cover.

(1) From the top side of the main b ody, remove the tie bands

fixing the wires.

(2) Remove the solders from the soldered section c on the

power transformer board 1.

(3) Remove the solders from the soldered sections d on the

power transformer board 2.

(4) Disconnect the wire from the connector CN251 on the pow-

er transformer board 1.

(5) Remov e the four screws P attaching th e power transform-

er.

2.12Removing the power/fuse board

(See Fig.13)

• Prior to performing the following procedure, remove the top

cover.

(1) From the back and top sides of the main body, remove the

screw Q and screw R attaching the power/fuse board.

(2) Remove the solders from the soldered sections e attaching

the power cord.

(3) From the reverse side of the power/fuse board, remove the

solders from the soldered sections f attaching the wires.

2.13Removing the power supply board

(See Fig.14)

• Prior to performing the following procedure, remove the top

cover.

(1) From the top side of the main body, disconnect the parallel

wires from the connectors CN203 and CN241 on the power

supply board.

(2) Disconnect the card wire from the connector CN201 on the

power supply board.

(3) Disco nnect the relay board from the connector CN291 on

the power supply board.

(4) Disco nnect the paral lel wire from the connecto r CN10 1 on

the headphone jack board and remove the tie band.

(5) Remove the solders from the soldered section c on the

power transformer board 1.

(6) Remove the three screws S attaching the power supply

board.

(7) Remo ve the power supply board from the hook g of the

chassis base bracket in the direction of the arrow, take out

the power supply board.

(8) Turn over the power supply board, remove the solders from

the soldered sections h attaching the wires.

2.14Removing the headphone jack board

(See Figs.14 and 15)

• Prior to performing the following procedure, remove the top

cover and front panel assembly.

(1) From the top side of the main body, disconnect the parallel

wire from the connector CN101 on the headphone jack

board. (See Fig.14)

(2) From th e front side of the main body, remove the nut and

screw T attaching the Bracket(phones) to the chassis base.

(See Fig.15)

Power transformer board 1

Tie band

P

P

Soldered sections d

Power cord

CN241

Parallel wires

CN203

CN291

Relay board

Hook g of the

chassis base bracket

Nut

S

T

CN251

Soldered section c

Tie band

P

Power transformer

P

Power transforme

board 2

R

Soldered sections f

Power / Fuse board

Soldered sections e

Q

Fig.13

Card wire

Fig.14

Headphone jack board

Power supply board

CN201

Power transformer board 1

Parallel wire

CN101

Headphone jack

board

Soldered section h

Soldered section c

Bracket(phones)

S

S

1-8 (No.22038)

Chassis base

Fig.15

Page 9

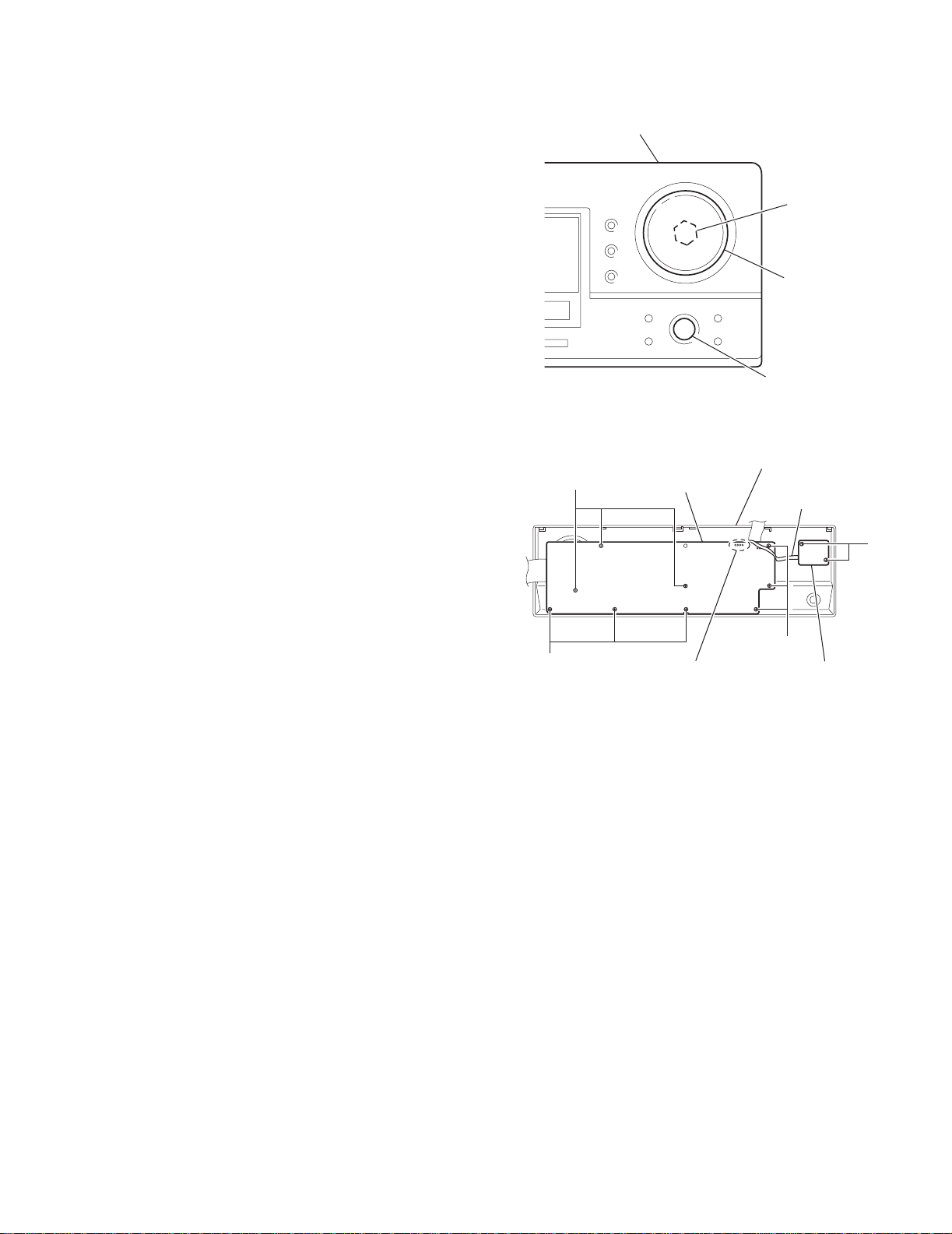

2.15Removing the system control board and power switch board

(See Figs.16 and 17)

• Prior to performing the following procedure, re move the top

cover and front panel assembly.

(1) Pull out the volume and jog knobs from the front side of the

front panel assembly, remove the nut attaching the system

control board. (See Fig.16)

(2) From the back side of the front panel assembly, remove the

nine screws U attaching the system control board. (See

Fig.17)

Reference:

Remove the solders of the soldered section I as required.

(3) Remove the solders of the soldered section i on the system

control board and disconnect the parallel wire. (See Fig.17)

(4) Remove the two screws V attaching the power switch

board. (See Fig.17)

Front panel assembly

U

System control board

Nut

Volume knob

Jog knob

Fig.16

Front panel assembly

Parallel wire

U

Soldered section i

Fig.17

V

U

Power switch board

(No.22038)1-9

Page 10

SECTION 3

Adjustment

3.1 Adjustment method

Tuner section

1. Tuner range

FM 87.5MHz to 108.0MHz

AM 522kHz to 1629kHz

Power amplifier section

Adjustment of idling current

Measurement location TP301 (Lch) , TP302 (Rch)

Adjustment part VR301 (Lch) , VR302 (Rch)

Attention

This adjustment does not obtain a correct adjustment value immediately after the amplifier is

used (state that an internal temperature has risen).

Please adjust immediately after using the amplifier after turning off the power supply of the

amplifier and falling an internal temperature.

<Adjustment method>

1. Set the volume control to minimum during this adjustment. (No signal & No load)

2. Set the surround mode OFF.

3. Turn VR301 and VR302 fully counterclockwise to warm up before adjustment.

If the heat sink is already warm from previous use the correct adjustment can not be made.

4. For L-ch, connect a DC voltmeter between TP301's B216 and B217 (Lch)

and, connect it between TP302's B218 and B219 (Rch).

5. Adjust the VR301 (Lch) and VR302 (Rch) so that the DC voltmeter indicates 2.0mV

immediately after turning the power on.

* It is not abnormal though the idling current might not become 0mA even if it is finished to turn variable

resistance (VR301, VR302) in the direction of counterclockwise.

VR301 (Lch)

Front amp. board (L)

TP301

VR301

CN301

TP301 (Lch)

VR302 (Rch)

Front amp. board (R)

TP302

VR302

CN302

TP302 (Rch)

1-10 (No.22038)

Page 11

SECTION 4

8

Description of major ICs

4.1 LP61L1024S-12-X (IC641) : SRAM

• Pin layout • Block diagram

DD

NC

A16

A14

A12

I/O1

I/O2

I/O3

Vss

1

2

3

4

5

A7

6

A6

7

A5

8

A4

9

A3

10

A2

11

A1

12

A0

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

A15

CS2

WE

A13

A8

A9

A11

OE

A10

CS1

I/O8

I/O7

I/O6

I/O5

I/O4

DD

• Pin function

I/O1 - I/O8 Data Input/Output

CS1

V

Vss

A0

A16

CS2

CS1

OE

WE

SYMBOL DESCRIPTION

A0 - A16 Address Input

, CS2 Chip Select Inputs

WE

OE

VDD Power Supply

Vss Ground

NC No Connection

DECODER

CONTROL

Write Enable Input

Output Enable Input

CORE

ARRAY

DATA I/O

I/O1

I/O

(No.22038)1-11

Page 12

4.2 AK4527BVQP (IC601): A/D, D/A converter

• Pin layout

4443424140393837363534

1

2

3

4

5

6

7

8

9

10

11

1213141516171819202122

Top View

• Pin function

No. Symbol I/O Function

1 SDOS I SDTO Source Select Pin (Note 1)

"L" : Internal ADC output "H" : DAUX input

2 OSKS I Control Mode Select Pin

"L" : 3-wire Serial "H" : I2C Bus

3 MIS - Soft Mute Pin (Note 1) Connect to GND

When this pin goes to "H" soft mute cycle is initialized.

When returning to "L" the output mute releases.

4 BICK I Audio Serial Data Clock Pin

5 LRCK I/O Input Channel Clock Pin

6 SDTI1 I DAC1 Audio Serial Data Input Pin

7 SDTI2 I DAC2 Audio Serial Data Input Pin

8 SDTI3 I DAC3 Audio Serial Data Input Pin

9 SDTO O Audio Serial Data Output Pin

10 D,AUX - Sub Audio Serial Data Input Pin Connect to GND

11 DFS - Double Speed Sampling Mode Pin (Note 1)

"L" : Normal Speed "H" : Double Speed

12 DEMI - Connect to GND

No internal bonding.

13 DEMO - Zero Input Detect Enable Pin Connect to GND

"L" : mode 7 (disable) at parallel mode

- zero detect mode is selectable by DZFM2-0 bits at serial mode.

- H : mode 0 (DZF is AND of all six channels)

14 MCKO - Output Buffer Power supply Pin 2.7V~5.5V

15 DVDD I Digital Power Supply Pin 4.5V~5.5V

16 DVSS - De-emphasis Pin 0V

17 PD

I Power-Down & Reset Pin

When "L" the AK4527B is powered-down and the control registers are reset to default state.

If the state of P/S or CAD0-1 changes then the AK4527B must be reset by PDN.

18 XTS - Test Pin Connect to GND

This pin should be connected to DVSS.

19 ICKS - Connect to GND No internal bonding.

20 ADIF - Analog Input Format Select Pin Digital Power Supply

H : Full-differential input "L" : Single-ended input

21 CAD1 - Chip Address 1 Pin Connect to GND

33

32

31

30

29

28

27

26

25

24

23

1-12 (No.22038)

Page 13

No. Symbol I/O Function

22 CAD0 O Chip Address 0 Pin Connect to GND

23 LOUT3 O DAC3 Lch Analog Output Pin

24 ROUT3 O DAC3 Rch Analog Output Pin

25 LOUT2 O DAC2 Lch Analog Output Pin

26 ROUT2 O DAC2 Rch Analog Output Pin

27 LOUT1 O DAC1 Lch Analog Output Pin

28 ROUT1 O DAC1 Rch Analog Output Pin

29 LIN- I Lch Analog Negative Input Pin

30 LIN+ I Lch Analog Positive Input Pin

31 RIN- I Rch Analog Negative Input Pin

32 RIN+ I Rch Analog Positive Input Pin

33 VREFL - Zero Input Detect 2 Pin (Note 2) Non Connect

When the input data of the group 1 follow total 8192LRCK cycles with "0" input data this pin

goes to "H".

OVF O Analog Input Overflow Detect Pin (Note 3)

This pin goes to "H" if the analog input of Lch or Rch is overflows.

34 VCOM O Common Voltage Output PinAVDD/2

Large external capacitor around 2.2uF is used to reduce power-supply noise.

35 VREFH - Positive Voltage Reference Input PinAVDD

36 AVDD - Analog Power Supply Pin4.5V~5.5V

37 AVSS - Analog Ground Pin0V

38 XTI - Zero Input Detect 1 Pin (Note 2) Non connect

When the input data of the group 1 follow total 8192 LRCK cycles with "0" input data this pin

goes to "H".

39 XTO I Master Clock Input Pin

40 P1S - Parallel / Serial Select Pin

"L" : Serial control mode "H" : Parallel control mode

41 CS

CSN I Chip select pin in 3-wire serial control mode

42 DIF1 I Audio Data Interface Format 1 Pin in parallel mode

SCL/CCLK I Control Data Clock Pin in serial control mode

43 LOOP0 I Loopback Mode 0 Pin in parallel control mode

SAD/CDTI I/O Control Data Input Pin in serial control mode

44 CDTD I Loopback Mode 1 Pin (Note 1)

Note:

(1) SDOS, SMUTE, DF S, and LOOP1 pins are ORed with register data if P/S = "L".

(2) The group 1 and 2 can be selected by DZFM2-0 bit if P/S = "L" and DZFME = "L".

(3) Thi s pin become s OVF pin if OVFE bit is set to "1" at serial control mode.

(4) All input pins should not be left floating.

I Audio Data Interface Format 0 Pin in parallel mode

This pin should be connected to DVDD at I2C bus control mode

I2C = "L" : CCLK(3-wire Serial) I2C = "H" : SCL(I2CBus)

Enables digital loop-back from ADC to 3 DACs.

I2C = "L" : CDTI(3-wire Serial) I2C = "H" : SDA(I2CBus)

Enable all 3 DAC channels to be input from SDTII.

(No.22038)1-13

Page 14

4.3 BA15218F-XE (IC427,IC609,IC610,IC650,IC651,IC661,IC690,IC691) : Dual operation amplifier

• Pin layout

OUT1 1

-IN1 2

+IN1 3

VEE 4

• Block diagram

Vcc

-IN

+IN

1

2

R1

Q5

Q1

Q2

D1

Q3 Q4

8 Vcc

7 OUT2

6 -IN2

5 +IN2

C2

R5

Q6

Q9

Q8

Q10

Q7

R7

Q11

R6

Q12

R8

Q18Q13

OTHER

CH

Q19

Q17Q16

C1

VEE

4.4 BA15218N (IC403) : Dual Ope. Amp.

• Pin layout / Block diaglam

+

1

-

1 2 3 4 5 6 7 8

OUT1 +IN1 +IN1

GND

+

-

+IN2 -IN2 OUT2

R3R2

R4

Q14 Q15Q114

R9

OUTPUT

2

Vcc

1-14 (No.22038)

Page 15

4.5 GP1UM281X (IC703) : Dual operation amplifier

GND Vcc Vout

R

L

Amp

4.6 IC-PST9139-T(IC403) : Regulator

• Terminal layout

123

B.P.FLimiter

Demodulator

Integrator

Comparator

• Block diagram

4.7 IMX9-W (IC652, IC662, IC682): Driver

• Pin layout & Block diagram

C

1

B

2

E

3

6

5

4

CO1

E

B

C

VCC

2

OUT

1

OP1

GND

3

(No.22038)1-15

Page 16

4.8 LA1838 (IC102) : FM AM IF AMP&detector, FM MPX Decoder

• Block Diagram

30

ALC

BUFF

FM

S-METER

FM IF

1

29

AM

OSC

S-CLRVE

PM

DET

2

28

REG

AM

MIX

SD

COMP

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

25

24

DET

TUNING

DRIVE

5

6

STEREO

DRIVE

7

22

23

P-DET

VCC

89

VCO

384KHz

21

DECODER

ANIT-BIRDIE

10

20

STEREO

5N

SW

FF

38k

11

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

17 16

/LS

14

PILOT

DET

15

• Pin Function

Pin No. Symbol I/O Function

1 FM IN I This is an input terminal of FM IF signal.

2 AM MIX O This is an out put terminal for AM mixer.

3 FM IF I Bypass of FM IF

4 AM IF I Input of AM IF Signal.

5 GND - This is the device ground terminal.

6

7

TUNED

STEREO

O When the set is tunning,this terminal becomes "L".

O Stereo indicator output. Stereo "L", Mono: "H"

8 VCC - This is the power supply terminal.

9 FM DET - FM detect transformer.

10 AM SD - This is a terminal of AM ceramic filter.

11 FM VSM O Adjust FM SD sensitivity.

12 AM VSM O Adjust AM SD sensitivity.

13 MUTE I/O When the signal of IF REQ of IC121(LC72131) appear, the signal of FM/AM IF output. //Muting

control input.

14

15

FM/AM

MONO

/ST

I Change over the FM/AM input. "H" :FM, "L" : AM

O Stereo : "H", Mono: "L"

16 L OUT O Left channel signal output.

17 R OUT O Right channel signal output.

18 L IN I Input terminal of the Left channel post AMP.

19 R IN I Input terminal of the Right channel post AMP.

20 RO O Mpx Right channel signal output.

21 LO O Mpx Left channel signal output.

22 MPX IN I Mpx input terminal

23 FM OUT O FM detection output.

24 AM DET O AM detection output.

25 AM AGC I This is an AGC voltage input terminal for AM

26 AFC - This is an output terminal of voltage for FM-AFC.

27 AM RF I AM RF signal input.

28 REG O Register value between pin 26 and pin28 besides the frequency width of the input signal.

29 AM OSC - This is a terminal of AM Local oscillation circuit.

30 OSC BUFFER O AM Local oscillation Signal output.

1-16 (No.22038)

Page 17

4.9 LC72136N (IC121) : PLL frequency synthesizer

•Pin layout

1

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

SDIN

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

• Block diagram

1

22

16

15

3

4

5

6

17

21

1/2

C

I/F

2B

Power

on

Reset

Data Shift Register & Latch

7821113

• Pin function

Pin

Symbol I/O Function

No.

1 XT I X'tal oscillator connect (75kHz)

2FM

/AM O LOW:FM mode

3 CE I When data output/input for 4pin(input)

and 6pin(output): H

4 DI I Input for receive the serial d ata from

controller

5 CLOCK I Sync signal input use

6 DO O Data output for Controller Output port

7 FM/ST/VCO O Low: MW mode

8AM

/FM O Open state after the power on reset

9 LW I/O Input/output port

10 MW I/O Input/output port

11 SDIN I/O Data input/output

12 IFIN I IF counter signal input

Reference

Driver

Swallow Counter

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

Symbol I/O Function

No.

18

19

20

12

13 IFCONT O IF signal output

14 - Not use

15 AMIN I AM Local OSC signal output

16 FMIN I FM Local OSC signal input

17 VCC - Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

18 PD O PLL charge pump output (H: Local

OSC frequency Height than Reference frequency.L: Low Agreement:

Height impedance)

19 LPFIN I Input for active lowpassfilter of PLL

20 LPFOUT O Output for active lowpassfilter of PLL

21 GND - Connected to GND

22 XT

I X'tal oscillator(75KHz)

(No.22038)1-17

Page 18

4.10 M62446AFP-X (IC428): 6 channel electronic volume

• Pin layout & Block diagram

OUT4

OUT3

OUT2

OUT1

AVD D

SWin

GNDS

SRin

SLin

GNDC

Cin

GNDR

Rin

GNDL

Lin

BYPASSR

BYPASSL

LTR E

LBASS3

LBASS2

LBASS1

10

11

12

13

14

15

16

17

18

19

20

21

1

2

3

4

5

6

7

8

9

OUTPUT

PORT

tone

volume

volume

volume

volume

volume

volume

MCU

I/F

tone

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

DVDD

CLK

DATA

LATCH

DGND

AGND

SWout

SRout

SLout

Cout

Rout

Lout

AVS S

CL1

CL2

CR1

CR2

RTRE

RBASS3

RBASS2

RBASS1

1-18 (No.22038)

Page 19

• Pin function

Pin No. Symbol I/O Function

1 OUT4 O PORT output 4

2 OUT3 O PORT output 3

3 OUT2 O PORT output 2

4 OUT1 O PORT output 1

5 AVDD - Analog positive power supply terminal

6 SWin I Volume input

7 GNDS - Ground terminal

8 SRin I Volume input

9 SLin I Volume inp ut

10 GNDC - Ground termin al

11 Cin I Volume input

12 GNDR - Ground termin al

13 Rin I Tone input

14 GNDL - Ground terminal

15 Lin I Tone input

16 BYPASSR I R channel volume input

17 BYPASSL I L channel volume input

18 LTRE I Tone treble frequency adjusting terminal

19 LBASS3 I Tone bass frequency adjusting terminal

20 LBASS2 I Tone bass frequency adjusting terminal

21 LBASS1 I Tone bass frequency adjusting terminal

22 RBASS1 I Tone bass frequency adjusting terminal

23 RBASS2 I Tone bass frequency adjusting terminal

24 RBASS3 I Tone bass frequency adjusting terminal

25 RTRE I Tone treble frequency adjusting terminal

26 CR2 O Tone output terminal

27 CR1 I R channel volume input

28 CL2 O Tone output terminal

29 CL1 I L channel volume input

30 AVSS - Analog negative power supply terminal

31 Lout O L channel output

32 Rout O R channel output

33 Cout O Volume output

34 SLout O Volume output

35 SRout O Volume output

36 SWout O Volume output

37 AGND - Analog ground termi n al

38 DGND - Digital ground terminal

39 LATCH I Latch input terminal

40 DATA I Data input terminal

41 CLK I Data transfer clock input terminal

42 DVDD - Digital power supply terminal

(No.22038)1-19

Page 20

4.11 MM1563DF-X (IC681) : Regulator

• Pin layout

756

(TOP VIEW)

1

234

• Block diagram

V

IN

7

Bias

Cont

5

Thermal

shutdown

GND

3

• Pin function

Pin No. Symbol Function

1 Vo Output pin

2 NC Not connect

3 GND Ground

4 Cn Noise decrease pin

5 CON T Control pin

Driver

Current

limiter

4

Cn

Reference

Vo

1

CONT

H

L

Output

ON

OFF

6 Sub Substrate pin, The 6pin must be connected to GND.

7 VIN Input pin

1-20 (No.22038)

Page 21

4.12 MM1613DN-X (IC683) : Regulator

• Pin layout • Block diagram

Vin

5

54

(TOP VIEW)

1

23

Cont

GND

1

2

Bias

Reference

3

Cn

Driver

Thermal

shutdown

• Pin function

Pin No. Symbol Function

1 Cont ON/OFF Control pin

Cont

H

L

Vo

ON

OFF

Cont pin must be connected with VIN pin, if it is not used.

2 GND Ground

3 Cn Noise decrease pin, Connecting 0.01uF capacitor can decrease output noise.

4 Vout If the noise decrease capacitor is not connected, the pin may be influenced by outside noise.

Output pin, The capacitor must be connected with output pin more than 1uF.

5 V in In put pin

The capacitor is required to connect with input pin more than 1uF.

Current

limiter

Vout

4

4.13 MM74HC08SJ-X (IC611) : Quad. 2-input AND gates

• Pin layout & Block diagram

Vcc

A1

B1

Y1

A2

B2

Y2

GND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

B4

A4

Y4

B3

A3

Y3

(No.22038)1-21

Page 22

4.14 MM74HCU04SJ-X (IC621) : Inverter

• Pin Layout

11A

21Y

32A

14

13

12

VCC

6A

6Y

4.15 NC7ST32P5-X (IC672) : 2-Input OR Gate

• Pin layout & Block diagram • Truth table

Vcc Y

54

INPUTS OUTPUT

ABY

LLL

LHH

1

23

A B GND

HLH

HHH

H : HIGH logic level

L : LOW logic level

4.16 NJM2246D (IC501) : Video switch

• Pin layout & Block diaglam

GND

8

6dB

AMP.

Vout

7

V+

6

Vin3

5

Control input - output signal

CTL 1 CTL 2 Output

LLVIN 1

HLVIN 2

L/H H VIN 3

42Y

53A

63Y

7

11

10

9

8GND

5A

5Y

4A

4Y

1

Vin1

1-22 (No.22038)

2

CTL1

3

Vin2

BIAS

4

CTL2

Page 23

4.17 MN101C35DME (IC701) : System control & FL driver

•Pin layout

100 76

1

75

25

51

26 50

• Pin function

Pin No. Symbol I/O Function

1 TXD / SBO0 / P00 I VOL. JOG IN_1

2 RXD / SBI0 / P01 I VOL. JOG IN_2

3 SBT0 / P02 I/O DATA (PLL)

4 SBO1 / P03 O CLK (PLL)

5 SBI1 / P04 O CE (PLL)

6 SBT1 / P05 I VIDEO S/C DVD

7 BUZZER / P06 I VIDEO S/C VCR

8VDD-+5V

9 OSC2 O 8MHz oscillation te rmi na l

10 OSC1 I 8MHz oscillation terminal

11 VSS - Ground

12 XI I Connect to ground

13 XO O Not connect

14 MMOD I Connect to ground

15 VREF- - Ground

16 AN0 / PA0 I Key input 1 (7 key)

17 AN1 / PA1 I Key input 2 (7 key)

18 AN2 / PA2 I Key input 3 (7 key)

19 AN3 / PA3 I Key input 4 (7 key)

20 AN4 / PA4 I Key input 5 (7 key)

21 AN5 / PA5 I INH IN

22 AN6 / PA6 I Chip select 1

23 AN7 / PA7 I Chip select 2

24 VREF+ - +5V

25 P07 I VIDEO S/C DBS

26 /RST / P27 I Reset input

27 RMOUT / TM0IO / P10 O RDS CLK OUT (RDS)

28 TM1IO / P11 I DCS input

29 TM2IO / P12 O DCS output

30 TM3IO / P13 I AV link VCR input

31 TM4IO / P14 O AV link VCR output

32 P15 I/O RDS DATA (RDS)

33 IRQ0 / P20 I PROTECTOR IN

34 SENS / IRQ1 / P21 I Remocon input

35 IRQ2 / P22 I TUNED IN (TUNER)

36 IRQ3 / P23 I STEREO IN (TUNER)

37 IRQ4 / P24 I RDS DAVN (RDS)

38 P25 I Self check input

39 SBO2 / P30 O COMMAND (DSP)

40 SBI2 / P31 I STATUS (DSP)

41 SBT2 / P32 O CLK (DSP)

42 P50 I MULTI. JOG_1

43 P51 I MULTI. JOG_2

44 P52 O RELAY S

45 P53 O RELAY C

46 P54 O RELAY L/R 1

47 DGT17 / P67 O RELAY L/R 2

48 DGT16 / P66 O RELAY HEADPHONE

49 DGT15 / P65 O GRID 16

50 DGT14 / P64 O GRID 15

Pin No. Symbol I/O Function

51 DGT13 / P63 O GRID14

52 DGT12 / P62 O GRID13

53 DGT11 / P61 O GRID12

54 DGT10 / P60 O GRID11

55 DGT9 / P41 O GRID10

56 DGT8 / P40 O GRID9

57 SEG0 / DGT7 / P77 O GRID8

58 SEG1 / DGT6 / P76 O GRID7

59 SEG2 / DGT5 / P75 O GRID6

60 SEG3 / DGT4 / P74 O GRID5

61 SEG4 / DGT3 / P73 O GRID4

62 SEG5 / DGT2 / P72 O GRID3

63 SEG6 / DGT1 / P71 O GRID2

64 SEG7 / DGT0 / P70 O GRID1

65 SEG8 / P87 O SEGMENT1

66 SEG9 / P86 O SEGMENT2

67 SEG10 / P85 O SEGMENT3

68 SEG11 / P84 O SEGMENT4

69 SEG12 / P83 O SEGMENT5

70 SEG13 / P82 O SEGMENT6

71 SEG14 / P81 O SEGMENT7

72 SEG15 / P80 O SEGMENT8

73 SEG16 / P97 O SEGMENT9

74 SEG17 / P96 O SEGMENT10

75 SEG18 / P95 O SEGMENT11

76 SEG19 / P94 O SEGMENT12

77 SEG20 / P93 O SEGMENT13

78 SEG21 / P92 O SEGMENT14

79 SEG22 / P91 O SEGMENT15

80 SEG23 / P90 O SEGMENT16

81 SEG24 / PC2 O

82 SEG25 / PC1 O

83 SEG26 / PC0 O

84 SEG27 / PB7 O

85 SEG28 / PB6 O

86 SEG29 / PB5 O RESET (DSP)

87 SEG30 / PB4 O READY (DSP)

88 SEG31 / PB3 O POWER ON

89 SEG32 / PB2 O SOURCE MUTE

90 SEG33 / PB1 O SUBWOOFER MUTE

91 SEG34 / PB0 O TUNER MUTE

92 SEG35 / PD7 O STANDBY LED

93 SEG36 / PD6 O SURROUND

94 SEG37 / PD5 O DATA (A.SW)

95 SEG38 / PD4 O CLK (A.SW)

96 SEG39 / PD3 O STB (A.SW)

97 SEG40 / PD2 O LATCH (VOL)

98 SEG41 / PD1 O DATA (VOL)

99 SEG42 / PD0 O CLK (VOL)

100 VPP - VPP

(No.22038)1-23

Page 24

4.18 SAA6588 (IC191) : RDS Detector

• Terminal Layout • Pin Function

Pin

Symbol I/O Function

MRO

NC

GND

OSCO

OSCI

1

2

3

4

5

20

19

18

17

16

NC

CIN

SCOUT

Vref

MPX

No.

1 MRO O Multi-path rectifier output

2 NC - Non connect

3 GND I Test control input pin

4 OSCO O Oscillator output

5 OSCI I Oscillator input

6 VSSD - Digital ground (0V)

VSSD

VDDD

DAVN

SDA

SCL

6

7

8

9

10

15

14

13

12

11

VSSA

VDDA

NC

GND

NC

7 VDDD - Digital power supply (5V)

8 DAVN O Data available output (active LOW)

9 SDA I/O IC-bus serial data I/O

10 SCL I IC-bus serial clock input

11 NC - Non connect

12 GND - Connect to ground

13 NC - Non connect

14 VDDA - Analog power supply (5V)

15 VSSA - Connect to ground

16 MPX I Multiplex input signal

17 Vref O Reference voltag e output

18 SCOUT O Band-pass filter output

19 CIN O Comparator output

20 NC I Level input

• Block Diagram

MPX

AFIN

LVIN

VDDA

16

13

20

14

VSSA

SCOUT

57 kHz

8th ORDER

BAND-PASS

PAUSE

DETECTOR

POWER

SUPPLY

AND RESET

15

18

17

Vref

19

CLOCK

COMPARATOR

MULTI-PATH

DETECTOR

TEST

CONTROL

3

TCON

RDS/RDBS

DEMODULATOR

SIGNAL QUALITY

DETECTOR

OSCILLATOR

AND CLOCK

1

MRO

OSCI OSCO

VDDDCIN

7

DAVN

12

MAD

11

10

8

2

9

PSWN

MPTH

SDA

SCL

RDS/RDBS

DECODER

INTERFACE

REGISTER

IC-BUS SLAVE

TRANSCEIVER

5

4

6

VSSD

1-24 (No.22038)

Page 25

4.19 TC74HC4072AF-X (IC612) : OR gate

• Block diagram

1Y

1

1A

2

1B

3

1C

4

1D

5

NC

6

GND

7

4.20 TC9164AN (IC402) : Analog switch

• Pin layout & Block Diagram

R-S1

S-2

VDD

S-3

27

26

252824

S-4

&

SHIFT

RESISTOR

COM-1

23

LATCH

S-5

22

S-6

21

COM-2

20

14

13

12

11

10

9

8

S-7

19

Vcc

2Y

2D

2C

2B

2A

NC

S-8

18

• Truth table

ABCDY

HXXXH

XHXXH

XXHXH

XXXHH

LLLLL

X : Don't care

COM316DATA15CK

17

VSS

2

L-S1

3

S-2

415

S-3

&

SHIFT

RESISTOR

S-4

LATCH

6

OM-1

7

S-5

8

S-6

9

OM-2

10

S-7

11

S-8

SHIFT RESISTOR

12

13ST14

COM3

GND

(No.22038)1-25

Page 26

4.21 TC9162AF-X (IC423) : Analog switch

• Pin Layout

28272625242322212019181716

123

• Block Diagram

L-S1

L-S2

L-COM1

L-S3

L-S4

L-COM2

15

4

5

6

789

2

3

4

5

6

7

1011121314

VSS

1

GND VDD

14

28

27

26

25

24

23

22

R-S1

R-S2

R-COM1

R-S3

R-S4

R-COM2

L-S5

L-S6

L-COM3

L-S7

L-COM4

ST

8

9

10

11

12

13

LEVEL SHIFTER

LATCH CIRCUIT

SHIFT REGISTER

LATCH CIRCUIT

LEVEL SHIFTER

21

20

19

18

17

16

15

R-S5

R-S6

R-COM3

R-S7

R-COM4

DATA

CK

1-26 (No.22038)

Page 27

4.22 TC9446F-025 (IC631): Digital signal processor for dolby digital (AC-3) / DTS audio decode

• Pin Function

Pin No. Symbol I/O Function

1 RST I Reset signal input terminal (L:reset H: normal operation)

2 MIMD I Microcomputer interface mode selection input terminal (L:serial H:IC bus)

3 MICS I Microcomputer interface chip select input terminal

4 MILP I Microcomputer interface latch pulse input

5 MIDIO I/O Microcomputer interface data I/O terminal

6 MICK I Microcomputer interface clock input terminal

7 MIACK O Microcomputer interface acknowledge output terminal

8~11 FI0~3 I Flag input terminal 0~3

12 IRQ I Interrupt input terminal

13 VSS - Digital ground terminal

14 LRCKA I Audio interface LR clock input terminal A

15 BCKA I Audio interface bit clock input terminal A

16~18 SDO0~2 O Audio interface data output terminal 0

19 SD03 - Non connect

20 LRCKB I Audio interface LR clock input terminal B

21 BCKB I Audio interface bit clock input terminal B

22 SDT0 I Audio interface data input terminal 0

23 SDT1 I Audio interface data input terminal 1

24 VDD - Power supply for digital circuit

25 LRCKOA O Audio interface LR clock output terminal A

26 BCKOA O Audio interface bit clock output terminal A

27, 28 TEST0,1 I Test input terminal 0/1 (L:test H: normal operation)

29~30 LRCKOBBCKOB - Non connect

31 TXO O SPDIF Output

32, 33 TEST2,3 I Test input terminal (L:test H: normal operation)

34 RX I SPDIF input terminal

35 VSS - Ground terminal for digital circuit

36 TSTSUB0 I Test sub input terminal 0 (L:test H: normal operation)

37 FCONT O VCO Frequency control output terminal

38, 39 TSTSUB1TSTSUB2 I Test sub input terminal 12 (L:test H: normal operation)

40 PDO O Phase detect signal output terminal

41 VDDA - Power supply for analog circuit

42 PLON I Clock selection input terminal (L:external clock H:VCO clock)

43 AMPI I amplifier input terminal for LPF

44 AMPO O amplifier output terminal for LPF

45 CKI I External clock input terminal

46 VSSA - Ground terminal for analog circuit

47 CKO O DIR Clock output terminal

48 LOCK O VCO Lock output terminal

49 VSS - Ground terminal for digital circuit

50 WR O External SRAM writing signal output terminal

51 OE O External SRAM output enable signal output terminal

52 CE O External SRAM chip enable signal output terminal

53 VDD - Power supply terminal for digital circuit

54~61 IO7~0 I/O External SRAM data I/O terminal 7~0

62 VSS - Ground terminal for digital circuit

63~70 AD0~7 O External SRAM address output terminal 0~7

71 VDD - Power supply terminal for digital circuit

72~80 AD8~16 O External SRAM address output terminal 8~16

81 VSS - round terminal for digital circuit

82~89 PO0~7 O General purpose output terminal 0~7

90 VDDDL - Power supply terminal for DLL

91 LPFO O LPF output terminal for DLL

92, 93 DLON,DLCKS I Refer to the undermentioned table

94 SCKO - Non connect

95 VSSDL - Ground terminal for DLL

96 SCKI I External system clock input terminal

97 VSSX - Ground terminal for oscillation circuit

98, 99 XO,XI I/O Oscillation I/O terminal

100 VDDX - Power supply terminal for oscillation circuit

DLCKS terminal DLON terminal DLL clock setting

L L SCKI input (DLL circuit OFF)

L H Four times XI clock

H L Three times XI clock

H H Six times XI clock

(No.22038)1-27

Page 28

4.23 UPD784215AGC167 (IC671): Digital signal controller

• Pin layout

~

100 76

1

~

25

~

26 50

• Pin function

Pin No. Symbol I/O Function

1~8 - Non connect

9 VDD - Power supply terminal

10 X2 O Connecting the crystal oscillator for system main clock

11 X1 I Connecting the crystal oscillator for system main clock

12 VSS - Connect to GND

13 XT2 O Connecting the crystal oscillator for system sub clock

14 XT1 I Connecting the crystal oscillator for system sub clock

15 RESET I System reset signal input

16 AUT ODATA I Output of DSP to general-purpose port

17 LOCK I Output of DSP to general-purpose port

18 DIGITAL0 I Output of DSP to general-purpose port

19 FORMAT I Output of DSP to general-purpose port

20 CHANNEL I Ou tput of DSP to general-purpose port

21 ERR I Output of DSP to general-purpose port

22 REST IN I Reset signa l input

23 AVDD - Power supply terminal

24 AVREF0 - Connect to GND

25 - Connect to GND

26 - Connect to GND

27 - Connect to GND

28 - Connect to GND

29 - Connect to GND

30 - Connect to GND

31 - Connect to GND

32 - Connect to GND

33 AVSS - Connect to GND

34,35 - Non connect

36 AV REF1 - Power supply terminal

37 RX - Not use

38 TX - Not use

39 - Non connect

40 DSPCOM I Communication port from IC701

41 DSPSTS O Status communication port to IC701

42 DSPCLK I Clock input from IC701

43 DSPRDY I Ready signal input from IC701

44 - Non connect

75

~

51

1-28 (No.22038)

Page 29

Pin No. Symbol I/O Function

45 MIDIO IN I/O Interface I/O terminal with microcomputer

46 MIDIO OUT I/O Interface I/O terminal with microcomputer

47 MICK O Interface I/O terminal with microcomputer of clock signal

48 MICS O Interface I/O terminal with microcomputer of chip select

49 MILP O Interface I/O terminal with microcomputer

50 MIACK O Interface I/O terminal with microcomputer

51 - Non connect

52 - Non connect

53 DSPRST O Reset signal output of DSP

54~63 - Non connect

64 CODEC OUT I/O Interface I/O terminal with microcomputer

65 CODEC IN I/O Interface I/O terminal with microcomputer

66 CODEC CLK O Interface I/O terminal with microcomputer of clock signal

67 CODEC CS O Interface I/O terminal with microcomputer of chip select

68 CODEC XTS - Non connect

69 - Non connect

70 - Non connect

71 PD O Reset signal output

72 GND - Connect to GND

73 - Non connect

74 - Non connect

75 - Non connect

76 - Non connect

77 - Non connect

78 - Non connect

79 - Non connect

80 - Non connect

81 VDD - Power supply

82 - Non connect

83 - Non connect

84 ANA/T-TONE O Test tone control

85 LEF-MIX O Control at output destination of LFE channel

86 - Non connect

87 D.MUTE O Mute of the digital out terminal is controlled

88 S.MUTE O Mute of the audio signal is controlled

89 O Non connect

90 ASW1 O Selection of digital input selector

91 ASW2 - Selection of digital input selector

92 ASW3 - Selection of digital input selector

93 ASW4 - Selection of digital input selector

94 TEST - Test terminal

95 - Non connect

96 - Non connect

97 - Non connect

98 - Non connect

99 - Non connect

100 - Non connect

(No.22038)1-29

Page 30

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.22038)

Printed in Japan

WPC

Loading...

Loading...