Page 1

SERVICE MANUAL

INTEGRATED DIGITAL TERRESTRIAL LCD TELEVISION

YA683<Rev.001>20093SERVICE MANUAL

LT-19DA1BJ/AK, LT-19DA1BU/AK

COPYRIGHT © 2009 Victor Company of Japan, Limited

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

COPYRIGHT © 2009 Victor Company of Japan, Limited

No.YA683<Rev.001>

2009/3

Page 2

SPECIFICATION

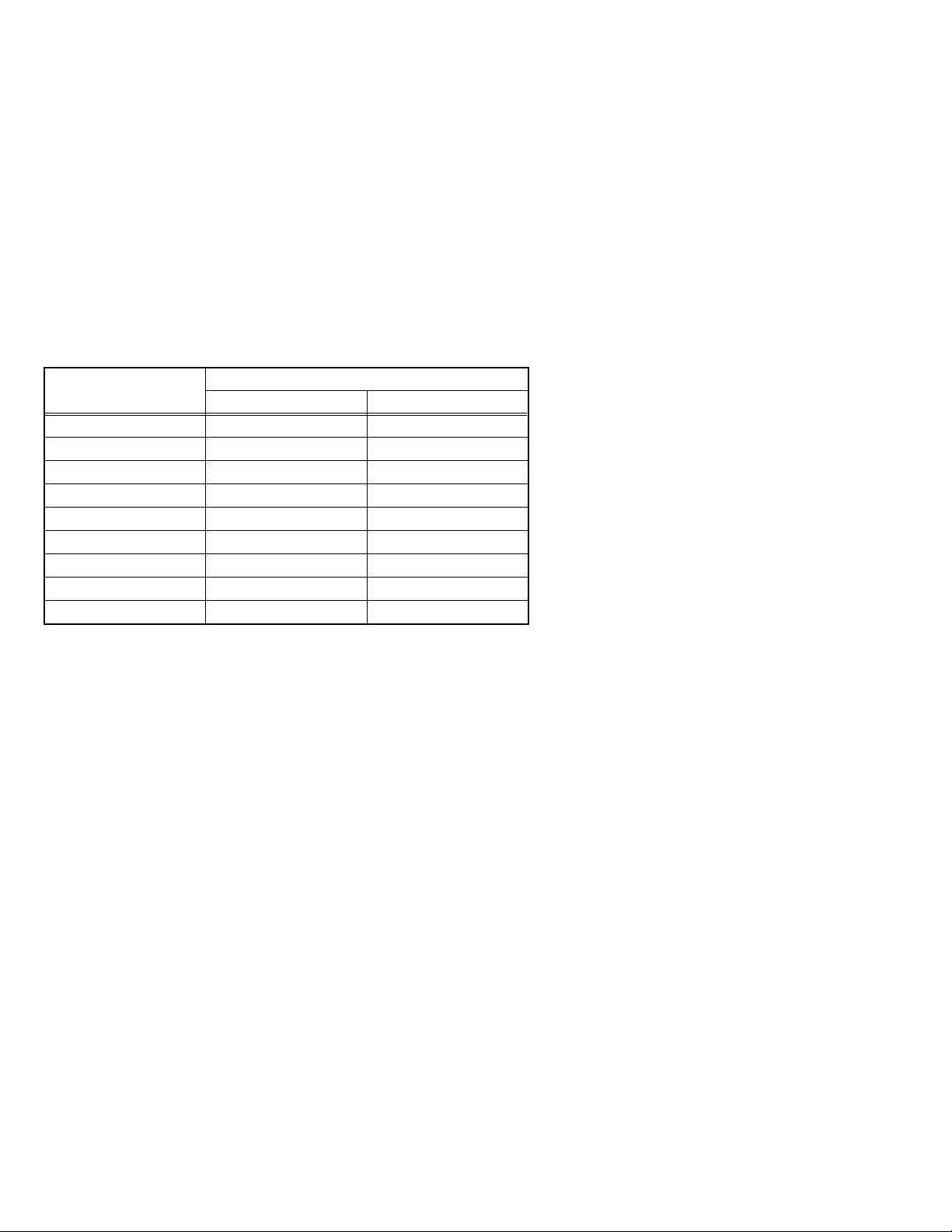

Items

Dimensions ( W × H × D ) 38.46 cm × 47.5 cm × 19.0 cm (With stand)]

34.53 cm × 47.5 cm × 9.45 cm (Without stand)]

Mass 4.4 kg (With stand)

4.1 kg (Without stand)

Power Input AC220V - AC240 V, 50 Hz

Power Consumption 68 W

TV RF System Analog CCIR (I) CCIR (B/G, I, D/K, L)

Digital DVB-T

Colour System PAL, SECAM, NTSC 3.58/4.43 [EXT only]

Stereo System NICAM (I) NICAM (B/G, I, D/K, L), A2 (B/G, D/K)

Receiving

Frequency

Intermediate

Frequency

Colour Sub

Carrier

Frequency

Teletext

System

LCD panel 19-inch wide aspect (16 : 10)

Screen Size Diagonal : 48.0 cm (H: 40.8 cm × V: 25.5 cm)

Display Pixels Horizontal : 1440 dots × Vertical : 900 dots

Audio Power Output 1 W + 1 W

Speaker 3.0 cm × 11.0 cm, oval type × 2

Aerial terminal (VHF/UHF) 75 Ω unbalanced, coaxial × 1

EXT-1

(Input)

EXT-2 (Input/Output) 21-pin Euro connector (SCART socket ) × 1

EXT-3

(Input)

EXT-4

(Digital Input)

EXT-5

(PC Input)

Headphone 3.5 mm stereo mini jack × 1

Remote Control Unit RM-C1893B (AA/R6 dry cell battery × 2)

Design & specifications are subject to change without notice.

Component Video

625p / 525p / 625i / 525i

Analog UHF: 470 MHz - 855.25 MHz VHF: 46.25 MHz - 470MHz

Digital UHF:474 MHz - 858 MHz

VIF 38.9MHz 38.9MHz (B/G, I, D/K, L)

SIF 32.9MHz (6.0MHz) 33.4MHz (5.5MHz:B/G)

PAL 4.43MHz

SECAM - 4.40625MHz / 4.25MHz

NTSC 3.58MHz / 4.43MHz

Analog FLOF (Fastext), TOP

Digital MHEG 5 UK profile EBU TEXT

S-Video Mini-DIN 4 pin × 1

Y: 1 V (p-p), Positive (Negative sync provided), 75 Ω

C: 0.286 V (p-p) (Burst signal), 75 Ω

Video 1V (p-p), Positive (Negative sync provided), 75 Ω, RCA pin jack × 1

Audio 500 mV (rms), High impedance, RCA pin jack × 2

RCA pin jack × 3

750p / 1125i

Video / Audio HDMI 2-row 19pin connector × 1

Y: 1 V (p-p) (Sync signal: ±0.35V(p-p), 3-value sync.), 75Ω / Pb/Pr: ±0.35V(p-p), 75 Ω

Y: 1 V (p-p), Positive (Negative sync.), 75 Ω / Cb/Cr: 0.7V(p-p), 75 Ω

Audio 500 mV(rms) (-4dBs), high impedance, RCA pin jack × 2

(Digital-input terminal is not compatible with picture signals of personal computer)

576i(625i),576p(625p),480i(525i),480p(525p),720p(750p),1080i(1125i) signals are available.

Video D-sub 15 pin × 1

R/G/B : 0.7 V (p-p), 75Ω

HD / VD : 1 V (p-p) to 5 V (p-p), high impedance

< Available signal >

VGA : 640 pixels × 480 pixels (Horizontal : 31.5 kHz / Vertical : 60 Hz)

SVGA : 800 pixels × 600 pixels (Horizontal : 37.9 kHz / Vertical : 60 Hz)

XGA : 1024 pixels × 768 pixels (Horizontal : 48.4 kHz / Vertical : 60 Hz)

WXGA : 1360 pixels × 768 pixels (Horizontal : 47.8 kHz / Vertical : 60 Hz)

LT-19DA1BJ LT-19DA1BU

Contents

UHF: 470 MHz - 855.25 MHz

CATV: 116MHz - 172MHz / 220MHz - 469MHz

32.9MHz (6.0MHz:I)

32.4MHz (6.5MHz:D/K)

1-2 (No.YA683<Rev.001>)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS [EXCEPT FOR UK]

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(6) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the cabinet (antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance rated up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

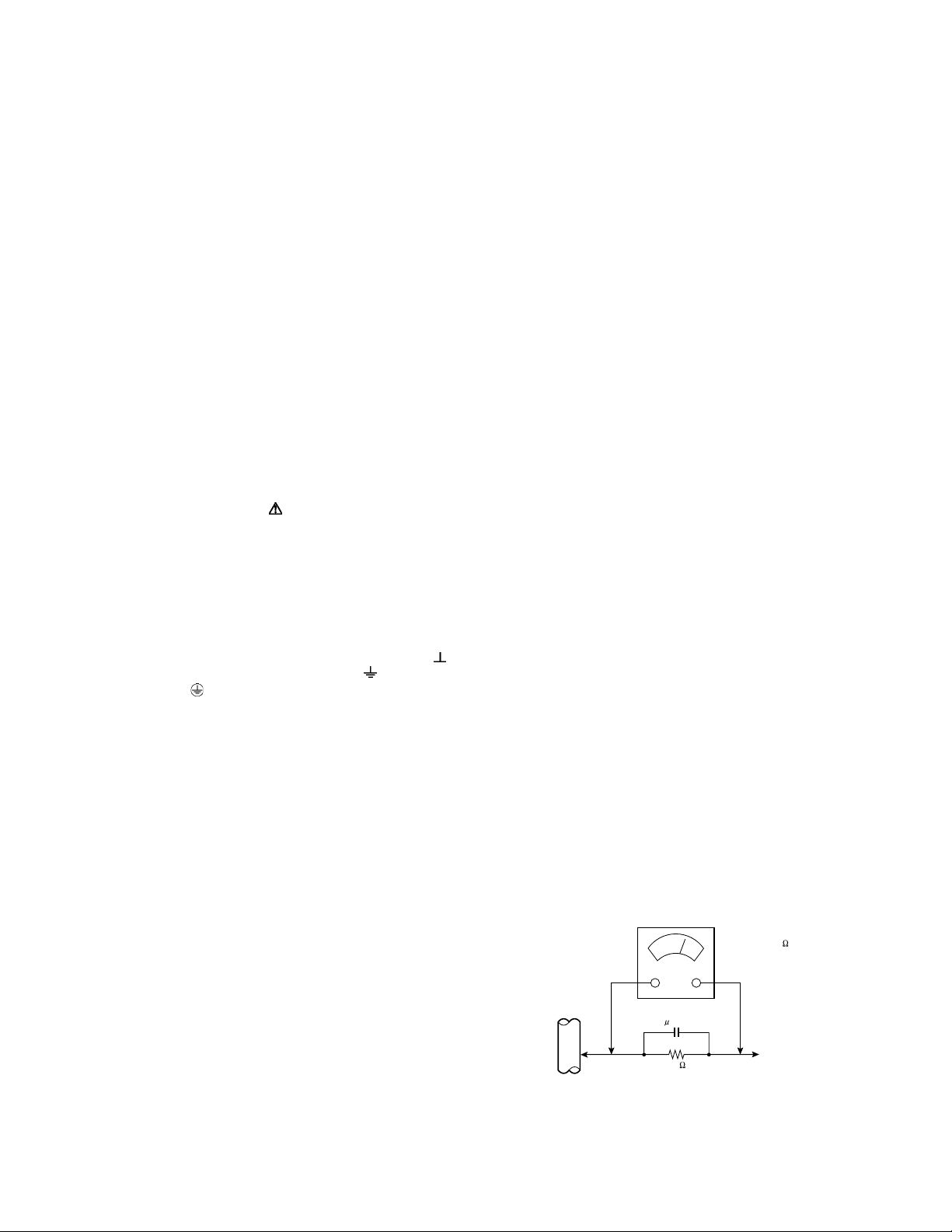

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.7mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.35V

AC (r.m.s.). This corresponds to 0.3mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

GOOD EARTH GROUND

1500 10W

PLACE THIS PROBE

ON EACH EXPOSED

ME TAL PAR T

(No.YA683<Rev.001>)1-3

Page 4

1.2 SAFETY PRECAUTIONS [FOR UK]

(1) The design of this product contains special hardware and many circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original circuits. Service should be performed by qualified personnel

only.

(2) Alterations of the design or circuitry of the product should not be made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer of responsibility for personal injury or property damage

resulting therefrom.

(3) Many electrical and mechanical parts in the product have special safety-related characteristics. These characteristics are often

not evident from visual inspection nor can the protection afforded by them necessary be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are

identified in the Parts List of Service Manual. Electrical components having such features are identified by shading on the

schematics and by ( ) on the Parts List in the Service Manual. The use of a substitute replacement which does not have the

same safety characteristics as the recommended replacement part shown in the Parts List of Service Manual may cause shock,

fire, or other hazards.

(4) The leads in the products are routed and dressed with ties, clamps, tubing’s, barriers and the like to be separated from live parts,

high temperature parts, moving parts and / or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it should be confirmed that they have been returned to

normal, after re-assembling.

WARNING

(1) The equipment has been designed and manufactured to meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant safety standards.

(4) It is essential that safety critical components are replaced by approved parts.

(5) If mains voltage selector is provided, check setting for local voltage.

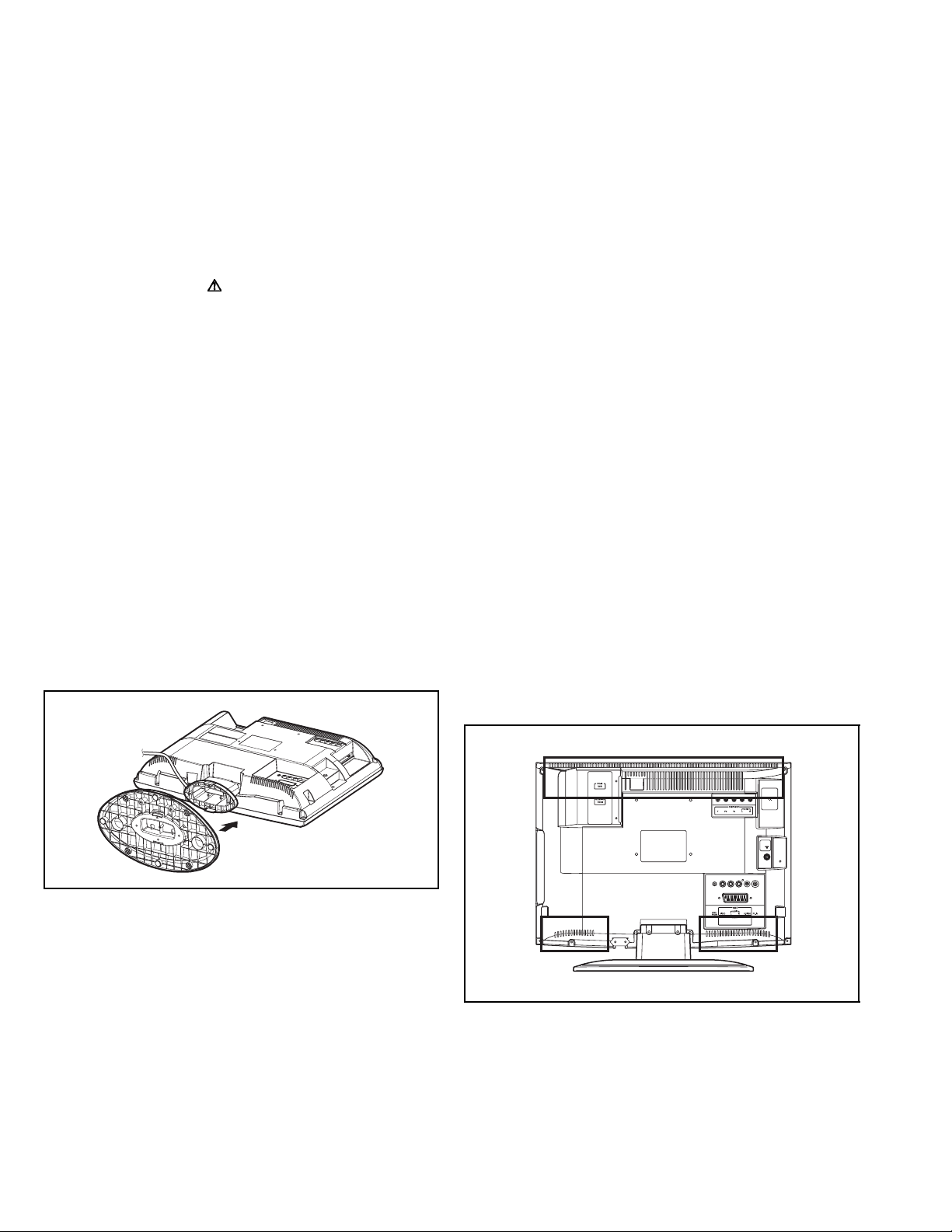

1.3 INSTALLATION

1.3.1 ATTACH THE STAND TO THE TV

When installing the unit on the floor, it is required to attach the

supplied stand.

To attach the stand to the TV, follow the procedure below.

(1) Spread a thick and soft cloth over a table. Place the main

unit face down onto it.

(2) Insert the stand to the main unit slowly.

1.3.2 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling

efficiency may deteriorate and temperature inside the unit will

rise. The temperature sensor that protects the unit will be

activated when internal temperature exceeds the pre-determined

level and power will be turned off automatically.Therefore,

please make sure pay attention not to block the heat dissipation

vent as well as the ventilation outlet behind the unit and ensure

that there is room for ventilation around it.

Ventilation hole

*The drawing may differ from the actual appearance.

1-4 (No.YA683<Rev.001>)

Page 5

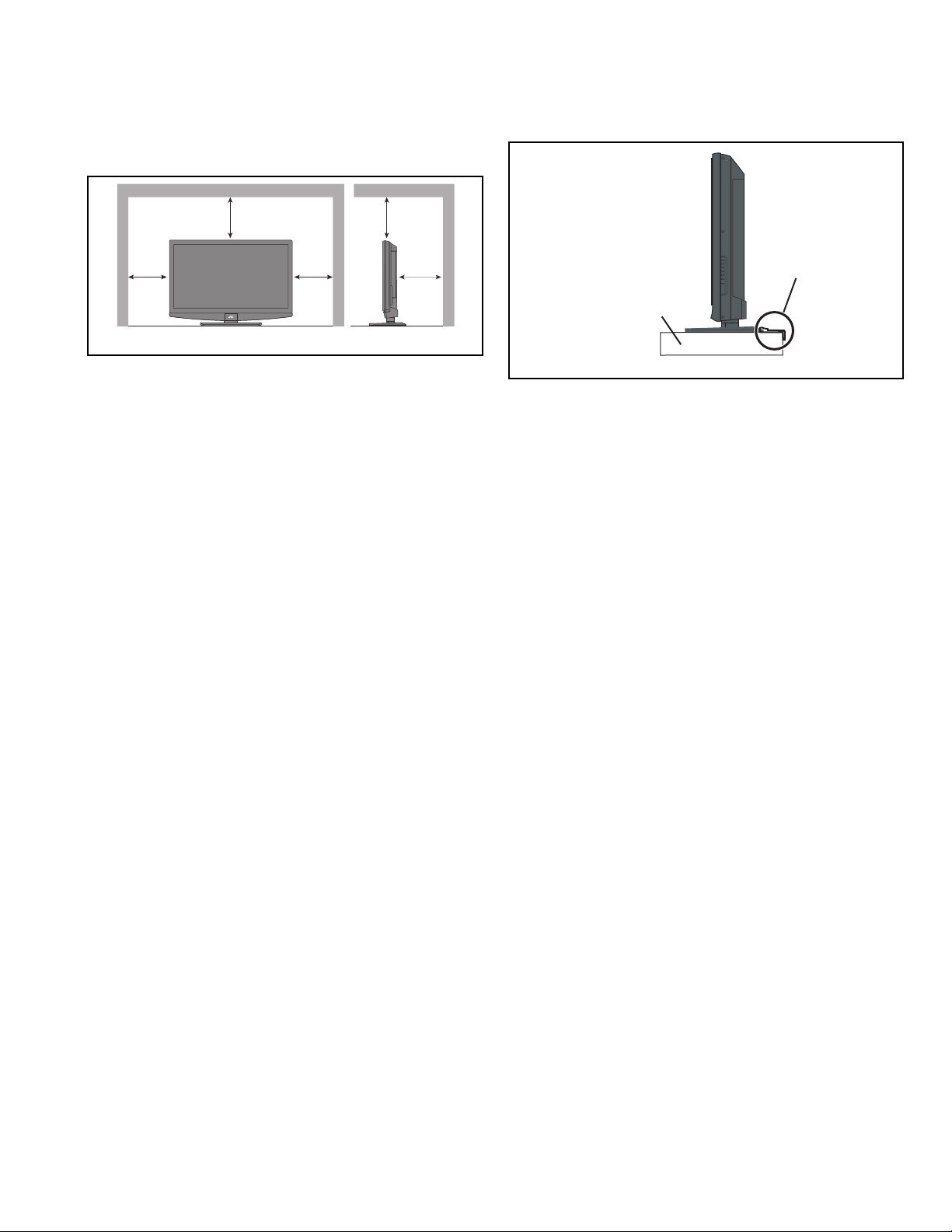

1.3.3 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified

below, between the unit with and the surrounding walls, as well

as the floor etc.Install the unit on stable flooring or stands.Take

precautionary measures to prevent the unit from tipping in order

to protect against accidents and earthquakes.

1.3.4 INSTALLATION REQUIREMENTS

To ensure safety in an emergency such as an earthquake, and

to prevent accidents, ensure that measures are taken to prevent

the TV dropping or falling over.

200 mm

150 mm

*The drawing may differ from the actual appearance.

150 mm

200 mm

50 mm

1.4 HANDLING LCD PANEL

1.4.1 PRECAUTIONS FOR TRANSPORTATION

When transporting the unit, pressure exerted on the internal LCD

panel due to improper handling (such as tossing and dropping)

may cause damages even when the unit is carefully packed. To

prevent accidents from occurring during transportation, pay

careful attention before delivery, such as through explaining the

handling instructions to transporters.

Ensure that the following requirements are met during

transportation, as the LCD panel of this unit is made of glass and

therefore fragile:

(1) USE A SPECIAL PACKING CASE FOR THE LCD PANEL

When transporting the LCD panel of the unit, use a special

packing case (packing materials). A special packing case

is used when a LCD panel is supplied as a service spare

part.

(2) ATTACH PROTECTION SHEET TO THE FRONT

Since the front (display part) of the panel is vulnerable,

attach the protection sheet to the front of the LCD panel

before transportation. Protection sheet is used when a LCD

panel is supplied as a service spare part.

(3) AVOID VIBRATIONS AND IMPACTS

The unit may be broken if it is toppled sideways even when

properly packed. Continuous vibration may shift the gap of

the panel, and the unit may not be able to display images

properly. Ensure that the unit is carried by at least 2

persons and pay careful attention not to exert any vibration

or impact on it.

(4) DO NOT PLACE EQUIPMENT HORIZONTALLY

Ensure that it is placed upright and not horizontally during

transportation and storage as the LCD panel is very

vulnerable to lateral impacts and may break. During

transportation, ensure that the unit is loaded along the

traveling direction of the vehicle, and avoid stacking them

on one another. For storage, ensure that they are stacked

in 2 layers or less even when placed upright.

It fixes in a band.

TV STAND

*The drawing may differ from the actual appearance.

1.3.5 NOTES ON HANDLING

When taking the unit out of a packing case, do not grasp the

upper part of the unit. If you take the unit out while grasping the

upper part, the LCD PANEL may be damaged because of a

pressure. Instead of grasping the upper part, put your hands on

the lower backside or sides of the unit.

1.4.2 OPTICAL FILTER (ON THE FRONT OF THE LCD PANEL)

(1) Avoid placing the unit under direct sunlight over a

prolonged period of time. This may cause the optical filter

to deteriorate in quality and color.

(2) Clean the filter surface by wiping it softly and lightly with a

soft and lightly fuzz cloth (such as outing flannel).

(3) Do not use solvents such as benzene or thinner to wipe the

filter surface. This may cause the filter to deteriorate in

quality or the coating on the surface to come off. When

cleaning the filter, usually use the neutral detergent diluted

with water. When cleaning the dirty filter, use water-diluted

ethanol.

(4) Since the filter surface is fragile, do not scratch or hit it with

hard materials. Be careful enough not to touch the front

surface, especially when taking the unit out of the packing

case or during transportation.

1.4.3 PRECAUTIONS FOR REPLACEMENT OF EXTERIOR

PARTS

Take note of the following when replacing exterior parts (REAR

COVER, FRONT PANEL, etc.):

(1) Do not exert pressure on the front of the LCD panel (filter

surface). It may cause irregular color.

(2) Pay careful attention not to scratch or stain the front of the

LCD panel (filter surface) with hands.

(3) When replacing exterior parts, the front (LCD panel) should

be placed facing downward. Place a mat, etc. underneath

to avoid causing scratches to the front (filter surface).

(No.YA683<Rev.001>)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

DIGITAL TUNER

This TV can receive both DVB-T (Digital terrestrial broadcasting),

DVB-S(Digital satellite broadcasting: DB9 only) and Analogue

terrestrial broadcasting.

HDMI INPUT

By connecting a HDMI compatible device, high definition

pictures can be displayed on your TV in their digital form.

2.2 MAIN DIFFERENCE LIST

PICTURE MODE

This function can adjust the picture settings automatically.

There are Standard, Dynamic, Movie and News in the

PICTURE MODE.

ZOOM

This function can change the screen size according to the

picture aspect ratio.

Items

Teletext System (Digital) MHEG 5 UK profile EBU TEXT

POWER CORD UK TYPE (3-pins) EU TYPE (2-pins)

MAIN PWB FU-1ESA19688-1 FU-1ESA19148-1

FUNCTION PWB FU-1ESA19688-2 FU-1ESA19148-2

IR SENSOR PWB FU-1ESA19688-1 FU-1ESA19148-3

JACK PWB FU-1ESA19688-4 FU-1ESA19148-4

INVERTER PWB FU-1ESA19502-1 FU-1ESA19502-1

JUNCTION PWB FU-1ESA19502-2 FU-1ESA19502-2

DIGITAL MAIN UNIT FU-1ESA19709 FU-1ESA19153

LT-19DA9BJ LT-19DA9BU

Contents

1-6 (No.YA683<Rev.001>)

Page 7

2.3 STANDARD NOTES FOR SERVICING

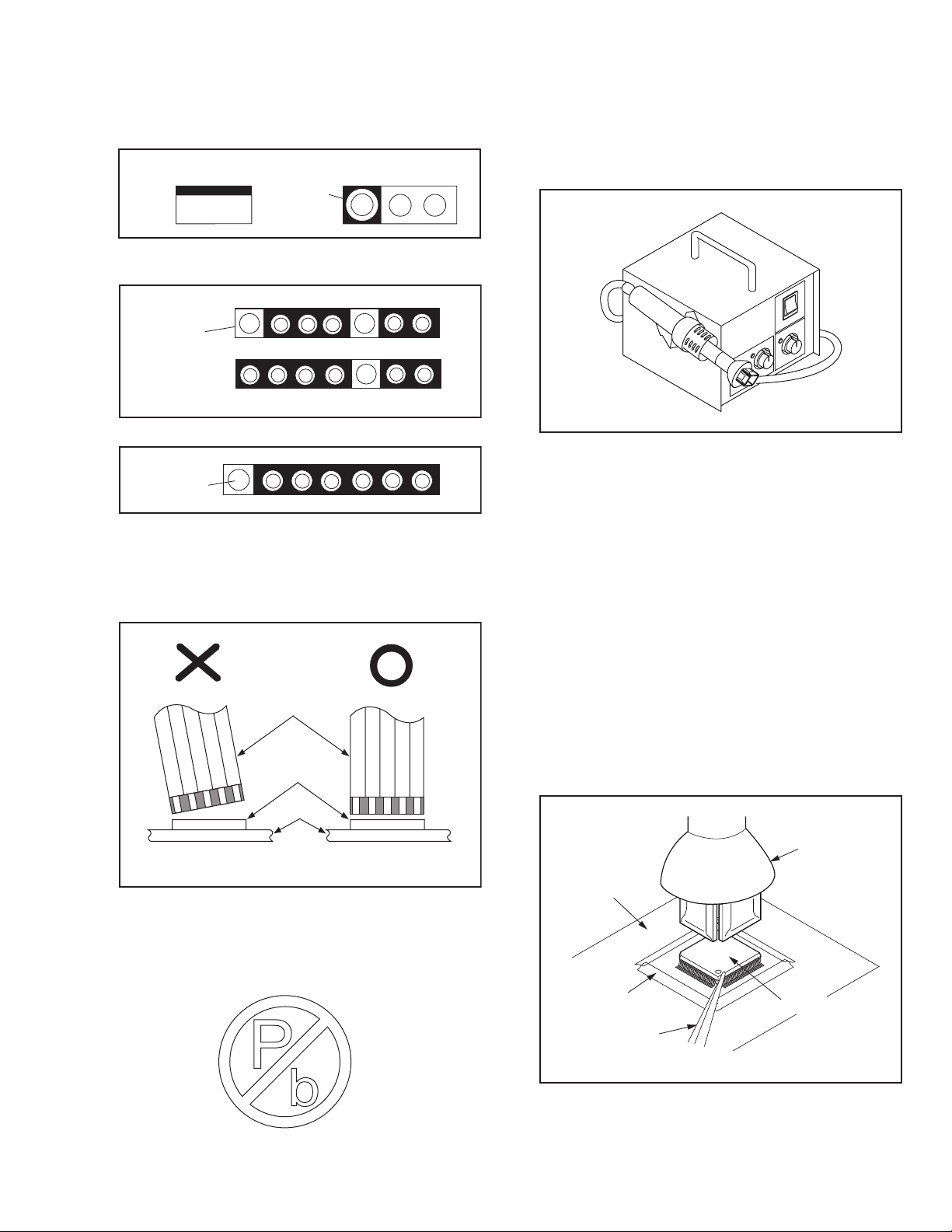

2.3.1 CIRCUIT BOARD INDICATIONS

(1) The output pin of the 3 pin Regulator ICs is indicated as

shown.

Top View

Bottom View

Input

Out

(2) For other ICs, pin 1 and every fifth pin are indicated as

shown.

In

5

Pin 1

10

(3) The 1st pin of every male connector is indicated as shown.

Pin 1

2.3.2 INSTRUCTIONS FOR CONNECTORS

(1) When you connect or disconnect the FFC (Flexible Foil

Connector) cable, be sure to first disconnect the AC cord.

(2) FFC (Flexible Foil Connector) cable should be inserted

parallel into the connector, not at an angle.

FFC Cable

Connector

2.3.4 HOW TO REMOVE / INSTALL FLAT PACK-IC

2.3.4.1 REMOVAL

WITH HOT-AIR FLAT PACK-IC DESOLDERING MACHINE:

(1) Prepare the hot-air flat pack-IC desoldering machine,

then apply hot air to the Flat Pack-IC (about 5 to 6

seconds). (Fig.2-1)

Fig.2-1

(2) Remove the flat pack-IC with tweezers while applying

the hot air.

(3) Bottom of the flat pack-IC is fixed with glue to the PWB;

when removing entire flat pack-IC, first apply soldering

iron to center of the flat pack-IC and heat up. Then

remove (glue will be melted). (Fig.2-6)

(4) Release the flat pack-IC from the PWB using tweezers.

(Fig.2-6)

CAUTION:

(1) The Flat Pack-IC shape may differ by models. Use an

appropriate hot-air flat pack-IC desoldering machine,

whose shape matches that of the Flat Pack-IC.

(2) Do not supply hot air to the chip parts around the flat

pack-IC for over 6 seconds because damage to the

chip parts may occur. Put masking tape around the flat

pack-IC to protect other parts from damage. (Fig.2-2)

(3) The flat pack-IC on the PWB is affixed with glue, so be

careful not to break or damage the foil of each pin or

the solder lands under the IC when removing it.

CBA

* Be careful to avoid a short circuit.

2.3.3 PB (LEAD) FREE SOLDER

Pb free mark will be found on PCBs which use Pb free

solder. (Refer to figure.) For PCBs with Pb free mark, be sure

to use Pb free solder. For PCBs without Pb free mark, use

standard solder.

Pb free mark

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig.2-2

(No.YA683<Rev.001>)1-7

Page 8

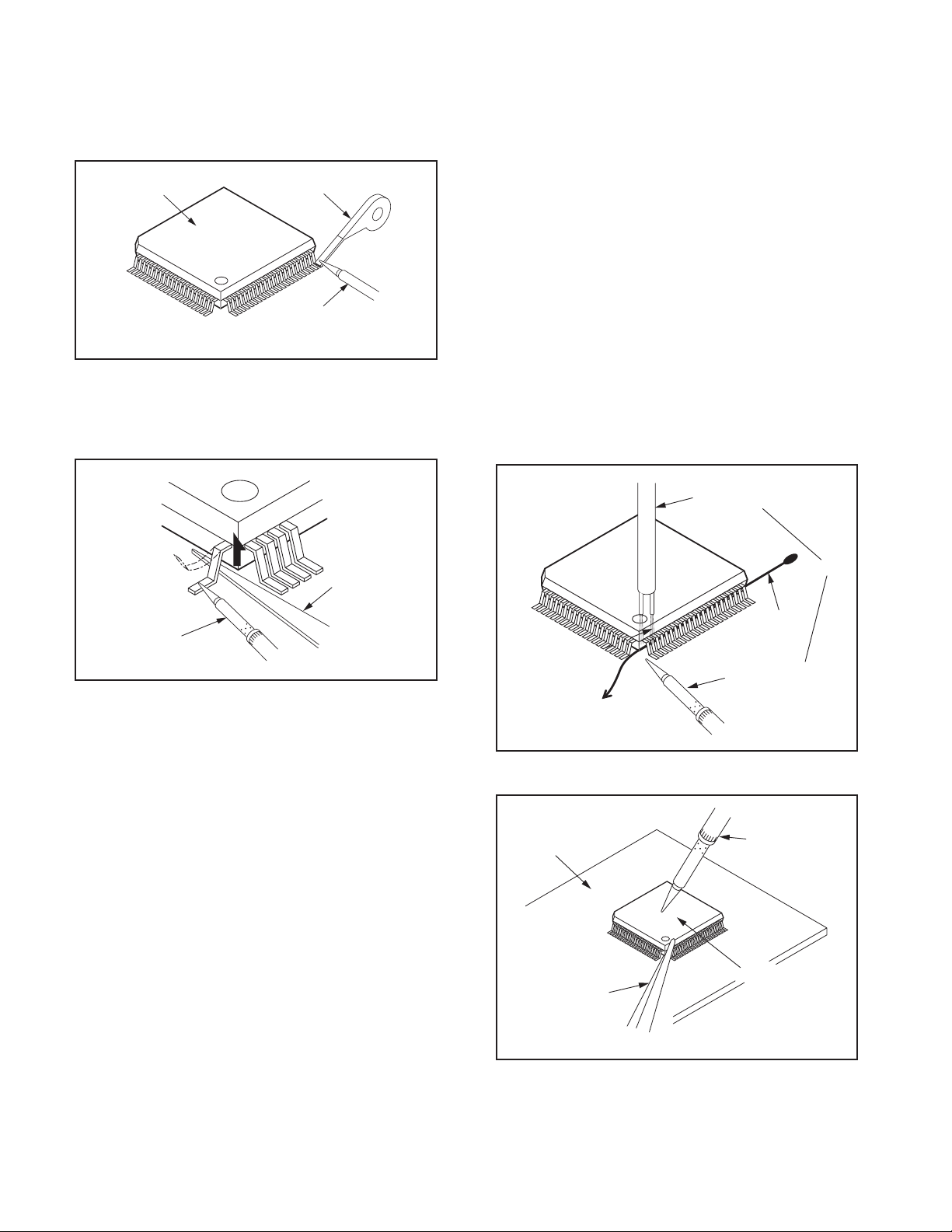

WITH SOLDERING IRON:

(1) Using desoldering braid, remove the solder from all pins

of the flat pack-IC. When you use solder flux which is

applied to all pins of the flat pack-IC, you can remove it

easily. (Fig.2-3)

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig.2-3

(2) Lift each lead of the flat pack-IC upward one by one,

using a sharp pin or wire to which solder will not adhere

(iron wire). When heating the pins, use a fine tip

soldering iron or a hot air desoldering machine. (Fig.2-4)

WITH IRON WIRE:

(1) Using desoldering braid, remove the solder from all pins

of the flat pack-IC. When you use solder flux which is

applied to all pins of the flat pack-IC, you can remove it

easily. (Fig.2-3)

(2) Affix the wire to a workbench or solid mounting point, as

shown in Fig.2-5.

(3) While heating the pins using a fine tip soldering iron or

hot air blower, pull up the wire as the solder melts so as

to lift the IC leads from the PWB contact pads as shown

in Fig.2-5.

(4) Bottom of the flat pack-IC is fixed with glue to the PWB;

when removing entire flat pack-IC, first apply soldering

iron to center of the flat pack-IC and heat up. Then

remove (glue will be melted). (Fig.2-6)

(5) Release the flat pack-IC from the PWB using tweezers.

(Fig.2-6)

NOTE:

When using a soldering iron, care must be taken to ensure

that the flat pack-IC is not being held by glue. When the flat

pack-IC is removed from the PWB, handle it gently because

it may be damaged if force is applied.

Hot Air Blower

Sharp

Pin

Fine Tip

Soldering Iron

Fig.2-4

(3) Bottom of the flat pack-IC is fixed with glue to the PWB;

when removing entire flat pack-IC, first apply soldering

iron to center of the flat pack-IC and heat up. Then

remove (glue will be melted). (Fig.2-6)

(4) Release the flat pack-IC from the PWB using tweezers.

(Fig.2-6)

To Solid

Mounting Point

CBA

Tweezers

or

Iron Wire

Soldering Iron

Fig.2-5

Fine Tip

Soldering Iron

Flat Pack-IC

1-8 (No.YA683<Rev.001>)

Fig.2-6

Page 9

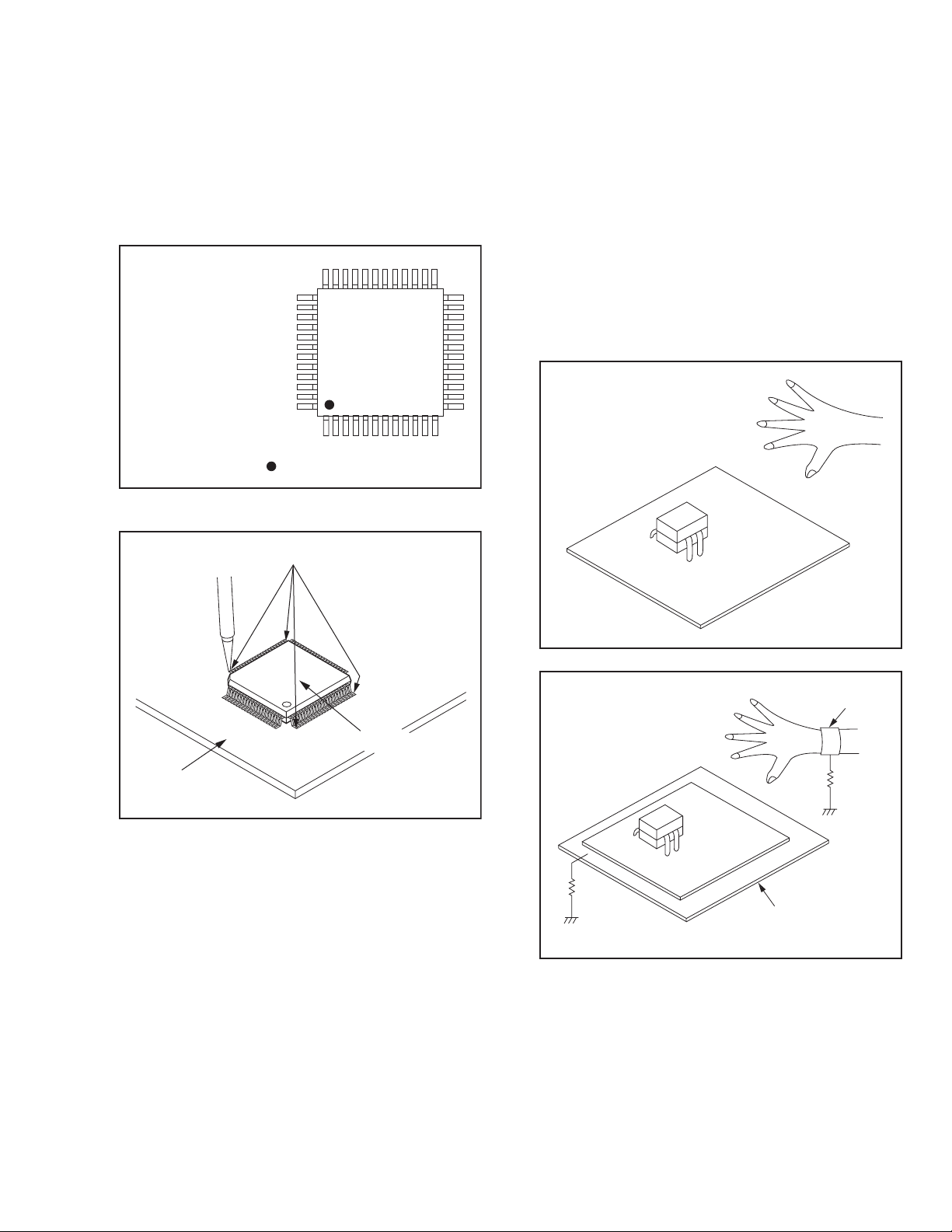

2.3.4.2 INSTALLATION

(1) Using desoldering braid, remove the solder from the foil of

each pin of the flat pack-IC on the PWB so you can install

a replacement flat pack-IC more easily.

(2) The z mark on the flat pack-IC indicates pin 1. (See Fig.2-

7.) Be sure this mark matches the 1 on the PCB when

positioning for installation. Then presolder the four corners

of the flat pack-IC. (See Fig.2-8.)

(3) Solder all pins of the flat pack-IC. Be sure that none of the

pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig.2-7

2.3.5 INSTRUCTIONS FOR HANDLING SEMICONDUCTORS

Electrostatic breakdown of the semi-conductors may occur due

to a potential difference caused by electrostatic charge during

unpacking or repair work.

2.3.5.1 GROUND FOR HUMAN BODY

Be sure to wear a grounding band (1MΩ) that is properly

grounded to remove any static electricity that may be charged on

the body.

2.3.5.2 GROUND FOR WORKBENCH

Be sure to place a conductive sheet or copper plate with proper

grounding (1MΩ) on the workbench or other surface, where the

semi-conductors are to be placed. Because the static electricity

charge on clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors with your

clothing.

<I

ncorrec

t

>

CBA

Presolder

Fig.2-8

Flat Pack-IC

<

C

orrec

1M

CBA

t

>

Grounding Band

1M

CBA

Conductive Sheet or

Copper Plate

(No.YA683<Rev.001>)1-9

Page 10

SECTION 3

DISASSEMBLY

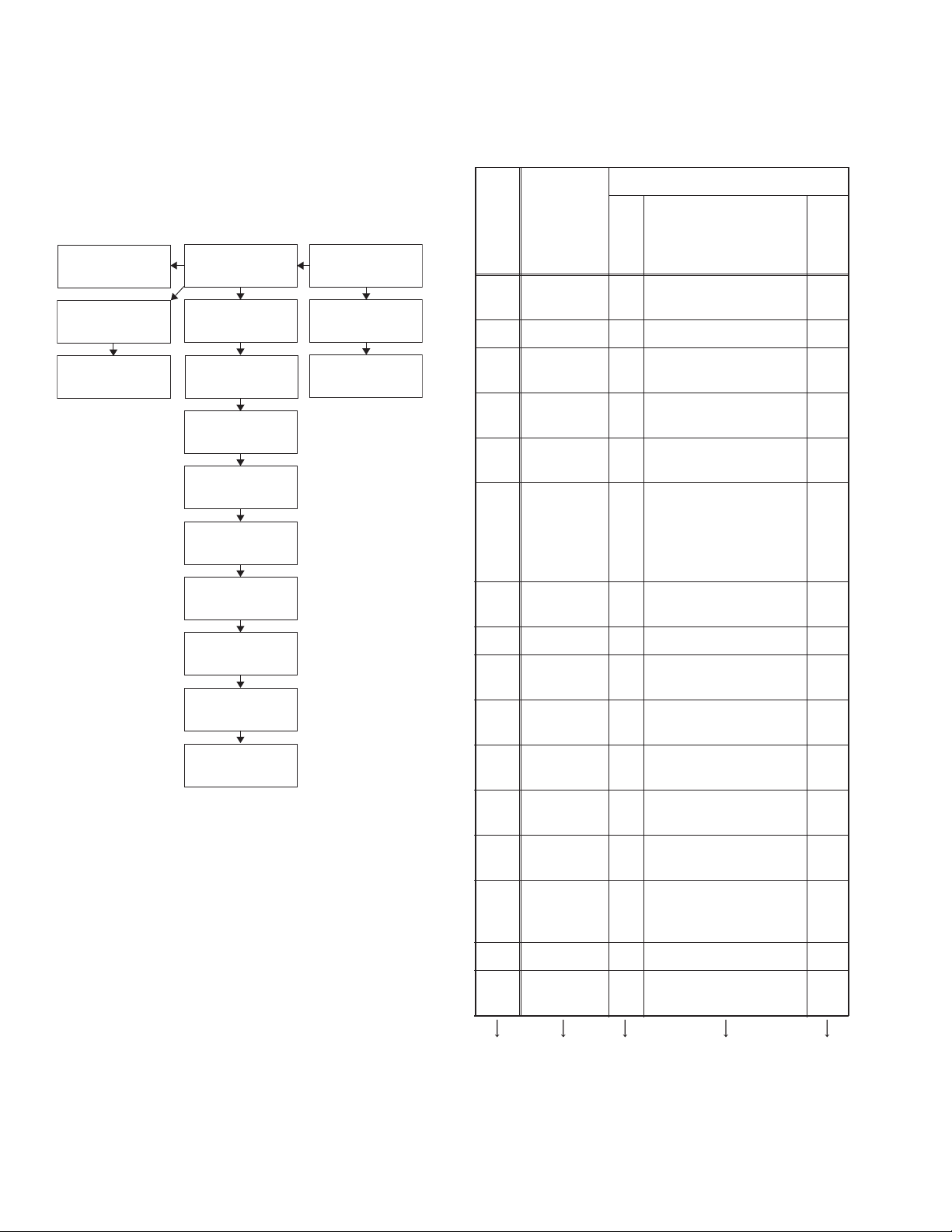

3.1 DISASSEMBLY FLOWCHART

This flowchart indicates the disassembly steps for the cabinet

parts, and the CBA in order to gain access to item(s) to be serviced. When reassembling, follow the steps in reverse order.

Bend, route and dress the cables as they were.

[15] Speaker(s)

[12] IR Sensor PWB

[13] Function PWB

[4] Rear Cabinet

[5] Jack PWB

[6] Shield Box

[1] Stand Cover

[2] Stand Neck

[3] Stand Hinge

Removal

Step/

Loc.

No.

Part

Remove/*Unhook/

Fig.

No.

Unlock/Release/

Unplug/Unclamp/

Desolder

[1]

Stand

Cover

D1 2(S-1) ---

[2] Stand Neck D1 2(S-2) ---

Stand

[3]

Hinge

D1 --------------- ---

Note

[7] Digital Main

Unit

[8] Shield(T)

[9] Main PWB

[10] Junction PWB

[11] Inverter PWB

[14] LCD Module

Assembly

[16] Front Cabinet

3.2 DISASSEMBLY METHOD

Note:

(1) Order of steps in procedure. When reassembling, follow

the steps in reverse order. These numbers are also used

as the Identification (location) No. of parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw, CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2), 2(L-2) = two Locking

Tabs (L-2)

(5) Refer to the following "Reference Notes in the Table."

Rear

[4]

Cabinet

[5] Jack PWB

2(S-3), 7(S-4),

D1

*7(L-1)

D2

2(S-5), *CN107 ---

D3

---

2(S-6), (S-7), 5(S-8),

6(S-9), *CN101A,

[6] Shield Box

D2

*CN102A, *CN103A,

D3

*CN104A, *CN4501,

---

*CN4502, FFC Shield

Digital Main

[7]

Unit

D2D32(S-10), Connector IC

Card OSU

---

[8] Shield(T) D2 (S-11a), 2(S-11b) ---

[9] Main PWB

Junction

[10]

PWB

Inverter

[11]

PWB

IR Sensor

[12]

PWB

Function

[13]

PWB

D2D36(S-12), *CN106,

*CN105A, *CN802

D2

*CN403A ---

D3

D2D34(S-13), *CN401,

*CN402, *CN451

D2

*CN301 ---

D3

D2

--------------- ---

D3

---

---

LCD

[14]

Module

D2 --------------- ---

Assembly

[15] Speaker(s) D2 4(S-14) ---

Front

[16]

Cabinet

D2 --------------- ---

(1) (2) (3) (4) (5)

1-10 (No.YA683<Rev.001>)

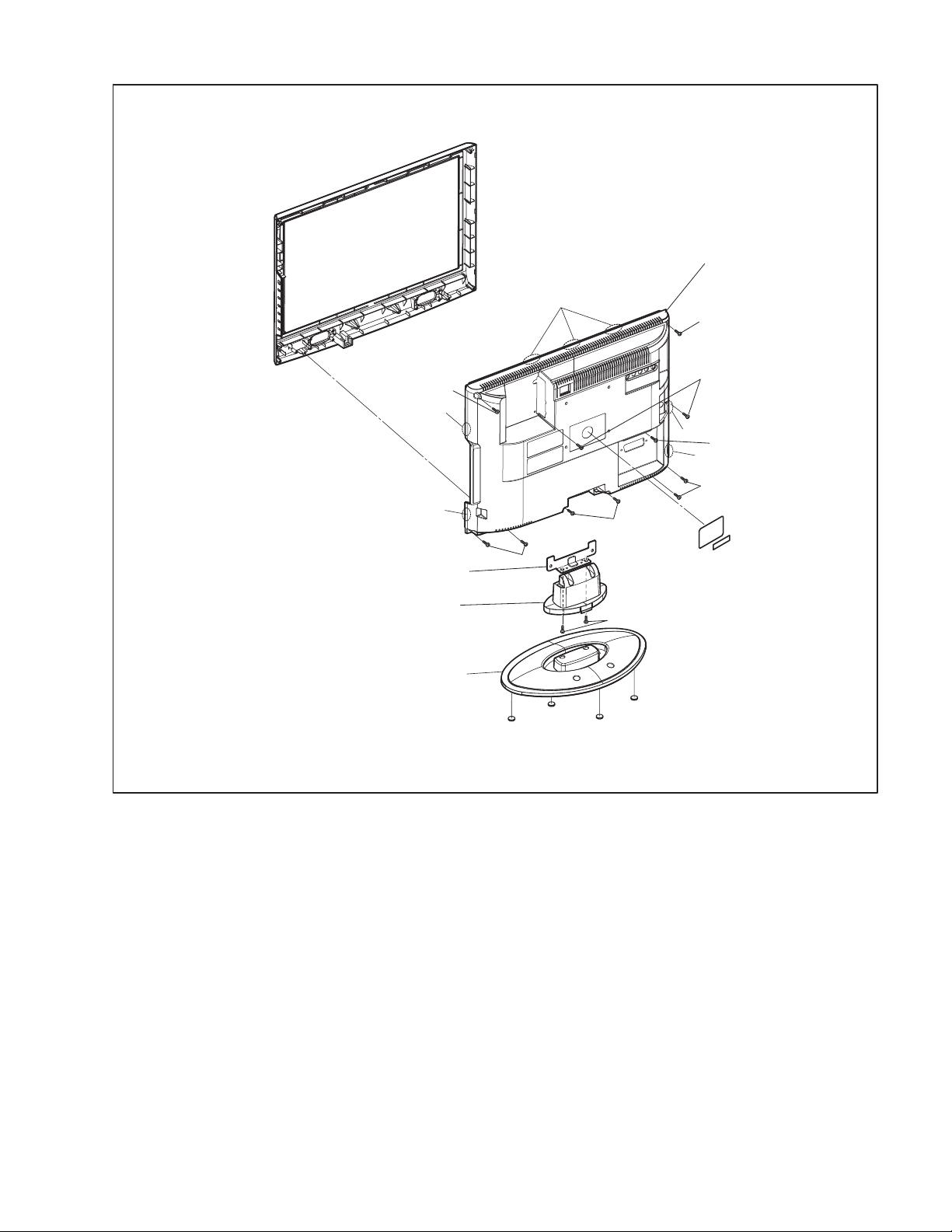

Page 11

(S-4)

(L-1)

(L-1)

(L-1)

(S-1)

[4] Rear Cabinet

(S-4)

(S-3)

(L-1)

(S-4)

(L-1)

(S-4)

[3] Stand Hinge

[2] Stand Neck

[1] Stand Cover

(S-4)

(S-2)

Fig. D1

(No.YA683<Rev.001>)1-11

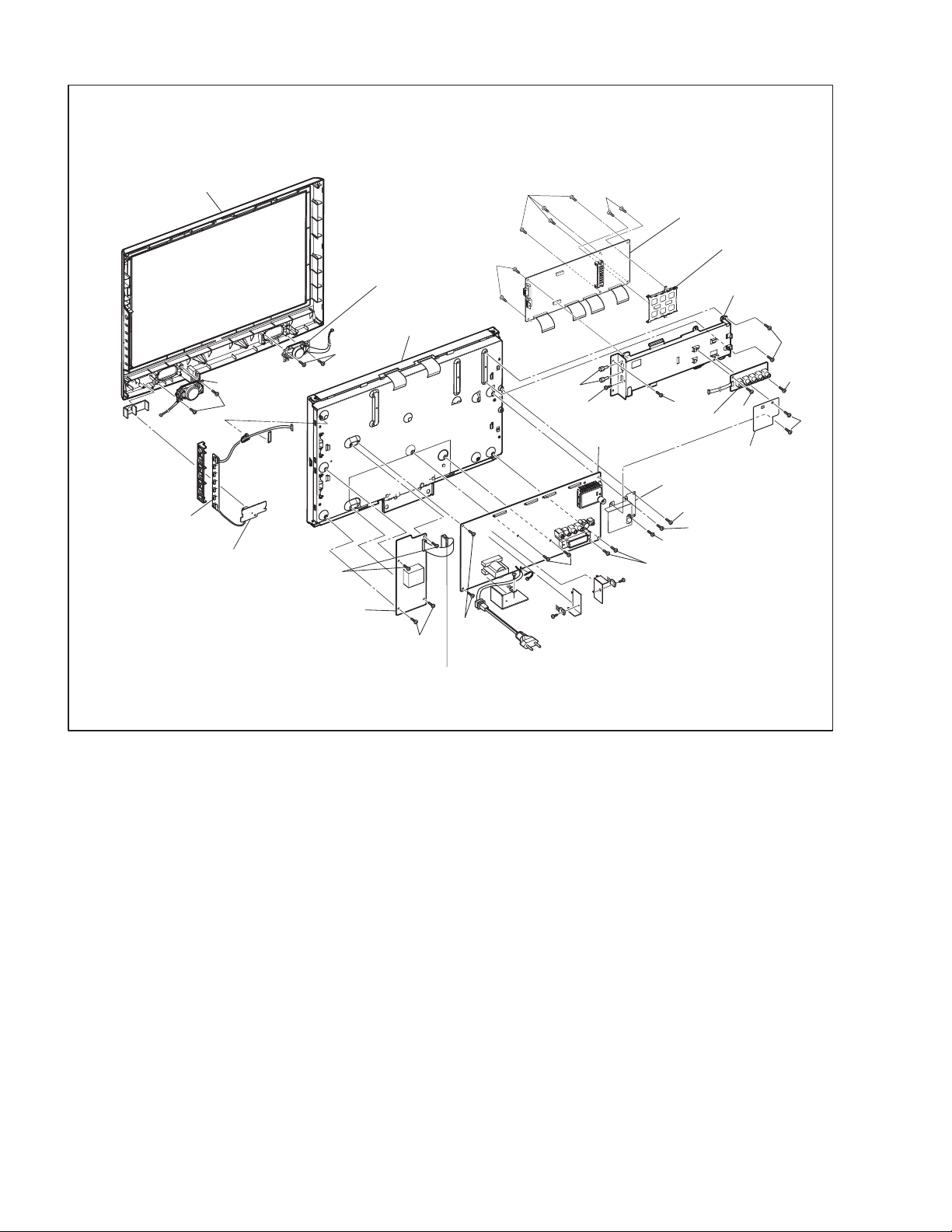

Page 12

[16] Front Cabinet

[13] Function

PWB

[12] IR Sensor

PWB

[15] Speaker

(S-14)

(S-13)

[15] Speaker

[14] LCD Module

Assembly

(S-14)

(S-9)

(S-9)

(S-10)

(S-6)

(S-7)

[5] Jack PWB

[9] Main PWB

(S-12)

[7] Digital Main

Unit

Connector IC

Card OSU

[6] Shield Box

(S-8)

(S-5)

FFC Shield

[8] Shield(T)

(S-11b)

(S-11a)

(S-11b)

(S-12)

(S-8)

(S-5)

(S-8)

[11] Inverter PWB

(S-12)

(S-13)

[10] Junction PWB

Fig. D2

1-12 (No.YA683<Rev.001>)

Page 13

SECTION 4

ADJUSTMENT

4.1 GENERAL NOTE: “PWB” IS ABBREVIATION FOR

“CIRCUIT BOARD ASSEMBLY.”

NOTE:

Electrical adjustments are required after replacing circuit

components and certain mechanical parts. It is important to

perform these adjustments only after all repairs and

replacements have been completed. Also, do not attempt

these adjustments unless the proper equipment is available.

4.2 TEST EQUIPMENT REQUIRED

(1) Pattern Generator

(2) Color Analyzer

4.3 HOW TO ENTER THE SERVICE MODE

(1) Turn the power on.

(2) While pressing [MUTE] button, press [i] button on the

remote control unit.

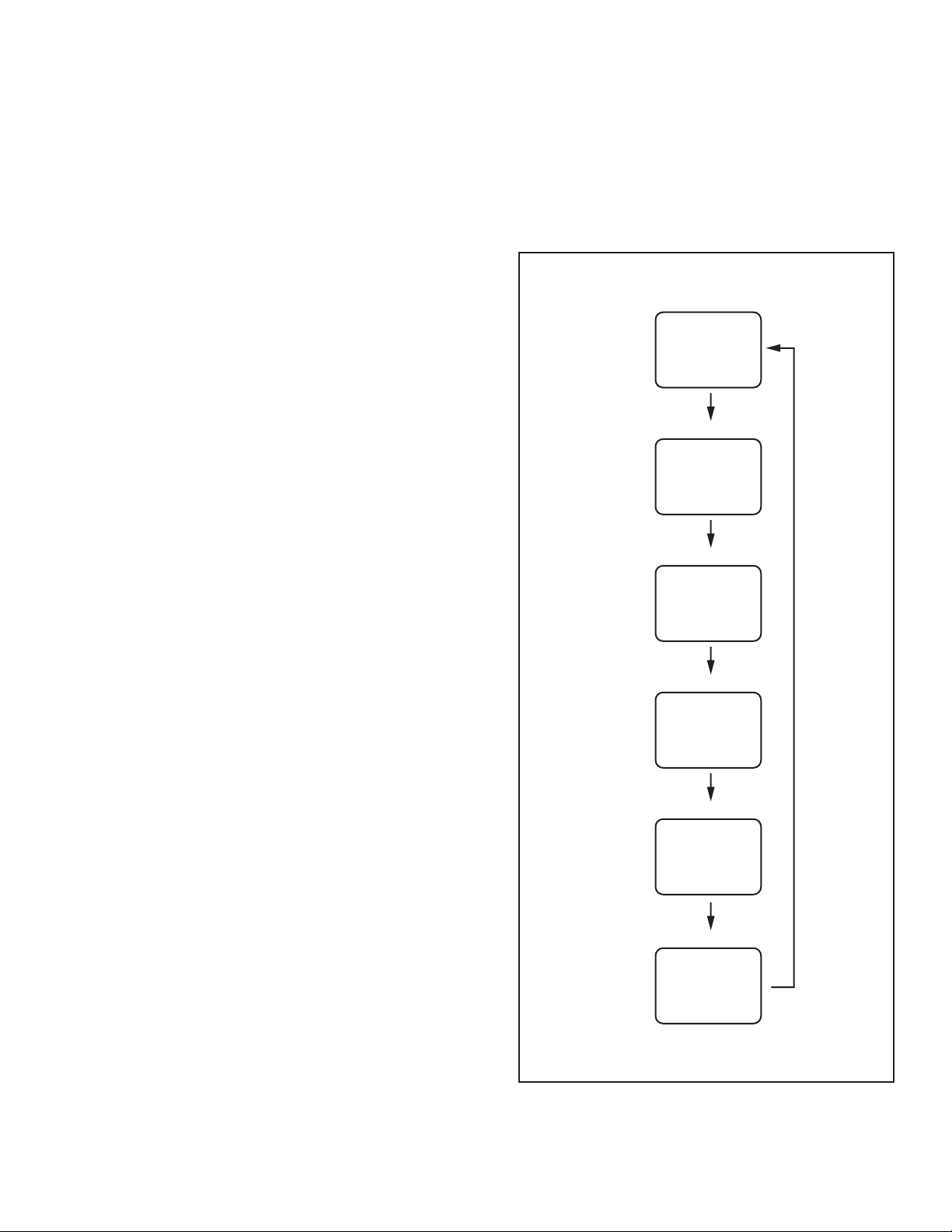

4.4 PURITY CHECK MODE

This mode cycles through full-screen displays of red, green, blue,

and white to check for non-active pixels.

(1) Enter the Service mode.

(2) Each time pressing [7] key on the service remote control

unit, the display changes as follows.

Purity Check Mode

White mode

[7] button

[7] button

Black mode

[7] button

Red mode

[7] button

Green mode

[7] button

Blue mode

[7] button

White 25% mode

Note:

When entering this mode, the default setting is White mode.

(No.YA683<Rev.001>)1-13

Page 14

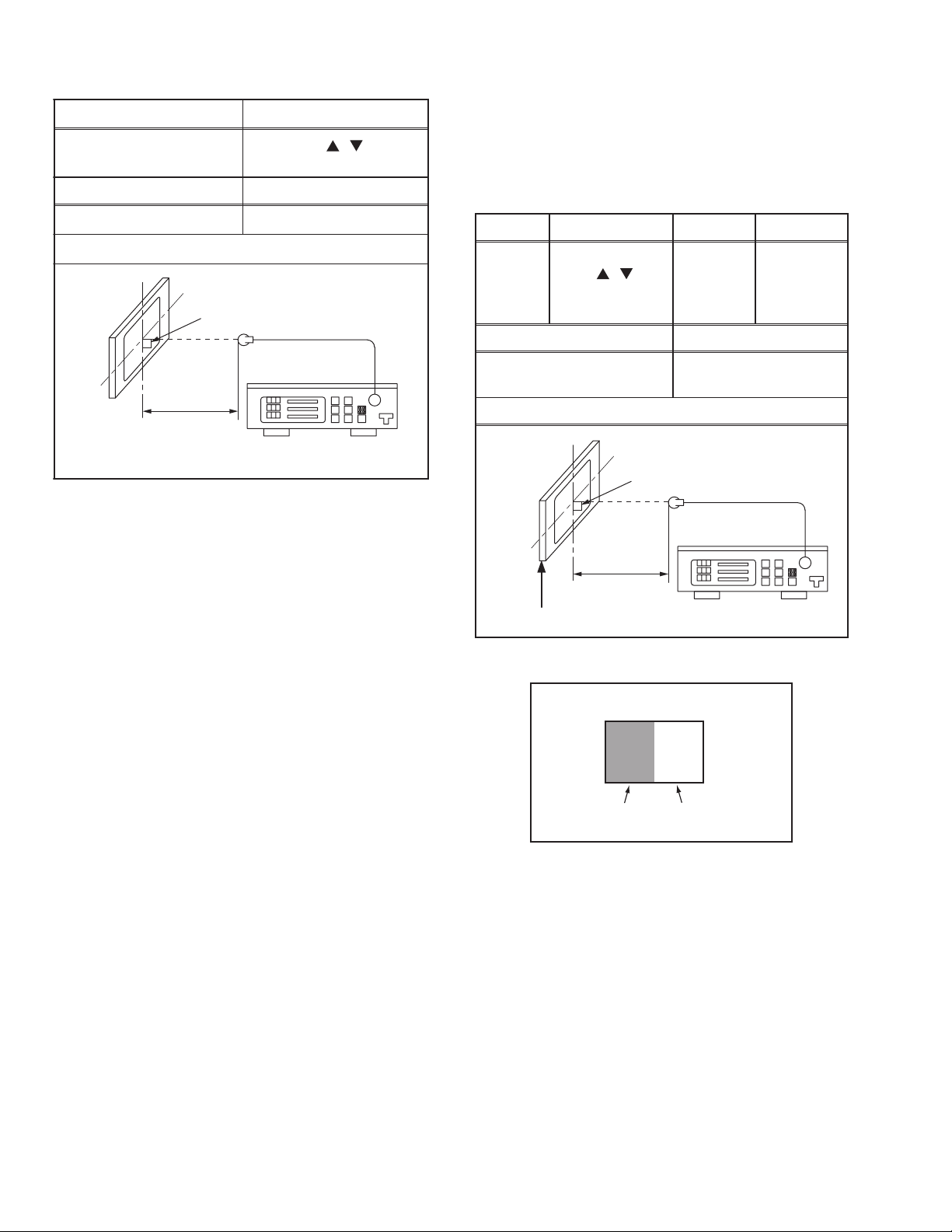

4.5 VCOM ADJUSTMENT.

Test Point

Screen

M. EQ. Spec.

Color analyzer

It carries out in a darkroom.

Perpendicularity

Figure

Adj. Point

[P ]

/

buttons

See below

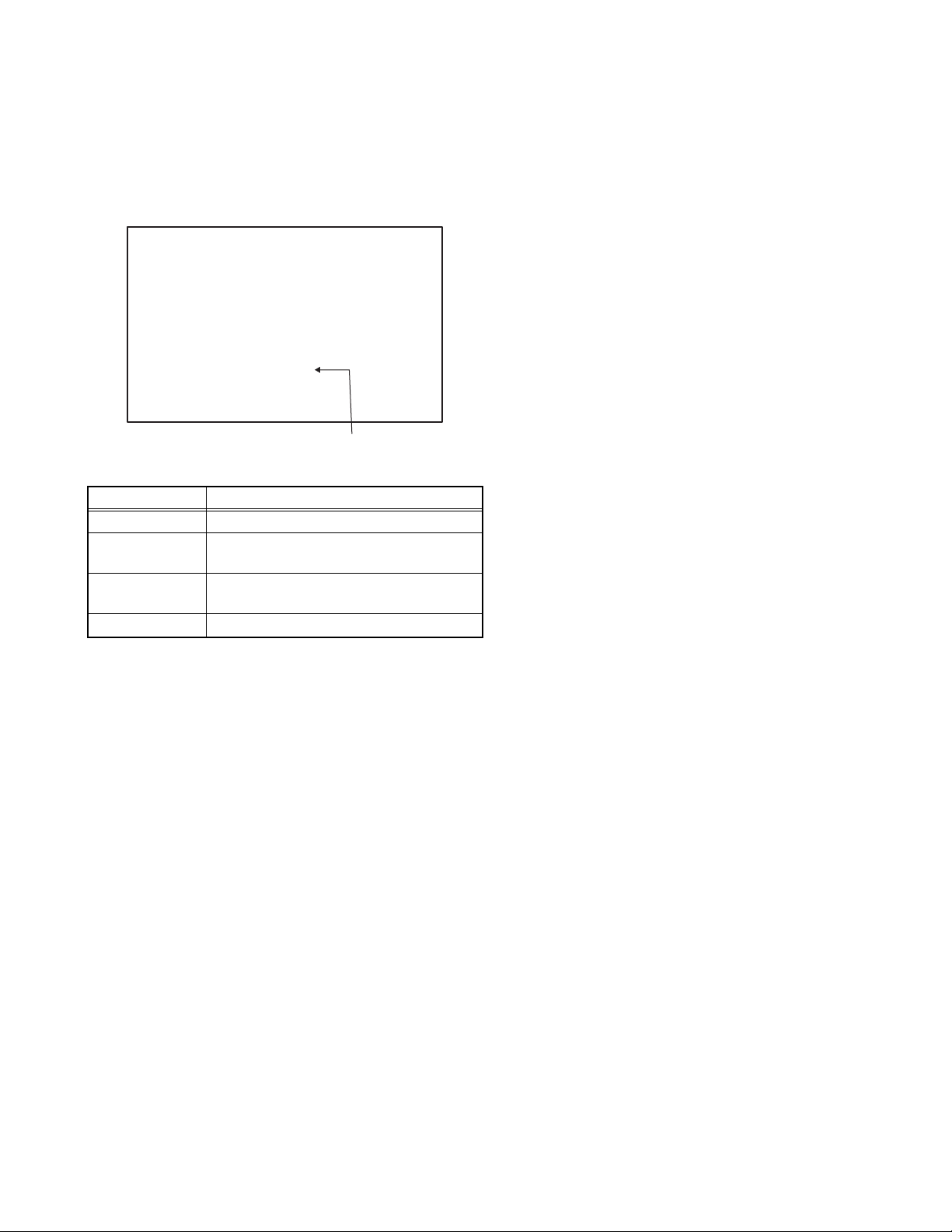

4.6 WHITE BALANCE ADJUSTMENT

The following adjustment normally are not attempted in the field.

Only when replacing the LCD Panel then adjust as a preparation.

PURPOSE:

To mix red, green and blue beams correctly for pure white.

SYMPTOM OF MISADJUSTMENT:

White becomes bluish or reddish.

Test Point

Adj. Point Mode Input

White Raster

Screen

[P ]

/

buttons

[VIDEO]

C/D

(APL 70%)

or

(APL 30%)

M. EQ. Spec.

L = 3 cm

Color Analyzer

(1) Operate the unit for more than 20 minutes.

(2) Set the color analyzer and bring the optical receptor to the

center on the LCD-Panel surface after zero point calibration as shown above.

NOTE:

The optical receptor must be set perpendicularly to the

LCD Panel surface.

(3) Enter the Service mode.

(4) [VCOM1]

Press [2] key on the service remote control unit.

[VCOM2]

Press [3] key on the service remote control unit.

(5) Press [P / ] bkey on the service remote control unit so

that the color analyzer value becomes minimum.

Pattern Generator,

Color analyzer

x= 0.272 ± 0.005

y= 0.278 ± 0.005

Figure

It carries out in a darkroom.

Perpendicularity

L = 3 cm

INPUT: WHITE 70%, 30%

(1) Operate the unit for more than 20 minutes.

(2) Input the White Raster(70%=70IRE, 25%=25IRE).

INPUT SIGNAL

30%=30IRE

Color Analyzer

70%=70IRE

1-14 (No.YA683<Rev.001>)

(3) Set the color analyzer to the CHROMA mode and bring the

optical receptor to the center on the LCD-Panel surface after zero point calibration as shown above.

NOTE:

The optical receptor must be set perpendicularly to the

LCD Panel surface.

(4) Enter the Service mode. Press [VOLUME -] button on the

service remote control unit and select “C/D” mode.

(5) [CUTOFF]

Press [3] key to select “COB” for Blue Cutoff adjustment.

Press [1] key to select “COR” for Red Cutoff adjustment.

[DRIVE]

Press [6] key to select “DB” for Blue Drive adjustment.

Press [4] key to select “DR” for Red Drive adjustment.

(6) In each color mode, press [P / ] buttons to adjust the

values of color.

(7) Adjust Cutoff and Drive so that the color temperature be-

comes 12000°K (x= 0.272 / y= 0.278 ±0.005).

Page 15

4.7 HOW TO VERIFY THE PROTECT MODE

The Sub CPU always surveys the power supply circuit. If the abnormal voltage is detected on the power supply circuit, a voltage

is not supplied.

Perform the following procedures for confirmation.

(1) Enter the service mode.

The following screen appears.

(2)

"*" differs depending on the models.

Code :

Boot :

System :

SubCPU :

Pic Code :

Picture :

Panel :

Other :

Safety :

HDMI1 Block0 :

Block1 :

HDMI2 Block1 :

**********-***

**** * ***

**** * ***

****

**-***-**-****-***

****

***

**

Safety_Non

**

**

**

SPAIN

Display protection mode

Indication of Safety

INDICATION DESCRIPTION

Safety_Non The power supply circuit is normal.

Safety1 The power supply circuit is abnormal.

(Protect1)

Safety2 The reduced voltage detection circuit is

abnormal. (Protect2)

Safety3 The inverter circuit is abnormal. (Protect3)

4.8 HOW TO INITIALIZE THE LCD TELEVISION

(1) Turn the power on.

(2) To enter the service mode.

• To cancel the service mode, press [POWER] key on the

remote control unit.

(3) Press [AV] key on the service remote control unit to initial-

ize the LCD television.

(4) "INITIALIZED" will appear in the upper right of the screen.

"INITIALIZED" color will change to green from red when

initializing is complete.

(No.YA683<Rev.001>)1-15

Page 16

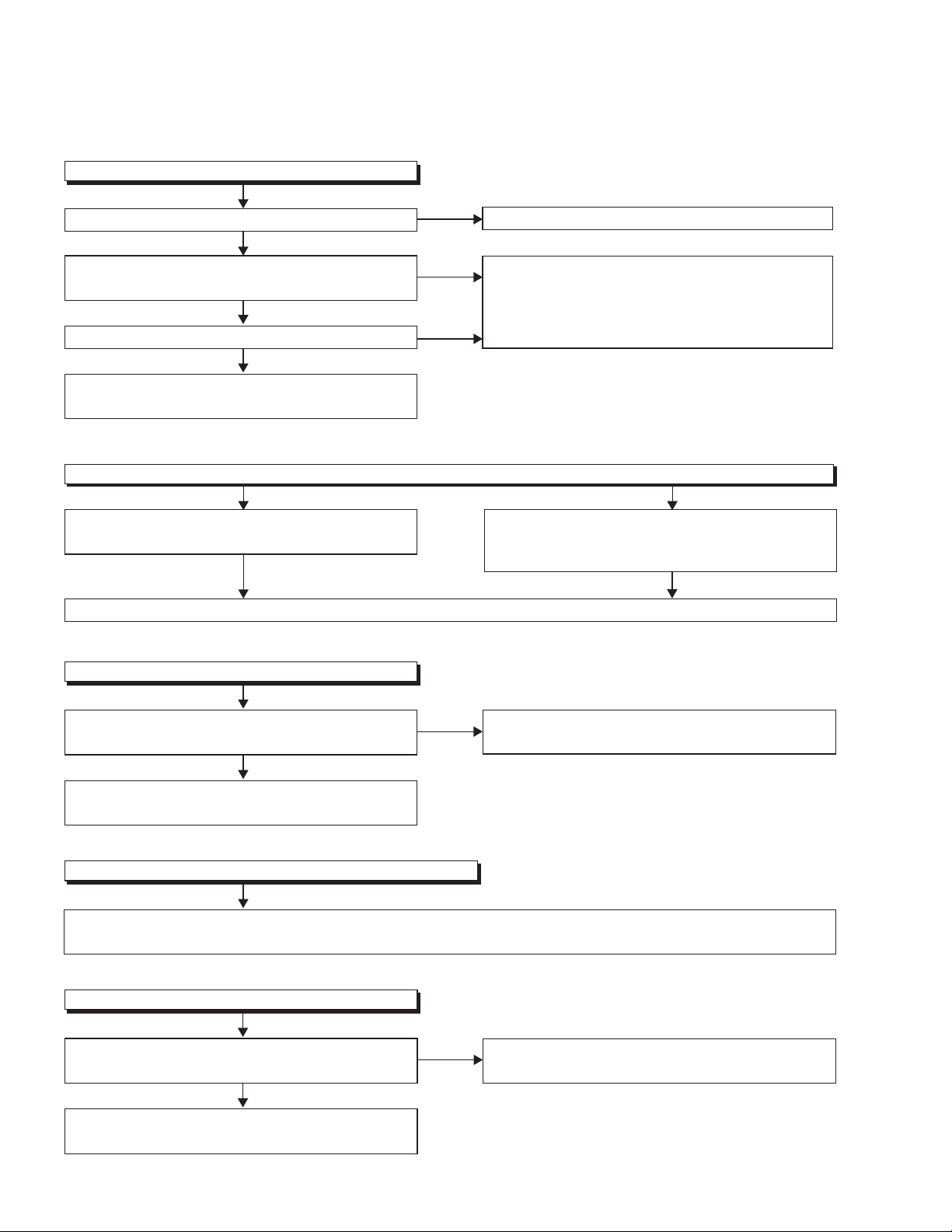

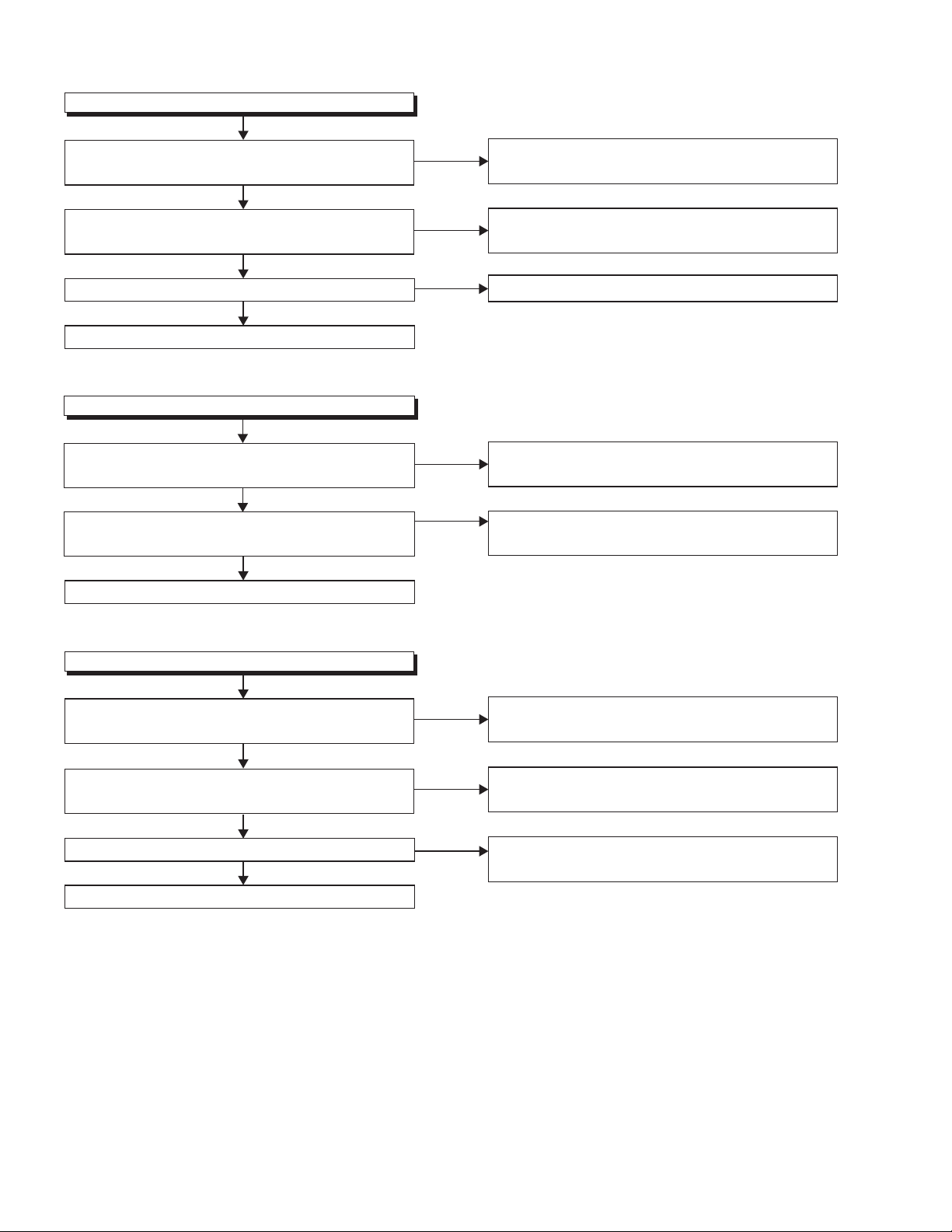

FLOW CHART NO.1

The power cannot be turned on.

SECTION 5

TROUBLESHOOTING

Is the fuse (F601) normal?

Ye s

Is normal state restored when once unplugged power

cord is plugged again several seconds?

Ye s

Is the AL +12V line voltage normal?

Ye s

Check each rectifying circuit of the secondar

and service it if defective.

FLOW CHART NO.2

The fuse blows out.

Check the prese

leaking or shorted and service it if defective.

After ser

FLOW CHART NO.3

When the output voltage fluctuates.

vicing, replace the fus

nce that the primary component is

e (F601).

y circuit

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and service it if defective.

(IC601, Q600, Q601, D611, D613, D614, D616,

T601, R610)

Check the prese

is shorted in each rectifying circuit of secondary side,

and service it if de

nce that the rectifying diode or circuit

fective.

Does the photocoupler circuit on the secondar

operate normally?

Ye s

Check IC601, D610, D615 and their pe

service it if defective.

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is any short-circuit on the rec

service it if defective. (IC900, IC902, D900, D903, D904, D905, D906, D924, D990, Q901, Q902, Q906, Q908, Q911, Q922, Q936)

FLOW CHART NO.5

+35V is not output.

Is appro

of D903?

Check if there is any leak or short-circuit on the loaded

circuit, and service it if defective.

ximately 35V voltage supplied to the cathode

Ye s

y side

riphery, and

tifying diode and the circuit in each rectifying circuit of the secondary side, and

No

No

Check IC601, Q900, D913 and their periphery, and

service it if defective.

Check D903, D908, C903 and their periphery circuit,

and service it defective.

1-16 (No.YA683<Rev.001>)

Page 17

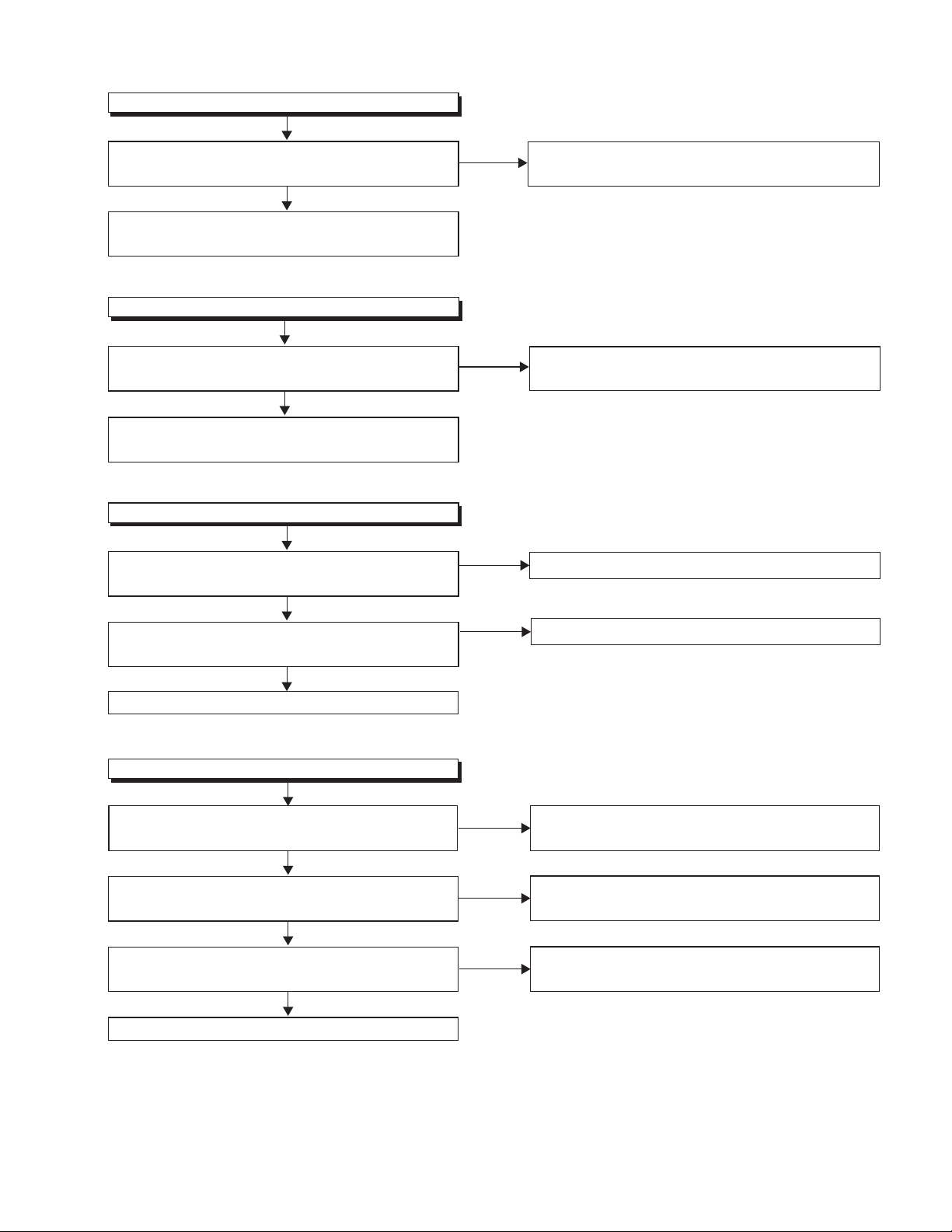

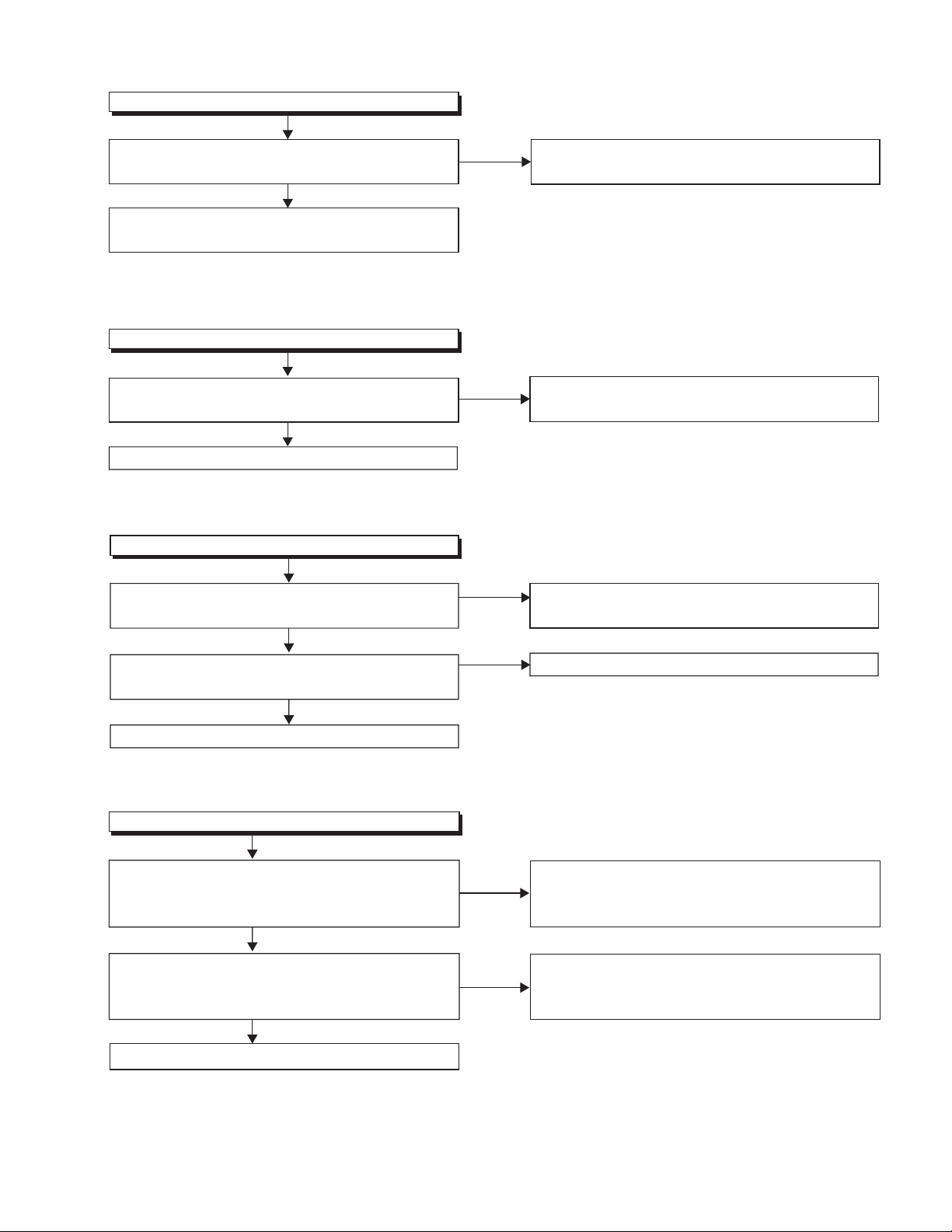

FLOW CHART NO.6

INV+22V is not output.

Is approximately 22V voltage supplied to the cathode

of D990?

Ye s

Check if there is any leak or short-circuit on the loaded

circuit, and service it if defective.

FLOW CHART NO.7

AL+3.3V is not output.

Is approximately 8V voltage supplied to the cathode

of D924?

Ye s

Check Q901, D916 and their periphery circuit, and

service it if defective.

FLOW CHART NO.8

P-ON+5V is not output.

Is appro

ximately 8V voltage supplied to the collector

of Q936?

Ye s

Is approximately 6V voltage supplied to the base of

Q936?

Ye s

No

No

No

No

Check D990, C902 and their periphery circuit, and

service it defective.

Check D924, C917 and their periphery circuit, and

service it if defective.

See FLO

W CHART No.7

See FLOW CHART No.9

Replace Q936.

FLOW CHART NO.9

LCD+24.5V is not output.

Is approximately 38V voltage supplied to the cathode

of D903?

Ye s

Is approximately 38V voltage supplied to the collector

of Q911?

No

Is the voltage of base on Q911 lower than the voltage

of emitter on Q911 when turning the power on?

Ye s

Replace Q911.

No

Ye s

No

Check D903, D908, C903 and their periphery circuit,

and service it if de

Check D923 and

fective.

their periphery circuit, and service it

if defective.

Check Q912 and

P-ON-H1 line, and service it if

defective.

(No.YA683<Rev.001>)1-17

Page 18

FLOW CHART NO.10

LCD+13V is not output.

Is approximately 23V voltage supplied to the cathode

of D990?

Ye s

Is approximately 18V voltage supplied to the collector

of Q922?

Ye s

Is approximately 13V voltage supplied to the base of Q922?

Ye s

Replace Q922.

FLOW CHART NO.11

LCD-6.8V is not output.

Is approximately

-12V voltage supp

lied to the anode of

D905?

Ye s

Is approximately -

11V voltage supplied to the base of

Q908?

Ye s

Replace Q908.

No

No

No

No

No

Check D990, C902 and their periphery circuit, and

service it if defective.

Check R953, R954, R955 and their periphery circuit,

and service it if def

ective.

See FLOW CHART No.9

Check D905, C

vice it if defective.

ser

905 and their periphery circuit, and

Check R945 and their periphery circuit, and service it

if defective.

FLOW CHART NO.12

LCD+3.3V is not output.

Is approximately 8V v

oltage supplied to the cathode of

D924?

Is approximately 7

V voltage supplied to the collector

of Q902?

Is approximately 4V voltage suppli

Replace Q902.

Ye s

Ye s

ed to the base of Q902?

Ye s

No

No

No

Check D924, C917 and their periphery circuit, and

vice it if defective.

ser

Check D974, D975 and their periphery circuit, and

service it if defective.

Check D920, R930 and their periphery circuit, and

service it if defective.

1-18 (No.YA683<Rev.001>)

Page 19

FLOW CHART NO.13

+3.5V is not output.

Is approximately 3.5V voltage supplied to the cathode

of D906?

Ye s

Check if there is any leak or short-circuit on the

loaded circuit, and service it if defective.

FLOW CHART NO.14

P-ON+3.3V is not output.

Is approximately 5V voltage supp

lied to the Pi

n(1) of

IC902?

Ye s

Replace IC902.

FLOW CHART NO.15

P-ON+9V is not output.

Is approximately 14V voltage supplied to the

collector of Q906?

Ye s

Is approximately 10V voltage supplied to the

base of Q906?

Ye s

Replace Q906.

No

No

No

No

Check D906, C907 and their periphery circuit, and

service it if defective.

Check D900, C900 and their periphery circuit, and

service it if defective.

r

Check D904, C904 and their pe

iphery circuit, and

service it if defective.

See FLO

W CHART No.9

FLOW CHART NO.16

The key operation is not functioning.

Are the contact point and installation

state of the key

switches (SW201, SW202, SW203, SW204,

SW205, SW206, SW207) normal?

Ye s

When pre

SW203, SW

voltage of P

ssing each switches (SW201, S

204, SW205, SW20

in(1) on CN

104A increase?

6, SW207) do the

Ye s

Replace Digital Main PWB Unit.

W202,

No

No

Re-install the switches (SW201, SW202, SW203,

SW204, SW205, SW206, SW207) correctly or

replace the poor switch.

Check the switches (SW201, SW202, SW203,

SW204, SW205, SW206, SW207) and their

periphery, and service it if defective.

(No.YA683<Rev.001>)1-19

Page 20

FLOW CHART NO.17

No operation is possible from the remote control unit.

Operation is possible from the unit.

Is 3.3V voltage supplied to Pin(2) of RS301 (remote

control receiver)?

No

Check AL+3.3V line and service it if defective.

Ye s

Is the "L" pulse sent out Pin(1) of RS301 (remote control

receiver) when the infrared remote control is activated?

No

Replace the RS301 (remote control receiver) or

remote control unit.

Ye s

Is the "L" pulse supplied to the P

Ye s

in(4) of CN104A?

No

Check the line between Pin(1) of RS301 (remote

control receiver) and Pin(4) of CN104A, and service

it if defective.

Replace Digital Main PWB Unit.

FLOW CHART NO.18

Picture does not appear normally. (Video input/S-Video input/Y/Pb/Pr input/RGB input)

Are the video signals outputted to the specific

terminal?

Are the luminance signals outputted to the Pin(23) of

CN101A?

Are the chrominance signals outputted to the Pin(25)

of CN101A?

Are the component video(Y/Pb/Pr) signals outputted

to the Pin(18, 20, 21) of CN101A?

Are the RGB video signals outputted to the Pin(3, 4, 5)

of CN102A?

Are the composite video signals outputted to the Pin(1)

No

No

No

No

No

Check the line between each pin of CN101A and

CN102A and input terminal and service it if defective.

Check the luminance signal line, and service it if

defective.

Check the chrominance signal line, and service it if

defective.

Check the component video(Y/Pb/Pr) signal line,

and service it if defective.

Check the RGB video signal line, and service it if

defective.

of CN102A?

Ye s

Replace Digital Main PWB Unit or LCD Module

Assembly.

Ye s

(RCA JACK input)

Are the composite video signals inputted to the Pin(2)

of IC851?

(SCART JACK input)

Are the composite video signals inputted to the Pin(1)

of IC851?

Ye s

Are the composite video signals outputted to the

Pin(15) of IC851?

Ye s

Check the line between Pin(15) of IC851 and Pin(1) of

CN102A, and service it if defective.

1-20 (No.YA683<Rev.001>)

No

No

No

Check the line between Pin(2) of IC851 and JK722,

and service it if defective.

Check the line between Pin(1) of IC851 and JK751,

and service it if defective.

Is approximately 9V voltage supplied to the Pin(16) of

IC851?

Ye s

No

Replace IC851. Check P-ON+9V line,

and service it if defective.

Page 21

FLOW CHART NO.19

Picture does not appear normally.

Are the DIF signals outputted to the Pin(20, 22) of CN103A?

Ye s

Replace Digital Main PWB Unit or LCD Module

Assembly.

FLOW CHART NO.20

Audio is not outputted normally. (Tuner input (Digital))

Are the DIF signals outputted to the Pin(20, 22) of

No

CN103A?

Ye s

Are the audio data signal outputted to the Pin(13) of

No

CN101A?

Ye s

Are the audio(L/R) signals outputted to the Pin(14,15)

No

of IC802?

Ye s

Are the audio(L/R) signals outputted to the Pin(11,14)

No

of IC801?

Ye s

No

Check the line between Pin(20, 22) of CN103A and

Pin(16, 17) of TU501, and TU501(Tuner Unit),

and service it if defective.

Check the line between Pin(20, 22) of CN103A and

Pin(16, 17) of TU501, and TU501(Tuner Unit), and

service it if defective.

Replace Digital Main Unit.

Check IC802 and the periphery circuit, and service it

if defective.

Check IC801 and the periphery circuit, and service it

if defective.

Check SP451,SP802, JK801 and their periphery

circuit, and service it if defective.

FLOW CHART NO.21

Audio is not outputted normally. (Audio input terminals)

Are the audio (L/R) signals outputted to the

Pin(3, 4) of CN103A?

Ye s

Are the audio data signal outputted to the Pin(13) of

CN101A?

Ye s

Are the audio(L/R) signals outputted to the Pin(14,15)

of IC802?

Ye s

Are the audio(L/R) signals outputted to the Pin(11,14)

of IC801?

Ye s

Check SP451,SP802, JK801 and their periphery

circuit, and service it if defective.

No

No

No

No

Check the line between Pin(3, 4) of CN103A and

each Audio input terminal(JK14, JK15, JK723, JK724,

JK725, JK751) and IC850, and service it if defective.

Replace Digital Main PWB Unit.

Check IC802 and the periphery circuit, and service

it if defective.

Check IC801 and the periphery circuit, and service

it if defective.

(No.YA683<Rev.001>)1-21

Page 22

Victor Company of Japan, Limited

Display Division 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YA683<Rev.001>)

Printed in Japan

VPT

Page 23

PARTS LIST

CAUTION

J The parts identified by the symbol are important for the safety . Whenever replacing these parts, be sure to use specified ones to secure the

safety.

J The parts not indicated in this Parts List and those which are filled with lines --- in the Parts No. columns will not be supplied.

J P.W. BOARD Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No. columns will be supplied.

ABBREVIATIONS OF RESISTORS, CAPACITORS AND TOLERANCES

RESISTORS CAPACITORS

CR Carbon Resistor C CAP. Ceramic Capacitor

FR Fusible Resistor E CAP. Electrolytic Capacitor

PR Plate Resistor M CAP. Mylar Capacitor

VR Variable Resistor CH CAP. Chip Capacitor

HV R High Voltage Resistor HV CAP. High Voltage Capacitor

MF R Metal Film Resistor MF CAP. Metalized Film Capacitor

MG R Metal Glazed Resistor MM CAP. Metalized Mylar Capacitor

MP R Metal Plate Resistor MP CAP. Metalized Polystyrol Capacitor

OM R Metal Oxide Film Resistor PP CAP. Polypropylene Capacitor

CMF R Coating Metal Film Resistor PS CAP. Polystyrol Capacitor

UNF R Non-Flammable Resistor TF CAP. Thin Film Capacitor

CH V R Chip Variable Resistor MPP CAP. Metalized Polypropylene Capacitor

CH MG R Chip Metal Glazed Resistor TAN. CAP. Tantalum Capacitor

COMP. R Composition Resistor CH C CAP. Chip Ceramic Capacitor

LPTC R Linear Positive Temperature Coefficient Resistor BP E CAP. Bi-Polar Electrolytic Capacitor

CH AL E CAP. Chip Aluminum Electrolytic Capacitor

CH AL BP CAP. Chip Aluminum Bi-Polar Capacitor

CH TAN. E CAP. Chip Tantalum Electrolytic Capacitor

CH AL BP E CAP. Chip Tantalum Bi-Polar Electrolytic Capacitor

RESISTORS

FGJ KMNRHZP

±1% ±2% ±5% ±10% ±20% ±30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

(No.YA683<Rev.001>)3-1

Page 24

CONTENTS

USING P.W. BOARD ................................................................................................................................................... 3-2

EXPLODED VIEW PARTS LIST ................................................................................................................................. 3-3

EXPLODED VIEW ....................................................................................................................................................... 3-4

PRINTED WIRING BOARD PARTS LIST [LT-19DA1BJ/AK] .................................................................................... 3-6

MAIN P.W. BOARD ASS'Y (FU-1ESA19688-1) ................................................................................................ 3-6

FUNCTION P.W. BOARD ASS'Y (FU-1ESA19688-2) ....................................................................................... 3-8

IR SENSOR P.W. BOARD ASS'Y (FU-1ESA19688-3) ...................................................................................... 3-8

JACK P.W. BOARD ASS'Y (FU-1ESA19688-4) ................................................................................................ 3-8

INVERTER P.W. BOARD ASS'Y (FU-1ESA19502-1) ....................................................................................... 3-9

JUNCTION P.W. BOARD ASS'Y (FU-1ESA19502-2) ....................................................................................... 3-9

PRINTED WIRING BOARD PARTS LIST [LT-19DA1BU/AK] ................................................................................. 3-10

MAIN P.W. BOARD ASS'Y (FU-1ESA19148-1) .............................................................................................. 3-10

FUNCTION P.W. BOARD ASS'Y (FU-1ESA19148-2) .....................................................................................3-12

IR SENSOR P.W. BOARD ASS'Y (FU-1ESA19148-3) ....................................................................................3-12

JACK P.W. BOARD ASS'Y (FU-1ESA19148-4) .............................................................................................. 3-12

INVERTER P.W. BOARD ASS'Y (FU-1ESA19502-1) .....................................................................................3-13

JUNCTION P.W. BOARD ASS'Y (FU-1ESA19502-2) .....................................................................................3-13

PACKING ................................................................................................................................................................... 3-14

PACKING PARTS LIST ............................................................................................................................................. 3-15

USING P.W. BOARD

P.W.B ASS'Y name

LT-19DA1BJ/AK LT-19DA1BU/AK

MAIN P.W.B FU-1ESA19688-1 FU-1ESA19148-1

FUNCTION P.W.B FU-1ESA19688-2 FU-1ESA19148-2

IR SENSOR P.W.B FU-1ESA19688-3 FU-1ESA19148-3

JACK P.W.B FU-1ESA19688-4 FU-1ESA19148-4

INVERTER P.W.B FU-1ESA19502-1

JUNCTION P.W.B FU-1ESA19502-2

DIGITAL MAIN P.W.B FU-1ESA19709 FU-1ESA19153

P.W.B ASS'Y No.

←

←

3-2(No.YA683<Rev.001>)

Page 25

EXPLODED VIEW PARTS LIST

Ref.No. Part No. Part Name Description Local

1 FU-1EM023085 REAR CABINET

2 FU-1EM023353 FRONT CABINET

3 FU-UG190EB LCD PANEL UNIT

4 FU-1EM222223A DECORATION PLATE

5 FU-DSD0806XQ001 SPEAKER

6 FU-DSD0806XQ001 SPEAKER

7 FU-WAB0182K5002 POWER CORD LT-19DA1BJAK

7 FU-WAE0172LW006 POWER CORD LT-19DA1BUAK

10 FU-1EM427137 REAR COVER

11 FU-1EM323959 SENSOR LED LENS

12 FU-1EM426377 STAND RUBBER FOOT (x4)

13 FU-1EM022467 STAND COVER

16 FU-1EM325277 STAND NECK

22 FU-1EM222143A FUNCTION KNOB

25 FU-1EM323797 WALL MOUNT BRACKET (x4)

26 FU-1EM122473 SHIELD BOX

27 FU-1EM325219 SHIELD (T)

28 FU-1EM427320 FFC SHIELD

29 FU-1EM323940 STAND HINGE

30 FU-0EM404486 CLOTH

31 FU-1EM424258 CLOTH

32 FU-1EM425861 GASKET (x2)

33 FU-0EM400076 CLOTH(B) (x4)

35 FU-GBJS3060 SCREW M3x6(x25)

36 FU-0EM408146A DOUBLE SEMS SCREW M4x9(x2)

37 FU-1EM422042 HEX SCREW (x2)

38 FU-FPJ32100 DOUBLE SEMS SCREW M2x10(x2)

39 FU-GBJP3100 SCREW M3x10(x8)

40 FU-FPJ32060 DOUBLE SEMS SCREW M2x6(x2)

41 FU-GBHP3100 SCREW M3x10(x7)

42 FU-GBHP4180 SCREW M4x18(x2)

43 FU-GBHS3060 SCREW M3x6(x2)

44 FU-GBHS3040 SCREW M3x4(x2)

50 FU-WX1A8CN0-012 WIRE ASSEMBLY 7pin CL107

51 FU-WX1A8CN0-013 WIRE ASSEMBLY 2pin CL451

52 FU-WX1A8CN0-013 WIRE ASSEMBLY 2pin CL802

53 FU-WX1A8CN0-006 WIRE ASSEMBLY 25pin CL3601

54 FU-WX1A8CN0-006 WIRE ASSEMBLY 25pin CL3701

55 FU-WX1A8CN0-005 WIRE ASSEMBLY 23pin CL3704

56 FU-WX1A8A70-101 FFC WIRE 55pin CL4501

57 FU-WX1A8A70-101 FFC WIRE 55pin CL4502

58 FU-WX1A8CN0-006 WIRE ASSEMBLY 25pin CL4503

59 FU-J6Q568CTK002 IC CARD CONNECTOR

101 FU-1ESA19688-1 MAIN PWB Please note that the TUNER is not included in MAIN PWB LT-19DA1BJAK

101 FU-1ESA19148-1 MAIN PWB Please note that the TUNER is not included in MAIN PWB LT-19DA1BUAK

102 FU-1ESA19688-2 FUNCTION PWB LT-19DA1BJAK

102 FU-1ESA19148-2 FUNCTION PWB LT-19DA1BUAK

103 FU-1ESA19688-3 IR SENSOR PWB LT-19DA1BJAK

103 FU-1ESA19148-3 IR SENSOR PWB LT-19DA1BUAK

104 FU-1ESA19688-4 JACK PWB LT-19DA1BJAK

104 FU-1ESA19148-4 JACK PWB LT-19DA1BUAK

105 FU-1ESA19502-1 INVERTER PWB

106 FU-1ESA19502-2 JUNCTION PWB

107 FU-1ESA19709 DIGITAL MAIN PWB LT-19DA1BJAK

107 FU-1ESA19153 DIGITAL MAIN PWB LT-19DA1BUAK

TU1 FU-UTUNPSGAL013 TUNER UNIT TU501

(No.YA683<Rev.001>)3-3

Page 26

EXPLODED VIEW

5

22

3333

44

3333

3333

5252

5656

5757

3535

3838

3535

33

3232

5454

5353

1111

3333

2222

5151

66

102102

3939

103103

55

3939

101101

3535

3535

3535

105105

3535

3535

106106

77

3737

353

3-4(No.YA683<Rev.001>)

Page 27

4040

5858

5555

107107

5959

3535

3939

2525

11

3535

2525

3939

4141

2525

4141

1010

4343

77

3535

2626

5050

3535

3535

104104

2828

TU1TU1

2727

4444

3030

3535

4141

4040

3535

4242

2929

SERIAL

4141

1616

NO.LABEL

RATING LABEL

1313

3636

1212

3636

3131

(No.YA683<Rev.001>)3-5

Page 28

PRINTED WIRING BOARD PARTS LIST [LT-19DA1BJ/AK]

MAIN P.W. BOARD ASS'Y (FU-1ESA19688-1)

Ref No. Part No. Part Name Description Local

IC601 FU-QPEL561L11AV PHOTO COUPLER

IC801 FU-QSZBA0SMS017 IC

IC802 FU-NSZBA0TTY192 IC AUDIO D/A

IC850 FU-QSZBA0TTS162 IC SWITCHING

IC851 FU-QSZBA0TTS163 IC SWITCH

IC900 FU-NSZBA0SJY041 IC REG 5V

IC902 FU-NSZBA0SJY062 IC REG

Q505 FU-NQS4KTC3199P TRANSISTOR

Q600 FU-QFWZ02SK3566 FET

Q601 FU-QQS02SC2120F TRANSISTOR

Q726 FU-NQS1KTA1267P TRANSISTOR

Q727 FU-NQS1KTA1267P TRANSISTOR

Q731 FU-NQS4KTC3199P TRANSISTOR

Q734 FU-NQS1KTA1267P TRANSISTOR

Q744 FU-NQS4KTC3199P TRANSISTOR

Q802 FU-NQS4KTC3199P TRANSISTOR

Q805 FU-NQS4KTC3199P TRANSISTOR

Q900 FU-NQS4KTC3199P TRANSISTOR

Q901 FU-QQS02SC2120F TRANSISTOR

Q902 FU-QQS02SC2120F TRANSISTOR

Q903 FU-NQS4KTC3199P TRANSISTOR

Q904 FU-NQS4KTC3199P TRANSISTOR

Q906 FU-QQS02SC2120F TRANSISTOR

Q907 FU-NQS1KTA1267P TRANSISTOR

Q908 FU-NQS4KTC3199P TRANSISTOR

Q911 FU-NQS1KTA1267P TRANSISTOR

Q912 FU-NQS4KTC3199P TRANSISTOR

Q920 FU-NQS4KTC3199P TRANSISTOR

Q922 FU-NQE0KTD2059P TRANSISTOR

Q936 FU-QQWZ2SC4881F POW TRANSISTOR

D501 FU-QDTZ001SS133 SI DIODE

D610 FU-QDTB00MTZJ22 ZENER DIODE

D611 FU-NDLZ001N5399 SI DIODE

D612 FU-QDTB0MTZJ5R6 ZENER DIODE

D613 FU-NDLZ001N5399 SI DIODE

D614 FU-NDLZ001N5399 SI DIODE

D615 FU-QDTZ001SS133 SI DIODE

D616 FU-NDLZ001N5399 SI DIODE

D621 FU-QDTZ001SS133 SI DIODE

D622 FU-QDTZ001SS133 SI DIODE

D624 FU-QDLZ001ZC18Q ZENER DIODE

D629 FU-QDTB00MTZJ33 ZENER DIODE

D701 FU-QDTB00MTZJ13 ZENER DIODE

D702 FU-QDTB00MTZJ13 ZENER DIODE

D755 FU-QDTB0MTZJ3R9 ZENER DIODE

D758 FU-QDTB00MTZJ13 ZENER DIODE

D802 FU-QDTZ001SS133 SI DIODE

D803 FU-QDTB0MTZJ4R7 ZENER DIODE

D900 FU-NDQZ000SB360 SB DIODE

D901 FU-NDL1000FR104 FR DIODE

D903 FU-NDL1000FR104 FR DIODE

D904 FU-NDLZ000FR154 DIODE

D905 FU-NDL1000FR104 FR DIODE

D906 FU-NDQZ000SB340 SB DIODE

D908 FU-QDLZ001ZC43Q DIODE

D909 FU-NDQZ001N4005 SI DIODE

D910 FU-QDTZ001SS133 SI DIODE

D911 FU-QDTZ001SS133 SI DIODE

D912 FU-QDTZ001SS133 SI DIODE

D913 FU-QDTB0MTZJ5R6 ZENER DIODE

D915 FU-QDTB00MTZJ33 ZENER DIODE

D916 FU-NSZBA0TJY036 IC REGULATOR

D918 FU-QDTB00MTZJ12 ZENER DIODE

D919 FU-QDTZ001SS133 SI DIODE

D920 FU-NSZBA0TJY036 IC REGULATOR

D922 FU-QDTZ001SS133 SI DIODE

D923 FU-QDTB00MTZJ24 ZENER DIODE

D924 FU-NDWZ000SB270 SB DIODE

D925 FU-QDTZ001SS133 SI DIODE

D926 FU-QDTB00MTZJ10 ZENER DIODE

D927 FU-QDTZ001SS133 SI DIODE

D928 FU-QDTB0MTZJ6R8 ZENER DIODE

D929 FU-QDTZ001SS133 SI DIODE

D930 FU-QDTZ001SS133 SI DIODE

D931 FU-QDTZ001SS133 SI DIODE

D935 FU-QDTZ001SS133 SI DIODE

D936 FU-NSZBA0TJY036 IC REGULATOR

D942 FU-QDTZ001SS133 SI DIODE

D944 FU-QDTZ001SS133 SI DIODE

D947 FU-QDTZ001SS133 SI DIODE

D948 FU-QDTZ001SS133 SI DIODE

D951 FU-QDTB00MTZJ15 ZENER DIODE

Ref No. Part No. Part Name Description Local

D953 FU-QDTZ001SS133 SI DIODE

D954 FU-QDTZ001SS133 SI DIODE

D955 FU-QDTB00MTZJ39 ZENER DIODE

D956 FU-QDTZ001SS133 SI DIODE

D966 FU-QDTZ001SS133 SI DIODE

D967 FU-QDTZ001SS133 SI DIODE

D970 FU-QDTZ001SS133 SI DIODE

D973 FU-QDTZ001SS133 SI DIODE

D974 FU-NDQZ001N4005 SI DIODE

D975 FU-NDQZ001N4005 SI DIODE

D985 FU-NSZBA0TJY036 IC REGULATOR

D986 FU-QDTZ001SS133 SI DIODE

D987 FU-QDTZ001SS133 SI DIODE

D988 FU-QDTZ001SS133 SI DIODE

D989 FU-QDTZ001SS133 SI DIODE

D990 FU-QDLZ030PHA20 SB DIODE

C102 FU-CHD1JJ3CH102 C CAPACITOR 1000pF 50V J

C103 FU-CHD1JJ3CH102 C CAPACITOR 1000pF 50V J

C104 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C105 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C508 FU-CHD1JK30B103 C CAPACITOR 0.01uF 50V K

C510 FU-CE1AMASDL101 E CAPACITOR 100uF 10V M

C512 FU-CHD1JJ3CH470 C CAPACITOR 47pF 50V J

C516 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C517 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C518 FU-CE1AMASDL102 E CAPACITOR 1000uF 10V M

C519 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C520 FU-CHD1JJ3CH470 C CAPACITOR 47pF 50V J

C524 FU-CE1CMAVSL330 E CAPACITOR 33uF 16V M

C525 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C526 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C600 FU-CT2E224MS037 CAPACITOR 0.22uF 250V

C601 FU-CT2E104DC017 CAPACITOR 0.1uF 250V

C615 FU-CA2H181DYG10 E CAPACITOR 180uF 400V M

C621 FU-CA3D471PAN04 C CAPACITOR 470pF 2kV

C623 FU-CA2A103DT018 CAPACITOR 0.01uF 100V J

C624 FU-CA2A152DT018 CAPACITOR 0.0015uF 100V J

C625 FU-CA2A473DT018 CAPACITOR 0.047uF 100V J

C642 FU-CA2E332MR101 CAPACITOR 3300pF 250V K

C702 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C703 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C707 FU-CHD1JJ3CH102 C CAPACITOR 1000pF 50V J

C710 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C711 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C712 FU-CHD1JK30B562 C CAPACITOR 5600pF 50V K

C714 FU-CHD1JK30B562 C CAPACITOR 5600pF 50V K

C716 FU-CHD1JK30B562 C CAPACITOR 5600pF 50V K

C718 FU-CHD1JK30B562 C CAPACITOR 5600pF 50V K

C720 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C721 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C722 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C723 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C731 FU-CHD1JK30B562 C CAPACITOR 5600pF 50V K

C732 FU-CHD1JK30B562 C CAPACITOR 5600pF 50V K

C733 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C734 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C741 FU-CHD1JK30B222 C CAPACITOR 2200pF 50V K

C742 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C744 FU-CHD1JK30B222 C CAPACITOR 2200pF 50V K

C745 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C747 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C751 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C753 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C756 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C758 FU-CE1CMAVSL470 E CAPACITOR 47uF 16V M

C788 FU-CE1CMASDL101 E CAPACITOR 100uF 16V M

C789 FU-CE0KMAVSL331 E CAPACITOR 330uF 6.3V M

C791 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C792 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C793 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C794 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C795 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C796 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C797 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C801 FU-CE1CMASDL471 E CAPACITOR 470uF 16V M

C802 FU-CE1CMASDL471 E CAPACITOR 470uF 16V M

C806 FU-CE1EMASDL470 E CAPACITOR 47uF 25V M

C808 FU-CE1AMASDL101 E CAPACITOR 100uF 10V M

C809 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C810 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C811 FU-CE1EMASDL470 E CAPACITOR 47uF 25V M

C812 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C816 FU-CE1JMASDL220 E CAPACITOR 22uF 50V M

C818 FU-CE1CMASDL471 E CAPACITOR 470uF 16V M

C819 FU-CHD1JK30B392 C CAPACITOR 3900pF 50V K

3-6(No.YA683<Rev.001>)

Page 29

Ref No. Part No. Part Name Description Local

Ref No. Part No. Part Name Description Local

C820 FU-CHD1JK30B392 C CAPACITOR 3900pF 50V K

C822 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C823 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C824 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C825 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C826 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C827 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C835 FU-CHD1JJ3CH102 C CAPACITOR 1000pF 50V J

C836 FU-CHD1JJ3CH102 C CAPACITOR 1000pF 50V J

C837 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C883 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C884 FU-CHD1AK30B105 C CAPACITOR 1uF 10V K

C892 FU-CHD1JJ3CH102 C CAPACITOR 1000pF 50V J

C894 FU-CHD1JJ3CH102 C CAPACITOR 1000pF 50V J

C895 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C896 FU-CHD1JJ3CH101 C CAPACITOR 100pF 50V J

C900 FU-CE1AMZNDL332 E CAPACITOR 3300uF 10V

C901 FU-CE1JMASDL2R2 E CAPACITOR 2.2uF 50V M

C902 FU-CE1EMZPDL222 E CAPACITOR 2200uF 25V M

C903 FU-CE1JMASDL101 E CAPACITOR 100uF 50V M

C904 FU-CE1EMASDL331 E CAPACITOR 330uF 25V M

C905 FU-CE1EMASDL470 E CAPACITOR 47uF 25V M

C907 FU-CE0KMASDL222 E CAPACITOR 2200uF 6.3V M

C909 FU-CA2A272DT018 CAPACITOR 0.0027uF 100V J

C910 FU-CE1JMASDL220 E CAPACITOR 22uF 50V M

C911 FU-CE1CMASDL471 E CAPACITOR 470uF 16V M

C912 FU-CE1JMASDL1R0 E CAPACITOR 1uF 50V M

C914 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C916 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C917 FU-CE1CMASDL102 E CAPACITOR 1000uF 16V M

C920 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C921 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C922 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C923 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C924 FU-CE1CMASDL471 E CAPACITOR 470uF 16V M

C925 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C926 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C927 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C940 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C941 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C951 FU-CE1CMASDL221 E CAPACITOR 220uF 16V M

C952 FU-CE1JMASDL100 E CAPACITOR 10uF 50V M

C953 FU-CE1AMASDL331 E CAPACITOR 330uF 10V M

C958 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

C999 FU-CHD1JZ30F104 C CAPACITOR 0.1uF 50V

Ω

R102 FU-RRXAJR5Z0100 MG RESISTOR 10

R103 FU-RRXAJR5Z0100 MG RESISTOR 10

R511 FU-RRXAJR5Z0101 MG RESISTOR 100

R512 FU-RRXAJR5Z0101 MG RESISTOR 100

R515 FU-RRXAJR5Z0102 MG RESISTOR 1k

R522 FU-RRXAJR5Z0221 MG RESISTOR 220

R525 FU-RRXAJR5Z0101 MG RESISTOR 100

R526 FU-RRXAJR5Z0470 MG RESISTOR 470

R600 FU-RXX2JZLZ0105 RESISTOR 1MΩ 1/2W J

R610 FU-RW051R2PG001 UNF.WW RESISTOR 1.2Ω 5W K

R620 FU-RCX4JATZ0824 C RESISTOR 820k

R621 FU-RCX4JATZ0824 C RESISTOR 820k

R622 FU-RCX4JATZ0824 C RESISTOR 820k

R623 FU-RCX4JATZ0824 C RESISTOR 820k

R624 FU-RCX4JATZ0394 C RESISTOR 390k

R632 FU-RCX4JATZ0391 C RESISTOR 390

R633 FU-RCX4JATZ0391 C RESISTOR 390

R634 FU-RCX4JATZ0331 C RESISTOR 330

R635 FU-RCX4JATZ0152 C RESISTOR 1.5k

R636 FU-RN02R68ZU001 O.M.F.RESISTOR 0.68Ω 2W J

R637 FU-RCX4JATZ0151 C RESISTOR 150

R638 FU-RCX4JATZ0562 C RESISTOR 5.6k

R639 FU-RCX4JATZ0271 C RESISTOR 270k

R701 FU-RRXAJR5Z0750 MG RESISTOR 75

R702 FU-RCX4JATZ0101 C RESISTOR 100

R704 FU-RCX4JATZ0471 C RESISTOR 470

R707 FU-RRXAJR5Z0750 MG RESISTOR 75

R708 FU-RRXAJR5Z0101 MG RESISTOR 100

R713 FU-RRXAJR5Z0750 MG RESISTOR 75

R714 FU-RCX4JATZ0101 C RESISTOR 100

R716 FU-RRXAJR5Z0473 MG RESISTOR 47k

R717 FU-RCX4JATZ0152 C RESISTOR 1.5k

R718 FU-RRXAJR5Z0183 MG RESISTOR 18k

R719 FU-RRXAJR5Z0473 MG RESISTOR 47k

R720 FU-RCX4JATZ0152 C RESISTOR 1.5k

R721 FU-RRXAJR5Z0183 MG RESISTOR 18k

R722 FU-RCX4JATZ0152 C RESISTOR 1.5k

R723 FU-RCX4JATZ0152 C RESISTOR 1.5k

R729 FU-RRXAJR5Z0102 MG RESISTOR 1k

R730 FU-RCX4JATZ0471 C RESISTOR 470

R732 FU-RRXAJR5Z0471 MG RESISTOR 470

R737 FU-RCX4JATZ0471 C RESISTOR 470

R738 FU-RRXAJR5Z0473 MG RESISTOR 47k

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/10W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/4W J

Ω

1/10W J

Ω

1/4W J

Ω

1/4W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/4W J

Ω

1/10W J

Ω

1/4W J

Ω

1/10W J

Ω

1/10W J

Ω

1/4W J

Ω

1/10W J

Ω

1/4W J

Ω

1/4W J

Ω

1/10W J

Ω

1/4W J

Ω

1/10W J

Ω

1/4W J

Ω

1/10W J

R739 FU-RRXAJR5Z0473 MG RESISTOR 47kΩ 1/10W J

R740 FU-RRXAJR5Z0470 MG RESISTOR 470

R741 FU-RCX4JATZ0561 C RESISTOR 560

R746 FU-RCX4JATZ0561 C RESISTOR 560

R751 FU-RRXAJR5Z0750 MG RESISTOR 75

R752 FU-RCX4JATZ0101 C RESISTOR 100

R756 FU-RCX4JATZ0153 C RESISTOR 15k

R757 FU-RRXAJR5Z0512 MG RESISTOR 5.1k

R758 FU-RRXAJR5Z0750 MG RESISTOR 75

R759 FU-RCX4JATZ0101 C RESISTOR 100

R761 FU-RCX4JATZ0471 C RESISTOR 470

R762 FU-RRXAJR5Z0101 MG RESISTOR 100

R763 FU-RRXAJR5Z0750 MG RESISTOR 75

R764 FU-RCX4JATZ0750 C RESISTOR 75

R765 FU-RRXAJR5Z0750 MG RESISTOR 75

R766 FU-RCX4JATZ0101 C RESISTOR 100

R767 FU-RRXAJR5Z0122 MG RESISTOR 1.2k

R768 FU-RCX4JATZ0471 C RESISTOR 470

R770 FU-RRXAJR5Z0750 MG RESISTOR 75

R771 FU-RCX4JATZ0101 C RESISTOR 100

R775 FU-RRXAJR5Z0103 MG RESISTOR 10k

R776 FU-RRXAJR5Z0103 MG RESISTOR 10k

R777 FU-RRXAJR5Z0183 MG RESISTOR 18k

R778 FU-RRXAJR5Z0183 MG RESISTOR 18k

R779 FU-RRXAJR5Z0473 MG RESISTOR 47k

R780 FU-RRXAJR5Z0473 MG RESISTOR 47k

R781 FU-RCX4JATZ0152 C RESISTOR 1.5k

R782 FU-RRXAJR5Z0102 MG RESISTOR 1k

R783 FU-RCX4JATZ0152 C RESISTOR 1.5k

R784 FU-RRXAJR5Z0103 MG RESISTOR 10k

R785 FU-RRXAJR5Z0104 MG RESISTOR 100k

R786 FU-RRXAJR5Z0103 MG RESISTOR 10k

R787 FU-RRXAJR5Z0183 MG RESISTOR 18k

R788 FU-RRXAJR5Z0183 MG RESISTOR 18k

R793 FU-RRXAJR5Z0393 MG RESISTOR 39k

R794 FU-RRXAJR5Z0102 MG RESISTOR 1k

R797 FU-RRXAJR5Z0102 MG RESISTOR 1k

R801 FU-RRXAJR5Z0563 MG RESISTOR 56k

R802 FU-RRXAJR5Z0273 MG RESISTOR 27k

R807 FU-RN024R7ZU001 O.M.F.RESISTOR 4.7Ω 2W J

R808 FU-RRXAJR5Z0103 MG RESISTOR 10k

R809 FU-RRXAJR5Z0103 MG RESISTOR 10k

R811 FU-RRXAJR5Z0473 MG RESISTOR 47k

R812 FU-RRXAJR5Z0222 MG RESISTOR 2.2kΩ 1/10W J

R813 FU-RCX4JATZ0103 C RESISTOR 10k

R814 FU-RRXAJR5Z0392 MG RESISTOR 3.9k

R816 FU-RRXAJR5Z0103 MG RESISTOR 10k

R817 FU-RRXAJR5Z0392 MG RESISTOR 3.9k

R818 FU-RRXAJR5Z0223 MG RESISTOR 22k

R822 FU-RRXAJR5Z0223 MG RESISTOR 22k

R824 FU-RRXAJR5Z0103 MG RESISTOR 10k

R825 FU-RCX4JATZ0103 C RESISTOR 10k

R829 FU-RCX4JATZ0121 C RESISTOR 120

R830 FU-RRXAJR5Z0104 MG RESISTOR 100k

R831 FU-RCX4JATZ0104 C RESISTOR 100k

R832 FU-RCX4JATZ0104 C RESISTOR 100k

R833 FU-RRXAJR5Z0330 MG RESISTOR 33

R834 FU-RRXAJR5Z0330 MG RESISTOR 33

R835 FU-RRXAJR5Z0330 MG RESISTOR 33

R836 FU-RRXAJR5Z0330 MG RESISTOR 33

R837 FU-RCX4JATZ0181 C RESISTOR 180

R838 FU-RCX4JATZ0181 C RESISTOR 180

R839 FU-RRXAJR5Z0473 MG RESISTOR 47k

R840 FU-RRXAZR5Z0000 MG RESISTOR 0

R842 FU-RRXAJR5Z0104 MG RESISTOR 100k

R843 FU-RCX4JATZ0104 C RESISTOR 100k

R844 FU-RCX4JATZ0104 C RESISTOR 100k

R845 FU-RRXAJR5Z0104 MG RESISTOR 100k

R846 FU-RRXAJR5Z0104 MG RESISTOR 100k

R847 FU-RCX4JATZ0104 C RESISTOR 100k

R848 FU-RRXAJR5Z0104 MG RESISTOR 100k

R849 FU-RRXAJR5Z0104 MG RESISTOR 100k

R850 FU-RRXAJR5Z0104 MG RESISTOR 100k

R852 FU-RRXAJR5Z0104 MG RESISTOR 100k

R854 FU-RRXAJR5Z0104 MG RESISTOR 100k

R855 FU-RRXAJR5Z0104 MG RESISTOR 100k

R856 FU-RCX4JATZ0104 C RESISTOR 100k

R857 FU-RRXAJR5Z0104 MG RESISTOR 100k

R858 FU-RCX4JATZ0104 C RESISTOR 100k

R859 FU-RCX4JATZ0104 C RESISTOR 100k

R890 FU-RRXAJR5Z0104 MG RESISTOR 100k

R891 FU-RRXAJR5Z0104 MG RESISTOR 100k

R892 FU-RCX4JATZ0104 C RESISTOR 100k

R893 FU-RCX4JATZ0104 C RESISTOR 100k

R894 FU-RRXAJR5Z0104 MG RESISTOR 100k

R895 FU-RCX4JATZ0104 C RESISTOR 100k

R896 FU-RRXAJR5Z0273 MG RESISTOR 27k

R897 FU-RRXAJR5Z0273 MG RESISTOR 27k

R900 FU-RCX4JATZ03R3 C RESISTOR 3.3

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

1/10W J

Ω

Ω

1/10W J

Ω

Ω

1/10W J

Ω

Ω

1/10W J

Ω

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

Ω

1/10W J

Ω

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

1/10W J

Ω

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

1/10W J

Ω

Ω

Ω

1/10W J

Ω

Ω

1/10W J

Ω

1/10W J

Ω

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/10W

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

1/4W J

(No.YA683<Rev.001>)3-7

Page 30

Ref No. Part No. Part Name Description Local

Ref No. Part No. Part Name Description Local

R904 FU-RCX4JATZ0123 C RESISTOR 12kΩ 1/4W J

R906 FU-RRXAFR5H4701 MG RESISTOR 4.7kΩ 1/10W F

R907 FU-RRXAFR5H4701 MG RESISTOR 4.7kΩ 1/10W F

R908 FU-RRXAFR5H3901 MG RESISTOR 3.9kΩ 1/10W F

R909 FU-RRXAFR5H3901 MG RESISTOR 3.9kΩ 1/10W F

R910 FU-RRXAFR5H8200 MG RESISTOR 820

R911 FU-RRXAFR5H5601 MG RESISTOR 5.6k

R912 FU-RRXAFR5H2400 MG RESISTOR 240Ω 1/10W F

R913 FU-RRXAFR5H2400 MG RESISTOR 240Ω 1/10W F

R914 FU-RRXAFR5H2400 MG RESISTOR 240Ω 1/10W F

R915 FU-RRXAFR5H2400 MG RESISTOR 240Ω 1/10W F

R916 FU-RRXAJR5Z0181 MG RESISTOR 180

R917 FU-RCX4JATZ0271 C RESISTOR 270k

R918 FU-RCX4JATZ0682 C RESISTOR 6.8k

R919 FU-RN01471ZU001 O.M.F.RESISTOR 470

R920 FU-RRXAJR5Z0103 MG RESISTOR 10k

R921 FU-RRXAJR5Z0683 MG RESISTOR 68k

R922 FU-RN02120ZU001 O.M.F.RESISTOR 120

R923 FU-RCX4JATZ0102 C RESISTOR 1k

R925 FU-RRXAFR5H3301 MG RESISTOR 3.3k

R926 FU-RRXAFR5H9101 MG RESISTOR 9.1k

R928 FU-RCX4JATZ0272 C RESISTOR 2.7k

R929 FU-RCX4JATZ0101 C RESISTOR 100

R930 FU-RRXAFR5H3001 MG RESISTOR 3k

R931 FU-RRXAFR5H9101 MG RESISTOR 9.1k

R936 FU-RRXAJR5Z0151 MG RESISTOR 150

R937 FU-RRXAJR5Z0272 MG RESISTOR 2.7k

R938 FU-RRXAJR5Z0103 MG RESISTOR 10k

R939 FU-RN02R82ZU001 RESISTOR 0.82

R942 FU-RRXAJR5Z0103 MG RESISTOR 10k

R943 FU-RRXAJR5Z0103 MG RESISTOR 10k

R944 FU-RCX4JATZ0272 C RESISTOR 2.7k

R945 FU-RRXAJR5Z0103 MG RESISTOR 10k

R947 FU-RCX4JATZ0473 C RESISTOR 47k

R948 FU-RN02R82ZU001 RESISTOR 0.82

R949 FU-RCX4JATZ0182 C RESISTOR 1.8k

R950 FU-RCX4JATZ0271 C RESISTOR 270k

R953 FU-RN02390ZU001 RESISTOR 390

R954 FU-RN02120ZU001 O.M.F.RESISTOR 120

R955 FU-RN02390ZU001 RESISTOR 390

R959 FU-RRXAFR5H1202 MG RESISTOR 12k

R960 FU-RRXAFR5H6200 MG RESISTOR 620

R961 FU-RRXAFR5H3001 MG RESISTOR 3k

R962 FU-RCX4JATZ0271 C RESISTOR 270k

R963 FU-RRXAJR5Z0682 MG RESISTOR 6.8k

R964 FU-RRXAJR5Z0103 MG RESISTOR 10k

R965 FU-RCX4JATZ0273 C RESISTOR 27k

R966 FU-RCX4JATZ0332 C RESISTOR 3.3k

R967 FU-RRXAJR5Z0103 MG RESISTOR 10k

R968 FU-RCX4JATZ0272 C RESISTOR 2.7k

R969 FU-RRXAJR5Z0332 MG RESISTOR 3.3k

R970 FU-RRXAJR5Z0332 MG RESISTOR 3.3k

R971 FU-RRXAFR5H8201 MG RESISTOR 8.2k

R972 FU-RRXAFR5H5101 MG RESISTOR 5.1k

R973 FU-RCX4JATZ0271 C RESISTOR 270k

R974 FU-RRXAJR5Z0101 MG RESISTOR 100

R975 FU-RCX4JATZ0271 C RESISTOR 270k

R976 FU-RRXAFR5H5601 MG RESISTOR 5.6k

R977 FU-RRXAJR5Z0272 MG RESISTOR 2.7k

R978 FU-RRXAJR5Z0822 MG RESISTOR 8.2k

R980 FU-RCX4JATZ0102 C RESISTOR 1k

R982 FU-RRXAFR5H5601 MG RESISTOR 5.6k

R983 FU-RRXAJR5Z0682 MG RESISTOR 6.8k

R985 FU-RCX4JATZ0272 C RESISTOR 2.7k

R986 FU-RRXAFR5H2400 MG RESISTOR 240Ω 1/10W F

R987 FU-RRXAJR5Z0101 MG RESISTOR 100

R994 FU-RRXAFR5H3301 MG RESISTOR 3.3k

R995 FU-RRXAFR5H0433 MG RESISTOR 43k

R997 FU-RN02R22ZU001 O.M.F.RESISTOR 0.22

L501 FU-LLARKBSTU100 INDUCTOR 10uH

L502 FU-LLARKBSTU100 INDUCTOR 10uH

L601 FU-LLEG0Z0XB008 LINE FILTER

L701 FU-LLAXJATTU2R2 INDUCTOR 2.2uH

L702 FU-LLAXJATTU2R2 INDUCTOR 2.2uH

L703 FU-LLAXJATTU2R2 INDUCTOR 2.2uH

L838 FU-LLAXJATTU2R2 INDUCTOR 2.2uH

L839 FU-LLAXJATTU2R2 INDUCTOR 2.2uH

L840 FU-LLAXJATTU2R2 INDUCTOR 2.2uH

T601 FU-LTT2PE0KT047 POWER TRANS

BC601 FU-LLBF00STU030 INDUCTOR

BC603 FU-LLBF00STU030 INDUCTOR

BC750 FU-LLBF00STU030 INDUCTOR

F601 FU-PBGZ20BAG021 FUSE 4A/250V