JVC KW-XG704UI, KW-V11E, KW-XG701EY, KW-XG701EU, KW-XG701EX Service Manual

...

Q

Q

3

7

6

3

1

5

1

5

0

SERVICE MANUAL

CD RECEIVER

TEL 13942296513 QQ 376315150 892498299

MA34620076SERVICE MANUAL

KW-XG700J, KW-XG701E, KW-XG701EX,

KW-XG701EY, KW-XG701EU, KW-XG704UI,

KW-XG705U, KW-XG705UN, KW-XG705UH,

KW-XG706U, KW-XG706UN, KW-XG706UH,

KW-XG707EE, KW-XG708UF

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

COPYRIGHT © 2007 Victor Company of Japan, Limited

w

13942296513

KW-XG700 KW-XG700

* Please refer to the mechanism manual (model TN2007-1010 (No.MY005 and No.MY005B)) for the CD mechanism.

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

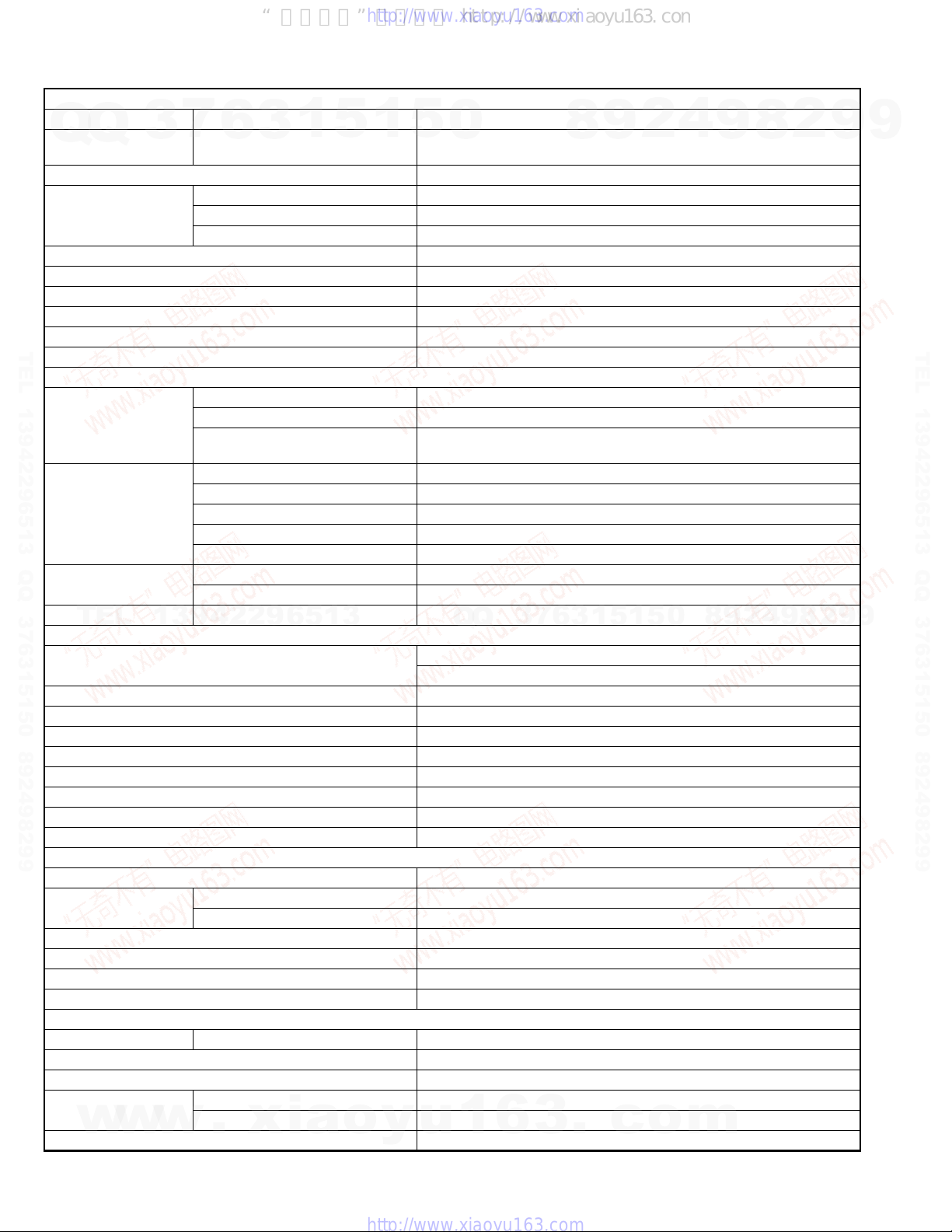

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

w

w

.

xia

o

y

u

Q

Q

1

6

3

6

7

3

3

.

1

5

c

1

5

o

0

KW-XG701

KW-XG707

9

8

m

2

4

9

8

2

9

9

COPYRIGHT © 2007 Victor Company of Japan, Limited

No.MA346

2007/6

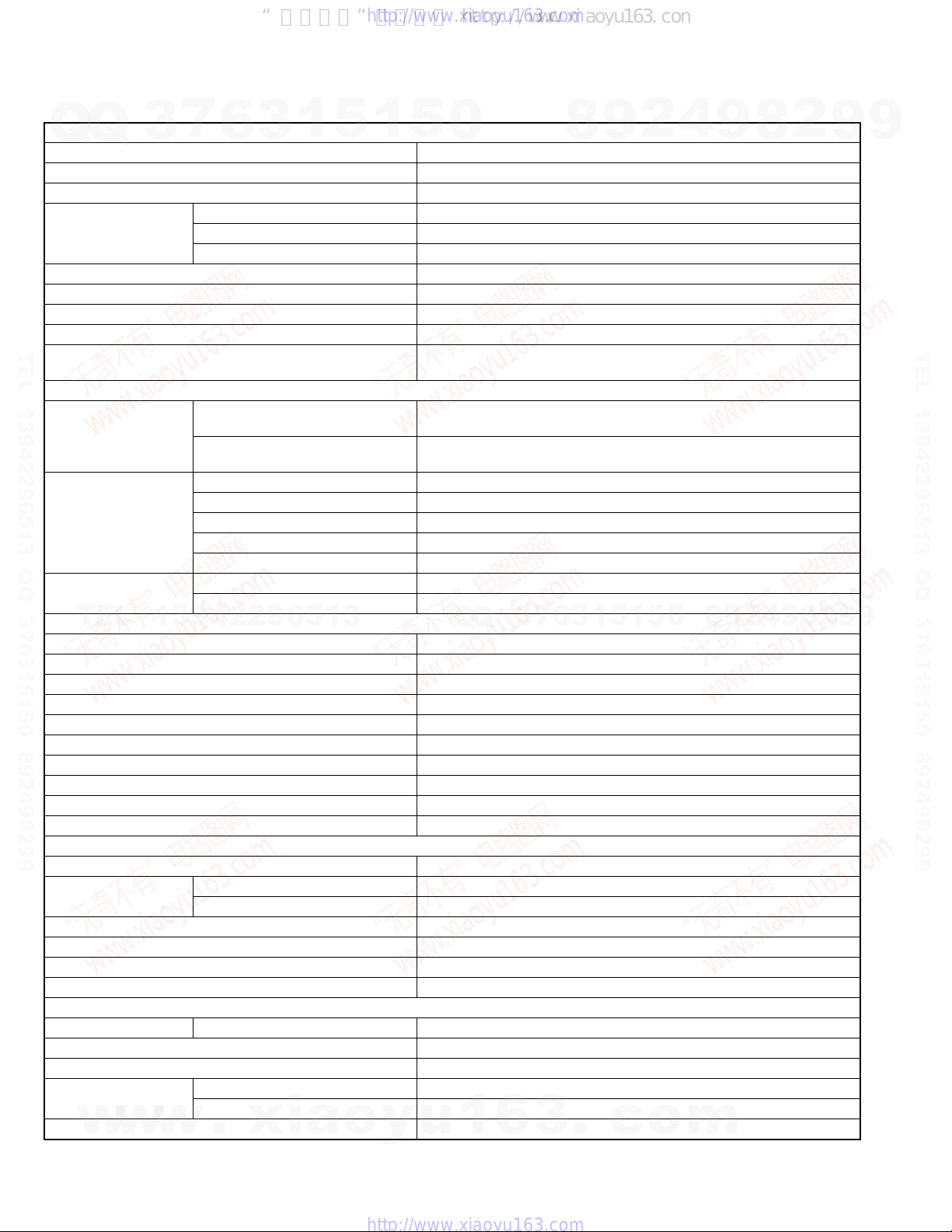

SPECIFICATION

KW-XG700

7

Q

Q

Power Output 20 W RMS × 4 Channels at 4 Ω and [< or =] 1% THD+N

Signal to Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB at 60 Hz

Frequency Response 40 Hz to 20 000 Hz

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Subwoofer-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

TEL 13942296513 QQ 376315150 892498299

Other Terminal CD changer, Steering wheel remote input, USB input terminal, Subwoofer input,

Frequency Range FM 87.5 MHz to 107.9 MHz (with channel interval set to 100 kHz or 200 kHz)

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

AM Tuner Sensitivity 20 µV

TEL

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

AAC (Advanced Audio Coding) Decoding Format Max. Bit Rate: 320 kbps

USB Standard USB 1.1

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class, MTP

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA/AAC/WAV

Max. Current Less than 500 mA

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D)

(approx.)

Mass 1.8 kg (4.0 lbs) (excluding accessories)

w

3

13942296513

w

w

6

Mid-range ±12 dB at 1 kHz

Treble ±12 dB at 10 kHz

AM 530 kHz to 1 710 kHz (with channel interval set to 10 kHz)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Selectivity 35 dB

Low Speed Maximum 1.5 Mbps

Installation Size 178 mm × 100 mm × 158 mm (7-1/16" × 3-15/16" × 6-1/4")

Set Size 178 mm × 100 mm × 178 mm (7-1/16" × 3-15/16" × 7-1/16")

.

xia

3

1

AUDIO AMPLIFIER SECTION

5

1

5

0

AUX (auxiliary) input jack

TUNER SECTION

87.5 MHz to 108.0 MHz (with channel interval set to 50 kHz)

531 kHz to 1 602 kHz (with channel interval set to 9 kHz)

CD PLAYER SECTION

o

y

Q

USB DEVICE

GENERAL

u

Q

1

3

6

6

7

3

8

3

.

9

1

1

5

c

2

5

o

4

0

m

9

8

9

8

2

4

9

2

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Design and specifications are subject to change without notice.

1-2 (No.MA346)

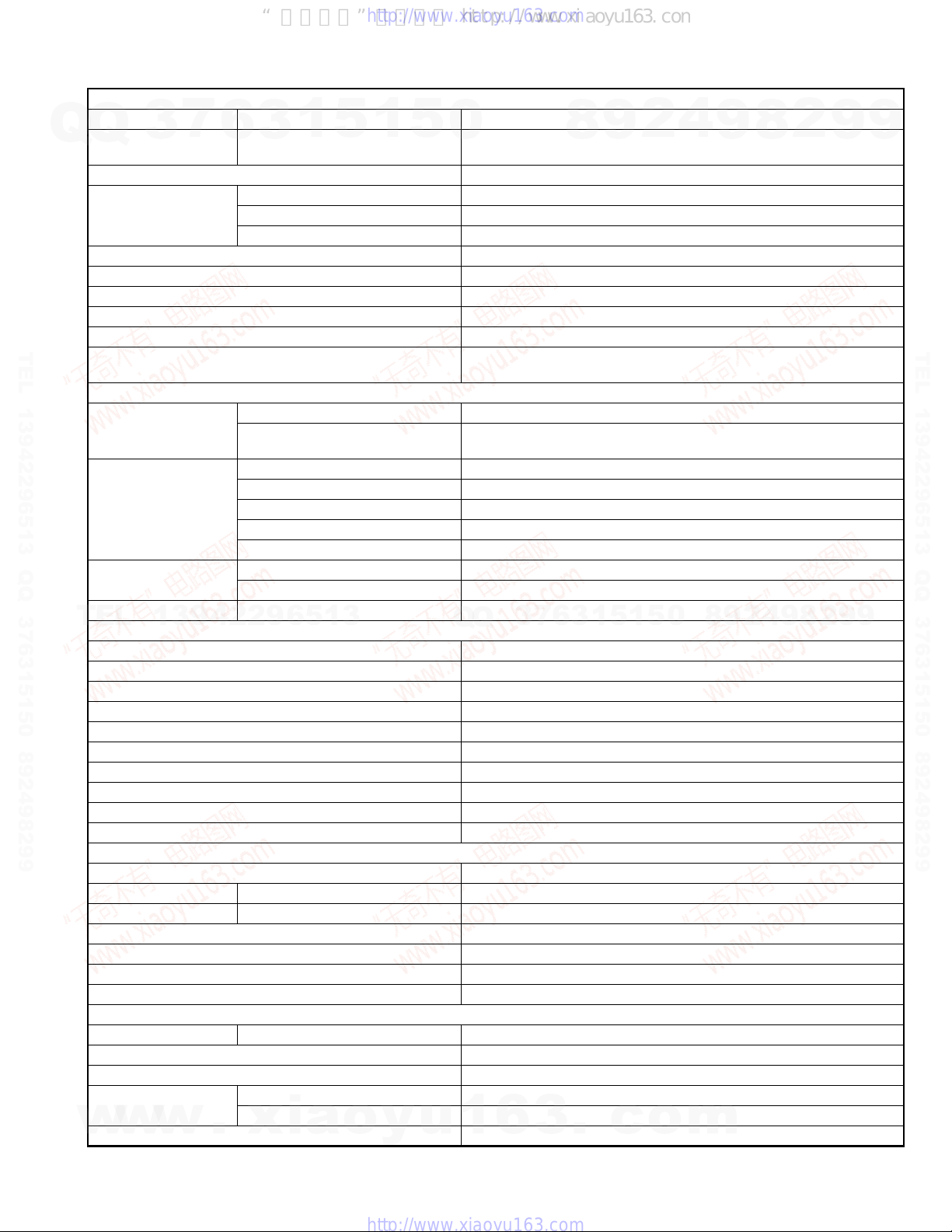

KW-XG701

AUDIO AMPLIFIER SECTION

Maximum Power Output Front and rear 50 W per channel

Q

Q

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB at 60 Hz

Frequency Response 40 Hz to 20 000 Hz

Signal to Noise Ratio 70 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

TEL 13942296513 QQ 376315150 892498299

Subwoofer-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Other Terminal CD changer, Steering wheel remote input, USB input terminal, Subwoofer input,

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

MW Tuner Sensitivity 20 µV

LW Tuner Sensitivity 50 µV

TEL

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

AAC (Advanced Audio Coding) Decoding Format Max. Bit Rate: 320 kbps

USB Standard USB 1.1

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class, MTP

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA/AAC/WAV

Max. Current Less than 500 mA

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

w

w

Mass 2.3 kg (excluding accessories)

3

7

6

Front and rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total har-

Mid-range ±12 dB at 1 kHz

Treble ±12 dB at 10 kHz

AM (MW) 522 kHz to 1 620 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Selectivity 35 dB

3

1

13942296513

Low Speed Maximum 1.5 Mbps

Installation Size 182 mm × 111 mm × 158 mm

w

Set Size 178 mm × 100 mm × 178 mm

.

xia

5

o

1

y

5

0

monic distortion.

AUX (auxiliary) input jack

TUNER SECTION

(LW) 144 kHz to 279 kHz

Q

Q

CD PLAYER SECTION

USB DEVICE

GENERAL

u

1

6

3

7

3

6

8

3

.

9

1

1

5

c

2

5

o

4

0

m

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Design and specifications are subject to change without notice.

(No.MA346)1-3

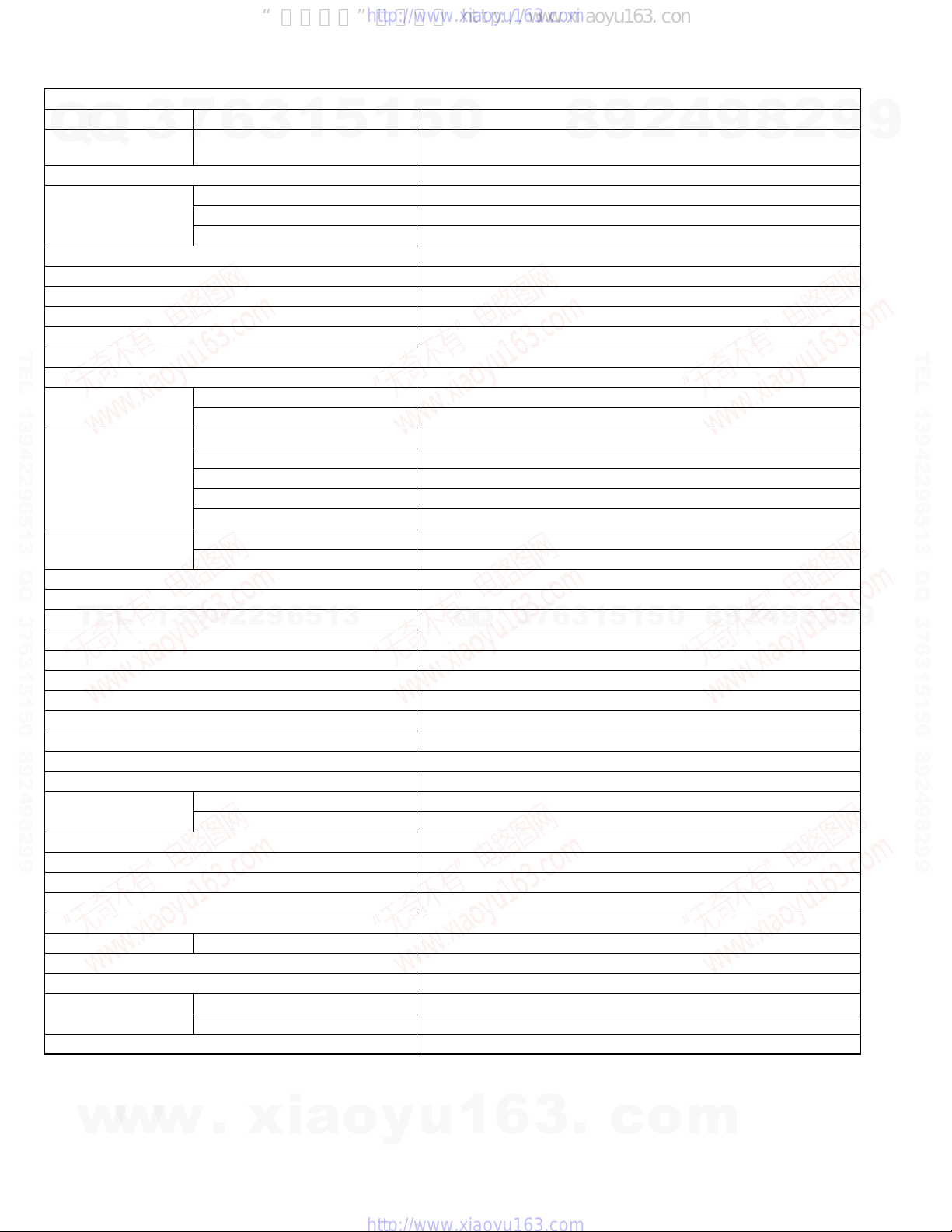

KW-XG704

AUDIO AMPLIFIER SECTION

Maximum Power Output Front and rear 50 W per channel

Q

Q

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB at 60 Hz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Subwoofer-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

TEL 13942296513 QQ 376315150 892498299

Other Terminal CD changer, USB input terminal, Subwoofer input, AUX (auxiliary) input jack

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

AM Tuner Sensitivity 20 µV

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

TEL

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range/Signal-to-Noise Ratio 96 dB/98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

USB Standard USB 1.1

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA/WAV

Max. Current Less than 500 mA

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

Mass 1.8 kg (excluding accessories)

7

3

13942296513

6

Front and rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total har-

Mid-range ±12 dB at 1 kHz

Treble ±12 dB at 10 kHz

AM 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Selectivity 35 dB

Low Speed Maximum 1.5 Mbps

Installation Size 178 mm × 100 mm × 158 mm

Set Size: 178 mm × 100 mm × 178 mm

3

1

5

1

5

0

monic distortion.

TUNER SECTION

CD PLAYER SECTION

Q

Q

USB DEVICE

GENERAL

3

7

6

8

3

9

1

5

1

2

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Design and specifications are subject to change without notice.

w

w

w

1-4 (No.MA346)

.

xia

o

y

u

1

6

3

.

c

o

m

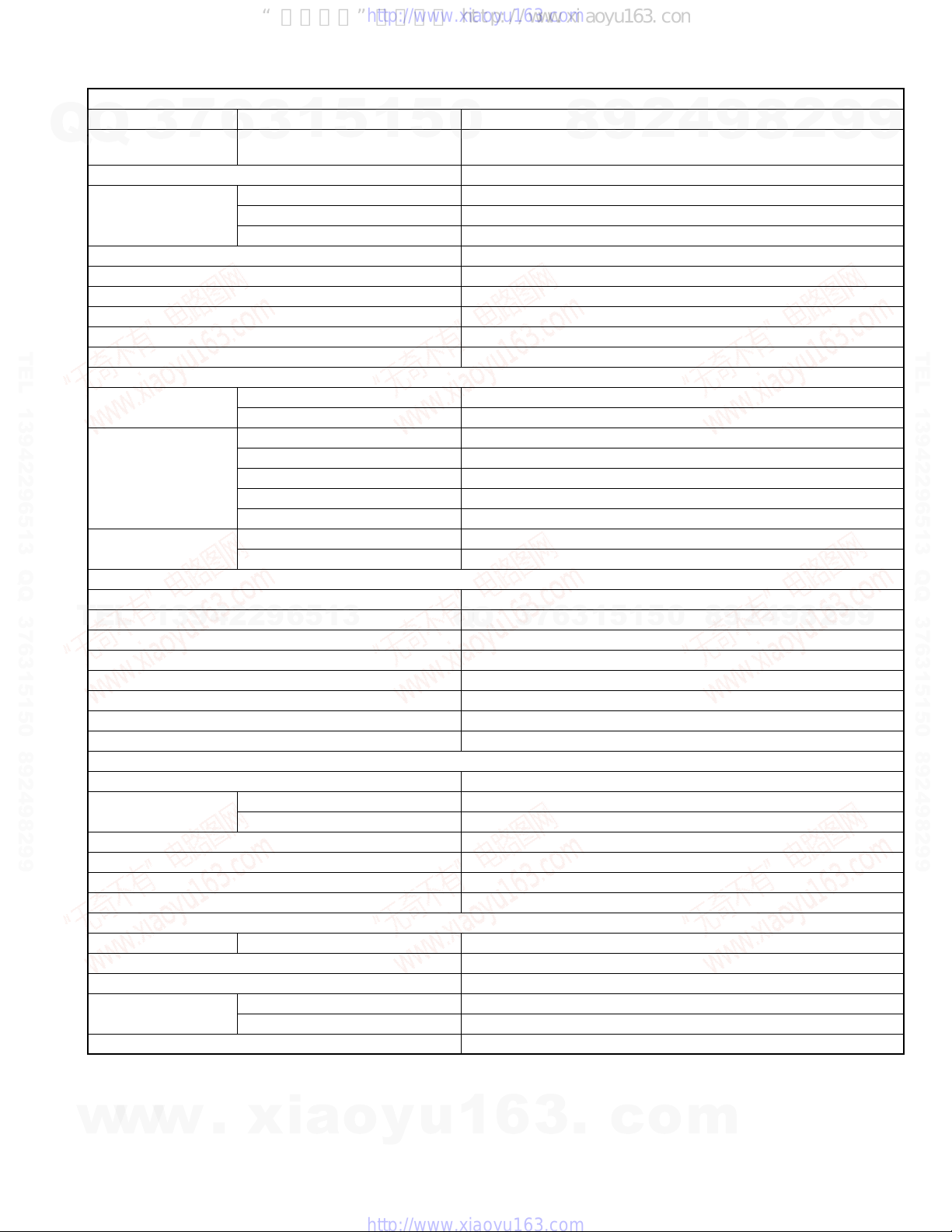

KW-XG705/KW-XG706/KW-XG708

AUDIO AMPLIFIER SECTION

Maximum Power Output Front and rear 50 W per channel

Q

Q

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB at 60 Hz

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

TEL 13942296513 QQ 376315150 892498299

Subwoofer-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Other Terminal CD changer, USB input terminal, Subwoofer input, AUX (auxiliary) input jack

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

AM Tuner Sensitivity 20 µV

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

TEL

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range/Signal-to-Noise Ratio 96 dB/98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

USB Standard USB 1.1

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA/WAV

Max. Current Less than 500 mA

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

Mass 1.8 kg (excluding accessories)

7

3

13942296513

6

Front and rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total har-

Mid-range ±12 dB at 1 kHz

Treble ±12 dB at 10 kHz

AM 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Selectivity 35 dB

Low Speed Maximum 1.5 Mbps

Installation Size 178 mm × 100 mm × 158 mm

Set Size 178 mm × 100 mm × 178 mm

3

1

5

1

5

0

monic distortion.

TUNER SECTION

CD PLAYER SECTION

Q

Q

USB DEVICE

GENERAL

3

7

6

8

3

9

1

5

1

2

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Design and specifications are subject to change without notice.

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

(No.MA346)1-5

KW-XG707

AUDIO AMPLIFIER SECTION

Maximum Power Output Front and rear 50 W per channel

Q

Q

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB at 60 Hz

Frequency Response 40 Hz to 20 000 Hz

Signal to Noise Ratio 70 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Subwoofer-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

TEL 13942296513 QQ 376315150 892498299

Other Terminal CD changer, USB input terminal, Subwoofer input, AUX (auxilliary) input jack

Frequency Range FM1/FM2 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

MW Tuner Sensitivity 20 µV

LW Tuner Sensitivity 50 µV

TEL

Type

Signal Detection System

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate: 192 kbps

AAC (Advanced Audio Coding) Decoding Format Max. Bit Rate: 320 kbps

USB Standard USB 1.1

Data Transfer Rate Full Speed Maximum 12 Mbps

Compatible Device Mass storage class, MTP

Compatible File System FAT 32/16/12

Playable Audio Format MP3/WMA/AAC/WAV

Max. Current: Less than 500 mA

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

w

Mass 2.3 kg (excluding accessories)

w

3

7

6

Front and rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than 0.8% total har-

Mid-range ±12 dB at 1 kHz

Treble ±12 dB at 10 kHz

FM3 65.00 MHz to 74.00 MHz

AM (MW) 522 kHz to 1 620 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

Selectivity 35 dB

3

1

13942296513

Low Speed Maximum 1.5 Mbps

Installation Size 182 mm × 111 mm × 158 mm

Set Size 178 mm × 100 mm × 178 mm

w

.

xia

5

o

1

5

0

monic distortion.

TUNER SECTION

(LW) 144 kHz to 279 kHz

Q

CD PLAYER SECTION

y

Q

Compact disc player

Non-contact optical pickup (semiconductor laser)

USB DEVICE

GENERAL

u

1

3

6

6

7

3

8

3

.

9

1

1

5

c

2

5

o

4

0

m

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

Design and specifications are subject to change without notice.

1-6 (No.MA346)

Q

Q

1.1 Safety Precautions

3

7

6

3

1

SECTION 1

PRECAUTION

5

1

5

0

8

9

2

4

9

8

2

9

9

!

!

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

7

3

Q

Q

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

(No.MA346)1-7

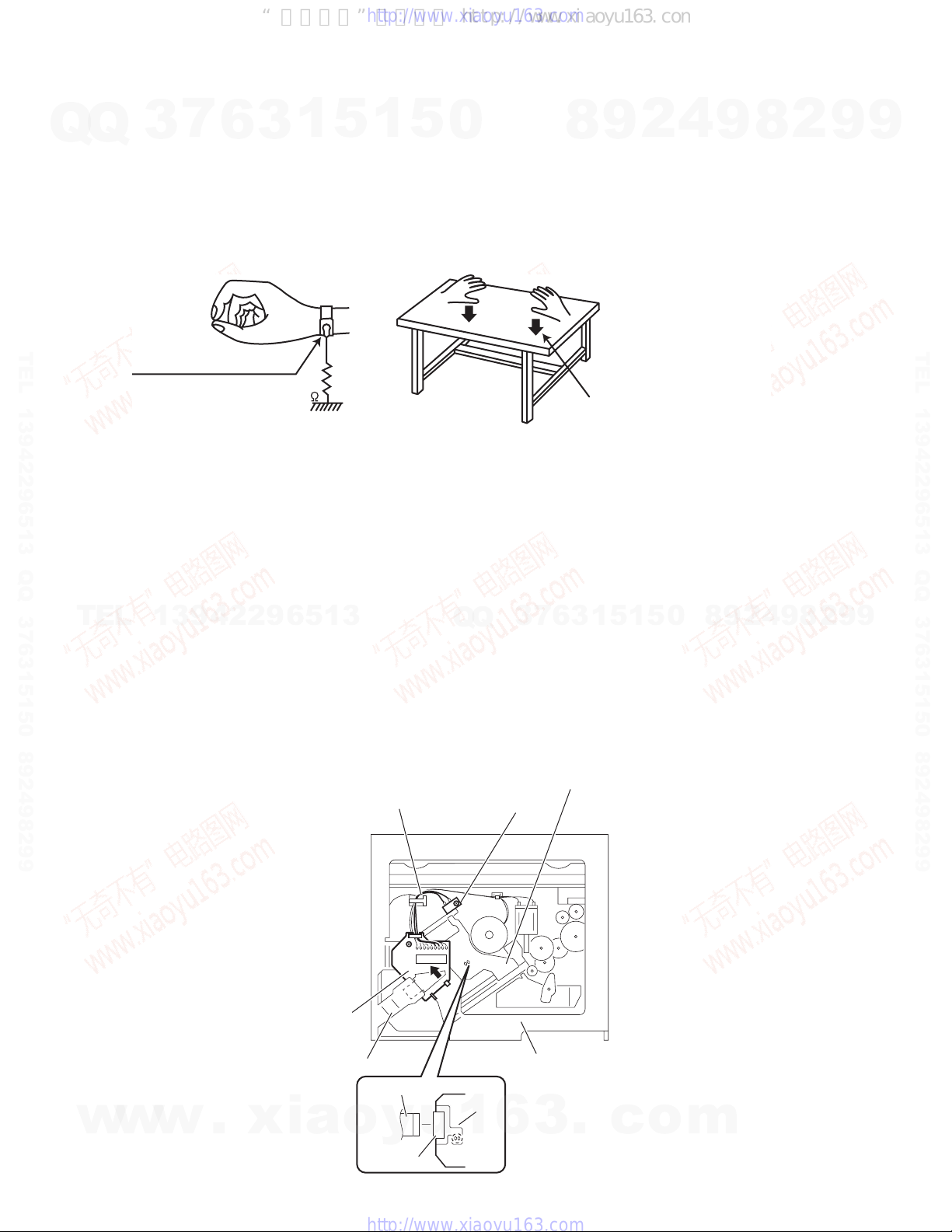

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

7

Q

Q

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

TEL

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the card wire is disconnected from the connector on the pickup unit.

(If the card wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the card wire.

(caption)

Anti-static wrist strap

1M

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

destroy the laser diode.

13942296513

Wires

Q

Q

Push switch

Conductive material

(conductive sheet) or iron plate

1

5

1

3

6

7

3

Pickup

5

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

Base board

Frame

Flexible wire

w

w

w

1-8 (No.MA346)

.

xia

o

y

Connector

u

Pickup

1

CD mechanism

assembly

6

3

.

c

o

m

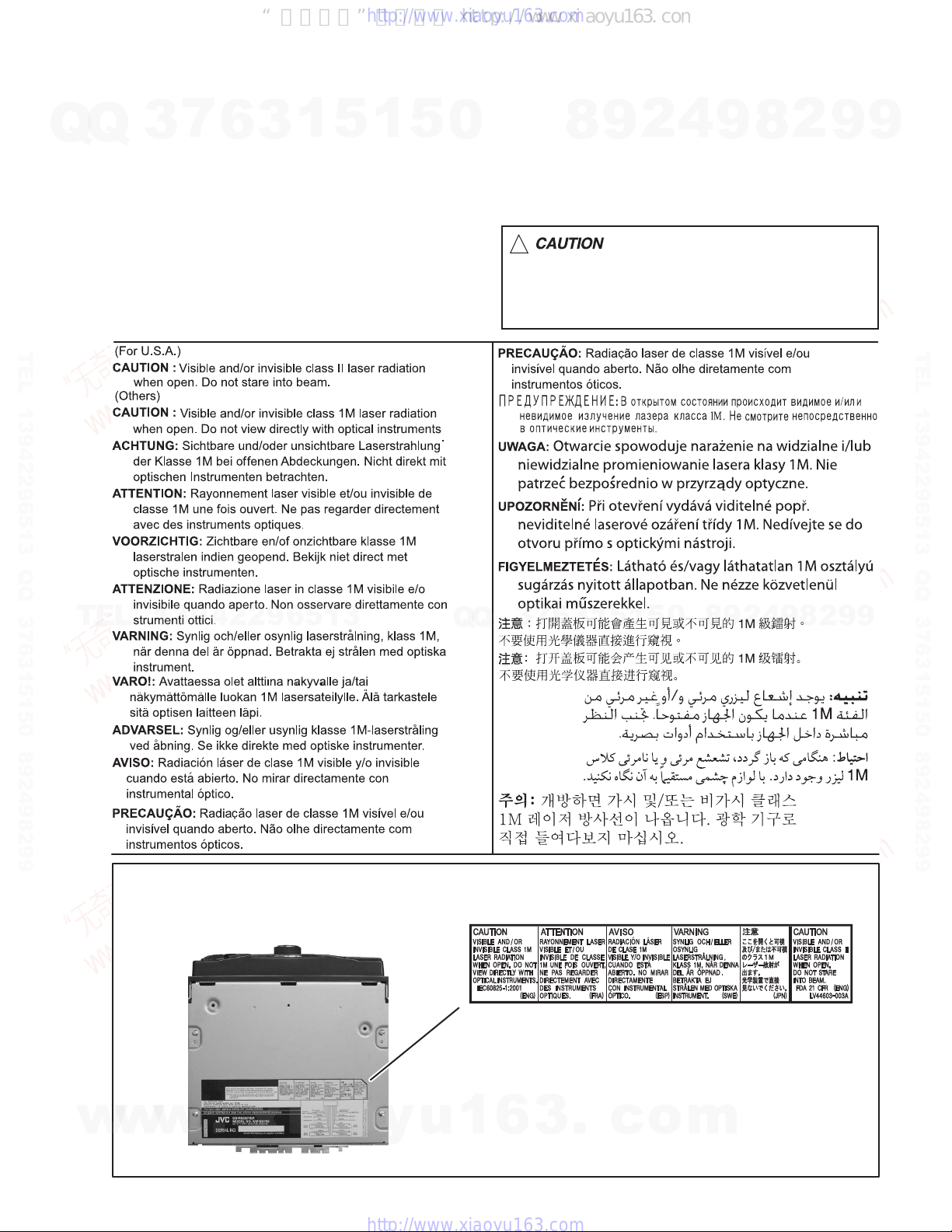

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

3

7

6

Q

TEL 13942296513 QQ 376315150 892498299

2.CAUTION :

Q

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

3

1

5

1

5

5.CAUTION : If safety switches malfunction, the laser is able

to function.

0

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

8

4

2

9

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

(No.MA346)1-9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

7

Q

Q

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

1-10 (No.MA346)

.

xia

o

y

u

1

6

3

.

c

o

m

7

Q

Q

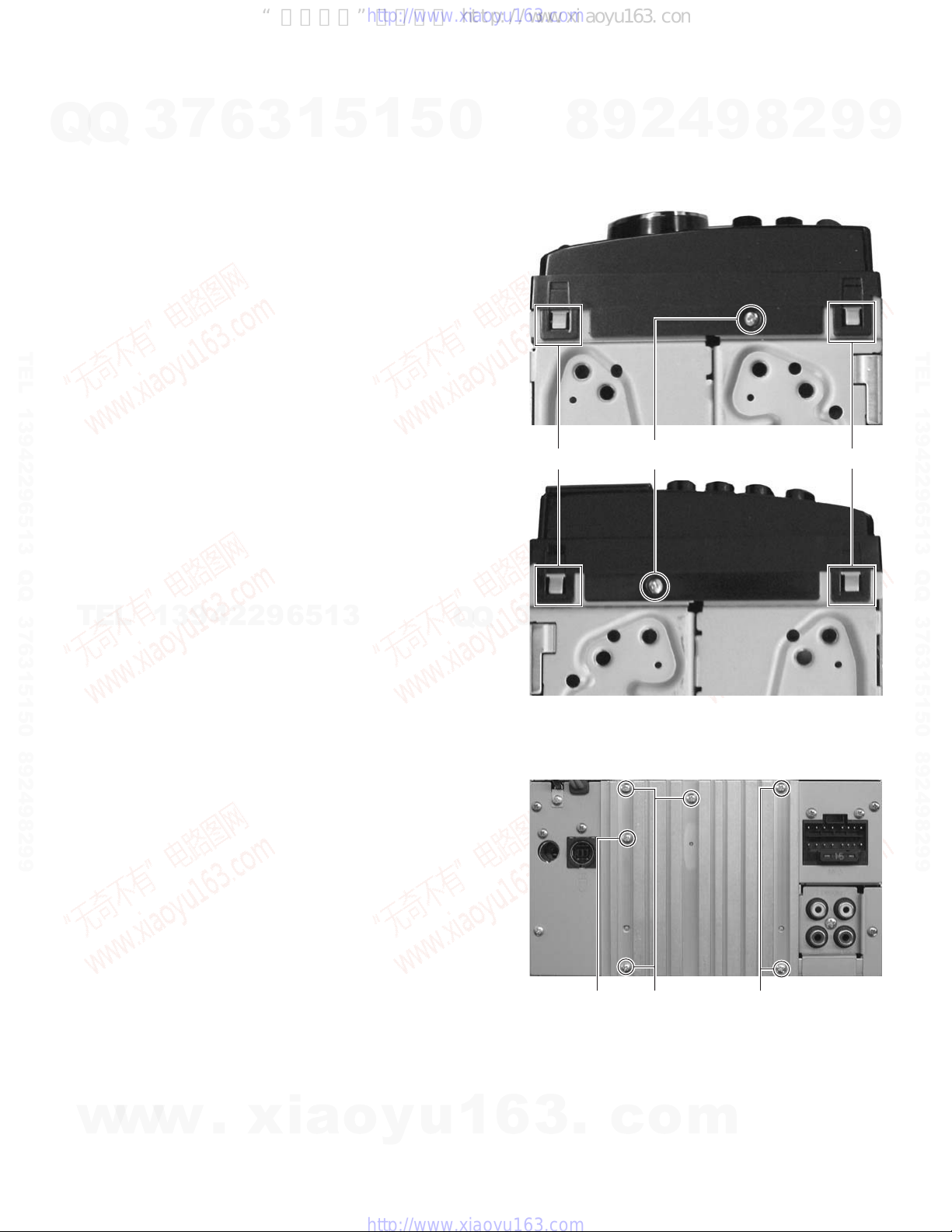

3.1 Main body

3.1.1 Removing the FRONT PANEL assembly

3

(See Fig.1)

(1) From the bottom side of main body, remove the two screws

A attaching the both side of the FRONT PANEL assembly.

(2) Disengage two hooks a engaged CHASSIS assembly.

6

3

1

SECTION 3

DISASSEMBLY

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

3.1.2 Removing the HEAT SINK

(1) Remove the five screws B and one screw C attaching the

13942296513

(See Fig.2)

HEAT SINK.

Q

Q

3

7

5

1

A

5

0

8

Fig.1

9

2

4

9

8

2

9

9

hook a hook a

1

3

6

TEL 13942296513 QQ 376315150 892498299

w

w

w

.

xia

o

y

u

1

6

3

.

c

BBC

o

Fig.2

m

(No.MA346)1-11

3.1.3 Removing the REAR BRACKET

(See Fig.3)

(1) Remove the seven screws D, two screws E and one screw

F attaching the REAR BRACKET.

Q

Q

3

7

6

3

1

5

1

5

0

D

8

9

2

4

9

8

E

2

9

9

TEL 13942296513 QQ 376315150 892498299

3.1.4 Removing the BOTTOM CHASSIS assembly

(See Fig.4)

(1) Remove the four screws G attaching the BOTTOM CHAS-

SIS assembly.

TEL

13942296513

DD

7

3

Q

Q

6

3

1

5

1

Fig.3

5

Fig.4

0

8

9

2

F

4

9

8

GG

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

1-12 (No.MA346)

.

xia

o

y

u

1

6

3

.

c

o

m

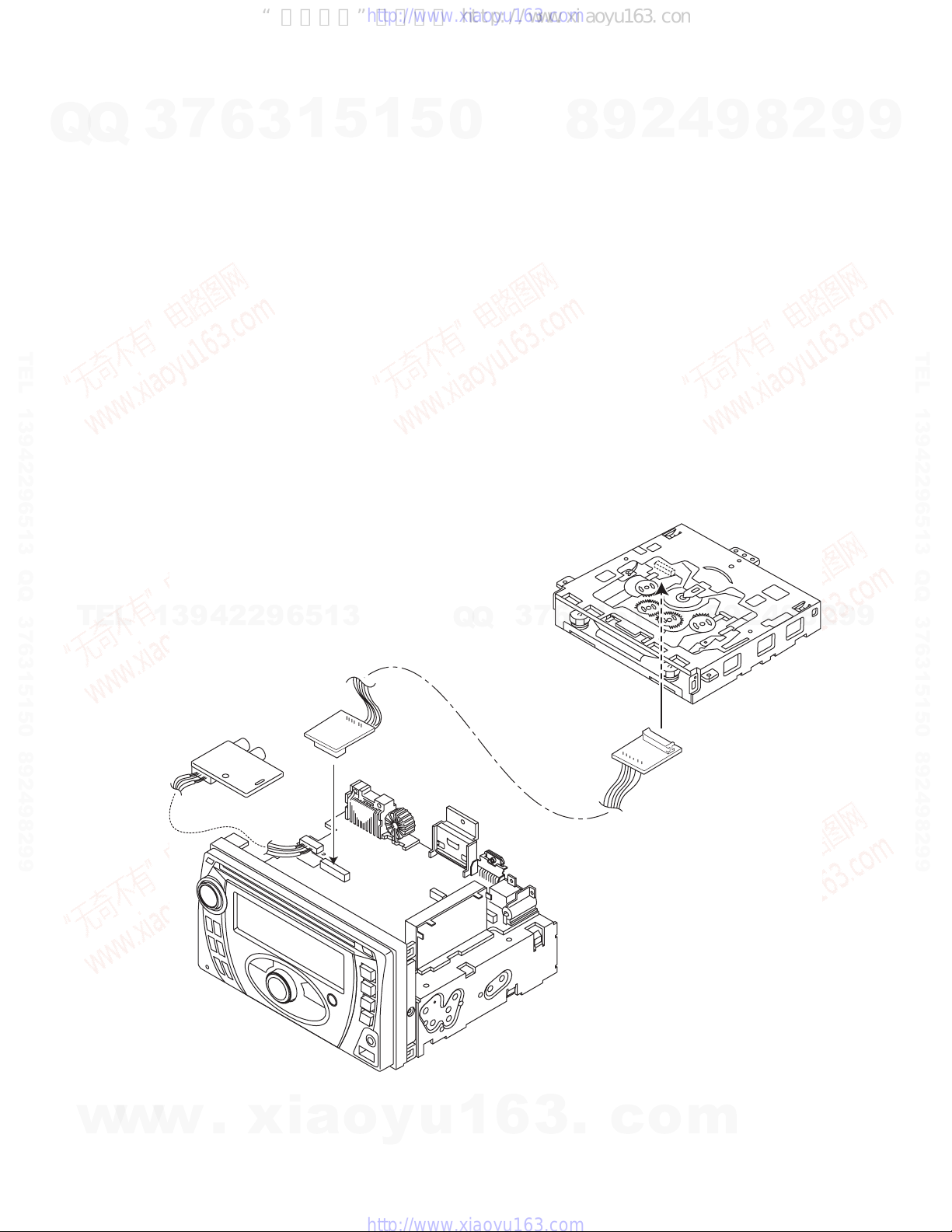

3.1.5 Removing the FUNC BOARD assembly

(See Fig.5)

(1) Remove the one screw H attaching the FUNC BOARD as-

Q

TEL 13942296513 QQ 376315150 892498299

sembly.

Q

(2) Disconnect the connecter wire from MAIN BOARD assem-

bly connected to connector CN322

assembly.

(3) Straighten hook b attaching the FUNC BOARD assembly.

3.1.6 Removing the MIDDLE CHASSIS

(See Fig.5)

(1) Remove the four screws J attaching the MIDDLE CHAS-

SIS.

(2) Disconnect the connector CN501

MIDDLE CHASSIS from the CD mechanism assembly in

an upward direction.

3.1.7 Removing the MAIN BOARD assembly

(See Fig.6)

(1) Remove the four screws K attaching the MAIN BOARD as-

sembly.

3

7

6

3

1

5

1

of the FUNC BOARD

of the main board on the

5

0

8

CN322

CN501

9

hook

2

b

4

H

Fig.5

9

8

2

9

9

JJ

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

K

6

3

1

5

1

5

0

8

Fig.6

9

2

4

9

8

2

9

K

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

(No.MA346)1-13

3.1.8 Removing the CD MECHANISM assembly

(See Fig.7)

(1) Remove the three screws L attaching the CD MECHA-

NISM assembly.

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

L

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

3.1.9 Removing the SWITCH BOARD assembly

(See Fig.8)

(1) Remove the volume knob from the front side of the FRONT

PANEL assembly.

(2) Remove the thirteen screws M and two screws N attaching

the SWITCH BOARD assembly.

TEL

13942296513

Q

MM

7

3

Q

6

3

1

5

1

L

Fig.7

5

N

0

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

3.2 CD mechanism assembly

For CD mechanism, please refer the MECHANISM MANUAL TN2007-1010 (No.MY005

w

w

w

1-14 (No.MA346)

.

xia

o

y

u

1

6

3

Fig.8

and No.MY005B).

.

c

o

M

m

SECTION 4

ADJUSTMENT

7

Q

Q

4.1 Adjustment method

4.1.1 Test instruments required for adjustment

TEL 13942296513 QQ 376315150 892498299

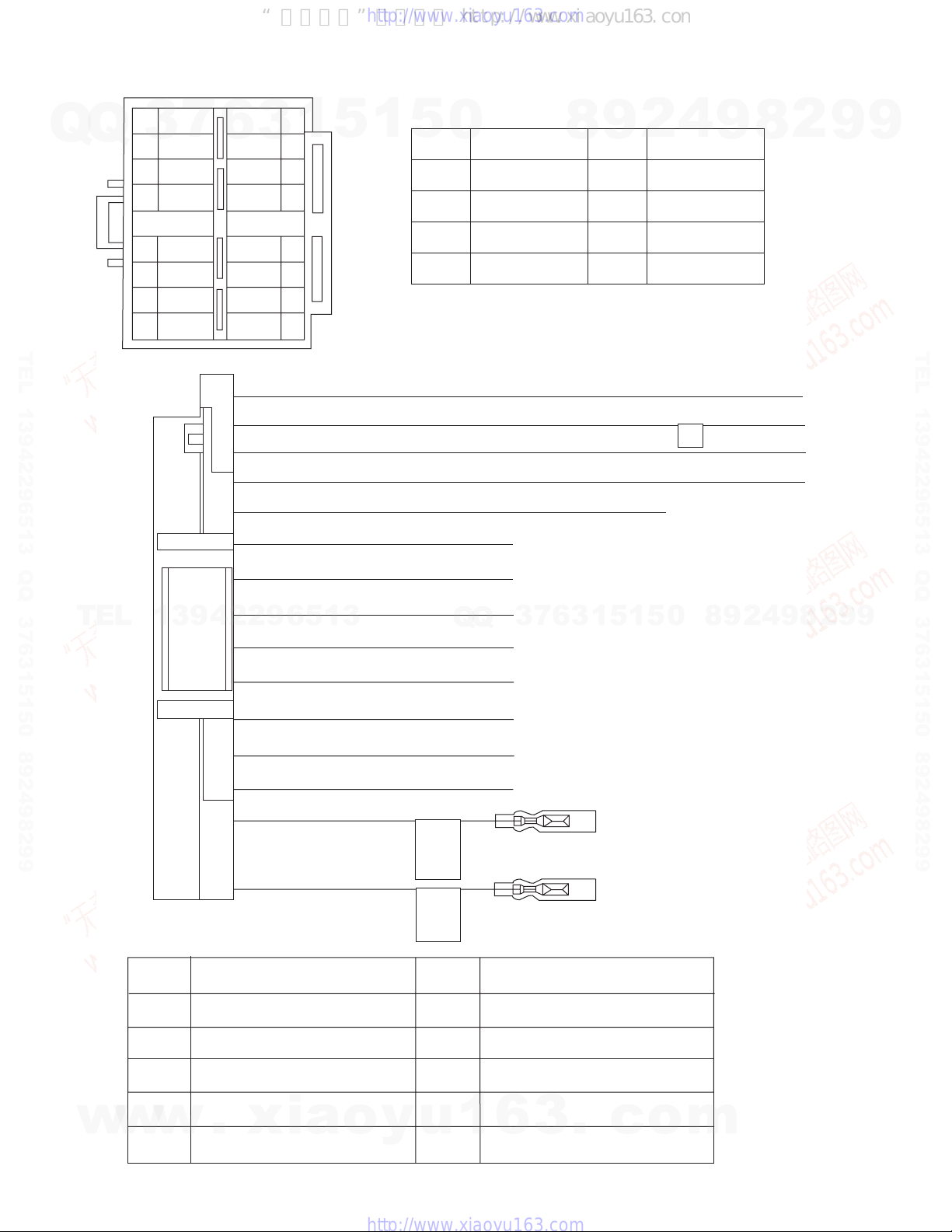

4.1.5 How to connect the extension cable for adjusting

Caution:

3

(1) Digital oscilloscope (100MHz)

(2) Electric voltmeter

(3) Digital tester

(4) Tracking offset meter

(5) Test Disc JVC :CTS-1000

(6) Extension cable for check

EXTSH002-22P × 1

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

6

3

1

5

1

5

0

4.1.2 Standard measuring conditions

Power supply voltage : DC14.4V(11 to 16V)

Load impedance : 20K.(2 Speakers connection)

Output Level : Line out 2.5V (Vol. MAX)

4.1.3 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

4.1.4 Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and antenna input.The loss of 6dB need not be considered since direct

reading of figures are applied in this working standard.

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Extension cable

EXTSH002-22P

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

(No.MA346)1-15

7

Q

Q

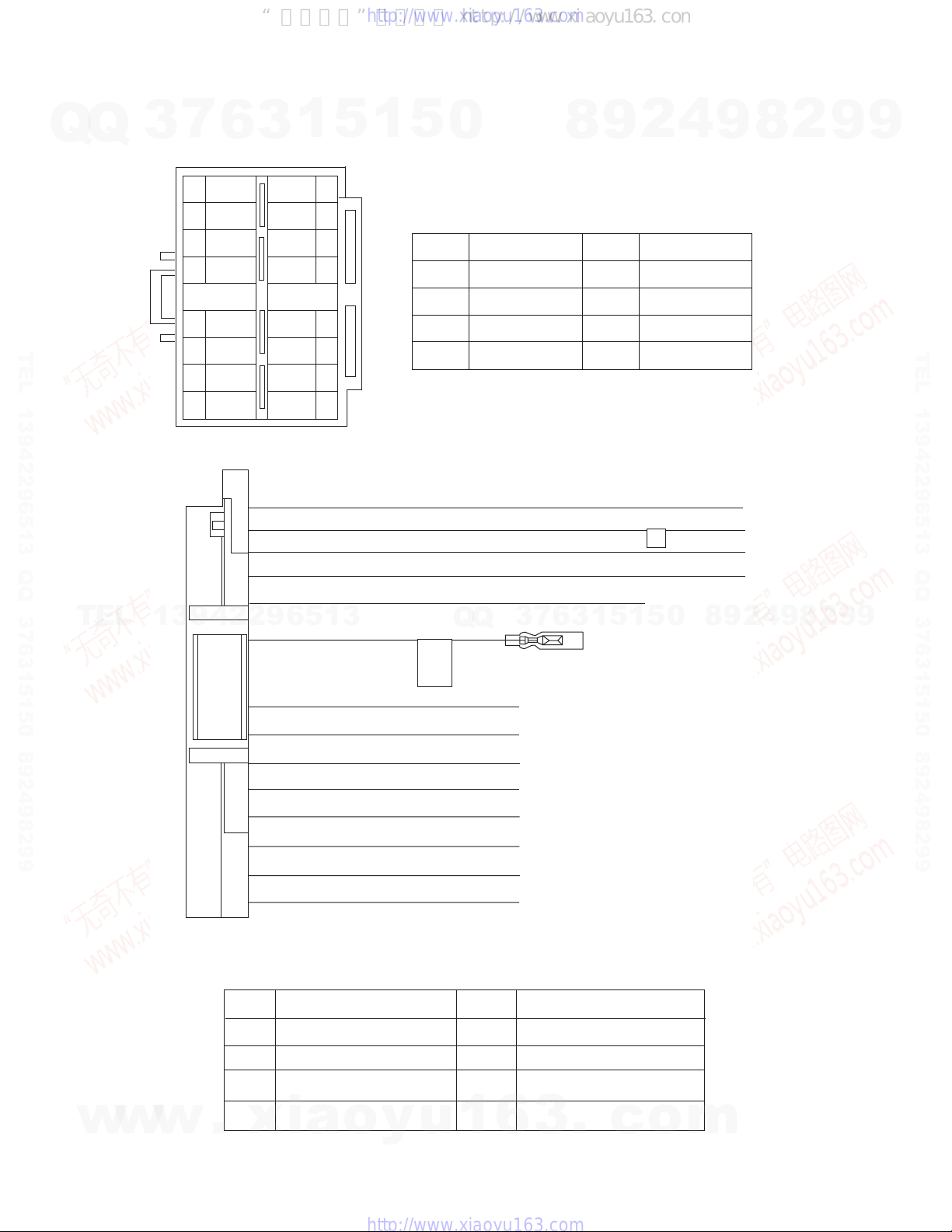

5.1 16 PIN CORD DIAGRAM (for KW-XG700)

3

6

3

1

SECTION 5

TROUBLESHOOTING

5

1

5

0

8

9

2

4

9

8

2

9

9

BK

8

RD

7

NC

6

BL/WH

5

WH

4

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

GN

3

2

VI

GY

1

OR/WH

WH/BK

GN/BK

VI/BK

GY/BK

16 YL

8 BK

7 RD

15 OR/WH

13 BR TEL

5 BL/WH

YL

NC

BR

16

15

14

13

12

11

10

9

MEMORY

GND

ACC

ILL

REMOTE

BK

RD

BL

WH

BR

Q

White

Q

Black

Red

Blue

Brown

3

7

6

3

GN

GY

OR

1

VI

YL

5

1

Green

Violet

Gray

Yellow

Orange

GND

0

5

8

9

2

4

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

11 GN/BK

10 VI/BK

12 WH/BK

RR

FR

FL

RL

TEL

.

xia

3 GN

2 VI

4 WH

1 GY

9 GY/BK

Rear Right

Front Right

Front Left

Rear Left

Telephone muting

o

RL+

RL-

RR+

RR-

FL+

FL-

FR+

FR-

y

REMOTE

CAUTION!

u

OUTPUT ONLY

REMOTE

ACC

MEMORY

GND

ILL

1

Remote out

ACC Line

Memory Backup Battery +

Ground

Illuminations Control

6

3

.

c

o

m

1-16 (No.MA346)

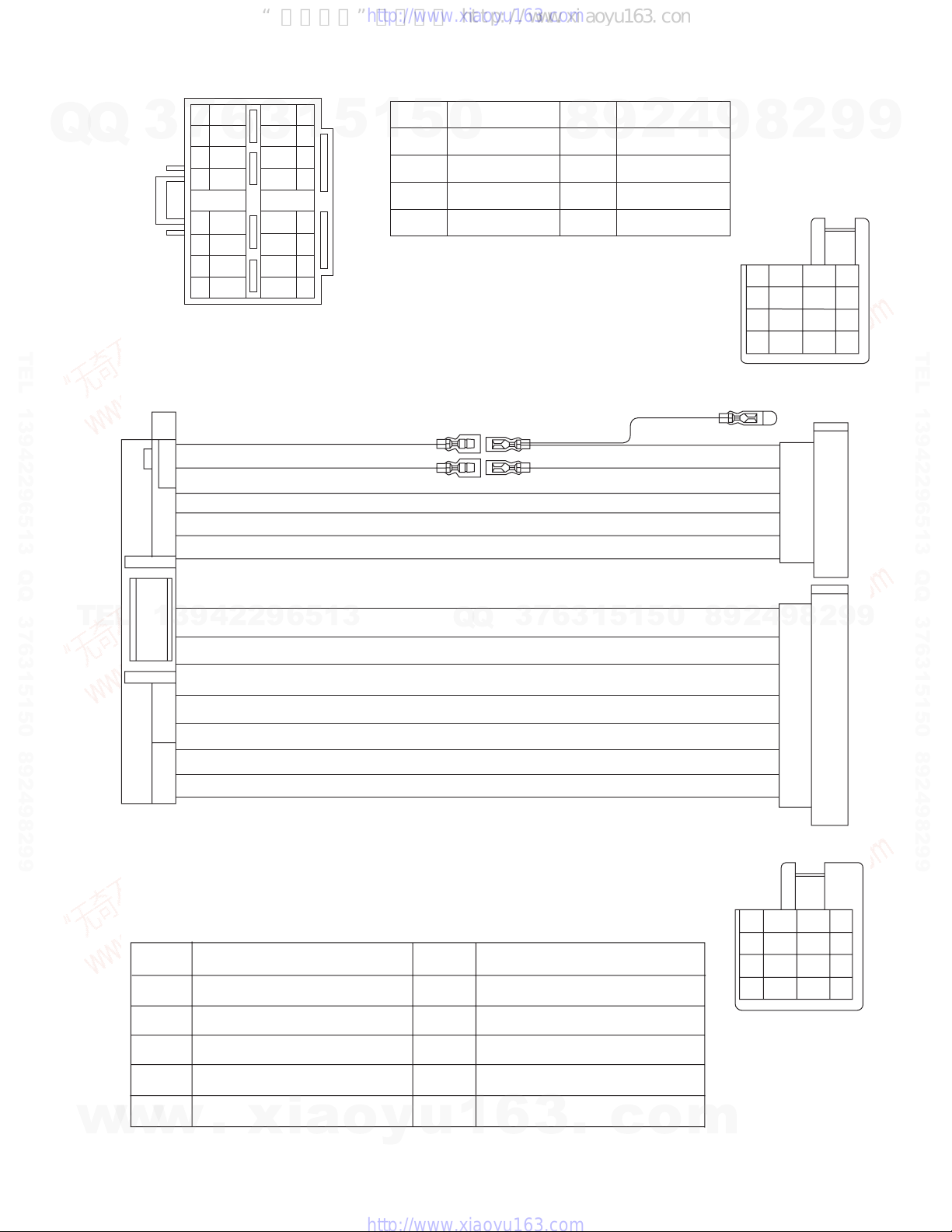

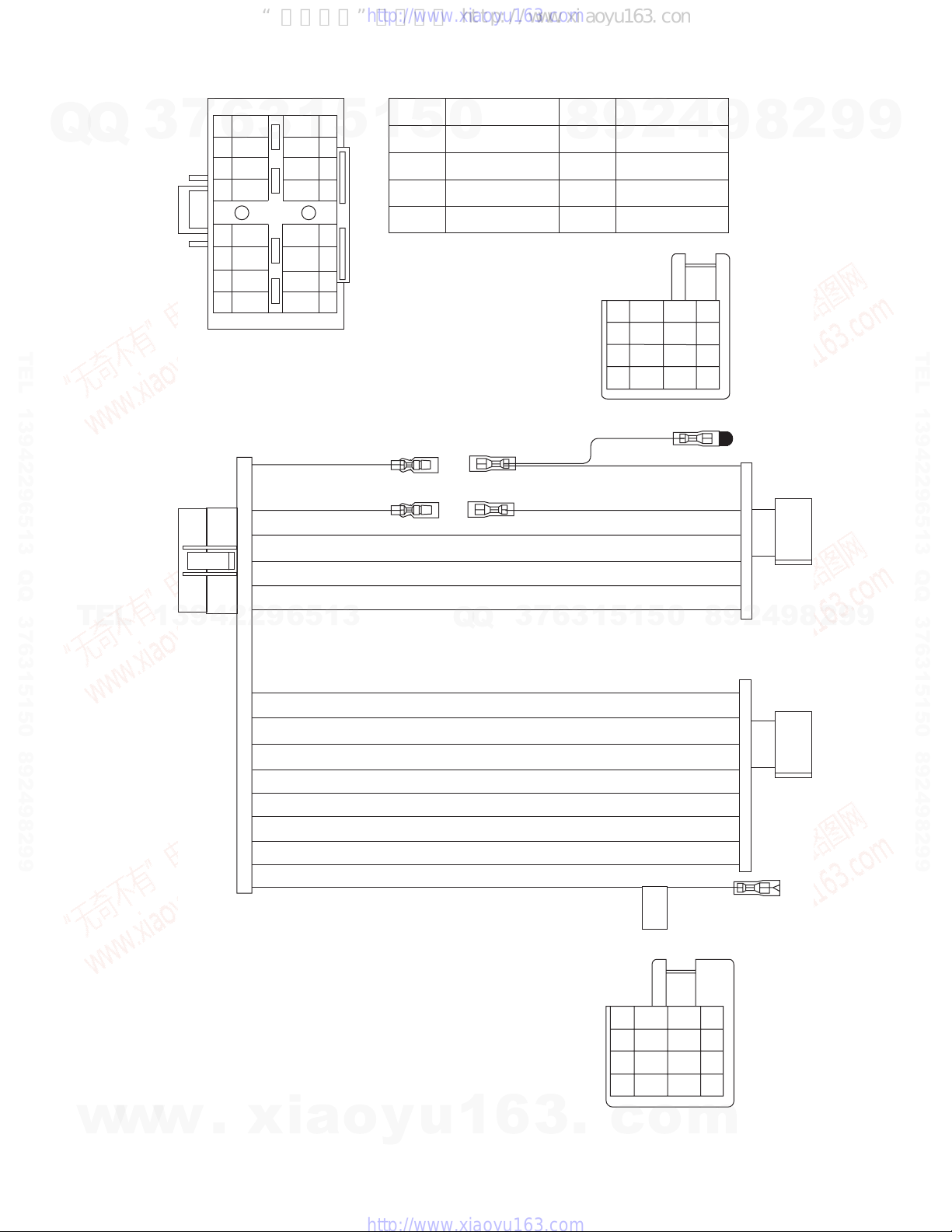

5.2 16 PIN CORD DIAGRAM (for KW-XG701, KW-XG707)

1

BK

5

RD

BL

WH

BR

BK

8

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

BL/WH

5

WH

4

3

2

1

7 RD

16 YL

15 OR/WH

8 BK

6 BL/WH

13 BR

6

RD

NC

GN

VI

GY

YL

3

OR/WH

NC

BR

WH/BK

GN/BK

VI/BK

GY/BK

16

1

15

14

13

12

11

10

9

MEMORY

GND

REMOTE

5

ACC

ILL

TEL

Black

0

Red

Blue

White

Brown

GN

8

VI

GY

YL

OR

9

Green

2

Violet

Gray

Yellow

Orange

4

RD

9

8

1

3

5

7

RD 7

YL 4

BL/WH

6

8

5

2

NC

NC

RD

2

BR

YL

OR/WH

BK

9

2

4

6

8

9

TEL 13942296513 QQ 376315150 892498299

TEL

3 GN

13942296513

11 GN/BK

2 VI

10 VI/BK

4 WH

12 WH/BK

1 GY

9 GY/BK

RR

FR

FL

Rear Right

Front Right

Front Left

RL+

RL-

RR+

RR-

FL+

FL-

FR+

FR-

ANT

ACC

TEL

Q

Q

Auto Antenna

ACC Line

Telephone Muting

3

7

6

3

1

5

1

5

0

8

9

2

1

3

5

7

7

4

8

1

2

5

6

3

4

VI

GY

WH

GN

9

8

VI/BK

GY/BK

WH/BK

GN/BK

2

9

2

4

6

8

9

RL

REMOTE

ILL

w

w

w

Rear Left

Remote

Illuminations Control

.

xia

MEMORY

o

y

GND

u

Ground

Memory Backup Battery+

1

6

3

.

c

o

m

(No.MA346)1-17

5.3 16 PIN CORD DIAGRAM (for KW-XG-704, KW-XG705, KW-XG706)

BK

8

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

7

6

5

4

3

2

1

RD

BL

BL/WH

WH

GN

VI

GY

YL

6

3

OR/WH

NC

BR

WH/BK

GN/BK

VI/BK

GY/BK

16 YL

8 BK

7 RD

15 OR/WH

13 BR

3 GN

11 GN/BK

16

1

15

14

13

12

11

10

9

5

MEMORY

1

GND

ACC

ILL

TEL

RL+

RL-

5

0

BK

RD

BL

WH White

BR

Black

Red

Blue

Brown

9

8

GN

VI Violet

GY

YL

OR Orange

2

Green

Gray

4

Yellow

GND

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

2 VI

10 VI/BK

4 WH

12 WH/BK

1 GY

9 GY/BK

5 BL/WH

6 BL

RR

FR

FL

Rear Right

Front Right

Front Left

RR+

RR-

FL+

FL-

FR+

FR-

REMOTE

ANT

REMOTE

CAUTION!

POWER

ANT

ACC

ILL

7

3

Q

Q

OUTPUT ONLY

ANTENNA

Auto Antenna

ACC Line

Illuminations Control

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

RL

w

1-18 (No.MA346)

REMOTE

w

w

TEL

Rear Left

Remote out

.

xia

Telephone muting

o

y

GND

MEMORY

u

1

Ground

Memory Backup Battery+

6

3

.

c

o

m

5.4 16 PIN CORD DIAGRAM (for KW-XG708)

YL1

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

3

13942296513

6

RD1

7

6

BL/WH

5

WH

4

3

GN

2

1

16

15

13

BL

VI

GY

7

YL1

8

6

3

RD1

BK

BL

OR/WH

BR

BK

8

7

1

OR/WH

NC

BR

WH/BK

GN/BK

VI/BK

GY/BK

16

15

14

13

12

11

10

9

5

1

BK

5

RD

BL

WH

BR

Black

0

Red

Blue

White

Brown

Q

Q

3

RD3

7

6

GN

8

VI

GY

YL

OR

3

9

1

1

3

5

7

5

Green

2

Violet

Gray

Yellow

Orange

NC

BL

RD2

5

1

4

BRNC

YL2

OR/WH

BK

0

9

2

4

6

8

RD2

YL 2

8

9

8

7

4

8

5

6

2

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

w

w

w

3

GN/BK

11

2

10

4

12

1

9

5

.

xia

GN

VI

VI/BK

WH

WH/BK

GY

GY/BK

BL/WH

o

y

u

1

6

3

.

1

3

5

7

c

VI

GY

WH

GN

o

VI/BK

GY/BK

WH/BK

GN/BK

m

7

8

1

2

5

6

3

4

2

4

6

8

(No.MA346)1-19

Loading...

Loading...