Page 1

SERVICE MANUAL

DVD/CD RECEIVER

MA446<Rev.001>20093SERVICE MANUAL

KD-AVX20E, KD-AVX20EU, KD-AVX20EE,

KD-AVX20UT, KD-AVX20A, KD-AVX40J,

KD-AVX40E, KD-AVX40EE

Except KD-AVX40J

Only for

KD-AVX40J

COPYRIGHT © 2009 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

Except KD-AVX40J

Only for KD-AVX40

Except KD-AVX20UT,

KD-AVX20A, KD-AVX40J

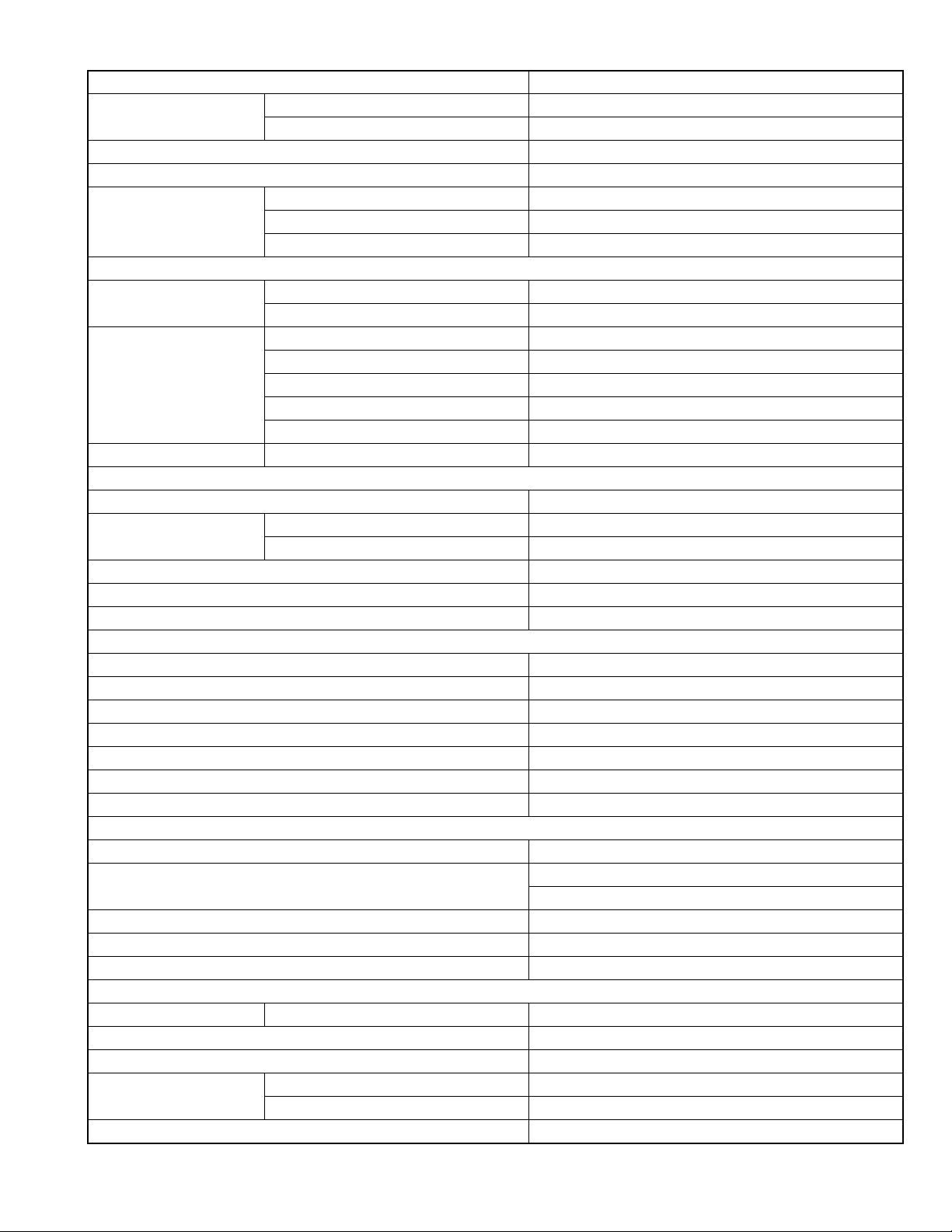

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

COPYRIGHT © 2009 Victor Company of Japan, Limited

No.MA446<Rev.001>

2009/3

Page 2

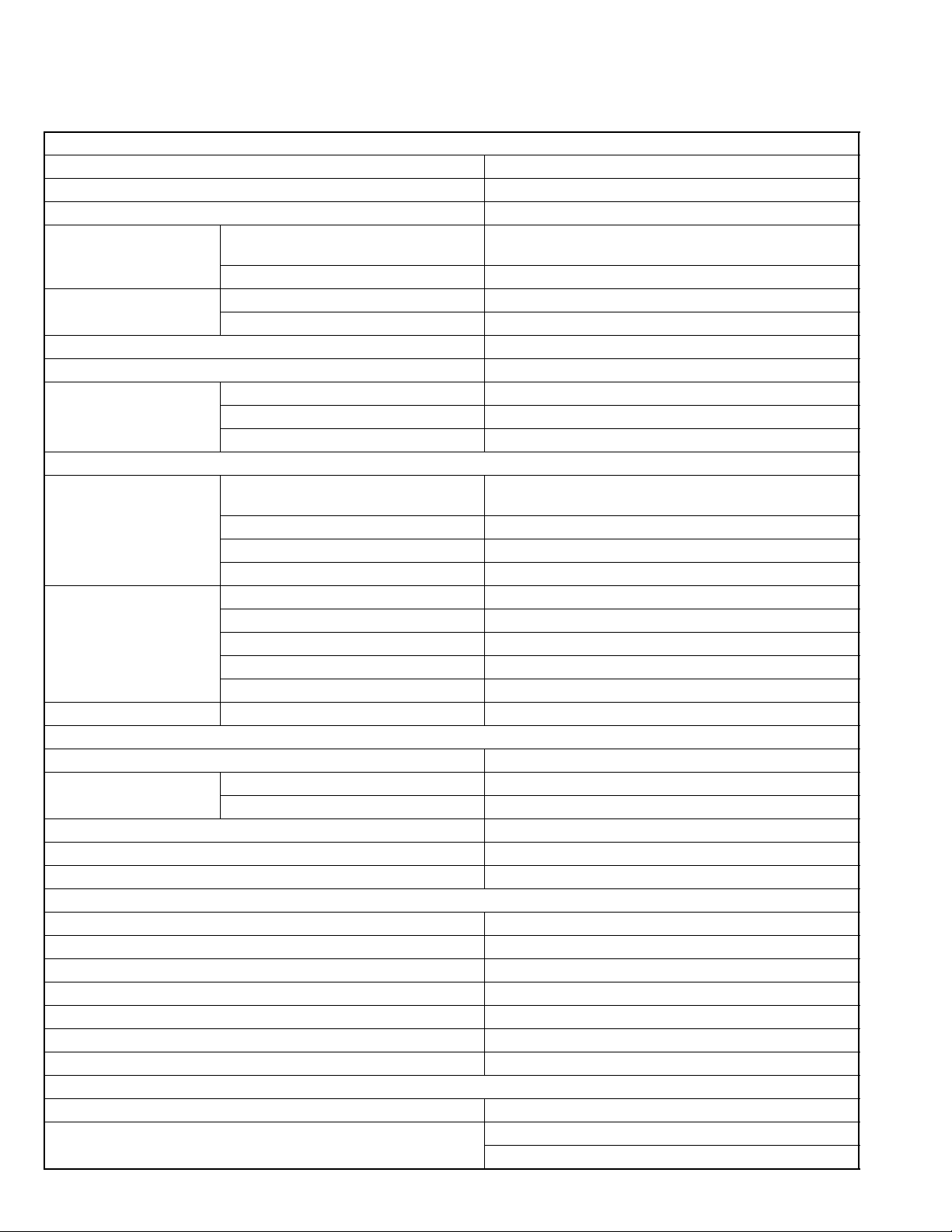

SPECIFICATION

KD-AVX40J

AMPLIFIER

Power Output 20 W RMS × 4 Channels at 4 Ω and < or = 1% THD+N

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies 60.0 Hz, 150.0 Hz, 400.0 Hz, 1.0kHz, 2.5kHz, 6.3kHz,

15.0kHz

Level ±10 dB

Audio Output Level

(REAR)/SUBWOOFER

Color System NTSC

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals Input LINE IN, VIDEO IN, USB input terminal, Antenna input

Frequency Range FM (with channel interval set to

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

AM Tuner Sensitivity/Selectivity 20 µV/40 dB

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

Screen Size 3.5 inch wide liquid crystal display

Number of Pixel 211 200 pixels: 960 (horizontal) × 220 (vertical)

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

Allowable Storage Temperature -10°C to +60°C (14°F to 140°F)

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed: Maximum 12 Mbps

LINE OUT

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 k Ω

Output VIDEO OUT, DIGITAL OUT

Others CD changer, OE REMOTE, MIC IN

FM/AM TUNER

87.5 MHz to 107.9 MHz

100 kHz or 200 kHz)

FM (with channel interval set to 50 kHz) 87.5 MHz to 108.0 MHz

AM (with channel interval set to 10 kHz) 530 kHz to 1 710 kHz

AM (with channel interval set to 9 kHz) 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

DVD/CD

VCD/CD 16 Hz to 20 000 Hz

MONITOR

USB

Low Speed: Maximum 1.5 Mbps

1-2 (No.MA446<Rev.001>)

Page 3

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

BLUETOOTH

Version Bluetooth 1.2 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m (10.9 yd)

Profile HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

GENERAL

Power Requirements Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 160 mm (7-3/16” × 2-1/16” × 6-5/16”)

Panel Size (approx.) 188 mm × 58 mm × 12 mm (7-7/16” × 2-5/16” × 1/2”)

Mass (approx.) 2.2 kg (4.9 lbs) (excluding accessories)

Design and specifications are subject to change without notice.

KD-AVX40/KD-AVX20 for Europe

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies

Signal-to-Noise Ratio 70 dB

Audio Output Level LINE OUT

(REAR)/SUBWOOFER:

Color System PAL

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals Input LINE IN, VIDEO IN, USB input terminal, Aerial input

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

MW Tuner Sensitivity/Selectivity 20 µV/40 dB

LW Tuner Sensitivity 50 µV

Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion

60.0 Hz, 150.0 Hz, 400.0 Hz, 1.0kHz, 2.5kHz, 6.3kHz, 15.0kHz

Level ±10 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Output VIDEO OUT, DIGITAL OUT

Others CD changer, OE REMOTE, MIC IN

FM/AM TUNER

AM (MW) 522 kHz to 1 620 kHz

(LW) 144 kHz to 279 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

(No.MA446<Rev.001>)1-3

Page 4

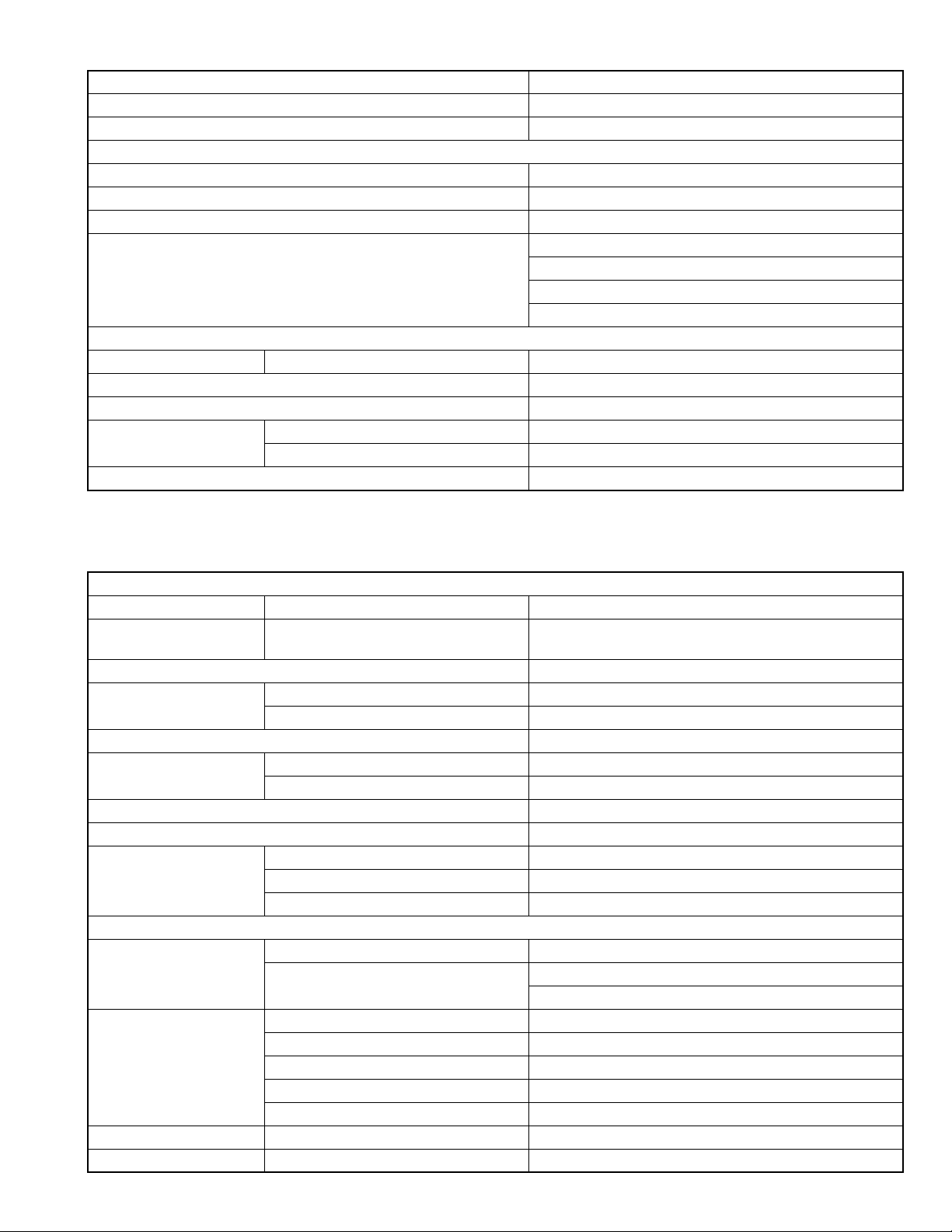

DVD/CD

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48/96 kHz 16 Hz to 22 000 Hz

VCD/CD 16 Hz to 20 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

MONITOR

Screen Size 3.5 inch wide liquid crystal display

Number of Pixel 211 200 pixels: 960 (horizontal) × 220 (vertical)

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

Allowable Storage Temperature -10°C to +60°C

Allowable Operating Temperature 0°C to +40°C

USB

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed: Maximum 12 Mbps

Low Speed: Maximum 1.5 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

BLUETOOTH (KD-AVX40 only)

Version Bluetooth 1.2 certified

Output Power +4 dBm Max. (Power class 2)

Service Area Within 10 m

Profile HFP (Hands-Free Profile) 1.5

OPP (Object Push Profile) 1.1

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

GENERAL

Power Requirements Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 160 mm

Panel Size (approx.) 188 mm × 58 mm × 12 mm

Mass (approx.) 2.2 kg (excluding accessories)

Design and specifications are subject to change without notice.

KD-AVX20UT/A

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output

(RMS)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies

1-4 (No.MA446<Rev.001>)

Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion

60.0 Hz, 150.0 Hz, 400.0 Hz, 1.0kHz, 2.5kHz, 6.3kHz, 15.0kHz

Level ±10 dB

Page 5

Signal-to-Noise Ratio 70 dB

Audio Output Level LINE

OUT (REAR)/SUBWOOFER

Color System NTSC/PAL

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals Input LINE IN, VIDEO IN, USB input terminal, Antenna input

Frequency Range FM 87.5 MHz to 108.0 MHz

FM Tuner Usable Sensitivity 9.3 dBf (0.8 µV/75 Ω)

AM Tuner Sensitivity/Selectivity 20 µV/40 dB

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48/96 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

Screen Size 3.5 inch wide liquid crystal display

Number of Pixel 211 200 pixels: 960 (horizontal) × 220 (vertical)

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL/NTSC

Aspect Ratio 16:9 (wide)

Allowable Storage Temperatur -10°C to +60°C

Allowable Operating Temperature 0°C to +40°C

USB Standards USB 2.0 Full Speed

Data Transfer Rat Full Speed: Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

Power Requirements Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D) Installation Size (approx.) 182 mm × 52 mm × 160 mm

Mass (approx.) 2.2 kg (excluding accessories)

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Output VIDEO OUT, DIGITAL OUT

Others CD changer, OE REMOTE

FM/AM TUNER

AM 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 40 dB

DVD/CD

VCD/CD 16 Hz to 20 000 Hz

MONITOR

USB

Low Speed: Maximum 1.5 Mbps

GENERAL

Panel Size (approx.) 188 mm × 58 mm × 12 mm

Design and specifications are subject to change without notice.

(No.MA446<Rev.001>)1-5

Page 6

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-6 (No.MA446<Rev.001>)

Page 7

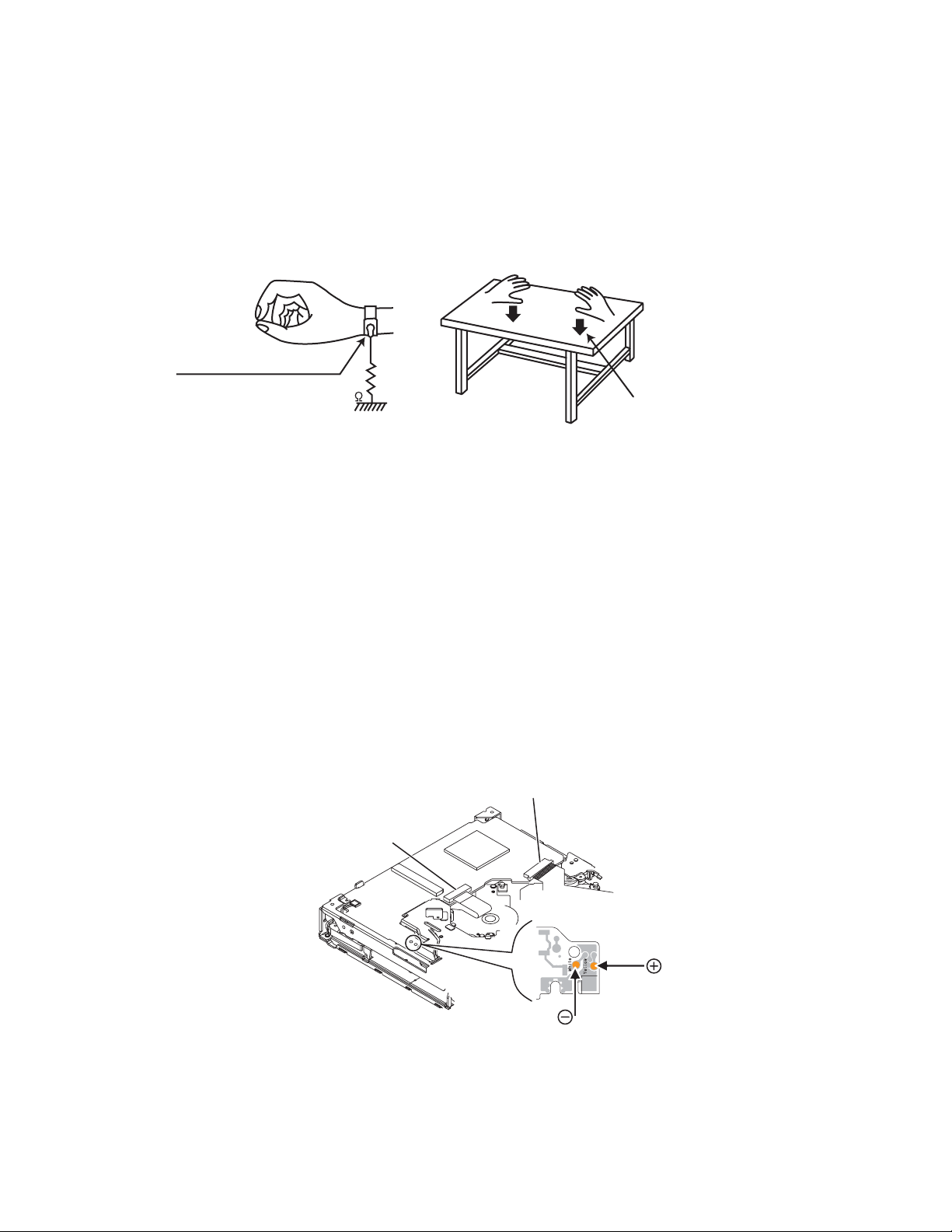

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the card wire is disconnected from the connector on the pickup unit.

(If the card wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the card wire.

CN101

CN164

TP79

TP79 TP81

R317

TP67

R312

R21

R357

Voltage supply

position

TP92

CENTER

WOOFER

DGND_7

TP81

D-

(No.MA446<Rev.001>)1-7

Page 8

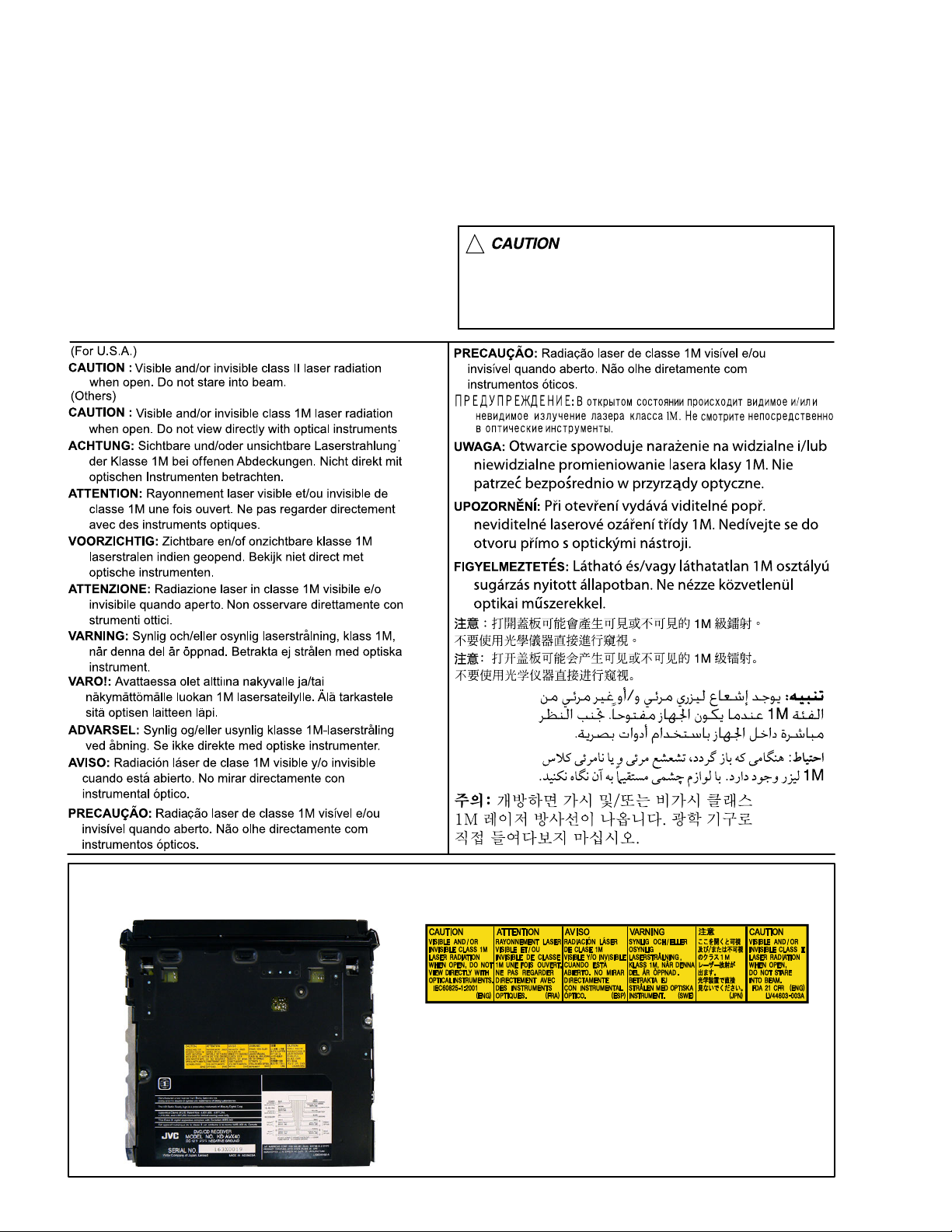

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-8 (No.MA446<Rev.001>)

Page 9

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

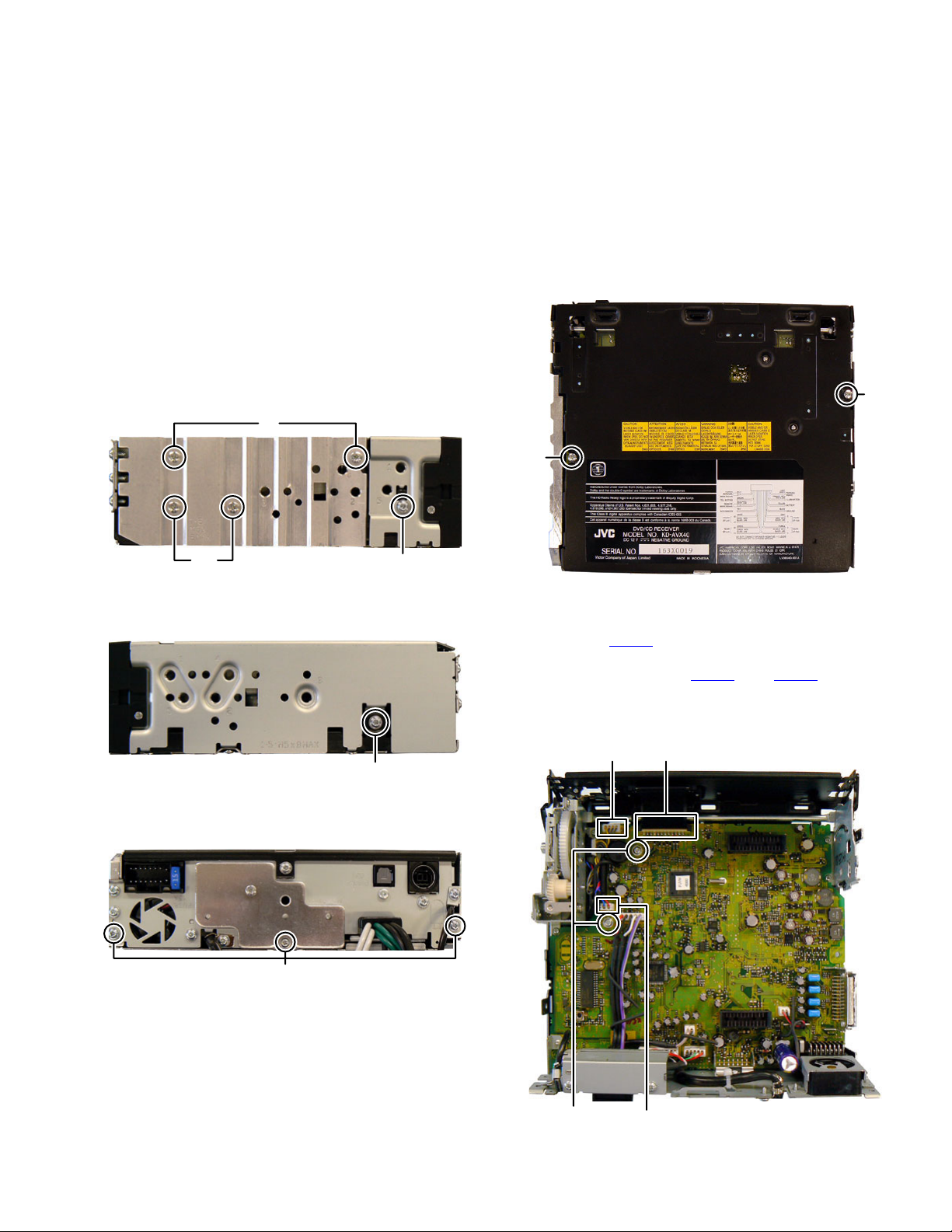

3.1 Main body (Used figure are KD-AVX40J)

3.1.1 Removing the Bottom chassis (See Fig.1 to 4)

(1) Remove the two screws A and two screws B attaching the

Heat sink. (See Fig.1)

(2) Remove the one screw C attaching the Bottom chassis.

(See Fig.1)

A

F

F

B

Fig.1

(3) Remove the one screw D attaching the Bottom chassis.

(See Fig.2)

C

D

Fig.2

(4) Remove the three screws E attaching the Bottom chassis.

(See Fig.3)

E

Fig.3

(5) Remove the two screws F attaching the Bottom chassis.

(See Fig.4)

Fig.4

3.1.2 Removing the Main board (See Fig.5 to 8)

(1) Disconnect the card wire from Front chassis connected to

connector CN962

(2) Disconnect the connector wire from Gear bracket unit con-

nected to connectors CN881 and CN891 of the Main

board. (See Fig.5)

(3) Remove the two screws G attaching the Main board. (See

Fig.5)

of the Main board. (see Fig.5)

CN962CN891

G

(4) Remove the one screw H attaching the Rear bracket. (See Fig.6)

CN881

Fig.5

(No.MA446<Rev.001>)1-9

Page 10

M

M

H

Fig.6

(5) Remove the one screw J attaching the Heat sink. (See

Fig.7)

(6) Remove the four screws K and one screw L attaching the

Rear bracket. (See Fig.7)

JL

K

Fig.7

(7) Disconnect the connector wires from Rear bracket con-

nected to connectors CN861

CN931

of the Main board. (See Fig.8)

, CN871, CN922, CN923 and

M

Fig.9

3.1.4 Removing the Connection board (See Fig.10)

(1) Disconnect the card wire from DVD mechanism connected

to connector CN395

(2) Disconnect the connector wire from BT antenna connected

to connector of RF module.

(3) Remove the three screws N attaching the Connection

board.

Connecotr

wire

of the Connection board.

CN395

N

RF module

CN931

CN861CN923CN871CN922

Fig.8

3.1.3 Removing the DVD mechanism (See Fig.9)

(1) Remove the three screws M attaching the DVD mecha-

nism.

1-10 (No.MA446<Rev.001>)

N

Fig.10

3.1.5 Removing the Panel A control board (See Fig.11)

(1) Remove the eight screws P attaching the Rear cover.

P

P

Fig.11

Page 11

3.2 DVD mechanism assembly section

3.2.1 Removing the Traverse mechanism assembly (See

Fig.1 to 6)

(1) Solder the short land section on the flexible wire of pickup.

(See Fig.1)

Caution:

* Solder the short land section on the flexible wire of pickup

before disconnecting the flexible wire form the connector

on the Front end board.

CN101

If the flexible wire is disconnected without attaching the

solder, the pickup may be destroyed by static electricity.

* When attaching the Traverse mechanism assembly, remove the solder from the short land section after connection

the flexible wire to the connector CN101

on the Front end

board.

(2) Voltage supply to TP79

and TP81 approx DC 3.0V until

Clamper is shift to loading complete position. (See Fig.2)

(3) Disconnect the flexible wires from Traverse mechanism assembly

connected to connector CN101

and CN164 of the Front end

board. (See Fig.2)

(4) Remove the five screws A attaching the Top cover assembly.

(See Fig.3)

(5) From the bottom side, disconnect the connector wire from

Top cover assembly connected to connector CN2

of the

Front end board. (See Fig.4)

(6) From the bottom side, remove the spring from Traverse

mechanism assembly. (See Fig.5)

(7) From the top side, pull up the traverse mechanism and disengage

three dumper positions. (See Fig.6)

A

Fig.3

CN2

Fig.4

CN164

Fig.1

Fig.2

Solder short part

CN101

R312

R357

TP79

TP79 TP81

R317

TP67

R21

TP92

CENTER

WOOFER

DGND_7

TP81

D-

Voltage supply

position

Fig.5

Dumper

(same color spring)

Dumper

(Different color spring)

Fig.6

(No.MA446<Rev.001>)1-11

Page 12

3.2.2 Removing the Front end board (See Fig.7)

(1) Remove the Motor wires from loading motor soldered to

TP79

and TP81 of the Front end board.

(2) Remove the two screws B attaching the Front end board.

TP81

TP79

B

B

Fig.7

3.2.3 Removing the Loading arm assembly (See Fig.8)

(1) Remove the Loading arm spring L from Loading arm assembly.

(2) Slide to left side and then disengage hook a then hook b.

hook b

Loading arm

assembly

Loading arm

spring L

Fig.9

C

hook

Loading arm spring L

Fig.8

3.2.4 Removing the Gear base assembly (See Fig.9, 10)

(1) Remove the Loading arm spring L. (See Fig.9)

(2) Remove the two screws C attaching the Gear base assembly.

(See Fig.10)

a

Fig.10

3.2.5 Removing the Loading arm holder. (See Fig.11)

(1) Remove the two screws D attaching the Loading arm holder.

(2) Remove the Loading arm spring R.

D

Loading arm

holder

Loading arm

spring R

1-12 (No.MA446<Rev.001>)

Fig.11

Page 13

3.2.6 Removing the Loading moor assembly (See Fig.12)

r

(1) Remove the three screws E attaching the Loading motor

assembly.

E

Fig.12

3.2.7 Removing the Slide cam assembly (See Fig.13)

(1) Slide to backward the Slide cam assembly and the remove

the Slide cam spring.

(2) Slide to frontward the slide cam assembly, and then take

out it.

Slide cam assembly

3.2.9 Removing the Loading motor (See Fig.15 to 18)

(1) Remove the A wheel gear. (See Fig.15)

(2) Remove the A worm gear, M connect gear and M wheel

gear by sequentially. (See Fig.16)

(3) Remove the two screws G attaching the Loading motor.

(Se Fig.17)

(4) When attaching the Loading motor, motor wire should arrange

to figure. (See Fig.18)

A Wheel gea

Fig.15

A worm gear

M connect gear

Slide cam spring

Fig.13

3.2.8 Removing the Photo board (See Fig.14)

(1) Pressing the hook c and then slide to backward (slide to the

arrow side) the Disc plate.

(2) Remove the one screw F attaching the Photo board.

hook

c

hook

c

Photo board

F

M wheel gear

Fig.16

G

Fig.17

Wire arrangement

Fig.14

Fig.18

(No.MA446<Rev.001>)1-13

Page 14

3.2.10 Removing the Roller assembly (See Fig.19)

(1) Remove the Slit washer.

(2) Remove the R middle gear.

(3) Remove the R connect gear.

(4) Snap off the part a of the Roller assembly.

(5) Lift up the part b of the Roller assembly, and then release

part c (When release part c, R collar R is easy to come off,

does not lose it).

CAUTION:

When reattach the Roller assembly, Middle gear should keep

direction and Slit washer should be change new part.

R middle gear

Direction

R collar R

R connect gear

Slit washer

3.2.11 Removing the Roller (See Fig.20)

(1) Remove the Slit washer.

(2) Pull out the Roller shaft.

CAUTION:

When reattach the Roller shaft, Slit washer should be change

new part.

slit

keep direction

keep direction

slit

part b

part c

small side

part a

Fig.20

Fig.19

1-14 (No.MA446<Rev.001>)

Page 15

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Digital tester

(3) Test Disc

(4) Extension cable : EXTAV70X-50PF

EXTGS004-26PL

EXTSH002-22P

(5) Extension studs : STDV001-3P

4.2 Standard measuring conditions

4.3 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

4.4 Dummy load

Exclusive dummy load should be used for AM, and FM.

For FM dummy load, there is a loss of 6dB between SSG output and antenna input.

The loss of 6dB need not be considered sincedirect reading of

figures are applied in this working standard.

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K ohm (2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.5 How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

CN901

C802

IC801

C801

C902

C901

R901

R806

D811

C812

R903

D981

R904

R902

R858

C982

16

C174

R857

D984

1

C274

9

C850

C845

8

IC371

TH721

C8082

Q8041

C8043

L8041

L8011

L8051

D901

R859

C852

C182

C380

C172

C374

C272

R273

C282

R283

C381

R183

R173

C379

C173

C183

C382

C273

C283

R375

C863

R374

Q8092

D8068

C8042

R8041

Q8011

C8063

Q8052

Q8053

C8054

D807

D8004

MARK

UL

PbF

CN861

C373

C185

2

C175

R181

R171

C372

C378

C285

C275

R281

R376

C377

R271

Q374

C375

R373

Q8098

D8069

Q8093

R8103

D8067

Q8091

Q8096

C8012

C8013

D8011

D8041

R8062

A

C831

Q371

Q373

D372

C8005

C9102

R8107

C376

C8031

Q8097

D8063

R8083

F805

R8101

R8100

R8105

R8102

R8059

R8042

Q8042

Q8095

C8044

Q8094

R8045

A

Q8043

R8214

R8061

C8062

C8061

R8013

Q8012

Q8013

R8012

C8014

R8051

C8052

Q8051

R8052

R8043

R8044

C8048

F801

D8051

C8058

C8022

D8021

C8024

C8021

RA801

L8021

R8022

R8021

Q8021

Q8022

R8108

D8062

D8061

Q8003

IC822

C828

Q807

Q806

L961

C966

C803

PP1

C9214

C9204

R179

R372

R378

R169

R269

D371

R370

R279

R8234

R8085

Q8083

R8084

R8000

Q372

R8049

IC803

R8058

C8018

R8217

C8016

R8019

F804

C8015

C8017

R8082

Q8084

R8047

C8027

C8001

C8047

R8018

C8084

R8086

R8002

D8001

R8017

R8029

F806

C8026

C8034

R8048

C8033

R8010

R8011

C8036

R8046

R8031

D8031

R8038

R8037

C8035

R8032

R8033

R8034

C827

Q8004

R8055

C8057

C8030

R8030

R8039

R8056

C8055

R8063

R8057

C8073

R8076

R8089

C8056

IC804

F803

C8025

R8025

R8016

R8078

R8077

C8045

R8028

R8027

5

10 11

R9999

C808

C807

C810

C805

R986

C809

C804

C811

R984

D3003

C3036

Q351

R302

R305

R303

R353

R301

C306

C353

C351

C357

R8036

R8035

C356

R358

R8015

C8032

R8026

IC721

Q863 Q864

D841

C721

C841

R947

R949

IC941

R906

R912

R910

R942

R943

R944

R946

Q955

C944

R955

R971

R911

R956

R972

R973

C732

R783

R795

IC731

C731

R784

Q953

Q952

R798

C715

C716

RA721

D731

R702

R703

R704

X702

X701

R781

R738

R8075

R8064

C8074

R710

L701

C701

R741

R737

R742

C702

R8074

C8072

C8003

R8073

D8071

C713

C800

Q701

L702

D975

D972

D991

CN922

CN871

R263

R163

PP5

L9004

CN923

12

C225

C125

C303

R356

C355

IC351

C354

R355

C844

R354

R357

Q844

D845

Q8006

D844

R846

R769

R770

R771

R337

R331

R766

R767

R773

RA726

RA725

R712

R709

R717

R716

R713

RA722

R714

R739

R745

D962

R987

C973

D974

2

D973

1

C115

R115

R116

C215

Q161

Q261

R215

R216

D251

D151

D342

R343

R162

R164

C161

R140

R351

Q843

RA729

R774

R775

R723

R724

RA723

D964

D963

R342

Q341

R341

C323

R340

C261

R240

R262

R349

R264

C223

C123

C224

R328

R324

R329

R323

C321

C325

IC701

R735

R734

R965

R322

IC321

C121

C131

C231

C221

C847

D846

R848

D847

R852

C846

Q847

Q8007

Q845

Q848

C848

D922

D921

TH700

C8006

R932

R9926

R9925

R796

R7003

R779

R765

R700

R790

R7001

R803

C9926

R934

C9925

R9924 C9927

RA728

R9923

RA727

IC934

IC933

R740

C923

R925

RA724

IC935

R926

R736

R730

C925

IC921

C921

R732

R922

R962

R961

R923

R755

R729

R728

R960

D969

D966

D968

D967

D971

R963

D970

D961

C974

D965

24

23

IC912

LVA10850

C124

C327

C324

C849

R856

Q849

CN931

C922

CN962

3

1

C866

-A1

PP3

L8

C20

R17

L11

C46

R34

C113

R334

R113

C7

C42

R335

C24

C11

C28

R119

IC332

C19

R219

C9

R352

C29

R35

C5

R213

C23

PP4

C213

X1

C222

D13

R9996

L6

C122

R9

C37

R38

C38

C36

C35

51

21

CN881

R9927

C9906

C931

L931

Q881

C9930

C927

R924

C881

C9905

L841

R937

L842

PP2

R8113

D808

R8114

BZ951

C952

41

CN891

CN860

1

D861

3

S1A

6

4

R165

R265

W1

D12

C27

R16

R22

C44

C22

D11

L10

L9

L3

C45

C8

L1

L5

C26

IC11

C30

C12

C10

C13

L2

C14

C25

IC881

C21

R14

C16

C41

C18

R19

R23

R21

R98

R99

R18

R36

C17

IC31

R39

X31

C34

C33

C31

C32

EXTAV70X-50PF

EXTGS004-26PL

EXTSH002-22P

C3103

C3104

C3108

1

IC399

R3040

25

R3034

C3023

R3037

R3038

C3025

R3041

C3026

C3027

IC397

C3014

1

C3013

C3015

C3106

T2A

50

R3183

C3102

R3185

C3006

CN395

R3186

C3002

C3004

R3184

TP3035

50

1

7

R3014

R3012R3013

1

CN398

26

R3033

R3035

R3036

R3039

C3022

R3028

C3107

R3105

R3109

C3151C3152

L827

C3024

Extension studs

STDV001-3P

(No.MA446<Rev.001>)1-15

Page 16

4.6 Service mode

4.6.1 Service mode 1 (Indication of a service mode 1 is nothing)

Keep this state more 2 seconds

while continuing pressing the

[STANDBY/ON ATTENUATOR] button

and [EJECT] button sequentially.

Screen indication

Exchanging it operate a menu of a service mode with the [ ] button

NO EJECT? 1

EMERGENCY EJECT? 2

and [ ] button. Operate choice of a menu with a [PLAY/PAUSE] button.

*1 : When an [PLAY/PAUSE] button is pushed in NO EJECT indication,

it is set by an EJECT prohibition mode.

When an [PLAY/PAUSE] button is pushed in EJECT OK indication,

it is set by a normal mode.

*2 : Forced EJECT movement

A screen becomes normal indication after an [PLAY/PAUSE] button was

pushed.

Multiplex push timing chart (Example: Service mode 2)

[SOURCE]

[EJECT]

[MENU]

[PLAY/PAUSE]

[FOLDER UP]

Within 0.5 seconds

Within 2 seconds

Key ON (Hold)

Key ON (Hold)

Key ON

Within 2 seconds

Key ON

Key ON

Within 2 seconds

Shift to Service Mode 2

1-16 (No.MA446<Rev.001>)

Page 17

4.6.2 Service mode 2

Set to service mode 2: [SOURCE] [EJECT] [MENU] [PLAY/PAUSE] [FOLDER UP]

Screen indication

SERVICE MODE 2

INITIALIZE ALL

INITIALIZE

INITIALIZE DVD

INITIALIZE BT

Exchanging it operate a menu of a service mode with the [ ] button

and [ ] button. Operate choice of a menu with a [PLAY/PAUSE] button.

INITIALIZE ALL

INITIALIZE ALL (Each EEPROM is initialized by a

NOW

INITIALIZE ALL

INITIALIZE ALL

OK **

factory shipment state.)

*EMain micon EEPROM initialization (user entry domain, error

history, speaker setting, sub area of J-version, data to pre-set )

*Panel micon EEPROM initialization (picture adjustment data)

*DVD unit EEPROM initialization (except a permanent domain)

*Bluetooth module EEPROM initialization

*After clear completion, a screen returns to normal indication

INITIALIZE

after OK indication was displayed for three seconds.

INITIALIZE (Initialization of a user area of each EEPROM)

NOW

INITIALIZE

INITIALIZE

OK **

*Main micon EEPROM initialization (a user entry domain )

(a user entry domain, speaker setting, sub area of J-version,

data to pre-set )

*Panel micon EEPROM initialization (picture adjustment data )

*DVD unit EEPROM initialization (except a permanent domain)

*After clear completion, a screen returns to normal indication

after OK indication was displayed for three seconds.

INITIALIZE DVD

Full initialization of EEPROM of a DVD unit

INITIALIZE DVD

OK **

( It is included a permanent domain)

After clear completion, this indication is continued

till an effective key is input.

INITIALIZE BT

INITIALIZE BT

OK **

Full initialization of EEPROM of Bluetooth

After clear completion, this indication is continued

till an effective key is input.

(No.MA446<Rev.001>)1-17

Page 18

4.6.3 Service mode 3

Set to service mode 3: [SOURCE] [EJECT] [MENU] [PLAY/PAUSE] [DISP]

Screen indication

SERVICE MODE 3

SERVICE MODE 3

INITIALIZE ALL

RUNNING MODE

Exchanging it operate a menu of a service mode with the [ ] button

and [ ] button. Operate choice of a menu with a [PLAY/PAUSE] button.

SERVICE MODE

SERVICE MODE

VERSION

AREA/REGION

TEMPERATURE

MEMORY CHECK

DVD NTSC/PAL

DVD CHECK MODE

* Exchanging it operate

a menu of a service

mode with the [ ]

button and [ ] button.

* Operate choice of a

menu with a [PLAY/PAUSE]

button.

* Return to previous menu

with a [BAND] button.

INITIALIZE ALL

NOW

INITIALIZE ALL

RUNNING MODE

* See "Running mode" for details.

SERVICE MODE

ERROR READ

ERROR CLEAR

BT VERSION

VERSION

MAIN V**** [**]

DISC

****

CH

******

PN V*** V *** [**] V***

SW BT MODULE V***

AREA/REGION

SYS-AREA : *

DISC-AREA : **

REGION : *

PANEL AREA : *

TEMPERATURE Temperature data reading

* Temperature data by the temperature sensor in the main micon

and DVD-PCB is read every 5 seconds and displayed in hex numbers.

MEMORY CHECK ( It is displayed only at the time of the disc insertion )

Memory residual quantity indication mode

* Data residual quantity of a disc is displayed by LCD.

* About the playback control-related key ([FSKIP], [BSKIP], [UP], [DOWN], [VOL]),

only movement is effective.

Indication does not change as memory residual quantity indication.

* About cancellation of this mode, press the [STANDBY/ON ATTENUATOR] button.

DVD NTSC/PAL

NTSC

PAL

DVD CHECK MODE

* See "DVD CHECK MODE" for details.

ERROR READ

DVD ERROR READ

CH ERROR READ

MECHA ERROR READ

READ ALL

DVD ERROR READ

Reading of a DVD unit error history

CH ERROR READ

Reading of a CD changer error history

MECHA ERROR READ

Reading of a door mechanism error history

READ ALL *Only the engineer use

Reading of a main micon EEPROM (All contents)

ERROR CLEAR

DVD ERROR CLEAR

CH ERROR CLEAR

MECHA ERROR CLEAR

BT VERSION

SW BT CORE ***

HW BT MODULE ***

SW BT MODULE ***

ADR-************

INITIALIZE ALL

OK **

Micon version indication

Main micon version and ROM correction version

DVD module version

CH version

Panel micon version and ROM correction version

Software version of BT Module

Area and region indication

Main micon area

DVD area

Region

PANEL area

DVD picture change

DVD module output picture setting (NTSC)

DVD module output picture setting (PAL)

Clear of each error history

A screen returns to following

indication after clear completion.

Bluetooth version indication

Software version of BT core

Hardware version of BT Module

Software version of BT Module

BT Address

INITIALIZE ALL (Each EEPROM is initialized by a

factory shipment state.)

* Main micon EEPROM initialization

(user entry domain, error history,speaker setting,

subarea of J-version, data to pre-set )

* Panel micon EEPROM initialization

(picture adjustment data)

*

DVD unit EEPROM initialization (except a permanent domain)

* Bluetooth module EEPROM initialization

*

After clear completion, a screen returns to normal indication

after OK indication was displayed for three seconds.

1-18 (No.MA446<Rev.001>)

Page 19

4.6.4 Service mode 4

Set to service mode 4: [SOURCE] [EJECT] [MENU] [PLAY/PAUSE] [REW]

Screen indication

SERVICE MODE 4

RDS S MODE

MONITOR S MODE

HD RADIO S MODE

Exchanging it operate a menu of a service mode with the [ ] button

and [ ] button. Operate choice of a menu with a [PLAY/PAUSE] button.

RDS S MODE

* RDS service mode (Only RDS model)

MONITOR S MODE

R/W CHROMA

DATA CLEAR

HD RADIO S MODE

* It is displayed in HD Radio unit connection.

*See "Monitor adjustment" for details.

CHROMA DATA read/write of NTSC/PAL signal processing IC

Clear of CHROMA DATA (return to an initial value)

4.7 DVD check mode

DVD CHECK MODE

NORMAL PLAY

EF OUT-TRACKING OFF

EF IN-TRACKING OFF

CD-LASER ON

DVD-LASER ON

DVDx1 JITTER MODE

DVD CHECK MODE

EEPROM DATA DISP

EEPROM DATA CLEAR

TEMPERATURE

SEARCH & JITTER

MONITOR

PLAY

DVD CHECK MODE

STOP

OPEN

CLOSE

Exchanging it operate a menu of a service mode with the [UP] button and [DOWN] button. Operate choice of a menu

with a [PLAY/PAUSE] button.

Command Mechanism unit operation Indication contents

NORMAL PLAY Start at normal speed

Laser current value, jitter value

(After start, jitter is measured by an inner position.)

EF OUT-TRACKING OFF Tracking off the outermost position of CD For EF phase error

EF IN-TRACKING OFF Tracking off the innermost position of CD For EF phase error

CD-LASER ON CD_LD lights and laser current is displayed. Laser current value, jitter value

DVD-LASER ON DVD_LD lights and laser current is displayed Laser current value, jitter value

DVDx1 JITTER MODE DVD x1 jitter measuring mode

Laser current value, jitter value

(for use in mechanism adjustment)

EEPROM DATA DISP Contents of EEPROM is displayed. EEPROM address

EEPROM contents

EEPROM DATA CLEAR Contents of EEPROM is initialized. EEPROM address

EEPROM contents

TEMPERATURE Temperature indication Temperature is displayed in hex numbers.

SEARCH & JITTER The search and jitter measurement to an appointed position

Position measured with VT-501 jitter value

of DVD.

MONITOR Monitor terminal setting

PLAY DVD x1 stopped start

Not displayed.

(After start, jitter is measured by an inner position.)

STOP Disc stopped, LD-OFF Not displayed.

OPEN OPEN Not displayed.

CLOSE CLOSE Not displayed.

(No.MA446<Rev.001>)1-19

Page 20

4.8 Error code tables

4.8.1 Mechanism error code

Error contents Details Error code Detailed error code

Disc loading error

(3) D1 time out 09 0013

Eject error

(3) B1 time out

(4) C1 time out

Error in loading wait Loading of a running mode

Disc was pulled out in a wait.

4.8.2 Disc error code

Error contents Details Error code Detailed error code

TOC read error TOC lead movement of a CD is not completed. 84 0059

First track access error Even if TOC reading passes after the end with CD running

mode for 30 seconds, the first track access is not finished.

Last track access error Even if first track passes after the end with CD running mode

for 30 seconds, the last track access is not finished.

T1 access error Even if T1 access passes in a DVD running mode for 30 sec-

onds, it is not finished.

T12 access error Even if T12 access passes in a DVD running mode for 30

seconds, it is not finished.

T24 access error Even if T24 access passes in a DVD running mode for 30

seconds, it is not finished.

Read-in area read error Read-in area read operation of DVD is not completed. 84 0072

DVD L1 layer adjustment error Adjustment of L1 layer of DVD is not finished normally. (in-

cluding focus jump failure)

DVD L0 layer adjustment error Adjustment of L0 layer of DVD is not finished normally. (in-

cluding focus jump failure)

NO DISC judgment Judgment without disc 80 0090

It is NO DISC by start failure Start is impossible 80 0091

It is stopped by playback inability. Stop in running mode playback 80 0093

Logic format NG Logic format analysis inability or non-correspondence logic

format

Seek access error It cannot arrive at an aim address even if it passes for 15

seconds.

01

01

09 0031

80 0060

80 0061

80 0069

80 0070

80 0071

80 0074

80 0075

80 0094

80 0095

0023

0024

4.8.3 Error codes of panel mechanism

PANEL ANGLE

1 Panel Close Main body

2

3

4

Open

1-20 (No.MA446<Rev.001>)

10 degrees

20 degrees

30 degrees

Open

Page 21

Detail

Open error

1. Time out error by OPEN position cannot detect.

Close error (ANGLE 1 error)

1. Time out error by ANGLE 1 position cannot detect.

Angle positioning error

Moving to 10 degrees (ANGLE 2 error)

1. Time out error by ANGLE 2 position cannot detect at moving to open position.

2. Missing to ANGLE 1 and detected ANGLE 2 position at moving to open position.

3. Time out error by ANGLE 2 cannot detect at moving close position.

Moving to 20 degrees (ANGLE 3 error)

1. Time out error by ANGLE 3 position cannot detect at moving to open position.

2. Missing to ANGLE 2 and detected ANGLE 3 position at moving to open position.

3. Time out error by ANGLE 3 cannot detect at moving close position.

Moving to 30 degrees (ANGLE 4 error)

1. Time out error by ANGLE 4 position cannot detect at moving to open position.

2. Missing to ANGLE 3 and detected ANGLE 4 position at moving to open position.

3. Time out error by ANGLE 4 cannot detect at moving close position.

Abnormal switch position at moving panel

The Panel move to open and close position, detected abnormal switch position. 0A0000

4.9 Running mode

Error code

(Service mode)

0A0001

0B0006

0D0021

0D0022

0D0023

0E0031

0E0032

0E0033

0F0041

0F0042

0F0043

Indication Explanation Operation contents of 1 cycle

RUNNING1 MECHA

RUNNING2 MECHA

RUNNING4 DVD

RUNNING5 DVD

RUNNING6 DVD

RUNNING7 DVD

RUNNING8 DVD

RUNNING9 DVD

* Cancellation of running1,2 : Press the [EJECT] key

* In running 1,2 cancellation, a door does not stop at the position and moves to a panel position.

* Cancellation of running3 to 8 : Press the [POWER] key

* The number of count and an error cord are displayed in running.

Playback contents in a running mode

•CD

The first track is played for 30 seconds.

•DVD

2 layer disc (Pit disc)

Title 1 (the L0 layer internal circumference) is played for 30 seconds.

→

Title 24 (L1layer internal circumference) is played for 30 seconds.

2 layer disc (Recordable disc)

Title 1 (the L0 layer internal circumference) is played for 30 seconds.

→

Title 24 (L1layer internal circumference) is played for 30 seconds.

1 layer disc

First chapter of title 1 is played for 30 seconds.

Door mecha running 1 Panel close → Panel open - -

Door mecha running 2 Panel close → Panel open → Panel detach position →

→

Panel angle 1 position → Panel angle 2 position

The last track is played for 30 seconds.

→

Title 12 (L0 layer circumference) is played for 30 seconds.

→

Title 12 (L0 layer circumference) is played for 30 seconds.

→

The last chapter of title 1 is played for 30 seconds.

DVD + Door mecha running1

DVD + Door mecha running2

DVD + Door mecha running3

DVD + Door mecha running4

DVD + Door mecha running5

DVD + Door mecha running6

3 position

Loading → Eject → Wait for 5 seconds + Door open/close Stop

Loading → Eject → Wait for 5 seconds + Door open/close Retry

Loading → Playback → Eject → Wait for 5 seconds + Door open/close Stop Stop

Loading → Playback → Eject → Wait for 5 seconds + Door open/close Retry Stop

Loading → Playback → Eject → Wait for 5 seconds + Door open/close Stop Retry

Loading → Playback → Eject → Wait for 5 seconds + Door open/close Retry Retry

→

(The last track is played in the case of less than till the last for 30 seconds.)

Panel angle

RETRY

NO RETRY

In mecha

error

Retry -

Stop -

In disc

error

-

-

(No.MA446<Rev.001>)1-21

Page 22

4.10 Monitor adjustment

* When adjusting, switch on the main unit and insert a test disc (VT-501). And play the test disc and pause it.

1. Set the service mode 4.

2. Exchanging it operate a menu of a service mode with the [UP] button and [DOWN] button.

3. Change data with the [B.SKIP]/[F.SKIP] buttons.

4. Write data with a [PLAY/PAUSE] button.

R/W CHROMA

Indication

00001 00000 00001 00000 00000 Fix Color amplitude revision ON/OFF

00002 00000 00003 00001 00001 Fix Color amplitude revision CAS

00003 00000 00063 00016 00016 Fix Color amplitude revision APC

00004 00000 00003 00001 00001 Fix Color amplitude revision CUS

00005 00000 00063 00010 00010 Fix Color amplitude revision APU

00006 00000 00001 00000 00000 Fix Black level extension ON/OFF

00007 00000 00001 00001 00001 Fix Black level extension FUNCTION

00008 00000 00511 00176 00176 Fix Black level extension START POINT

00009 00000 00511 00128 00128 Fix Black level extension OFFSET

00010 00000 00255 00040 00040 Adjust Enhancer revision effect adjustment (NTSC)

00011 00000 00255 00040 00040 Adjust Enhancer revision effect adjustment (PAL)

00012 00000 00255 00010 00010 Adjust Limiter of the horizontal enhancer (NTSC)

00013 00000 00255 00010 00010 Adjust Limiter of the horizontal enhancer (PAL)

00014 00000 00255 00000 00000 Adjust Filter choice of the horizontal enhancer (NTSC)

00015 00000 00255 00000 00000 Adjust Filter choice of the horizontal enhancer (PAL)

00016 00000 00003 00000 00000 Adjust Tap change of the brightness outline revision (NTSC)

00017 00000 00003 00000 00000 Adjust Tap change of the brightness outline revision (PAL)

00018 00000 00127 00000 00000 Adjust

00019 00000 00127 00000 00000 Adjust Adjustment of the quantity of brightness outline core ring (PAL)

00020 00000 00006 00003 00003 Adjust Adjustment of the brightness outline revision gain (NTSC)

00021 00000 00006 00003 00003 Adjust Adjustment of the brightness outline revision gain (PAL)

00022 00000 00255 00128 00128 Fix Change in TINT of the whole picture (NTSC)

00023 00000 00255 00128 00128 Fix Change in TINT of the whole picture (PAL)

00024 00000 00255 00128 00128 Fix

00025 00000 00255 00128 00128 Fix

00026 00000 00255 00125 00125 Adjust Tint adjustment (NTSC)

00027 00000 00255 00132 00132 Adjust Tint adjustment (PAL)

00028 00000 00255 00033 00036 Adjust Color adjustment (NTSC)

00029 00000 00255 00033 00036 Adjust Color adjustment (PAL)

00030 00000 00511 00064 00064 Fix Set the offset DC of the input video signal (NTSC)

00031 00000 00511 00064 00064 Fix Set the offset DC of the input video signal (PAL)

00032 00000 00001 00000 00000 Fix Quantity of transmission revision of the YUV DC

00033 00000 00255 00016 00016 Fix Quantity of transmission revision of the YUV DC

00034 00000 01023 00495 00476 Adjust Contrast adjustment between the black - white (NTSC)

00035 00000 01023 00510 00493 Adjust Contrast adjustment between the black - white (PAL)

00036 00000 00511 00359 00359 Fix Conversion coefficients from YUV to RGB (PRCL)

Minimum

value

Maximum

value

Initial

value

Reference

register

value

Reference register value

Adjustment of the quantity of brightness outline core ring

(NTSC)

Change with the deepness of the color of the whole picture

(NTSC)

Change with the deepness of the color of the whole picture

(PAL)

1-22 (No.MA446<Rev.001>)

Page 23

00037 00000 00255 00227 00227 Fix Conversion coefficients from YUV to RGB (PBCL)

00038 00000 00255 00218 00218 Fix Conversion coefficients from YUV to RGB (YCL)

00039 00000 00255 00199 00199 Fix Conversion coefficients from YUV to RGB (BCL)

00040 00000 00511 00261 00261 Fix Conversion coefficients from YUV to RGB (RCL)

00041 00000 00001 00001 00001 Fix Noise shaving (NTSC)

00042 00000 00001 00001 00001 Fix Noise shaving (PAL)

00043 00000 00127 00026 00026 Adjust Black level adjustment (NTSC)

00044 00000 00127 00026 00026 Adjust Black level adjustment (PAL)

00045 00000 00127 00050 00050 Fix Gain setting of Red signal (NTSC)

00046 00000 00127 00050 00050 Fix Gain setting of Red signal (PAL)

00047 00000 00127 00050 00050 Fix Gain setting of Green signal (NTSC)

00048 00000 00127 00050 00050 Fix Gain setting of Green signal (PAL)

00049 00000 00127 00050 00050 Fix Gain setting of Blue signal (NTSC)

00050 00000 00127 00050 00050 Fix Gain setting of Blue signal (PAL)

00051 00000 00127 00057 00057 Fix Set the cut-off of the Red signal (NTSC)

00052 00000 00127 00057 00057 Fix Set the cut-off of the Red signal (PAL)

00053 00000 00127 00057 00057 Fix Set the cut-off of the Green signal (NTSC)

00054 00000 00127 00057 00057 Fix Set the cut-off of the Green signal (PAL)

00055 00000 00127 00057 00057 Fix Set the cut-off of the Blue signal (NTSC)

00056 00000 00127 00057 00057 Fix Set the cut-off of the Blue signal (PAL)

00057 00000 00001 00001 00001 Fix ON/OFF change of the gamma revision

00058 00000 00255 00004 00004 Fix Adjust 1 gamma revision point position of a Red signal

00059 00000 00255 00008 00008 Fix Adjust 2 gamma revision point position of a Red signal

00060 00000 00255 00012 00012 Fix Adjust 3 gamma revision point position of a Red signal

00061 00000 00255 00016 00016 Fix Adjust 4 gamma revision point position of a Red signal

00062 00000 00255 00020 00020 Fix Adjust 5 gamma revision point position of a Red signal

00063 00000 00255 00024 00024 Fix Adjust 6 gamma revision point position of a Red signal

00064 00000 00255 00028 00028 Fix Adjust 7 gamma revision point position of a Red signal

00065 00000 00255 00035 00035 Fix Appoint gamma revision gain 1 of the Red signal

00066 00000 00255 00035 00035 Fix Appoint gamma revision gain 2 of the Red signal

00067 00000 00255 00035 00035 Fix Appoint gamma revision gain 3 of the Red signal

00068 00000 00255 00035 00035 Fix Appoint gamma revision gain 4 of the Red signal

00069 00000 00255 00035 00035 Fix Appoint gamma revision gain 5 of the Red signal

00070 00000 00255 00035 00035 Fix Appoint gamma revision gain 6 of the Red signal

00071 00000 00255 00035 00035 Fix Appoint gamma revision gain 7 of the Red signal

00072 00000 00255 00035 00035 Fix Appoint gamma revision gain 8 of the Red signal

00073 00000 00255 00004 00004 Fix Adjust 1 gamma revision point position of a Green signal

00074 00000 00255 00008 00008 Fix Adjust 2 gamma revision point position of a Green signal

00075 00000 00255 00012 00012 Fix Adjust 3 gamma revision point position of a Green signal

00076 00000 00255 00016 00016 Fix Adjust 4 gamma revision point position of a Green signal

00077 00000 00255 00020 00020 Fix Adjust 5 gamma revision point position of a Green signal

00078 00000 00255 00024 00024 Fix Adjust 6 gamma revision point position of a Green signal

00079 00000 00255 00028 00028 Fix Adjust 7 gamma revision point position of a Green signal

00080 00000 00255 00035 00035 Fix Appoint gamma revision gain 1 of the Green signal

00081 00000 00255 00035 00035 Fix Appoint gamma revision gain 2 of the Green signal

00082 00000 00255 00035 00035 Fix Appoint gamma revision gain 3 of the Green signal

00083 00000 00255 00035 00035 Fix Appoint gamma revision gain 4 of the Green signal

(No.MA446<Rev.001>)1-23

Page 24

00084 00000 00255 00035 00035 Fix Appoint gamma revision gain 5 of the Green signal

00085 00000 00255 00035 00035 Fix Appoint gamma revision gain 6 of the Green signal

00086 00000 00255 00035 00035 Fix Appoint gamma revision gain 7 of the Green signal

00087 00000 00255 00035 00035 Fix Appoint gamma revision gain 8 of the Green signal

00088 00000 00255 00004 00004 Fix Adjust 1 gamma revision point position of a Blue signal

00089 00000 00255 00008 00008 Fix Adjust 2 gamma revision point position of a Blue signal

00090 00000 00255 00012 00012 Fix Adjust 3 gamma revision point position of a Blue signal

00091 00000 00255 00016 00016 Fix Adjust 4 gamma revision point position of a Blue signal

00092 00000 00255 00020 00020 Fix Adjust 5 gamma revision point position of a Blue signal

00093 00000 00255 00024 00024 Fix Adjust 6 gamma revision point position of a Blue signal

00094 00000 00255 00028 00028 Fix Adjust 7 gamma revision point position of a Blue signal

00095 00000 00255 00035 00035 Fix Appoint gamma revision gain 1 of the Blue signal

00096 00000 00255 00035 00035 Fix Appoint gamma revision gain 2 of the Blue signal

00097 00000 00255 00035 00035 Fix Appoint gamma revision gain 3 of the Blue signal

00098 00000 00255 00035 00035 Fix Appoint gamma revision gain 4 of the Blue signal

00099 00000 00255 00035 00035 Fix Appoint gamma revision gain 5 of the Blue signal

00100 00000 00255 00255 00035 Fix Appoint gamma revision gain 6 of the Blue signal

00101 00000 00255 00035 00035 Fix Appoint gamma revision gain 7 of the Blue signal

00102 00000 00255 00035 00035 Fix Appoint gamma revision gain 8 of the Blue signal

00103 00000 00255 00106 00106 Adjust Adjust the horizontal indication point of the picture (NTSC)

00104 00000 00255 00112 00112 Adjust Adjust the horizontal indication point of the picture (PAL)

00105 00000 00255 00020 00020 Adjust Adjust the vertical indication point of the picture (NTSC)

00106 00000 00255 00028 00028 Adjust Adjust the vertical indication point of the picture (PAL)

00107 00000 00127 00042 00042 Fix AD clock gain adjustment (NTSC)

00108 00000 00127 00042 00042 Fix AD clock gain adjustment (PAL)

00109 00000 00007 00001 00001 Fix Noise reduction of the Y signal (NTSC)

00110 00000 00007 00001 00001 Fix Noise reduction of the Y signal (PAL)

00111 00000 00003 00048 00048 Fix Choose a YC separation filter (NTSC)

00112 00000 00003 00048 00048 Fix Choose a YC separation filter (PAL)

00113 00000 00007 00000 00000 Fix Color pulling out filter setting (NTSC)

00114 00000 00007 00000 00000 Fix Color pulling out filter setting (PAL)

00115 00000 00007 00001 00001 Adjust Choose com movement mode and color BPF (NTSC)

00116 00000 00007 00001 00001 Adjust Choose com movement mode and color BPF (PAL)

00117 00000 01023 00180 00180 Fix Vertical dot cancellation setting (NTSC)

00118 00000 01023 00180 00180 Fix Vertical dot cancellation setting (PAL)

00119 00000 00063 00000 00000 Adjust Noise reduction setting (NTSC)

00120 00000 00063 00000 00000 Adjust Noise reduction setting (PAL)

00121 00000 01023 00320 00320 Fix Quantity of brightness adjustment setting (NTSC)

00122 00000 01023 00320 00320 Fix Quantity of brightness adjustment setting (PAL)

00123 00000 00255 00176 00176 Fix Brightness gain adjustment (NTSC)

00124 00000 00255 00176 00176 Fix Brightness gain adjustment (PAL)

00125 00000 00511 00128 00128 Adjust Color signal output level setting (NTSC)

00126 00000 00511 00128 00128 Adjust Color signal output level setting (PAL)

00127 00000 00006 00004 00004 Fix ACC movement mode setting

00128 00000 00255 00160 00160 Fix

00129 00000 00255 00160 00160 Fix

C signal filter characteristic setting of the Y/C separation part

(NTSC)

C signal filter characteristic setting of the Y/C separation part

(PAL)

1-24 (No.MA446<Rev.001>)

Page 25

00130 00000 16383 00220 00220 Fix Amplitude killer off level setting

00131 00000 16383 00212 00212 Fix Amplitude killer on level setting

00132 00000 00127 00071 00071 Fix Clamp DC level adjustment setting

00133 00000 00015 00015 00015 Fix Clamp speed adjustment setting

00134 00000 00063 00049 00049 Fix

00135 00000 00063 00049 00049 Fix

00136 00000 65535 14976 14976 Fix Horizontal phase comparison gain setting (NTSC)

00137 00000 65535 14976 14976 Fix Horizontal phase comparison gain setting (PAL)

00138 00000 00063 00055 00055 Fix Horizontal loop filter setting 1

00139 00000 00015 00010 00010 Fix Horizontal loop filter setting 2

00140 00000 00015 00007 00007 Fix Horizontal loop filter setting 3

00141 00000 00015 00000 00000 Fix Synchronization separation burst clock setting (NTSC)

00142 00000 00015 00001 00001 Fix Synchronization separation burst clock setting (PAL)

00143 00000 00255 00252 00252 Fix

00144 00000 00255 00252 00252 Fix

00145 00000 00511 00326 00326 Fix DOKIDET 01

00146 00000 00511 00082 00082 Fix DOKIDET 02

00147 00000 00511 00033 00033 Fix DOKIDET 03

00148 00000 00026 00000 00000 Fix Unused

00149 00000 00026 00000 00000 Fix Unused

00150 00000 00255 00000 00000 Fix Sub career center frequency setting (NTSC)

00151 00000 00255 00000 00000 Fix Unused

00152 00000 00255 00000 00000 Fix Sub career center frequency setting (PAL)

00153 00000 00255 00000 00000 Fix Unused

00154 00000 00255 00018 00018 Adjust Coordinate the delay of the C signal with a Y signal (NTSC)

00155 00000 00255 00020 00020 Adjust Coordinate the delay of the C signal with a Y signal (PAL)

00156 00000 00255 00000 00000 Fix Coordinate the VCOM amplitude of the LCD (NTSC)

00157 00000 00255 00000 00000 Fix Coordinate the VCOM amplitude of the LCD (PAL)

00158 00000 00255 00000 00000 Fix Coordinate VCOM center value of the LCD (NTSC)

00159 00000 00255 00000 00000 Fix Coordinate VCOM center value of the LCD (PAL)

00160 00000 00009 00004 00004 Fix

00161 00000 00009 00006 00006 Fix Set a variable range of the indication VSYNC frequency (PAL)

00162 00040 00110 00090 00090 Fix Set time when indication VSYNC frequency changes (NTSC)

00163 00040 00110 00060 00060 Fix Set time when indication VSYNC frequency changes (PAL)

00164 00000 00007 00000 00000 Fix CLAMP MODE (NTSC)

00165 00000 00007 00000 00000 Fix CLAMP MODE (PAL)

Noise filter band setting of horizontal synchronization signal

and vertical synchronizing signal (NTSC)

Noise filter band setting of horizontal synchronization signal

and vertical synchronizing signal (PAL)

Free run center value setting of horizontal synchronization signal (NTSC)

Free run center value setting of horizontal synchronization signal (PAL)

Set a variable range of the indication VSYNC frequency

(NTSC)

(No.MA446<Rev.001>)1-25

Page 26

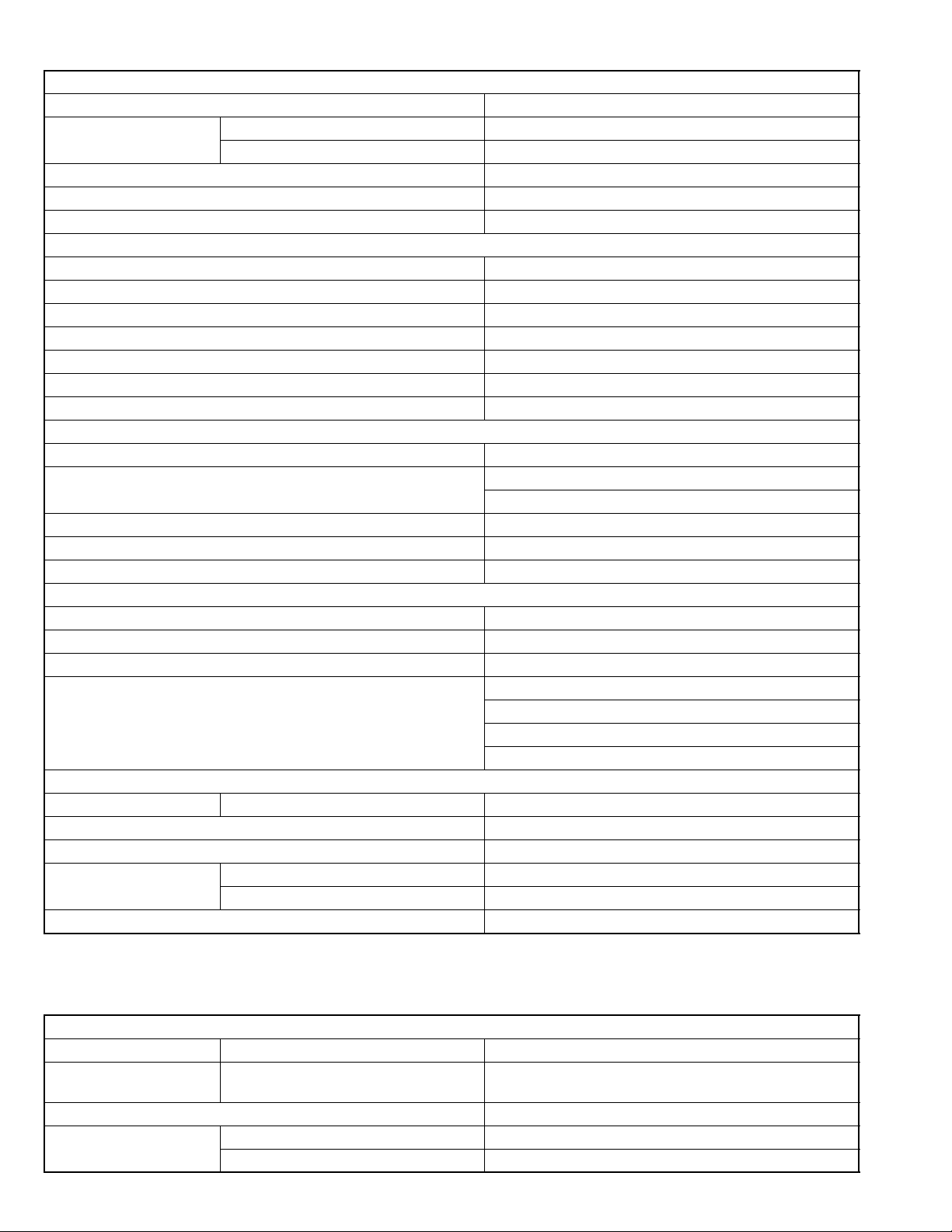

SECTION 5

TROUBLESHOOTING

5.1 16 PIN CORD DIAGRAM (for KD-AVX40J, KD-AVX20UT/A)

16

15

13

1

2

8

GN/BK

7

6

VI/BK

5

4

BL/WH

3

2

1

BK

YL

RD

OR/WH

BR

GN

VI

BL

RD

BK

WH

WH/BK

GY/BK

GY

BR

YG

OR/WH

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

VI

GN

Black

Red

Blue

White

Violet

Green

GY

BR

YG

OR

YL

Gray

Brown

Yellow Green

Orange

Yellow

10

12

11

14

3

4

8

7

5

6

9

BL/WH

BL

GN

GN/BK

VI

VI/BK

WH

WH/BK

GY

GY/BK

YG

1-26 (No.MA446<Rev.001>)

Page 27

5.2 16 PIN CORD DIAGRAM (for KD-AVX40E/EE, KD-AVX20E/EU/EE)

8

7

6

5

4

3

2

1

2

16

1

3

13

15

GN

GN/BK

VI/BK

VI

NC

BL/WH

RD

BK

RD1

YL1

BK

BL/WH

BR

OR/WH

WH

WH/BK

GY/BK

GY

BR

YG

OR/WH

YL

9

10

11

12

13

14

15

16

BK

RD

BL

WH

VI

GN

Black

Red

Blue

White

Violet

Green

RD3

GY

BR

YG

OR

YL

Gray

Brown

Yellow Green

Orange

Yellow

RD2

YL2

7

4

8

5

1

3

2

5

7

6

NC

NC

BL/WH

RD

BR

YL

OR/WH

BK

2

4

6

8

10

12

11

14

8

7

5

6

9

GN

GN/BK

VI

VI/BK

WH

WH/BK

GY

GY/BK

YG

7

8

1

2

5

VI/BK

VI

1

6

GY

3

3

4

WH

5

GN

7

GY/BK

WH/BK

GN/BK

2

4

6

8

(No.MA446<Rev.001>)1-27

Page 28

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA446<Rev.001>)

Printed in Japan

VPT

Loading...

Loading...