Page 1

SERVICE MANUAL

DVD/CD RECEIVER

MA16520055

KD-AVX1

Area suffix

J ------------- Northern America

E ------------- Southern Europe

A ------------------------ Australia

UT ------------------------- Taiwan

UN --------------------- Indonesia

U -------------------- Other Areas

KD-AVX1

OK

DISP

SOURCE

MENU

D

T/P

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

BACK

BAND

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA165

2005/5

Page 2

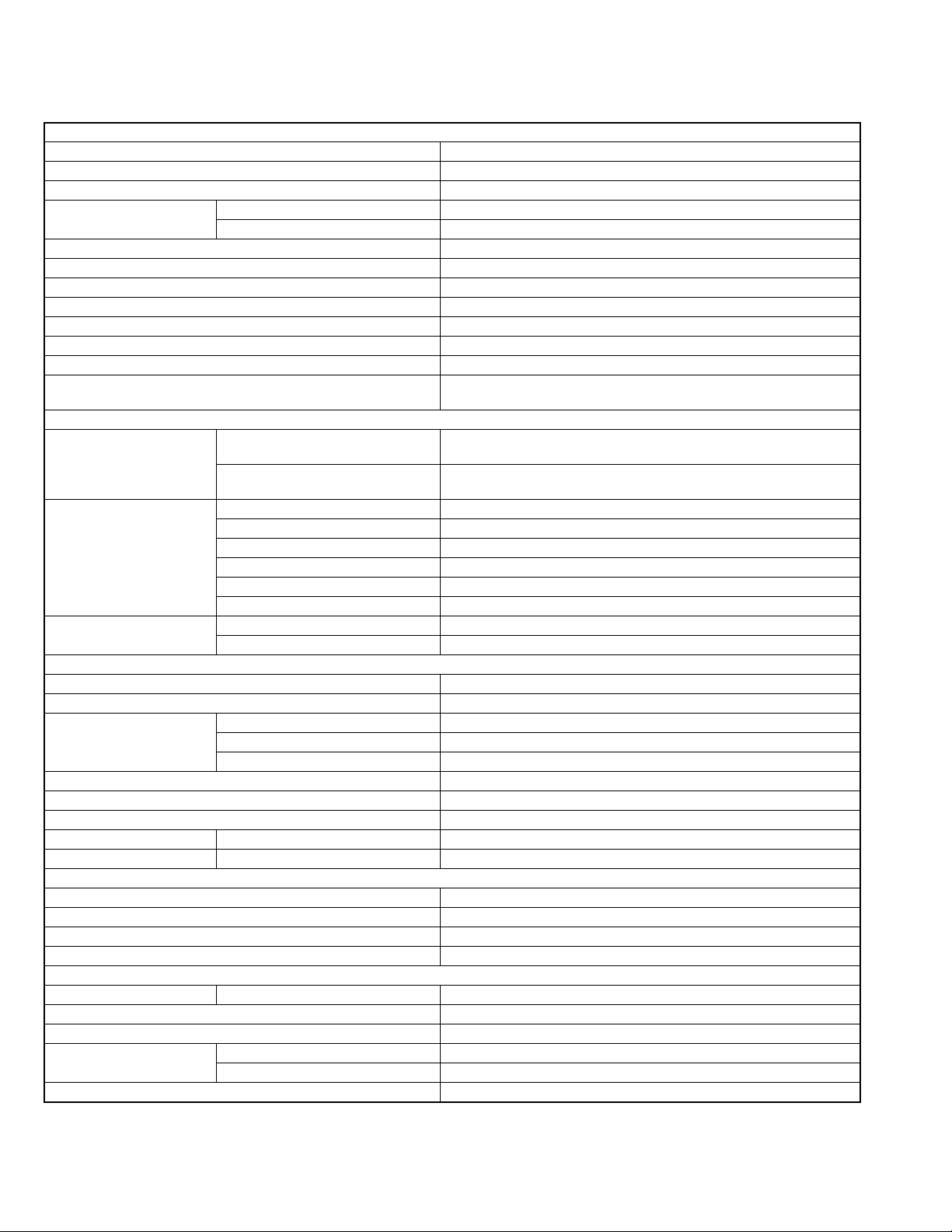

SPECIFICATION

for NORTHERN AMERICA version

AUDIO AMPLIFIER SECTION

Power Output 20 W RMS

Signal to Noise Ratio 80 dBA (reference: 1 W into 4

Load Impedance 4

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.5 kHz, 6.3 kHz, 15 kHz

Level ±10 dB

Line-In Level/Impedance 1.5 V/20 k

Line-Out Level/Impedance 5.0 V/20 k

Output Impedance 1 k

Subwoofer-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Color System NTSC

Video Input (composite) 1 Vp-p/75

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals 2nd AUDIO OUT, DIGITAL OUT (optical), CD changer, Steering wheel re-

TUNER SECTION

Frequency Range FM 87.5 MHz to 107.9 MHz (with channel interval set to 200 kHz)

AM 530 kHz to 1 710 kHz (with channel interval set to 10 kHz)

FM Tuner Usable Sensitivity 11.3 dBf (1.0

50 dB Quieting Sensitivity 16.3 dBf (1.8

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

AM Tuner Sensitivity 20

Selectivity 35 dB

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD fs=48 kHz 16 Hz to 22 000 Hz

DVD fs=96 kHz 16 Hz to 44 000 Hz

VCD, CD, MP3, WMA 16 Hz to 20 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

MP3 Max. Bit Rate 320 kbps

WMA (Windows Media Audio) Max. Bit Rate 192 kbps

MONITOR SECTION

Screen 3-inch liquid crystal panel

Number of Pixels 123 200 pixels

Drive Method TFT (Thin Film Transistor) active matrix format

Color system NTSC

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0

Dimensions (W

Mass (approx.) 2.0 kg (4.5 lbs) (excluding accessories)

× H × D) Installation Size (approx.) 182 mm × 52 mm × 160 mm (7-3/16" × 2-1/16" × 6-5/16")

Panel Size (approx.) 188 mm

Ω (4 Ω to 8 Ω allowance)

Ω

mote input (OE REMOTE)

87.5 MHz to 108.0 MHz (with channel interval set to 50 kHz)

531 kHz to 1 602 kHz (with channel interval set to 9 kHz)

µV

GENERAL

° C to +40° C (32° F to 104° F)

× 4 Channels at 4 Ω and [< or =] 1% THD+N

Ω)

Ω load

Ω load (full scale)

Ω

µV/75 Ω)

µV/75 Ω)

× 58 mm × 18 mm (7-7/16" × 2-5/16" × 3/4")

1-2 (No.MA165)

Page 3

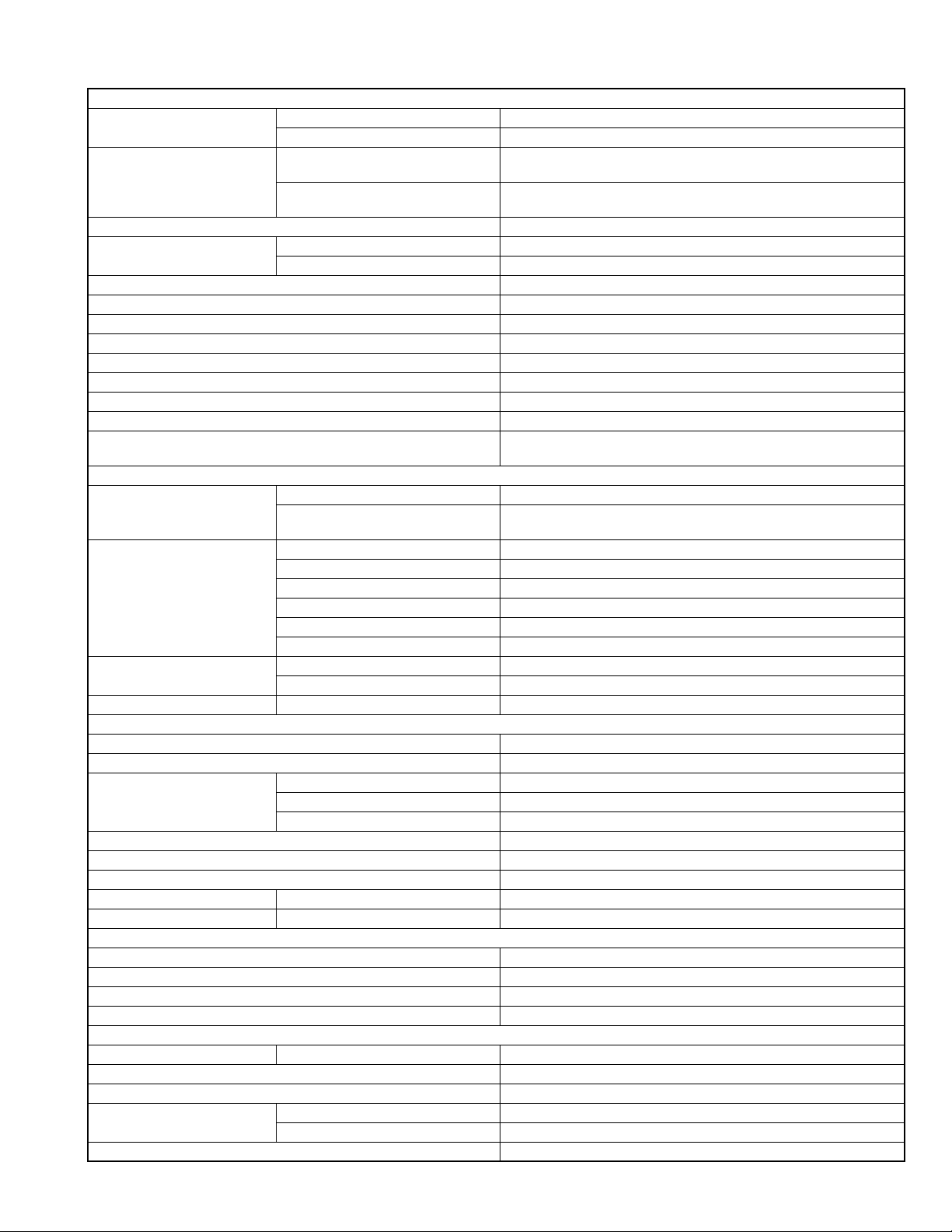

for EUROPE version

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 20 W per channel into 4

harmonic distortion.

Rear 20 W per channel into 4

harmonic distortion.

Load Impedance 4

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.5 kHz, 6.3 kHz, 15 kHz

Level ±10 dB

Signal-to-Noise Ratio 70 dB

Line-In Level/Impedance 1.5 V/20 k

Line-Out Level/Impedance 5.0 V/20 k

Output Impedance 1 k

Subwoofer-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Color System PAL

Video Input (composite) 1 Vp-p/75

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals 2nd AUDIO OUT, DIGITAL OUT (optical), CD changer, Steering wheel re-

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM (MW) 522 kHz to 1 620 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0

50 dB Quieting Sensitivity 16.3 dBf (1.8

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

MW Tuner Sensitivity 20

Selectivity 35 dB

LW Tuner Sensitivity 50

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD fs=48 kHz 16 Hz to 22 000 Hz

DVD fs=96 kHz 16 Hz to 44 000 Hz

VCD, CD 16 Hz to 20 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

MP3 Max. Bit Rate 320 kbps

WMA (Windows Media Audio) Max. Bit Rate 192 kbps

MONITOR SECTION

Screen 3-inch liquid crystal panel

Number of Pixels 123 200 pixels

Drive Method TFT (Thin Film Transistor) active matrix format

Color System PAL

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0

Dimensions (W

Mass (approx.) 2.0 kg (excluding accessories)

× H × D) Installation Size (approx.) 182 mm × 52 mm × 160 mm

Panel Size (approx.) 188 mm

Ω (4 Ω to 8 Ω allowance)

Ω load

Ω load (full scale)

Ω

Ω

mote input (OE REMOTE)

(LW) 144 kHz to 279 kHz

µV/75 Ω)

µV/75 Ω)

µV

µV

°C to +40°C

× 58 mm × 18 mm

Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

(No.MA165)1-3

Page 4

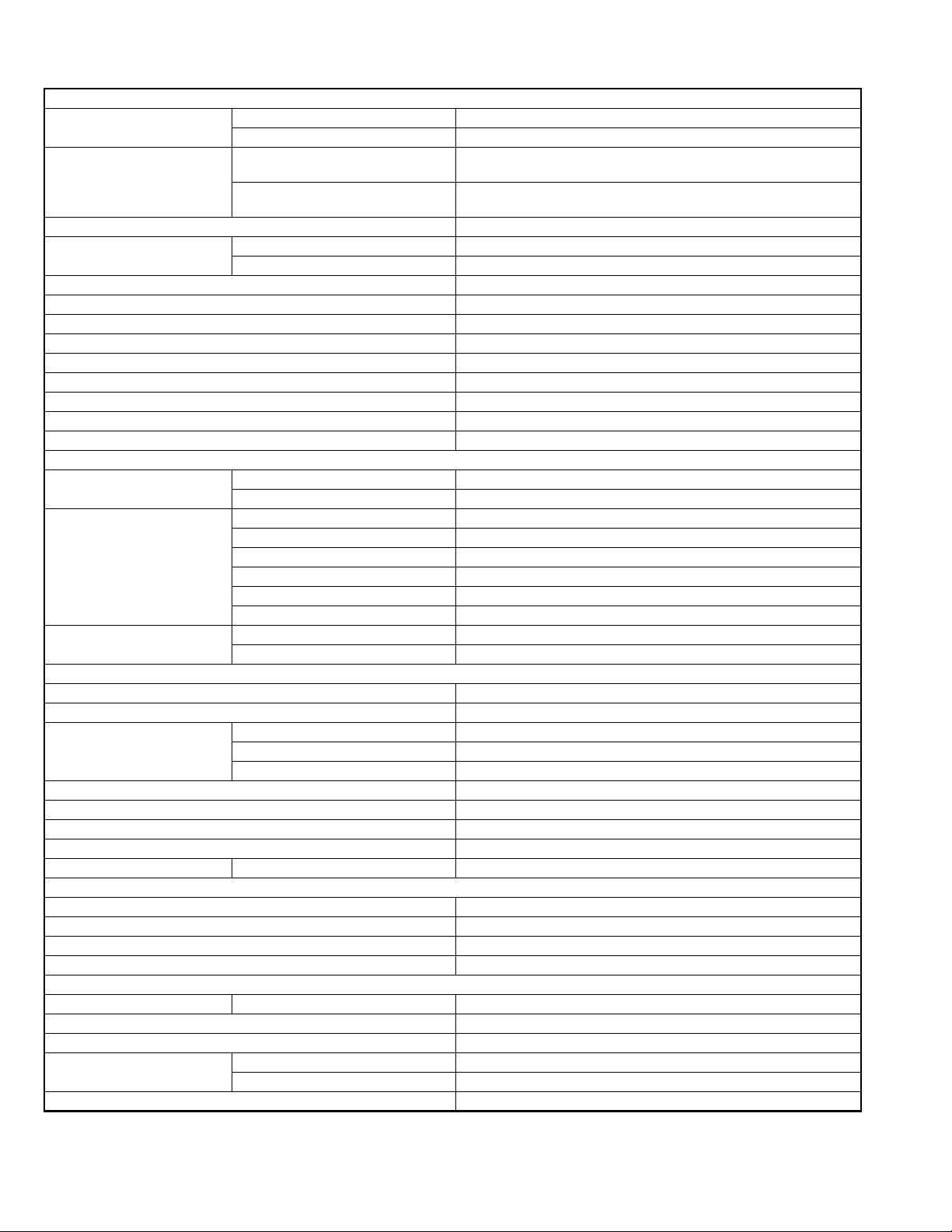

for ASIA & AUSTRALIA version

AUDIO AMPLIFIER SECTION

Maximum Power Output Front 50 W per channel

Rear 50 W per channel

Continuous Power Output (RMS) Front 20 W per channel into 4

harmonic distortion.

Rear 20 W per channel into 4

harmonic distortion.

Load Impedance 4

Equalizer Control Range Frequencies 60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.5 kHz, 6.3 kHz, 15 kHz

Level ±10 dB

Signal-to-Noise Ratio 70 dB

Line-In Level/Impedance 1.5 V/20 k

Line-Out Level/Impedance 5.0 V/20 k

Output Impedance 1 k

Subwoofer-Out Level/Impedance 2.0 V/20 kΩ load (full scale)

Color System NTSC/PAL

Video Input (composite) 1 Vp-p/75

Video Output (composite) 1 Vp-p/75 Ω

Other Terminals 2nd AUDIO OUT, DIGITAL OUT (optical), CD changer

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz

AM 531 kHz to 1 602 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0

50 dB Quieting Sensitivity 16.3 dBf (1.8

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

Capture Ratio 1.5 dB

AM Tuner Sensitivity 20

Selectivity 35 dB

DVD/CD PLAYER SECTION

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response DVD fs=48 kHz 16 Hz to 22 000 Hz

DVD fs=96 kHz 16 Hz to 44 000 Hz

VCD, CD 16 Hz to 20 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

MP3 Max. Bit Rate: 320 kbps

WMA (Windows Media Audio) Max. Bit Rate 192 kbps

MONITOR SECTION

Screen 3-inch liquid crystal panel

Number of Pixels 123 200 pixels

Drive Method TFT (Thin Film Transistor) active matrix format

Color system NTSC/PAL

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0

Dimensions (W

Mass (approx.) 2.0 kg (excluding accessories)

× H × D) Installation Size (approx.) 182 mm × 52 mm × 160 mm

Panel Size (approx.) 188 mm

Ω (4 Ω to 8 Ω allowance)

Ω load

Ω load (full scale)

Ω

Ω

µV/75 Ω)

µV/75 Ω)

µV

°C to +40°C

× 58 mm × 18 mm

Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

Ω, 40 Hz to 20 000 Hz at no more than 0.8% total

Design and specifications are subject to change without notice.

1-4 (No.MA165)

Page 5

1.1 Safety Precautions

SECTION 1

PRECAUTIONS

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MA165)1-5

Page 6

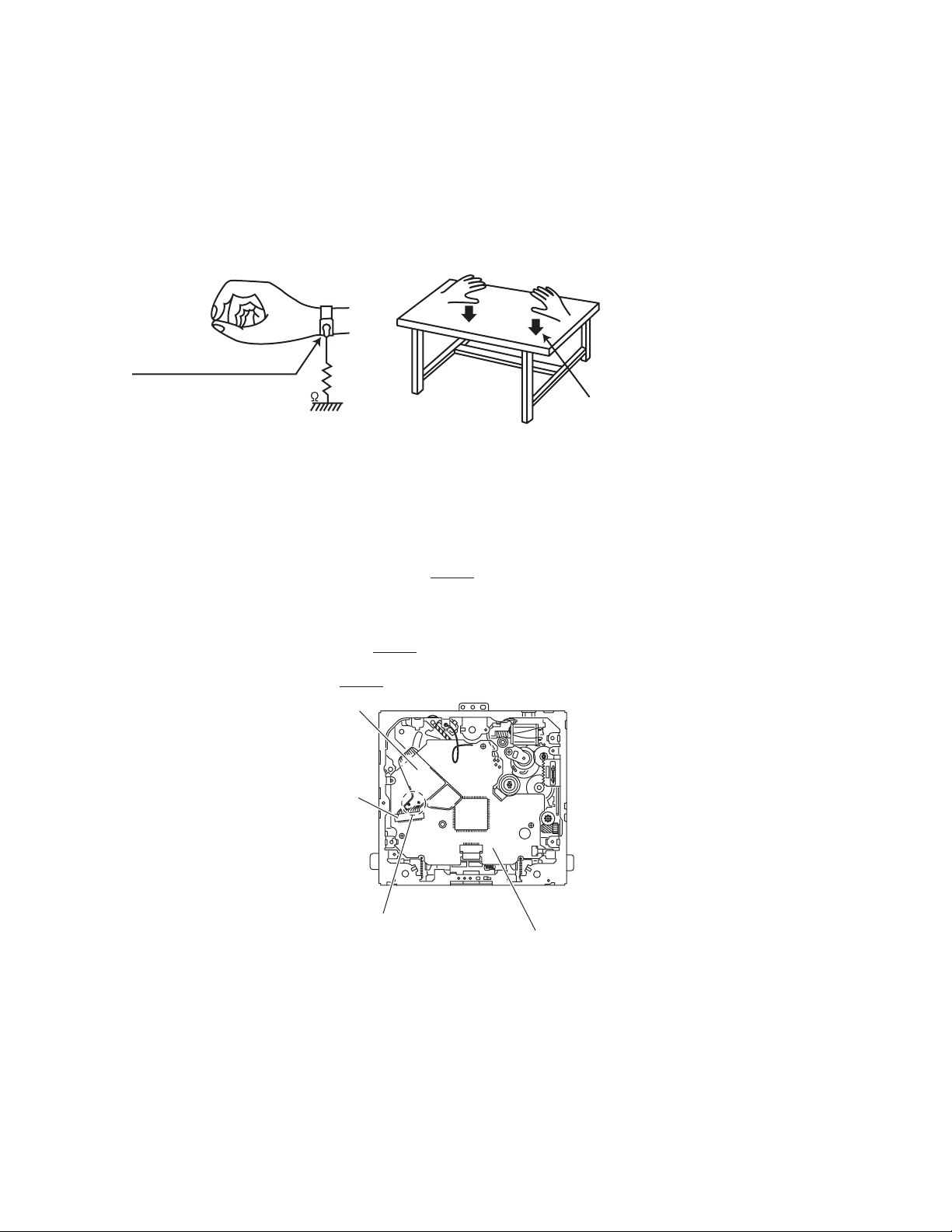

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Before disconnecting the flexible wire from the connector CN101

on the flexible wire.

Caution:

If you do not follow this instruction, the DVD pickup may be damaged.

(2) Disconnect the flexible wire from the connector CN101

(3) Remove the solders from the short-circuit points on the flexible wire after replacing the DVD pickup.

(4) Connect the flexible wire to the connector CN101

Flexible wire

CN101

on the mechanism control board.

on the mechanism control board.

on the mechanism control board, solder the short-circuit points

1-6 (No.MA165)

Short-circuit points

Mechanism control board

Page 7

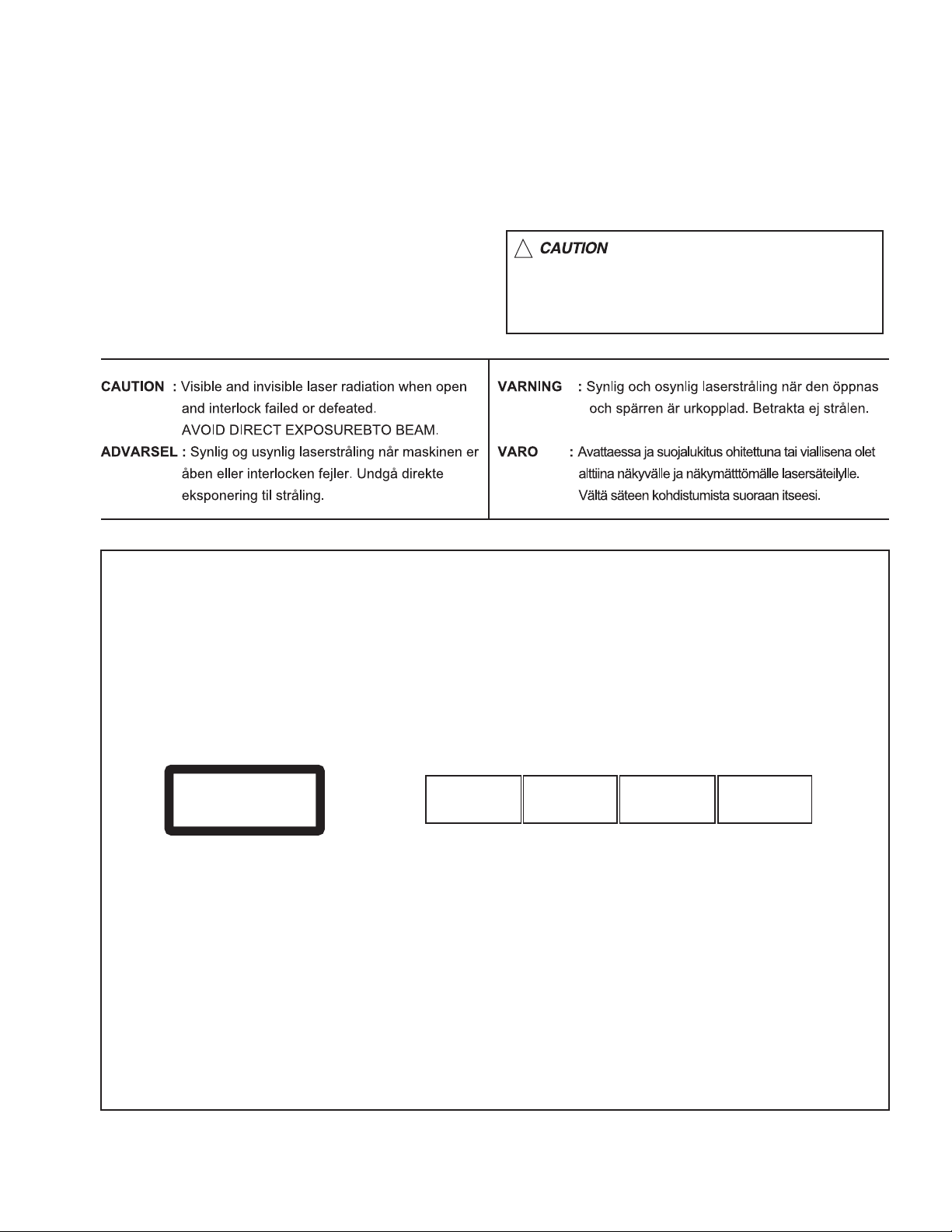

1.4 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CAUTION : Visible and Invisible

CLASS 1

LASER PRODUCT

laser radiation when open and

interlock failed or defeated.

AVOID DIRECT EXPOSURE TO

BEAM. (e)

ADVARSEL : Synlig og usynlig

laserstråling når maskinen er

åben eller interlocken fejeler.

Undgå direkte eksponering til

stråling. (d)

VARNING : Synlig och

osynling laserstrålning när

den öppnas och spärren är

urkopplad. Betrakta ej

strålen. (s)

VARO : Avattaessa ja suojalukitus

ohitettuna tai viallisena olet alttiina

näkyvälle ja näkymättömälle

lasersäteilylle. Vältä säteen

kohdistumista suoraan itseesi. (f)

(No.MA165)1-7

Page 8

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-8 (No.MA165)

Page 9

SECTION 3

DISASSEMBLY

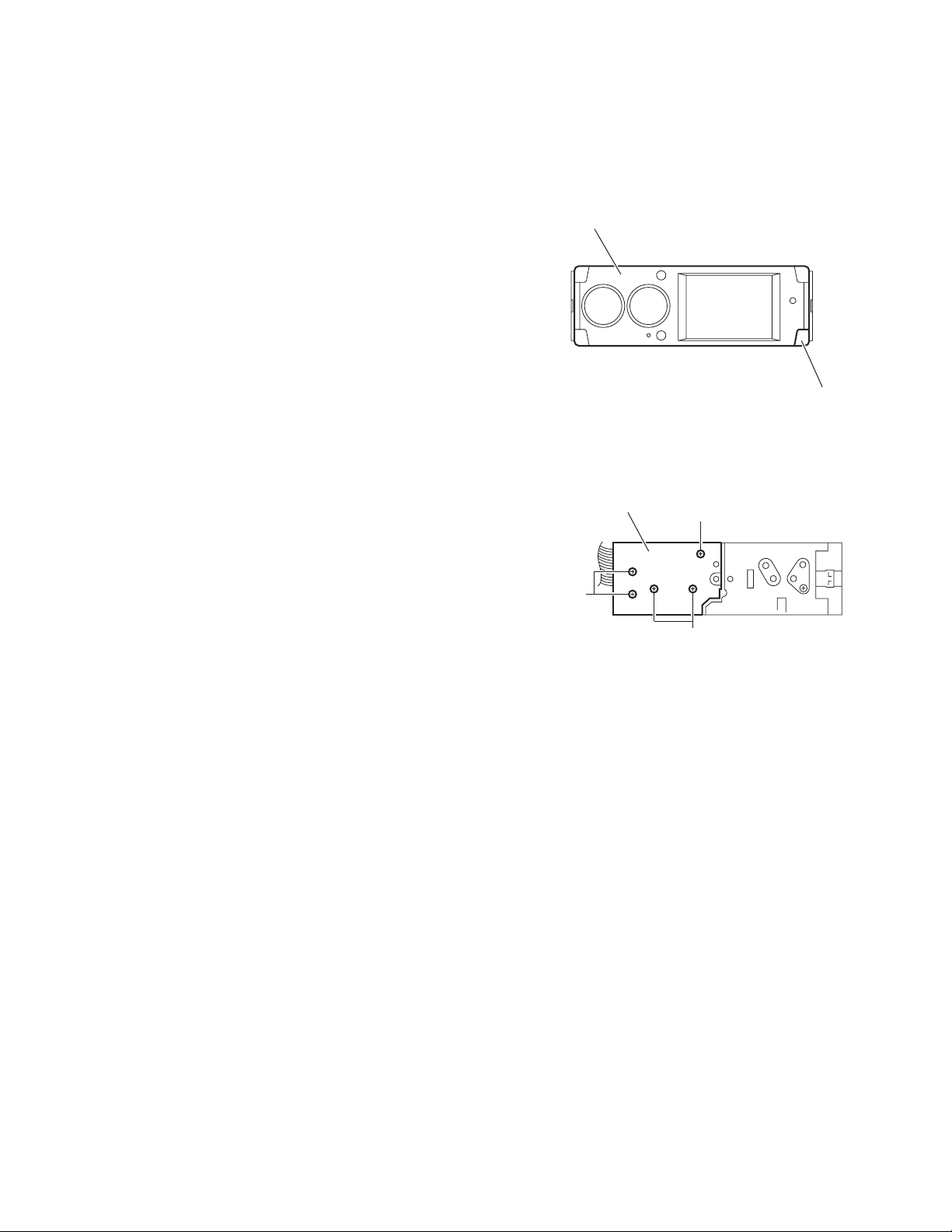

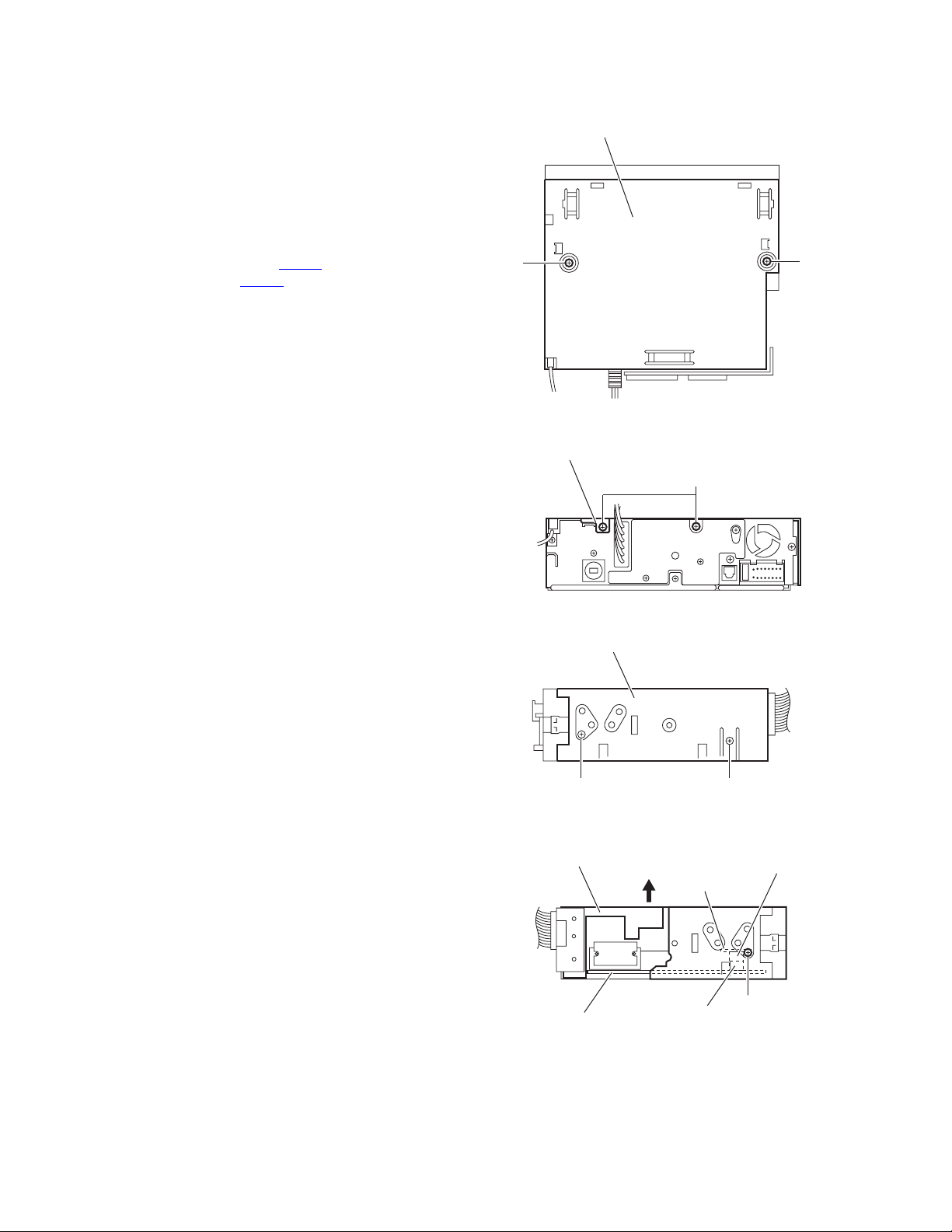

3.1 Main body section

3.1.1 Removing the panel assembly

(See Fig.1)

(1) Push the button(detach) in the lower right part of the panel

assembly.

(2) Remove the panel assembly.

3.1.2 Removing the side heat sink

(See Fig.2)

Reference:

Remove the panel assembly as required.

(1) From the left side of the main body, remove the two screws

A and three screws B attaching the side heat sink.

(2) Remove the side heat sink from the main body.

Panel assembly

Side heat sink

Button(detach)

Fig.1

B

B

A

Fig.2

(No.MA165)1-9

Page 10

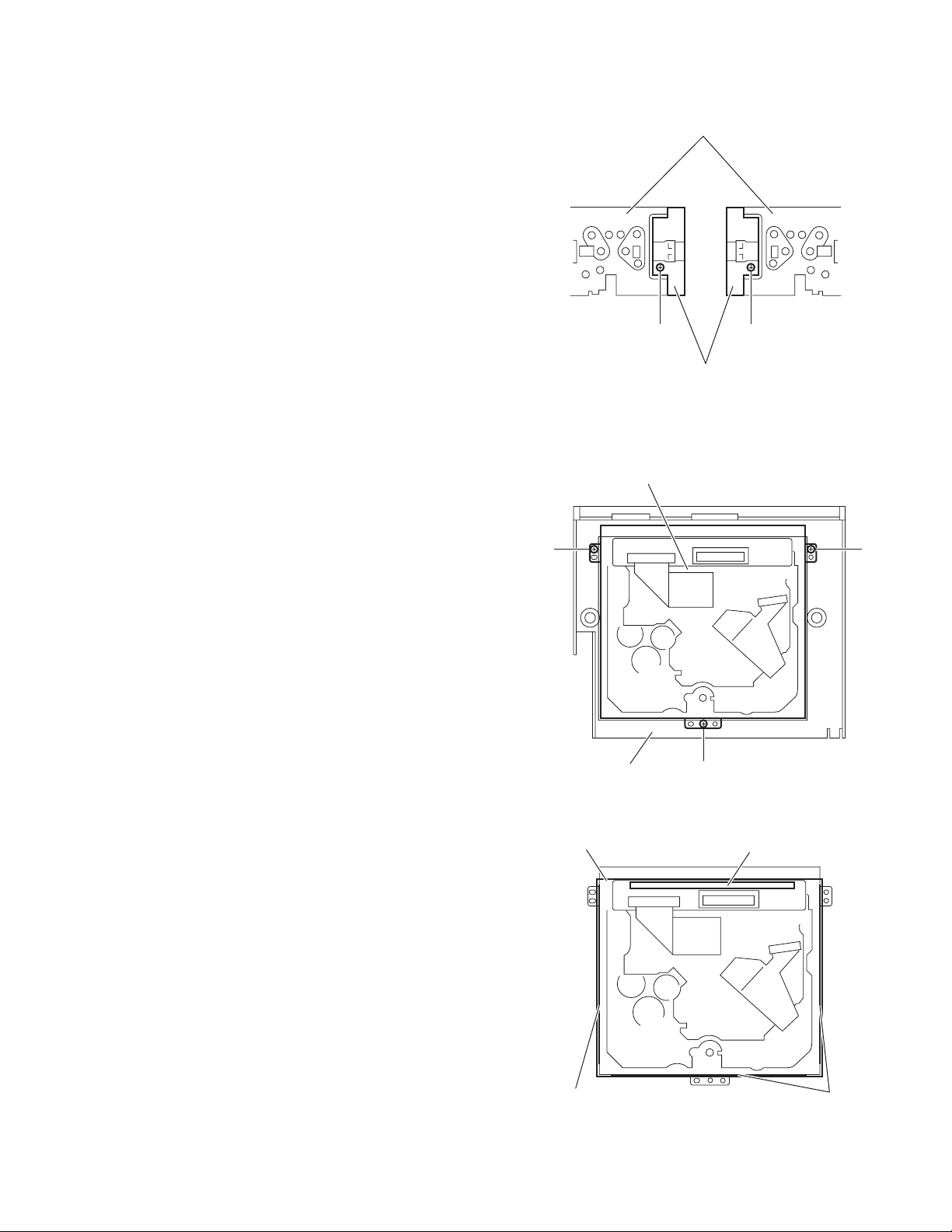

3.1.3 Removing the top chassis assembly

(See Figs.3 to 6)

• Remove the panel assembly and side heat sink.

(1) From the top side of the main body, remove the two screws

C attaching the top chassis assembly. (See Fig.3.)

(2) From the back side of the main body, remove the two

screws C attaching the top chassis assembly. (See Fig.4.)

(3) From the both sides of the main body, remove the two

screws C and screw D attaching the top chassis assembly.

(See Figs.5 and 6.)

(4) Lift the top chassis assembly in the direction of the arrow

and disconnect the connector CN966

board from the connector CN961

Fig.6.)

(5) Take out the top chassis assembly from the main body.

on the main sub

on the main board. (See

Top chassis assembly

C

Top chassis assembly

C

Fig.3

C

Fig.4

Top chassis assembly

C D

Fig.5

Top chassis assembly

Main board

Fig.6

Main sub board

CN961

C

CN966

1-10 (No.MA165)

Page 11

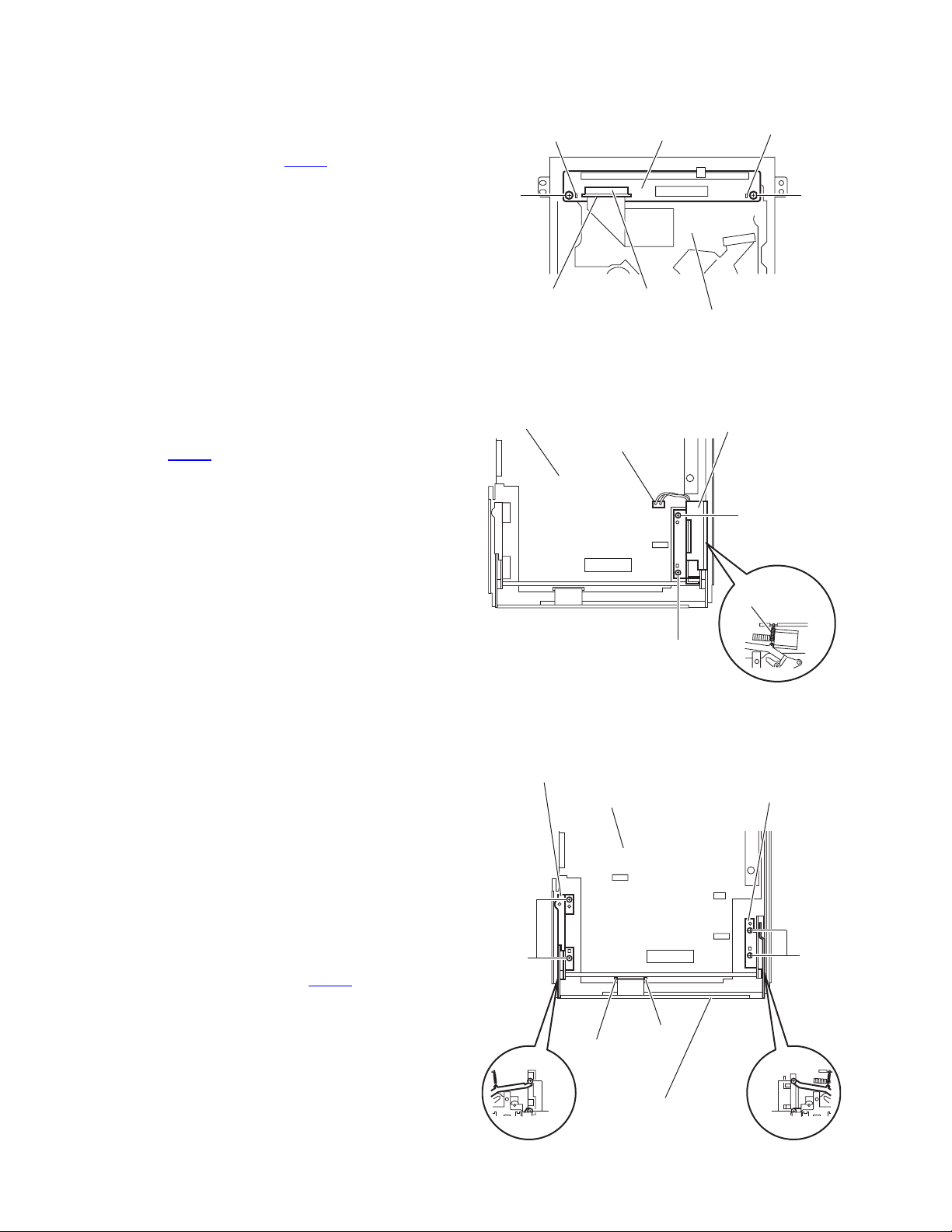

3.1.4 Removing the front chassis assembly

(See Fig.7)

• Remove the panel assembly, side heat sink and top chassis

assembly.

(1) From the both sides of the top chassis assembly, remove

the two screws E attaching the front chassis assembly.

(2) Remove the front chassis assembly from the top chassis

assembly.

3.1.5 Removing the DVD mechanism assembly

(See Figs.8 and 9)

• Remove the panel assembly, side heat sink and top chassis

assembly.

Reference:

Remove the front chassis assembly as required.

(1) From the inside of the top chassis assembly, remove the

three screws F attaching the DVD mechanism assembly

and take out the DVD mechanism assembly. (See Fig.8.)

(2) From the side of the DVD mechanism assembly, remove

the double-stick tape fixing the insulator. (See Fig.9.)

(3) From the top side of the DVD mechanism assembly, re-

move the spacer attaching the insulator. (See Fig.9.)

(4) Remove the insulator from the top chassis assembly.

Reference:

When the resolution of DVD mechanism assembly is done sequentially, remove the main sub board. (See next Fig.10.)

Top chassis assembly

E E

Front chassis assembly

DVD mechanism assembly

F

Fig.7

F

Top chassis assembly

Insulator

Double-stick tape

F

Fig.8

Spacer

Double-stick tape

Fig.9

(No.MA165)1-11

Page 12

3.1.6 Removing the main sub board

(See Fig.10)

• Remove the panel assembly, side heat sink, top chassis as-

sembly and DVD mechanism assembly.

(1) From the top side of the DVD mechanism assembly, re-

lease the lock of the connector CN965

board and disconnect the card wire.

(2) Remove the two screws G attaching the main sub board on

the DVD mechanism assembly and remove the main sub

board.

Reference:

When attaching the main sub board, align the projections a in

the holes of the main sub board before attaching the screws G.

3.1.7 Removing the loading unit assembly

(See Fig.11)

• Remove the panel assembly, side heat sink and top chassis

assembly.

(1) From the inside of the main body, disconnect the wire from

the connector CN881

(2) Remove the two screws H attaching the loading unit as-

sembly.

(3) Remove the tension spring and take out the loading unit

assembly.

Note:

When disassembling, do not lose the tension spring.

on the main board.

on the main sub

a

G

Lock

Main board

Main sub board

CN965

DVD mechanism assembly

Fig.10

Motor bracket assembly

CN881

a

G

H

3.1.8 Removing the arm bracket assemblies (L)/(R)

(See Fig.12)

• Remove the panel assembly, side heat sink, top chassis as-

sembly and loading unit assembly.

(1) Remove the two screws J and screw K attaching the arm

bracket assembly (L).

(2) Take out the arm bracket assembly (L).

(3) Remove the two screws J and screw K attaching the arm

bracket assembly (R).

(4) Take out the arm bracket assembly (R).

3.1.9 Removing the front bracket assembly

(See Fig.12.)

• Remove the panel assembly, side heat sink and top chassis

assembly.

(1) Release the lock of the connector CN962

board in an upward direction and disconnect the flexible

wire.

(2) Remove the four screws K attaching the front bracket as-

sembly and take out the front bracket assembly.

on the main

Fig.11

Arm bracket assembly (L)

Main board

J

CN962

Tension spring

H

Arm bracket assembly (R)

J

Lock

1-12 (No.MA165)

Front bracket assembly

K

K

Fig.12

Page 13

3.1.10 Removing the connector board

(See Figs.13 to 15)

• Remove the panel assembly, side heat sink, top chassis as-

sembly and front bracket assembly.

(1) From the front side of the front bracket assembly, remove

the two screws M. (See Fig.13.)

(2) Remove the joints b and remove the detach lever from the

front bracket assembly. (See Fig.13.)

Reference:

When attaching the detach lever, insert the end of the

torsion spring in the hole c of the front bracket assembly.

(See Fig.13.)

(3) From the back side of the front bracket assembly, remove

the screw N attaching the connector cover. (See Fig.14.)

(4) Remove the connector cover in the direction of the arrow

while releasing the tabs d in an upward direction. (See

Fig.14.)

(5) Remove the reinforce plate and take out the connector

board from the front bracket assembly. (See Fig.15.)

Front bracket assembly

Fig.13

Connector cover

d

N

Fig.14

Connector board

M

Detach lever

Torsion spring

b

c

b

d

Reinforce plate

Front bracket assembly

Fig.15

(No.MA165)1-13

Page 14

3.1.11 Removing the main board

(See Figs.16 and 17)

• Remove the panel assembly, side heat sink, top chassis as-

sembly, loading unit assembly and arm bracket assemblies

(L)/(R).

(1) From the back side of the main body, remove the screw P

attaching the rear bracket. (See Fig.16.)

(2) From the top side of the main body, take out the rod gear.

(See Fig.17.)

Reference:

When attaching the rod gear, attach the washers with it

as before. (See Fig.17.)

(3) Release the lock of the connector CN962

board in an upward direction and disconnect the flexible

wire. (See Fig.17.)

(4) Release the lock of the connector CN891

the card wire. (See Fig.17.)

(5) Remove the three screws P attaching the main board to the

bottom chassis assembly. (See Fig.17.)

(6) Take out the main board from the bottom chassis assem-

bly.

Reference:

When attaching the main board, attach the main board under

the sections e of the bottom chassis assembly as before. (See

Fig.17.)

on the main

and disconnect

Rear bracket

Bottom chassis assembly

Rod gear

Washer

P

P

Fig.16

e

CN962

Lock

e

Washer

Lock

P

Main board

CN891

Fig.17

1-14 (No.MA165)

Page 15

3.1.12 Removing the rear bracket

(See Fig.18)

• Remove the panel assembly, side heat sink, top chassis as-

sembly, loading unit assembly, arm bracket assemblies (L)/(R)

and main board.

(1) From the back side of the main board, remove the two

screws Q attaching the rear heat sink.

(2) Remove the three screws R, screw R' and screw S attach-

ing the rear bracket.

Reference:

When attaching the screw R', attach the wire holder with

it as before.

(3) Remove the joints f of the rear bracket in the direction of

the arrow.

(4) Remove the car cable in the direction of the arrow from the

rear bracket.

3.1.13 Removing the panel switch board

(See Fig.19)

• Remove the panel assembly, side heat sink, top chassis as-

sembly, loading unit assembly, arm bracket assemblies (L)/(R)

and main board.

(1) From the inside of the bottom chassis assembly, take out

the insulator.

(2) Remove the two screws T attaching the panel switch

board.

(3) Take out the panel switch board from the bottom chassis

assembly.

Wire holder

R'

Rear bracket

Insulator

Car cable

R

Rear heat sink

Q

Fig.18

Panel switch board

R

f

S

Bottom chassis assembly

Fig.19

T

(No.MA165)1-15

Page 16

3.1.14 Removing the panel board

(See Figs.20 and 21)

• Remove the panel assembly.

(1) From the back side of the panel assembly, remove the sev-

en screws U attaching the rear cover to the panel assembly. (See Fig.20.)

(2) From the inside of the rear cover, release the lock of the

connector CN582

card wire. (See Fig.21.)

(3) Remove the five screws V attaching the panel board and

take out the panel board from the rear cover. (See Fig.21.)

3.1.15 Removing the switch board

(See Figs.20 and 22)

• Remove the panel assembly.

(1) From the back side of the panel assembly, remove the sev-

en screws U attaching the rear cover to the panel assembly. (See Fig.20.)

(2) From the inside of the panel assembly, release the lock of

the connector CN583

the card wire. (See Fig.22.)

(3) Take out the switch board from the panel assembly.Take

out the switch board from the panel assembly.

Note:

Do not lose the compression spring when taking out the switch

board. (See Fig.22.)

on the panel board and disconnect the

on the switch board and disconnect

U

U

Panel board

V

Rear cover

Fig.20

Rear cover

CN582

U

Front panel assembly

Lock

V

V

Fig.21

Lock

Compression spring

CN583

Fig.22

Panel assembly

Switch board

1-16 (No.MA165)

Page 17

3.2 DVD mechanism assembly

3.2.1 Removing the mechanism control board

(See Fig.1)

Caution:

Before disconnecting the flexible wire extending from the DVD

pickup, solder the short-circuit point on the flexible wire using

a grounding soldering iron. If you do not follow this instruction,

the DVD pickup may be damaged.

(1) Turn over the body, and solder the short-circuit points on

the flexible wire extending from the DVD pickup.

(2) Disconnect the flexible wire from connector CN101

mechanism control board.

(3) Disconnect the card wire from connector CN201

mechanism control board.

(4) Disconnect the flexible wire from connector CN202

mechanism control board.

(5) Unsolder two soldered points a on the mechanism control

board and remove the wire extending from the feed motor.

(6) Remove the screw A attaching the lug wire.

(7) Remove the two screws B and screw C attaching the

mechanism control board.

Caution:

• As the flexible wire to be connected to CN101

attach it to the mechanism control board using a double

tape.

• After reassembling, unsolder the short-circuit points.

on the

on the

on the

, make sure to

Flexible wire

Double tape

CN101

B

Short-circuit points

A

Lug wire

B

CN201

Feed motor

a

C

CN202

Mechanism control board

Fig.1

(No.MA165)1-17

Page 18

3.2.2 Removing the top cover

(See Fig.2)

(1) Remove the two screws D attaching the top cover on the

back of the body.

(2) Remove the top cover upward.

Reference:

When reassembling, set part b of the top cover under the

bending part c of the chassis frame.

3.2.3 Removing the mechanism section

(See Fig.2 to 4)

• Remove the top cover.

(1) From the bottom of the body, remove the screw E attaching

the lug wire. (See Fig.2.)

(2) Remove the two screws F attaching the right and left stop-

pers on the front side. (See Fig.2.)

(3) Remove the two floating springs on the bottom of the body.

(See Fig.3.)

(4) Move the mechanism section upward and remove from the

chassis frame.

The three damper springs come off from the dampers.

(See Fig.4.)

Caution:

• When reassembling, reattach the damper spring to the

damper respectively and insert the three shafts on the bottom of the mechanism to the dampers.

• Before inserting the shaft to the dampers, apply IPA to the

hole of damper.

Floating spring

Fig.3

Mechanism section

Stopper

F

Top cover

Stopper

F

D

D

b

c

E

Lug wire

Damper SP.(F)

(Silver)

Damper (F)

(Black)

Damper SP.(F)

(Silver)

Damper (F)

(Black)

Fig.4

Damper SP.(R)

(Red)

Damper (R)

(Purple)

Chassis frame

1-18 (No.MA165)

Fig.2

Page 19

3.2.4 Removing the clamper unit

(See Fig.5 to 7)

• Remove the top cover and the mechanism section.

(1) Remove the clamper2 spring on the bottom of the mecha-

nism section. (See Figs.5.and 6.)

(2) Release the part d of the clamper spring from the bending

part of the chassis base assembly. (See Fig.7.)

(3) Move the clamper unit in the direction of the arrow and turn.

Release the two joints e and f, then remove the clamper

unit upward. (See Fig.6.)

3.2.5 Reattaching the clamper unit

(See Fig.5 to 9)

(1) Attach the clamper spring to the clamper unit. (See Fig.8.)

(2) Move the clamper unit to set the side joints e and f to each

boss of the chassis base assembly. Make sure that part g

is inserted to the notch of the chassis base assembly. (See

Figs.5 and 9.)

(3) Move the part d of the clamper spring to the outside of the

bending part of the chassis base assembly. (See Fig.7.)

(4) Attach the clamper2 spring to the chassis base assembly.

(See Figs.5 and 6.)

Caution:

When reattaching, temporarily hook the end of the clamper

spring as shown in the figure to make the work easy. (See

Fig.8.)

Clamper unit

Clamper2 spring

Chassis base assembly

Fig.6

Clamper spring

Clamper spring

f

Clamper2 spring

Chassis base assembly

g

d

Chassis base assembly

Fig.7

e

Fig.5

(No.MA165)1-19

Page 20

Clamper unit

Clamper unit

Clamper spring

Fig.8

1-20 (No.MA165)

Fig.9

g

Notch

Page 21

3.2.6 Removing the front unit

(See Fig.10 to 12)

• Remove the top cover and the mechanism section.

(1) Disconnect the flexible wire from connector CN202

mechanism control board at the bottom of the body. (See

Fig.10.)

(2) Remove the screw G attaching the front unit on the top of

the body. (See Fig.11.)

(3) Move the front unit toward the front to release joint h, and

release two joints i and j on the right side of the chassis

base assembly. Then remove the front unit upward. (See

Figs.11 and 12.)

(4) Remove the two screws H attaching the switch board. (See

Fig.12.)

Reference:

You can remove the switch board only without removing the

front unit.

Caution:

When reassembling, attach the flexible wire extending from

the switch board using the double tape. (See Figs.10 and 12.)

Mechanism control board

on the

G

Front unit

h

Fig.11

CN202

Double tape

Fig.10

Flexible wire

Double tape

j

i

H

Switch board

Front unit

G

Fig.12

h

(No.MA165)1-21

Page 22

3.2.7 Removing the loading arm assembly

(See Fig.13 , 14)

• Remove the top cover, the mechanism section and the front

unit.

(1) From the top of the body, move the loading arm assembly

from the front side upward, and release the bosses from

the right and left joints k and m of the chassis base assembly.

(2) Release the boss from notch n of the connect arm on the

right side of the body, and release the boss from notch p of

the slide cam assembly on the left side.

m

Loading arm assembly

Side cam

assembly

p

m

k

Fig.13

Loading arm assembly

k

n

n

Connect arm

1-22 (No.MA165)

Fig.14

Page 23

3.2.8 Removing the rod (L)(R)/roller assembly

(See Fig.15 and 16)

• Remove the top cover, the mechanism section, the front unit

and the loading arm assembly.

(1) Release the rod (L) and (R) from the joints q at the bottom

of the loading arm assembly (See Fig.15.)

(2) Remove the roller assembly from the loading arm assem-

bly. (See Fig.16.)

(3) Remove the two collars and washer from the roller assem-

bly. (See Fig.16.)

Caution:

After attaching the loading arm assembly to the roller assembly, attach the rod (L) and (R). Attach the rods to the right and

left collars of the roller. (See Fig.15.)

When reattaching the rod (L) and (R) to the loading arm assembly, engage each joint as shown in Fig.15. As joints q of

the rod (L), let the rod through q before reattaching it.

Collar

Collar

Rod(R) Rod(L)

q

q

q

Collar

Rod(L)

Rod(R)

q

Loading arm assembly

Fig.15

Roller assembly

Loading arm assembly

q

Rod(L)

q

Collar

Washer

Rod(R)

Fig.16

(No.MA165)1-23

Page 24

3.2.9 Removing the DVD pickup assembly

(See Fig.17 to 19)

• Remove the mechanism control board.

(1) From the bottom of the body, turn the feed gear in the di-

rection of the arrow to move the DVD pickup outwards.

(See Fig.17.)

(2) Remove the screw J attaching the thrust spring. (See

Fig.17.)

(3) Remove the DVD pickup assembly upward on the L.S.gear

side and release from sub shaft at joint r. Move the lead

screw of the DVD pickup assembly in the direction of the

arrow to release from joint s. (See Fig.18.)

Caution:

• When releasing the lead screw at joint s, the L.S.collar

comes off at the end of the lead screw. When reassembling, reattach the L.S.collar to the lead screw and

engage joint s. (See Fig.18.)

• When reattaching the L.S.collar, reattach it to the point

s of the lead screw, and to the rod (M). Make sure that

the L.S.collar is set on the rod (M) spring. (See Fig.18.)

(4) Remove the screw K attaching the rack spring/ rack plate

on the DVD pickup. (See Fig.19.)

(5) Pull out the lead screw. (See Fig.19.)

Caution:

Perform adjustment after replacing the pickup.

DVD Pickup assembly

DVD Pickup assembly

Feed gear

J

Thrust spring

Fig.17

s

L.S.collar

Rod(M)

Lead screw

Sub shaft

L.S.collar

r

L.S.gear

Fig.18

K

Rack spring

Lead screw

Rack plate

DVD Pickup

Fig.19

1-24 (No.MA165)

Page 25

3.2.10 Removing the spindle motor

r

(See Fig.20)

• Remove the mechanism control board.

Remove the two screws L attaching the spindle motor on the

bottom of the body.

Caution:

Perform adjustment when reattaching the spindle motor.

3.2.11 Removing the feed motor assembly

(See Fig.21 and 22)

• Remove the mechanism control board.

(1) Remove the feed TRI. spring on the bottom of the body.

(See Fig.21.)

(2) Remove the two screws M attaching the feed motor as-

sembly. (See Fig.21.)

(3) Remove the slit washer from the motor H. assembly and

pull out the worm wheel. (See Fig.22.)

Remove the two screws N attaching the feed motor. (See

Fig.22.)

Spindle motor

Feed TRI. spring

L

Fig.20

M

Feed motor assembly

Fig.21

Slit washer

Worm wheel

Feed moto

N

Motor H. assembly

Fig.22

(No.MA165)1-25

Page 26

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Jitter meter

(3) Digital tester

(4) Electric voltmeter

(5) Tracking offset meter

(6) Test Disc : VT501 or VT502

(7) Extension studs : STDV001-3P

(8) Extension cable : EXTDV002-30P

4.3 Connection method

Connection procedure

(1) Attach the front chassis assembly to the main board.

(2) Attach the heat sink and rear bracket to the main board.

(3) Attach the extension studs to the DVD mechanism assembly.

(4) Connect the DVD mechanism assembly and the main board with a extension cable.

4.2 Standard measuring conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 4Ω(2 Speakers connection)

Line Output 20KΩ

Caution:

Be sure to attach the heat sink and rear bracket onto the power

amplifier IC and regulator IC respectively, before supply the

power. If voltage is applied without attaching these parts, the

power amplifier IC and regulator IC will be destroyed by heat.

Extension cable

EXTDV002-30P

Heat sink

Extension studs

STDV001-3P

Rear bracket

Extension stud

STDV001-3P

1-26 (No.MA165)

Page 27

4.4 Adjustment method for jitter

After replacing the pickup, set the unit in the service mode to display a jitter value on the LCD.

Confirm that the jitter value measured with a jitter meter is within 12% of the jitter value displayed on the LCD. If it is within 12%, then

adjustment is not necessary.

If the measured jitter value is outside the 12% tolerance range, perform the following adjustments.

4.4.1 Adjustment procedure

(1) Connect each unit shown in Fig.1.

(2) Set the unit to the service mode and display a jitter value (hex data) on the LCD.

(3) Turn each of the screws a, b and c, by a half-turn per step, in the direction that reduces the jitter value in order to minimize it .

(Do not turn a screw more than a half turn at a time, but adjust the screws in the cycle of a → b → c → a.)

(4) After completing the adjustment, secure the screws with screw lock paint.

c

b

a

Jitter value adjustment procedure (Pickup horizontal level adjustment relative to the DVD recording surface)

(For the adjustment tool use a 3 mm wrench and not a screwdriver, this procedure will make the adjustment easier.)

3 mm wrench

(No.MA165)1-27

Page 28

4.5 Jitter value conversion table

Load the test DVD and set the unit to the service mode. A jitter value converted to the hex value is displayed on the LCD. Refer to the

corresponding decimal notation value shown in the following Jitter Conversion Table.

The adjustment is OK if the jitter value measured with a jitter meter is within 12% of the jitter value displayed on the LCD.

If the measured jitter value is outside the 12% tolerance range, adjust it to minimize the difference between the measured value and

the displayed value.

Indicated

on the LCD

EF56

EF22

EEEE

EEBA

EE86

EE52

EE1E

EDEA

EDB6

ED82

ED4E

ED1A

ECE6

ECB2

EC7E

EC4A

EC16

EBE2

EBAE

EB7A

EB46

EB12

EADE

EAAA

EA76

EA42

EA0E

E9DA

E9A6

E972

E93E

E90A

E8D6

E8A2

E86E

E83A

E806

E7D2

Jitter value

(%)

4.7

4.8

4.9

5.0

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

6.0

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

7.0

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

8.0

8.1

8.2

8.3

8.4

Indicated

on the LCD

E79E

E76A

E736

E702

E6CE

E69A

E666

E632

E5FE

E5CA

E596

E562

E52E

E4FA

E4C6

E492

E45E

E42A

E3F6

E3C2

E38E

E35A

E326

E2F2

E2BE

E28A

E256

E222

E1EE

E1BA

E186

E152

E11E

E0EA

E0B6

E082

E04E

E01A

Jitter value

(%)

8.5

8.6

8.7

8.8

8.9

9.0

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

10.0

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

11.0

11.1

11.2

11.3

11.4

11.5

11.6

11.7

11.8

11.9

12.0

12.1

12.2

Indicated

on the LCD

DFE6

DFB2

DF7E

DF4A

DF16

DEE2

DEAE

DE7A

DE46

DE12

DDDE

DDAA

DD76

DD42

DD0E

DCDA

DCA6

DC72

DC3E

DC0A

DBD6

DBA2

DB6E

DB3A

DB06

DAD2

DA9E

DA6A

DA36

DA02

D9CE

D99A

D966

D932

D8FE

D8CA

D896

D862

Jitter value

(%)

12.3

12.4

12.5

12.6

12.7

12.8

12.9

13.0

13.1

13.2

13.3

13.4

13.5

13.6

13.7

13.8

13.9

14.0

14.1

14.2

14.3

14.4

14.5

14.6

14.7

14.8

14.9

15.0

15.1

15.2

15.3

15.4

15.5

15.6

15.7

15.8

15.9

16.0

Calculation

1-28 (No.MA165)

Indicated on the LCD Jitter (%)

E9A6 7.5

Page 29

4.6 Service mode

4.6.1 Standard input/output conditions

Power supply voltage DC14.4V(11 to 16V)

Load impedance 4Ω(2 Speakers connection)

Line Output 20KΩ

4.6.2 Service mode setting procedure

(The DVD does not need to be loaded before starting the following procedure.)

[STANDBY/ON ATTENUATOR] button

[MENU] button

[UP] button

[VOLUME+/VOLUME-] button

[OK] button

[EJECT] button

4.6.3 Operation procedures

1. Service mode 1 (Indication is displayed in SERVICE MODE.)

Keep this state more than 2 seconds

while continuing pressing the

[STANDBY/ON ATTENUATOR] button

and [EJECT] button sequentially.

Screen indication

SERVICE MODE

NO EJECT

EMERGENCY EJECT12

[BACK] button

[DOWN] button

Exchanging it operate a menu of a service mode with the [UP] button

and [DOWN] button. Operate choice of a menu with a [OK] button.

1 : When an [OK] button is pushed in NO EJECT indication, it is set

by an EJECT prohibition mode.

When an [OK] button is pushed in EJECT OK indication, it is set

by a normal mode.

2 : Forced EJECT movement

A screen becomes normal indication after an OK button was pushed.

[F.SKIP] button[B.SKIP] button

[DISPLAY] button

(No.MA165)1-29

Page 30

2. Service mode 2

Keep this state more than 2 seconds

while continuing pressing the

[DISP] button, [VOLUME-] button

and [EJECT] button sequentially.

Screen indication

SERVICE MODE2

INITIALIZE DVD

3. Service mode 3

Keep this state more than 2 seconds

while continuing pressing the

[DISP] button, [VOLUME+] button

and [EJECT] button sequentially.

SERVICE MODE 2

OK

Press the [OK] button.

Full initialization of EEPROM of a DVD unit

(It is included a permanent domain)

After clear completion, this indication is continued

till an effective key is input. (OK )

Screen indication

SERVICE MODE3

INITIALIZE ALL

INITIALIZE

SERVICE MODE

RUNNING MODE

Exchanging it operate a menu of a service mode with the [UP] button

and [DOWN] button. Operate choice of a menu with a [OK] button.

INITIALIZE ALL (Each EEPROM is initialized by a factory shipment state.)

Main micon EEPROM initialization (except a ROM correction domain)

Panel micon EEPROM initialization

(except factory adjustment data domain and ROM correction domain)

DVD unit EEPROM initialization (except a permanent domain)

After clear completion, a screen returns to normal indication after OK indication was

displayed for three seconds.

INITIALIZE (Initialization of a user area of each EEPROM)

Main micon EEPROM initialization (a user entry domain and picture adjustment data)

DVD unit EEPROM initialization (except a permanent domain)

After clear completion, a screen returns to service mode indication after OK indication

was displayed for three seconds.

1-30 (No.MA165)

A

Page 31

A

Screen indication

SERVICE MODE

VERSION

AREA/REGION

TEMPERATURE

MEMORY CHECK

DVD NTSC/PAL

DVD CHECK MODE

Exchanging it operate a menu

of a service mode with the [UP]

button and [DOWN] button.

Operate choice of a menu with

a [OK] button.

Return to previous menu with

a [BACK] button.

SERVICE MODE

ERROR READ

ERROR CLEAR

VERSION

MAIN

JD4

CH

PANEL

Micon version indication

Main micon version and ROM correction version

JD4 version

CH version

Panel micon version and ROM correction version

AREA/REGION

SYS-AREA

JD4-AREA

JD4-REGION

:

:

:

Area and region indication

Main micon area

JD4 area

JD4 region

TEMPERATURI Temperature data reading

Temparature data by the temperature sensor in the

main micon is read every 5 seconds and displayed

in hex numbers.

MEMORY CHECK

Memory residual quantity indication mode

Data residual quantity of a disc is displayed by LCD.

About the plaback control-related key ([FSKIP],

[BSKIP], [UP], [DOWN], [VOL]), only movement is

effective.

Indication does not change as memory residual

quantity indication.

About cancellation of this mode, press the

[STANDBY/ON ATTENUATOR] button.

DVD NTSC/PAL

NTSC

PAL

DVD picture change

JD4 output picture setting

(NTSC)

JD4 output picture setting

(PAL)

DVD CHECK MODE

See "DVD CHECK MODE" for details.

B

C

(No.MA165)1-31

Page 32

B

C

ERROR READ

DVD ERROR READ

CD ERROR READ

MECHA ERROR READ

DVD ERROR READ

E-1

:

E-2

:

E-3

:

E05

:

TOTAL

:

E04

E03

E02

E01

:

:

:

:

Reading of a DVD unit error history

Reading of a history of an error stored in

a DVD unit

Indication of latest three error codes and

first five error code

Indication of total error count

Error code

Detailed error code

CH ERROR READ

E-1

:

E-2

:

E-3

:

E05

:

TOTAL

:

E04

E03

E02

E01

:

:

:

:

ERROR CLEAR

DVD ERROR CLEAR

CD ERROR CLEAR

MECHA ERROR CLEAR

Reading of a CH changer error history

Reading of a history of an error stored in

a DVD unit

Indication of latest three error codes and

first five error code

Indication of total error count

Error code

Detailed error code

MECHA ERROR READ

E-1

:

E-2

:

E-3

:

E05

:

TOTAL

:

E04

E03

E02

E01

:

:

:

:

Reading of a door mechanism error history

Reading of a history of an error stored in

a DVD unit

Indication of latest three error codes and

first five error code

Indication of total error count

Error code

Detailed error code

Clear of each error history

A screen returns to following

indication after clear completion.

1-32 (No.MA165)

RUNNING MODE

See "Running mode" for details.

Page 33

4. Service mode 4

Keep this state more than 2 seconds

while continuing pressing the

[DISP] button, [BACK] button and

[EJECT] button sequentially.

Screen indication

SERVICE MODE4

RDS S MODE

MONITOR S MODE

Exchanging it operate a menu of a service mode with the [UP] button

and [DOWN] button. Operate choice of a menu with a [OK] button.

4.6.4 DVD check mode

DVD CHECK MODE

NORMAL PLAY

EF OUT-TRACKING OFF

EF IN-TRACKING OFF

CD-LASER ON

DVD-LASER ON

DVDx1 JITTER MODE

Exchanging it operate a menu of a service mode with the [UP] button

and [DOWN] button. Operate choice of a menu with a [OK] button.

NORMAL PLAY

EF OUT-TRACKING OFF

EF IN-TRACKING OFF

CD-LASER ON

DVD-LASER ON

DVDx1 JITTER MODE

EEPROM DATA DISP

EEPROM DATA CLEAR

TEMPERATURE

SEARCH & JITTER

MONITOR

PLAY

STOP

OPEN

CLOSE

Command

RDS S MODE

VER=V

SPI=

PI =

TP =

MS =

MONITOR S MODE

R/W CHROMA 1

R/W CHROMA 2

DATA CLEAR

PTY=

SM =

SQ =

TA =

PI =

RDS service mode

Only RDS model

See "Monitor adjustment" for details.

CHROMA DATA read/write of NTSC/PAL signal processing IC

CHROMA DATA read/write of TFT driver IC

Clear of CHROMA DATA of 1,2 (return to an initial value)

DVD CHECK MODE

EEPROM DATA DISP

EEPROM DATA CLEAR

TEMPERATURE

SEARCH & JITTER

MONITOR

PLAY

Mechanism unit operation Indication contents

Start at normal speed

(After start, jitter is measured by an inner position.)

Tracking off the outermost position of CD

Tracking off the innermost position of CD

CD_LD lights and laser current is displayed.

DVD_LD lights and laser current is displayed.

DVD x1 jitter measuring mode

(for use in mechanism adjustment)

Contents of EEPROM is displayed.

Contents of EEPROM is initialized.

Temperature indication

The search and jitter measurement to an appointed

position of DVD.

Monitor terminal setting

DVDx1 speed start

(After start, jitter is measured by an inner position.)

Disc stopped, LD-OFF

OPEN

CLOSE

DVD CHECK MODE

STOP

OPEN

CLOSE

Laser current value, jitter value

For EF phase error

For EF phase error

Laser current value, jitter value

Laser current value, jitter value

Laser current value, jitter value

EEPROM address

EEPROM contents

EEPROM address

EEPROM contents

Temperature is displayed in hex

numbers.

Position measured with VT-501

Jitter value

Not displayed.

Not displayed.

Not displayed.

Not displayed.

(No.MA165)1-33

Page 34

4.6.5 Error code tables

Mechanism error code

Error contents

Disc loading error

B1 time out

C1 time out

D1 time out

C2 time out

B2 time out

A2 time out

F1 time out

A0 (Switch state without existence)

G1 time out

Eject error

F2 time out

A1 time out

B1 time out

C1 time out

D1 time out

C2 time out

B2 time out

A0 (Switch state without existence)

G2 time out

Error in loading wait

Loading re-execution NG Eject

Eject re-execution NG Loading

Details Error code

Loading of a running mode

Disc was pulled out in a wait.

Running mode error

Running mode error

0x99

0x99

0x99

0x99

0x99

0x99

0x99

0x99

0x99

0x01

0x01

0x01

0x01

0x01

0x01

0x01

0x01

0x01

0x09

0x09

0x01

Detailed error code

0x0011

0x0012

0x0013

0x0014

0x0015

0x0016

0x0017

0x0018

0x0019

0x0021

0x0022

0x0023

0x0024

0x0025

0x0026

0x0027

0x0028

0x0029

0x0031

0x0032

0x0033

Disc error code

Error contents

TOC read error

First track access error

Last track access error

T1 access error

T12 access error

T24 access error

Read-in area read error

SDRAM read/write error

DVD L1 layer adjustment error

NODISC judgment

It is NODISC by start failure.

It is stopped by playback inability.

Details Error code

TOC lead movement of a CD is not completed.

Even if TOC reading passes after the end with

CD running mode for 30 seconds, the first track

access is not finished.

Even if first track passes after the end with

CD running mode for 30 seconds, the last track

access is not finished.

Even if T1 access passes in a DVD running

mode for 30 seconds, it is not finished.

Even if T12 access passes in a DVD running

mode for 30 seconds, it is not finished.

Even if T24 access passes in a DVD running

mode for 30 seconds, it is not finished.

Read-in area read operation of DVD is not

completed.

Read/write to SDRAM is not normal.

Adjustment of L1 layer of DVD is not finished

normally. (including focus jump failure)

Judgment without disc

Start is impossible.

Stop in running mode playback

0x84

0x80

0x80

0x80

0x80

0x80

0x84

0x80

0x80

0x80

0x80

0x80

Detailed error code

0x0059

0x0060

0x0061

0x0069

0x0070

0x0071

0x0072

0x0073

0x0074

0x0090

0x0091

0x0093

1-34 (No.MA165)

Page 35

4.6.6 Running mode

Indication

RUNNING1 MECHA

RUNNING2 MECHA

RUNNING3 DVD

RUNNING4 DVD

RUNNING5 DVD

RUNNING6 DVD

RUNNING7 DVD

RUNNING8 DVD

Explanation

Door mecha running1

Door mecha running1

DVD+Door mecha running1

DVD+Door mecha running2

DVD+Door mecha running3

DVD+Door mecha running4

DVD+Door mecha running5

DVD+Door mecha running6

Operation contents of 1 cycle

Panel close Panel open

Panel close Panel open Panel detach position

Panel angle 3 position Panel angle 1 position

Panel angle 2 position

Loading Eject Wait for 5 seconds+Door open/close

Loading Eject Wait for 5 seconds+Door open/close

Loading Playback Eject Wait for 5 seconds+Door open/close

Loading Playback Eject Wait for 5 seconds+Door open/close

Loading Playback Eject Wait for 5 seconds+Door open/close

Loading Playback Eject Wait for 5 seconds+Door open/close

In mecha error

-

-

Stop

Retry

Stop

Retry

Stop

Retry

In disc error

-

-

-

Stop

Stop

Retry

Retry

SDRAM inspection

-

-

-

Execution

Execution

Non-execution

Non-execution

Cancellation of running1,2 : Press the [EJECT] key

In running 1,2 cancellation, a door does not stop at the position and moves to a panel open position.

Cancellation of running3 to 8 : Press the [POWER] key

The number of count and an error cord are displayed in running.

Playback contents in a running mode

CD

The first track is played for 30 seconds. The last track is played for 30 seconds.

(The last truck is played in the case of less than till the last for 30 seconds.)

DVD

2layer disc

Title 1 (the L0 layer internal circumference) is played for 30 seconds. Title 12 (L0 layer circumference) is played for 30 seconds.

Title 24 (L1 layer internal circumference) is played for 30 seconds.

1layer disc

First chapter of title 1 is played for 30 seconds. The last chapter of title 1 is played for 30 seconds.

4.6.7 Writing method for micon ROM correction

For main ROM correction and panel ROM correction, prepare two pieces of disc.

(Do not put both data in one piece of disk.)

Insert the disc which ROM correction data were written in at.

Folder name : ROM Correction

File name : Please Wait

Folder name : ROM Correction

File name : OK 1940 (Indication is different by ROM correction IC.)

If OK is displayed, ROM correction is completion. Disc is ejected automatically.

Pull the power supply cord and wait more than 30 seconds. (Even reset is possible.)

Switch on the main body again and confirm a version.

Confirmation method of a version

Keep this state more than 2 seconds while continuing pressing the [DISP] button, [VOLUME+] button and

[EJECT] button sequentially to enter this set in service mode 3.

Select the service mode and press the [OK] button.

Select the version and press the [OK] button.

ROM correction is completion if displayed on a screen as follows.

PANEL V [V001]

PANEL : panel ROM correction

MAIN : main ROM correction

ROM correction version

When it was confirmed a version without reset, a part of [V001] is displayed in [E001].

When a ROM collection is not completed even if writing of EEPROM is completed, this indication appears.

Movement of this case is movement before the ROM collection.

(No.MA165)1-35

Page 36

4.6.8 Update method of firm ware

Power on.

Insert the disc which a farm was written in at.

Screen indication

VERSION UP DISC

PROGRAM WRITING MODE

CURRENT VERSION 0735

NEW VERSION 0795

READING...

If "PLEASE EJECT" was displayed

after the writing end, take out a disc.

Current version

Version to write in

Close a panel and confirm a version.

Power off.

Confirmation method of a version

Keep this state more than 2 seconds while continuing pressing

the [DISP] button, [VOLUME+] button and [EJECT] button

sequentially to enter this set in service mode 3.

Select the service mode and press the [OK] button.

Select the version and press the [OK] button.

JD4

It is a version written in.

1-36 (No.MA165)

Page 37

4.6.9 Monitor adjustment

When adjusting, switch on the main unit and insert a test disc (VT-501). And play the test disc and pause it.

(Exit for VCO FREE-RUN adjustment)

R/W CHROMA 1

1. Set the service mode 4.

2. Exchanging it operate a menu of a service mode with the [UP] button and [DOWN] button.

3. Change data with the [B.SKIP]/[F.SKIP] buttons.

4. Write data with a [OK] button.

When performing the VCO FREE-RUN N adjustment, set the NTSC mode (Service mode 3 Service mode

DVD NTSC/PAL) and turn the input into the no input. Connect the frequency counter to the point (TP661 or

TP681-GND) on the panel board and set the frequency into 15.62 0.01 (kHz).

When performing the VCO FREE-RUN P adjustment, set the PAL mode (Service mode 3 Service mode

DVD NTSC/PAL) and turn the input into the no input. Connect the frequency counter to the point (TP661 or

TP681-GND) on the panel board and set the frequency into 15.73 0.01 (kHz).

Indication

COM AMPLITUDE

BRIGHT GAIN

COLOR GAIN N

COLOR GAIN P

TINT N

TINT P

BLACK LIMITER

BRIGHT

APERTURE

R SUB BRIGHT

B SUB BRIGHT

W PEAK LIMITER

GAMMA1

GAMMA2

CONTRAST

R SUB CONTRAST

B SUB CONTRAST

VCO FREE RUN N

VCO FREE RUN P

PLL STOP POS

V POSITION

H POSITION

PWM FREQUENCY

BRST CLN PLS POS

PWM DUTY

COM DC

DC OUTPUT

Minimum value

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Maximum value

0xFF

0xFF

0xFF

0xFF

0xFF

0xFF

0x7F

0xFF

0x7F

0xFF

0xFF

0x7F

0xFF

0xFF

0xFF

0xFF

0xFF

0xFF

0xFF

0x0F

0x07

0x1F

0x0F

0x07

0xFF

0xFF

0xFF

Initial value

0x80

0x80

0x80

0x80

0x80

0x80

0x40

0x80

0x40

0x80

0x80

0x40

0x80

0x80

0x80

0x80

0x80

0x80

0x80

0x00

0x00

0x00

0x08

0x00

0x80

0x80

0x80

Production jig initial value Reference register value

0x80

0x80

0x5F

0x62

0x82

0x80

0x5E

0xA3

0x40

0x88

0x88

0x7F

0x80

0xFF

0x64

0x74

0x78

0x8C

0x89

0x08

0x02

0x1F

0x08

0x03

0xFF

0x80

0x65

0x80

0x80

0x60

0x62

0x6D

0x80

0x5E

0xA3

0x40

0x88

0x89

0x7F

0x80

0xFF

0x65

0x71

0x74

0x8F

0x8B

0x08

0x02

0x1F

0x08

0x03

0xFF

0x80

0x43

Fix

Fix

Adjust

Adjust

Adjust

Adjust

Fix

Adjust

Fix

Adjust

Adjust

Fix

Fix

Fix

Adjust

Adjust

Adjust

Adjust

Adjust

Fix

Fix

Fix

Fix

Fix

Fix

Fix

Adjust

15.62 kHz

15.73 kHz

R/W CHROMA 2

1. Set the service mode 4.

2. Exchanging it operate a menu of a service mode with the [UP] button and [DOWN] button.

3. Change data with the [B.SKIP]/[F.SKIP] buttons.

4. Write data with a [OK] button.

Indication

H POSITION

V POSITION

HDO POSITION

BRIGHT

R BRIGHT

B BRIGHT

COMLEVEL M

COMLEVEL E

COMDC M

COMDC E

VCO N

VCO P

Minimum value

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Maximum value

0x1F

0x0F

0x1F

0x7F

0x7F

0x7F

0x1F

0x1F

0x3F

0x3F

0xFF

0xFF

0x10

0x08

0x00

0x40

0x40

0x40

0x10

0x10

0x29

0x32

0x80

0x80

Production jig initial value Reference register valueInitial value

0x12

0x08

0x02

0x4D

0x3E

0x40

0x09

0x10

0x33

0x32

0x70

0x76

0x13

0x08

0x02

0x4E

0x3E

0x41

0x08

0x10

0x31

0x32

0x61

0x69

Adjust

Adjust

Fix

Adjust

Adjust

Adjust

Adjust

Fix

Adjust

Fix

Adjust

Adjust

(No.MA165)1-37

Page 38

5.1 16 PIN CORD DIAGRAM [for E version]

SECTION 5

TROUBLESHOOTING

GN

GN/BK

VI/BK

VI

NC

BL/WH

RD

BK

YL

RD

BR TEL

BL/WH

OR/WH

BK

WH

WH/BK

GY/BK

GY

BR

L. GN

OR/WH

YL

MEMORY

Choking Coil

ACC

REMOTE

ILL

GND

BK

RD

BL

WH

BR

L.GN

Black

Red

Blue

White

Brown

Light Green

GN

VI

GY

YL

OR

Green

Violet

Gray

Yellow

Orange

RD

YL

RD

NC

NC

BL/WH

RD

BR

YL

OR/WH

BK

RR

FR

FL

RL

REMOTE

VI

VI/BK

GY

GY/BK FR-

WH

WH/BK

GN RL+

GN/BK

L.GN

VI/WH

Rear Right

Front Right

Front Left

Rear Left

Remote

RR+

RR-

FR+

FL+

FL-

RL-

PARKING

REVERS

ACC

TEL

GND

MEMORY

PARKING

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

Parking Brake

VI

GY

WH

GN

PARKING

BRAKE

VI/BK

GY/BK

WH/BK

GN/BK

ILL

REVERS

1-38 (No.MA165)

Illuminations Control

Revers Gear Signal

ANT

Auto Antenna

Page 39

5.2 16 PIN CORD DIAGRAM [for A, J, U, UN, UT version]

GN

GN/BK

VI/BK

VI

BL

BL/WH

RD

BK

GN

WH

GN/BK

WH/BK

VI/BK

GY/BK

VI

GY

BL

WH

WH/BK

GY/BK

GY

BR

L. GN

OR/WH

YL

RL+

FL+

RL-

FL-

RR-

FR-

RR+

FR+

ANT

BK

RD

BL

WH

BR

L.GN

Black

Red

Blue

White

Brown

Light Green

GN

VI

GY

YL

OR

Green

Violet

Gray

Yellow

Orange

RR

FR

FL

RL

BL/WH

BR

OR/WH

RD

BK

YL

L.GN

Rear Right

Front Right

Front Left

Rear Left

VI/WH

REMOTE

TEL

ILL

ACC

GND

MEMORY

PARKING

TEL MUTING

REVERS

POWER ANTENNA

REMOTE OUT

Choking Coil

ACC

TEL

GND

MEMORY

ILLUMINATION

CONTROL

YL

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

GND

PARKING

BRAKE

REMOTE

ILL

REVERS

Remote

Illuminations Control

Revers Gear Signal

PARKING

ANT

Parking Brake

Auto Antenna

(No.MA165)1-39

Page 40

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA165)

Printed in Japan

VPT

Loading...

Loading...