Page 1

SERVICE MANUAL

DVD RECEIVER WITH MONITOR

MA425<Rev.001>200812SERVICE MANUAL

KD-AV7100JW, KD-AV7100EU,

KD-AV7100EE, KD-AV7100U,

KD-AV7100US, KD-AV7100A

COPYRIGHT © 2008 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

COPYRIGHT © 2008 Victor Company of Japan, Limited

No.MA425<Rev.001>

2008/12

Page 2

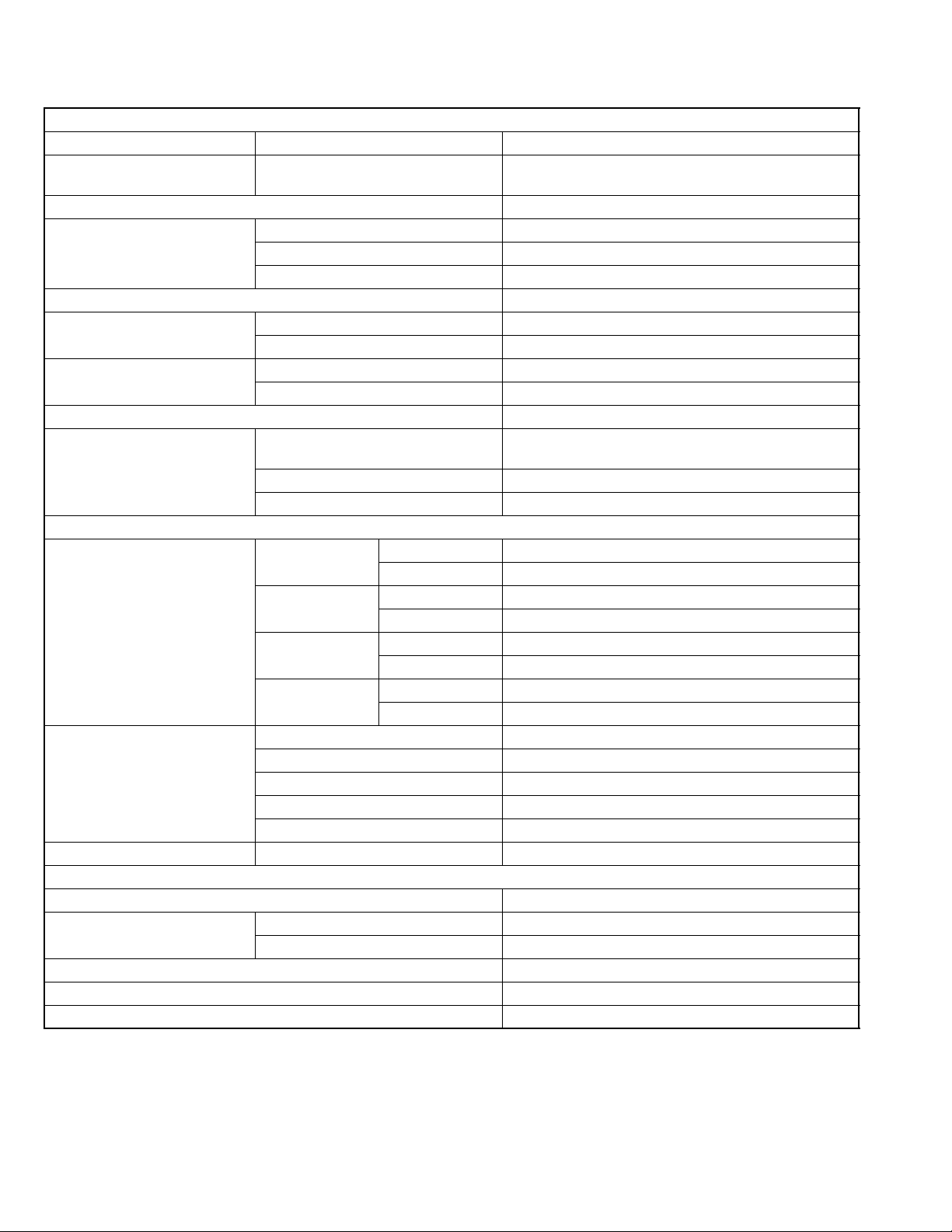

SPECIFICATION

AMPLIFIER

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 20 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±14 dB (60 Hz, 80 Hz, 100 Hz, 200 Hz)

Treble ±14 dB (10 kHz, 12.5 kHz, 15 kHz, 17 kHz)

Q (Q-slope) Q1.0, Q1.25, Q1.5, Q2.0

Signal-to-Noise Ratio 70 dB

Audio Output Level FRONT/

REAR/ CENTER/ SUB WOOFER

Color System NTSC/PAL*1

Video Output (composite) 1 Vp-p/75Ω

Other Terminals Input AV IN, CAMERA, AUX (auxiliary) input jack, USB input

Frequency Range USA FM 87.5 MHz - 107.9 MHz/200 kHz

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

AM Tuner Sensitivity/Selectivity 20 µV/35 dB

Signal Detection System Non-contact optical pickup (semiconductor laser)

Frequency Response DVD, fs=48 kHz 16 Hz to 22 000 Hz

Dynamic Range 93 dB

Signal-to-Noise Ratio 95 dB

Wow and Flutter Less than measurable limit

Line-Out Level/Impedance 4.0 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

for Spanish NTSC

terminal, Aerial input

Output AV OUT

Others iPod, OE REMOTE*2

FM/AM TUNER

AM 530 kHz - 1 710 kHz/10 kHz

S-Amer1 FM 87.5 MHz - 107.9 MHz/100 kHz

AM 530 kHz - 1 710 kHz/10 kHz

Europe FM 87.50 MHz - 108.00 MHz/50 kHz

AM 522 kHz - 1 620 kHz/9 kHz

Other FM 87.50 MHz - 108.00 MHz/50 kHz

AM 531 kHz - 1 602 kHz/9 kHz

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 35 dB

DVD/CD

VCD/CD 16 Hz to 20 000 Hz

1-2 (No.MA425<Rev.001>)

Page 3

SD

Compatible File System FAT 32

Capacity 2 Gbytes

Data Transfer Rate Maximum 10 Mbps

USB

USB Standards USB 1.1

Data Transfer Rate Full Speed: Maximum 12 Mbytes

Low Speed: Maximum 1.5 Mbytes

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current Less than 500 mA/5 V

MONITOR

Screen Size 7 inch wide liquid crystal display

Number of Pixel 336 960 pixels: 480 x 3 (horizontal) × 234 (vertical)

Drive Method TFT (Thin Film Transistor) active matrix format

Color System NTSC/PAL

for Spanish NTSC

Aspect Ratio 16:9 (wide)

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Storage Temperature -10°C to +60°C

Allowable Operating Temperature 0°C to +50°C

Dimensions (W × H × D):

With trim plate and sleeve attached

Mass (approx.) 2.5 kg (including trims and sleeve)

Installation Size (approx.) 182 mm × 53 mm × 159 mm

Panel Size (approx.) 188 mm × 58 mm × 13 mm

Detachable Panel Size (approx.) 134 mm × 22 mm × 19 mm

*1 Use an external monitor which can switch the color system (NTSC/PAL) automatically. ( A, EU/US, U, EE )

*2 Not used for this unit. ( A, EU/US, U, JW )

Design and specifications are subject to change without notice.

(No.MA425<Rev.001>)1-3

Page 4

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

!

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

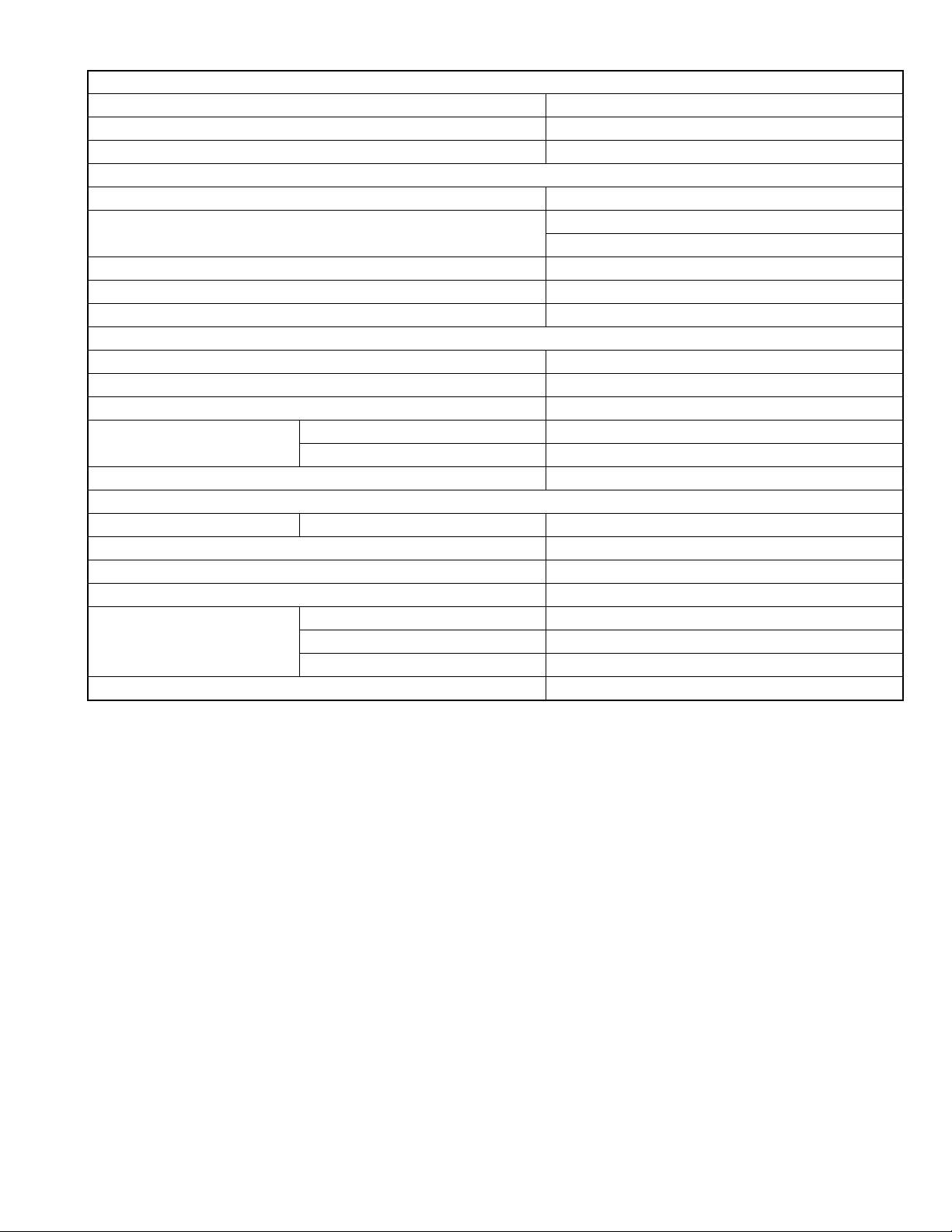

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-4 (No.MA425<Rev.001>)

Page 5

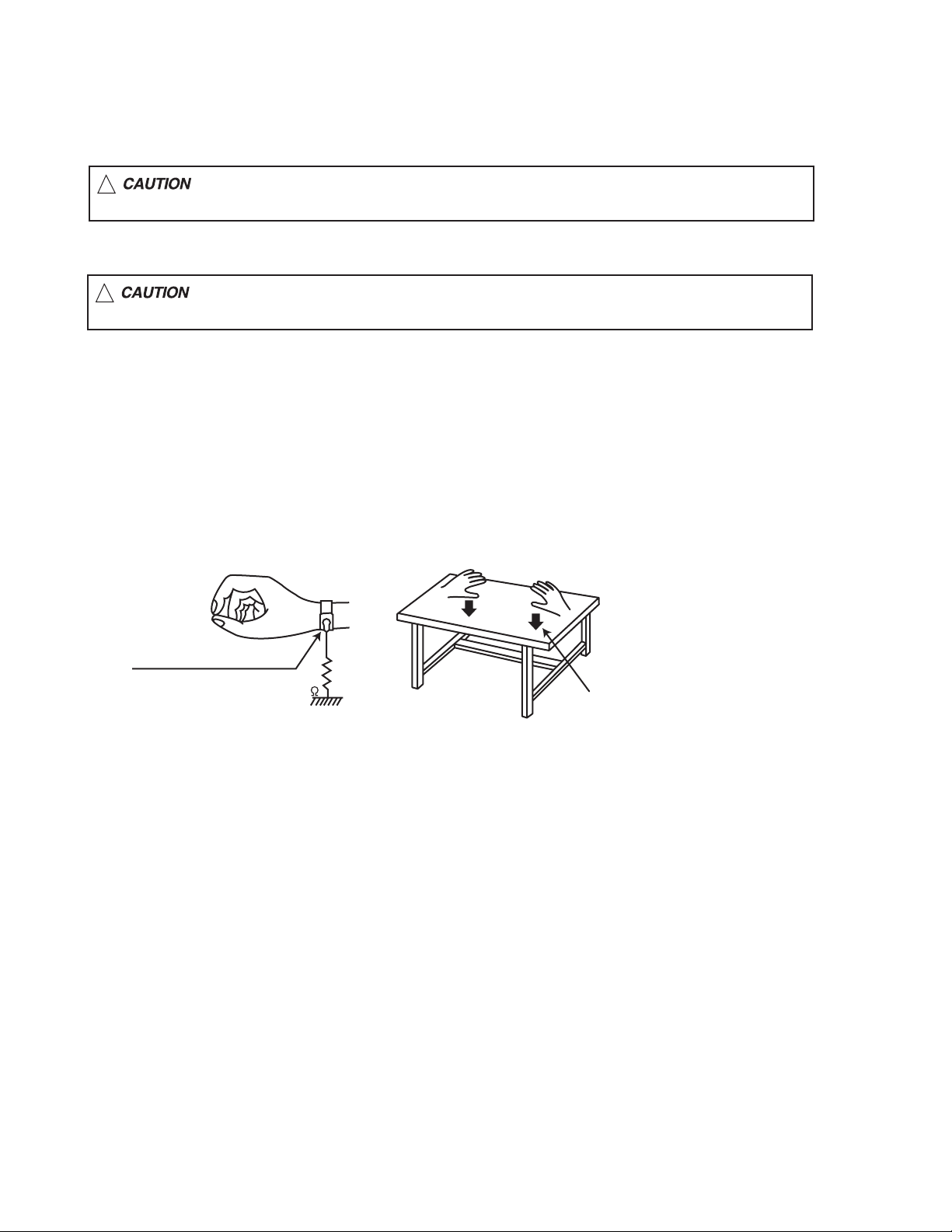

1.4 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

(No.MA425<Rev.001>)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MA425<Rev.001>)

Page 7

SECTION 3

A

r

DISASSEMBLY

3.1 Main body (Used figure are KD-AV7100E)

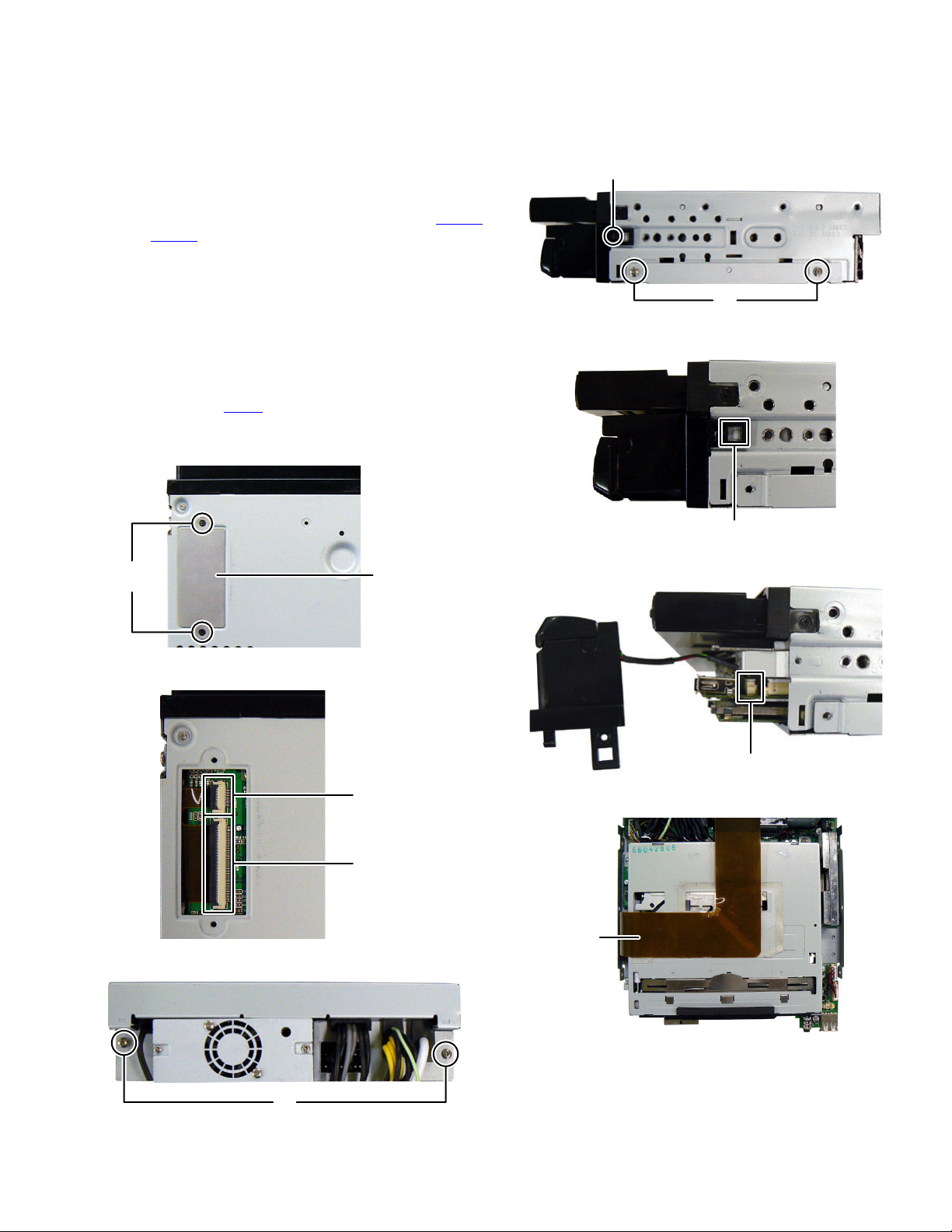

3.1.1 Removing the Top chassis (See Fig.1 to 7)

(1) Remove the two screws A attaching the FPC cover. (See

Fig.1)

(2) Disconnect the FPC wire connected to connector CON11

and CON19 of the Main board. (See Fig.2)

(3) Remove the two screws B attaching the Top chassis. (See

Fig.3)

(4) Remove the four screws C attaching the both side of the

Top chassis. (See Fig.4)

(5) Remove the two screws D attaching the both side of the

Front chassis. (See Fig.4)

(6) Disengage two hooks a engaged both side of the Front

chassis. (See Fig.5)

(7) Disconnect the connector wire from Front chassis connect-

ed to connector CON2

(8) Tear off an FPC from a CD mechanism and then remove

the Top chassis. (See Fig.7)

of the USB board. (See Fig.6)

D

C

Fig.4

hook a

Fig.1

Fig.2

FPC cove

CON11

CON19

Fig.5

CON2

Fig.6

FPC

Fig.7

B

Fig.3

(No.MA425<Rev.001>)1-7

Page 8

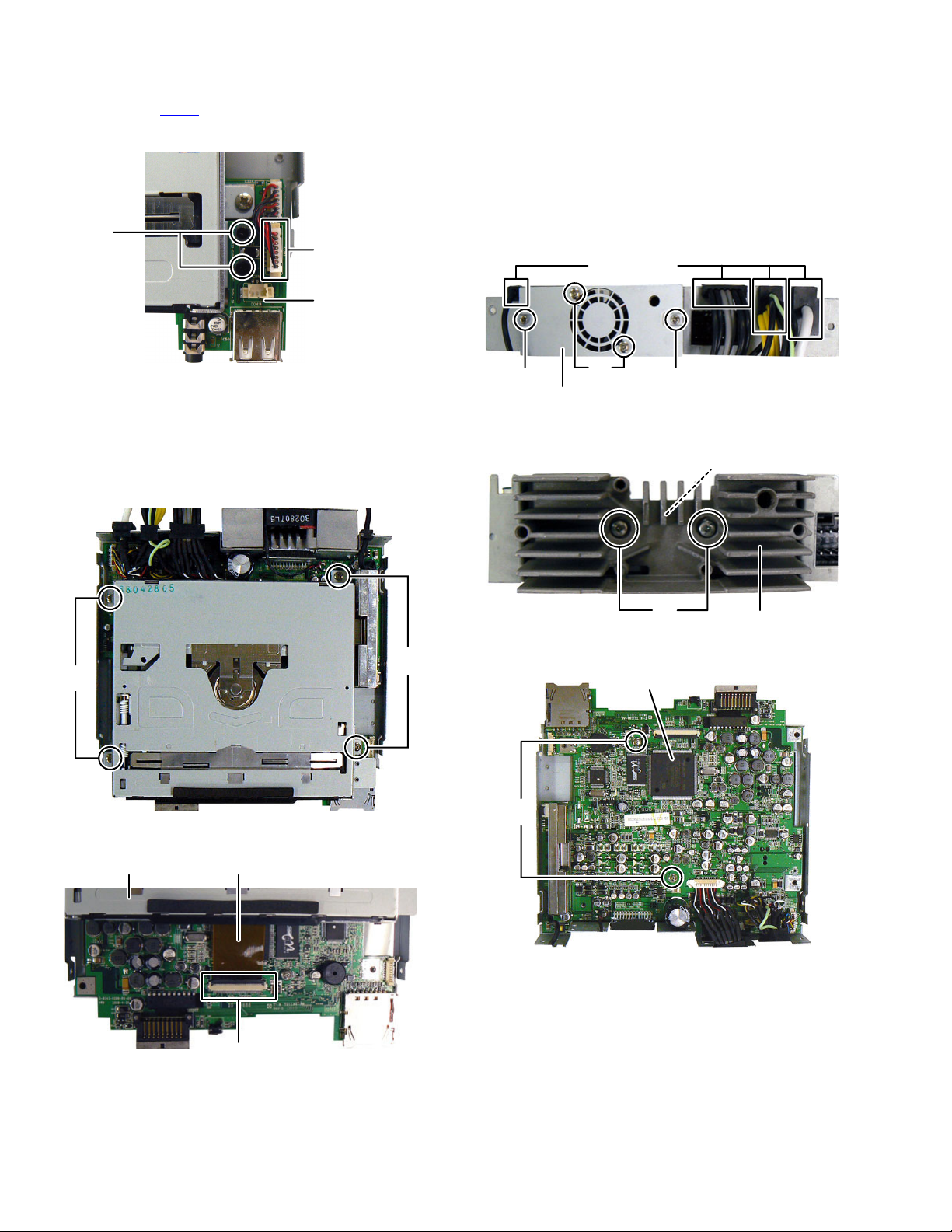

3.1.2 Removing the USB board (See Fig.8)

(1) Disconnect the connector wire from Main board connected

to connector CON1

(2) Remove the two screws E attaching the USB board.

of the USB board.

E

CON1

USB board

3.1.4 Removing the Main board (See Fig.11 to 13)

(1) Remove the Signal cables from Bottom chassis. (See

Fig.11)

(2) Remove the two screws G attaching the FAN. (See Fig.11)

(3) Remove the two screws H attaching the FAN cover. (See

Fig.11)

(4) Remove the two screws J attaching the Heat sink with IC

bracket. (See Fig.12)

(5) Remove the two screws K attaching the Main board. (See

Fig.13)

Signal cables

Fig.8

3.1.3 Removing the CD mechanism (See Fig.9, 10)

(1) Remove the four screws F attaching the CD mechanism.

(See Fig.9)

(2) Disconnect the FPC from CD mechanism connected to

connector CON16 of the Main board. (See Fig.10)

F

Fig.9

F

HH

G

FAN cover

Fig.11

IC bracket inside

J

Fig.12

Main board

Heat sink

K

CD mechanism

1-8 (No.MA425<Rev.001>)

FPC

Fig.13

CON16

Fig.10

Page 9

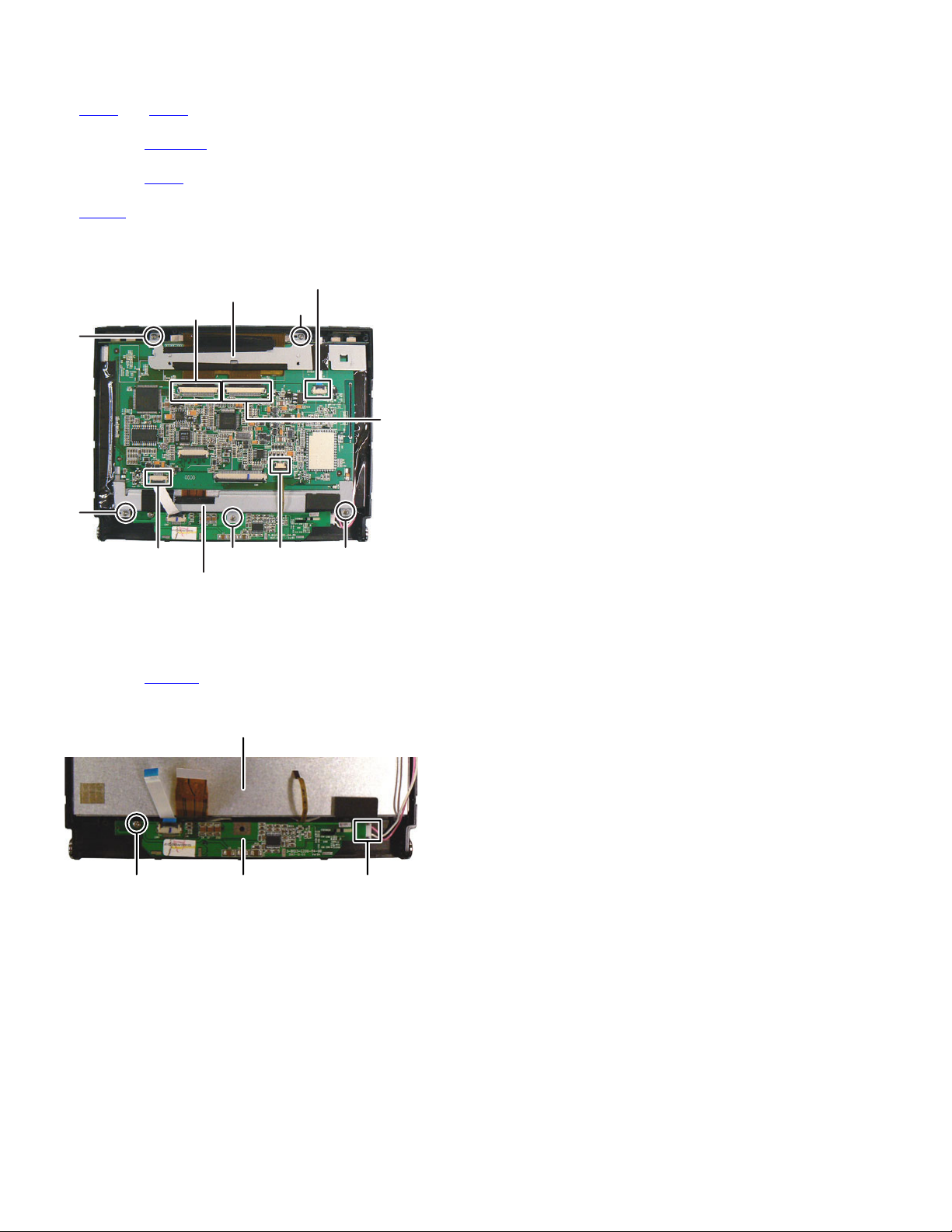

3.1.5 Removing the Key board (See Fig.14)

(1) Remove the Volume knob.

(2) Remove the six screws L attaching the Rear cover.

L

L

Fig.14

3.1.6 Removing the LCD monitor (See Fig.15 to 18)

There are two ways of methods to exclude monitor block.

Method 1: Press [OPEN] button.

Method 2: After remove the Top chassis, supply voltage approx

3.0V to Motor (See Fig.15)

(1) Remove the two screws M attaching the FPC cover. (See

Fig.16)

(2) Remove the two screws N and two screws P attaching the

L panel cover. (See Fig.16)

(3) Disconnect the FPC from drive unit connected to connector

of the TFT board. (See Fig.17)

CON1

(4) Remove the six screws Q attaching the both side of the

Screen panel. (See Fig.18)

FPC

CON1

Fig.17

Q

Fig.18

M

P

N

Motorapprox 3.0V

Fig.15

FPC cover

M

P

N

L panel cover

Fig.16

(No.MA425<Rev.001>)1-9

Page 10

3.1.7 Removing the TFT board (See Fig.19)

(1) Disconnect the FPC from LCD connected to connector

CON2

and CON4 of the TFT board.

(2) Disconnect the card wire from LCD board connected to

connector CON7404

(3) Disconnect the card wire from CCLF board connected to

connector CON5 of the TFT board.

(4) Disconnect the FPC from LCD lens connected to connector

of the TFT board.

CON20

(5) Remove the two screws R attaching the PCB bracket.

(6) Remove the three screws S attaching the PCB bracket.

of the TFT board.

PCB bracket

CON2

CON7404

R

R

CON4

S

CON5

PCB bracket

3.1.8 Removing the CCLF board (See Fig.20)

(1) Disconnect the connector wire from LCD lens connected to

connector CON102

(2) Remove the one screw T attaching the CCLF board.

of the CCLF board.

CON20

S

Fig.19

LCD lens

S

T

1-10 (No.MA425<Rev.001>)

CON102CCLF board

Fig.20

Page 11

SECTION 4

ADJUSTMENT

4.1 ADJUSTMENT

4.1.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Digital tester

(3) Test Disc

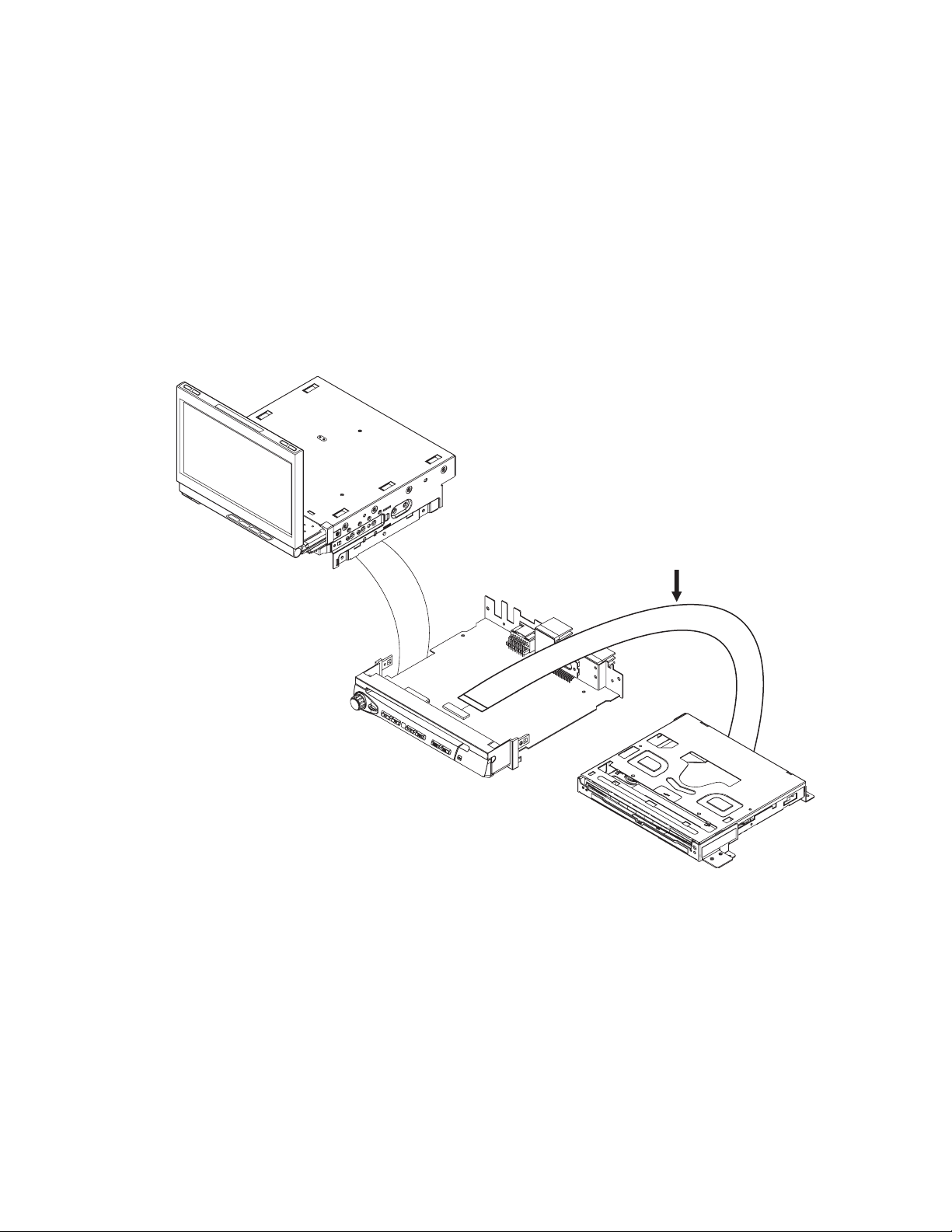

(4) Extension cable : EXTAV70X-50PF

4.1.2 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

4.1.5 How to connect the extension cable for adjusting

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

4.1.3 Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K ohm (2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.1.4 Dummy load

Exclusive dummy load should be used for AM,and FM. For FM

dummy load,there is a loss of 6dB between SSG output and antenna input.The loss of 6dB need not be considered since direct

reading of figures are applied in this working standard.

Extension cable

EXTAV70X-50PF

(No.MA425<Rev.001>)1-11

Page 12

4.1.6 Service mode

• When adjusting, switch on the main unit and insert a test disc (VT-501). And play the test disc and pause it.

(1) Power ON

(2) Use the remote controller (RM-RK253).

(3) Push the button of remote controller with the following order.

[SRC] button → [ 1 ] button → [ 2 ] button

(4) Exchanging it operate a menu of a service mode with the [ ] button and [ ] button.

(5) Change data with the [ ]/[ ] buttons.

(6) Write data with a [INFO ] button of the main body.

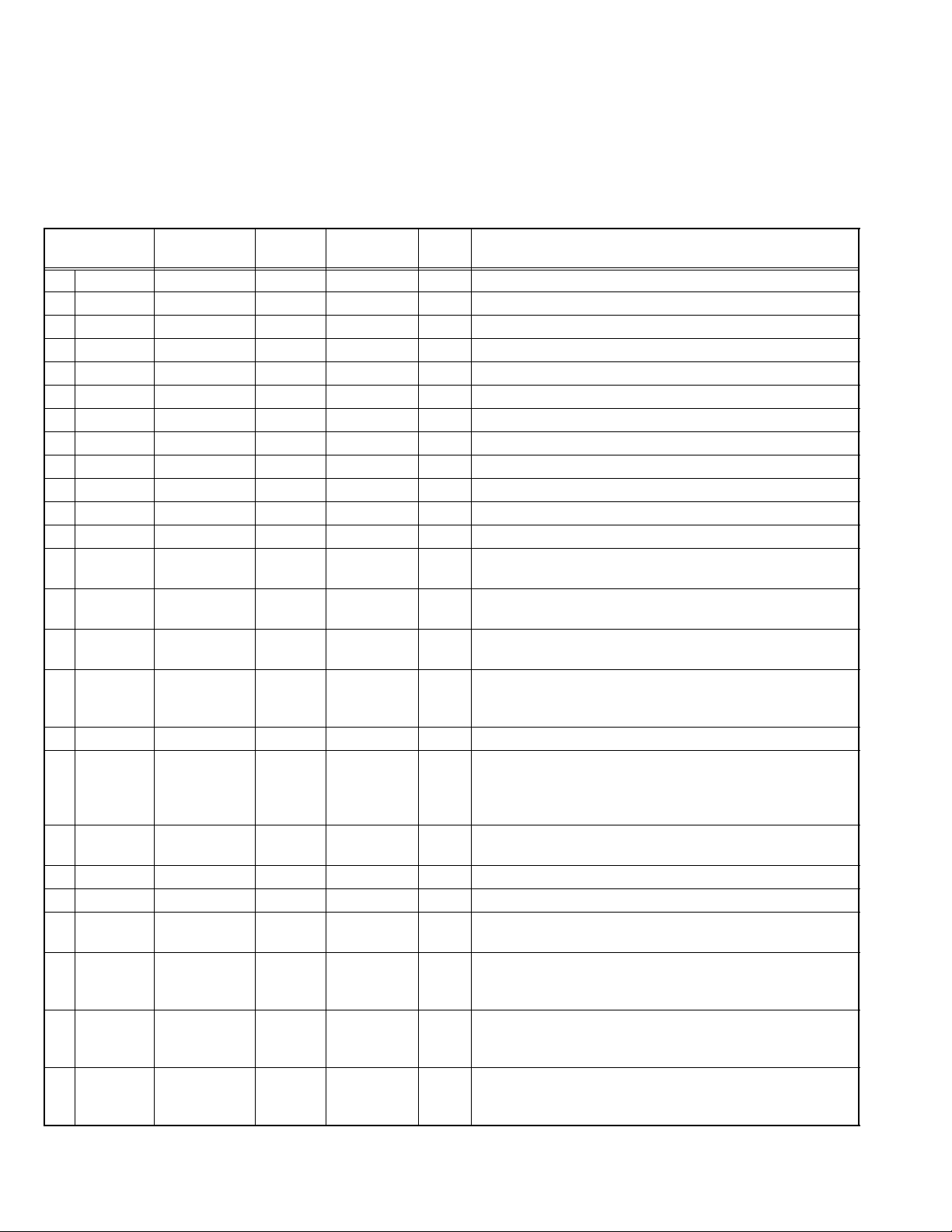

Indication Minimum value Maximum

value

1 Data - - - - Only factory use

2 Version - - - - Only factory use

3 Sch - - - - Only factory use

4 Pcb - - - - Only factory use

5 KeyCode - - - - Only factory use

6 Counter - - - - Only factory use

7 Count MSB - - - - Only factory use

8 Count LSB - - - - Only factory use

9 FM LOC *1 00 FF 40 Adjust STOP sensitivity adjustment of FM LOC mode

10 AM LOC 00 FF A0 Adjust STOP sensitivity adjustment of AM LOC mode No use

11 FM DX *1 00 FF 40 Adjust STOP sensitivity adjustment of FM DX mode

12 AM DX *1 00 FF 50 Adjust STOP sensitivity adjustment of AM DX mode

17 CTRST 00 7F 60 Adjust Contrast control

18 CLOR 80 FF A0 Adjust Color control

19 TINT 00 FF A0 Adjust Tint control (Base Band TINT)

20 SHAP 00 FF 30 Adjust Comb filter for base-band color signal of NTSC

21 BRT 00 FF 98 Adjust Brightness control

22 SUBC 00 FF 60 Adjust Auto Brightness Limiter start point

23 W/BLIM 00 FF FA Adjust White clipping voltage for RGB signal exceeding over white

24 GM1 10 FF A8 Adjust Correction peak point

25 GM2 10 FF 50 Adjust Boost gain correction peak point

26 SUBT-RB 00 FF A8 Adjust Sub brightness control for R output singal

27 DRVR 00 FF 1A Adjust Mute switch for RGB output signal

28 DRVG 00 FF 18 Adjust Relative amplitude of R-Y color difference signal

29 DRVB 00 FF 18 Adjust Relative amplitude of G-Y color difference signal

Reference

register value

Detail

Power save

Chroma trap filter for Y input

RGB input coupling mode

CW out mode

Sharpness control

Auto Brightness Limiter off

Auto Brightness Limiter Gain

Controls the Y amplitude

Limit voltage for RGB signal exceeding below black

Sub brightness control for B output signal

Insert fixed level blue signal for RGB output

Gain control for R video signal

Relative phase of R-Y color difference signal

Gain control for G video signal

Relative phase of G-Y color difference signal

Gain control for B video signal

1-12 (No.MA425<Rev.001>)

Page 13

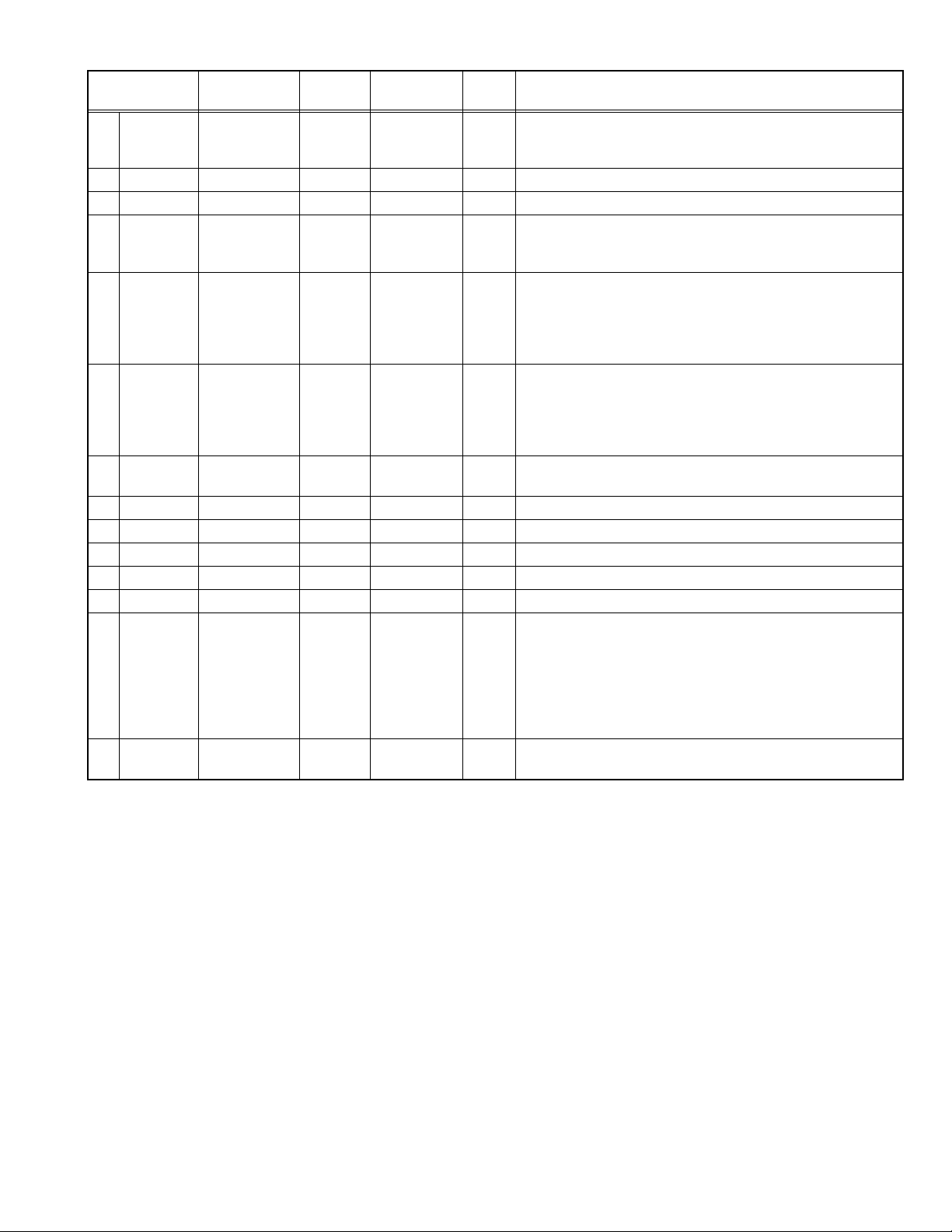

Indication Minimum value Maximum

value

30 V-SW 00 FF AA Adjust Synchronization mode

31 COMA 00 FF A3 Adjust Common Pulse Amplitude

32 COMDC 00 FF 26 Adjust Reference DC output

33 VFRE 00 FF 00 Fix Force Dotclk for T-Con stopping

34 SINHI 00 FF 00 Fix SECAM Inhibit

35 PDCK 00 FF A7 Fix Polarity control for Compare Pulse input signal

36 PADJ 10 FF 20 Fix VD phase phase

37 VPHASE 00 07 00 Adjust VD out Phase

37 HPHASE 00 1F 11 Adjust HD out Phase

38 GM2RGB 00 FF 00 Adjust Gamma2 Gain extension for R,G,B

39 T1 00 FF 00 Fix For IC testing at plant

40 T2 00 FF 00 Fix For IC testing at plant

41 SID_S 00 FF 02 Fix SECAM Gate pulse phase

42 S_BLK 10 FF 88 Fix R-Y Black level adjust for SECAM

Reference

register value

Detail

Polarity cobtrol for the WIDEBLK input signal

Video switch

AFC2 Phase control

Driving ability of pulse output stage

Low pass filter for Y input

Dot clock PLL

Polarity switch of video signal inverter

Polarity switch of common pulse inverter

Polarity control for VD output signal

Polarity control for HD output signal

Control the Divider for the Dot clock output signal

DOTCLK adjustment

DOTCLK adjustment

SECAM ID sensitivity

SECAM ID mode

Enhance the higher side of SECAM Bell filter

PAL/NTSC ID sensitivity for digital comb filter

Select chroma BPF frequency response

ABCL SW

B-Y Black level adjust for SECAM

*1 Seek stop sensitivity SSG setting

FM

97.9MHz or 98.1MHz LOC: 33dBuV (min.) 43dBuV (max.) 38dBuV (normal)

400Hz (sig.) 22.5kHz (Dev.) DX : 18dBuV (min.) 28dBuV (max.) 23dBuV (normal)

AM

999kHz or 1000kHz 24dBuV (min.) 34dBuV (max.) 29dBuV (noemal)

400Hz (Sig.) 30%

(No.MA425<Rev.001>)1-13

Page 14

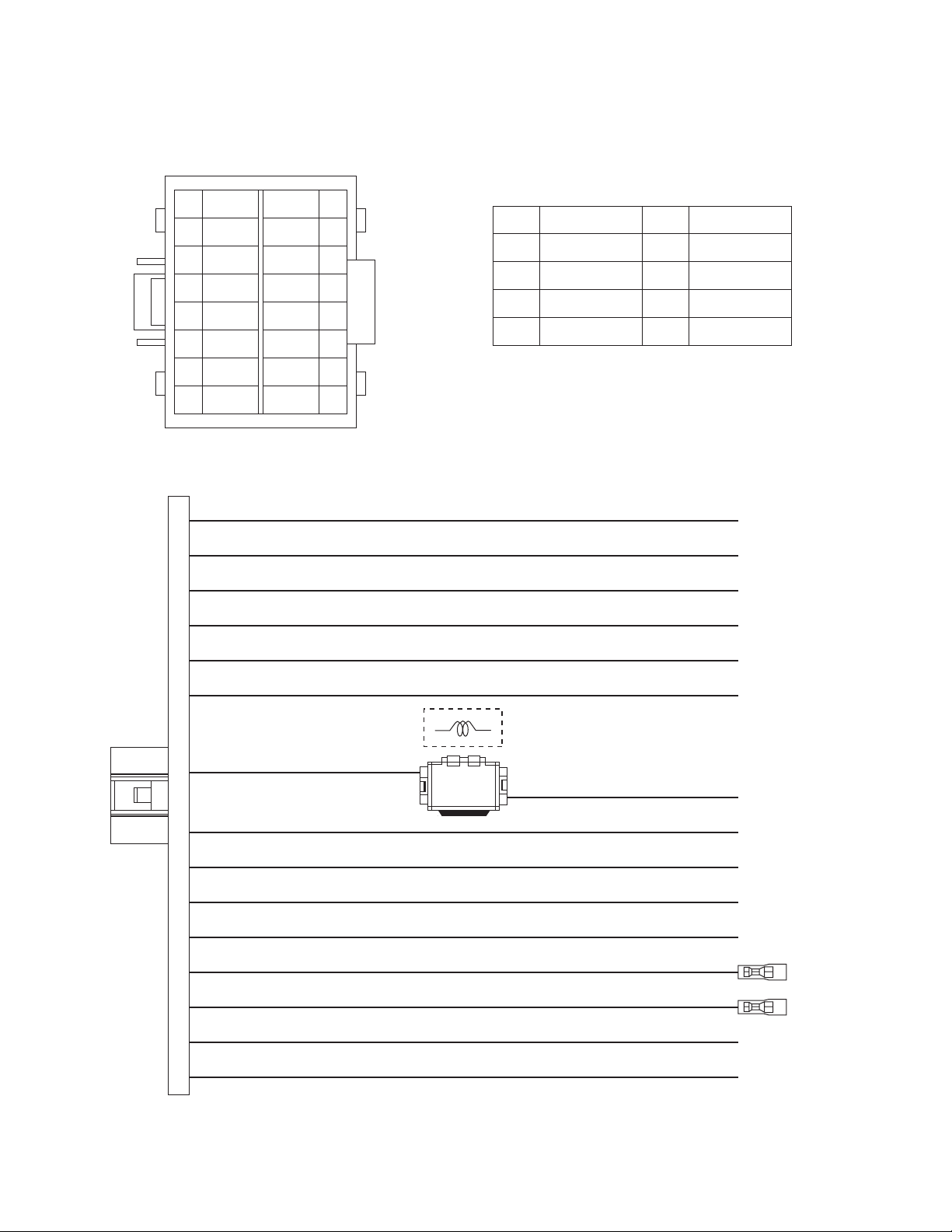

5.1 16 PIN CORD DIAGRAM (for JW,U,A)

SECTION 5

TROUBLESHOOTING

9

10

11

12

13

14

15

16

1

2

3

4

5

7

GN/BK

GN

VI/BK

VI

BL

BL/WH

RD

BK

WH/BK

WH

GY/BK

GY

VI/WH

OR/WH

WH/BK

WH

GY/BK

GY

VI/WH

NC

OR/WH

YL

1

WH

2

BK

3

GY

4

5

OR

6

7

8

VI

White

Black

Gray

Violet

Orange

YL

GN

BL

RD

Yellow

Green

Blue

Red

YL

8

GN/BK

9

GN

10

VI/BK

11

VI

12

WH/BK

13

BL/WH

14

RD

15

BK

16

1-14 (No.MA425<Rev.001>)

Page 15

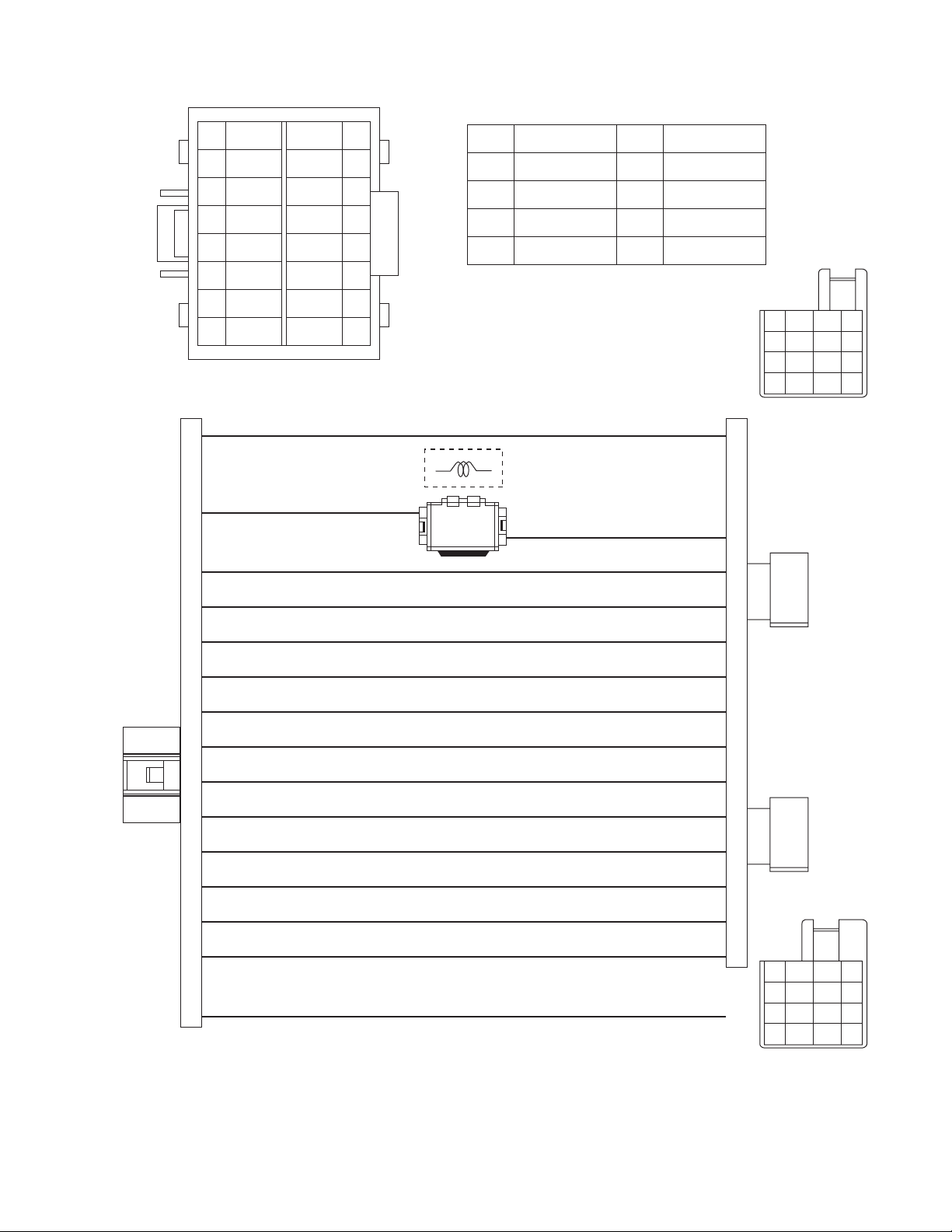

5.2 16 PIN CORD DIAGRAM (for EU,EE,US)

9

10

11

12

13

14

15

16

6

8

14

7

15

16

12

11

4

3

2

1

10

9

5

GN/BK

GN

VI/BK

VI

NC

BL/WH

RD

BK

BR

YL

BL/WH

OR/WH

RD

BK

VI

VI/BK

GY

GY/BK

WH

WH/BK

GN

GN/BK

VI/WH

WH/BK

WH

GY/BK

GY

VI/WH

BR

OR/WH

YL

1

2

3

WH

BK

GY

4

5

BR

VI

White

Black

Gray

Violet

Brown

OR

YL

GN

BL

RD

Orange

Yellow

Green

Blue

Red

6

7

BR

NC

8

1

3

5

7

1

3

5

7

NC

BL/WH

RD

VI

GY

WH

GN

YL

OR/WH

BK

VI/BK

GY/BK

WH/BK

GN/BK

2

4

6

8

2

4

6

8

(No.MA425<Rev.001>)1-15

Page 16

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA425<Rev.001>)

Printed in Japan

VPT

Page 17

SCHEMATIC DIAGRAMS

DVD RECEIVER WITH MONITOR

KD-AV7100JW,KD-AV7100EU

KD-AV7100EE,KD-AV7100U

KD-AV7100US,KD-AV7100A

DVD-ROM No.SML2008Q3

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2008 Victor Company of Japan, Limited.

2-1

2-2

2-14 to 16

No.MA425SCH<Rev.001>

2008/12

Page 18

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

Page 19

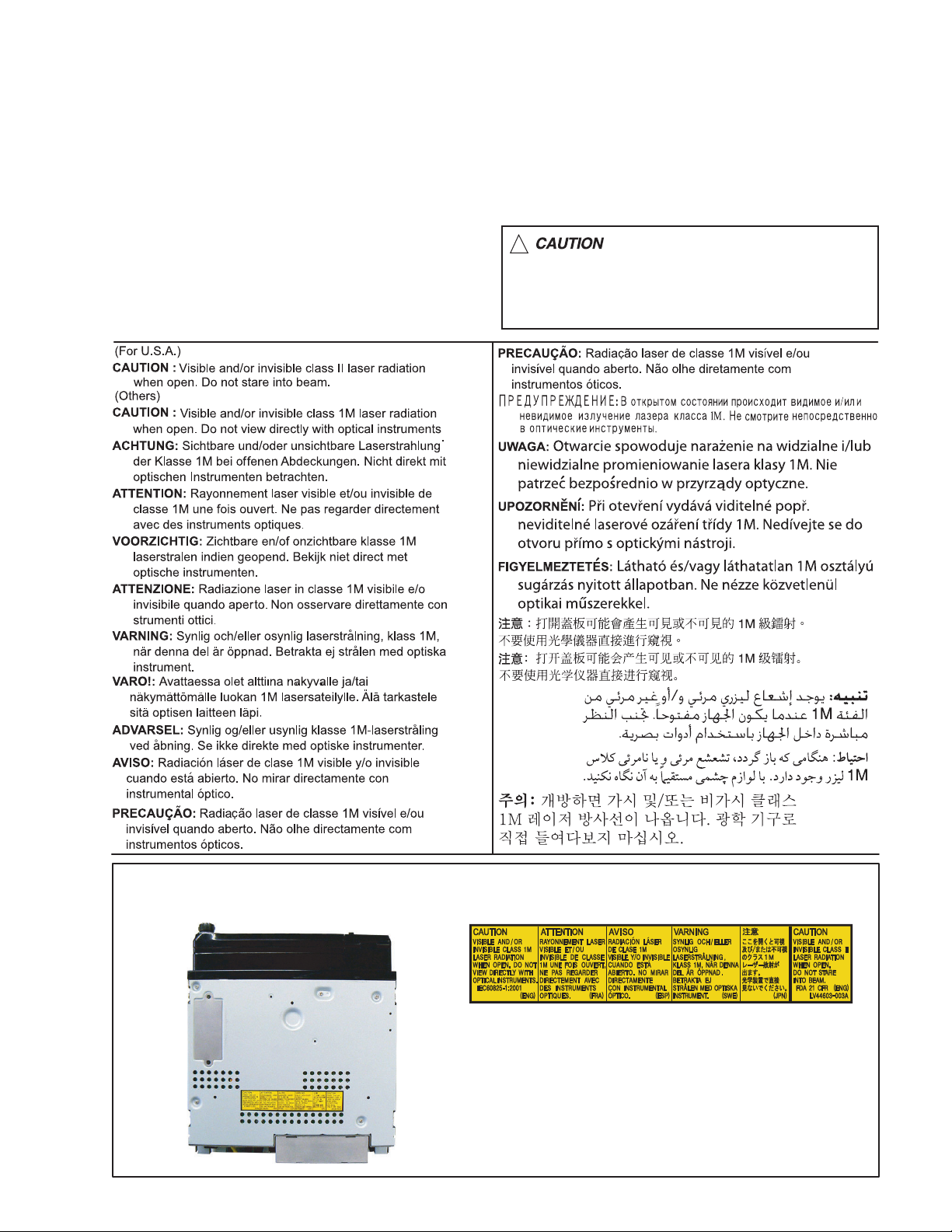

Block diagram

CON20

TOUCH

PANEL

TFT LCD

MODULE

LCD

MODULE

CON102

IL, OUTL, OUTR

D1,D101 to D103

LED

X+/-, Y+/-

TOUCH PANEL CTL.

VR, VG, VB

VCOM

CON10

STVL, STVR, MOD, OEV, OEH

STHL, STHR, CPH1 to 3, CKV, L/R

UD

CON2

CON4

LCD_R1 to R7, LCD_R17

LCD_C01 to C60

U11

AMP

U401

LCD BACKLIGHT

SW401 to SW404

KEY MATRIX

CCFL & monitor control section

U101

CCFL DRIVER

PWR_5V

SW101 to SW103,SW2

KEY MATRIX

U3

COM_OUT, DACOUT

TOSC_CLOCK, TOSC_CS, TOSC_DATA_IN, TOSC_DATA_OUT, TOSC_PEN_IRQ

U1,U12

Timing CTL

U20

LCD DRIVER

LCD_D5V

D401 to D404

LIGHTING

AD_KEY, AD_KEY1

Operate Key & Lighting

CCFL_POWER

ABRT, CCFL_EN

TFT section

D5V_SDA, D5V_SCL

PWR_D5V

CN401

CON1

AD_KEY1

4.43MHZ

CSY

IC7102

HD_OUT, VD_OUT

Y-GATE

HSYNC, VSYNC, MODE1, MODE2, NPC, RL

AD_KEY

AD_KEY1

ABRT

CON7404 CON5

Y1

VCOM-FRP

U4

VIDEO

DSP

RED-OUT, GREEN-OUT, BLUE-OUT, TB1318_CS

CVBS/CSYNC

SYNC

SCK

SDA

RIN, GIN, BIN, FBKG

IC15

SYNC SEPARATE

U10

CCFL_EN

OSD

TFT_SCL, TFT_SDA

TFL_CTL

LED_ABRT

DISPLAY DRIVE UNIT

A.VCC7V5

LCD_CTL_5V

KEY_PWR_5V

CON1

Q8

A.VCC7V5 REG

D14V

T3V3

IC6

T3V3 REG

T5V

Q1

Q10,Q11

5V REG

D5V

IC5

T5V

Q5,Q7

T5V REG

D14V

to IC28

I2C_SDA_TO_FM/AM, I2C_SCL_TO_FM/AM

TUNER_SSTOP, TUNER_AFS, LEVEL(FSU)

to IC48

SYNC_DET

V_M_SDA, V_M_SCL

DVD_RED_S(Y/R/V)

DVD_GREEN_S(CVBS/G/Y)

DVD_BLUE_S(C/B/U)

DVD_CVBS(CVBS/C)

DVD_REDS_TO_TFT

DVD_GREENS_TO_TFT

DVD_BLUES_TO_TFT

DVD_CVBS_TO_TFT

to IC25

IC13

IC17

VIDEO

SW.

TU1

FM/AM TUNER

FM/AM_A_L_TO_ASP

FM/AM_A_R_TO_ASP

IPOD_POWOR_ON

UART_TR_TO_IPOD

IPOD_AUDIO_LCH_TO_ASP

IPOD_AUDIO_RCH_TO_ASP

IPOD_VIDEO_S

CAMERA_VIDEO_S, EXTRA_VIDEO_S, REAR_VIDEO_OUT_1_CH

IR_REMOTE

REMOTE_RECEIVER

IC42,Q40

IPOD RECHANGE

/UART_RE_FROM_IPOD

DET_UNIT

OP AMP.

IC15

VIDEO AMP.

DET_BREAK BREAK

Q63

Q64

IPOD_RECHANGER_PWR

UART_RE_FROM_IPOD

Q33

Q34

IPOD_AUDIO_LCH

IPOD_AUDIO_RCH

IC8

IPOD_VIDEO_S_COMM

Q28

LINEATE_REMOTE

POWER_+B

CON8

OE REMOTE

ANT1

ANT

CON13

IPOD

CAMERA

VIDEO IN

VIDEO OUT

PARKING

CON6

AUX_AU_L_1

AUX IN

USB

AUX_AU_R_1

AUX In & USB Jack

CON14CON3

D+/-

SW509,D1,D2

EJECT_KEY1

EJECT SW/LED

SW1 to SW4,SW501 to SW503

KEY MATRIX

U501

REMOCON

EN501

REMOTE

POWER_KEY

ENCODER_A, ENCODER_B

ENCODER

D4 to D6,D11 to D14,Q1,Q2,Q4

POWER/DISC PORT LED

D510 to D514,D516 to D521

LIGHTING DISPLAY

DISC_MO_FIN

DISC_MO_RIN

LOADER_SW_4

LOADER_SW_5

INSERT_DISC_DET

DVD

traverse

mechanism

CON16

DVD section

A_SIGNAL to F_SIGNAL, CD_MD, DVD_MD

CD_LED_CTL, DVD_LED_CTL

FOCUS, TRACK, SPDL, SLED

MOTOR_5954_CS, FG, HOME_SW

DVD/CD_SWITCH, SIGNAL_GAIN, DVD_RF_SIGNAL

IC51

EEPROM

IC50

SDRAM

SD_DET, MPEG_CLK_TO_SD

MPEG_DATA_TO_SD_DATA-0 to 2

MPEG_DATA_TO_SD_CD/DATA-3

IC3

SD CARD

MPEG_DATA_TO_SD_CMD

DIGITAL_+5V

KEYI_SCAN_1

POWER_LED

DISC_DET

D5V

CON10

CON1

CON2

CON14

CON1

Control

panel

section

DISC_OPEN

IC4

DISC_CLOSE

MOTOR

DRIVER

MPEG_I2C_SCL_TO_D/A

MPEG_I2C_SDA_TO_D/A

[SDRAM_]

ADD:00 to 11, DATA:00 to 15

PCLK, DQML, BA0, BA1

CAS, RAS, CS, WE

27MHz

AUX_AU_L_1

AUX_AU_R_1

D+/-

Y3

DISC_EJECT

IR_REMOTE

KEYI_SCAN_1, UNIT_POWER_ON

ENCODER_A, ENCODER_B

POWER_LED_ON/OFF

DISC_PORT_LED_CTL

KEY_MCU_+5V

Q68,Q69

KEY MCU

+5V REG.

KEY_IN_DET

SW2

ST SW

RESET

SW1

RESET SW

MCU_RESET

MCU_RESET_DVD

[FLASH_]ADD:00 to 20, DATA:00 to 15

OE, WE, CE, CE_FLASH2, DOWN_CTL

IC48

DVD

SDIN1 to 3, MCLK, SCLK, LRCK

DA_DATA,DA_CS, DA_CLOCK

CPU

MCU_UART_RE

MCU_UART_TR

MCU_+5V

Q25,Q26

CON11 CON19

TFT_MOOTR_FIN

TFT_MOTOR_RIN

TFT_MOTOR_3

TFT_V_POSITION_SW

TFT_H_POSITION_SW

TFT_OPERATION_A

PHOTOTRANSISTOR_OUT

IC29

IC30

SHIFT

REG.

STROBE

DATA

CLOCK

Q20,Q35

RESET

MPEG_RESET

IC2,IC49,IC16

FLASH ROM

DVD_MAIN_AL,DVD_MAIN_AR

DVD_REAR_AL, DVD_REAR_AR, DVD_ACENT, DVD_ASUB

IC54

DAC

DAC_MUTE_DET

BUZ,Q21

BUZZER

TOSC_DATA_IN

TOSC_DATA_OUT

TOSC_PEN_IRQ

TOSC_CLOCK

TOSC_CS

I2C MULTIPLEXER

IC27

EEPROM

MAIN

Y1

8MHz

MCU_BEEPMPEG_BEEP

RDI

TDO

TFT_SDA

TFT_SCL

IC28

MCU_SDAI(I2C_SDA_TO_ASP)

MCU_SCLI(I2C_SCL_TO_ASP)

MUTE_REAR_AUDIO

MUTE_FRONT_AUDIO

System control section

IC25

DET_REVERSE

TEL_MUTE_DET

CPU

MPEG_1V8_CH_CTL

MCU_UPDATA_PWR_CTL

SERVO +3V3

SERVO +1V8

IC33,IC34

SERVO REG.

VPP/ICCSEL

Q41,Q42

VPP REG.

IC53

E.VOL

SEL_5.1_CHANNEL

FRONT_AUDIO_SRC_SEL1,2

PWR_IR_LED_CTL

+5V

LED PWR +5V

AUDIO 12V

AUDIO 12V

AUDIO N12V

FRONT_L

FRONT_R

ASP-6CH_FRONT_L

ASP-6CH_FRONT_R

ASP-6CH_SUBWOOFER

REAR_L, REAR_R

EXTRA_AU_LCH_TOASP

EXTRA_AU_RCH_TOASP

DAC_MUTE_DET_CONV

IR LED +5V

LED_ABRT

IR LED +5V REG.

LED PWR +5V REG.

IC7303,Q48,Q55,Q56

AUDIO +/-12V REG.

AUDIO_REAROUT_LCH

AUDIO_REAROUT_RCH

IC5

IC6

IC7

Q3

Q45

SEL

POWER_ON_CTL

+5V

POWER +12V

Q1,Q2

Q43,Q54

EXTRA_AU_LCH_TOMATRIX

EXTRA_AU_RCH_TOMATRIX

AUDIO_CENTER

AUDIO_SUBWOOFER

AUDIO_FRONT_L-CH

AUDIO_FRONT_R-CH

AUDIO_REAR_L-CH

AUDIO_REAR_R-CH

Q22,Q31,Q32,Q79,Q80

MUTE CTRL

AUTO_ANT_CTL

MUTE_POWER

POWER +12V/+5V REG.

SERVO +5V

DIGITAL +5V

+5V

Amplifier section

IC1

LINE IN AMP.

IC12,Q74,Q76 to Q78

REAR AMP/MUTE

REAR_LINE_OUT_MUTE

IC9 to IC11

Q7 to Q14

Q17,Q18,Q46,Q47

Q62,Q65,Q66

Q70,Q71,Q72

5.1ch AMP/MUTE

FRONT_LINE_OUT_MUTE

MUTE

POWER

IC41,Q49 to Q53

AUTO ANTENNA

Q29,Q30

MUTE

POWER REG.

IC31,IC32,Q36

DET_ILLUMI

AUDIO +9V

Q15

DIMMER

FAN_PWR_CTL

POWER+12V

AUDIO +9V REG.

MCU +5V

MCU +5V REG.

EXTRA_AUDIO_LCH

EXTRA_AUDIO_RCH

LINEOUT_LCH_REAR

LINEOUT_RCH_REAR

CENTER_5.1CH

SUBWOOFER_5.1CH

LCH_5.1CH_FRONT

RCH_5.1CH_FRONT

LCH_5.1CH_SUROUND

RCH_5.1CH_SUROUND

AUDIO_FRONT_LCH_TO_AMP

AUDIO_FRONT_RCH_TO_AMP

AUDIO_REAR_LCH_TO_AMP

AUDIO_REAR_RCH_TO_AMP

AMP_FRONT_LCH+/AMP_FRONT_RCH+/-

IC23

AMP_REAR_LCH+/AMP_REAR_RCH+/-

AMP.

P-ANT

P-CON

POWER +B

ACC_DET

Q37

IC18,Q38

Q27

ACC

Q4,Q5,Q24

FAN REG.

POWER +12V

POWER +B

POWER +B

ACC

ILLUMI

REVERSE

TEL-MUTE

FAN_PWR

LINE IN

REAR

LINE OUT

CON5

5.1CH

AUX OUT

FRONT

/REAR

SPEAKER

CON3

P.ANTENA

MEMORY

ACC

ILLUMI

REVERSE

REMOTE

M

FAN

MOTOR

2-1

Page 20

Standard schematic diagrams

Main section 1

NC

SD-CARD

12

13

DIGITAL_GND

JBUS_AU_L_TO_ASP

EXTRA_AU_LCH_TOMATRIX

IPOD_AUDIO_LCH_TO_ASP

JBUS_AU_R_TO_ASP

EXTRA_AU_RCH_TOMATRIX

IPOD_AUDIO_RCH_TO_ASP

AUX_AU_L_1

AUX_AU_VM

AUX_AU_R_1

DVD_MAIN_AL

DVD_MAIN_AL

DVD_MAIN_AR

DVD_MAIN_AR

10KR410KR510KR610KR710KR810K

100R

100R

R3

R57

R58

DVD-6CH_FRONT_L

DVD-6CH_FRONT_R

ASP/DVD-6CH_AUDIO_BUS

DVD_MAIN_AR_TO_ASP

DVD_MAIN_AL_TO_ASP

R473

SHELL

SHELL

SHELL

IC3

EXTRA_AU_LCH_TOASP

EXTRA_AU_RCH_TOASP

DVD_MAIN_AL_TO_ASP

DVD_MAIN_AR_TO_ASP

FM/AM_A_L_TO_ASP

FM/AM_A_R_TO_ASP

DVD_REAR_AL

DVD_REAR_AR

DVD-6CH_REAR_L

DVD-6CH_REAR_R

SD_CARD_WRITE_PRO

1011

9

8

7

6

5

4

3

2

1

C420

10pF

12

14

15

11

1

5

2

4

ANALOG_GND

10K

R75

DVD_ASUB

DVD_ACENT

DVD_MAIN_AL

OPEN

R51

DVD-6CH_CENTER

DVD-6CH_SUBWOOFER

C330

C419

10pF

10pF

6E7

IC5

1Y0

1Y1

1Y2

1Y3

2Y0

2Y1

2Y2

2Y3

8

C13

1nF

ANALOG_GND

DVD_REAR_AL

DVD_MAIN_AR

OPEN

OPEN

R9

R52

C281

10pF

DIGITAL_GND

GND16VCC

C148

TC116

TC98

DVD_REAR_AR

OPEN

R10

33pF/25V/NC

0.01uF/25V

ANALOG_GND

74HC4052

VEE

13

1Z

3

2Z

FRONT_AUDIO_SRC_SEL1

10

S0

9

S1

FRONT_AUDIO_SRC_SEL2

10nF

ANALOG_GND

105

C115

100uF/16V

C117

10uF/16V

105

C135

DVD_ASUB

DVD_ACENT

OPEN

OPEN

R11

R12

ANALOG_GND

DIGITAL_GND

C15

C14

DIGITAL_GND

R118

ZD36

105

C85

105

C86

105

C87

105

C112

105

C113

105

C114

105

ZD15

10V

DVD-6CH_AUDIO_BUS

SEL_5.1_CHANNEL

NC

R28

R29

R30

L28

IND-SMT-1210

R31

R32

C12

10uF/10V

ZD13

ZD14

10V

10V

ANALOG_GND

AUDIO_+9V

100uH

100K

R116

ANALOG_GND

470R

7V

IC53

1

SE3L

2

SE3R

3

SE2L

4

SE2R

5

SE1L

6

SE1R

7

DIFFL

8

DIFFG

9

DIFFR

10

CREF

TDA7418

R498

75R

75R

75R

75R

75R

100K

R117

R357

R358

10K

R450

SD_DET

DATA_2

DATA_1

DATA_0

DIGITAL_GND

SD_CLK

SERVO_+3V3

DIGITAL_GND

SD_CMD

CD/DATA_3

EXTRA_AU_LCH_TOASP

EXTRA_AU_RCH_TOASP

MCU_UART_RE

ASP_+9V

ANALOG_GND

MUTE/MUXOUT

SEL_6CH_ASP/DVD

10K

OUTSW

4K7

OUTLF

OUTLR

OUTRR

OUTRF

R451

10K

VDD

SDA

SCL

GND

SD-CARD

DATA_1

SD_CMD

SD_CLK

DATA_0

DATA_2

CD/DATA_3

20

19

18

17

16

15

14

13

12

11

C

B

ANALOG_GND

R249

ASP_+9V

100uF/16V

ANALOG_GND

Q3

2N3904

B

R356

10K

C

E

Q45

2N3904

R425

R426

E

FB92

FB93

FB111

4K7

C118

TC106

FB87

FB89

FB90

DIGITAL_GND

105

600R

600R

600R

600R

600R

600R

B

C83

100pF

DIGITAL_GND

ANALOG_GND

470uH

IND-SMT-CD43

L4

10K

12K

ANALOG_GND

ASP/DVD-6CH_AUDIO_BUS

AUDIO_+9V

R16

R18

R20

R22

R24

R26

1K

R337

C

Q25

3904

E

FRONT_R

FRONT_L

ASP-6CH_REAR_L

ASP-6CH_FRONT_L

ASP-6CH_SUBWOOFER

DVD-6CH_REAR_L

DVD-6CH_FRONT_L

DVD-6CH_SUBWOOFER

ASP-6CH_REAR_R

ASP-6CH_FRONT_R

TP13

DVD-6CH_REAR_R

DVD-6CH_FRONT_R

DVD-6CH_CENTER

R355

75R

75R

75R

75R

75R

75R

DIGITAL_+5V

1K

R340

C

B

E

AUDIO_+9V

I2C_SDA_TO_ASP

I2C_SCL_TO_ASP

SOFT_MUTE

FRONT_L

REAR_L

REAR_R

FRONT_R

ASP-6CH_SUBWOOFER

74HC4053

ANALOG_GND

ANALOG_GND

74HC4053

AUDIO_SW_+9V

1K

MPEG_DATA_TO_SD_DATA-1

MPEG_DATA_TO_SD_CMD

MPEG_CLK_TO_SD

MPEG_DATA_TO_SD_DATA-0

MPEG_DATA_TO_SD_DATA-2

MPEG_DATA_TO_SD_CD/DATA-3

ANALOG_GND

RDI

Q26

3904

FRONT_L

REAR_L

FRONT_R

REAR_R

105-->10K

C8

105-->10K

C7

ANALOG_GND

6E7

IC6

12

13

12

13

VEE

1Y0

2

2Y0

5

3Y0

1Y1

1

2Y1

3

3Y1

GND16VCC

8

C5

1uF/25V

6E7

IC7

VEE

1Y0

2

2Y0

5

3Y0

1Y1

1

2Y1

3

3Y1

GND16VCC

AUDIO_SW_+9V

8

ANALOG_GND

ANALOG_GND

R362

R361

R360

R359

R363

R364

R365

R366

100K-->0R

100K-->0R

OPEN-->12K

OPEN-->12K

R429

R430

ANALOG_GND

14

1Z

15

2Z

4

3Z

11

S1

10

S2

9

S3

C3

0.001uF/25V

AUDIO_SW_+9V

ANALOG_GND

14

1Z

15

2Z

4

3Z

11

S1

10

S2

9

S3

C4

0.001uF/25V

C6

TC2

10uF/16V

1uF/25V

TAN-TYPE-B

SD_BUS

12K

12K

12K

12K

10K

10K

10K

10K

R162

R161

ANALOG_GND

SEL_6CH_ASP/DVD

ANALOG_GND

SEL_6CH_ASP/DVD

SERVO_+3V3

R392

10K

DATA_2

ASP-6CH_FRONT_L

ASP-6CH_REAR_L

ASP-6CH_FRONT_R

ASP-6CH_REAR_R

ASP-6CH_FRONT_L

ASP-6CH_REAR_L

ASP-6CH_FRONT_R

ASP-6CH_REAR_R

NC/100K

R13

R15

ANALOG_GND

10K

NC/100K

R352

R14

ANALOG_GND

10K

R401

R402

R431

10K

10K

47K

DATA_1

DATA_0

SD_CLK

ASP/DVD-6CH_AUDIO_BUS

AUDIO_REAROUT_RCH

AUDIO_REAROUT_LCH

NC/100K

NC/100K

R318

R351

NC/100K

NC/100K

R353

R354

R432

R439

10K

10K

SD_CMD

CD/DATA_3

SD-CARD

AUDIO_BUS

AUDIO_REAR_L-CH

AUDIO_FRONT_L-CH

AUDIO_SUBWOOFER

AUDIO_REAR_R-CH

AUDIO_FRONT_R-CH

AUDIO_CENTER

AUDIO_BUS

AUDIO_FRONT_L-CH

AUDIO_REAR_L-CH

AUDIO_FRONT_R-CH

AUDIO_REAR_R-CH

AUDIO_SUBWOOFER

AUDIO_CENTER

E

C

SC3265

Q18

B

E

C

R87

AMPLIFIER

+

-

TC19

C56

R102

AMPLIFIER

+

-

TC25

C64

R371

AMPLIFIER

+

-

TC31

C74

+

-

+

-

+

-

0R/NC

R93

470R

8

VDD+

7

2OUT

6

2IN-

5

2IN+

ANALOG_GND

0R/NC

R369

470R

8

VDD+

7

2OUT

6

2IN-

5

2IN+

ANALOG_GND

0R/NC

R405

470R

8

VDD+

7

2OUT

6

2IN-

5

2IN+

ANALOG_GND

C

AMP_V_FP

E

C

AMP_V_FP

E

C

AMP_V_FP

TC18

C55

TC24

C63

TC30

C73

SC3265

SC3265

SC3265

B

Q9

C57

3K9

R62

E

B

Q13

C65

3K9

R96

E

B

Q66

C75

3K9

R95

100uF/16V-->NC

1uF/25V

120pF/25V

B

R370

R105

100uF/16V-->NC

1uF/25V

B

100uF/16V

1uF/25V

120pF/25V

AUDIO_FRONT_LCH_TO_AMP

TC23

10uF/16V

IC9

1

30K

10uF/16V

ANALOG_GND

10uF/16V

10uF/16V

ANALOG_GND

10uF/16V

10uF/16V

ANALOG_GND

10uF/16V

R86

R66

C59

1.5nF/25V

R101

R100

C67

1.5nF/25V

R115

R113

C77

1.5nF/25V

C58

C66

C76

TC22

TC20

TC28

TC26

TC34

TC32

1.5nF/25V

1.5nF/25V

1.5nF/25V

3K9

30K

3K9

30K

3K9

C60

ANALOG_GND

AMP_V_FN

ANALOG_GND

TC29

C68

ANALOG_GND

AMP_V_FN

ANALOG_GND

TC35

C78

ANALOG_GND

AMP_V_FN

ANALOG_GND

120pF/25V

100uF/16V-->NC

1uF/25V

AUDIO_FRONT_RCH_TO_AMP

10uF/16V

120pF/25V

100uF/16V-->NC

1uF/25V

10uF/16V

120pF/25V

100uF/16V

1uF/25V

1OUT

2

1IN-

3

1IN+

4

VDD-

IC11

1

1OUT

2

1IN-

3

1IN+

4

VDD-

IC10

1

1OUT

2

1IN-

3

1IN+

4

VDD-

R94

R90

C62

R88

C

SC3265

Q65

C70

R103

120pF/25V

C

SC3265

Q72

R406

R390

C120

R372

ANALOG_GND

4K7

4K7

0.01uF/25V

20K

C71

0.01uF/25V

ANALOG_GND

TC21

30K

AUDIO_REAR_LCH_TO_AMP

R63

ANALOG_GND

4K7

4K7

0.01uF/25V

20K

C125

0.01uF/25V

ANALOG_GND

TC27

30K

AUDIO_REAR_RCH_TO_AMP

R97

ANALOG_GND

4K7

4K7

0.01uF/25V

20K

C121

0.01uF/25V

ANALOG_GND

TC33

30K

R110

10uF/16V

10uF/16V

10uF/16V

ANALOG_GND

LCH_5.1CH_FRONT

ANALOG_GND

R64

ANALOG_GND

RCH_5.1CH_FRONT

ANALOG_GND

R98

ANALOG_GND

SUBWOOFER_5.1CH

ANALOG_GND

R111

C

E

E

0R/NC

C

R92

470R

R

ANALOG_GND

0R/NC

R368

470R

ANALOG_GND

C

E

E

0R/NC

R404

470R

ANALOG_GND

SC3265

20K

C

E

SC3265

E

C

20K

SC3265

20K

ANALOG_GND

B

Q17

SC3265

B

Q7

C

C72

R65

0.01uF/25V

ANALOG_GND

ANALOG_GND

B

Q62

SC3265

B

Q11

C126

R99

0.01uF/25V

ANALOG_GND

ANALOG_GND

B

Q71

SC3265

B

Q46

C122

R112

0.01uF/25V

ANALOG_GND

R91

R89

0.01uF/25V

LCH_5.1CH_SUROUND

R367

R104

0.01uF/25V

RCH_5.1CH_SUROUND

R397

R373

0.01uF/25V

CENTER_5.1CH

Q10

KRA304

4K7

ANALOG_GND

KRA304

4K7

C61

ANALOG_GND

R

ANALOG_GND

Q14

KRA304

4K7

ANALOG_GND

KRA304

4K7

C69

ANALOG_GND

ANALOG_GND

Q70

KRA304

4K7

ANALOG_GND

KRA304

4K7

C119

ANALOG_GND

ANALOG_GND

AMP_V_FN AUDIO_N12V

L27

L42

FRONT_LINE_OUT_MUTE

Q8

FRONT_LINE_OUT_MUTE

FRONT_LINE_OUT_MUTE

Q12

FRONT_LINE_OUT_MUTE

FRONT_LINE_OUT_MUTE

Q47

FRONT_LINE_OUT_MUTE

AUDIO_12VAMP_V_FP

470uH

470uH

2-2

Page 21

Main section 2

FB23

C/B/U

FB26

Y/R/V

CVBS/G/Y

CVBS/C

EXTRA_V_CVBS_DET

EXTRA_VIDEO_S

IPOD_VIDEO_S

CAMERA_VIDEO_S

FB28

FB29

R152

DVD_CVBS

AMP_GND

47uF/16V

0.47uF/50V

ANALOG_GND

Q23

KRC402(NC)

SEL_5.1_CHANNEL

SOD-106

SOD-106

1N4004

D44

D45

AMP_FRONT_LCH-

1u/50V

C240

FAN_PWR_FRONT

IC4

LB1641

1

GND

2

VOUT1

3

12

VZ1

C16

4

VR

R34

5

IN1

R33

6

IN2

7

VCC1

8

VCC2

9

VZ2

10

VOUT2

ANALOG_GND

ANALOG_GND

TC38

R193

47uF/16V-->10uF/16V

ANALOG_GND

1K

20K

R192

R257

ANALOG_GND

SOD-106

SOD-106

SOD-106

SOD-106

SOD-106

1N4004

AMP_FRONT_LCH+

1N4004

1N4004

D42

D43

AMP_FRONT_RCH+

AMP_FRONT_RCH-

ILLUMI

TEL-MUTE

POWER_+BGND

1N4004

1N4004

D40

D41

AMP_REAR_LCH-

REVERSE

D39

AMP_REAR_LCH+

AMP_FRONT_RCH+

56

78

910

11 12

13 14

15 16

AMP_REAR_RCH+

P-CON

P-ANT

PWR_CON_DEFINE_BUS

470uH

L6

IND-SMT-1210

ACC

MOTOR_GND

103

1K

1K

103

103

12

12

C17

C184

2

103

1

C116

POWER_+12V

470uH

L53

MOTOR_GND

R261

5K6-->12K

POWER_+12V

R191

2N3904

Q22

4K7-->1K

23

R190

1

10K-->NC

MUTE_AMP

AMP_GND

SOD-106

1N4004

1N4004

D38

AMP_REAR_RCH+

AMP_REAR_RCH-

AMP_FRONT_LCH-

AMP_FRONT_LCH+

AMP_FRONT_RCH-

CON3

CON-PWR

12

34

AMP_REAR_LCH-

AMP_REAR_LCH+

AMP_REAR_RCH-

DISC_MO_FIN

DISC_OPEN

DISC_CLOSE

DISC_MO_RIN

IND-SMT-1210

MUTE_POWER

47K

SERVO_GND

1K5

CON19

54

CON-SMT-52PIN

GND

ZD6

4V7

12

12

103

C185

R128

0.1uF/25V

C186

TC117

100uF/16V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

300R

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

5253

PHOTOTRANSISTOR_OUT

TFT_OPERATION_A

TFT_V_POSITION_SW

1K8

1K8

1K8

FB63

FB65

FB74

1234567891011

CON11

C154

C155

C156

0.01uF/25V

AMP_FRONT_RCH-

VCC

6

VCC

20

S-GND

13

IC23

47pF/25V

R187

47pF/25V

R186

SERVO_GND

20K

1K

C32

1uF/25V

SERVO_GND

IND-SMT-1210

15uH

24

23

22

21

20

19

18

17

16

SERVO_GND

R70

R132

0.01uF/25V

AMP_FRONT_LCH+

AMP_FRONT_LCH-

AMP_REAR_RCH+

AMP_FRONT_RCH+

8

9

OUT1+

P-GND1

IN112IN2

11

TC51

R182

100K

AUDIO_FRONT_RCH_TO_AMP

AMP_AUDIO_BUS

IND-SMT-1210

L5

15uH

TC3

22uF/6V3

ECAP-SMT-4.0

VIDEO_+5V

R G B

VIDEO_SW+5V

220R

220R

7

OUT1-

0.33uF/50V

C11

600R

75R 1%

R114

600R

75R 1%

R133

600R

75R 1%

R149

600R

75R 1%

R164

680R

SERVO_GND

75R

75R

75R

75R

R301

R323

R325

75R

75R

75R

SERVO_GND

L1

IND-SMT-0805

C9

150P

SERVO_GND

C30

L2

IND-SMT-0805

C29

150P

SERVO_GND

C40

L3

IND-SMT-0805

C39

150P

SERVO_GND

C47

L8

IND-SMT-0805

C46

150P

SERVO_GND

C27

1uF/25V

C28

680pF/25V

SERVO_GND SERVO_GND

DVD_RED_S

10uF/10V

DVD_GREEN_S

10uF/10V

DVD_BLUE_S

10uF/10V

DVD_RGB_BUS

R140

10uF/10V

R296

10uF/10V

R297

10uF/10V

R299

10uF/25V

75R

R135

75R-->NC

SERVO_GND

11P

1.1uH

11P

1.1uH

11P

1.1uH

11P

1.1uH

220K

C38

2.2nF/25V

C22

C133

C134

C44

C145

C146

C200

C21

75R 1%

160P

R122

C31

75R 1%

160P

R134

C41

75R 1%

160P

R150

C48

75R 1%

160P

R165

18K

VIDEO_SW+5V

D33

1N4148

R108

R136

SERVO_GND

10uF/25V

D59

1N4148

SERVO_GND

DVD_BLUE_S

DVD_RED_S

DVD_GREEN_S

DVD_CVBS

R148

IC13

1

VIN

2

HD-OUT

4

PD-OUT

5

HOSC-R

BA7071F

100K

R131

C53

VIDEO_SW+5V

R151

R167

SYNC-OUT

IC17

FMS6502

1

2

3

4

5

6

7

9

11

13

15

1K

1K

AMP_GND

ANALOG_GND

C42

C33

VD-OUT

VCC

GND

VIDEO_SW+5V

C79

1uF/25V

IN1

GND

IN2

VDD

IN3

GND

IN4

IN5

IN6

IN7

IN8

C153

0.1uF/25V

0.47uF/25V

0.47uF/25V

C84

1uF/25V

ADDR1

8

R169

1K(NC)

POWER_+B

ANALOG_GND

C150

100K(NC)

C149

100K(NC)

8

R126

7

R125

6

3

SERVO_GND

L49

TC114

47uF/6V3

ECAP-SMT-6.5

SERVO_GND

ADDR0

SCL

10

12

R168

C141

10pF/25V

1K(NC)

AMP_FRONT_RCH+

TP45

TP44

GND

OUT1

OUT2

OUT3

VDD

OUT4

OUT5

OUT6

GND

SDA

14

C23

10pF/25V

SERVO_GND

0.01uF/25V

0.01uF/25V

AMP_REAR_RCH-

AMP_REAR_LCH+

AMP_REAR_LCH-

AMP_REAR_RCH-

AMP_REAR_RCH+

AMP_FRONT_RCH-

2

3

5

17

OUT2-

OUT2+

OUT3+

P-GND2

TC52

0.33uF/50V

R183

100K

AUDIO_REAR_RCH_TO_AMP

SYNC_DET

DIGITAL_+5V

10uF/10V

C165

10uF/10V

C147

10uF/10V

C142

C50

75R/10uF/10V

C166

10uF/10V

C191

10uF/10V

V_M_SCL

V_M_SDA

C157

AMP_REAR

_LCH+

AMP_FRONT_LCH-

AMP_FRONT_LCH+

18

19

21

23

24

OUT3-

OUT4-

OUT4+

P-GND3

P-GND4

AC-GND

ST-BY

IN4

IN3

4

14

15

TC53

TC54

0.33uF/50V

0.33uF/50V

R184

R185

100K

100K

ANALOG_GND

AUDIO_FRONT_LCH_TO_AMP

AUDIO_REAR_LCH_TO_AMP

DVD_REDS_TO_TFT

DVD_GREENS_TO_TFT

DVD_BLUES_TO_TFT

CVBS_TO_TFT

REAR_CVBS

EXTRA_V_CVBS_DET

R123

AMP_AUDIO_OUT_BUS

AMP_REAR_LCH-

TP43

TP42

TP41

TP40

TP38

TP39

TAB

1

HSD

25

TC56

SVR

10

TC55

16

MUTE

22

TDA7560

C159

C158

C152

47pF/25V

100K(NC)

R189

47pF/25V

C151

R188

100K(NC)

AMP_GND

1uF/25V

1uF/25V

MOTOR_GND

300R

300R

300R

300R

FB12

R160

TFT_MOTOR_FIN

TFT_MOTOR_RIN

TFT_H_POSITION_SW

1K8

1K8

1K8

FB84

FB85

FB91

TESTPOINT-1

FB49

600R

600R

600R

600R

FB7

FB9

R157

FB10

R159

NC

DIGITAL_+5V

TFT_MOTOR_3

TP5

FAN_PWR

1

300R

1

ACCOM1

ACCOM

3

C161

0.01uF/25V

SERVO_GND

TOSC_DATA_IN

TOSC_DATA_OUT

LED_ABRT

TOSC_CS

TFT15V

TOSC_PEN_IRQ

LED_PWR_+5V

DIGITAL_GND

ABRT_PWM

POWER_+12V

SELECT-TELEPHONE

RX_BT

TX_BT

BT_POWER_CTL

BT_AUDIO_R_+

BT_AUDIO_R_-

BT-5V

BT_AUDIO_L_+

BT_AUDIO_L_-

NC

MIC-

BT_AGND

MIC+

CCFL_GND

100uH

FAN_PWR

FB48

Q24

KTD1624-->KTC2020D

GND

DVD_REDS_TO_TFT

DVD_GREENS_TO_TFT

DVD_BLUES_TO_TFT

CVBS_TO_TFT

TB1318_CS

KEY_SCAN_2

KEY_SCAN_REF_GND

TFT_SCL

TFT_SDA

I2C_SCL_TO_LCD

I2C_SDA_TO_LCD

TOSC_CLOCK

C37

100nF

TFTN10V

POWER_+12V

1

R194

ZD7

12V

DIGITAL_+5V

SERVO_GND

DIGITAL_+5V

TESTPOINT-1

TP7

C162

0.01uF/25V

TC6

220uF/6V3

ANALOG_GND

300R

DIGITAL_GND

R195

FU7

!

21

CON-SMT-19PIN-A

CON5

14

SHELL

SHELL

CON-SMT-12PIN

CON6

17

SHELL

SHELL

CON-SMT-15PIN

CON14

SHELL

SHELL

POWER_+12V

0R-->NC

FUSE-1206

0.2A

1

2

3

4

5

6

7

8

9

10

11

1213

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1516

FAN_PWR_CTL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1920

GND12

TP32

FB66

!

FB20

FB21

FB22

FB24

FB25

FB27

1K8

FB5

TP33

TP34

TP35

TP36

33p

FB69

33p

FB70

33p

FB71

33p

FB72

33p

FB73

33p

FB4

12

!

FU5

TP4

600R

FB13

600R

FB6

EX_VGND

FB8

600R

12

FUSE

FU3

!

FB15

12

FU4

!

1K8

FB16

600R

12

FU1

FB68

104

R289

FUSE

600R

R290

C10

R155

R156

C422

C423

C424

C425

C426

C1

FUSE

FB47

FB14

FB31

1K8

FUSE

30K

1

10K

KEY_MCU_+5V

LED_PWR_+5V

KEY_SCAN_REF_GND

1K8

DIGITAL_GND

1K8

1K8

POWER_LED_ON/OFF

1K8

1K8

1K8

DISC_PORT_LED_CTL

DIGITAL_GND

600R

R291

600R

R292

600R

R293

600R

R294

600R

R295

600R

R83

SERVO_GND

REAR_VIDEO_OUT_1_CH

EXTRA_VIDEO_S

CAMERA_VIDEO_S

1K

1K

R287

R288

100R

100R

300R

0.01uF/25V

C160

TC57

100uF/16V

1uF/25V

C106

6

4

TC58

100uF/16V

FB51

FB52

FB53

FB54

FB17

100R-->NC

0R

TP16

TP17

TP18

TP31

TP37

TP46

TP47

TP48

TP49

R

R166

TP50

TP51

TP52

TP53

L31

IND-SMT-CD75

2N3906

Q4

TRANS-PNP

R154

470R

23

GND

KEY_SCAN_1

ENCODER_A

ENCODER_B

UNIT_POWER_ON

IR_REMOTE

1K

SERVO_GND

R505

100R

100R

R342

4R7

FAN_PWR_FRONT

GND

Q5

2N3904

KEY_CON_BUS

10R

10R

10R

10R

10R

10R

ANALOG_GND

1K

ANALOG_GND

EXTRA_AUDIO_LCH

EXTRA_AUDIO_RCH

C43

1uF/25V

LCH_5.1CH_FRONT

RCH_5.1CH_FRONT

LCH_5.1CH_SUROUND

RCH_5.1CH_SUROUND

SUBWOOFER_5.1CH

CENTER_5.1CH

SERVO_GND

ZD4

SOD-323

5V6

LINEOUT_LCH_REAR

LINEOUT_RCH_REAR

EXTRA_AUDIO_VM

BRAKE

SERVO_GND

KEY_MCU_+5V

GND

POWER_+12V

22K

1213

SHELL14SHELL

GND

CON-SMT-12PIN

DC_DC_GND

LINEATE_REMOTE

R73

R74

2K2

R61

SOD-323

6V2(NC)

GND

FB33

270R

ZD45

GND

CON-SMT-2PIN

23

1K

SHELL

1

SHELL

CON8

4

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-3

Page 22

Main section 3

POWER_+B

TP27

GND

D24

SOD-SS33A

TC78

C212

1N5404SOD-SS33A

6800uF/20V

GNDGND

TP11

ANALOG_GND

SHELL_GND

0.01uF/25V-->NC

C224

DIGITAL_GND

C392

SHELL_GND_4

1uF/25V

GND14

GND

GND

0.01uF/25V

1N5404

SHELL_GND_2

JP20

JUMP

FM/AM_GND

D23

TP28

SHELL_GND_2 SHELL_GND_3

JUMP

JUMP

JUMP

JUMP

JUMP

JUMP

JUMP

JUMP

0.01uF/25V

C382

JP18

JP1

JP2

JP3

JP5

JP6

JP8

JP9

0.01uF/25V

C24

AMP_GND

C391

0.01uF/25V-->NC

C383

SERVO_GND

0.01uF/25V

SERVO_GND

CON_GND

ANALOG_GND

CCFL_GND

DIGITAL_GND

AMP_GND

FM/AM_GND

MOTOR_GND

TP9

0R/1206

C384

C389

GND

POWER_ON_CTL

0.01uF/25V

E

C215

0.01uF/25V

DC_DC_GND

C414

0.01uF/25V

C412

47pF/25V

V_TEST

C413

4.7nF/25V

TC4

47uF/16V

DIGITAL_GNDDIGITAL_GND

DC_DC_GND

7K5

R17

C49

22uF/25V

DIGITAL_GND

DC_DC_GND

IC18

31

XC6202P502PR

2

DIGITAL_GND

JUMP

JUMP

JUMP

+5V

TP20

TC68

TC69

470uF/6V3

470uF/6V3

C201

22uF/16V

100uF/10V

3K3(1%)

R306

1K(1%)

DC_DC_GND

R307

TC67

DIGITAL_GND

JP26

JP27

JP28

C428

104

C143

10uF/16V

MCU_+5V

TP26

470uH

L24

C205

0.01uF/25V

DIGITAL_GND

SHELL_GND

FOR RDS NC

C223

RDS_QUAL

RDS_DAT

DIGITAL_GND

MPX_TO_RDS

RDS_+5V

470R(NC)

10uF/16V(NC)

10e??(NC)

560pF/25V(NC)

22nF/25V(NC)

R327

TC73

C221

R452

C377

DIGITAL_GND

TP12

IC36

1

2

3

4

5

6

7

8

TDA7479

QUAL

RDDA

VREF

MPX

OSEL

GND

ARI

FILOUT

RDCL

OSCOUT

OSCIN

EXTRES

FSEL

16

1K(NC)

10e??(NC)

C219

TC93

R326

TP2

0.022uF/25V(NC)

100uF/6V3(NC)

15

T57

14

13

12

VS

11

10

TM

9

R324

RDS_CLK

100K(NC)

R328

RDS_+5V

DIGITAL_GND

4.332M(NC)

Y2

22pF/25V(+-0.25)(NC)

C222

22pF/25V(+-0.25)(NC)

0R(NC)

R329

DIGITAL_GND

POWER_+12V

470R

R310

TC79

100uF/16V

POWER_+B

GND

TP21

1

ZD11

ZDIODE-REF

23

TLC431

ANALOG_GND

R302

R303

R304

Q37

KTC2020D

0R

0R

180K

C213

0.01uF/25V

1

2

3

4

4K7

R305

39K

R311

15K

R312

ANALOG_GND

POWER_+12V

5

S

D

6

S

D

7

S

D

8

G

D

IRF7205

IC31

Q36

KRC402

TP25

ANALOG_GND

TC65

100uF/16V

TC80

100uF/16V

TP19

GND

AUDIO_+9V

TC46

100uF/16V

GND

C214

1uF/25V

DC_DC_GND

22uH

L13

CDH_8B28

1uF/25V

POWER_+B

D31

SOD-214AC

C45

22uF/25V

C416

SK34

SOD-106

1N4004

TC99

100uF/16V

DC_DC_GND

22uF/25V

B+_PWR

D55

470R

JUMP

JUMP

JUMP

R285

JP23

JP24

JP25

TP55

SERVO_GND

L48

IC32

C397

3

SW

0.01uF/25V

1

BS

2

IN

4

C36

0.1uF/25V

GND

MPS1423

C199

ZD12

18V

CDH_8B28

22uH

COMP

Q38

KTD1624C

C

B

DIGITAL_GND

8

SS

7

EN

5

FB

6

DC_DC_GND

JP29

JUMP

0.01uF/25V-->NC

C276

DC_DC_GND

DIGITAL_GND

MPEG_1V8_CH_CTL

+5V

IND-SMT-CD75

L16

L15

IND-SMT-CD75

JP15

JUMP

C385

GND

L17

IND-SMT-CD75

0.01uF/25V-->NC

100uH

100uH

100uH

4.7K-->NC

R440

R443

MOTOR_+5V

TC70

220uF/6V3

SERVO_GND

C202

22uF/16V

DIGITAL_GND

TC71

470uF/6V3

+5V

L19

100uH

22uF/16V

C203

22uF/16V

SERVO_GND

L18

IND-SMT-CD75

IND-SMT-CD75

D21

1N4004

1N4004

D1

C206

1K

TP22

SERVO_+5V

100uH

DIGITAL_+5V

22R---->NC

Q58

2N3904---->NC

IC33

32

LDO

1

C204

22uF/16V

SERVO_GND

IC34

32

R438

SERVO_GND

LDO

1

120R---->NC

R437

SERVO_GNDSERVO_GND

10R---->NC

TP23

TP24

R433

R435

330R/100R---->0R

R436

220R---->NC

SERVO_GND

SERVO_+3V3

100R

R308

SERVO_GND

SERVO_+1V8

100R

R309

C211

22uF/16V

C332

22uF/16V

NC

FM/AM_+9V

2

0R

0R

1

0R

0R

FM/AM_+9V

C227

0.22uF/25V

FM/AM_GND

ANT1

ESD1

12

ESD

JP12

JUMP

R601

R602

R330

R331

FM/AM_+5V

C226

C228

1uF/25V

1uF/25V

FM/AM_GND

FM/AM_GND

FM-AM-TUNER1 TU1

1

FM/AM-ANT

2

NC

3

NC

4

RF-GND-1

5

8V5

6

RF-GND-2

7

5V

8

SW-FLAG

9

FSU-LEVEL

10

VCC-8V5

11

ADJ-CH

12

AMST/MP

13

SSTOP

14

QUALY-OUT

15

AFS

16

VT-TEST

17

MPXW

18

MPX

19

R-CH

20

L-CH

21

GND

22

SDA

23

SCL24SHELL

FST-TDA7540-N

SHELL

SHELL

SHELL

POWER_+B MCU_+5V

100K 1206

D11

1N4148

R130

POWER_H/L_DET

27K 1%

C26

D10

0.01uF/25V

DIGITAL_GND

VPP/ICCSEL

Q41

2N3906

1N4148

C234

103

DIGITAL_GND

CE

47K

R345

B

Q42

KRC402

C

B

MCU_UPDATA_PWR_CTL

E

100K

R346

C233

22uF/16V

DIGITAL_GND

R465

DIGITAL_GND

27

26

25

FM/AM_GND

AUDIO_12V

DIGITAL_GND

GND

FM/AM_GND

TP3

AUDIO_+9V

DIGITAL_+5V

L26

100uH

IND-SMT-CD43

100uH

L20

IND-SMT-1210

L21

100uH

IND-SMT-1210

L22

100uH

IND-SMT-CD54

L23

IND-SMT-1210

100uH

TP29

TC83

100uF/6V3

FM/AM_GND

TC74

47uF/6V3

DIGITAL_GND

TC75

10uF/16V

TC76

220uF/6V3

TC77

22uF/6V3

C229

1uF/25V

C208

1uF/25V

C209

1uF/25V

FM/AM_GND

C210

104

SERVO_GND

FM/AM_+9V

RDS_+5V

FM/AM_+5V

VIDEO_+5V

DA_A_+5V

TUNER_SSTOP

TUNER_AFS

FM/AM_+5V

FM/AM_GND

R333

R335

10K

10K

R334

FM/AM_A_R_TO_ASP

FM/AM_A_L_TO_ASP

10K

I2C_SDA_TO_FM/AM

I2C_SCL_TO_FM/AM

FM/AM_GND

FM/AM_GND

MPX_TO_RDS

ANALOG_GND

FM/AM_GND

FM/AM_GND

FM/AM_+9V

FM/AM_GND

FM/AM_+5V

LEVEL(FSU)

FM/AM_+9V

C403NCC411

FM/AM_GND

ANALOG_GND

2-4

Page 23

Main section 4

AUDIO_REAROUT_RCH

AUDIO_REAROUT_LCH

POWER_ON_CTL

R376

AMP_V_R AUDIO_+9V

AMP_V-REF_R

E

C

SC3265

Q78

B

R424

TC113

10uF/16V

120pF/25V

TC92

TC91

B

1

2

3

4

TC109

1uF/25V

IC12

1OUT

1IN-

1IN+

VDD-

POWER_+B

R375

270K-->27K-->22K

2

C

E

3

TC112

ANALOG_GND

TC110

1K

R378

GND

R412

R411

C129

1.5nF/25V

RES2010

C128

10uF/16V

10uF/16V

Q52

2N3904

1

B

10K

10K

R377

GND

C130

3K9

ANALOG_GND

AMP_V-REF_R

ANALOG_GND

1.5nF/25V

C247

0.1uF/25V

CE

Q51

1uF/50V

CE

Q50

3.3uF/50V

22K

R380

RES2010

1K

R379

B

2K2

R374

2N3906

B

D26

1N4148

47K

KTA2014

100R

R413

AMPLIFIER

+

-

100uF/16V

C124

Q49

KTA1718D

CE

+

-

8

VDD+

7

2OUT

6

2IN-

5

2IN+

ANALOG_GND

180K

R382

AMP_V_R

R383

DIGITAL_+5V

R414

TC108

100uF/16V

1uF/25V

C123

120pF/25V

C127

3K9

R407

4K7

C248

4

G

3

S

2

S

1

S

IC41

IRF7205

R389

D27

1N4004

1N4004

D28

C132

Q53

2N3904

2

C3E

1nF/25V

D

D

D

D

NC

0.01uF/25V

TC111

270K-->27K-->22K

R408

1

B

8

7

6

5

4K7

R381

GND

ANALOG_GND

3K3

20K

ANALOG_GND

10K

10uF/16V

R385

D29

P-CON

ANALOG_GND

LINEOUT_RCH_REAR

R409

10K

NC

1N4004

1N4004

D30

C

E

100R

ANALOG_GND

R387

R386

GND

4K7

R388

GND

ANALOG_GND

B

Q77

SC3265

20K

R410

R421

C131

0.01uF/25V

LINEOUT_LCH_REAR

AUTO_ANT_CTL

POWER_ON_CTL

P-ANT

3K3

Q76

KRA304

KRA304

ANALOG_GND

ANALOG_GND

Q74

ANALOG_GND

LINEATE_REMOTE

JBUS-AUDIO-L

JBUS-AUDIO-VM

JBUS-AUDIO-R

REAR_LINE_OUT_MUTE

EXTRA_AUDIO_LCH

EXTRA_AUDIO_VM

EXTRA_AUDIO_RCH

IR_REMOTE

REAR_LINE_OUT_MUTE

IPOD_AUDIO_LCH

IPOD_AUDIO_VM

IPOD_AUDIO_RCH

R82

10uF/16V

TC40

22uF/16V

TC41

TC42

10uF/16V

10K

C90

R141

0.01uF/25V

ANALOG_GND

10K

R54

10K

R40

ANALOG_GND

ANALOG_GND

D46

SOD-323

R504

1N4148

D47

SOD-323

1N4148

1K-->NC

ANALOG_GND

10uF/16V

100uF/16V

10uF/16V

10K

C432

R211

0.01uF/25V

10uF/16V

22uF/16V

10uF/16V

10K

C52

R80

0.01uF/25V

4K7-->47K

REMOTE_RECEIVER

ZD31

10V

R503

ZD32

10V

TC138

TC139

TC140

ANALOG_GND

TC10

TC11

TC12

ANALOG_GND

3

2

5

4

BA3121F

ZD35

10V

ANALOG_GND

ZD28

ZD29

10V

10V

ZD1

ZD2

10V

10V

MCU_+5V

47K(NC)

B

CE

R500

IC14

IN-1

IN-VM

IN-2

GND

ZD30

10V

ANALOG_GND

ZD3

10V

ANALOG_GND

2N3906

Q63

10K(NC)-->100K

1

3

2

5

4

BA3121F

3

2

5

4

BA3121F

OUT-VM

IC1

IN-1

IN-VM

IN-2

GND

IC8

IN-1

IN-VM

IN-2

GND

OUT-1

OUT-2

VCC

6

7

8

C82

0.01uF/25V

ANALOG_GND

TC37

OUT-1

OUT-VM

OUT-2

OUT-1

OUT-VM

OUT-2

VCC

VCC

R139

TC39

47uF/16V

10uF/16V

1

6

7

8

C429

0.01uF/25V

ANALOG_GND

1

6

7

8

C51

0.01uF/25V

ANALOG_GND

TC101

TC8

100R

AUDIO_+9V

R208

TC102

47uF/16V

R76

TC9

47uF/16V

ANALOG_GND

10uF/16V

100R

AUDIO_+9V

10uF/16V

100R

AUDIO_+9V

100K

R142

ANALOG_GND

ANALOG_GND

ANALOG_GND

100K

R143

100K

R213

100K

R518

JBUS_AU_L_TO_ASP

JBUS_AU_R_TO_ASP

EXTRA_AU_LCH_TOMATRIX

EXTRA_AU_RCH_TOMATRIX

100K

R314

ANALOG_GND

IPOD_AUDIO_LCH_TO_ASP

IPOD_AUDIO_RCH_TO_ASP

100K

R519

ANALOG_GND

MCU_+5V

20K(NC)-->100K

R502

C

Q64

B

R501

10K(NC)-->100K

2N3904(NC)

E

REMOTE_RECEIVER

DIGITAL_GND

DIGITAL_GND

180K

C249

Q43

KRC402

R320

B

1nF/25V

4K7

R526

C

B

LED_ABRT

MCU_BEEP

MPEG_BEEP

1N4148

1N4148

D18

D16

R55

B

10K

POWER_+12V

3K9

3K9

3K9

R60

C

Q21

2N3904

E

3K9

R56

R59

R218

C18

104

12

BEEP

BUZ

BUZZER

L46

470uH

10K

R442

12K

R434

LED_PWR_+5V

D15

2N3906

1N4004

Q54

D32

CE

1N4004

ANALOG_GND

E

DIGITAL_GND

DIGITAL_GND

2-5

Page 24

Main section 5

MPEG_I2C_SCL_TO_D/A

MPEG_I2C_SDA_TO_D/A

+3V3

SERVO_GND

SERVO_+3V3

+3V3

JUMP

1K

4K7

SERVO_GND

JP10

JUMP

R322

NC

NC

R319

L51

IND-SMT-0603

R487

10K

JP4

R39

R38

R488

10K

SERVO_GND

D+

D-

600R

L37

IND-SMT-CD43

C302

8

VCC

7

WC

6

SCL

5

SDA

10K

10K

10K

10K

10K

SERVO_GND

1A/1206

R260

R259

R506

R507

R508

102pF

C283

+3V3

10nF/25V

GND

EEPROM

IC51

S0

S1

S2

FLASH_ADD:[00:20]

SERVO_GND

1

2

3

4

SERVO_GND

TOSC_PEN_IRQ

TOSC_DATA_IN

TOSC_CLOCK

TOSC_DATA_OUT

TOSC_CS

WE

FLASH_ADD:01

FLASH_ADD:02

120R

C430

C431

33P

33P

SERVO_GND

+3V3

C294

MPEG_DATA_TO_SD_DATA-2

MPEG_DATA_TO_SD_CD/DATA-3

CE

OE

FLASH_ADD:[00:20]

FB75

VDD_PCLK

SERVO_+3V3

L14

IND-SMT-CD43

MPEG_CLK_TO_SD

FLASH_DATA:[00:15]

SERVO_GND

CE_FLASH2

SERVO_GND

SERVO_GND

SERVO_GND

DSPVCC18

10uH

MPEG_I2C_SCL_TO_D/A

SD_DET

DSPVCC18

+3V3

+3V3

+3V3

FB67

+3V3

MPEG_I2C_SDA_TO_D/A

FLASH_ADD:20

FLASH_ADD:00

FLASH_DATA:02

FLASH_DATA:10

FLASH_DATA:03

FLASH_DATA:11

FLASH_DATA:04

FLASH_DATA:12

FLASH_DATA:05

FLASH_DATA:13

FLASH_DATA:06

FLASH_DATA:14

FLASH_DATA:07

FLASH_DATA:15

FLASH_ADD:16

FLASH_ADD:15

FLASH_ADD:14

FLASH_ADD:13

FLASH_ADD:12

FLASH_ADD:11

FLASH_ADD:10

FLASH_ADD:09

FLASH_ADD:08

FLASH_ADD:18

FLASH_ADD:17

FLASH_ADD:07

FLASH_ADD:06

FLASH_ADD:05

FLASH_ADD:04

FLASH_ADD:03

FLASH_ADD:02

FLASH_ADD:01

FLASH_ADD:19

120R

SDRAM_ADD:04

SDRAM_ADD:03

SDRAM_ADD:05

SDRAM_ADD:02

SDRAM_ADD:06

SDRAM_ADD:01

SDRAM_ADD:07

MPEG_DATA_TO_SD_DATA-0

MPEG_DATA_TO_SD_DATA-1

MPEG_DATA_TO_SD_CMD

SD_CARD_WRITE_PRO

SERVO_+3V3

R119

+3V3

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

IC48

ZORAN36966

SDRAM_ADD:[00:11]

+3V3_FOR_VIDEO

C295

R109

DVD_LED_CTL

DVD_MD

TRACK

CD_LED_CTL

FOCUS

179

180

181

182

183

184

211

+3V3

SERVO_GND

SDRAM_DATA:11

SDRAM_DATA:10

SDRAM_DATA:05

SDRAM_DATA:04

SDRAM_DATA:[00:15]

0R

CD_MD

175

176

177

178

+3V3

SERVO_GND

SDRAM_DATA:12

SDRAM_DATA:03

R81

220R

R25

220R

R120

10K

1K

FLASH_DATA:09

FLASH_DATA:00

FLASH_DATA:08

FLASH_DATA:01

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

1

2

3

4

5

6

7

8

9

5354555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899

+3V3

SERVO_GND

SDRAM_ADD:10

SDRAM_ADD:08

SDRAM_ADD:00

SDRAM_ADD:11

SDRAM_ADD:09

SDRAM_CS

SDRAM_BA0

SDRAM_BA1

SDRAM_RAS

SERVO_GND

+3V3

SDRAM_WE

SDRAM_CAS

SERVO_GND

190

191

192

193

SERVO_GND

PCLK

SDRAM_DQML

SLED

DSPVCC18

187

188

189

SDRAM_DATA:08

SDRAM_DATA:07

VDD_PCLK

SPDL

185

186

SDRAM_DATA:09

SDRAM_DATA:06

MPEG_VIDEO_IN

R483

15.4K(1%)

C292

R48

100nF

0R

170

171

172

173

174

+1V8

SDRAM_DATA:14

SDRAM_DATA:13

SDRAM_DATA:02

SDRAM_DATA:01

DSPVCC18

V_REF

33R

SERVO_GND

165

166

167

168

169

+3V3

SERVO_GND

SDRAM_DATA:15

SDRAM_DATA:00

C307

R181

164

L36

162

163

IND-SMT-0805

C293

160

161

100

101

159

102

C309

0R/ 0.5A/0805

TC126

220uF/6V3

10nF

157

158

103

104

R41

R43

R68

L35

IND-SMT-1206

C290

10nF

SERVO_GND

C289

C287

+3V3

C310

22R

22R

22R

C343

1nF

1nF

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

+3V3

SERVO_GND

0R/ 1A/1206

C291

10nF

100uF/6V3

R202

R42

R67

R69

C344

E_SIGNAL

C_SIGNAL

A_SIGNAL

L34

TC105

SERVO_GND

C288

R478

FB36

FB35

FB34

FB32

FB37

FB38

0R/NC

FB41

FB42

FB103

R471

R129

R247

22R

22R

22R

C345

IND-SMT-CD43

33pF

392R(1%)

R477

R391