Page 1

SERVICE MANUAL

DVD VIDEO RECORDER

YD05920055

DR-M100SEF, DR-M100SEK,

DR-M100SEL, DR-M100SER,

DR-M100SEU, DR-M100SEY,

DR-M100SEZ

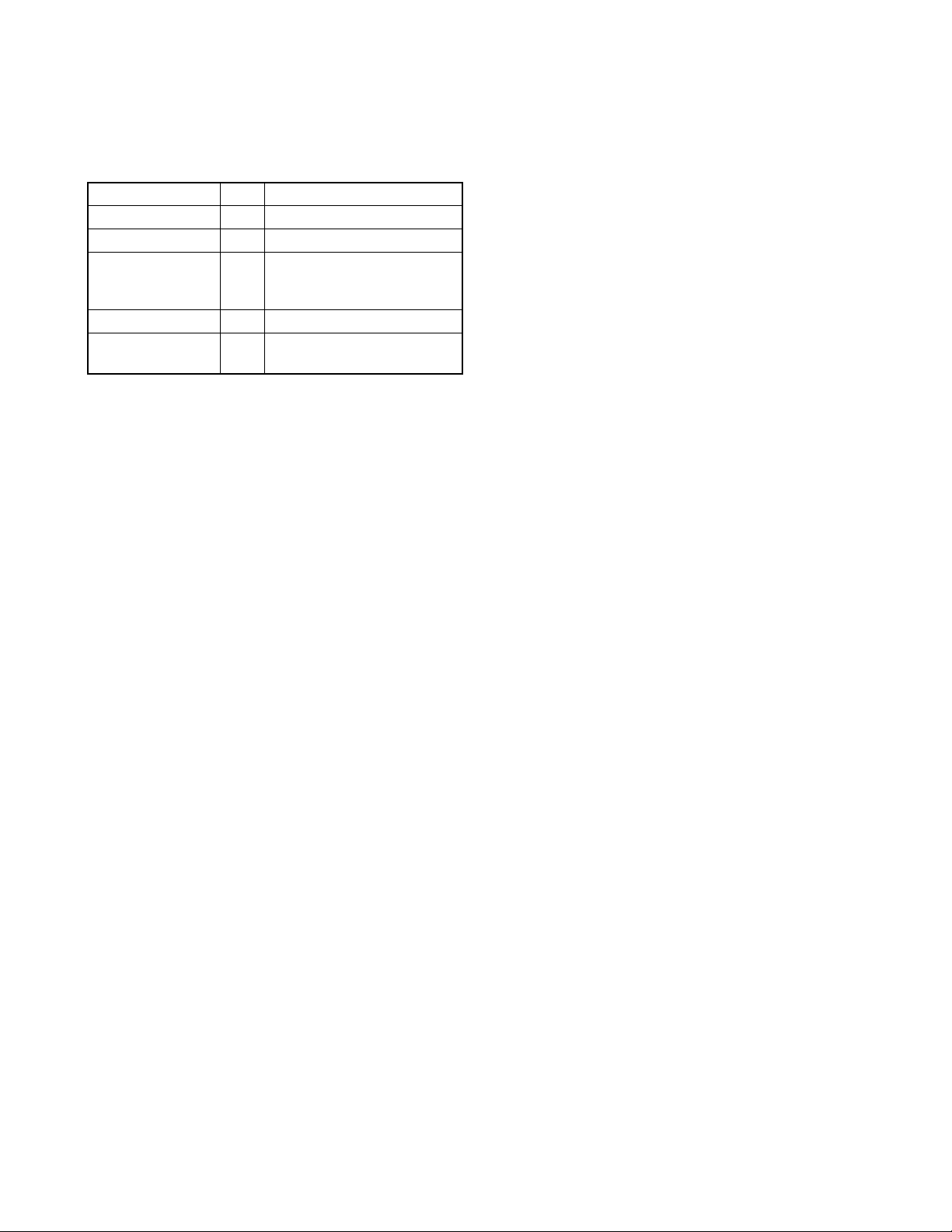

Area Suffix

EF --------- French Republic

EK ------------------------ U.K.

EL ------------ South Europe

ER ---- Russian Federation

EU -------- Western Europe

EY -------- Northern Europe

EZ --------- Eastern Europe

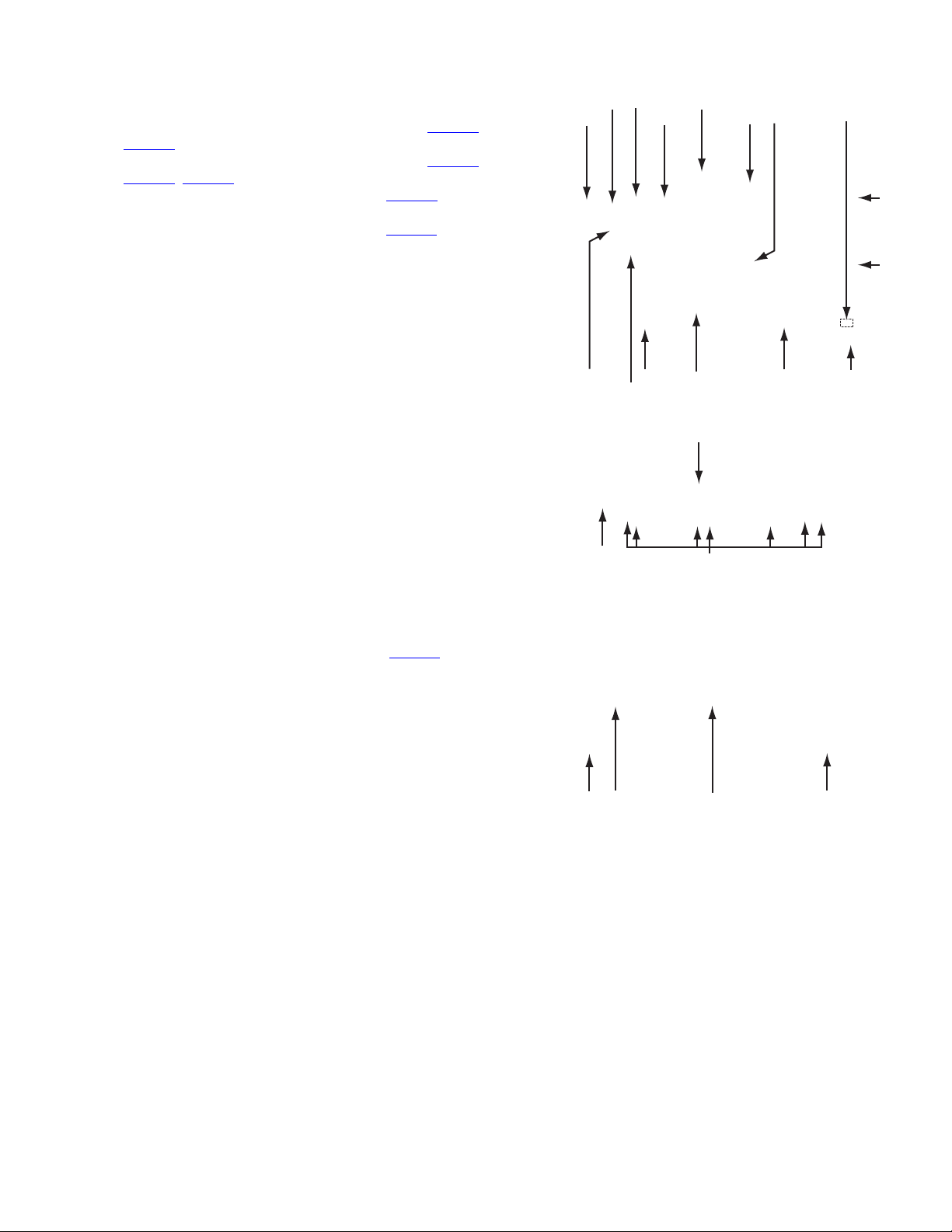

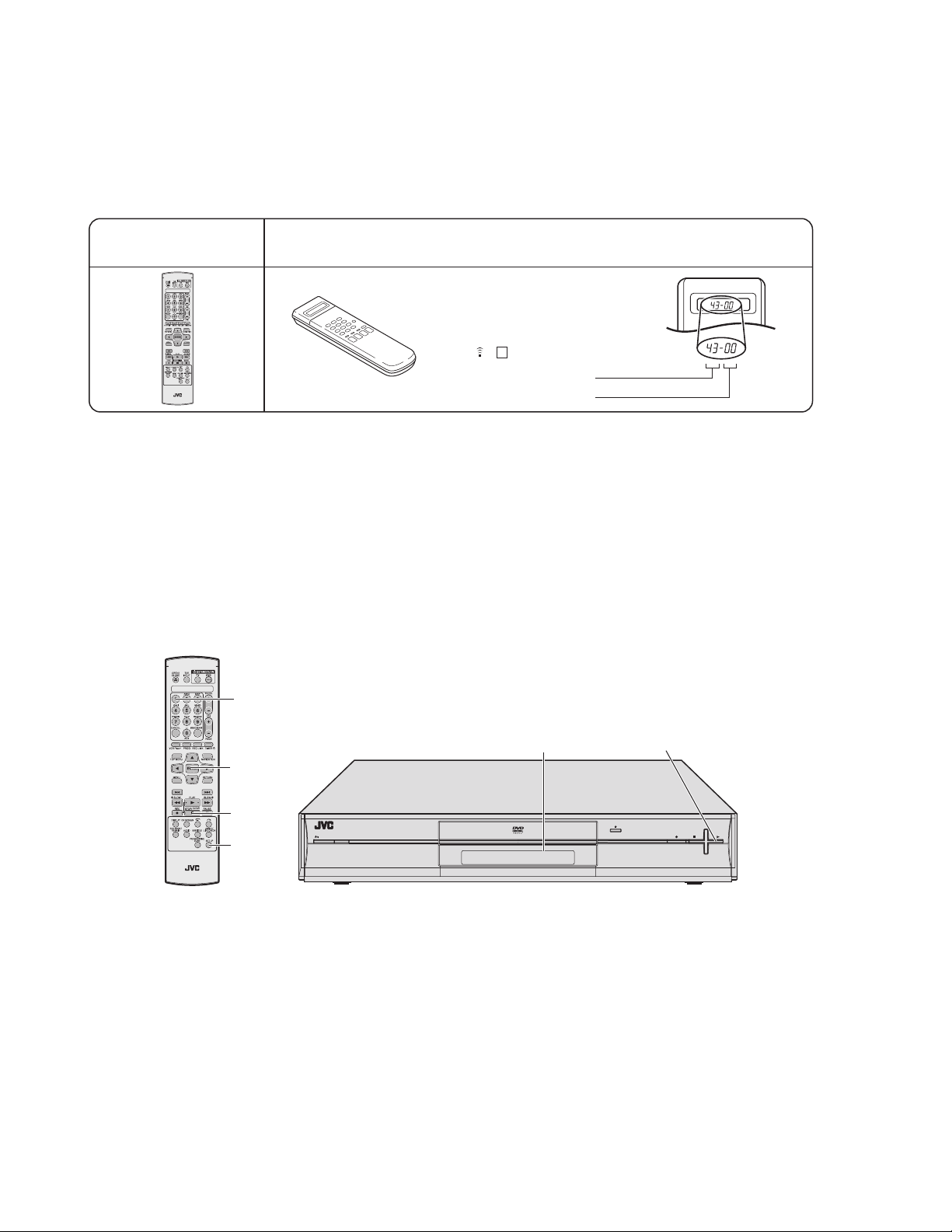

Only ver.EF,ER

Only ver.EK

STANDBY/ON

DR-M100SEU,DR-M100SEK,DR-M100SEL,DR-M100SEY

DR-M100SEZ,DR-M100SEF,DR-M100SER [D5R10]

Since the whole mechanism assembly unit is replaced, the DVD recorder

mechanism of this unit need not be adjusted.

Only ver.ER

RAM/RW

Only ver.EL,EU,EY,EZ

+

PR

PUSH-OPEN

-

PR

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YD059

2005/5

Page 2

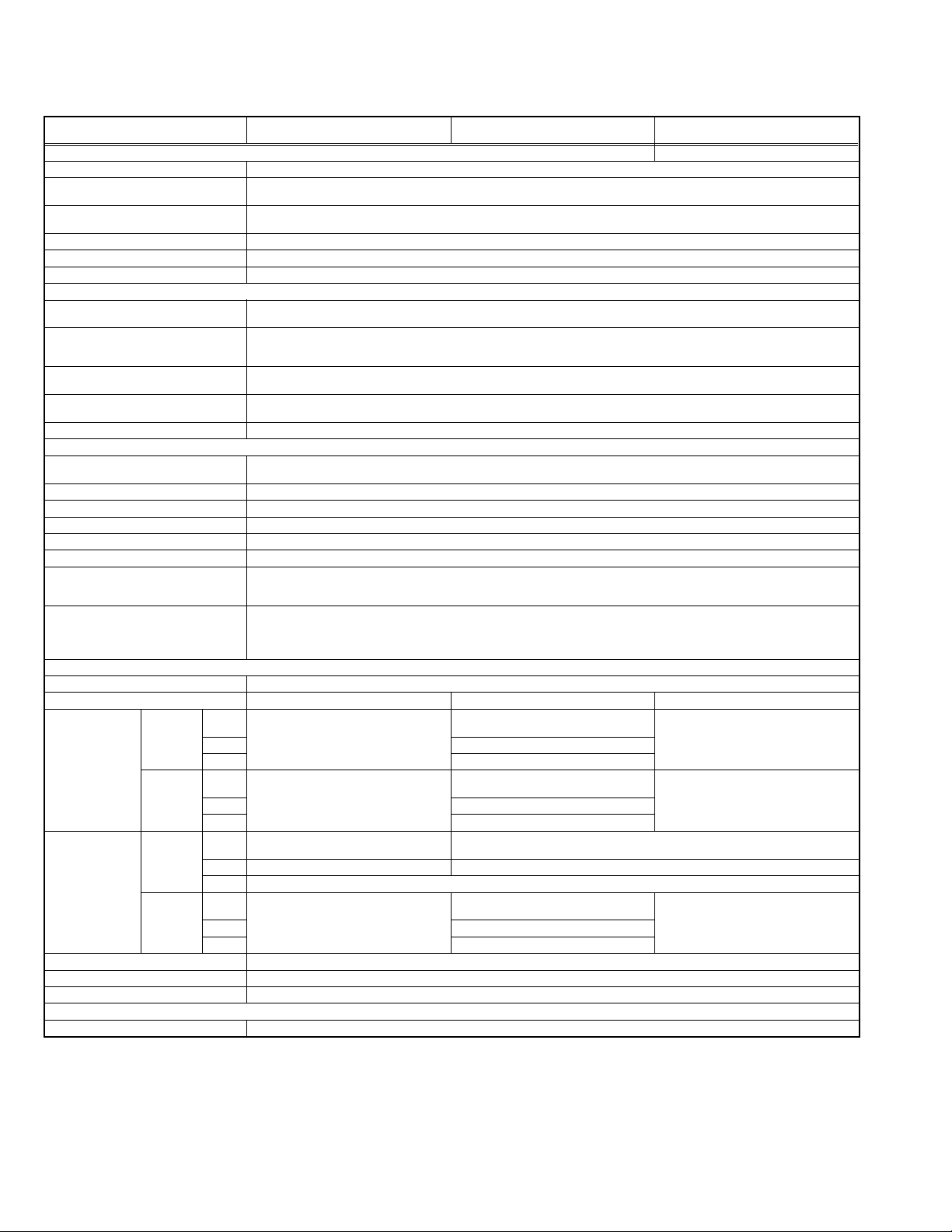

SPECIFICATION

GENERAL

Power requirement AC 220 V - 240 V~, 50 Hz/60 Hz

Power consumption Power on : 31 W

Temperature Operating : 5°C to 35°C

Operating position Horizontal only

Dimensions (W × H × D) 435 mm × 70 mm × 300 mm

VIDEO/AUDIO

Recordable disc DVD-RAM 12 cm (4.7 GB/9.4 GB),DVD-RAM 8 cm (1.4 GB/2.8 GB),DVD-R 12 cm(4.7 GB),DVD-R 8 cm(1.4 GB),DVD-RW

Recording format DVD-RAM : DVD Video Recording format

Recording time Maximum 8 hours (with 4.7 GB disc)

Audio recording system Dolby Digital (2 ch)

Video recording compression system MPEG2 (CBR/VBR)

Input/Output

S-video input Y:1.0 Vp-p, 75 ohms

Video input 1.0 Vp-p, 75 ohms (pin jack)

Audio input 2Vrms (pin jack)

Audio output 2Vrms (pin jack)

21-pin SCART connectors IN/OUT x 1, IN/DECODER x 1

Component video output Y : 1.0 Vp-p, 75 ohms

Digital audio output Coaxial

TUNER/TIMER

Tuning system Frequency synthesized tuner

TV channel storage capacity - 99 positions (+position AUX) -

Channel coverage

(SECAM L)

Channel coverage

(PAL B/G)

ACCESSORIES

Frequence VHF - LOW: 49 MHz -65 MHz/

Canaux VHF - LOW: 2-4

Frequence VHF 47 MHz-143 MHz/

Canaux VHF - LOW: E2-E4, X, Y, Z

Clock reference Quartz

Program capacity 30 days programmable timer/8 programs

Memory backup time Approx. 10 min.

Provided accessories RF cable,21-pin SCART cable,Infrared remote control unit,”AA” battery x 2

Power off : 6.4 W

Storage : -20°C to 60°C

Weight 3.4 kg

12 cm(4.7 GB),DVD-RW 8 cm(1.4 GB)

DVD-R : DVD-Video format

DVD-RW : DVD-Video format, DVD Video Recording format

(XP) : Approx. 1 hour,(SP) : Approx. 2 hours,(LP) : Approx. 4 hours,(EP) : Approx. 6 hours,(FR) : Approx. 1 hour - 8 hours

Linear PCM (XP mode only)

C : 0.3 Vp-p, 75 ohms

i.Link 4-pin for DV input

PB/PR: 0.7 Vp-p, 75 ohms

Corresponding to copy protection

Corresponding to Dolby Digital and DTS Digital Surround

Bit stream

Selectable in digital audio output setting menu

Hyper 300MHz-470MHz

UHF 470 MHz -862 MHz

Hyper CATV

UHF 21-69

143 MHz-470 MHz

Hyper - 302 MHz -470 MHz

UHF 470 MHz -862 MHz

Hyper S21-S41

UHF E21-E69

DR-M100SEK DR-M100SEF DR-M100SEL,DR-M100SER,DR-

HIGH: 104 MHz -300 MHz

HIGH: 5-10 CATV

LOW: 47 MHz -89 MHz/

HIGH: 104 MHz -300 MHz

HIGH:E5-E12,S1-S20,M1-M10,U1-U10

M100SEU,DR-M100SEY,DR-M100SEZ

-

-

-

Specifications shown are for SP mode unless otherwise specified. E. & O.E. Design and specifications subject to change without notice.

• Manufactured under licence from Dolby Laboratories. “Dolby” and double-D symbol are trademarks of Dolby Laboratories.

• “DTS “ and “DTS DIGITAL OUT “ are trademarks of Digital Theater Systems, Inc.

• VIDEO Plus+ and PlusCode are registered trademarks of Gemstar Development Corporation. The VIDEO Plus+ system is manufactured under license from Gemstar Development Corporation.

• This product incorporates copyright protection technology that is protected by method claims of certain U.S. patents and other intellectual property

rights owned by Macrovision Corporation and other rights owners. Use of this copyright protection technology must be authorized by Macrovision

Corporation, and is intended for home and other limited viewing users only unless otherwise authorized by Macrovision Corporation. Reverse engineering or disassembly is prohibited.

1-2 (No.YD059)

Page 3

1.7 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABEL

On mechanism assembly

(No.YD059)1-5

Page 4

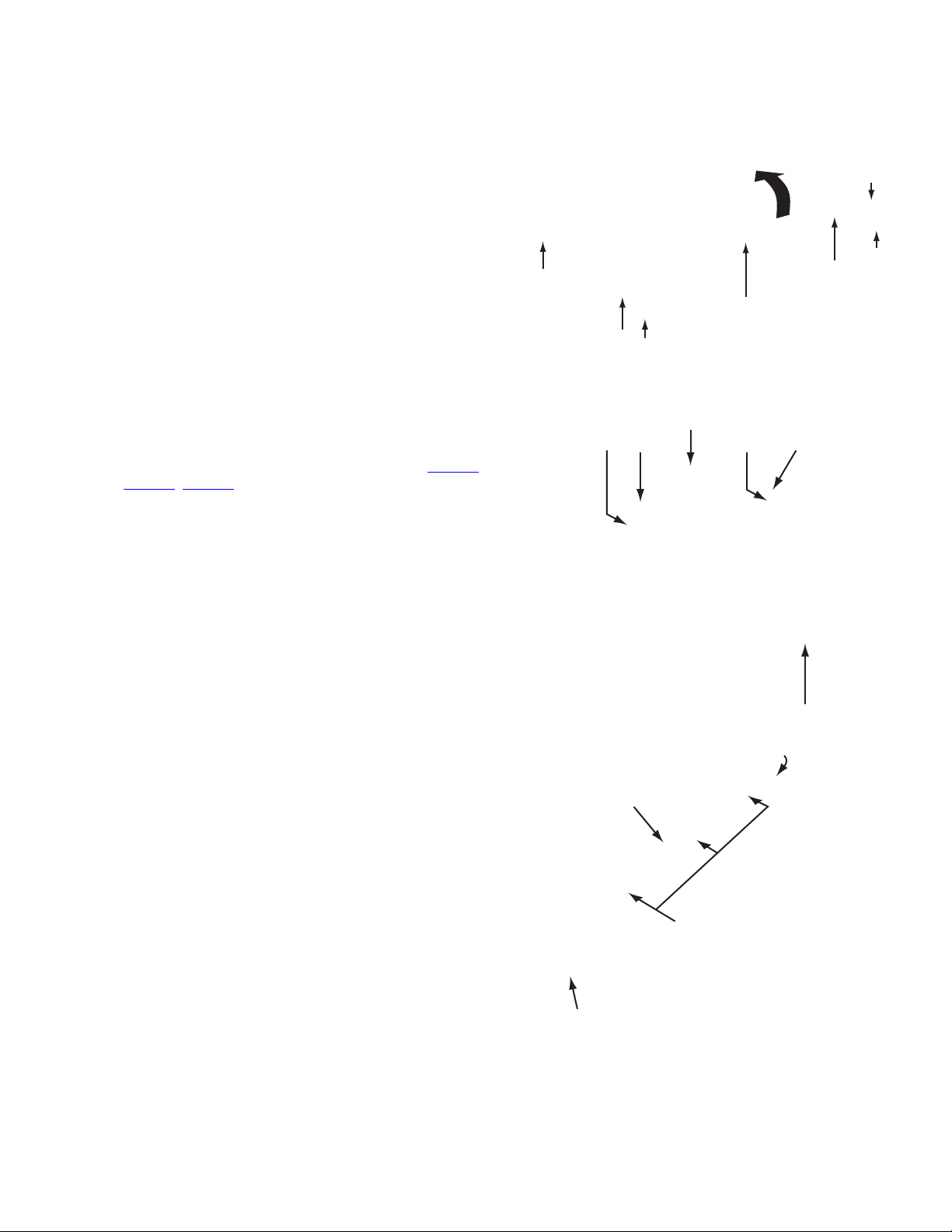

SECTION 3

TOP COVER

Hook b

DISASSEMBLY

3.1 Main body section

3.1.1 Remove the top cover (See figure 1)

(1) Remove the four screws A attaching the top cover on both

sides of the main body.

(2) Remove the five screws B attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rear of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

3.1.2 Remove the front panel assembly (See figure2, figure 3)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the mechanism assembly.

(1) Disconnect the card wires from connectors CN7002

CN7003, CN4001 on the main board and display board.

(2) Hooks a and b are removed respectively, and the front

panel assembly is removed.

,

A x 2

A x 2

CN4001

TOP COVER

TOP COVER

B

B

Fig.1

Front panel assembly

CN7002

CN7003

B

Display board

B

B

Main board

Fig.2

Hook a

Front panel assembly

Hook b

Hook a

Fig.3

(No.YD059)1-7

Page 5

3.1.3 Remove the drive unit (See figure 4)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the front panel assembly.

(1) Disconnect the socket wire from connector CN5302 on the

main board.

(2) Disconnect the card wire from connector CN2201

digital board.

(3) Remove the four screws C attaching the drive unit.

on the

Digital board

Drive

C

unit

C

3.1.4 Remove the digital board (See figure 5)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire from connectors CN2201

CN1103

(2) Disconnect the socket wire from connectors CN1101,

CN1102, CN1801 on the digital board.

(3) Remove the four screws D attaching the digital board.

on the digital board.

CN2201

C

C

CN5302

Main board

Fig.4

Digital board

CN1101

,

CN1801

D

D

D

CN2201

D

CN1102

CN1103

Fig.5

1-8 (No.YD059)

Page 6

3.1.5 Remove the main board (See figure 6, figure 7)

• Prior to performing the following procedure, remove the top

cover, drive unit.

(1) Disconnect the card wire from connectors CN4001

CN4103 on the main board.

(2) Disconnect the socket wire from connectors CN1101

CN1102

(3) Disconnect the socket wire from connector CN5303, on the

main board.

(4) Disconnect the power cord from connector CN5001

main board.

(5) Remove the six screws E attaching the main board.

(6) Remove the eight screws F and G attaching the rear panel

with main board.

, CN7001 on the digital board and display board.

, on the

CN1101

Digital board E

,

,

CN4001

Display board

CN7001

E

CN5001

E

E

3.1.6 Remove the dispiay board (See figure 8)

• Prior to performing the following procedure, remove the top

cover, drive unit, front panel assembly.

(1) Disconnect the socket wire from connector CN7001

display board.

(2) Remove the two screws H attaching the display board.

on the

CN1102

CN4103

G

E

Main board

Rear panel

Fig.6

F

Fig.7

Display board HH CN7001

Fig.8

CN5303

E

(No.YD059)1-9

Page 7

3.2 Loading mechanism assembly

3.2.1 Remove the clamper base (See figure 1, figure 2)

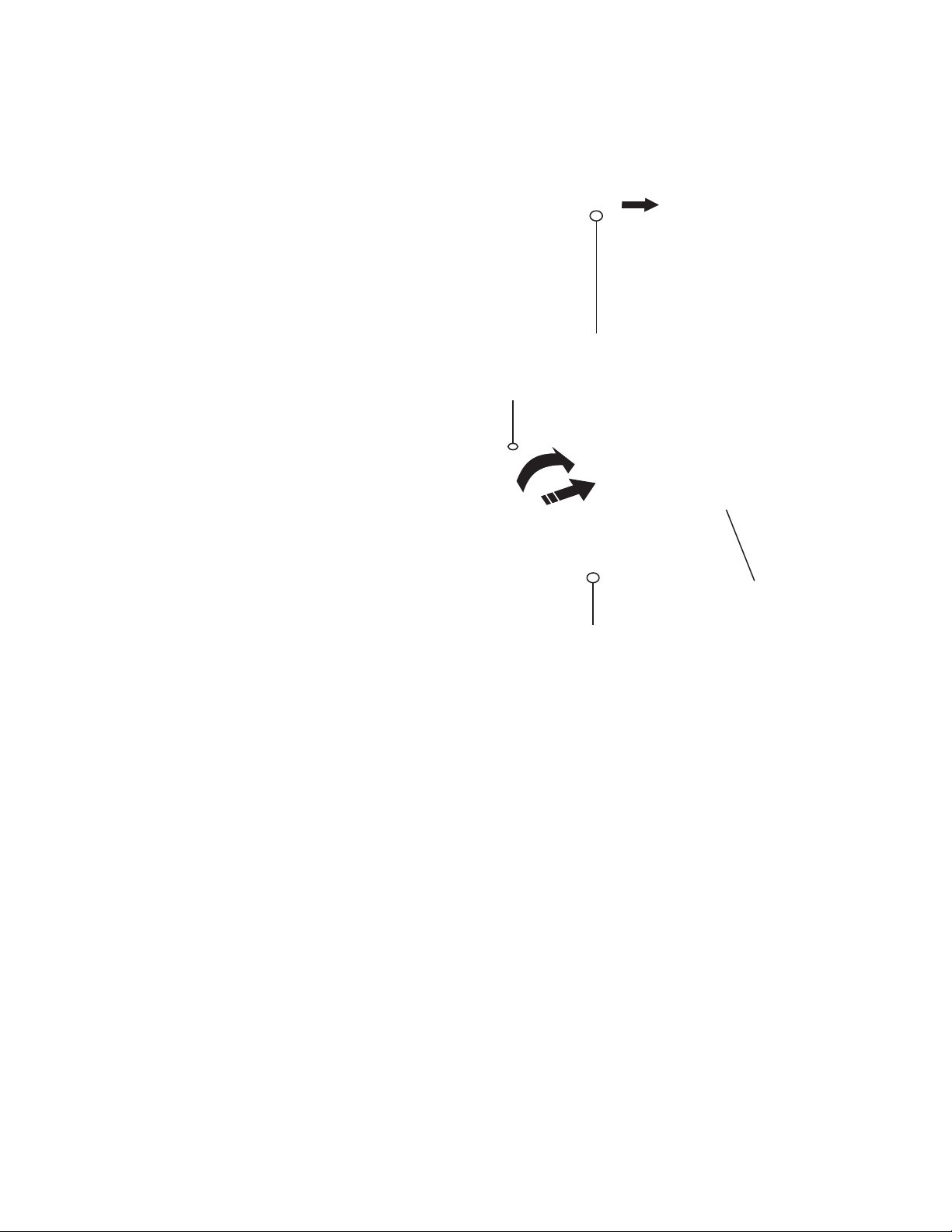

(1) The part a on the reverse side of a mechanism assembly is

made to slide in the direction of an arrow with a driver etc.

(A tray ejects a few.)

(2) Remove the two screws A attaching the clamper base.

(3) After making a clamper base slide in the direction of an ar-

row, it raises upward and removes.

(4) A tray is removed.

Par t a

Fig.1

A

A

Clamper base

Fig.2

1-10 (No.YD059)

Page 8

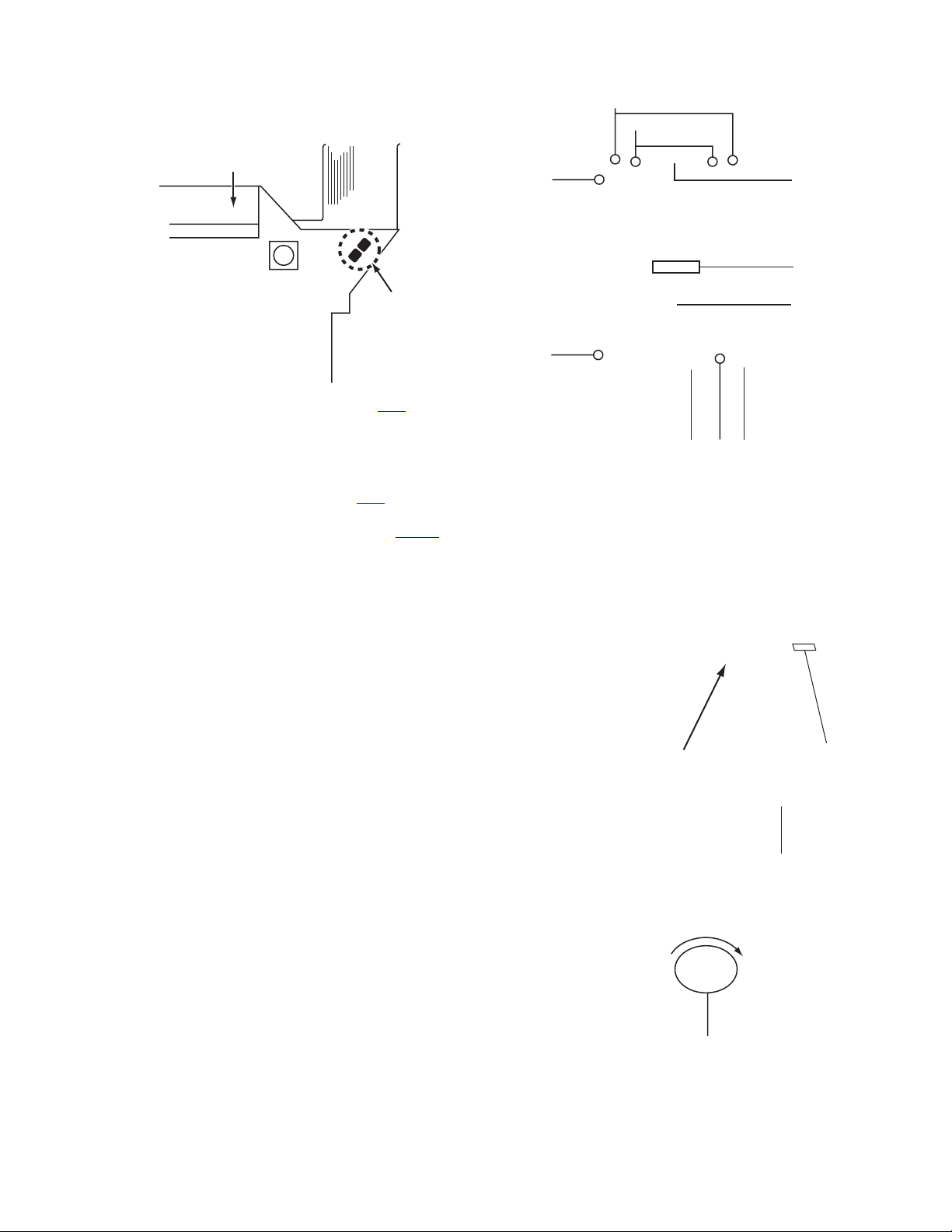

3.2.2 Remove the traverse mechanism assembly (See figure 3, figure 4, figure 5)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) It solder to part b section on the pick-up unit.

㧯

Pick-up unit

E

D

Leaf spring

CN1

Par t b

(2) Disconnect the card wire from connector CN1

up unit.

ATTENTION:

Please extract the wire after short-circuited on the pickup unit in part b with solder. Please remove the solder of

part b after connecting the wire with CN1

bling.

(3) Disconnect the flexible wire from connector CN301

servo control board.

(4) Remove the one screw B attaching the mechanism brack-

et.

(5) Remove the four screws C and D attaching the leaf spring.

(6) Remove the two screws E and F attaching the traverse

mechanism assembly.

(7) When a traverse mechanism assembly is in the lowest po-

sition, a gear 1 is turned clockwise, and since a traverse

mechanism assembly is moved to the upper position, it is

removed.

on the pick-

when reassem-

on the

Pick-up unit

F

Traverse mechanism

Mechanism

bracket

B

assembly

Fig.3

Servo control board

Fig.4

Traverse mechanism assembly

Gear 1

Fig.5

CN301

(No.YD059)1-11

Page 9

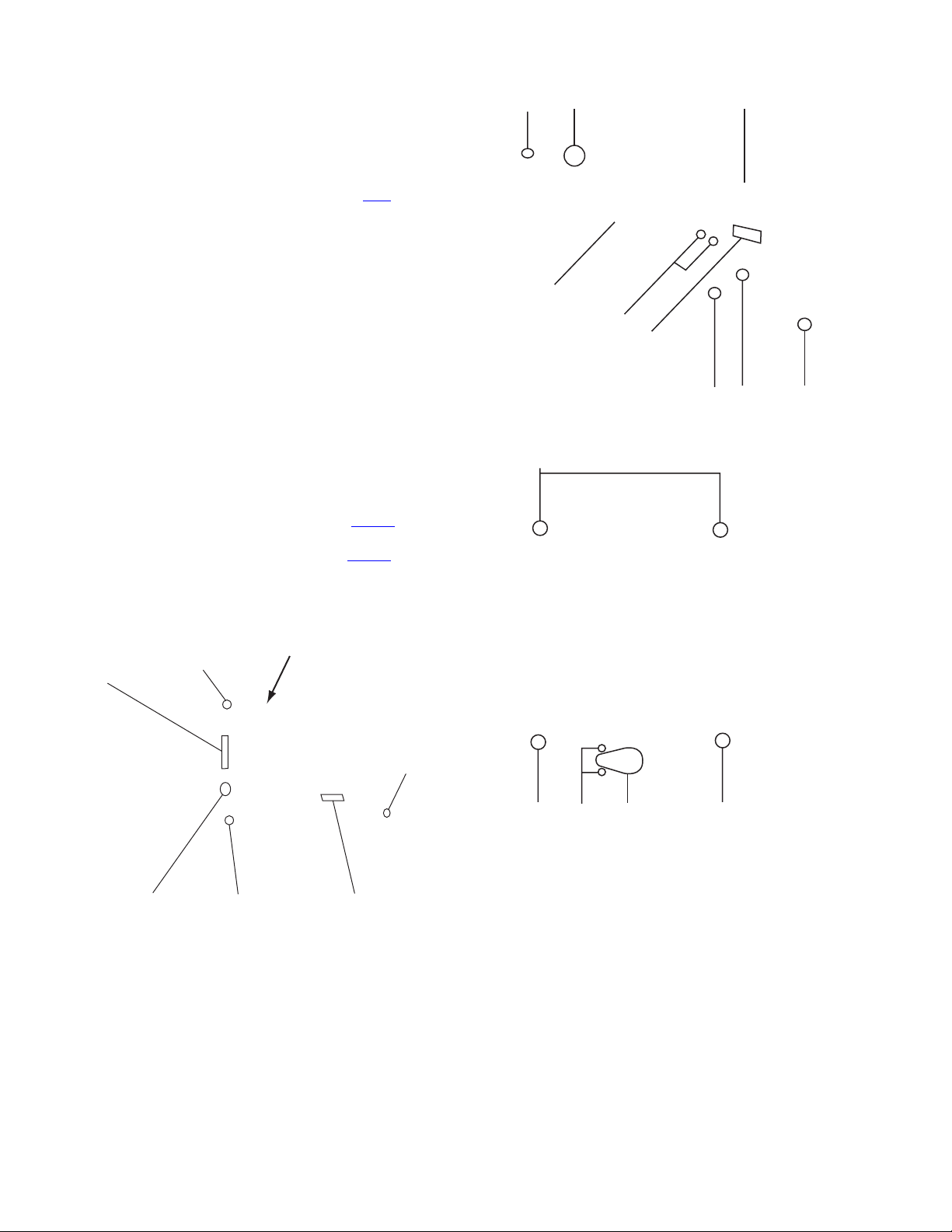

3.2.3 Remove the flexible wire assembly (See figure 6)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) Remove the four screws G and H attaching the flexible wire

assembly.

(2) Remove the solder part c soldered to the feed motor.

(3) Remove the two screws I attaching the shaft guide.

(4) Disconnect the flexible wire from connector CN1

spindle motor board.

on the

Par t c

G

Flexible wire

assembly

Spindle motor assembly

I

CN1

3.2.4 Remove the servo control board and board bracket (See figure 7, figure 8)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) Remove the soler part d and e soldered on the servo con-

trol board.

(2) Disconnect the flexible wire from connector CN301

servo control board.

(3) Disconnect the card wire from connector CN101

servo control board.

(4) Remove the two screws J attaching the servo control

board.

(5) Remove the four screws K attaching the board bracket.

on the

on the

K

Servo control board

CN101

J

Par t e

Fig.6

Fig.8

H

G

G

KKLBelt

Par t d

3.2.5 Remove the loading motor (See figure 7, figure 8)

• Prior to performing the following procedure, remove the

clamper base and tray.

(1) Remove the soler part d soldered on the servo control

board.

(2) A belt is removed.

(3) Remove the two screws L attaching the loading motor.

1-12 (No.YD059)

J

Fig.7

CN301

Page 10

SECTION 4

ADJUSTMENT

4.1 Timer clock adjustment (for only ver.EU,EL,EY,EZ,ER)

If an error comes to arise for a clock, the following procedure will adjust.

Signal (A1) No signal

Mode (B) EE

Equipment (C) Frequency counter

Measuring point (D1)

Adjustment part (F) C3033 (TIMER CLOCK)

Specified value (G) 1024.008 ±0.001 Hz

(1) Connect the frequency counter to the measuring point (D1).

(2) Connect the short wire between the short point (D2) and Vcc (5V).

(3) Short the leads of capacitor (D3) once in order to reset the microprocessor of the system controller.

(4) Disconnect the short wire between the short point (D2) and Vcc then connect it again.

(5) Adjust the Adjustment part (F) so that the output frequency becomes the specified value (G).

IC3001 pin 29

(D2)

IC3001 pin 83

(D3)

C3021 + and -

(976.5549 ±0.0010 usec)

(No.YD059)1-13

Page 11

SECTION 5

TROUBLESHOOTING

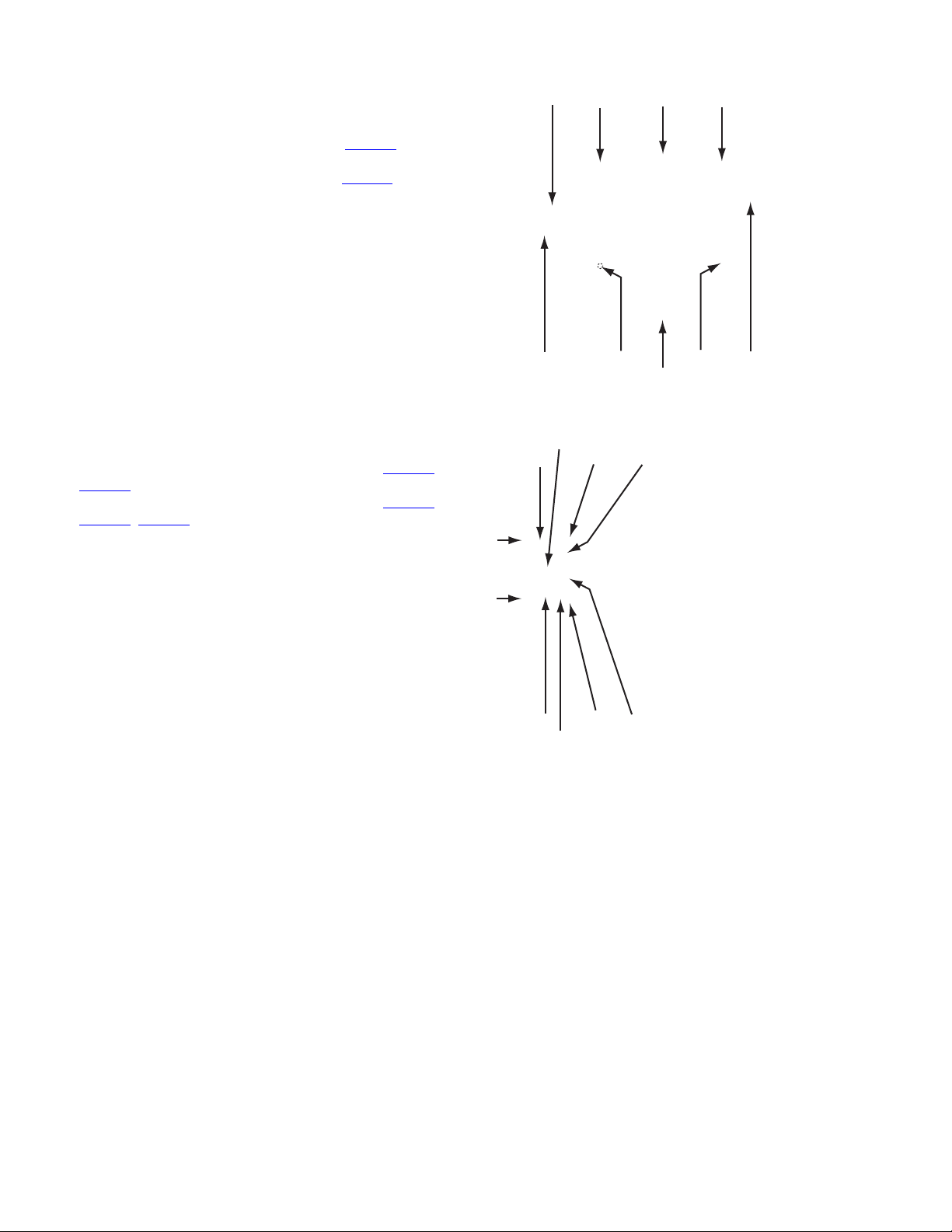

5.1 JIG Mode

The following remote control units are required to set and cancel JIG mode.

For setting : a remote control unit attached to product.

For cancellation : JIG remote control unit (part number : PTU94023B)

Remote control unit

attached to product

JIG remote control unit

JIG remote control unit

[Data transmission]

Set the data code,

and then press the

" " button.

3

Custom code

43:A Code

53:B Code

6F:C Code

7F:D Code

Data code

Initial mode

When the main body is set to JIG mode and when the main body is under JIG mode, the remote control unit attached to product operates only in "Remote Control Code 1". Since main body is in "Remote Control Code 3" when it is shipped and just after its batteries

are changed, "Remote Control Code 3" needs to be changed to "Remote Control Code 1."

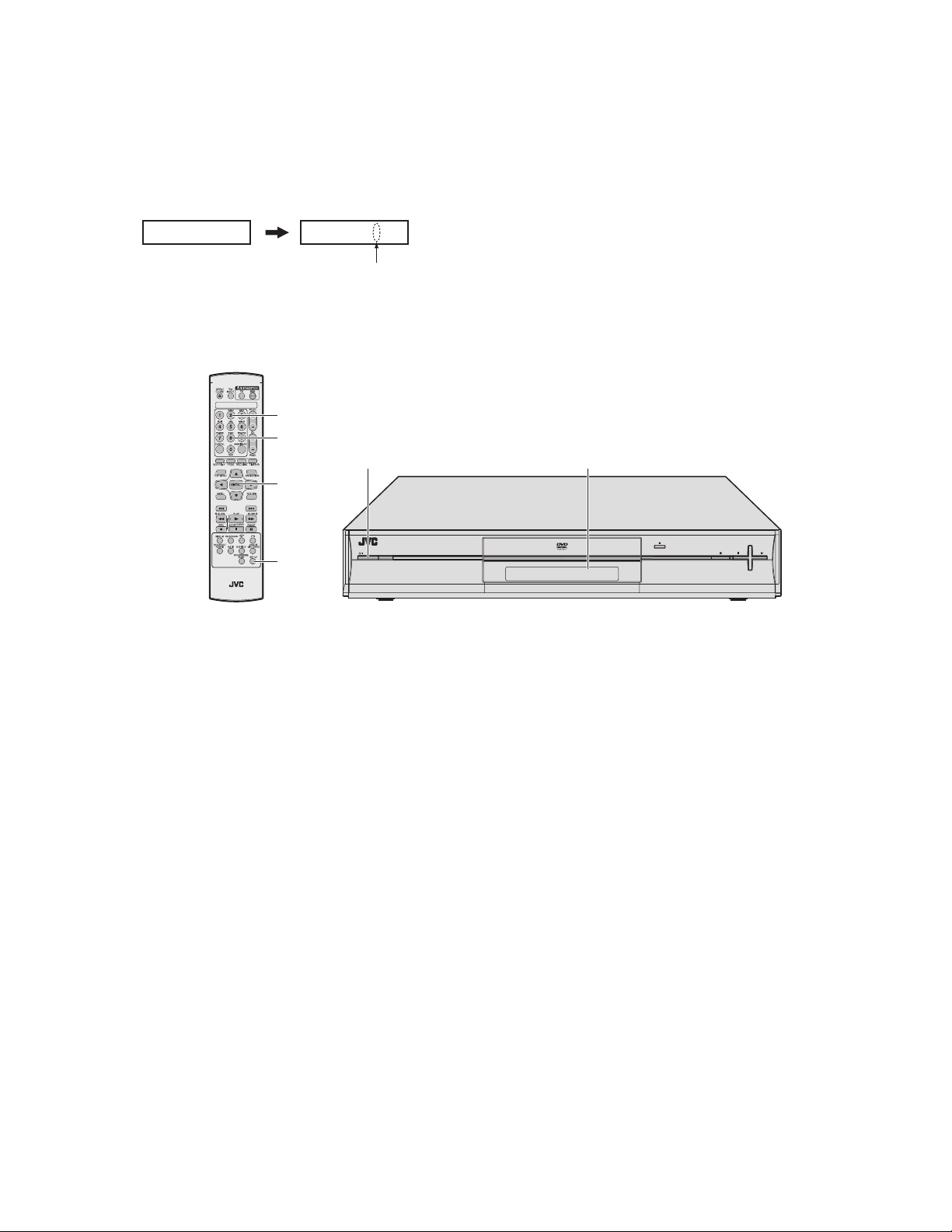

< Changing Remote Control Code >

(1) Press the numeric button "1" of the remote control unit while pressing the "SET UP" button of the remote control unit. Then,

press the "ENTER" button, and then release the "SET UP" button.

(2) Press the "PLAY" button of the main body for five seconds or longer while the main body is in stand-by mode, and a current

remote control code of the main body is displayed in FL indicator of the main body.

(3) While keeping the state of (2), press the "STOP" button of the remote control unit toward the main body.

(4) The code that was set by the remote control unit blinks for 5 seconds, before the code is set to the main body.

When the FL indicator changes to "DVD1," it shows that the remote control code has been changed to "1."

"(1) a-c" shows the order of pressing the buttons.

(1)b

(1)c

(3)

(1)a

STANDBY/ON

RAM/RW

(2),(4)

DVD 1

(2)

+

CH

PUSH-OPEN

-

CH

1-14 (No.YD059)

Page 12

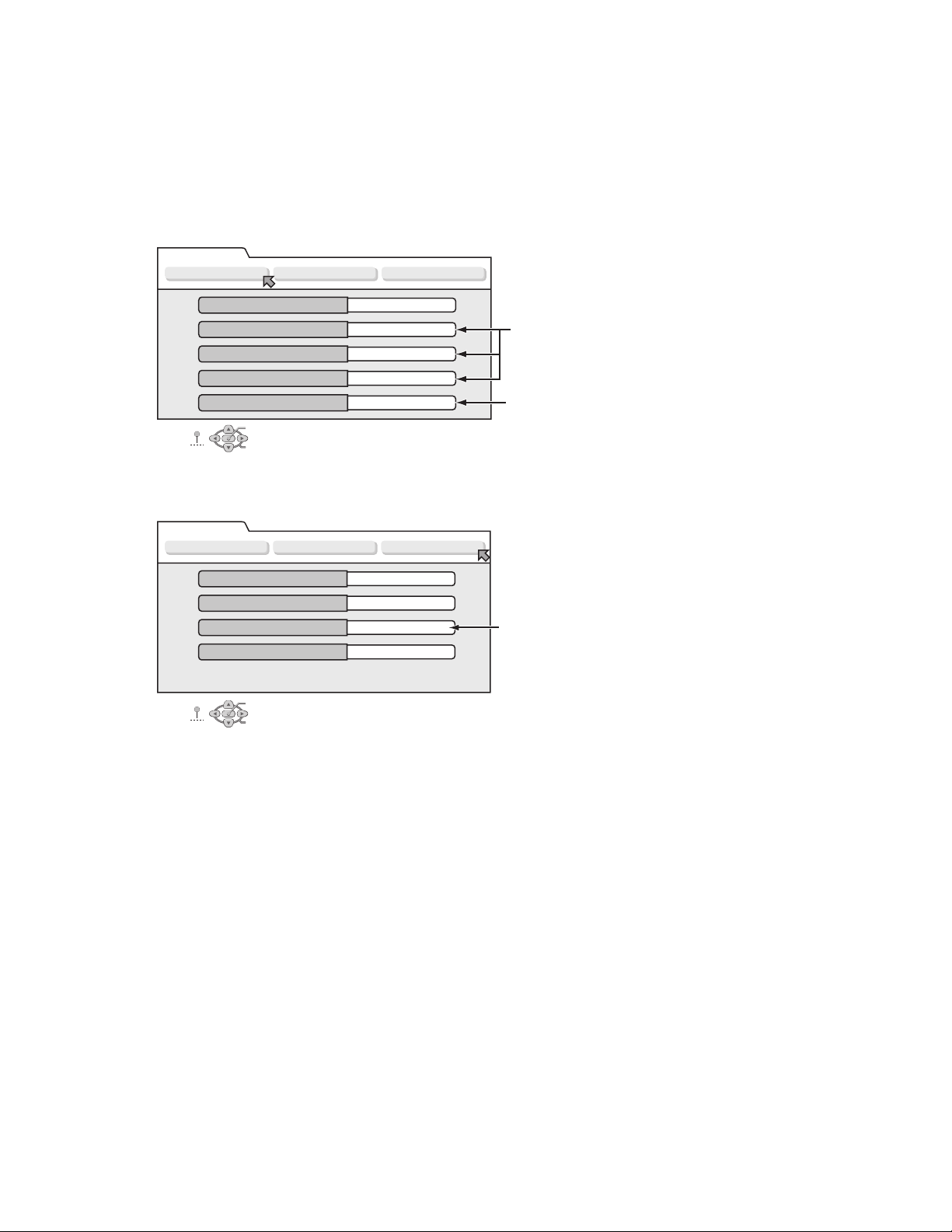

5.1.1 Setting JIG mode

To display SYSTEM INFO or to upgrade firmware, the main body needs to be set to JIG mode.

(1) Turn the main body ON.

(2) Press the buttons of the remote control unit attached to product in the following order : "SET UP" → "2" → "8" → "ENTER"

(3) When a colon ":" between "hour" and "minute" of a clock in FL indicator blink, it means that the main body has been set to JIG

mode properly.

[ Example ]

Not in JIG mode In JIG mode

15 : 07

15 07

A colon blinks.

(4) Turn the main body OFF, and then turn it ON again.

*Once the main body is set to JIG mode, the JIG mode cannot be cancelled even if the power cord is pulled out from the wall

socket.

"(2) a-d" shows the order of pressing the buttons.

(2)b

(2)c

(3)(1),(4)

(2)d

+

CH

PUSH-OPEN

-

CH

(2)a

STANDBY/ON

RAM/RW

15:07

5.1.2 Canceling JIG mode

(1) Transmit "43-9D" to the main body by using JIG remote control unit.

(Please end a setting menu pushing “SET UP” button of the remote control unit appended to the commodity beforehand when

a setting menu is displayed.)

(2) A colon ":" between "hour" and "minute" of a clock in FL indicator light.

(3) Turn the main body OFF, and then turn it ON again.

NOTE:

After repair work, be sure to cancel JIG mode. Before returning product to a user, confirm that a colon ":" between "hour" and

"minute" of a clock in FL indicator light.

(No.YD059)1-15

Page 13

5.2 Displaying SYSTEM INFO

In the SYSTEM INFO there is information including firmware versions of the main body and the drive unit.

(1) Set the main body to JIG mode.

(2) Transmit "43-8B" to the main body by using JIG remote control unit.

(Please end a setting menu pushing “SET UP” button of the remote control unit appended to the commodity beforehand when

a setting menu is displayed.)

(3) SYSTEM INFO menu is displayed in the television screen.

(4) To move cursor in SYSTEM INFO, use the "", "", "", and "" buttons of a remote control unit attached to product.

< VERSION >

SYSTEM INFO

VERSION INITIALIZE INFORMATION

CPRM Key Download

C-Ware / A-Ware

JVRI / Host

1394 / OSD

Analog / BE-R / FE-R

SET UP

ENTER

SELECT

SELECT WITH [CURSORS]

THEN PRESS [ENTER]

Done

PROD124 / JVC03_49

0124 / V0155_3E

0055 / 2005M04

100 / 2 / 2

< INFORMATION >

SYSTEM INFO

VERSION INITIALIZE INFORMATION

Silicon version of E5

BSP

Drive firmware version

Drive last error

SET UP

ENTER

SELECT WITH [CURSORS]

THEN PRESS [ENTER]

SELECT

NOTE :

Items other than the ones described above are not used in service work.

1B0

1.2/101

6706

00 00 00

Version of firmware

This part is updated after the firmware of the

main body is updated.

System controller version

/ Region code (Backend) / Region code (Frontend)

Version of firmware of mechanism drive

(5) To quit the SYSTEM INFO menu, transmit "43-8B" to the main body by using JIG remote control unit.

(6) Cancel JIG mode.

1-16 (No.YD059)

Page 14

5.3 Updating the firmware of the main body

• Firmware update disk supports CD-R media.

• When firmware update is necessary. information is available from the homepage of DIGITAL VIDEO STORAGE CATEGORY, CS

group.

• Please check the details of the update disc creation method by JS-NET.

(1) Set the main body to JIG mode.

(2) Transmit "43-70" to the main body by using JIG remote control unit.

(3) "UPDATE" appears in FL indicator. Load disk for update on the tray, and close the tray.

(4) Update processing is started automatically.

(5) Then, "FW UPDATE" appears in FL indicator. It takes approx. 3 minutes at maximum to update firmware.

(6) The tray is ejected. Then, take out the disk and close the tray.

(7) Turn the main body OFF, and pull out the power cord from the wall socket. Then, plug the power cord into the wall socket.

(8) "PLEASE" and "WAIT" blink alternately and it is displayed in FL indicator. Then, turn the main body ON.

(9) Display the SYSTEM INFO menu, and check the version of the firmware.

(10) Cancel JIG mode.

ATTENTION :

Firmware may sometimes not be update successfully.

If firmware is not update successfully, the tray opens, and "ERROR" appears in FL indicator.

If firmware is update successfully, the tray opens, and "OPEN" appears in FL indicator.

If the power cord is pulled out from the wall socket while "ERROR" appears, data in the flash memory is destroyed and the main

body cannot start: the flash memory needs to be replaced.

After update procedure, pay enough attention to FL indicator when the tray opens.

When "ERROR" appears, update firmware again in the following way to restore the firmware.

(1) Transmit "43-70" to the main body by using JIG remote control unit while the tray opens.

(2) When "UPDATE" appears in FL indicator, close the tray and make the main body read the disk. Update starts.

(3) The following procedures are the same as a usual update.

5.4 Updating the firmware of the drive unit

• Firmware update disc supports only DVD-RAM media.

• When firmware update is necessary, written discs are distributed by DIGITAL VIDEO STORAGE CATEGORY, CS group.

(1) Turn the main body ON.

(2) Load the update DVD-RAM disc on the tray and close the tray.

(3) “READING” is displayed in the FL indicator and the update is started.

(4) In a short while “READING” in the FL indicator disappears, open the tray to remove the disc and close the tray.

(5) Turn the power OFF and pull out the power code from the wall socket, then plug the power cord into the wall socket again.

(6) Set to the JIG mode and check the firmware version of the drive.

5.5 Setting after the drive unit replacement

When the drive unit is replaced, it is necessary to set a region code. Service drive units for replacement are not set for any region

code, and they are in an indefinite condition.

Make sure to set region code after attaching the drive unit to the main body.

Without the setting of the region code, discs that have regions cannot be played back.

(1) Replace a drive unit.

(2) Turn POWER switch of the unit ON.

(3) Set the main body to JIG mode.

(4) Insert a DVD-RAM disc in the unit to make the unit read the DVD-RAM disc.(The DVD-RAM disk used in this procedure is not a

disk for upgrade. If it is a DVD-RAM disk, it is good anything.)

(5) Send "43-F2" to the unit by using JIG remote control unit.

(6) "2 REGION" is displayed on FL display.

(7) Set the unit to STANDBY.

(8) Turn the POWER switch ON.

(9) To cancel JIG MODE, send "43-9D" to the unit by using JIG remote control unit.

(10) Colon is displayed on a clock on FL display.

(11) Setting is completed in the procedure above.

(No.YD059)1-17

Page 15

5.6 Taking out a disc

5.6.1 Method 1

There is compulsive tray ejection mode by electric operation.

(1) AC Plug is pulled out at once and inserted again.

(2) It is displayed on FL display as "PLEASE" and "WAIT" blink alternately, and while it blinks, pushing the EJECT button of a main

body is continued.

(3) After a while, a tray opens (About 20 seconds).

(4) A disk is removed, the tray is pushed, and a tray is made to close.

(5) "PLEASE" and "WAIT" blink alternately and it is displayed in FL indicator, and it will be in a standby state.

(6) If the POWER button is pushed, it will usually be operating.

5.6.2 Method 2

When a disk is not able to be taken out by operation of "Method 1"

A tray can be ejected mechanically, without switching on a power supply.

(1) A drive unit is removed from a main body.

(2) The part a on the reverse side of a drive unit is made to slide in the direction of an arrow with a screw driver etc.

(3) Since a tray ejects a few, a tray is pulled out manually.

Par t a

5.7 Initialization to the factory shipment state

When the initialization is operated, internal information changes as follows. It is essential to obtain the client’s permission before the

operation.

• All DVD library is all deleted.

• All the DVD initial settings go back to the initial status.

(1) Set to the JIG mode.

(2) Transmit “43-6F” with the JIG remote control unit.

(3) FL indicator displays “FACTORY”, and changes to “CHECK OK” after blinking for a short while.

(4) Pull out the power code from the wall socket.

(5) The JIG mode is forced to cancel at the same time with the initialization, check whether the JIG mode is canceled by plugging

the power code into the wall socket again. (The colon “:” in time display should be continuously ON, not blinking.)

If the JIG mode is not canceled, transmit “43-9D” with JIG remote control unit to cancel the JIG mode.

5.8 When it is displayed in FDP, “RESET”

When the following operations are carried out, “RESET” is displayed in the FDP of the main body.

(1) When the “POWER” button and the “STOP” button of the main body are pressed at the same time

(2) When the code “9B” is transmitted to the main body by using JIG remote control unit

(3) When transmission failure occurs between the main CPU and the DVD host CPU due to defect

If “RESET” is displayed in the FDP after the power code is plugged into the outlet, check the followings.

• The peripheral circuitry of each microcomputer

• Whether the wire between the DVD drive and the board is properly connected

• Whether the wire between the main board and the digital board is properly connected

1-18 (No.YD059)

Page 16

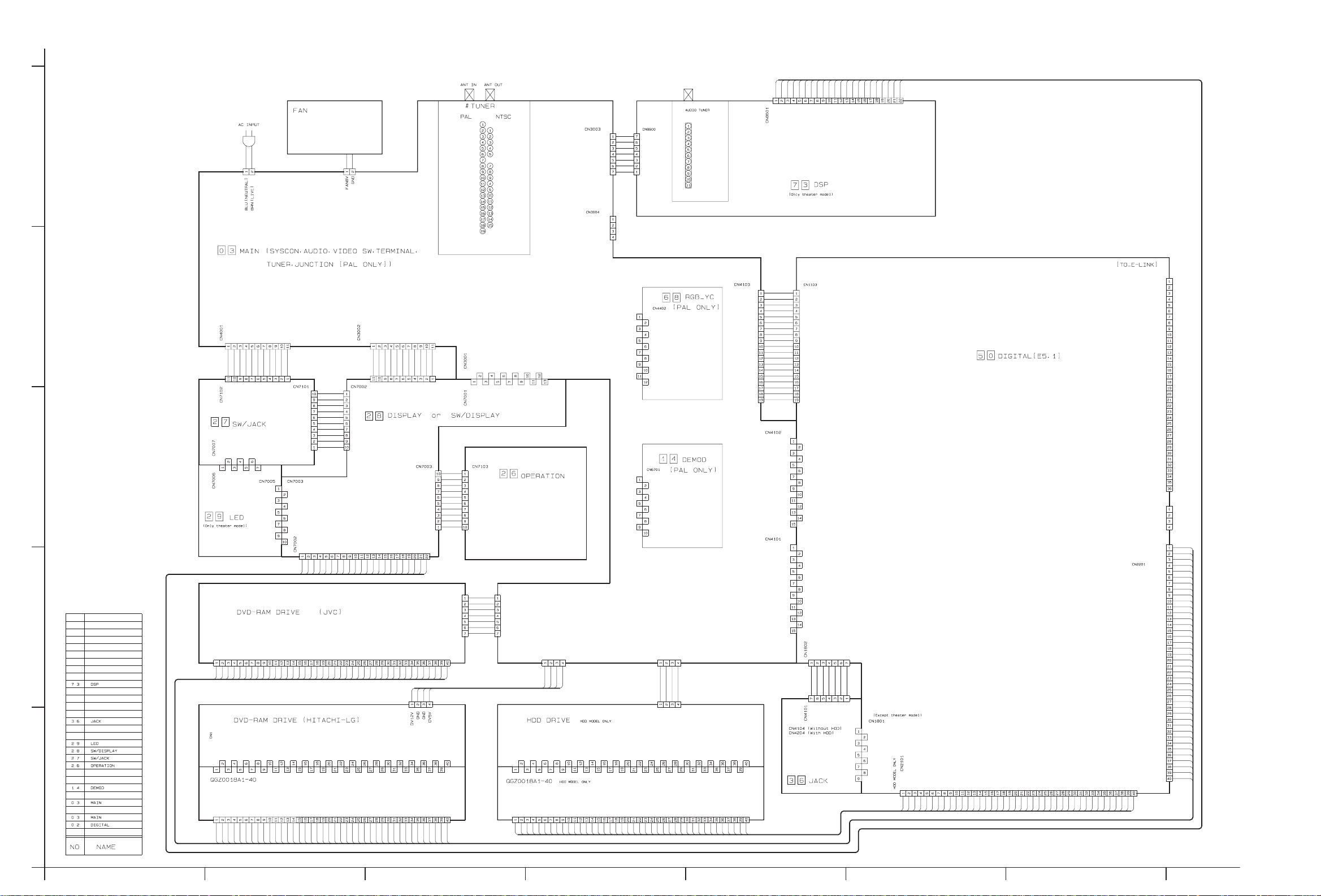

SCHEMATIC DIAGRAMS

DVD VIDEO RECORDER

DR-M100SEF, DR-M100SEK,

DR-M100SEL, DR-M100SER,

DR-M100SEU, DR-M100SEY,

DR-M100SEZ

CD-ROM No.SML200505

Area Suffix

EF --------- French Republic

EK ------------------------ U.K.

EL ------------ South Europe

ER ---- Russian Federation

EU -------- Western Europe

EY -------- Northern Europe

EZ --------- Eastern Europe

Only ver.EF,ER

Only ver.EK

STANDBY/ON

DR-M100SEU,DR-M100SEK,DR-M100SEL,DR-M100SEY

DR-M100SEZ,DR-M100SEF,DR-M100SER [D5R10]

Since the whole mechanism assembly unit is replaced, the DVD recorder

mechanism of this unit need not be adjusted.

COPYRIGHT 2005 Victor Company of Japan, Limited

Only ver.ER

RAM/RW

Only ver.EL,EU,EY,EZ

+

PR

PUSH-OPEN

-

PR

No.YD059SCH

2005/5

Page 17

Wiring diagram

AVC

TU_DI

VOL_DT

VOL_CK

DSP_CLK

DSP_RESET

SYS_RESET[L]

P_CTL[H]

A_MUTE[H]

GND

SY_OUT

SC_OUT

V_Y_OUT/C/R_OUT

R_PR_OUR/Pr_G_OUT

G_Y_OUT/Y_V_OUT

B_PB_OUT

GND

C_IN/R_IN

YV_IN

GND

G_TX

IRTX

G_RX

GND

P_MUTE[H]

CN1102

AO_IEC958

AO_MCLK

AO_SCLK

AO_D[0]

AO_FSYNC

DAC_RST[L]

A_DAC_CS

DAC_SCL

DAC_SDA

GND

GND

AI_D[0]

AI_SCLK

AI_FCYNC

AI_MCLK

CN1101

K_BUS_OUT

K_BUS_IN

K_BUS_REQ

K_BUS_CLK

GND

SW5V

D5V

D3.3V

GND

GND

D2.5V

D2.5V

GND

D1.8

D1.8

GND

GND

TPB-

TPB+

TU_DO

TPA-

TU_CK

TPA+

TU_CE

TU_PON

RDS_CLK

RDS_DATA

GND

(Only theater model)

GND

DGND

DSP_READY

DSP_STATUS

DSP_COM

BLUE_LED

STB

GND

RC_IN

AL5V

S1

KEY1

S2

KEY2

LED2

KED1

BLUE_LED

S_DATA_FRSYS

S_DATA_TOSYS

[no pin]

AUDIO IN

CH SW

SW5V

CONV.CTL[H]

VIDEO IN

AS/[no pin]

NC

NC

NC

SCL

SDA

AFT

AUDIO OUT

SIF OUT

TU[30V]

NC

VIDEO OUT

S_CLK

RC_IN

GND

AL5V

GND

BACK_UP_GND

[Except theater model]

CN5302

DV12V

GND

GND

DV5V

SW3.3V

SW1.8V

GND

RSTSTA

GND

HD_AT[7]

DC3.5[-]

-29V

CN5301

HD_AT[8]

HD_AT[6]

DC3.5[+]

DV12V

HD_AT[9]

[Except theater model]

GND

GND

DV5V

HD_AT[5]

HD_AT[10]

HD_AT[4]

HD_AT[11]

HD_AT[3]

HD_AT[12]

GND

GND

SW5V

SW-12V

SW+12V

D.GND

UEC956

HD_AT[2]

HD_AT[13]

GND

TU_CE

TU_DTI

TU_CK

TU_DT0

AGND

TU_L

TU_9V

TU_R

NC

RDS

AGND

D5V

5.8V

3.3V

C_FROM_RGB

Y_FROM_RGB

GND

REAR2_Y_IN

H_OUT

V_OUT

SYNC

FSC2

SW5V

REAR2_RC_IN

REAR G_IN

REAR2_B_IN

GND

I2C_DATA

I2C_CLK

GND

DEMOD_[R]

DEMOD_[L]

SW5V

GND

COMP

SIF

HDD MODEL ONLY

12V

GND

GND

5V

CN5304

HD_AT[1]

HD_AT[14]

HD_AT[0]

HD_AT[15]

GND

KEY

DMARQ

GND

DIOW

GND

DIOR

GND

IORDY

CAB_SEL

DMACK

GND

INT_ATA

IOCSI6-

ATA-A 1

PDIAG-

ATA-A 0

ATA-A 2

CS1FX

CS3FX

DASP-

BB[AL5V]

AUDIO IN

MOD SDA

5

CN5001

CN5303

MB[SW5V]

MOD SCL

VIDEO IN

TU[30V]

RF AGC

SW1

SW2

AS

SCL

SDA

AFT

AUDIO OUT

SIF OUT

TU[30V]

IF TP

VIDEO OUT

4

F.AUDIO[L]_IN

GND

F.AUDIO[R]_IN

GND

FRONT_VIDEO_IN

GND

GND

FRONT_Y_IN

GND

FRONT_C_IN

HP_L

HP_GND

HP_R

HP_DET

GND

KEY_IN_2

KEY_IN_1

GND

KEY1

KEY2

BLUE LED

AL5V

GND

S15

S14

S13

S12

S4

DC3.5[+]

-29V

DC3.5[-]

GND

GND

AL5V

BACK_UP_GND

S_CLK

S_DATA_TOSYS

S_DATA_FRSYS

STB

[Only theater model]

3

HDD_LED

ILUMI_LED

DVD_LED

KEY_IN_1

KEY_IN_2

GND

HP-DET

HP-R

HP-GND

HP-L

DGND

DSP_READY

DSP_STATUS

DSP_COM

DSP_CLK

DSP_RESET

VOL_CK

VOL_DT

AVC

TU_DI

TU_DO

TU_CK

TU_CE

TU_PON

RDS_CLK

RDS_DATA

S_MUTE

SW_PON

SETUP

HP-R

HP-GND

HP-L

2

RSTSTA

GND

HD_AT[7]

HD_AT[8]

HD_AT[6]

HD_AT[9]

HD_AT[5]

HD_AT[10]

HD_AT[4]

HD_AT[11]

HD_AT[3]

HD_AT[12]

HD_AT[2]

HD_AT[13]

HD_AT[1]

HD_AT[14]

HD_AT[0]

GND

KEY

HD_AT[15]

DMARQ

GND

DIOW

GND

DIOR

GND

IORDY

CAB_SEL

DMACK

GND

INT_ATA

IOCSI6-

ATA-A 1

PDIAG-

ATA-A 0

ATA-A 2

CS1FX

CS3FX

DASP-

GND

RSTSTA

GND

HD_AT[7]

HD_AT[8]

HD_AT[6]

HD_AT[9]

HD_AT[5]

HD_AT[10]

HD_AT[4]

HD_AT[11]

HD_AT[3]

HD_AT[12]

HD_AT[2]

HD_AT[13]

HD_AT[1]

HD_AT[14]

HD_AT[0]

HD_AT[15]

GND

KEY

DMARQ

GND

DIOW

GND

DIOR

GND

IORDY

CAB_SEL

DMACK

GND

INT_ATA

IOCSI6-

ATA-A 1

PDIAG-

ATA-A 0

ATA-A 2

CS1FX

CS3FX

DASP-

GND

1

S_MUTE

GND

GND

TPB+

TPB+

GND

TPATPA+

GND

GND

SETUP

SW_PON

HP_R

HP_L

HP_GND

GND

DASP-

CS3FX

CS1FX

CN1202

GND

RD/WR[L]

UWE[L]/UDS[L]

OE[L]/LDS[L]

MEDUSA_INT[L]

DTACK[L]

MADD[6]/MDT[0]

MADD[7]/MDT[1]

MADD[8]/MDT[2]

MADD[9]/MDT[3]

MADD[10]/MDT[4]

MADD[11]/MDT[5]

MADD[12]/MDT[6]

MADD[13]/MDT[7]

GND

MADD[14]/MDT[8]

MADD[15]/MDT[9]

MADD[16]/MDT[10]

MADD[17]/MDT[11]

MADD[18]/MDT[12]

MADD[19]/MDT[13]

MADD[20]/MDT[14]

MADD[21]/MDT[15]

MADD[1]

MADD[2]

MADD[3]

MADD[4]

MADD[5]

RST[L]

ALE

CS_L[1]

UART1_RTS

UART11_TX

UART1_RX

UART1_CTD

GND

CN1402

JLIP_RX

GND

JLIP_TX

D3.3V

GND

DASPCS3FX

CS1FX

ATA-A 2

ATA-A 0

PDIAG-

ATA-A 1

IOCSI6INT-ATA

GND

DMACK

CAB_SEL

IORDY

GND

DIOR

GND

DIOW

GND

DMARQ

KEY

GND

HD_AT[15]

HD_AT[0]

HD_AT[14]

HD_AT[1]

HD_AT[13]

HD_AT[2]

HD_AT[12]

HD_AT[3]

HD_AT[11]

HD_AT[4]

HD_AT[10]

HD_AT[5]

HD_AT[9]

HD_AT[6]

HD_AT[8]

HD_AT[7]

GND

ATA_A 2

ATA_A 0

PDIAG-

ATA_A 1

IOCSI6-

INT_ATA

GND

DMACK

CAB_SEL

IORDY

GND

DIOR

GND

DIOW

GND

DMARQ

HD_AT[15]

KEY

GND

HD_AT[0]

HD_AT[14]

HD_AT[1]

HD_AT[13]

HD_AT[2]

HD_AT[12]

HD_AT[3]

HD_AT[11]

HD_AT[4]

HD_AT[10]

HD_AT[5]

HD_AT[9]

HD_AT[6]

RSTSTA

HD_AT[8]

HD_AT[7]

GND

RSTSA

RSTSTA

GND

HD_AT[7]

HD_AT[8]

HD_AT[6]

HD_AT[9]

HD_AT[5]

HD_AT[10]

HD_AT[4]

HD_AT[11]

HD_AT[3]

HD_AT[12]

HD_AT[2]

HD_AT[13]

HD_AT[1]

HD_AT[14]

HD_AT[0]

GND

KEY

HD_AT[15]

DMARQ

GND

DIOW

GND

DIOR

GND

IORDY

CAB_SEL

DMACK

GND

INT_ATA

IOCSI6-

ATA-A 1

PDIAG-

ATA-A 0

ATA-A 2

CS1FX

CS3FX

DASP-

GND

RSTSTA

GND

HD_AT[7]

HD_AT[8]

HD_AT[6]

HD_AT[9]

HD_AT[5]

HD_AT[10]

HD_AT[4]

HD_AT[11]

HD_AT[3]

HD_AT[12]

HD_AT[2]

HD_AT[13]

HD_AT[1]

HD_AT[14]

HD_AT[0]

GND

KEY

HD_AT[15]

DMARQ

GND

DIOW

GND

DIOR

GND

IORDY

CAB_SEL

DMACK

GND

INT_ATA

IOCSI6-

ATA-A 1

PDIAG-

ATA-A 0

ATA-A 2

CS1FX

CS3FX

DASP-

GND

p10727001a_rev1

A

BCDEFG

2-3 2-4

Page 18

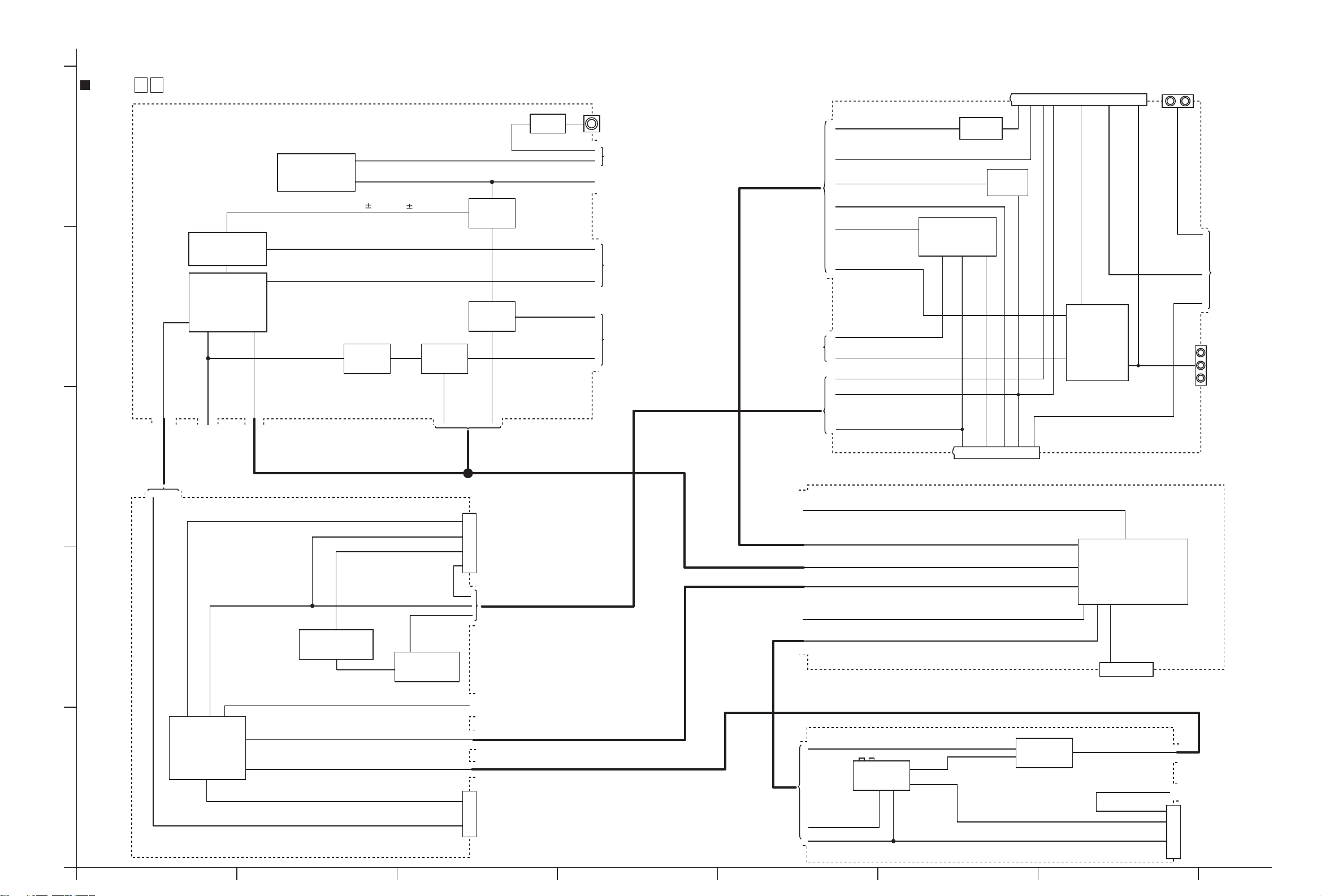

Block diagrams

MAIN 0 3

Audio signal control section (SHEET 2)

5

2chDA converter

4

SHEET 6

3

IC8201

24bit

A/D converter

IC8001

TU_AUDIO[L/R]

TO

A_MUTE2[H]

Muting

Q8203,Q8205

AOUTL AOUTR

DAC_SDA DAC_SCL A_DAC_CS DAC_RST[L]

AO_D[0] AO_SCLK AO_FSYNC AO_MCLKO

AI_D[0] AI_SCLK AI_MCLK0 AI_FSYNC

OP.AMP.

ACD_RST[L]

I2C_CLK2

I2C_DATA2

A_MUTE1[H]

IC8303

AV Switch

IC8302

AO_IEC958

OP.AMP.

IC8202

AV Switch

IC8301

AV2_HAV1_L

IC8501

AUDIO_OUT1[L/R]

LINE_OUT[L/R]

AUDIO_IN2[L/R]

DEC_OUT[L/R]

AUDIO_IN1[L/R]

J8501

COAXIAL OUT

TO SHEET 7

TO SHEET 4

TO SHEET 7

TO SHEET 4

TO SHEET 7

RAPID_SW BIAS/RGB_CTL

4_3[L] P50_I/O AV_YC_IN[H] TV[L]

AV1_L

SCR_ID

AV2_H RGB_TH[H]

SWITCH

IC7303 IC7304

VMUTE[L] YC_MIX[L]

PB/B_OUT PR/R_OUT

PY/G_OUT V/Y_OUT

SCOUT SYOUT

REAR1_C_IN REAR1_Y_IN

REAR1_V_IN

REAR2_RC_IN REAR2_G_IN

REAR2_B_IN REAR2_Y_IN

L-2 SCART Terminal

Q7310 to

Q7312

J7302

SWITCH

IC7302

R

G

B

L-1 SCART Terminal

J7301

V_OUT

R

G

B

V_OUT

Video driver

IC7301

DEC_OUT[L/R] AUDIO_IN2[L/R]

Input/output terminal section

(SHEET 4)

J7304

AUDIO OUT

AUDIO_OUT1[L/R]

LINE_OUT[L/R]

AUDIO_IN1[L/R]

TO

SHEET 2

J7309

COMPONENT

VIDEO OUT

TO

HDD_P_CTL[H] DVD_P_CTL[H] FAN_CTL P.CTL[H] P.SAVE[L]

SHEET 1

SCR_ID 4_3[L] TV[L] RGB_TH[H] AV1_YC_IN[H] BIAS/RGB_CTL AV1_L AV2_H

REAR2_Y_IN

REAR2_RC_IN

TO CN4402

SHEET 17

FSC2

C_FROM_RGB

Y_FROM_RGB

H_OUT

V_OUT

SYNC

REAR2_RC_IN

2

REAR2_Y_IN

REAR1_C_IN

REAR1_V_IN

REAR1_Y_IN

VPS/PDC Slicer

IC4201

SYNIN

YTODIGI CTODIGI

REAR2_B_IN

REAR2_G_IN

RGB_IN[H]

Video switch

IC4202

TO

SHEET 7

TO SHEET 7

SYNC_DET

I2C_DATA2 I2C_CLK2 PD[L]

Video controller

IC4001

1

F_AUDIO[L/R]

TU_VIDEO

FRONT_VIDEO FRONT_Y_IN FRONT_C_IN

CN4001CN4401

TO CN7102

SHEET 9

Video signal control section (SHEET 3)

P_MUTE[H] RAPID_SW V_MUTE[L] P50_I/O YC_MIX[L] RAPID_IN

ADC_RST[L] A_MUTE1[H] I2C_CLK2 I2C_DATA2 AV1_L AV2_H

I2C_DATA2 I2C_CLK2 SYNC_DET PD[L] RGB_IN[H]

G_TX IRTX G_RX K_BUS_OUT K_BUS_IN K_BUS_CLK

K_BUS_REQ SYS_RESET P.CTL[H]

TU_V_MUTE[H] TU_DATA TU_CLK AFC SW_1 SW_2 RF_AGC

System controller section (SHEET 5)

AFC

RF_AGC

SW_1 SW_2

TU_V_MUTE[H]

Tuner

TU6001

TU_DATA TU_CLK

VIDEO_OUT

COMP SIF

Muting

Q6030

Tuner section (SHEET 6)

System controller

STB RC_IN S_CLK

S_DATA_TOSYS LED_OUT

S_DATA_FRSYS

CN3001

TO CN7001

SHEET 9

TU_VIDEO

DEMOD[L/R]

IC3001

TO SHEET 2

TO CN6701

SHEET 8

CN6701

A

BCD EFG

2-5 2-6

Page 19

DIGITAL 5 0

CN4104

IEEE1394

5

PHY_RESET[L]

PHY_LREQ PHY_CLK

PHY_CNA PHY_CTL[0],[1]

PHY_DATA[0-7] PHY_LPS

PHY_LINK_ON

controller

IC1801

TPA+ TPA- TPB+ TPB-

CN1801

IEEE1394 section (SHEET 10)

J4112

IEEE1394

terminal

VI_D2 to D9 VIDEO_27M E5_RESET_L SIO_SCL SIO_SDA

C_IN VY_IN

Video

decoder

IC1901

Video decoder section (SHEET 13)

RA1613 to

RA1616

4

SDRAM_A_17

SDRAM_DQ0 to 15

RA1609 to

DDR_DQ0 to 15

RA1612

SDRAM_A0 to 15

SDRAM_CKE

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

RA1625 to

RA1628

RA1634

DDR_DQ16 to 31SDRAM_DQ16 to 31

DDR SDRAM

IC1601

DDR_BA0,1

DDR_A0 to 12

DDR_CKE

DDR_RAS_L

DDR_CAS_L

DDR_WE_L

DDR SDRAM

IC1602

ATA_DMAACK[L] ATA_INTRQ ATA_ADD0 to 4 ATA_DIOR[L]

ATA_DIOW[L] ATA_IORDY ATA_DAT0 to 15 ATA_RESET

ATA_DMARQ

ATAPI Interface section (SHEET 14)

MADD1 to 22

RD/WR[L] E5_RESET[L] OE[L]/LDS[L] CS[0]

CN2201

To Front end board

of drive unit

64Mbit Flash

IC1201

3

SDRAM_DQM0 to 3

SDRAM_DQS0 to 3

RA1635

DDR_DQM0 to 3

DDR_DQS0 to 3

LH_AR6 to 22

R1601 to R1604

SDRAM_CLK0,1

SDRAM_CLK_L0,1

R1606 to

R1609

DDR_CLK0,1

DDR_CLK_L0,1

ALE MADD6 to 21

IC1202

IC1203

DDR SDRAM section (SHEET 11)

FLASH-ROM section (SHEET 15)

C_IN YV_IN

2

G_Y_OUT B_PB_OUT G_TX IRTX G_RX SYS_RESET[L] A_MUTE[H]

SY_OUT SC_OUT V_Y_OUT R_PR_OUT

AI_MCLK AI_FSYNC AI_SCLK AI_D[0] DAC_SDA DAC_SCL A_DAC_CS

DAC_RST[L] AO_FSYNC AO_D[0] AO_SCLK AO_IEC958

K_BUS_CLK K_BUS_REQ K_BUS_IN K_BUS_OUT

Media

processor

IC1401

E5_RESET_L VI_D2 to D9 VIDEO_27M SIO_SCL SIO_SDA

AI_SCLK AI_FSYNC AI_MCLKO V_Y_OUT SY_OUT SC_OUT

G_Y_OUT B_PB_OUT R_PR_OUT AO_D_0 AO_SCLK AO_FSYNC

AO_IEC958 AO_MCLK AI_D_0 SPI_CLK A_DAC_CS SPI_MOSI

A_MUTE2_H G_TX G_RX IRTX K_BUS_CLK K_BUS_REQ

SYS_RESET_L K_BUS_OUT K_BUS_IN DAC_RST_L

ATA_DMAACK[L] ATA_INTRQ ATA_ADD0 to 4

ATA_DIOR[L] ATA_DIOW[L] ATA_IORDY

ATA_DAT0 to 15 ATA_RESET ATA_DMARQ

1

RD/WR[L] ALE OE[L]/LDS[L] MADD1 to 22 CS[0] E5_RESET[L]

Digital junction section (SHEET 16)

CN1103

TO CN4103

SHEET 7

CN1102

TO CN4102

SHEET 7

CN1101

TO CN4101

SHEET 7

Media processor (SHEET 12)

A

BCDEFG

2-7 2-8

Page 20

MAIN 0 3

DISPLAY 2 8

-29V DC3.9V[+/-]

AC IN

5

4

AC-DC

D5001

Switching

regurator

IC5101

Powe r

transformer

T5001

SW-12V SW12V SW5V AL5.8V D1.8V D2.5V

FAN_CTL P.CTL[H]

DVD_P.CTL[H]

P.SAVE[L]

5V REG.

IC5303

DV5V REG.

IC5308

DV5 V

DV1 2V

DV1.8V REG.

IC5304

DV1.8V

Power supply section (SHEET 1)

D5V

TO SHEET 9

TO each sheet

TO SHEET 5

CN5303 CN5302

TO Fan assembly

TO each sheet

TO DRIVE UNIT

FL Display driver

IC7001

G1 to G10

S1 to S18

FL Display

DI7001

KEY1

OPERATION 2 6

Power switch

S7101

LIGHTING

D7106

Power switch section (SHEET 9)

KEY1,KEY2

STB S_DATA_FRSYS

S_DATA_TOSYS S_CLK

CN7003

CN7103

RC-IN

Remote controller

IC7101

BLUE_LED

CN7002

CN7001

TO CN3001

SHEET 5

FL Display section (SHEET 9)

MAIN 0 3

3

TO SHEET 2

TO SHEET 3

TO SHEET 4

2

TO SHEET 5

DEMOD 1 4

1

TO CN6701

SHEET 6

AO_IEC958 AO_MCLKO AO_SCLK AO_D[0] AO_FSYNC

DAC_RST[L] A_DAC_CS DAC_SCL DAC_SDA AI_D[0] AI_SCLK

AI_FSYNC AI_MCLKO

A_MUTE2[H]

YTODIGI CTODIGI SYNC_DET1

PB/B_OUT PY/G_OUT PR/R_OUT V/Y_OUT SC_OUT SY_OUT

P.CTL[H] SYS_RESET[L] HDD_P.CTL[H] P_MUTE[H] G_RX

IRTX G_TX

K_BUS_OUT K_BUS_IN K_BUS_REQ K_BUS_CLK

Input/output relay section (SHEET 7)

I2C_DATA I2C_CLK DEMOD[L/R]

CN6701

COMP SIF

Demodulator

IC6701

Demodulator section (SHEET 8)

TO CN1102

SHEET 16

CN4103CN4102 CN4101

TO CN1103

SHEET 16

TO CN1101

SHEET 16

SW/JACK 2 7

Operation switch

S7132 S7135

S7112 to S7115

FRONT_C/Y_IN

CN7102

TO CN4001

SHEET 3

FRONT_VIDEO_IN

FRONT_A[L/R]_IN

Operation switch section (SHEET 9)

RGB_YC 6 8

RGB-Y/C Converter section (SHEET 17)

IC4403

H_OUT

V_OUT

YOUT

2IN-1OUT Switch

IC4402

Y_FROM_RGB

REAR2_Y_IN

KEY1,KEY2

LIGHTING

D7111

RGB-Y/C Converter

IC4401

C_FROM_RGB

SYNC

FSC2

CN4402

TO CN4401

SHEET 3

BLUE_LED

R_IN

G_IN

B_IN

CN7101

J7001

Front S-video IN

J7002

Front A/V IN

Video AMP.

IC4404

REAR2_RC_IN

REAR2_G_IN

REAR2_B_IN

A

BCD EFG

2-9 2-10

Page 21

Standard schematic diagrams

Power supply section

DC3.9V[+]

DC3.9V[-]

-29V

SW-12V

FAN_CTL

P.CTL[H]

SW12V

D5V

SW5V

AL5.8V

P.SAVE[L]

HDD_P.CTL[H]

GND

3.3V

BT2

45V

DVD_P.CTL[H]

SW2.5V

SW3.3V

CN5303

TO FAN UNIT

CN5301

CN5304

CN5302

D2.5V

D1.8V

CN5305

Not use

Not use

To each sheet

TO SHEET 9

TO SHEET 5

TO

SHEET 5

To each

sheet

TO SHEET 5

TO DRIVE UNIT

Not use

Q5316

D5315

R5318

D5309

D5310

Q5302

D5323

R5323

Q5301

C5334

C5340

C5310

C5312

Q5304

R5322

R5324

C5311

R5341

Q5311

C5333

D5307

C5341

C5316

Q5303

R5319

Q5308

Q5305

IC5304IC5306

Q5312

C5342

CP5302

IC5303

R5337

Q5309

C5336

C5343

R5336

B5503

D5308

C5344

B5502

B5501

C5317

C5328 C5329

IC5311

C5348

C5319

C5318

C5320

R5333

R5335R5309

C5330

C5349C5335

C5321

R5344

C5351

C5331

C5350

C5322

R5332

R5334

D5201

CP5301

C5201

C5347

C5346

D5318

D5202

B5506

D5215

D5210

D5203

D5214

D5211

C5202

D5212

D5301

D5204

C5204

D5205

D5206

C5205

D5207

D5208

D5209

C5208

D5213

IC5307

C5326

L5206

C5209

5

F5001

CN5001

DANGEROUS VOLTAGE

LF5001

C5001

IC5101

C5002

D5001

C5003

R5101

D5103

R5103

R5109

D5101

C5102

T5001

C5101

4

R5105

C5104

R5106

D5104

C5106

R5107

R5108

3

C5005

C5105

C5004

PC5101

R5301

R5302

C5301

C5302

IC5301

2

R5303

D5106

C5103

R5306

R5104C5107

R5304

R5305

D5105

R5102

D5319

IC5310

C5345

1

L5205

L5204

C5206

D5302

L5202

L5203

C5307

R5343

D5304

C5308

C5210

C5203

R5328

C5304

R5307

D5303

L5201

C5305

C5207

C5323

C5306

C5327

D5305 D5306

C5303

IC5309

R5308

R5329

R5315

B5301

D5316

R5314

C5309

R5310

D5311

D5312

D5313

C5313

B5504

R5320

IC5308

IC5302

B5505

Q5306

Q5313

R5311

C5315

C5325

R5312

C5314

C5324

R5321

Q5314

C5332

Q5307

R5313

D5321

D5320

Q5310

D5322

D5314

C5339

Q5315

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

* Refer to the "JVC" column of

a table for this model.

A

BCDEFG

2-11 2-12

p20494001a_rev1

SHEET 1

Page 22

Audio signal control section

AV1_L

AV2_H

I2C_CLK2

I2C_DATA2

A_MUTE1[H]

ADC_RST[L]

TO

SHEET 5

5

TU_AUDIO[R]

TU_AUDIO[L]

TO

SHEET 6

F_AUDIO[R]

TO

SHEET 3

F_AUDIO[L]

AUDIO_IN1[R]

AUDIO_IN1[L]

AUDIO_IN2[R]

TO

4

3

2

1

AUDIO_IN2[L]

SHEET 4

TO

SHEET 1

SW5V

3.3V

SW12V

SW-12V

3.3V

J8501

D5V

GND

R8506

C8505

C8506

C8504

R8504

K8501

L8501

R8505

R8007 R8008

C8503

B8011

B8003

B8012

C8501

C8502

R8002R8001

R8013 R8014

D8001

R8038

IC8501

R8015 R8016

R8502

R8501

R8503

R8507

C8014

C8005

C8007

C8008

C8009

C8010

C8011

C8012

R8022

R8023

R8024

R8026

R8031

C8021

R8017

R8019

R8020

R8021

IC8001

R8321

C8321

C8022

C8322

R8326

R8032

R8325

C8023

R8036

C8024

R8323

C8324 C8323

C8026

C8025

R8324

IC8303

R8322

C8027

C8028

R8037

R8033

R8034

R8040

R8041

C8029

R8035

R8042R8043

C8202

R8205

R8201

R8045 R8044

C8201

IC8201

R8202 R8203 R8204

R8206

R8220

R8218

C8206

R8217

R8219

R8214

R8212

C8203

R8211

R8213

R8222

R8221

C8205

R8216

R8215

C8208

C8207

C8204

C8306

R8301

IC8301

Q8201

C8209

C8211

C8304

R8307

C8301

C8308

C8210

IC8202

C8212

IC8302

R8224

C8302

C8305

R8306

C8316

R8302

C8307

R8223

Q8302

Q8202

R8308

R8313

C8311

C8317

C8303

R8304

R8315

C8312

C8318

R8303

C8315

C8217

C8215

R8310

R8234

R8233

Q8301

C8314

R8250

R8249

R8242

R8241

R8305

R8316

C8313

Q8205

Q8203

B8001

R8252

R8244

B8002

TO

SHEET 4

AUDIO_OUT1[L]

AUDIO_OUT1[R]

LINE_OUT[L]

LINE_OUT[R]

DEC_OUT[L]

DEC_OUT[R]

A_MUTE2[H]

AI_IEC958

TO SHEET 5

DAC_SDA

DAC_SCL

A_DAC_CS

DAC_RST[L]

AO_FSYNC

AO_D[0]

AO_SCLK

AO_MCLKO

AI_D[0]

AO_IEC958

TO SHEET 7

TO

SHEET 7

AI_SCLK

TO

AI_FSYNC

AI_MCLK0

SHEET 7

A

BCD EFG

2-13 2-14

p20496001a_rev0

SHEET 2

Page 23

Video signal control section

5

TO

SHEET 1

TO

SHEET 5

SW5V

I2C_DATA2

I2C_CLK2

GND

SEPA_IN[H]

PD[L]

GND

L4005

L4301

C4302

C4301

D4301

R4319

C4319

IC4304

R4317

C4310

R4311

R4318

C4318

C4304

R4304

Q4302

R4305

R4306

Q4303

R4307

R4308

C4305

C4307

C4306

IC4301

C4308

R4314

R4313

C4309

R4309

R4310

4

3

2

TO

SHEET 7

DTV_Y_OUT

DTV_C_OUT

TO

SHEET 6

TO

SHEET 2

YTODIGI

CTODIGI

TU_VIDEO

F_AUDIO[R]

F_AUDIO[L]

GND

CN4001

D4001

C4001

C4002

C4003

R4004

C4005

C4006

C4007 R4006

C4008

C4009

C4010

C4011

C4012

R4001

R4002

C4004

R4005

R4015C4045

R4007

D4002

R4003

L4001

C4013

IC4001

L4002

C4047

C4044

R4008C4014

C4015

C4042

C4016

Q4001

R4017

R4009

R4014

C4017

R4013

C4018

C4048

R4018

B4001

R4010

C4019

R4019

L4003

C4020

C4049

C4021

L4004

R4016C4046

C4050

C4022

C4036

C4023

R4021

R4020

C4024

C4025

C4065

C4035

R4011

L4007

C4033

C4032

C4029

C4028

C4027

C4026

C4034

C4030

C4031

C4216

C4217 C4218

IC4202

L4202

L4201

C4201

C4202

C4205

C4203

X4201

R4202

C4206

R4203

R4216

R4215

Q4201

C4204

R4204

IC4201

R4211

R4201

R4206

R4217

WR2

R4209

C4207

R4210

C4208

C4209

C4210

R4212

SYNC_DET

I2C_CLK2

I2C_DATA2

SECAM_DET[H]

TO

SHEET 7

SYNC_DET1

RGB_IN[H]

CN4401

TO

SHEET 5

TO CN4402

SHEET 17

1

TO CN7102

SHEET 9

R4036

R4040

R4041

REAR2_B_IN

REAR2_G_IN

REAR1_C_IN

REAR1_V_IN

REAR1_Y_IN

REAR2_RC_IN

REAR2_Y_IN

TO

SHEET 4

p10737001a_rev0

SHEET 3

A

BCDEFG

2-15 2-16

Page 24

Input/output terminal section

J7309

5

TO SHEET 5

4

3

4_3[L]

TV[L]

GND

D7304

R7301

R7302

Q7301

R7303

Not use

R7304

Q7302

CN7301

R7305

R7335

R7336

R7354

R7353

L7307

R7337

R7338

L7310

L7305

L7306

C7332

C7328

C7329

L7308

L7309

C7352 C7353

C7330

C7331

L7311

L7312

C7333

R7339

C7334 C7335

C7354 C7355

R7340

Q7310

R7378

Q7311

R7343

J7301

R7345

B7313

B7314

R7346

R7347

B7317

C7336

Q7316

C7346C7345

R7344

R7309

R7349

R7351

R7341

R7342

R7361

B7318

D7302

R7350

Q7313

C7347

Q7312

R7362

Q7321

Q7315

Q7314

L7304

R7352

R7348

R7320

R7319

B7303

R7318

B7316

B7315

P50_I/O

SCR_ID

R[H]

BIAS/RGB_CTL

AV1_YC_IN[H]

RAPID_SW

B7339

B7340

REAR1_C_IN

REAR1_V_IN

REAR1_Y_IN

SW5V

SW12V

RF5V

GND

SW-12V

SY_OUT

SC_OUT

V_MUTE[L]

YC_MIX[L]

RAPID_IN

AV1_L

AV2_H

RGB_TH[H]

B7319

L7301

C7301

C7363

C7327

C7372

WR1

IC7305

R7367

C7311

B7301

L7325

C7368

Q7317

C7369

C7326

R7368

IC7302

IC7301

C7302

C7313

C7304

C7364

C7305

C7357

IC7304

L7316

R7315

R7314

C7365

C7306

C7307

R7316

R7317

C7366

C7308

L7318

C7359

C7309

C7371

C7367

C7310

C7303

B7337

B7338

TO SHEET 5

TO SHEET 3

TO SHEET 1

TO SHEET 7

TO SHEET 5

R7357

J7302

R7358

D7303

R7359

R7360

C7340

C7317

R7313

TU_VIDEO

TO SHEET 6

C7316

B7307

C7319

B7308

C7318

L7321C7341

R7310

IC7303

C7314

TO SHEET 3

B7309

REAR2_B_IN

REAR2_RC_IN

B7310

B7311

B7312

REAR2_Y_IN

REAR2_G_IN

2-17 2-18

2

C7351

C7350

C7348

C7349

L7313

R7355

L7314

R7356

L7302

J7304

C7387

1

C7389

A

L7303

C7388

C7390

R7365

R7366

DEC_OUT[L]

LINE_OUT[L]

DEC_OUT[R]

LINE_OUT[R]

AUDIO_IN1[L]

AUDIO_IN2[L]

AUDIO_IN1[R]

AUDIO_OUT1[L]

AUDIO_OUT1[R]

AUDIO_IN2[R]

TO SHEET 2

BCD EFG

C7312

C7315

R7312

R7311

PB/B_OUT

PY/G_OUT

PR/R_OUT

TO SHEET 7

V/Y_OUT

p10738001a_rev0

SHEET 4

Page 25

System controller section

RGB_IN[H]

SCR_ID

TO

SHEET 3

5

SHEET 4

4

SHEET 1

3

SECAM_DET[H]

BIAS/RGB_CTL

TO

TO

SHEET 3

Not use

TO

Not use

SYS_RESET[L]

TO

SHEET 7

SEPA_IN[H]

4_3[L]

TV[L]

RGB_TH[H]

AV1_YC_IN[H]

AV1_L

AV2_H

P_MUTE[H]

RAPID_SW

V_MUTE[L]

I2C_DATA2

I2C_CLK2

PD[L]

CN3003

SW-12V

P.SAVE[L]

SW5V

SW12V

DVD_P.CTL[H]

HDD_P.CTL[H]

FAN_CTL

P.CTL[H]

AL5.8V

CN3004

K_BUS_OUT

K_BUS_IN

K_BUS_CLK

K_BUS_REQ

GND

P.CTL[H]

GND

D5V

3.3V

45V

GND

L3001

R3218

D3003

R3219

D3004

C3010 C3011

Q3004

R3214 R3213

C3042

D3002

B7451

R3234

C3040

C3039

R3061

R3056

R3057

R3058

R3062

R3063

R3065

R3067

R3068

R3069

R3070

R3072

R3074

R3075

R3076

R3220

R3084

R3242

R3083 C3035

R3085

R3089

R3093

R3094

D3005

R3087

R3088

R3090

R3091

R3092

R3100

R3201

C3001

C3002

R3003

R3004

R3005

R3006

R3007

R3008

R3009

IC3001

R3010

R3013

R3014

R3015

R3060

R3016

R3059

R3017

R3018

R3019

R3020

R3055

R3021

R3054

R3022

C3003

C3004

C3005

C3006

C3007

R3053

R3052

C3038

C3037

R3025

R3050

R3049

R3047

R3045

R3035

R3032

R3031

R3029

R3028

R3027

R3026

R3204

C3029

R3205

R3206

C3030

C3024

R3221

R3222

R3226

R3223

R3225

R3228

R3042

R3227

R3224

X3002

X3001

IC3002

C3025

C3026

C3033

C3034R3086

C3032

C3031

C3027

R3229

C3028

B7201

Q3005

C3054

R3209

C3021

L7201

R3207

C3020

R7202

B3901

R7203

Q7201

C7202

IC3004

C3041

C7452

R7457

Q7452

R7456

C7453

Q7451

R7204

R7455

R7453

R7454

C7456

C7451

C7454

D7451

R7458

R7459

R7451

R7452

C7455

D7453

G_TX

IRTX

G_RX

CN7451

Not use

J7451

AV1_L

AV2_H

ADC_RST[L]

AI_IEC958

A_MUTE1[H]

I2C_DATA2

I2C_CLK2

SHEET 2

SYNC_DET

I2C_DATA2

I2C_CLK2

SHEET 3

CN3901

Not use

TO

SHEET 7

J7451

TO

TO

2

1

BACK_UP_GND

S_DATA_TOSYS

S_DATA_FRSYS

TO

SHEET 9

LED_OUT

S_CLK

RC_IN

AL5V

R3231

R3232

R3233

R3202

STB

GND

R3235

D3008

Q3007

P50_I/O

YC_MIX[L]

RAPID_IN

R[H]

TU_V_MUTE[H]

TU_DATA

TU_CLK

SW_2

SW_1

AFC

RF_AGC

TO

SHEET 4

TO

SHEET 6

p10739001a_rev0

SHEET 5

A

BCDEFG

2-19 2-20

Page 26

Tuner section

5

GND

RF5V

SW5V

SW12V

BT2

SW3.3V

SW2.5V

TO

SHEET 1

L6804

C6807

C6805

4

TU6001

L6002

C6014

L6003

C6013

C6012

C6831

C6832

C6808

C6806

C6801

C6802

C6804

C6803

L6801

L6802

L6803

CN6801

TU_AUDIO[L]

GND

TU_AUDIO[R]

CN6701

Not use

TO

SHEET 2

3

L6701

R6080

C6027

C6028

L6005

2

R6032

C6037

R6020

C6020

R6021

C6021

C6032

R6033

C6005

R6834

R6836

R6835

R6833

C6751

C6752

TO CN6701

SHEET 8

CN6802

Not use

C6006

D6002

R6031

Q6031

1

TO SHEET 5

SW_1

SW_2

AFC

TU_CLK

TU_DATA

TU_V_MUTE[H]

R6030

Q6030

R6831

R6830

Q6830

B6831B6830

Q6831

DTV_Y_OUT

GND

DTV_C_OUTRF_AGC

GND

TU_VIDEO

GND

TO SHEET 3

p20489001a_rev1

SHEET 6

A

BCD EFG

2-21 2-22

Page 27

Input/output relay section

5

TO CN1103 SHEET 16

TO CN1101 SHEET 16TO CN1102 SHEET 16

CN4103

CN4102

4

TO SHEET 3

TO SHEET 4

YTODIGI

CTODIGI

PB/B_OUT

PY/G_OUT

PR/R_OUT

V/Y_OUT

SC_OUT

SY_OUT

C4082

C4080

C4079

3

A_MUTE2[H]

AO_IEC958

AO_MCLKO

AO_SCLK

AO_D[0]

AO_FSYNC

TO SHEET 2

2

DAC_RST[L]

A_DAC_CS

DAC_SCL

DAC_SDA

AI_D[0]

AI_SCLK

AI_FSYNC

AI_MCLK0

C4078

B4101

CN4101

R4147

D1.8V

D2.5V

3.3V

D5V

TO SHEET 1

SW5V

AL5.8V

K_BUS_CLK

K_BUS_REQ

K_BUS_IN

K_BUS_OUT

G_TX

IRTX

G_RX

P_MUTE[H]

HDD_P.CTL[H]

SYNC_DET1

SYS_RESET[L]

P.CTL[H]

TO SHEET 5

TO SHEET 3

TO SHEET 5

GND

RF5V

1

Q4101

C4110

C4109

C4084

R4104

R4105

GND

p20497001a_rev0

SHEET 7

A

BCDEFG

2-23 2-24

Page 28

Demodulator section

5

R6713R6715

C6714C6716

R6716C6718

B6702

4

TO CN6701

SHEET 6

3

CN6701

L6701

R6704

K6707

C6724

C6719

C6720

C6722

C6723

R6720

R6721

K6706

B6703

IC6701

R6712R6714

C6715C6717

R6711

C6713

D6701

R6710C6721

K6705

C6712

C6711

R6709

R6708

2

R6701

C6701

R6702

B6701

Q6701

R6703

C6702

L6702

C6705

R6705

R6706

1

C6703

C6704

C6706

K6701

K6702

R6707

C6710

X6701

C6709

C6708

K6708

C6707

R6719

p20495001a_rev1

SHEET 8

A

BCD EFG

2-25 2-26

Page 29

FL Display and operation switch section

IC7101

R7101

5

4

3

C7101

D7101 R7103

D7102

IC7001

S7101

S7102 S7104

C7001

R7002

R7001

C7008

S7103

CN7103

CN7003

D7103

R7009

R7015

R7005

R7007

R7006

R7013

R7014

D7034

D7033

D7032

D7035

R7003

C7005

C7004

R7102

R7104

D7104

D7106

D7105

R7105

C7102

Q7101

R7106

CN7002

J4112

J7001

J7002J7002J7002

D7111

R7111

D7112

R7112 C7111

K4*04

K4*03

K4*02

K4*01

Q7110

B4*22

R7113

R7156

KA4*01

B4*21

B4*23

KA4*02

B4*24

R7152

R7153

C7152 C7153

R7154

C7154

R7155

D7113

D7114

D7115

D7116

D7117

K4*05

K4*06

K4*07

R7151

C7151

C7155

S7131

S7132 S7112

S7133 S7113

S7134 S7114

S7135 S7115

CN4104

TO CN1801

SHEET 10

CN7102

TO CN4001

SHEET 3

S7111

D7031

L7001

C7002

R7021

CN7101

Not use

DI7001DI7001DI7001DI7001

DI7001

C7007

C7010

C7012

D7021

C7011

C7003

R7010

CN7001

CN3001

2

CN3002

LED_OUT

STB

S_DATA_FRSYS

S_DATA_TOSYS

S_CLK

RC_IN

AL5V

GND

BACK_UP_GND

DC3.9V[-]

-29V

DC3.9V[+]

TO

SHEET 5

TO

SHEET 1

1

p20479001a_rev0

SHEET 9

A

BCDEFG

2-27 2-28

Page 30

IEEE1394 Section

DIGITAL50

(1394PHY)

K1802

NQR0022-002X

5

FROM/TO

4

MEDIA PROCESSOR

TO

SHEET 12

3

PHY_RESET_L

PHY_LREQ

PHY_CLK

PHY_CNA

PHY_CTL_0

PHY_CTL_1

PHY_DATA_[0-7]

PHY_LPS

PHY_LINK_ON

PHY_DATA_[0-7]

PHY_DATA_0

PHY_DATA_1

PHY_DATA_2

PHY_DATA_3

PHY_DATA_4

PHY_DATA_5

PHY_DATA_6

PHY_DATA_7

1

2

3

4

RA1804

100

49AGND

TPBIAS1

TPBIAS0

32 AGND

AGND

TPA1+

TPA1-

TPB1+

TPB1-

AVDD

AGND

TPA0+

TPA0-

TPB0+

TPB0-

AGND

T

C1803

22/6.3

R1

R0

#

CN1802

QGF1016C2-07W

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

C1813

0.1

TPBIAS0

R1819

750

_0.5%

R1818

5.6k

_0.5%

TPA0+

TPA0-

TPB0+

TPB0-

LF1801

NQR0568-005X

1

2

3

45

8

7

6

TPA+

TPA-

TPB+

TPB-

7 GND

6 TPA+

5 TPA-

4 GND

3 TPB+

2 TPB-

1 GND

#

CN1801

QGB1231L2-09W

9 GND

8 GND

7 TPA+

6 TPA-

5 GND

4 TPB+

3 TPB-

2 GND

1 GND

Not use

TO CN4104

SHEET 9

R1820

10k

OPEN

R1822

C1809 12p

C1805

1

24.576M

63DGND

18 DGND

1801_XO

61DVDD

62DVDD

19 C/LKON

20 PC0

IC1801

TSB41AB2PAP

64DGND

1

R1801

R1802

R1824 100

R1825 100

1

2

3

4

8

7

6

5

8

7

6

5

RA1803

100

100

100

LREQ

2

SYSCLK

3

CNA

4

CTL0

5

CTL1

6

D0

7

D1

8

D2

9

D3

D4

10

D5

11

D6

12

D7

13

PD

14

LPS

15

NC

16

17 DGND

C1808 12p

X1801

NAX0551-001X

NAX0666-001X

1801_XI

58PLLGND

59XI

60XO

21 PC1

22 PC2

23 ISO

C1810 0.1

C1807

56PLLVDD

57PLLGND

24 CPS

25 DVDD

K1801

NQR0022-002X

0.1

53RESET

54FILTER0

55FILTER1

26 DVDD

27 TESTM

28 BRIDGE

C1804

52AVDD

29 TEST0

0.1

51AVDD

30 AVDD

50AGND

31 AVDD

2

SHEET 16

1

FROM

DIGIJUNCTION

TO

D3.3V

GND

10k

0`

R1823

876

123

RA1801

10k

R1807

8

765

5

1

234

4

RA1802

10k

10k

R1803

10k

R1804

R1806

OPEN

R1808

10k

10k

R1809

390k

R1810

0.1

C1811

1k

R1821

0.1

C1812

R1813 56

C1801 1

.NOTES:UNLESS OTHERWISE SPECIFIED

ALL RESISTANCE VALUES ARE IN OHMS.

ALL INDUCTANCE VALUES ARE IN H.

# MARK

Ref

Dest

Key

OTHER

A

CN1801NOCN1802

NO

YES

YESTHEATER

BCD EFG

ALL CAPACITANCE VALUES ARE IN F.

ELECTROLYTIC

CERAMIC

OS

ORGANIC SEMICONDUCTOR

T

TANTAL

2-29 2-30

R1816 56

R1815 56

R1814 56

C1802 270p

R1817 5.1k

1394PHY

p30137001a_rev0

SHEET 10

Page 31

DDR SDRAM Section

DIGITAL50

(DDR_SDRAM)

DDR_SDRAM

5

4

3

2

SHEET 12

TO SHEET 16

1

TO

FROM/TO

MEDIA PROCESSOR

SDRAM_DQ_[0-15]

SDRAM_DQ_[16-31]

SDRAM_A_17

SDRAM_A_15

SDRAM_A_14

SDRAM_A_[0-12]

SDRAM_CKE

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

SDRAM_DQM_[0-3]

SDRAM_DQS_[0-3]

SDRAM_CLK_0

SDRAM_CLK_1

SDRAM_CLK_L_0

SDRAM_CLK_L_1

SDRAM_VREF

DIGI JUNCTIONFROM

SSTL2_VDD

SDRAM_DQ_0

SDRAM_DQ_1

SDRAM_DQ_2

SDRAM_DQ_3

SDRAM_DQ_4

SDRAM_DQ_5

SDRAM_DQ_6

SDRAM_DQ_7

SDRAM_DQ_8

SDRAM_DQ_9

SDRAM_DQ_10

SDRAM_DQ_11

SDRAM_DQ_12

SDRAM_DQ_13

SDRAM_DQ_14

SDRAM_DQ_15

SDRAM_DQ_16

SDRAM_DQ_17

SDRAM_DQ_18

SDRAM_DQ_19

SDRAM_DQ_20

SDRAM_DQ_21

SDRAM_DQ_23

SDRAM_DQ_27

SDRAM_DQ_26

SDRAM_DQ_25

SDRAM_DQ_31

SDRAM_DQ_30

SDRAM_DQ_29

SDRAM_DQ_28

SDRAM_A_3

SDRAM_A_2

SDRAM_A_1

SDRAM_A_0

SDRAM_A_11

SDRAM_A_8

SDRAM_A_6

SDRAM_A_4

SDRAM_A_12

SDRAM_A_9

SDRAM_A_7

SDRAM_A_5

SDRAM_A_10

SDRAM_A_15

SDRAM_A_14

SDRAM_A_17

SDRAM_RAS_L

SDRAM_CKE

SDRAM_CAS_L

SDRAM_WE_L

SDRAM_DQM_0

SDRAM_DQM_1

SDRAM_DQM_2

SDRAM_DQM_3

SDRAM_DQS_0 DDR_DQS_0

SDRAM_DQS_1 DDR_DQS_1

SDRAM_DQS_2 DDR_DQS_2

SDRAM_DQS_3 DDR_DQS_3

SDRAM_CLK_0 DDR_CLK_0

SDRAM_CLK_1 DDR_CLK_1

SDRAM_CLK_L_0 DDR_CLK_L_0

SDRAM_CLK_L_1 DDR_CLK_L_1

SDRAM_CKE

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

SDRAM_CLK_0

SDRAM_CLK_1

SDRAM_CLK_L_0

D3.3V

GND

SDRAM_CLK_L_1

0`

R1701

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

1

2

3

4

1

2

3

4

4

3

2

1

R1642

33

4

3

2

1

4

3

2

1

R1601 33

R1602 33

R1603 33

R1604 33

R1606 22

R1607 22

R1608 22

R1609 22

5

6

7

8

C1701 0.1

B1702

C1654

0.1

5

6

7

8

5

6

7

8

5

6

7

8

5

6

7

8

5

6

7

8

5

6

7

8

5

6

7

8

5

6

7

8

5

6

7

8

8

7

6

5

8

7

6

5

5

6

7

8

5

6

7

8

5

6

7

8

#

IC1701

VDDQ4VREF

AVIN

VSENSE

PVIN

VTT

R1703

OPEN

RA1609

33

RA1610

33

RA1611

33

RA1612

33

RA1613

33

RA1614

33

RA1615

33

RA1616

33

RA1625

33

RA1626

33

RA1627

33

RA1628

33

RA1634

33

RA1635

33

B1701

#

C1707

OPEN

#

DDR_DQ_0

DDR_DQ_1

DDR_DQ_2

DDR_DQ_3

DDR_DQ_4

DDR_DQ_5

DDR_DQ_6

DDR_DQ_7

DDR_DQ_8

DDR_DQ_9

DDR_DQ_10

DDR_DQ_11

DDR_DQ_12

DDR_DQ_13

DDR_DQ_14

DDR_DQ_15

DDR_DQ_16

DDR_DQ_17

DDR_DQ_18

DDR_DQ_19

DDR_DQ_20

DDR_DQ_21

DDR_DQ_22SDRAM_DQ_22

DDR_DQ_23

DDR_DQ_27

DDR_DQ_26

DDR_DQ_25

DDR_DQ_24SDRAM_DQ_24

DDR_DQ_31

DDR_DQ_30

DDR_DQ_29

DDR_DQ_28

DDR_A_3

DDR_A_2

DDR_A_1

DDR_A_0

DDR_A_11

DDR_A_8

DDR_A_6

DDR_A_4

DDR_A_12

DDR_A_9

DDR_A_7

DDR_A_5

DDR_A_10

DDR_BA_1

DDR_BA_0

DDR_CS_0

DDR_RAS_L

DDR_CKE

DDR_CAS_L

DDR_WE_L

DDR_DQM_0

DDR_DQM_1

DDR_DQM_2

DDR_DQM_3

3

C1704

2

SD

0.1

1

GND

C1702

1

C1703

OPEN

T

C1705

22/4

C1706

10

R1704

OPEN

VTT

C1621

C1622

C1646

0.1

C1623

0.1

0.1

0.1

RA1617

100

RA1618

100

RA1619

100

RA1620

100

RA1629

100

RA1630

100

RA1631

100

RA1632

100

RA1633

C1624

0.1

8

7

6

5

8

7

6

5

8

7

6

5

8

7

6

5

C1642

0.1

1

2

3

4

1

2

3

4

1

2

3

4

4

3

2

1

R1605

100

4

3

100

2

1

C1625

C1626

0.1

0.1

DDR_DQ_0

1

DDR_DQ_1

2

DDR_DQ_2

3

DDR_DQ_3

4

DDR_DQ_4

1

DDR_DQ_5

2

DDR_DQ_6

3

DDR_DQ_7

4

DDR_DQ_8

1

DDR_DQ_9

2

DDR_DQ_10

3

DDR_DQ_11

4

DDR_DQ_12

1

DDR_DQ_13

2

DDR_DQ_14

3

DDR_DQ_15

4

C1610

0.1

DDR_DQ_15

C1605

0.1

DDR_DQ_14

DDR_A_0

8

DDR_A_1

7

DDR_A_2

6

DDR_A_3

5

DDR_A_4

8

DDR_A_5

7

DDR_A_6

6

DDR_A_7

5

DDR_A_8

8

DDR_A_9

7

DDR_A_11

6

DDR_A_12

5

5

DDR_A_10

6

DDR_BA_1

7

DDR_BA_0

8

DDR_CKE

5

DDR_RAS_L

6

DDR_CAS_L

7

DDR_WE_L

8

C1627

0.1

DDR_DQ_13

DDR_DQ_12

DDR_DQ_11

C1606

0.1

DDR_DQ_10

DDR_DQ_9

DDR_DQ_8

C1607

0.1

DDR_DQS_1 DDR_DQS_3

R1620

100

0.1

R1618

100

DDR_DQM_1

DDR_WE_L

DDR_CAS_L

DDR_RAS_L

DDR_CS_0 DDR_CS_0

DDR_BA_0

DDR_BA_1

DDR_A_10

DDR_A_0

DDR_A_1

DDR_A_2

DDR_A_3

C1612

0.1

1

VDD

2

D0

3

VDDQ

4

D1

5

D2

6

VSSQ

7

D3

8

D4

9

VDDQ

D5

10

D6

11

VSSQ

12

D7

13

NC

14

VDDQ

15

LDQS

16

NT5DS16M16CS-6K

NC

HY5DU561622DT-J

17

VDD

18

DNU

19

LDM

20

WE

21

CAS

22

RAS

23

cs

24

NC

25

BA0

26

BA1

27

A10/AP

28

A0

29

A1

30

A2

31

A3

32

VDD

33

IC1601

VSS

66

D15

65

VSSQ

64

D14

63

D13

62

VDDQ

61

D12

60

D11

59

VSSQ

58

D10

57

D9

56

VDDQ

55