Page 1

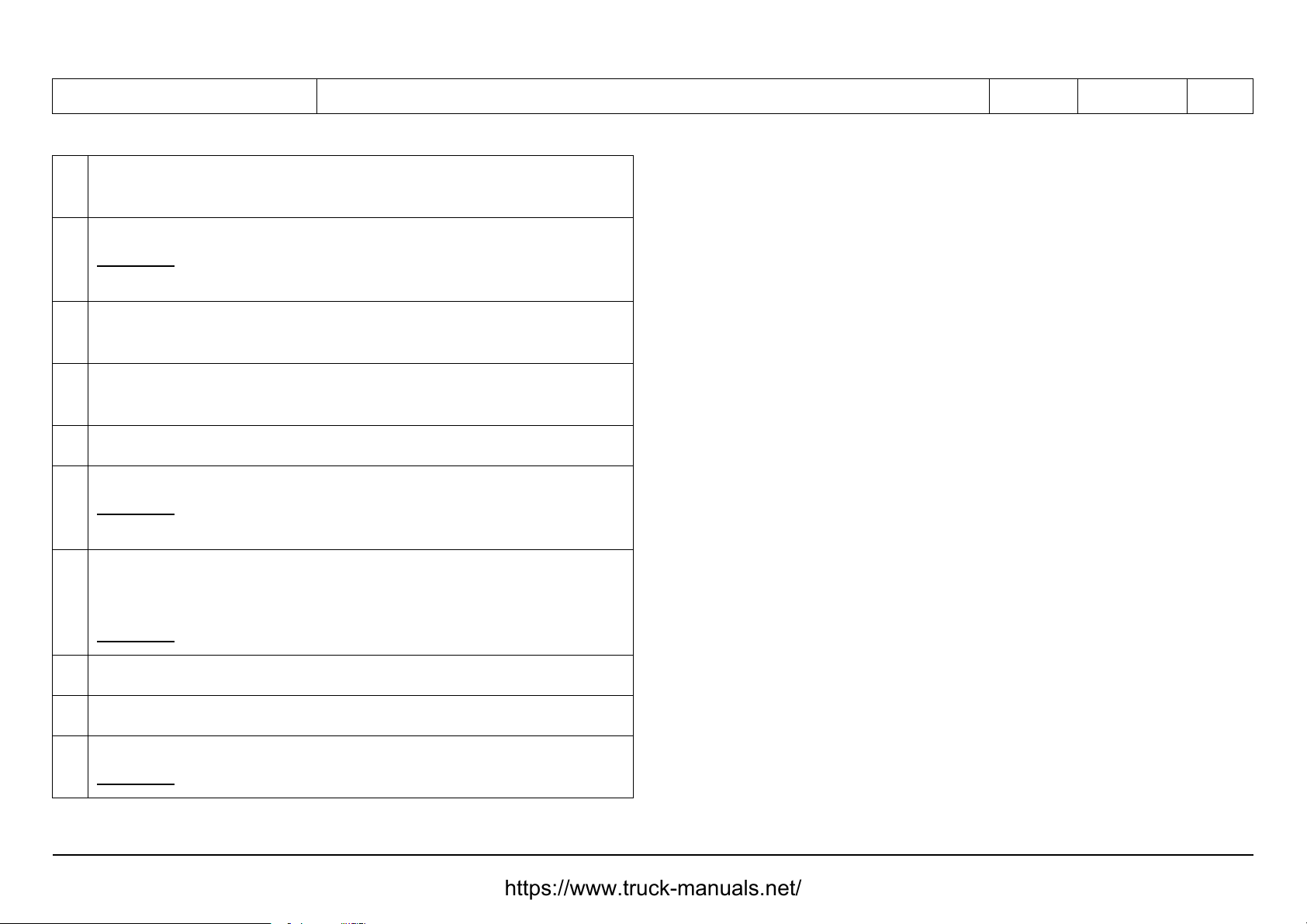

õUNGHEINRICH Event Messages

F

Function group

Event Messages

03.151

G

This display units shows a four-digit event message for every

Z

event. Trucks that only use one luminous display (e.g. LED) show

the event through a flashing code (see "Display System”).

Each event message is also stored in the master logbook. The

master logbook describes the event in more detail through the sub

index behind the event message (FEXX).

Event numbering display

F E XX S

F Function group; E Event group

XX Event number S Sub index

The first two characters “F, E” refer to the category. The middle

Z

two digits “XX” refer to the event. From these two digits the range:

•1 to 50 describes standard events (uniform basic events)

which can occur in any function group.

•51 to 99 describes specific events.

The event is described in further detail through the last characters

“S” (single digit/multi-digit).

This process ensures that a unique number is assigned to each

event. Example:

E

XX

S Sub-index

Event group

Event number

Sub-division of function group "F"

System:

Overlapping functions that cannot be assigned to any other

0

function group)

Example: seat switch / deadman switch or master controller

1Travel

2Hydraulics (load handling)

3Steering and travel

4Displays/controls, interface

5Charger (either on-board or external charger)

6Reserved

7Reserved

8Reserved

Special functions

9

Example: ISM

ï í ðë ï

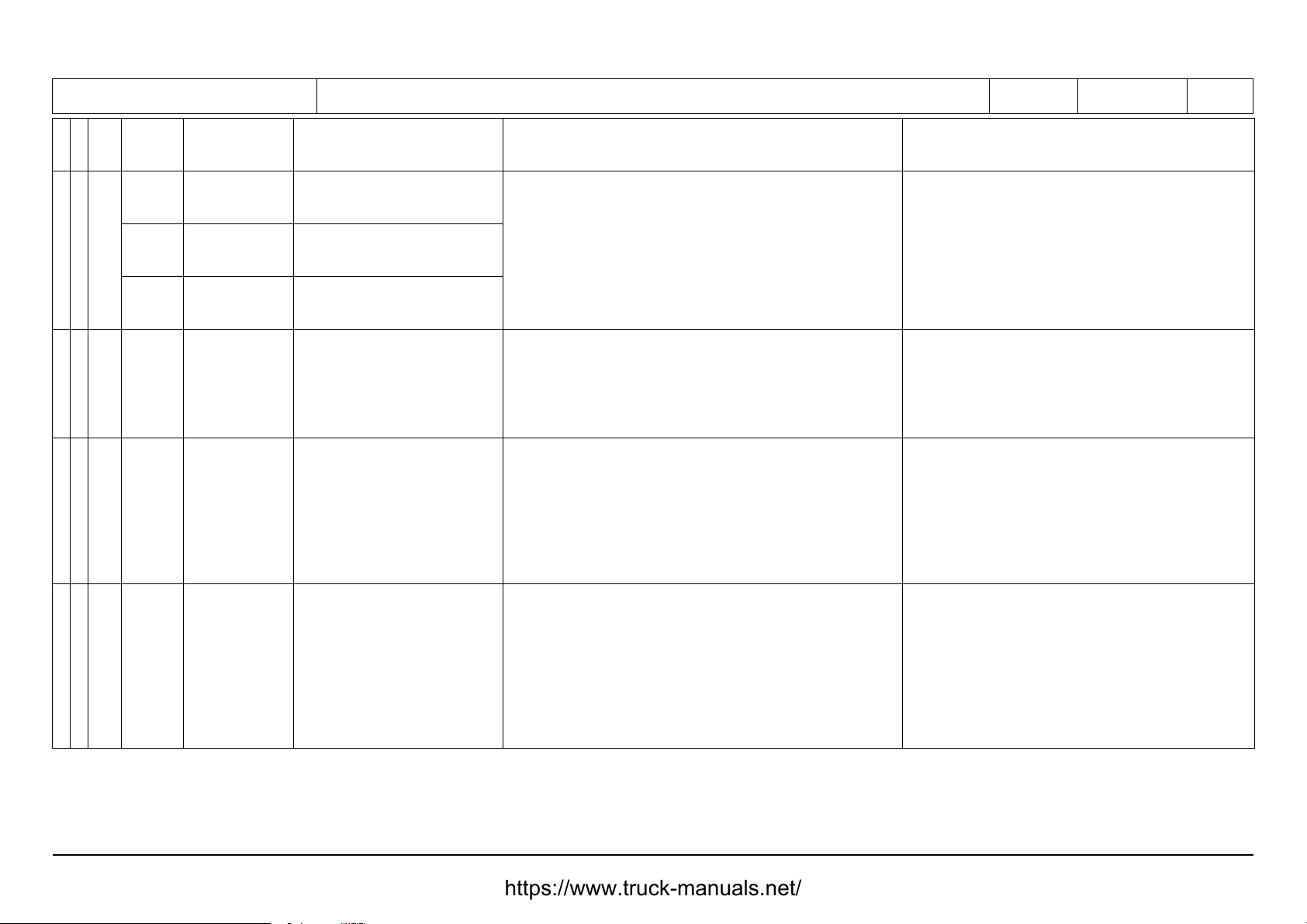

Page 2

õUNGHEINRICH Event Messages

Sub-division of event group “E”

Display system

03.152

G

Fault reset or

0

no fault

General fault / additional functions

1

Example:

Logic error, e.g. both directions selected simultaneously

Current

2

(input interface, device-internal, output interface)

Voltage

3

(input interface, device-internal, output interface)

4Temperature

Hardware

5

Example: Output transformer short circuit, EEPROM not

responding, …

Software

(internal software, application software, data record /

6

parameters)

Example:

7Additional modules

EEPROM data error

The system distinguishes between:

•event messages caused by operator errors.

•event messages caused by truck errors.

For operator errors there are three versions that can be displayed

in the truck depending on the display unit options.

•Event number display (e.g. CANDIS)

•Pictogram display

•Text message display

For truck errors the event number and possibly a fault graphic icon

(e.g. service key) will also be displayed.

Trucks that only use one luminous display (e.g. LED) use the

following flashing code:

•Each character of the four-digit event number is shown with a

2 Hz / 0.5 sec frequency (flashing).

The figure “zero” is displayed by flashing ten times.

Z

•After each character of the four-digit event message there is

a pause (LED off) of one second.

•After the complete four-digit event message a 3 second

pause (LED off) is set.

8CAN monitoring

External fault

9

Example: ISM

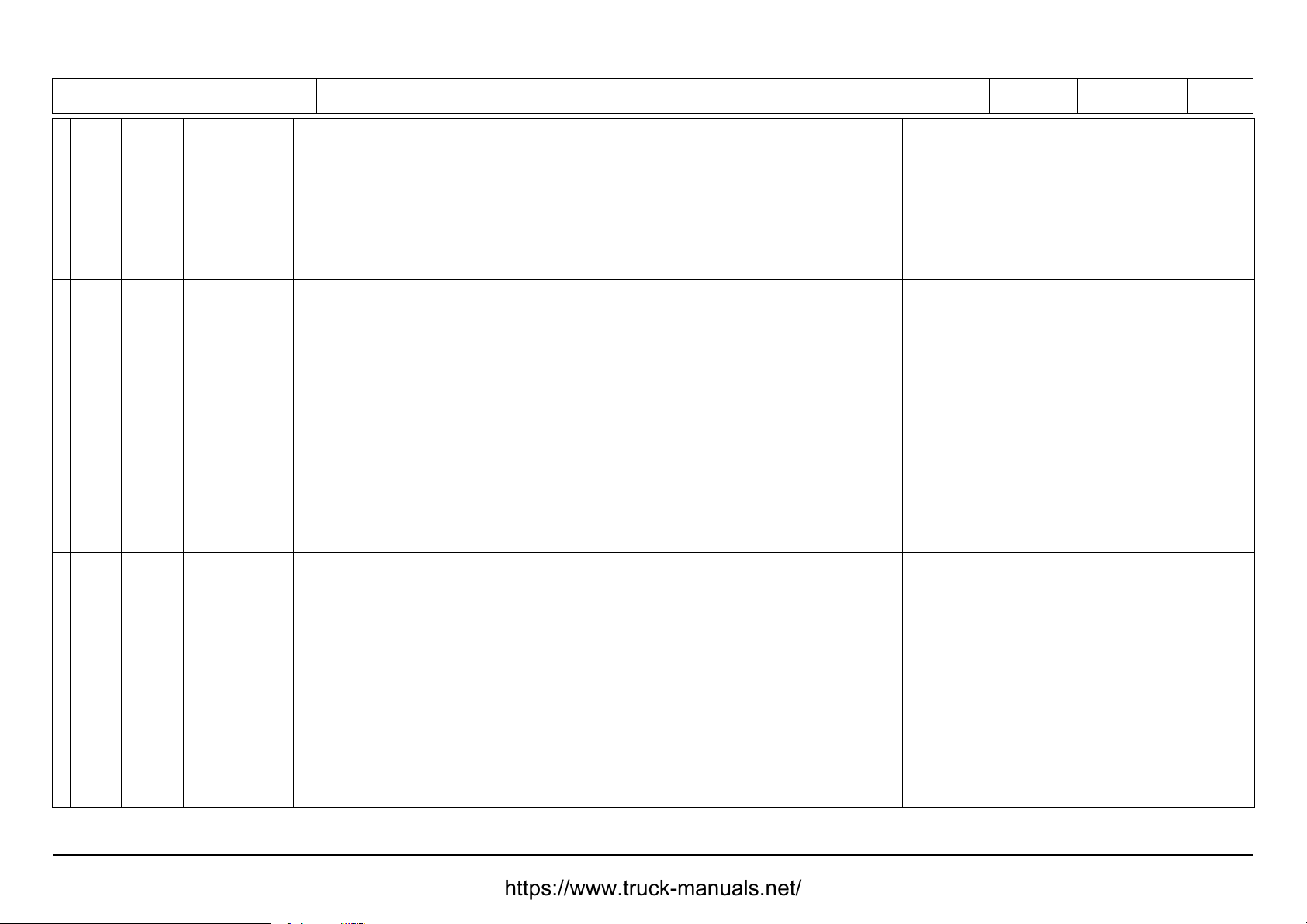

Page 3

õUNGHEINRICH Event Messages

03.153

Description / cause / action and effects

The following table lists the event message with a description / cause / action and effect.

Z

Each event group (E) with the corresponding event number (XX) can be combined with different function groups (F), hence in the following

table the placeholder “F” is used for the first character “F” of the four-digit event number.

It also shows the operating status when the event occurred:

Operating status Explanation

Occurs during / directly after truck power up

Bootloader

(basic initialisation of components, possible change to flash mode).

Example: Checking the RAM / ROM (memory check)

G

System start

Self test

OperationOccurs during operation

System endOccurs during truck power-down (correct powering down of components, …)

UndefinedCan occur at any time

Occurs during installation of operating software of individual components.

Example: correct hardware installed, ...

Occurs during the self-test of each component, as coordinated by the master

The main contactor is then closed

Page 4

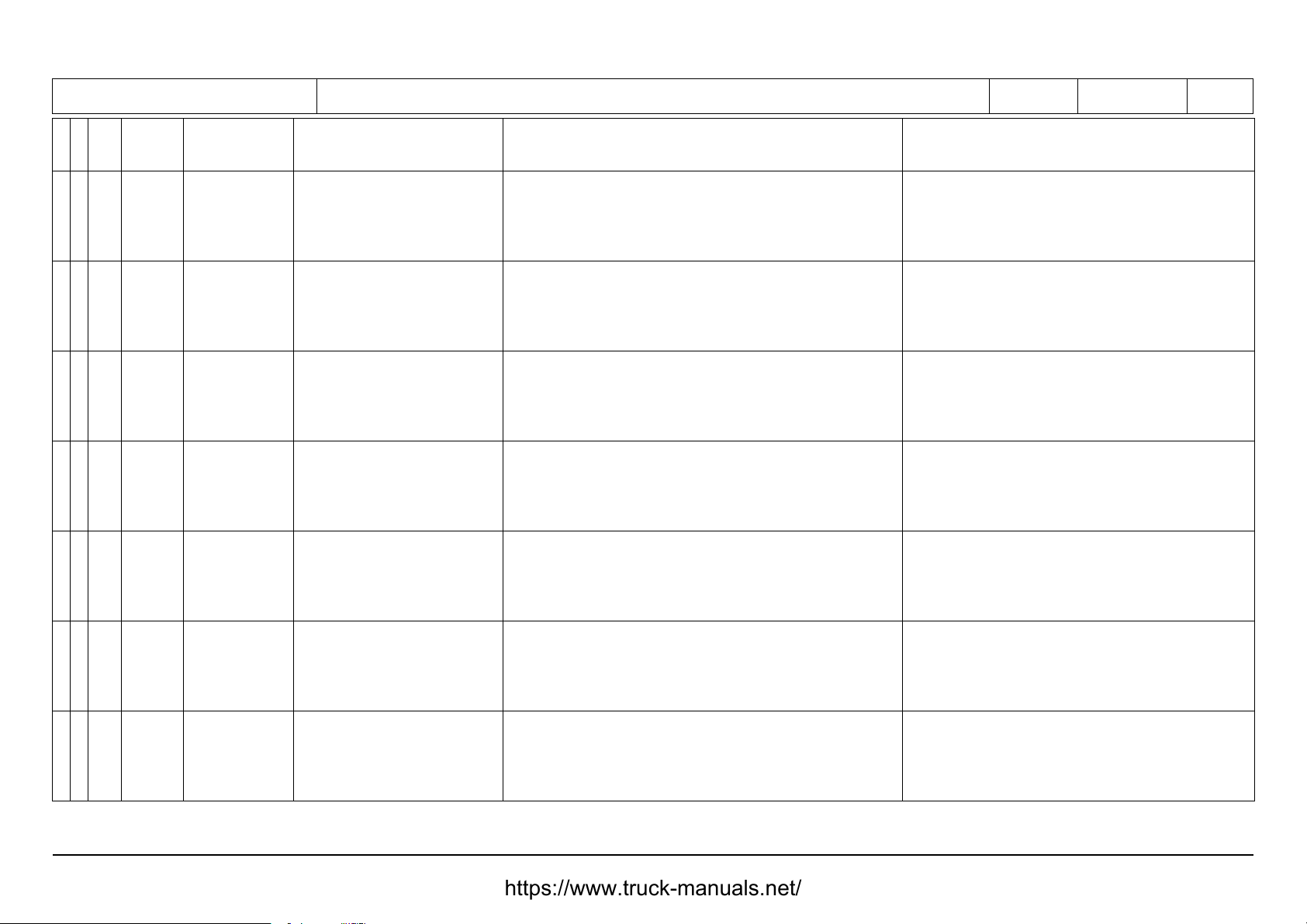

õUNGHEINRICH Event Messages

“Event messages” table

03.154

G

F E XX SOperational

Status

_1011System start

_1

_12Self test

02

_13Self test

_14

1Self test

Self test

Operation

DescriptionCause / Triggering EventAction

Supply via unexpected key

switch input

Contact closed instead of

open

Contact open instead of

closed

Main contactor permanently

on

Main contactor feedback

input implausible

Evaluation of three key switch inputs. Possible

encodings are 1, 2 or 4, otherwise the event message is

triggered.

On power-up the capacitor voltage should be one volt

(1V) below the battery voltage.

When the main contactor has switched on the capacitor

voltage should be the same as the battery voltage (within

500msec.), otherwise the event message is produced.

An attempt is being made to open the main contactor.

The event message is triggered if the monitoring system

detects that the main contactor has not opened after T >

time limit.

Feedback signal from main contactor status implausible

with main contactor control (error activated after limit

time)

-Check key switch input connection against the

wiring diagram;

-Replace controller;

-Test the main contactor output of the controller;

-Check wire connection;

-Replace contactor;

-Test the main contactor output of the controller;

-Check wire connection;

-Replace contactor;

-Replace controller;

Lithium-ion battery 24V/110Ah (in the case of

repeated faults):

-Check the harness of the lithium-ion battery and

replace if necessary;

-Replace battery contactor;

-Replace battery management system (BMS);

-Test the main contactor output of the controller;

-Check wire connection;

-Replace contactor;

_103

1Self test

2Self test

3Self test

Output transformer faulty

(phase U)

Output transformer faulty

(phase V)

Output transformer faulty

(phase W)

The semi-jumpers 1, 2 and 3 are controlled in turned for

50 msec at 25% PWM (pulse width modulation) when

the output transformer is closed (“Output transformer

deactivated” signal).

The event message is issued if at the end of the 50msec

period of the respective phase the following applies:

V

Phase_X

< (V

capacitor

/ 2) - 25%

-Replace controller;

Page 5

õUNGHEINRICH Event Messages

03.155

G

F E XX SOperational

DescriptionCause / Triggering EventAction

Status

1Self test

_104

2Self test

3Self test

_1044Operation

Output transformer faulty

(phase U)

Output transformer faulty

(phase V)

Output transformer faulty

(phase W)

Error bit set for power

stageID

_1051Self testMotor cutout

Semi-jumpers 1, 2 and 3 are controlled in turn for

50msec at 25% PWM (pulse width modulation).

The event message is issued if at the end of the 50msec

period of the respective phase the following applies:

V

Phase_X

V

Phase_X

> (V

< (V

capacitor

capacitor

/ 4) 25% or

/ 4) - 25%

"Error, power stage ID : The power card of the power

stage can only obtain faulty information (ID) about the

identity and hence suitability of the card for the intended

powering of the operating system when the error bit is

set"

Semi-jumpers 1, 2 and 3 are controlled in turn for

50msec at 25% PWM (pulse width modulation).

The event message is issued if at the end of the 50msec

period of at least one of the two non-controlled phases

the following applies:

V

Phase

V

Phase

> (V

< (V

capacitor

capacitor

/ 4) 25% or

/ 4) - 25%

-Replace controller;

-Replace controller;

-Check motor connection wire (wire breakage);

-Replace motor;

_1052Self test

"Combi controller behaviour

for non-controlled power

stages" logic implausible

Semi-jumpers 1, 2 and 3 of a combi controller power

partare controlled in turn for 50msec at 25% PWM

(pulsewidth modulation).

The event message is issued if at the end of the 50msec

period of at least one of the semi-jumpers of the other

power part the following applies:

V

Phase_X

V

Phase_X

> (V

< (V

capacitor

capacitor

/ 2) + 15% or

/ 2) - 15%

-Switch the truck off and on again;

-Check the motor connections;

-Check for a short between two power stages

ormotors;

-Replace signal-evaluating controller;

Page 6

õUNGHEINRICH Event Messages

03.156

G

F E XX SOperational

Status

_1061Operation

_1062Operation

_1063Operation

DescriptionCause / Triggering EventAction

Safety switch inputs

implausible

Deadman switch inputs

implausible

Slack-chain switch inputs

implausible

The safety switch consists of a NC and a NO contact.

When the button is pressed both contacts connect

simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation combinations 0/0 and 1/1 (500msec.)

trigger the event message.

For a valid combination (0/1 or 1/0, 500msec) the event

message and the truck response are reset. For an

implausible condition the seat switch is considered to

beopen (-> the truck brakes with the coasting ramp).

During operation combinations 0/0 and 1/1 trigger the

event message. The event message can only be reset

by resetting the truck. The activation limit is 2000msec.

During operation combinations 0/0 and 1/1 trigger the

event message. For a valid combination (0/1 or 1/0),

theevent and the truck response are reset. The

activation limit is 1000msec.

-Check safety switch wire connection;

-Check safety switch;

-Replace safety switch;

Safety switches can include:

Z

- Deadman (foot switch),

- Seat switch,

- Tiller switch.

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_1064Operation

_1065Operation

Cabin gate inputs

implausible

Optional cabin gate inputs

implausible

During operation combinations 0/0 and 1/1 trigger the

event message. For a valid combination (0/1 or 1/0),

theevent and the truck response are reset. The

activation limit is 2000msec.

During operation combinations 0/0 and 1/1 trigger the

event message. For a valid combination (0/1 or 1/0),

theevent and the truck response are reset. The

activation limit is 2000msec.

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

Page 7

õUNGHEINRICH Event Messages

03.157

G

F E XX SOperational

Status

_1066Operation

_1067Operation

_1068Operation

_1069Operation

DescriptionCause / Triggering EventAction

Sideshift index inputs

implausible

Aisle recognition right inputs

implausible

Aisle recognition left inputs

implausible

Load handling inputs: no

signal

During operation combinations 0/0 and 1/1 trigger the

event message after a traverse path of more than 30mm.

For a valid combination (0/1 or 1/0), the event and the

truck response are reset. The activation limit is 0msec.

During operation combinations 0/1 and 1/0 trigger the

event message after the truck has travelled more than

100mm. The event message can only be reset by

resetting the truck. The activation limit is 100msec.

During operation combinations 0/1 and 1/0 trigger the

event message after the truck has travelled more than

100mm. The event message can only be reset by

resetting the truck. The activation limit is 100msec.

During operation combinations 0/0 and 1/1 trigger the

event message. The event message can only be reset

by resetting the truck. The activation limit is 2000 msec.

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Test sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_10610Operation

_10611Operation

Load sensing inputs: no

signal

Logic test: signal at working

platform raised inputs

improbable

If the weight display > 300 kg the load sensors must be

applied. The event message can only be reset by

resetting the truck. The activation limit is 2000 msec.

During operation combinations 0/0 and 1/1 trigger the

event message. The event message can only be reset

by resetting the truck. The activation limit is 2000 msec.

-Check wiring with multimeter;

-Test sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Test sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

Page 8

õUNGHEINRICH Event Messages

03.158

G

F E XX SOperational

Status

_10612Operation

_10613Operation

_10614Operation

_10615Operation

DescriptionCause / Triggering EventAction

Logic test: signal at left/right

gate lock inputs improbable

Logic test: No signal for gate

lock despite gate lock being

applied

Logic test: Signal for gate

lock present despite gate

lock not being applied

Logic test: No signal for gate

lock despite the lift

mechanism being above the

set height

During operation combinations 0/1 and 1/0 trigger the

event message. The activation limit is 2000 msec.

During operation no feedback triggers the message

when applied. The activation limit is 2000 msec.

During operation a feedback triggers the message

without being applied. The activation limit is 2000 msec.

During operation no feedback triggers the message

when lift mechanism is above the set height. The

activation limit is 2000 msec.

-Check wiring with multimeter;

-Test sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Test sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Test sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Test sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_1071Operation

Operator protection switch

inputs implausible

The body protection switch consists of a NC and a NO

contact. When the button is pressed both contacts

connect simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation combinations 0/0 and 1/1 (500msec.)

trigger the event message.

For a valid combination (0/1 or 1/0, 500msec) the event

message and the truck response are reset.

-Check wire connections;

-Check operator protection switch;

-Replace operator protection switch;

Page 9

õUNGHEINRICH Event Messages

03.159

G

F E XX SOperational

Status

_1072Operation

_1081Operation

_1082Operation

DescriptionCause / Triggering EventAction

Acknowledge button inputs

implausible

Touch mode switch inputs

implausible

"Crawl speed redundant

inputs" logic implausible

During operation combinations 0/0 and 1/1 (500 msec.)

trigger the event message.

For a valid combination (0/1 or 1/0, 500msecs) the event

and the truck response are reset.

The touch mode button consists of a NC and a NO

contact. When the button is pressed both contacts

connect simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation combinations 0/0 and 1/1 (500msec.)

trigger the event message.

For a valid combination (0/1 or 1/0, 500msec) the event

message and the truck response are reset.

The "inching" button consists of a NC and a NO contact.

When the button is pressed both contacts switch

simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation the combinations

0/0 and 1/1 (switched for 500msec.) activate the event

message.

For a valid combination (0/1 or 1/0, switched for 500

msec.)

the event and truck response are reset. The status is

assessed as an actuated status (adjustable inching

speed active)

-Check wire connections;

-Check button;

-Replace button;

-Check wire connection;

-Check touch mode button;

-Replace touch mode button;

-Check wire connections;

-Check crawl speed button;

-Replace crawl speed button;

_1083Operation

“Stop" button redundant

inputs” logic improbable

The "Stop" button consists of an NC and an NO contact.

When the button is pressed both contacts switch

simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation the combinations

0/0 and 1/1 (500msec) trigger the event message.

For a valid combination (0/1 or 1/0, 500msec) the event

message and the truck's response are reset.

-Check parameter reading (side pedestrian mode

activated?);

-Check wire connections;

-Press "Stop" button;

-Replace "Stop" button;

Page 10

õUNGHEINRICH Event Messages

03.1510

G

F E XX SOperational

Status

_1084

_1085

Self test

Operation

Self test

Operation

DescriptionCause / Triggering EventAction

“Handbrake lever redundant

inputs” logic implausible

“Parking brake switch

redundant inputs” logic

implausible

The "handbrake lever" switch consists of a NC and a NO

contact. When the button is pressed both contacts switch

simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation the combinations

0/0 and 1/1 (switched for 500msec.) activate the event

message.

For a valid combination (0/1 or 1/0, switched for

500msec) the event message and the truck's response

are reset.

The "parking brake" switch consists of a NC and a NO

contact. When the button is pressed both contacts switch

simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation the combinations

0/0 and 1/1 (switched for 500msec.) activate the event

message.

For a valid combination (0/1 or 1/0, switched for 500

msec.) the event message and the truck's response are

reset.

-Check wire connections;

-Check “handbrake lever” switch;

-Replace “handbrake lever” switch;

-Check wire connections;

-Check options keypad;

-Replace options keypad:

_1091Operation

Weigher button inputs

implausible

The weigher button consists of a NC and a NO contact.

When the button is pressed both contacts connect

simultaneously. As a result, only the 0/1 and 1/0

combinations should occur.

During operation combinations 0/0 and 1/1 (500msec.)

trigger the event message.

For a valid combination (0/1 or 1/0, 500msec) the event

message and the truck response are reset.

-Check wire connection;

-Check weigher button;

-Replace weigher button;

Page 11

õUNGHEINRICH Event Messages

03.1511

G

F E XX SOperational

Status

_1101Operation

_1102Operation

_1111Operation

_1112Operation

DescriptionCause / Triggering EventAction

Lift/lower digital setpoints

are invalid

Lift/lower analog setpoints

are invalid

Braking setpoint and release

contact implausible

Braking setpoint and release

contact implausible

During operation the combination 1/1 for both buttons

pressed simultaneously for 500 msec triggers the

following event message.

For a valid combination (0/0, 0/1 or 1/0 [button not

pressed / only one button pressed]; 500msec) the event

message and the truck response are reset.

During operation the limits for 1/1 [both buttons pressed

simultaneously] for 500 msec have been exceeded.

For a valid combination (0/0, 0/1 or 1/0 [button not

pressed / only one button pressed]; 500msec) the event

message and the truck response are reset.

The event message is triggered if the following applies

for T = 250msec:

V

brake pedal

Logic signal release contact = 1

The event message is triggered if the following applies

for T = 250msec:

V

brake pedal

Logic signal release contact = 0

< 12.5% and

> 25% and

-Check wire connection;

-Check button;

-Replace button;

-Check wire connection;

-Check button;

-Replace button;

-Check wire connection;

-Check pedal power supply;

-Replace pedal;

-Replace signal-evaluating controller;

-Check wire connection;

-Check pedal power supply;

-Replace pedal;

-Replace signal-evaluating controller;

_1113Operation

_1114Operation

Braking setpoint and full

brake contact implausible

Braking setpoint and full

brake contact implausible

The event message is triggered if the following applies

for T = 250msec:

V

brake pedal

Logic signal full brake contact = 1

The event message is triggered if the following applies

for T = 250msec:

V

brake pedal

Logic signal full brake contact = 0

< 65% and

> 80% and

-Check wire connection;

-Check pedal power supply;

-Replace pedal;

-Replace signal-evaluating controller;

-Check wire connection;

-Check pedal power supply;

-Replace pedal;

-Replace signal-evaluating controller;

Page 12

õUNGHEINRICH Event Messages

03.1512

G

F E XX SOperational

Status

_1115Operation

_1116Operation

_1117Operation

_1121Operation

_1122Operation

DescriptionCause / Triggering EventAction

Combination "brake

setpoint" against brake

pressure invalid (movement

without brake pressure)

Combination "brake

setpoint" against brake

pressure invalid (brake

pressure without movement)

Sum of the voltages

"Braking 1 setpoint" to

"Braking 2 setpoint" invalid

Travel setpoint and release

contact invalid

Travel setpoint and release

contact invalid

The event message is triggered

if for T = 250 ms the following applies:

•V

brake pedal

> 80% and brake pressure < 40bar

The event message is triggered

if for T = 250 ms the following applies:

•V

brake pedal

< 20% (> 7 volt ) and brake pressure

>20bar

The event message is triggered

if for T = 250 ms the following applies:

•V

brake pedal

•V

brake pedal

1 + V

1 + V

brake pedal

brake pedal

2 > 5.5V or

2 < 4.5V

The event message is triggered if the following applies

for T = 250msec:

V

accelerator pedal

< 12.5% and

Logic signal release contact = 1

The event message is triggered if the following applies

for T = 250msec:

V

accelerator pedal

> 25 % and

Logic signal release contact = 0

-Check brake fluid level;

-Check proximity sensor;

-Check pressure sensors;

-Check brake fluid level;

-Check proximity sensor;

-Check pressure sensors;

-Check the cable connection;

-check accelerator-pedal power supply /

tiller head power supply;

-replace accelerator pedal / tiller arm;

-replace the controller that is evaluating the

signal;

-Check wire connection;

-Check accelerator pedal/tiller arm power supply;

-Replace accelerator pedal / tiller arm;

-Replace signal-evaluating controller;

-Check wire connection;

-Check accelerator pedal/tiller arm power supply;

-Replace accelerator pedal / tiller arm;

-Replace signal-evaluating controller;

_1123Operation

Total voltage "Travel1

setpoint" to "Travel2

setpoint" invalid

The event message is triggered

if for T = 250 ms the following applies:

•V

brake pedal

V

brake pedal

1 + V

brake pedal

2 < 4.5V

2 > 5.5V or V

brake pedal

1 +

-Check wire connection;

-Check accelerator pedal/tiller arm power supply;

-Replace accelerator pedal / tiller arm;

-Replace signal-evaluating controller;

Page 13

õUNGHEINRICH Event Messages

03.1513

G

F E XX SOperational

Status

_1131Operation

_1132Operation

_1141Self test

DescriptionCause / Triggering EventAction

Travel direction 1 and travel

direction 2 invalid

Direction setting signal

improbable (direction

sensor)

Motor speed signal

implausible

During operation the combination 1/1 [both travel

direction switch / button / twin pedal pressed] for 500

msec triggers the following event message.

For a valid combination (0/0, 0/1 or 1/0 [travel direction

switch/button/twin pedal not pressed or only one travel

direction switch/button/twin pedal pressed]; 500msec)

the event message and the truck response are reset.

If more than one direction sensor is installed:

While the truck is travelling, the system monitors if by

mistake more than one direction sensor (travel direction

switch on pilot, external direction sensor or twin pedal) is

installed. If this is the case, the event is triggered

Logic test: after a short period of motor control, the

speed sensor does not supply any signals

-Check wire connection;

-Check travel direction switch/button/twin pedal;

-Check travel direction switch/button/twin pedal;

-Replace signal-evaluating controller;

-Check parameter settings;

-Check installed accelerator (hardware);

-Check installed Pilots (hardware);

-Check travel direction switch / button / twin

pedal;

-Replace travel direction switch / button / twin

pedal;

-Rectify mechanical blockage of drive system;

-Check speed sensor power supply;

-Check wire connection;

-Replace speed sensor;

-Replace signal-evaluating controller;

_1151Operation

_1152Operation

_1161OperationIrregular speed signal

Motor powers without

setpoint

Motor powers without

setpoint

Motor powered for 500 msec without setpoint.

Logic: implausible status in controller

Convergence problem in monitor for the motor speed

Logic: implausible status in monitor

Jump from n_motor > 10% to n_motor < 1% and for

T = 80 msec. the following applies: n_motor < 1%

-Check motor connections;

-Check motor model, replace if necessary;

-Check motor connections;

-Check motor model, replace if necessary;

-Check speed sensor power supply;

-Check wire connection;

-Replace speed sensor;

-Replace signal-evaluating controller;

Page 14

õUNGHEINRICH Event Messages

03.1514

G

F E XX SOperational

Status

_1162Operation

DescriptionCause / Triggering EventAction

Irregular speed signal (large

jump in evaluated speed

signal)

Incrementer damaged

The AC-3 Power Control (U8) has identified the sensor

bearing as being damaged. The AC-3 Power Control

(U8) monitors sensor to ensure the impulse wires are

single-channel, and to check for sudden changes in the

pulse rate and for constant power supply.

Sensor is damaged (broken wire, short circuit, incorrect

pulses);

Operating system wrongly flags a fault;

AC-3 Power Control component (sensor bearing control)

is faulty

Jump from n_Motor> 10 % to n_Motor< 1 % and

For T = 80 msec.:

n_motor< 1%

No signals from incremental transmitter 1B5.

-Check incrementer signals with multimeter;

-Check speed sensor power supply;

-Check wire connection;

-Replace speed sensor;

-Replace signal-evaluating controller;

-Manually move the shuttle to the channel start,

remove any blockage (use recovery vehicle);

-Reduce load on shuttle;

-Drive: check setpoint specification, motor

controller 9U19 and drive motor including

carbon brushes and incremental transmitter

1B5;

-Check wire connection;

-If the shuttle is overloaded, increase the travel

speed;

_1163Operation

_1171Operation

Implausible value for the

engine-speed signal

A speed sensor channel

does not pulse

Engine control unit is sending an incorrect value for the

engine-speed signal.

Both speed sensor tracks are counted. When the first

deviation limit is reached the system waits for a feasible

signal from the suspected broken track. When the

second limit is reached the event message is generated.

-Check speed-sensor power supply;

-Check the wiring;

-Replace speed sensor;

-Replace the controller that is evaluating the

signal;

-Check speed sensor incrementer channels;

-Replace speed sensor;

-Replace signal-evaluating controller;

Page 15

õUNGHEINRICH Event Messages

03.1515

G

F E XX SOperational

Status

_1172Operation

_1173Operation

DescriptionCause / Triggering EventAction

A speed sensor channel

does not pulse

No speed signal from the

travel impulse sensor

although travel sensor

indicates greater than

0.5km/h.

Incrementer damaged

The AC-3 Power Control (U8) has identified the sensor

bearing as being damaged. The AC-3 Power Control

(U8) monitors sensor to ensure the impulse wires are

single-channel, and to check for sudden changes in the

pulse rate and for constant power supply.

Sensor is damaged (broken wire, short circuit, incorrect

pulses);

Operating system wrongly flags a fault;

AC-3 Power Control component (sensor bearing control)

is faulty

Both sensor tracks are counted. When the first deviation

limit is reached the system waits for a feasible signal

from the suspected broken track. When the second limit

is reached the event is generated.

The counts for both incrementers are compared.

Ifthetravel incrementer supplies a speed signal of

>0.05km/h and the travel pulse contact controller

incrementer a speed signal of 0 km/h, the event is

triggered. The activation limit is 100msec.

-Check incrementer signals with multimeter;

-Check speed sensor power supply;

-Check wire connection;

-Replace speed sensor;

-Replace signal-evaluating controller;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

_1174Operation

_1175Operation

No speed signal from travel

sensor although travel

impulse sensor indicates

greater than 0.5 km/h.

Deviation of more than

0.25km/h between travel

impulse sensor and travel

sensor

The counts for both incrementers are compared. If the

travel incrementer supplies a speed signal of 0 km/h and

the travel pulse contact controller incrementer a speed

signal of > 0.05 km/h, the event is triggered. The

activation limit is 100msec.

The counts for both incrementers are compared. If the

speed signals of both incrementers differ by more than

0.025 km/h, the event is triggered. The activation limit is

100msec.

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

Page 16

õUNGHEINRICH Event Messages

03.1516

G

F E XX SOperational

Status

_1176Operation

_1177Operation

_1178Operation

_1179Operation

_11710Operation

DescriptionCause / Triggering EventAction

Directions obtained from

travel sensor and travel

impulse sensor are

contradictory

One incremental track

height measurement of the

proportional lift pulses, the

other does not

One incremental track

height measurement of the

free lift pulses, the other

does not

One incremental track

height measurement of the

auxiliary lift pulses, the other

does not

Main lift does not lower

despite the hydraulic motor

turning

The counts for both incrementers are compared. If the

speed of both incrementers > 0.01 km/h and the

directions of the speed signals for both incrementers are

contradictory, the event is triggered. The activation limit

is 100msec.

Both sensor tracks are counted. When the first deviation

limit is reached the system waits for a feasible signal

from the suspected broken track. When the second limit

is reached the event is generated.

Both sensor tracks are counted. When the first deviation

limit is reached the system waits for a feasible signal

from the suspected broken track. When the second limit

is reached the event is generated.

Both sensor tracks are counted. When the first deviation

limit is reached the system waits for a feasible signal

from the suspected broken track. When the second limit

is reached the event is generated.

The counts for both incrementers are compared. If the lift

controller incrementer supplies a speed signal, but the lift

height measurement incrementer does not supply a

signal after one second, the event is triggered. The

activation limit is 20msec.

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

_11711Operation

Main lift lowers despite the

hydraulic motor not turning

The counts for both incrementers are compared. If the lift

height measurement incrementer supplies a speed

signal, but the lift controller incrementer does not supply

a signal after one second, the event is triggered. The

activation limit is 20msec.

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

Page 17

õUNGHEINRICH Event Messages

03.1517

G

F E XX SOperational

Status

_11712Operation

_11713Operation

_11714Operation

_11715Operation

_11716Operation

_11717Operation

DescriptionCause / Triggering EventAction

Excessive deviation

between lift speed and pump

speed

Proportional lift incrementer

1: One channel defective

Proportional lift incrementer

2: One channel defective

Free lift incrementer 1:

Onechannel defective

Free lift incrementer 2:

Onechannel defective

Aux. lift incrementer 1:

Onechannel defective

The counts for both incrementers are compared. If the

incrementers for the lift control and lift height

measurement are not synchronised within three

seconds, the event is triggered. The activation limit is

100msec.

Channel A or channel B are defective on the incrementer

Channel A or channel B are defective on the incrementer

Channel A or channel B are defective on the incrementer

Channel A or channel B are defective on the incrementer

Channel A or channel B are defective on the incrementer

-Check the hydraulic system for leaks;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

_11718Operation

_11719Operation

_11720Operation

Logic test: Main lift does not

lower despite pump rotating

LH load wheel sensor

incrementer deviation

RH load wheel sensor

incrementer deviation

The counts for both incrementers are compared.

If the lift controller incrementer supplies a speed signal,

but the lift height measurement incrementer does not

supply a signal after one second, the event is triggered.

The activation limit is 20 msec.

Incorrect counting detected between ChA and ChB.

Incorrect counting detected between ChA and ChB.

-Check incrementer signals with multimeter;

-Check wiring with multimeter;

-Replace speed sensor;

-Check mounting position of sensor to magnet;

-Replace sensor;

-Check mounting position of sensor to magnet;

-Replace sensor;

Page 18

õUNGHEINRICH Event Messages

03.1518

G

F E XX SOperational

Status

LH load wheel sensor

_11721Operation

_11722Operation

_11723Operation

_1181Undefined

_1191OperationCabin position implausible

excessive deviation from

reading to drive wheel

RH load wheel sensor

excessive deviation from

reading to drive wheel

Three channel incrementer

comparison with sensor

bearing incrementer

Speed sensor in load wheel

sensor damaged

DescriptionCause / Triggering EventAction

Incorrect counting detected between LH load wheel

sensor and drive wheel incrementer.

Incorrect counting detected between RH load wheel

sensor and drive wheel incrementer.

The sensor bearing and three channel incrementer are

synchronised with respect to each other every 120 mm.

The error is generated if the sensor bearing deviates

from the three channel sensor by >= 5 mm.

This event message is not currently used.

The event message is triggered

if for T >= time limit the following applies:

•A change in status of the platform lower-limit sensor

from the neutral position into the "Platform raised"

position is detected while driving

-Check mounting position of sensor to magnet;

-Check tyre quality;

-Replace sensor;

-Check mounting position of sensor to magnet;

-Check tyre quality;

-Replace sensor;

-Test the electrical function of the sensor bearing

-Test the mechanical function of the sensor

bearing

-Check speed sensor power supply;

-Check wire connection;

-Replace speed sensor;

-Replace signal-evaluating controller;

-Check wiring from controller to platform lower

limit sensor;

-Check / replace lower limit sensor;

-Check lift motor power cables;

- Replace the signal-generating controller;

Page 19

õUNGHEINRICH Event Messages

03.1519

G

F E XX SOperational

Status

_1201OperationDrive wheel slip excessive

_1211Self testOutput stage faulty

_1221

“Digital signal” logic/signal

shape implausible

DescriptionCause / Triggering EventAction

Excessive slip / drive has probably been tipped

The AC-3 Power Control (U8) has detected excessive

deviation (slip) between the phase current frequency and

the speed.

The activation limit is 20msec.

More torque is required from / placed on the motor than it

can provide / accept;

Field current is reduced excessively;

Error accompanying sensor bearing control or output

stage protection;

Operating system does not allow enough slip for the

driven motor;

AC-3 Power Control component is damaged

The lift actuator jumper is controlled for max. 40 msec at

100 % PWM (pulse width modulation).

The event message is triggered if the pump voltage

drops within this time below 10% of the capacitor

voltage: V

This event message is triggered if the signal shape or

modulation of a digital signal is implausible.

pump

> V

capacitor

/ 10.

-Check motor connection wire (wire breakage);

-Check motor model, replace if necessary;

-Check motor and replace if necessary;

-Check motor connection wire (wire breakage);

-Check motor model, replace if necessary;

-Replace controller;

-Replace tiller head;

_1231Operation

_1232Operation

Brake response switch

signal implausible (in idle)

Brake response switch

signal implausible (in idle)

The event message is triggered if after the brake applies

the feedback switch does not report this status (after

1sec.).

The event message is triggered if after the brake is

released the feedback switch does not report this status

(after 300msec.).

-Remove physical blockage from the brake;

-Check wire connection;

-Check switch and replace if necessary;

-Replace signal-evaluating controller;

-Remove physical blockage from the brake;

-Check wire connection;

-Check switch and replace if necessary;

-Replace signal-evaluating controller;

Page 20

õUNGHEINRICH Event Messages

03.1520

G

F E XX SOperational

Status

_1233Operation

_1234Operation

_1235System start

_1236Operation

DescriptionCause / Triggering EventAction

Brake response switch

signal implausible (speed >

1km/h)

Brake does not hold on a

ramp (failsafe brake)

Failsafe brake does not hold

(on system start or motor

start)

Left load wheel brake not

controlled but feedback

signal present

This event message is triggered if the response switch

signals applied status during travel.

The event message is triggered

if for T > 250 ms the drive system

•reports an actual rotational speed > 20rpm when the

brake is applied.

On system start or engine start, the traction drives are

subjected to a travel request for a test time. If a truck

actual speed is detected, this event will be triggered.

Left load wheel brake not controlled but feedback signal

is still present

The activation limit is 1000msec.

-Remove physical blockage from the brake;

-Check wire connection;

-Check switch and replace if necessary;

-Replace signal-evaluating controller;

-Check brake wear, replace wear parts / brake if

necessary.

-Measure current through the magnetic coil (you

should not be able to measure any current when

the brake is applied).

-Replace signal-issuing controller;

-Check brake wear, replace wear parts / brake if

necessary.

-Measure current through the magnetic coil (you

should not be able to measure any current when

the brake is applied).

-Replace signal-issuing controller;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_1237Operation

_1238Operation

Left load wheel brake

controlled although

feedback signal missing

Right load wheel brake not

controlled but feedback

signal present

Left load wheel brake controlled but feedback signal is

not present

The activation limit is 1000 msec.

Right load wheel brake not controlled but feedback

signal is still present

The activation limit is 1000 msec.

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

Page 21

õUNGHEINRICH Event Messages

03.1521

G

F E XX SOperational

Status

Right load wheel brake

_1239Operation

_12310System start

_12311Operation

_1241OperationLift height signal implausible

controlled although

feedback signal missing

hydraulic fail-safe brake

cannot be released

Parking brake feedback

contacts implausible

DescriptionCause / Triggering EventAction

Right load wheel brake controlled but feedback signal is

not present.

The activation limit is 1000 msec.

for 500 msec.: brake energised and pressure on

emergency stop mechanism > 3 bar

If the combinations 0/0 and 1/1 appear for longer than

the limit time, a message is activated.

The lift height sensor sequence is implausible. This

event message is triggered if the following applies for

T=> 500msec:

Sequence of 2 lift height signals is implausible, e.g.

Toplift height signal without Bottom lift height signal

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Listen to check if emergency stop mechanism

switches:

-If so, check the pressure sensor and replace if

necessary;

-If not, check the relay and replace if necessary;

-Check brake wear, replace wear parts / brake if

necessary;

-Check wire connection;

-Check switch and replace if necessary;

-Replace signal-evaluating controller;

-Check wire connection;

-Check sensor and replace if necessary;

-Replace signal-evaluating controller;

_1242Operation

_1243Operation

“Stacking height redundant

inputs” logic implausible

“Free lift sensor redundant

inputs” logic implausible

The event message is triggered

if for T = 100 ms the following applies:

•NC and NO contacts have the same status

The event message is triggered

if for T = 250 ms the following applies:

•NC and NO contacts have the same status

When the event occurs, the master assumes that the

truck is in the mast lift stage.

-Check wire connection;

-Check sensor and replace if necessary;

-Replace signal-evaluating controller;

-Check wire connection;

-Check sensor and replace if necessary;

Page 22

õUNGHEINRICH Event Messages

03.1522

G

F E XX SOperational

Status

_1244Operation

_1245Operation

_1246Operation

_1247Operation

DescriptionCause / Triggering EventAction

Lifting stroke greater than 2x

free lift, however mast lift

has not been detected

“Lift limit switch redundant

inputs” logic implausible

“Initial lowering limit

redundant inputs” logic

implausible

Logic: lift system limit

switchfaulty.

Integrated lift stroke is greater than 2x the set free lift

height, however sensor indicates free lift. When the

event occurs, the master assumes that the truck is in the

mast lift stage.

The event message is triggered

if for T = 100 ms the following applies:

•NC and NO contacts have the same status

The event message is triggered

if for T = 100 ms the following applies:

•NC and NO contacts have the same status

No positive signal at 7B38.1 - 7B38.4 during lifting or

lowering.

-Check wire connection;

-Check sensor and replace if necessary;

-Check wire connection;

-Check sensor and replace if necessary;

-Replace signal-evaluating controller;

-Check wire connection;

-Check sensor and replace if necessary;

-Replace signal-evaluating controller;

-If possible, do not use the lift system, as the lift

limit is deactivated. The lift mechanism could

move too far and be damaged;

-If absolutely necessary, carefully lower the

platform manually. Note that lowering must end

as soon as the shuttle can move freely

underneath the pallets;

-Check limit switches 7B38.1–7B38.4; check

signal feedback at inputs R3–R6 of the main

controller 8U37;

-Check the wiring;

_1248Operation

_1251Operation

Lift stroke greater than 1.5x

free lift, however mast lift

has not been detected

Signal on load sensing

inputs is implausible

Integrated lift stroke is greater than 1.5x the set free lift

height, however sensor indicates free lift.

When the event occurs, the master assumes that the

truck is in the mast lift stage.

Event is reset when mast lift is detected.

During operation combinations 0/0 and 1/1 trigger the

event message. The event message can only be reset

by resetting the truck. The activation limit is 2000msec.

-Check free-lift sensor (position, contamination);

-Check free-lift height setting (JUDIT);

-Check pump drive (e.g. worn pump?);

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

Page 23

õUNGHEINRICH Event Messages

03.1523

G

F E XX SOperational

Status

_1252Operation

_1261Operation

_1262Operation

_1263Operation

Description Cause / Triggering Event Action

No load sensing signal when

weight > 300 kg

Feedback from a main

contactor contact or the

emergency stop relay

although the Emergency

Disconnect switch is not

activated.

Feedback from the

Emergency Disconnect

switch at channel 1 of the

Safe computer although the

Emergency Disconnect

switch has not been

activated

Feedback from the main

contactor level 1 control at

channel 1 of the Safe

computer although contactor

level 1 has not been

activated.

Plausibility test: If the weight display >300kg the load

sensors must be applied. The event message can only

be reset by resetting the truck. The activation limit is

2000msec.

Feedback from a main contactor contact or the

emergency stop relay although the Emergency

Disconnect switch is not activated. The event message

can only be reset by resetting the truck. The activation

limit is 100msec.

Feedback from the Emergency Disconnect switch at

channel 1 of the Safe computer although the Emergency

Disconnect switch has not been activated. The event

message can only be reset by resetting the truck. The

activation limit is 100msec.

Feedback from the main contactor level 1 control at

channel 1 of the Safe computer although contactor level

1 has not been activated. The event message can only

be reset by resetting the truck. The activation limit is

100msec.

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_1264Operation

Feedback from the main

contactor level 2 control at

channel 1 of the Safe

computer although contactor

level 1 has not been

activated.

Feedback from the main contactor level 2 control at

channel 1 of the Safe computer although contactor level

1 has not been activated. The event message can only

be reset by resetting the truck. The activation limit is

100msec.

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

Page 24

õUNGHEINRICH Event Messages

03.1524

G

F E XX SOperational

Status

_1265Operation

_1266Operation

_1267Operation

DescriptionCause / Triggering EventAction

Feedback from the

Emergency Disconnect

switch at channel 2 of the

Safe computer although the

Emergency Disconnect

switch has not been

activated

Feedback from the main

contactor level 1 control at

channel 2 of the Safe

computer although contactor

level 1 has not been

activated.

No feedback from the

Emergency Disconnect

switch at channel 1/2 of the

Safe computer although the

Emergency Disconnect

switch has been activated

Feedback from the Emergency Disconnect switch at

channel 2 of the Safe computer although the Emergency

Disconnect switch has not been activated. The event

message can only be reset by resetting the truck. The

activation limit is 100msec.

Feedback from the main contactor level 1 control at

channel 2 of the Safe computer although contactor level

1 has not been activated. The event message can only

be reset by resetting the truck. The activation limit is

200msec.

No feedback from the Emergency Disconnect switch at

channel 1/2 of the Safe computer, although activated

The event message can only be reset by resetting the

truck. The activation limit is 200msec.

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_1268Operation

_1269Operation

_12610Operation

No feedback from relay K1

despite Safe computer

activation

No feedback from relay K2

despite Safe computer

activation

No feedback from relay K3

despite Safe computer

activation

No feedback from relay K1 although the Safe computer

has been activated. The event message can only be

reset by resetting the truck. The activation limit is

200msec.

No feedback from relay K2 although the Safe computer

has been activated. The event message can only be

reset by resetting the truck. The activation limit is

200msec.

No feedback from relay K3 although the Safe computer

has been activated. The event message can only be

reset by resetting the truck. The activation limit is

200msec.

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

Page 25

õUNGHEINRICH Event Messages

03.1525

G

F E XX SOperational

Status

_12611Operation

_12612Operation

_12613Operation

_12614System start

_12615Operation

DescriptionCause / Triggering EventAction

No feedback from relay K4

despite Safe computer

activation

No feedback from main

contactor 1 despite "main

contactor 1" signal activation

No feedback from main

contactor 2 despite "main

contactor 2" signal activation

Test routine for emergency

stop circuit by the Safe

computer has failed

Different input statuses

between the two Safe

computers

No feedback from relay K4 although the Safe computer

has been activated. The event message can only be

reset by resetting the truck. The activation limit is

200msec.

No feedback from main contactor 1 although the Safe

computer has been activated. The event message can

only be reset by resetting the truck. The activation limit is

200msec.

No feedback from main contactor 2 although the Safe

computer has been activated. The event message can

only be reset by resetting the truck. The activation limit is

200msec.

Power up test for emergency stop circuit by the Safe

computer has failed The event message can only be

reset by resetting the truck. The activation limit is

20msec.

Redundant controllers of the Safe computer have

detected different input statuses. The event message

can only be reset by resetting the truck. The activation

limit is 100msec.

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_12616System start

_12617System start

Comparison of channel A /

channel B of external

Emergency Disconnect of

APM + PLC for diversity

Monitoring of APM+

Emergency Stop cancel

request and the

power supply.

The error is triggered for the combination 1/0 or 0/1.

Activation limit 100 ms.

The Emergency Stop request is withdrawn via the

CanBus, however there is no corresponding Emergency

Disconnect feedback.

-Check information in the truck display;

-Assess wiring;

-Check CAN-Bus;

-Check information in the truck display;

-Assess wiring;

-Check CAN-Bus;

Page 26

õUNGHEINRICH Event Messages

03.1526

G

F E XX SOperational

Status

_12618System start

_1271Operation

_1281Operation

_1282Operation

_1291Operation

_1292Operation

_1293Operation

DescriptionCause / Triggering EventAction

Monitoring of APM+

Emergency Stop cancel

request and the

power supply.

Main Lift lowers without

activation signal

Main lift: free lift has lowered

before proportional lift

Main lift: proportional lift has

lowered before free lift

Main lift: Permissible

lowering speed exceeded

Aux. lift: Permissible

lowering speed exceeded

Sideshift: Permissible speed

exceeded

The Emergency Stop request is set via the CanBus,

however there is no corresponding Emergency

Disconnect feedback.

Main Lift stage has lost height without request. The

event message appears as soon as the lift height lowers

by more than 50mm without request.

The free lift stage has moved hydraulically although the

proportional lift stage was not fully retracted.

The proportional lift stage has moved hydraulically

although the free lift stage was not fully retracted.

The permissible lowering speed has been exceeded.

The permissible lowering speed has been exceeded.

The permissible sideshift speed has been exceeded.

-Check information in the truck display;

-Assess wiring;

-Check CAN-Bus;

-Check mast mechanics;

-Check mast hydraulics;

-Check mast mechanics;

-Check mast hydraulics;

-Check mast mechanics;

-Check mast hydraulics;

-Check mast mechanics;

-Check mast hydraulics;

-Compare actual speed with data sheet values;

-If it is too high, adjust to data sheet value;

-Compare the actual sideshift speed with the

data sheet values;

-If the sideshift speed has been exceeded, set it

to the data sheet values;

_1294Operation

_1301Operation

Rotate: Permissible speed

exceeded

Main lift does not reach pretension moment in

prescribed time

The permissible rotating speed has been exceeded.

The pre-tension moment could not be established in the

set time.

-Compare the actual rotating speed with the data

sheet values;

-If the rotating speed has been exceeded, set it

to the data sheet values;

-Check the pre-tension torque with JUDIT and

adjust if necessary;

-Check mechanical system of the mast;

-Check mast hydraulics;

Page 27

õUNGHEINRICH Event Messages

03.1527

G

F E XX SOperational

Status

_1302Operation

_1303Operation

_1304Operation

_1311System start

_1312System start

DescriptionCause / Triggering EventAction

Aux. lift does not reach pretension moment in

prescribed time

Pallet clamp does not reach

the "CLOSED" end position

in the prescribed time

Pallet clamp does not reach

the "OPEN" end position in

the prescribed time

Emergency stop circuit

power-up test: Emergency

Stop switch activated, but

CAN-BUS not OK

Emergency stop circuit

power-up test: no activation

of any pulse contact

controllers

The pre-tension moment could not be established in the

set time.

The pallet clamp "CLOSED" end position could not be

reached in the set time.

The pallet clamp "OPEN" end position could not be

reached in the set time.

CAN-BUS status damaged during booting. The event

message can only be reset by an Emergency Stop reset.

The activation limit is 1000msec.

No pulse contact controller has reported charge circuit

activation. The charging of the pulse contact controllers

must be finished within 10seconds. The activation limit

is 1000msec.

-Check the pre-tension torque with JUDIT and

adjust if necessary;

-Check mechanical system of the mast;

-Check mast hydraulics;

-Check the hydraulic setpoint and adjust if

necessary;

-Check the pallet clamp mechanisms for

sluggishness;

-Check the hydraulic setpoint and adjust if

necessary;

-Check the pallet clamp mechanisms for

sluggishness;

-Check wiring with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check the charging voltage on the controllers;

-Check wiring;

_1313System start

_1314System start

Emergency stop circuit

power-up test: no lift

controller activation

Emergency stop circuit

power-up test: no traction

controller activation

The hydraulic controller has not reported charge circuit

activation. The charging of the pulse contact controllers

must be finished within 10 seconds. The activation limit

is 1000msec.

The traction controller has not reported load circuit

activation. The charging of the pulse contact controllers

must be finished within 10 seconds. The activation limit

is 1000msec.

-Check the charging voltage on the controllers;

-Check wiring;

-Check the charging voltage on the controllers;

-Check wiring;

Page 28

õUNGHEINRICH Event Messages

03.1528

G

F E XX SOperational

Status

_1315System start

_1316System start

_1317System start

_1321System start

DescriptionCause / Triggering EventAction

Emergency stop circuit

power-up test: no steering

controller activation

Emergency stop circuit

power-up test: no release of

main contactor level 2

Emergency stop circuit

power-up test: non-defined

EMERGENCY STOP error

power circuit activated

during charging

The steering controller has not reported load circuit

activation. The charging of the pulse contact controllers

must be finished within 10 seconds. The activation limit

is 1000 msec.

Feedback contact of second main contactor level not

closed within 10 seconds. The activation limit is

1000msec.

Other non-separated event message in main contactor

circuit. This event message does not occur in normal

operation. The activation limit is 1000msec.

Charge

The AC-3 Power Control (U8) has been activated while

its internal capacitors were charging.

The main contactor was opened during active control.

Power circuit activated during charging. The activation

limit is 20msec.

The main contactor was disconnected during active

control;

The control system was activated before the main

contactor was closed and the internal capacitors were

charged;

Installation of the AC-3 Power Control component is

damaged;

AC-3 Power Control component (voltage measurement)

is damaged;

-Check the charging voltage on the controllers;

-Check wiring;

-Check the charging voltage on the controllers;

-Check wiring;

The event message should not occur.

Z

Otherwise contact troubleshooting specialists;

-Check power cables (main current connections,

integrated charging circuit wiring,...);

-Check main current fuses and replace if

necessary;

-Replace AC-3 Power Control interface card;

_1322Self test

Capacitor pre-charge cannot

be switched off

The capacitor voltage should reduce by at least 1 V

within 750 msec. of the pre-charge circuit being switched

off.

-Replace controller;

Page 29

õUNGHEINRICH Event Messages

03.1529

G

F E XX SOperational

Status

_1323Self test

_1331Operation

_1332Operation

_1333Operation

DescriptionCause / Triggering EventAction

Capacitor pre-charge

(output stage pre-charge)

not complete

Ground system track 1 left

actual value sensor system:

invalid channel A / channel

B value relationship

Ground system track 2 left

actual value sensor system:

invalid channel A / channel

B value relationship

Ground system track 3 left

actual value sensor system:

invalid channel A / channel

B value relationship

The condition (V-key - V-cap.) < limit voltage is not met

within a fixed time after activating the pre-charge circuit.

Switch status of ground sensors unequal. The activation

limit is 20msec.

Switch status of ground sensors unequal. The activation

limit is 20msec.

Switch status of ground sensors unequal. The activation

limit is 20msec.

-Check battery voltage;

-Check key switch voltage;

-Check controller power connections for short

circuits;

-Check harness for short circuit;

-Replace component;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace

ifnecessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace

ifnecessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

_1334Operation

_1335Operation

Ground system track 1 right

actual value sensor system:

invalid channel A / channel

B value relationship

Ground system track 2 right

actual value sensor system:

invalid channel A / channel

B value relationship

Switch status of ground sensors unequal. The activation

limit is 20msec.

Switch status of ground sensors unequal. The activation

limit is 20msec.

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

Page 30

õUNGHEINRICH Event Messages

03.1530

G

F E XX SOperational

Status

_1336Operation

_1341Operation

_1343Operation

_1345Operation

_1347Operation

DescriptionCause / Triggering EventAction

Ground system track 3 right

actual value sensor system:

invalid channel A / channel

B value relationship

Brake force governor: invalid

channel A / channel B value

relationship

Traverse sensor system:

invalid channel A / channel

B value relationship

Rotate sensor system:

invalid channel A / channel

B value relationship

Left hand support

mushroom: invalid channel

A / channel B value

relationship

Switch status of ground sensors unequal. The activation

limit is 20msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

-Check wiring with multimeter;

-Check sensor system with multimeter;

-Check computer component inputs;

-Repair faulty components and replace if

necessary;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

_1349Operation

_13411Operation

_13413Operation

Right hand support

mushroom: invalid channel

A / channel B value

relationship

Steering actual value sensor

systems: invalid channel A /

channel B value relationship

Steering setpoint device:

invalid channel A / channel

B value relationship

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

Page 31

õUNGHEINRICH Event Messages

03.1531

G

F E XX SOperational

Status

_13415Operation

_13421Operation

_13423Operation

_13425Operation

_13427Operation

_13429Operation

DescriptionCause / Triggering EventAction

Steering setpoint device

optional: invalid channel A /

channel B value relationship

Hydraulic setpoint device:

invalid channel A / channel

B value relationship

Travel setpoint device:

invalid channel A / channel

B value relationship

Hydraulic setpoint device

optional: invalid channel A /

channel B value relationship

Travel setpoint device

optional: invalid channel A /

channel B value relationship

Accelerator pedal setpoint

device: invalid channel A /

channel B value relationship

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

Analog sensor value relationship deviates by more than

2.5°. The activation limit is 100 msec.

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Measure sensor signals with multimeter;

-Replace sensor;

-Check sensor wiring;

-Check sensor;

-Switch the truck off and on again;

-Inquire about software update;

-Replace signal-issuing controller;

_13431Operation

_13433Operation

Brake pedal setpoint device:

invalid channel A / channel