Page 1

High energy eciency with

maintenance-free AC drive

motor

Precise control with electric

steering and JetPilot

Safe cornering with Curve

Control

“SpeedControl”, our smooth

electronic control system

Semi-automatic remote

coupling release directly

from the operator platform

(optional)

EZS 350/350 XL

Electric tow tractor (5,000 kg)

The Jungheinrich EZS 350 is a versatile,

economical tow tractor for towing

trailers up to 5000 kg. Attaching several

trailers allows the loading areas to

be varied. This contributes to flexible

material turnover.

The coupling is visible from any position

and easily accessible. The semi-automatic remote coupling release (optional)

allows the coupling/releasing of trailers

without the operator having to leave the

platform. This saves time and costs. A

further advantage: The tractor is available

with several dierent couplings and can

thus be adapted to any type of trailer.

The 24 V drive motor with its 3-phase AC

technology ensures a high performance.

The advantages: Powerful acceleration

and high maximum speed. Combined

with significant energy savings, extended

operating times and minimised maintenance costs (due to omission of carbon

brushes). This is due to the optimisation

between drive motor and the electronic

control, as well as the regenerative

braking.

The main ergonomic advantages are

the low stand-on platform for frequent

mounting and dismounting and the short

distance from operator position to load.

The EZS operates eortlessly in confined

spaces due to its very tight turning circle.

Its turning radius is so smallow that the

operator will feel that they are turning

on the spot. The JetPilot steering wheel,

supportive backrest and automatic Curve

Control speed reduction as well as the

load wheels with CSE tyres provide

comfort and safety, especially in corners.

Page 2

EZS 350/350 XL

h

14

1009

Pulling ability

475

218 412

a

2

Wa

1335

175

h

7

y

l

1

148

Ast

h

10

m

2

b11b

1

a

2

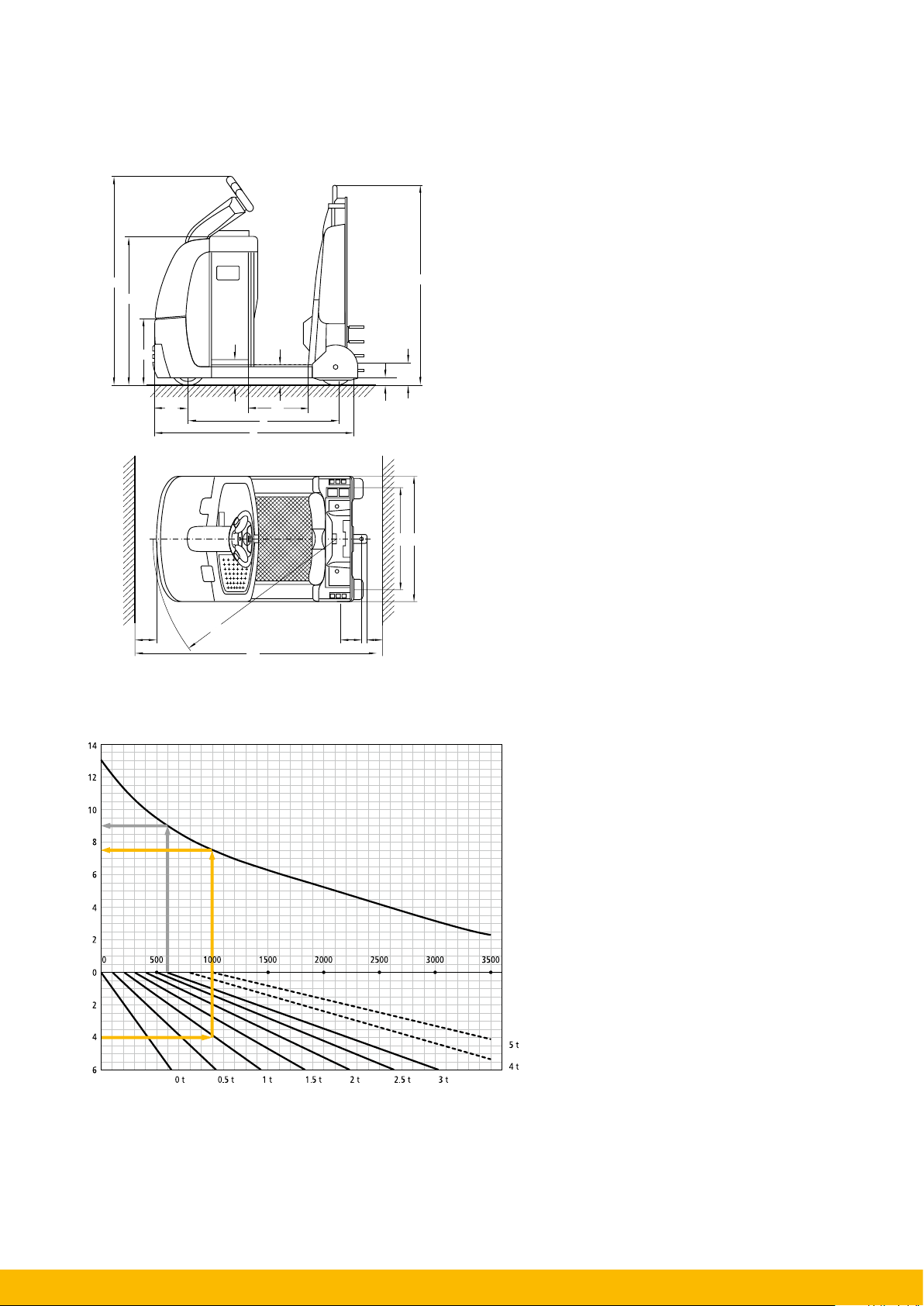

v=speed [km/h], m=incline [%], F=drawbar pull [N]

Example:

1. The EZS can operate with a 3 tonne load on

the level. For this a tractive force of 600 N is

required and an approx speed of 9Km/h can

be achieved.

2. The EZS 350 can operate on a 4% gradient

with a 1 ton load. This requires 1000 N tractive

eort and an approx speed of 7.5 Km/h can be

reached.

Note:

For loads over 1000N continuous operationis

not recommend.

Gradients of over 4% - The use of braked

trailers is recommend!

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EZS 350 EZS 350 XL

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation stand-on

1.5 Load capacity/rated load Q t 5

1.7 Rated tractive power F N 1000

Identification

1.9 Wheelbase y mm 980 1147

2.1.1 Net weight incl. battery (see row 6.5) kg 976 1110

2.3 Axle load, w.o. load, front / rear kg 520 / 456 590 / 520

Weights

3.1 Tyres Vu/Su

3.2 Tyre size, at front mm Ø 230 x 77

3.3 Tyre size, at rear mm Ø 250 x 80

chassis

3.5 Wheels, number front/rear (× = driven wheels) 1x/2

Wheels /

3.7 Track width, rear b

4.2.1 Total height h15 mm

4.8.1 Standing height h

4.9 Height of tiller in drive position min. / max. h

4.12 Coupling height h10 mm 158

4.19 Overall length l1 mm 1350

4.21 Total width b1/b2 mm 810

4.32 Floor clearance centre wheelbase m

Basic dimensions

4.35 Turning radius W

5.1 Travel speed, w. / w.o. load km/h 7 / 12.5

5.5 Drawbar pull w. / w.o. load N 1000

5.6 Max. drawbar pull, laden/unladen N 3200

Perform-

ance data

5.10 Service brake electro-magnetic

6.1 Drive motor rating S2 60 min. kW 2.8

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 465 24 / 620

6.5 Battery weight kg 370 470

Electrics

6.6 Energy consumption according to VDI cycle kWh/h 0.9 7

8.1 Type of drive control AC SpeedControl

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 66

Misc.

mm 680

11

mm 132

7

mm 1399

14

mm 50

2

mm 1220 1370

a

2)

3)

6)

5)

4)5)

5)

1)

Issue: 06/2010

2)

1444

6)

1517

4)

1000

1)

At 9 km/h

2)

JetPilot height

3)

Other coupling heights available

4)

Rated tractive power

5)

See diagram

6)

Total length without coupling, as different coupling systems are available

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may result in

different values.

Page 4

Benefit from the advantages

Backrest with folding seat JetPilot steering wheel Easy entry and exit Different couplings available

Innovative 3-phase AC technology

Jungheinrich 3-phase AC motors oer

you higher performance while simultaneously reducing operating costs. Make

the most of these advantages:

• High level of eciency with excellent

energy management.

• Powerful acceleration.

• Rapid change in direction of travel

• No carbon brushes – maintenancefree drive motor.

• Two-year warranty on the drive motor.

Comfortable and safe operation

The SpeedControl impulse control

and Curve Control automatic speed

reduction when cornering provide

smooth, safe travel adjustable for every

application:

• The speed set by the drive switch is

maintained under all travel conditions

including every travel situations including gradients / descents.

• 3 adjustable travel programmes for

individual adjustment to set requirements.

• Regenerative braking with energy recovery when slowing down.

• Safe cornering, the operator has the

truck under control at all times.

Optimum ergonomics

• Low stand-on platform for frequent,

eortless mounting and dismounting.

• Short distances for the operator from

platform to coupling or to the load.

• Coupling can be seen from any

position and is easily accessible.

• Trailers are coupled and released

quickly and easily through semi-automatic remote release from the operator position (optional).

• Electric steering with JetPilot steering

wheel.

• Various couplings are available for different trailer types.

Robust construction for hard

• Chassis made of high-quality 8 mm

sheet steel.

• Extra high front chassis apron.

Long operating times

Energy-saving 3-phase AC technology

and large battery capacities allow extended operating times:

• Standard version: 3 PzS 420 (450) Ah.

Well informed at any time

Function display and instruments, give

the operator a constant flow of information.

• “CanDis” (optional) informs on battery

charge condition, operating hours and

fault codes.

• Truck activation via PIN and choice

of 3 travel programmes via keyboard

(optional).

• Adjustable travel parameters via CanDis

and CanCode (optional).

Additional equipment

Extensive accessories provide individual

adjustment to your application requirements:

• Pedestrian operation from both sides

via a button in the backrest.

• Semi-automatic remote coupling

release.

• Additional collision protection made of

steel and/or rubber.

• Holder for radio data transmission

terminal.

(optional)

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EZS 350/350 XL_012014_en_UK_000

Loading...

Loading...