Page 1

Manoeuvrable and compact

Maintenance-free 3-phase AC

drive motor

Integrated charger

Wide range of coupling

options

EZS 010

Mini pedestrian controlled tow tractor (1,000 kg)

The Jungheinrich EZS 010 is a versatile,

economic mini tow tractor for pulling up

to 1000 kg trailers. Ideal for moving loads

in restricted areas. Instead of time-consuming and energy-sapping manual

work, trailers can now be moved faster,

more eciently and more easily. Designed for a wide range of applications,

such as furniture wholesale, industry,

supermarkets or hospitals. Anywhere

where smaller loads must be transported

over short distances, the EZS 010 is the

clear choice with compelling advantages:

• Wide variety of coupling systems for

many dierent trailer types.

• Clearly visible, easily accessible coupling.

• 24-volt 3-phase AC drive motor.

• Ergonomic safety tiller arm

• Compact, user-friendly design.

• Turns on the spot.

• Drive tyre protected by chassis.

• A choice of three travel programmes.

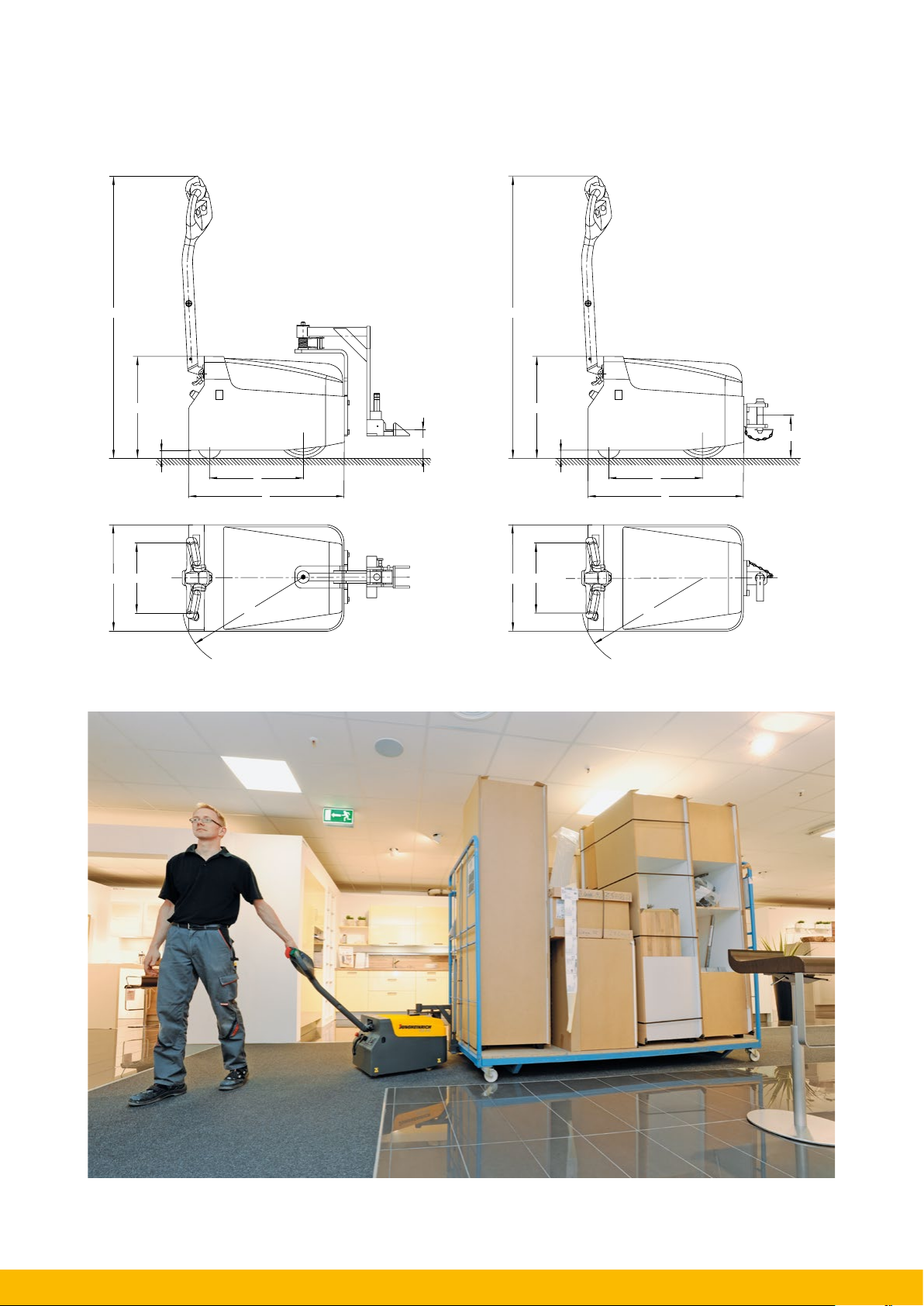

Page 2

EZS 010

h

14

465

m

2

h

10

y

l

1

b

b

11

1

Wa

h

14

465

m

2

h

10

y

l

1

b

b

11

1

Wa

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EZS 010

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation pedestrian

1.5 Load capacity/rated load Q t 1

1.7 Rated tractive power F N 200

Identification

1.9 Wheelbase y mm 415

2.1.1 Net weight incl. battery (see row 6.5) kg 190

2.3 Axle load, w.o. load, front / rear kg 85 / 105

Weights

3.1 Tyres Vulkollan, Vollgummi

3.2 Tyre size, at front mm Ø 100 x 40

3.3 Tyre size, at rear mm Ø 230 x 70

3.5 Wheels, number front/rear (× = driven wheels) 2 / 1x

3.6 Track width, front b

3.7 Track width, rear b

Wheels / chassis

4.2.1 Total height h15 mm

4.9 Height of tiller in drive position min. / max. h

4.12 Coupling height h

4.19 Overall length l1 mm 700

4.21 Total width b

4.32 Floor clearance centre wheelbase m

Basic dimensions

4.35 Turning radius W

5.1 Travel speed, w. / w.o. load km/h 5.4 / 6

5.5 Drawbar pull w. / w.o. load N 200

5.6 Max. drawbar pull, laden/unladen N 600

Perform-

ance data

5.10 Service brake electro-magnetic

6.1 Drive motor rating S2 60 min. kW 1.0

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 63

trics

Elec-

6.5 Battery weight kg 46

8.1 Type of drive control 3-phase AC technology

Misc.

mm 315

10

mm 370

11

mm 1270

14

mm 150

10

mm 480

1/b2

mm 35

2

mm 570

a

Issue: 09/2009

1)

1)

With single plug-in coupling

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Clearly arranged controls always

in view

Easy trailer shunting Ergonomic tiller Individual coupling solutions to suit

Innovative 3-phase AC technology

Jungheinrich 3-phase AC motors oer

you higher performance while simultaneously reducing operating costs. Make

the most of these advantages:

• High level of eciency with excellent

energy management.

• Powerful acceleration.

• Rapid change in direction of travel

• No carbon brushes - maintenance-free

drive motor.

• Two-year warranty on the drive motor.

Constant information flow

Extensive display and setting instruments

provide a complete overview at all times:

• Combined discharge indicator (3

colour LED) with load status display.

• CanDis (optional) provides information

on battery charge status, service hours

and error codes.

• PIN activation of truck and choice

of 3 travel programmes via keypad

(optional).

• Adjustable drive parameters via CanDis and CanCode (optional).

Work ergonomically

The new tiller arm has been designed to

match the ergonomic requirements of

the operator:

• Colour coding and buttons with

countersunk/raised shape for intuitive

operation.

• Grip position ideally suited to the operator’s hand posture.

• Crawl speed button underneath the

tiller arm for easy access and travelling

with the tiller upright.

• High protection level of Electric Controller to IP 65 giving low risk of breakdown.

• Rocker switches for equally good

operation in any tiller position.

Minimum maintenance work

The AC drive system and small number

of moving parts keeping running costs to

a minimum:

• Maintenance-free 3 Phase drive motor

with no carbon brushes.

the trailer

• Easy access to all parts inside onepiece front panel with just 2 Retaining

fasteners.

• Excellent protection against dust and

humidity through enclosure of controller and plugs to IP 54.

Easy charging

The battery can be recharged at any

socket with the on-board charger.

Individual coupling solutions

Individual coupling solutions enable the

truck to be used with a range of trailer

types. Both standard couplings (e.g.

single plug couplings) and modified

couplings can be used.

• Standard couplings attached to

the chassis if the trailer has its own

steering.

• Coupling arm can be used with a

modified receptacle for non-self steering trailers. This ensures easy steering

and eortless direction of trailers.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EZS 010_012014_en_UK_000

Loading...

Loading...