Page 1

Travel in any direction thanks

to electronically controlled

all-wheel steering

Sensitive operation with

SOLO-PILOT control lever

Drive, lift and steering motors

use 3-phase AC technology

Jungheinrich Curve Control

for optimum stability

Hydraulic fork positioning for

various load widths (optional)

ETV Q20/Q25

Electric multi-directional reach truck (2,000/2,500 kg)

Jungheinrich multi-directional reach

trucks are used wherever long loads are

transported in narrow aisles and need to

be elevated at height. With their electric

all-wheel steering they can transport

loads up to 8 m long, maximising space

in the warehouse.

There are five travel programs available,

ranging from modified normal travel,

turning on the spot through to transverse and parallel travel. In ‘enhanced

normal travel’, the already small turning

radius is reduced further by simultaneous

load wheel steering. The advantages of

360° steering are also available: Minimum turning radius and rapid direction

change. This makes the ETV Q clearly

superior to any conventional 4-way

reach truck.

Uncomplicated, intuitive handling with

ergonomically arranged displays and

controls matched with outstanding

visibility makes operating the truck

simplicity itself. In addition, assistance

systems increase productivity:

• Jungheinrich Curve Control reduces

the maximum travel speed when cornering, depending on the steer angle.

• Weighing systems allow weights to be

checked at the press of a button.

• Mast reach cushioning reduces

mast sway during stacking and retrieval operations, thereby increasing

throughput.

In addition to excellent performance, the

truck oers outstanding eciency:

• Greater travel / lift performance for

more pallet throughput.

• Long operating times due to energy

recovery on braking the truck and load

lowering.

• Less aisle width required as a result of

the proven reach principle.

A number of options and battery versions

ranging from 620 to 930 Ah ensure that

the trucks can be adapted to any application.

Page 2

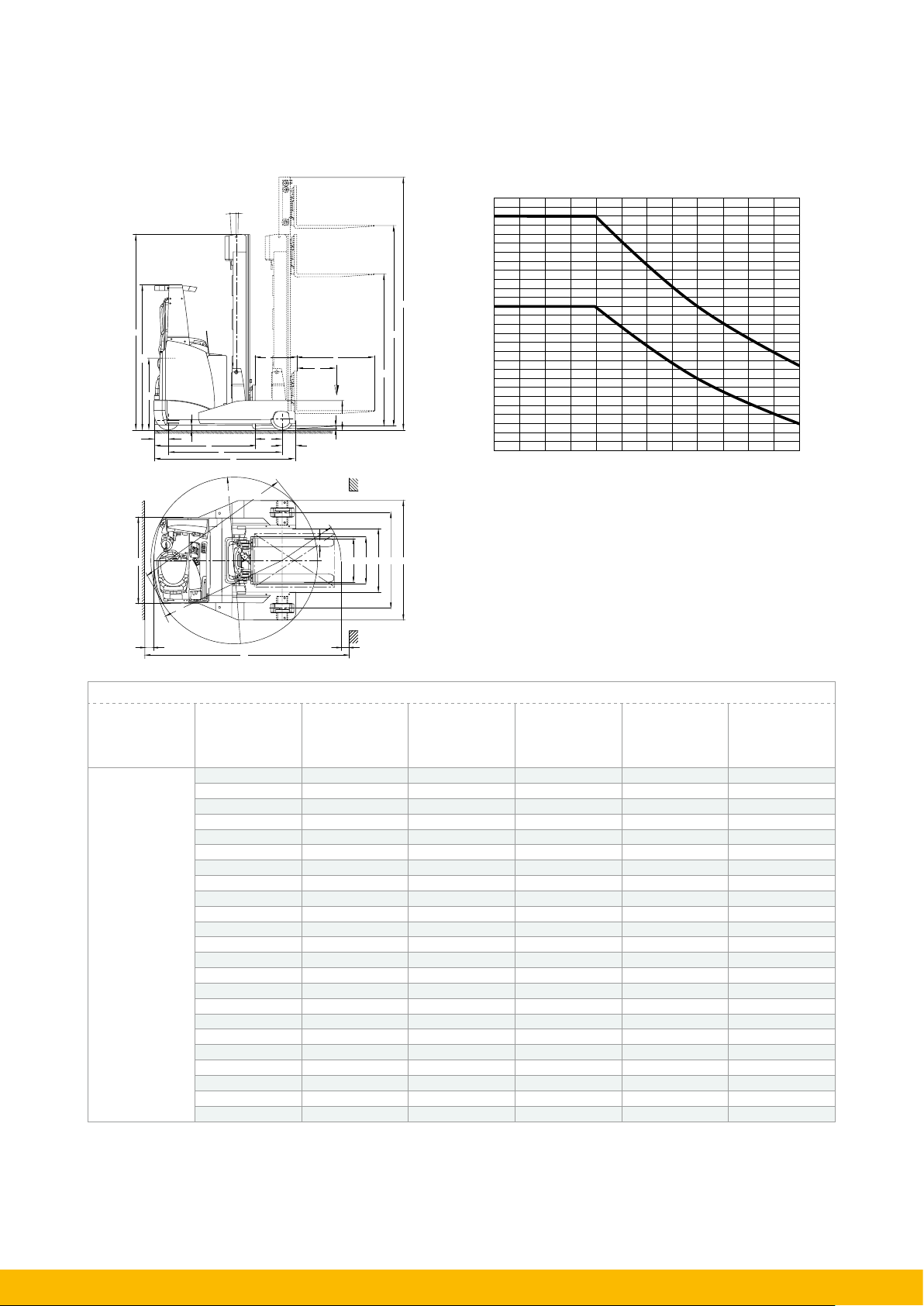

ETV Q20/Q25

2600

2500

2400

2300

2200

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

400 500 600 700 800 900 1000

ETV Q25

ETV Q20

h

1

h

6

h

7

m

210

2

l

2

b

2

l

4

x

y

l

7

Wk

D

Capacity

h

4

h

3

l

c

x

s

1

h

2

Q

h

8

Load centre distance “c” in mm

e

b11b

b

b

b

5

1

4

3

Wa

a

2

Ast

Lift

h

3

(mm) (mm) (mm) (mm) (°) (°)

DZ

4250 2050 1320 4996 1/5 4700 2200 1470 5446 1/5 -

5000 2300 1570 5746 1/5 -

5300 2400 1670 6046 1/5 -

5560 2480 1750 6306 1/3 5600 2500 1770 6346 1/3 5900 2600 1870 6646 1/3 6050 2650 1920 6796 1/3 6200 2700 1970 6946 1/3 2/5

6500 2800 2070 7246 0.5/2 6800 2900 2170 7546 0.5/2 2/5

6950 2950 2220 7696 0.5/2 2/5

7100 3000 2270 7846 0.5/2 -

7400 3100 2370 8146 0.5/2 2/5

8000 3300 2570 8746 0.5/1 2/5

8420 3440 2710 9166 0.5/1 2/5

8720 3540 2810 9466 0.5/1 2/5

9110 3670 2940 9856 - 2/5

9620 3840 3110 10366 - 2/5

9950 3950 3220 10696 - 2/5

10220 4040 3310 10966 - 2/5

10520 4140 3410 11266 - 2/5

10700 4200 3470 11446 - 2/5

a

2

Standard mast types ETV Q20/Q25

Lowered mast

height

h

1

Free lift

h

2

Extended mast

height

h

4

Mast tilt forward /

back

α/β

Tilt forks forward

/ back

α/β

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ETV Q20 ETV Q25

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation transverse seat

1.5 Load capacity/rated load Q t 2 2.5

1.6 Load centre distance c mm 600

1.8 Load distance x mm 449

Identification

1.8.1 Load distance, mast reached forward x1 mm 230

1.9 Wheelbase y mm 1528 1683

2.1.1 Net weight incl. battery (see row 6.5) kg 4060 4150

2.3 Axle load, w.o. load, front / rear kg 2310 / 1750 2490 / 1660

2.4 Axle loading forks forward with load at front / rear kg 670 / 5390 600 / 6050

Weights

2.5 Axle loading forks retracted with load at front / rear kg 1940 / 4120 2260 / 4390

3.1 Tyres Vulkollan ®

3.2 Tyre size, at front mm Ø 343 x 140

3.3 Tyre size, at rear mm Ø 343 x 140

chassis

3.5 Wheels, number front/rear (× = driven wheels) 1x / 2

Wheels /

3.7 Track width, rear b

mm 1420

11

4.1 Tilt of mast/fork carriage forward/backward α/β ° 1/5

4.2 Mast height (lowered) h

mm 2400

1

4.2.1 Total height h15 mm

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

mm 1670

2

mm 5300

3

mm 6046

4

mm 2150

6

mm 1057

7

4.10 height of support arms h8 mm 442

4.19 Overall length l

mm 2439

1

4.20 Length incl. back of forks l2 mm 1289

4.21 Total width b1/b2 mm 1760 / 1270

4.22 Fork dimensions s/e/l mm 50 / 140 / 1150

4.23 Fork carriage ISO 2328, class/type A, B 2B

4.24 Fork carriage width b

Basic dimensions

4.25 Width over forks b

4.26 Width between support arms/loading surfaces b

4.28 mast reach l

mm 800

3

mm 356 / 737

5

mm 940

4

mm 679

4

4.32 Floor clearance centre wheelbase m2 mm 95

4.32.1 Ground clearance at lowest point mm 55

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2756

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2792

truck diagonal mm 2277 2432

4.35 Turning radius W

mm 1741

a

4.37 length over the support arms l7 mm 1957 2112

5.1 Travel speed, w. / w.o. load km/h 14 / 14

5.2 Lift speed, w. / w.o. load m/s 0.32 / 0.6 0.3 / 0.6

5.3 Lower speed, w. / w.o. load m/s 0.5 / 0.5

5.4 Traverse speed w. / w.o. load m/s 0.12 / 0.12

5.7 Gradeability laden/unladen % 7 / 11 6 / 11

5.8 Max. gradeability, laden/unladen % 10 / 15

5.9 Acceleration time w. / w.o. load S 4.6 / 4.3 5 / 4.4

Performance data

5.10 Service brake electric / hydraulic

6.1 Drive motor rating S2 60 min. kW 6.9

6.2 Lift motor rating at S3 15% kW 10.0

6.3 Battery according to DIN 43531/35/36 A,B,C, no DIN 43531 - C

6.4 Battery voltage/nominal capacity K5 V/Ah 48 / 620

Electrics

6.5 Battery weight kg 995

8.1 Type of drive control Mosfet / AC

8.2 working pressure for attachments bar 150

8.3 oil flow for attachments l/min 20

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 70

2)

3)

2)

2)

2)

2)

2)

4)

1)

5)

Issue: 03/2010

2)

532

2)

2511

2)

1361

2)

762

2854

2)

2872

4)

1893

1)

11.0 / 11.0 km/h in the fork direction

2)

different battery sizes change these values

3)

mast-dependent

4)

Turning radius for turning on the spot: 1230 mm

5)

with regenerative lowering option 14 kW

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Jungheinrich masts lift loads at

height

Ergonomic cab SOLO-PILOT

High-performance mast

Jungheinrich masts guarantee maximum

safety and space utilisation to high lift

heights.

• Lift heights up to 10,700 mm.

• Lowest clearances at high lift heights.

• Extremely long life through cold-rolled

mast sections.

• High residual capacities even at high lift

heights.

• Patented mast reach cushioning

(optional).

• Energy recovery through patented regenerative lowering (optional).

Fork adjuster with extended fork

shank (optional)

Ideally adjustable to various load widths

for safe transporting of long loads.

• Easy adjustment at the press of a

button.

• Straddle width up to 2060 mm.

• Integrated design with short chassis

length for narrow aisle widths.

• Three versions with dierent chassis

widths available.

Ergonomic operator position

The operator workplace provides ideal

working conditions for relaxed performance.

• Five buttons for rapid and easy travel

program selection.

• Comfort seat, fully adjustable for all

operators (seat position / backrest

height / bodyweight).

• Plenty of storage options.

• Generous space.

• 3-phase steering of all three wheels

can be changed from 180° to 360°.

• Standard automotive layout of pedals.

SOLO-PILOT control lever

The control lever for activating all hydraulic functions and also selecting the

direction of travel and sounding the

horn.

• All the controls are within the field of

vision and are clearly designated for a

specific function.

• Maximum throughput eciency due

to simultaneous operation of two

hydraulic functions (e.g. lifting and

traversing).

• Extra attachments – e.g. fork adjuster

(optional) – are also controlled by the

SOLO-PILOT.

• Precision operation through sensitive

application of all functions.

• Comfortable posture with padded

armrest.

Easy-to-read driver’s display

• Travel direction and wheel position

display.

• Battery status with residual time display.

• A choice of three travel programs for

individual adaptation to each application.

• Service hours and time.

• Lift height (optional).

• Load weight (optional).

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ETV Q20/Q25_012014_en_UK_000

Loading...

Loading...