Page 1

Superelastic tyres and

high ground clearance for

combined warehouse and yard

use

Optimal view, even with high

loads, due to side-facing seat

Sensitive operation with

SOLO-PILOT control lever

Drive, lift and steering motors

use 3-phase AC technology

Jungheinrich Curve Control

for optimum stability

Driver’s cab for frequent

outdoor use (optional)

ETV C16/C20

Electric reach truck (1,600/2,000 kg)

Super-elastic tyres, high ground clearance, space-saving design, high performance data and optimum ergonomic

working conditions. These are the exceptional strengths of the Jungheinrich

ETV C16/ETV C20 reach trucks.

Advantages:

• Ideal for use anywhere indoor and

outdoors operation with dierent types

of ground conditions. Whether on a

smooth concrete floor in the warehouse or a bumpy asphalt surface

around the HGV loading dock.

• Space-saving design with narrow

working aisle widths from 2829 mm

(according to VDI when picking up

Euro pallets lengthways).

• Higher throughput levels – while

simultaneously reducing the maintenance cost – through constant use

of 3-phase AC technology. • Easy and

intuitive handling due to ergonomically

configured displays and controls. Not

only does the display of the instrument

panel contribute to safety but it also

provides excellent visibility.

The Jungheinrich ETV C16/ETV C20

reach trucks therefore guarantee the best

design for cost-eective stacking and retrieval at high lift heights and in confined

spaces. Whether working in pallet or

drive-through racking systems, in single

shift or multishift applications or for

frequent outdoor use with the comfortable weatherproof cab (optional) – the

ETV C16/ETV C20 reach trucks oer the

ideal solution for every application.

Page 2

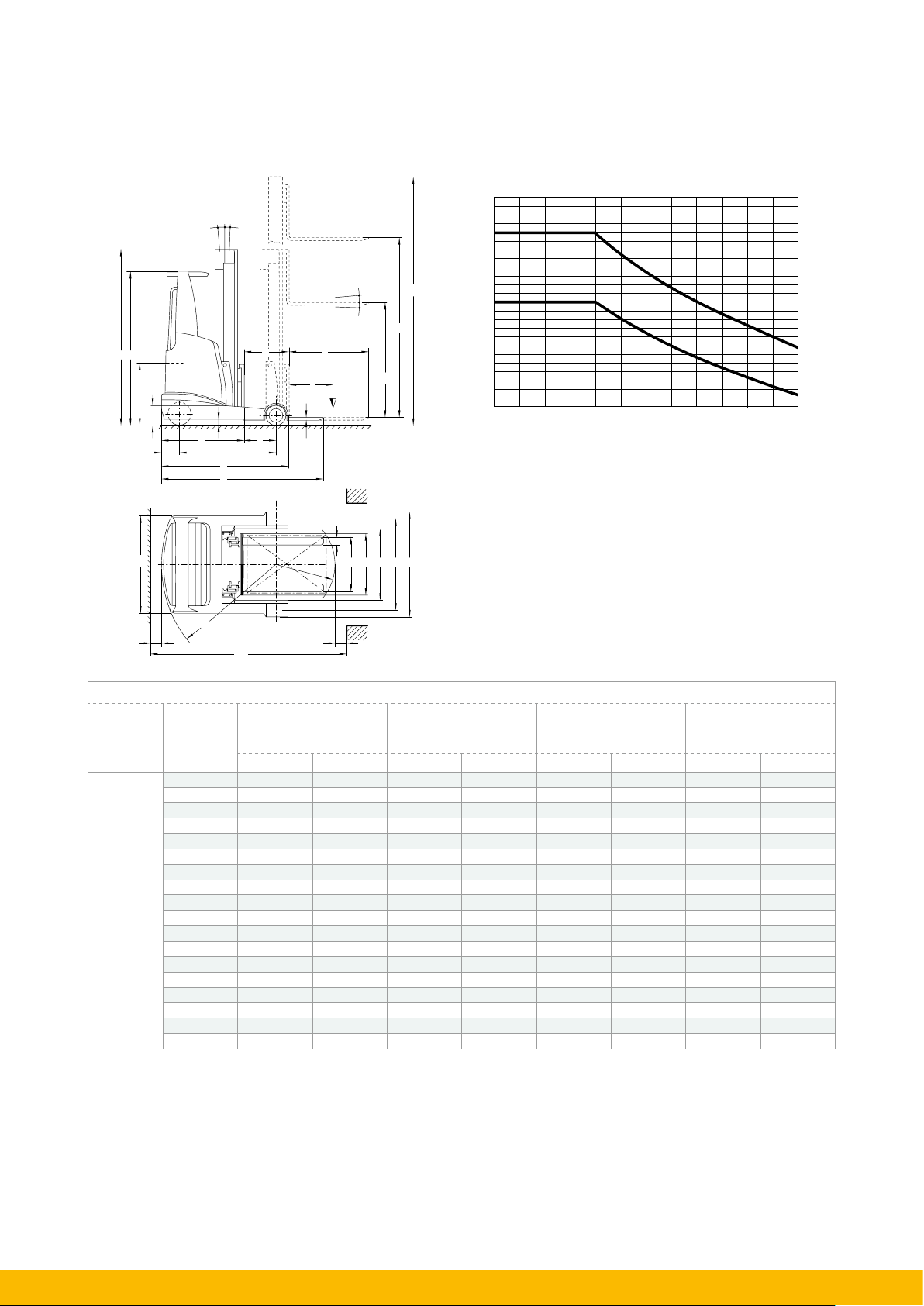

ETV C16/C20

400 500 600 700 800 900 1000

2200

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

ETV C20

6

Capacity

h1h

6

h

b

Duplex ZT

Triplex DZ

l

4

7

h

8

m

2

l

2

280

2

a

2

Wa

x

y

l

7

l

1

Ast

c

s

l

Q

e

b5b3b4b11b

a

2

h

4

h

3

h

2

Load centre distance “c” in mm

1

Standard mast types ETV C16/C20

Lift

h

Lowered mast height

3

h

1

Free lift

h

2

Extended mast height

h

4

Mast tilt forward / back

(mm) (mm) (mm) (mm) (°)

ETV C16 ETV C20 ETV C16 ETV C20 ETV C16 ETV C20 ETV C16 ETV C20

2900 1950 - 80 - 3544 - 2/5 -

3400 2200 - 80 - 4044 - 2/5 -

3600 2300 - 80 - 4244 - 2/5 4000 2500 - 80 - 4644 - 2/5 4400 2700 - 80 - 5044 - 2/5 -

4250 1950 - 1306 - 4894 - 2/5 -

4550 2050 - 1406 - 5194 - 2/5 -

4700 - 2200 - 1470 - 5446 - 2/4

5000 2200 2300 1556 1570 5644 5746 2/5 2/4

5300 2300 2400 1656 1670 5944 6046 2/4 2/4

5600 2400 2500 1756 1770 6244 6346 2/4 2/4

5900 2500 2600 1856 1870 6544 6646 2/4 2/4

6200 2600 2700 1956 1970 6844 6946 2/4 2/4

6500 2700 - 2056 - 7144 - 2/4 6800 2800 2900 2156 2170 7444 7546 2/4 2/4

6950 - 2950 - 2220 - 7696 - 2/4

7100 2900 - 2256 - 7744 - 2/4 -

7400 - 3100 - 2370 - 8146 - 2/4

ETV C1

α/β

Page 3

Issue: 04/2008

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ETV C16 ETV C20

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation transverse seat

1.5 Load capacity/rated load Q t 1.6 2

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 400

1.8.1 Load distance, mast reached forward x1 mm 290

1.9 Wheelbase y mm 1460 1520

2.1.1 Net weight incl. battery (see row 6.5) kg 3640 4010

2.3 Axle load, w.o. load, front / rear kg 2230 / 1410 2410 / 1600

2.4 Axle loading forks forward with load at front / rear kg 670 / 4570 510 / 5500

Weights

2.5 Axle loading forks retracted with load at front / rear kg 1965 / 3275 2146 / 3864

3.1 Tyres SE

3.2 Tyre size, at front mm 200/50 -10

3.3 Tyre size, at rear mm 180/60 -10

chassis

3.5 Wheels, number front/rear (× = driven wheels) 1x / 2

Wheels /

3.7 Track width, rear b

mm 1210 1240

11

4.1 Tilt of mast/fork carriage forward/backward α/β ° 2/4

4.2 Mast height (lowered) h1 mm 2300 2400

4.2.1 Total height h15 mm

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

mm 1656 1670

2

mm 5300

3

mm 5944 6046

4

mm 2250

6

mm 1157

7

4.10 height of support arms h8 mm 464

4.19 Overall length l

mm 2484

1

4.20 Length incl. back of forks l2 mm 1334

4.21 Total width b1/b2 mm 1370 / 1270 1400 / 1270

4.22 Fork dimensions s/e/l mm 40 / 120 / 1150 50 / 140 / 1150

4.23 Fork carriage ISO 2328, class/type A, B 2B

4.24 Fork carriage width b

4.25 Width over forks b

Basic dimensions

4.26 Width between support arms/loading surfaces b

4.28 mast reach l

mm 800

3

mm 356 / 692 356 / 712

5

mm 940

4

mm 690

4

4.31 Floor clearance with load under mast m1 mm 90

4.32 Floor clearance centre wheelbase m

mm 80

2

4.32.1 Ground clearance at lowest point mm 55

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2784

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2829

truck diagonal mm 2205 2255

4.35 Turning radius W

4.37 length over the support arms l

mm 1735 1795

a

mm 1986 2046

7

5.1 Travel speed, w. / w.o. load km/h 11.8 / 12.2

5.2 Lift speed, w. / w.o. load m/s 0.4 / 0.7 0.32 / 0.6

5.3 Lower speed, w. / w.o. load m/s 0.5 / 0.5

5.4 Traverse speed w. / w.o. load m/s 0.2 / 0.2 0.15 / 0.15

5.7 Gradeability laden/unladen % 7 / 10 6 / 10

5.8 Max. gradeability, laden/unladen % 10 / 15

5.9 Acceleration time w. / w.o. load S 5.2 / 4.8 5.4 / 4.6

Performance data

5.10 Service brake electric

6.1 Drive motor rating S2 60 min. kW 6.9

6.2 Lift motor rating at S3 15% kW 10.0

6.3 Battery according to DIN 43531/35/36 A,B,C, no DIN 43531 - C

6.4 Battery voltage/nominal capacity K5 V/Ah 48 / 560

Electrics

6.5 Battery weight kg 937

8.1 Type of drive control Mosfet control AC

8.2 working pressure for attachments bar 150

8.3 oil flow for attachments l/min 20

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 70

2)

3)

2)

2)

2)

2)

2)

1)

421

2524

1374

711

2829

2871

2)

2)

2)

2)

2)

2)

1)

11.0 / 11.0 km/h in the fork direction

2)

different battery sizes change these values

3)

mast-dependent

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Ergonomic cab SOLO-PILOT Ergonomic operator cabin

High-performance mast

Jungheinrich masts ensure maximum

safety and maximise space utilisation

even at high lift heights:

• Excellent load visibility.

• Integrated side shift.

• Lowest overhead clearance requirement at high lift heights.

• Smooth mast tilt.

• High quality profiles provide an extremely long lifespan.

• High residual lift capacity even at high

lift heights.

• Lift heights of up to 7400 mm.

• Integrated hose routing, also for

auxiliary hydraulics (no hose reel).

Ergonomic workstation

The operator position provides ideal

working conditions for relaxed performance.

• The entry / exit step clearly visible from

above.

• Horizontally and vertically adjustable

steering wheel.

• Comfort seat, fully adjustable for all

operators (seat position / backrest

height / bodyweight).

• The side-facing seat configuration

oers perfect visibility, even when

transporting high loads.

• Plenty of storage options.

• Important truck controls are within

easy reach.

• Generous space.

• Electric 180° steering and optimally

positioned steering wheel.

• Automatic positioning of the sideshift (centre position) at the touch of a

button (optional)

Easy operation with SOLO-PILOT

The control lever for combines all hydraulic functions ,the horn and allows

selecting the direction of travel.

• All controls are within the operator’s

field of vision and a single function is

clearly assigned to each one.

• Extra attachments – e.g. a fork positioner (optional) – can be comfortably

controlled with the SOLO-PILOT.

• Precision operation by sensitive activation of all functions.

• Comfortable posture with adjustable

armrest.

Easy to read operator display

High quality instruments for displaying

the most important operating data.

• Travel direction and drive wheel

position display.

• Battery condition with discharge status

display.

• Three adjustable travel programmes to

cater for every requirement.

• Operating hours and clock.

• Lift height (optional).

• Load weight (optional).

More eciency and economy using

Powerful 3rd Generation AC technology

for drive, lift and steering oers many advantages over conventional DC motors.

• Powerful acceleration.

• Quick reversing without delay.

• High operational availability due to

maintenance free motors without

carbon brushes.

• Longer operational times through

regenerative battery charging when

reducing travel speed.

• Two year guarantee on drive and lift

motors.

All weather cabin (optional)

• All weather cabin in 3 variations (Economy/Comfort 1/ Comfort 2) for the

protection of the operator in regular

outdoor usage.

• “Economy” with roof and front screen.

• “Comfort 1” with roof, front and side

screens for protection against frequent

rain.

• “Comfort 2” with roof, front & side

screens and door for all round protection.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ETV C16/C20_012014_en_UK_000

Loading...

Loading...