Page 1

Drive, lift and steering motors

use 3-phase AC technology

Optimised vehicle geometry

saves space

Electric 180° steering

Sensitive hydraulic operation

with SOLO-PILOT control

lever

Optimum stability with Curve

Control

ETV 110/112

Electric reach truck (1,000/1,200 kg)

Space-saving design, high performance

data and optimum ergonomic working

conditions. These are the strengths of

our reach trucks ETV 110 and ETV 112.

Advantages:

• Saves space with narrow working aisles

from 2,659 mm (as per VDI, when

picking up a pallet lengthways). With

its slim support arms, the ETV 110/112

can pull a lengthways Euro pallet back

between the support arms – despite its

compact outer width of only 1120 mm.

This creates more room during operation with oncoming trac in block

warehouses or in drive-in racking.

• Higher throughput – as well as increased availability – due to consistent

use of 3-phase AC technology for all

drive motors.

• Relaxed operators thanks to performance-enhancing ergonomics. The

operator is immediately aware of the

added comfort: Via the lowered entry

step, they are able to comfortably access their 3-way adjustable seat with

an adjustable armrest and a steering

wheel adjustable in both horizontal and

vertical directions.

• Automatic speed reduction when cornering. Curve Control limits the maximum travel speed and acceleration

when cornering. The risk of rocking or

even tipping over is drastically reduced.

Our 110 and 112 reach trucks provide the

best solution for cost-eective stacking

and retrieval at high lift heights and in

confined spaces. Whatever the need

– handling pallets, operating in drivethrough or drive-in racking, in extremely

narrow areas or with low clearance

heights, for single shift or multishift

applications – our 110 and 112 reach

trucks are the perfect solution for every

application.

Page 2

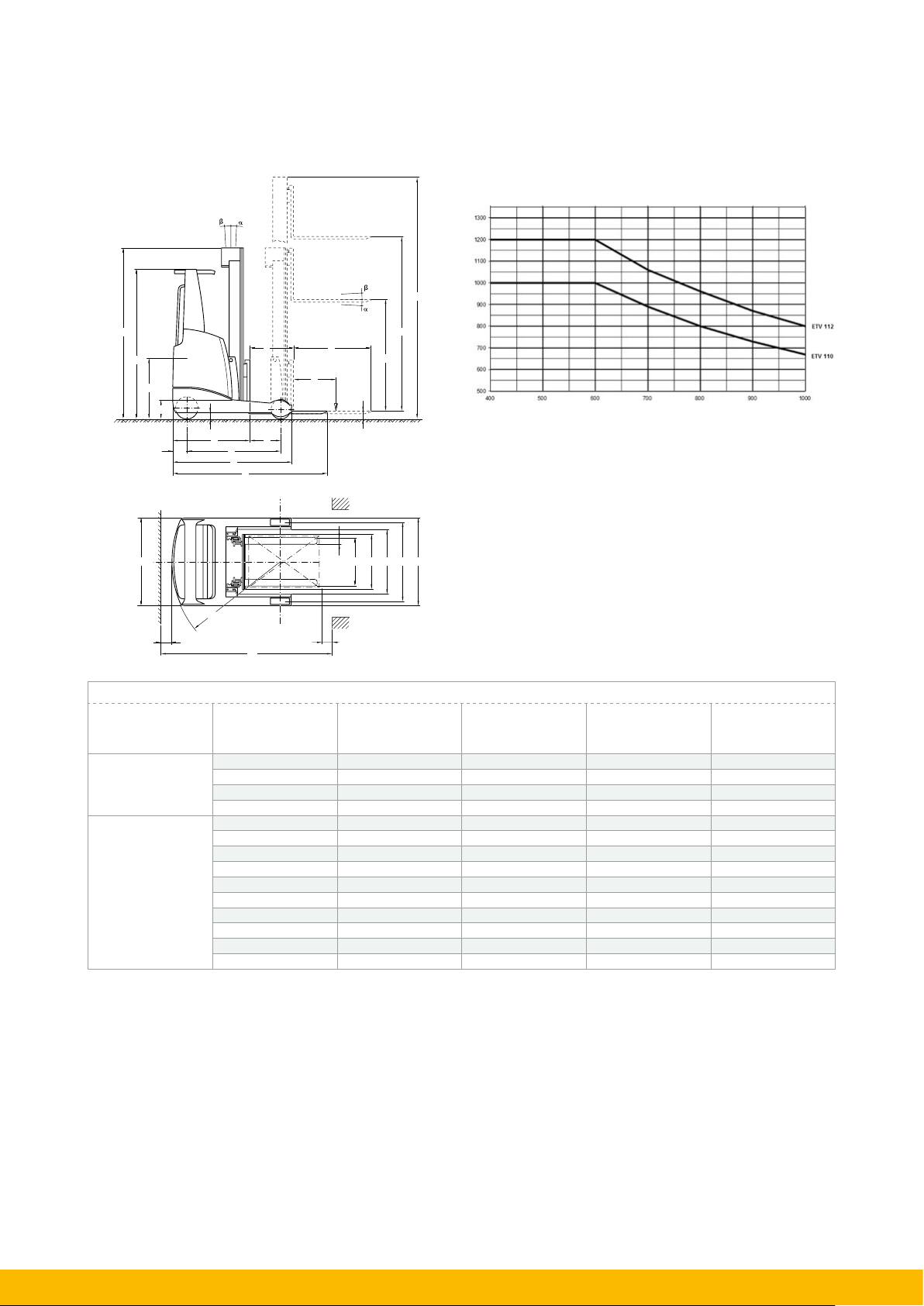

ETV 110/112

Capacity

h

4

h

1

h

6

h

7

b

2

Duplex ZT

Triplex DZ

h

l

4

h

8

m

2

l

2

210

a

W

a

2

x

y

l

7

l

1

A

st

c

a

2

l

Q

e

b5b3b4b11b

3

h

2

s

1

Load centre distance “c” in mm

Standard mast types ETV 110/112

Lift

h

Lowered mast height

3

h

1

Free lift

h

2

Extended mast height

h

4

Mast tilt forward / back

α/β

(mm) (mm) (mm) (mm) (°)

3090 2050 100 3667 2/5

3390 2200 100 3967 2/5

3590 2300 100 4167 2/5

3790 2400 100 4367 2/5

4550 2050 1408 5192 2/5

5000 2200 1558 5642 1/3

5240 2280 1638 5882 1/3

5300 2300 1658 5942 1/3

5600 2400 1758 6242 1/3

5900 2500 1858 6542 1/3

6200 2600 1958 6842 1/3

6500 2700 2058 7142 0.5/2

6800 2800 2158 7442 0.5/2

7100 2900 2258 7742 0.5/2

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ETV 110 ETV 112

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation transverse seat

1.5 Load capacity/rated load Q t 1 1.2

1.6 Load centre distance c mm 600

1.8 Load distance x mm 345

Identification

1.8.1 Load distance, mast reached forward x1 mm 170

1.9 Wheelbase y mm 1300 1385

2.1.1 Net weight incl. battery (see row 6.5) kg 2560 2580

2.3 Axle load, w.o. load, front / rear kg 1587 / 973 1587 / 993

2.4 Axle loading forks forward with load at front / rear kg 634 / 2926 516 / 3264

Weights

2.5 Axle loading forks retracted with load at front / rear kg 1282 / 2278 1361 / 2419

3.1 Tyres Vulkollan ®

3.2 Tyre size, at front mm Ø 343 x 114

3.3 Tyre size, at rear mm Ø 230 x 85

chassis

3.5 Wheels, number front/rear (× = driven wheels) 1x / 2

Wheels /

3.7 Track width, rear b

mm 993

11

4.1 Tilt of mast/fork carriage forward/backward α/β ° 1/3

4.2 Mast height (lowered) h

mm 2300

1

4.2.1 Total height h15 mm

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

mm 1658

2

mm 5300

3

mm 5942

4

mm 2150

6

mm 1057

7

4.10 height of support arms h8 mm 265

4.19 Overall length l

mm 2315

1

4.20 Length incl. back of forks l2 mm 1165

4.21 Total width b1/b2 mm 1120 / 1120

4.22 Fork dimensions s/e/l mm 40 / 80 / 1150

4.23 Fork carriage ISO 2328, class/type A, B 2B

4.24 Fork carriage width b

Basic dimensions

4.25 Width over forks b

4.26 Width between support arms/loading surfaces b

4.28 mast reach l

mm 800

3

mm 296 / 677

5

mm 900

4

mm 515

4

4.31 Floor clearance with load under mast m1 mm 85

4.32 Floor clearance centre wheelbase m

mm 80

2

4.32.1 Ground clearance at lowest point mm 30

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2603

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2659

4.35 Turning radius Wa mm 1515 1600

4.37 length over the support arms l

mm 1640 1725

7

5.1 Travel speed, w. / w.o. load km/h 11 / 11

5.2 Lift speed, w. / w.o. load m/s 0.48 / 0.7 0.43 / 0.7

5.3 Lower speed, w. / w.o. load m/s 0.5 / 0.5

5.4 Traverse speed w. / w.o. load m/s 0.2 / 0.2

5.7 Gradeability laden/unladen % 7 / 10

5.8 Max. gradeability, laden/unladen % 10 / 15

5.9 Acceleration time w. / w.o. load S 4.8 / 4.4 4.9 / 4.4

Performance data

5.10 Service brake electric

6.1 Drive motor rating S2 60 min. kW 6.9

6.2 Lift motor rating at S3 15% kW 10.0

6.3 Battery according to DIN 43531/35/36 A,B,C, no DIN 43531 - B

6.4 Battery voltage/nominal capacity K5 V/Ah 48 / 280

Electrics

6.5 Battery weight kg 556

8.1 Type of drive control Mosfet / AC

8.2 working pressure for attachments bar 150

8.3 oil flow for attachments l/min 20

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 68

1)

3)

1)

1)

1)

1)

1)

2)

Issue: 03/2011

1)

430

1)

600

1)

2628

1)

2668

1)

different battery sizes change these values

2)

in load direction 10 km/h

3)

mast-dependent

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Ergonomic cab SOLO-PILOT compact chassis

High performance mast

Our masts ensure maximum safety and

utilisation of warehouse capacity at high

heights. Strengths:

• Excellent visibility towards the load.

• Integrated sideshift.

• Lowest closed mast height with high

lift heights.

• Extremely long service life due to high

quality mast profiles.

• High residual capacities up to high lift

heights.

• Lift heights up to 7100 mm with mast

tilt.

Ergonomic cab

The operator cab provides ideal working

conditions for excellent performance

and support for the operator. Its strength:

• Comfortable seat with adjustment

options (sitting position/backrest/body

weight) for every operator.

• The important operating functions

are easily accessible without reaching

round.

• Generous space.

• 3-phase AC steering (180° or as an

option 360°) with stress-free steering

wheel position.

• Horizontal/vertical steering wheel adjustment.

Eortless operation with SOLOPILOT

Incorporating the control levers for all

hydraulic functions as well as travel direction selection and horn.

• All operating functions are in view.

• Additional attachments, such as fork

spreaders (optional), are also easily

controlled with the SOLO-PILOT.

• Precise operation through sensitive

control of all functions.

• Comfortable working position with adjustable armrest.

Easily read operator display

High quality display of important operating information.

• Travel direction and wheel position

indicator.

• 180°/360° steering mode.

• Battery discharge display with residual

running time.

• Three adjustable travel programs to suit

every requirement.

• Operating hours and time.

Greater eciency with three-phase

technology

Powerful 3-phase AC technology for

the drive system, lift and steering drives

oers many advantages over conventional DC motors.

• Powerful acceleration.

• Rapid reversing

• No carbon brushes and a maintenance-free drive motor ensure a high

degree of operational availability.

• Longer operating times thanks to

energy recovery when reducing speed.

• Two-year warranty on drive and lift

motors.

The frame is as narrow as possible.

The right chassis width for every application: The ETV 110/112 has an outer

width of 1120 mm – ideal for drive-in

racking or block storage. Euro pallets

can be picked up lengthwise between

the wheel arms just as they can be by a

truck with a larger chassis width of 1,250

- 1,290 mm.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ETV 110/112 _012014_en_UK_000

Loading...

Loading...