Page 1

Multi-pallet transport of up to

three pallets

Ergonomic operator seat

layout

180° / 360° steering

High travel speeds

3-phase AC technology (48 V)

for high torques and dynamic

movement

ESE 420/430

Electric sideways-seated pallet truck (2,000/3,000 kg)

The ESE 420/430 electric sideways

seated pallet trucks are ideal for multipallet transport over long distances. Their

48-volt 3-phase AC motors ensure a

smooth starts, powerful acceleration and

high maximum speeds. The best basis for

high throughput rates.

This high performance level is extremely

easy to achieve and oers very high

levels of safety: Travel speed, brakes and

deadman switch are all controlled by

easily reached pedals. The lift functions

are operated using the SOLO-PILOT

control lever, which is readily to hand.

The optional height-adjustable footplate

and the adjustable steering wheel ensure

comfortable seating positions for all

operators. The steering can be switched

between 180° and 360°. The 360°

steering mode facilitates manoeuvring

by allowing seamless changes of direction with only a few turns of the steering

wheel. The changeover between forwards and reverse can also be performed

simply by pressing a button. The large

display oers a quick overview of the

steering setting, battery status and the

available travel programs.

With battery capacities of up to 620 Ah

and a robust design, the ESE 420/430 is

the ideal truck for intensive applications.

Page 2

ESE 420/430

Page 3

Issue: 06/2009

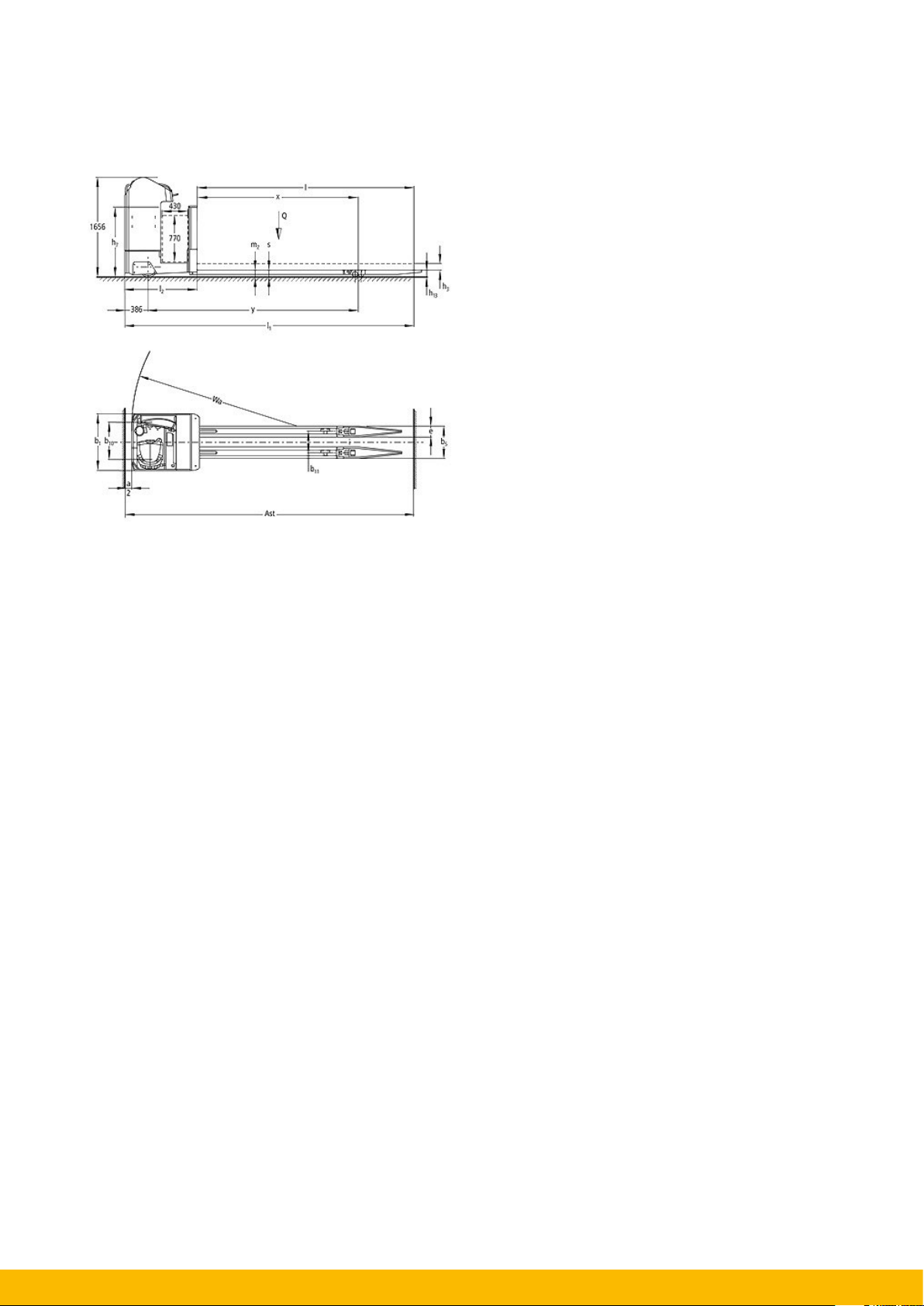

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ESE 420 ESE 430

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 2 3

1.6 Load centre distance c mm 1200

Identification

1.8 Load distance x mm 1840

1.9 Wheelbase y mm 2260

2.1.1 Net weight incl. battery (see row 6.5) kg 2395 2475

2.2 Axle load, w. load, front / rear kg 2561 / 1900 2890 / 2980

2.3 Axle load, w.o. load, front / rear kg 1886 / 590 1916 / 559

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 343 x 114

3.3 Tyre size, at rear mm Ø 85 x 80 Ø 90 x 92

3.4 Additional wheels (dimensions) mm Ø 285 x 100

3.5 Wheels, number front/rear (× = driven wheels) 2-1x/4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 604

10

mm 380

11

4.2.1 Total height h15 mm

4.4 Lift h

4.8 Seat height/stand height h

4.15 Lowered height h

4.19.4 Total length including fork length l

4.20 Length incl. back of forks l

4.21 Total width b

mm 115

3

mm 1200

7

mm 90

13

mm 3625

1

mm 1225

2

mm 1000

1/b2

4.22 Fork dimensions s/e/l mm 60 / 180 / 2400 70 / 200 / 2400

4.25 Width over forks b

Basic dimensions

4.32 Floor clearance centre wheelbase m

mm 560 580

5

mm 30 20

2

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 3865

4.35 Turning radius W

mm 3105

a

5.1 Travel speed, w. / w.o. load km/h 13 / 14

5.2 Lift speed, w. / w.o. load m/s 0.056 / 0.06

5.3 Lower speed, w. / w.o. load m/s 0.052 / 0.05

data

5.7 Gradeability laden/unladen % 6 / 15

Performance

5.10 Service brake electric

6.1 Drive motor rating S2 60 min. kW 6.9

6.2 Lift motor rating at S3 15% kW 3.0

6.3 Battery according to DIN 43531/35/36 A,B,C, no A

6.4 Battery voltage/nominal capacity K5 V/Ah 48 / 620

Electrics

6.5 Battery weight kg 945

8.1 Type of drive control Mosfet / AC

Misc.

3)

3)

1)

3)

1480

2211

3953

2750

3)

3)

2)

3)

1)

diagonal according to VDI: + 128 mm

2)

Diagonal travel according VDI: +83 mm

3)

Load section lowered: + 89 mm

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Controls Comfortable seated position with

Greater eciency with three-phase

AC technology

Powerful three-phase AC technology

oers a whole range of advantages over

conventional DC motors:

• Powerful acceleration.

• No carbon brushes – maintenancefree drive motor.

• Two-year warranty on the drive motor.

generous

Easy operation with SOLO-PILOT

The control lever for activating all hydraulic functions and also selecting the

direction of travel and sounding the

horn.

• All controls are within the operator‘s

field of vision and are clearly allocated

to a single function.

• Precise operation by sensitive activation of all functions.

Ergonomic Drivers cab

• Comfortable armrest.

The operator position provides ideal

working conditions for relaxed, high productivity operations. Its strengths:

• Adjustable seat (seating position / body

weight) for all drivers.

• Height-adjustable footplate (optional).

• Important controls within easy reach.

• Generous space.

• 180°/360° three-phase steering with

optimised steering wheel position.

• Steering wheel adjustment.

Easy-to-read driver‘s display

High quality control panel displaying the

most important operating data.

• Travel direction and wheel position

display.

• Steering setting.

• Battery status with residual time display.

• Speed.

• Distance covered.

Safe entry with low step height and

grab handle

• A choice of three travel programmes

for individual matching to every operations.

• Operating hours and time of day.

Powerful battery

4 PzS 620 Ah

Robustly built for intensive applications

• Robust frame for continuous use at full

rated load.

• Torsion-resistant forks manufactured

with strong reinforced steel. Available

in a wide variety of versions.

Reduced maintenance cost

Easy-service components ensure

reduced long-term operating costs:

• Maintenance-free three-phase drive

motor with no carbon brushes.

• Easy to service with outstanding accessibility to all components.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ESE 420/430_012014_en_UK_000

Loading...

Loading...