Page 1

Cost-eective operation due

to double-deck lorry loading

Ergonomics of sideways

travel improve performance

Narrow design and

maximum manoeuvrability

High speed and acceleration

characteristics

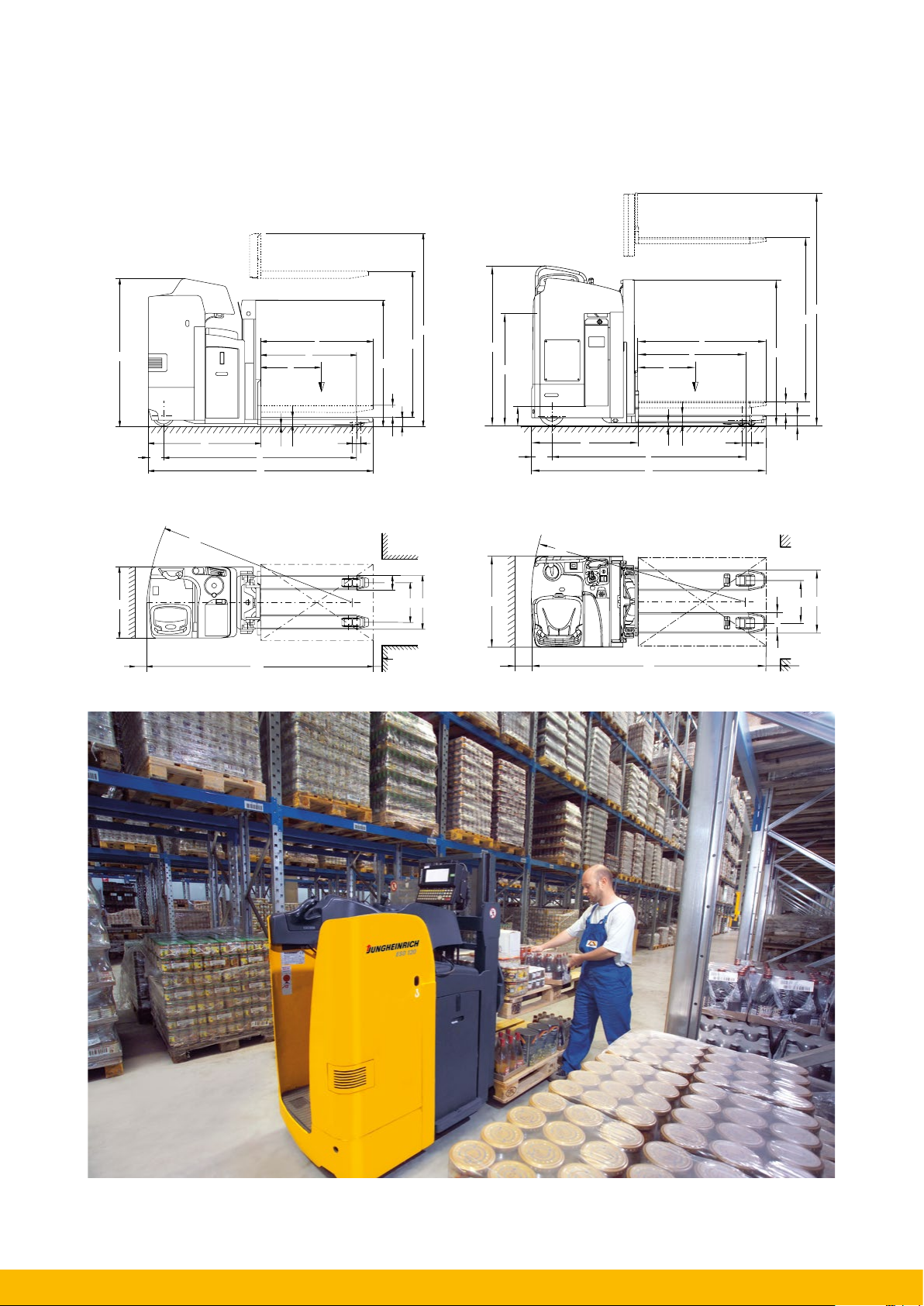

ESD 120/220

Electric stand-on / sideways-seated stacker (2,000 kg)

The Jungheinrich ESD 120 / 220 range

of stackers are highly flexible trucks. As

double-deck stackers they can lift two

Euro pallets simultaneously with both

mast and support arm lift: ideal for loading and unloading lorries with two tiers.

The ESD 120 / 220 can also be used as a

conventional stacker in the warehouse.

The width of the ESE 120 stand-on

truck is just 760 mm. This makes pallet

positioning inside a lorry as well as fast

lorry loading unloading easy. The foldup seat oers additional comfort when

travelling over longer distances. It acts

as a comfortable backrest when folded

up. The low entry height assists with

frequent entry and exit.

The 820 mm wide ESD 220 is a pure sitdown truck, giving the operator maximum comfort. It is therefore particularly

suited to travelling over long distances.

The adjustable foot height ensures a

relaxed working position for drivers of all

sizes.

All trucks are fitted with powerful AC 24

V drive motors for high acceleration and

top speeds. The robust design oers particular advantages – the chassis and load

sections can handle capacities of up to

2,000 kg.

Other advantages include:

• High travel speeds and acceleration.

• Extremely strong chassis for very high

operational demands.

• Display with steering position and

travel programme selection (optional

on the ESD 220).

• Electric steering for easy manoeuvring.

• Excellent energy management for low

operating costs.

Page 2

ESD 120/220

2

2

2

2

ESD 120

1350

b

ESD 220

h

4

h

h

l

x

c

Q

l

2

179

m

s

2

y

l

1

95

Wa

4

h

3

h

1

h

5

h

13

1434

h

7

165

l

187

2

y

l

1

I

x

c

Q

m

s

2

95

Wa

e

b11b

2

5

b

2

3

h

1

h

5

h

13

b

b

11

5

e

a

Ast

a

a

Ast

a

Page 3

Issue: 09/2010

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ESD 120 ESD 220

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation stand/seat seat

1.5 Load capacity/rated load Q t 2

1.5.1 Load capacity/mast lift Q t 1

1.5.2 Load capacity/support arm lift Q t 2

Identification

1.6 Load centre distance c mm 600

1.8 Load distance x mm 930

1.9 Wheelbase y mm 1835 / 1905

4)

4)

2.1.1 Net weight incl. battery (see row 6.5) kg 1258 1350

2.2 Axle load, w. load, front / rear kg 1220 / 2038 1340 / 2010

2.3 Axle load, w.o. load, front / rear kg 884 / 374 982 / 368

Weights

3.1 Tyres Polyurethan Vulkollan

3.2 Tyre size, at front mm Ø 230 x 78 Ø 230 x 77

3.3 Tyre size, at rear mm Ø 85 x 75 Ø 85 x 85

3.4 Additional wheels (dimensions) mm Ø 140 x 54

3.5 Wheels, number front/rear (× = driven wheels) 1+1x/4 2-1x/4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 475 544

10

mm 380

11

4.2 Mast height (lowered) h1 mm 1250 1309

4.4 Lift h

4.5 Extended mast height h

4.6 Initial lift h

4.8 Seat height/stand height h

4.8.1 Standing height h

4.15 Lowered height h

4.19 Overall length l

mm 1660

3

mm 2250 2150

4

mm 105 110

5

mm 950

7

mm 245

7

mm 90

13

mm 2260 2185

1

4.19.1 total length (long) mm 2330

4.20 Length incl. back of forks l

4.21 Total width b

Basic dimensions

4.22 Fork dimensions s/e/l mm 65 / 190 / 1190 65 / 185 / 1190

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m

mm 1070 / 1140 995

2

mm 760 820

1/b2

mm 570

5

mm 20 25

2

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2399

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2485 / 2555

4.35 Turning radius Wa mm 2015 / 2085

2)

4)

5.1 Travel speed, w. / w.o. load km/h 7.5 / 9.2 9.1 / 9.1

5.2 Lift speed, w. / w.o. load m/s 0.14 / 0.22 0.2 / 0.39

5.3 Lower speed, w. / w.o. load m/s 0.23 / 0.17 0.47 / 0.47

data

5.8 Max. gradeability, laden/unladen % 6 / 12 8 / 14

Performance

5.10 Service brake electro-mechanical electric

6.1 Drive motor rating S2 60 min. kW 2.0 2.8

6.2 Lift motor rating at S3 15% kW 2.2 3.0

6.3 Battery according to DIN 43531/35/36 A,B,C, no 43535 B no

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 375 24 / 465

Electrics

6.5 Battery weight kg 288 380

8.1 Type of drive control SpeedControl AC SpeedControl

Misc.

5)

926

1734

1925

3)

3)

1)

3)

1)

Diagonal in accordance with VDI: + 211 mm

2)

Diagonal in accordance with VDI: + 213 mm

3)

Load section lowered: + 78 mm

4)

Load section raised / lowered: + 90 mm

5)

Mast lift capacity: max. 1 t

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Ergonomic arrangement of operator position on the ESD 120

Comfortable seating position with

height-adjustable footplate

Innovative 3-phase AC technology

Better performance simultaneously combined with reduced operating costs. Your

advantages (for ESD 220):

• High level of eciency with excellent

energy management.

• Powerful acceleration.

• Rapid direction change.

• No carbon brushes – maintenancefree drive motor.

• Two-year warranty on the drive motor.

Productivity-enhancing ergonomics

The layout of the operators cab, which

is sideways on to the travel direction

ensures high visibility and reduces potential neck complaints. A safety switch in

the foot well ensures maximum safety.

ESD 120

• Fold-up seat acts as a backrest when

the driver is standing.

• Footrest for better support when

seated.

ESD 220

• Comfort seat with weight adjustment.

• Padded armrest.

• Padded knee cushion.

Grab handle for safe access and for

the fitting of various options

Travel comfortably and safely

Safe speed regulation with SpeedControl,

this ensures maximum safety and simple

travel speed control in all situations.

• Roll-back protection on gradients with

automatically activated brake.

• Constant travel speed on up and down

gradients.

• Energy recovery with regenerative

braking.

• Smooth, jerk free operation.

Flexible options

ESD 120

• Transport of two pallets simultaneously

with double-deck load section.

• Rapid loading and unloading of HGVs.

• Easy pallet positioning directly on HGV

side wall due to narrow truck width of

760 mm.

• Comfortable entry and exit due to low

entry height.

ESD 220

• Drive and lift control via multifunction

lever

• Comfortable seat makes it ideal for

long distances.

• Easy manoeuvrability due to compact

design.

• Ideal for block stacking.

Powerful battery

ESD 120

• Short battery compartment: 3 PzS 375

Ah.

• Long battery compartment: 4 PzS 500

Ah.

• Lateral battery exchange

ESD 220

• 3 PzS 465 Ah.

• Lateral battery exchange.

Additional equipment

• Dierent load wheels (depending on

the application).

• Cold store version.

• Code lock.

• Steering wheel on the left (ESD 120).

• Load guard.

• Battery discharge indicator and

steering position display (optional on

the ESD 220).

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ESD 120/220_042014_en_UK_000

Loading...

Loading...