Page 1

Truck width of just 820 mm

Narrow aisle width for use in

confined warehouse areas and

block storage

Ergonomic sideways seated

position for fatigue-free travel

Multifunction lever for

eortless operation

3-phase AC technology

for dynamic movement

operations

ESC 214/216/214z/216z

Electric sideways-seated truck (1,400/1,600 kg)

The Jungheinrich electric sideways seat

stackers ESC 214/216 are ideally suitable

for longer transport distances during

stacking and retrieval. With a width of

just 820 mm and a short working aisle

width, the ESC shows particular strength

in applications where space is limited and

in block storage warehouses.

The comfortable sideways seating position provides the operator with excellent

visibility. An advantage which comes

into its own during frequent changes of

direction. Individual height adjustment

of the foot well provides a relaxed work

environment for operators of varied

heights.

Other features include:

• Powerful, innovative 2.8 kW threephase drive motor for high acceleration

and performance

• High residual capacities and powerful

lift motor.

• Extremely durable frame for very high

operational demands.

• Display with steering position display

and travel program selection (optional).

• Electric steering for easy manoeuvring

with a few turns of the steering wheel

• Excellent energy management for low

operating costs

The initial lift of the ESC 214z/216z allows

it to cope extremely easily with uneven

floor conditions. All travel and lift functions are performed using the multifunction lever which is within easy reach.

Thanks to the compact design and excellent ergonomics, the ESC is the ideal

stacker for working in restricted spaces.

Page 2

ESC 214/216/214z/216z

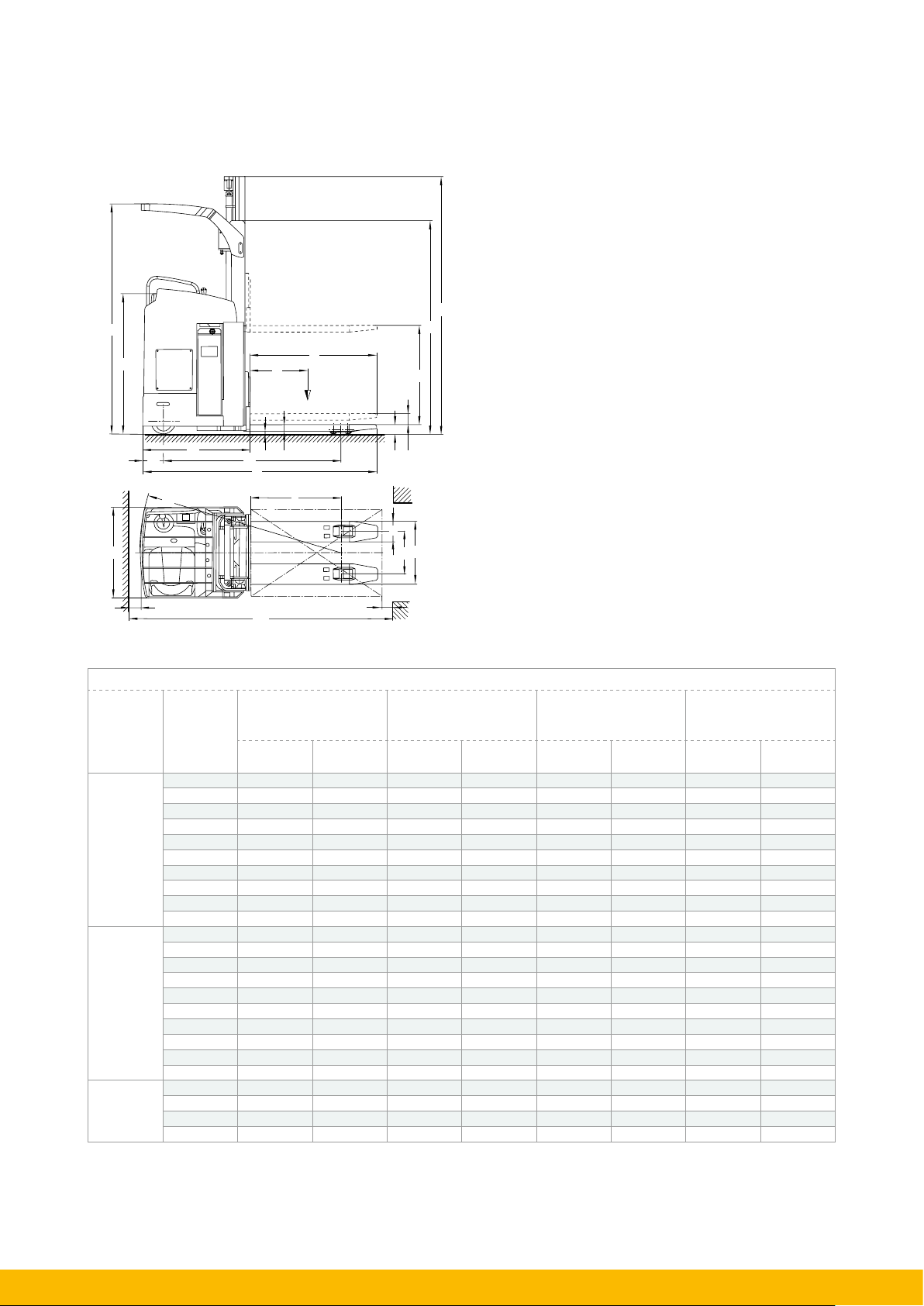

sh

h

6

1278

l

C

Q

h

1

h

3

h

4

b

2

a

2

Duplex ZT

Duplex ZZ

Triplex DZ

l

2

187

Wa

m

2

y

l

1

x

Ast

h

13

5

e

b

b

5

11

a

2

Standard mast types ESC 214/216/214z/216z

Lift

h

Lowered mast height

3

h

1

Free lift

h

2

Extended mast height

h

4

Height of overhead guard

(mm) (mm) (mm) (mm) (mm)

ESC 214 /

214z

ESC 216 /

216z

ESC 214 /

214z

ESC 216 /

216z

ESC 214 /

214z

ESC 216 /

216z

ESC 214 /

214z

2800 - 1995 - 100 - 3372 - 2093

2900 1995 - 100 - 3422 - 2093 -

3100 - 2145 - 100 - 3672 - 2243

3200 2145 - 100 - 3722 - 2243 -

3500 - 2345 - 100 - 4072 - 2288

3600 2345 - 100 - 4122 - 2288 4000 - 2595 - 100 - 4572 - 2288

4100 2595 - 100 - 4622 - 2288 4200 - 2695 - 100 - 4772 - 2288

4300 2695 - 100 - 4822 - 2288 2800 - 1945 - 1373 - 3372 - 2093

2900 1945 - 1420 - 3422 - 2093 -

3100 - 2095 - 1523 - 3672 - 2243

3200 2095 - 1570 - 3722 - 2243 -

3500 - 2295 - 1723 - 4072 - 2288

3600 2295 - 1770 - 4122 - 2288 4000 - 2545 - 1973 - 4572 - 2288

4100 2545 - 2020 - 4622 - 2288 4200 - 2645 - 2073 - 4772 - 2288

4300 2645 - 2120 - 4822 - 2288 4200 - 1945 - 1376 - 4770 - 2093

4300 1945 - 1426 - 4830 - 2093 -

5250 - 2295 - 1726 - 5820 - 2288

5350 2295 - 1776 - 5880 - 2288 -

h

6

ESC 216 /

216z

Page 3

Issue: 06/2010

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ESC 214 ESC 216 ESC 214z ESC 216z

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 1.4 1.6 1.4 1.6

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 860 860 874

1.9 wheelbase y mm 1648 1648 1677

2.1.1 Net weight incl. battery (see row 6.5) kg 1590 1590 1660 1660

2.2 Axle load, w. load, front / rear kg 1316 / 1674 1340 / 1850 1285 / 1775 1370 / 1890

Weights

2.3 Axle load, w.o. load, front / rear kg 1113 / 477 1113 / 477 1162 / 498 1162 / 498

3.1 Tyres Polyurethan

3.2 Tyre size, at front mm Ø 230 x 77

3.3 Tyre size, at rear mm Ø 85 x 85

3.4 additional wheels (dimensions) mm Ø 140 x 126

3.5 Wheels, number front/rear (× = driven wheels) 2-1x/4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 544

10

mm 385

11

4.2 mast height (lowered) h1 mm 1995

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.6 Initial lift h

4.7 Height of overhead guard h

mm 100

2

mm 2900 2800 2900 2800

3

mm 3422

4

mm 125 125

5

mm 2095

6

4.8 Seat height/stand height h7 mm 950

4.15 Lowered height h

4.19.4 Total length including fork length l

4.20 Length incl. back of forks l

4.21 Total width b

Basic dimensions

4.22 fork dimensions s/e/l mm

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2383

mm 90

13

mm 2125 2125 2140 2140

1

mm 975 975 990 990

2

mm 820

1/b2

60 / 185 /

1150

mm 570

5

mm 30 30 25 25

2

60 / 185 /

1150

1)

2383

1)

4.35 turning radius Wa mm 1843 1843 1872

5.1 Travel speed, w. / w.o. load km/h 9.1 / 9.1

5.2 Lift speed, w. / w.o. load m/s 0.15 / 0.24 0.13 / 0.24 0.14 / 0.23 0.14 / 0.23

5.3 Lower speed, w. / w.o. load m/s 0.42 / 0.42 0.42 / 0.42 0.42 / 0.38 0.42 / 0.38

data

5.7 Gradeability laden/unladen % 7 / 12

Performance

5.10 Service brake electric

6.1 Drive motor rating S2 60 min. kW 2.8

6.2 Lift motor rating at S3 10% kW 3

6.3 Battery according to DIN 43531/35/36 A,B,C, no no

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 465

Electrics

6.5 Battery weight kg 380

8.1 type of drive control AC SpeedControl

Misc.

4)

3)

60 / 185 /

1150

2398

2)

2)

1)

2)

2)

874

2)

1677

65 / 185 /

1150

1)

2398

2)

1872

1)

Diagonal in accordance with VDI: + 190 mm

2)

Load section raised: - 78 mm

3)

See mast table

4)

Twin roller design

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Grab handle for safe access and for

the fitting of various options

Comfortable seating position with

height-adjustable footplate

Innovative 3-phase AC technology

Better performance simultaneously coupled with reduced operating costs. Make

the most of these advantages:

• High level of eciency with excellent

energy management.

• Powerful acceleration.

• Rapid change in direction of travel

• No carbon brushes - maintenance-free

drive motor.

• Two-year warranty on the drive motor.

Productivity-enhancing ergonomics

The arrangement of the operator workstation, sideways on to the direction of

travel, ensures optimum visibility and

reduces potential neck complaints due

to frequent changes in direction. A safety

switch in the foot -well ensures maximum safety.

• Comfortable seat with adjustment for

body weight.

• Padded armrest.

• Padded knee area.

• Grab handle for safe entry (also serves

as the mounting point for storage or

for a radio data terminal).

Ergonomic layout of all controls Excellent visibility through the mast

Travel comfortably and safely

Safe speed regulation by electronic

Speed-Control. Speed-Control ensures

maximum safety and eortless control of

speed in all situations.

• Roll-back protection on gradients by

self-acting brake.

• Constant travel speed both ways on

gradients.

• Energy recovery by regenerative braking.

• Particularly smooth stepless operation.

Easy operation and good all-round

visibility

• Operation of all drives and lift functions by multifunction lever within easy

reach.

• Proportional hydraulics for precise load

positioning.

• Smooth electric steering.

• Protected seating position within the

enclosed truck profile.

• Free all-round view with no obstructive

struts; good visibility through the mast

and overhead guard.

Narrow truck with high manoeuvrability

• With a truck width of only 820 mm, the

ESC is ideal for use in narrow aisles and

block storage.

• Narrow working aisle width and well

protected operator position for outstanding operation in narrow working

aisles.

Robustness and service-friendliness

• Ease access to the controller and

electronics.

• Side opening access to the drive components.

• Robust, enclosed chassis.

Powerful battery

• 3 PzS 465 Ah

• Lateral battery exchange on rollers.

Additional equipment

• Various storage options

• Heated seat

• Load guard

• Display (travel direction, steering setting, battery status, operating hours,

time of day, travel programs)

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ESC 214/216/214z/216z_112013_en_UK_000

Loading...

Loading...