Page 1

EFG 213-320

09.09 -

Operating instructions G

51151902

03.13

EFG 213

EFG 215

EFG 216k

EFG 216

EFG 218k

EFG 218

EFG 220

EFG 316k

EFG 316

EFG 318k

EFG 318

EFG 320

Page 2

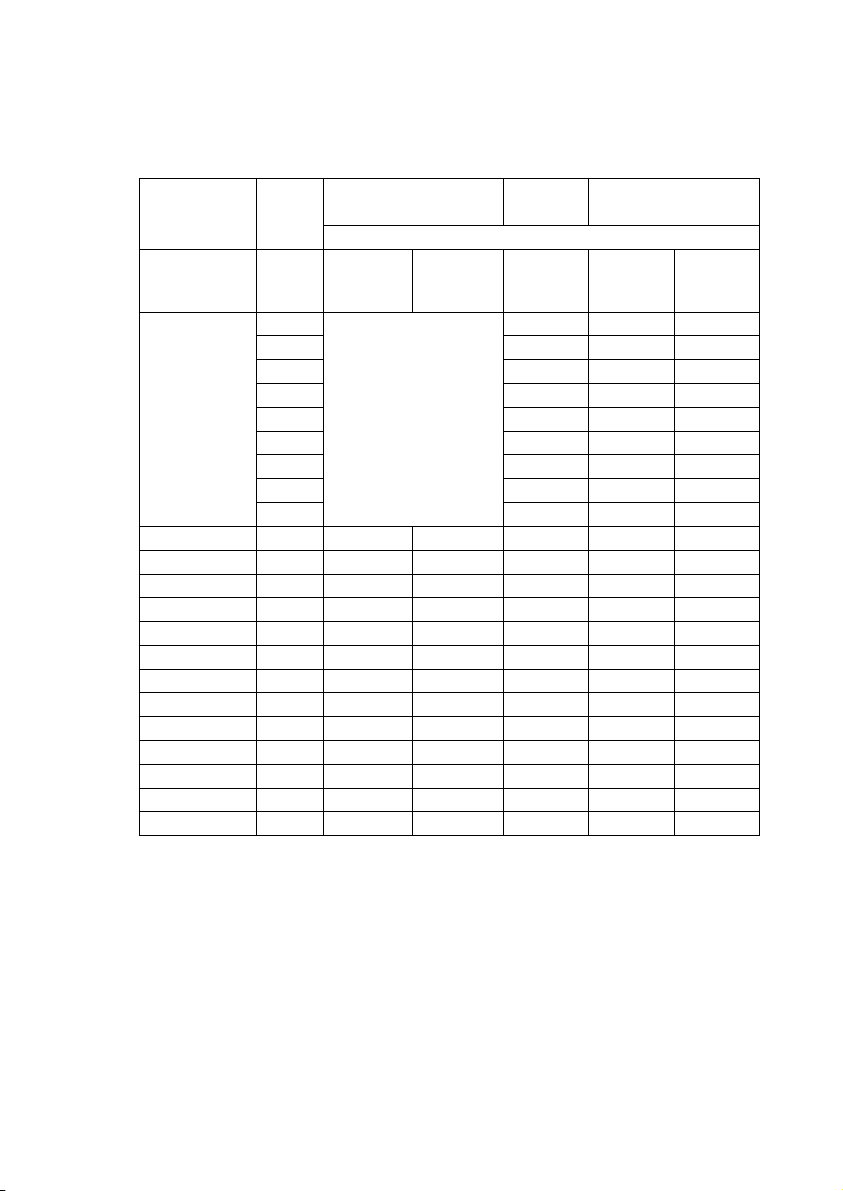

Declaration of Conformity

Jungheinrich AG, Am Stadtrand 35, D-22047 Hamburg

Manufacturer or agent acting in the European Union

Type Option Serial no. Year of

EFG 213

EFG 215

EFG 216k

EFG 216

EFG 218k

EFG 218

EFG 220

EFG 316k

EFG 316

EFG 318k

EFG 318

EFG 320

Additional information

On behalf of

Date

G EU Conformity Declaration

The undersigned hereby declare that the powered industrial truck described below in

detail complies with the European Directives 2006/42/EC (Machinery Directive) and

2004/108/EEC (Electromagnetic Compatibility - EMC) including amendments as well

as the legislative decree to incorporate the directives in national law. The signatories

are in each case individually authorized to compile the technical documents.

manufacture

03.13 EN

3

Page 3

03.13 EN

4

Page 4

Foreword

Notes on the operating instructions

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide

sufficient instruction for the safe operation of the industrial truck. The information is

provided clearly and concisely. The chapters are arranged by letter and the pages are

numbered continuously.

The operator manual details different industrial truck models. When operating and

servicing the industrial truck, make sure that the particular section applies to your

truck model.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to

alter the design, equipment and technical features of the system. No guarantee of

particular features of the truck should therefore be assumed from the present

operating instructions.

Safety notices and text mark-ups

Safety instructions and important explanations are indicated by the following

graphics:

DANGER!

Indicates an extremely hazardous situation. Failure to comply with this instruction will

result in severe irreparable injury and even death.

WARNING!

Indicates an extremely hazardous situation. Failure to comply with this instruction

may result in severe irreparable injury and even death.

CAUTION!

Indicates a hazardous situation. Failure to comply with this instruction may result in

slight to medium injury.

NOTE

Indicates a material hazard. Failure to comply with this instruction may result in

material damage.

Z Used before notices and explanations.

t Indicates standard equipment

o Indicates optional equipment

03.13 EN

5

Page 5

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - Germany

Tel: +49 (0) 40/6948-0

www.jungheinrich.com

03.13 EN

6

Page 6

Contents

A Correct Use and Application ................................................... 11

1 General.................................................................................................... 11

2 Correct application................................................................................... 11

3 Approved application conditions.............................................................. 12

4 Proprietor responsibilities ........................................................................ 13

5 Adding attachments and/or optional equipment ...................................... 13

B Truck Description .................................................................... 15

1 Application ............................................................................................... 15

1.1 Truck models and rated capacity............................................................. 15

2 Assemblies and Functional Description................................................... 16

2.1 Travel direction definition......................................................................... 16

2.2 Assembly Overview ................................................................................. 17

2.3 Functional Description ............................................................................. 18

3 Technical Specifications .......................................................................... 19

3.1 Performance data .................................................................................... 20

3.2 Dimensions .............................................................................................. 22

3.3 Weights.................................................................................................... 28

3.4 Mast versions .......................................................................................... 29

3.5 Tyre type.................................................................................................. 30

3.6 Engine Data ............................................................................................. 31

3.7 EN norms................................................................................................. 32

3.8 Conditions of use ..................................................................................... 33

3.9 Electrical requirements ............................................................................ 33

4 Identification points and data plates ........................................................ 34

4.1 Indication Points ...................................................................................... 34

4.2 Data plate ................................................................................................ 36

4.3 Truck capacity plate................................................................................. 37

4.4 Attachment capacity plate ....................................................................... 38

5 Stability .................................................................................................... 38

03.13 EN

C Transport and Commissioning ................................................ 39

1 Transport ................................................................................................. 39

2 Truck laden.............................................................................................. 39

2.1 Centre of gravity of the truck ................................................................... 39

2.2 Lifting the truck by crane ......................................................................... 40

2.3 Loading with another industrial truck ....................................................... 42

3 Securing the truck during transport ......................................................... 43

4 Using the Truck for the First Time ........................................................... 45

7

Page 7

D Battery - Servicing, Recharging, Replacement ....................... 47

1 Safety Regulations Governing the Handling of Lead-Acid Batteries ....... 47

1.1 General notes on handling batteries........................................................ 49

2 Battery types............................................................................................ 50

2.1 Battery dimensions .................................................................................. 51

3 Exposing the battery................................................................................ 52

4 Charging the battery ................................................................................ 53

4.1 Charging the battery with a stationary charger ........................................ 53

4.2 Charging the battery with an on-board charger ....................................... 54

5 Battery removal and installation .............................................................. 58

5.1 Battery holder assembly .......................................................................... 59

5.2 Removal and installation using an EJE pallet truck with Snapfit battery

holder (o)................................................................................................ 61

5.3 Removal and installation using a hand pallet truck with Snapfit battery

holder (o)................................................................................................ 64

5.4 Removal and installation using a multi-adapter (o) ................................ 67

5.5 Removal and installation using a worktable for crane loading (o) .......... 69

5.6 Removal and installation using a fork shoe (o) ...................................... 71

5.7 Removal and installation using a roller conveyor (o).............................. 73

5.8 Hook-on battery door removal and installation (o) ................................. 74

E Operation ................................................................................ 75

1 Safety Regulations for the Operation of the Forklift Truck....................... 75

2 Displays and Controls.............................................................................. 77

2.1 Control panel with display unit ................................................................. 81

2.2 Armrest control panel switch (o)............................................................. 85

2.3 Side compartment control panel switch (o) ............................................ 86

2.4 Display ..................................................................................................... 87

3 Preparing the Truck for Operation ........................................................... 90

3.1 Checks and operations to be performed before starting daily operation . 90

3.2 Entry and exit........................................................................................... 93

3.3 Trucks with reduced headroom (o)......................................................... 93

3.4 Setting up the operator position............................................................... 94

3.5 Seat Belt .................................................................................................. 98

4 Industrial Truck Operation ....................................................................... 100

4.1 Safety regulations for truck operation ...................................................... 100

4.2 Preparing the truck for operation ............................................................. 103

4.3 Setting the time........................................................................................ 104

4.4 Parking the truck securely ....................................................................... 105

4.5 Emergency Disconnect............................................................................ 106

4.6 Travel....................................................................................................... 107

4.7 Steering ................................................................................................... 109

4.8 Brakes ..................................................................................................... 110

4.9 Adjusting the forks ................................................................................... 114

4.10 Replacing the forks.................................................................................. 115

4.11 Lifting, transporting and depositing loads ................................................ 116

4.12 Operating the lift mechanism and integrated attachments ...................... 118

4.13 Safety instructions for operating additional attachments ......................... 125

4.14 Operating additional attachments for the SOLO-PILOT .......................... 129

8

03.13 EN

Page 8

03.13 EN

4.15 Operating additional attachments for the Multi Pilot ................................ 131

4.16 Fitting additional attachments.................................................................. 133

5 Towing trailers ......................................................................................... 135

6 Optional equipment ................................................................................. 137

6.1 CanCode keypad ..................................................................................... 137

6.2 Assistance systems ................................................................................. 141

6.3 Steel cab.................................................................................................. 143

6.4 Sliding windows ....................................................................................... 144

6.5 Automatic / mechanical folding gate ........................................................ 145

6.6 Panel door ............................................................................................... 146

6.7 Operator position extension..................................................................... 146

6.8 Adjusting the driver’s seat ....................................................................... 147

6.9 Heating .................................................................................................... 148

6.10 Removable load backrest ........................................................................ 149

6.11 Lift cutout override ................................................................................... 149

6.12 Fire extinguisher ...................................................................................... 150

6.13 Tilt angle display...................................................................................... 150

6.14 Rockinger coupling with hand lever or remote control............................. 151

6.15 Camera system ....................................................................................... 152

6.16 Control layout “N” .................................................................................... 153

7 Troubleshooting....................................................................................... 154

7.1 Troubleshooting ....................................................................................... 154

7.2 Operating the truck without its own drive system .................................... 156

7.3 Emergency lowering ................................................................................ 159

F Industrial Truck Maintenance .................................................. 161

1 Operational Safety and Environmental Protection................................... 161

2 Maintenance Safety Regulations............................................................. 162

2.1 Consumables and used parts .................................................................. 163

2.2 Wheels..................................................................................................... 163

2.3 Lift Chains................................................................................................ 164

2.4 Hydraulic system ..................................................................................... 165

3 Lubricants and Lubrication Schedule ...................................................... 166

3.1 Handling consumables safely .................................................................. 166

3.2 Lubrication Schedule ............................................................................... 168

3.3 Consumables........................................................................................... 169

4 Maintenance and repairs ......................................................................... 171

4.1 Preparing the truck for maintenance and repairs .................................... 171

4.2 Lifting and jacking up the truck safely...................................................... 172

4.3 Opening the rear panel ............................................................................ 173

4.4 Checking the wheel attachments............................................................. 174

4.5 Replacing wheels .................................................................................... 175

4.6 Hydraulic system ..................................................................................... 177

4.7 Replacing the hydraulic oil filter ............................................................... 179

4.8 Replacing the ventilation/discharge filter ................................................. 179

4.9 Check the gear oil level ........................................................................... 180

4.10 Heating .................................................................................................... 181

4.11 Adding window washer system fluid........................................................ 181

4.12 Checking electrical fuses......................................................................... 182

4.13 Cleaning .................................................................................................. 186

4.14 Working on the electrical system............................................................. 189

9

Page 9

4.15 Restoring the truck to service after maintenance and repairs ................. 190

5 Decommissioning the industrial truck ...................................................... 191

5.1 Prior to decommissioning ........................................................................ 192

5.2 During decommissioning ......................................................................... 192

5.3 Restoring the truck to service after decommissioning ............................. 193

6 Safety tests to be performed at intervals and after unusual incidents ..... 194

7 Final de-commissioning, disposal............................................................ 195

8 Human vibration measurement ............................................................... 195

9 Servicing and Inspection ......................................................................... 196

10 Maintenance checklist EFG 213-220....................................................... 197

10.1 Operating company ................................................................................. 197

10.2 Customer service..................................................................................... 200

11 Maintenance checklist EFG 316-320....................................................... 208

11.1 Operating company ................................................................................. 208

11.2 Customer service..................................................................................... 211

10

03.13 EN

Page 10

Appendix

JH Traction Battery Operating Instructions

These operating instructions apply only to Jungheinrich battery models. If using

Z

another brand, refer to the manufacturer's operating instructions.

0506.GB

1

Page 11

0506.GB

2

Page 12

A Correct Use and Application

1 General

The truck must be used, operated and serviced in accordance with the present

instructions. All other types of use are beyond its scope of application and may result

in damage to personnel, the industrial truck or property.

2 Correct application

NOTE

The maximum load and load distance are indicated on the capacity plate and must

not be exceeded.

The load must rest on the load handler or be lifted by an attachment approved by the

manufacturer.

The load must be fully raised,see "Lifting, transporting and depositing loads" on

page 116.

– Lifting and lowering loads.

– Transporting lowered loads over short distances.

– Do not travel with a raised load (>30 cm).

– Do not carry or lift passengers.

– Do push or pull load units.

– Occasional towing of trailer loads.

– When towing trailer loads the load must be secured on the trailer.

– The permissible trailer load must not be exceeded.

03.13 EN

11

Page 13

3 Approved application conditions

– Operation in industrial and commercial environments.

– Permissible temperature range -20°C to 40°C.

– Operation only on secure, level surfaces with sufficient capacity.

– Do not exceed the permissible surface and spot load limits on the travel routes.

– Operation only on routes that are visible and approved by the operating company.

– Negotiating inclines up to a maximum of 15 %.

– Do not travel across or at an angle on inclines. Travel with the load facing uphill.

– Operation in partially public traffic.

WARNING!

Use under extreme conditions

Using the truck under extreme conditions can result in malfunctions and accidents.

XSpecial equipment and authorisation are required if the truck is to be constantly

used in extreme conditions, especially in dusty or corrosive atmospheres.

XThe truck cannot be used in areas at risk of explosion.

XIn adverse weather conditions (thunder, lightning) the industrial truck must not be

operated outside or in endangered areas.

12

03.13 EN

Page 14

4 Proprietor responsibilities

For the purposes of the present operating instructions the “operating company” is

defined as any natural or legal person who either uses the industrial truck himself, or

on whose behalf it is used. In special cases (e.g. leasing or renting) the proprietor is

considered the person who, in accordance with existing contractual agreements

between the owner and user of the industrial truck, is charged with operational duties.

The proprietor must ensure that the industrial truck is used only for the purpose it is

intended for and that danger to life and limb of the user and third parties are excluded.

Furthermore, accident prevention regulations, safety regulations and operating,

servicing and repair guidelines must be followed. The operating company must

ensure that all users have read and understood these operating instructions.

NOTE

Failure to comply with the operating instructions invalidates the warranty. The same

applies if improper work is carried out on the truck by the customer or third parties

without the permission of the manufacturer.

5 Adding attachments and/or optional equipment

The mounting or installation of additional equipment which affects or enhances the

performance of the industrial truck requires the written permission of the

manufacturer. Local authority approval may also need to be obtained.

Local authority approval however does not constitute the manufacturer’s approval.

03.13 EN

13

Page 15

14

03.13 EN

Page 16

B Truck Description

1 Application

The EFG 213-320 is a three- or four-wheel electric sit-down counterbalanced truck. It

is a cantilever counterbalanced truck which can lift, transport and deposit loads using

the load handler attached in front.

Closed bottom pallets can also be lifted.

1.1 Truck models and rated capacity

The rated capacity depends on the model. The rated capacity can be derived from

the model name.

EFG213

EFG Model name

2Series

13 Rated capacity x 100 kg

The rated capacity is not generally the same as the permissible capacity. The

capacity can be found on the capacity plate attached to the truck.

03.13 EN

15

Page 17

2 Assemblies and Functional Description

2.1 Travel direction definition

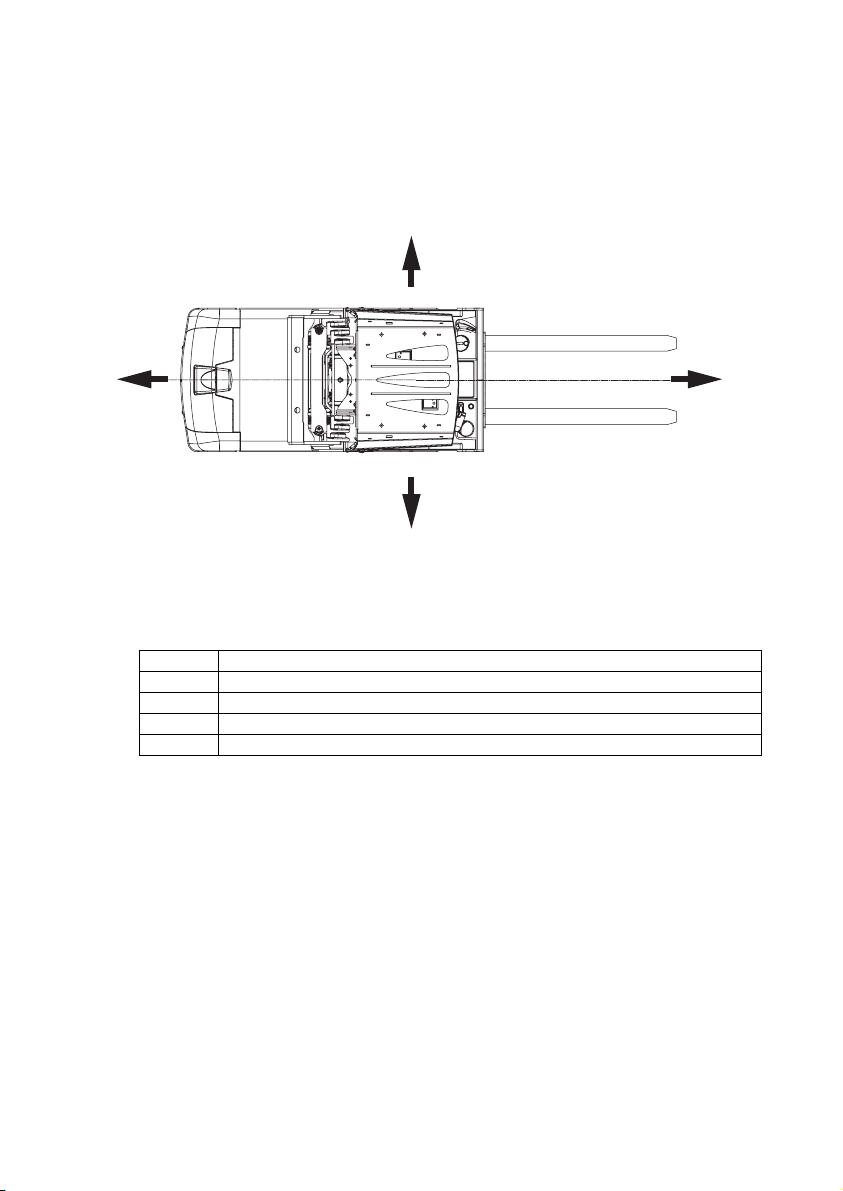

The following determinations have been made for travel direction specification:

1

2

4

The following conventions have been agreed for travel direction specification:

Item Travel direction

1Links

2 Reverse

3Forward

4 Right

3

16

03.13 EN

Page 18

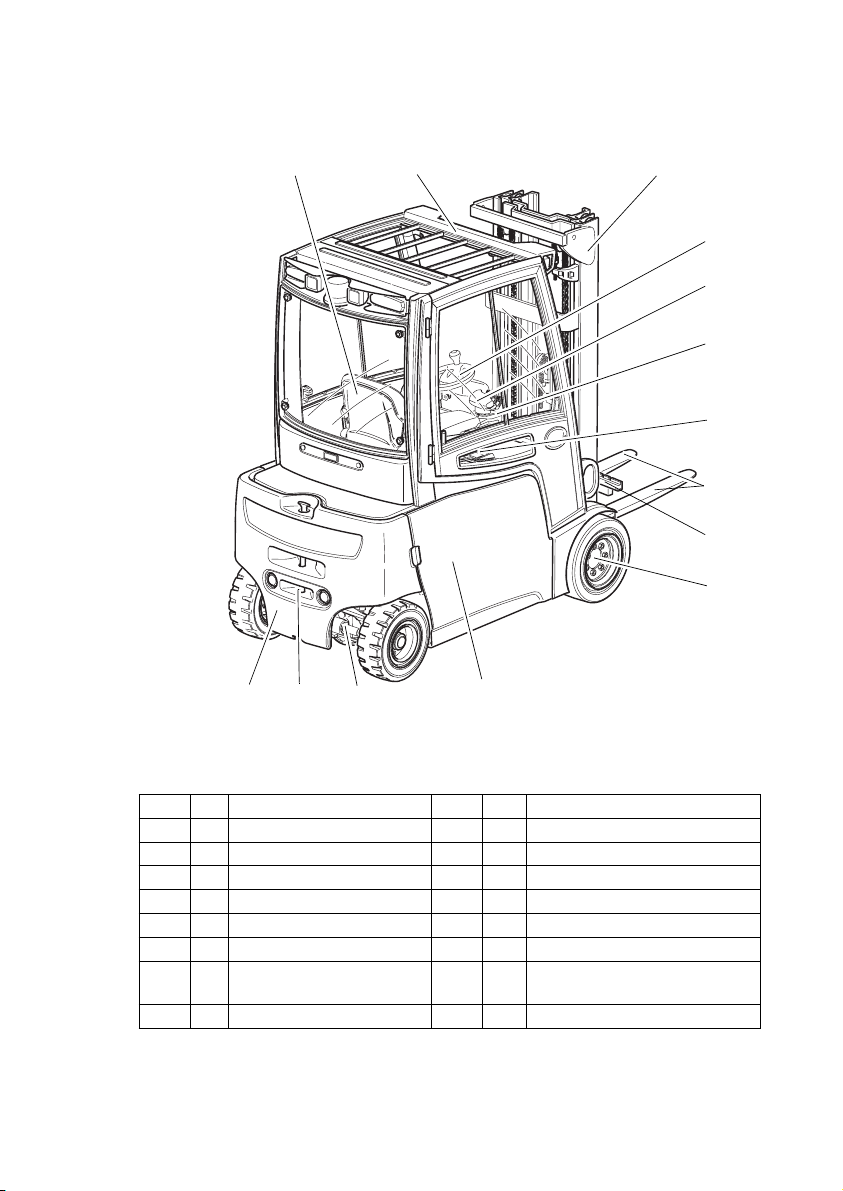

2.2 Assembly Overview

12

12

13

14

3

4

5

6

7

8

9

10

11

03.13 EN

Item Component Item Component

1 t Driver's seat 8 t Fork tines

2 t Overhead guard 9 t Fork carriage

3 t Mast 10 t Drive system

4 t Steering wheel 11 t Battery door

5 t Lifting mechanism control 12 t Steer axle

6 t Control and display unit 13 t Trailer coupling

7 t Emergency Disconnect

14 t Counterweight

switch

t Standard equipment

17

Page 19

2.3 Functional Description

Chassis

The chassis, in conjunction with the counterweight, forms the supporting base

structure of the truck. It is used to support the main components.

Operator position and overhead guard

The overhead guard comes in a range of models and protects the operator from

falling objects and other external

influences. All the controls are ergonomically arranged. The steering column and

driver's seat can be adjusted individually.

The controls and warnings on the control and display unit enable the system to be

monitored during operation, thereby ensuring a very high level of safety.

Steering

The electric steering offers a high level of efficiency and ergonomics. The height and

tilt angle of the steering column are adjustable and can be set to suit all operators.

The low cross-section means the operator has maximum legroom at all times.

The steering is particularly smooth, offering a high level of efficiency. As a result

the overall energy consumption is reduced significantly.

The steer angle is shown in the display.

Wheels

There is a choice of super elastic or fully rubber tyres as well as optional pneumatic

tyres.

Drive and brake system

The 2 motor front drive provides maximum traction to the drive wheels at all times.

When cornering, the exact speed required for the wheel on the inside or outside of

the bend respectively is set in proportion to the steer angle.

The service brake is a maintenance-free disk brake. The truck also brakes

regeneratively via the drive motors. The energy recovered in the process is fed back

to the battery.

The parking brake operates both automatically and manually.

18

03.13 EN

Page 20

Emergency Stop safety feature

If the system recognises a fault in the steering, an emergency stop

is automatically introduced. The truck brakes to a halt, the travel direction does not

change.

An event message is shown in the control and display unit. The truck performs a selftest

whenever it is switched on. Travel is only enabled again

when the truck is operational and the parking brake (= emergency stop) released.

Hydraulic system

A multi-pilot valve allows for sensitive operation of the functions via the controls. A

speed-controlled hydraulic pump ensures a proportionate and efficient supply to the

hydraulic functions.

Mast

Two or three-stage masts, optionally with free lift function; narrow mast sections

ensure excellent visibility of the forks and attachments. Fork carriage and mast run

on permanently lubricated and hence maintenance-free support rollers.

Attachments

The trucks can be optionally fitted with mechanical and hydraulic attachments.

3 Technical Specifications

All technical details refer to standard trucks.

Values indicated with *) may vary, depending on the

types of equipment used (e.g. mast, cabin, tyres etc.).

Z The technical specifications comply with the German "Industrial Truck Data Sheet"

Guidelines.

Technical modifications and additions reserved.

03.13 EN

19

Page 21

3.1 Performance data

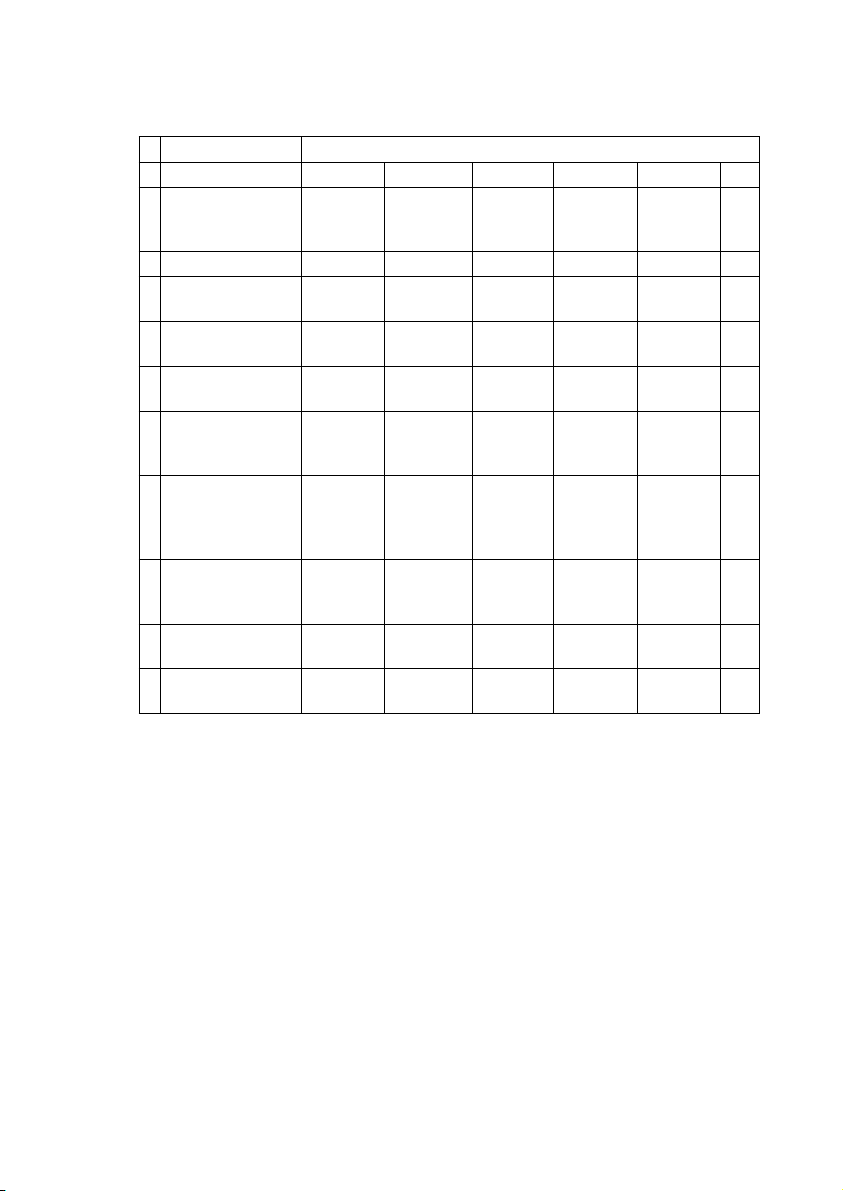

EFG 213-220

Description EFG

213 215

Q Rated capacity

(where

C = 500 mm)

1

1300 1500 1600 1800 2000 kg

)

C Load centre 500 500 500 500 500 mm

Travel speed

Lift speed

with / without load

Lowering speed

with / without load

16/16 16/16 16/16 16/16 16/16

0.48/0.60 0.46/0.60 0.49/0.60 0.44/0.55 0.40/0.55 m/s

0.55/0.55 0.55/0.55 0.55/0.55 0.55/0.55 0.55/0.55 m/s

Gradeability

(30 min)

7.6/12.5 7.3/12.3

with / without load

Max. gradeability

2

) (5 min)

28.0/35.0 27.0/35.0 27.0/35.0

with / without load

Acceleration

(10 m)

3.6/3.2 3.8/3.4 3.8/3.4 3.9/3.5 4.0/3.5 s

with / without load

Max. operating

pressure

Oil flow for

attachments

1)

for vertical mast.

2)

The values shown represent the maximum gradeability to overcome short

200 200 200 200 200 bar

25 25 25 25 25

differences in height and surface unevenness (surface edges). The truck must not

operate on inclines of more than 15%.

216k 218k

216 218

7.3/12.3 6.2/10.7

7.0/11.5 5.9/10.5

26.0/35.0

25.0/35.0

220

km/

h

5.7/10.4 %

24.0/35.0 %

l/

min

20

03.13 EN

Page 22

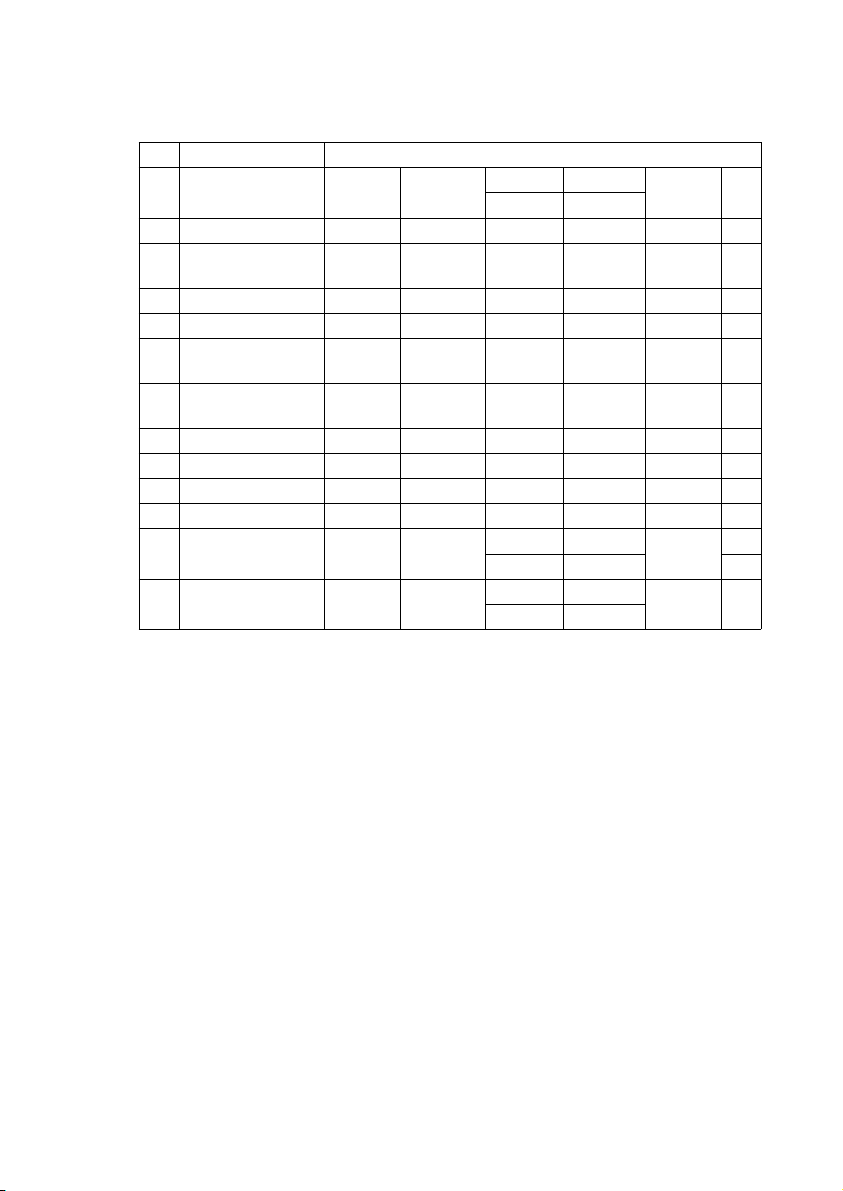

EFG 316-320

Description EFG

316k 316 318k 318 320

Q Rated

capacity (where

1600 1600 1800 1800 2000 kg

C = 500 mm)1)

C Load centre 500 500 500 500 500 mm

Travel Speed *

Lift speed

w / w.o. load

Lowering speed

w / w.o. load

17/17 17/17 17/17 17/17 17/17

0.49/0.60 0.49/0.60 0.44/0.55 0.44/0.55 0.40/0.55 m/s

0.55/0.55 0.55/0.55 0.55/0.55 0.55/0.55 0.55/0.55 m/s

km/

h

Gradeability

(30 min)

7.3/12.3 7.0/11.5 6.2/10.7 5.9/10.5 5.7/10.4 %

w./w.o. load

Max. gradeability

2)

(5 min)

27.0/35.0 27.0/35.0 26.0/35.0 25.0/35.0 24.0/35.0 %

w./w.o. load

Acceleration

(10 m)

3.8/3.4 3.8/3.4 3.9/3.5 3.9/3.5 4.0/3.5 s

w./w.o. load

Max. operating

pressure

Oil flow for

attachments

1)

for vertical mast.

2)

The values shown represent the maximum gradeability to overcome short

200 200 200 200 200 bar

25 25 25 25 25

l/

min

differences in height and surface unevenness (surface edges). The truck must not

operate on inclines of more than 15%.

03.13 EN

21

Page 23

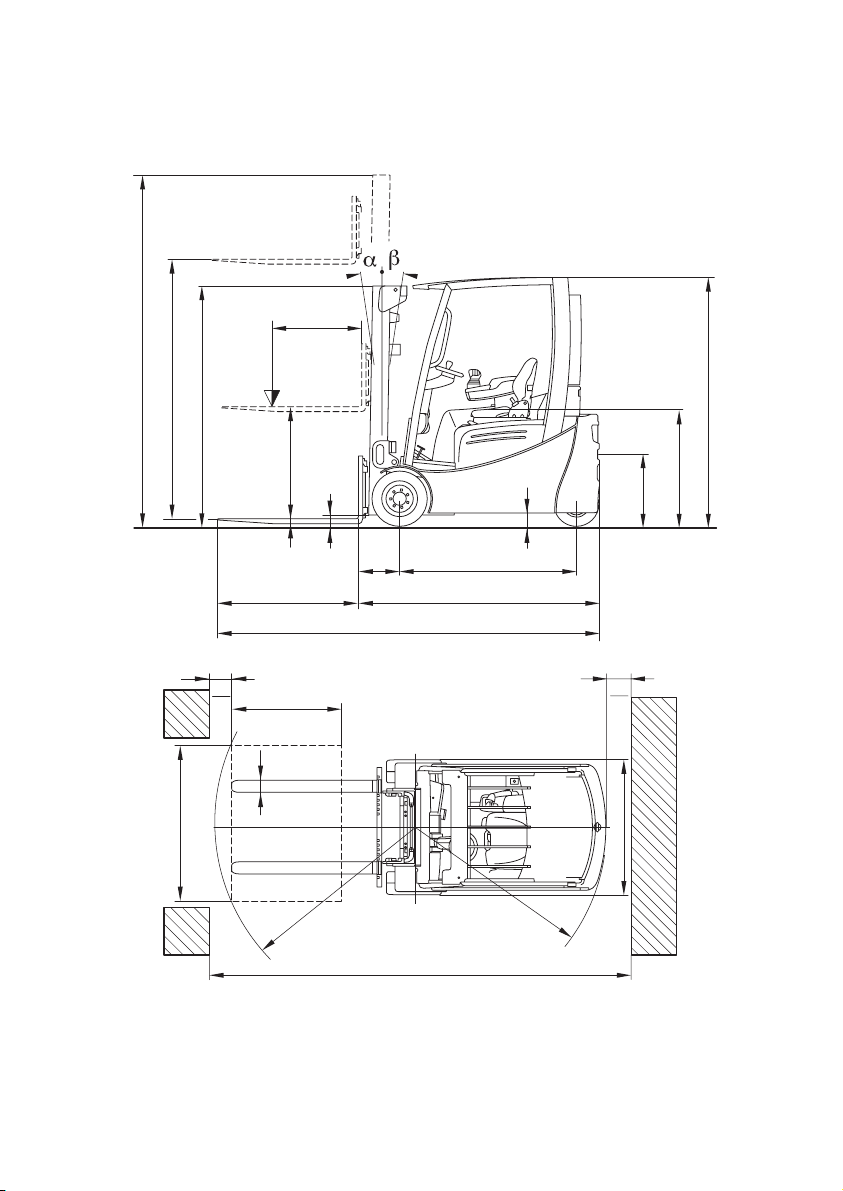

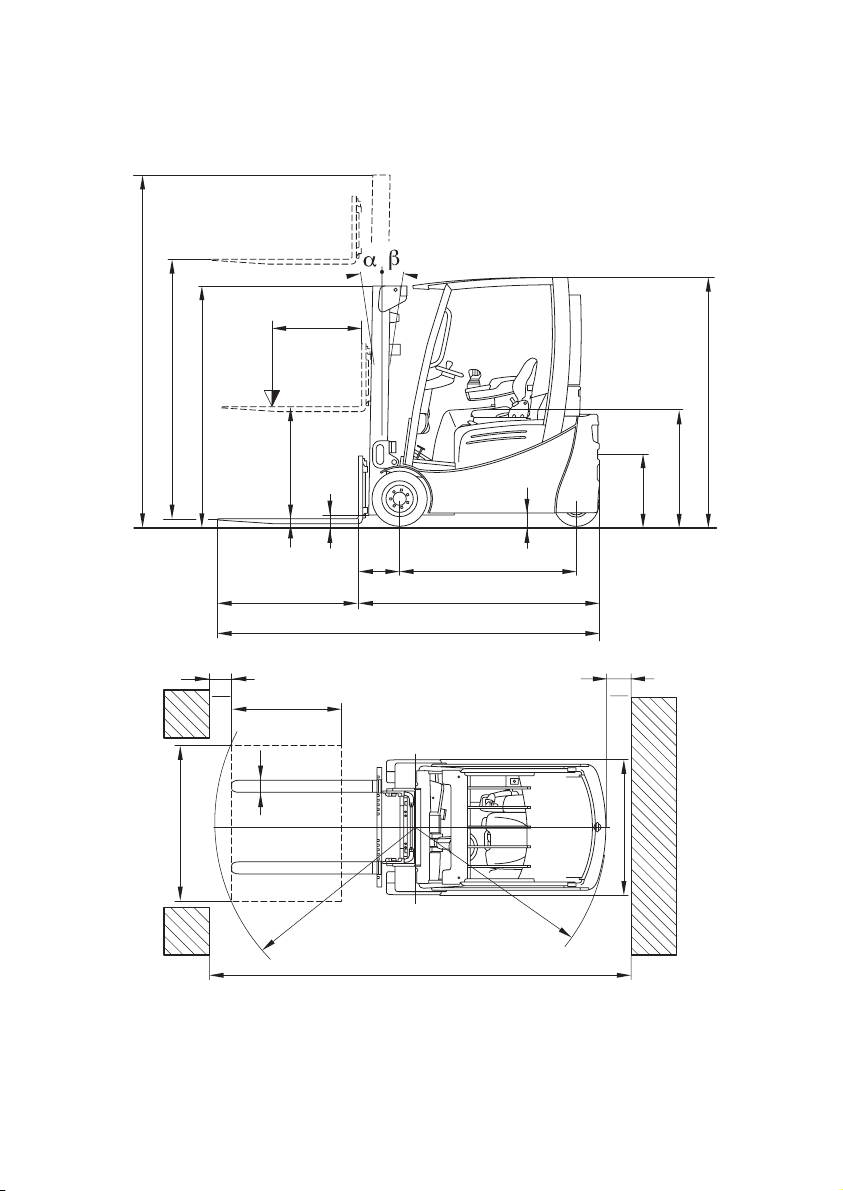

3.2 Dimensions

EFG 213-220

Description EFG

213 215

a/2 Safety distance 100 100 100 100 100 mm

h1Mast height

retracted

2000 2000 2000 2000 2000 mm

h2Free lift 150 150 150 150 150 mm

h3Lift 3000 3000 3000 3000 3000 mm

h4Mast height

extended

h6Overhead guard

height

3560 3560 3560 3587 3587 mm

2040 2040 2040 2040 2040 mm

h7Seat height 920 920 920 920 920 mm

h10Coupling height 560 560 560 560 560 mm

Į Mast tilt, fwd. 7 7 7 7 7 °

ȕ Mast tilt, back 7 7 7 7 7 °

L1Length including

forks

L2Headlength

2924 2924

1774 1774

216k 218k

216 218

3037 3037

3145 3145 mm

1887 1887

1995 1995

220

3145

mm

1995 mm

22

03.13 EN

Page 24

c

h

4

h

3

h

Q

h

1

h

2

h

10

m

m

x

1

l

L

1

y

L

2

2

6

h

7

03.13 EN

a

2

l

6

a

2

e

b

12

W

R

A

st

a

b

23

Page 25

EFG 213-220

Description EFG

213 215

216k 218k

216 218

220

b Overall width 1060 1060 1060 1120 1120 mm

e Fork width 100 100 100 100 100 mm

m1Ground clearance

with load below

80 80 80 80 80 mm

mast

m2Centre wheel

base ground

100 100 100 100 100 mm

clearance

Ast Working aisle

width for

pallet 800x1200

3226 3226

3339 3339

3446 3446

3446 mm

longit.

Ast Aisle width for

pallet 1000x1200

diag.

Wa Turning radius

3104 3104

1440 1440

3216 3216

3323 3323

1548 1548

1655 1655

3323 mm

1655 mm

x Load distance 335 335 340 340 340 mm

y Wheel distance

1249 1249

1357 1357

1465 1465

1465 mm

24

03.13 EN

Page 26

c

h

4

h

3

h

Q

h

1

h

2

h

10

m

m

x

1

l

L

1

y

L

2

2

6

h

7

03.13 EN

a

2

l

6

a

2

e

b

12

W

R

A

st

a

b

25

Page 27

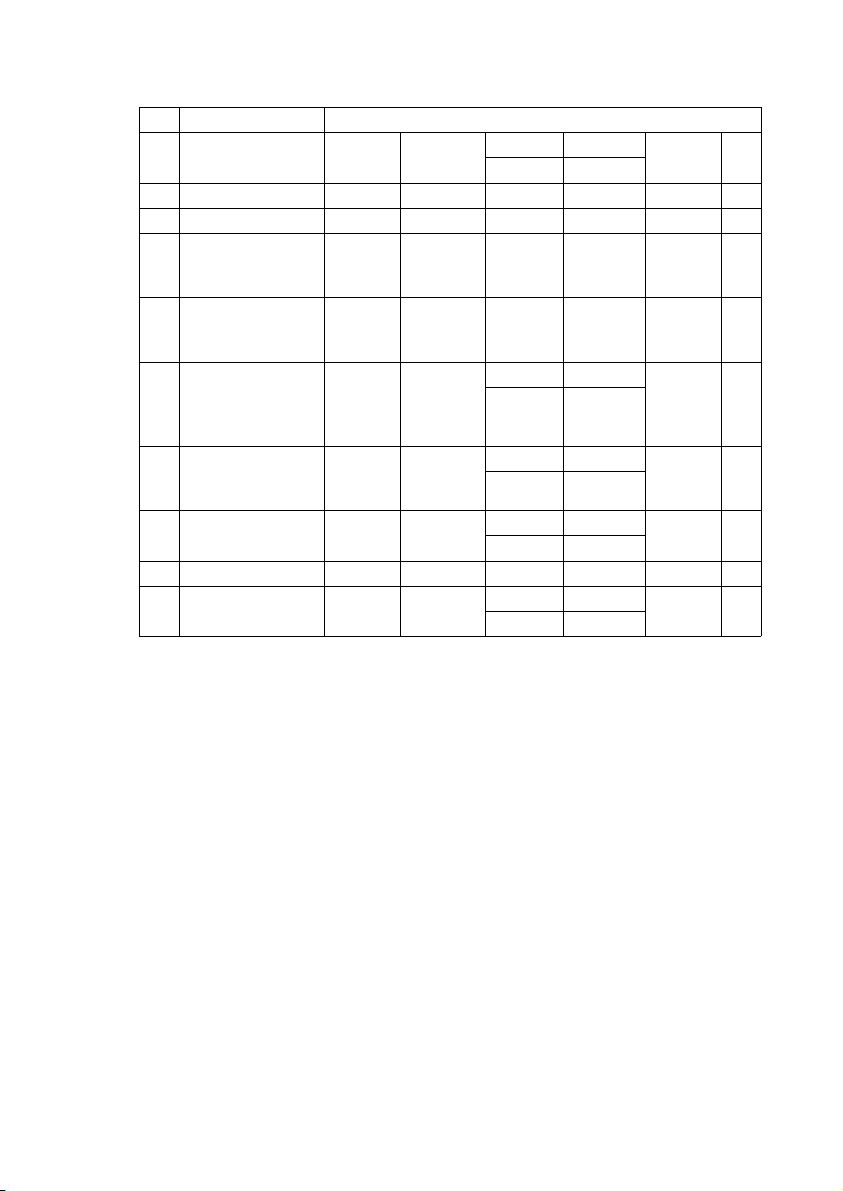

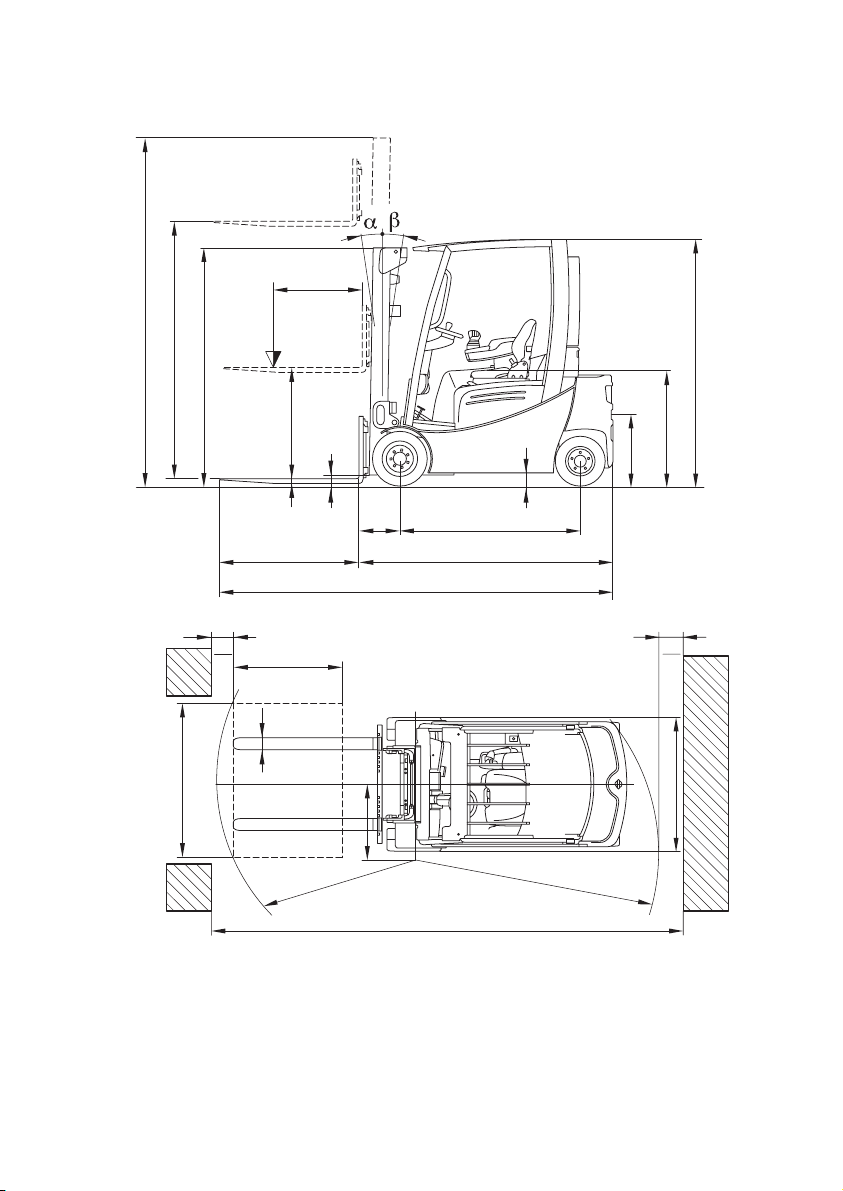

EFG 316-320

Description EFG

316k 316 318k 318 320

a/2 Safety distance 100 100 100 100 100 mm

h1Mast height

retracted

Free lift 150 150 150 150 150 mm

h

2

h

Lift 3000 3000 3000 3000 3000 mm

3

h4Mast height

extended

h6Overhead guard

height

2000 2000 2000 2000 2000 mm

3560 3560 3587 3587 3587 mm

2040 2040 2040 2040 2040 mm

h7Seat height 920 920 920 920 920 mm

h10Coupling height 410/580 410/580 410/580 410/580 410/580 mm

Į Mast tilt, fwd. 7 7 7 7 7 °

ȕ Mast tilt, back 7 7 7 7 7 °

L1Length including

forks

3140 3248 3140 3248 3248 mm

L2Headlength 1990 2098 1990 2098 2098 mm

b Overall width 1060 1060 1120 1120 1120 mm

e Fork width 100 100 100 100 100 mm

m1Ground clearance

with load below

80 80 80 80 80 mm

mast

m2Centre wheel

base ground

100 100 100 100 100 mm

clearance

Ast Working aisle

width for

pallet 800x1200

3599 3725 3599 3725 3725 mm

longit.

Ast Aisle width for

pallet 1000x1200

3403 3526 3403 3526 3526 mm

transv.

Wa Turning radius 1859 1985 1859 1985 1985 mm

x Load distance 340 340 340 340 340 mm

y Wheel distance 1400 1508 1400 1508 1508 mm

26

03.13 EN

Page 28

c

h

4

h

3

h

Q

h

1

h

2

h

10

6

h

7

s

m

x

1

l

L

a

2

l

6

L

1

m

y

2

2

a

2

e

b

12

b

13

R

A

st

W

a

b

03.13 EN

27

Page 29

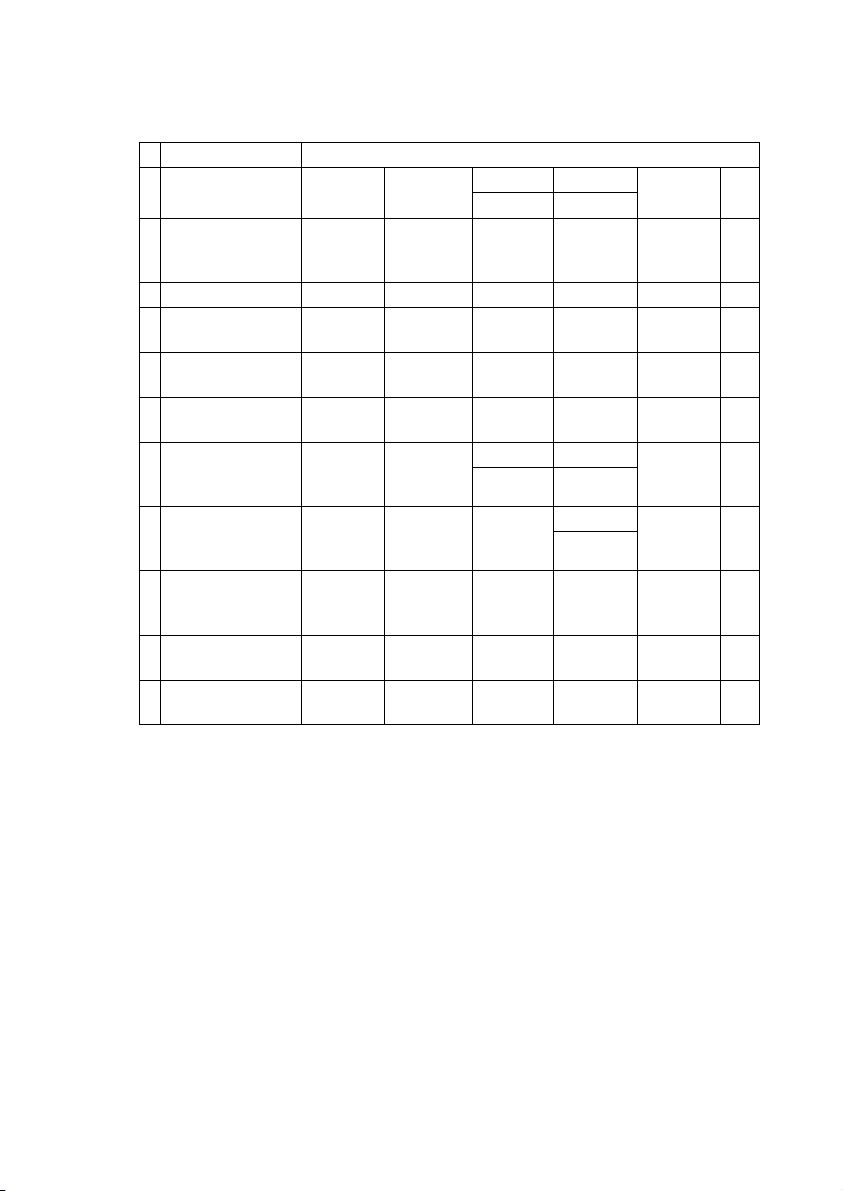

3.3 Weights

Z All dimensions in kg.

EFG 213-220

Description EFG

Net weight

(including battery)

Front axle load (without lifting

load)

Front axle load (with lifting

load)

Rear axle load (without lifting

load)

Rear axle load (with lifting

load)

EFG 316-320

Description EFG

Net weight

(including battery)

Front axle load (without

lifting load)

Front axle load (with lifting

load)

Rear axle load (without

lifting load)

Rear axle load (with lifting

load)

213 215

2733 2978

1326 1310

3545 3870

1407 1668

488 608

316k 316 318k 318 320

3035 3001 3175 3141 3306

1380 1493 1385 1499 1489

4004 4043 4336 4367 4676

1655 1508 1790 1642 1817

631 558 638 574 630

216k 218k

216 218

3000 3256

3057 3207

1411 1409

1496 1520

4052 4380

4060 4405

1589 1846

1561 1686

548 675

597 602

220

3382

1501

4706

1881

676

28

03.13 EN

Page 30

3.4 Mast versions

Z All dimensions in mm.

EFG 216-220 and 316-320

VDI 3596

Description

ZT

ZZ 2300 1055 990 1605 2850 2915

DZ 4350 1405 1340 1955 4900 4965

Lift h

3

Free lift h

2

Retracted

height h

Extended height h

1

EFG

213/215/

216k/216/

316/316k

2300

218k/218/

220/318/

318k/320

213/215/

216k/216/

316/316k

218k/218/

220/318/

318k/320

1650 2850 2885

3000 2000 3550 3585

3100 2050 3650 3685

3300 2150 3850 3885

3600 2300 4150 4185

150

4000 2500 4550 4585

4500 2800 5050 5085

5000 3050 5550 5585

5500 3400 6050 6085

3000 1405 1340 1955 3550 3615

3100 1455 1390 2005 3650 3715

3300 1555 1490 2105 3850 3915

3600 1705 1640 2255 4150 4215

4000 1905 1840 2455 4550 4615

4500 1455 1390 2005 5050 5115

4800 1555 1490 2105 5350 5415

5000 1630 1565 2180 5550 5615

5500 1805 1740 2355 6050 6115

6000 2005 1940 2555 6550 6615

6500 2255 2190 2805 7050 7115

4

03.13 EN

Special trucks are not included in this overview.

29

Page 31

3.5 Tyre type

NOTE

When replacing tyres/rims fitted at the factory, always use original spare parts or tyres

approved by the manufacturer. Otherwise the manufacturer's specification cannot be

guaranteed.

If you have any queries please contact the manufacturer's customer service

department.

EFG 213-220

Description EFG

213/215

216k/216

SE *) 18x7-8 200/50-10 200/50-10

Full rubber*) 18x7x12ǩ

Front tyres

Pneumatic*) 180/70-8 - LI125 not available not available

Tyre pressure bar 10,0 - -

Torque (Nm) 240 240 240

SE *) 140/55-9 140/55-9 140/55-9

Full rubber*) 15x5x11¼ 15x5x11¼ 15x5x11¼

Rear tyres

Pneumatic*) 125/75-8 - LI100 not available not available

Tyre pressure bar 10,0 - -

Torque (Nm) 240 240 240

*) The models listed in the table correspond to the standard version. Other tyres can

be used depending on the truck's equipment.

218k

218

220

30

03.13 EN

Page 32

EFG 316-320

Description EFG

316k

316

318k

318

SE *) 18x7-8 200/50-10 200/50-10

Full rubber*) 18x7x12ǩ 18x7x12ǩ 18x7x12ǩ

Front tyres

Pneumatic*) 180/70-8 - LI125

(PR 16)

not available not available

Tyre pressure bar 10,0 - -

Torque (Nm) 240 240 240

SE *) 16x6-8 16x6-8 16x6-8

Full rubber*) 15x5x11¼ 15x5x11¼ 15x5x11¼

Rear tyres

Pneumatic*) 150/75-8 - LI113

(PR 16)

not available not available

Tyre pressure bar 10,0 - -

Torque (Nm) 240 240 240

*) The models listed in the table correspond to the standard version. Other tyres can

be used depending on the truck's equipment.

3.6 Engine Data

EFG 216-220 and 316-320

Description EFG

213 / 215 / 216k / 216

218k / 218 / 220

Drive motor 2 x 4.5kW 2 x 4.5kW

Lift motor 11.5kW 11.5kW

Steer motor 0.9kW 0.9kW

316k / 316 / 318k / 318

320

320

03.13 EN

31

Page 33

3.7 EN norms

Noise emission level

– EFG 213-220: 68 dB(A)

– EFG 316-320: 67 dB(A)

*+/- 3 dB(A) depending on the truck's equipment

in accordance with EN 12053 as harmonised with ISO 4871.

Z The noise emission level is calculated in accordance with standard procedures and

takes into account the noise level when travelling, lifting and when idle. The noise

level is measured at the level of the driver's ear.

Vibration

– EFG 213-220: 0,53m/s²

– EFG 316-320: 0,51 m/s²

in accordance with EN 13059.

Z The vibration acceleration acting on the body in the operating position is, in

accordance with standard procedures, the linearly integrated, weighted

acceleration in the vertical direction. It is calculated when travelling over thresholds

at constant speed (standard truck version). These recordings were taken on a

single occasion and must not be confused with the human vibrations of the "2002/

44/EC/Vibrations" operator directive. The manufacturer offers a special service to

measure these human vibrations, see "Human vibration measurement" on

page 195.

Electromagnetic compatibility (EMC)

The manufacturer confirms that the truck adheres to the limits for electromagnetic

emissions and resistance as well as the static electricity discharge test in accordance

with EN 12895 as well as the standardised instructions contained therein.

Z No changes to electric or electronic components or their arrangement may be

made without the written agreement of the manufacturer.

WARNING!

Medical equipment can be damaged by non-ionised radiation

Electrical equipment on the truck emitting non-ionised radiation (e.g. wireless data

transmission) can affect operators' medical equipment (pacemakers, hearing aids

etc.) and result in malfunctions. Consult with a doctor or the medical equipment

manufacturer to clarify whether it can be used near the industrial truck.

32

03.13 EN

Page 34

3.8 Conditions of use

Ambient temperature

– operating at -20°C to 40°C

Z Special equipment and authorisation are required if the truck is to be used

continually in conditions of extreme temperature or condensing air humidity

fluctuations.

3.9 Electrical requirements

The manufacturer certifies compliance with the requirements for the design and

manufacture of electrical equipment, according to EN 1175 "Industrial Truck Safety Electrical Requirements", provided the truck is used according to its purpose.

03.13 EN

33

Page 35

4 Identification points and data plates

4.1 Indication Points

Z Warnings and notices such as capacity charts, strap points and data plates must

be legible at all times. Replace if necessary.

1716 18 1915

XXX

20

21

22

34

28

17

24

27

29

26

25

(mm) Q (kg)

D (mm)

23

24

03.13 EN

Page 36

Item Component

15 Do not drive, or operate the forward tilt, with the load in the raised position

16 Wear seat belt

17 Strap points for crane lifting

18 Tipover caution, no passengers

19 Lift limit

20 Do not step onto or beneath the load, risk of trapping with moving mast

21 Read operating instructions

22 Capacity (or reduced capacity)

23 Data plate, behind the battery door

24 Jack contact points

25 Model description

26 Risk of trapping, in chassis behind the battery door

27 Serial number, on chassis behind the battery door

28 Test plaque (o)

29 Add hydraulic oil

03.13 EN

35

Page 37

4.2 Data plate

Z The illustration shows the standard version for EU member states. The data plate

may differ in other countries.

30 31 3332 34

Item Description Item Description

30 Type 36 Year of manufacture

31 Serial number 37 Load centre (mm)

32 Rated capacity (kg) 38 Output

33 Battery voltage (V) 39 Min./max. battery weight (kg)

34 Net weight w.o. battery (kg) 40 Manufacturer

35 Option 41 Manufacturer’s logo

3635

37

38

39

40

41

Z For queries regarding the truck or ordering spare parts always quote the truck serial

number (31).

36

03.13 EN

Page 38

4.3 Truck capacity plate

CAUTION!

Accident risk from fork replacement

If you replace the forks with ones that differ from the originals, the capacity will

change.

XWhen replacing the forks you must attach an additional capacity plate to the truck.

XTrucks supplied without forks are given a capacity plate for standard forks (length:

1150 mm).

The capacity plate (22) gives the capacity (Q in kg) of the truck for a vertical mast.

The maximum capacity is shown as a table with a given load centre of gravity D (in

mm) and the required lift height H (in mm).

The capacity plate (22) of the truck indicates the truck's capacity with the forks as

originally supplied.

Example of how to calculate the maximum capacity:

03.13 EN

h3 (mm)

4250

3600

2900

D (mm) 500 600 700

850

1105

1250

Q (kg)

850

1105

1250

600

850

850

22

For a load centre of gravity D of 600 mm and a max. lift height h3 of 3600 mm the

maximum capacity Q is 1105 kg.

Lift height restriction

The arrow shaped markings (42 and 43) on the

42 43

inner and outer masts show the operator when

the prescribed lift limits have been reached.

37

Page 39

4.4 Attachment capacity plate

The attachment capacity plate is next to the truck's capacity plate and gives the

truck’s capacity Q (in kg) in conjunction with the respective attachment. The serial

number for the attachment indicated on the capacity plate must match the data plate

of the attachment.

5 Stability

The truck's stability has been tested according to latest technological standards.

These take into account the dynamic and static tipover forces that can occur if used

correctly.

Stability can also be affected by the following factors:

– Tyre type

–Mast

– Attachment

– Transported load (size, weight and centre of gravity)

WARNING!

Loss of stability can cause accidents

Changing the components can alter the stability.

38

03.13 EN

Page 40

C Transport and Commissioning

1 Transport

Transport can be carried out in two different ways, depending on the height of the

mast and the local conditions.

– Vertically, with the mast assembled (for low heights)

– Vertically, with the mast dismantled (for large heights), all mechanical connections

and hydraulic lines between the basic truck and the mast separated.

2 Truck laden

2.1 Centre of gravity of the truck

WARNING!

An altered centre of gravity can result in tipovers when cornering.

The overall centre of gravity can vary depending on the truck's equipment (especially

the mast version).

For trucks without a mast the centre of gravity will move significantly in the direction

of the counterweight.

XDrive carefully and with modified speed to avoid tipping over.

The picture shows the approximate centre of

gravity location.

03.13 EN

39

Page 41

2.2 Lifting the truck by crane

WARNING!

All persons involved in loading by crane must be trained

Incorrect crane loading procedures due to untrained personnel can cause the truck

to fall. There is a risk of injury to personnel and a risk of material damage to the truck.

XLoading must only be performed by specialist personnel trained for this purpose.

The specialist personnel must be instructed in securing loads on road vehicles and

handling load securing devices. In each case correct measurements must be taken

and appropriate safety measures applied.

DANGER!

Crane slings can tear, resulting in accidents

XOnly use crane lifting gear with sufficient capacity.

XLoading weight = Net weight of truck (+ battery weight for electric trucks).

XThe mast must be tilted back fully.

XThe crane lifting gear on the mast must have a minimum clear length of 2 m.

XCrane slings should be fastened in such a way that they do not come into contact

with any attachments or the overhead guard when lifting.

XDo not stand under a swaying load.

XThe truck should only be handled by people who are trained in using lifting slings

and tools.

XWear safety shoes when lifting the truck by crane.

XDo not walk into or stand in a hazardous area.

XAlways attach the crane lifting gear to the prescribed strap points and prevent them

from slipping.

Z Truck net weight: see "Data plate" on page 36.

40

03.13 EN

Page 42

Lifting the truck by crane

Requirements

– Park the truck securely, see "Parking the

truck securely" on page 105.

Procedure

• Secure the crane slings to the attachment

points (44) and (45.

• Raise and load the truck.

• Lower and deposit the truck carefully (see

"Parking the truck securely" on page 105).

• Secure the truck with wedges to prevent it

from rolling away.

This concludes the loading by crane.

44

45

03.13 EN

41

Page 43

2.3 Loading with another industrial truck

WARNING!

The truck can be damaged

The truck to be loaded can be damaged when loading with another industrial truck.

XOnly trained specialist personnel should load the truck.

XUse only trucks with sufficient capacity for loading.

XOnly for loading and unloading.

XThe forks of the second industrial truck must be sufficiently long

XTransporting over long distances prohibited.

Loading the truck with a second industrial truck

Requirements

– Park the truck securely, see "Parking the truck securely" on page 105.

Procedure

• Raise the truck with the forks at the side between the axles.

• Raise the truck slightly and make sure it is securely positioned on the forks. If

necessary adjust or secure the forks with stops.

• Carefully load/unload the truck, see "Lifting, transporting and depositing loads" on

page 116.

• Lower the truck slowly onto the ground and prevent it from rolling away.

The truck is now loaded.

42

03.13 EN

Page 44

3 Securing the truck during transport

WARNING!

Accidental movement during transport

Improper fastening of the truck and mast during transport can result in serious

accidents.

XLoading must only be performed by specialist personnel trained for this purpose.

The specialist personnel must be instructed in securing loads on road vehicles and

handling load securing devices. In each case correct measurements must be taken

and appropriate safety measures applied.

XThe truck must be securely fastened when transported on a lorry or a trailer.

XThe lorry or trailer must have fastening rings.

XUse wedges to prevent the truck from moving.

XUse only fastening belts with sufficient strength.

XUse non-slip materials to securing the load aids (pallet, wedges, ...) e. g. non-slip

mats.

Securing with a mast Securing without a mast

3

46

13

03.13 EN

47

46

13

48

47

43

Page 45

Securing the industrial truck for transport

Requirements

– Position the industrial truck securely on a lorry or trailer, see "Parking the truck

securely" on page 105.

Tools and Material Required

– 2 fastening belts with a tensioner

– Retaining wedges.

Procedure

• Secure the truck with the fastening belt (46) at the top cross member of the mast (3)

and the trailer coupling (13) or over the mud guard (48) and the trailer coupling (13).

• Tighten the fastening belt (46) with the tensioner (47).

The truck is now secured for transport.

44

03.13 EN

Page 46

4 Using the Truck for the First Time

Safety Instructions for Assembly and Commissioning

WARNING!

Incorrect assembly can result in accidents

The assembly of the truck at the application site, commissioning and operator training

must only be performed by the manufacturer's customer service representatives who

have been specially trained for these tasks.

XThe hydraulic lines may only be connected to the basic truck / mast interface when

the mast has been properly assembled.

XOnly then can the truck be started.

XIf several trucks have been delivered, make sure that the serial numbers of the load

handlers, masts and basic trucks always match.

WARNING!

The use of unsuitable energy sources can be hazardous

Rectified AC current will damage the assemblies (controllers, sensors, motors etc.)

of the electronic system.

Unsuitable cable connections (too long, insufficient wire cross-section) to the battery

(tow cables) can overheat, setting the truck and battery on fire.

XThe truck must only be operated with battery current.

XCable connections to the battery (tow leads) must be less than 6 m long and have

a minimum cross-section of 50 mm².

Preparing the truck for operation after delivery or transport

Procedure

• Check the equipment is complete.

• Check the hydraulic oil level, see "Hydraulic system" on page 177.

• Check the transmission oil level, see "Check the gear oil level" on page 180.

• Install the battery if necessary, see "Battery removal and installation" on page 58.

• Charge the battery, see "Charging the battery" on page 53.

The truck can now be started, see "Preparing the Truck for Operation" on page 90.

Z To operate the truck without its own drive system, see "Operating the truck without

its own drive system" on page 156.

03.13 EN

45

Page 47

46

03.13 EN

Page 48

D Battery - Servicing, Recharging,

Replacement

1 Safety Regulations Governing the Handling of Lead-Acid

Batteries

Maintenance personnel

Batteries may only be charged, serviced or replaced by trained personnel. This

operator manual and the manufacturer’s instructions concerning batteries and

charging stations must be observed when carrying out the work.

Fire Protection

Do not smoke and avoid naked flames when handling batteries. Wherever an

industrial truck is parked for charging there must be no inflammable material or

consumables capable of creating sparks within a minimum distance of 2 m from the

truck. The room must be ventilated. Fire protection equipment must be available.

CAUTION!

The use of unsuitable fire protection equipment can result in scalding

Extinguishing fires with water can cause a reaction with the battery acid. This can

result in scalding from the acid.

XUse powder extinguishers.

XNever extinguish a burning battery with water.

Battery maintenance

03.13 EN

The battery cell covers must be kept dry and clean. Terminals and cable shoes must

be clean, lightly greased with terminal grease and must be securely tightened.

Batteries with non insulated terminals must be covered with a non slip insulating mat.

CAUTION!

Before closing the battery panel make sure that the battery cable cannot be

damaged. There is a risk of short circuits with damaged cables.

Battery disposal

Batteries may only be disposed of in accordance with national environmental

protection regulations or disposal laws. The manufacturer’s disposal instructions

must be followed.

47

Page 49

48

03.13 EN

Page 50

1.1 General notes on handling batteries

WARNING!

Batteries can be hazardous

Batteries contain an acid solution which is poisonous and corrosive. Avoid contact

with battery acid at all times.

XDispose of used battery acid in accordance with regulations.

XAlways wear protective clothing and goggles when working with batteries.

XDo not let battery acid come into contact with skin, clothing or eyes. If necessary,

rinse with plenty of clean water.

XIn the event of physical damage (e.g. skin or eye contact with battery acid) call for

a doctor immediately.

XSpilled battery acid should be neutralised immediately with plenty of water.

XOnly batteries with a sealed battery container may be used.

XFollow national guidelines and legislation.

WARNING!

Unsuitable batteries that have not been approved for the truck by the

manufacturer can be hazardous

The design, weight and dimensions of the battery have a considerable effect on the

operational safety of the truck, in particular its stability and capacity. The use of

unsuitable batteries that have not been approved for the truck by the manufacturer

can lead to a deterioration of the braking system during energy recovery operations

and also cause considerable damage to the electrical control system. The use of

batteries that have not been approved by the manufacturer can therefore affect the

health and safety of personnel.

XOnly manufacturer-approved batteries may be used on the truck.

XBattery equipment may only be replaced with the agreement of the manufacturer.

XWhen replacing/installing the battery make sure the battery is securely located in

the battery compartment of the truck.

XDo not use batteries that have not been approved by the manufacturer.

03.13 EN

Park the truck securely before carrying out any work on the batteries (see "Parking

the truck securely" on page 105).

49

Page 51

2 Battery types

CAUTION!

Always use batteries with insulated covers or live components.

The battery weights are indicated on the battery data plate.

The truck will be equipped with different battery models, depending on the

application. The following table shows which combinations are included as standard:

Truck model Description Capacity

EFG 213 48V - 4PzS 460 Ah

EFG 215 48V - 4PzS 460 Ah

EFG 216k 48V - 5PzS 575 Ah

EFG 216 48V - 6PzS 690 Ah

EFG 218k 48V - 5PzS 575 Ah

EFG 218 48V - 6PzS 690 Ah

EFG 220 48V - 6PzS 690 Ah

EFG 316k 48V - 5PzS 575 Ah

EFG 316 48V - 6PzS 690 Ah

EFG 318k 48V - 5PzS 575 Ah

EFG 318 48V - 6PzS 690 Ah

EFG 320 48V - 6PzS 690 Ah

50

03.13 EN

Page 52

2.1 Battery dimensions

Battery 48 V

Dimension (mm)

Truck model

EFG 213/215 830 522 612 627 715

EFG 216k/

218k/

316k/318k

EFG 216/

218/220/

316/318/320

L max. W max. H1 +/-

2mm

H2 +/-

2mm

830 630 612 627 855

830 738 612 627 1025

Rated weight

(-5/+8%)in kg

03.13 EN

51

Page 53

3 Exposing the battery

49

Requirements

– Park the truck securely, see "Parking the truck securely" on page 105.

– Load handler lowered.

– Key switch set to OFF.

– Key removed.

– Set the Emergency Disconnect OFF.

Procedure

• Open the battery door (49) as far as the stop.

• Pull the battery connector (50) and let it drop down from the battery.

The battery is now exposed.

50

52

03.13 EN

Page 54

4 Charging the battery

WARNING!

The gases produced during charging can cause explosions

The battery produces a mixture of nitrogen and hydrogen (electrolytic gas) during

charging. Gassing is a chemical process. This gas mixture is highly explosive and

must not be ignited.

XSwitch the charging station and truck off first before connecting/disconnecting the

charging cable of the battery charging station to/from the battery connector.

XThe charger must be adapted to the battery in terms of voltage and charge

capacity.

XBefore charging, check all cables and plug connections for visible signs of damage.

XVentilate the room in which the truck is being charged.

XThe battery cell surfaces must be exposed during charging to ensure adequate

ventilation.

XDo not smoke and avoid naked flames when handling batteries.

XWherever an industrial truck is parked for charging there shall be no inflammable

material or lubricants capable of creating sparks within 2 m around the truck.

XFire protection equipment must be on hand.

XDo not lay any metallic objects on battery.

XIt is essential to follow the safety regulations of the battery and charger station

manufacturers.

4.1 Charging the battery with a stationary charger

Z When charging, the battery door must be exposed by at least 200 mm to provide

sufficient ventilation.

03.13 EN

Requirements

– Park the truck securely, see "Parking the truck

securely" on page 105.

– Battery exposed.

– Charger switched off.

– Disconnect the battery connector (50) from the

truck connector (51).

Procedure

• Connect the battery connector (50) to the

charging lead (52)

of the stationary charger and turn on the charger.

The battery is now charged.

51

50

52

53

Page 55

4.2 Charging the battery with an on-board charger

NOTE

Improper use of the on-board charger can cause material damage

The on-board charger consisting of a battery charger and battery controller must not

be opened. If faulty, contact the manufacturer’s customer service department.

XThe charger must only be used for batteries supplied by Jungheinrich or other

approved batteries provided it has been adapted by the manufacturer's customer

service department.

XBatteries must never be swapped from truck to truck.

XDo not connect the battery to two chargers simultaneously.

Mains connection

The mains lead may vary depending on the size of the on-board charger.

– On-board charger with 65 Ah: 16 A; 230 V; 3 pin

– On-board charger with 130 Ah: 16 A; 400 V; 5 pin

DANGER!

Risk of electric shock and burning

Damaged and unsuitable wires can cause electric shocks and can overheat, resulting

in fires.

XOnly use mains cables with a maximum length of 30 m.

XFully unreel the cable reel when using it.

XAlways use original manufacturer’s mains cables.

XInsulation safety, acid and caustic ratings must comply with the manufacturer's

mains cable.

54

03.13 EN

Page 56

Z When charging, the battery door must be exposed by at least 200 mm to provide

sufficient ventilation.

Charge the battery

Requirements

– Park the truck securely, see "Parking the truck securely" on page 105.

– Battery exposed.

– Charger switched off.

– Disconnect the battery connector (50) from the truck connector (51).

Procedure

• Connect the on-board charger to the mains socket using the mains cable.

• Charging begins automatically.

• When the truck is switched on the charging status and the residual capacity are

shown on the display unit, see "Display" on page 87.

The battery is now charged.

Z If the battery warning indicator (53) lights up after charging the battery, the battery

must be topped up with water when the truck is switched off.

53

am

100 %

pm

km/h

inch lbs

m kg eff code err

03.13 EN

55

Page 57

Battery charger LED displays

Green LED Meaning

Flashing Charging

Lit Charging complete

Red LED Meaning

Flashing Error

Battery controller LED displays

White LED Meaning

Flashing Radio network activated

Blue LED Meaning

Lit

Electrolyte level too low (measured

after each charge)

Yellow LED Meaning

Flashing rolling Charging

Lit Charge status

Red LED Meaning

Flashing Error

56

03.13 EN

Page 58

Float charge:

The compensation charge starts automatically when charging is complete.

Partial charging:

The charger is designed to automatically adapt to partially charged batteries. This

keeps battery wear to a minimum.

Z If a charging operation has to be

interrupted, press the button (54). Only

remove the mains connector when the

green LED goes out.

Charging starts again when the mains

cable is reconnected to the mains

socket.

54

03.13 EN

57

Page 59

5 Battery removal and installation

WARNING!

Accident risk during battery removal and installation

Due to the battery weight and acid there is a risk of trapping or scalding when the

battery is removed and installed.

XNote the "Safety regulations for handling acid batteries" section in this chapter.

XWear safety shoes when removing and installing the battery.

XUse only batteries with insulated cells and terminal connectors.

XPark the truck on a level surface to prevent the battery from sliding out.

XMake sure the crane slings have sufficient capacity to replace the battery.

XUse only approved battery replacement devices (battery roller stand, replacement

trolley etc.).

XMake sure the battery is securely located in the truck's battery compartment.

58

03.13 EN

Page 60

5.1 Battery holder assembly

CAUTION!

The battery holder can only be fitted to Jungheinrich AG pallet trucks (EJE) or

hand pallet trucks with notice signs.

Requirements

– EJE or hand pallet truck available with holes in accordance with assembly

instructions, see "Assembly instructions" on page 60.

Procedure

• Open the safety catch (55).

• To do this press the pedals (56).

• Insert bent pins (57) into the forks of the EJE

or hand pallet truck.

• Push the battery holder down and fit the

bolts (58) in the holes.

• Close the safety catch (55).

• To do this press the pedals (56).

• Secure the locking plate (59) against theft with

4 screws (o).

56 57 58

55

03.13 EN

59

59

Page 61

5.1.1 Assembly instructions

1150

16

Ø

x4

Procedure

• Drill 4 holes with a 16 mm diameter into the EJE or hand pallet truck according to

the drill patterns.

• Make sure there is sufficient distance between the connecting rod and the bottom

of the forks.

458

130

90

Z Attach safety notices to the EJE.

60

03.13 EN

Page 62

5.2 Removal and installation using an EJE pallet truck with Snapfit

battery holder (o)

CAUTION!

Trapping hazard

Trapping hazard when replacing the battery.

XWhen replacing the battery do not reach between the battery and the chassis.

XWear safety shoes.

Removing the battery

Requirements

– Truck parked securely, see "Parking the truck securely" on page 105.

– Battery exposed, see "Exposing the battery"

on page 52.

Tools and Material Required

– Battery trolley with four wheels

– EJE pallet truck with Snapfit battery holder

– Charging station intended for the battery

type (60) (o)

Procedure

•

• Close the safety catch (55).

• To do this press the pedals (56).

• Bring the EJE pallet truck approx. 7,9 in (200

mm) underneath the truck base so that it is

central with the battery.

• Raise the fork tines of the EJE pallet truck until

they are just under the truck base.

60

03.13 EN

•

• Push the ramps (61) into the plate recess and

align them with the chassis (62).

• Bring the EJE pallet truck up to the battery at

crawl speed.

55 56

61

62 62

61

Page 63

•

• Engage the safety catch (55) on the battery

trolley.

• Make sure the safety catch (55) is firmly

engaged in the battery trolley.

Z Do not raise the fork tines.

• Undo the battery lock (63).

•

• Remove the the battery with the EJE pallet

truck at crawl speed as far as the stop (64).

• Raise the fork tines until the battery can be

pulled clear of the battery compartment.

NOTE

Risk of material damage

Risk of material damage to the truck

chassis while the battery is being pulled

out.

XRaise the fork tines. While pulling out

the battery, do not allow it to strike the

truck chassis on the top or bottom.

• Bring the battery to the charging station for

charging.

•

• Place the battery carefully onto the charging

station (60).

• Undo the safety catch (55) and remove the

EJE pallet truck.

The battery is now removed and positioned

securely for charging.

5563

64

60

62

03.13 EN

Page 64

Battery installation

Procedure

•

• Drive the EJE pallet truck and battery to the

truck.

• Deposit the battery replacement trolley with

the rollers (65) on the rails of the truck base.

• Lower the forks of the EJE pallet truck until the

battery is horizontal.

• Align the heights and push the forks of the EJE

pallet truck underneath the truck base.

NOTE

Risk of material damage

Inserting the battery can cause material

damage to the truck chassis.

XLower the forks and avoid striking the

top or bottom parts of the chassis when

inserting the battery.

• Insert the battery in the truck.

• Close the battery lock (63).

•

• Undo the safety catch (55).

• To do this press the pedals (56).

• Move the EJE pallet truck away from the truck.

• Close the battery door.

The battery is now inserted.

63

65

03.13 EN

55 56

63

Page 65

5.3 Removal and installation using a hand pallet truck with Snapfit

battery holder (o)

CAUTION!

Trapping hazard

Trapping hazard when replacing the battery.

XWhen replacing the battery do not reach between the battery and the chassis.

XWear safety shoes.

Removing the battery

Requirements

– Truck parked securely, see "Parking the truck securely" on page 105.

– Battery exposed, see "Exposing the battery"

on page 52.

Tools and Material Required

– Battery trolley with four rollers

– Hand pallet truck with Snapfit battery holder

– Charging station intended for the battery

type (60) (o)

Procedure

•

• Close the safety catch (55).

• To do this press the pedals (56).

• Fully lower the hand pallet truck.

• Move the hand pallet truck up to the centre of

the battery until Snapfit contacts the truck

chassis.

60

•

• Raise the forks of the hand pallet truck until the

recess (66) is exposed.

• Move the hand pallet truck into the battery

compartment until the safety catches lock the

battery trolley.

• Make sure both safety catches (55) are

securely engaged in the battery

replacement trolley.

64

55

56

66

56

03.13 EN

Page 66

•

• Open the battery lock (63).

• Raise the hand pallet truck (approx. 20 mm)

until the battery can be freely pulled out of the

battery compartment.

NOTE

Risk of material damage

Removing the battery can cause material

63

damage to the truck chassis.

XRaise the forks and avoid striking the

top or bottom parts of the chassis when

removing the battery.

• Remove the battery.

• Bring the battery to the charging station for charging.

•

• Place the battery carefully onto the charging

station (60)

60

The battery is now removed and positioned

securely for charging.

03.13 EN

65

Page 67

Battery installation

Procedure

•

• Move the hand pallet truck and battery to the

truck.

• Raise and move the hand pallet truck into the

battery compartment until the forks contact the

truck chassis.

• Deposit the battery trolley with the rollers (65)

on the base of the truck.

• Lower the forks of the hand pallet truck until

the battery is horizontal.

• Insert the battery in the truck.

•

• Close the battery lock (63).

• Lower the hand pallet truck.

•

• Undo the safety catch (55).

• To do this press the pedals (56).

• Move the hand pallet truck away from the

truck.

• Close the battery door.

The battery is now inserted.

65 67

63

55

56

66

03.13 EN

Page 68

5.4 Removal and installation using a multi-adapter (o)

CAUTION!

Trapping hazard

Trapping hazard when replacing the battery.

XWhen replacing the battery do not reach between the battery and the chassis.

XWear safety shoes.

Battery removal and installation

Requirements

– Park the truck securely, see "Parking the truck securely" on page 105.

– Battery exposed, see "Exposing the battery" on page 52.

– Battery disconnected.

Tools and Material Required

– Multi-adapter

– Battery trolley with six rollers

– Pallet truck with a fork length of 1150 mm

Procedure

•

• Push the pallet truck and the multi-adapter

up to the

stop (68) under the battery.

• Set the multi-adapter to the straight ahead

position using the alignment device

(69).

03.13 EN

•

• Raise the multi-adapter with the pallet

truck as far as the

height stop (70).

• Prevent the pallet truck from rolling away.

• Undo the battery lock (63).

•

• Pull the battery (71) out by its handle.

• The battery trolley must engage securely in

the safety catch (72).

• Lower the pallet truck slightly to move it.

The battery is now removed and can be taken

to the charging station for charging.

68 69

70

63

71

72

67

Page 69

Z Battery assembly is the reverse order.

Release the retaining hook (72) using your foot. Insert the rollers of the battery

replacement trolley into the battery compartment guides and push the battery into

the battery compartment.

WARNING!

After inserting the battery close the battery lock and then lower the pallet truck.

68

03.13 EN

Page 70

5.5 Removal and installation using a worktable for crane loading (o)

CAUTION!

Trapping hazard

Trapping hazard when replacing the battery.

XWhen replacing the battery do not reach between the battery and the chassis.

XWear safety shoes.

Battery removal and installation

Requirements

– Park the truck securely, see "Parking the truck securely" on page 105.

– Battery exposed, see "Exposing the battery" on page 52.

– Battery disconnected.

Tools and Material Required

– Side table

– Battery trolley with six rollers

– Pallet truck with a fork length of 1360 mm

– Crane lifting gear

Procedure

•

• Push the hand pallet truck with the

worktable as far as the

stop (68) underneath the

battery.

03.13 EN

•

• Raise the worktable and the pallet truck as

far as the stop (70).

• Undo the battery lock (63).

68

63

70

69

Page 71

•

• Pull the battery (71) out by its handle.

• The battery trolley must engage securely in

the safety catch (72).

• Strap the crane lifting harness to the battery

container. The hooks must be fitted in such

71

a way that when the crane lifting harness is

slackened, they do not fall onto the battery

cells.

72

• Lift out the battery with the crane. The

battery replacement trolley remains secured

to the worktable via the safety catches (72).

The battery is now removed and can be taken to the charging station for charging.

Z Battery assembly is the reverse order.

Release the retaining hook (72) using your foot. Insert the rollers of the battery

replacement trolley into the battery compartment guides and push the battery into

the battery compartment.

WARNING!

After inserting the battery close the battery lock and then lower the pallet truck.

70

03.13 EN

Page 72

5.6 Removal and installation using a fork shoe (o)

CAUTION!

Trapping hazard

Trapping hazard when replacing the battery.

XWhen replacing the battery do not reach between the battery and the chassis.

XWear safety shoes.

Battery removal and installation

Requirements

– Truck parked securely, see "Parking the truck securely" on page 105.

– Battery exposed, see "Exposing the battery"

on page 52.

– Battery disconnected.

– Battery lock released.

Tools and Material Required

– Fork shoe

– Second fork lift truck with a capacity to match

the battery weight. The battery weights are

indicated on the battery data plate.