Page 1

Operating instructions

50451814

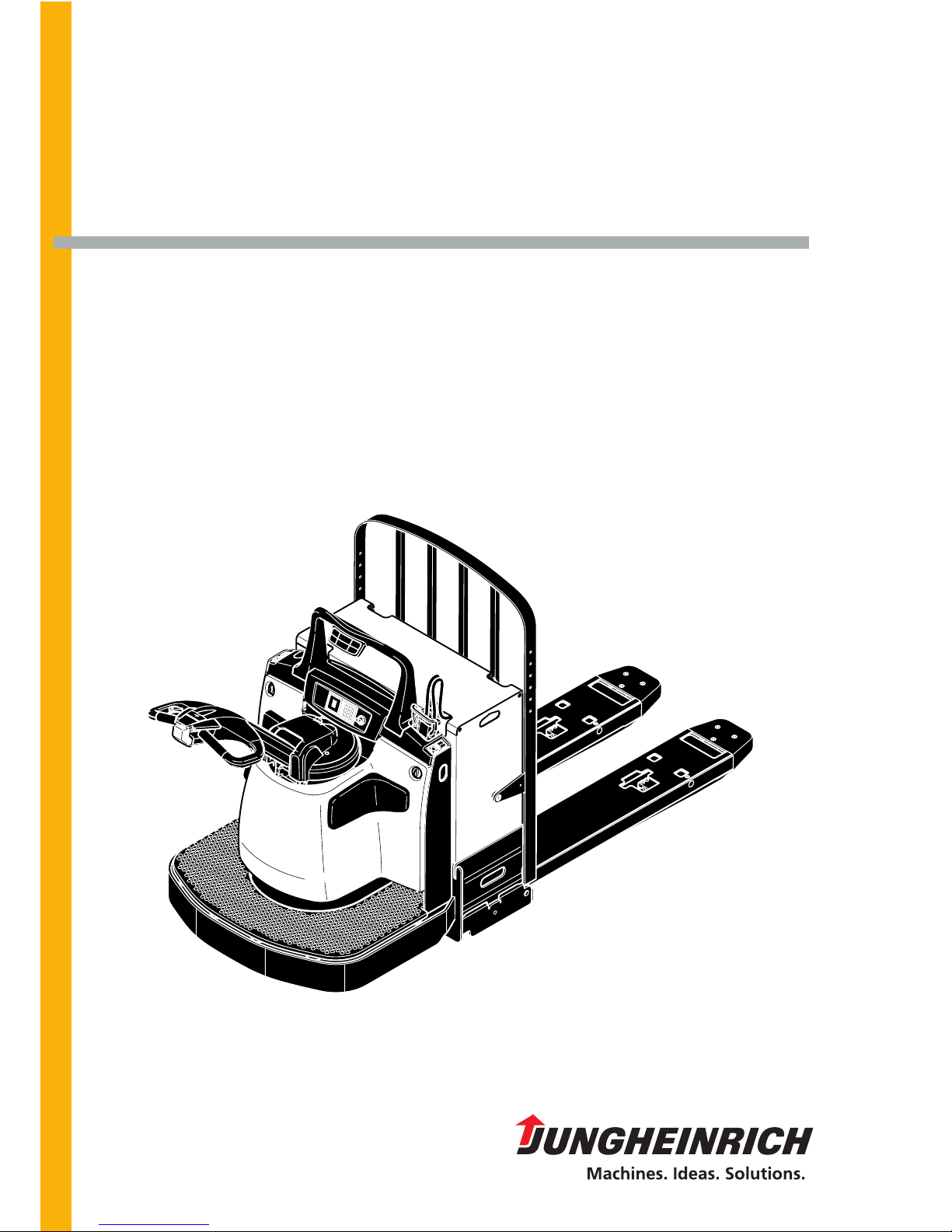

ECR 327/336

10.05 -

03.07

Instrucciones de servicio

u

E

Page 2

0108.USA

Foreword

Safe operation of the industrial truck requires specialist knowledge, which is acquired

from this Operating Manual, from the training required by OSHA under 29 CFR

1910.178, and by training operators in factory installations and their functions. Safe

operation of the industrial truck requires knowledge that can be acquired from this

ORIGINAL OPERATING MANUAL. The information is set out concisely and in a clear

format. The chapters are organized alphabetically, each starting at page 1. The page

identifier consists of the chapter letter and page number.

For example: Page B2 is the second page of Chapter B.

Various types of industrial trucks are described in this Operating Manual. When

operating the truck and carrying out maintenance work, make certain you use the

description corresponding to your vehicle type.

Safety instructions and important information, and their relative importance, are

indicated by the following safety warning symbols and indicator words:

QwD This message indicates a hazardous situation that, if not avoided, will result

in death or serious injury. The instructions, safety precautions, actions, or

procedures relating to this message must be observed to avoid the risk of

death or serious injury.

QwW This message indicates a hazardous situation that, if not avoided, could

result in death or serious injury. The instructions, safety precautions, actions,

or procedures relating to this message must be observed to avoid the

potential risk of death or serious injury.

QwK This message indicates a situation that may lead to minor or moderate injury

if disregarded. The instructions, safety precautions, actions, or procedures

relating to this message must be observed to avoid the risk of minor or

moderate injury.

IMPORTANT This message appears if special precautionary measures are needed to

ensure that the correct action is taken or to prevent damage to or malfunction

of the industrial truck or a component.

NOTICE This message appears if special information, instructions, or indications are

needed with regard to procedures, equipment, tools, pressures, loads, and

other special data.

t Indicates component fitted as standard.

o Indicates optional extra.

Page 3

0108.USA

It is impossible for the manufacturer to foresee every possible operational

circumstance that could involve a potential danger. For that reason, the warnings in

this manual and on the equipment itself do not encompass all possible

circumstances. If you use a tool, procedure, working method, or operating technique

not expressly recommended by the manufacturer, you must make sure yourself that

it does not present a safety risk to you or to anyone else. You must also ensure that

the product will not be damaged or made unsafe through operation, lubrication,

maintenance, or the chosen repair measures.

The information, technical data, and illustrations contained in this document are

based on the information available at the time of publication. Specifications, torques,

pressures, measurements, settings, illustrations, and all other data are subject to

change at any time. These changes relate to the performance of the product. Before

executing a task, you should request the most up-to-date and comprehensive

information from the manufacturer / dealer. You can also obtain additional copies of

the manual from your dealer.

In the interests of technical advancement, the manufacturer reserves the right to

make changes, while retaining the essential features of the type of vehicle described,

without correcting this Operating Manual at the same time.

Copyright

Copyright of this operating manual remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY

Phone: +49 (0) 40/6948-0

www.jungheinrich.com

Page 4

I 1

0705.USA

Table of contents

A Compliance with regulations -

Legislation and common sense

B Recognition and avoidance of risks

C Appropriate use

D Vehicle description

1 Description of use ............................................................................... D 1

2 Components ........................................................................................ D 2

3 Technical data ..................................................................................... D 3

3.1 Performance data ................................................................................ D 3

3.2 Dimensions ......................................................................................... D 4

3.3 Axle and drive wheel loads ................................................................. D 6

3.4 US standards ...................................................................................... D 15

3.5 Operating conditions ........................................................................... D 16

4 Position of signs and nameplates ...................................................... D 17

4.1 Nameplate, vehicle .............................................................................. D 18

4.2 Sign - Qmax (15) ................................................................................. D 19

4.3 Sign - Danger battery (16) ................................................................... D 19

4.4 Sign - Warning battery size (17) .......................................................... D 19

4.5 Sign - Warning stay clear (18) ............................................................. D 20

4.6 Sign - Warning jog button coast, left (20a) (o) ................................... D 20

4.7 Sign - Warning jog button coast, right (20b) (o) ................................. D 20

4.8 Sign - Warning stay clear stop truck (24) ............................................ D 21

4.9 Sign - Warning charger (25) ................................................................ D 21

4.10 Sign - Warning electrical device (27) .................................................. D 22

4.11 Sign - Warning coast system (28) (o) ................................................ D 22

Page 5

0705.USA

I 2

E Operation

1 Description of controls and indicators ................................................. E 1

2 Starting the vehicle .............................................................................. E 5

2.1 Preparing for operation ....................................................................... E 5

2.2 Driving, steering, braking .................................................................... E 6

2.3 Raising and lowering load units .......................................................... E 13

2.4 Switching off and securing the vehicle ................................................ E 14

2.5 Adjusting the fork height ...................................................................... E 14

3 Important general aspects affecting the safe use of the truck ............. E 15

3.1 Training, certification, and approval to use the truck ........................... E 15

3.2 Damage and repairs to the industrial truck ......................................... E 17

3.3 Aspects in relation to loading .............................................................. E 18

3.4 Operating environment ........................................................................ E 19

3.5 Safety devices and warning signs ....................................................... E 22

3.6 Lifting of people ................................................................................... E 23

4 Operating the industrial truck .............................................................. E 25

4.1 Safety regulations for industrial truck operators .................................. E 25

4.2 General operation of the truck ............................................................. E 25

4.3 Ensuring that the industrial truck is properly equipped ....................... E 28

4.4 Opening and closing railroad cars ....................................................... E 29

4.5 Safe loading and transportation .......................................................... E 30

4.6 Preventing overturning and tipping ..................................................... E 31

4.7 Supervising and securing the truck ..................................................... E 32

4.8 Lifting of people ................................................................................... E 32

5 Keypad (CANCODE) (o) .................................................................... E 34

5.1 Code lock ............................................................................................ E 34

5.2 Travel program .................................................................................... E 36

5.3 Parameters .......................................................................................... E 36

5.4 Parameter settings .............................................................................. E 37

5.5 Travel parameters ............................................................................... E 41

6 Information display (CANDIS) (o) ...................................................... E 42

6.1 Discharge monitor function ................................................................. E 43

6.2 Operating hours indicator .................................................................... E 43

6.3 Power-up test ...................................................................................... E 43

7 Discharge indicator (LEA) (t) ............................................................. E 44

8 Troubleshooting .................................................................................. E 45

Page 6

I 3

0705.USA

F Battery – Maintaining, recharging, replacing

1 Safety regulations for handling lead-acid batteries ............................. F 1

2 Battery type ......................................................................................... F 2

3 Uncovering the battery ........................................................................ F 3

4 Charging the battery ............................................................................ F 4

5 Removing and installing the battery .................................................... F 5

5.1 Removal, standard design .................................................................. F 5

5.2 Removal, "removal from side" (o) ...................................................... F 6

5.3 Installing the battery ............................................................................ F 6

G Industrial truck maintenance and troubleshooting

1 Operational safety and environmental protection ................................ G 1

2 Safety regulations for industrial truck maintenance ............................ G 1

3 Maintenance and inspection ............................................................... G 7

4 Maintenance checklist ........................................................................ G 8

5 Lubrication chart .................................................................................. G 10

5.1 Operating resources ............................................................................ G 11

6 Description of maintenance and servicing jobs ................................... G 12

6.1 Preparing the industrial truck for maintenance and servicing ............. G 12

6.2 Opening the front cover ....................................................................... G 13

6.3 Removing the motor cover .................................................................. G 13

6.4 Checking the hydraulic oil level ........................................................... G 14

6.5 Checking the electrical fuses .............................................................. G 15

6.6 Restarting the vehicle after cleaning or

maintenance work G 16

7 Extended shutdown of the industrial truck .......................................... G 16

7.1 Measures required before shutdown ................................................... G 16

7.2 Measures required during the shutdown period .................................. G 17

7.3 Restarting the vehicle after shutdown ................................................. G 17

8 Safety inspections at regular intervals and after exceptional events .. G 18

H Transportation and commissioning

1 Securing the vehicle during transportation .......................................... H 1

2 Handling by crane ............................................................................... H 1

3 Commissioning .................................................................................... H 1

3.1 Adjusting the support roller forces before start-up .............................. H 2

4 Non-automotive movement of the vehicle ........................................... H 4

Page 7

0705.USA

I 4

Page 8

A 1

0705.USA

A Compliance with regulations -

Legislation and common sense

In 1998, OSHA produced a report on its wide-ranging study into the use of powered

industrial trucks in industry. This report was published in the US Federal Register/

vol. 63, no. 230. In this report OSHA sets out the many reasons why employers are

required to train their employees in connection with the use of powered industrial

trucks and why untrained personnel must be prohibited from using industrial trucks

except in controlled operating conditions such as a training session. The report shows

how extremely important a training program as required by the OSHA guidelines is

for the safety of equipment and personnel in connection with the use of powered

industrial trucks. 29 CFR part 1910.178. In simple terms, thorough training prior to the

use of an industrial truck is extremely important and must take place before an

industrial truck is used, since accidents leading to injury and death or property

damage are almost always the consequence of disregarding the underlying risks held

by the use of industrial trucks or of ignoring safety instructions and safety precautions

designed to minimize or eliminate such risks. The OSHA training program specifically

addresses these risks. The evidence contained in the OSHA report demonstrates that

the statutory training requirements for operators and employers are based on

experience and general judgment.

Jungheinrich industrial trucks satisfy the requirements of 29 CFR 1910.178 and

ASME B 56.1. Jungheinrich representatives are always on hand to provide advice on

issues surrounding the loading, operation, use and maintenance of powered

industrial trucks.

According to the OSHA report, knowledge and skills to operate an industrial truck

powered by an electric drive are not innate in human beings. Quite the contrary: This

knowledge can only be acquired through theoretical and practical training. This

means that having an industrial truck which complies with statutory regulations and

standards, is only one half of the safety equation. It is the responsibility of you, the

operator, and your employer to be aware of your responsibilities and of all national

and regional regulations and laws governing training requirements and the safe use

of powered industrial trucks, not only because the law requires it but because it is a

matter of common sense.

Powered industrial trucks may only be operated by trained and tested persons.

Training programs must satisfy OSHA requirements and as a minimum

address the topics mentioned here.

Employers and operators should pay especial attention to the section in ASME

regulations B56.1 concerning the operator.

"Safe operation is the responsibility of the operator" ASME B56.1 – 2003, Part

II Section 5.1.1.

Page 9

0705.USA

A 2

Page 10

B 1

0705.USA

B Recognition and avoidance of risks

In its 1998 investigation into the use of powered industrial trucks, OSHA determined

the ways in which accidents commonly occur and the causes of these accidents.

OSHA concluded that considerable risks to operators themselves and to other people

in their immediate vicinity can be put down to the inadequate or non-existent training

of operating personnel. According to OSHA, incorrect and unsafe operation are the

principal causes of accidents in connection with powered industrial trucks and the

resulting injuries and fatalities. It is therefore no coincidence that in reviewing its own

research, OSHA found that in almost all cases, accidents were attributable to

situations or actions, which the operator, or the employer and the operator together,

could have influenced or could have done better. This finding was confirmed by a

simple check of the accident causes cited by OSHA. Of the 208 accidents

investigated involving powered industrial trucks, 184 of which were fatal accidents or

resulted in serious injuries, a full 50 percent of them were due to loading problems,

including overloading, unstable loads, dropped loads or incorrect lifting of loads. 25

percent of the cases involved the tipping or overturning of the truck. A further 20

percent of the accidents were caused by the truck falling from a platform or a trailer

or by persons falling from an elevated position in a truck. Although only 4% of the

accidents were due to an absence of training and instruction, OSHA nevertheless

noted that many accidents could also have been caused by inadequate training. For

example, the overturning of a vehicle could just as easily be caused by poor or

inadequate instruction of the operator with regard to the loading of the vehicle. Other

less frequent accident causes, which could nevertheless still have been avoided by

employers and operators, were excessive speeds and the use of inappropriate

equipment.

The following measures are, therefore, of vital importance:

– Operators must be trained and aptitude-tested before working with a powered

industrial truck.

– Operators must be physically, mentally and emotionally capable of operating a

powered industrial truck.

– Operators must possess and apply all practical knowledge in relation to the safe

loading and correct operation of the vehicle. The capacity limits of the machine

must be known and must never be exceeded.

– All circumstances which could cause the vehicle to tip or to overturn, must be

avoided. Attention must be paid in this regard to shifting centers of gravity, correct

loading and the safe transport of loads, and to anticipatory driving, taking account

of edges, bends, slopes, and other driving conditions.

– Without appropriate driver training and the correct type of truck, passengers should

never be carried nor people lifted under any circumstances. Furthermore, the

correct procedure for this must be observed.

– Traffic rules must always be observed. Drivers must always be aware of the

position of colleagues and of other trucks and must pay attention to local

conditions.

The manufacturer shall not be held liable for the consequences of the dismantling of

the industrial truck or for modifications outside the manufacturer's control.

Page 11

0705.USA

B 2

The manufacturer's liability is limited to the configuration of the machine or plant

described in the declaration of conformity. The manufacturer is absolved from all

liability if modifications or additions are made or equipment from another

manufacturer is used. In such a case the manufacturer's liability is transferred to the

user/customer.

This Operating Manual shall cease to be valid if the machine is modified by a

company outside our Group, even if original spare parts are used and our company

logo can still be seen on the machine.

Page 12

C 1

0705.USA

C Appropriate use

NOTICE This Operating Manual contains all necessary information for the transport,

commissioning, normal use, maintenance, and servicing of the industrial

truck it describes, in accordance with ASME B56.1-2003, UL 583, and ANSI

Z535.4-2002. You should read these instructions carefully to ensure the safe

and correct use of the industrial truck.

The industrial truck described in this Operating Manual is suitable for lifting and

transporting loads.

This vehicle must be used and maintained in accordance with the information set out

in this Operating Manual. Any other usage constitutes improper use and may lead to

damage or injury. In particular, overloading as a result of excessive weight or

unbalanced loads must be avoided. The maximum permissible loading capacity is

stated on the nameplate and on the load diagram sticker on the industrial truck. The

industrial truck may not be used in areas where there is a risk of fire or explosion, or

a corrosive or dusty atmosphere.

This Operating Manual must be kept available throughout the entire period of use of

the vehicle.

Duties of the owner: Depending on the context cited in this Operating Manual, the

user of a fork lift truck can refer to several people, including the owner of the truck,

anyone who leases or borrows the truck, and the operator as defined in ASME B56.1-

2003. Generally speaking, the employer is the user, whereas his or her employee will

frequently perform the duties of the operator as described in the OSHA regulations.

Every user must know and apply the applicable rules and regulations relating to the

use and operation of the truck. The Operating Manual applies to all users and is

aimed at the people who actually operate the truck.

The operator and owner must ensure that the industrial truck is used correctly and

only within its design limits, and that all health and safety risks to operators or third

parties are avoided. The relevant accident prevention regulations and all relevant

safety provisions, along with operating, servicing and maintenance instructions, must

also be followed. The operator and owner must also ensure that anyone using the

truck has read and understood this Operating Manual. The owner must ensure that

all operators of the truck have read and understood this Operating Manual and that

they have successfully completed all legally required training and aptitude testing

before working with the truck.

Operators and users should understand that the vehicle operation changes if the

functions of manually operated trucks are automated (for example, rail-mounted

trucks or trucks with inductive guidance), resulting in changes to performance

features and maintenance procedures and requiring additional safety precautions.

If a manually operated industrial truck is adapted to include an automatic function, the

implications of the automation on all other functions must be considered. Other

functions may also need to be automated to some degree.

NOTICE Failure to comply with the content of this Operating Manual shall invalidate

the warranty. The same shall apply if the customer and/or third parties repair

or modify the machine without the approval of our customer service

department.

Page 13

0705.USA

C 2

Attachment of accessories: The attachment or installation of accessories, and

modifications and/or additions to the hardware or software, which adversely affect or

change the nominal power, the safe operation, the emergency devices or other

functions of the industrial truck, are permissible only with the prior, express, written

approval of the manufacturer.

If such approval is granted, the nameplates, markings or warnings with regard to load

capacity, operation, and maintenance must be altered accordingly.

Local authority approval must be obtained if necessary.

Local authority approval does not, however, release the owner from his or her duty to

obtain approval from the manufacturer.

If the industrial truck is fitted with accessories, including fork extensions, the user

must ensure that the truck is labeled to identify the accessories and that the

approximate weight of the truck and the combined accessories is shown, together

with the load capacity of the truck and accessories at maximum lift with a laterally

centered load.

If the modifications are associated with alterations and repairs to the basic functions,

these changes must be made in accordance with the criteria and procedures set

down by the manufacturer.

The basic functions comprise the following elements:

– Steering (guidance)

– Travel speed

– Controller and sensors

– Lift and load influencing

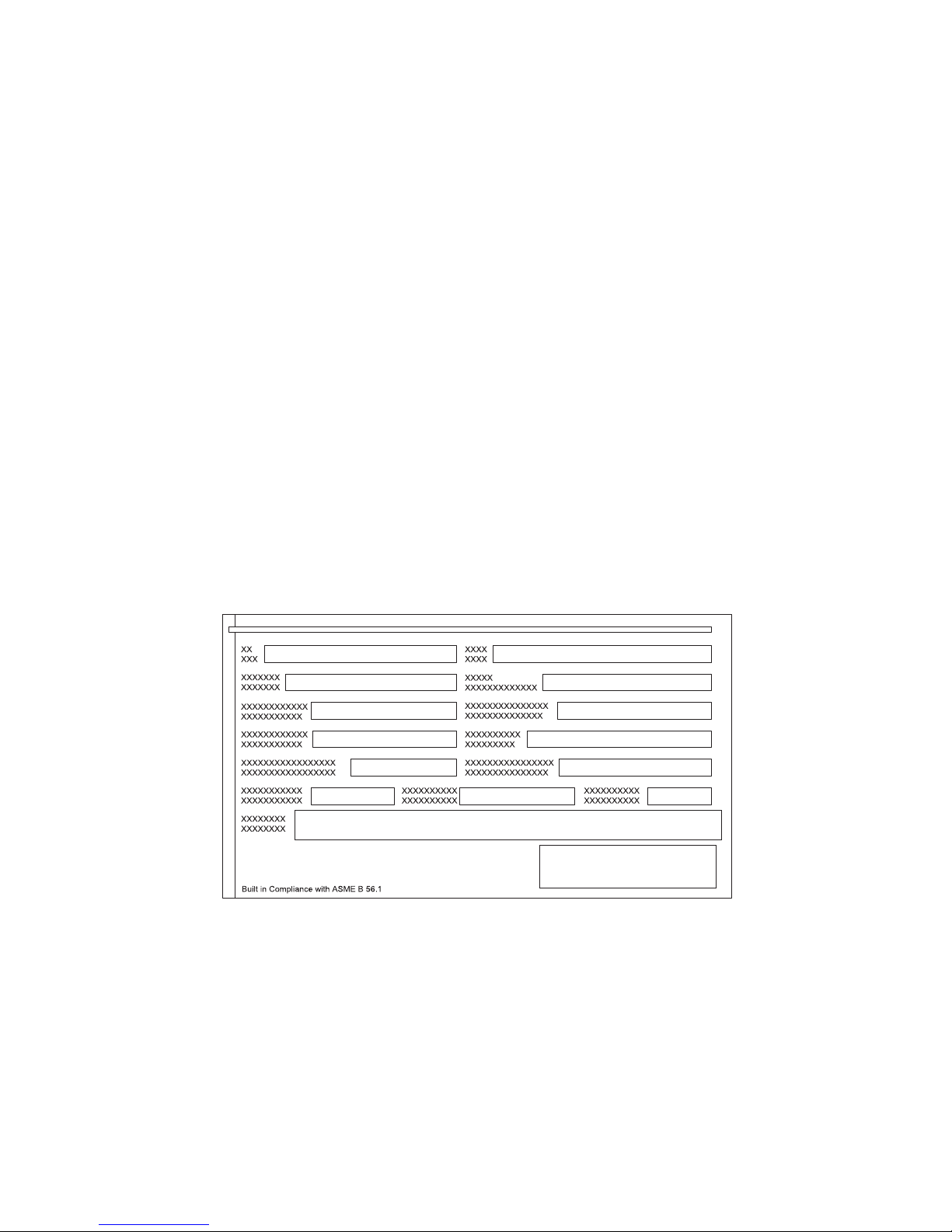

Nameplate: We recommend that you copy the details from the nameplate onto the

diagram below to ensure that this important data is available to the operator and that

this Operating Manual is not accidentally used for another machine.

The operator is responsible for ensuring that all nameplates, warning signs and

instruction signs are in place and are legible (see "Position of signs and nameplates"

in Chapter D).

QwW The use of an industrial truck involves certain risks, which cannot be fully

excluded even with the use of electrical devices; these risks can, however,

be minimized through intelligence, consideration, and common sense. It is,

therefore, essential that operators are qualified, diligent, and physically and

mentally fit, and have been thoroughly trained in the safe use of the machine

and in materials handling techniques.

Page 14

C 3

0705.USA

General instructions for operators and owners

QwW The instructions set out below apply to all users, including managers,

supervisors, operators, carriers, and employees working in the vicinity of

industrial trucks. The user is responsible for the safe use of this fork lift truck,

and employers and operators must work closely together to ensure that the

safety regulations applying to the use of the truck are observed and enforced.

1. This Operating Manual must be read before the industrial truck is used for the

first time and its content observed when using the truck.

2. The owner and operator must ensure that the industrial truck is used only for its

originally intended purpose. The owner and operator must NOT:

– Permit the industrial truck to be used for any other than its designated purpose

– Disable the safety systems

– Overload the industrial truck or use it if the arrangement of the load does not

match that shown in the load diagram

(see "Load capacity" in Chapter D)

– Use the industrial truck as a crane

– Lift or carry people

– Lock a control in position

– Ignore conventional practice in connection with the handling of loads

– Carry loads over people's heads

– Push or pull loads

– Take part in games, such as races

– Carry loads, which are not fully balanced

3. The owner and operator must check the load-bearing capacity of floors (to

prevent damage), shelves, and in general all gangways in which the industrial

truck may possibly be used.

4. Read the instructions on the signs attached to the industrial truck and ensure

that they are always legible.

5. This Operating Manual must be made available to all operators.

6. Ensure that only trained, tested, and responsible people who are capable of

operating the vehicle safely are allowed to operate the industrial truck.

7. Ensure that the industrial truck cannot be moved when it is not in use.

8. An industrial truck which is clearly not in good working order, must not be used.

9. The industrial truck must never be used to transport a load or to apply a force if

the maximum permissible operating load would be exceeded as a consequence.

10. The industrial truck must only be used in the manner for which the truck was

designed.

11. Read the safety instructions applicable for this industrial truck and comply with

these instructions without exception.

12. The manufacturer accepts no liability for consequences arising from the

dismantling of the industrial truck or from modifications outside the

manufacturer's control.

Page 15

0705.USA

C 4

13. The manufacturer's liability is limited to the configuration of the machine

described in the Declaration of Conformity. The manufacturer is absolved from

all liability if modifications or additions are made or equipment from another

supplier is used. In such a case the manufacturer's liability is transferred to the

user.

14. This Operating Manual shall cease to be valid if the machine is modified by a

company outside our Group, even if original spare parts are used and our

company logo still appears on the machine.

15. Exceptional operating conditions require additional safety precautions and

special operating instructions.

16. Supervision is essential to the safe use of powered industrial trucks.

17. The batteries must comply with the minimum and maximum weight range as

specified on the nameplate.

18. Wheel chocks and wheel locks (where fitted) are only suitable for holding the

industrial truck in the required position on a level surface.

QwW Extreme danger can arise from an overloaded truck, obstacles to free

passage of the load, impact with objects or pedestrians, poor maintenance,

and the use of equipment for which the industrial truck was not designed or

developed. Changes to the load, dimensions, coupling method, and/or

position, and also to the surface of the ground or the battery weight, can have

a negative impact on the load capacity and safe operation of the industrial

truck. Only stable or securely-fastened loads may be transported.

The user is responsible for ensuring the load is stable and secure. This should be

checked where necessary.

Page 16

D 1

0705.USA

D Vehicle description

1 Description of use

The vehicle is a three-wheel electric pedestrian pallet truck with operator stand-on

platform. Additional support rollers improve its cornering stability.

It is designed for use on level ground for the transport and picking of goods.

It can be used to pick up block pallets or stringer pallets that are beyond the range of

barrows or trolleys.

Loads can be stacked and unstacked and transported over relatively long distances.

The rated load capacity is stated on the nameplate or load plate (Qmax).

Page 17

0705.USA

D 2

2 Components

Item Designation Item Designation

1 t Tiller 8 t Forks

2 o Information display

(CANDIS)

9 t Battery connector/EMERGENCY

STOP

3 t Discharge indicator (EA) 10 t Battery

4 o Keypad

(CANCODE)

11 o

Leg cushion

5 o Access module ISM 12 t Support rollers

6 t Switch latch 13 t Drive wheel

7 o Safety guard 14 t Fixed operator stand-on platform

t = Fitted as standard o = Optional extra

1 2, 3 4,5 6 7

10

9

111312 1214

8

Page 18

D 3

0705.USA

3 Technical data

NOTICE The technical data specification complies with the German guidelines for

"Type sheets for industrial trucks".

Z

Subject to technical modification.

3.1 Performance data

*)On the extended fork version, the load center is in the center of the forks.

Designation ECR 327 ECR 336

Q Rated load capacity 6000 (2700) 8000 (3600) lb (kg)

c Load center distance with

standard fork length *

)

23.6 (600) 23.6 (600) in (mm)

Travel speed

with/without rated load

6.8/9.3 (11/15) 5.9/9.3

(9.5/15)

m/h (km/h)

Lift speed

with/without rated load

(0.39/0.50) (0.37/0.50) cm/s

Page 19

0705.USA

D 4

3.2 Dimensions

(all dimensions in inches (mm))

Designation Standard

l

2

Overall length at front 42.2 (1073)

h

13

Lowered height of fork 3.3 (83)

h

3

Lift height 5.7 (145)

b

1

Vehicle width 35.8 (910)

b

11

Track width 13.0 / 17.8 (331 / 451)

e

Fork width

Standard tip forks

Extended tip forks

9.0 (229)

9.8 (249)

a Safe distance 7.9 (200)

Service weight: see nameplate, vehicle

ll1yW

a

Standard tip forks

35.7 (908) 78.0 (1980) 49.4 (1254) 65.6 (1667)

41.7 (1060) 83.9 (2132) 55.4 (1407) 71.7 (1820)

47.8 (1213) 90.0 (2285) 61.5 (1561) 77.7 (1974)

53.7 (1365) 95.9 (2437) 67.5 (1714) 83.7 (2127)

59.7 (1517) 101.9 (2589) 73.5 (1866) 89.7 (2279)

95.7 (2432) 138.0 (3504) 109.6 (2783) 125.8 (3196)

102.8 (2610) 145.0 (3682) 116.6 (2961) 132.8 (3374)

Extended tip forks

83.7 (2127) 125.9 (3199) 81.5 (2069) 97.7 (2482)

92.8 (2356) 135.0 (3428) 81.5 (2069) 97.7 (2482)

95.7 (2432) 138.0 (3504) 81.5 (2069) 97.7 (2482)

102.8 (2610) 145.0 (3682) 81.5 (2069) 97.7 (2482)

Page 20

D 5

0705.USA

1475 mm ( 58.1")

y

e

124 mm (4.9")

415 mm

(16.3")

c

L

h

3

b

1

L

2

a

/

2

a

/

2

h

13

240 mm (9.4")

(L1)

b

11

b

5

x

W

a

Standard Tip Forks

x =185 mm (7.3")

Extendet Tip Forks Forks

x =592 mm (23.3") 2133 mm (84")

x =821 mm (32.5") 2362 mm (93")

x =897 mm (35.3") 2438 mm (96")

x =1075 mm (42.3") 2616 mm (103")

Page 21

0705.USA

D 6

3.3 Axle and drive wheel loads

Unladen vehicle, including 510 Ah battery

Drive wheel load

while moving

in fork direction

(level ground) in lb (kg)

1140 (517)

1232 (559)

1285 (583)

1032 (468)

1074 (487)

1276 (579)

1312 (595)

1376 (624)

1336 (606)

1321 (599)

1287 (584)

Drive wheel load

while moving

in drive direction

(level ground) in lb (kg)

1360 (617)

1453 (659)

1506 (683)

1274 (578)

1316 (597)

1519 (689)

1554 (705)

1596 (724)

1556 (706)

1541 (699)

1508 (684)

Load axle

in lb (kg)

637 (289)

584 (265)

573 (260)

569 (258)

567 (257)

606 (275)

619 (281)

686 (311)

756 (343)

783 (355)

840 (381)

Drive axle

in lb (kg)

1856 (842)

1949 (884)

2002 (908)

2046 (928)

2088 (947)

2291 (1039)

2326 (1055)

2092 (949)

2052 (931)

2037 (924)

2004 (909)

Vehicle weight

in lb (kg)

2493 (1131)

2533 (1149)

2575 (1168)

2615 (1186)

2654 (1204)

2897 (1314)

2945 (1336)

2778 (1260)

2809 (1274)

2820 (1279)

2844 (1290)

Forkoverhang

in inches (mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches (mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 22

D 7

0705.USA

Vehicle with 2700 kg load and 150 mm load carriage travel,

including 510 Ah battery

Drive wheel load

while moving in

fork direction

(level ground)

in lb (kg)

2262 (1026)

1836 (833)

2412 (1094)

2299 (1043)

2482 (1126)

3201 (1452)

3300 (1497)

2363 (1072)

2002 (908)

1929 (875)

1898 (861)

Drive wheel load

while moving in

drive direction

(level ground)

in lb (kg)

2482 (1126)

2057 (933)

2632 (1194)

2542 (1153)

2725 (1236)

3444 (1562)

3543 (1607)

2584 (1172)

2222 (1008)

2149 (975)

2119 (961)

Load axle

in lb (kg)

5467 (2480)

5933 (2691)

5399 (2449)

5254 (2383)

5110 (2318)

4634 (2102)

4583 (2079)

5650 (2563)

6043 (2741)

6127 (2779)

6182 (2804)

Drive axle

in lb (kg)

2978 (1351)

2553 (1158)

3128 (1419)

3313 (1503)

3496 (1586)

4215 (1912)

4314 (1957)

3080 (1397)

2718 (1233)

2646 (1200)

2615 (1186)

Vehicle weight

in lb (kg)

8446 (3831)

8485 (3849)

8527 (3868)

8567 (3886)

8607 (3904)

8849 (4014)

8898 (4036)

8730 (3960)

8761 (3974)

8772 (3979)

8796 (3990)

Load center

(LC)

in inches (mm)

19.7 (500)

23.6 (600)

23.6 (600)

26.9 (683)

29.9 (759)

47.9 (1216)

51.4 (1305)

41.9 (1064)

46.4 (1178)

47.2 (1200)

47.2 (1200)

Forkover-

hang

in inches

(mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches

(mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 23

0705.USA

D 8

Vehicle with 3600 kg load and 150 mm load carriage travel,

including 510 Ah battery

Drive wheel load

while moving in

fork direction

(level ground)

in lb (kg)

2615 (1186)

2048 (929)

2795 (1268)

2736 (1241)

2965 (1345)

3851 (1747)

3968 (1800)

2701 (1225)

2229 (1011)

2138 (970)

2103 (954)

Drive wheel load

while moving in

drive direction

(level ground)

in lb (kg)

2835 (1286)

2269 (1029)

3016 (1386)

2978 (1351)

3208 (1455)

4094 (1857)

4211 (1910)

2921 (1325)

2449 (1111)

2359 (1070)

2324 (1054)

Load axle

in lb (kg)

7099 (3220)

7705 (3495)

7000 (3175)

6803 (3086)

6612 (2999)

5968 (2707)

5899 (2676)

7297 (3310)

7800 (3538)

7901 (3584)

7961 (3611)

Drive axle

in lb (kg)

3331 (1511)

2765 (1254)

3512 (1593)

3750 (1701)

3979 (1805)

4866 (2207)

4982 (2260)

3417 (1550)

2945 (1336)

2855 (1295)

2820 (1279)

Vehicle weight

in lb (kg)

10430 (4731)

10470 (4749)

10511 (4768)

10551 (4786)

10591 (4804)

10833 (4914)

10882 (4936)

10714 (4860)

10745 (4874)

10756 (4879)

10780 (4890)

Load center

(LC)

in inches (mm)

19.7 (500)

23.6 (600)

23.6 (600)

26.9 (683)

29.9 (759)

47.9 (1216)

51.4 (1305)

41.9 (1064)

46.4 (1178)

47.2 (1200)

47.2 (1200)

Forkover-

hang

in inches

(mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches

(mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 24

D 9

0705.USA

Unladen vehicle, including 600 Ah battery

Drive wheel load

while moving

in fork direction

(level ground) in lb (kg)

1261 (572)

1358 (616)

1413 (641)

1162 (527)

1206 (547)

1415 (642)

1451 (658)

1510 (685)

1468 (666)

1455 (660)

1420 (644)

Drive wheel load

while moving

in drive direction

(level ground) in lb (kg)

1481 (672)

1578 (716)

1634 (741)

1404 (637)

1448 (657)

1658 (752)

1693 (768)

1731 (785)

1689 (766)

1675 (760)

1640 (744)

Load axle

in lb (kg)

668 (303)

611 (277)

597 (271)

591 (268)

586 (266)

619 (281)

633 (287)

703 (319)

776 (352)

800 (363)

860 (390)

Drive axle

in lb (kg)

1978 (897)

2075 (941)

2130 (966)

2176 (987)

2220 (1007)

2429 (1102)

2465 (1118)

2227 (1010)

2185 (991)

2172 (985)

2136 (969)

Vehicle weight

in lb (kg)

2646 (1200)

2685 (1218)

2727 (1237)

2767 (1255)

2806 (1273)

3049 (1383)

3097 (1405)

2930 (1329)

2961 (1343)

2972 (1348)

2996 (1359)

Forkoverhang

in inches (mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches (mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 25

0705.USA

D 10

Vehicle with 2700 kg load and 150 mm load carriage travel,

including 600 Ah battery

Drive wheel load

while moving in

fork direction

(level ground)

in lb (kg)

2390 (1084)

1962 (890)

2540 (1152)

2429 (1102)

2615 (1186)

3340 (1515)

3439 (1560)

2496 (1132)

2136 (969)

2061 (935)

2030 (921)

Drive wheel load

while moving in

drive direction

(level ground)

in lb (kg)

2610 (1184)

2183 (990)

2760 (1252)

2672 (1212)

2857 (1296)

3582 (1625)

3682 (1670)

2716 (1232)

2357 (1069)

2282 (1035)

2251 (1021)

Load axle

in lb (kg)

5492 (2491)

5959 (2703)

5423 (2460)

5276 (2393)

5130 (2327)

4647 (2108)

4597 (2085)

5670 (2572)

6060 (2749)

6146 (2788)

6202 (2813)

Drive axle

in lb (kg)

3106 (1409)

2679 (1215)

3256 (1477)

3444 (1562)

3629 (1646)

4354 (1975)

4453 (2020)

3212 (1457)

2853 (1294)

2778 (1260)

2747 (1246)

Vehicle weight

in lb (kg)

8598 (3900)

8638 (3918)

8679 (3937)

8719 (3955)

8759 (3973)

9001 (4083)

9050 (4105)

8882 (4029)

8913 (4043)

8924 (4048)

8948 (4059)

Load center

(LC)

in inches (mm)

19.7 (500)

23.6 (600)

23.6 (600)

26.9 (683)

29.9 (759)

47.9 (1216)

51.4 (1305)

41.9 (1064)

46.4 (1178)

47.2 (1200)

47.2 (1200)

Forkover-

hang

in inches

(mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches

(mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 26

D 11

0705.USA

Vehicle with 3600 kg load and 150 mm load carriage travel,

including 600 Ah battery

Drive wheel load

while moving in

fork direction

(level ground)

in lb (kg)

2745 (1245)

2178 (988)

2930 (1329)

2864 (1299)

3097 (1405)

3990 (1810)

4109 (1864)

2833 (1285)

2366 (1073)

2269 (1029)

2238 (1015)

Drive wheel load

while moving in

drive direction

(level ground)

in lb (kg)

2965 (1345)

2399 (1088)

3150 (1429)

3106 (1409)

3340 (1515)

4233 (1920)

4352 (1974)

3053 (1385)

2586 (1173)

2489 (1129)

2458 (1115)

Load axle

in lb (kg)

7121 (3230)

7727 (3505)

7017 (3183)

6825 (3096)

6631 (3008)

5981 (2713)

5911 (2681)

7317 (3319)

7815 (3545)

7923 (3594)

7978 (3619)

Drive axle

in lb (kg)

3461 (1570)

2895 (1313)

3646 (1654)

3878 (1759)

4112 (1865)

5004 (2270)

5123 (2324)

3549 (1610)

3082 (1398)

2985 (1354)

2954 (1340)

Vehicle weight

in lb (kg)

10582 (4800)

10622 (4818)

10664 (4837)

10703 (4855)

10743 (4873)

10985 (4983)

11034 (5005)

10866 (4929)

10897 (4943)

10908 (4948)

10933 (4959)

Load center

(LC)

in inches (mm)

19.7 (500)

23.6 (600)

23.6 (600)

26.9 (683)

29.9 (759)

47.9 (1216)

51.4 (1305)

41.9 (1064)

46.4 (1178)

47.2 (1200)

47.2 (1200)

Forkover-

hang

in inches

(mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches

(mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 27

0705.USA

D 12

Unladen vehicle, including 750 Ah battery

Drive wheel load

while moving

in fork direction

(level ground) in lb (kg)

1411 (640)

1526 (692)

1292 (586)

1345 (610)

1391 (631)

1314 (596)

1351 (613)

1404 (637)

1660 (753)

1647 (747)

1612 (731)

Drive wheel load

while moving

in drive direction

(level ground) in lb (kg)

1631 (740)

1746 (792)

1534 (696)

1587 (720)

1634 (741)

1590 (721)

1627 (738)

1647 (747)

1881 (853)

1867 (847)

1832 (831)

Load axle

in lb (kg)

769 (349)

694 (315)

672 (305)

659 (299)

653 (296)

666 (302)

675 (306)

763 (346)

836 (379)

860 (390)

919 (417)

Drive axle

in lb (kg)

2127 (965)

2242 (1017)

2306 (1046)

2359 (1070)

2405 (1091)

2637 (1196)

2674 (1213)

2418 (1097)

2377 (1078)

2363 (1072)

2328 (1056)

Vehicle weight

in lb (kg)

2897 (1314)

2937 (1332)

2978 (1351)

3018 (1369)

3058 (1387)

3300 (1497)

3349 (1519)

3181 (1443)

3212 (1457)

3223 (1462)

3247 (1473)

Forkoverhang

in inches (mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches (mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 28

D 13

0705.USA

Vehicle with 2700 kg load and 150 mm load carriage travel,

including 750 Ah battery

Drive wheel load

while moving in

fork direction

(level ground)

in lb (kg)

2549 (1156)

2116 (960)

2412 (1094)

2608 (1183)

2795 (1268)

3236 (1468)

3338 (1514)

2385 (1082)

2321 (1053)

2251 (1021)

2218 (1006)

Drive wheel load

while moving in

drive direction

(level ground)

in lb (kg)

2769 (1256)

2337 (1060)

2654 (1204)

2851 (1293)

3038 (1378)

3512 (1593)

3613 (1639)

2628 (1192)

2542 (1153)

2471 (1121)

2438 (1106)

Load axle

in lb (kg)

5584 (2533)

6056 (2747)

5505 (2497)

5348 (2426)

5201 (2359)

4694 (2129)

4638 (2104)

5734 (2601)

6127 (2779)

6208 (2816)

6265 (2842)

Drive axle

in lb (kg)

3265 (1481)

2833 (1285)

3426 (1554)

3622 (1643)

3810 (1728)

4559 (2068)

4661 (2114)

3399 (1542)

3038 (1378)

2967 (1346)

2934 (1331)

Vehicle weight

in lb (kg)

8849 (4014)

8889 (4032)

8931 (4051)

8970 (4069)

9010 (4087)

9253 (4197)

9301 (4219)

9134 (4143)

9164 (4157)

9176 (4162)

9200 (4173)

Load center

(LC)

in inches (mm)

19.7 (500)

23.6 (600)

23.6 (600)

26.9 (683)

29.9 (759)

47.9 (1216)

51.4 (1305)

41.9 (1064)

46.4 (1178)

47.2 (1200)

47.2 (1200)

Forkover-

hang

in inches

(mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches

(mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 29

0705.USA

D 14

Vehicle with 3600 kg load and 150 mm load carriage travel,

including 750 Ah battery

Drive wheel load

while moving in

fork direction

(level ground)

in lb (kg)

2906 (1318)

2332 (1058)

2793 (1267)

3038 (1378)

3276 (1486)

3884 (1762)

4006 (1817)

2720 (1234)

2549 (1156)

2456 (1114)

2425 (1100)

Drive wheel load

while moving in

drive direction

(level ground)

in lb (kg)

3126 (1418)

2553 (1158)

3036 (1377)

3280 (1488)

3519 (1596)

4160 (1887)

4281 (1942)

2963 (1344)

2769 (1256)

2676 (1214)

2646 (1200)

Load axle

in lb (kg)

7211 (3271)

7824 (3549)

7108 (3224)

6903 (3131)

6704 (3041)

6030 (2735)

5957 (2702)

7383 (3349)

7884 (3576)

7987 (3623)

8042 (3648)

Drive axle

in lb (kg)

3622 (1643)

3049 (1383)

3807 (1727)

4052 (1838)

4290 (1946)

5207 (2362)

5328 (2417)

3735 (1694)

3265 (1481)

3172 (1439)

3142 (1425)

Vehicle weight

in lb (kg)

10833 (4914)

10873 (4932)

10915 (4951)

10955 (4969)

10994 (4987)

11237 (5097)

11285 (5119)

11118 (5043)

11149 (5057)

11160 (5062)

11184 (5073)

Load center

(LC)

in inches (mm)

19.7 (500)

23.6 (600)

23.6 (600)

26.9 (683)

29.9 (759)

47.9 (1216)

51.4 (1305)

41.9 (1064)

46.4 (1178)

47.2 (1200)

47.2 (1200)

Forkover-

hang

in inches

(mm)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

7.3 (185)

23.3 (592)

32.3 (821)

35.3 (897)

42.3 (1075)

Fork length

in inches

(mm)

35.7 (908)

41.7 (1060)

47.8 (1213)

53.7 (1365)

59.7 (1517)

95.7 (2432)

102.8 (2610)

83.7 (2127)

92.8 (2356)

95.7 (2432)

102.8 (2610)

Page 30

D 15

0705.USA

3.4 US standards

Continuous sound pressure level at ear level:

63 db(A)

determined by the ASME test procedure defined in

ASME B56.11.5

NOTICE The continuous sound pressure level is a value determined in accordance

with the standard, taking into account the sound pressure level while driving,

lifting and at idle. The sound pressure level is measured at ear level.

Vibrations: a

w,zS

= 3.08 ft/s2 (0.94 m/s2).

NOTICE The vibration acceleration acting on the body in the operating position is the

linearly integrated, weighted acceleration in the vertical direction. It is

determined by driving over shock waves at a constant speed.

Electromagnetic compatibility (EMC)

The manufacturer confirms compliance with the limit values for electromagnetic

interference and interference resistance and electrostatic discharge testing as set out

in the table below:

Interference resistance

The following limit values apply for industrial trucks/transportation systems:

Environmental phenomenon Test value Unit

1.1 Frequency

Electromagnetic field

Amplitude modulation

27-1000 *

10

80

MHz

V/m (unmodulated, rms)

% AM (1 kHz)

1.2 Frequency

Electromagnetic field

Pulse modulation

900 ± 5

10

50

200

MHz

V/m (unmodulated, rms)

% operating cycle

Repetition frequency Hz

1.3 Electrostatic

discharge

4 contact

8 air

discharge

kV (discharge voltage)

* The frequency range has been expanded to include low-frequency

interference in the wiring.

Page 31

0705.USA

D 16

NOTICE Very strong electromagnetic fields can adversely affect the performance of

the industrial truck. In the same way, machinery that is highly sensitive to

electromagnetic fields may also be adversely affected by the industrial truck.

Be sure that emitted interference from the industrial truck cannot interfere

with the operation of adjacent machinery.

NOTICE Electrical or electronic components and their configuration may not be

modified without the prior written approval of the manufacturer.

3.5 Operating conditions

Ambient temperature:

- during operation: 41°F (+5°C) through 104°F (+40°C)

Ambient temperature measured over 24 hours:

77°F (25°C), max.

Maximum indoor humidity 70%, without condensation

NOTICE Industrial trucks intended for use in environments with temperatures below

41°F (5°C) or in refrigerated warehouses with extreme temperature or

humidity variations require special equipment and approval.

NOTICE If the vehicle is to be used for extended periods at temperatures below 32°F

(0°C), we recommend that you fill the hydraulic system with a low-viscosity

oil in accordance with the manufacturer's instructions.

Page 32

D 17

0705.USA

4 Position of signs and nameplates

NOTICE The vehicle nameplate (23) can be accessed by opening the front cover (see

Chapter F).

Item Designation

15 Sign - Qmax

16 Danger battery 2x (1x opposite)

17 Warning battery size 2x (1x opposite)

18 Warning stay clear

19 Attachment point for handling by crane

20a Warning jog button coast, left (o)

20b Warning jog button coast, right (o)

21 Nameplate, battery

22 Attachment point for jack

23 Nameplate, vehicle

24 Warning stay clear stop truck

25 Warning charger

26 Vehicle serial number

27 Warning electrical device

28 Warning coast system (o)

16

20a

20b

25

19

22

23

23

26

28

27

19

22

17

21

24

15

18

opposite

(not shown)

Page 33

0705.USA

D 18

4.1 Nameplate, vehicle

NOTICE In the event of queries about the vehicle or when ordering spare parts, please

quote the serial number (30).

Item Designation Item Designation

29 Model 37 Manufacturer

30 Serial no. 38 Battery code

31 Rated load capacity 39 Battery weight, min./max.

32 Battery voltage 40 Drive output

33 Empty weight without battery 41 Load center distance

34 Residual load capacity 42 Year of manufacture

35 Lift height, max. 43 Option

36 Manufacturer's logo

37

36

3933

4032

4131

4230

4329

38

35

34

Page 34

D 19

0705.USA

4.2 Sign - Qmax (15)

4.3 Sign - Danger battery (16)

4.4 Sign - Warning battery size (17)

Qmax

6000 lbs

Page 35

0705.USA

D 20

4.5 Sign - Warning stay clear (18)

4.6 Sign - Warning jog button coast, left (20a) (o)

4.7 Sign - Warning jog button coast, right (20b) (o)

Page 36

D 21

0705.USA

4.8 Sign - Warning stay clear stop truck (24)

4.9 Sign - Warning charger (25)

Page 37

0705.USA

D 22

4.10 Sign - Warning electrical device (27)

4.11 Sign - Warning coast system (28) (o)

Page 38

E 1

0705.USA

E Operation

1 Description of controls and indicators

Item Control or indicator

Function

1 Switch latch t Switches the control current on and off. Remove

the key to prevent the vehicle being switched on by

unauthorized persons.

2 Discharge indicator (EA) t Displays the battery capacity

3 Information display (CANDIS) o Operating hours indicator

Shows the residual battery capacity and the

number of operating hours already completed by

the vehicle

4 Keypad (CANCODE) o Code settings, access authorization

Travel program enabling

5 Access module ISM o Starts/switches off the vehicle.

Displays important information, prompts, shock

events, and error messages.

Sets date and time.

6 Tiller t Swiveling tiller; steering and braking

7 Jog button o Travel switch for travel in tiller direction. Coasting

at 5.6 km/h (3.5 mph).

8 Travel regulator t Controls the direction of travel and speed (see

Section 4.2).

9 "Down" rocker switch t Lowers the fork.

10 "Up" rocker switch t Raises the fork.

11 Anti-collision button t Safety function. Automatically moves the vehicle

for approximately 3 s in the direction of travel (R)

and then switches it off until the travel regulator is

moved briefly to neutral.

12 Warning signal button (horn) t Sounds the warning signal.

13 Tiller locking lever o Locks the tiller in the travel position.

14 Jog button o Travel switch for travel in tiller direction. Coasting

at 5.6 km/h (3.5 mph).

15 Brake button o Brakes the vehicle mechanically.

16 High-speed button t Moves the vehicle in ride-on mode at 15 km/h,

max. (9.3 mph) in the tiller direction or 9.0 km/h,

max. (5.6 mph) in the fork direction.

t = Fitted as standard o = Optional extra

Page 39

0705.USA

E 2

12

12

16

16

10

17

9

18

10 11 10

99

88

77

12

6

2, 3 4, 5 1

141315

19

14 15

R

Page 40

E 3

0705.USA

Item Control or indicator

Function

17 Coast LED o Flashes:

– when a jog button is pressed and the vehicle is

coasting.

Lights up:

– when the battery capacity is down between 30%

and 0% with a standard battery.

– when the battery capacity is down between 40%

and 0% with a maintenance-free battery.

18 Jog button o Travel switch for travel in tiller direction. Coasting

at 5.6 km/h (3.5 mph).

19 Battery connector

(EMERGENCY STOP)

t The electric circuit is broken, all electrical functions

switch off and the vehicle brakes are automatically

applied.

t = Fitted as standard o = Optional extra

Page 41

0705.USA

E 4

12

12

16

16

10

17

9

18

10 11 10

99

88

77

12

6

2, 3 4, 5 1

141315

19

14 15

R

Page 42

E 5

0705.USA

2 Starting the vehicle

QwW Before the vehicle can be started, operated or used to lift a load unit, the

driver must ensure that there is nobody in the danger zone.

Daily checks and actions before startup

– Visually inspect the entire vehicle (especially wheels and load-handling equipment)

for signs of damage.

– Check for steering play.

– Visually inspect the battery fixings and cable connections.

2.1 Preparing for operation

– Insert the key in the switch latch (1) and turn it clockwise to the "I" position.

Or:

– On vehicles without a switch latch, enter the enable code via the CANCODE (4, o).

On delivery, the CANCODE start PIN is factory set to 2580. Enter the code via the

keypad and press the Set button to confirm.

– Check that the warning signal (horn) (12) is working correctly.

The vehicle is now ready for use. The discharge indicator (EA) (2) shows the charge

level of the battery.

On vehicles with an information display (CANDIS) (3, o), the remaining battery

capacity is displayed.

2, 312 12 4, 5

1

Page 43

0705.USA

E 6

2.2 Driving, steering, braking

QwW Extra care must be taken when driving and steering, especially outside the

perimeter of the vehicle.

In ride-on mode, keep an adequate distance from the vehicle.

Emergency stop

– Pull out the battery connector (19).

All electrical functions are switched off. The magnetic brake is applied and brakes the

vehicle with the highest brake step.

Driving

IMPORTANT Do not drive the vehicle unless all covers are closed and properly locked.

The main direction of travel is travel in the tiller direction (V). Extra care must

be taken when traveling in the load direction (R).

NOTICE Travel in the load direction (R) should be limited to shunting and to picking up

and setting down loads.

– Prepare for operation (see Section 2.1).

– Move the tiller (6) in the travel range "F".

– Turn the travel regulator (8) in the desired direction of travel (forward (V) or

backward (R)).

The vehicle starts moving in the chosen direction. The speed of travel is controlled

with the travel regulator (8). The maximum speed is 5.6 km/h (3.5 mph). If the highspeed button (16) is held down (t) in ride-on mode, the maximum speed of travel is

15 km/h (9.3 mph) in the tiller direction (V) and 9 km/h (5.6 mph) in the fork direction

(R).

R

R

V

8

6

13

19

16

F

V

B

B

Page 44

E 7

0705.USA

Press the high-speed button and release (o, parameter setting): If the high-speed

button (16) is pressed and released in ride-on mode, the maximum speed of travel is

15 km/h (9.3 mph) in the tiller direction (V) and 9 km/h (5.6 mph) in the fork direction

(R). If the travel regulator (8) is reset and the speed of travel drops to 0, high-speed

travel is deactivated. The maximum vehicle speed is then reset to 5.6 km/h (3.5 mph)

and the high-speed button must be pressed again.

Maneuvering in tight spaces (t): If there is no room to move the tiller in the travel

range "F" in order to start the vehicle (vehicle with tiller against obstacle), press the

high-speed button (16) and move the travel regulator (8) at the same time. The

vehicle starts to move at creep speed.

Steering

QwW In tight bends the driver is standing over the outer perimeter of the vehicle.

– Move the tiller (6) to the left or right.

Braking

QwW The vehicle's braking response largely depends on the travel surface

conditions. The driver should adapt his or her driving style accordingly.

The vehicle can be braked in three ways:

– With the service brake (brake for emergencies and hazardous situations)

– With the plug brake

– With the coasting brake

Braking with the service brake:

IMPORTANT Use this brake in an emergency or hazardous situation.

– Move the tiller (6) to one of the braking ranges (B).

The travel motor is braked with the motor brake. In borderline cases the magnetic

brake is automatically applied.

When the vehicle is stationary, the magnetic brake acts as a parking brake.

IMPORTANT If the tiller is released, it moves to the upper braking range (B).

Vehicle with locking tiller (13, o):

– Move the tiller to the lower or upper braking range B (the lock is released if the tiller

is moved toward the upper braking range B).

Page 45

0705.USA

E 8

Braking with the plug brake:

– Turn the travel regulator (8) in the opposite direction of travel until the vehicle is

stationary.

The vehicle is braked by reversal. When the vehicle is stationary, the magnetic brake

is applied.

Braking with the coasting brake

– Release the travel regulator or move it to the 0 position. The vehicle is braked

regeneratively until it is stationary. When the vehicle is stationary, the magnetic

brake is applied.

NOTICE The braking force is adjustable (parameter setting)

R

R

V

8

6

13

19

16

F

V

B

B

Page 46

E 9

0705.USA

Traveling with the jog button (7, o / 14, o / 18 o)

QwW Extra care must be taken when driving and steering, especially outside the

perimeter of the vehicle.

In ride-on mode, keep an adequate distance from the vehicle.

Vehicle tiller without locking lever with coasting brake (o)

– Move the tiller to the travel position (F).

– Press the jog button (7, o).

The vehicle starts moving at 5.6 km/h (3.5 mph), max., in the direction of travel V (with

button 14,

o only if the tiller is in the upright position).

– Release the jog button (7, o).

NOTICE The coasting brake is applied when you release the JOG button.

V

7

14

15

18

15

14

F

8

B

B

Page 47

0705.USA

E 10

Vehicle tiller with locking lever (13, o)

NOTICE In ride-on mode or order picking mode the tiller can be locked in the travel

position with the locking lever (13).

– Pull the tiller locking lever (13) up.

– Move the tiller down until it locks.

– When the tiller is locked, the vehicle is in coasting mode.

– Press the jog button (7, o / 14, o).

The vehicle starts moving in the direction of travel V at 5.6 km/h (3.5 mph), max.

– Release the jog button (7, o / 14, o).

The vehicle coasts for a predefined distance and is then braked automatically.

To brake the vehicle during coasting:

– Move the tiller to the lower or upper braking range B (the lock is released if the tiller

is moved toward the upper braking range B)

or

– Press the brake button (15, o)

NOTICE The LED (17) flashes when the vehicle is in coasting mode.

V

7

13

14

15

15

14

F

B

B

Page 48

E 11

0705.USA

Vehicle tiller without locking lever in coasting mode (o)

NOTICE To activate the coasting brake for the first time, move the tiller to the travel

position and press the JOG button.

– Press the jog button (7, o / 14, o / 18, o).

The vehicle starts moving at 5.6 km/h (3.5 mph), max., in the direction of travel V (with

button 14, o only if the tiller is in the upright position).

– Release the jog button (7,

o / 14, o / 18, o).

The vehicle coasts for a predefined distance (configurable) and is then braked

automatically.

V

7

14

15

18

15

14

F

8

B

B

Page 49

0705.USA

E 12

Z

Once the JOG button has been pressed, coasting mode remains active for a

predefined period. To activate coasting mode again, move the tiller to the travel

position again and press the JOG button.

QwW If the tiller is released in the upper braking range B, the vehicle is not braked.

To brake the vehicle during coasting:

– Move the tiller to the lower braking range B

or

– Press the brake button (15, o)

or

– Turn the twist handle

or

– Press the anti-collision button.

NOTICE The LED (17) flashes when the vehicle is in coasting mode. Deactivated by

turning the twist handle (8) or when the predefined time is over.

Page 50

E 13

0705.USA

2.3 Raising and lowering load units

IMPORTANT Before lifting a load unit, the driver must be sure that it is palleted correctly

and does not exceed the permitted load capacity of the vehicle.

– Move the vehicle's fork arms as far as possible under the load unit. Long goods

must not be picked up transversely.

IMPORTANT The load unit must be picked up so that it does not project significantly

(< 2 inches (50 mm)) beyond the tips of the fork arms.

Raising and lowering

NOTICE The fork is raised or lowered at a predefined speed by pressing the "Up" or

"Down" buttons.

Raise

– Press the "Up" rocker switch (9). Hold down the rocker switch until the lift height is

reached.

Lower

– Press the "Down" rocker switch (8) to lower the fork.

98

9 8

Page 51

0705.USA

E 14

2.4 Switching off and securing the vehicle

When the vehicle is left, even for a short time, it must be switched off and secured.

QwW Do not park the vehicle on a slope.

– Lower the fork completely.

– On vehicles with a locking tiller (13, o), push the tiller into the upper braking range

B (this releases the lock).

– Turn the switch latch (1) to position "0" and remove the key.

2.5 Adjusting the fork height

IMPORTANT In the event of wear on the drive

wheel or support rollers, the fork

base height or fork tip height

must be adjusted. This is

necessary to ensure that the

fork can still be moved easily

into and out of pallets.

The fork base height is adjusted with a

bolt and counter nut located between the

load frame and drive frame (20) on both

sides.

The fork tip height is adjusted with the pull rod adjusting nuts (21).

IMPORTANT These adjustments may only be made by authorized and appropriately

trained employees.

113

21

20

Page 52

E 15

0705.USA

3 Important general aspects affecting the safe use of the truck

3.1 Training, certification, and approval to use the truck

Driver's permit: Powered industrial trucks may only be used by people who have

been trained to operate powered industrial trucks in accordance with 29 CFR

1910.178, who have demonstrated to the owner or his or her representative their

competence to move and transport loads, and who have been expressly authorized

by the owner or his or her representative to operate powered industrial trucks.

The operator must be sufficiently capable, both physically and mentally and in terms

of eyesight and hearing, to operate the industrial truck safely.

Prohibition of unauthorized use: During his or her working hours, the operator is

responsible for the industrial truck. He or she must prohibit unauthorized people from

driving or operating the industrial truck.

Operator training: Employees who have not been trained to use a powered

industrial truck may drive an industrial truck for training purposes only and only under

the direct supervision of an instructor. This training should be carried out in an open

area away from other industrial trucks, obstacles and pedestrians.

The operator training program should deal with the documented Operating Manual

and the manufacturer's procedures, the employer's regulations for the site at which

the trainee is to use the industrial truck, and the working conditions prevailing at this

site, together with the special features of the industrial truck to be operated by the

trainee. All new operators must complete the training program, regardless of their

previous experience.

The training program provides for the following:

– The careful selection of operators, taking account of their physical suitability, their

personal approach to their work and their aptitude.

– The significance of safety for operators, storage areas, sites, and for other

employees, including mention of all safety provisions and their meaning.

– General principles of powered industrial trucks and components in terms of safety,

in other words loading, mechanical limitations, stability, braking power, etc.

– Introduction to the equipment, the position and function of the controls, explanation

of the mode of operation when used correctly, and reference to problems when

used incorrectly.

– Supervised practical exercises simulating the actual day-to-day tasks to be carried

out by the operator, including loading, etc.

– Refresher courses as a condensed version of the main course, and periodic

assessment of the operator "in action".

Page 53

0705.USA

E 16

The principal duty of the operator is the safe operation of the powered industrial truck

in accordance with the instructions covered in the training program.

Failure to observe the safety regulations when operating the industrial truck or

improper use or maintenance of a powered industrial truck can have the following

consequences:

– Death or serious injury to the operator or to other people;

– Damage to the industrial truck or to other property.

The training program should focus on the safe and appropriate use of the industrial

truck, with the goal of preventing injury to the operator or to other people and property

damage. To this end the following topics should be covered:

1. General information about the industrial truck(s) to be operated by the trainee,

including:

– Technical data on the powered industrial truck, including differences between

industrial trucks used in the area of work;

– Differences in comparison to a car;

– Meaning of the information on the nameplate, including rated load capacity,

warnings and instructions attached to the industrial truck;

– Operating instructions and warnings set out in the Operating Manual for the

industrial truck, together with inspection and maintenance instructions to be

followed by the operator;

– Type of drive motor and its features;

– Type of steering;

– Braking response and braking distance, laden and unladen;

– Visibility to front and rear, laden and unladen;

– Load capacity when handling loads, weight and load center distance;

– Stability characteristics, laden and unladen, and with and without attachments;

– Position of controls, function, operation, recognition of symbols;

– Possible load-handling equipment, attachments; transport of loads;

– Filling and charging the battery;

– Safety devices and barriers for certain types of industrial truck;

– Other features of a particular industrial truck;

2. The operating environment and its influence on the operation of the industrial

truck, including:

– Floor surface and nature of the sub-floor, including temporary conditions;

– Equipment for filling and charging the battery;

– Use of "classified" industrial trucks in areas presenting a risk of fire or explosion

as defined in ANSI/NFPA 505.

– Narrow gangways, doors, overhead cables and pipe systems, and other

enclosed areas;

– Areas in which the industrial truck may possibly be operated alongside other

powered industrial trucks, vehicles or pedestrians;

– Use and load capacity of elevators;

– Other special operating conditions and hazards, which the operator could

encounter.

Page 54