Page 1

Ergonomic order picking

with lifting load section

Easy handling with JetPilot

steering wheel system

Optimum energy utilisation

through maintenance-free

3-phase AC drive motor

Curve control automatically

reduces speed when

cornering (optional)

Second level picking

using lifting stand-on

platform (optional)

ECE 310

Horizontal order pickers with lifting load section (1,000 kg)

The Jungheinrich ECE 310 horizontal

order picker is particularly suitable for

applications where the ergonomic

depositing of goods on the pallet is also

of importance as well as the time/cost

optimisation.

Its excellent technical performance is

underpinned by a 24 V drive motor with

3-phase AC technology. The advantages:

Powerful acceleration and high maximum speed. Considerable energy saving,

prolonged operating time and low maintenance all at the same time (through

omission of carbon brushes). This is due

to the optimised eciency, the technical

relationship between the drive motor

and drive electronic control as well as

regenerative braking.

The immediate proximity of operator

to load and the fixed stand-on platform

are the pivotal points for rapid, safe and

ecient order picking. The load section

with a capacity of 1000 kg can be raised

up to 700 mm, so that the operator is

able to deposit the load comfortably at

the ‘correct’ height. The lifting stand-on

platform (optional) facilitates comfortable order picking even at the second

racking level.

Dependent on the application require-

ment, the ECE can be equipped with two

dierent steering choices: The steering

wheel (JetPilot) and the tiller steering

(optional).

The advantages of the JetPilot steering

wheel: Intuitive controls plus safe and

secure grip, similar to a car, provide

first-class operator comfort. No twisting

of the body when cornering (thereby

lessening the strain on the neck and

spinal column). One-handed operation

and automatic adjustment to straight line

travel on return of the steering wheel.

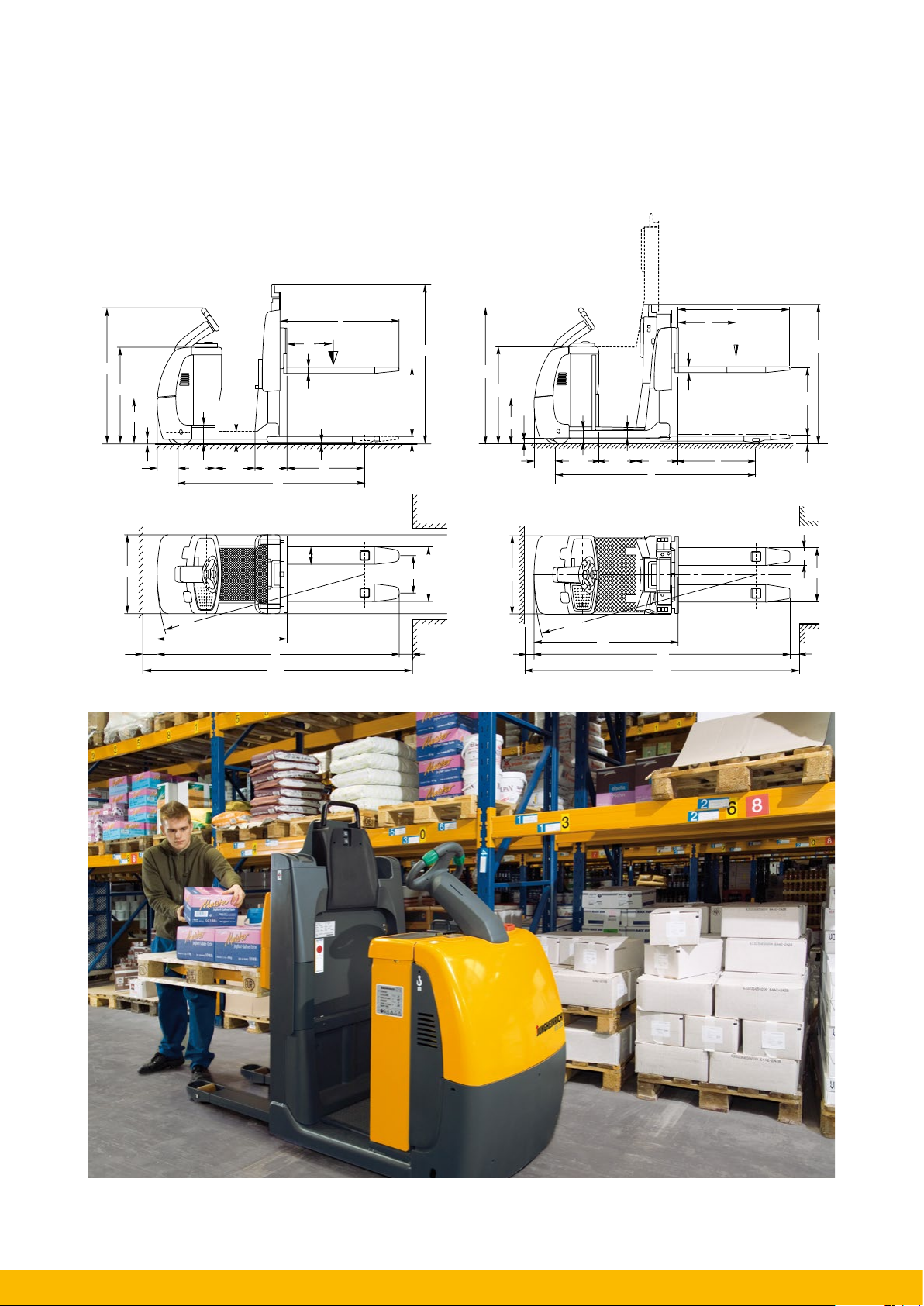

Page 2

ECE 310

ECE 310

1399

1009

175

474

50

218 257380 412 x

b

1

132

Wa

l

a

2

2

Ast

ECE 310 HP

l

c

Q

1635

l

c

Q

1434

1399

s

h

3

1010

15017550

s

h

3

474

m

2

y

e

h

b11b

13

445 390 437

218

y

x

h

13

e

b

5

1

b

5

Wa

l

l

1

a

2

a

2

2

l

1

Ast

a

2

Page 3

Issue: 01/2008

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ECE 310 ECE 310 HP

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation order picker

1.5 Load capacity/rated load Q t 1

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 800

1.9 Wheelbase y mm 1920 2070

2.1.1 Net weight incl. battery (see row 6.5) kg 1614 1716

2.2 Axle load, w. load, front / rear kg 1296 / 956 1324 / 1020

2.3 Axle load, w.o. load, front / rear kg 372 / 872 420 / 926

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 230 x 78

3.3 Tyre size, at rear mm Ø 85 x 95

3.4 Additional wheels (dimensions) mm Ø 180 x 65

3.5 Wheels, number front/rear (× = driven wheels) 2-1x/2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

4.4 Lift h3 mm 700

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 60 / 180 / 1150

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m

Basic dimensions

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2985 3140

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2911 3066

4.35 Turning radius W

5.1 Travel speed, w. / w.o. load km/h 9.5 / 12.5

5.2 Lift speed, w. / w.o. load m/s 0.08 / 0.11

5.3 Lower speed, w. / w.o. load m/s 0.12 / 0.05

data

5.8 Max. gradeability, laden/unladen % 6 / 15

Performance

5.10 Service brake electro-magnetic

6.1 Drive motor rating S2 60 min. kW 2.8

6.2 Lift motor rating at S3 15% kW 1.5

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 465

Electrics

6.5 Battery weight kg 370

8.1 Type of drive control AC SpeedControl

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 67

Misc.

mm 500

10

mm 380

11

mm 1399

14

mm 90

13

mm 2491 2641

1

mm 1341 1491

2

mm 810

1/b2

mm 560

5

mm 25

2

mm 2145 2300

a

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

ECE 310 with lifting stand-on platform (HP)

JetPilot – exclusive from

Jungheinrich

Innovative 3-phase AC technology

Jungheinrich motors in 3-phase AC

technology provide you with more performance eciency and reduce your

operating costs at the same time. Make

the most of these advantages:

• High degree of eciency with excellent energy management.

• Powerful acceleration.

• Rapid change in direction of travel.

• No carbon brushes – maintenancefree drive motor.

• Two-year warranty on the drive motor.

Comfortable travel

The SpeedControl impulse control

system facilitates comfortable, safe travel

with adjustment options for every application:

• The speed stipulated on the travel

switch will be maintained in every

travel situation – even on uphill and

downhill gradients.

• 3 adjustable travel programs for individual adjustment to any requirements.

• Regenerative braking with energy recovery when slowing down.

Rugged construction for the toughest

applications

• Frame made from high-grade, 8-mm

steel sheet.

• Extra-high frame apron on front cover.

Comfortable and safe order picking

The hydraulic lifting stand-on platform (optional) oers the best solution

for frequent replenishment and order

picking from the second rack level:

• Fast and safe lifting of the operator up

to battery cover height.

• Comfortable operation of the platform

via a foot switch. This keeps the operator’s hands free for order picking.

• High degree of order picking eciency

due to immediate proximity of operator

to load.

Fully informed at all times

Extensive display provides a complete

overview:

• CanDis (optional) provides information

on the battery discharge status,

number of operating hours and fault

codes.

• Activation of truck via PIN and selection of 3 travel programs via keypad

(optional).

• Adjustable travel parameters via CanDis

and CanCode (optional).

Individual steering

Dierent steering concepts facilitate

tailor-made application:

• JetPilot electric steering wheel. In the

options packages with lifting operator

platform, the JetPilot can also be raised

(both optional).

• Electric tiller steering (optional).

• Suitable for all steering: Jungheinrich

Curve Control (optional). Automatic

speed reduction dependent on steering

angle when cornering.

Additional equipment

Extensive accessories for individual

tailoring to your requirements:

• Pedestrian operation from both sides

via a button in the backrest.

• A variety of backrest designs.

• Additional steel and/or rubber rear protection bumper.

• Various accessories for order picking

from second racking level.

• Holder for radio data components.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ECE 310_042014_en_UK_000

Loading...

Loading...