Page 1

High energy eciency with

maintenance-free AC drive

motor

High-performance version for

maximum throughput

Easy handling with JetPilot

electric steering wheel

Wide range of accessories

2nd level picking using lifting

stand-on platform (optional)

ECE 220/225

Horizontal order picker (2,500 kg)

Through a combination of the latest

technology and numerous ergonomic

advantages, the Jungheinrich ECE 220

/ 225 optimise both cost and speed of

order picking.

Its excellent technical performance is

underpinned by a 24 V drive motor with

3-phase AC technology. Its advantages:

Powerful acceleration and high top

speed. Combined with significant energy

savings, extended operating times and

minimised maintenance (due to the

omission of carbon brushes). This is due

to the optimised eciency, the relationship between the drive motor and drive

electronic control as well as regenerative

braking.

There are also ergonomic advantages

for the operator/machine/load interface:

The immediate proximity of the operator

to the load and the stand-on platform is

key to safe and ecient order picking.

The lifting stand-on platform (optional)

facilitates comfortable order picking even

at the second racking level.

The ECE oers a choice of two different electric steering systems: Tiller

steering or the JetPilot steering wheel.

The advantages of tiller steering:

Eortless steering with only 60° tiller

angle required for a 90° steering angle.

The operator and tiller always remain

safely within the truck contours. The advantages of the JetPilot steering wheel:

Intuitive controls plus safe and secure

grip, similar to a car, provides first-class

operator comfort. No twisting of the

body when cornering (thus lessening the

strain on the neck and spinal column).

One-handed operation and automatic

adjustment to straight line travel on

return of the steering wheel.

With its high drive performance and

ergonomically optimised operator workplace, the ECE is always ahead of the

pack, even in the most demanding of

conditions.

Page 2

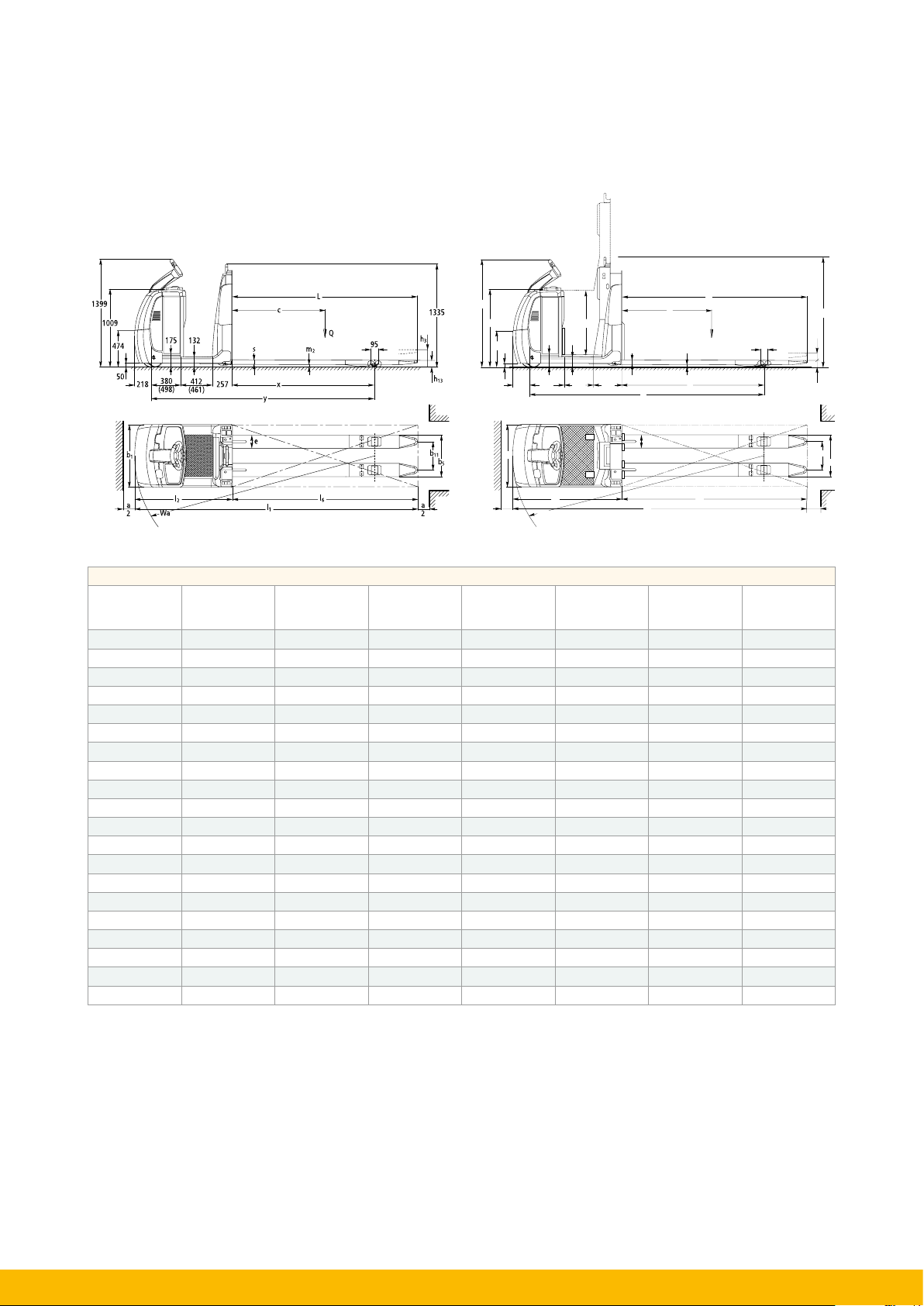

ECE 220/225

1399

ECE 225

Values in brackets apply to XL

ECE 225

1009

474

50

218 450 383 365 x

b

1

a

2

175 150

l

2

Wa

840

HP = Hydraulic lifting platform

L

c

Q

s

m

2

y

e

l

l

1

6

Fork length-dependent dimensions

Fork length

l

(mm)

Fork overhang

(mm)

Capacity

Q

(t)

Overall length

l

1

(mm)

1)

Wheelbase

y

(mm)

Turning radius

Wa

(mm)

Load distance

x

(mm)

1000 186 2.0 2267 1863 2081 814 2467

1150 186 2.0 2417 2013 2231 964 2667

1250 186 2.0 2517 2113 2331 1064 2717

1400 186 2.5 2667 2263 2481 1214 2867

1400 560 2.0 2667 1891 2109 842 2867

1450 560 2.0 2717 1941 2159 892 2917

1600 186 2.5 2867 2463 2681 1414 3067

1600 560 2.0 2867 2091 2309 1042 3067

1880 560 2.5 3147 2371 2589 1322 3347

1950 560 2.5 3217 2441 2659 1392 3467

2180 800 2.5 3447 2429 2647 1380 3647

2280 800 2.5 3547 2529 2747 1482 3747

2310 186 2.5 3577 3173 3391 2124 3797

2400 560 2.5 3667 2889 3107 1480 3867

2400 800 2.5 3667 2649 2867 1600 3867

2430 900 2.5 3697 2597 2797 1530 3905

2550 800 2.5 3817 2799 3017 1750 4017

2850 800 2.5 4117 3099 3317 2050 4317

2900 800 2.5 4167 3149 3367 2100 4367

3100 800 2.5 4367 3349 3567 2300 4567

1)

ECE 220/225 XL: Values + 167 mm; ECE 220/225 HP: Values + 150 mm

2)

With raised load section = values - 89 mm

95

h

h

13

Working aisle

width

Ast

1433

3

a

2

b

11

b

5

Page 3

Issue: 09/2011

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model ECE 225

Standard XL HP

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation order picker

1.5 Load capacity/rated load Q t 2.5

Identification

1.6 Load centre distance c mm 1200

1.8 Load distance x mm 1600

1.9 Wheelbase y mm 2649

2)

2.1.1 Net weight incl. battery (see row 6.5) kg 1114 1215 1270

2.2 Axle load, w. load, front / rear kg 1173 / 2441 1233 / 2842 1465 / 2305

2.3 Axle load, w.o. load, front / rear kg 853 / 261 933 / 282 970 / 300

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 230 x 77

3.3 Tyre size, at rear mm Ø 85 x 85

3.4 Additional wheels (dimensions) mm Ø 180 x 65

3.5 Wheels, number front/rear (× = driven wheels) 1+1x/4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 485

10

mm 338 / 368 / 498

11

4.2.1 Total height h15 mm

4.4 Lift h

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

mm 125

3

mm 1399

14

mm 90

13

mm 3667 3834 3817

1

mm 1267 1434 1417

2

mm 810

1/b2

4.22 Fork dimensions s/e/l mm 60 / 172 / 2400

Basic dimensions

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 3867

mm 510 / 540

5

mm 30

2

1)

4.35 Turning radius Wa mm 2867 3034 3017

5.1 Travel speed, w. / w.o. load km/h 9.5 / 12.5 9.3 / 12.3 9.5 / 12.5

5.2 Lift speed, w. / w.o. load m/s 0.06 / 0.07

5.3 Lower speed, w. / w.o. load m/s 0.06 / 0.05

data

5.8 Max. gradeability, laden/unladen % 6 / 15

Performance

5.10 Service brake generated

6.1 Drive motor rating S2 60 min. kW 2.8

6.2 Lift motor rating at S3 10% kW 1.5

6.3 Battery according to DIN 43531/35/36 A,B,C, no no

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 465 24 / 620 24 / 465

6.5 Battery weight kg 370 450 370

Electrics

6.6 Energy consumption according to VDI cycle kWh/h 0.59 0.61 0.59

6.7 Throughput eciency t/h 161 163

6.8 Energy consumption at max. throughput kWh/h 0.64 0.65

8.1 Type of drive control AC SpeedControl

8.4

Misc.

Sound pressure level at operator’s ear according to EN

12053

dB (A) 67

2816

4034

2)

1)

2799

4017

2)

1)

1)

Diagonal travel according VDI: + 94 mm

2)

Load section lowered: 90 mm

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Comfortable operation and fast

order picking

Order picking from the second

rack-level

Innovative 3-phase AC technology

Better performance coupled with

reduced operating costs. Make the most

of these advantages:

• High eciency levels with excellent

energy management.

• Rapid acceleration for high productivity.

• Rapid change in direction of travel.

• No carbon brushes - maintenance-free

drive motor.

• Two-year warranty on the drive motor.

Travel in comfort

The Speed Control impulse control

system facilitates comfortable, safe travel

with adjustable options for every application:

• The speed set by the drive switch is

maintained under all travel conditions

– even on gradients / descents.

• 3 adjustable travel programmes for

individual adjustment of any requirement.

• Regenerative braking with energy recovery when slowing down.

Rugged construction for the hardest

applications

• Chassis manufactured from high

quality steel.

• Extra-high wrap around chassis apron

on front cover.

JetPilot – exclusive from Jungheinrich

• Tension proof fork sections with strong

pull rods – no bending even with heavy

loads and long forks.

• Carrying capacity 2.5 tonnes for up to

3 pallets simultaneously.

Comfortable and safe order picking

The hydraulic lifting stand-on platform

(optional) oers the best basis for frequent replenishment and order picking

from the second rack level:

• Safe and fast raising and lowering of

the operator, up to the height of the

battery cover.

• Comfortable operation of the platform

by a foot-controlled button. This keeps

the operator’s hands free for order

picking.

• High order picking eciency through

immediate proximity of operator to

load.

• The Jet -Pilot can be raised together

with the platform, allowing for positioning of the truck even with a raised

platform (optional).

Long operating times

Energy-ecient 3-phase AC technology

and high battery capacities allow for long

operating times:

• Standard version: Battery 3 PzS 465 Ah.

• High-performance XL version: Battery

4 PzS 465 / 620 Ah

• Lateral battery exchange (optional) for

multi-shift use

Always informed

Extensive display provides a complete

overview:

• CanDis (optional) informs of battery

state of charge, operational hours and

fault codes.

• Activation of the truck using a PIN

and a choice of 3 travel programme

settings by keypad (optional).

• Programmable travel parameters by

CanDis and CanCode (optional).

Individual steering

Dierent steering concepts to facilitate a

tailor-made application:

• Electric tiller steering with productive

steering ratio.

• Electric steering wheel with Jet- Pilot.

• Curve Control (optional): Maximum

safety with automatic travel speed

reduction when cornering.

Additional accessories

An extensive range of accessories allow

individual adjustment to your application:

• Edging buttons located in the backrest

on both sides of the truck for pedestrian edging operations.

• A variety of backrest designs

• Extra collision protection from steel or

rubber.

• Additional accessories for working at

the second rack-level.

• Holder for radio data transmission

equipment.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_ECE 220/225_012014_en_UK_000

Loading...

Loading...