Page 1

Quality engineering - Made

in Germany: functional,

robust and reliable

Jungheinrich drive axle

and maintenance-free

wet-disc brakes with

electric parking brake

High visibility in all directions

due to unique ‘vision

window’ mast design

Truck design concept giving

high productivity with

low fuel consumption and

high dynamic stability

Rugged Kubota industrial

engines with high

torque at low revs

4 point cushion mounted drive

train giving a low-vibration

operators cab area

DFG/TFG 425/430/435

Diesel and LPG forklifts with hydrodynamic drive

(Torque Converter) (2,500/3,000/3,500 kg)

Our robust torque converter counterbalance trucks give you high productivity

coupled with high reliability in all applications. The simple design of the torque

converter drive train allows it to be used

in a wide range of rugged and industrial operations; in addition it provides

smooth power take up whilst accelerating, producing optimum eciency at all

speeds.

The rugged Kubota engines have been

tried and tested throughout the world

in harsh environments, including high

and low temperatures, high humidity

and tough terrains, returning optimum

reliability.

Giving the strong benefit of lower fuel

consumption and minimal noise. These

robust engines are specifically designed

for use in fork lift trucks. Giving you outstanding reliability and a long service life.

High levels of eciency are delivered

through the Jungheinrich drive axle with

integrated, maintenance free wet-disc

brakes. Eliminating unnecessary costs

associated with brake wear and lowering

overall lifetime costs. The enclosed design of the braking system helps protect

it by eliminating ingress of water or dust,

which is typical in harsh conditions.

The operators cab is designed with the

operator in mind.

The visibility in all directions is class leading enhancing all round safety, resulting

in a safe and productive driver maximising throughput throughout the shift.

Due to the unique Jungheinrich counterweight design, the centre of gravity

is both low and centred between both

front and rear the axles. This results in

best in class dynamic stability and driving

safety without unnecessary external

electronic stability systems.

Page 2

DFG/TFG 425/430/435

kg

3500

3000

2500

2000

1500

1000

Capacity

DFG/TFG 435

DFG/TFG 430

DFG/TFG 425

Load centre distance “c” in mm

Page 3

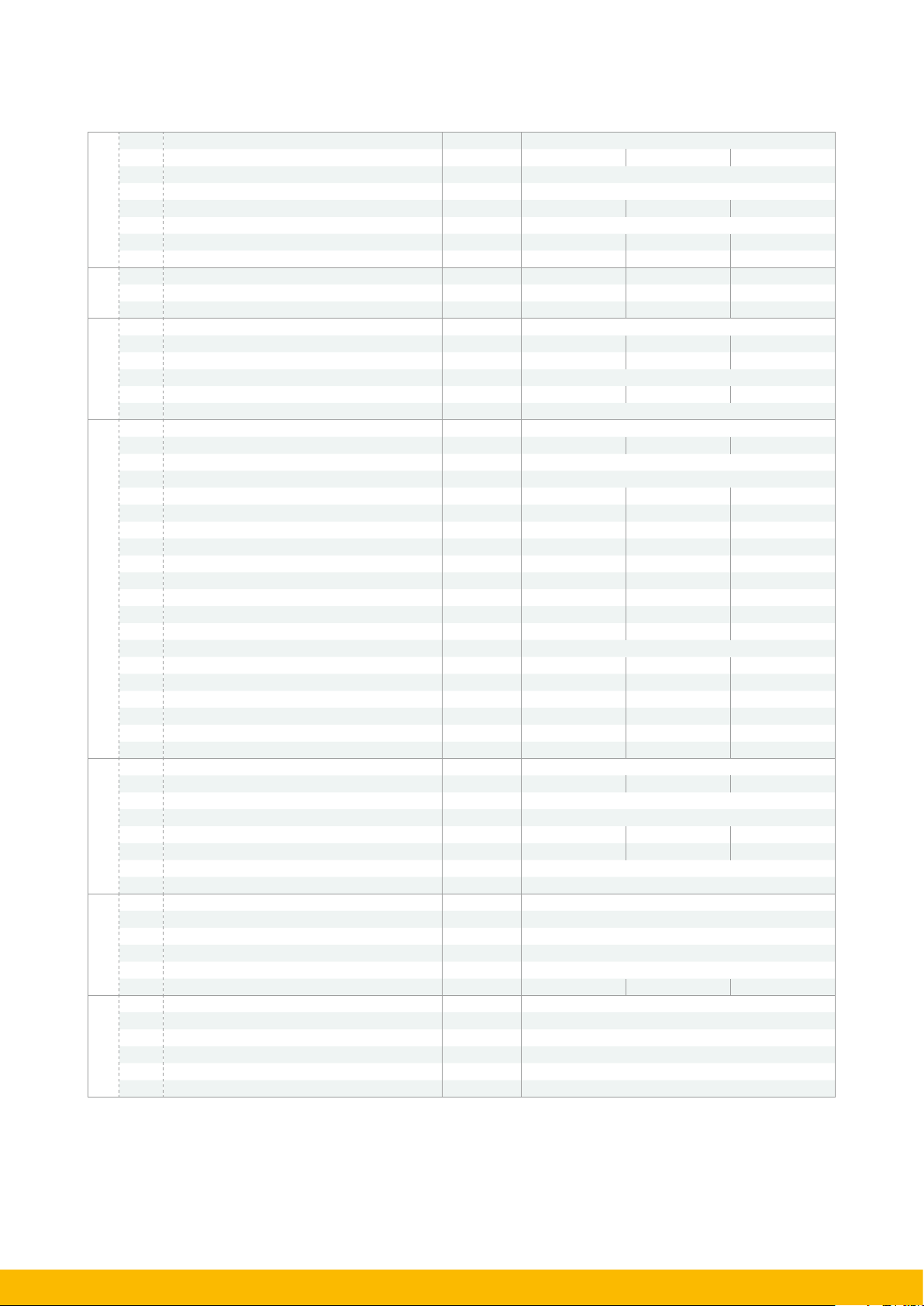

DFG/TFG 425/430/435

Standard mast types DFG 425/DFG 430/DFG 435/TFG 425/TFG 430/TFG 435

Lowered mast height

DFG 425 /

TFG 425

DFG 430 /

TFG 430

h

1

DFG 435 /

TFG 435

DFG 425 /

TFG 425

Duplex ZT

Duplex ZZ

Triplex DZ

Lift

h

3

(mm) (mm) (mm) (mm) (°)

2900 2129 2122 2201 150 150 150 3502 3659 3689 6/8 6/8

3100 2229 2222 2301 150 150 150 3702 3859 3889 6/8 6/8

3300 2329 2322 2401 150 150 150 3902 4059 4089 6/8 6/8

3500 2429 2422 2501 150 150 150 4102 4259 4289 6/8 6/8

3700 2529 2522 2601 150 150 150 4302 4459 4489 6/8 6/8

4000 2679 2672 2751 150 150 150 4602 4759 4789 6/8 6/8

4300 2879 2872 2951 150 150 150 4902 5059 5089 6/8 6/8

4500 2979 2972 3051 150 150 150 5102 5259 5289 6/8 6/6

3100 2194 2187 2266 1614 1448 1497 3680 3839 3869 6/8 6/8

3300 2294 2287 2366 1714 1548 1597 3880 4039 4069 6/8 6/8

3500 2394 2387 2466 1814 1648 1697 4080 4239 4269 6/8 6/8

3700 2494 2487 2566 1914 1748 1797 4280 4439 4469 6/8 6/8

4000 2644 2637 2716 2064 1898 1947 4580 4739 4769 6/8 6/8

4400 2094 2087 2166 1514 1348 1397 4980 5139 5169 6/8 6/6

4700 2194 2187 2266 1614 1448 1497 5280 5439 5469 6/6 6/6

5000 2294 2287 2366 1714 1548 1597 5580 5739 5769 6/6 6/6

5500 2494 2487 2566 1914 1748 1797 6080 6239 6269 6/6 6/6

6000 2694 2687 2766 2114 1948 1997 6580 6739 6769 6/6 6/6

6500 2894 2887 2966 2314 2148 2197 7080 7239 7269 6/6 6/6

7000 3094 3087 3166 2514 2348 2397 7580 7739 7769 6/6 6/6

7500 3294 3287 3366 2714 2548 2597 8080 8237 8269 6/6 6/6

Free lift

h

2

DFG 430 /

TFG 430

DFG 435 /

TFG 435

Extended mast height

DFG 425 /

TFG 425

DFG 430 /

TFG 430

h

4

DFG 435 /

TFG 435

Mast tilt forward /

back

α/β

DFG 425 /

DFG 430 /

TFG 425 /

TFG 430

DFG 435 /

TFG 435

Page 4

Issue: 05/2014

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model DFG 425 DFG 430 DFG 435

1.3 Drive Diesel

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 2.5 3 3.5

1.6 Load centre distance c mm 500

Identification

1.8 Load distance x mm 472 493 498

1.9 Wheelbase y mm 1650 1700 1780

2.1 Service weight kg 3660 4190 4570

2.2 Axle load, w. load, front / rear kg 5480 / 680 6390 / 800 7170 / 900

2.3 Axle load, w.o. load, front / rear kg 1510 / 2150 1640 / 2550 1710 / 2860

Weights

3.1 Tyres LUFT

3.2 Tyre size, at front mm 7.00-12 27x10-12 27x10-12

3.3 Tyre size, at rear mm 6.00x9 6.50x10 6.50x10

3.5 Wheels, number front/rear (× = driven wheels) 2x/2

3.6 Track width, front b

3.7 Track width, rear b

Wheels / chassis

4.1 Tilt of mast/fork carriage forward/backward α/β ° 6/8

4.2 Mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 40 / 100 / 1050 45 / 125 / 1050 50 / 125 / 1050

4.23 Fork carriage ISO 2328, class/type A, B 2A 3A 3A

Basic dimensions

4.24 Fork carriage width b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 3987 4133 4248

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 4187 4333 4448

4.35 Turning radius W

4.36 Smallest pivot point distance b

5.1 Travel speed, w. / w.o. load km/h 17 / 18

5.2 Lift speed, w. / w.o. load m/s 0.55 / 0.57 0.58 / 0.6 0.48 / 0.5

5.3 Lower speed, w. / w.o. load m/s 0.55 / 0.55

5.5 Drawbar pull w. / w.o. load N 18000

5.7 Gradeability laden/unladen % 24 / 27 20 / 26 18 / 24

5.9.2 Acceleration laden/unladen to 15 m S 5.4 / 4.8 5.6 / 4.8 5.8 / 5

5.10 Service brake hydraulic

Performance data

5.11 Parking brake hydraulic

7.1 Engine manufacturer / type Kubota V2403-M-T

7.2 Engine output according to ISO 1585 kW 36.5

7.3 Rated revolutions per minute /min 2200

7.4 No. of cylinders 4

engine

7.4.1 Cubic capacity cm³ 2434

Combustion

7.5 Fuel consumption acc. to VDI cycle l/h 3.2 3.7 3.9

8.1 Type of drive control hydrodynamic

8.2 Working pressure for attachments bar 210

8.3 Oil flow for attachments l/min 40

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 82

Misc.

8.5 Trailer coupling, model/type DIN Bolzen

8.6 Steering hydraulic

mm 990 1034 1034

10

mm 940

11

mm 2129 2122 2201

1

mm 150

2

mm 2900

3

mm 3502 3659 3689

4

mm 2175 2180 2180

6

mm 1130 1135 1135

7

mm 420 430 430

10

mm 3617 3768 3863

1

mm 2567 2718 2813

2

mm 1192 1296 1296

1/b2

mm 1120

3

mm 106 104 131

1

mm 141 155 153

2

mm 2315 2440 2550

a

mm 720 730 750

13

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 5

Issue: 05/2014

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model TFG 425 TFG 430 TFG 435

1.3 Drive LPG

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 2.5 3 3.5

1.6 Load centre distance c mm 500

Identification

1.8 Load distance x mm 472 493 498

1.9 Wheelbase y mm 1650 1700 1780

2.1 Service weight kg 3640 4170 4550

2.2 Axle load, w. load, front / rear kg 5460 / 680 6370 / 800 7150 / 900

2.3 Axle load, w.o. load, front / rear kg 1490 / 2150 1630 / 2540 1700 / 2850

Weights

3.1 Tyres LUFT

3.2 Tyre size, at front mm 7.00-12 27x10-12 27x10-12

3.3 Tyre size, at rear mm 6.00x9 6.50x10 6.50x10

3.5 Wheels, number front/rear (× = driven wheels) 2x/2

3.6 Track width, front b

3.7 Track width, rear b

Wheels / chassis

4.1 Tilt of mast/fork carriage forward/backward α/β ° 6/8

4.2 Mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 40 / 100 / 1050 45 / 125 / 1050 50 / 125 / 1050

4.23 Fork carriage ISO 2328, class/type A, B 2A 3A 3A

Basic dimensions

4.24 Fork carriage width b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 3987 4133 4248

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 4187 4333 4448

4.35 Turning radius W

4.36 Smallest pivot point distance b

5.1 Travel speed, w. / w.o. load km/h 18 / 19

5.2 Lift speed, w. / w.o. load m/s 0.58 / 0.6 0.59 / 0.61 0.5 / 0.52

5.3 Lower speed, w. / w.o. load m/s 0.55 / 0.55

5.5 Drawbar pull w. / w.o. load N 17000

5.7 Gradeability laden/unladen % 23 / 27 20 / 26 17 / 24

5.9.2 Acceleration laden/unladen to 15 m S 5.7 / 5 6.2 / 5.4 6.5 / 5.6

5.10 Service brake hydraulic

Performance data

5.11 Parking brake hydraulic

7.1 Engine manufacturer / type Kubota WG2503-L

7.2 Engine output according to ISO 1585 kW 36.5

7.3 Rated revolutions per minute /min 2200

7.4 No. of cylinders 4

engine

7.4.1 Cubic capacity cm³ 2491

Combustion

7.5.1 Fuel consumption acc. to VDI cycle kg/h 3.2 3.8 4.3

8.1 Type of drive control hydrodynamic

8.2 Working pressure for attachments bar 210

8.3 Oil flow for attachments l/min 40

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 82

Misc.

8.5 Trailer coupling, model/type DIN Bolzen

8.6 Steering hydraulic

mm 990 1034 1034

10

mm 940

11

mm 2129 2122 2201

1

mm 150

2

mm 2900

3

mm 3502 3659 3689

4

mm 2175 2180 2180

6

mm 1130 1135 1135

7

mm 420 430 430

10

mm 3617 3768 3863

1

mm 2567 2718 2813

2

mm 1192 1296 1296

1/b2

mm 1120

3

mm 106 104 131

1

mm 141 155 153

2

mm 2315 2440 2550

a

mm 720 730 750

13

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 6

DFG/TFG 425/430/435

Standard delivery specification

• Operators cab entry handle on upright

of overhead load guard. High visibility

overhead load guard suitable, as standard, for containers.

• Hydraulic steering on demand with

load sensing technology.

• Steering column with adjustable tilt.

• Travel direction lever mounted on

steering column.

• Individual hydraulic levers on the operators dashboard.

• Instrumentation with glare-free display

for hour meter and tank capacity. Indicator lights for: - engine oil

pressure, coolant temperature, battery

charge, parking brake, transmission oil

temperature, brake fluid level, neutral

display, low fuel level warning (diesel),

electronic preheating (diesel) and water

in the diesel filter.

• Acoustic warning for excess coolant

temperature.

• MSG20 faux leather seat with automatic lap belt and mechanical suspension.

Setting options: Fore and aft adjustment, backrest tilt and weight adjustment (up to 130 kg).

• Functional storage compartments

suitable for everyday use including a

drink holder.

• Anti-noise and vibration rubber floor

mat.

• Standard automotive pedal layout.

• Wet maintenance-free disc brakes

with electric parking brake and audible

safety warning.

• Two front halogen spotlights and two

brake/rear lights on rear counterweight.

• Hydraulic control valve incorporating

load sensing technology.

• Full-flow hydraulic oil filtration with

suction and return filtering for maximum oil purity.

• Heavy duty cyclonic air cleaner.

• Oil cooler for torque converter and

transmission oil.

• Closed pressurised cooling system.

• Enclosed towbar on counterweight.

• Full length belly plate.

Page 7

Benefit from the advantages

Entry via a deep, wide step. Large,

strong grab handle welded to the

overhead guard.

Powerful and ecient drive concept

• Tried and tested in harsh construction

environments, industrial engines from

Kubota in diesel and LPG models.

• Sturdy and modern engines. Designed

for durability, high load capacity and

reliability.

• High torque at low engine revs.

• Engine timing via inclined spurtoothed

wheels.

• Engines with low emissions (diesel

engines as per Directive 97/68/ EU

stage 3A).

Ergonomic operator workstation

• The visibility in all directions is class

leading enhancing all round safety.

• Entry via a deep, wide step. The step is

clearly visible from the seated position.

• Large, strong grab handle welded to

the overhead guard.

• Generous knee and legroom thanks

to slim and easily adjustable steering

column.

• Ergonomic steering wheel oset to

the left.

• Eortless operation with hydraulic

power assisted steering.

• Large, level footwell with vibration

absorbing floor mat.

• Sturdy hydraulic levers positioned for

easy use even when wearing gloves.

• Comfortable operators seat with

excellent suspension and numerous

adjustment options.

• Displays and switches for additional

equipment (e.g. lighting and wipers) are

positioned within the operator’s reach

and field of vision.

• Numerous storage options, such as

drink holder, documents clip and a

compartment for every day objects.

• Electrically applied parking brake, easily

operated at the push of a button. Eliminating the usual knock on/knock o

lever which restricts access in the knee

and entry area.

• Automotive pedal layout with non-slip

anti vibration surface.

Display in the operator’s field of

vision.

Automotive pedal configuration

with non-slip surface.

Mast and hydraulics

• Smooth transitions provided by the

mast cushioning system.

• High residual capacity at high lift

heights.

• High visibility due to unique vision

window.

• Flush face mast channels reducing the

lost load centre.

• Hydraulic hoses routed for optimum

visibility.

• Vision windows in the free lift cylinder

cross-member, make it safer to work at

higher racking levels.

• Hydraulic control valve incorporating

load sensing technology. Due to the

lower pressure level, the load sensing

system reduces the energy consumption whilst keeping the unnecessary

pumping losses to a minimum.

Jungheinrich drive axle with

maintenance-free wet-disc brakes

• Axle concept with optimised eciency

for low fuel consumption.

• The oil immersed wet-disc braking

system is maintenance-free. There are

virtually no service costs (in comparison with conventional drum braking

systems).

• No negative eect on braking due to

environmental influences or service

related downtime due to the enclosed

design.

Uncoupled power train

Improved operator comfort and reduction of human vibrations to a minimum

through:

• Floating drive unit.

• Drive shaft combination with universal

joints.

Optimum view of the load thanks

to lift mast design giving ideal

visibility.

Enclosed high-performance cooling

system with combi cooler

• Heavy duty combi cooler in full

aluminium design for engine coolant, converter and transmission oil –

without the common plastic manifold

which are susceptible to faults.

• Easy to clean with radiator cores of the

cooling elements for engine coolant,

converter and transmission oil.

• No coolant evaporation due to completely enclosed pressurised system.

• Reliable operation without a reduction

in performance even at extreme ambient temperatures.

Easy to maintain and repair

• Optimum access to engine compartment due to 90° opening and

L-shaped cover.

• Side sections and floor plate easily detachable without the need for tools.

• Minimal truck downtime thanks to

simple, rapid and cost-eective

maintenance – expert knowledge not

required.

• Use of sturdy, high-quality components.

• No truck-specific diagnostic tools or

special software required.

• Large fuel filter with water separator.

• Oil change interval 500 hours.

Reliable, heavy-duty electrical

equipment

• Splash-proof electrics, plug and connections.

• Easily accessible at all times, compact

fuse box on the operators console in

the drivers compartment.

Jungheinrich high-mounted fully

floating axle for high degree of

passive safety

Even during dynamic travel, outstanding driving stability through reduced

pendulum motion is guaranteed by the

high pivot point of the steering axle. The

risk of tip over is minimised by applying

basic physics. Without the additional use

of electronic assistance systems.

Page 8

Benefit from the advantages

Simple, fast and affordable maintenance.

Side sections are easily detachable

without tools.

Optimised counterweight design

• The counterweight design displaces

the centre of gravity downwards and

forwards.

• The truck’s centre of gravity is low and

is situated between the front and rear

axles.

Electrically applied parking brake,

easily operated at the push of a

button.

Additional comfort equipment in

dierent models (optional)

• Windscreen and rear window made of

single-pane safety glass.

• Overhead roof panel made of laminated safety glass.

• Heated rear window (with vertical

sliding window).

• Wipers and washer system for windscreen and rear window.

• Steel doors with sliding windows.

• Heating including windscreen demisters.

• Panoramic interior mirror.

• Left and right rear view mirrors.

• Armrest.

• Comfort seats in fabric or synthetic

leather.

Heating including air demister for

windscreen.

Benefit from our safety and

environmental benefits:

• Automatic hydraulic and travel interlock when the operator leaves the

seat. All hydraulic functions and travel

are only possible when the seat is

occupied.

• Acoustic warning when the operator’s

seat is vacated, if the parking brake is

not applied.

• Transmission is automatically placed

into neutral as soon as operator leaves

the truck.

• All diesel engines comply with the EU

exhaust emissions stage 3A regulations.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_DFG/TFG 425/430/435_052014_en_UK_000

Loading...

Loading...