Page 1

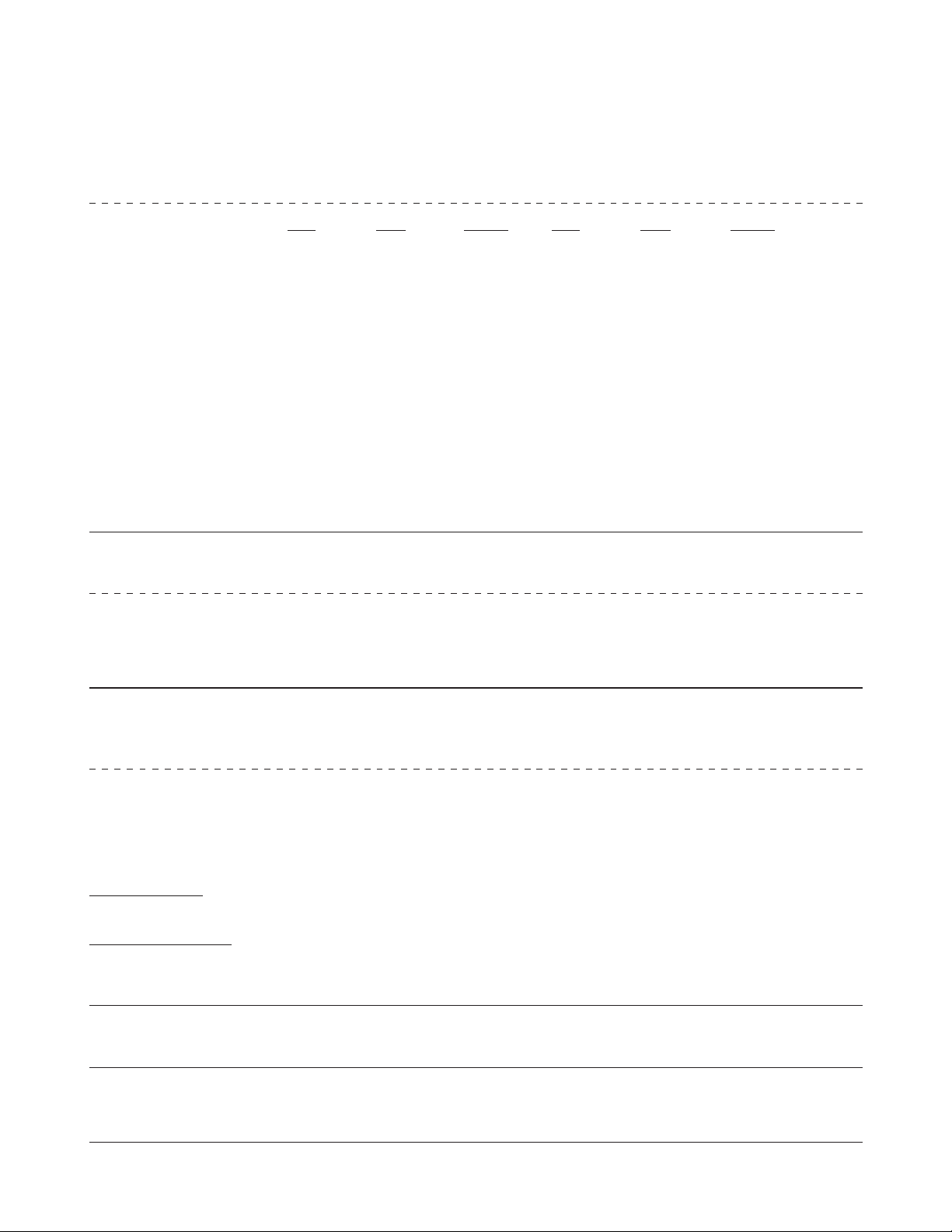

Jøtul F 602 USA

Jøtul F 602 USA

Installation and Operating Instructions for the USA and Canada

Kindly save these instructions for future reference.

Ce document doit être conservé pendant toute la vie de l'appareil.

Page 2

USA

Table of contents

General information

Possible hazards to avoid

when using the Jøtul F 602 USA ..................................... 2

Installation

Safety notice .......................................................................... 3

Top Exit or Rear Exit............................................................. 3

Fasten the Legs ..................................................................... 3

Plan Ahead

Chimney connector ............................................................. 3

Wall Pass-Through................................................................ 4

Chimneys................................................................................ 4

Masonry Chimneys .............................................................. 5

Listed Metal Prefabricated Chimneys ............................. 5

Connection to the Chimney

Masonry Chimneys .............................................................. 5

Prefabricated Chimneys ..................................................... 5

Clearances to Combustibles

Floor Protection .................................................................... 6

Alternate Floor Protection .................................................. 6

Clearances to Adjacent Combustible Materials .......... 6

Using a Rear Heat Shield .................................................... 6

to Reduce Clearance in Alcove Installations ................. 6

Using Wall Protectors

to Reduce Clearances in Alcove Installations ............... 6

Alcove Installation ................................................................ 6

Operation

Wood Storage ........................................................................ 8

Creosote and Soot Formation and

the Need for Removal......................................................... 8

Breaking in Your Stove ....................................................... 8

Controls

Front Door Latch ...................................................................8

Air Control .............................................................................. 9

Building a Fire ....................................................................... 9

Reloading ............................................................................... 9

Reloading Procedure ........................................................... 9

Ash Removal .......................................................................... 9

Maintenance

General .................................................................................. 10

Glass Replacement ............................................................ 10

Glass Cleaning ..................................................................... 10

Jøtul F 602 Woodstove Clearances ......... 7

Figures and Diagrams ..................... 21-26

General Information

The Owner's Manual describes the installation and

operation of the Jøtul F 602 USA non-catalytic wood

heater. This heater meets the U.S. Environmental

Protection Agency's emission limits for wood heaters sold

after July 1, 1990. Under specific test conditions, this heater

has shown heat output at rates ranging from 9,600 to

42,000 BTU's per hour.

When installing, operating, and maintaining your Jøtul F

602 USA, follow the guidelines given in these instructions.

Save these instructions, and make them available to

anyone using the stove.

A number of areas of the U.S. and Canada require a building

permit to install a solid-fuel burning appliance. NFPA 211

(National Fire Protection Association, Standard for

Chimneys, Fireplaces, Vents, and Solid Fuel Burning

Appliances) or CAN/CSA B-365 (Installation Code for SolidFuel Burning Appliances and Equipment) may apply to the

installation of solid fuel burning appliances in your area.

Your Jøtul dealer has knowledge of your local codes and

can provide assistance in making sure your installation is

safe and legal. Also contact your insurance representative,

building inspector, or fire officials to determine what

regulations apply in your area.

The Jøtul F 602 USA has been tested and listed to

ANSI-UL 1482, and ULC S627 by Intertek Testing ServicesWarnock Hersey of Middelton, Wisconsin.

Possible Hazards to Avoid When

Using the Jøtul F 602 USA

Any use of fire in a house represents a certain danger.

With intense overfiring, temperatures on the surface of

the Jøtul F 602 USA can exceed 1 000 0F (536 0C).

Comply with the following guidelines:

• Never overfire the stove. If any part of the stove or

chimney glows, you are overfiring, and a house fire or

serious damage to the stove or chimney could result.

Immediately close down the air control if you notice

this condition.

• Teach children that the stove is hot and must not be

touched.

• Never use gasoline, gasoline-type lantern fuel,

• Never use kerosene, charcoal lighter fluid or similar

liquids to start or "freshen up" a fire in this heater.

They can ignite with explosive force, causing bodily

injury or death. Keep all such liquids far away from the

heater while it is in use.

• Never use the stove if there are combustible gases in

the house. The fumes from certain cleaning fluids,

2

Page 3

USA

adhesives, and paints are a few examples of

combustible gases. Remember, the operating

woodstove is a source of "open flame".

• Avoid creating a "low pressure" condition in the room

where the stove is operating, such as by operating an

exhaust fan or a clothes dryer. A low-pressure

condition could cause poisonous gases to be drawn

out of the stove into the room. Some fuel will during

combustion separate carbon monoxide and generate

it in the burnchamber. Carbon monoxide is toxic, so

please follow the guidelines in this manual to avoid

smoke "roll out" from the burnchamber. You can

prevent a low-pressure condition by providing

adequate outside combustion air within 24" of the

stove.

• Never operate the Jøtul F 602 USA if it has cracked or

broken glass. Replace damaged glass only with the

proper glass panel available from your Jøtul dealer.

• Never burn trash of any kind in the stove.

• Keep combustible materials far away from the stove.

• Never modify the stove in any way.

• Do not dry clothes over the stove, since they could fall

and ignite.

• Use only seasoned wood in your stove. Never use

fireplace coal or synthetic logs that have not been

approved for the stove.

• Always wear protective gloves when adding fuel to

the fire.

• If you for some reason experience smoke "roll out"

from the fireplace, it might activate smoke detectors

(if installed).

• Do not connect this heater to any air distribution duct.

Note! This stove is not approved for use in mobile homes.

Top Exit or Rear Exit

The Jøtul F 602 USA has two flue outlet positions. If you

wish to top-exit the stove, place the cover plate in the

rear position and secure it with the screws and nuts, then

secure the flue collar to the top with the two remaining

screws.

To rear -exit the stove, secure the cover plate in the top

position with the two screws, then secure the flue collar

to the rear with the two remaining screws and two nuts.

When fastening the plate or flue collar to the rear, it may

be necessary to reach in through the top opening and

hold the nuts with a wrench.

Attaching the Legs

The Jøtul F 602 USA has four tapped leg bolt holes in the

bottom plate. Fasten each leg to the bottom with a bolt

and with a washer between the bolt head and the leg.

Plan Ahead

A safe stove installation involves several elements,

including: (A) the chimney connector, (B) the chimney itself,

(C) the connection between the chimney connector and

chimney, and (D) protection of combustible materials in

the vicinity of the stove. Each of these elements is equally

important for a safe stove installation.

Installation

Safety Notice

If this solid fuel room heater is not properly installed a

house fire may result. For your safety, follow the

installation directions. Contact local building or fire officials

about restrictions and installation inspection requirements

in your area.

Please read this entire manual before you install and use

your new stove. Failure to follow instructions may result

in property damage, bodily injury, or even death.

We recommend that you have your Jøtul F 602 USA

installed by a professional installer of solid fuel room

heaters.

A. Chimney Connector (Stove Pipe)

Chimney connector is also sometimes called stove pipe

or flue pipe, and it is used to connect the stove to the

chimney. The chimney connector should be 6" diameter

black steel, with a minimum thickness of 24 gauge.

Do not use aluminium or galvanized steel pipe as a chimney

connector. These materials cannot withstand the extreme

temperatures of a wood fire and can give off toxic fumes

when heated.

Matching enamel pipe is available for your Jøtul F 602

USA. Contact your Authorised Jøtul dealer for more

information.

Do not use chimney connector pipe as a chimney.

The factory-supplied adapter must be used for fitting the

stove's flue collar to the chimney connector.

Chimney connector sections must be attached to the

3

Page 4

USA

stove's flue collar adapter and to each other with the

crimped end toward the stove (fig. 2, page 20).

The space between the flue collar adapter and the

chimney connector should be sealed with stove cement

or an appropriately size piece of gasket. This allows any

small amounts of condensed creosote to run into the

stove rather then onto the outside of the pipe or the stove

top. All joints, including the adapter to the flue collar, should

be secured with three sheet metal screws to ensure that

the sections will not separate.

For proper operation the chimney connector should be as

short as possible. Horizontal lengths should have an

upward slope from the stove of 1/4" per foot. Avoid using

more than two 90 degree elbows or total runs of pipe

greater than 1 0'.

No part of the chimney connector may pass through an

attic or roof space, closet or other concealed space, or

through a floor or ceiling. Whenever possible, avoid

passing the chimney connector through a combustible

wall.

Wall Pass-Through

When your installation unavoidably requires that the

chimney connector pass through a combustible wall to

reach the chimney, extreme care must be taken. In the

U.S., the National Fire Protection Association's publication

NFPA 21 1, Standard for Chimneys, Fireplaces, Vents, and

Solid Fuel Burning Appliances, permits four methods for

passing through a combustible wall. In Canada, refer to

CAN/CGA B356. Before beginning the installation, contact

local building officials to make sure the proposed passthrough method meets local building code requirements.

An approved installation that uses a section of listed solid

fuel insulated factory-built chimney as a pass- through

for the chimney connector, must have an inside diameter

which is 2" larger than the chimney connector- a minimum

length of 12" -and at least 1" of insulation thickness. The

chimney section is installed with at least 2" of air space

between the outer chimney wall and adjacent combustible

materials.

Sheet steel support plates are used on both ends of the

chimney section to keep the connector centred. The

opening around the chimney section is closed on both

sides of the wall with sheet steel plates and the chimney

section is securely fastened to the plates. Fasteners used

to support the chimney section should never penetrate

the inner flue liner.

See NFPA-211 for other approved wall passthrough

methods.

B. Chimneys

There are two types of chimneys suitable for the

Jøtul F 602 USA. An approved masonry chimney, or a listed

residential-type building heating appliance chimney.

When selecting a chimney type and the location for the

chimney in the house, keep this in mind: it is the chimney

that makes the stove work, not the stove that makes the

chimney work. This is because a chimney actually creates

suction, called draft, which pulls air through the stove.

Several factors affect draft: the height, cross-sectional

area, and temperature of the chimney, as well as the

proximity of surrounding trees or buildings.

A commonly used method to pass through a wall directly

to a masonry chimney requires removal of all combustible

material from at least 12" around the entire chimney

connector. The space is then filled with at least 12" of

brick around a fireclay liner. Be sure to locate it so that

the top of the chimney connector will be at least 18" below

the ceiling.

To construct the brick pass-through, you will need an

opening of 30" x 30" minimum. It will be necessary to cut

wall studs, install headers, and construct a sill frame to

maintain proper dimensions and to hold the weight of

the brick. Minimum 3-1/2" (4" nominal) thick solid bricks

are to be used.

The fireclay liner (ASTM C35 or equivalent), minimum 5/8"

wall thickness, must not penetrate into the chimney

beyond the inner surface of the chimney flue liner and

must be firmly cemented in place. If it is necessary to cut

a hole in the chimney liner, use extreme care to keep it

from shattering. Refractory mortar must be used at the

junction to the chimney liner. (See figure 3, page 21)

4

In general, a short masonry chimney on the exterior of

the house will give the poorest performance. This is

because it can be very difficult to warm up, and in

extremely cold northern areas it may not work at all.

A tall masonry chimney inside the house is easier to keep

warm and will work best.

This guideline gives the necessary chimney requirements

based on the U.S. national code (NFPA-211). However, many

local codes differ from the national code to take into

account climate, altitude, or other factors. It is important

that you check with your local building officials to find out

what codes apply in your area before constructing a

chimney.

Page 5

USA

Masonry Chimneys

The minimum requirements for a properly constructed

chimney include the following:

• The foundation must be large enough to support the

intended chimney without settling.

• The masonry wall of the chimney, if brick or modular

block, must be a minimum of 4" nominal thickness. A

mountain- or rubble-stone wall must be at least 12"

thick.

• The chimney must have a fireclay flue liner (or

equivalent with a minimum thickness of 5/8" and must

be installed with refractory mortar. There must be at1/

2" air space between the flue liner and chimney wall.

• The preferred fireclay flue liner size has a nominal

size of 8" x 8", and should not be larger than 8" x12". lf

round fireclay liners are used, the inside diameter

should be 6" and not larger than 8". lf an existing

chimney with larger tiles is used it should be relined

with an appropriate liner.

• No other appliance can be vented into the same flue.

• An airtight cleanout door should be located at the base

of the chimney.

A chimney inside the house must have at least 2" of

clearance to the combustible structure. A chimney outside

the house must have at least 1" clearance to the

combustible structure. Fire stops must be installed at the

spaces where the chimney passes through floors and/or

ceilings. Remember that there must be air space around

the chimney, and that insulation must be 2" or more from

the chimney.

A chimney, wether masonry or prefabricated metal, must

be the required height above the roof or other obstruction

for safety and for proper draft operation. The requirement

is that the chimney must at least 3' higher than the highest

point where it passes through the roof and at least 2'

higher than the be at least and highest part of the roof or

structure that is within 10' of the chimney, measured

horizontally (fig. 4, page 21).

Chimneys shorter than 14' may not provide adequate draft.

This could result in smoke spilling the room from the door

or joints in the stove or pipe. In addition, inadequate draft

can cause puffing. A too-strong draft, on the other hand,

cause excessive temperatures and can shorten burn

times. Excessive drafts can be corrected by having your

dealer install a barometric damper at 0.1 " of water

column. lf you suspect you have draft problem, consult

your dealer.

Listed Metal Prefabricated Chimneys

The heater must be connected to a listed Type HT per

UL 103 or ULC S629 prefabricated chimney. When a metal

prefabricated chimney is used, the manufacturer's

installation instructions must be followed precisely. You

must also purchase (from the same manufacturer) and

install the ceiling support package or wall pass through,

the "T" section package, the firestops (when needed), the

insulation shield, the roof flashing, the chimney cap, etc.

Maintain the proper clearance to the structure as

recommended by the manufacturer. This clearance is

usually a minimum of 2", although it may vary by

manufacturer or for certain components.

There are basically two methods of metal chimney

installation. One method is to install the chimney inside

the residence through the ceiling and the roof (fig. 5,

page 22).

The other method is to install an exterior chimney that

runs up the outside of the residence.

C. Connection to the Chimney

Masonry Chimneys

When connecting to a masonry chimney, the chimney

connector must slide completely inside the chimney

thimble (or breach) to the inner surface of flue liner, make

sure the connector does not protrude past the inside of

the flue liner as that will reduce the flow area available

for the smoke and ultimately cause problems with your

chimney system. The chimney connector should be sealed

into the thimble with refractory cement and the connector

should also be mechanically fastened to the chimney.

See fig. 6, page 22.

Prefabricated Chimneys

Always follow the chimney manufacturer's instructions

and use all the components required by the manufacturer.

Do not take shortcuts or use make shift methods for

securing the chimney connector to the chimney.

Note: The clearances expressed in inches are those

approved for installations in the United States. The

clearances in parentheses that are expressed in

centimeters are those approved for installations in Canada.

Different test standards for the respective countries may

result in differences in the clearance requirements.

5

Page 6

USA

Clearances to

Combustibles

Floor Protection

A bottom heat shield is required in all installations. In

addition, your stove must be placed on a noncombustible

surface that extends 8" beyond the sides and back of the

stove and 16" in the front of the stove. This will result in

an overall base that is 28 1/2" wide x 45- 1/2" deep . This

is the minimum floor protector size. Floor protection

must also be used under the stove pipe and must

extend 2" beyond either side of the pipe (fig. 7, page

22).

The floor protection must have a minimum R value of

D. 45.

Warning! Never put any type of floor protection on top of

carpeting.

Alternate Floor Protection

All floor protection materials must be non-combustible

(i.e., metals, brick, stone, mineral fiber boards, etc.). Any

organic materials (i.e., plastics, wood, paper products, etc.)

are combustible and must not be used. The floor protector

specified may include some form of thermal designation

such as R-value (thermal resistance), k-factor (thermal

conductivity), or C-factor (thermal conductance).

The easiest means of determining if a proposed alternate

floor material meets requirements listed in the appliance

manual is to follow the procedure: See page 26.

hearth in it that you plan to use, it is extremely

important that the entire system be examined for

safety. Many older homes may have faulty chimneys,

or previous owners may have covered combustible

walls or studs with brick veneers. Heat is conducted

readily through brick and could ignite unseen

combustibles behind it.

Contact local building or fire official about restrictions and

installation requirements in your area.

Using a Rear Heat Shield to Reduce

Clearance in Alcove lnstallations

The Jøtul F 602 USA optional rear heat shield, PN HS50,may

be used only in top-exiting parallel installations to reduce

clearance as shown in figures 11,12,13, page 23.

Using Wall Protectors to Reduce

Clearances

The wall protector must be non-combustible, such as a

minimum 24 gauge galvanized steel or its equivalent. The

wall protector must be elevated 1" from the floor to

provide an air space of at least 1" between the shield and

the combustible wall. See figures 16, 17, and 18 on pages 23

and 24 for approved sizing specifications.

Alcove installation

When installed with a listed double wall pipe and with

wall protection, the Jøtul F 602 USA can be placed in an

alcove that has a minimum height of 96”1 and a maximum

depth of 48", and a minimum width of 41". The clearances

for this installation are shown in figure 14-15, page 23.

Clearance to Adjacent Combustible

Materials

The diagrams in figures 8-9-10 - page 22, give the required

clearances you must maintain from unprotected

combustible materials or objects.

A combustible is anything that can burn, and in the case

of stove installations, these combustibles may not be

visible. lf you are not sure of the combustible nature of

any material in the vicinity of your planned stove

installation, you should check with your local fire off icials.

Remember that "fire resistant" materials are considered

combustible; they are difficult to ignite, but they will burn.

lf you have recently purchased a home that has a stove

6

When installed with a listed double wall pipe and with a

stove heat shield, the Jøtul F 602 USA can be placed in an

alcove that has a minimum height of 96”1 and a maximum

depth of 24”2, and a minimum width of 55". The clearances

for this installation are shown in fig. 12-13, page 23.

In an alcove, the height of the wall protector, including the

air space at the bottom, must be at least 41" (104 cm) (see

fig. 15, page 23). Both side walls and the rear wall must be

protected by the wall protector (fig. 14, page 22).

(1See NFPA 211 for ceiling clearance reductions with

protection.)

Page 7

Jøtul F 602 Woodstove Clearances

Stove clearances Unprotected surfaces Protected surfaces (NFPA 211)

Top vent/vertical

Side Rear Corner Side Rear Corner

Single wall pipe 21" 13.5" 13" 13" 11" 9"

W/out rear heatshield 535mm 345mm 330mm 330mm 280mm 230mm

Single wall pipe 21" 11" 11" 13" 11" 9"

With rear heatshield 535mm 280mm 280mm 330mm 280mm 230mm

Shielded single wall pipe 21" 9" 9" 13" 8" 8"

With rear heatshield 535mm 230mm 230mm 330mm 205mm 205mm

Double wall pipe 24" 9" 9" 13" 8" 8"

With rear heatshield 610mm 230mm 230mm 300mm 205mm 205mm

Double wall pipe 24" 15" 15" 12" 8" 8"

W/out rear heatshield 610mm 380mm 380mm 305mm 205mm 205mm

USA

Connector Unprotected surface Protected surface (NFPA 211)

clearances (pipe) Vertical installation Vertical installation

Single wall pipe 18" 6"

460mm 150mm

Double wall pipe pipe mfgr.listing pipe mfgr.listing

Connector Unprotected surface Protected surface (NFPA 211)

clearances (pipe) Horizontal installation Horizontal installation

Single wall pipe 18" 9"

460mm 230mm

Double wall pipe pipe mfgr.listing pipe mfgr.listing

Very Important:

Top vent/vertical - assumes the connector pipe is exiting off the top of the stove and traveling vertically. If top vented

to any horizontal runs - the stove’s position is dictated by the connector pipe clearances.

Rear vent/horizontal - assumes the connector pipe exits from the rear of the stove and runs horizontally to the

chimney. If rear vented to vertical run - the stove position is dictated by the connector pipe clearances.

Minimum alcove dimensions:

Unprotected surface Protected surface (NFPA 211)

Vertical venting. Vertical venting

Assumes top exit: Assumes top exit:

Minimum alcove width 55” (1400mm) 41” (1040 mm)

Maximum alcove depth 48” (1220mm) 48” (1220 mm)

Height above the top of the stove 71” (1805mm) 71” (1805 mm)

7

Page 8

USA

Operation

Before building a fire in your new stove, please read

the following section carefully.

The stove is designed to burn natural wood only. Higher

efficiencies and lower emissions generally result when

burning air-dried seasoned hardwoods, as compared to

softwoods or to green or freshly-cut hardwoods.

Do not burn:

• Coal

• Garbage

• Cardboard

• Treated or painted Wood Solvents

• Treated or painted Wood

• Chemical Chimney Cleaners

• Colored Paper

• Any syntethic fuel or logs that have not been approved

for wood stoves.

Burning treated wood, garbage, solvents, colored paper,

chemical chimney cleaners, or trash may result in release of

toxic fumes.

will depend on how you operate your stove, but it is

important to inspect the flue after every two weeks of

use. An accumulation of 1/4" or more on the sides of the

flue or connector is considered hazardous and should be

removed.

In the event that creosote in your chimney or flue

connector ignites, the resulting fire is often accompanied

by a roaring noise and a crackling sound as flakes of burned

creosote break loose. lf you suspect you are having a

chimney fire, immediately close the draft regulator and

make sure the stove door is closed. Call the fire

department and get everyone safely out of the house.

Trying to extinguish the fire in the stove will not help. In

fact it can make the matter worse by allowing oxygen

through the door, which then supports the fire in the

chimney. When the roaring and crackling has stopped, you

should resist the temptation to open the door and look at

the fire. The fire may have suffocated, but could rekindle

when you open the door. After a chimney fire, do not use

your stove until the chimney and the flue connector has

been cleaned and inspected to ensure that no damage

has been sustained.

Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter fluid, or similar liquids to start or "freshen

up" a fire in this heater. Keep all such liquids far away

from the heater while it is in use.

Wood Storage

When storing wood outside, it should be covered and

stored off the ground to protect it from the elements.

Make certain that the woodpile has good air circulation

through it in order to promote drying to aid in the seasoning

process.

To obtain the best performance from your stove, we

recommend using seasoned hardwood that has been dried

and stored under cover for at least one year. Burning

unseasoned or wet wood causes the rapid development

of creosote and reduces the heat value of the wood.

Creosote and Soot Formation and

the Need for Removal

When wood is burned slowly, it produces tar and other

organic vapors which combine with expelled moisture to

form creosote. These creosote vapors condense in the

relatively cool chimney flue of a slow burning fire. The

creosote that accumulates in the flue is highly flammable

and is the fuel of chimney fires. To prevent a chimney fire,

the creosote needs to be removed by sweeping the

chimney and flue connector. The frequency of sweeping

Breaking in Your Stove

A cast iron stove should be "broken in" gradually. Five

consecutive small fires must be built in the stove prior to

operating the stove continuously. Each fire should be a

little larger than the previous one, and the last fire should

be a full-sized load. Allow the stove to cool completely

between fires.

It is normal for new painted stoves to emit a smell or

even some smoke during the first few fires. This is caused

by the seasoning of the high temperature paint, and the

odor will diminish with each fire and eventually disappear.

Opening a window or door near the stove will help provide

additional ventilation and reduce the odor.

Controls

Front Door Latch

The latch for the front door is conveniently located to the

left of the door's center. To open the door, simply raise

the latch and pull the door toward you. To shut the door,

raise the latch, push the door tightly against the stove

front, and lower the latch. See fig. 19 A, page 24.

8

Page 9

USA

Air Control

The sliding air control (See fig. 19 B, page 24) is located

in the bottom center of the front door.

Sliding the control to the right opens the air control and

increases the heat output; sliding it to the left closes the

control and decreases the heat output.

Slide the control fully to the right when first starting or

reviving a fire, or when maximum heat is required. Position

the control in the middle or left of the middle when less

heat is needed and when longer burn times are desired.

You will determine the best settings for your particular

needs as you gain experience with your stove.

Hot while in operation. Keep children, clothing and

furniture away. Do not store fuel within the clearances

listed previously.

Building a Fire

A good fire will efficiently utilize your fuel, keep the glass

in the door clean, keep emissions and creosote to an

absolute minimum, require less work, and be very

predictable.

A Good Foundation

Reloading

Reload the stove while it is still hot and there are plenty

of hot to ignite the fresh fuel load. It is a good idea to

include a smaller piece or two of wood at the base of the

new load to help the stove recover more quickly to its

operating temperature.

Reloading Procedure

• Always wear gloves when tending your stove.

• Push the air control to the right to the full open

position.

• Wait a few seconds and open the door.

• Use a stove shovel or similar tool to break up any

remaining charcoal and to drag some live embers

toward the front where combustion air enters.

• Load the fuel (Smaller pieces first).

• Close the door.

• Wait 5-10 minutes and adjust the air control to desired

setting.

Note: lf the charcoal bed present at reloading time is

relatively deep (2"-3") and your wood is well seasoned, it

is possible to add the fresh fuel load, close the door and

reset the air control for the desired heat output rate

within 5 minutes.

• Make sure the air control handle is fully to the right.

Open the front door and cover the bottom of the stove

with tightly crupled newspaper. Criss-cross a generous

double handful of dry kindling, such as split pieces of

scrap lumber, on top of the paper. lf you don't have

scrap lumber, split some of your best dry wood down

to finger-sized pieces and use that. Place three or

four 1 " -2" split pieces of dry wood on top of the kindling.

• Light the paper evenly across the front and close the

door.

• Continue to add 1" - 2" pieces of split dry wood until a

healthy bed of glowing coals has formed.

• You can now add three or four small-to-medium pieces

of wood. Allow this wood to burn for several minutes.

Once you are sure the wood is burning well, adjust the

air control to your desired heat output level. Moving it

to the right increases the heat; moving it to the left

decreases the heat. Avoid operating the stove with

the air control closed completely.

• In order for secondary combustion to occur, the fire

must be well established with temperatures above

1.0000F (6000C) in the firebox.

• lf the fire dies out, this cause is most likely either an

insufficient bed of coals, reducing the air supply too

soon, or using wood that is either too large or not dry

enough.

Ash Removal

Ash removal will be required every day or two during

normal operation, and is most easily done when the fire

has burned down to coals.

Use a shovel to push or rake any hot coals first to one

side. Shovel out the exposed ash, and push or rake the hot

coal to the other side. Remove the ash from the second

side as well, and then spread the hot coals evenly across

the firebox. Wood may now be added to start a new fire.

When removing ash from a stove that is in operation,

close and latch the door before taking the ashes outside

for safe disposal. It is always a good idea to wear heavy

protective gloves while removing and disposing of the

ashes from your stove.

Ashes should be placed in a metal container used

exclusively for ashes, with a tight fitting lid. The closed

container of ashes should be placed outdoors, well away

from all combustible materials, pending final disposal. lf

ashes are disposed of by burisl in soil or otherwise

dispersed, they should be retained in the closed container

until all cinders have thoroughly cooled.

Overfiring will result if the stove is operated with the

door open. This could cause damage to the stove, void the

warranty or lead to a house fire.

9

Page 10

USA

Warning: Operate your Jøtul F 602 USA only with the

door fully closed. Keep the door fully closed except

when loading fuel or removing ashes. A partially open

door may result in overfiring.

Maintenance

General

At least once a year, perform a routine maintenance

check. A good time to do this is when you are cleaning

the chimney and the connector. You should clean the

chimney and connector whenever accumulations of

soot and creosote reach 1/4" thick, which may be several

times a year, depending on how the stove is operated.

Thoroughly clean the entire stove. Brush all ash and soot

out of the stove. It is better to brush out the ash and soot

than to vacuum it out because soot particles are small

enough to pass through most vacuum bags.

In a dark room, use a strong light to inspect the stove

inside and out for cracks or leaks at corners and joints.

Cracked pants should be replaced. Leaks at joints can be

patched with stove furnace cement.

Check the door and window gaskets for tightness. To check

the front door gasket, put a dollar bill halfway into the

stove, close and latch the door, and try pulling the dollar

out. lf it can be removed easily the, seal is too loose. Check

several spots around the door. To replace the gasket,

scrape out all old gasket material and gasket cement.

Spread a 1/8" bead of stove cement into the bottom of

the groove and press in new gasket.

The door requires 36" of 1/4" diameter high density gasket.

The gasket between the glass panel and the door receives

very little wear. The best indication that it needs to be

replaced is streaks on the glass caused by air leaking

around the gasket.

Glass Replacement

To prevent cracking of the glass operate the doors gently.

Do not shut the door by striking or slamming.

working surface. The steps are the same:

Clean off any residual gasket material from the door using

a wire brush if necessary.

The replacement gasket is self-adeshive. Measure enough

gasket to go from the upper right corner of the glass,

down the right side, across the bottom and back up to the

upper left corner and then add about 2-1/2". Please note

that the top of the glass is not gasketed. A small amount

of air is allowed to enter through the that area to help

keep the glass clean.

• Peel off about 10" of the self-adhesive backing strip.

Leaving about 1-1/4"of gasket "tail" overlapping, apply

the gasket to the groove on the door, making sure that

the adhesive is facing the door.

• Press the gasket firmly in place.

• Peel off the remaining adhesive backing and apply the

remaining gasket, again leaving a "tail" at the upper

left corner.

• Press the gasket firmly in place.

• Center the glass panel left and right on top of the

gasket. Slide the glass toward the bottom of the door

until it hits stops.

• Hold the glass in place with your hand and wrap the

gasket "tails" over the top of the glass and down the

outer edges. You will have to twist the gasket so the

adhesive will face the glass. Press the "tails" firmly on

the glass.

• Replace the air control slide and the upper and lower

retainer manifolds and screws.

It is extremely important that the retainers be tightened

a small amount at a time and following a pattern similar

to tightening the lug bolts on an automobile wheel. They

should end up equally tightened and not over-tightened.

It may be necessary to retighten once again after the

stove has been burned and the new gasket has been

seated.

Glass Cleaning

From time to time, clean off the accumulated ash from

the inside surfaces of the glass panels. lf this fly ash is

allowed to remain on the surface for extended periods, it

could eventually cause the glass to become permanently

etched and somewhat cloudy. Any creosote which might

deposit on the glass will burn off during the next hot fire.

lf the stove's glass is cracked or broken, you must replace

it before operating your stove. Carefully remove any

broken pieces. Replace the panel only with the correct

Jøtul replacement glass, and do not use substitutes.

The glass can be replaced with the door still mounted to

the stove or the door can be removed and placed on a flat

10

Never clean the glass while it is hot and never use any

abrasive materials to clean the glass. Cool water and a

soft cloth or paper towel are usually all that is required.

Rinse thoroughly with clean water after washing and dry

completely before burning your stove.

Page 11

CANADA

Table des matières

Information d’ordre général

Dangers possibles à éviter pendant L’ utilisation

du “Jøtul F 602 USA” ................................................................ 11

Installation

Avis de sécurité .......................................................................... 12

Sortie des fumées par le dessus ou par l’arrière ..............12

Fixation des pieds ..................................................................... 12

Organisez-vous d´avance

Raccord de cheminée (tuyau de poêle) .............................. 13

Traverse murale..........................................................................13

Cheminées ................................................................................. 14

Cheminées de maçonnerie ................................................... 14

Cheminées métalliques préfabriquées homologuées ...15

Connexion à la cheminée .......................................................15

Dégagement jusqu’aux matériaux

Protection de plancher ............................................................15

Dégagements jusqu´aux matériaux combustibles ........ 15

Utilisation de protège-murs pour diminuer les

dégagements d’installations en alcôve ............................. 16

Installation en alcôve .............................................................. 16

Fonctionnement

Entreposage/Rangement du bois....................................... 16

Formation de créosote et de suie et nécessité

de les éliminer ............................................................................17

Rodage de poêle .......................................................................17

Commandes

Loquet - Porte de devant ........................................................17

Préparation de feu .................................................................... 17

Bonne fondation ...................................................................... 18

Rechargement ........................................................................... 18

Information d’ordre

général

Le manuel du propriétaire décrit l’installation et le

fonctionnement du poêle à bois, non catalytique, Jøtul F

602 USA. Ce poêle est conforme aux limites imposées par

l’agence américaine pour la protection contre les

émissions des poêles à bois vendus après le 1er juillet

1990. Ce poêle a en outre démontré, sous conditions de

test spécifiques, que sa puissance calorifique pouvait

s’étendre entre 9 600 et 42 000 Btu/h.

Pendant l’installation, le fonctionnement ou l’entretien

du poêle Jøtul F 602 USA, veillez à suivre les directives du

présent manuel. Conservez-les et tenez-les à la disposition

de toute personne susceptible de se servir de ce poêle.

Plusieurs régions des États-Unis et du Canada requièrent

un permis de construction pour l’installation d’un appareil

de chauffage à combustible solide. La norme canadienne

CAN/CSA(ACNOR) B-365 (Code d’installation pour appareils

et équipement à combustible solide) ou codes similaires

pourront s’appliquer à l’installation d’appareils de

chauffage à combustible solide dans votre région. Votre

concessionnaire Jøtul est au courant de ces codes locaux

et pourra vous renseigner sur la sûreté et la légalité de

votre installation. Communiquez, en outre, avec votre

agent d’assurance, votre inspecteur de la construction ou

les responsables officiels de la prévention des incendies

afin de déterminer quels règlements s’appliquent dans

votre région.

Le Jøtul F 602 USA a été testé et homologué

conformément à la norme CAN-ULC S627 de Scarborough,

Ontario.

Entretien

Généralités ................................................................................. 19

Remplacement du verre......................................................... 19

Nettoyage de panneau du verre..........................................20

Jøtul F 602 Woodstove Clearances ............. 7

Diagrammes......................................... 21-26

Dangers possibles à éviter lorsque

vous employez un poêle à bois

Jøtul F 602 USA

Un feu allumé dans une maison représente toujours

certains dangers. Les surfaces d’un poêle Jøtul F 602 USA

soumises à une surchauffe intense pourront en pousser

la température au-delà de 1 000°F (536°C).

Conformez-vous aux directives suivantes :

• Ne surchauffez jamais le poêle. L’incandescence de

l’une quelconque des parties du poêle signifie

surchauffe et risque éventuel d’un incendie ou de

graves dommages au poêle ou à la cheminée. En

l’occurrence, fermez immédiatement le distributeur

d’air.

11

Page 12

CANADA

• Faites comprendre aux enfants qu’un poêle chauffe

et qu’ils risquent de se brûler en y touchant.

• N’employez jamais de l’essence, du carburant pour

lanternes genre essence, kérosène, allumeur liquide

de charbon de bois ou autre liquide similaire dans ce

poêle pour commencer un feu ni pour le raviver. Ceuxci risquent de s’enflammer avec une vigueur explosive

pouvant causer des blessures graves et parfois

mortelles. Conservez tous ces liquides éloignés du

poêle en fonctionnement.

• N’employez jamais ce poêle dans une résidence où

sont conservées des sources de gaz de combustion

tels que certains liquides nettoyants d’usage

domestique, adhésifs et peintures pour n’en nommer

que quelques-uns. Souvenez-vous qu’un poêle à bois

est, lui-même, une «source de flammes nues».

• Évitez de créer une pression basse dans la pièce

chauffée généralement causée par l’utilisation d’un

appareil tel qu’un ventilateur d’échappement, une

sécheuse à linge etc., ceci pouvant libérer les vapeurs

toxiques du poêle dans la pièce chauffée. Pour parer à

cette condition, prévoyez suffisamment d’air de

combustion extérieur dans un rayon de 24 po. (61 cm)

autour du poêle.

• N’employez jamais un poêle Jøtul F 602 USA si une

vitre est fêlée ou brisée. Ne remplacez le verre

endommagé que par un panneau Jøtul F 602 USA

approprié acheté chez votre concessionnaire Jøtul.

• Ne brûlez jamais aucun déchet quel qu’il soit dans ce

poêle.

• Éloignez tous matériaux combustibles à une distance

considérable du poêle.

• Ne modifiez jamais le poêle de quelque manière que

ce soit.

• Ne suspendez jamais du linge au-dessus du poêle; il

risquerait en effet de s’enflammer en tombant.

• N’employez que du bois sec dans votre poêle.

• N’utilisez jamais de charbon de bois pour cheminées

ni des bûches synthétiques non approuvés pour poêles

à bois.

• Portez toujours des gants protecteurs pour ajouter

du carburant au feu.

• Si des fumées s’échappent du foyer, cela peut activer

les détecteurs de fumées (s’ils sont installés).

• Ne reliez pas ce poêle à un conduit de distribution

d’air.

• Ce poêle n’a pas été approuvé pour usage dans les

maisons mobiles.

Installation

Avis de sécurité

L’installation non appropriée de ce poêle à combustible

solide risque de causer un incendie. Assurez votre sécurité

en respectant les directives d’installation et consultez les

autorités locales de la construction et de la prévention

des incendies au sujet des limitations et des exigences

relatives aux inspections particulières à votre région.

Veuillez lire ce manuel tout entier avant d’installer et

d’utiliser votre nouveau poêle. Tout manquement à

observer ces directives risque de causer dommages

matériels, blessures graves ou même la mort de

personnes présentes.

Nous vous recommandons de faire installer votre poêle

Jøtul F 602 USA par un installateur professionnel de poêles

à combustible solide.

Sortie des fumées par le dessus ou

par I’arrière

Votre poêle Jøtul F 602 USA vous offre deux positions de

sortie de fumée.

Si vous choisissez la position supérieure, posez la plaquette

appropriée en position arrière, maintenez-la avec vis et

écrous puis fixez la virole du conduit de fumée à la partie

supérieure au moyen des deux vis restantes.

Si vous préférez la position arrière, posez la plaquette

appropriée en position par le dessus, maintenez-la avec

les deux vis, puis fixez la virole du conduit de fumée à

l’arrière au moyen des deux vis restantes et des deux

écrous.

Lorsque vous attachez la plaquette ou la virole du conduit

de fumée à l’arrière, il sera peut-être nécessaire

d’introduire votre main dans l’orifice supérieur et de

maintenir les écrous avec une clé anglaise.

Fixation des pieds

Le Jøtul F 602 USA est fourni avec quatre orifices

prépercés dans la plaque du fond. Attachez chaque pied à

cette plaque de fond avec un boulon et une rondelle entre

la tête de boulon et le pied.

12

Page 13

CANADA

Organisez-vous d’avance

Plusieurs éléments, d’importance égale, contribuent à

l’installation sûre de votre poêle : (A) le raccord de

cheminée; (B) la cheminée-même; (C) la connexion entre

le raccord et la cheminée et (D) la protection des

matériaux combustibles dans la proximité immédiate du

poêle.

A. Raccord de cheminée (Tuyau de

poêle)

Le raccord de cheminée, également appelé tuyau de poêle

ou conduit de fumée est employé pour relier le poêle à la

cheminée. Il se composera d’acier noir, son diamètre sera

de 15-1/4 cm et son calibre d’épaisseur #24.

Ne vous servez jamais d’un raccord composé de tuyau

d’aluminium ou d’acier galvanisé, ces matériaux chauffés

ne pouvant soutenir les températures extrêmes d’un feu

de bois et risquant de dégager des vapeurs toxiques.

Un tuyau d’émail assorti est disponible pour votre poêle

Jøtul F 602 USA. Veuillez demander de plus amples

renseignements à votre concessionnaire Jøtul.

travers combles ou vides sous toits, armoires ou autres

espaces dissimulés, planchers ni plafonds. Évitez autant

que possible de faire passer un raccord de cheminée à

travers un mur combustible.

Traverses murales

Lorsque votre installation requiert inévitablement de faire

passer le raccord de cheminée de votre poêle à travers

un mur combustible, d’extrêmes précautions devront être

prises. La norme CAN/CSA(ACNOR) B-365 (Code

d’installation pour appareils et équipement à combustible

solide) prévoit quatre méthodes à cet effet.

Avant de commencer votre installation, renseignez-vous

auprès de vos autorités locales de la construction sur la

méthode de traverse proposée, pour votre poêle,

compatible avec les codes locaux de la construction.

La méthode la plus commune de traverser un mur pour

atteindre une cheminée de maçonnerie exige le retrait

de tous matériaux combustibles dans un rayon d’au moins

30.5 cm autour du raccord tout entier pour être remplacés

par une épaisseur de briques de 30.5 cm (35.5 cm) cm au

moins autour d’une chemise argileuse. Veillez à placer

celle-ci de sorte que le dessus du raccord de cheminée

soit au moins 45-314 cm plus bas que le plafond.

N’employez jamais un tuyau de raccord en guise de

cheminée.

L’adaptateur fourni en usine servira à ajuster l’orifice

d’échappement de fumée de votre poêle au raccord de

cheminée.

Les sections de raccord de cheminée doivent être

attachées à l’adaptateur de sortie de fumée du poêle puis

l’une à l’autre - l’extrémité plissée dirigée vers le poêle.

(Illustr. 2, page 21).

L’espace entre l’adaptateur de sortie des fumées du poêle

et le raccord de cheminée doit être scellé avec un ciment

à poêle ou un joint de mastic de poêle à bois,

approximativement dimensionné. Ceci permettra à toute

petite quantité de créosote condensée de passer dans le

poêle plutôt que de s’accumuler à l’extérieur du tuyau ou

à l’orifice du dessus de poêle. Tous les joints, y compris

l’adaptateur de sortie des fumées seront fermement

maintenus par trois vis à tôle, pour empêcher les sections

de se séparer.

Pour un fonctionnement approprié, le raccord de cheminée

sera aussi court que possible. Les tuyaux horizontaux

auront une pente ascendante, depuis le poêle, d’ 0.6 cm.

Évitez d’utiliser plus de deux coudes à 90° ou une longueur

totale de tuyau supérieure à 305 cm.

Aucune partie du raccord de cheminée ne passera à

Pour construire le «passe muraille» de brique, une

ouverture d’au moins 76 cm x 76 cm est nécessaire. Des

poteaux muraux seront en outre coupés, des boutisses

installées et un encadrement construit conformément

aux dimensions appropriées pour soutenir le poids des

briques. Des briques solides de 9 cm (format nominal

10 cm seront employées. La chemise argileuse (ASTM C35

ou équivalent) d’une épaisseur murale de 1 -1 /2 cm ne

pénétrera pas la cheminée au-delà de la surface

intérieure de la chemise de celle-ci et sera fermement

cimentée en position.

S’il s’avère nécessaire de découper un cercle dans la

chemise de la cheminée, prenez toutes précautions

possibles pour l’empêcher de se briser. Un mortier

réfractaire sera employé au point de jonction de la

chemise de cheminée.(Illustr. 3, page 21)

Une installation approuvée utilisant une section de

cheminée isolée homologuée pour combustible solide,

construite en usine en guise de traverse murale (passemuraille) pour le raccord de cheminée.

Le diamètre intérieur de la section de cheminée sera 5 cm

plus large que celui du raccord de cheminée; il mesurera

30.5 cm au moins et sera isolé sur une épaisseur d’au moins

2-1/2 cm.

Cette section installée présentera un espace d’air d’au

moins 5 cm entre la paroi extérieure de la cheminée

proprement dite et les matériaux combustibles adjacents.

13

Page 14

CANADA

Des plaques d’appui en feuille d’acier sont utilisées à

chaque extrémité de la section de cheminée afin que le

raccord demeure bien centré. L’orifice autour de la section

de cheminée est bouché de chaque côté de la paroi murale

avec des plaques en feuille d’acier auxquelles la section

de cheminée est alors fermement attachée. Les attaches

utilisées pour soutenir la section de cheminée ne pourront,

en aucune circonstance, pénétrer la chemise intérieure

du conduit de fumée.

Voyez la norme ; La norme CAN/CSA(ACNOR) B-365 pour

toute autre méthode passe-muraille, approuvée.

B. Cheminées

Deux types de cheminée conviennent pour votre poêle

Jøtul F 602 USA : une cheminée de maçonnerie approuvée

ou une cheminée d’appareil de chauffage de type

résidentiel, homologuée pour sa sûreté.

Rappelez-vous, lorsque vous choisissez un type de

cheminée et son emplacement dans la maison que c’est

grâce à elle que le poêle peut fonctionner et non pas grâce

au poêle que la cheminée fonctionne. Cela est dû au fait

que la cheminée crée une aspiration appelée tirage qui

attire I’air à travers le poêle.

Cheminées de maçonnerie

Les exigences minimales pour construction appropriée

d’une cheminée de maçonnerie comprennent ce qui suit :

La fondation doit être suffisamment large pour soutenir

la cheminée envisagée sans affaissement.

Le mur de maçonnerie de la cheminée, soit en briques,

soit en blocs modulaires, sera d’une épaisseur nominale

d’au moins 10 cm. Un mur de blocaille ou de moellons

bruts aura au moins 30.5 cm d’épaisseur.

La cheminée doit être doublée d’une chemise argileuse

(ou équivalente) d’au moins 1 -1 /2 cm et doit être installée

au moyen de mortier réfractaire. Un espace minimal d’11/4doit séparer la chemise du conduit de fumée du mur

de la cheminée.

Le diamètre nominal préférable de la chemise argileuse

de cheminée est de 20-1/4 x 20-1/4 cm; il ne pourra, en

aucun cas, dépasser un diamètre maximal 20-1/4 x 30.5

cm. Une chemise circulaire requiert un diamètre intérieur

de 15-1/4 cm - jamais plus de 20-1/4 cm. Si une cheminée à

tuiles de plus grande dimension est employée, elle sera

redoublée avec une chemise appropriée.

Aucun autre appareil ne sera aéré par le même conduit.

Le tirage réagit à plusieurs facteurs : hauteur, superficie

en coupe et température de la cheminée, ainsi que la

proximité d’arbres ou de constructions environnants.

Une courte cheminée de maçonnerie à I’extérieur de la

maison donne, généralement la performance la moins

satisfaisante du fait qu’elle s’avère exceptionnellement

difficile à chauffer et même impossible dans certaines

régions extrêmement froides du Grand Nord.

Une haute cheminée de maçonnerie à I’intérieur de la

maison facilite le chauffage et fonctionne le mieux.

Les présentes directives vous indiquent les exigences

spéciales requises d’après le code national canadien, la

norme CAN/CSA(ACNOR) B-365. Néanmoins, de nombreux

codes locaux diffèrent du code national afin de tenir

compte de facteurs tels que climat et altitude etc. Il est

important que vous vérifiiez, auprès des autorités locales

de la construction quels codes s’appliquent dans votre

région avant de procéder à la construction d’une

cheminée.

Une trappe de nettoyage hermétique sera située à la base

de la cheminée.

Le dégagement d’une cheminée à I’intérieur de la maison

doit être d’au moins 5 cm jusqu’à la structure combustible.

Celui d’une cheminée extérieure sera d’au moins 2.5 cm

jusqu’à la structure combustible. Des coupe-feu doivent

être installés aux endroits où la cheminée traverse le

plancher et (ou) le plafond .

Souvenez-vous que la cheminée doit être entourée d’un

vide d’air suffisant et que le matériau isolant doit être

éloigné de 5 cm ou plus de la cheminée.

Une cheminée, de maçonnerie ou métallique

préfabriquée, sera de la hauteur requise, au-dessus du

toit, ou de toute autre obstruction, pour en assurer la

sécurité et le tirage approprié. Il est par conséquent

nécessaire qu’elle soit d’au moins 3 pieds (91-1/2 cm) plus

haut que le point le plus élevé auquel elle traverse le toit

et d’au moins 2 pieds (61 cm) plus haut que la partie du

toit ou de la structure la plus élevée dans une limite de 10

pieds (305 cm) de distance de la cheminée, mesurés

horizontalement. (Illustr. 4, page 21).

14

Aucune cheminée de moins de 14 pieds ne peut assurer

un tirage adéquat ; elle permettra, au contraire, à la fumée

de s’échapper dans la pièce par la porte ou les joints du

poêle ou du conduit de fumée. En outre, un tirage

Page 15

CANADA

inadéquat pourra causer des retours de flammes dans la

boîte à feu. D’autre part, un tirage trop vigoureux, en

causant des températures excessives, risque de

raccourcir les durées de combustion. Vous pourrez

remédier à des tirages excessifs en faisant installer, par

votre concessionnaire, un registre barométrique réglé

pour une colonne d’eau de 0-1/4 cm. Si vous soupçonnez

un problème de tirage, consultez donc votre

concessionnaire.

Cheminées métalliques

préfabriquées, homologuées.

Lorsque vous employez une cheminée métallique

préfabriquée, suivez à la lettre les directives d’installation

du fabricant. Vous devrez en outre acheter et installer

I’ensemble de support de plafond, ou de «passe-muraille»,

I’ensemble de section en Té, les coupe-feu éventuellement

requis, I’écran isolant, le chaperon de toiture, chapiteau

de cheminée etc., tous provenant du même fabricant.

Respectez le dégagement approprié jusqu’à la structure,

tel que recommandé par le fabricant. De règle générale,

ce dégagement doit être d’au moins 5 cm bien qu’il puisse

varier selon le fabricant ou le type de certaines

composantes. (Illustr. 5 page 22)

C. Connexion à la cheminée

Cheminées de maçonnerie

Lorsque vous raccordez votre poêle à une cheminée de

maçonnerie, le raccord doit glisser complètement à

I’intérieur de la rosace (ou «trouée») jusqu’à la surface

intérieure de la chemise argileuse. Assurez-vous que le

raccord ne fasse pas saillie au-delà de I’intérieur de la

chemise, ce qui risquerait de diminuer la section de

passage de fumée et de causer, en conséquence, des

problèmes pour votre système de cheminée. Le raccord

de cheminée sera scellé dans la rosace au moyen d’un

ciment réfractaire et sera, en outre, attaché

mécaniquement à la cheminée. (Illustr. 6, page 22).

Cheminés préfabriquées

Suivez toujours les directives du fabricant de cheminée

et n’employez que les composantes recommandées par

lui. Ne vous laissez pas tenter par des «raccourcis» ou

des solutions de facilité lorsque vous fixez le raccord à la

cheminée.

Dégagements jusqu’aux

combustibles

Protection de plancher

Un écran de fond thermique est inclus aux éléments

standard du poêle Jøtul F 602 USA et doit être présent

dans toutes installations. De plus, le poêle sera placé sur

une protection de plancher non combustible s’étalant sur

20-1/4 cm au moins au-delà des côtés et de I’arrière du

poêle et de 40-1/2 cm par-devant ce qui vous donnera une

protection de plancher de 84 cm de long par 115-1/2 cm de

côté. Cette protection doit aussi recouvrir la surface pardessous toutes sections horizontales de raccord de

cheminée (tuyau de poêle) et doit s’étaler sur au moins 5

cm au-delà de chaque côté du tuyau. (Illustr. 7, page 22).

Le poêle sera posé sur un protège-plancher non

combustible, homologué, comprendra de 0.9 cm

d’épaisseur de carton à I’enrouleuse, d’une conductivité

thermique de K-0.84 Btu-po. par pi.

qu’il n’y ait aucun espace entre les briques ou les tuiles

éventuellement utilisées afin d’éviter que des étincelles

ou des braises n’enflamment le plancher.

Une bonne méthode à suivre pour la fabrication de votre

protection de plancher est de couvrir la couche de

protection avec une plaque décorative non combustible

ou d’un renfort de carrelage tel que Wonderboard (MD)

ou Durock (MD)

Ne posez jamais aucun genre de protection de plancher

par-dessus tapis ou moquette.

Dégagements jusqu’aux matériaux

combustibles adjacents

Le diagramme de I’illustr 8-9-10-page 22, stipule les

dégagements requis à respecter jusqu’aux matériaux ou

objets combustibles, non protégés.

Un combustible signifie tout ce qui est susceptible de

brûler et peut parfois être invisible, en ce qui concerne les

installations de poêle. Si vous n’êtes pas rassuré sur la

combustibilité des matériaux environnant la surface

d’installation prévue pour votre poêle, vérifiez auprès des

responsables locaux de la prévention des incendies.

Souvenez-vous que les matériaux soi-disant «résistants

au feu» bien que longs à s’allumer, brûleront

éventuellement. Ils sont, par conséquent, considérés

comme combustibles.

2

/hre -°F. Veillez à ce

15

Page 16

CANADA

Si vous avez récemment acheté une maison avec un âtre

que vous prévoyez d’utiliser, il s’avère essentiel que la

sécurité du système soit vérifiée auparavant. De

nombreuses maisons anciennes ont des cheminées

défectueuses ou les murs et poteaux combustibles

peuvent avoir été recouverts d’un placage de briques par

les propriétaires précédents. La brique étant un excellent

conducteur de chaleur risque d’enflammer les

combustibles qu’elle dissimule.

Communiquez avec vos autorités locales de la construction

et de la prévention des incendies au sujet des limitations et

exigences d’installation imposées dans votre région.

Utilisation d’écrans thermiques pour diminuer les

dégagements

L’écran thermique arrière facultatif du poêle Jøtul F 602

USA peut être employé pour sortie des fumées par le

dessus pour diminuer le dégagement d’installations

parallèles, (Illustr. 11,12,13, page 23).

Utilisation de protège-murs pour

diminuer les dégagements

d’installations en alcôve

Le protège-mur d’une installation en aIcôve sera non

combustible - en acier galvanisé, par exemple, de calibre

minimal #24 ou équivalent. Il sera élevé d’2.5 cm d’espace

d’air au-dessus du plancher et sera monté de manière à

ménager également 2.5 cm d’espace d’air au moins entre

I’écran et le combustible. La hauteur du protège-mur, y

compris celle de I’espace d’air au bas du mur doit être

d’au moins 102-1/2 cm (Illustr. 15, page 21). Les deux murs

latéraux ainsi que le mur arrière seront protégés par ce

matériau. (Illustr. 14, page 23).

Notes :

1

Renseignez-vous auprès de votre concessionnaire sur les

diminutions de dégagement de plafond avec protection.

2.

Si la largeur de I’un des deux murs latéraux est supérieure

à 61 cm, (le dégagement du mur latéral le plus large sera de

63-1/2 cm.

Fonctionnement

Avant de préparer un feu dans votre nouveau poêle,

veuillez lire attentivement le chapitre suivant.

Ce poêle a été conçu uniquement pour le brûlage de bois

naturel. Le brûlage de bois séché à I’air a pour résultat

des rendements plus efficaces et des émissions moins

élevées comparativement au brûlage de bois tendre, vert

ou bois dur fraîchement coupé.

Ne brûlez jamais :

*ni charbon

*ni ordures ménagères

* ni carton

* ni solvants

* ni bois sec peint

* ni nettoyants chimiques de cheminée

* ni papier peint

*- ni déchets

* ni aucun carburant ou bûche synthétique quel qu’il soit,

non approuvé pour poêles à bois.

Le brûlage de bois traité, ordures ménagères, solvants,

papier peint, nettoyants chimiques de cheminée et

déchets risque de libérer des vapeurs toxiques.

Installation en alcôve

Lorsque vous installez votre poêle Jøtul F 602 USA avec

un tuyau homologué à double paroi et une protection

murale, vous pourrez le poser dans une aIcôve dont la

hauteur minimale est de 244 cm et la largeur maximale

122 cm et la longueur minimale 103 cm.

Les dégagements pour une installation de ce genre sont

indiqués dans l’illustration 14-15, page 23.

Lorsque vous installez votre poêle Jøtul F 602 USA avec

un tuyau homologué à double paroi et un écran thermique

pour poêle, vous pourrez le poser dans une alcôve dont la

hauteur minimale est de 244 cm(1). l et la largeur maximale

61 cm(2) et la longueur minimale 139-3/4 cm. Les

dégagements pour une installation de ce genre sont

indiqués dans l’illustr. 12-13, page 23.

16

N’employez jamais de I’essence, du carburant pour

lanternes genre essence, kérosène, allumeur liquide de

charbon de bois ou autre liquide similaire dans ce poêle

pour commencer un feu ni pour le raviver. Conservez tous

ces liquides éloignés du poêle en fonctionnement.

Entreposage/Rangement du bois.

Entreposage/Rangement du bois

Tout bois entreposé à I’extérieur sera couvert et le tas

sera surélevé au-dessus du sol pour le protéger des

intempéries. Veillez à I’entasser de manière à laisser

suffisamment d’espace pour la circulation d’air afin de

faciliter le processus de séchage.

Pour que votre poêle vous offre le meilleur rendement

possible, nous vous recommandons d’utiliser du bois dur,

séché et entreposé couvert pendant au moins un an. Le

Page 17

CANADA

brûlage de bois non séché ou encore humide en diminuera

la capacité calorifique en causant I’accumulation rapide

de créosote et diminuera la puissance calorifique du bois

employé.

Formation de créosote et de suie et

nécessité de les éliminer

Lorsque le bois brûle lentement, il produit du goudron et

d’autres vapeurs organiques qui, combinés à I’humidité

expulsée, forment de la créosote, dont les vapeurs se

condensent dans le conduit de fumée relativement froid

du tuyau de cheminée. Cette créosote accumulée est

extrêmement inflammable ; elle est à l’origine de la

plupart des feux de cheminée. Pour éviter un feu de

cheminée, il vous faudra donc I’éliminer en ramonant la

cheminée et le raccord du tuyau de fumée. La fréquence

de ramonage dépendra du fonctionnement de votre poêle;

néanmoins, il sera prudent de vérifier le tuyau de cheminée

toutes les deux semaines d’utilisation du poêle. Une

accumulation d’1/4 po. (0.6 cm) ou plus sur les parois de

tuyau ou de raccord est considérée dangereuse et doit

être nettoyée.

Au cas où la créosote accumulée dans le tuyau de

cheminée ou le raccord s’enflammerait, le feu de cheminée

est généralement signalé par un ronflement bruyant et

des crépitements au fur et à mesure que la créosote se

détache. Si vous soupçonnez un feu de cheminée, fermez

immédiatement le régulateur de tirage et assurez-vous

que la porte du poêle est close. Appelez les pompiers et

faites sortir toutes les personnes présentes pour les

mettre à I’abri.

Vous ne pouvez essayer d’éteindre le feu depuis I’intérieur

du poêle; en fait, vous risqueriez d’empirer la situation en

permettant la pénétration d’oxygène par la porte qui à

son tour, continuerait d’alimenter le feu de cheminée.

Lorsque le ronflement et les crépitements cessent,

résistez à la tentation d’ouvrir la porte du poêle pour

examiner le feu. Même si vous êtes parvenu à le suffoquer,

il risque de se raviver lorsque vous ouvrez la porte. Après

un feu de cheminée, n’employez votre poêle que lorsque

la cheminée et le raccord auront été nettoyés et inspectés

afin de vous assurer de I’absence de tout dommage.

Une certaine odeur et même de la fumée sont normales

pendant les quelques premiers feux. Ceci est dû au

traitement de la peinture soumise à une température

élevée ; I’odeur devrait diminuer avec chaque feu et

éventuellement disparaître. Une fenêtre ou porte ouverte

à proximité du poêle produira un supplément d’aération

et aidera à diminuer l’odeur.

Commandes

Loquet - Porte de devant

Le loquet de la porte avant est situé de manière pratique

à gauche du centre de la porte. Pour ouvrir celle-ci,

soulevez simplement le loquet et tirez la porte vers vous.

Pour fermer, soulevez le loquet, pressez la porte

fermement contre I’avant du poêle et abaissez le loquet.

(Voyez illustr. 19 A, page 24)

Commande d’air

La commande d’air coulissante (Illustr. 19 B, page 24) est

située sur le panneau avant, au-dessus de la porte de

chargement de combustible.

Le glissement de la commande vers la droite augmente

I’admission d’air et la sortie de chaleur ; son glissement

vers la gauche diminue I’admission d’air et la sortie de

chaleur.

Glissez intégralement la commande vers la droite pour

mettre un feu en marche, pour le raviver ou lorsqu’un

chauffage maximal est désiré. Positionnez la commande

au milieu ou à gauche du milieu pour une chaleur moins

forte et lorsque des durées prolongées de brûlage sont

requises. Vous déterminerez les meilleurs réglages pour

votre usage personnel au fur et à mesure que vous vous familiariserez avec votre poêle.

Le poêle est chaud pendant son fonctionnement. Eloignez

les enfants et ne gardez pas de vêtements ou de meubles

à proximité. Ne stockez pas de combustible à l’intérieur

des dégagements énumérés précédemment.

Rodage du poêle

Un poêle de fonte doit être «rodé» graduellement. Cinq

petits feux seront allumés consécutivement avant

d’utiliser le poêle en continu. Chaque feu sera un peu plus

conséquent que le précédent et le dernier sera

d’importance normale. Laissez le poêle refroidir

complètement entre les feux.

Préparation d’un feu

Un feu bien préparé utilisera efficacement votre

combustible, conservera la vitre propre, les émissions et

la créosote au minimum, demandera moins de travail et

ses réactions seront extrêmement faciles à prévoir.

17

Page 18

CANADA

Bonne fondation

Assurez-vous que la poignée de commande d’air primaire

est bien poussée intégralement vers la droite et que le

tisonnier de la commande de mise en marche est en

position ouverte (tiré intégralement vers I’extérieur).

Ouvrez la porte du devant et couvrez le fond du poêle de

papier journal chiffonné serré. Entrecroisez une généreuse

double poignée de bûchettes sèches - des morceaux de

bois de retaille fendu par exemple, par-dessus le papier.

Si vous ne disposez pas de bois de retaille, fendez-en vousmême dans du bois sec, en bâtonnets d’un doigt

d’épaisseur environ et servez-vous en comme de

bûchettes. Placez alors quatre morceaux de 2-1/2 à 5 cm

de bois sec fendu sur le dessus des bûchettes.

Allumez uniformément le papier tout au long de I’avant

du poêle et fermez la porte.

Continuez à ajouter des morceaux de 2-1/2 à 5 cm de bois

sec fendu jusqu’ à ce qu’un lit de braises incandescentes

ait bien pris.

Vous pouvez maintenant ajouter trois ou quatre morceaux

de bois - petite à moyenne dimension, que vous laisserez

brûler plusieurs minutes. Dès que vous êtes convaincu

que ce bois brûle bien, fermez I’admission d’air de mise en

marche (tisonnier intégralement enfoncé) et réglez la

commande d’air primaire au niveau de sortie de chaleur

désiré et pour maintenir des températures de

fonctionnement sûres et sans danger. Un déplacement

vers la droite augmente la chaleur ; vers la gauche, il la

diminue. Évitez d’employer le poêle si la commande d’air

est complètement fermée.

Lorsqu’un feu meurt, cela est probablement dû à un lit de

braises insuffisant, lequel diminue I’admission d’air trop

rapidement ou à I’usage d’un bois trop épais ou

insuffisamment séché.

Rechargement

Rechargez le poêle encore chaud et dont les braises

restantes suffisent à enflammer la nouvelle charge de

combustible. Il sera bon d’insérer un morceau ou deux de

bois plus petits à la base de la nouvelle charge pour aider

le poêle à récupérer plus rapidement sa température de

fonctionnement.

Méthode de rechargement

• Portez toujours des gants lorsque vous prenez soin de

votre poêle.

• Poussez la commande d’air à droite, en position ouverte

intégrale.

• Attendez quelques secondes avant d’ouvrir la porte.

• Employez une pelle à poêle ou un outil similaire pour

briser les restes de charbon de bois et pour attirer

quelques braises vers I’avant du poêle par lequel entre

I’air de combustion.

• Chargez le combustible (morceaux plus petits d’abord).

• Fermez la porte.

• Attendez 5 à 10 minutes puis réglez la commande d’air

au niveau désiré.

Avis : Si le lit de charbon de bois présent au moment de

recharger est relativement profond ( 5 à 7 1/2 cm) et si

votre bois est bien sec, le moment est venu d’ajouter une

nouvelle charge de combustible, de fermer la porte, de

régler à nouveau la commande d’air au taux désiré de

sortie de chaleur - tout cela en 5 minutes seulement.

Retrait des cendres

Le retrait des cendres est requis chaque jour ou deux

pendant une saison de fonctionnement normal ; il est bien

plus facile à effectuer lorsque le bois brûlé est calciné en

charbons.

Avec une pelle, poussez tout d’abord les braises chaudes

d’un côté ou de I’autre. Ramassez à la pelle les cendres

exposées et repoussez les braises chaudes de l’autre côté.

Enlevez également les cendres de ce côté puis étalez

uniformément les braises chaudes à travers la boîte à

feu. Vous pouvez maintenant ajouter du nouveau bois pour

commencer un nouveau feu.

Lorsque vous enlevez les cendres d’un poêle en

fonctionnement, fermez et loquetez la porte avant de

sortir les cendres à I’extérieur pour en disposer sans

danger. Le port de gants protecteurs épais est toujours

une bonne idée tandis que vous enlevez et disposez des

cendres de votre poêle.

Les cendres devraient être placées dans un contenant de