Page 1

Jøtul GZ 550 DV II

Acadia

Direct Vent Gas

Fireplace

WARNING:

IF THE INFORMATION IN THESE INSTRUCTIONS ARE NOT FOLLOWED EXACTLY, A FIRE

OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS

OF LIFE.

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

INSTALLATION:

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER, SERVICE AGENCY OR LICENSED GAS SUPPLIER.

WHAT TO DO IF YOU SMELL GAS:

• DO NOT TRY TO LIGHT ANY APPLIANCE.

• DO NOT TOUCH ANY ELECTRICAL

SWITCHES.

• DO NOT USE THE PHONE IN YOUR

BUILDING. IMMEDIATELY CALL YOUR GAS

SUPPLIER FROM A NEIGHBOR’S PHONE.

• FOLLOW YOUR GAS SUPPLIER’S

INSTRUCTIONS.

• IF YOU CANNOT REACH YOUR GAS

SUPPLIER, CALL THE FIRE DEPARTMENT.

Installation

and

Operation

Instructions

AVERTISSEMENT:

ASSUREZ-VOUS DE BIEN SUIVRE LES INSTRUCTIONS DANS CETTE NOTICE POUR

REDUIRE AU MINIMUM LE RISQUE D’INCENDIE

OU POUR EVITER TOUT DOMMAGE MATERIEL,

TOUTE BLESSURE OU MORTALIT’E.

NE PAS ENTREPOSER NI UTILISER D’ESSENCE

NI OU LIQUIDES INFLAMMABLES DANS LE

VOISINAGE DE CET APPAREIL OU DE TOUT

AUTRE APPAREIL.

L’INSTALLATION LE SERVICE DOIVENT

ETRE EXECUTES PAR UN INSTALLATEUR

QUALIFIE, AGENCE DE SERVICE OU LE

FOURNISSEUR DE GAZ.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ.

• NE PAS TENTER D’ALLUMER L’APPAREIL

• NE TOUCHEZ A AUCUM NTERRUPTEUR.

• NE PAS VOUS SERVIR DES TELEPHONES

SET TROUVANT DANS LE BATIMENT OU

VOUS VOUS TROUVEZ.

• APPELEZ IMMEDIATEMENT VOTRE

FOURNISSEUR DE GAZ CHEZ UN VOISIN.

SUIVEZ LES INSTRUCTIONS DU FOURNISSEUR.

• SI VOUS NE POUVEZ REJOINDRE LE

FOURNISSEUR DE GAZ, APPELEZ LE SERVICE DES INCENDIES.

1

Page 2

Welcome to Jøtul...

Congratulations on the purchase of your new

Jøtul GZ 550 DV II Acadia Gas Fireplace.

We at Jøtul are glad you’ve made the decision to

warm your hearth with a Jøtul product. Your new

fireplace exemplifies our experience gained over 150

years as the world’s largest manufacturer of solid fuel

burning appliances. We’ve been making fine quality

cast iron wood and coal stoves and fireplaces

continuously since 1853.

The Jøtul GZ550 DV II Acadia fireplace combines

advanced gas technology with the warm, traditional

elements of cast iron. With proper care and use, your

fireplace will provide you with many years of safe,

dependable and satisfying service.

The Jøtul GZ550 DV II Acadia is a direct vented gas

heater designed and approved for installation into a

variety of configurations where close clearance to

combustible material is required. Please take a few

minutes to familiarize yourself with this manual and

the features of your new Jøtul fireplace.

2

Page 3

Table of Contents

BLOWER

IGNITOR

HI

LO

AUTO

MANUAL

OFF

ON

OFF

BURNER

AUTO

MANUAL

OFF

HI

LO

Specifications ................................... 4

Installation / Service Tools ............ 5

General Information....................... 5

Safety Information .......................... 6

Installation Requirements

Framing ............................................ 6

Mantel Clearances ........................ 8

Hearth Protection ......................... 8

Vent Requirements ....................... 9

Vertical Termination ................... 10

Horizontal Termination..............11

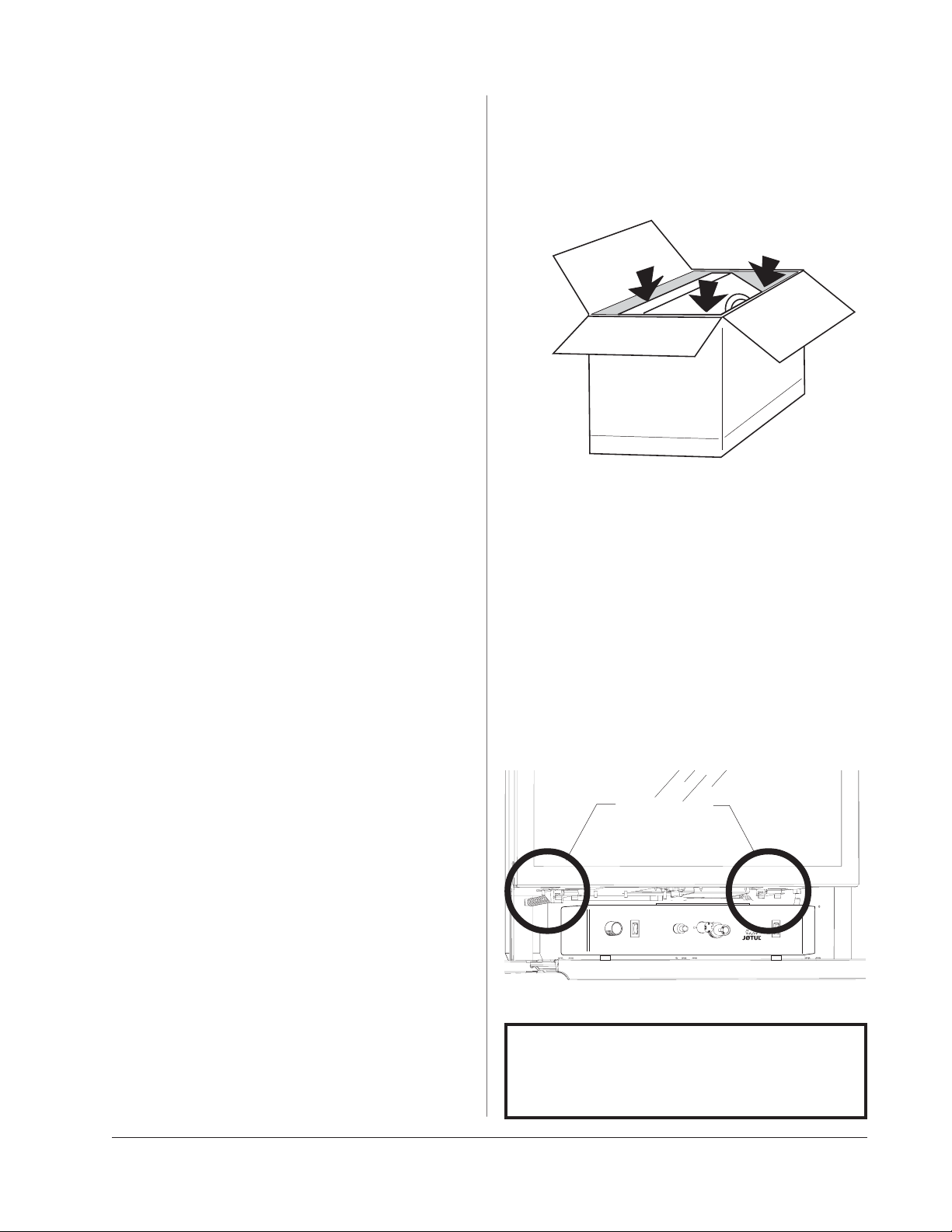

Unpacking the Fireplace

1. Before you remove the carton, remove the cast

iron parts that are packed around the fireplace

cabinet.

Terminal Clearances.................... 11

Vent Restrictor ............................. 12

Fireplace Assembly

Blower Installation...................... 12

Gas Connection ............................ 14

Gas Pressure..................................14

High Altitude Adjustment ........ 15

Fuel Conversion............................ 16

Wall Thermostat ..........................19

Remote Control ............................19

Antique Brick Kit .......................... 20

Log Set Installation ..................... 21

Surround Assembly..................... 22

Double Door Installation ........... 22

System Check................................23

Operation.........................................25

Maintenance................................... 26

2. Lift the shipping carton off of the fireplace

cabinet.

3. Unpack the Firebox. The Logset is packaged inside

the firebox. Remove the Glass Panel Frame to

unpack the firebox:

• Locate the right and left spring latches on the

underside of the firebox floor. Release each latch

by pulling them forward to disengage the frame

body.

• Pull the Glass Frame away from the firebox and

lift to disengage it from the three steel tabs

located at the top of the firebox. Set the glass out

of the way.

Do not unpack the logs until you are ready to

install them.

Spring Latches

Glass Replacement........................ 26

Service Log ....................................... 27

Illustrated Parts Breakdown ....... 28

Replacement Parts List.................29

Accessories ......................................30

Lighting Instructions .... Back Cover

Pull each Spring Latch to disengage them from the

Glass Frame.

PLEASE READ THESE INSTRUCTIONS IN

THEIR ENTIRETY AND MAKE THEM

AVAILABLE TO ANYONE USING OR

SERVICING THIS APPLIANCE.

3

Page 4

Jøtul GZ 550 DV II Acadia

Direct Vent Gas Fireplace

Manufactured and Distributed by:

Jøtul A.S.A.

Fredrikstad, Norway

Jøtul North America

Portland, Maine

Test Standards

This appliance complies with

National Safety standards

and is tested and listed by

Intertek Testing Services of

Middleton, Wisconsin to ANSI

Z21.88-2002•CSA 2.33-M02

and CAN/CGA 2.17--M91,

CSA P.4.-01.2 for Canada.

DO NOT ATTEMPT TO ALTER OR MODIFY THE CONSTRUCTION OF THE APPLIANCE OR ITS COMPONENTS.

ANY MODIFICATION OR ALTERATION WILL VOID THE

WARRANTY, CERTIFICATION AND LISTING OF THIS

APPLIANCE.

THIS HEATER MUST BE INSTALLED AND

MAINTAINED BY A QUALIFIED SERVICE

AGENCY.

IN THE COMMENWEALTH OF

MASSACHUSETTS, THIS PRODUCT

MUST BE INSTALLED BY A LICENSED

PLUMBER OR GAS-FITTER.

DO NOT ATTEMPT TO ALTER OR

MODIFY THE CONSTRUCTION OF THIS

APPLIANCE OR ITS COMPONENTS. ANY

MODIFICATION OR ALTERATION WILL

VOID THE WARRANTY, CERTIFICATION

AND LISTING OF THIS APPLIANCE.

Specifications

Input Rates

Natural Gas

28,000 BTU/hr. maximum input

16,000 BTU/hr. minimum input

Propane

28,000 BTU/hr. maximum input

15,500 BTU/hr. minimum input

Inlet Pressure: MIN MAX

Natural Gas: 5.0 WC (1.24 kPa) 11.0 WC (2.74 kPa)

Propane: 12.0 WC (2.98 kPa) 14.9.0 WC (3.71 kPa)

Manifold Pressure: MIN MAX

Natural Gas: 1.2 WC (.29 kPa) 3.8 WC (.94 kPa)

Propane: 2.9 WC (.72 kPa) 11.0 WC (2.74 kPa)

THIS FIREPLACE IS SHIPPED AS A

NN

AA

TURAL GAS TURAL GAS

N

A

TURAL GAS FIREPLACE ONLY. IF

NN

AA

TURAL GAS TURAL GAS

USE WITH PROPANE IS DESIRED,

THE FIREPLACE MUST BE CONVERTED TO USE WITH PROPANE.

FOR YOUR CONVENIENCE THIS

FIREPLACE IS SHIPPED WITH A

PROPANE CONVERSION KIT.

www.nficertified.org

We at Jøtul North America are dedicated to

manufacturing the finest quality hearth

products you can be assured will give you

many years of safe, dependable service.

To ensure your confidence, we recommend

that whenever possible, our products be

installed and serviced by professionals who

are certified by the National Fireplace

Institute (NFI) or, in Canada, by Wood Energy

Technical Training (WETT).

4

Page 5

General Information

IMPORTANT:

SAVE THESE INSTRUCTIONS.

THIS HEATER MUST BE INSTALLED AND

MAINTAINED BY A QUALIFIED SERVICE

AGENCY.

DO NOT ATTEMPT TO ALTER OR

MODIFY THE CONSTRUCTION OF THIS

APPLIANCE OR ITS COMPONENTS. ANY

MODIFICATION OR ALTERATION WILL

VOID THE WARRANTY, CERTIFICATION

AND LISTING OF THIS APPLIANCE.

1. The installation and repair of this appliance must

be done by a qualified service person. Failure to

properly install and maintain this heater could

result in an unsafe or hazardous installation,

which may result in a fire, explosion, property

damage, personal injury or loss of life.

2. This appliance should be inspected before use

and at least annually. More frequent cleaning

may be required due to excessive lint from

carpeting, bedding material, etc. It is imperative

that control compartments, burners and circulating air passageways of the appliance be kept

clean.

`S’assurer que le bruleur et le compartiment des

commandes sont propres. Voir les instructions

d’installation et d’utilisation qui accompagnent

l’appareil.

3. The installation must conform to local codes. Your

local Jøtul authorized dealer can assist you in

determining what is required in your area for a

safe and legal installation. Some areas require a

permit to install a gas burning appliance. Always

consult your local building inspector or authority

having jurisdiction to determine what regulations

apply in your area.

In the absence of local codes, the installation

requirements must comply with the current

National codes. In the U.S., these requirements

are established in the National Fuel Code, ANSI

Z223.1.(NFPA 54). In Canada, the codes have been

established in CAN/CGA B149 Fuel Installation

Code.

Installer l’appareil selon les codes ou reglements

locaux, ou, en l’absence de tels reglements, selon

les Codes d’installation CAN/CGA-B149.

4. DO NOT OPERATE THIS FIREPLACE IF ANY PART HAS

BEEN UNDER WATER.

Immediately call a qualified service technician to

inspect the heater and to replace any part of the

control system and any gas control which has

been under water.

Ne pas se servir de cet appareil s’il a ete’ plonge

dans l’eau, completement ou en partie. Appeler

un technicien qualifie pour inspecter l’appareil et

remplacer toute partie du syste’me de controle et

toute commande qui ont ete plonges dans l’eau.

5. Do not operate the fireplace with the glass front

removed, cracked or broken. Replacement of the

glass should be done by a licensed or qualified

service person. Only remove glass for routine

service. Always handle glass carefully.

Pour utilisation avec les portes en verre cerifiers

aved l’appareil seulemend ou. Ne pas utiliser avec

des portes on verre.

6. Notify your insurance company before proceding

with installation of this fireplace.

7. This appliance may be installed in an aftermarket

permanently located, manufactured (mobile)

home, where not prohibited by local codes. This

appliance is only for use with the type(s) of gas

indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a

certified kit is used.

Cet appareil peut être installé dans un maison

préfabriquée (mobile) déjà installée à demeure si

les règlements locaux le permettent. Cet appareil

doit être utilisé uniquement avec les types de gas

indiqués sur la plaque signalétique. Ne pas

l’utiliser avec d’autres gas sauf si un kitde conversion certifié est installé.

Suggested Tools for

Installation and Service

• External regulator (for Propane only)

• Piping which complies with local code

• Manual shutoff valve - T-Handle in MA

• Sediment trap - if required by code

• 10mm open end wrench

• 1/2”, 7/16” open end wrench

• Phillips head screwdriver

• Flat head screwdriver •Tee joint

• Pipe wrench •Pipe sealant

• 1/4” nut driver •Torx T20 screwdriver

• Gloves •Safety glasses

• Leak test solution •Power Drill

• Reciprocating Saw

5

Page 6

Safety Information

Installation

Due to the high operating temperatures this

appliance should be located out of traffic and

away from furniture, draperies, etc. Maintain

proper clearance to combustible mantels and

fireplace trim.

Children and adults should be alerted to the

hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition.

Young children should be supervised while they

are in the same room as the Acadia gas fireplace.

Surveiller les enfants. Garder les vetements, les

meubles, l’essence ou autres liquides a vapeur

inflammables loin de l’appareil.

Clothing or other flammable materials should not

be placed ON or NEAR the Acadia gas fireplace.

Never allow any to use the fireplace if they are

unfamiliar with its operation.

NEVER store or use gasoline or any other flam-

mable vapors or liquids in the vicinity of the

Acadia gas fireplace.

Never burn any solid materials (wood, cardboard,

paper, coal, etc.) in this gas fireplace. Use with

natural gas or propane fuel ONLY.

Any safety screen, glass or guard removed for

servicing the appliance must be replaced prior to

operating the appliance.

Do not slam or strike the glass panel.

Wear gloves and safety glases while performing

maintenance procedures.

Electrical Hazard

Be aware of electrical wiring locations when

cutting holes in walls and ceilings for termination.

The optional Acadia Blower (155630) must be

electrically grounded in accordance with local

codes or, in the absence of local codes, with the

current ANSI/NFPA 70, National Electrical Code or

CSA C22.1-Canadian Electrical Code.

The Acadia Blower is supplied with a three-prong

(grounding) plug for protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle. DO

NOT CUT OR REMOVE THE GROUNDING PRONG

FROM THE PLUG.

Always disconect the power supply when per-

forming routine service on the fireplace.

Requirements

The GZ 550 DV Acadia Gas Fireplace and its vent

system must be installed within a totally enclosed

structure. The fireplace must be connected to the

specified vent and termination cap outside the

building. Do not vent into another room or inside

any part of a building. Under no circumstances may

the flow of combustion or ventilation air be obstructed.

The approved vent configurations described

herein are derived from extensive testing under

controlled laboratory conditions. Gas appliance

performance can be negatively affected by variables

present in the installation environment, i.e: strong

prevailing winds, steep roofs, nearby trees, snow

accumulation, etc. These conditions should be taken

into consideration by the installer and home owner.

In such instances, system performance can often be

improved by an increase in the vent height or

installation of a high wind termination cap.

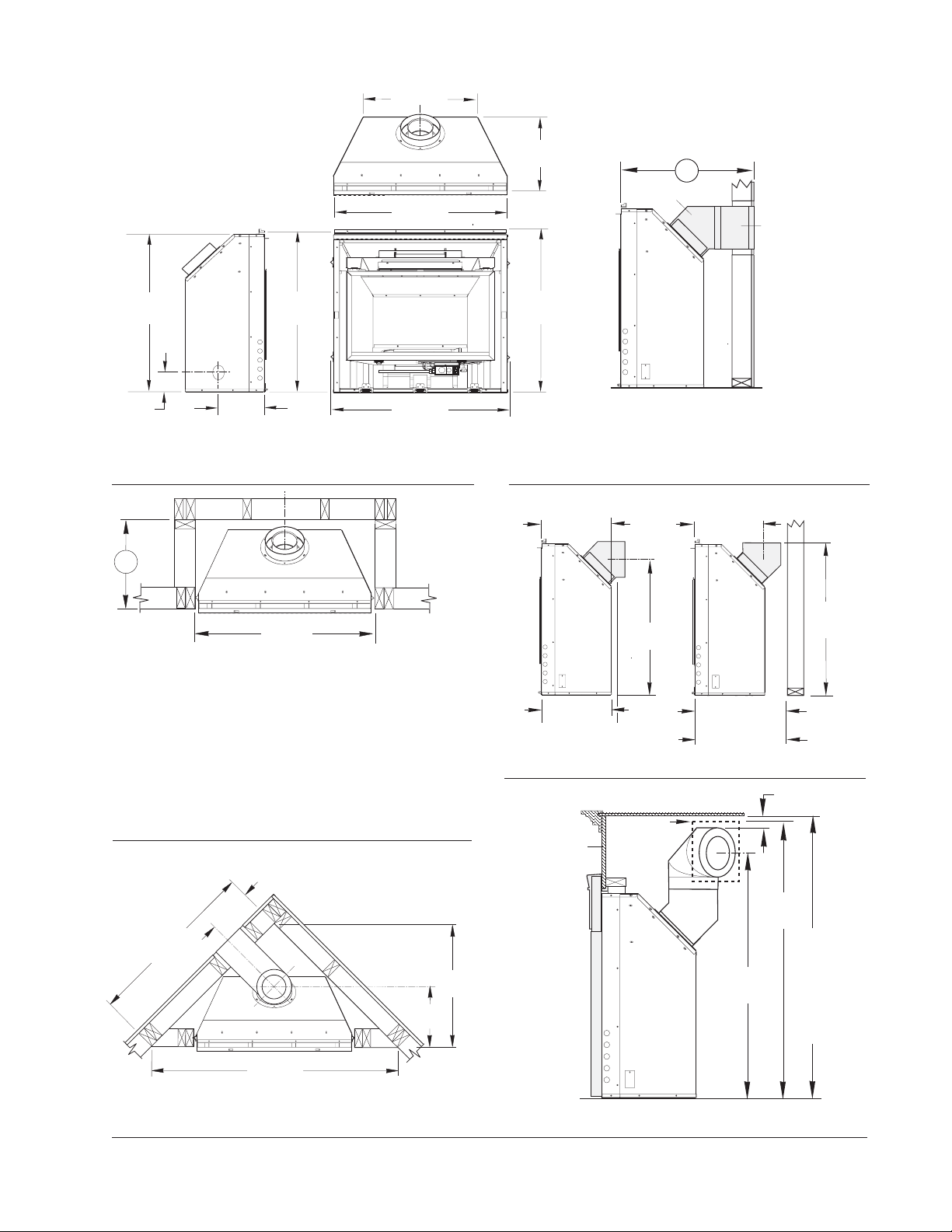

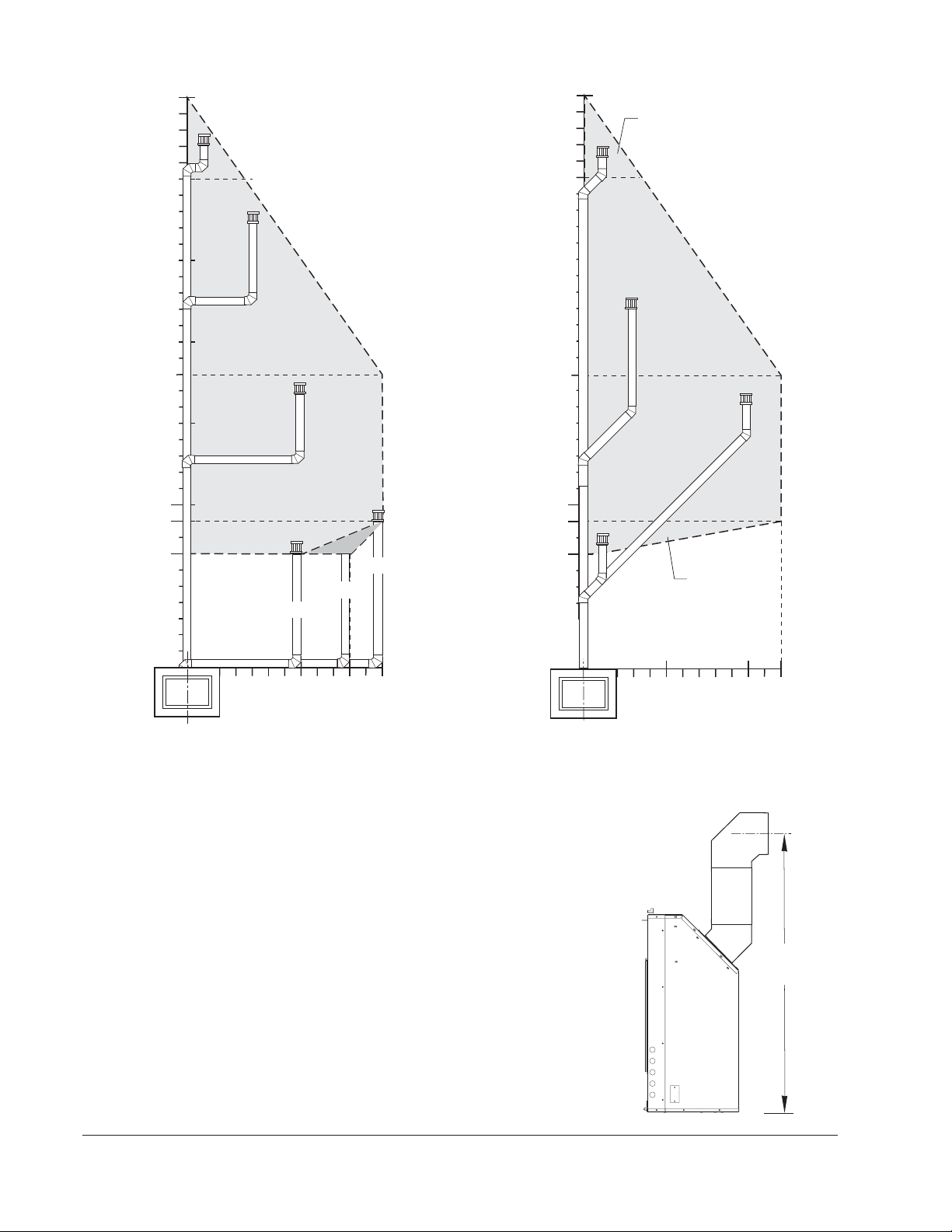

Placement and Framing

The combustible framing members of the fireplace

enclosure may be placed in direct contact with the

fireplace cabinet as specified in the illustrations on

the following pages. Use the standoffs integrated

into the sides and top of the front opening to locate

a combustible header and side framing members as

shown in the illustrations. See fig. 1.

Electrical Power: If the optional Blower (#155630)

will be used, be sure to include provision for a

properly grounded, 120 volt house current outlet at

the fireplace structure.

Parallel Installation

Although it is possible to place combustible framing

members in direct contact with the rear surface of

the cabinet, the fireplace must be located forward

of the back wall with adequate clearance to accommodate the vent adaptor and subsequent lengths

of vent pipe. Consideration must also be given to

maintaining a minimum 1 inch (25 mm) clearance

between a vertical vent pipe and any combustible

materials to the rear of the unit. See Figs. 2, 3, and 4.

Corner Installation

A corner installation will require that the Vent

Adaptor be installed in a top exit position. Horizontal

terminations will then require use of a 90° elbow.

Figs. 5 and 5a show rear termination with 5/8

Simpson Dura-Vent Wall Thimble #1247.

6

Page 7

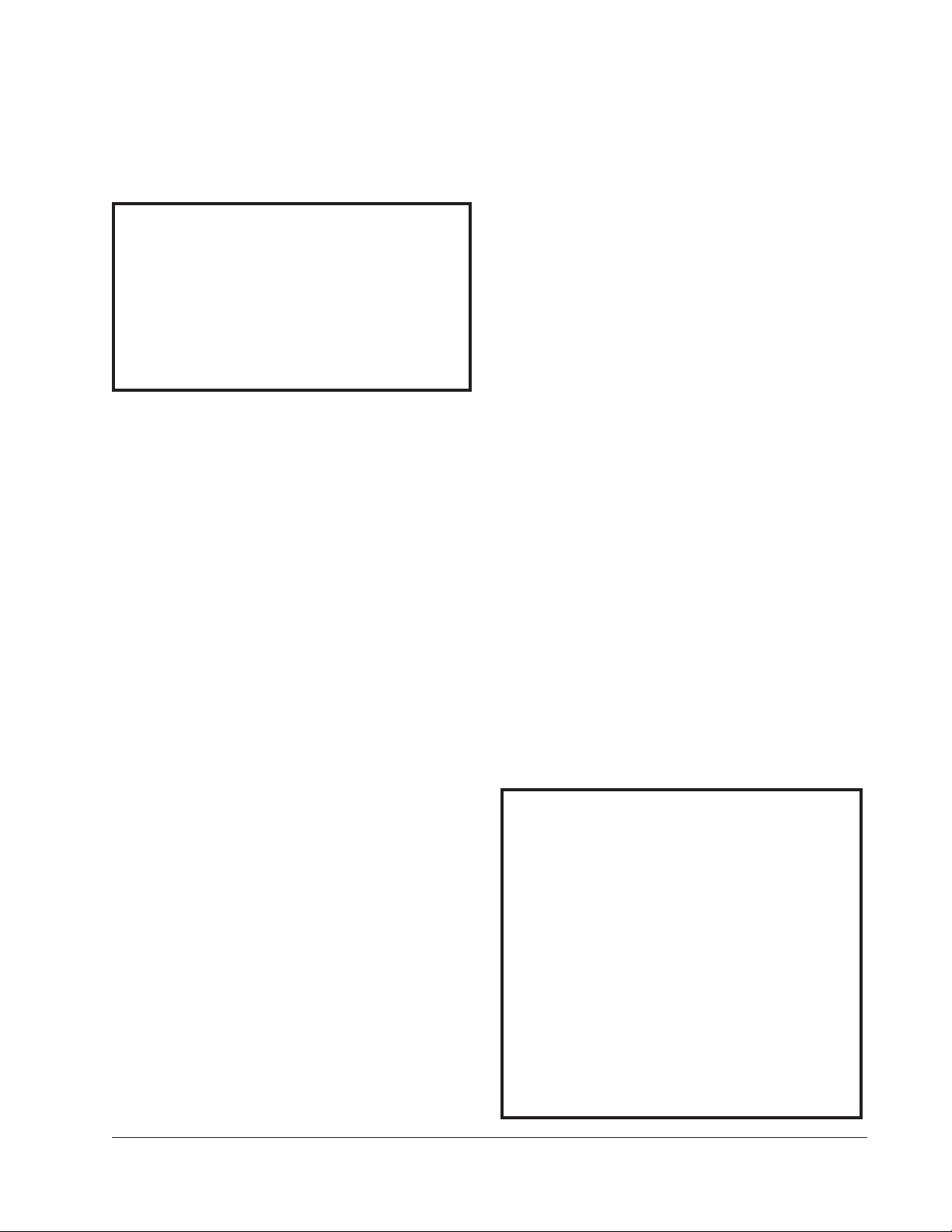

Figure 1. Cabinet Dimensions.

Header Standoff Height: 36 1/2”

35

890 mm

35 3/4 *

910 mm

25

635 mm

35 3/4

900 mm

16 1/4

410 mm

36 1/2

921 mm

Figure 2. Minimum horizontal vent

allowance through wall.

A

5/8 Vent Adaptor

6 Vent

Section

Wall Cutout :

4/6 Pipe - 10”x10”

5/8 Pipe - 11”x11”

Observe all vent

and termination

clearance

requirements.

4

100 mm

8

200 mm

970 mm

NOTE: DO NOT INSTALL CABINET ON FLOOR SURFACE

LOWER THAN THE FRONTAL HEARTH SURFACE.

* Wallboard Standoff Height

A

38

(970 mm)

Horizontal Vent: Minimum depth accomodates the length of

Vent Adaptor and one 6 vent section through wall construction.

Vent Adaptor: 5/8

Vertical Vent: Minimum depth includes 1 inch clearance

between Vent Adaptor and combustible wall construction.

Vent Adaptor: 5/8 4/6

A = 21 3/4

A = 21 1/2 20

Figure 3. Depth requirement to rear wall.

38

Security Vent:

A = 25 1/4 (645 mm)

Security Termination has no slip adjustibility.

Simpson DuraVent and Amerivent:

25 3/4 (660 mm)

A =

Rear Exit

16 1/4

(415 mm)

16 1/4

(413 mm)

19 1/4

(490 mm)

32 3/4

(830 mm)

Top Exit

16 1/4

(415 mm)

5/8 Vent

4/6 Vent

Figure 4. Vent Adaptor orientation.

WALL OPENING

CUSTOM

MANTEL

CABINET

5/8 VENT

11 x 11

280 mm x 280 mm

See text for

details.

21 1/2

(546 mm)

20

(510 mm)

2

50 mm

Min. Vent

Clearance

38 3/4

(990 mm)

9

230 mm

41

1041 mm

56 1/2

1435 mm

Figure 5. Corner framing dimensions.

16

410 mm

28 1/2

730 mm

48 1/2

1232 mm

49 1/4

1232 mm

Minimum

43

1092 mm

mantel

shelf

height to

cover vent

wall

thimble

Figure 5a. Corner Installation - 5/8 vent, rear termination.

7

Page 8

Hearth Protection

The GZ550 Acadia is approved for installation

without hearth protection. Combustible materials

may be used on the floor directly under and in front

of the fireplace. NOTE: The floor surface under the

unit must be level with, or higher than, the surface

in front of the unit to allow the fireplace Controls

Door to fully open.

Facing and Clearance Requirements

The following clearance and hearth specifications

are the minimum requirements for the GZ550

Acadia gas fireplace. Measure clearances from the

steel fireplace cabinet - not the cast iron surround

panels. See Figures 6 - 8.

A combustible surface is anything that can burn

(i.e. sheet rock, wallpaper, wood, fabrics etc.). These

surfaces are not limited to those that are visible and

also include materials that are behind non-combustibles.

If you are not sure of the combustible nature of

a material, consult your local fire officials. “Fire

Resistant” materials are considered combustible they are difficult to ignite, but will burn. “Firerated” sheet rock is also considered combustible.

Maintain the proper clearances to the appliance

to allow adequate flow of ventilation air around

the fireplace.

Mantel and Trim Clearance

12

13 1/2

12

10 1/2

9

7 1/2

4 1/2

TOP OF CABINET

35

Figure 7. Minimum Mantel Clearances. Measure

clearances from the top of the fireplace cabinet

before installation of the cast iron surround panels.

4 8

MANTEL

AREA

DRYWALL

UPPER TRIM

2 1/2 Max. Depth

HEADER

STANDOFF

CAST IRON SURROUND PANELS

Wallboard

Header

10”

(250 mm)

Figure 6. Header and Side Standoffs

8

Standoff

Standoffs

TOP TRIM

4 1/2

1.2 cm

SIDE TRIM

GZ550 DV

SIDE WALL

10

2.55 cm

Cabinet

4 1/2

1.2 cm

Figure 8. Minimum Side Wall and Trim Clearance.

Measured from the cabinet, not standoffs or cast iron

panels.

Page 9

Horizontal Overhang

Vertical W

all

Termination

Cap

18.

min.

Lowest Discharge

Opening

18 min.

18.

min.

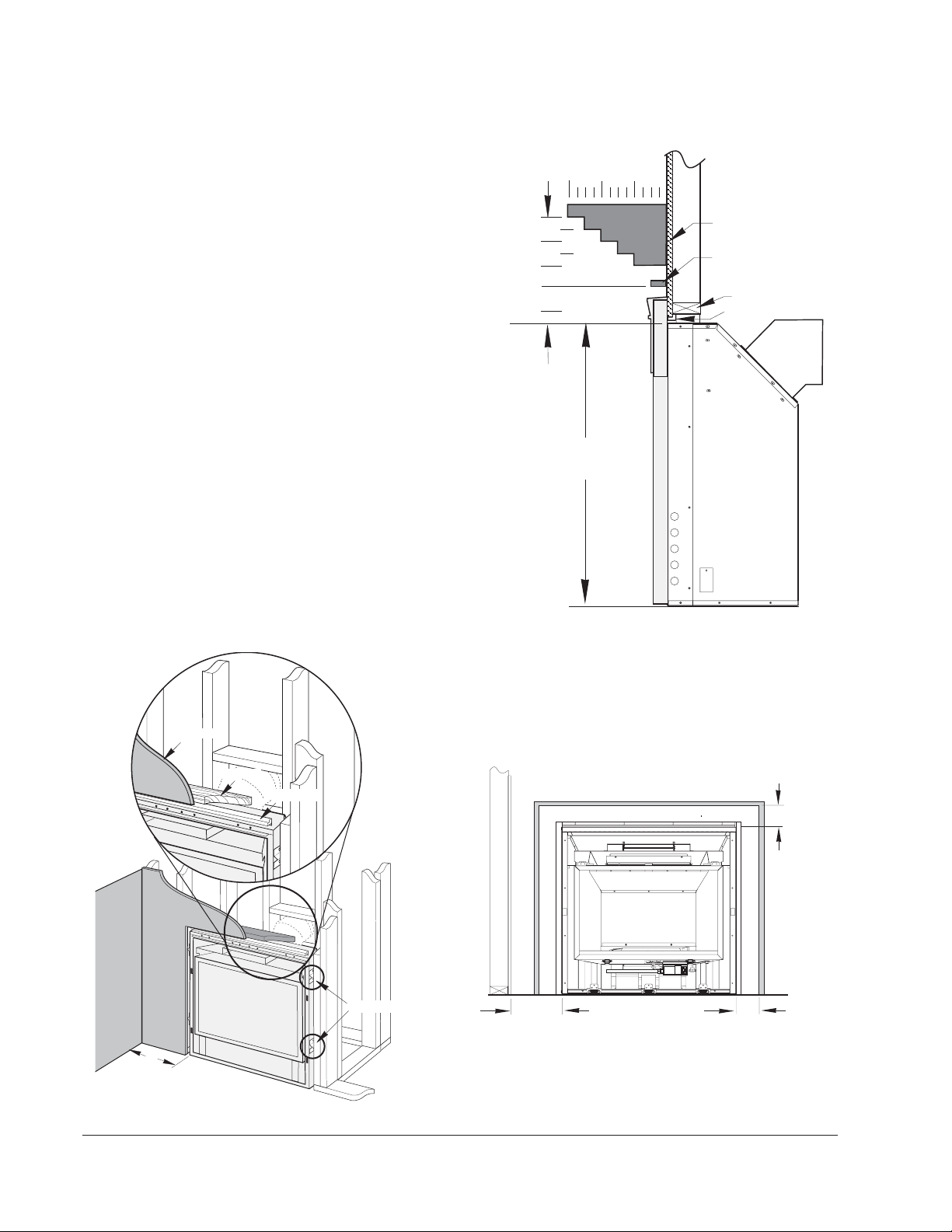

Vent Requirements

The GZ550 DV Acadia Gas Fireplace is approved for

use with direct vent components produced by the

following manufacturers:

• Simpson Dura-Vent Corporation, 5/8 and 4/6 pipe

• Security Vent Ltd. International, 5/8 and 4/6 pipe

• Amerivent Corporation, 4/6 pipe

• Selkirk Metalbestos Corp. MDV Direct Vent Systems

Use vent components from a single vent manufacturer. Do not combine parts from different

manufacturers in a single installation.

The vent termination must fall within the shaded area

designated in the diagrams in Figures 12 - 14.

Venting Guidelines

The minimum height for a vertical termination

cap must be no less than 7' from the top of the

unit. The maximum height must not exceed 35'.

The minimum vent height above the roof or

adjacent walls is specified by major building

codes. Use the Gas Vent Rule as a general guide.

See fig.10. requirements of the approval listing

and the manufacturer’s instructions.

Clearance (airspace) between Vent and Combustibles:

Top - 2” (51 mm) Sides/Bottom - 1” (25 mm)

Wall Cutout Dimensions:

4/6 Pipe - 10” x 10” 5/8 Pipe - 11” x 11”

Any horizontal run must rise 1/4” per foot.

Install venting in accordance with the vent

manufacturers’ instructions. Never modify any

venting component, or use any damaged venting

product.

THE GAS APPLIANCE AND VENT SYSTEM MUST BE

VENTED DIRECTLY TO THE OUTSIDE OF THE BUILDING.

DO NOT CONNECT VENT TO A

CHIMNEY SERVING A SOLID FUEL

OR ANOTHER GAS APPLIANCE.

Joint Sealing Requirement:

Apply a 1/8” bead of hightemperature (750°F) sealant

to the male section of the

inner vent pipe. See fig. 9.

The cement should seal

the inner pipe from the

outer pipe.

Figure 9. Seal each inner joint before joining pipe.

Figure 10. Gas Vent Height Rule: Vertical vent

termination height above roof.

Do not recess the vent terminal into a wall or siding.

Inspect the vent system annually for blockage and

deterioration. If the vent-air intake system is

disassembled for any reason, reinstall according to

the instructions provided for initial installation.

Installation of any components not manufactured

or approved by Jøtul or failure to meet all clearance requirements will void all warranties and

may result in property damage, bodily injury, or

loss of life.

IN DESIGNING THE VENT SYSTEM, DO NOT

COUNT THE 45° ELBOW CONNECTED TO THE

VENT COLLAR AS AN ELBOW.

45° Elbow

6” Vent Section

Wall Support

S

E

A

L

A

N

T

Wall Termination

Figure 11. Typical minimum horizontal vent

configuration - 5/8 Simpson DuraVent. Do not use

4/6 pipe in this configuration.

9

Page 10

35

Restrictor

Fully Closed

35

Restrictor

Fully Closed

Height in Feet

18

10

Minimum

Height

Max.Two

Elbows -

90° or 45°

30

From Vent Collar

9

7

Restrictor

2/3 Closed

Restrictor

1/3 Closed

Restrictor

Open

4/6 Vent

5/8 Vent

Both

30

18

Restrictor

From Vent Collar

Height in Feet

10

1/3 Closed

9

7

Restrictor

2/3 Closed

Restrictor

Open

Max.Two 45°

Elbows

10

12

7

Horizontal Run in Feet

Figure 12. Vent Window for vertical termination

using 5/8 or 4/6 pipe.

Vertical Termination

The vent must terminate within the shaded area

designated on the graphs in Figs. 12 and 13.

• Maximum Elbows - Two 90° or Two 45° (Do not

count the first elbow off the vent collar.)

• Use the restrictor settings indicated in the graph

as general guide. The specific characteristics of

your installation may require different settings.

Horizontal Termination

The vent must terminate within the shaded area

designated in Figs. 15 and 16. (Do not count the first

elbow off the vent collar.)

• Max. Elbows - One 90° or one 45°.

• Use of 4/6 pipe requires a minimum 1 foot rise. Fig. 16.

5

Horizontal Run in Feet

Figure 13. Vent Window for offset vertical

termination using 5/8 or 4/6 pipe.

Figure 14. Minimim

centerline for

horizontal

termination of 4/6

pipe

10

12

52

(990 mm)

10

Page 11

12

12

9

5

From Vent Collar

Height in Feet

3

Max. One 90°

Elbow

5

10

12

Horizontal Run in Feet

Figure 15. Horizontal termination -5/8 pipe.

Horizontal Termination Clearance

9

5

From Vent Collar

Height in Feet

1

3

Horizontal Run in Feet

Figure 16. Horizontal Termination - 4/6 Pipe.

Minimum 1 ft. rise required.

Max. One 90°

5

Elbow

10

12

Figure 17. Vent Terminal Clearances - National Fuel Gas Code.

A = Clearance above grade, veranda, porch , deck, or

balcony : *12 inches (30 cm) minimum.

B = Clearance to window or door that may be opened:

Min. 9 inches, U.S. / *12 inches (30 cm) CAN.

We recommend 12in. minimum to prevent condensation on the window.

C = Clearance to permanently closed window:

Min. 9 inches, U.S. / *12 inches (30 cm) CAN

We recommend 12in. minimum to prevent condensation on the window.

D = Vertical clearance to ventilated soffit located above

the terminal within a horizontal distance of 2 feet (60 cm)

from the centerline of the terminal: 18 inches

(46 cm) minimum.

E = Clearance to unventilated soffit: *12 inches (46 cm)

minimum.

F = Clearance to outside corner: Min. 9 inches, U.S. / *12

inches (30 cm) CAN. We strongly recommend 12 inches,

particularly where windy conditions pevail.

* As specified in CGA B149 Installation Codes. Note: Local Codes

and Regulations may require different clearances.

G = Clearance to inside corner: Min. 6 inches, U.S. / *12

H = *Not to be installed above a meter/regulator assembly

I = Clearance to service regulator vent outlet:

J = Clearance to nonmechanical air supply inlet to building

K = Clearance to a mechanical air supply inlet: *6 feet

L = ** Clearance above paved sidewalk or a paved driveway

M = Clearance under veranda, porch, deck, or balcony:

** A vent shall not terminate directly above a sidewalk or driveway

which is located between two single family dwellings and serves

both dwellings.*

1

on a minimum of two sides beneath the floor.*

inches (30 cm) CAN. We strongly recommend 12 inches,

particularly where windy conditions pevail.

within 3 feet (90 cm) horizontally from the center-line

of the regulator.

3 feet, U.S. / 6 feet (1.8 m), CAN.

or the combustion air inlet to any other appliance:

*12 inches (30 cm) minimum.

(1.8 m) minimum.

located on public property: *7 feet (2.1 m) min.

*12 inches (30 cm) minimum.

Only permitted if veranda, porch, deck, or balcony, is fully open

1

11

Page 12

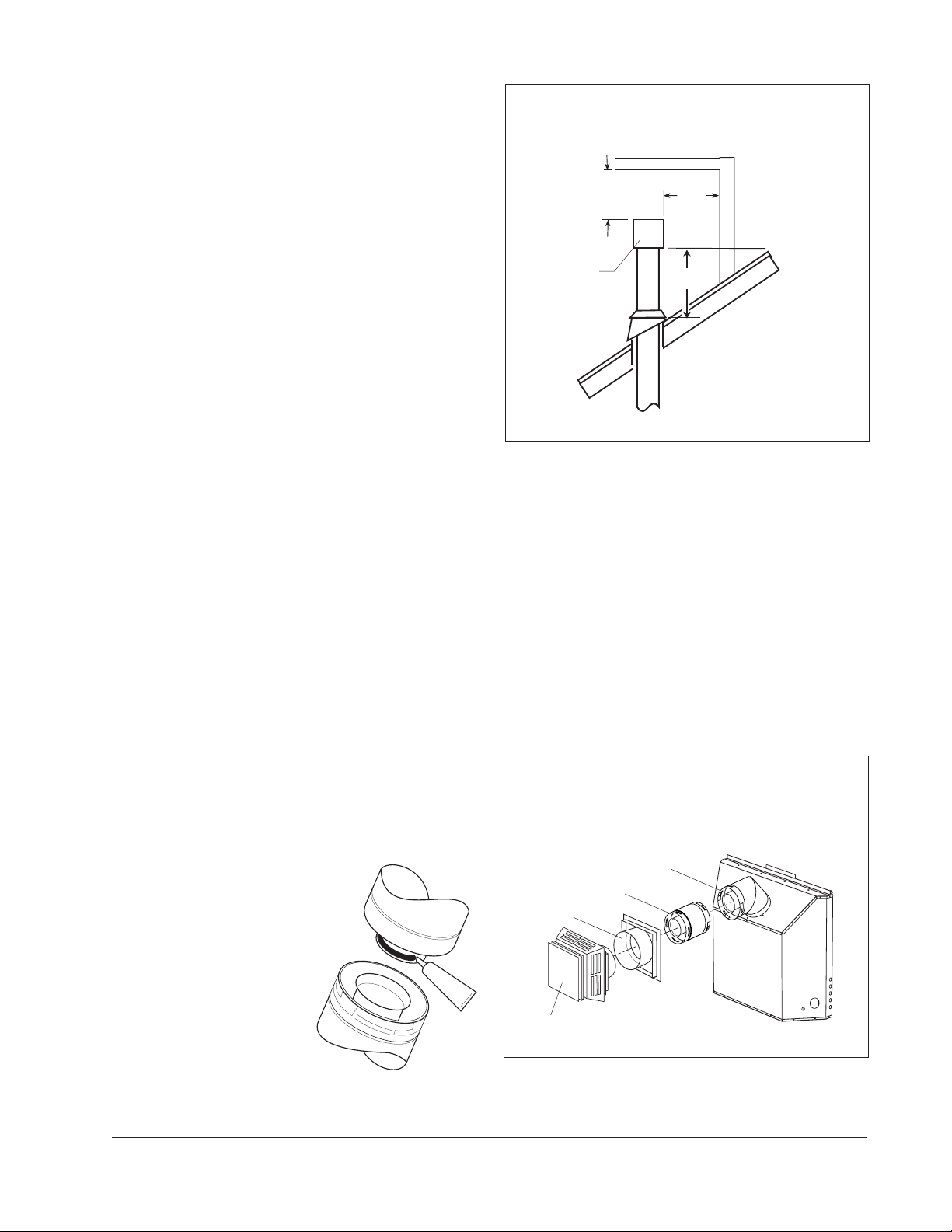

Figure 18.

M

Wall Vent Terminal /

Overhang Clearances

12

305

mm

3

76 mm

2 1/2

64 mm

Variable Vent Restriction

Vent restriction is accomplished by sliding a restrictor panel over the combustion air intake ports

located at the back of the firebox. See Fig 19. The

panel is set in a fully open position at the factory.

Use the Vent Window diagrams in Figs. 12-13 as a

starting point to determine the best restriction

setting. Follow these steps to adjust the restriction

as necessary:

1. Remove the Controls Panel to access the adjustment lever at the rear of the valve compatment.

Simply loosen the two wingnuts that secure the

panel to the cabinet floor and pull the panel

forward. You do not need to disconnect any wires.

2. Locate the vent restriction wingnut protruding

from the firebox floor at the rear of the valve

compartment. Loosen the wingnut and push the

lever to the left to increase restriction in one inch

increments, e.g: 1 inch travel = 1/3 closed position.

The ideal restrictor setting for a particular vent

system will vary depending on the specific installation characteristics. Once the fireplace is operating,

further restrictor adjustment may be necessary to

obtain the best performance. See the Operation

chapter of this manual for more information.

Fully Closed

2/3 Closed

1/3 Closed

Full Open

BLOWER

MANUAL

OFF

AUTO

LO

HI

Figure 19. Vent restrictor adjustment.

IGNITOR

ON

HI

OFF

LO

BURNER

Fireplace Installation

Optional Blower

Install the optional Blower (155630) before

installing the gas supply line.

Power Requirement

The blower must be electrically grounded in accordance with local codes or, in the absence of local

codes, with the current NFPA 70- National Electrical

Code or CSA C22.1-Canadian Code.

A three-prong (grounding) power supply plug is

included for protection against shock hazard and

should be plugged directly into a properly grounded

three-prong receptacle. DO NOT CUT OR REMOVE

THE GROUNDING PRONG FROM THE PLUG.

Blower Function

In the Auto mode, the blower is controlled by a heat

activated switch (snapstat) that will turn the fan on

and off as the firebox heats and cools. Use the

Manual mode to over-ride the snapstat. If the blower

is not needed, place the blower control switch in the

OFF position and the snapstat will not function.

CAUTION: Always unplug the Blower when

performing any routine service to the Acadia gas

fireplace.

Installation

1. Loosen the two wingnuts that secure the Control

Panel to the fireplace floor. Pull the panel forward

and swing it to the right to access the rear of the

cabinet. Do not disconnect any wires.

2. Insert a rubber grommet at each corner of the

Base Plate as shown in fig. 20.

3. Engage the Blower unit base with the four studs

at the rear of the fireplace cabinet floor. See fig. 21.

4. Insert the Snapstat into the slot in the Snapstat

Bracket and, using the M6 nuts and 10 mm socket,

attach the Control Switch / Snapstat Bracket to

the two studs protruding from the firebox floor.

See fig. 22.

5. Connect the Blower Wire harness to the switch

connector at the back of the Control Panel and

two other leads to either terminal on the

snapstat.

6. Run the power cord to the duplex receptacle in

the side of the cabinet. Gather slack cord into the

side cavity, away from the plumbing and other

wiring. Reposition and secure the Control Panel.

12

Page 13

O

U

F

6

Final Cabinet Positioning

1

5

6

1. #129374 Fan/Motor Unit- 125 cfm., variable speed

2. #220012 Base Plate

3. #220637 Snapstat (140°F - 120°F)

4. #220989 Snapstat Bracket

5. #220055 Rubber Grommets, 4

6. #9930 M6 Hex Flange nuts, 2

Figure 20. Blower Kit 155630 contents.

Figure 21. Blower location.

1. If appropriate, attach the 4/6 Vent Adaptor

2

Collar:

• Remove the 5/8 Collar supplied with the unit.

4

3

• Align the 4/6 Collar as shown in fig. 23 and

secure to the unit using the original screws. Be

sure the single round fastener hole is oriented to

the 12 o-clock position for proper vent alignment.

1. Side Standoffs: Remove the retainer screws. Using

vise grips or pliers, fold each standoff at the

perforations. Secure each standoff using the

screws previously removed. See fig. 24.

2. Wall Stud Brace: Loosen, bend, and position each

cabinet Retainer Strap for attachment to the

fireplace enclosure. See fig. 24.

3. Locate the fireplace cabinet in its final position

within the enclosure. Confirm that the first 45°

Elbow is correctly aligned for final vent assembly

and secure it to the Vent Collar using 3, #10 sheet

metal screws.

4. Confirm that the cabinet is positioned to align its

forward edge with the finished surface of the

wall facing. The stud braces allow approximately

2 inches of forward adjustment to accommodate

most any facing thickness. Secure the braces to

the enclosure frame.

5. Complete the gas line and electrical power

routing as appropriate for blower and thermostat functions.

Snapstat Bracket

BLOWER

MANUAL

OFF

AUTO

LO

HI

IGNITOR

ON

HI

OFF

LO

Figure 22. Install snapstat bracket and switch box.

For correct vent pipe

alignment, be sure the

round hole is oriented to

the 12- o’clock position

Figure 23. 4/6 Vent Collar orientation.

BURNER

MAN

OF

AUT

Standoff in shipping position.

Remove, bend and

reattach each Standoff.

Remove, bend and

reattach each Wall

Stud Brace.

Figure 24. Standoff and Stud Brace orientation.

13

Page 14

Connect the Gas Supply

Gas Supply Requirements

ALL INSTALLATIONS MUST COMPLY WITH LOCAL

CODE OR IN THE ABSENCE OF LOCAL CODE, MUST

COMPLY WITH THE MOST RECENT EDITION OF THE

NATIONAL FUEL GAS CODE ANSI Z223.1/NFPA 54 OR

CAN-B149.

Shutoff Valve

All codes require a gas shutoff valve (gas cock)

and union to be installed in the supply line and in

the same room as the appliance. This allows for the

disconnection of the fireplace for servicing and

maintenance. See fig. 25.

A T-handle gas shutoff valve is required in

Massachusetts in compliance with Code 248CMR.

The fireplace and gas control valve must be

disconnected from the gas supply piping during any

pressure testing of the system at test pressures in

excess of 1/2 psig. For pressures lower than 1/2 psig,

isolate the gas supply by closing the manual shutoff

valve.

Leak test:

• Mix a 50-50 solution of water and dish soap.

• Light appliance- see lighting instructions on page

23 of this manual or on the fireplace’s rating

plate.

• Brush or spray all joints and connections with the

soapy water solution.

• If bubbles appear at any connection or seam or a

gas odor is detected, immediately turn gas

control knob to the OFF position.

Tighten or reconnect the leaking joint and retest

for any gas leaks.

Control Valve Connection

The gas supply line connection is made to the

left side of the valve. The gas supply line should be a

minimum 3/8" diameter, or the appropriate size to

provide sufficient gas pressure to the valve regardless of the input setting.

The use of flexible gas appliance connectors is

acceptable in many areas in the U.S. In Canada,

methods vary depending on local code. If local codes

permit, use flexible gas line for ease of installation

and service. For those locales where flexible gas

lines are not permitted, use the 3/8” iron fitting to

make the connection at the left side of the Control

Valve. See Figures 25 and 26.

Secure all joints tightly using appropriate tools

and sealing compounds (for propane units, be sure

to use compounds that are propane resistant). Turn

on gas supply and test for gas leaks using a soapy

water solution. Never use an open flame to check

for leaks.

Figure 25. Gas supply line fittings.

Gas Pressure

Proper gas pressure provides a consistent flow

of gas to the appliance and is instrumental in

checking for gas leaks. The gas control valve on the

fireplace is equipped with pressure test points for

gauge connections. The gauge connections are

located on the front of the valve under the On/Off/

Pilot knob. Gauge connections are identified by:

• IN/E for inlet or supply pressure (the amount of

gas coming to the valve.)

•OUT/A for manifold pressure (the amount of gas

that is coming out of the valve to the burner.)

14

EA

Figure 26. Pressure test point as located on the

front of the valve.

Page 15

The appliance must be isolated from the gas

supply line by closing its individual manual gas

shutoff valve (gas cock) during any pressure testing

of the gas supply piping system that is equal to or

less than pressures of 1/2 psig (3.5 kPa).

Inlet Pressure

Natural Gas: 5.0 WC (1.24 kPa) 11.0 WC (2.74 kPa)

Propane: 12.0 WC (2.98 kPa) 14.9 WC (3.71kPa)

MIN MAX

Natural Gas: 1.2 WC (.29 kPa) 3.8 WC (.94 kPa)

Propane: 2.9 WC (.72 kPa) 11.0 WC (2.74 kPa)

ALWAYS TEST PRESSURE WITH VALVE CONTROL KNOB

SET ON HIGH. Symptoms of incorrect gas pressure

include:

Insufficient gas pressure:

• Small pilot flame which can result in insufficient

millivolts.

• Little variation in flame picture between HI and

LO settings.

• Insufficient gas to support more than one appli-

ance causing nuisance outages or gas surges.

Excessive gas pressure:

• Permanent damage to valve causing complete

appliance shut down.

• Too large a pilot flame resulting in overheating of

the power generator and consequent shut down.

• Sooting due to impingement and/or incorrect fuel

to air mix.

MIN MAX

Manifold Pressure

DANCE WITH THE MANUFACTURER’S INSTRUCTIONS

AND ALL CODES AND REQUIREMENTS OF THE

AUTHORITY HAVING JURISDICTION. THE INFORMATION STICKER MUST BE COMPLETED BY THE INSTALLER AND APPLIED TO THE APPLIANCE AT THE

TIME OF THE CONVERSION. THE QUALIFIED SERVICE

AGENCY PERFORMING THIS WORK ASSUMES RESPONSIBILITY FOR THIS DERATING.

In Canada: This unit has been tested for installation

at high altitudes in accordance with Canadian test

standard CAN/CGA-2.17. THE DERATING SHALL BE

CARRIED OUT IN ACCORDANCE WITH THE REQUIREMENTS OF THE PROVINCIAL AUTHORITIES HAVING

JURISDICTION AND IN ACCORDANCE WITH THE

REQUIREMENTS OF THE CAN1-B-149.1 AND .2

INSTALLATION CODE.

Derating Procedure

1. Follow Steps 1-4 of the Fuel Conversion procedure

outlined on page 14.

2. Remove the original orifice. Consult Table 1 to

determine the correct orifice size for your elevation and fuel type. Install the appropriate orifice

included in the high altitude kit.

3. Fill out the high altitude conversion label and

attach to the rating plate or fireplace cabinet floor

See Figure 27.

4. Reassemble the firebox components.

5. It may be necessary to adjust the air shutter on

the burner tube. See the AIR SHUTTER/FLAME

APPEARANCE section of this manual for more

details.

High Altitude Adjustment

Installations located at altitudes from 2000 - 4500 ft.

(610 M - 1370 M), require compensation for the

thinner air (less volume of air per cubic foot). Higher

altitudes affect the atmospheric pressure and heat

value of gaseous fuels. The lower oxygen content in

the air and the lower gas viscosity require the use of

a different orifice to achieve efficient, clean combustion at the burner tube.

For high altitude installations consult the local

gas distributor or the authority having jurisdiction

for proper rating methods. If the installer must

convert the unit to adjust for varying altitudes, use

Jøtul High Altitude Kit (#155610-NG / #155611-LP).

In the U.S: THE DERATING KIT MUST BE INSTALLED

BY AN AUTHORIZED SERVICE TECHNICIAN IN ACCOR-

High Altitude Orifice Chart

Elevation Fuel

0 - 2000 ft. Natural Gas #38 129130

(0 - 610 m) Propane 1.55 mm 220048

2001 - 4500 ft. Natural Gas #39 129367

(611 - 1370 m) Propane 1.50 mm 129146

Table 1. High Altitude Orifice Chart.

THIS STOVE HAS BEEN CONVERTED FOR USE AT AN

ALTITUDE OF: ________________

Orifice Size: ____________ Manifold Press. _____

Input Btu/Hr. ___________ Fuel Type __________

Date of Conversion ___________

Figure 27. High Altitude Conversion Label.

Orifice

Size

Part No.

15

Page 16

Fuel Conversion

The GZ550 DV Acadia Fireplace is designed to for use

with either Natural gas or Propane. It is shipped

from the factory configured to use Natural gas. A

conversion kit is included for conversion to Propane

use if desired. Check the identification label on the

Control Valve to confirm that the correct fuel is used.

WARNING:

THE CONVERSION KIT IS TO BE IN-

STALLED BY AN AUTHORIZED JØTUL

SERVICE TECHNICIAN IN ACCORDANCE

WITH THE MANUFACTURER’S INSTRUCTION AND ALL CODES AND REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION. FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE. THE

QUALIFIED AGENCY PERFORMING THIS

WORK ASSUMES RESPONSIBILITY FOR

THIS CONVERSION.

IN CANADA:

THE CONVERSION SHALL BE CARRIED

OUT IN ACCORDANCE WITH THE REQUIREMENTS OF THE PROVINCIAL AUTHORITIES

HAVING JURISDICTION AND IN ACCORDANCE WITH THE REQUIREMENTS OF THE

CAN1-B149.1 AND .2 INSTALLATION CODE.

Cet equipement de conversion sera installe par une

agence qualifiee de service conformement aux

instructions du fabricant et toutes exigences et

codes applicables de l’autorises avoir la juridiction.

Si l’information dans cette Instruction n’est pas

suivie exactement, un fey, explosion ou production

de protoxyde de carbone peut resulter blessure

personnelle de vie. L’agence qualifiee de service est

esponsable de l’installation n’est pas propre et

complete jusqu’a l’operation de l’appareil converti

est cheque suivant les criteres etablis dans les

instructions de proprietaire provisionnees avec

l’equipement.

Tools required:

1/4” Nut driver, 7/16” and 1/2” open end wrench or

deep well socket, 4 mm allen wrench, Torx t20 or

slotted screwdriver.

Conversion Kit Contents:

• 1 Regulator Tower labeled for Propane

• 3 Regulator Tower Screws

• 1 Burner Orifice (#38 NG, 1.55 mm LP)

• 1 Pilot Orifice ( #30 for LP, #51 for NG)

• Label A - to be completed and applied to the back

of the fireplace.

• Label B - apply to the fireplace Rating Plate as

designated on the plate.

WARNING: If appropriate, be sure to unplug the

blower before proceeding with this conversion.

Fuel Conversion Procedure

1. Remove the Glass Frame:

• Follow the removal procedure detailed on page 1.

2. Empty the firebox:

• Lift and remove the Fettle and Logset package.

CAUTION: THE LOGS ARE FRAGILE. Handle them

with care and set aside out of the way.

• Remove the Burner Skirt. Lift and tilt it to clear

the firebox opening. See fig. 28.

3. Change the Burner Orifice:

• Loosen the locknut on the Air Shutter Stem,

located under the firebox floor to the right of the

Control Valve. Pull the stem forward as far as it

will go. This will allow you to disengage the

Burner Assembly. See fig. 29.

• Lift the rear of the Burner Tube and rotate

slightly forward. Slide the tube back enough to

disengage it from the Air Shutter and Burner

Orifice, then lift out. See fig. 30.

• Slide the Air Shutter back out of the way to

expose the orifice. See fig. 31. Using a ½” open

end wrench or deep well socket remove the

burner orifice and replace with the appropriate

orifice, supplied in the kit.

16

Page 17

Figure 28. Lift the Burner Skirt up and out of the firebox.

Pull Frame Spring

Latch to release.

Air Shutter

Wingnut

4. Change the Pilot Orifice:

• FROM WITHIN THE FIREBOX, disengage the

Pilot Hood by releasing the retainer clip as

shown in fig. 32. Using the 4 mm hex key

supplied, unscrew the pilot orifice (counterclockwise). Replace with the appropriate

orifice:

#51 for Natural gas

#30 for Propane

Tighten new orifice into the base of the pilot

assembly.

• Replace Pilot Hood by pushing it into the

base.

Pilot Hood

Pilot Orifice

Retainer Clip

Figure 29. Frame latch and air shutter stem location.

Burner Tube

Air

Shutter

Figure 30. Move shutter forward to disengage the

burner tube assembly. .

Burner Orifice

PILOT ASSEMBLY

Figure 32. Pilot Orifice replacement.

Figure 31. Move air shutter back to access the

burner orifice.

17

Page 18

5. Replace the Burner Tube:. Slip the end of the tube

into the Air Shutter and SLIDE TUBE FORWARD TO

COMPLETELY COVER THE BURNER ORIFICE.

6. Adjust the Air Shutter: See fig. 33.

• Slide the shutter BACK to open the inlet, slide

FORWARD to close. The standard settings are:

Natural gas - 1/4” open

Propane - 1/2” open

• Tighten the wing nut on the Air Shutter Stem.

• Replace the Burner Skirt.

7. Change the Regulator: See fig. 34.

• Using a Torx T-20 screwdriver or small flat head

screwdriver, remove the three specialty screws

from the front of the valve regulator.

• Remove the regulator tower and gasket.

BE SURE TO REMOVE THE BLACK RUBBER GASKET

FROM THE VALVE.

• Install the new variable regulator tower with

the new rubber gasket. Thoroughly tighten new

regulator to valve body.

8. Apply the Conversion Labels:

• Apply LABEL A to the cabinet floor so that it

may be seen by anyone servicing the fireplace.

• Apply LABEL B to the Rating Plate in the space

provided.

9. Reassemble the fireplace, apply gas to the system

and check for gas leaks including all gas lines

before and after the valve. NEVER USE AN OPEN

FLAME TO CHECK FOR GAS LEAKS.

IMPORTANT: Correct gas pressure is essential for

efficient and safe operation. It is important that

the correct gas pressure be established at the

time of the installation. For more details, see the

Gas Pressure section of this manual on page 12.

WHEN LIGHTING THIS APPLIANCE, ALWAYS REFER TO

THE LIGHTING INSTRUCTIONS ON THE BACK COVER

OF THIS MANUAL.

Figure 33. Adjust Air Shutter as appropriate. Fully

open position is shown here. Slide shutter forward to

close.

Be sure to

remove the black

rubber gasket

from the valve.

Apply small

conversion notice

label here.

Figure 34.

Valve Regulator replacement.

18

Page 19

Wall Thermostat Installation

Use Jøtul Thermostat #129706 or a 750 millivolt DC

two-wire circuit thermostat to automatically control

your fireplace operation. The thermostat should be

placed in the same room as the heater, typically 5’

off the floor. Avoid drafty areas or any area that

may affect the accuracy of the thermostat.

The thermostat should be connected to the

Acadia using a minimum of 16 gauge wire with a

maximum length of 35 feet of wire.

Connect the two thermostat wire leads to the

two lower terminals on the terminal block located

to the right of the ON/OFF/T’STAT switch. Do not

overtighten the connections. IT IS NOT NECESSARY

TO DISCONNECT ANY OTHER WIRES. See Figure 34.

At the thermostat, the two wires should be

connected to the two connections screw on the

thermostat base plate per the manufacturer’s

instructions.

For thermostatic function, place the ON/OFF/TSTAT switch in the T-STAT position and the pilot

flame must be lit.

Remote Control

The optional Jøtul Remote Control can be installed

on the Acadia gas fireplace. Using the wire supplied with the remote, connect the remote directly

to the gas control valve. See fig. 36

Connect one receiver lead to the terminal

labelled TH. Connect the other receiver lead to the

terminal labeled TH/TP. DO NOT DISCONNECT ANY

OTHER WIRES FROM THE VALVE, AND DO NOT OVER

TIGHTEN THE TERMINAL SCREWS.

Place the receiver unit under the control valve

on the floor of the fireplace cabinet.

CAUTION:

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING

THE CONTROLS. WIRING ERRORS

CAN CAUSE IMPROPER AND DANGEROUS OPERATION. ALWAYS

VERIFY PROPER OPERATION AFTER

SERVICING THE APPLIANCE.

THERMOPILE

TH

TP

TH

TP

VALV E

TERMINAL

BLOCK

Figure 36. ZG550 Acadia Wiring Diagram

ROCKER

SWITCH

OPTIONAL

THERMOSTAT

REMOTE

CONTROL

ON

OFF

STAT

or

ATTENTION:

AU MOMENT DE L’ENTRETIENDES

COMMANDES, ETIQUETEZ TOUS LES

FILS AVANT LE DEBRANCHEMENT.

DES ERREURS DE CABLAGE

PEUVENT ENTRAIUN

FONCTIONNEMENT INADEQUAT ET

DAGEREUX.

19

Page 20

Brick Panel Assembly

Install the optional Brick Panels before placing the

Logset. Place the panels in position in the order as

numbered in fig. 37. No fasteners or tools are

required.

Upper Rear Panel,

220031

4

Pull Frame Latches to

Release Frame

Left Side

Panel,

220997

1

3

2

Lower Rear Panel,

220030

Right Side

Panel,

220996

Figure 37. Panel installation order.

1. Remove the Glass Frame, if you have not already

done so. Open the lower control panel and locate

the two frame latches under the firebox floor. See

fig. 38 . Pull the latch handle forward to

disengage it from the bottom of the glass frame.

You can then pull the frame out and up off of the

three retainer tabs at the top of the firebox

opening. Set the Glass Frame out of the way.

2. Remove the Fettle and Logset. These parts are not

fastened. Simply lift them out of the firebox.

3. Install the Side Panels. Set the bottom edge of

each side panel on the Burner Skirt and against

the firebox wall. Push the panel forward against

the front lip of the firebox opening. See fig. 39.

4. Install the Lower Rear Panel. Orient the panel so

that the beveled edge is on top and the mortar

joints align with those on the side panels. Set the

bottom edge on the shelf above the restrictor

adjustment slots at the back of the firebox. The

panel should fit snugly between the two side

panels. See fig. 40.

5. Install the Upper Rear Panel. This will also be a

snug fit. Set the panel up high and then carefully

lower it to seat its lower edge against the top of

the other rear panel. The side panels will hold it in

place.

Figure 38. Glass Frame latch locations.

Side

Panel

Burner Skirt

Figure 39. Install the Side Panels.

Bevelled Edge

20

Figure 40. Install Lower Rear Panel.

Page 21

Logset Assembly

Unpack and arrange the five logs as outlined below.

CAUTION: The logs are fragile. Handle with care.

1. Seat Right Log (1) on the pin on the right side of

the Burner Skirt. fig. 41.

2. Set Rear Log (2) on the pins at the rear of the

Burner Skirt. This log should overlap the back of

the Right Log.

3. Set the Left Log (3) on the pins at the left side of

the Burner Skirt.

4. Set the end of Front Log (4) into the pocket at

the rear of Left Log (3). Engage the other end

with the pin in the middle of the Burner Plate.

Fig. 42.

5. Engage the upper end of the Cross-over Log (5)

with the pin in the Rear Log. Fig. 42. Set the

Cross-over Log across the top of the lower end of

the Front Log (4) as illustrated.

6. Spread a layer of ember stones evenly over the

surface of the Burner Plate. Allow for 1/4”

clearance between the stones and the inner

edge of the Burner Skirt. Avoid blocking the pilot

flame area with ember stones. See Fig. 43.

7. Replace the Glass Panel Frame: Engage the top

of the frame with the three tabs at the top of

the firebox. Push the bottom of the frame

against the firebox face and pull the Frame

Latches out to engage them with the slots in the

bottom of the frame.

3

2

Figure 41. Install Right Log, Rear Log and Left Log in

that order.

5

4

Figure 42. Install Front and Cross-over logs as shown.

1

Pilot

Area

Figure 43. Install ember stones, keeping clearance

around the pilot crossover area.

21

Page 22

Surround Assembly

1. Install the Lower Grill / Control Door.

• Secure the hinges to the cabinet frame using

the hex head screws provided in the hardware

bag. fig. 44.

2. Install each of the Side castings onto the

cabinet by engaging the hanger tabs with the

holes in the cabinet frame. See fig. 52 for

orientation.

3. Install the Right and Left Upper Grill plates.

4. Attach the Inner Panel to the Center Plate. The Inner

Panel may be reversed to show the winter scene.

(Note: Blue Black Panel is enamelled on one side only).

5. Hang the Center Plate in position.

Optional Double Door

The Double Door set is fully assembled and requires

no tools for installation. Use the 4 mm hex key

supplied with the doors to adjust the door alignment

at the eight socket head hinge screws.

Door Installation

Unpack the door set and inspect the parts for

damage. Notify your dealer if any damage is found.

You may wish to remove the doors from the

frame to lighten the assembly and ease installation.

They simply lift off of the hinges.

The door assembly attaches to the fireplace by

engaging the three slots in the upper frame with the

corresponding steel tabs at the top of the firebox.

See fig. 45.

A dimple located on the inside of the frame at

each lower corner engages with corresponding holes

in the glass frame to hold the bottom of the door

assembly securely to the firebox. See A, fig. 46.

1. Open the Control Access Door. Hang the door

frame onto the firebox by engaging the tabs with

the holes in the frames. See fig. 45.

2. Push the frame over to one side and engage the

dimple on that lower corner with the hole in the

side of the glass frame. You will feel it lock into

place.

3. Push the frame assembly over to the opposite side

and push that lower corner down to engage with

the firebox.

Door Alignment Adjustment

You can adjust the door alignment if necessary by

loosening the hinge screws (See B, fig. 46 and fig.

Figure 44. Install the Lower Grill / Control Door.

Figure 45. Hang the frame on the cabinet.

B

B

A

A

Figure 46. Rear view of door frame.

Loosen

screws to

adjust

door

alignment

Figure 47. Door adjustment points.

22

Page 23

System Check

1. PURGING THE GAS LINE: When lighting the

appliance for the first time it will take a few

moments to clear the gas line of air. Once this

purge is complete, the appliance will operate as

described in the lighting instructions located on

the fireplace’s rating plate and back cover of this

manual.

2. PILOT FLAME: The pilot flame should be steady,

not lifting or floating. The flame should be blue

in color around the pilot hood, with traces of

yellow toward the outer edges. It is imperative

that the pilot flame engulf the top 3/8” of the

thermopile (power generator) and the top 1/8” of

the quick drop out thermocouple. The pilot flame

should project out of the pilot hood 1” at all three

ports. See Figure 48.

3. BURNER ADJUSTMENT: Your Jøtul GZ550 Acadia

gas fireplace is equipped with a variable gas

control valve. This valve provides easy adjustment of the flame height appearance and heat

output. To adjust the flame between the HI and

LO setting, rotate the HI/LO knob, located in the

center of the valve face. Flame height will adjust

approximately 1.0” to 1.5” between the HI and LO

settings.

NO SMOKE OR SOOT SHOULD BE PRESENT. CHECK

LOG PLACEMENT IF ANY SOOT OR SMOKE IS DETECTED. IF SOOT OR SMOKE PERSISTS, THE AIR

SHUTTER MAY NEED TO BE ADJUSTED.

Flame Appearance / Air Shutter

Adjustment

THE ACADIA GAS FIREPLACE IS SHIPPED FROM THE

FACTORY EQUIPPED TO USE NATURAL GAS. IF THE

BURNER HAS BEEN CONVERTED FOR USE WITH

PROPANE, IT WILL BE NECESSARY TO ADJUST THE AIR

SHUTTER ON THE BURNER TUBE TO ACHIEVE THE

PROPER GAS TO AIR MIX. See Figure 26.

WARNING:

AIR SHUTTER ADJUSTMENTS SHOULD ONLY

BE PERFORMED BY A QUALIFIED PROFES-

SIONAL SERVICE TECHNICIAN.

The air shutter adjustment can also help achieve the

desired flame appearance. Generally, flame appearance is a matter of individual preference, however a

warm yellowish flame is most common. See fig. 49.

Closing the air shutter - will generate very long

yellow flames resulting in soot. Sooting produces

black deposits on the logs, on the inside walls of

the appliance, and potentially on the exterior

termination cap.

Sooting is caused by incomplete combustion in

the flames and lack of combustion air entering

the air shutter opening.

Opening the air shutter - will generate a flame that is

blue and transparent, or an “anemic” flame. This

flame is generally more efficient but not as pretty.

CAUTION:

DO NOT ATTEMPT TO ALTER THE FLAME

APPEARANCE BY POSITIONING THE GAS

VALVE IN ANY OTHER POSITION OTHER

THAN THE FULL “ON” POSITION.

Pilot Hood

(3mm)

Thermocouple

Ignitor

1/8

Min.

(25mm)

Figure 48 Correct Pilot Flame Pattern

1

3/8

(8mm)

Min.

Thermopile

23

Page 24

Air Shutter Adjustment

1. Open the Lower Grill panel and locate the Air

Shutter adjustment stem extending down from

the right side of the firebox floor. See figs. 49.

2. Loosen the locknut and push the stem BACK (to

the rear of the firebox) to open the air inlet

increasing airflow into the burner. Push the stem

FORWARD to decrease the air inlet. Make adjustments in 1/8” (3 mm) increments and allow time

for flame pattern to respond to the new setting.

Retighten the locknut when the desired flame

pattern is established.

3. Reassemble the fireplace including glass assembly. Allow the fireplace to burn 15 -20 minutes on

the HIGH setting, observing the flame continuously.

4. If the flame appears weak, slow, or sooty, repeat

the process described above until the flame is as

desired.

Air Inlet Settings

Natural Gas - 1/4” open

Propane - 1/2” open

IMPORTANT: Run the fireplace for a minimum

of 15 to 20 minutes to produce an accurate

representation of the flame appearance. This

warm-up should be done before and between

any air shutter adjustment.

Air Shutter Adjustment Stem

Figure 49. Air Shutter adjustment location.

Figure 50. Proper flame pattern.

24

Page 25

Operation

1. Your Acadia gas fireplace can be operated manu-

ally using the On/Off/T-stat rocker switch or it can

be automatically controlled using an optional

wall-mounted thermostat and/or remote control

device. A separate switch is provided for the

optional forced air blower kit.

Familiarize yourself with the location and function of the controls. See Figs. 51 and 52.

Gas Control - Used to control the Pilot light and

gas flow from the supply line.

Regulator - Allows you to adjust heat output and

flame intensity.

Piezo Ignitor - Push button pilot light ignition.

ON/OFF/ T’STAT Switch - Allows for manual or

thermostatic control of the burner.

Always follow the Lighting Instructions located

on the inside Back Cover of this manual.

2. For the first several hours of operation, it is

common that you will detect some odor as the

metal and manufacturing materials cure under

heat. This condition is temporary and can be

alleviated by allowing plenty of fresh air to

circulate through the area.

3. Condensation may develop on the glass upon

each lighting of the appliance. This “fog” will

disappear as the glass heats.

4. Keep the controls and the area under the appli-

ance free of debris; vacuum this area frequently.

Always keep the appliance area clear and free

from combustible materials, gasoline and other

flammable liquids.

When a vacuum is used on any service for the

fireplace, ALWAYS be sure the fireplace is completely cold.

5. Remember, your fireplace utilizes a continuously

burning pilot flame. Exercise caution when using

household products containing combustible

vapors.

6. CAUTION: DO NOT OPERATE THIS APPLIANCE

WITH THE GLASS REMOVED, CRACKED OR BROKEN. REPLACEMENT OF THE GLASS SHOULD BE

DONE BY A LICENSED OR QUALIFIED SERVICE

PERSON. USE ONLY REPLACEMENT GLASS PROVIDED BY YOUR AUTHORIZED JØTUL DEALER.

NEVER USE ANY SUBSTITUTE MATERIALS.

Pilot Assembly

Figure 51. The pilot assembly is located at the right

rear corner of the burner plate under the right log.

Gas Control

Knob

IGNITOR

HI LO

Piezo Ignitor

Regulator

BURNER

ON

OFF

TSTAT

On/Off/T’stat Switch

Figure 52. Burner Controls.

WARNING:

OBSERVE CAUTION NEAR THE GLASS

PANEL. THE GLASS MAY SHATTER

WHEN STRUCK BY AN OBJECT. ALWAYS

HANDLE THE GLASS PANEL WITH CARE.

25

Page 26

Maintenance

The Acadia gas fireplace and its venting system

should be inspected before use and at least annually

by a qualified service technician.

IMPORTANT:

ALWAYS TURN OFF THE GAS SUPPLY TO

THE FIREPLACE AND UNPLUG THE

FORCED AIR BLOWER BEFORE ANY SERVICE WORK IS PERFORMED ON THE FIREPLACE.

General Cleaning

The firebox should be vacuumed annually to remove

any surface build up. Use a soft brush attachment

and handle the logs carefully as they are fragile. Be

sure to vacuum or wipe off the pilot assembly and

burner orifice and burner tube.

Glass Care

Clean the glass only when necessary. Wipe the

surface with a clean, dampened, soft cloth. Follow

with a dry, soft towel. Take care not to scratch the

glass surface.

Glass Panel or Gasket Removal

1. Open the Lower Grill Panel.

2. Release the glass clips at either side of the bottom

of the firebox.

3. Swing the bottom of the glass frame out and lift

to disengage it from the three retainer tabs at the

top of the firebox.

4. Lay the assembly on a flat surface and carefully lift

the metal tabs that secure the glass panel to the

frame. Remove the old gasket material.

5. Install the new glass panel and gasket in the glass

frame and secure with metal tabs. Do not over

tighten tabs as that may damage the glass.

ONLY USE JØTUL AUTHORIZED PARTS. NEVER SUBSTITUTE NON-JØTUL PARTS ON THIS FIREPLACE.

WARNING:

DO NOT USE ABRASIVE CLEANERS ON

THE GLASS. NEVER CLEAN THE GLASS

WHEN IT IS HOT.

Gasket Inspection

It is important that the glass gasket be inspected at

least annually. Examine the ribbon gasket for signs

of deterioration and make sure the gasket has a

positive seal. Replace the gasket if necessary. Refer

to the replacement parts list on page 28.

Figure 53. Replacing the glass gasket.

26

Page 27

RETAIN THIS MANUAL FOR REFERENCE AND

MAKE IT AVAILABLE TO ANYONE USING OR SERVICING THE FIREPLACE.

SERVICE LOG:

First Year

MODEL NAME: GZ 550 DV Acadia Gas Fireplace

SERIAL NUMBER:__________________________

DATE OF PURCHASE:_______________________

AUTHORIZED DEALER:_____________________

NAME OF INSTALLER:______________________

TYPE OF FUEL:_____________________________

WAS FIREPLACE CONVERTED?__________________

NOTES:

Name of Technician________________________

Company Name____________________________

Date of service_____________________________

Work Performed____________________________

____________________________________________

____________________________________________

SERVICE LOG:

Second Year

Name of Technician________________________

Company Name____________________________

Date of service_____________________________

BLOWER

POWER

SUPPLY

G

G

W

BK

W

BLU

BLU

MANUAL OFF AUTO

BK

SNAP STAT

GRY

YEL

TERM

SWITCH

BLU

BK

BK

RHEOSTAT

BRN

BLU

Figure 54. ZG550 DV Acadia Blower Wiring Diagram

Work Performed____________________________

____________________________________________

____________________________________________

SERVICE LOG:

Third Year

Name of Technician________________________

Company Name____________________________

Date of service_____________________________

Work Performed____________________________

____________________________________________

____________________________________________

27

Page 28

76

77

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

78

123124

125

122

121

120

51

50

46

43

49

48

44

45

42

47

39

37 38

79

80

81

82

83

105

104

41

40

100

36

126

113

112

111

108

118

119

117

116

115

114

110

109

107

101

106

99

103

102

97

98

96

95

94

93

92

91

90

89

88

87

86

84

85

35

34

33

32

31

30

29

28

27

26

28

GZ550 Acadia

1

lllustrated Parts Breakdown

3

2

25

24

23

22

21

20

5

4

6

7

9

8

10

11

12

13

14

15

16

17

18

19

Page 29

GZ 550 DV Acadia Parts

No. Description Part Number

1. Screw, #8 x 1/2 Sheet metal 117917

2 Adaptor, 8” 129784

3. Gasket, 8” Adaptor 129775

4. M6 Hex Nut 9930

5. Adaptor, 5” 129782

6. Gasket, 5” Adaptor 129774

7. Air Intake Manifold 220952

8. Gasket, 5” Adaptor 129774

9. Top Shroud, Level 1 220955

10. Screw, #8 X 1/2” Sheet metal 117917

11. Support Bracket 220964

12. Screw, #8 x 1/2 Sheet metal 117917

13. Cabinet Wall, Rear 220961

14. Stand-ott, 1” Framing 220969

15. Wallstud Brace 220011

16. Screw, #8 x 1/2 Sheet metal 117917

17. Screw, #8 x 1/2 Sheet metal 117917

18. Cabinet Wall, Left 220959

19. Rivet, .125 x .250 117946

20. Lanyard, 062 Wire (Rating Plate) 129159

21. Rating Plate 220913

22. Cool Air Channel 220957

23. Air Intake Gasket 129773

24. Air Intake Restrictor Plate 220963

25. Latch Assembly 220049

26. M6 Hex Nut 9930

27. M6 Hex Nut 9930

28. M6 Wingnut 117975

29. M6 x 12 Flat Head Phillips Screw 117967

30. M6 x 12 Hex Bolt 117130

31. Cabinet Base 220958

32. 10-32 x 3/8 Phillips Screw 117911

33. Valve Bracket 220945

34. Terminal Block Bracket 220930

35. M4 Hex Nut 117922

36. Terminal Block, 2 Pole 129154

37. Igniter Bracket 129679

38. M4 x 8 Phillips Screw 117920

39. Ignitor 3902573

40. M4 x 12 Phillips Screw 117921

41. Knob Extension, On/Off 129729

42. Knob Extension, Hi/Lo 129730

43. Rheostat Nut 220717

44. Knob, Rheostat Control 220709

45. On / Off Switch 220703

46. Controls Board 220944

47. M4 Hex Nut 117922

48. Hinge Adaptor 12979392

49. M4 x 10 Hex Bolt 117921

50. Control Door Hinge 901043

51. M5 x 10 Screw 117970

52. Lanyard, .062 Wire - Control Door 220574

53. Screw, #8 x 1/2 Sheet metal 117917

54. Control Door - Matte Black 10395892

Control Door - Blue Black 10395827

Control Door - Jøtul Iron Gray 10395885

55. M5 x 10 Screw 117970

56. Ceramic Glass, Replacement (inc. gasket) 154987

57. Gasket, Glass Tadpole 129124

58. Glass Clip, Tinnerman 220042

59. Glass Frame 129757

60. Cool Air Channel 220957

61. Cabinet Wall, Right 220960

62. Fettle, Blue Black Enamel 11039627

63. Andiron, Blue Black Enamel 10396727

64. Hang Tab 129680

65. M6 x 12 Hex Bolt 11730

66. Log, Left 220993

67. Log, Front 220995

68. Log, Cross-over 220701

69. Log, Right 220994

70. Log, Rear 220992

71. Surround Leg, Right / Matte Black 10395792

Surround Leg, Right / Blue Black 10395727

Surround Leg, Right / Jøtul Iron 10395785

72. Surround Leg, Left / Matte Black 10395992

Surround Leg, Left / Blue Black 10395927

Surround Leg,Left / Jøtul Iron 10395985

73. Hang Tab 129680

74. M6 x 12 Hex Bolt 11730

75. Surround Breastplate, Right / Matte Black 10395692

Surround Breastplate, Right / Blue Black 10395627

Surround Breastplate, Right / Jøtul Iron 10395685

76. Surround Keystone / Matte Black 10395592

Surround Keystone / Blue Black 10395527

Surround Keystone / Jøtul Iron 10395585

77. Tablet / Matte Black 10396692

Tablet / Blue Black 10396627

Tablet / Jøtul Iron 10396685

78. Surround Breastplate, Left / Matte Black 10395492

Surround Breastplate, Left / Blue Black 10395427

Surround Breastplate, Left/ Jøtul Iron 10395485

79. Pilot Assembly - NG 129471

80. Spacer, Pilot Assembly 220546

81. Gasket, Pilot Assembly 129670

82. Primary Air Shutter Assembly 220790

83. Orifice Holder 129668

84. Gas Valve - NG (50% TD) 220520

85. Compression Nipple, 3/8 NTP - 5/16 220044

86. Rheostat Assembly 155831

87. Wire Harness Assembly 155830

88. M6 x 20 Hex Bolt 117117

89. Tube Holder, Cast Iron 155612

90. Venturi Tube 155612

91. M6 Wingnut 117975

92. M6 AS Series Fastener 155612

93. Gasket, Air Intake Restrictor 220987

94. Burner Base, Cast Iron 155612

95. Subfloor - Burner Skirt 220783

96. Gasket, Burner 155612

97. Exhaust Baffle 220954

98. Burner Plate Assembly 155612

99. M6 Hex Nut 9930

100. Flex Tube, 5/16” x 14” 129390

101. #8 x 1/2” Sheet metal Screw 117917

102. M6 Wingnut 117975

103. Cover Plate, Primary Air Restrictor 220388

104. Compression Nut - 5/16 129464

105. Compression Sleeve - 5/16 129463

106. Gasket, Cover Plate 220395

107. Jam Nut 129152

108. Orifice, #38 - NG 129130

Orifice, 1.55 - LP 220048

109. Gasket, Heat Exchanger 129673

110. Heat Exchanger 220950

111. Glass Frame Hanger 129760

112. #8 x 1/2” Sheet metal Screw 117917

113. Relief Door Guide 220004

114. #8 x 1/2” Sheet Metal Screw 117917

115. Gasket, Relief Door 129772

116. Relief Door 129759

117. Top Shroud, Level 2 220956

118. #8 x 1/2” Sheet Metal Screw 117917

119. Keystone Heat Shield 220009

120. #8 x 1/2” Sheet Metal Screw 117917

121. Cabinet Top 220962

122. Firebox 220947

123. #8 x 1/2” Sheet Metal Screw 117917

124. Sheetrock Standoff 220789

125. #8 x 1/2” Sheet Metal Screw 117917

126. #8 x 3/4” Sheet Metal Screw 117986

127. Air Deflector, Burner Skirt 221102

128. Ember Stones, 4 oz. * 220702

129. Thermocouple * 129766

130. Electrode * 129765

131. Thermopile * 3094527

* not illustrated

29

Page 30

GZ 550 DV Optional Accessories

• Antique Brick Kit ............................................ 155805

• Two Speed Blower, 125 / 60 c.f.m............. 155630

• 4” x 6-5/8” Adaptor Kit ................................ 154974

• High Altitude Conversion Kit - NG ........... 155610

• High Altitude Conversion Kit - LP ............. 155611

• Fuel Conversion Kit - LP................................ 155594

• Fuel Conversion Kit - NG.............................. 155595

• Wall Thermostat ............................................ 750003

• Remote Control .............................................. 129706

• QuickFace Fronts w/ Screen

Steel Rectangular, Matte Black.................. 154964

Steel Arch, Matte Black ................................ 154965

Brushed Stainless Steel, Rectangular ...... 154968

Brushed Stainless Steel Arch...................... 154969

• Arched Double Doors, Matte Black .......... 350560

• Arched Double Doors, Blue Black.............. 350561

• Double Door Basket Screen ........................ 154973

30

Page 31

LIGHTING INSTRUCTIONS

FOR YOUR SAFETY, READ BEFORE LIGHTING.

WARNING:

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY

RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS OF LIFE.

A. This appliance has a pilot which must be lit

by hand. When lighting the pilot, follow

these instructions exactly.

B. BEFORE LIGHTING, smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle to the floor.

WHAT TO DO IF YOU SMELL GAS:

• Extinguish any open flame.

• Open windows.

• Do not light any appliance.

• Do not touch any electrical switches.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone.

LIGHTING INSTRUCTIONS