Page 1

Jøtul F 400

Installation and Operating Instructions for USA/Canada 2

Montering- og bruksanvisning - Norsk 21

Montering- och bruksanvisning - Svenska 27

Jøtul F 400

Installation and Operating Instructions - English 32

Manuel d'installation et d'utilisation - Francais 37

Instrucciones para instalación - Español 42

Manuale di installazione ed uso - Italiano 48

Montage- und Bedienungsanleitung - Deutsch 53

Installatie- en montagehandleiding - Nederlands 59

Monterings-. og bruksanvisningen må oppbevares under hele produktets levetid. These instructions must

be kept for future references. Wir empfehlen Ihnen, die Montage- und Bedienungsanleitung für spätere

Zwecke sorgfältig aufzubewahren. Ce document doit être conservé pendant toute la vie de l'appareil.

Page 2

USA/Canada

Installation and Operation Instructions for USA/Canada

Installation et fonctionnement pour Canada

Safety Notice: If this solid fuel room heater is not properly installed, a house fire may result. For your

safety, follow the installation directions. Contact local building or fire officials about restrictions and

installation inspection requirements in your area. Kindly save these instructions for future reference.

Avis de sécurité: Une installation non appropriée de ce poêle de chauffage risque de provoquer un

incendie. Assurez votre sécurité en respectant les directives d’installation suivantes. Consultez les

autorités locales du bâtiment ou de la prévention des incendies au sujet des restrictions et exigences

relatives aux inspections d’installations dans votre région.

Tested and listed by ITS, Intertek Testing Services, Middleton, Wisconsin.

Tested to U.S. Standards: ANSI/UL 737 and ANSI/UL 1482, Canadian Standards: CAN/ULC-S627-M93

Standards

The Jøtul F 400 woodstove has been tested and listed to;

U.S. Standards: ANSI/UL 737 and ANSI/UL 1482.

Canadian Standards: CAN/ULC-S627-M93

Tests performed by:

ITS, Intertek Testing Services, Middleton, WI

Manufactured by:

Jøtul AS, P.O. Box 1411, Fredrikstad, Norway

Distributed by:

Jøtul North America, P.O. Box 1157

400 Riverside Street, Portland, ME 04104

This heater meets the U.S. Environment Protection Agency’s

Emissions limits for wood heaters manufactured and sold

after July 1, 1990.

Under specific test conditions, this heater has shown heat

output at rates ranging from 11,300 to 27,800 BTU’s per

hour.

The Jøtul F 400 woodstove is only listed to burn wood. Do

not burn any other fuels.

Check Building Codes

When installing, operating and maintaining your Jøtul F 400

woodstove, follow the guidelines presented in these

instructions, and make them available to anyone using or

servicing the stove.

Your city, town, county or province may require a building

permit to install a solid fuel burning appliance.

In the U.S., the National Fire Protection Association’s Code,

NFPA 211,

Solid Fuel Burning Appliances

apply to the installation of a solid fuel burning appliance in

your area.

In Canada, the guideline is established by the CSA Standard,

CAN/CSA-B365-M93, Installation Code for Solid-FuelBurning Appliances and Equipment.

Always consult your local building inspector or authority

having jurisdiction to determine what regulations apply in

your area.

Standards for Chimneys, Fireplaces, Vents and

, or similar regulations, may

Read this entire manual before you install and use your

new room heater.

Save these instructions and make them available to anyone

using or servicing the stove.

Jøtul pursues a policy of continual product development. Products as supplied may therefore differ in specification, colour, or type of

accessories, from those illustrated or otherwise described in publications and brochures.

2

Jøtul North America

400 Riverside Street

Portland, Maine 04104

Page 3

USA/Canada

Table of Contents

Standards and Safety Notices

Standards / Codes..................................................................... 2

Safety Notices ............................................................................. 3

Installation .................................................................................. 3

Assembly Before Installation

Unpack the Stove ..................................................................... 4

Flue Collar Reversal ................................................................. 4

Chimney Connector ................................................................ 4

Chimney Requirements ......................................................... 4

Masonry Chimneys .................................................................. 4

Prefabricated Chimneys ..........................................................5

Chimney Height......................................................................... 5

Wall Pass-Throughs................................................................... 5

Connecting to the Chimney

Masonry Chimney.................................................................... 6

Hearthmount / Fireplaces...................................................... 6

Prefabricated Chimneys ......................................................... 6

Clearances to Combustibles

Floor Protection ........................................................................ 6

Clearances to Walls and Ceilings.......................................... 6

Using Shields to Reduce Clearances ....................................7

Alcove Installation .....................................................................7

Mobile Home Installation....................................................... 7

Clearance Diagrams ................................................................. 8

Clearance Chart ......................................................................... 9

Operation

Wood Fuel .................................................................................10

Controls...................................................................................... 10

Break-in Procedure.................................................................. 10

Starting / Maintaining the Fire ........................................... 10

Adding Fuel................................................................................ 11

Formation of Creosote ........................................................... 11

Maintenance

Ash Removal .............................................................................. 11

Glass Care ................................................................................... 11

Cleaning ...................................................................................... 11

Glass Removal .......................................................................... 12

General Maintenance

Gaskets ....................................................................................... 12

Gasket replacement................................................................ 12

Gasket List .................................................................................. 12

Chimney System ..................................................................... 12

Accessories

Firescreen ................................................................................... 12

Stove-top Thermometer ....................................................... 13

Outside Air Kit ........................................................................... 13

Floor Bracket Kit ...................................................................... 13

Rear Heat Shield ....................................................................... 13

Bottom Heat Shield ................................................................. 13

Illustrations

Figures................................................................................ 14 - 17

Parts Diagram and List ........................................................... 18

Appendix A

Alternate Floor Protection ..................................................... 18

Safety Notices

• Burn solid wood fuel only.

• Do not use chemicals or fluids to start the fire. Do not

burn garbage or flammable fluids.

• If this room heater is not properly installed, a house fire

may result. To reduce the risk of fire, follow the

installation instructions. Failure to follow these

instructions may result in property damage, bodily

injury, or loss of life.

• Contact the local building or fire officials about

restrictions and installation inspection requirements in

your area.

• Do not connect this stove to any air distribution duct or

system.

• Extremely hot while in operation! Keep children,

clothing and furniture away. Contact will cause skin

burns.

• Avoid creating a low pressure condition in the room

where the stove is operating. Be aware that operation

of an exhaust fan or clothes dryer can create a low

pressure area and consequently promote flow reversal

through the stove and chimney system. In some cases,

the optional Outside Air Kit #154335 can be used to

alleviate this condition. The chimney and building,

however, always work together as a system - provision

ofoutside air, directly or indirectly to an atmospherically

vented appliance will not guarantee proper chimney

performance. Consult your local Jøtul authorized dealer

regarding specific installation/performance issues.

• Jøtul recommends that this stove be installed by a

professional solid fuel technician or that you consult

one if you do the work yourself. Also, consult your

insurance company regarding any other specific

requirements.

Installation

If this solid fuel room heater is not properly installed, a

house fire may result. For your safety, follow the installation

directions. Contact the local building or fire officials about

restrictions and installation inspection requirements in your

area.

Your local officials have final authority in determining if a

proposed installation is acceptable. Any requirement by

the local authority having jurisdiction that is not specifically

addressed in this manual, defaults to NFPA 211, and local

codes in the U.S. or in Canada, CAN/CSA-B365-M and local

codes.

3

Page 4

USA/Canada

Assembly Before Installation

Unpack the Stove

Inspect the stove for damage. Contact your dealer

immediately if any damage is found. Do not install the stove

if any damage is evident.

Contents:

• Inspection Cover (Not for use in US/Canada)

• Door Handle

• Hardware Bag

Flue Collar Reversal

The Flue Collar is oriented in the Top Exit position. If a Rear

Exit position is required, remove the two mounting bolts,

and turn the collar 180 degrees. Secure the collar using the

same bolts, nuts and washers.

Chimney Connector

Use 6” single wall or listed 6” double-wall stovepipe to

connect the stove to the chimney. Single wall stovepipe

must be black iron or stainless steel and have a minimum

thickness of 24 gauge. Do not use aluminum or galvanized

steel pipe for chimney connection - these materials are

not suitable for use with solid fuel.

Follow these guidelines regarding chimney connector

construction:

• Do not use chimney connector as a chimney. It is intended

only for use as a connection device.

• Each connector section must be oriented with the male

(crimped) end pointing toward the stove. See fig. 2.

• Secure all connector joints with three sheet metal

screws.

• For the best performance, the chimney connector should

be as short and direct as possible, including no more

than two 90° elbows.

• The maximum vertical run of single wall stovepipe

should not exceed 10 ft. (305 cm). The maximum

horizontal run should not exceed 3 ft. (92 cm) with a 1/4”

rise per foot.

• No part of the chimney connector may pass through an

attic or roof space, closet or other concealed space, or

through a floor or ceiling. All sections of the chimney

connectors must be accessible for cleaning. Where

passage through a wall or partition of combustible

construction is desired, the installation must conform

with NFPA 211 or CAN/CSA-B365, and is also addressed

in this manual.

• Do not connect this stove to a chimney flue servicing

another appliance.

Chimney Requirements

There are two types of chimneys suitable for the Jøtul F

400 :

1. A code-approved masonry chimney with a ceramic tile

or listed steel flue liner.

2. A prefabricated chimney complying with the

requirements for Type HT (2100°F) chimneys per UL 103

or ULC S629.

The chimney size should not be less than the cross-sectional

area of the flue collar, and not more than three times

greater than the cross-sectional area of the flue collar.

When selecting a chimney type and the location for the

chimney in the house, keep this in mind: It is the chimney

that makes the stove work, not the stove that makes the

chimney work. This is because a chimney actually creates

a suction, called “draft” which pulls air through the stove.

Several factors affect draft: chimney height, cross-sectional

area (size), and temperature of the chimney, as well as the

proximity of surrounding trees or buildings.

A short masonry chimney on the exterior of a house will

give the poorest performance. This is because it can be

very difficult to warm the chimney thereby creating

inadequate draft. In extremely cold climates, it may be

necessary to reline the chimney or extend its height to

help establish draft.

A tall, interior masonry chimney is easier to keep warm

and will perform the best under a variety of weather and

environmental conditions.

The following guidelines give the necessary chimney

requirements based on the national code (ANSI-NFPA 211

for the US. And CSA CAN-B365 for Canada). However, many

local codes differ from the national code to take into

account climate, altitude, or other factors. Your local

building inspector is the final approving authority. Consult

them prior to installation.

Do not connect the stove to any air distribution duct or

system.

Masonry Chimneys

When installing the Jøtul F 400 into a masonry chimney

you must conform to all of the following guidelines:

• The masonry chimney must have a fireclay liner or

equivalent, with a minimum thickness of 5/8” (14 mm)

and must be installed with refractory mortar. There

must be at least ½” (12.7 mm) air space between the

flue liner and chimney wall.

• The fireclay flue liner must have a nominal size of 8” X

8” (20 cm x 20 cm), and should not be larger than 8”X 12”

(20 cm x 30 cm). A round fireclay liner must have a

minimum inside diameter of 6” (15 cm) and maximum

inside diameter of 8” (20 cm). A larger chimney should

be relined with an appropriate code approved liner.

4

Page 5

USA/Canada

• Brick or modular block must be a minimum of 4” (10 cm)

nominal thickness. Stone construction must be at least

12” (30 cm) thick.

• A newly-built chimney must conform to local codes, or,

in their absence, must comply with national regulations.

• An existing chimney must be inspected by a professional

licensed chimney sweep, fire official, or code officer to

ensure that the chimney is in proper working order.

• No other appliance may be vented into the same flue.

• An airtight clean-out door should be located at the base

of the chimney.

Prefabricated Chimneys

A prefabricated metal chimney must be tested and listed

for use with solid fuel burning appliances. High Temperature

(HT) Chimney Standard UL 103 for the U.S. and High

Temperature Standard ULC S-629 for Canada.

The manufacturer’s installation instructions must be

followed precisely. Always maintain the proper clearance

to combustibles as established by the pipe manufacturer.

This clearance is usually a minimum of 2”, although it may

vary by manufacturer or for certain chimney components.

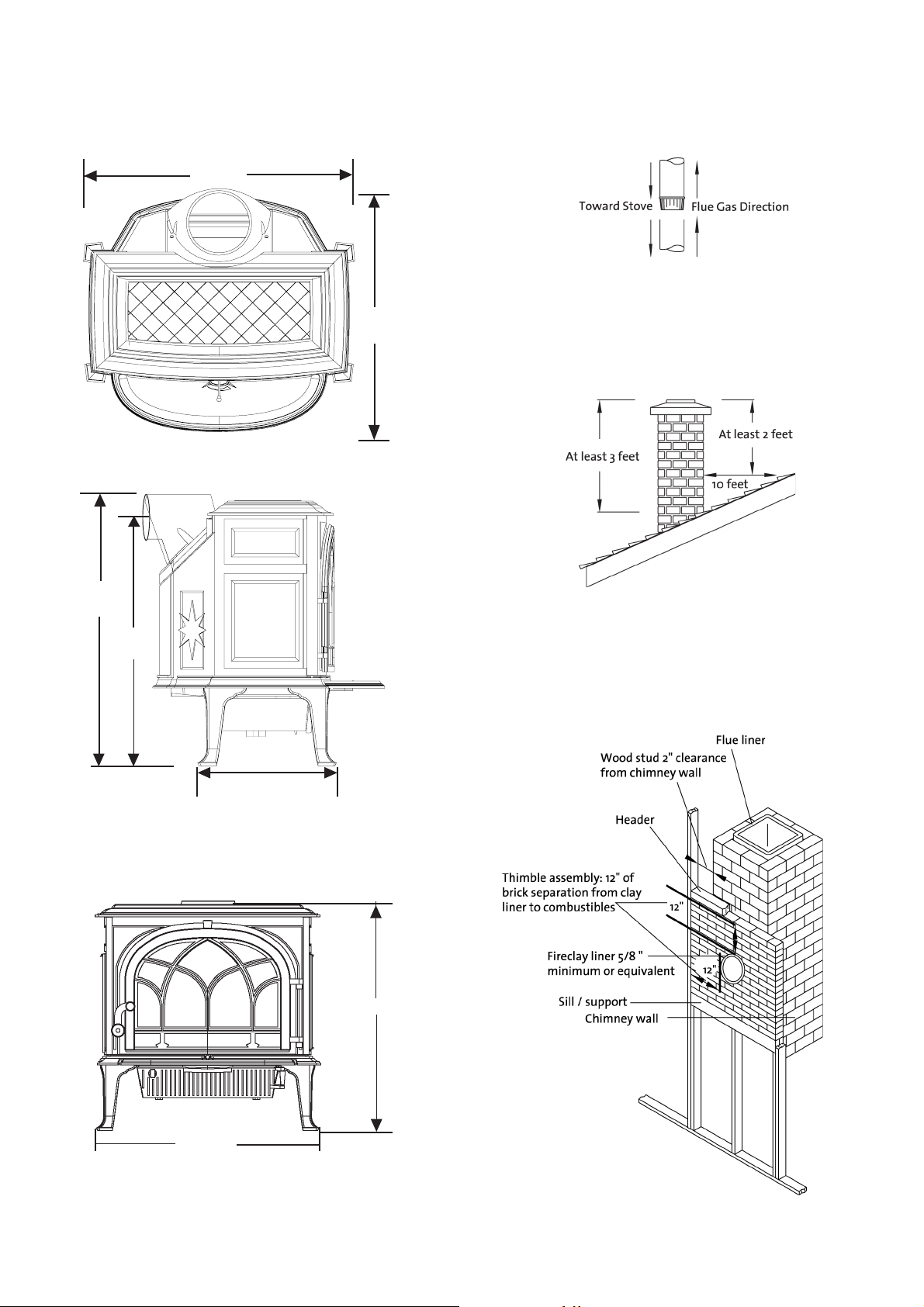

Chimney Height

The chimney must be at least 3 feet (92 cm) higher than

the highest point where it passes through the roof and at

least 2 feet (61 cm) higher than the highest part of the roof

or structure that is within 10 feet (3.05 m) of the chimney,

measured horizontally. See figure 3.

Chimneys shorter than 14 feet (4.27 m) may not provide

adequate draft. Inadequate draft can result in smoke

spillage when loading the stove, or when the door is open.

Poor draft can also cause back puffing (ignition of gas buildup inside the firebox) and sluggish performance. The

minimum height does not, in itself, guarantee proper

chimney performance.

Excessive chimney height can promote over-strong draft

resulting in high stove temperatures and short burn times.

Excessive draft can be corrected by installing a butterfly

damper. Your Jøtul dealer is an expert resource to consult

regarding draft issues or other performance-related

questions.

Wall Pass-Throughs

Common Method:

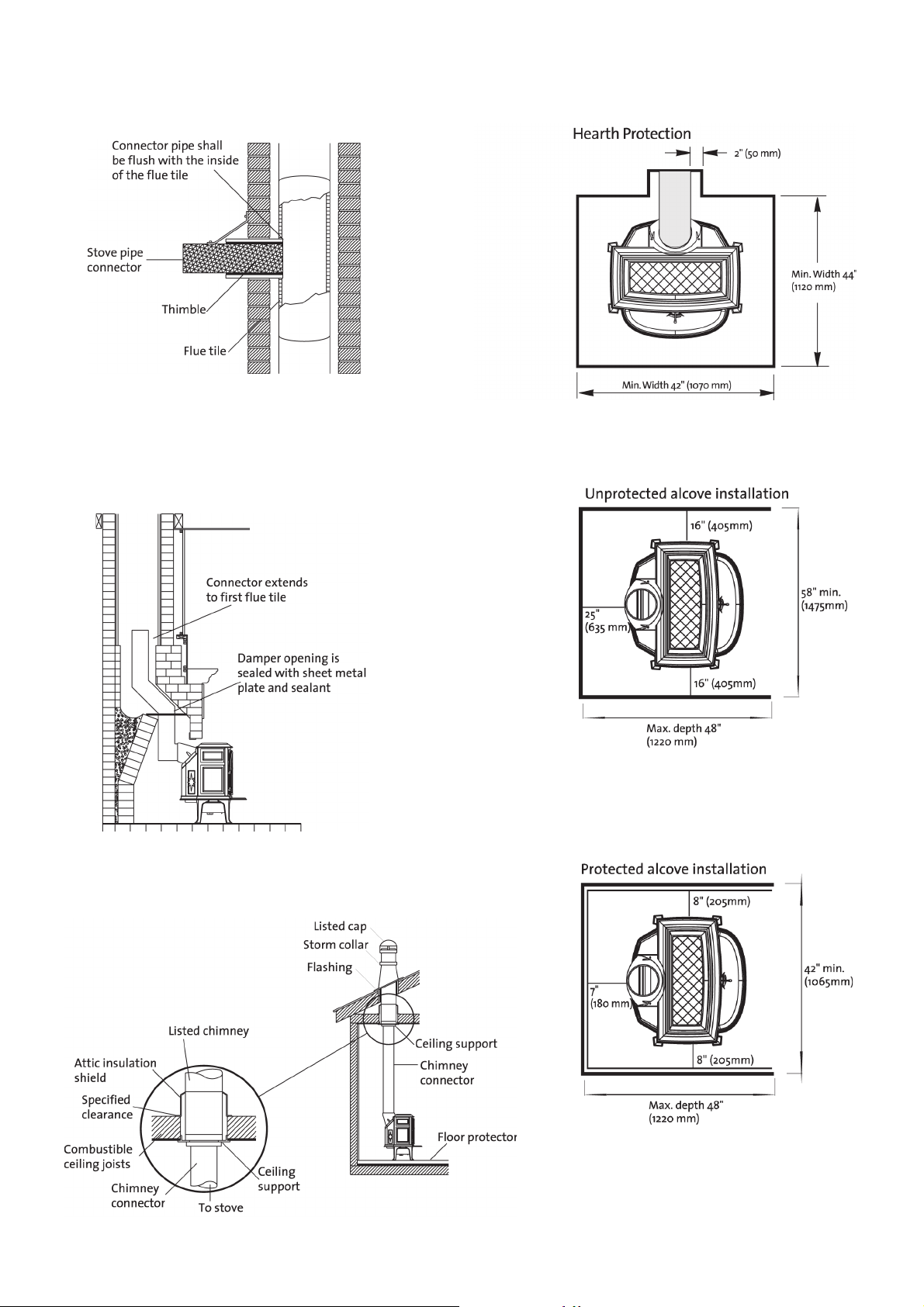

• See figures 4 and 5. Remove all combustible materials

from the pass-through area ( around the chimney

connector), a minimum 12” (30.5 cm). A 6” (15.2 cm)

diameter connector will require a 31” x 31” (78.7 x 78.7

cm) square opening.

• The opening must be filled with at least 12” (30.5 cm) of

brick around a fireclay liner. The liner must be ASTM C35

or equivalent, having a minimum wall thickness of 5/8”

(16 mm).

• The Pass-through must be at least 18” (45.7 cm) from

combustible ceiling materials.

• It will be necessary to cut wall studs, install headers,

and construct a sill frame to maintain the proper

dimensions and to support the weight of the brick.

• The bricks must be solid brick with a minimum of 3 ½

inches thick (nominal 4” / 102 mm).

• Refractory mortar must be used at the junction of the

chimney and the pass-through liner. The pass-through

liner must not penetrate the chimney liner beyond the

inner surface of the chimney liner. Use extreme care

when constructing the hole in the chimney liner as the

tiles can shatter easily.

In Canada

The installation must conform to CAN/CSA-B365,

Installation Code for Solid Fuel Burning Appliances and

Equipment. Before proceeding be sure to consult your local

building inspector.

Common Method:

• This method requires the removal of all combustible

materials from at least 18” (45.7 cm) around the chimney

connector’s proposed location. A 6” round liner requires

a minimum opening 43” x 43” (109.2 x 109.2) square.

• Locate the pass-through at least 18” from combustible

ceiling materials.

• The space that is cleared of combustible materials must

remain empty. Sheet metal panels can be used to cover

the area. However, when using a panel on both sides of

the wall, each cover must be installed on

noncombustible spacers at least 1” from the wall. If one

panel of sheet metal is to be used it may be installed

flush to the wall.

See section

your local building inspector, authorized Jøtul Dealer, NFPA

211 in the U.S. or CAN/CSA-B635 in Canada for other

approved wall pass-through methods.

5.3.1 and 5.3.2 of CAN/CSA - B365-M91.

Consult

In the U.S.

The National Fire Protection Association’s publication, NFPA

211,

Standard for Chimneys, Fireplaces, Vents and Solid Fuel

Burning Appliances

through a combustible wall. Before proceeding with any

method be sure to consult with your local building officials

to discuss any local code requirements.

permits four methods for passing

5

Page 6

USA/Canada

Connecting to the Chimney

Masonry Chimney

When installing a Jøtul F 400 into a masonry chimney

through a “thimble” (the opening through the chimney wall

to the flue), the thimble must consist of ceramic tile or

steel and be securely cemented in place.

The chimney connector/stove pipe must slide completely

inside the thimble to the inner surface or the flue liner. It

may be necessary to make use of a thimble sleeve (a pipe

with a slightly smaller diameter than standard stove pipe).

See figure 5

The connector pipe or thimble sleeve must not protrude

into the flue liner or otherwise restrict draft.

Use refractory cement to seal the seam between the

chimney connector, sleeve, and thimble.

Do not connect this stove to a chimney flue servicing

another appliance of any kind.

..

.

..

Clearance to Combustibles

Floor Protection (For both U.S. and Canada)

The Jøtul F 400 requires

of hearth protection:

1.1.

1. Any UL, ULC or WH listed hearth board. (No bottom heat

1.1.

shield required).

2.2.

2. Any noncombustible material that has a minimum

2.2.

R- value of 2.0. (No bottom heat shield required.)

3.3.

3. Any noncombustible material with the use of the stove’s

3.3.

bottom heat shield.

All forms of protection must include a noncombustible

surface extending a minimum of 18” (460 mm) in front of

the stove, and 8” (200 mm) from the sides and back of the

stove (measured from side and back panels).

This will result in a minimum floor protection of 42”W X

44”D. See figure 8.

In a rear vent installation, the floor protection must also

extend under the stove pipe a minimum of 2” (50 mm)

beyond either side of the pipe. See figure 8

one

of the following three forms

..

.

..

Hearthmount into a Masonry

Fireplace

The Jøtul F 400 may be installed into a masonry fireplace

provided the height of the opening is a minimum of 29 1/2”.

Use of the Short Leg Package will reduce the stove height

by 2 1/4” (57 mm).

Building code requires that the fireplace damper plate be

removed or securely fixed in the open position. A connector

pipe must then extend from the stove’s flue exit through

the damper area of the fireplace and into the chimney tile

liner. See figure 6.

The inside area of the flue liner must not be less than the

area of the stove flue collar and cannot be more than three

times greater than the cross sectional area of the stove

flue collar.

If the chimney liner is too large to accommodate the stove,

an approved relining system must be installed to resize

the flue.

A new sheet metal damper block-off plate

around the connector pipe at the damper frame and sealed

with the proper sealant (usually High-Temp Silicone).

must be

installed

Consult appendix A at the back of this section for alternate

floor protection methods and materials.

Clearances to Walls and Ceilings

The clearances listed and diagramed in this manual have

been tested to UL and ULC standards and are the minimum

clearances to combustible materials specifically

established for the Jøtul F 400 .

A combustible surface is anything that can burn (i.e. sheet

rock, wall paper, wood, fabrics etc.). These surfaces are

not limited to those that are visible and also include

materials that are behind noncombustible materials.

If you are not sure of the combustible nature of a material,

consult your local fire officials.

Remember: “Fire Resistant” materials are considered

combustible; they are difficult to ignite, but will burn. Also

“Fire-rated” sheet rock is also considered combustible.

Contact your local building officials about restrictions and

installation requirements in your area.

Prefabricated Chimneys

When connecting the Jøtul F 400 to a prefabricated metal

chimney always follow the pipe manufacture’s instructions

and be sure to use the components that are required. This

usually includes some type of “smoke pipe adapter” that is

secured to the bottom section of the metal chimney and

allows the chimney pipe to be secured to it with three sheet

metal screws. See figure 7.

6

See pages 8-9 for complete clearance requirements and

diagrams

..

.

..

Page 7

USA/Canada

Using Shields to Reduce Clearances

Chimney Connector Heat Shields: Use only connector heat

shielding listed for use with solid fuel heaters. The

connector heat shield must begin 1” above the lowest

exposed point of the connector pipe and extend vertically

a minimum of 25” (640 cm) above the top surface of the

stove.

Double Wall Connector: Listed double wall pipe is an

acceptable alternative to connector pipe heat shields.

Wall-Mounted Protection: When reducing clearances

through the use of wall mounted protection:

••

•

In the U.S. refer to NFPA 211, Standard for Chimneys,

••

Fireplaces, Vents and Solid Fuel Burning Appliances, for

acceptable materials, proper sizing and construction

guidelines.

••

•

In Canada, refer to CAN/CSA-B365,

••

Solid-Fuel Burning Appliances and Equipment, also for

acceptable materials, proper sizing and construction

guidelines.

Stove Mounted Heat shield: Rear Heat Shield #154385 is

approved for use with the Jøtul F 400 in the US. and Canada.

No other heat shield may be used.

Installation Code for

Mobile Home Installation

The Jøtul F 400 has been approved for use in mobile homes

in the U.S. and Canada with the following stipulations:

1.1.

1. The stove must be secured to the floor of the mobile

1.1.

home. Use Floor Bracket Kit #750304.

2.2.

2. The stove is provided outside air for combustion.

2.2.

Outside Air Kit #154335 (see page 16 for more details).

3.3.

3. Use only listed double-wall pipe for the chimney

3.3.

connection.

4.4.

4. The stove must be grounded to the mobile home

4.4.

chassis.

5.5.

5. The stove must otherwise be installed in accordance to

5.5.

24CRR, Part 3280 (HUD).

Consult with your local building inspector or fire officials

about restrictions and requirements in your area, prior to

installing the stove.

Warning!

Do not install this stove in a bedroom/sleeping room. Do

not install the stove in any way that might compromise the

structural integrity of the mobile home floor, walls, ceiling,

or roof.

Notice:

accessories that permit clearance reduction. Use only those

accessories that have been tested by an independent

laboratory and carry the laboratory’s testing mark. Be sure

to follow all of the manufacturer’s instructions.

Many manufacturers have developed woodstove

Alcove Installation

The Jøtul F 400 can be installed in an Alcove as diagrammed

in figures 9 and 10.

1.1.

1. The stove must be installed with listed double wall pipe.

1.1.

2.2.

2. In a protected alcove installation both side walls and

2.2.

rear wall must be protected per NFPA 211 or CAN/CSAB365. The wall protection must be elevated 1” (25 mm)

from the floor and spaced at least 1” (25 mm) off the

combustible wall, using noncombustible spacers, to

allow for air circulation behind the shield.

3.3.

3. The height of the wall protection including the bottom

3.3.

air space must be 48” (121 cm).

4.4.

4. The Bottom Heat Shield is required in all

4.4.

installations.

5.5.

5. Alcove floor protection must consist of a UL/ULC or

5.5.

WHI listed hearth pad or a non combustible material

with a minimum R value of 2.0.

6.6.

6. Minimum ceiling height in an unprotected installation,

6.6.

off the top of the stove is 58”(148 cm). The minimum

ceiling height off the top of the stove in a protected

ceiling installation is 36 (91.5 cm).

Alcove

7

Page 8

USA/Canada

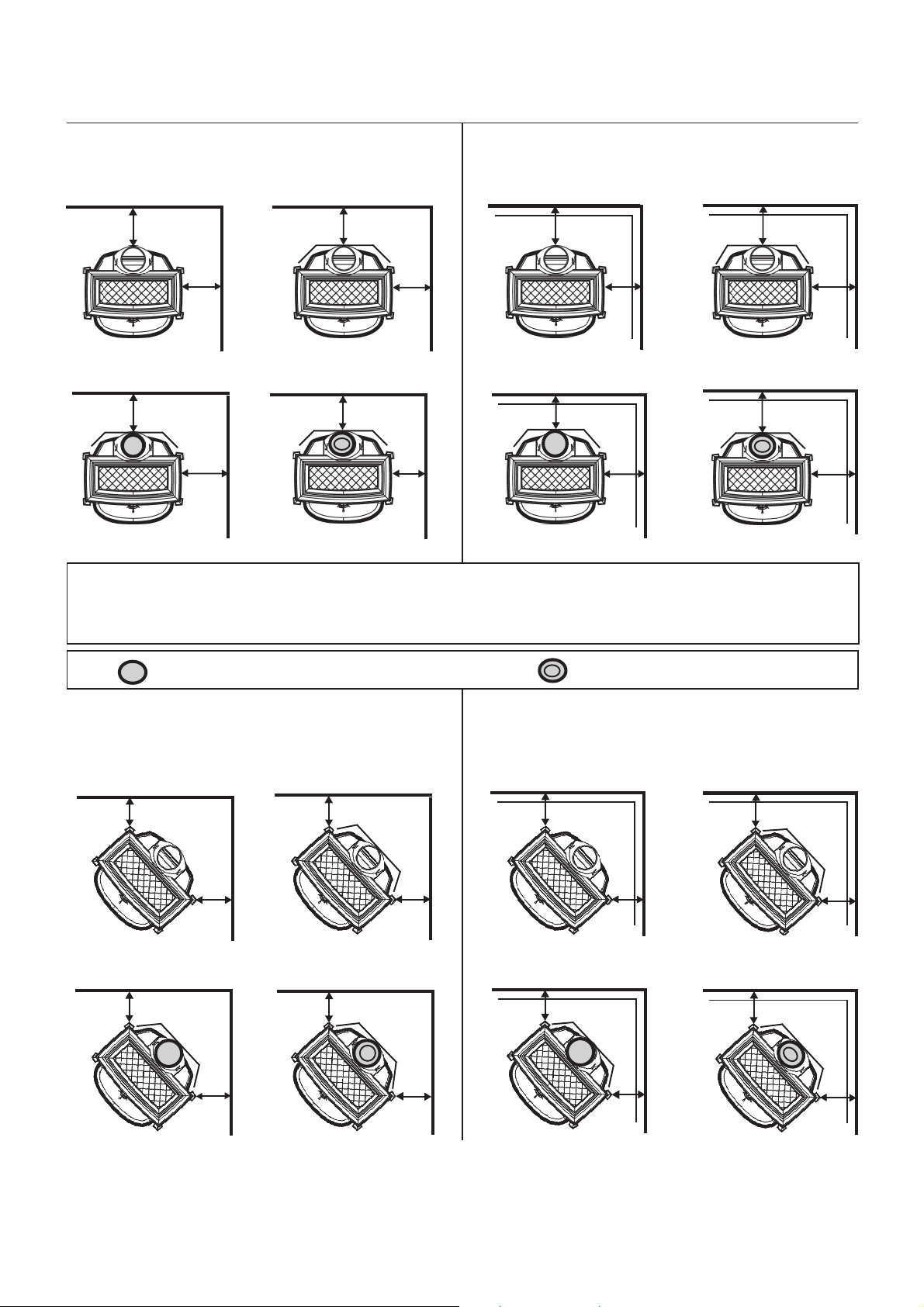

Jøtul F 400 Woodstove Clearances

Unprotected Surface

Parallel to the Wall

B

A

N

M

Connector heatshields and double wall pipe must be a listed product.

Protected Surface

Parallel to the Wall

H

G

T

S

E

D

Q

P

Important:

Always follow the manufacturer’s instructions.

PER NPER N

PER N

PER NPER N

CAN/CSA-B365 CAN/CSA-B365

CAN/CSA-B365

CAN/CSA-B365 CAN/CSA-B365

K

W

FPFP

A 211 orA 211 or

FP

A 211 or

FPFP

A 211 orA 211 or

V

J

= SINGLE WALL PIPE WITH CONNECTOR SHIELDS = DOUBLE WALL PIPE

Unprotected Surface

Corner Installation

C

C

O

O

Protected Surface

Corner Installation

I

I

U

U

F

F

R

R

PER NPER N

PER N

PER NPER N

CAN/CSA-B365 CAN/CSA-B365

CAN/CSA-B365

CAN/CSA-B365 CAN/CSA-B365

L

X

FPFP

A 211 orA 211 or

FP

A 211 or

FPFP

A 211 orA 211 or

L

X

8

Page 9

USA/Canada

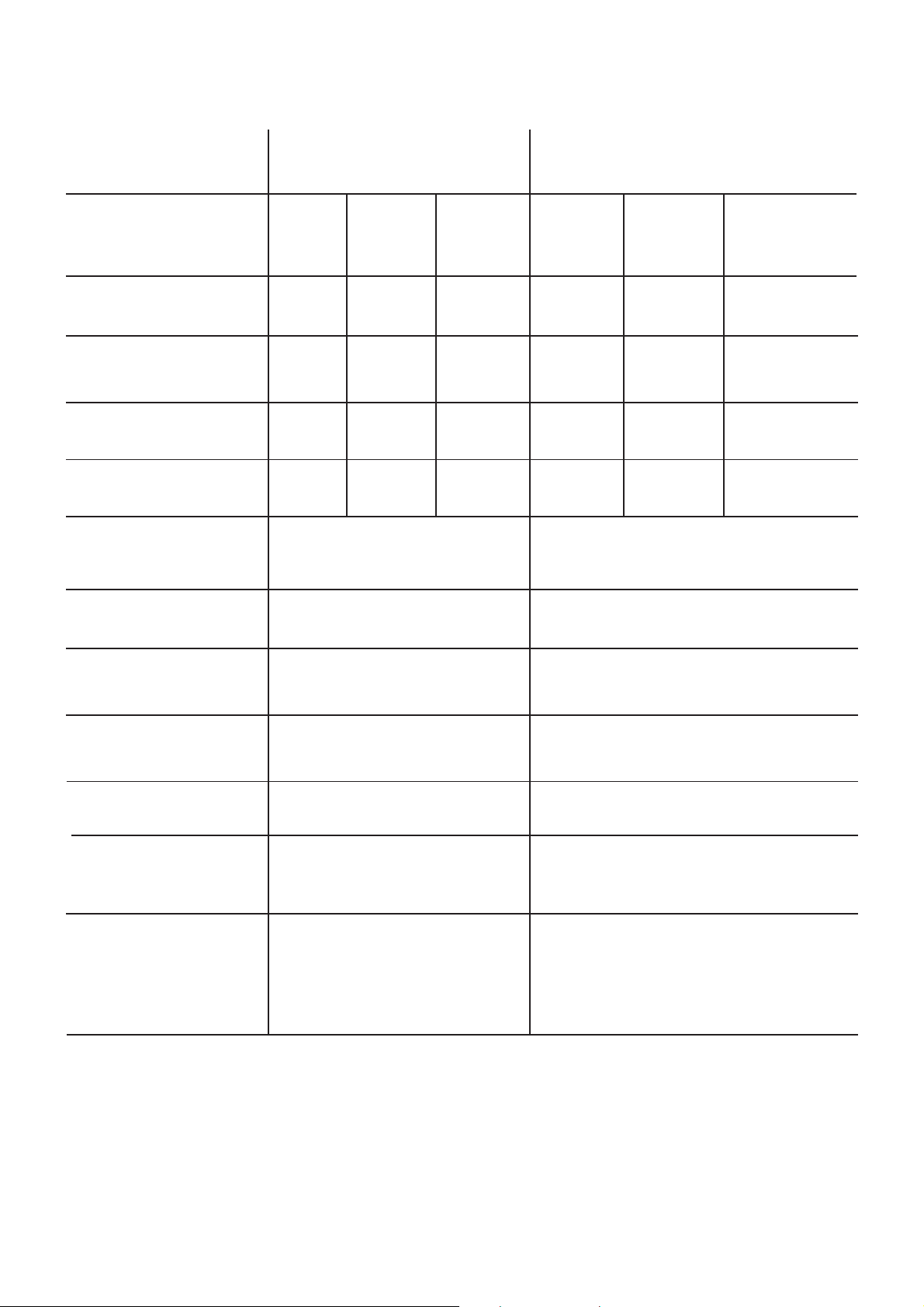

Jøtul F 400 Woodstove Clearances

Stove Unprotected Surface Protected Surface Installation

Clearances Installation PER NFPA211 OR CAN/CSA -B365-M93

Side Rear Corner* Side Rear Corner*

Stove -no heatshield 19" A 25" B 18" C 11” D 7" E 8" F

single wall pipe 485mm 635mm 460mm 280mm 180mm 205mm

Stove -with rear heatshield 18" G 18" H 13" I 11” J 7” K 8" L

single wall pipe 460mm 460mm 330mm 280mm 180mm 205mm

Stove -no heatshields 16” 19” 13” 8” 7” 6”

double wall pipe 405mm 485mm 330mm 205mm 180mm 150mm

Stove -with rear heatshield 15" M 7" N 11" O 8" P 7" Q 6" R

with connector shield 380mm 180mm 280mm 205mm 180mm 150mm

Stove -rear heatshield 15" S 7" T 11" U 8" V 7" W 6" X

with double wall pipe 380mm 180mm 280mm 205mm 180mm 150mm

Connector Unprotected Surface Protected Surface

Clearances (Pipe) Vertical Installation Vertical Inatallation

per NFPA211 OR CAN/CSA-B365-M93

Single wall pipe 25" 12"

635mm 300mm

Single wall pipe 18” 7”

with rear heatshield 460mm 180mm

Single wall pipe 7" 7"

with connector shields 180mm 180mm

Double wall pipe 7" 7"

180mm 180mm

Connector Unprotected Surface Protected Surface

Clearances (Pipe) Horizontal Installation Horizontal Installation

per NFPA211 OR CAN/CSA-B365-M93

Single wall connector 18" 460mm 7" 180mm

Double wall Pipe 6" 150mm 6" 150mm

Mantel and Trim Stove to 1" thick or less, side trim 13" 300mm

Clearances Stove to 1" thick or less, top trim 23" 585mm

Stove to mantel- maximum mantel depth 12" 25" 635mm

9

Page 10

USA/Canada

Operation

Please read the following section completely, before

building a fire in your new Jøtul F 400 .

Use Solid Wood Fuel Only

First this stove is designed to burn natural wood only. Wood

that has been air-dried for a period of 6 to 14 months will

provide the cleanest, most efficient heat.

Do not burn:

*Coal *Treated or painted wood

*Garbage *Chemical Chimney cleaners

*Cardboard *Colored paper

*Solvents *Any synthetic fuel or logs

The burning of any of these materials can result in the

release of toxic fumes. Never use gasoline, gasoline-type

lantern fuel, kerosene, charcoal lighter fluid, or similar

liquids to start or “freshen-up” the fire. Always keep such

liquids away from the heater at all times.

Important:

the glass panel. The logs should always be spaced at least

one inch from the glass to allow for proper air flow within

the firebox.

Never build or allow the fire to rest directly on

does not occur too quickly and cause damage. The following

steps describe the proper break-in procedure for the Jøtul

F 400 :

1.

Light a small fire of newspaper and kindling. Only allow

the stove to reach a maximum surface temperature of

200°F (93° C). Burn for approximately 1 hour.

2.

Allow the stove to cool to room temperature.

3.3.

3. Light a second fire, allowing the stove to reach a

3.3.

maximum temperature of 300°F (149°C) for 1 hour.

4.

Cool the stove to room temperature.

5. Light a third fire and gradually allow the stove to reach

a surface temperature of 400°F (204°C).

..

6

. Cool stove to room temperature. This completes the

..

“break-in” procedure.

To monitor the stove’s temperature, use a magnetic stovetop thermometer, placed directly on the corner of the stove’s

top plate.

::

Note

:

Keep the stove under 400°F (204°C) surface

::

temperature during any “break-in fire”, with the exception

of the last “break-in” fire. If the temperature exceeds

400°F, move the primary air control lever all the way to the

left to shut off the air supply completely. It is normal that

the stove top temperature will continue to climb until the

fuel burns down somewhat. Once the fire is out and the

stove has cooled to room temperature, continue the breakin procedure. Never attempt to reduce the temperature

by removing burning logs from the fire.

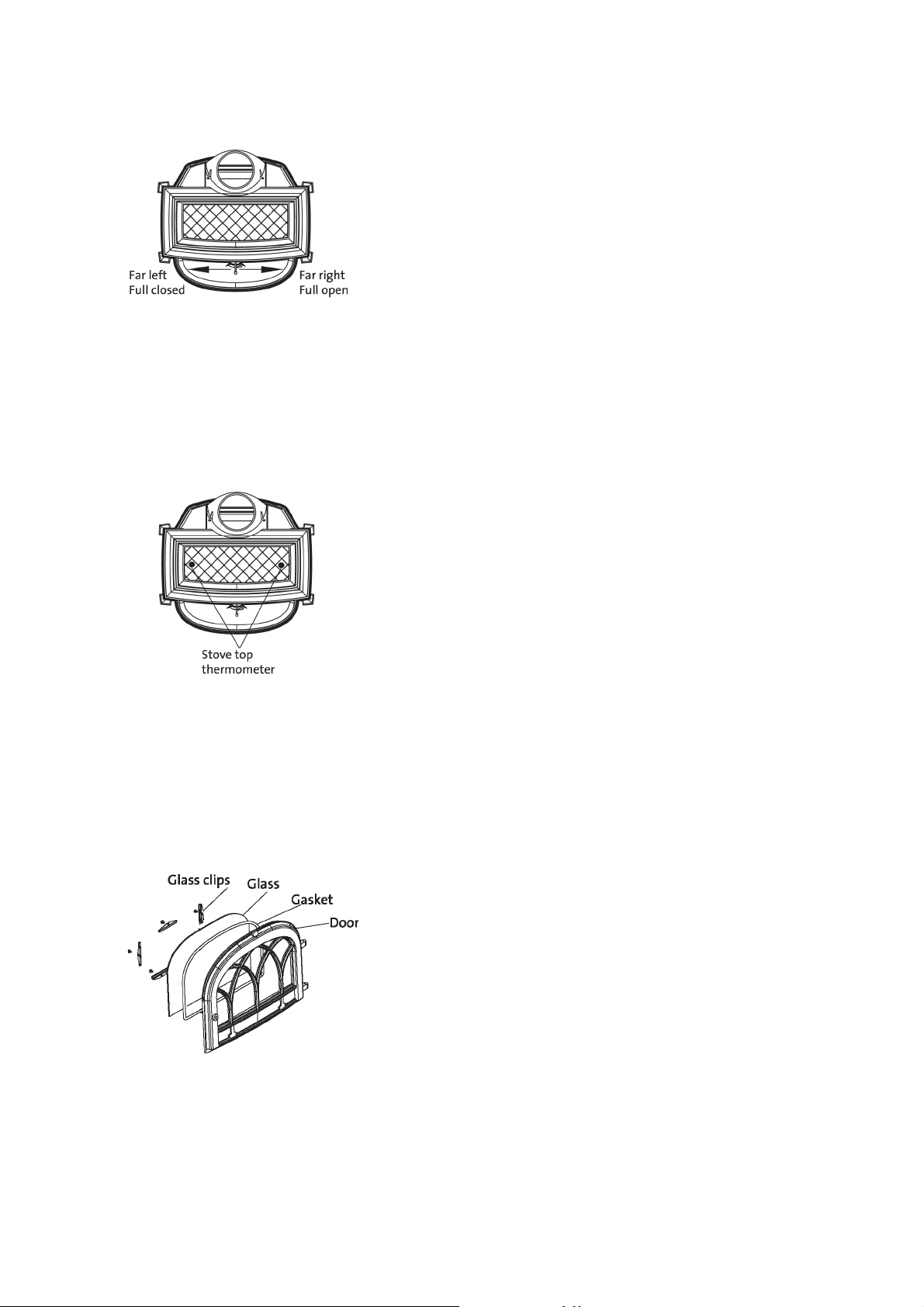

Controls on the Jøtul F 400

Combustion air is controlled by the Primary Air Lever,

located above the ashlip on the front of the stove. The

lever actuates a shutter over the air inlet which regulates

the volume of primary air entering the firebox and affects

heat output and burn time.

When first starting or reviving the fire: the primary control

lever should be at the far right position

maximum amount of air into the stove. The greater the

amount of air entering the stove, the hotter and faster the

fire will burn. Moving the lever to the left reduces the airflow

into the stove which prolongs the fire at a lower heat

output. See

figure 11.figure 11.

figure 11.

figure 11.figure 11.

, ,

,

which allows the

, ,

Air Flow / Performance

Primary air enters the firebox directly above the glass panel

on the door. The incoming air creates a turbulent barrier or

“airwash” between the glass and the fire. Reducing the

flow of primary air directly reduces the effectiveness of

the airwash. Determining the primary air setting for the

best overall performance for your particular needs and

installation will only be established over time through trial

and error.

Break-In Procedure

The Jøtul F 400 is constructed of cast iron and stove

furnace cement. This type of construction requires the

stove to be “broken-in” gradually so that heat expansion

Note:Note:

Note:

It is normal for a new painted stove to emit an odor

Note:Note:

and smoke during its first several fires. This is caused by

the seasoning of the high temperature paint and will

diminish with each fire. Opening a window or door to provide

additional ventilation will alleviate this condition.

Starting and Maintaining a Fire

Burn only solid wood directly on the bottom grate of the

stove. Do not elevate the fire in any way.

• The ash pan door on the stove must always be securely

closed when the stove is in operation.

• Burning the stove with the Ash Door open will over-fire

the stove and cause interior damage.

1. With the primary air control lever in the full open position

(to the right), start with several sheets of crumbled

newspaper placed directly on the grate. On top of the

newspaper, place several pieces of small dry kindling

(approx. 1” in diameter) with two to three larger logs

(approx. 3” to 5” in diameter) on top.

2. Light the fire and close the door, slowly building the fire

by adding larger and larger logs. Be sure to follow the

break-in procedure before creating a hot fire that might

damage the stove.

3. Once the stove has reached a surface temperature

range of between 400° and 600°, (204°C -316°C), adjust

the primary air control lever as necessary to generate

the heat output and burn time desired.

Jøtul recommends use of a magnetic stove top

thermometer to monitor the surface temperature of

the stove. The optimum surface temperature range for

10

Page 11

USA/Canada

the most efficient burn is between 400° and 600°

(204°C -316°C).

See figure 12 for the best locations to place a stove-top

thermometer.

Never overfire the stove. If any part of the stove or chimney

glows, you are overfiring. A house fire or serious damage to

the stove or chimney could result. If this condition occurs,

immediately close down the air control.

Adding Fuel

When reloading the stove while it is still hot and a bed of

hot embers still exist, follow this reloading procedure:

• Always wear gloves when tending to the stove.

• Push the air control lever to the full open position (far

right).

• Wait a few seconds before opening the door.

• Use a stove tool or poker to distribute the hot embers

equally around the firebox.

• Load the fuel, usually with smaller logs first.

• Close the door, be sure to latch the door tightly.

• Wait 5 – 10 minutes before adjusting the primary air to

the desired heat output setting. (If you have at least a

2” thick ember bed when reloading, it may be possible

to close the door and immediately adjust the air control

setting).

Maintenance

Ash Removal

For your protection always wear safety gloves when

handling the ash pan.

Ash removal will be required periodically depending on how

frequently the stove is used. The Jøtul F 400 is equipped

with an exterior ash pan assembly that allows easy ash

removal without opening the front door.

The ash pan door is located under the front ashlip of the

stove. To open the ash door, engage the receptacle end of

the door handle with the square fitting on the ash door

latch. Rotate the door counterclockwise to unlatch the

door and clockwise to latch the door.

With a gloved hand

the ash pan. Always close the ash pan door before leaving

to dispose of the ashes.

The ashes should be placed in a metal container equipped

with a tight sealing lid. The container should be placed on a

noncombustible floor or on the ground, well away from all

combustible materials, pending final disposal. If the ashes

are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container

until all cinders have thoroughly cooled.

,,

, grasp the ash pan handle and remove

,,

The Formation of Creosote

When wood is burned slowly and at low temperatures, it

produces tar and other organic vapors, which combine with

moisture to form creosote. The slow moving smoke carries

the creosote vapors, which condense in the cooler chimney

flues, and this creosote then sticks to the chimney walls.

The creosote that accumulates in the chimney is highly

flammable and is the

chimney fires it is important to have the chimney and

chimney connector pipe inspected and/or cleaned

semiannually. A qualified chimney sweep or other

authorized service person can provide this service.

It is also important to remember that chimney size,

temperature and height all affect draft which in turn

affects the formation of creosote. Be sure to follow the

installation and operation guidelines established in this

manual.

fuel of chimney fires. To prevent

Glass Care

Cleaning

On occasion it will be necessary to clean the carbon deposits

and fly ash off of the glass. If the carbon and fly ash are

allowed to remain on the glass for an extended period of

time it could eventually cause the glass to become etched

and cloudy. Any creosote that might develop on the glass

will burn off during the next hot fire.

Follow this cleaning procedure:

1. Glass needs to be completely cool.

2. Only use a cleaner that is specifically designed for this

purpose. The use of abrasives will damage the glass

and ultimately leave the glass frosted.

3. Rinse and dry glass completely before burning the stove.

Caution!

avoid cracking or breaking the glass. Never use the door to

push wood into the firebox. If the glass becomes cracked

or broken follow the replacement procedure below. Never

operate the stove with a cracked or broken glass panel.

Always operate the door slowly and carefully to

Important: Replace glass only with ceramic glass panel

specifically designed for the Jøtul F 400 . Do not use

substitutes. Replacement glass is available from your local

Jøtul dealer.

11

Page 12

USA/Canada

Glass Removal

1. Remove the door from the stove and place on a flat

surface.

2. Carefully remove all of the glass clips from the inside of

the door.

3. Gently remove the glass panel and gasketing.

4. Using a wire brush, remove all remaining debris from

the glass area .

5. Apply a small bead of gasket/stove cement and the

new gasket. Do not overlap the ends of the gasket

rope.

6. Center the new glass panel over the gasket and reinstall

the glass clips. See figure 13.

7. It may be necessary to retighten the glass clips after

the stove has be burned and the gasketing has been

seated.

Important:

clips slowly and in an alternating pattern as you would

tighten the lugs on an automobile wheel.

It is extremely important to tighten the glass

General Maintenance

As with your car, regular maintenance will prolong the life

of your stove and ensure satisfactory performance.

4. Gently press the new gasket into the cement to seat it

in the channel. Close and latch the door and then reopen.

Wipe any excess cement squeezed out from around

the gasket.

Gasket List for the Jøtul F 400

Description Size Length

Top Plate Gasket 3/8" LD 7

Smoke Outlet Gasket 3/16” LD/SA 3'

Ash Housing Gasket 3/16” LD/SA 4'

Ash Door Gasket 5/16” LD 4'

Glass Gasket 3/8" LD 5'

Door Gasket 5/16" LD 5,8'

Chimney System

The Jøtul F 400 is designed to burn cleanly and efficiently

when used according to the guidelines in this manual. In

order to maintain proper performance, you should inspect

the chimney and chimney connector at least twice a year

and clean when creosote and fly ash deposits exceed 1/4”

in any part of the system. Failure to keep the chimney

system free of creosote and build up could result in a

serious chimney fire.

At least once per year you should perform the following

maintenance procedures:

• Thoroughly clean the stove. Use a soft cloth with soap

and water to clean enamel surfaces. Be sure the stove

is cold, before cleaning.

• Empty stove of all soot and ashes. Only use a vacuum

for this job if the vacuum is specifically designed for

ashes.

• Inspect the stove seams. Use a utility light to inspect

the stove inside and out for cracks or leaks. Replace all

cracked parts and repair any cement leaks with furnace

cement.

Gaskets

Check door and glass panel gaskets for tightness. To check

the seal of the front door, close and latch the door on a

dollar bill and slowly try to pull the dollar bill free. If it can

be easily removed, the seal is too loose. Check several spots

around the door, and repeat the procedure on the ash pan

door as well.

Gasket Replacement

1. Use pliers and a putty knife to remove the old gasket

from the door.

2. Thoroughly clean the channel with a wire brush.

3. Apply a small bead of cement to the channel.

Accessories

Use only accessories that are specifically designed for use

with the Jøtul F 400 .

Firescreen (# 129650)

The Jøtul F 400 has been approved for use as an open

fireplace, with front door open. Care should be taken when

operating the stove as a fireplace.

••

• Always have the Firescreen in place, attached to the

••

stove front.

••

• Never overload the stove. For the best appearance, burn

••

logs in the traditional three log configuration.

••

• When you operate the stove with the screen in place,

••

efficiency is sacrificed for the sake of aesthetics, much

as with a conventional fireplace. Wood will burn at a

much faster rate as combustion air is uncontrolled. Most

of the heat value of the wood will be lost up the chimney.

Not all installations will support the use of the

firescreen. Moderate or low draft conditions may result

in smoke spillage from the stove when using the

firescreen.

12

Page 13

USA/Canada

Warning: Operate your Jøtul F 400 with the front door fully

open and the firescreen in place or fully closed. A partially

opened door may result in overfiring. Also, if the door are

left partly open, gas and flame may be drawn out of the

stove opening, creating risks from both fire and smoke.

Stove-Top Thermometer (# 5002)

Jøtul recommends the use of a magnetic stove-top

thermometer to monitor the surface temperature of the

stove. The optimum surface temperature range for the

most efficient, clean burn is between 400° and 600°.

Outside Air Kit (#154335)

Your local building code may require that an outside air

supply be connected to the stove. Jøtul Outside Air Kit 154335

must be used in these installations unless otherwise

specified by the local code official. While the use of outside

air may be beneficial in some installations, in itself, such a

system does not guarantee proper chimney performance.

The Outside Air Kit includes an adapter collar to attach the

air duct to the stove. Installation will require these

additional materials not included in the kit:

the performance of the appliance.

3. A mechanical ventilation system:

ventilation system (air change or heat recovery):

a. The ventilation system may be able to provide

sufficient combustion makeup air for the solid-fuel

appliance.

b. The homeowner should be informed that the

ventilation system might need to be rebalanced by a

ventilation technician after installation of the appliance.

Note: Provision of outside air to the stove, directly or

indireclty, may fail to remedy the problems outlined above.

Chimney performance is determined by a variety of

interelating factors which may not be affected by the air

supply. Your local Jøtul authorized dealer is your best resource

for information regarding chimney and stove performance

issues.

If the house has a

Floor Bracket Kit (#750304)

Use of the Floor Bracket Kit is required in all mobile home

installations to secure the stove to the floor. Complete

installation instructions and diagrams are supplied with

each Floor Bracket Kit.

1. 3” (80 mm) diameter flexible metallic Air Duct - of

appropriate length to reach from the stove to the

outside of the house.

2. Weatherproof Duct Cap for the duct termination on

the outside of the house.

3. Rodent Screen - no larger than 1/4” (5 mm) mesh.

Outside air should be considered if:

1. The stove does not “draw” steadily. Smoke rollout occurs

when the door are opened. Fuel burns poorly. Backdrafts

occur with or without a fire burning.

2.2.

2. Other fuel-fired equipment in the house, such as

2.2.

fireplaces or other heating appliances, smell, do not

operate properly, suffer smoke roll-out when opened,

or back-draft whether or not there is combustion

present.

3.3.

3. Opening a window slightly on a calm (windless) day

3.3.

alleviates any of the above symptoms.

4. The house is equipped with a well-sealed vapor barrier

and tight fitting windows and/or has any powered

devices that exhaust house air.

5. There is excessive condensation on the windows in the

winter.

6. A ventilation system is installed in the house.

Rear Heat Shield (# 154385)

A stove rear heat shield has been specifically designed for

the Jøtul F 400 to reduce clearances off the rear of the

stove to combustible materials. Use of the heat shield does

not affect the clearance off the sides of the appliance. See

pages 8-9 for specific clearance requirements. Complete

installation instructions are supplied with the heat shield.

No other type of heat shield may be used on the rear of the

Jøtul F 400 .

Bottom Heat Shield (# 154384)

The bottom heat shield supplied with your stove has been

specifically designed for the Jøtul F 400 . It is required in all

alcove installations. Use of the bottom heat shield does not

affect the floor protection requirements described on page

6 of this manual.

No other type of heat shield may be used on the bottom of

the Jøtul F 400 .

If these or other indications suggest that infiltration air is

inadequate to supply sufficient air for the stove, additional

combustion air should be provided from the outdoor.

Outside combustion air can be provided to the appliance

by the following means:

1. Direct connection: The Jøtul F 400 has been tested and

approved for use with the outside air kit listed above.

2. Indirect method: Outside air is ducted to a point no closer

than (12”) 300 mm from the stove, to avoid affecting

13

Page 14

USA/Canada

Fig. 1

25 3/4”

Fig. 2

23 1/4”

Fig. 3

29 1/2”

top exit

25 1/2”

rear exit

Fig. 4

13”

28 1/2”

14

26 1/2”

Page 15

USA/Canada

Fig. 5

Fig. 6

Fig. 8

Fig. 9

Fig. 7

Fig. 10

Protection and

air space must

comply with

NFPA 211OR

CAN/CSA-B365.

15

Page 16

USA/Canada

Fig. 11

Fig. 12

16

Fig. 13

Draw. no. 1-1714

Page 17

USA/Canada

17

Page 18

USA/Canada

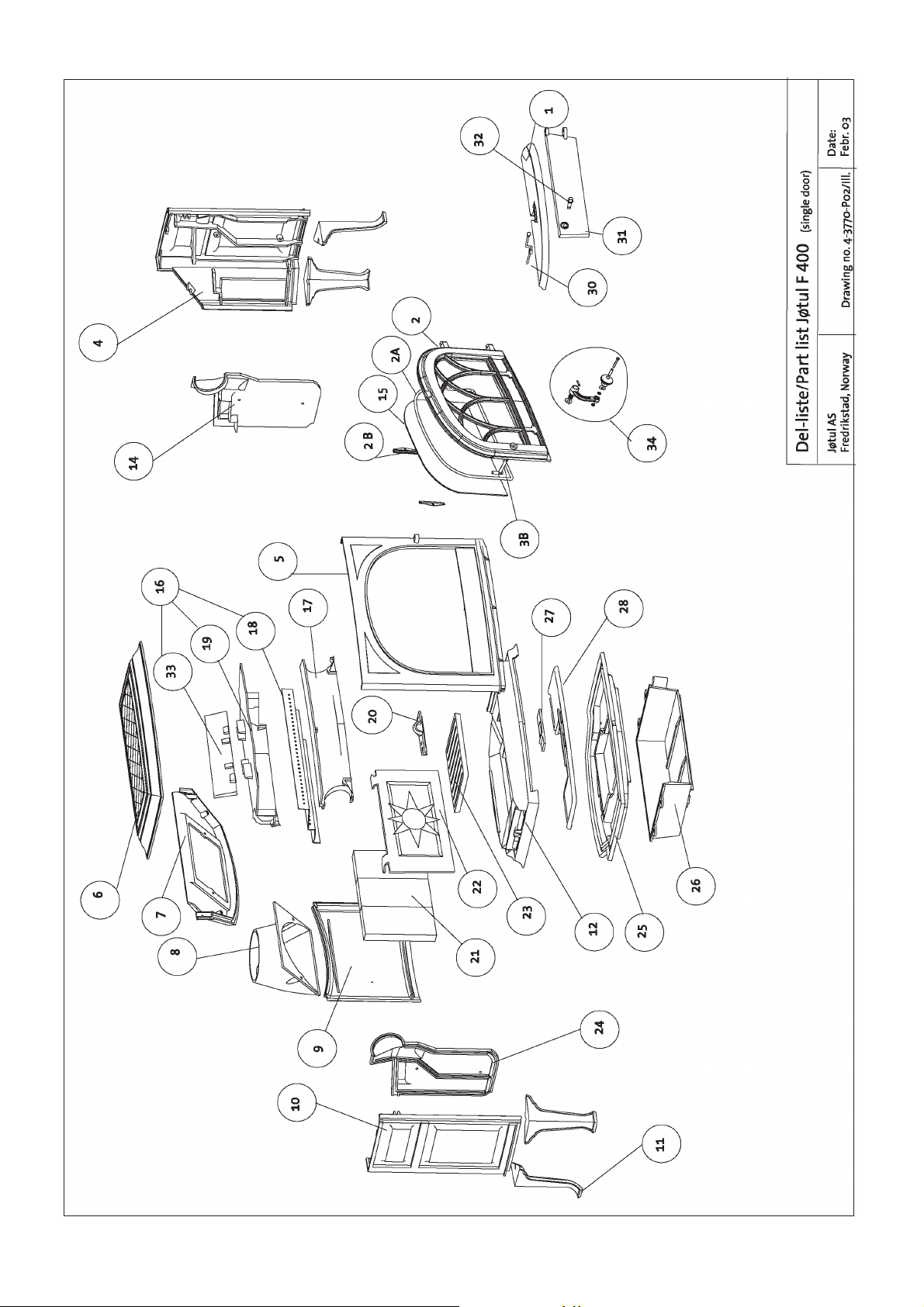

Parts list for the Jøtul F 400

woodstove

Consult your dealer for part numbers and

replacement parts.

1 Ashlip

2 Door

2A Gasket

2B Glass clips

3B Latch

4 Right side panel

5 Front panel

6 Top casting

7 Upper back panel

8 Smoke outlet

9 Back panel

10 Left side panel

11 Leg (long leg)

12 Upper bottom panel

13 Front door handle

14 Right burn plate

15 Glass panel

16 Airchamber

17 Air wash manifold

18 Top baffle (stainless steel)

19 Baffle cover (cast iron)

20 Air inspection cover

21 Rear burn plate

22 Fire brick (3)

23 Bottom grate

24 Left burn plate

25 Lower bottom panel

26 Ashpan housing

* Ashpan

27 Air slider/valve

28 Air devider

30 Air control lever (chrome)

Allen head screw

31 Ashpan door

* Ashpan door pin

32 Ash door handle

33 Baffle plate II

34 Latch compl.

* Not shown

Appendix A

Alternate floor protection

All floor protection materials must be non-combustible ie. metal,

brick, stone, mineral fiber boards). Any combustible material may

not be used.

The easiest means of determining if a proposed alternate floor

material meets requirements listed in this manual is to follow this

procedure.

R-value = thermal resistance

k-value = thermal conductivity

C-value = thermal conductance

1. Convert the specification to R-value;

a. If R-value is given, no conversion is needed.

b. If k-value is given with a required thickness (T) in inches:

R=1/k X T.

c. If C-value is given: R=1/C.

2. Determine the R-value of the proposed alternate floor protector.

a. Use the formula in Step 1 to convert values not expressed

as “R”.

b. For multiple layers, add R-values of each layer to determine

overall R-value.

3. If the overall R-value of the sustem is greater than the R-value of

the specified floor protector, the alternate is acceptable.

Example:

The specified floor protector should be 3/4” thick material with a kfactor of 0.84. The proposed alternate is 4” brick with a C-factor of

1.25 over 1/8” mineral board with a k-factor of 0.29.

Step A. Use formula above to convert specifications to R-value. R=1/

k X T= 1/.84 X .75 = .893

Step B. Calculate R of proposed system.

• 4” brick of C-1.25, therefore

• R brick = 1/C = 1/1.25 = 0.80.

• 1/8” mineral board of k = 0.29 therefore

• R mineral board = 1/.29 X 0.125 = 0.431

Total R = R brick + R mineral board=

0.8 + 0.431=1.231

Step C. Compare proposed system R = 1.231 to specified R of 0.893.

Since R is greater than required, the system is acceptable.

Definitions:

Thermal conductance =

C = Btu = W

(hr)(ft2)(F) (m2)(K)

Thermal conductivity =

k = Btu = W = (Btu)

(hr)(ft2)(F) (m2)(K) (hr)(ft)(F)

Thermal resistance=

R = Btu = (m2)(K) = (Btu)(inch)

(hr)(ft2)(F) W (hr)(ft2)(F)

18

The Jøtul F 400 Castine woodstove requires floor protection with a

minimum insulating r value of 0.5.

Alcove installation require a minimum r value of 1.6. (If a ul/ulc or

whi listed hearth pad is not used.)

Page 19

19

Page 20

NORSK

20

Page 21

NORSK

Innhold

Forhold til myndighetene

Tekniske data for Jøtul F 400 ................................................... 21

Sikkerhetsregler ........................................................................... 22

Brannforebyggende tiltak ........................................................ 22

Installasjon av Jøtul F 400

Fundamentering ......................................................................... 22

Skorstein ........................................................................................ 22

Luftsirkulasjon .............................................................................. 22

Montering før installasjon........................................................ 22

Kontroll av funksjoner ............................................................... 23

Montering av røykrør ................................................................ 23

Tilslutning til skorstein .............................................................. 23

Bruksanvisning

Første gangs opptenning og daglig bruk ........................... 24

Ved første gangs oppfyring ..................................................... 24

Daglig bruk ................................................................................... 24

Vedlikehold

Rengjøring av glass .................................................................... 24

Fjerning av aske ........................................................................... 24

Rensing og sotfjerning i produktet ....................................... 24

Feiing av røykrør til skorstein .................................................. 25

Kontroll av ildstedet ................................................................... 25

Utvendig vedlikehold ................................................................ 25

Vedlengde-, mengde-, og kvalitet .......................................... 25

Jøtuls definisjon av kvalitetsved............................................. 25

Servicearbeider

Utskifting av brennplater .......................................................... 25

Utskifting av hvelv ......................................................................25

Ekstrautstyr

Korte bein ...................................................................................... 25

Skjermplate - bak ........................................................................ 25

Figurer-tegninger ............................................... 64-65

Forhold til myndighetene

Jøtul F 400 er et rentbrennende produkt og har

produktdokumentasjon for luftforurensning og

brannteknisk sikkerhet utstedt av SINTEF, Norges

Branntekniske Laboratorium med registreringsnr. SINTEF

045-089 Dette er påført produktets typeskilt.

Installasjon av et ildsted må være i henhold til det enkelte

lands lover og regler og din forhandler kan tilby deg hjelp

for å sørge for at installasjonen er sikker og lovlig.

Monterings-, installasjons- og bruksanvisninger er vedlagt

produktet. Installasjonen kan først tas i bruk når den er

kontrollert av godkjent kontrollør.

Ifølge Forskrift om brannforebyggende tiltak og tilsyn, skal

eier melde fra til kommunen når det har vært installert

nytt ildsted ellerforetatt andre vesentlige endringer ved

fyringsanlegget.

Det er viktig å forsikre seg om at pipen er riktig

dimensjonert for ildstedet og at pipetilslutningen er tett

og fungerer korrekt. Røykgass som trenger inn i lukkede

rom kan representere en alvorlig helsefare.

Et typeskilt av varmebestandig material er plassert på

skjermplaten for askehuset. Det inneholder følgende

informasjon; produsent, adresse, produktnavn,

katalognummer, produksjonsnummer, effekt,

godkjenningsnummer.

Tekniske data for Jøtul F 400:

Materiale: Støpejern

Overflatebehandling: Sort lakk og emalje

Type brensel: Ved

Maks. vedlengde: 50 cm

Trekksystem: Luftspyling

Forbrenningssystem: Sekundærforbrenning

Røykuttak: Topp/bak

Røykrør: Ø 150 mm

Mulighet for stålpipe: Ja

Vekt ca.: 158 kg

Tilleggsutstyr: Skjermplate-bak, korte ben (155

mm)

Produktmål,

brannmurmål Se fig. 1

21

Page 22

NORSK

Sikkerhetsregler

Advarsel! Man må forsikre seg om at det er nok tilførsel av

uteluft til det rommet hvor ildstedet blir installert.

Utilstrekkelig luft-tilførsel kan forårsake at røykgasser

kommer ut i rommet. Dette er meget farlig! Symptomer

på dette kan være tretthet, kvalme og uvelhet.

Krav til gulvplate: Skal ildstedet anbringes på gulv av

brennbart materiale, må hele gulvet under ildstedet, og

min. 300 mm foran ildstedet, dekkes av en plate av ikke

brennbart materiale.

Avstand fra produkt til vegg av brennbart materiale (fig.1):

Ved montering av skjermplate bak på produktet, kan

Ildstedet plasseres med en avstand på 100 mm til vegg av

brennbart materiale. Avstanden til sidevegg må være min.

300 mm.

(NB. Skjermplate er tilleggsutstyr)

NB! Røykrøret må skjermes når avstand fra ytterkant

røykrør til vegg av brennbart materiale er mindre enn 300

mm. (Skjermplate for røykrør kan bestilles hos din

Jøtulforhandler).

• La ilden brenne ut. Slukk den aldri med vann da dette

kan skade produktet.

• Ildstedet blir varmt under fyring, og kan forårsake

forbrenning hvis det berøres.

• Aske må plasseres forsvarlig utendørs, eller tømmes

der dette ikke medfører brannfare.

• Til ethvert ildsted bør det være en

oppbevaringsbeholder av ikke-brennbart materiale med

lokk for sot og aske.

• Sot og aske må oppbevares i denne beholderen minst 1

uke, for å være sikker på at siste gnist er slukket. Må

beholderen tømmes før den tid, skal rikelig med vann

slås i beholderen og røres om.

• Ta gjerne vare på asken. Den er utmerket i bruk som

gjødsel til f.eks. roser.

Installasjon av Jøtul F 400

NB! Kontroller at ildstedet er fri for skader før installasjonen

begynner.

Produktet er tungt! Sørg for hjelp når det skal settes opp

og monteres.

Avstand fra produkt til brannmur (fig. 1):

Ved rettveggsmontering er det mulig å plassere ildstedet

med en avstand på 40 mm

skjermplate- når denne er montert. Uten skjermplate er

ildstedet godkjent for plassering med en avstand på 100

mm fra produktets bakvegg/side til brannmur.

Krav til brannmur: Brannmuren skal være minst 100 mm

tykk og være utført av teglstein, betongstein eller

lettbetong. Andre materialer og konstruksjoner med

tilfredsstillende dokumentasjon kan også benyttes, f.eks.

Jøtul Brannpanel. NB! Bruk av naturstein er ikke tillatt.

Montering av ildsted i nisje: Et frittstående ildsted er tillatt

plassert i en nisje dersom denne er oppført med brannmurs

tykkelse. Nisjens minimumsmål må gi 100 mm fri avstand

fra produktet til bakvegg og sider. Nisjens høyde skal være

produktets maksimale høyde + nisjens dybde. Fronten må

være åpen.

Uisolert røykrør:

etasjeskiller eller vegg, skal det støpes eller mures rundt,

slik at rørets ytre flate ikke kommer nærmere brennbart

materiale enn min. 300 mm. Isolerte røykrør kan ha en

annen avstand, jfr. eventuelt brannteknisk

produktdokumentasjon for røykrøret.

Hvis uisolert røykrør går gjennom

mellom brannmur og

Fundamentering

Dersom Jøtul F 400 skal plasseres på et tregulv, bør man

forsikre seg om at gulvet under ildstedet er dimensjonert

for dette.

Skorstein

Ildstedet kan tilknyttes teglstensskorstein,

elementskorstein eller stålskorstein. Minimum

skorsteinstverrsnitt må være 177 cm 2. (Tilsvarer Ø150 mm).

Tilslutning til skorstein må utføres i henhold til

skorsteinsleverandørenes monteringsanvisninger.

Luftsirkulasjon

Bruk av ildsted krever rikelig frisklufttilgang til rommet der

produktet er plassert. Dersom huset er tett, bør rommet

utstyres med ekstra frisklufttilførsel gjennom ventiler.

Mekanisk avtrekk bør ikke brukes i et rom med ildsted.

Dette kan skape undertrykk og kan trekke giftige gasser

inn i rommet.

Montering før installasjon

Brannforebyggende tiltak

Enhver bruk av ildstedet kan representere en viss fare.

Ta derfor hensyn til følgende anvisninger:

• Sørg for at møbler og annet brennbart materiale ikke

kommer for nær ildstedet. Det skal være en avstand

foran ildstedet på minst 600 mm.

22

Jøtul F 400 selges i mange land, som har forskjellige krav til

ildsteder. Dette medfører at du som har kjøpt ildstedet i

Europa, må foreta noen små endringer før du installerer

produktet.

Rett innenfor dørene sitter det en inspeksjonsluke som er

festet med 2 stk. skruer i ytterkanten. Inspeksjonsluken

skrues av og erstattes med en tilsvarende del som ligger i

Page 23

NORSK

askeskuffen. Denne er merket: Europa

midten (fig. 6) demonteres, og settes på den nye

inspeksjonsluken som er merket Europa.

• Topplaten er festet med 2 stk. transportskruer. Disse

må fjernes p.g.a. bestemmelser om tilgang til å feie

røykrør. Dette gjøres ved at røykstussen først skrues

av - slik at man kommer til de to transportskruene som

sitter iskrudd fra innsiden av produktet - mellom

sidestykker og topplate. Obs. Topplaten skal ligge løst

montert på produktet.

• Askeleppen, som ligger inne i brennkammeret, settes

på plass under døren.

• I brennkammeret ligger det også en skjermplate som

skal festes under askehuset. Skjermplaten brettes ut,

(fig. 2A) og festes med 2 skruer som er festet i askehuset

(fig. 2B).

• Skru dørknottene på håndtakene til hoveddøren og

askedøren. (Se fig. 3 B+C og fig. 7.)

. .

. Sikkerhetsskruen i

. .

Kontroll av funksjoner (fig. 3)

Når produktet er oppstilt, kontroller

Disse skal bevege seg lett, og virke tilfredsstillende.

alltid

betjeningsorganene.

Tilslutning til skorstein

Bor hull for røykrøret. Avstand fra ovn til skorstein skal

være som vist i fig. 1. Bruk alltid murstuss ved montering på

skorstein. På element-skorsteinene skal leverandørens

anbefalte murstuss brukes. Følg nøye leverandørens

monterings-/og bruksanvisning ved tilslutning til skorstein

med hensyn til tørketid av mørtel/ovnskitt, før ildstedet

tas i bruk.

Se til at røykrøret aldri heller inn mot skorsteinen. Det skal

minimum være vannrett, aller helst ha noen millimeters

stigning.

NB! En korrekt og tett tilslutning er meget viktig for

produktets funksjon.

Vær obs på at det er særdeles viktig at tilslutninger har en

viss fleksibilitet. Dette for å forhindre at setninger i huset

fører til sprekkdannelser.

Trekkventil (A)

Venstre posisjon = lukket.

Høyre posisjon = fullt åpnet.

Dørhåndtak (B)

Mot venstre = åpnet.

Mot høyre = lukket.

Askedør (C). Åpne døren ved å dreie håndtaket mot klokken.

Bruk en hanske e.l. og trekk skuffen ut.

NB! Fjern asken kun når ildstedet er kaldt.

Montering av røykrør

Ildstedet bør prøvemonteres først uten at det tas hull i

skorsteinen. Se fig. 1 for mål til vegg av brennbart materiale.

Ildstedet monteres med Ø150 mm røykrør. Dette skal være

av godkjent tykkelse.

Jøtul F 400 er fra fabrikk montert for topputtak av røykrøret.

Ønsker man bakuttak, løsnes de to skruene på sidene, og

stussen roteres 1800. Fest skruene godt igjen.

• Røykrør Ø150 mm plasseres med den smaleste enden

av røret direkte inn i produktets røykuttak. På begge

sider av røykuttaket er det plassert en skrue (fig. 4-A).

Disse skal brukes til å feste røykrøret.

• Merk av på røykrøret hvor skruene treffer når røret er

helt i bunnen av røykuttaket, og bor et hull på 5,5 mm i

røykrøret for skruen.

• Bruk pakningssnor til å tette mellom røykrør og

produktets røykuttak.

• Skru fast røykrøret.

NB! Det er viktig at sammenføyningene/røykrørene er helt

tette. Falsk luft e.l. kan ødelegge funksjonen.

23

Page 24

NORSK

Bruksanvisning

Første gangs opptenning og daglig

bruk

Jøtul F 400 er et rentbrennende produkt som ved hjelp av

ekstra tilførsel av forbrenningsluft, sørger for en

etterbrenning av skadelige gasser og partikler. Det er viktig

at systemet blir brukt riktig.

Ildstedet er utstyrt med betjeningsmuligheter som er

beskrevet i avsnittet:

Ved første gangs oppfyring

Åpne trekkventilen under døren fullt ved å skyve ventilen

helt til høyre

begynn med et lite bål. Øk mengden etterhvert og fyr friskt

et par timers tid. La det brenne ut og gjenta så dette en

gang til.

NB! Lukt under innfyring:

Lakkerte produkter: Under første gangs oppfyring kan

ildstedet gi fra seg en irriterende gass som kan lukte noe.

Gassen er ikke giftig, men det bør foretas en skikkelig

utlufting av rommet. Fyr med god trekk til samtlige gasser

har brent ut - til hverken røyk eller lukt merkes mer.

Emaljerte produkter: De første gangene et nytt ildsted

brukes, kan det danne seg kondensvann på overflaten. Dette

må tørkes bort for å unngå at det dannes varige flekker

når overflaten blir varm.

(fig. 3-A). Legg i avispapir, fliser og ved, og

Kontroll av funksjoner.

Med overfyring forstås et for stort ilegg av ved, og/eller

ikke regulert trekk.

Trekken i skorsteinen bør ikke overstige 2,5 mmVs (25 Pa).

Et sikkert tegn på overfyring er at produktet får glødende

punkter. Redusér da trekkinnstillingen øyeblikkelig.

OBS! Hvert ilegg bør brenne ned til glør før du på nytt legger i.

Vedlikehold

Rengjøring av glass

Jøtul F 400 er utstyrt med topptrekk (luftspyling). Ved hjelp

av trekkventilen suges det luft inn i overkant av ildstedet

og spyles nedover langs innsiden av glasset. Dette systemet

har den fordelen at det gir bedre forbrenning og reduserer

sotbelegget på glasset.

Det vil allikevel alltid dannes noe sot på glasset, men

mengden vil være avhengig av de stedlige trekkforhold og

regulering av trekkventilen. Mesteparten av sotbelegget

vil normalt bli brent av når trekkventilen blir regulert opp

til maks., og det fyres friskt i ildstedet.

Et godt råd! Ved vanlig rengjøring; fukt et kjøkkenpapir med

varmt vann og ta på litt aske fra brennkammeret. Gni over

glasset og tørk deretter av glasset med rent vann. Dersom

det er behov for å rengjøre glasset grundigere, er en

glassrens å anbefale (følg bruksanvisningen på flasken)

Fjerning av aske

.

Daglig bruk

Tenn opp ved hjelp av avispapir og noe finkløyvd ved. Legg

to halvstore trestykker ut/inn på hver sin side i peisbunnen.

Krøll litt avispapir (evt. never fra bjørkeved) mellom disse,

legg litt finkløvd ved på kryss og tvers, og tenn opp. Øk

vedstørrelsen etterhvert.

Trekkventilen (fig. 3- A) reguleres når veden har antent

skikkelig og brenner godt. Kontrollér at etterbrenning

(sekundærforbrenning) starter. Dette sees best ved å

kontrollere at gule stikkflammer brenner ved hvelvet.

Deretter regulerer du forbrenningen til ønsket

varmeavgivelse ved hjelp av trekkventilen.

Bruk alltid kvalitetsved. Det gir det beste resultatet, og vil

ikke påføre produktet skader.

Fyr aldri med følgende materialer:

- husholdningsavfall, plastposer o.l.

- malt eller impregnert trevirke (som er meget giftig)

- spon og- laminerte plater

- rekved (drivved)

Dette kan skade produktet, og er forurensende.

NB! Bruk aldri væsker som bensin, parafin, rødsprit e.l. til

opptenning. Du kan skade både deg selv og produktet.

NB! Advarsel mot overfyring: Ildstedet må aldri overfyres.

Jøtul F 400 har askeskuff som gjør det enkelt å fjerne asken.

Skrap asken gjennom risten i fyrbunnen og ned i

askeskuffen. Bruk en hanske el.lignende- ta tak i håndtaket

til askeskuffen og bær asken ut. Se til at askeskuffen aldri

blir så full at det hindrer asken i å komme gjennom fyrristen

og ned i skuffen.

Dette må utføres kun når ildstedet er kaldt.

Sørg for at døren til askeskuffen er godt stengt under fyring

i ildstedet.

Se forøvrig beskrivelse av hvordan håndtere aske under:

Brannforebyggende tiltak.

Rensing og sotfjerning i produktet

Under fyring vil det kunne danne seg et sotbelegg på

innsiden av ildstedets varmeflater. Sot har en god

isolerende effekt, og vil derfor redusere ildstedets

varmeavgivelse.

En årlig rengjøring innvendig vil være nødvendig for å få

maksimalt varmeutbytte av produktet. Foreta dette gjerne

i forbindelse med feiing av skorstein og piperør.

24

Page 25

NORSK

Feiing av røykrør til skorstein

Feiing av røykrør kan utføres gjennom feieluken i røykrøret,

eller ved å løfte vekk topplaten og feie gjennom produktets

røykuttak.

Kontroll av ildstedet

Jøtul anbefaler at du selv kontrollerer ditt ildsted nøye etter

at feiing/rengjøring er gjennomført. Kontrollér alle synlige

overflater for sprekker. Se også til at alle sammenføyninger

er tette, og at pakninger ligger riktig. Pakninger som er slitt

eller deformerte, bør byttes ut.

Rens pakningssporet godt, påfør keramisk lim (fås kjøpt

hos din lokale Jøtul forhandler), og press pakningen godt

på plass. Etter kort tid er sammenføyningen tørr.

Utvendig vedlikehold

Lakkerte produkter vil etter noen års bruk kunne endre farge.

Overflaten bør pusses og børstes fri for løse partikler før

ny Jøtul ovnslakk påføres.

Emaljerte produkter skal kun tørkes med en tørr klut. Bruk

ikke vann og såpe. Eventuelle flekker fjernes med et

rensemiddel (Stekeovnsrens e.l.).

Servicearbeider

Utskifting av brennplater

• Ildstedet har sidebrennplater som er skrudd fast. Den

bakre brennplaten står løst- bare holdt på plass av

sidestykkene.

• Ved utskifting må hvelvet først fjernes, så løsnes

skruene - og brennplatene fjernes.

Utskifting av hvelv

• Løft av topplaten

• Hvelvet hviler oppe på brennplatene.

• Ved demontering må brakettene, som holder hvelvet

klemt ned mot brennplatene, løsnes. Bruk en hammer

og slå disse forsiktig ut mot dørene. Se fig. 5

• Løft hvelvet opp og ut gjennom toppen.

• Ved tilbakemontering, følg samme fremgangsmåte i

omvendt rekkefølge.

Ekstrautstyr

Vedlengde, mengde og kvalitet

Maks. vedlengde er 50 cm. Veden legges parallelt med

brennkammerets bakvegg. Jøtul F 400 har med sin

virkningsgrad en varmeavgivelse på nominell 7,0 kW. Etter

beregninger tilsvarer nominell varmeavgivelse forbruk av

ca. 2,8 kg kvalitetsved pr. time.

Jøtuls definisjon av kvalitetsved

God kvalitetsved bør være tørket slik at vanninnholdet er

på ca 20-25%.

For å oppnå dette, bør veden hugges

ettervinteren. Den kløyves og stables på en slik måte at

den blir luftet. Stablene må overdekkes for ikke å trekke

for store mengder regnvann. Veden bør tas inn tidlig høst,

og stables/lagres for bruk kommende vinter.

Med kvalitetsved menes det meste av kjent norsk trevirke,

som bjørk, gran og furu.

Energimengde i 1 kg ved varierer lite. På den annen side

varierer egenvekten hos de ulike typene ved relativt mye.

Dette innebærer at energimengden (kWh) i en bestemt

volummengde, f.eks. gran, er mindre enn for den samme

volummengde av eik som har høyere egenvekt.

Energimengden til 1 kg kvalitetsved er ca. 3,8 kWh. 1 kg helt

tørr ved (0 % fuktighet) gir ca 5 kWh, mens ved med en

fuktighetsgrad på 60%, bare gir ca 1,5 kWh/kg.

senest

på

Korte bein - høyde 155 mm

Sort lakk - kat.nr. 350173

Blå sort emalje - kat.nr 350174

Sjøgrønn emalje - kat. nr. 350328

Edelhvit emalje - kat. nr. 350176

Skjermplate bak

Sort: kat.nr. 350694

Aluzink lakkert: kat .nr. 350695

Ved montering av skjermplate bak på produktet, kan

Ildstedet plasseres med en avstand på 100 mm til vegg av

brennbart materiale. Avstanden til sidevegg må være min.

300 mm.

25

Page 26

SVENSKA

26

Page 27

SVENSKA

Innehåll

Myndigheternas bestämmelser

Teknisk specifikation Jøtul F 400 ........................................... 27

Säkerhetsregler ............................................................................ 27

Avstånd från produkten

till vägg av brännbart material ............................................... 28

Avstånd från produkten till brandvägg ................................ 28

Brandförebyggande åtgärder .................................................. 28

Installation av Jøtul F 400

Underlag ........................................................................................ 28

Skorsten ......................................................................................... 28

Luftcirkulation .............................................................................. 28

Montering före installation ......................................................28

Kontroll av funktioner ............................................................... 29

Montering av rökrör .................................................................. 29

Anslutning till skorsten ............................................................. 29

Bruksanvisning

Första gångs upptändning och dagligt användande ...... 29