Jonsered 2036 Workshop Manual

1

Workshop Manual

Chain Saws

Contents

This manual covers models:

2036/2040

2041/2045/2050

2054/2055

625/630/670

2077/2083

2095

General recommendations 2

1. Safety equipment 3

2. Starter unit 17

3. Electrical system 23

4. Fuel system 35

5. Centrifugal clutch 55

6. Lubrication system 65

7. Cylinder and piston 77

8. Crankshaft and crankcase 93

9. Tools 115

10. Technical data 127

2

502 51 02-01

General recommendations

Keep this in mind:

– Do not start the engine without the clutch and clutch drum fitted.

– Do not touch hot parts such as the silencer and clutch before

they have cooled sufficiently to avoid burn injuries.

– Avoid getting petrol on bare skin or in the mouth.

– Wipe up spilled oil immediately from the floor to avoid slipping

and subsequent injury.

– Do not use tools which are worn or fit badly, e.g. nuts and

screws.

– Never start the engine indoors. Exhaust fumes are toxic!

+ Always work on a tidy work bench.

+ Always work methodically to be sure that all parts are correctly

assembled and that screws and nuts are tightened.

+ Use protective cream on your hands. It reduces the risk of

infection and enables dirt to be more easily washed off.

Prolonged contact with motor oil can be hazardous to health.

+ Use special tools when so recommended in order to work

correctly.

Fire hazard

Handle petrol with respect since it is highly inflammable.

Do not smoke and make sure that there are no naked flames or

sparks in the vicinity.

Make sure that there is a functioning fire extinguisher in the vicinity.

Do not attempt to extinguish a petrol fire with water.

Toxic fumes

Read the instructions carefully when using cleaning liquids.

Make sure that there is adequate ventilation when handling petrol,

trichloroethylene and other viscous liquids.

The engine exhaust fumes are toxic. T est run the engine only when

there is good ventilation, preferably outdoors.

Special tools

Some work operations in this workshop manual require the use

of special tools. In each section where this is appropriate the tool

and order number are illustrated.

We recommend the use of special tools partly to avoid personal

injury and partly to eliminate expensive damage to the

components in question.

Sealing surfaces and gaskets

Make sure that all sealing surfaces are clean and free from the

residue of old gaskets. Use a tool which will not damage the

sealing surface when cleaning it. Scratches and irregularities

are removed with a fine, float cut file.

Sealing rings

Always replace a sealing ring which has been dismantled. The

sensitive sealing lip can easily be damaged and result in poor

sealing capacity. The surface which the seal seals must also be

completely undamaged. Lubricate the sealing lip with grease

before it is fitted and make sure that it is not damaged, e.g. by

shoulder and splines on a shaft. Use tape or conical sleeve as

protection. It is important that the sealing ring is correctly turned

for it to function as intended.

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

WARNING

!

3

Safety equipment

1

1.

Contents

Dismantling 4

Disassembly 4

Fitting 6

Dismantling, mod. 2054/2055 7

Fitting, mod. 2054/2055 9

Dismantling, mod. 2077/2083 10

Fitting, mod. 2077/2083 11

Checking of automatic function 12

Checking of brake action 13

Chain catcher 13

Throttle lock 13

4

Safety equipment

1

!

505 38 17-05

!

In addition to the chain brake the chain catcher and

right-hand guard on the rear handle are also considered part of the chain saw’s safety equipment.

It is obviously important that the chain brake

functions as intended, but it is also important that

the chain catcher is undamaged and in position. In

the event of a chain break this will catch up the

chain so that the hand will not be injured.

WARNING!

Protective goggles must be

worn during all work on the

chain brake to prevent personal injury if for some reason the

brake spring should fly off.

Dismantling

Dismantle the chain brake from the chain

saw.

Disassembly

Release the chain brake.

Press out the one half of the hand guard’s

bearing.

Press out the other half of the hand guard’s

bearing.

Dismantling

Remove the guide bar's attachment nuts

and lift off the clutch cover with the chain

brake.

Clean from sawdust and dirt.

WARNING!

The brake spring is tensioned with a

very large force and can cause personal injury if the brake is not

released prior to further work.

Disassembly

Release the chain brake.

Unscrew the screw to the hand guard’s

bearing completely, and then screw in

approx. 2 turns.

Drive out the bearing by tapping the screw

with a hammer.

Press out the other half of the bearing by

means of suitable mandrel, e.g.

505 38 17-05.

Lift off the hand guard.

5

Safety equipment

1

!

Remove the screws and the cover over

the brake spring.

Bend up the brake spring.

Press out the toggle-joint’s bearing pin

and lift off the complete brake mechanism.

Press out the plate spring with a suitable

mandrel.

Remove the screws and lift off the cover

over the brake spring.

WARNING!

The brake spring is tensioned and

can slip out of its position.

Use a screwdriver and carefully bend up

the spring.

Press out the toggle-joint’s bearing pin by

means of a suitable mandrel.

Lift off the complete brake mechanism.

Press out the plate spring with a suitable

mandrel, and replace if necessary.

Clench the spring eye with a pair of pliers

so that it is easier to fit the new spring.

6

Safety equipment

1

0,8 mm

The brake band must have a minimum

thickness of 0.8 mm at the most worn

point.

Remove the screw and replace the brake

band.

Dismantle the lock-ring and the pin in

order to replace the spring inside the

hand guard.

Assembly

Grease the spring and fit it in the hand

guard.

Check the wear on the brake band.

At the most worn point the band must

have a thickness of at least 0.8 mm.

Otherwise it should be replaced with a

new band.

Remove the screw and fit a new brake

band.

Check after fitting that the brake band

does not touch the toggle-joint and obstruct its movement.

Inside the hand guard there is a spring

which is accessible for replacement after

the lock-ring and pin are dismantled.

Use a small screwdriver to remove the

lock-ring.

Assembly

Grease the spring and push it in the hand

guard as far as it goes.

Fit the pin and lock-washer.

NOTE!

The pin should not go through the eye on

the spring.

Check that the spring is turned correctly.

7

Safety equipment

1

!

A

B

Fit the brake mechanism in the clutch

cover.

Lubricate the bearing points with thin oil.

Press down the brake spring by means of

a Phillips screwdriver.

Fit the cover.

Grease the bearing surfaces and fit the

hand guard.

Check that the brake functions.

Dismantling

Mod. 2054/2055

Remove the screw, sleeve and washer

for the hand guard’s bearing on the starter unit side, including the clutch cover,

guide bar and chain.

Clean!

Place the brake mechanism in position

on the clutch cover.

Press in the toggle-joint’s bearing pin (A)

and place the tubular pin (B) in position.

Lubricate the bearing points with thin oil.

Press down the brake spring in the clutch

cover by means of a Phillips screwdriver.

WARNING!

Observe care to avoid injury if the

screwdriver slips.

Fit the cover over the spring mechanism.

Grease the bearing points for the hand

guard.

Press down the hand guard over the

bearing and fit both bearing sleeves.

NOTE!

Check that the bearing sleeves are placed

on the correct side.

Tension and release the chain brake a

number of times to check that it functions.

Dismantling

Mod. 2054/2055

On these models the chain brake’s hand

guard has an extra bearing point on the

starter unit side.

Remove the screw, sleeve and washer

for this bearing.

Remove the clutch cover, guide bar and

chain.

Clean from sawdust and dirt.

8

Safety equipment

1

Dismantle the protective plate over the

guide bar attachment and the chain brake.

Release the chain brake!

Remove the plate clamp over the brake

spring and bend away the spring.

Remove the lock-ring round the hand

guard’s bearing pin and lift off the brake

mechanism.

Replace the plate insert in the hand guard

if the pins are worn by first pressing out

the fitted pin.

Remove the protective plate over the

guide bar attachment.

Remove the screws and lift off the chain

brake.

Release the chain brake!

!

WARNING!

The brake spring is tensioned with a

very large force and can cause personal injury if the brake is not released

prior to further work.

Remove the screw and plate clamp over

the brake spring.

Carefully bend away the spring by means

of a screwdriver.

NOTE!

The spring has a certain tension even

when the brake is released, and therefore

it should be dismantled carefully.

Remove the lock-ring round the hand

guard’s bearing pin and lift off the brake

mechanism.

If the pins on the plate insert in the hand

guard are worn the complete insert can

easily be replaced.

Press out the fitted pin with a suitable

mandrel and replace the insert.

9

Safety equipment

1

0,8 mm

Dismantle the brake mechanism and

replace worn or damaged parts.

Fit the brake spring and plate clamp over

the spring.

Fit the chain brake on the crankcase.

Screw tight the cover plate over the guide

bar attachment and fit the brake’s bearing

on the starter unit side.

Dissassemble the brake mechanism and

replace worn or damaged parts.

The brake band should have a minimum

thickness of 0.8 mm at the most worn

place.

Assembly

Mod. 2054/2055

Fit the brake in the reverse order to dismantling.

Begin with by fitting the hand guard.

Lubricate all moving parts with thin oil.

Fit the brake spring by means of a Phillips

screwdriver.

WARNING!

Observe care to avoid injury if the

screwdriver slips.

!

Fit the plate clamp over the spring.

Fit the chain brake on the crankcase.

NOTE!

Make sure that the guide pin on the brake

fits into the hole in the crankcase before

the screws are tightened.

Fit the cover plate on the guide bar attachment.

Screw tight the screw for the brake’s

bearing on the starter unit side.

Do not forget the washer between the

crankcase and brake!

10

Safety equipment

1

!

Dismantling

Mod. 2077/2083

Dismantle the chain brake’s bearing on

the starter unit side.

Remove the clutch cover, guide bar and

chain.

Clean!

Remove the screws and lift off the chain

brake.

Release the chain brake!

Lift up the toggle-joint carefully by means

of a screwdriver.

Dismantle the hand guard.

Press the hand guard out of the bearing.

Dismantling

Mod. 2077/2083

Remove the screw, sleeve and washer

for the chain brake’s bearing on the starter unit side.

Remove the clutch cover, guide bar and

chain.

Clean from sawdust and dirt.

Remove the screws and lift off the chain

brake.

Release the chain brake!

!

NOTE!

The other end of the spring is controlled

by a pin which goes into the centre.

For this reason do not try to lift up the

spring there.

Dismantle the hand guard.

Remove the lock-ring by means of a small

screwdriver.

Hold your thumb over so that the ring

does not fly away.

Press out the hand guard from the bearing.

WARNING!

Observe care so that the sprin loaded

catch does not fly away.

WARNING!

The brake spring is tensioned with a

very large force and can cause personal injury if the brake is not released

prior to further work.

Lift up the toggle-joint carefully by

means of a screwdriver.

Hold your hand over.

11

Safety equipment

1

0,8 mm

Replace the hand guard’s bearing pin if it

is worn.

Press out the sprung tubular pin and pull

out the plate insert from the hand guard.

Clean and check all parts.

The thickness of the brake band should

be at least 0.8 mm.

Assembly

Mod. 2077/2083

Fit the brake in the reverse order to dismantling.

Press down the hand guard in the correct

position.

The hand guard’s bearing pin can now

easily be replaced.

Press out the spring tensioned tubular

pin and pull out the complete plate insert

from the hand guard.

Replace the insert if the bearing pin is

worn.

Clean all the parts of the chain brake and

check them for wear or damage.

The brake band should have a minimum

thickness of 0.8 mm at the most worn

part.

Replace the brake band if it is worn more

than this.

Assembly

Mod. 2077/2083

Fit the brake in the reverse order to dismantling.

Begin by fitting the hand guard.

Lubricate the bearing pin and catch with

oil.

Place the catch in position with the

extruding part downwards.

Press away the catch by means of a

screwdriver and press down the hand

guard in the correct position.

Fit the lock-ring on the bearing pin.

12

Safety equipment

1

A

B

Fit the brake band (A) and place the

toggle-joint in position over its bearing

pin (B).

Press together the brake spring far

enough so that the guide pin in the back

of the spring housing is released.

Press down the spring and check that the

pin goes into the centre of the spring.

Press down the brake band in its rear

attachment (A).

Place the toggle-joint in position over its

bearing pin (B).

Make sure that it is correctly positioned.

Press the brake spring over the guide pin.

Push the guide sleeve in the spring and

outside of the guide pin.

Press the spring together by means of a

suitable Phillips screwdriver far enough

so that the guide pin in the back edge of

the spring housing is released.

Press down the spring and check that the

pin goes into the centre of the spring.

Fit the chain brake on the engine.

Check that the guide pin on the chain

brake goes into the corresponding hole in

the crankcase.

L

H

Checking of the automatic function

NOTE!

The engine should be switched off during this check.

Hold the saw approx. H mm over a stable object.

Release the front handle and allow the saw to turn round the back handle by virtue of

its own weight. When the guide bar point hits the object the brake should be activated.

H, cm/inch L, inch

45/14 11 – 16

55/22 18 – 22

65/26 24 – 28

80/32 30 – 36

13

Safety equipment

1

Checking of the brake

effect

Start the engine.

Hold the handle with both hands and rev

up.

Release the chain brake by turning the

left wrist towards the hand guard without

releasing the grip round the front handle.

The chain should stop immediately.

Chain catcher

Replace the chain catcher if it is deformed

or cracked.

Checking of the brake

effect

Place the saw on a stable surface and

start the engine.

Hold the handle with both hands and rev

up.

Release the chain brake by turning the

left wrist towards the hand guard without

releasing the grip round the front handle.

The chain should stop immediately.

Chain catcher

The chain catcher has the purpose of

catching the chain if it breaks.

It is therefore important that it is not

deformed or cracked. Replace if this

should be the case.

Throttle lock

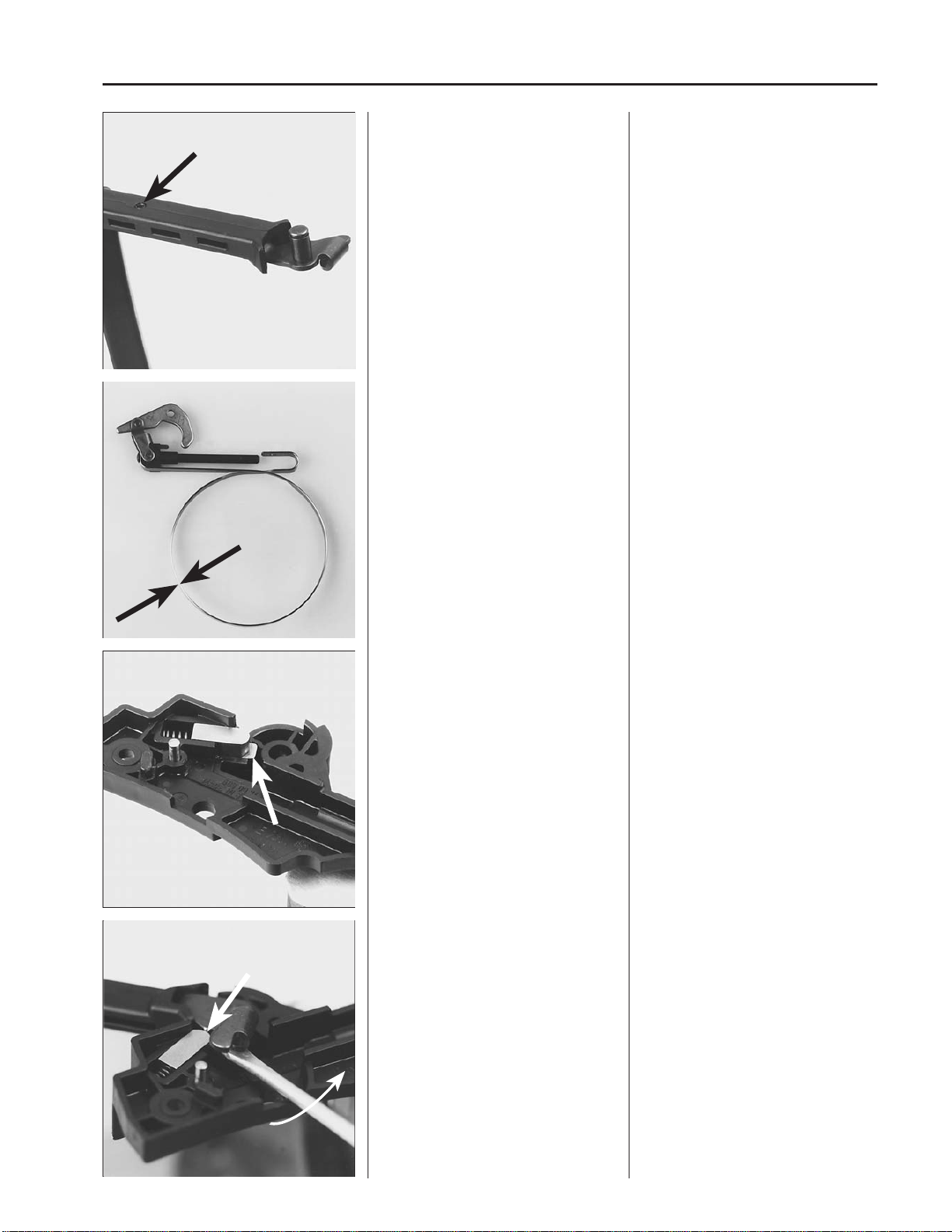

Dismantling

Remove the screws.

Remove the handle half, throttle control

and lock.

Throttle lock

Dismantling

Remove the screws which hold the handle

halves together and where appropriate

also the screw which holds the spring for

the vibration damper.

Lift off the handle half and throttle control

together with the lock.

14

Fitting, mod. 2036/2040

Fit in the reverse order to dismantling.

2

1

Safety equipment

1

Check that the throttle cable is correctly

fitted.

Do not lubricate!

Fitting mod. 2041/2045/2050

Check that the throttle cable is correctly

fitted.

Do not lubricate!

Fitting mod. 2054/2055

Check that the spring and throttle cable

are correctly connected.

Fitting mod. 2036/2040

Replace any damaged parts and fit in the

reverse order to dismantling.

Note the following:

● Make sure that the spring comes on

the correct side of the barrier in the

throttle control.

● Check that the throttle cable's ball lug

sits in the recess (1).

● Check that the throttle cable is flush

with the cam curve on the throttle

control (2).

● Do not lubricate!

Fitting mod. 2041/2045/2050

Note the following:

● Fit the throttle cable from the correct

side in the throttle control.

● Check that the throttle cable is

correctly positioned so that it is not

clenched when the handle half is fitted.

● Do not lubricate!

Fitting mod. 2045/2055

Note the following:

● The positioning of the spring in the

throttle control.

● The connection of the throttle cable

from underneath to the throttle control

catch.

● Do not lubricate!

15

Safety equipment

1

Dismantling mod. 625/630/670

Press out the fitted pin and dismantle the

cover.

Dismantle the spring and throttle control

lock.

Fitting mod. 625/630/670

Fit the throttle control lock in the reverse

order to dismantling.

Dismantling mod. 2095

Dismantle the handle half.

Dismantling mod. 625/630/670

Press out the fitted pin approx. 13-14 mm

so that the throttle control lock comes

loose.

Dismantle the covers by means of pressing a screwdriver into the back edge of

the covers.

If the handle is electrically heated see

chap. 3 ”Electrical system”.

Press out the sprung tubular pin which is

located behind the cover far enough so

that the spring and the throttle control

lock can be lifted off.

Fitting mod. 625/630/670

Replace damaged or worn parts and fit in

the reverse order to dismantling.

NOTE!

The sprung tubular pin should go through

the spring eyelet.

Dismantling mod. 2095

Remove the screws and lift off the handle

half.

16

1

2

Safety equipment

1

Fitting mod. 2095

Replace damaged or worn parts and fit in

the reverse order to dismantling.

Fitting mod. 2095

Replace damaged or worn parts.

Fit in the reverse order to dismantling.

Pay attention to the following:

● The spring’s straight shank should be

fitted in the throttle control lock (1).

● Make sure the throttle wire housing is

well pressed down in the recess (2).

● Check that the short-circuiting cable

sits in the recess so that it is not

clenched when the handle half is

screwed tight.

17

Contents

Dismantling 18

Replacement of return spring 19

Replacement of starter cord 20

Assembly 21

Replacement of starter pawls 22

Starter unit

2.

2

18

2

Starter unit

WARNING!

When working on the starter unit wear protective glasses to avoid eye injuries in the

event that the return spring flies out.

!

Dismantling

1. Dismantle the starter from the engine

unit.

Dismantling

1. Remove all screws and lift off the

starter.

2. Release the spring tension.

2. Release the spring tension.

Pull out the starter cord approx. 30

cm. Brake the cord wheel with the

thumb and place the cord in one of the

recesses on the pulley.

3. Allow the pulley to slowly rotate backwards.

3. Allow the pulley to slowly rotate backwards.

NOTE!

Brake the rotation with the thumb.

WARNING!

Observe care so that the thumb is not

injured by the reinforcement ribs on

the pulley or the cord's attachment

screw.

!

19

Starter unit

2

!

!

!

!

4. Remove the screw and the washer.

5. Remove the pulley and spring cassette, and return spring.

4. Remove the screw and washer in the

centre of the pulley.

5. Lift off the pulley carefully.

6A.Remove the screws which hold the

spring cassette and lift off.

WARNING!

Wear protective glasses. The return spring

can fly out and cause

injury.

WARNING!

Wear protective glasses.

6B.Remove the screws which hold the

cover disc over the return spring.

Dismantle the spring by giving the

starter housing a sharp tap against

the work bench with the spring turned

downwards.

WARNING!

Wear protective glasses.

WARNING!

Wear protective glasses. The return spring

can fly out and cause

injury.

Replacing return spring

Dismantle the pulley as described above.

A. Fit a new spring cassette.

Replacing return spring

Dismantle the pulley as described above.

A. Place a new spring cassette in the

starter housing and tighten the

screw(s).

6. Dismantle the cover disc and return

spring from the starter unit housing.

20

2

Starter unit

!

!

B. Press down a new spring in the starter

housing.

B. Return spring without cassette.

Leave the lock shackle round the

spring in position.

1. Place the spring over its seat in the

starter housing.

2. Press down the spring in the correct

position by means of the thumbs and

let the lock shackle slide over the

spring.

3. Fit the cover plate off the spring.

Replacing starter cord

1. Fit and lock the cord at the pulley as

per one of the methods shown in the

diagrams.

Tips!

The knot on the starter cord in the starter

handle may be difficult to untie. It is easier

if the knot is first knocked with a hammer

against a hard surface.

2. Anchor the cord in the starter handle. 2. Enter the cord through the socket in

the starter housing and anchor it in

the starter handle by means of a knot.

Fold down the free end and pull the

knot securely into the handle.

WARNING!

Wear protective glasses.

WARNING!

Wear protective glasses.

21

Starter unit

2

1 – 3 r

+ 1/2 r

max

Assembly

1. Wind the cord approx. 4 turns clockwise round the pulley.

2. Fit the pulley.

3. Increase the spring tension.

4. Check the spring tension.

With a fully withdrawn cord it should

be possible to turn the pulley

at least

another half turn.

Assembly

1. Wind the cord approx. 4 turns clockwise round the pulley.

2. Lubricate the pulley’s bearing pin and

the return spring with a few drops of

motor oil or non-freezing lubricant and

fit the pulley.

Check that the return spring grips the

pulley. The spring may require to be

bent out further from the bearing pin.

3. Put the washer in place and tighten

the screw.

4. Increase the spring tension.

With a fully withdrawn cord it should

be possible to turn the pulley

at least

another half turn.

Tension the spring more by:

● Pulling the cord approx. 30 cm and

braking the pulley with the thumb.

● Lift up the cord in one of the recesses

on the pulley.

● Wind the cord 1-3 turns clockwise

round the hub of the pulley.

● Pull out the starter cord fully.

5. Check the spring tensions.

With a fully withdrawn cord it should

be possible to turn the pulley

at least

another half turn.

Repeat the spring tensioning if

necessary.

22

2

Starter unit

503 21 22-01

5. Assemble the starter in the reverse

order to dismantling.

Replacing starter pawls

See chapter 3 ”Electrical system”.

6. Assemble the starter.

Pull out the starter cord a little. Put the

starter in position. Release the starter

cord and check that the pawls grip the

pulley.

Tighten the screws.

NOTE!

If the threads in the crankcase (made of

plastic) are for any reason damaged an

oversize screw (No. 503 21 22-01) is

recommended.

Replacing starter pawls

See chapter 3 ”Electrical system”.

23

Electrical system

3.

3

Contents

Checking ignition spark 24

Replacing spark plug protection 26

Dismantling 28

Starter pawls 20

Assembly 30

Electrically heated handles 31

Replacing the generator 33

24

3 Electrical system

502 71 13-01

Checking ignition spark

Clean the electrodes and check the

electrode gap.

If the electrodes are worn down more

than 50% the plug should be replaced.

Check if there is a spark when starting.

Try with test plug No. 502 71 13-01 if

there is no spark.

Checking ignition spark

Remove the plug and clean from soot by

means of steel brush.

Check the electrode gap. It should be 0.5

mm – 0.7 mm (.020 – .028").

Adjust the gap to correct value with side

electrode.

If the electrodes are worn down more

than 50 % the plug should be replaced.

An overlarge gap implies stress on the

ignition module and the risk of short

circuiting.

Make sure that the stop contact is in start

position.

Earth the plug to the cylinder and pull the

start handle.

There should be a spark between the

electrodes.

If there is no spark try with the test plug

No. 502 71 13-01.

If there is a spark the fault lies in the plug.

Replace plug.

The chain saw is fitted with an electronic system

consisting of flywheel, ignition coil, and trigger

unit. Certain saw models are fitted with a generator system to heat the handles and carburettor.

The ignition system is electronic and completely

without moving parts. A defective component

cannot be repaired and must be replaced.

The ignition spark in an electronic ignition system has a very short burn time and may therefore

be experienced as weak and sometimes difficult

to see during trouble shooting.

NOTE!

When testing the chain saw’s heating system the

guide bar, chain and clutch cover must be fitted

before the engine is started!

25

Electrical system

3

A

B

Try with a new plug

If there is no spark disconnect the short

circuiting contact.

Replace the contact if necessary.

Try with a new plug.

If there is still no spark remove the short

circuiting cable from either the ignition

module or short circuiting contact.

If there is no spark the fault lies in the stop

contact.

Replace the contact.

Check the connections of the ignition

cable.

Still no spark?

Check the plug connection.

Pull off the rubber protection at the plug

(A) and ignition module (B) and check

that the ignition cable is undamaged. Cut

off a piece of the cable to ensure good

contact.

Lubricate the cable ends with a little

grease to simplify fitting and prevent

moisture from penetrating into the connections.

Lubricate the cable ends with grease.

Mod. 2077/2083

Check that the earth cable is undamaged

and that it has metallic contact with the

crankcase.

Mod. 2077/2083

Check that the earth cable between the

crankcase and stop contact is undamaged

and that it has metallic contact with the

crankcase.

Use an ohm-meter and measure the

resistance in the cable between the stop

contact and connection at the crankcase.

The instrument should give a full reading

if the cable is in good condition.

26

3

Electrical system

502 51 34-05

0.3 mm

502 50 06-01

Check other cables and connections. Still no spark?

Check the other cables and connections

for poor contact (dirt, corrosion, cable

break and damaged insulation).

Tips!

Use an Ohm-meter to check if there is a

cable break, e.g. as a result of pinching.

Check the air gap.

Adjust the air gap.

Replacing spark plug

protection

1. Take ignition cable through the spark

plug protection.

2. Make a hole in the ignition cable for

the contact spiral.

Still no spark?

Check the air gap between the flywheel

permanent magnet and ignition module.

The gap should be 0.3 mm (.012").

Use air gap measure 502 51 34-05.

Adjust the air gap to correct size.

● Release screws.

● Place the feeler gauge and press the

ignition module to the flywheel.

● Tighten the screws and check the air

gap again.

If there is still no spark the ignition system

should be replaced.

Replacing spark plug

protection

1. Lubricate the ignition cable with a little

grease and take it through the plug

protection.

2. Cut off a piece of the ignition cable

(approx. 5 mm, .20") and make a hole

in the cable for the contact spiral by

means of pliers No. 502 50 06-01.

27

3

Electrical system

504 91 06-05

3. Fit the contact spiral on the ignition

cable.

3. Fit the contact spiral on the ignition

cable and make sure that the wire is

folded along the cable.

4. Pull the contact spiral into the spark

plug protection.

NOTE!

It is important that the point of the contact

spiral meets the middle of the ignition

cable to prevent sparking.

Fit a piston stop No. 504 91 06-05 alt.

502 50 33-01 in the spark plug hole.

Fit a piston stop No. 504 91 06-05 alt.

502 50 33-01 in the spark plug hole.

Make sure that the piston stop is screwed

down to the bottom.

Dismantle the starter pawls.

Mod. 2054/2055

On earlier versions of these models the

starter pawls sit on a bridge which can be

lifted off when the flywheel nut is

dismantled.

Dismantling

Dismantle the plug, cylinder cover, starter unit, and air bar.

Dismantle the ignition module and release the other cable connections.

Dismantling

Dismantle the plug, cylinder cover, starter unit, and air conductor.

Dismantle the ignition module by removing the two screws.

Release the other cable connections and

lift off the ignition module.

Dismantle the starter pawls by releasing

the screws. Make sure that the small

washer close to the flywheel is not mislaid.

Mod. 2054/2055

On earlier versions of these models the

starter pawls sit on a bridge which can be

lifted off when the flywheel nut is

dismantled.

28

3

Electrical system

502 51 49-01

502 51 94-01

Mod. 2036/2040

Dismantle the flywheel by using a

hammer.

Mod. 2036/2040

Thread the nut on the shaft to protect the

threads.

Snap the springs loose and fold down the

starter pawls to leave space for the

hammer.

Grip the flywheel and lift up the engine

unit.

Give a few smart blows with the hammer

on the flywheel nut until the flywheel

releases from the shaft.

Tips!

Use a pressure piece to protect the

threads on the shaft and so that it is also

easier to use the hammer.

Remove the flywheel nut.

Pull off the flywheel.

Tips!

If the flywheel is tight give a few smart

taps with a hammer on the extractor screw.

Remove the flywheel nut by means of a

suitable socket wrench.

Pull off the flywheel by means of withdrawing tool 502 51 49-01 which is

screwed in the hole for the starter pawls.

NOTE!

Centre the withdrawing tool over the shaft

centre. Select suitable screws and tighten

the withdrawing tool.

Tips!

The flywheel may sit very tightly on the

shaft.

To simplify dismantling give a few smart

taps with a hammer on the extractor

screw. Hold the chain saw in the air with

the handle on the withdrawing tool.

29

3

Electrical system

504 90 90-01

Mod. 2054/2055

Pull off the flywheel.

Mod. 2054/2055

Pull off the flywheel by means of ball

bearing puller No. 504 90 90-01.

NOTE!

The claws on the tool should be placed on

and opposite the permanent magnet on

the flywheel so that this is not damaged.

Is the flywheel stuck?

Lift up the engine unit by holding the tool

and hit the tool screw a few times with a

hammer.

Starter pawls

Check the starter pawls for wear and

damage.

Replace damaged parts.

Starter pawls

Check the starter pawls for wear and

damage.

Replace damaged parts.

For starter pawls which are mounted on a

separate bridge the entire unit must be

replaced.

Mod. 2036/2040

Press out the journals by means of a

suitable mandrel.

Replace damaged parts.

Mod. 2036/2040

Replace the starter pawls and springs in

the following way if they are housed on a

journal pressed in the flywheel.

Place the flywheel on support blocks and

press out the journals by means of a

suitable mandrel.

Replace damaged parts.

Make sure that the spring is not pinched

when the journal is pressed into the

flywheel.

Check that the starter pawls move easily.

30

3

Electrical system

0.3 mm

Assembly

Check that the keyway and key in the

crankshaft are undamaged.

Assembly

Check that the keyway and key in the

crankshaft are undamaged.

Fit a new key and make sure that it fits

correctly in the keyway.

Check that the keyway and the cast key

respectively in the flywheel are undamaged.

Fit the flywheel.

Check that the keyway and cast key

respectively in the flywheel are undamaged.

Fit the flywheel on the crankshaft and

check that the key and keyway are

correctly positioned before the flywheel

nut is tightened.

Tighten the nut to a torque of 25–35 Nm

Fit the ignition module.

Adjust the air gap (0.3 mm, .012")

Fit the other cables.

Fit the other parts in the reverse order to

dismantling.

Fit the ignition module

Adjust the air gap to the correct size

(0.3 mm, .012").

See also page 26.

Fit the other cables and make sure that

they are correctly positioned in cable

grooves etc. so that they cannot be

damaged.

Fit the other parts in the reverse order to

dismantling.

When fitting the starter pawls check the

following:

● Washer between flywheel and starter

pawls.

● The spring is not clenched.

● The starter pawls move freely.

● Use Locktite on the screw.

Loading...

Loading...