John Deere Valve Service Manual

- - ------------

Engine Repair

CYLINDER HEAD, VALVES, AND CAMSHAFT

PRELIMINARY VALVE CHECKS

During disassembly, inspect the valve train for the

following malfunctions and causes.

Sticking Valves

Carbon deposits on valve stem

Worn valve guides

Warped valve stems

Cocked or broken valve springs

Worn or distorted valve seats

Insufficient lubrication

Warped, Worn, or Distorted Valve

Guides

Lack of lubrication

Cylinder head distortion

Excessive heat

Unevenly tightened cylinder head cap screws

Cylinder Head, Valves and Camshaft 20-05-1

Group 05

Camshaft Failures

Scored camshaft lobes due to inadequate lubrica-

tion

Excessive end play due to thrust plate wear

Broken or warped camshaft due to improper timing

Checking Valve Clearance

Four-Cylinder Engine

Distorted Cylinder Head and Cylinder

Head Gasket Leakage

Improperly tightened cylinder head cap screws

Faulty gasket installation

Incorrect gasket material

Excessive oil pressure

Improper cylinder liner height above cylinder block

Worn or Broken Valve Seats

Misaligned valves

Distorted cylinder head

Carbon deposits on seats due to incomplete com-

bustion

Valve spring tension too weak

Excessive heat

Improper valve clearance

Improper valve timing

Burned, Pitted, Worn, or Broken Valves

Worn or distorted valve seats

Worn valve guides

Insufficient cooling

Insufficient lubrication

Cocked or broken valve springs

Preignition

Improper engine operation

Improper valve train timing

Faulty valve rotators

Warped or distorted valve stems

"Stretched" valves due to excessive spring tension

Warped cylinder head

Bent push rods

Carbon build-up on valve seats

Rocker arm failure

Fig. 1-Sening "TOC"

1. Rotateengine to position No. 1 piston at TDC of

its compression stroke.

2. Turn flywheel until timing mark on flywheel lines

up with mark on housing (Fig. 1).

TM-1106 (Jan-79) Litho in U.S.A.

Engines - 400 Series

20-05-2 Cylinder Head, Valves, and Camshaft

Engine Repair

Checking Valve Clearance-Continued

Four Cylinder Engine

4

E I

T2284?N

VALVE CLEARANCE SPECIFICATION

Intake and Exhaust Valves

Fig. 2-Four-Cylinder Valve Clearance Adjustment

3

I E

3. Adjust valve clearance on No. 1 and 3 exhaust

valves and No. 1 and 2 intake valves.

4. Rotateflywheel 360 degrees until No.4 piston is

at TOC of its compression stroke.

5. Adjust valve clearance on No. 2 and 4 exhaust

valves and No. 3 and 4 intake valves to the specifica-

tion listed above.

2

E I

1

I E

0.018 In. (0.46 mm)

Six Cylinder Engine

.......

,

II

R 27478NJlj

Fig. 3-Setting "TOC"

1. UseJOE-81 Engine RotationTool Set (A, Fig.3)

to position No. 1 piston at TOC of its compression

stroke.

2. Turnflywheel untiltiming pin engagestiming hole

inflywheel and both valves on No. 1cylinder are in the

up position (rocker arms loose).

OF ENGINE-

432 1

E I lEE I I E

TM-1106 (Jan-79) Litho in U.S.A.

NO. I TDC COMPRESSIONSTROKE

6 5 4 3 2 1

EI IE EI IE EI IE

R 11117

Intake Valves

Exhaust Valves

NO.6 TDC COMPRESSION STROKE

VALVE CLEARANCE SPECIFICATIONS

Fig. 4-Six-Cylinder Valve Clearance Adjustment

Engines - 400 Series

0.018 in. (0.46 mm)

0.028 in. (0.71 mm)

-------.

Engine Repair

Cylinder Head, Valves, and Camshaft 20-05-3

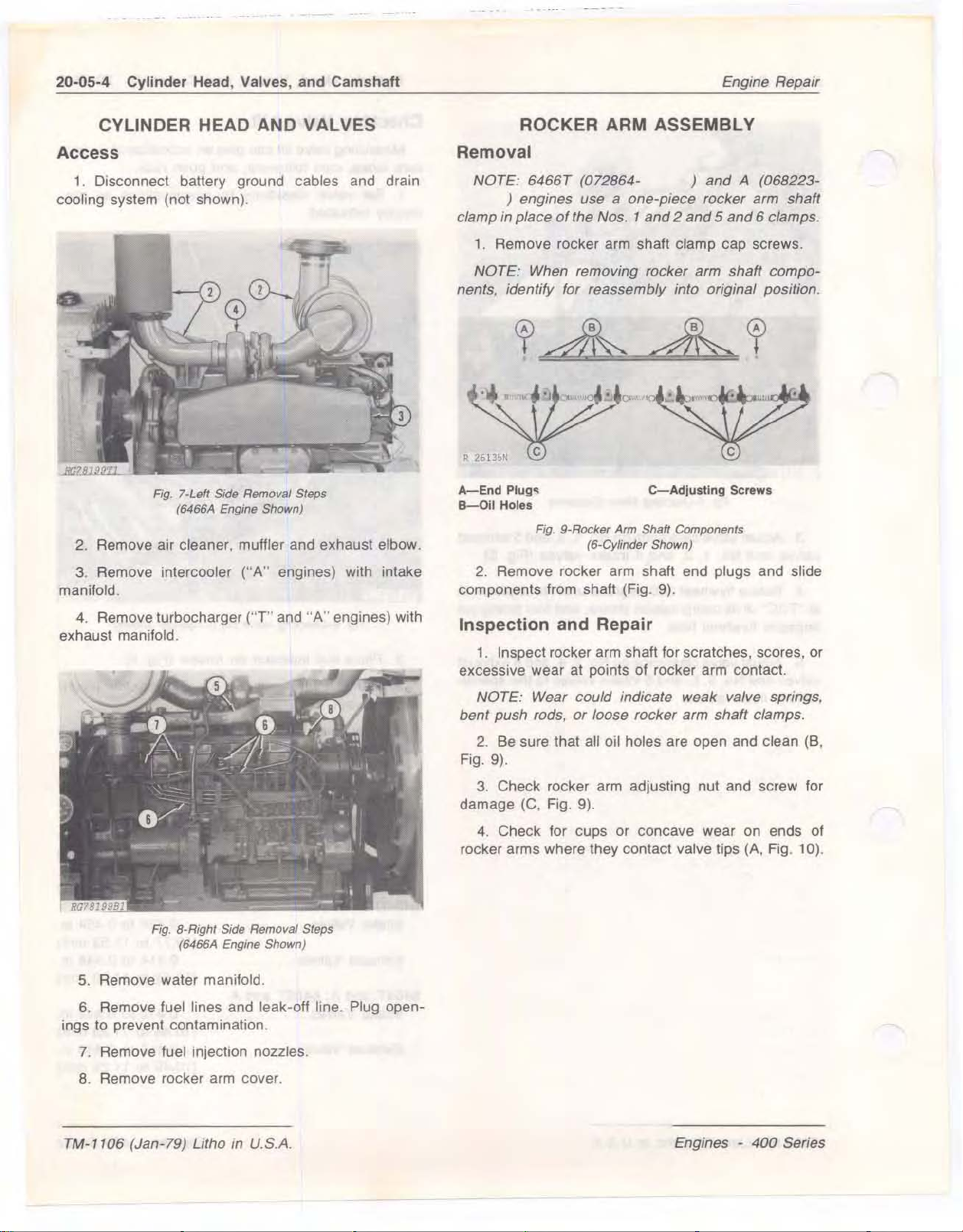

Checking Valve Lift

Measuringvalve liftcan give an indicationofwear to

cam lobes, cam followers, and push rods.

1. Set valve clearance to specifications as pre-

viously indicated.

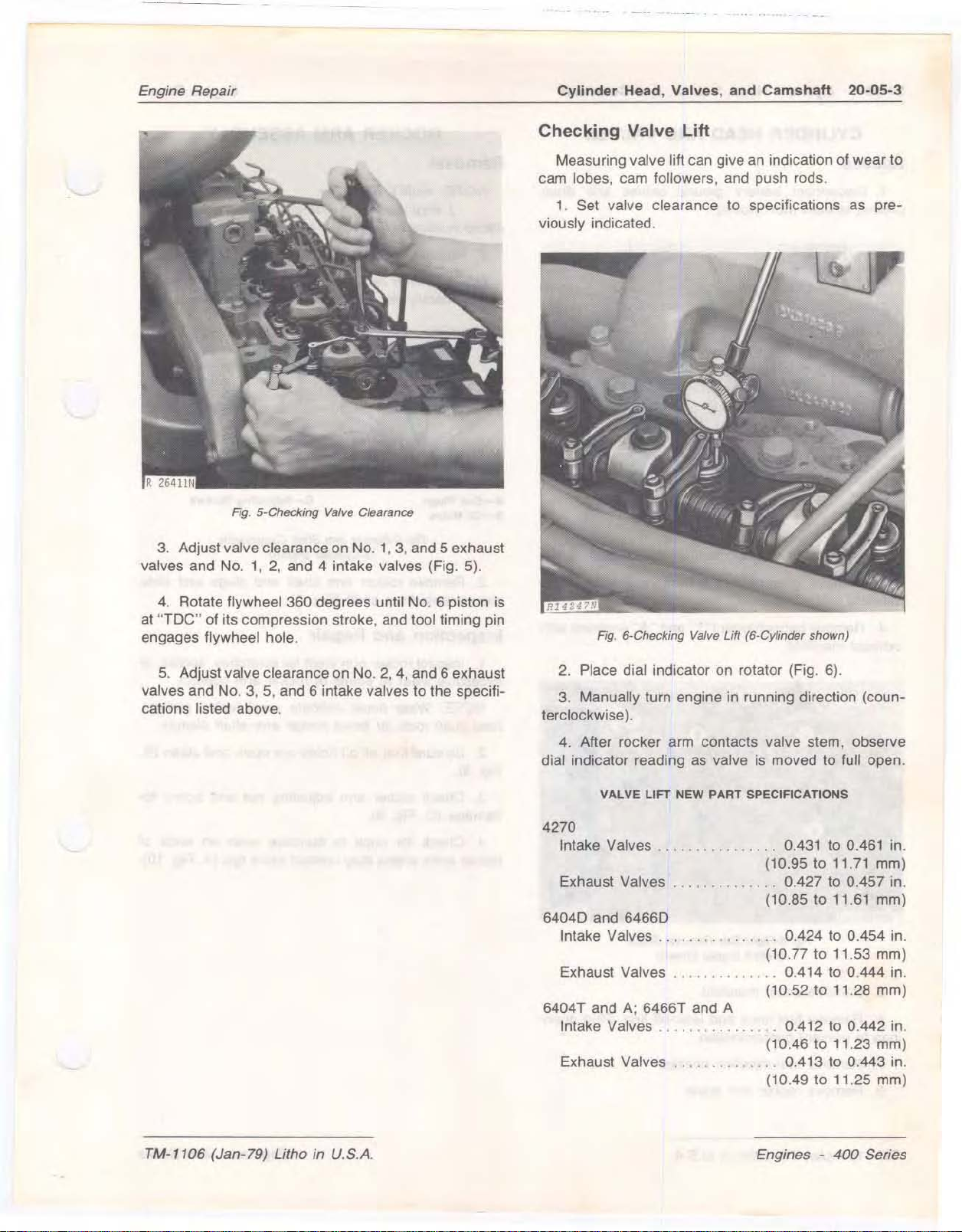

Fig. 5-Checking Valve Clearance

3. Adjust valve clearance on No.1, 3, and 5 exhaust

valves and No.1, 2, and 4 intake valves (Fig. 5).

4. Rotate flywheel 360 degrees until NO.6 piston is

at "TOG" of its compression stroke, and tool timing pin

engages flywheel hole.

5. Adjustvalve clearance on No.2, 4, and 6 exhaust

valves and No.3, 5, and 6 intake valves to the specifi-

cations listed above.

Fig. 6-Checking Valve Lift (6-Cylinder shown)

2. Place dial indicator on rotator (Fig. 6).

3. Manually turn engine in running direction (coun-

terclockwise) .

4. After rocker arm contacts valve stem, observe

dial indicator reading as valve is moved to full open.

VALVE LIFT NEW PART SPECIFICATIONS

4270

Intake Valves. . . . . . . . . . . . . . .. 0.431 to 0.461 in.

(10.95 to 11.71 mm)

Exhaust Valves 0.427 to 0.457 in.

(10.85 to 11.61 mm)

64040 and 64660

Intake Valves. . . . . . . . . . . . . . .. 0.424 to 0.454 in.

(10.77 to 11.53 mm)

Exhaust Valves. . . . . . . . . . . . .. 0.414 to 0.444 in.

(10.52 to 11.28 mm)

6404T and A; 6466T and A

Intake Valves. .. . . . . . . . . . . . .. 0.412 to 0.442 in.

(10.46 to 11.23 mm)

Exhaust Valves. . . . . . . . . . .. .. 0.413 to 0.443 in.

(10.49 to 11.25 mm)

TM-1106 (Jan-79) Litho in U.S.A.

Engines - 400 Series

-. -- --- --- - ..-

- - --------

u

20-05-4 Cylinder Head, Valves, and Camshaft Engine Repair

CYLINDER HEAD AND VALVES

Access

1. Disconnect battery ground cables and drain

cooling system (not shown).

-

I

Fig. 7-Left Side Removal Steps

(6466A Engine Shown)

2. Remove air cleaner, mufflerand exhaust elbow.

ROCKER ARM ASSEMBLY

Removal

NOTE: 6466T (072864- ) and A (068223-

) engines use a one-piece rocker arm shaft

clampinplace of the Nos. 1and 2 and5 and 6 clamps.

1. Remove rocker arm shaft clamp cap screws.

NOTE: When removing rocker arm shaft compo-

nents, identify for reassembly into original position.

A-End Plug..

B-Oil Holes

Fig. 9-Rocker Arm Shaft Components

(6-Cylinder Shown)

C-Adjusting Screws

3. Remove intercooler ("A" engines) with intake

manifold.

4. Removeturbocharger ("T"and "A"engines) with

exhaust manifold.

Fig.8-Right Side Removal Steps

(6466A Engine Shown)

5. Remove water manifold.

6. Remove fuel lines and leak-off line. Plug open-

ings to prevent contamination.

2. Remove rocker arm shaft end plugs and slide

components from shaft (Fig. 9).

Inspection and Repair

1. Inspect rocker arm shaft for scratches, scores, or

excessive wear at points of rocker arm contact.

NOTE: Wear could indicate weak valve springs,

bent push rods, or loose rocker arm shaft clamps.

2. Be sure that all oil holes are open and clean (B,

Fig. 9).

3. Check rocker arm adjusting nut and screw for

damage (C, Fig. 9).

4. Check for cups or concave wear on ends of

rocker arms where they contact valve tips (A, Fig. 10).

7. Remove fuel injection nozzles.

8. Remove rocker arm cover.

TM-1106 (Jan-79) Litho in U.S.A.

Engines - 400 Series

Loading...

Loading...