Page 1

10/50/125/250 Amp

6V/12V Battery Charger-

Engine Starter

OPERATOR’S MANUAL

TY25862 Battery Charger- Engine

Starter

OMTY25885 Issue 16Sep04 (ENGLISH/FRENCH)

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

If this product contains a gasoline engine:

WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects or other reproductive harm.

The State of California requires the above two warnings.

JohnDeereMerchandiseDivision 00-99-000459/904

Litho in USA

Page 2

Foreword

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your battery charger- engine starter

correctly. Failure to do so could result in personal

injury or equipment damage. This manual and safety

signs on your battery charger- engine starter may also

be available in other languages. (See your John Deere

dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your battery charger- engine starter

and should remain with the charger when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners.

WRITE PRODUCT INFORMATION in the Specification

section. Accurately record all the numbers to help in

tracing the battery charger- engine starter should it be

stolen. Your distributor also needs these numbers

when you order parts. File the product information in a

secure place.

WARRANTY is provided as part of John Deere’s

support program for customers who operate and

maintain their equipment as described in this manual.

The warranty is explained in the Warranty section at

the end of this manual.

OURGP12,0000105 –19–01JUN04–1/2

This warranty provides you the assurance that John

Deere will back its products where defects appear within

the warranty period. In some circumstances, John Deere

also provides field improvements, often without charge to

the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to change

its performance beyond the original factory specifications,

the warranty will become void and field improvements

may be denied.

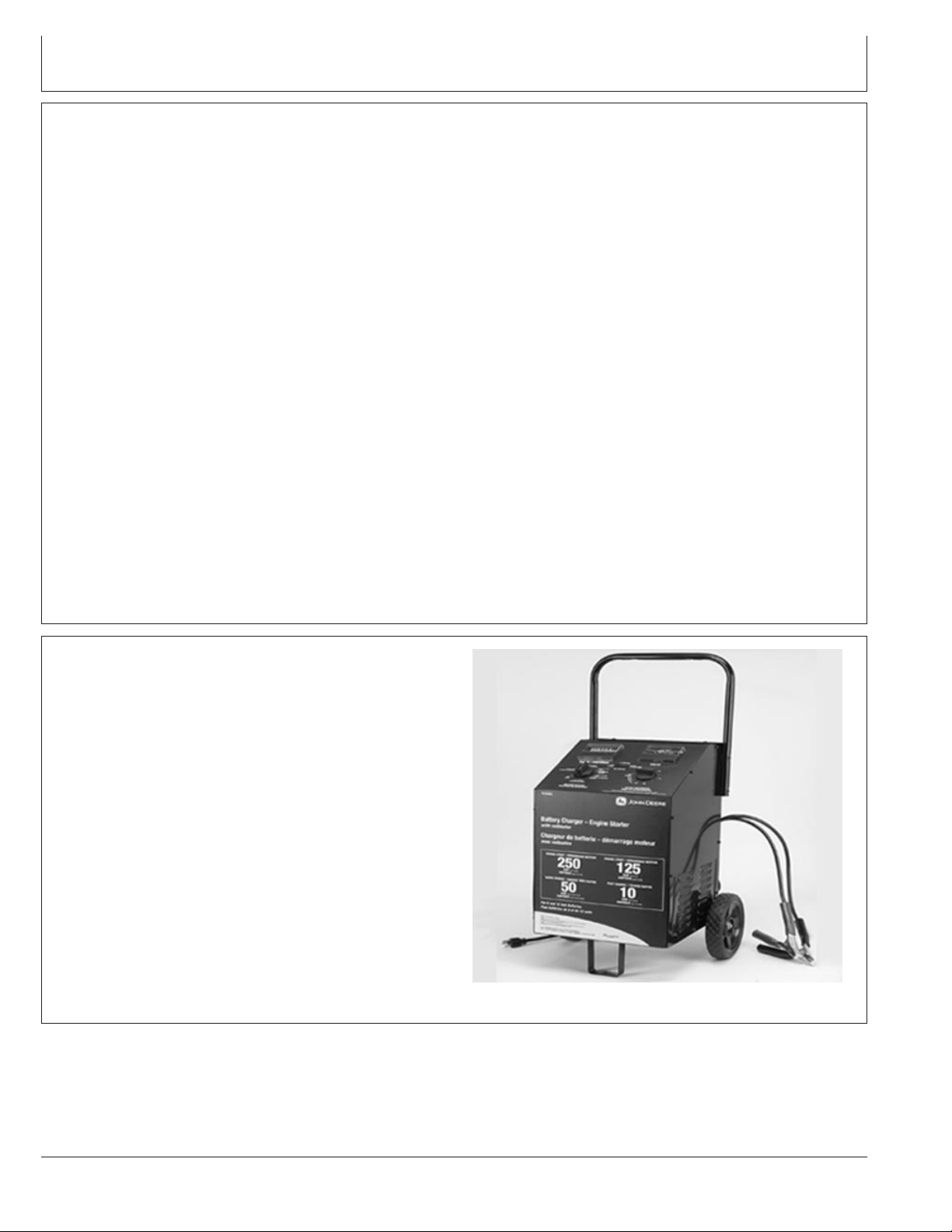

TY25862 Battery Charger- Engine Starter

TYB4754 –UN–07SEP04

OURGP12,0000105 –19–01JUN04–2/2

091604

PN=2

Page 3

Contents

Page

Safety ................................05-1

Assembly Instructions

Assembly Parts .........................10-1

Assembly Tools .........................10-1

Assembly Procedure .....................10-2

Controls and Operation

Preparing Battery ........................15-1

Positioning Battery Charger ................15-1

Checking Battery State-of-Charge ...........15-2

Identifying Battery Reserve Capacity

(RC) Rating...........................15-2

Estimating Battery Recharge Time ...........15-3

Activating and Charging a Dry Battery ........15-4

Testing Battery Installed in Vehicle ..........15-5

Testing Battery Outside of Vehicle ...........15-7

Charging Battery Installed in Vehicle .........15-8

Charging Battery Outside of Vehicle.........15-11

Starting Engine.........................15-14

Troubleshooting

Troubleshooting Battery Charger ............20-1

Storage

Storing Battery Charger- Engine Starter .......25-1

Specifications

Battery Charger- Engine Starter

Specifications .........................30-1

Record Product Information ................30-1

Warranty

Warranty...............................35-1

All information, illustrations and specifications in this manual are based on

the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

COPYRIGHT2004

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTIONManual

i

All rights reserved

091604

PN=1

Page 4

Contents

ii

091604

PN=2

Page 5

Safety

Recognize Safety Information

This is a safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the

potential for personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safety-alert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

DX,ALERT –19–29SEP98–1/1

T81389 –UN–07DEC88

TS187 –19–30SEP88

DX,SIGNAL –19–03MAR93–1/1

Learn how to operate the machine and how to use

controls properly. Do not let anyone operate without

instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

05-1

TS201 –UN–23AUG88

DX,READ –19–03MAR93–1/1

091604

PN=5

Page 6

Safety

Prevent Battery Explosions

Keep sparks, lighted matches, and open flame away from

the top of battery. Battery gas can explode.

Never check battery charge by placing a metal object

across the posts. Use a voltmeter or hydrometer.

Do not charge a frozen battery; it may explode. Warm

battery to 16°C (60°F).

Prevent Acid Burns

Sulfuric acid in battery electrolyte is poisonous. It is strong

enough to burn skin, eat holes in clothing, and cause

blindness if splashed into eyes.

Avoid the hazard by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is added.

4. Avoiding spilling or dripping electrolyte.

5. Use proper jump start procedure.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize the acid.

3. Flush your eyes with water for 15—30 minutes. Get

medical attention immediately.

DX,SPARKS –19–03MAR93–1/1

TS204 –UN–23AUG88

If acid is swallowed:

1. Do not induce vomiting.

2. Drink large amounts of water or milk, but do not

exceed2L(2quarts).

3. Get medical attention immediately.

05-2

TS203 –UN–23AUG88

DX,POISON –19–21APR93–1/1

091604

PN=6

Page 7

Wear Protective Clothing

Wear close fitting clothing and safety equipment

appropriate to the job.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones

while operating machine.

Safety

Handle Chemical Products Safely

Direct exposure to hazardous chemicals can cause

serious injury. Potentially hazardous chemicals used with

John Deere equipment include such items as lubricants,

coolants, paints, and adhesives.

A Material Safety Data Sheet (MSDS) provides specific

details on chemical products: physical and health hazards,

safety procedures, and emergency response techniques.

Check the MSDS before you start any job using a

hazardous chemical. That way you will know exactly what

the risks are and how to do the job safely. Then follow

procedures and recommended equipment.

(See your John Deere dealer for MSDS’s on chemical

products used with John Deere equipment.)

DX,WEAR2 –19–03MAR93–1/1

TS206 –UN–23AUG88

TS1132 –UN–26NOV90

05-3

DX,MSDS,NA –19–03MAR93–1/1

091604

PN=7

Page 8

Safety

Dispose of Waste Properly

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful waste used

with John Deere equipment include such items as oil, fuel,

coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids. Do not use

food or beverage containers that may mislead someone

into drinking from them.

Do not pour waste onto the ground, down a drain, or into

any water source.

Air conditioning refrigerants escaping into the air can

damage the Earth’s atmosphere. Government regulations

may require a certified air conditioning service center to

recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste

from your local environmental or recycling center, or from

your John Deere dealer.

Recycle Waste

TS1133 –UN–26NOV90

DX,DRAIN –19–03MAR93–1/1

05-4

091604

PN=8

Page 9

Safety

IMPORTANT SAFETY INSTRUCTIONS- SAVE THESE INSTRUCTIONS

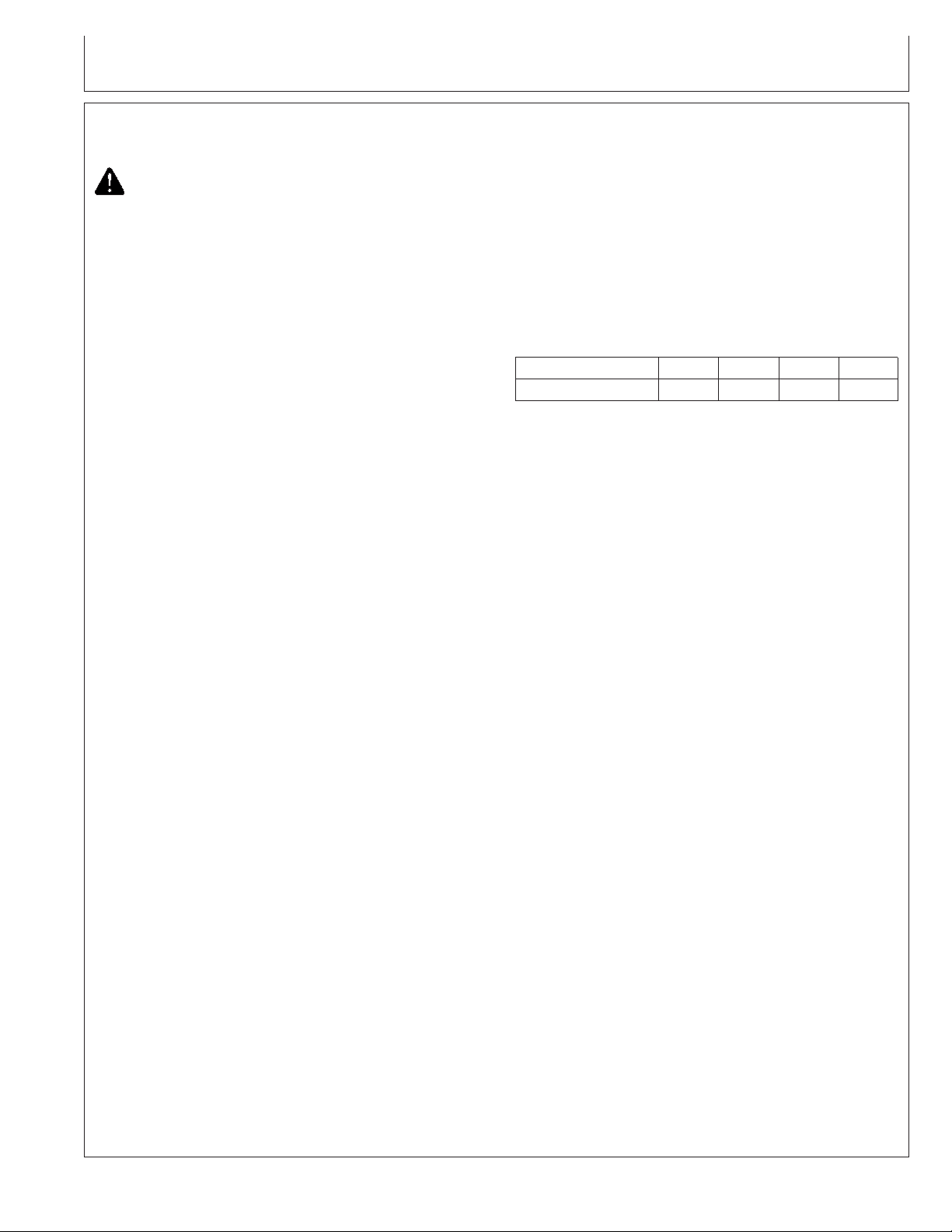

CAUTION: RISK OF EXPLOSIVE GASES.

Working in the vicinity of lead-acid batteries

is dangerous. Batteries generate explosive

gases during normal battery operation. Read

this manual and follow the instructions

exactly EACH TIME you use this battery

charger.

To reduce risk of battery explosion, follow

these instructions and the instructions

published by battery manufacturer. Review

the cautionary markings on the battery,

battery charger, and engine compartment.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds,

chemicals known by the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

1. SAVE THESE INSTRUCTIONS. This manual

contains important safety and operating instructions

for your battery charger. Read and understand this

manual before using the battery charger.

2. To reduce risk of electric shock, do not operate

battery charger when unit is exposed to water. Do

not expose battery charger to rain or snow.

3. Use of an attachment not recommended or sold by

the battery charger manufacturer may result in a

risk of fire, electric shock or injury to persons.

4. To reduce the risk of damage to electric plug and

cord, pull by plug rather than cord when

disconnecting battery charger.

5. Use of an extension cord is not recommended. Use

of an improper extension cord could result in fire or

electric shock. If an extension cord must be used,

make sure:

a. the pins on plug of extension cord are the same

number, size, and shape as those on plug of

charger,

b. the extension cord is properly wired and in good

electrical condition, and

c. the wire size is large enough for the length of

cord for the ampere rating of this battery charger

as specified below.

Length of Cord (Ft.) 25 50 100 150

AWG Size of Cord 16 14 10 8

6. Never alter AC cord or grounding plug provided. If

temporary adapter must be used to plug battery

charger into a two pole outlet, connect the

grounding hardware on the adapter to a properly

grounded outlet using the center screw of the outlet

plate. Be sure the center screw of the outlet plate is

grounded.

7. Locate battery power cord so it cannot be stepped

on, tripped over, or subjected to damage or stress.

Do not operate battery charger with damaged cord

or plug. Replace cord or plug immediately.

8. Do not operate battery charger if it has received a

sharp blow, been dropped, or otherwise damaged

in any way. Take it to a qualified service technician.

9. Do not disassemble battery charger. Take charger

to a qualified service technician when service or

repair is necessary. Incorrect assembly may result

in electric shock or fire.

10. To reduce risk of electric shock, unplug battery

charger from outlet before attempting any

maintenance or cleaning.

05-5

OURGP12,000010D –19–02JUN04–1/1

091604

PN=9

Page 10

Personal Precautions

Safety

1. Wear complete eye protection and clothing

protection. Avoid touching eyes when working near

batteries.

2. Have plenty of fresh water and soap nearby, in

case battery acid contacts skin, clothing, or eyes.

3. Someone should be within range of your voice or

close enough to come to your aid when you work

near a lead-acid battery.

4. If battery acid contacts skin or clothing, wash

immediately with soap and water. If acid enters eye,

immediately flood eye with running cold water for

15—30 minutes and get medical attention

immediately.

5. Batteries generate explosive gases! NEVER smoke

or allow a spark or flame in the vicinity of battery or

engine. Always operate battery charger in an open,

well ventilated area.

6. Do not drop a metal tool onto the battery. It might

spark or short-circuit the battery or other electrical

part that may cause an explosion.

7. Remove personal metal items such as rings,

bracelets, necklaces, and watches when working

near a lead-acid battery.

8. Use the battery charger for charging LEAD-ACID

batteries only. The charger is not intended to supply

power to a low voltage electrical system other than

in a starter-motor application. Do not use the

battery charger for charging dry-cell batteries that

are commonly used with home appliances. These

batteries may burst and cause injury to persons or

damage to property.

9. NEVER charge a frozen battery.

10. Never allow battery acid to drip on charger when

reading specific gravity or filling battery.

11. Never set battery on top of battery charger.

Battery Charger Connection Precautions

CAUTION: Connect and disconnect DC

clamps only after removing AC cord from

electrical outlet.

Never allow battery charger clamps to touch

each other.

Do not connect both battery charger clamps

directly to the battery.

1. Locate battery charger as far from battery as cables

permit.

OURGP12,000010C –19–02JUN04–1/1

2. When connecting battery charger, attach one clamp

to battery and the other clamp to a grounding point

away from the battery.

3. Read the Controls and Operation section before

connecting the battery charger.

4. When connecting each clamp, rock or twist the

clamp back and forth several times to make a good

connection. Do not twist or rock the first clamp after

the second clamp has been connected.

OURGP12,000010E –19–02JUN04–1/1

05-6

091604

PN=10

Page 11

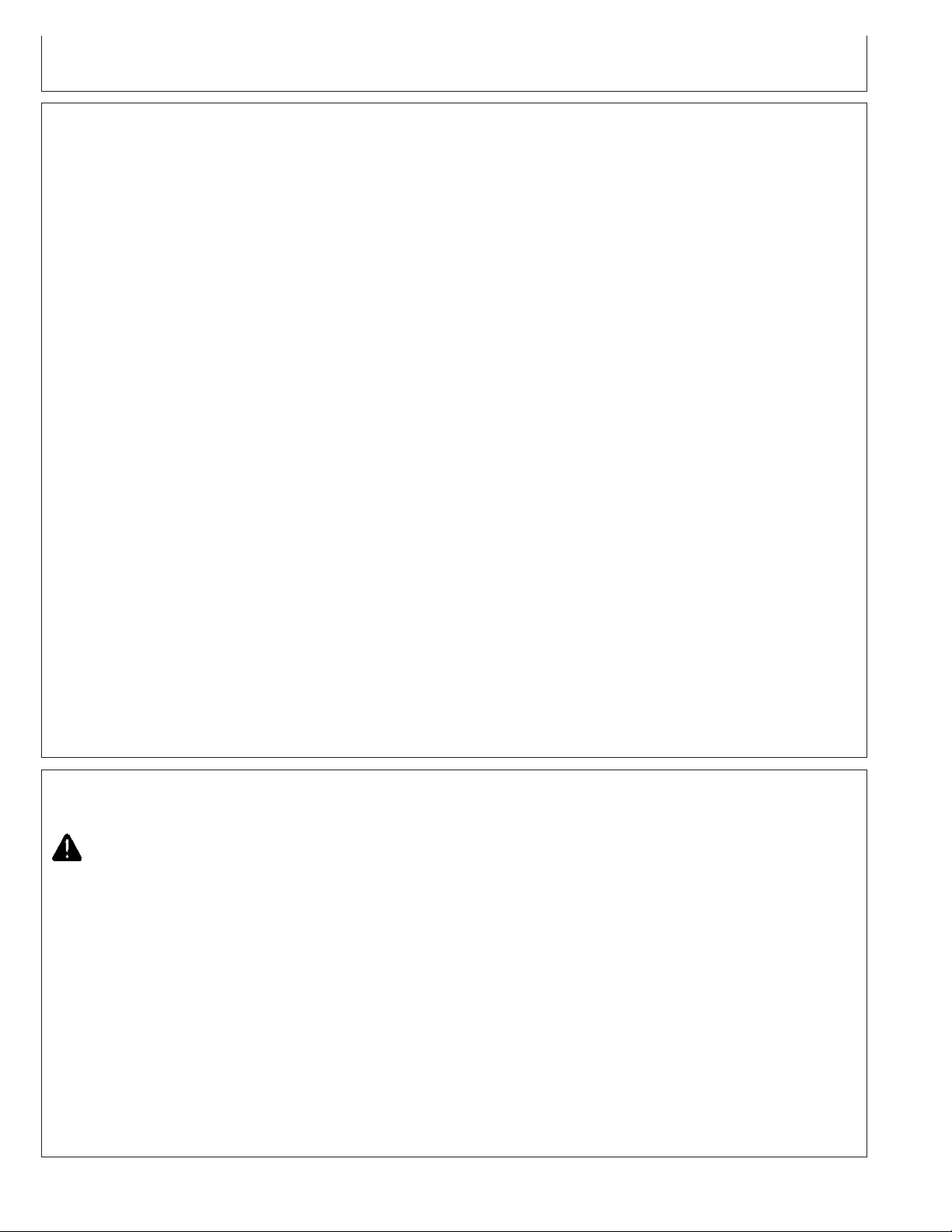

Safety Sign

Safety

Safety Decal Location

Safety Decal

TYB4740 –UN–08SEP04

TYB4740A –UN–08SEP04

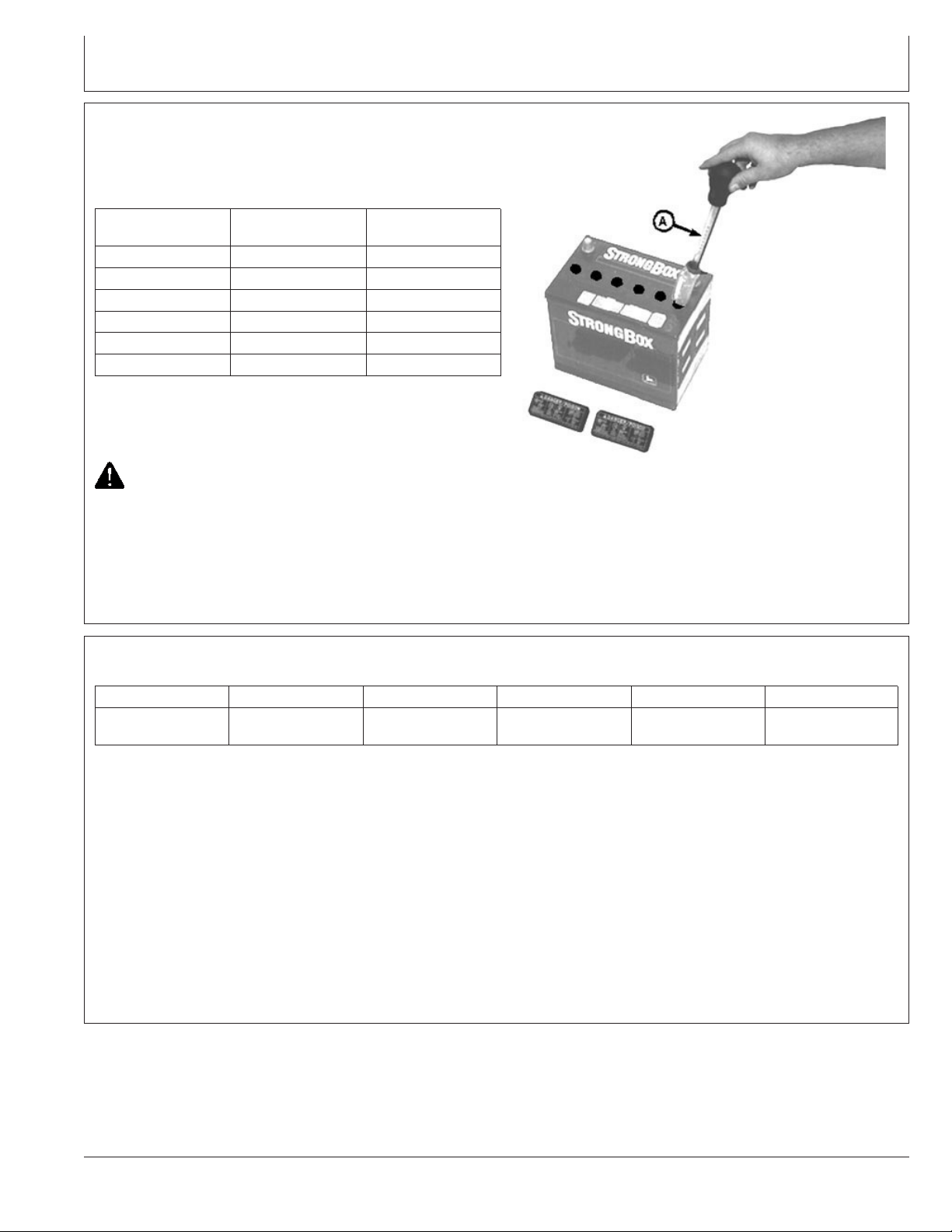

NOTE: Safety decal (A) is located on back of battery

charger- engine starter housing.

05-7

OURGP12,000010F –19–02JUN04–1/1

091604

PN=11

Page 12

Assembly Instructions

Assembly Parts

CAUTION: Before operating charger, wheels

must be installed to ensure proper ventilation

and to meet minimum UL requirements for

ground clearance for sparking components.

The following parts are provided for assembly.

• (2) Screws, 10-32

• (2) Screws 1/4-20

• (2) Wheels

• (2) Axle caps

• (2) Axle brackets

• (1) Axle

• (1) Mounting Foot

• (1) Handle

Assembly Tools

The following tools are suggested for assembly.

• Wrench, 5/16 in.

• Wrench, 3/8 in.

• Hammer

• Screwdriver

OUOD006,0000119 –19–03JUN04–1/1

OUOD006,000011A –19–03JUN04–1/1

10-1

091604

PN=12

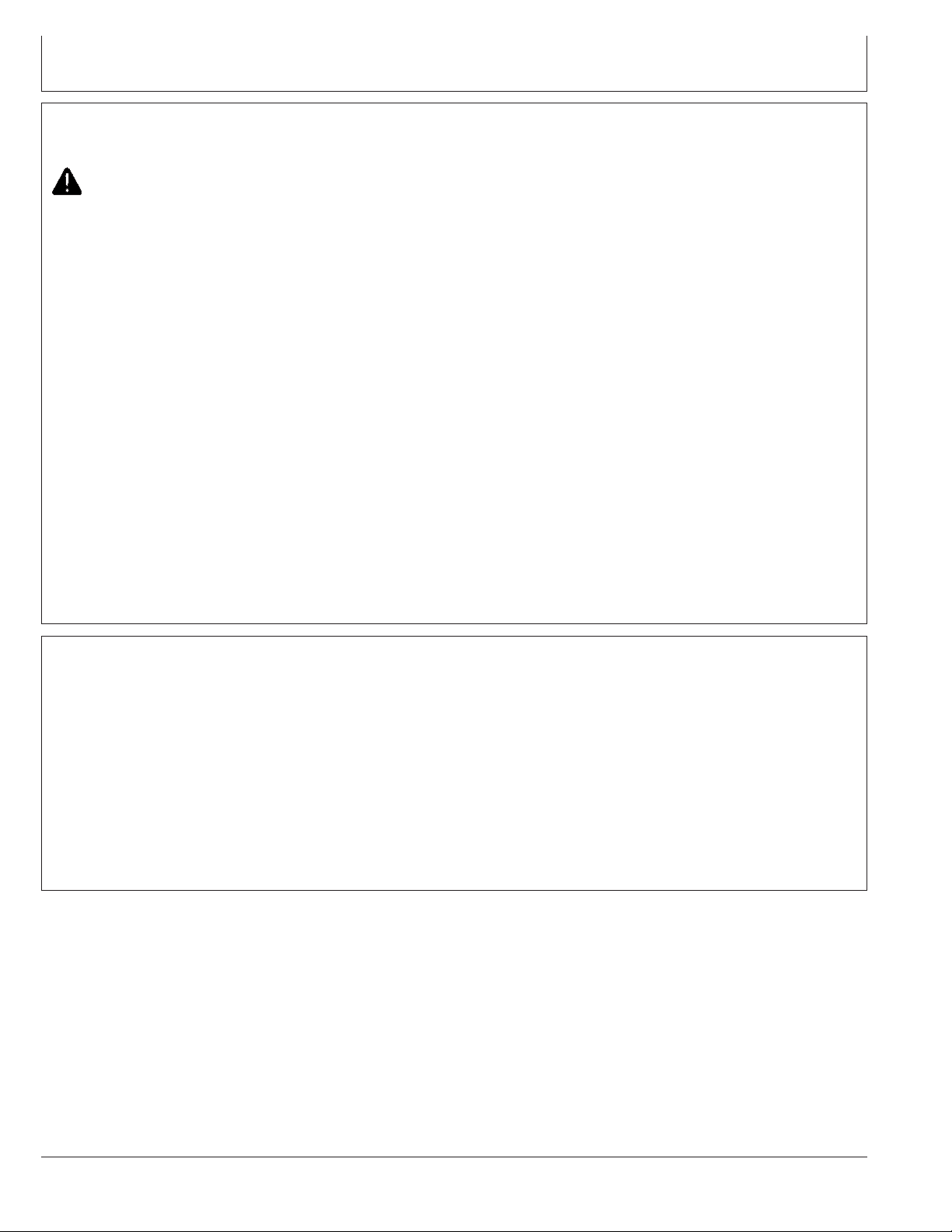

Page 13

Assembly Instructions

Assembly Procedure

1. Position battery charger- engine starter on its side.

2. Install mounting foot (A) with two 1/4-20 screws.

A—Mounting Foot

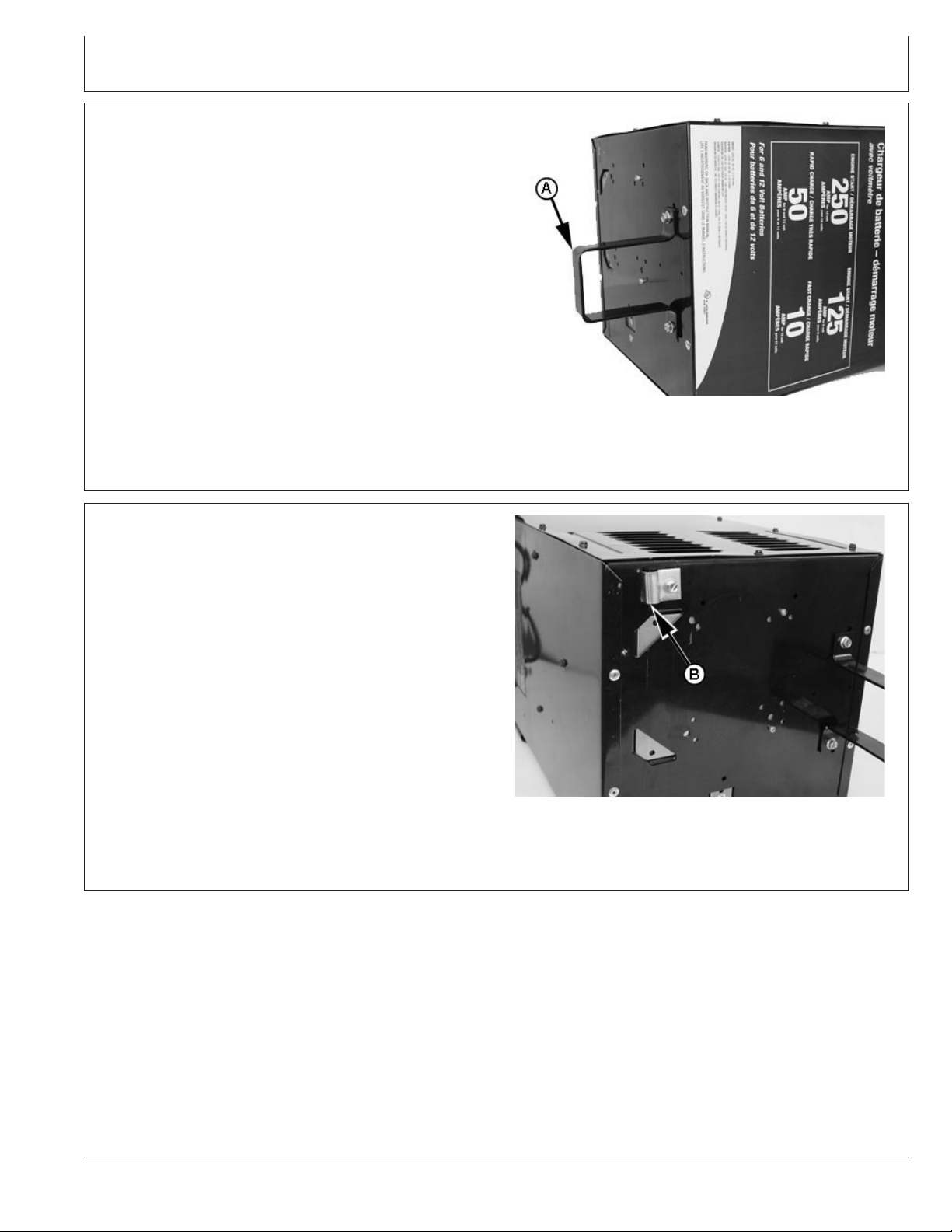

3. Insert end of each axle bracket (B) in slot and fasten

bracket with a 10-32 screw.

B—Axle Bracket

Install Mounting Foot

TYB4746 –UN–08SEP04

OUOD006,000011B –19–03JUN04–1/6

TYB4747 –UN–08SEP04

Install Axle Brackets

Continued on next page

10-2

OUOD006,000011B –19–03JUN04–2/6

091604

PN=13

Page 14

4. Install axle into axle cap (C) with a hammer.

5. Slide one wheel (D) onto axle as shown.

C—Axle Cap

D—Wheel

Assembly Instructions

6. Insert axle (E) through both axle brackets.

E—Axle

Continued on next page

Install Wheel on Axle

TYB4748 –UN–08SEP04

OUOD006,000011B –19–03JUN04–3/6

TYB4749 –UN–08SEP04

Install Axle

OUOD006,000011B –19–03JUN04–4/6

10-3

091604

PN=14

Page 15

Assembly Instructions

7. Position charger on opposite side.

8. Slide remaining wheel onto axle as shown and install

axle cap (F) with a hammer.

F—Axle Cap

9. Position charger on its wheels and mounting foot.

10. Remove two top screws (G) from each side of

charger. Position handle (H) as shown, and reinstall

screws (G).

G—Screws

H—Handle

Install Wheel

TYB4750 –UN–08SEP04

OUOD006,000011B –19–03JUN04–5/6

TYB4751 –UN–08SEP04

Install Handle

10-4

OUOD006,000011B –19–03JUN04–6/6

091604

PN=15

Page 16

Preparing Battery

Controls and Operation

CAUTION: A marine (boat) battery must be

removed and charged on shore. To charge it

onboard requires equipment specially

designed for marine use.

1. Make sure battery is a 6 volt or 12 volt lead-acid

battery.

2. Make sure all vehicle accessories are off.

3. If battery must be removed from vehicle to charge,

always remove grounded terminal from battery first.

4. Make sure area around battery is well ventilated.

Gases can be forcefully blown away using a piece

of cardboard or other nonmetallic material as a fan.

5. Study battery manufacturer’s specific precautions,

such as removing or not removing cell caps while

charging, and recommended rates of charge.

6. For batteries with removable vent caps, add distilled

water to each cell until battery acid reaches level

specified by battery manufacturer. Do not overfill.

7. Clean battery terminals.

OUOD006,000000E –19–15JUN04–1/1

Positioning Battery Charger

CAUTION: Risk of explosion. Battery gases

produced during charging can explode.

Ventilate area. Keep sparks and flames away.

1. Position the battery charger in a clean, dry, well

ventilated place as far from the battery as cables

permit.

2. Never place the battery charger directly above battery

being charged. Gases from battery will corrode and

damage charger.

3. Never allow battery acid to drip on battery charger

when reading gravity or filling battery.

4. Do not operate battery charger in a closed area, or

restrict ventilation in any way.

5. Do not set battery on top of battery charger or battery

charger on top of battery.

Risk of Battery Explosion

TS204 –UN–23AUG88

15-1

OUOD006,0000079 –19–14SEP04–1/1

091604

PN=16

Page 17

Controls and Operation

Checking Battery State-of-Charge

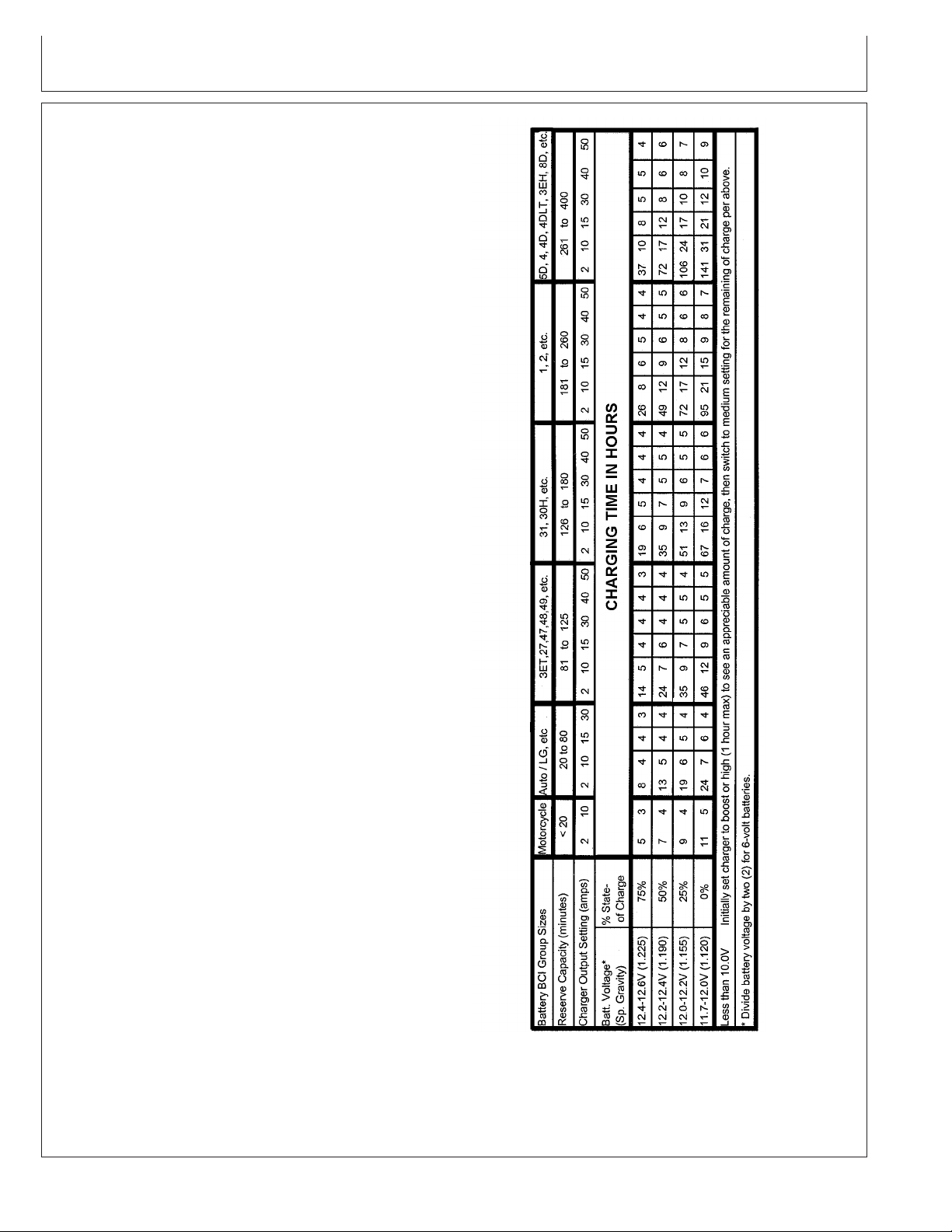

Use a voltmeter or hydrometer (A) to determine state-of

charge. Refer to chart to obtain percent of charge.

Voltmeter Reading Hydrometer Battery Test

Reading Reading

12 Volt Battery* Specific Gravity Percent of Charge

12.4 or greater 1.265 100%

12.39 to 12.25 1.225 75%

12.24 to 12.10 1.190 50%

12.09 to 11.96 1.155 25%

11.95 to 0 1.120 0%

* 6 volt battery voltmeter readings are one-half of 12 volt

battery readings shown.

CAUTION: Do NOT attempt to charge a frozen

battery.

NOTE: Any battery 25% charged or less may readily

freeze and should be charged at once.

Identifying Battery Reserve Capacity (RC) Rating

Checking State-of-Charge

TYK275 –UN–08OCT96

A—Hydrometer

OUOD006,0000057 –19–17AUG04–1/1

Typical Group Sizes Auto, LGC, etc. 3ET, 47, 48, 49 31, 30H 1, 2 5D, 4 4D, 3EH, 8D

Reserve Capacity 80 or less 81-125 126-180 181-260 261 or more

Rating

Time needed to completely recharge a battery

depends on the battery’s electrical capacity and

present state of charge. Battery electrical reserve (RC

rating) is given in minutes, and is needed when

Most batteries have a label attached showing the

battery’s type and/or reserve capacity rating. If this

information is not found on the battery, use the above

chart to determine reserve capacity (RC) rating.

estimating recharge time.

OUOD006,0000059 –19–18AUG04–1/1

15-2

091604

PN=17

Page 18

Controls and Operation

Estimating Battery Recharge Time

1. Use table to determine time needed to completely

recharge battery based on battery type, present state

of charge, and charging rate (amps).

2. If recharge time cannot be estimated from the table,

calculate recharge time using the following formula:

Recharge capacity (minutes) x 0.6 x 1.25 ÷ charge rate

(amps) = approximate hours needed to recharge a

totally discharged battery.

EXAMPLE:

80 x 0.6 x 1.25 ÷ 10 = 6 hours

NOTE: Example uses an 80 minute reserve capacity

battery and 10 amp charge rate.

When battery is not totally discharged, adjust charge

time estimate using % DISCHARGED figure for

calculation.

EXAMPLE:

6 hours x 0.75 = 4.5 hours

NOTE: Example shows adjusted time when battery is

25% charged (75% discharged). If battery was

75% charged, discharged figure of 0.25 would be

used in adjusted calculation to arrive at 1.5 hours.

15-3

Estimating Recharge Time

TYB4797 –19–18AUG04

OUOD006,000005A –19–18AUG04–1/1

091604

PN=18

Page 19

Controls and Operation

Activating and Charging a Dry Battery

Listed below are six steps to activate a dry-charged

battery.

1. Remember Safety. Always wear protective

glasses, gloves, and clothing when handling

batteries and sulfuric acid electrolyte.

2. Prepare the Battery. Remove vents and date code

punch outs. If the battery or electrolyte is below

60°F, activation will be slower.

3. Add Electrolyte. Fill each cell with electrolyte until

the level just touches the bottom of the “split vent”

at the bottom of the vent well. Do not over fill by

covering the split. If the split is covered, the gases

created during charging will not escape properly,

and will cause increased splashing and acid loss.

Under filling can reduce the performance and life of

the battery.

4. Let the Battery Absorb the Acid. It takes time for

the battery plates and separators to absorb the

acid. A 15 to 30 minute stand time before charging

is recommended. Gentle rocking of the battery will

help dislodge trapped air bubbles.

5. Charge the Battery. Charge the activated battery

to ensure that it starts its life at 100%

state-of-charge. Activated batteries should be

charged at no more than 1% of CCA for 30

minutes, and up to 6 hours in cases of extremely

high humidity storage. For example, a 625 CCA

battery should be charged at 6 amps. Reduce the

charging rate if excessive gassing occurs.

Charging is recommended when:

a. The voltage of the activated battery is below

12.4 volts, even after 15 minutes stand time.

b. The battery will not be installed within the next

30 days.

c. The outside temperature is below 32°F.

d. The battery has been in storage for more than

two years.

6. Top off the Electrolyte Level. Add electrolyte as

required to bring the level back up to the bottom of

the split vent in the bottom of the vent well. The

acid level may have dropped due to absorption into

the plates and separators. Replace the service

vents.

Service hints for longer battery life:

• Add only pure drinking water or distilled water to the

battery after it is placed in service.

• Disconnect the ground cable when the vehicle is

stored for more than three months. Cleaning the

battery top, adding water, and charging the battery

before vehicle storage will reduce discharge and

sulfation battery failures.

• Specific gravity is the best indicator of battery

state-of charge.

15-4

OUOD006,0000058 –19–17AUG04–1/1

091604

PN=19

Page 20

Controls and Operation

Testing Battery Installed in Vehicle

CAUTION: A marine (boat) battery must be

removed and charged on shore. To charge it

onboard requires equipment specially designed

for marine use.

Stay clear of fan blades, belts, pulleys, and

other parts that can cause injury.

Battery gases produced during charging can

explode. Ventilate area. Keep sparks and flames

away.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known by the State of California to cause cancer and

reproductive harm. Wash hands after handling.

IMPORTANT: DO NOT plug battery charger into

power receptacle or set any charger

controls until ALL connections have

been made.

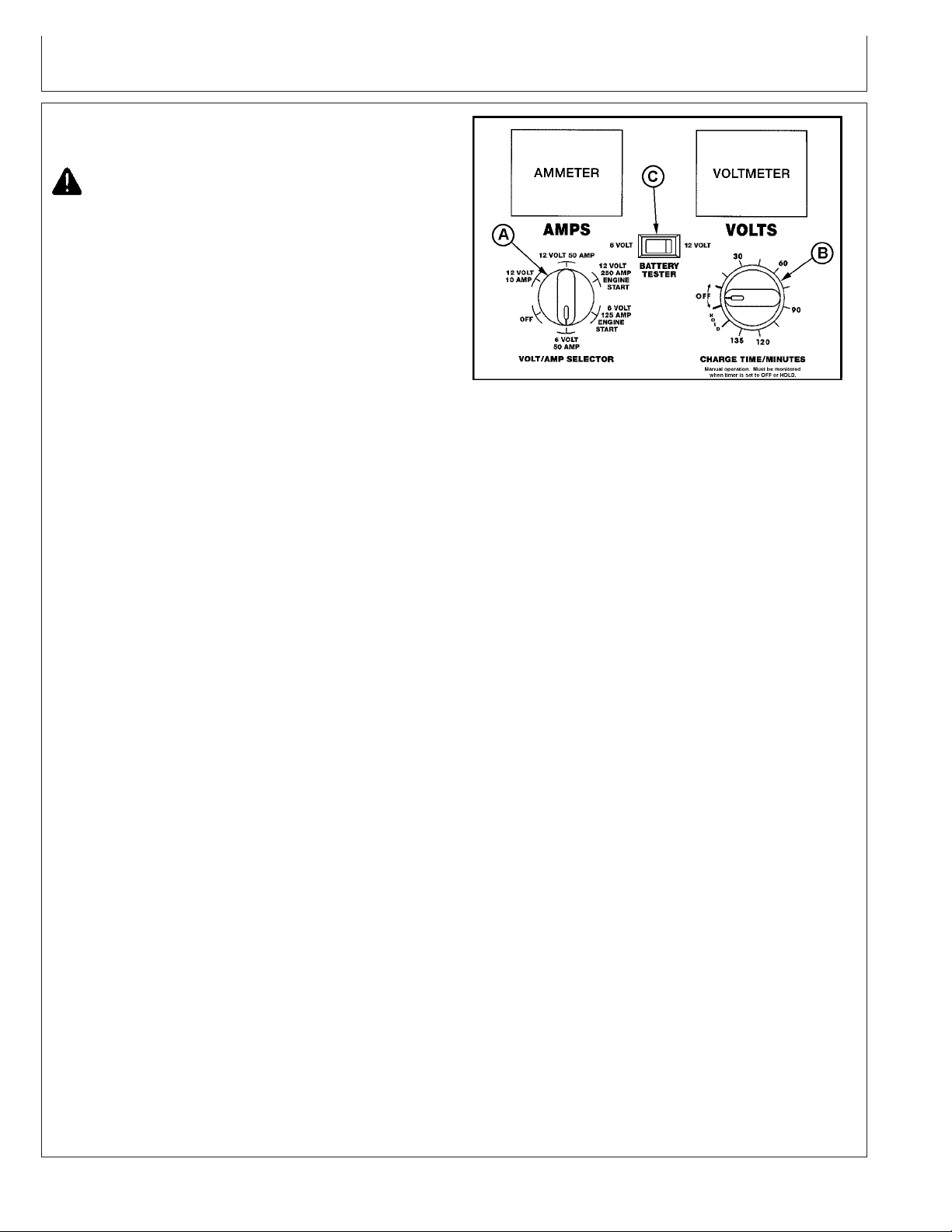

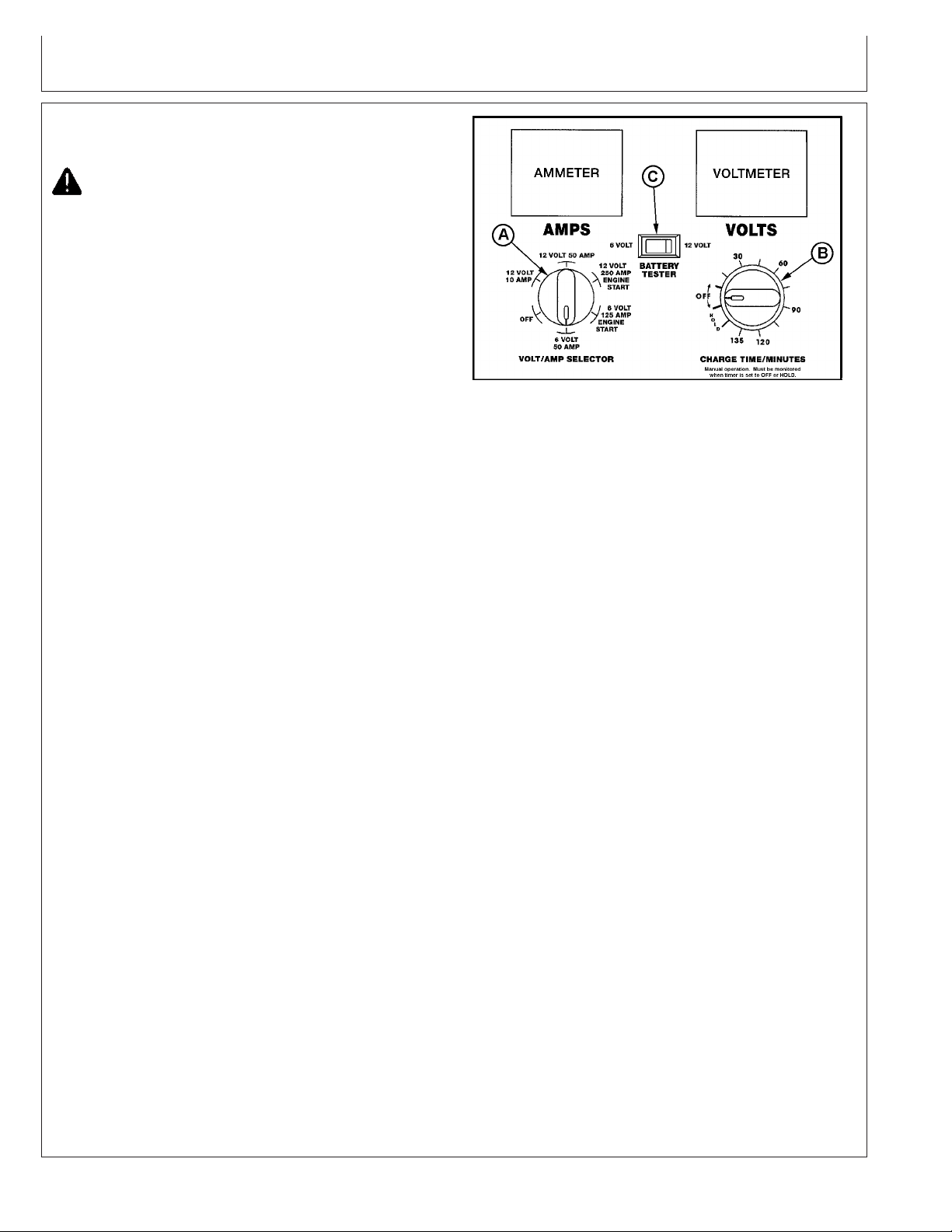

Control Panel

TYB4741 –UN–31AUG04

A—Charge Rate Switch

B—Charge Time Switch

C—6 Volt/12 Volt Battery Tester Switch

Turn all vehicle switches OFF (ignition,

lights, radio, etc.) before connecting

battery charger.

Turn all battery charger and time

switches OFF before connecting battery

charger.

NOTE: Unit serves as a voltmeter only, not as a load

tester.

Battery charger need not be plugged into AC

outlet to test battery.

1. Set charge rate switch (A) and charge time switch (B)

to OFF position.

2. Set the battery tester switch (C) to 6 Volt or 12 Volt to

match the voltage of the battery being tested.

Continued on next page

15-5

OURGP12,0000001 –19–09JUN04–1/2

091604

PN=20

Page 21

Controls and Operation

3. Position AC and DC cords to reduce risk of damage by

hood, door, or moving engine parts.

4. Determine which battery terminal is the POSITIVE

terminal. (The Positive terminal may be identified with

a POS, P, or +, and usually has a larger diameter than

the Negative terminal (NEG, N, —).

5. Determine which battery terminal is grounded

(connected) to the chassis.

6. Connect one clamp of the battery charger to the

UNGROUNDED battery terminal using (a) or (b) below:

a. Negative-Grounded Vehicles: Connect Positive

(red) clamp (D) of battery charger to Positive

(Ungrounded) battery terminal.

b. Positive-Grounded Vehicles: Connect Negative

(black) clamp of battery charger to Negative

(Ungrounded) battery terminal.

NOTE: Twist or rock clamp back and forth several times

to make a good connection.

IMPORTANT: Do not connect ground clamp to the

carburetor, fuel lines, or sheet metal

body parts.

7. Connect remaining battery charger clamp to a

heavy-gauge metal part of vehicle chassis or engine

block, as far from battery as possible.

NOTE: For accurate battery voltage, turn headlamps on

for a couple minutes, then turn them off and wait

a couple minutes before reading meter.

8. Observe voltmeter color code indication to determine

battery charge.

Negative Ground Connections

TYB4752 –UN–25JUN04

D—Positive (Red) Clamp

15-6

OURGP12,0000001 –19–09JUN04–2/2

091604

PN=21

Page 22

Controls and Operation

Testing Battery Outside of Vehicle

CAUTION: Risk of explosion. Battery gases

produced during charging can explode. Keep

sparks and flames away.

When disconnecting battery, remove battery

ground cable first.

A marine (boat) battery must be removed and

charged on shore. To charge it onboard

requires equipment specially designed for

marine use.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known by the State of California to cause cancer and

reproductive harm. Wash hands after handling.

IMPORTANT: DO NOT plug battery charger into

power receptacle or set any charger

controls until ALL connections have

been made.

Control Panel

TYB4741 –UN–31AUG04

A—Charge Rate Switch

B—Charge Time Switch

C—6 Volt/12 Volt Battery Tester Switch

Turn all battery charger and time

switches OFF before connecting battery

charger.

NOTE: Unit serves as a voltmeter only, not as a load

tester.

Battery charger need not be plugged into AC

outlet to test battery.

1. Set charge rate switch (A) and charge time switch (B)

to OFF position.

2. Set the battery tester switch (C) to 6 Volt or 12 Volt to

match the voltage of the battery being tested.

3. Determine which battery terminal is the POSITIVE

terminal and which is the Negative terminal. (The

Positive terminal may be identified with a POS, P, or +,

and usually has a larger diameter than the Negative

terminal (NEG, N, —).

Continued on next page

15-7

OURGP12,0000002 –19–09JUN04–1/2

091604

PN=22

Page 23

Controls and Operation

4. To keep a safe distance from the battery, attach an

6-gauge or heavier insulated jumper cable (D), at least

61 cm (24 in.) long, to the Negative battery terminal.

(Jumper cable is not provided.)

5. Connect Positive (red) clamp (E) of battery charger to

Positive terminal of battery. Rock or twist clamp back

and forth to improve connection.

6. Holding free end of jumper cable, stand as far from

battery as possible. Face away from battery, and

connect Negative (black) clamp (F) to free end of

jumper cable. Rock or twist clamp back and forth to

improve connection.

NOTE: For accurate battery voltage, turn headlamps on

for a couple minutes, then turn them off and wait

a couple minutes before reading meter.

7. Observe voltmeter color code indication to determine

battery charge.

Battery Charger Connections

TYB4755 –UN–25JUN04

D—Insulated Jumper Cable

E—Positive (Red) Clamp

F—Negative (Black) Clamp

Charging Battery Installed in Vehicle

CAUTION: Risk of explosion. Battery gases

produced during charging can explode.

Ventilate area. Keep sparks and flames away.

Stay clear of fan blades, belts, pulleys, and

other parts that can cause injury.

NEVER charge a frozen battery.

A marine (boat) battery must be removed and

charged on shore. To charge it onboard

requires equipment specially designed for

marine use.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known by the State of California to cause cancer and

reproductive harm. Wash hands after handling.

OURGP12,0000002 –19–09JUN04–2/2

Continued on next page

15-8

OURGP12,0000118 –19–03JUN04–1/3

091604

PN=23

Page 24

Controls and Operation

IMPORTANT: DO NOT plug battery charger into

power receptacle or set any charger

controls until ALL connections have

been made.

Turn all vehicle switches OFF (ignition,

lights, radio, etc.) before connecting

battery charger.

Turn all battery charger and time

switches OFF before connecting battery

charger.

1. Position AC and DC cords to reduce risk of damage by

hood, door, or moving engine parts.

2. Determine which battery terminal is the POSITIVE

terminal. (The Positive terminal may be identified with

a POS, P, or +, and usually has a larger diameter than

the Negative terminal (NEG, N, —).

3. Determine which battery terminal is grounded

(connected) to the chassis.

4. Connect one clamp of the battery charger to the

UNGROUNDED battery terminal using (a) or (b) below:

a. Negative-Grounded Vehicles: Connect Positive

(red) clamp (A) of battery charger to Positive

(Ungrounded) battery terminal.

b. Positive-Grounded Vehicles: Connect Negative

(black) clamp of battery charger to Negative

(Ungrounded) battery terminal.

NOTE: Rock or twist clamp back and forth several times

to make a good connection.

IMPORTANT: Do not connect ground clamp to the

carburetor, fuel lines, or sheet metal

body parts.

5. Connect remaining battery charger clamp to a

heavy-gauge metal part of vehicle chassis or engine

block, as far from battery as possible.

6. Plug battery charger AC power cord into 120-volt AC

receptacle.

Negative Ground Connections

TYB4726 –UN–25JUN04

A—Positive (Red) Clamp

Continued on next page

15-9

OURGP12,0000118 –19–03JUN04–2/3

091604

PN=24

Page 25

Controls and Operation

IMPORTANT: Voltage for charge rate selected must

match battery voltage.

NOTE: Battery charger is NOT automatic, and can

overcharge a battery if permitted to operate for

extended periods of time. Monitor the charging

often.

7. Set charge rate switch (B) to desired Volt/Amp

position. Refer to following Charge Rate Table.

8. Set charge time switch (C) from OFF position to

desired time position. Refer to Charge Rate Table for

time for charge rate selected in previous step.

NOTE: When charge state is not known, start with a timer

setting of one hour or less.

BATTERY SIZE/RATING

200-315 CCA 40-60 RC 2.5 - 3 NR

315-550 CCA 60-85 RC 3 - 4 0.6 - 1

550-875 CCA 85-125 RC 4- 5 1 - 1.3

MARINE/

DEEP CYCLE

55 MC 4 NR

80 MC 5 NR

105 MC 6 NR

CHARGE RATE/CHARGE TIME

(HOURS)*

10 AMP 50 AMP

TY25862 Control Panel

TYB4742 –UN–31AUG04

B—Charge Rate Switch

C—Charge Time Switch

* - Based on battery at 50% charge.

NR - Not Recommended

CCA - Cold Cranking Amps

RC - Reserve Capacity

MC - Marine Capacity

9. When battery is fully charged, turn charge rate and

charge time switches OFF, disconnect AC cord,

remove clamp from the vehicle chassis or engine

block, and then remove the clamp from the battery

terminal.

15-10

OURGP12,0000118 –19–03JUN04–3/3

091604

PN=25

Page 26

Controls and Operation

Charging Battery Outside of Vehicle

CAUTION: Risk of explosion. Battery gases

produced during charging can explode.

Ventilate area. Keep sparks and flames away.

When disconnecting battery, remove battery

ground cable first.

NEVER charge a frozen battery.

A marine (boat) battery must be removed and

charged on shore. To charge it onboard

requires equipment specially designed for

marine use.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known by the State of California to cause cancer and

reproductive harm. Wash hands after handling.

IMPORTANT: DO NOT plug battery charger into

power receptacle or set any charger

controls until ALL connections have

been made.

Turn all battery charger and time

switches OFF before connecting battery

charger.

1. Determine which battery terminal is the POSITIVE

terminal and which is the Negative terminal. (The

Positive terminal may be identified with a POS, P, or +,

and usually has a larger diameter than the Negative

terminal (NEG, N, —).

Continued on next page

OURGP12,0000110 –19–02JUN04–1/3

15-11

091604

PN=26

Page 27

Controls and Operation

2. To keep a safe distance from the battery, attach an

6-gauge or heavier insulated jumper cable (A), at least

61 cm (24 in.) long, to the Negative battery terminal.

(Jumper cable is not provided.)

3. Connect Positive (red) clamp (B) of battery charger to

Positive terminal of battery. Rock or twist clamp back

and forth to improve connection.

4. Holding free end of jumper cable, stand as far from

battery as possible. Face away from battery, and

connect Negative (black) clamp (C) to free end of

jumper cable. Rock or twist clamp back and forth to

improve connection.

5. Plug battery charger power cord into 120-volt AC

receptacle.

Battery Charger Connections

TYB4727 –UN–25JUN04

A—Insulated Jumper Cable

B—Positive (Red) Clamp

C—Negative (Black) Clamp

Continued on next page

OURGP12,0000110 –19–02JUN04–2/3

15-12

091604

PN=27

Page 28

Controls and Operation

NOTE: Battery charger is NOT automatic, and can

overcharge a battery if permitted to operate for

extended periods of time. Monitor the charging

often.

NOTE: Charger may produce a buzzing noise during

charging. This is normal. Continue to charge the

battery. Noise may continue after battery charger

is disconnected from battery.

6. Set charge rate switch (D) to desired Volt/Amp

position. Refer to following Charge Rate Table.

7. Set charge time switch (E) from OFF position to

desired time position. Refer to Charge Rate Table for

time for charge rate selected in previous step.

NOTE: When charge state is not known, start with a timer

setting of one hour or less.

BATTERY SIZE/RATING

200-315 CCA 40-60 RC 2.5 - 3 NR

315-550 CCA 60-85 RC 3 - 4 0.6 - 1

550-875 CCA 85-125 RC 4- 5 1 - 1.3

MARINE/

DEEP CYCLE

55 MC 4 NR

80 MC 5 NR

105 MC 6 NR

CHARGE RATE/CHARGE TIME

(HOURS)*

10 AMP 50 AMP

* - Based on battery at 50% charge.

NR - Not Recommended

CCA - Cold Cranking Amps

RC - Reserve Capacity

TY25862 Control Panel

TYB4753 –UN–31AUG04

D—Charge Rate Switch

E—Charge Time Switch

MC - Marine Capacity

8. When battery is fully charged, turn charge rate and

charge time switches OFF, disconnect AC cord,

remove clamp from the jumper cable, and then remove

the clamp from the battery terminal.

15-13

OURGP12,0000110 –19–02JUN04–3/3

091604

PN=28

Page 29

Controls and Operation

Starting Engine

CAUTION: Risk of explosion. Battery gases

produced during charging can explode.

Ventilate area. Keep sparks and flames away.

Stay clear of fan blades, belts, pulleys, and

other parts that can cause injury.

Do not use for marine (boat) applications. A

marine (boat) battery must be removed and

charged on shore. To charge it onboard

requires equipment specially designed for

marine use.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known by the State of California to cause cancer and

reproductive harm. Wash hands after handling.

IMPORTANT: DO NOT plug battery charger into

power receptacle or set any charger

controls until ALL connections have

been made.

Turn all vehicle switches OFF (ignition,

lights, radio, etc.) before connecting

battery charger.

Turn all battery charger and time

switches OFF before connecting battery

charger.

1. Position AC and DC cords to reduce risk of damage by

hood, door, or moving engine parts.

2. Determine which battery terminal is the POSITIVE

terminal. (The Positive terminal may be identified with

a POS, P, or +, and usually has a larger diameter than

the Negative terminal (NEG, N, —).

3. Determine which battery terminal is grounded

(connected) to the chassis.

Continued on next page

15-14

OURGP12,0000004 –19–09JUN04–1/3

091604

PN=29

Page 30

Controls and Operation

4. Connect one clamp of the battery charger to the

UNGROUNDED battery terminal using (a) or (b) below:

a. Negative-Grounded Vehicles: Connect Positive

(red) clamp (A) of battery charger to Positive

(Ungrounded) battery terminal.

b. Positive-Grounded Vehicles: Connect Negative

(black) clamp of battery charger to Negative

(Ungrounded) battery terminal.

NOTE: Rock or twist clamp back and forth several times

to make a good connection.

IMPORTANT: Do not connect ground clamp to the

carburetor, fuel lines, or sheet metal

body parts.

5. Connect remaining battery charger clamp to a

heavy-gauge metal part of vehicle chassis or engine

block, as far from battery as possible.

6. Plug battery charger AC power cord into 120-volt AC

receptacle.

A—Positive (Red) Clamp

Continued on next page

Negative Ground Connections

TYB4726 –UN–25JUN04

OURGP12,0000004 –19–09JUN04–2/3

15-15

091604

PN=30

Page 31

Controls and Operation

CAUTION: NEVER charge a frozen battery.

IMPORTANT: Do not use battery charger to start

vehicle without a battery in it.

7. Turn charge time switch (B) from OFF to HOLD

position.

8. Set charge rate switch (C) to the Engine Start position

for the voltage of the vehicle being started.

IMPORTANT: Do NOT crank engine for more than 3

seconds at a time. Wait for at least 4

minutes between attempts to start

engine.

NOTE: In extremely cold weather, or when battery is

severely exhausted, charge battery for 5 minutes

before cranking engine.

9. Crank the engine for no more than 3 seconds.

TY25862 Control Panel

TYB4742 –UN–31AUG04

B—Charge Time Switch

C—Charge Rate Switch

10. If engine does not start: Wait 240 seconds (4

minutes) before attempting to start vehicle again.

NOTE: In extremely cold weather, or when battery is

severely exhausted, wait 240 seconds (4 minutes)

after cranking engine, then charge battery for 5

more minutes before attempting to start vehicle

again.

If engine starts:Turn charge rate switch to OFF

position, unplug AC power cord, disconnect clamp to

ground (chassis or engine block), then disconnect

clamp to battery terminal.

OURGP12,0000004 –19–09JUN04–3/3

15-16

091604

PN=31

Page 32

Troubleshooting

Troubleshooting Battery Charger

Symptom Problem

No meter reading. (AC cord Clamps not making good connection. Rock or twist clamps back and forth

unplugged.) to improve connection.

Battery voltage is too low. Plug AC cord into outlet.

Charger will not turn on when AC outlet is dead. Check for voltage at outlet.

properly connected.

Poor electrical connection. Check connections.

Charger makes clicking noise. Circuit breaker is cycling. Check switch position.

Battery is defective. Check battery.

Battery is severely discharged . Continue charging until battery can

Solution

Use a different outlet.

Rock or twist clamps back and forth

for better connection.

take a charge. If problem continues

for 20 minutes, stop charging and

have battery checked.

Battery connections are reversed. Shut off charger and correct lead

connections.

OUOD006,0000008 –19–09JUN04–1/1

20-1

091604

PN=32

Page 33

Storage

Storing Battery Charger- Engine Starter

CAUTION: Battery electrolyte is dangerous and

corrosive. Wear eye protection and protective

clothing when cleaning clamps.

Clean clamps each time battery charger is used to

prevent corrosion from battery electrolyte.

Store battery charger in a clean, dry place.

TY25862 Battery Charger- Engine Starter

OUOD006,0000009 –19–09JUN04–1/1

TYB4754 –UN–07SEP04

25-1

091604

PN=33

Page 34

Specifications

Battery Charger- Engine Starter

Specifications

Model .................................................................................................... TY25862

Type ...................................................................................................... Battery Charger/Engine Starter

Maximum Input

— Voltage ............................................................................................ 120 Volts

— Cycles ............................................................................................. 60 Hz

Charging Output

— Amperage (Charging) ..................................................................... 10 or 50 Amps

— Amperage (Starting) ....................................................................... 125 or 250 Amps

— Voltage ............................................................................................ 6 or 12 Volts

Dimensions (w/ Wheels, but w/o Handle)

— Width ............................................................................................... 39-1/2 cm (15-1/2 in.)

— Height ............................................................................................. 58 cm (22-3/4 in.)

— Depth .............................................................................................. 35 cm (13-3/4 in.)

Power Cord ......................................................................................... 14 gauge, 182 cm (6 ft.) Long

Output Cables ..................................................................................... 6 gauge, 182 cm (6 ft.) Long

Clamps ................................................................................................ 300 Amp, Top/Side Mount

Total Reach ......................................................................................... 365 cm (12 ft.)

Record Product Information

NOTE: Battery charger date code is located on the back

of the charger housing.

Write your John Deere part number, date code, and date

of purchase in the spaces provided below. Your dealer

needs this information when ordering parts and when filing

warranty claims.

John Deere Part Number

Date Code (MS/Year/Week (MSyyww) Format)

Date of Purchase

(To be filled in by purchaser)

OUOD006,000000A –19–09JUN04–1/1

30-1

OUOD006,000000C –19–10JUN04–1/1

091604

PN=34

Page 35

Warranty

Warranty

John Deere Company (“John Deere”) warrants to the

original purchaser of each new John Deere Battery

Charger that it will repair or replace, as John Deere

elects, any part of the battery charger that is defective

in material or workmanship as delivered to the

purchaser if the defect appears within one year from

date of purchase. This warranty applies only to

purchases from authorized John Deere dealers.

To obtain performance of this warranty, the purchaser

must request such performance from a John Deere

dealer authorized to sell new John Deere Battery

Chargers. At the time of such request, the purchaser

must present proof of purchase documentation that

includes a date of purchase (bill of sale, for example),

make the product available at the dealer’s place of

business, and inform the dealer of what the purchaser

believes to be the defect in the product.

If John Deere elects to repair the product, only new or

remanufactured parts or components, furnished or

approved by John Deere, will be used. If any such part

or component is defective in material or workmanship

when installed in the product, John Deere will repair or

replace, as it elects, such defective part or component

provided the defect is reported to an authorized John

Deere dealer within 90 days of installation or before

expiration of the product’s warranty, whichever is later.

John Deere is not responsible for the following:

1. Transportation to and from the dealership, or

service calls made by the dealer.

2. Used products of any make.

3. Any product that has been altered or modified in

ways not approved by John Deere.

4. Depreciation or damage caused by normal wear,

lack of reasonable and proper maintenance, failure

to follow operating instructions, misuse, or lack of

proper protection during storage.

5. Normal maintenance and replacement of wear

items.

6. Premiums charged for overtime labor requested by

the purchaser.

Other than as stated in this section of the manual,

neither John Deere nor any company affiliated with it

makes any warranties, or representations, as to

materials, workmanship, quality or performance of the

products covered under this warranty. IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE

EXPRESSLY DISCLAIMED. THE ONLY REMEDIES

THE PURCHASER HAS IN CONNECTION WITH THE

BREACH OF PERFORMANCE OF ANY WARRANTY

ON JOHN DEERE PRODUCTS ARE THOSE SET

FORTH HEREIN. IN NO EVENT WILL THE DEALER,

JOHN DEERE, OR ANY COMPANY AFFILIATED

WITH JOHN DEERE BE LIABLE FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES. (NOTE: SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS OR THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY

TO YOU.)

The selling dealer makes no warranty of his own on

any item warranted by John Deere, and makes no

warranty on any other item unless he delivers to the

purchaser a separate written warranty certificate

specifically warranting the item. The dealer has no

authority to make any representation or promise on

behalf of John Deere, or to modify the terms or

limitations of this warranty in any way.

NOTE: This warranty gives you specific legal rights,

and you may have other rights which vary from

state to state.

35-1

OUOD006,000005B –19–19AUG04–1/1

091604

PN=35

Page 36

Warranty

35-2

091604

PN=36

Page 37

Chargeur de

batterie-de´marrage

6/12V 10/50/125/250A

LIVRET D’ENTRETIEN

Chargeur de batterie-de´marrage

moteur TY25862

OMTY25885 E´dition 16Sep04 (FRENCH)

John Deere Merchandise Division

Litho in USA

Page 38

Avant-propos

Introduction

MERCI d’avoir achete´un produit John Deere.

LIRE ATTENTIVEMENT CE LIVRET pour assimiler les

me´thodes d’utilisation et d’entretien correctes de ce

chargeur de batterie-de´marrage moteur. Respecter

cette re`gle pour e´viter tout risque de blessures ou de

de´gaˆts mate´riels. Il se peut que ce livret et les

autocollants de se´curite´du chargeur de

batterie-de´marrage moteur soient disponibles dans

d’autres langues. (Consulter le concessionnaire John

Deere pour les commander.)

CE LIVRET DOIT EˆTRE CONSIDE´RE´comme faisant

partie inte´grante du chargeur de batterie-de´marrage

moteur et doit l’accompagner lors de sa revente.

LES MESURES donne´es dans cette publication sont

exprime´es en unite´sme´triques et leurs e´quivalents US

habituels. N’utiliser que les pie`ces de rechange et les

e´le´ments de fixation approprie´s.

INSCRIRE LES COORDONNE´ES DU PRODUIT a`la

section "Caracte´ristiques". Noter correctement tous les

nume´ros afin de faciliter les recherches en cas de vol.

Les communiquer e´galement au distributeur lors de

toute commande de pie`ces. Conserver les

coordonne´es du produit dans un endroit suˆr.

LA GARANTIE fait partie du programme de soutien

offert par John Deere aux clients qui utilisent et

entretiennent leur e´quipement de la fac¸on de´crite dans

ce livret. La garantie est stipule´ea`la section

"Garantie" a`la fin de ce manuel.

OURGP12,0000105 –28–01JUN04–1/2

Cette garantie fournit l’assurance que John Deere se

portera garant de ses produits si des de´fauts apparaissent

durant la pe´riode de garantie. Dans certains cas, John

Deere apporte aussi des ame´liorations sur le terrain,

souvent sans frais pour le client, meˆme si le produit n’est

plus sous garantie. Si le mate´riel est maltraite´ou modifie

´

pour changer ses performances au-dela`des spe´cifications

d’origine, la garantie est annule´e et les ame´liorations sur

le terrain peuvent eˆtre refuse´es.

Chargeur de batterie-de´marrage moteur TY25862

TYB4754 –UN–07SEP04

OURGP12,0000105 –28–01JUN04–2/2

092704

PN=2

Page 39

Table des matie`res

Page

Se´curite´...............................05-1

Instructions d’assemblage

Pie`ces d’assemblage .....................10-1

Outils d’assemblage ......................10-1

Proce´dure d’assemblage ..................10-1

Commandes et fonctionnement

Pre´paration de la batterie ..................15-1

Positionnement du chargeur de batterie .......15-1

Ve´rification de l’e´tat de charge de la batterie . . . 15-2

Calcul de la capacite´nominale de re´serve

d’une batterie .........................15-2

Estimation du temps de charge de la batterie. . . 15-3

Activation et charge d’une batterie se`che......15-4

Mise a`l’essai d’une batterie installe´e dans

un ve´hicule ...........................15-5

Mise a`l’essai d’une batterie hors du ve´hicule . . 15-7

Charge d’une batterie installe´e dans un

ve´hicule .............................15-8

Charge d’une batterie hors du ve´hicule ......15-11

De´marrage du moteur ...................15-14

De´pannage

De´pannage du chargeur de batterie ..........20-1

Rangement

Rangement du chargeur de

batterie-de´marrage moteur ...............25-1

Caracte´ristiques

Caracte´ristiques du chargeur de

batterie-de´marrage moteur ...............30-1

Enregistrement des coordonne´es du produit....30-1

Garantie

Garantie ...............................35-1

Toutes les informations, illustrations et caracte´ristiques contenues dans la

pre´sente publication sont a`jour au moment de la publication, le

constructeur se re´servant le droit d’apporter sans notification toute

modification juge´e approprie´e.

COPYRIGHT2004

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTIONManual

i

All rights reserved

092704

PN=1

Page 40

Table des matie`res

ii

092704

PN=2

Page 41

Se´curite

Identification des symboles de mise en garde

Voici le symbole de mise en garde. Il apparaıˆt sur la

machine ou dans la pre´sente publication pour pre´venir

d’un risque potentiel de blessure.

Respecter tous les conseils de se´curite´ainsi que les

consignes ge´ne´rales de pre´vention des accidents.

´

Compre´hension des termes de mise en

garde

Le symbole de mise en garde est accompagne´d’un

terme, tel que DANGER, AVERTISSEMENT ou

ATTENTION. Le terme DANGER signale les dangers les

plus graves.

Les affichettes de se´curite´avec DANGER ou

AVERTISSEMENT signalent des dangers spe´cifiques. Les

affichettes de se´curite´intitule´es ATTENTION de´crivent

des pre´cautions d’ordre ge´ne´ral. Le terme ATTENTION

fait e´galement re´fe´rence aux messages de se´curite´de ce

livret.

DX,ALERT –28–29SEP98–1/1

T81389 –UN–07DEC88

TS187 –28–30SEP88

DX,SIGNAL –28–03MAR93–1/1

05-1

092704

PN=5

Page 42

Se´curite

´

Respect des consignes de se´curite

´

Lire attentivement tous les messages de se´curite´dans ce

livret et sur les affichettes de se´curite´appose´es sur la

machine. Maintenir les affichettes de se´curite´en bon e´tat.

Remplacer les affichettes de se´curite´manquantes ou

endommage´es. S’assurer que l’e´quipement neuf et les

pie`ces de rechange comportent les affichettes de se´curite

les plus re´centes. Des affichettes de se´curite´de rechange

sont disponibles aupre`s du concessionnaire John Deere.

Apprendre la fac¸on correcte de faire fonctionner la

machine et d’en utiliser les commandes. Ne laisser

personne se servir de la machine sans instructions.

Maintenir la machine en bon e´tat de marche. Les

modifications non autorise´es de la machine risquent d’en

alte´rer le fonctionnement et/ ou la se´curite´et d’en

raccourcir la vie utile.

Si une partie quelconque de ce livret ne semble pas

compre´hensible, contacter le concessionnaire John Deere

qui fournira les explications ne´cessaires.

´

TS201 –UN–23AUG88

Pre´vention d’explosion des batteries

Tenir les e´tincelles et les flammes vives a`l’e´cart de la

partie supe´rieure de la batterie. Les gaz de´gage´s par la

batterie peuvent exploser.

Ne jamais ve´rifier la charge d’une batterie en plac¸ant un

objet me´tallique entre les bornes. Utiliser un voltme`tre ou

un hydrome`tre.

Ne pas charger une batterie gele´e sous peine d’explosion.

Chauffer la batterie a`16 °C (60 °F).

DX,READ –28–03MAR93–1/1

TS204 –UN–23AUG88

DX,SPARKS –28–03MAR93–1/1

05-2

092704

PN=6

Page 43

Se´curite

Pre´vention des bruˆlures d’acide

L’acide sulfurique contenu dans l’e´lectrolyte des batteries

est toxique. Il est suffisamment concentre´pour bruˆler la

peau, trouer les veˆtements et causer la ce´cite´en cas de

contact avec les yeux.

Pour e´viter ces risques:

1. Remplir les batteries dans un endroit bien ventile´.

2. Porter des lunettes de protection et des gants en

caoutchouc.

3. E´viter de respirer les vapeurs quand de l’e´lectrolyte est

ajoute´.

4. E´viter de re´pandre et de laisser goutter l’e´lectrolyte.

5. Utiliser la proce´dure correcte de de´marrage a`l’aide de

caˆbles volants.

En cas de contact avec l’acide:

1. Rincer la partie atteinte avec de l’eau.

2. Appliquer du bicarbonate de soude ou de la chaux

e´teinte sur l’endroit touche´pour neutraliser l’acide.

3. Se rincer les yeux a`l’eau pendant 15 a`30 minutes.

Consulter imme´diatement un me´decin.

En cas d’ingestion d’acide:

´

TS203 –UN–23AUG88

1. Ne pas provoquer le vomissement.

2. Boire de grandes quantite´s d’eau ou de lait sans

exce´der2l(2quarts).

3. Consulter imme´diatement un me´decin.

Veˆtements de protection

Porter des veˆtements ajuste´setl’e´quipement de se´curite

convenant au travail.

La se´curite´de l’utilisation de l’e´quipement exige toute

l’attention de l’ope´rateur. Ne pas porter d’e´couteurs lors

de l’utilisation de la machine.

DX,POISON –28–21APR93–1/1

´

TS206 –UN–23AUG88

DX,WEAR2 –28–03MAR93–1/1

05-3

092704

PN=7

Page 44

Se´curite

Se´curite´de la manipulation des produits

chimiques

L’exposition directe aux produits chimiques dangereux

peut causer de graves blessures. Dans les mate´riels John

Deere, certains produits chimiques, tels que lubrifiants,

liquides de refroidissement, peintures et adhe´sifs, entrent

dans cette cate´gorie.

Une fiche signale´tique offre des de´tails spe´cifiques

concernant les produits chimiques: Les dangers pose´s

aux biens et a`la sante´, les proce´dures de se´curite´et les

techniques de re´ponse de secours.

Consulter la fiche signale´tique avant d’entreprendre tout

travail exigeant l’usage d’un produit chimique dangereux.

Ceci permet de savoir exactement quels sont les risques

et les mesures a`prendre pour exe´cuter la taˆche en toute

se´curite´. Suivre ensuite les proce´dures et le mate´riel

recommande´.

(Consulter le concessionnaire John Deere pour obtenir les

fiches signale´tiques concernant les produits chimiques

utilise´s avec le mate´riel John Deere.)

´

TS1132 –UN–26NOV90

E´limination correcte des de´chets

L’e´limination incorrecte des de´chets peut nuire a

l’environnement. Dans les mate´riels John Deere, certains

liquides ou e´le´ments tels que huile, combustible, liquides

de refroidissement et de frein, filtres et batteries peuvent

eˆtre source de pollution apre`s leur e´limination.

Recueillir a`la vidange les liquides dans des re´cipients

e´tanches. Ne pas utiliser de re´cipients pour aliments ou

boissons qui pourraient eˆtre utilise´s par me´garde pour

boire ou manger.

Ne pas de´verser de de´chets sur le sol, dans un e´gout ni

dans une source d’eau quelconque.

Les re´frige´rants utilise´s dans les circuits de climatisation

sont nuisibles a`l’atmosphe`re s’ils sont rejete´s dans l’air.

Les re´glementations gouvernementales peuvent exiger

que les re´frige´rants soient re´cupe´re´s et recycle´s par un

centre de recyclage agre´e´.

`

DX,MSDS,NA –28–03MAR93–1/1

TS1133 –UN–26NOV90

Recyclage des de´chets

Se renseigner aupre`s des autorite´s environnementales, du

centre de recyclage local, ou du concessionnaire John

Deere pour les me´thodes de recyclage ou de mise au

rebut approprie´es.

05-4

DX,DRAIN –28–03MAR93–1/1

092704

PN=8

Page 45

Se´curite

´

CONSIGNES DE SE´CURITE´IMPORTANTES A`CONSERVER

ATTENTION: RISQUES DE GAZ EXPLOSIFS.

Il est dangereux de travailler a`proximite´de

batteries au plomb-acide. Les batteries

produisent des gaz explosifs durant leur

fonctionnement normal. Lire ce manuel et

suivre les instructions a`la lettre CHAQUE

FOIS que ce chargeur de batterie est

employe´.

Pour re´duire le risque d’explosion de la

batterie, suivre ces instructions ainsi que les

consignes publie´es par le fabricant de la

batterie. Passer en revue les indications

figurant a`meˆme la batterie, le chargeur de

batterie et le compartiment moteur.

AVERTISSEMENT: Ilae´te´porte´a`la connaissance

de l’E´tat de Californie le fait que le plomb et ses

compose´s qui se trouvent dans les bornes de batterie

ainsi que dans les accessoires connexes sont une

cause de cancer et de complications pre´judiciables a

`

l’appareil reproductif. Se laver les mains apre`s avoir

touche´a`ces pie`ces.

1. CONSERVER CES CONSIGNES. Le pre´sent

manuel contient d’importantes consignes sur la

se´curite´et l’utilisation du chargeur de batterie. Lire

et comprendre ce manuel avant d’utiliser le

chargeur.

2. Pour re´duire le risque d’e´lectrocution, ne pas utiliser

le chargeur de batterie lorsque l’unite´est en contact

avec de l’eau. Ne pas exposer le chargeur a`la

pluie ou la neige.

3. L’emploi d’un accessoire non recommande´ou autre

que vendu par le fabricant du chargeur de batterie

peut causer un risque d’incendie, d’e´lectrocution ou

de blessure.

4. De´brancher le chargeur de batterie en tirant sur la

fiche et non pas sur le cordon pour e´viter

d’endommager ces composants.

5. Il est de´conseille´d’utiliser une rallonge e´lectrique.

L’emploi d’une rallonge inapproprie´e peut eˆtre la

cause d’un incendie ou d’une e´lectrocution. Si une

rallonge doit eˆtre employe´e, elle doit remplir les

conditions suivantes:

a. la fiche de la rallonge et celle du chargeur

posse`dent le meˆme nombre de broches, de la

meˆme taille et de la meˆme forme;

b. la rallonge est correctement caˆble´eetenbon

e´tat du point de vue e´lectrique;

c. le calibre du caˆble est suffisant pour la longueur

du cordon, compte tenu de l’intensite´nominale

du chargeur de batterie spe´cifie´e ci-dessous.

Longueur du cordon 25 50 100 150

(Ft.)

Calibre AWG du 16 14 10 8

cordon

6. Ne jamais modifier le cordon c.a. ou la fiche de

mise a`la terre fournie. Si un adaptateur temporaire

doit eˆtre employe´pour brancher le chargeur de

batterie dans une prise a`deux poˆles, relier la prise

de terre de l’adaptateur a`une prise de courant a

`

contact de mise a`la terre par l’interme´diaire de la

vis centrale de la plaque de la prise. S’assurer que

la vis centrale de la plaque de la prise est mise a`la

terre.

7. Placer le cordon e´lectrique de la batterie de fac¸on a

e´viter que l’on puisse marcher dessus ou se

prendre les pieds dedans, ou que quelque chose

l’abıˆme. Ne pas se servir du chargeur de batterie si

son cordon ou sa fiche est endommage´(e).

Remplacer imme´diatement le cordon ou la fiche.

8. Ne pas se servir du chargeur de batterie s’il a e´te

´

fortement heurte´, s’il est tombe´ou s’il a subi tout

autre de´gaˆt. Le faire re´viser par un re´parateur

qualifie´.

9. Ne pas de´sassembler le chargeur de batterie.

Confier toute intervention ou re´paration ne´cessaire

sur le chargeur a`un re´parateur qualifie´.Un

assemblage incorrect peut causer une e´lectrocution

ou un incendie.

10. Pour re´duire le risque de chocs e´lectriques,

de´brancher le chargeur de batterie au niveau de la

prise avant d’intervenir dessus pour un entretien

ou nettoyage.

`

05-5

OURGP12,000010D –28–02JUN04–1/1

092704

PN=9

Page 46

Pre´cautions personnelles

Se´curite

´

1. Porter des lunettes de protection enveloppantes et

des veˆtements protecteurs. E´viter de se toucher les

yeux lorsque l’on travaille pre`s de batteries.

2. Disposer d’eau fraıˆche en abondance et de savon a

proximite´au cas ou`l’acide de la batterie entrerait

en contact avec la peau, les veˆtements ou les yeux.

3. Se tenir a`porte´e de voix ou a`proximite´physique

de quelqu’un lorsque l’on travaille pre`s d’une

batterie au plomb-acide, en cas d’urgence.

4. Si l’acide de batterie entre en contact avec la peau

ou un veˆtement, laver imme´diatement au savon et

a`l’eau. En cas de pe´ne´tration de l’acide dans les

yeux, se rincer imme´diatement et abondamment a

`

l’eau froide courante pendant 15 a`30 minutes puis

tout de suite consulter un me´decin.

5. Les batteries de´gagent des gaz explosifs! NE

JAMAIS fumer a`proximite´d’une batterie ou d’un

moteur, ni en approcher une e´tincelle ou flamme

nue. Toujours utiliser un chargeur de batterie dans

un endroit ouvert et bien ventile´.

court-circuit dans la batterie ou sur une autre pie`ce

e´lectrique, ce qui pourrait provoquer une explosion.

7. Enlever les articles personnels en me´tal tels que

`

bagues, bracelets, colliers et montres lors du travail

a`proximite´d’une batterie au plomb-acide.

8. N’utiliser le chargeur que sur des batteries au

PLOMB-ACIDE. Le chargeur n’est pas fait pour

fournir de la tension a`un circuit e´lectrique a`basse

tension autre que celui d’un de´marreur. Ne pas se

servir du chargeur sur des batteries a`anode se`che

du type couramment employe´dans les appareils

me´nagers. Ces batteries risqueraient d’e´clater et de

causer des blessures ou des de´gaˆts mate´riels.

9. NE JAMAIS charger une batterie gele´e.

10. Ne jamais laisser tomber de l’acide sur le

chargeur lorsque l’on rele`ve la densite´ou que l’on

remplit la batterie.

11. Ne jamais poser la batterie sur le chargeur.

6. Ne rien faire tomber de me´tallique sur la batterie.

Cela risquerait de causer une e´tincelle ou un

Pre´cautions de raccordement du chargeur de batterie

ATTENTION: Brancher et de´brancher les

pinces c.c. seulement apre`s avoir de´branche

le cordon c.a. de la prise e´lectrique.

Ne jamais laisser les pinces du chargeur de

batterie se toucher.

Ne pas connecter les deux pinces du

chargeur a`meˆme la batterie.

1. Placer le chargeur aussi loin de la batterie que les

caˆbles le permettent.

´

2. Pour le raccordement du chargeur, relier une pince

a`la batterie et l’autre a`un point de mise a`la terre

e´loigne´de la batterie.

3. Avant de raccorder le chargeur de batterie, lire la

section "Commandes et fonctionnement".

4. Imprimer plusieurs mouvements de va-et-vient ou

de torsion a`chaque pince branche´e pour s’assurer

de son bon contact. Ne plus bouger la premie`re

pince une fois la deuxie`me mise en place.

OURGP12,000010C –28–02JUN04–1/1

05-6

OURGP12,000010E –28–02JUN04–1/1

092704

PN=10

Page 47

Se´curite

´

Autocollant de se´curite

´

Emplacement de l’autocollant de se´curite

Autocollant de se´curite

´

´

TYB4740 –UN–08SEP04

TYB4740A –UN–08SEP04

NOTE: L’autocollant de se´curite´(A) se situe au dos

du boıˆtier du chargeur de batterie-de´marrage

moteur.

05-7

OURGP12,000010F –28–02JUN04–1/1

092704

PN=11

Page 48

Instructions d’assemblage

Pie`ces d’assemblage

ATTENTION: Avant d’utiliser le chargeur, les

roues doivent eˆtre mises en place pour assurer

une ventilation ade´quate et satisfaire les

exigences minimum UL de garde au sol en ce

qui concerne les composants faisant jaillir des

e´tincelles.

Les pie`ces suivantes sont fournies pour l’assemblage.

• (2) vis 10-32

• (2) vis 1/4-20

• (2) roues

• (2) chapeaux d’essieu

• (2) supports d’essieu

• (1) essieu

• (1) pied de fixation

• (1) poigne´e

Outils d’assemblage

OUOD006,0000119 –28–03JUN04–1/1

Il est sugge´re´de disposer des outils suivants pour

l’assemblage.

• Cle´5/16 in.

• Cle´3/8 in.

• Marteau

• Tournevis

Proce´dure d’assemblage

1. Placer le chargeur de batterie-de´marrage moteur sur

son flanc.

2. Poser le pied de fixation (A) a`l’aide des deux vis

1/4-20.

A—Pied de fixation

OUOD006,000011A –28–03JUN04–1/1

Suite voir page suivante

10-1

Pose du pied de fixation

TYB4746 –UN–08SEP04

OUOD006,000011B –28–03JUN04–1/6

092704

PN=12

Page 49

Instructions d’assemblage

3. Introduire l’extre´mite´de chaque support d’essieu (B)

dans la fente et fixer le support avec une vis 10-32.

B—Support d’essieu

4. Faire rentrer l’essieu dans son chapeau (C) a`l’aide

d’un marteau.

5. Enfiler une roue (D) sur l’essieu, comme illustre´.

C—Chapeau d’essieu

D—Roue

Pose des supports d’essieu

TYB4747 –UN–08SEP04

OUOD006,000011B –28–03JUN04–2/6

TYB4748 –UN–08SEP04

Installation de la roue sur l’essieu

Suite voir page suivante

10-2

OUOD006,000011B –28–03JUN04–3/6

092704

PN=13

Page 50

Instructions d’assemblage

6. Faire entrer l’essieu (E) dans ses deux supports.

E—Essieu

7. Retourner le chargeur du coˆte´oppose´.

8. Enfiler l’autre roue sur l’essieu comme indique´et

enfoncer le chapeau d’essieu (F) avec un marteau.

F—Chapeau d’essieu

Suite voir page suivante

Installation de l’essieu

TYB4749 –UN–08SEP04

OUOD006,000011B –28–03JUN04–4/6

TYB4750 –UN–08SEP04

Pose de la roue

OUOD006,000011B –28–03JUN04–5/6

10-3

092704

PN=14

Page 51

Instructions d’assemblage

9. Positionner le chargeur sur ses roues et son pied de

fixation.

10. Enlever les deux vis supe´rieures (G) de chaque coˆte

du chargeur. Orienter la poigne´e (H) comme indique

et remettre les vis (G) en place.

G—Vis

H—Poigne´e

´

´

TYB4751 –UN–08SEP04

Pose de la poigne´e

OUOD006,000011B –28–03JUN04–6/6

10-4

092704

PN=15

Page 52

Commandes et fonctionnement

Pre´paration de la batterie

ATTENTION: Une batterie-marine (pour

bateau) doit eˆtre sortie et charge´ea`terre. Il

faudrait pour la charger a`bord un mate´riel

spe´cial pour usage marin.

1. La batterie doit eˆtre du type plomb-acide 6 ou 12

volts.

2. S’assurer que tous les accessoires du ve´hicule sont

a`l’arreˆt.

3. Si la batterie doit eˆtre sortie du ve´hicule pour eˆtre

charge´e, toujours retirer d’abord la borne de terre

de la batterie.

4. S’assurer que la batterie se trouve dans un endroit

bien ventile´. Les gaz peuvent eˆtre disperse´sa`l’aide

Positionnement du chargeur de batterie

ATTENTION: Risque d’explosion. Les gaz

de´gage´s par la batterie durant la charge

peuvent exploser. Ventiler l’endroit. Tenir a

l’e´cart des e´tincelles et flammes.

`

d’un morceau de carton ou autre mate´riau non

me´tallique faisant office d’e´ventail.

5. E´tudier les consignes particulie`res du fabricant de

la batterie, concernant notamment le retrait ou non

des cache-e´le´ment pour la charge et le re´gime de

charge recommande´.

6. Dans le cas des batteries avec bouchons a`e´vent

qui se retirent, verser de l’eau distille´e dans chaque

e´le´ment jusqu’a`ce que l’acide de batterie arrive au

niveau prescrit par le fabricant. E´viter de trop

remplir.

7. Nettoyer les bornes de la batterie.

OUOD006,000000E –28–15JUN04–1/1

1. Placer le chargeur dans un endroit propre, sec et bien

ventile´, aussi loin de la batterie que les caˆbles le

permettent.

2. Ne jamais placer le chargeur juste au-dessus de la

batterie a`charger. Les gaz e´manant de la batterie

causeraient corrosion et de´gaˆts au chargeur.

3. Ne jamais laisser tomber de l’acide sur le chargeur

lorsque l’on rele`ve la densite´ou que l’on remplit la

batterie.

4. Ne pas faire fonctionner le chargeur dans un endroit

ferme´ni perturber la ventilation d’une manie`re

quelconque.

5. Ne pas poser la batterie sur le chargeur ou vice-versa.

Risque d’explosion de la batterie

TS204 –UN–23AUG88

OUOD006,0000079 –28–14SEP04–1/1

15-1

092704

PN=16

Page 53

Commandes et fonctionnement

Ve´rification de l’e´tat de charge de la batterie

Se servir d’un voltme`tre ou hydrome`tre (A) pour

de´terminer l’e´tat de charge. Consulter le taux de charge

dans le tableau.

Releve´du voltme`tre Releve´de Releve´du testeur

Batterie 12 V* Densite

12,4 ou plus 1,265 100 %

12,39 a`12,25 1,225 75 %

12,24 a`12,10 1,190 50 %

12,09 a`11,96 1,155 25 %

11,95 a`0 1,120 0 %

l’hydrome`tre de batterie

´

Taux de charge

* Les re´sultats au voltme`tre d’une batterie 6 volts sont la

moitie´de ceux indique´s pour une batterie 12 volts.

ATTENTION: NE PAS tenter de charger une

batterie gele´e.

A—Hydrome`tre

NOTE: Toute batterie n’ayant plus que 25 % de charge

ou moins risque de geler et devrait

imme´diatement eˆtre recharge´e.

Calcul de la capacite´nominale de re´serve d’une batterie

Ve´rification de l’e´tat de charge

TYK275 –UN–08OCT96

OUOD006,0000057 –28–17AUG04–1/1

Tailles de groupes Automobile, LGC, 3ET, 47, 48, 49 31, 30H 1, 2 5D, 4 4D, 3EH, 8D

types etc.

Capacite´nominale 80 ou moins 81-125 126-180 181-260 261 ou plus

de re´serve

Le temps requis pour charger une batterie a`plein

de´pend de sa capacite´e´lectrique et de son e´tat de