Page 1

JOHN DEERE

WORLDWIDE COMMERCIAL & CONSUMER

EQUIPMENT DIVISION

2160

January 2004

Trail Buck Utility ATV

500, 650, 650EX and 650EXT

TM2160 JANUARY 2004

TECHNICAL MANUAL

North American Version

Litho in U.S.A.

Page 2

Page 3

INTRODUCTION

Introduction

Manual Description

This technical manual is written for an experienced

technician and contains sections that are specifically for

this product. It is a part of a total product support program.

The manual is organized so that all the information on a

particular system is kept together. The order of grouping is

as follows:

• Table of Contents

• Specifications and Information

• Identification Numbers

• Tools and Materials

• Component Location

• Schematics and Harnesses

• Theory of Operation

• Operation and Diagnostics

• Diagnostics

• Tests and Adjustments

• Repair

• Other

Safety

Technical Data

Engine

Electrical

Drive Train

Steering

Suspension

NOTE: Depending on the particular section or system

being covered, not all of the above groups may be

used.

The bleed tabs for the pages of each section will align with

the sections listed on this page. Page numbering is

consecutive from the beginning of the Safety section

through the last section.

We appreciate your input on this manual. If you find any

errors or want to comment on the layout of the manual

please contact us.

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

notice.

COPYRIGHT© 2004

Deere & Co.

John Deere Worldwide Commercial and

Consumer Equipment Division

All rights reserved

Previous Editions

COPYRIGHT©

Brakes

Body / Frame

Introduction

Page 4

INTRODUCTION

Introduction - 4

Page 5

SAFETY

Safety

Recognize Safety Information

MIF

This is the safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe servicing

practices.

Understand Signal Words

A signal word - DANGER, WARNING, or CAUTION - is

used with the safety-alert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

Replace Safety Signs

Handle Fluids Safely - Avoid Fires

Be Prepared For Emergencies

MIF

• When you work around fuel, do not smoke or work near

heaters or other fire hazards.

• Store flammable fluids away from fire hazards. Do not

incinerate or puncture pressurized containers.

• Make sure machine is clean of trash, grease, and

debris.

• Do not store oily rags; they can ignite and burn

spontaneously.

• Be prepared if a fire starts.

• Keep a first aid kit and fire extinguisher handy.

• Keep emergency numbers for doctors, ambulance

service, hospital, and fire department near your telephone.

Replace missing or damaged safety signs. See the

machine operator’s manual for correct safety sign

placement.

Use Care In Handling and Servicing Batteries

MIF

MIF

Safety - 1

Page 6

SAFETY

Prevent Battery Explosions

• Keep sparks, lighted matches, and open flame away

from the top of battery. Battery gas can explode.

• Never check battery charge by placing a metal object

across the posts. Use a volt-meter or hydrometer.

• Do not charge a frozen battery; it may explode. Warm

battery to 16°C (60°F).

Prevent Acid Burns

• Sulfuric acid in battery electrolyte is poisonous. It is

strong enough to burn skin, eat holes in clothing, and

cause blindness if splashed into eyes.

Avoid acid burns by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is added.

4. Avoiding spilling or dripping electrolyte.

5. Use proper jump start procedure.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize the acid.

3. Flush your eyes with water for 10 - 15 minutes.

4. Get medical attention immediately.

If acid is swallowed:

1. Drink large amounts of water or milk.

2. Then drink milk of magnesia, beaten eggs, or vegetable

oil.

3. Get medical attention immediately.

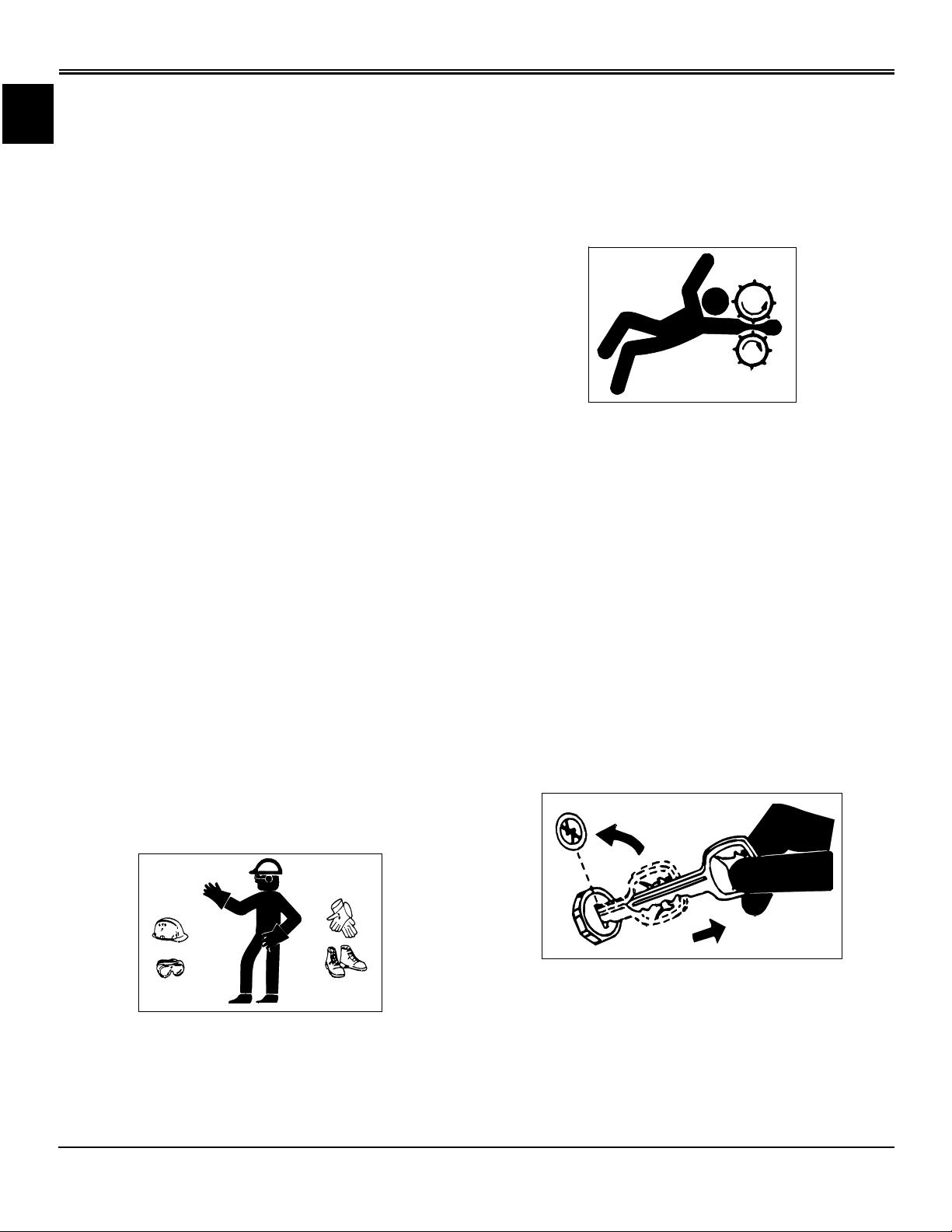

such as earmuffs or earplugs to protect against

objectionable or uncomfortable loud noises.

Operating equipment safely requires the full attention of the

operator. Do not wear radio or music headphones while

operating machine.

Service Machines Safely

MIF

Tie long hair behind your head. Do not wear a necktie,

scarf, loose clothing, or necklace when you work near

machine tools or moving parts. If these items were to get

caught, severe injury could result.

Remove rings and other jewelry to prevent electrical shorts

and entanglement in moving parts.

Use Proper Tools

Use tools appropriate to the work. Makeshift tools and

procedures can create safety hazards. Use power tools

only to loosen threaded parts and fasteners. For loosening

and tightening hardware, use the correct size tools. DO

NOT use U.S. measurement tools on metric fasteners.

Avoid bodily injury caused by slipping wrenches. Use only

service parts meeting John Deere specifications.

Park Machine Safely

Wear Protective Clothing

MIF

Wear close fitting clothing and safety equipment

appropriate to the job.

Prolonged exposure to loud noise can cause impairment or

loss of hearing. Wear a suitable hearing protective device

Safety - 2

MIF

Before working on the machine:

1. Lower all equipment to the ground.

2. Stop the engine and remove the key.

3. Disconnect the battery ground strap.

4. Hang a “DO NOT OPERATE” tag in operator station.

Page 7

SAFETY

Support Machine Properly and Use Proper

Lifting Equipment

MIF

If you must work on a lifted machine or attachment,

securely support the machine or attachment.

Do not support the machine on cinder blocks, hollow tiles,

or props that may crumble under continuous load. Do not

work under a machine that is supported solely by a jack.

Follow recommended procedures in this manual.

Lifting heavy components incorrectly can cause severe

injury or machine damage. Follow recommended

procedure for removal and installation of components in the

manual.

Work In Clean Area

Before starting a job:

1. Clean work area and machine.

Work In Ventilated Area

MIF

Engine exhaust fumes can cause sickness or death. If it is

necessary to run an engine in an enclosed area, remove

the exhaust fumes from the area with an exhaust pipe

extension.

If you do not have an exhaust pipe extension, open the

doors and get outside air into the area.

Warning: California Proposition 65 Warning

Gasoline engine exhaust from this product contains

chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Remove Paint Before Welding or Heating

2. Make sure you have all necessary tools to do your job.

3. Have the right parts on hand.

4. Read all instructions thoroughly; do not attempt

shortcuts.

Using High Pressure Washers

Directing pressurized water at electronic/electrical

components or connectors, bearings, hydraulic seals, fuel

injection pumps or other sensitive parts and components

may cause product malfunctions. Reduce pressure and

spray at a 45 to 90 degree angle.

Illuminate Work Area Safely

Illuminate your work area adequately but safely. Use a

portable safety light for working inside or under the

machine. Make sure the bulb is enclosed by a wire cage.

The hot filament of an accidentally broken bulb can ignite

spilled fuel or oil.

Avoid potentially toxic fumes and dust. Hazardous fumes

can be generated when paint is heated by welding,

soldering, or using a torch. Do all work outside or in a well

ventilated area. Dispose of paint and solvent properly.

Remove paint before welding or heating: If you sand or

grind paint, avoid breathing the dust. Wear an approved

respirator. If you use solvent or paint stripper, remove

stripper with soap and water before welding. Remove

solvent or paint stripper containers and other flammable

material from area. Allow fumes to disperse at least 15

minutes before welding or heating.

Service Tires Safely

MIF

Explosive separation of a tire and rim parts can cause

serious injury or death.

Do not attempt to mount a tire unless you have the proper

equipment and experience to perform the job.

Always maintain the correct tire pressure. Do not inflate the

tires above the recommended pressure. Never weld or heat

a wheel and tire assembly. The heat can cause an increase

in air pressure resulting in a tire explosion. Welding can

Safety - 3

Page 8

SAFETY

structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and extension

hose long enough to allow you to stand to one side and

NOT in front of or over the tire assembly. Use a safety cage

if available.

Check wheels for low pressure, cuts, bubbles, damaged

rims or missing lug bolts and nuts.

Service Cooling System Safely

Direct exposure to hazardous chemicals can cause serious

injury. Potentially hazardous chemicals used with John

Deere equipment include such items as lubricants,

coolants, paints, and adhesives.

A Material Safety Data Sheet (MSDS) provides specific

details on chemical products: physical and health hazards,

safety procedures, and emergency response techniques.

Check the MSDS before you start any job using a

hazardous chemical. That way you will know exactly what

the risks are and how to do the job safely. Then follow

procedures and recommended equipment.

Dispose of Waste Properly

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful waste used

with John Deere equipment include such items as oil, fuel,

coolant, brake fluid, filters, and batteries. Use leakproof

containers when draining fluids. Do not use food or

beverage containers that may mislead someone into

drinking from them. Do not pour waste onto the ground,

down a drain, or into any water source. Inquire on the

proper way to recycle or dispose of waste from your local

environmental or recycling center, or from your John Deere

dealer.

MIF

Explosive release of fluids from pressurized cooling system

can cause serious burns.

Shut off machine. Only remove filler cap when cool enough

to touch with bare hands. Slowly loosen cap to first stop to

relieve pressure before removing completely.

Handle Chemical Products Safely

Live With Safety

MIF

Before returning machine to customer, make sure machine

is functioning properly, especially the safety systems. Install

all guards and shields.

MIF

Safety - 4

Page 9

SPECIFICATIONS TABLE OF CONTENTS

Specifications

Table of Contents

Fastener Torques..............................................7

Metric Fastener Torque Values ......................7

Inch Fastener Torque Values .........................8

General Information..........................................9

Gasoline .........................................................9

Gasoline Storage............................................9

4 - Cycle Gasoline Engine Oil ......................10

Break-In Engine Oil - 4-Cycle Gasoline........10

Hydrostatic Transmission and Hydraulic Oil.11

Gear Case Oil...............................................12

Gear Transmission Grease ..........................12

Alternative Lubricants...................................12

Synthetic Lubricants .....................................13

Lubricant Storage .........................................13

Mixing of Lubricants .....................................13

Oil Filters ......................................................13

Coolant Specifications...................................13

Gasoline Engine Coolant..............................13

Gasoline Engine Coolant Drain Interval .......14

Specifications - Trail Buck.............................15

Engine Specifications - 500..........................15

Engine Specifications - 650..........................15

Engine Specifications - 500 and 650............15

Electrical Specifications................................18

Carburation Specifications ...........................19

Cooling Specifications ..................................19

Drive Train Specifications.............................20

Steering Control Specifications ....................20

Suspension Specifications ...........................20

Brakes Specifications...................................20

Tires and Wheels Specifications ..................21

Dimension Specifications .............................21

Capacities Specifications .............................21

Torque Specifications...................................22

Specifications Table of Contents - 5

Page 10

SPECIFICATIONS TABLE OF CONTENTS

Specifications Table of Contents - 6

Page 11

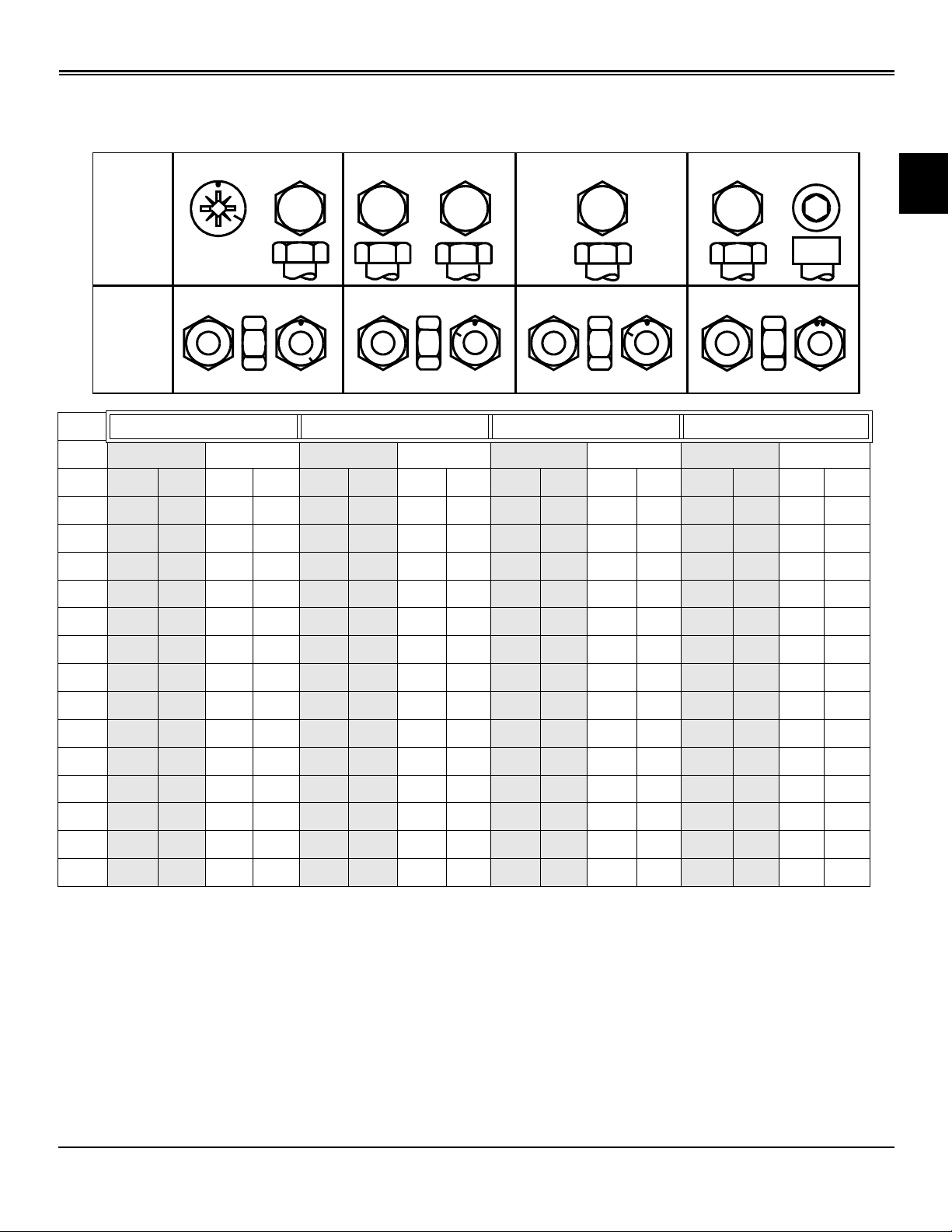

SPECIFICATIONS FASTENER TORQUES

Fastener Torques

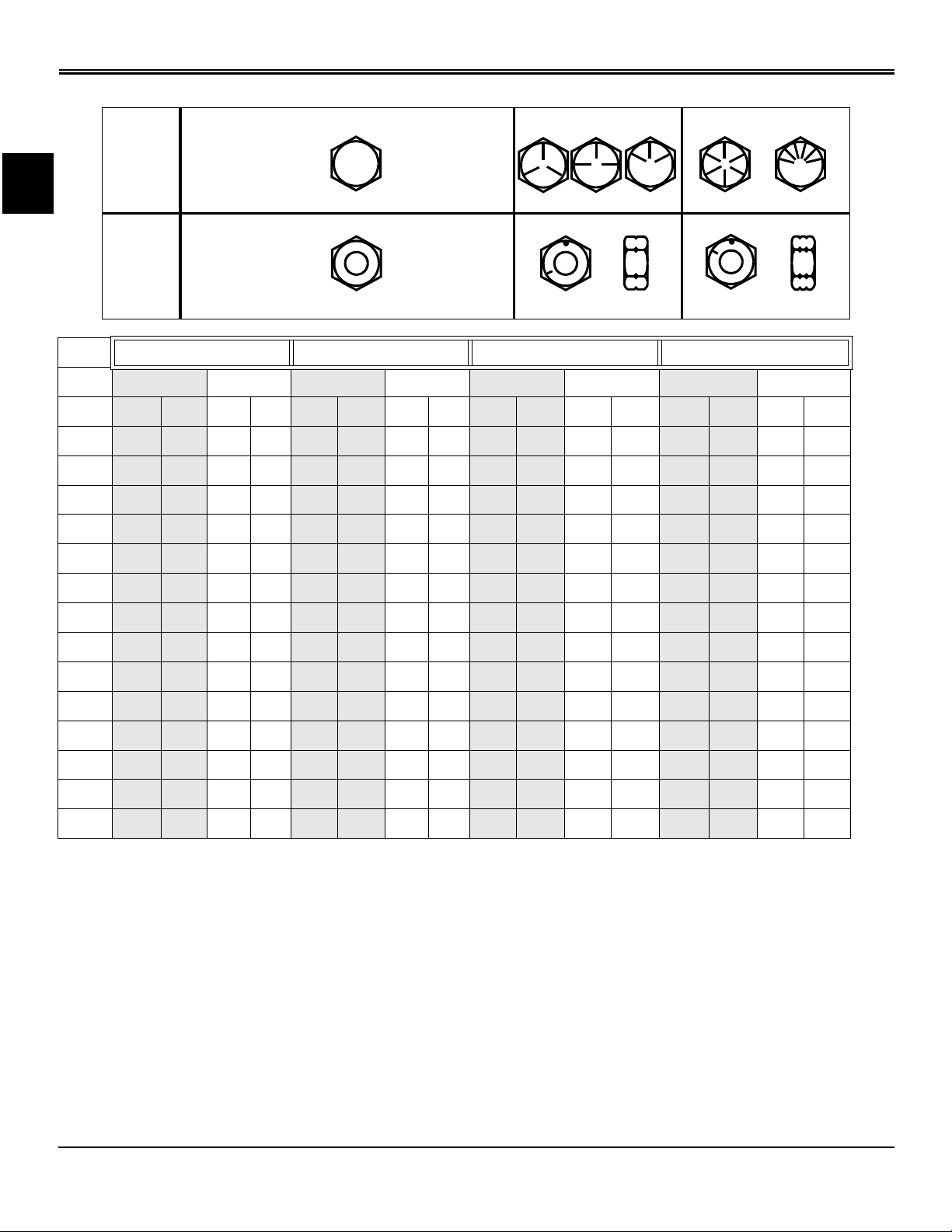

Metric Fastener Torque Values

4.8

Property

Class

and

Head

Markings

4.8

4.8

8.8

8.8

8.8

9.8

9.8

9.8

10.9

10.9

10.9

12.9

12.9

12.9

12.9

Property

Class

and

Nut

Markings

5

5

5 10

10

MIF

10

10

10

10

12

12

12

Class 4.8 Class 8.8 or 9.8 Class 10.9 Class 12.9

Lubricated a Dry a Lubricated a Dry a Lubricated a Dry a Lubricated a Dry a

SIZE N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft

M6 4.8 3.5 6 4.5 9 6.5 11 8.5 13 9.5 17 12 15 11.5 19 14.5

M8 12 8.5 15 11 22 16 28 20 32 24 40 30 37 28 47 35

M10 23 17 29 21 43 32 55 40 63 47 80 60 75 55 95 70

M12 40 29 50 37 75 55 95 70 110 80 140 105 130 95 165 120

M14 63 47 80 60 120 88 150 110 175 130 225 165 205 150 260 109

M16 100 73 125 92 190 140 240 175 275 200 350 225 320 240 400 300

M18 135 100 175 125 260 195 330 250 375 275 475 350 440 325 560 410

M20 190 140 240 180 375 275 475 350 530 400 675 500 625 460 800 580

M22 260 190 330 250 510 375 650 475 725 540 925 675 850 625 1075 800

M24 330 250 425 310 650 475 825 600 925 675 1150 850 1075 800 1350 1000

M27 490 360 625 450 950 700 1200 875 1350 1000 1700 1250 1600 1150 2000 1500

M30 675 490 850 625 1300 950 1650 1200 1850 1350 2300 1700 2150 1600 2700 2000

M33 900 675 1150 850 1750 1300 2200 1650 2500 1850 3150 2350 2900 2150 3700 2750

M36 1150 850 1450 1075 2250 1650 2850 2100 3200 2350 4050 3000 3750 2750 4750 3500

DO NOT use these hand torque values if a different torque

value or tightening procedure is given for a specific

application. Torque values listed are for general use only

and include a ±10% variance factor. Check tightness of

fasteners periodically. DO NOT use air powered wrenches.

Shear bolts are designed to fail under predetermined loads.

Always replace shear bolts with identical grade.

Fasteners should be replaced with the same grade. Make

sure fastener threads are clean and that you properly start

thread engagement. This will prevent them from failing

when tightening.

When bolt and nut combination fasteners are used, torque

values should be applied to the NUT instead of the bolt

head.

Tighten toothed or serrated-type lock nuts to the full torque

value.

a “Lubricated” means coated with a lubricant such as

engine oil, or fasteners with phosphate and oil coatings.

“Dry” means plain or zinc plated (yellow dichromate Specification JDS117) without any lubrication.

Reference: JDS - G200.

Specifications Fastener Torques - 7

Page 12

SPECIFICATIONS FASTENER TORQUES

Inch Fastener Torque Values

SAE

Grade

and Head

Markings

No Marks

1 or 2

b

5

5.1

5.2

8

8.2

5

8

SAE

Grade

and Nut

Markings

2

No Marks

MIF

Grade 1 Grade 2b Grade 5, 5.1 or 5.2 Grade 8 or 8.2

Lubricated a Dry a Lubricated a Dry a Lubricated a Dry a Lubricated a Dry a

SIZE N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft N•m lb-ft

1/4 3.7 2.8 4.7 3.5 6 4.5 7.5 5.5 9.5 7 12 9 13.5 10 17 12.5

5/16 7.7 5.5 10 7 12 9 15 11 20 15 25 18 28 21 35 26

3/8 14 10 17 13 22 16 27 20 35 26 44 33 50 36 63 46

7/16 22 16 28 20 35 26 44 32 55 41 70 52 80 58 100 75

1/2 33 25 42 31 53 39 67 50 85 63 110 80 120 90 150 115

9/16 48 36 60 45 75 56 95 70 125 90 155 115 175 130 225 160

5/8 67 50 85 62 105 78 135 100 170 125 215 160 215 160 300 225

3/4 120 87 150 110 190 140 240 175 300 225 375 280 425 310 550 400

7/8 190 140 240 175 190 140 240 175 490 360 625 450 700 500 875 650

1 290 210 360 270 290 210 360 270 725 540 925 675 1050 750 1300 975

1-1/8 470 300 510 375 470 300 510 375 900 675 1150 850 1450 1075 1850 1350

1-1/4 570 425 725 530 570 425 725 530 1300 950 1650 1200 2050 1500 2600 1950

1-3/8 750 550 950 700 750 550 950 700 1700 1250 2150 1550 2700 2000 3400 2550

1-1/2 1000 725 1250 925 990 725 1250 930 2250 1650 2850 2100 3600 2650 4550 3350

DO NOT use these hand torque values if a different torque

value or tightening procedure is given for a specific

application. Torque values listed are for general use only

and include a ±10% variance factor. Check tightness of

fasteners periodically. DO NOT use air powered wrenches.

Shear bolts are designed to fail under predetermined loads.

Always replace shear bolts with identical grade.

Fasteners should be replaced with the same grade. Make

sure fastener threads are clean and that you properly start

thread engagement. This will prevent them from failing

when tightening.

When bolt and nut combination fasteners are used, torque

values should be applied to the NUT instead of the bolt

head.

Tighten toothed or serrated-type lock nuts to the full torque

value.

a “Lubricated” means coated with a lubricant such as

engine oil, or fasteners with phosphate and oil coatings.

“Dry” means plain or zinc plated (yellow dichromate Specification JDS117) without any lubrication.

b “Grade 2” applies for hex cap screws (Not Hex Bolts) up

to 152 mm (6 in.) long. “Grade 1” applies for hex cap

screws over 152 mm (6 in.) long, and for all other types of

bolts and screws of any length.

Reference: JDS - G200

Specifications Fastener Torques - 8

Page 13

SPECIFICATIONS GENERAL INFORMATION

General Information

Gasoline

4 - Cycle Engines

c

CAUTION: Avoid Injury! Gasoline is

HIGHLY FLAMMABLE, handle it with care.

DO NOT refuel machine while: indoors,

always fill gas tank outdoors; machine is

near an open flame or sparks; engine is

running, STOP engine; engine is hot, allow

it to cool sufficiently first; smoking.

Help prevent fires: fill gas tank to bottom of

filler neck only; be sure fill cap is tight after

fueling; clean up any gas spills

IMMEDIATELY; keep machine clean and in

good repair - free of excess grease, oil,

debris, and faulty or damaged parts; any

storage of machines with gas left in tank

should be in an area that is well ventilated

to prevent possible igniting of fumes by an

open flame or spark, this includes any

appliance with a pilot light. To prevent fire

or explosion caused by STATIC ELECTRIC

DISCHARGE during fueling:•ONLY use a

clean, approved POLYETHYLENE PLASTIC

fuel container and funnel WITHOUT any

metal screen or filter.

To avoid engine damage:

• DO NOT mix oil with gasoline;

• ONLY use clean, fresh unleaded gasoline with an

octane rating (anti-knock index) of 87 or higher;

• fill gas tank at the end of each day's operation to help

prevent condensation from forming inside a partially filled

tank;

• keep up with specified service intervals.

Use of alternative oxygenated, gasohol blended, unleaded

gasoline is acceptable as long as:

MIF

IMPORTANT: Avoid damage! California

Proposition 65 Warning: Gasoline engine

exhaust from this product contains chemicals

known to the State of California to cause cancer,

birth defects, or other reproductive harm.

Gasoline Storage

IMPORTANT: Avoid damage! Keep all dirt, scale,

water or other foreign material out of gasoline.

Keep gasoline stored in a safe, protected area. Storage of

gasoline in a clean, properly marked (“UNLEADED

GASOLINE”) POLYETHYLENE PLASTIC container

WITHOUT any metal screen or filter is recommended. DO

NOT use de-icers to attempt to remove water from gasoline

or depend on fuel filters to remove water from gasoline.

Use a water separator installed in the storage tank outlet.

BE SURE to properly discard unstable or contaminated

gasoline. When storing the machine or gasoline, it is

recommended that you add John Deere Gasoline

Conditioner and Stabilizer (TY15977) or an equivalent to

the gasoline. BE SURE to follow directions on container

and to properly discard empty container.

• the ethyl or grain alcohol blends DO NOT exceed 10%

by volume or

• methyl tertiary butyl ether (MTBE) blends DO NOT

exceed 15% by volume

RFG (reformulated) gasoline is acceptable for all machines

designed for use of regular unleaded fuel. Older machines

(that were designed for leaded fuel) may see some

accelerated valve and seat wear.

Specifications General Information - 9

Page 14

SPECIFICATIONS GENERAL INFORMATION

4 - Cycle Gasoline Engine Oil

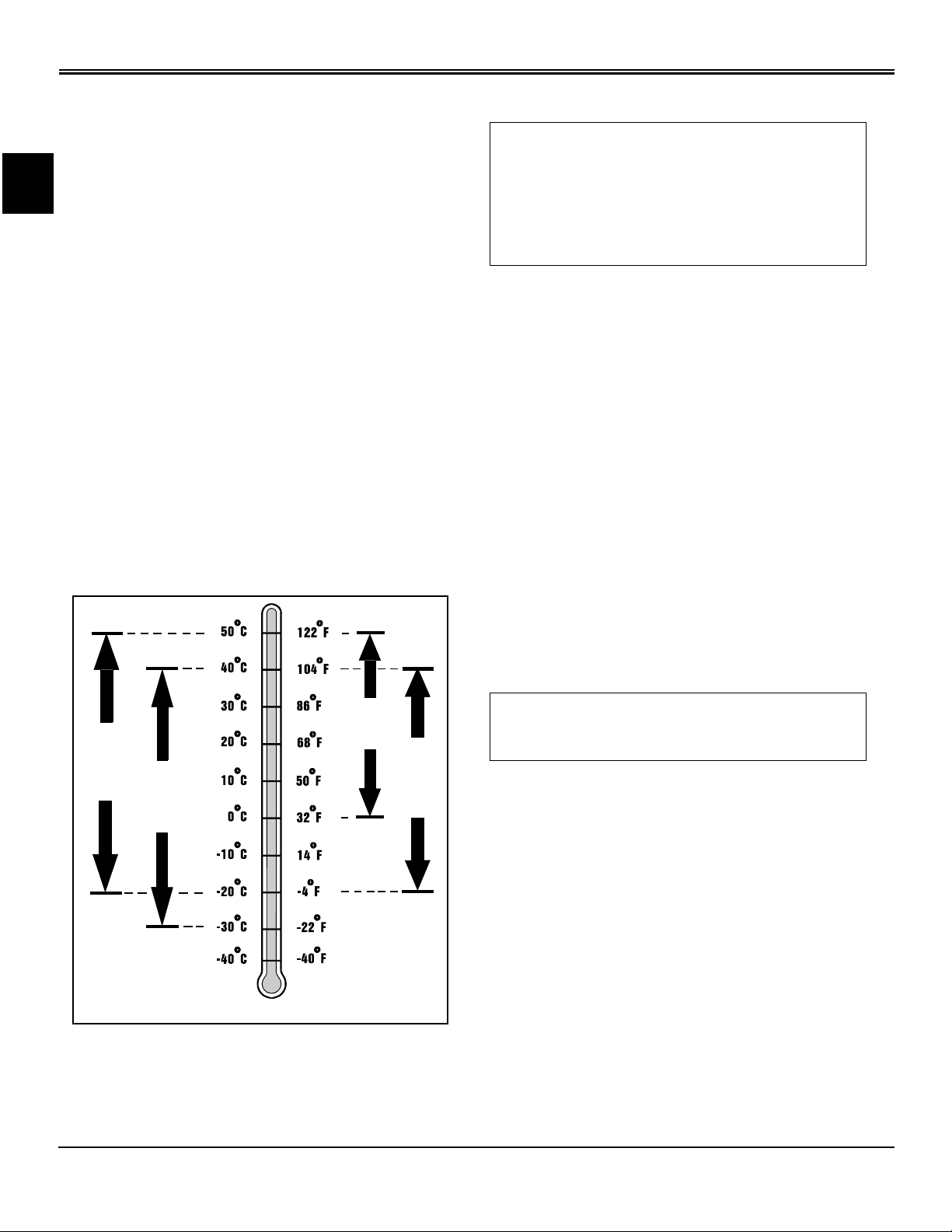

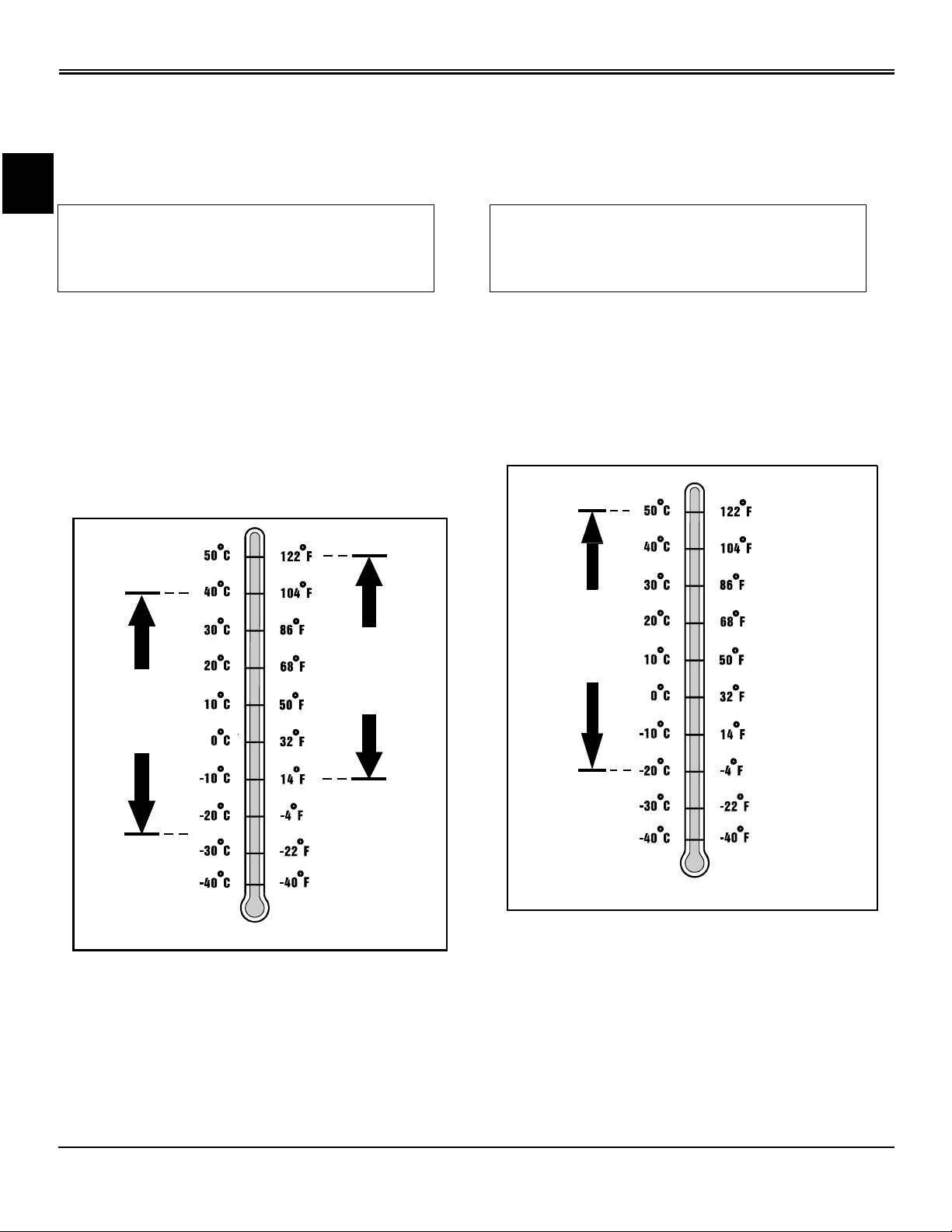

Use the appropriate oil viscosity based on the expected air

temperature range during the period between

recommended oil changes. Operating outside of these

recommended oil air temperature ranges may cause

premature engine failure.

The following John Deere oils are PREFERRED:

• PLUS - 4® - SAE 10W-40;

• TORQ - GARD SUPREME® - SAE 5W-30.

The following John Deere oils are also recommended,

based on their specified temperature range:

• TURF - GARD® - SAE 10W-30;

• PLUS - 4® - SAE 10W-30;

• TORQ - GARD SUPREME® - SAE 30.

Other oils may be used if above John Deere oils are not

available, provided they meet one of the following

specifications:

• SAE 10W-40 - API Service Classifications SG or higher;

• SAE 5W-30 - API Service Classification SG or higher;

• SAE 10W-30 - API Service Classifications SG or higher;

• SAE 30 - API Service Classification SC or higher.

Break-In Engine Oil - 4-Cycle Gasoline

IMPORTANT: Avoid damage! ONLY use a quality

break-in oil in rebuilt or remanufactured engines

for the first 5 hours (maximum) of operation. DO

NOT use oils with heavier viscosity weights than

SAE 5W-30 or oils meeting specifications API SG

or SH, these oils will not allow rebuilt or

remanufactured engines to break-in properly.

The following John Deere oil is PREFERRED:

• BREAK - IN ENGINE OIL.

John Deere BREAK - IN ENGINE OIL is formulated with

special additives for aluminum and cast iron type engines

to allow the power cylinder components (pistons, rings, and

liners as well) to “wear-in” while protecting other engine

components, valve train and gears, from abnormal wear.

Engine rebuild instructions should be followed closely to

determine if special requirements are necessary.

John Deere BREAK - IN ENGINE OIL is also

recommended for non-John Deere engines, both aluminum

and cast iron types.

The following John Deere oil is also recommended:

• TORQ - GARD SUPREME® - SAE 5W-30.

If the above recommended John Deere oils are not

available, use a break-in engine oil meeting the following

specification during the first 5 hours (maximum) of

operation:

• SAE 5W-30 - API Service Classification SE or higher.

SAE 10W-40

SAE 5W-30

PREFERRED

AIR TEMPERATURE

SAE 30

IMPORTANT: Avoid damage! After the break-in

period, use the John Deere oil that is

recommended for this engine.

SAE 10W-30

MIF

Specifications General Information - 10

Page 15

SPECIFICATIONS GENERAL INFORMATION

JDM J20C

BREAK-IN OIL

SAE 5W-30

PREFERRED

AIR TEMPERATURE

MIF

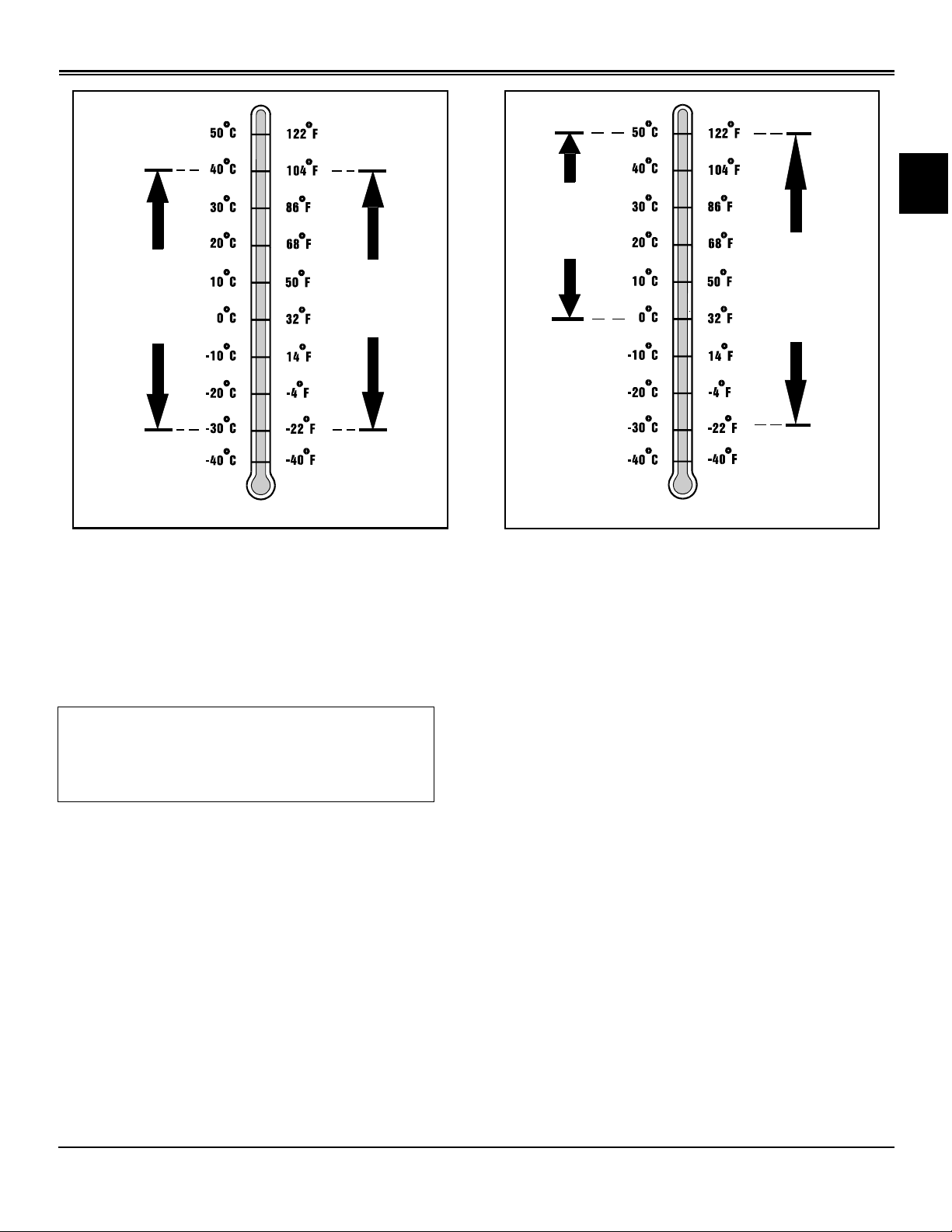

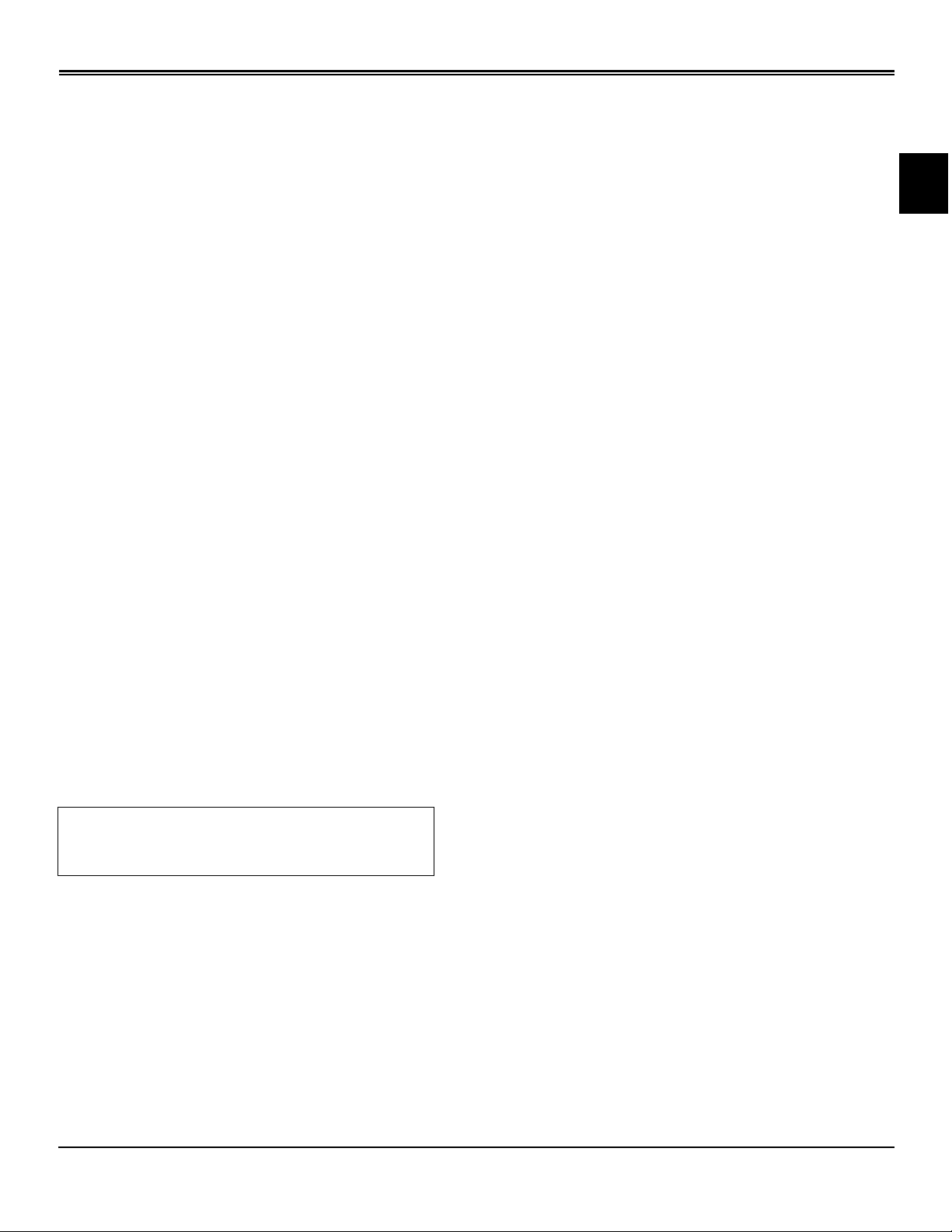

Hydrostatic Transmission and Hydraulic Oil

Use the appropriate oil viscosity based on these air

temperature ranges. Operating outside of these

recommended oil air temperature ranges may cause

premature hydrostatic transmission or hydraulic system

failures.

IMPORTANT: Avoid damage! Use only the oils

recommended. HY-GARD® - JDM J20C can be

mixed with 5W30 or 10W30 in this application.

Do not use LOW VISCOSITY HY - GARD® oil.

5W30 or 10W30

PREFERRED

AIR TEMPERATURE

MIF

The following John Deere transmission and hydraulic oil is

PREFERRED:

• HY-GARD® - JDM J20C.

The following John Deere oil is also recommended if above

preferred oil is not available:

• 5W30 or 10W30.

Other oils may be used if above recommended John Deere

oils are not available, provided they meet one of the

following specifications:

• John Deere Standard JDM J20C.

Specifications General Information - 11

Page 16

SPECIFICATIONS GENERAL INFORMATION

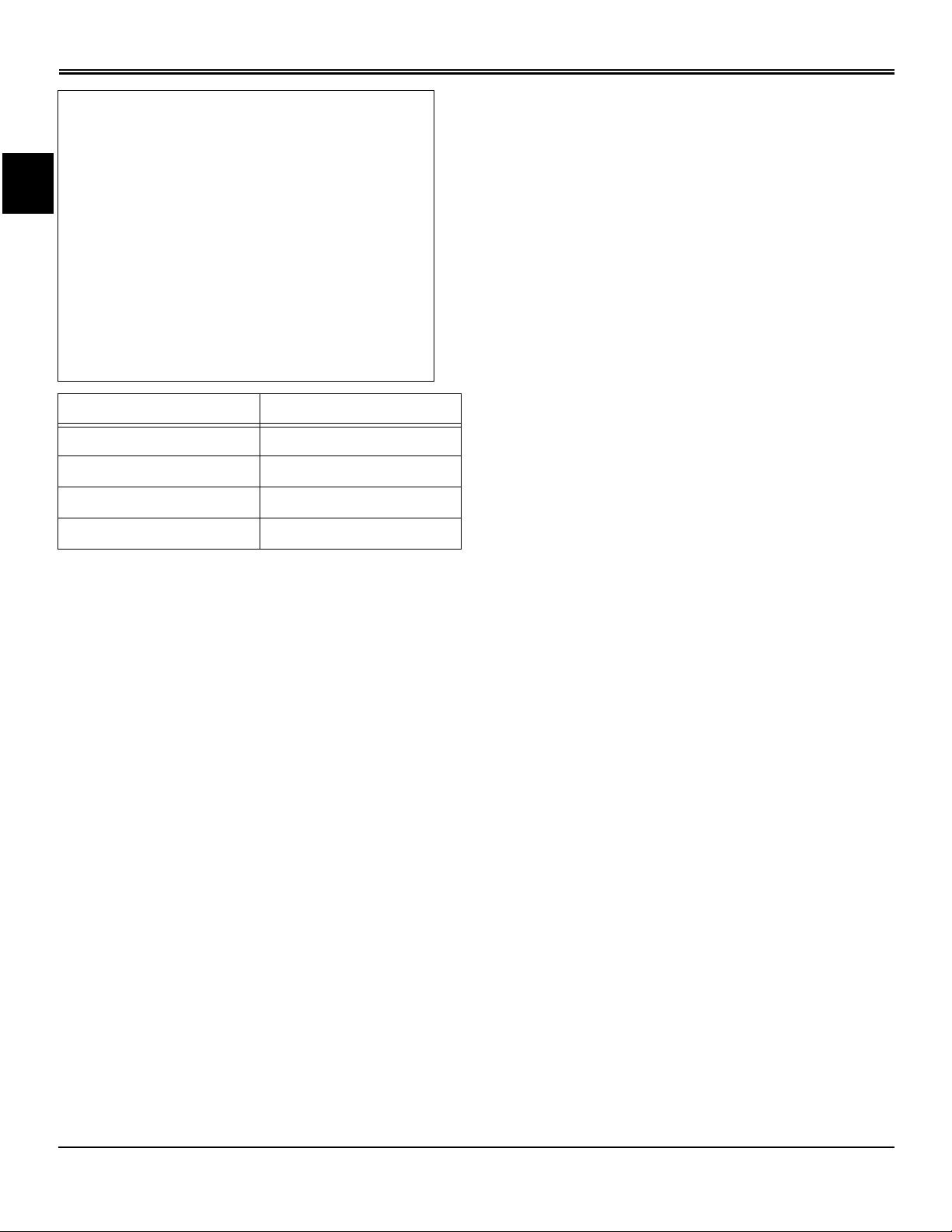

Gear Case Oil

Use the appropriate oil viscosity based on the air

temperature ranges. Operating outside of these

recommended oil air temperature ranges may cause

premature gear case failure.

IMPORTANT: Avoid damage! ONLY use a quality

oil in this gear case. DO NOT mix any other oils

in this gear case. DO NOT use BIO-HY-GARD® in

this gear case.

The following John Deere gear case oil is PREFERRED:

• GL-5 GEAR LUBRICANT® - SAE 80W-90.

The following John Deere gear case oil is also

recommended if above preferred oil is not available:

• GL-5 GEAR LUBRICANT® - SAE 85W-140.

Other gear case oils may be used if above recommended

John Deere gear case oils are not available, provided they

meet the following specification:

• API Service Classification GL - 5.

Gear Transmission Grease

Use the following gear grease based on the air temperature

range. Operating outside of the recommended grease air

temperature range may cause premature gear

transmission failure.

IMPORTANT: Avoid damage! ONLY use a quality

gear grease in this transmission. DO NOT mix

any other greases in this transmission. DO NOT

use any BIO - GREASE in this transmission.

The following John Deere gear grease is PREFERRED:

• NON-CLAY HIGH-TEMPERATURE EP GREASE® -

JDM J13E4, NLGI Grade 2.

Other greases may be used if above preferred John Deere

grease is not available, provided they meet the following

specification:

• John Deere Standard JDM J13E4, NLGI Grade 2.

SAE 80W-90

PREFERRED

AIR TEMPERATURE

SAE 85W-140

MIF

JDM J13E4

NLGI Grade 2

AIR TEMPERATURE

MIF

Alternative Lubricants

Use of alternative lubricants could cause reduced life of the

component.

If alternative lubricants are to be used, it is recommended

that the factory fill be thoroughly removed before switching

to any alternative lubricant.

Specifications General Information - 12

Page 17

SPECIFICATIONS COOLANT SPECIFICATIONS

Synthetic Lubricants

Synthetic lubricants may be used in John Deere equipment

if they meet the applicable performance requirements

(industry classification and/or military specification) as

shown in this manual.

The recommended air temperature limits and service or

lubricant change intervals should be maintained as shown

in the operator’s manual, unless otherwise stated on

lubricant label.

Avoid mixing different brands, grades, or types of oil. Oil

manufacturers blend additives in their oils to meet certain

specifications and performance requirements. Mixing

different oils can interfere with the proper functioning of

these additives and degrade lubricant performance.

Lubricant Storage

All machines operate at top efficiency only when clean

lubricants are used. Use clean storage containers to

handle all lubricants. Store them in an area protected from

dust, moisture, and other contamination. Store drums on

their sides. Make sure all containers are properly marked

as to their contents. Dispose of all old, used containers and

their contents properly.

Coolant Specifications

Gasoline Engine Coolant

The engine cooling system when filled with a proper

dilution mixture of anti-freeze and deionized or distilled

water provides year-round protection against corrosion,

cylinder or liner pitting, and winter freeze protection down

to -37°C (-34°F).

The following John Deere coolant is PREFERRED:

• COOL-GARD® PRE-DILUTED SUMMER COOLANT

(TY16036).

This coolant satisfies specifications for “Automobile and

Light Duty Engine Service” and is safe for use in John

Deere Lawn and Grounds Care/Golf and Turf Division

equipment, including aluminum block gasoline engines and

cooling systems.

The above preferred pre-diluted anti-freeze provides:

• adequate heat transfer

• corrosion-resistant chemicals for the cooling system

• compatibility with cooling system hose and seal material

• protection during extreme cold and extreme hot weather

operations

Mixing of Lubricants

In general, avoid mixing different brands or types of

lubricants. Manufacturers blend additives in their lubricants

to meet certain specifications and performance

requirements. Mixing different lubricants can interfere with

the proper functioning of these additives and lubricant

properties which will downgrade their intended specified

performance.

Oil Filters

IMPORTANT: Avoid damage! Filtration of oils is

critical to proper lubrication performance.

Always change filters regularly.

The following John Deere oil filters are PREFERRED:

• AUTOMOTIVE AND LIGHT TRUCK ENGINE OIL

FILTERS.

Most John Deere filters contain pressure relief and antidrainback valves for better engine protection.

Other oil filters may be used if above recommended John

Deere oil filters are not available, provided they meet the

following specification:

• ASTB Tested In Accordance With SAE J806.

• chemically pure water for better service life

• compliance with ASTM D4656 (JDM H24C2)

specifications

If above preferred pre-diluted coolant is not available, the

following John Deere concentrate is recommended:

• COOL-GARD® CONCENTRATED SUMMER

COOLANT CONCENTRATE™ (TY16034).

If either of above recommended engine coolants are

available use any Automobile and Light Duty Engine

Service ethylene glycol base coolant, meeting the following

specification:

• ASTM D4985 (JDM H24A2).

Read container label completely before using and follow

instructions as stated.

Specifications Coolant Specifications - 13

Page 18

SPECIFICATIONS COOLANT SPECIFICATIONS

IMPORTANT: Avoid damage! To prevent engine

damage, DO NOT use pure anti-freeze or less

than a 50% anti-freeze mixture in the cooling

system. DO NOT mix or add any additives/

conditioners to the cooling system in Lawn and

Grounds Care/Golf and Turf Division equipment.

Water used to dilute engine coolant concentrate

must be of high quality - clean, clear, potable

water (low in chloride and hardness - Table 1) is

generally acceptable. DO NOT use salt water.

Deionized or distilled water is ideal to use.

Coolant that is not mixed to these specified

levels and water purity can cause excessive

scale, sludge deposits, and increased corrosion

potential.

Property Requirements

Total Solids, Maximum 340 ppm (20 grns/gal)

Total Hardness, Maximum 170 ppm (10 grns/gal)

Chloride (as Cl), Maximum 40 ppm (2.5 grns/gal)

Sulfate (as SO4), Maximum 100 ppm (5.8 grns/gal)

Mix 50 percent anti-freeze concentrate with 50 percent

distilled or deionized water. This mixture and the pre-diluted

mixture (TY16036) will protect the cooling system down to 37°C (-34°F) and up to 108°C (226°F).

Certain geographical areas may require lower air

temperature protection. See the label on your anti-freeze

container or consult your John Deere dealer to obtain the

latest information and recommendations.

Gasoline Engine Coolant Drain Interval

When using John Deere Pre-Diluted (TY16036) Automobile

and Light Duty Engine Service coolants, drain and flush the

cooling system and refill with fresh coolant mixture every

36 months or 3,000 hours of operation, whichever comes

first.

When using John Deere Concentrate (TY16034)

Automobile and Light Duty Engine Service coolants, drain

and flush the cooling system and refill with fresh coolant

mixture every 24 months or 2,000 hours of operation,

whichever comes first.

If above John Deere Automobile and Light Duty Engine

Service coolants are not being used; drain, flush, and refill

the cooling system according to instructions found on

product container or in equipment operator’s manual or

technical manual.

Specifications Coolant Specifications - 14

Page 19

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK

Specifications - Trail Buck

Engine Specifications - 500

Stroke (500 cc Engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 mm (2.5 in.)

Displacement (500 cc Engine). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498 cc (30.4 cu in.)

Horsepower @ 7200 rpm (500 cc Engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.6 kW (37 hp)

Engine Specifications - 650

Stroke (650 cc Engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 mm (3.2 in.)

Displacement (650 cc Engine). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 644 cc (39.3 cu in.)

Horsepower @ 7100 rpm (650 cc Engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.3 kW (42 hp)

Engine Specifications - 500 and 650

General Specifications

Make. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rotax 4-TEC, 4 stroke Over Head Camshaft (OHC), Liquid cooled

Starting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electric with Optional Recoil

Number of Cylinder(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Number of Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 valves

Decompressor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatic

Bore (Standard). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm (3.9 in.)

Compression Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.5:1

Maximum HP RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7000 ± 100 rpm

Lubrication . . . . . . . . Wet sump with replaceable oil filter (lubrication of engine and transmission simultaneously)

Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full flow

Air Filter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 stage foam filter

Exhaust System Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nelson, stainless steel

Exhaust System Spark Arrester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .USDA approved

Valves

Intake Valve Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.0° BTDC

Intake Valve Closing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.0° ABDC

Exhaust Valve Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50.0° BBDC

Exhaust Valve Closing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0° ATDC

Intake Valve Stem Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.961 mm (0.2347 in.)

Intake Valve Stem Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.975 mm (0.2352 in.)

Intake Valve Stem Diameter (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.930 mm (0.2330 in.)

Exhaust Valve Stem Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.946 mm (0.2341 in.)

Exhaust Valve Stem Diameter (New maximum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.960 mm (0.2346 in.)

Exhaust Valve Stem Diameter (Wear limit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.930 mm (0.2330 in.)

Valve Guide Diameter (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.060 mm (0.2386 in.)

Valve Spring Free Length (New) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.45 mm (1.789 in.)

Valve Spring Free Length (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43.00 mm (1.693 in.)

Intake Valve Seat Contact Width (New). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.10 to 1.30 mm (0.043 to 0.0051 in.)

Intake Valve Seat Contact Width (Wear limit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 mm (0.07 in.)

Exhaust Valve Seat Contact Width (New). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.25 to 1.55 mm (0.049 to 0.061 in.)

Exhaust Valve Seat Contact Width (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 mm (0.078 in.)

Specifications Specifications - Trail Buck - 15

Page 20

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK

Pistons

Piston Measurement (New) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99.951 to 99.969 mm (3.935 to 3.936 in.)

Piston Measurement (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99.80 mm (3.929 in.)

Piston/Cylinder Clearance (New) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.031 to 0.059 mm (0.001 to 0.002 in.)

Piston/Cylinder Clearance (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.090 mm (0.004 in.)

Piston Ring Type 1st . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rectangular

Piston Ring Type 2nd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Taper-face

Piston Ring Type 3rd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Oil Scraper Ring

Piston Ring End Gap Rectangular (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm (0.006 in.)

Piston Ring End Gap Taper-face (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm (0.006 in.)

Piston Ring End Gap Oil Scraper Ring (New minimum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15 mm (0.006 in.)

Piston Ring End Gap Rectangular (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.35 mm (0.014 in.)

Piston Ring End Gap Taper-face (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.35 mm (0.014 in.)

Piston Ring End Gap Oil Scraper Ring (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 mm (0.012 in.)

Piston Ring End Gap All (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm (0.06 in.)

Piston/Ring Groove Clearance Rectangular (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 mm (0.001 in.)

Piston/Ring Groove Clearance Taper-face (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015 mm (0.0006 in.)

Piston/Ring Groove Clearance Oil Scraper Ring (New minimum). . . . . . . . . . . . . . . . . . . . . . . . 0.020 mm (0.0008 in.)

Piston/Ring Groove Clearance Rectangular (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.070 mm (0.0028 in.)

Piston/Ring Groove Clearance Taper-face (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.060 mm (0.0024 in.)

Piston/Ring Groove Clearance Oil Scraper Ring (New maximum) . . . . . . . . . . . . . . . . . . . . . . . 0.055 mm (0.0021 in.)

Rocker Arm

Rocker Arm Bore Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.007 mm (0.7877 in.)

Rocker Arm Bore Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.020 mm (0.7881 in.)

Rocker Arm Bore Diameter (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.035 mm (0.7887 in.)

Rocker Arm Shaft Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.980 mm (0.7866 in.)

Rocker Arm Shaft Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.007 mm (0.7877 in.)

Rocker Arm Shaft Diameter (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.965 mm (0.7860 in.)

Cylinder

Cylinder Screw M11 (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216.5 mm (8.524 in.)

Cylinder Bore (New) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100.00 mm (3.94 in.)

Cylinder Taper (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.038 mm (0.0015 in.)

Cylinder Taper (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.090 mm (0.004 in.)

Cylinder Out of Round (New maximum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.01 mm (0.0004 in.)

Cylinder Out of Round (Wear limit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 mm (0.0008 in.)

Camshaft and Cam

Camshaft Bearing Journal PTO Side (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.967 mm (0.9829 in.)

Camshaft Bearing Journal PTO Side (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.980 mm (0.9835 in.)

Camshaft Bearing Journal PTO Side (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.960 mm (0.9827 in.)

Camshaft Bearing Journal Magneto Side (New minimum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.927 mm (1.5719 in.)

Camshaft Bearing Journal Magneto Side (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.935 mm (1.5722 in.)

Camshaft Bearing Journal Magneto Side (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.920 mm (1.5716 in.)

Camshaft Bore PTO Side (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.987 mm (0.9837 in.)

Camshaft Bore PTO Side (New maximum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.000 mm (0.9842 in.)

Camshaft Bore PTO Side (Wear limit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.020 mm (0.9850 in.)

Specifications Specifications - Trail Buck - 16

Page 21

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK

Camshaft Bore Magneto Side (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.984 mm (1.5742 in.)

Camshaft Bore Magneto Side (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.000 mm (1.5748 in.)

Camshaft Bore Magneto Side (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.020 mm (1.5756 in.)

Cam Lobe Intake (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.369 mm (1.235 in.)

Cam Lobe Intake (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.569 mm (1.243 in.)

Cam Lobe Intake (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.300 mm (1.232 in.)

Cam Lobe Exhaust (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.147 mm (1.226 in.)

Cam Lobe Exhaust (New maximum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.347 mm (1.234 in.)

Cam Lobe Exhaust (Wear limit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.100 mm (1.224 in.)

Crankshaft

Crankshaft Axial Clearance (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 mm (0.0078 in.)

Crankshaft Axial Clearance (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 mm (0.0196 in.)

Crankshaft Pin Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.017 mm (1.7723 in.)

Crankshaft Pin Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.033 mm (1.7729 in.)

Crankshaft Pin Diameter (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.990 mm (1.7710 in.)

Crankshaft Journal Diameter MAG Side (New minimum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54.976 mm (2.1644 in.)

Crankshaft Journal Diameter MAG Side (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54.995 mm (2.1651 in.)

Crankshaft Journal Diameter MAG Side (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54.950 mm (2.1634 in.)

Crankshaft Journal Diameter PTO Side (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.974 mm (1.8099 in.)

Crankshaft Journal Diameter PTO Side (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.990 mm (1.8102 in.)

Crankshaft Journal Diameter PTO Side (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.940 mm (1.8086 in.)

Crankshaft Radial Clearance MAG Side (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.07 mm (0.0028 in.)

Crankshaft Radial Clearance PTO Side (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.07 mm (0.0028 in.)

Connecting Rod

Connecting Rod Big End Diameter (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45.080 mm (1.774 in.)

Connecting Rod Big End Clearance (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.09 mm (0.0035 in.)

Connecting Rod Big End Axial Play (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.150 mm (0.06 in.)

Connecting Rod Big End Axial Play (New maximum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.302 mm (0.01 in.)

Connecting Rod Big End Axial Play (Wear limit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 mm (0.02 in.)

Connecting Rod Small End Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.01 mm (0.9059 in.)

Connecting Rod Small End Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.02 mm (0.9063 in.)

Connecting Rod Small End Diameter (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.07 mm (0.9080 in.)

Piston Pin

Piston Pin Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.996 mm (0.9053 in.)

Piston Pin Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.000 mm (0.9055 in.)

Piston Pin Diameter (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.990 mm (0.9051 in.)

Piston Pin Bore Clearance (Wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.080 mm (0.0035 in.)

Drive Belt (New nominal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.00 mm (1.260 in.)

Drive Belt (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.00 mm (1.181 in.)

Governor Cup Roller Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.70 mm (0.539 in.)

Governor Cup Roller Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.90 mm (0.547 in.)

Governor Cup Roller Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.20 mm (0.519 in.)

Centrifugal Lever

Centrifugal Lever Pivot Bolt Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.078 mm (0.239 in.)

Specifications Specifications - Trail Buck - 17

Page 22

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK

Centrifugal Lever Pivot Bolt Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.100 mm (0.240 in.)

Centrifugal Lever Pivot Bolt Diameter (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.000 mm (0.236 in.)

Centrifugal Lever Bore Diameter (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.200 mm (0.244 in.)

Centrifugal Lever Pivot Bolt Bore Diameter (New minimum). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.113 mm (0.241 in.)

Centrifugal Lever Pivot Bolt Bore Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.171 mm (0.243 in.)

Centrifugal Lever Pivot Bolt Bore Diameter (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.300 mm (0.248 in.)

Drive Pulleys

Drive Pulley Sliding Half Large Bushing (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.000 mm (2.165 in.)

Drive Pulley Sliding Half Large Bushing (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.002 mm (2.166 in.)

Drive Pulley Sliding Half Large Bushing (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.200 mm (2.173 in.)

Drive Pulley Sliding Half Small Bushing (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.000 mm (1.181 in.)

Drive Pulley Sliding Half Small Bushing (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.002 mm (1.182 in.)

Drive Pulley Sliding Half Small Bushing (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.200 mm (1.189 in.)

One-Way Clutch Bushing Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.990 mm (1.574 in.)

One-Way Clutch Bushing Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.085 mm (1.578 in.)

One-Way Clutch Bushing Diameter (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.100 mm (1.579 in.)

Driven Pulley Sliding Half Bushing Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . 30.000 mm (1.181 in.)

Driven Pulley Sliding Half Bushing Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . 30.002 mm (1.182 in.)

Driven Pulley Sliding Half Bushing Diameter (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.200 mm (1.189 in.)

Driven Pulley Fixed Half Bushing Diameter (New minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.000 mm (1.181 in.)

Driven Pulley Fixed Half Bushing Diameter (New maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.002 mm (1.182 in.)

Driven Pulley Fixed Half Bushing Diameter (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.200 mm (1.189 in.)

Torque Gear On Driven Pulley (Service limit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.500 mm (.295 in.)

Main Shaft MAG Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.990 mm (0.708 in.)

Main Shaft PTO Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.950 mm (0.982 in.)

Bevel Gear Shaft PTO Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.990 mm (0.984 in.)

Electrical Specifications

Magneto/Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400 W @ 6000 rpm

Ignition system Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I.D.I. (Inductive Discharge Ignition)

Ignition timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not Adjustable

Spark Plug Quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Spark Plug Make and Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .NKG DCPR8E

Spark Plug Gap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.6 - 0.7 mm (0.024 - 0.027 in.)

Spark Plug Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 N•m (159 lb-in.)

Trigger Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190 - 300 ohms

Battery Charging Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 ± 0.01 ohms

Ignition Coil Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.85 to 1.15 ohms @ 20° C (68° F)

Ignition Coil Secondary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3 to 11.7 ohms @ 20° C (68° F)

Engine RPM Limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7400

Battery

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrolyte Battery Type

Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 volts

Nominal Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 A•h

Power Starter Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 kW

Specifications Specifications - Trail Buck - 18

Page 23

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK

Lights

Headlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x 35 W

Taillight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5/25 W

Pilot Lamp Cluster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LEDS, 0.7 V approximately (each)

Fuses

Location no. 1 (spare 15 A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N.A.

Location no. 2 (spare 15 A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N.A

Location no. 3 (accessories) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 A (power outlet and auxiliary supply)

Location no. 4 (fan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 A

Location no. 5 (main) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 A

Location no. 6 (charging system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 A

Carburation Specifications

Carburetor Type . . . . . Mikuni constant depression type with manual choke and ECS (Enrichner Coasting System)

Carburetor Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BSR42

Fuel Pump Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mikuni

Fuel Pump Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . External (vacuum operated)

Engine Idle Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1100 ± 100 rpm

Main Jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152.5

Pilot Jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Needle Jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-6

Jet Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6DGY17-53

Clip Position Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Choke Plunger Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Variable Choke

Adjustment

Throttle Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 mm (.02 in.)

Preliminary Pilot Screw Turn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Float Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 ± 0.5 mm (0.390 ± 0.020 in.)

Fuel

Fuel Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Regular Unleaded Gasoline

Octane No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 (Ron + Mon)/2

Cooling Specifications

CoolantEthyl Glycol/water mix (50% coolant, 50% water), Use coolant specifically designed for aluminum engines)

Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Thermostatic

Fan Thermostat Switch ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95° C (203° F)

Fan Thermostat Switch OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90° C (194° F)

Engine Thermostat Opening Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75° C (167° F)

Engine Thermostat Closing Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85° C (185° F)

Radiator Cap Opening Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 kPa (16 psi)

Specifications Specifications - Trail Buck - 19

Page 24

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK

Drive Train Specifications

Transmission Type . . . CVT (Continuous Variable Transmission), Dual Range (HI-LO) With Park Brake, Neutral and

Reverse

Engagement RPM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1450 ± 100 rpm

Front Differential. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shaft Driven/Single Auto-Lock Differential (pump driven)

Front Differential Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6:1

Rear Axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shaft Driven/Solid Axle

Rear Axle Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.6:1

Steering Control Specifications

Turning Radius 4-Wheel Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2100 mm (83 in.)

Total Toe (vehicle on ground) Each Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 ± 4 mm (0.315 ± 0.157 in.)

Camber Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°

Tie-Rod Maximum Length Unengaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 ± 5 mm (0.787 ± 0.197 in.)

Suspension Specifications

Front

Suspension type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Independent Suspension - Double A-Arm

Suspension Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178 mm (7 in.)

Shock Absorber Qty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shock Absorber Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Oil

Spring Free Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270 mm (11 in.)

Spring Color Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Orange/Black/Black

Front Preload Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N.A.

Rear

Suspension type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rigid Swing Arm

Suspension Travel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190.5 mm (7.5 in.)

Shock Absorber Qty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shock Absorber Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Oil

Spring Free Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 mm (6.3 in.)

Spring Color Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . White/Red/Black

Front Preload Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Settings

Brakes Specifications

Front Brake Qty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 discs

Front Brake Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic

Rear Brake Qty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 disc

Rear Brake Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mechanical Cable/Hydraulic

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Transmission Brake and Brake Lever Lock on LH Brake Lever

Caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Floating

Lining Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Semi Metallic

Minimum Pad Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 mm (0.04 in.)

Minimum Brake Disc Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 mm (0.18 in.)

Maximum Brake Disk Warpage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 mm (0.01 in.)

Specifications Specifications - Trail Buck - 20

Page 25

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK

Tires and Wheels Specifications

Tires

Pressure Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 kPa recommended; 35 kPa minimum (5.5 psi); (5 psi)

Pressure Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 kPa recommended; 28 kPa minimum (4.5 psi); (4 psi)

Tire Tread Depth (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 mm (0.16 in.)

Size Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 x 8 x 12

Size Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 x 11 x 12

Wheels

Size Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 x 6.5

Size Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 x 8

Dimension Specifications

Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2071 mm (81.5 in.)

Overall Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1194 mm (47 in.)

Overall Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1143 mm (45 in.)

Dry Weight 4-Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338 kg (745 lb)

Wheel Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1296 mm (51 in.)

Wheel Track Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 992 mm (39 in.)

Wheel Track Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 940 mm (37 in.)

Front and Under Engine Ground Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244 mm (9.6 in.)

Rear Rigid Axle Ground Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188 mm (7.4 in.)

Capacities Specifications

Liquid

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.8 L (5.8 U.S. gal)

Fuel Tank Reserve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 L (1.1 U.S. gal)

Engine/Transmission Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 L (3.17 qt)

Engine/Transmission Oil Type . . . . . . . . . . . . .SAE 10W40, 4-stroke mineral based oil SG, SH or SJ or synthetic oil

Differential Oil Capacity (Front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650 ml (22 U.S. oz)

Differential Oil Capacity (Rear) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 ml (10 U.S. oz)

Differential Oil Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Synthetic Polyolester Oil 75W90 (API GL5)

CV Joint Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TEXACO, HTBJ Grease (M3014), ONLY

Propeller Shaft Grease. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SHELL, Alvania EP-2, ONLY

Hydraulic Brakes Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250 ml (8.5 U.S. oz)

Hydraulic Brakes Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brake Fluid DOT 4, ONLY

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 L (2.65 qt)

Body and Frame

Weight Distribution Front/Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49/51%

Front Storage Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 kg (22 lb)

Rack Front (including front storage tray). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 kg (90 lb)

Rack Rear (including tongue weight) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 kg (175 lb)

Total Vehicle Load Allowed (including driver, all other loads and added accessories) . . . . . . . . . . . 220 kg (485 lb)

Gross Vehicle Weight Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540 kg (1200 lb)

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 kg (1100 lb)

Specifications Specifications - Trail Buck - 21

Page 26

SPECIFICATIONS SPECIFICATIONS - TRAIL BUCK