Page 1

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Manual Stair Robot SR1750 HE

Page 2

AATA INTERNATIONAL B.V.

Stairrobot

Type number : SR 1750 HE

Serial number :

Year of construction : 2001

Owner :

Manufacturer :

Manual Stair Robot SR1750 HE

Publication: 29-07-04

AATA International b.v

Willem 2 straat 1e

6021 EA Budel

The Netherlands

Tel : 0031-(0) 495 518214

Fax : 0031-(0) 495 518515

e-mail:

aata@aata.nl

http:www.aata.nl

No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise without the written permission of AATA

International b.v.

The content of this manual is subject to change without notice. Product specification and design are subject to

change without notice.

Page 2 of 28

Page 3

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Preface

AATA International is an innovative and dynamical company, specialised in stair climbing

equipment. Stairrobots are active in over 30 countries worldwide.

This manual is written for machine operators and for technician who take care for the

maintenance of the machine. Although the tiniest details are not set out, the manual is a

useful help for people who are dealing with the machine on a daily basis.

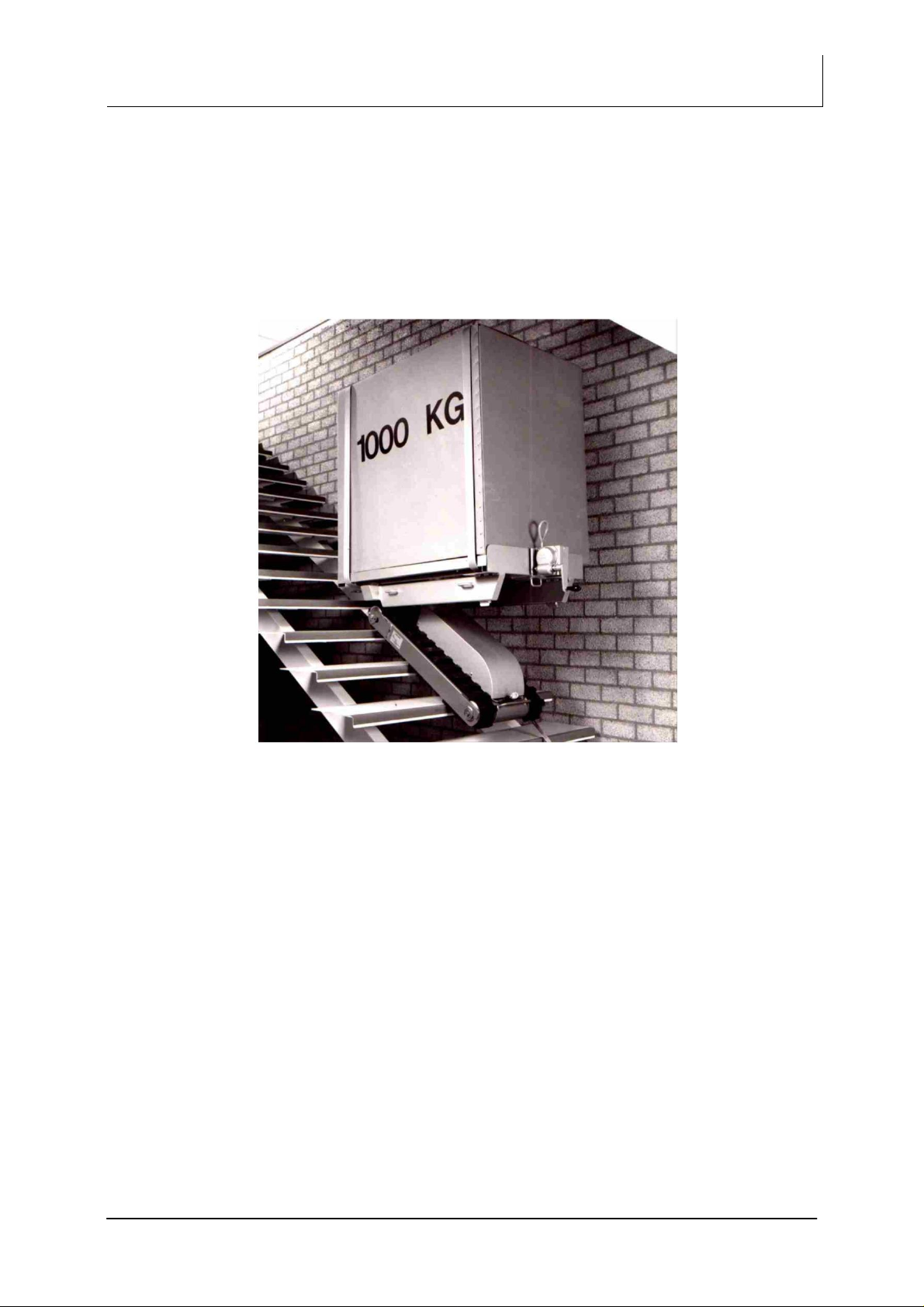

The stairrobot SR 1750 HE has been used for over 20 years by many well known companies

and transport contractors worldwide who are involved in the movement of heavy loads into

and out of customers premises.

The stairrobot SR 1750 HE is designed to carry unit loads weighing up to 1000 kg up- and

down stairs. The accessory equipment, stair approach ramp, manoeuvring dolly and the

turntable, have been designed to assist the movement up to and onto the stairs and the take

off from the top and journey to the final destination.

This manual should be used in conjunction with the cd-rom instruction video, which is

placed on the inside of the manuals cover.

Read this manual and view the instruction cd-rom carefully before putting the SR 1750HE

into operation. Always take note of the safety rules as mentioned in chapter “safety”.

A copy of this manual should be kept with the machine, so the operator has it at his disposal.

AATA International b.v.

Page 3 of 28

Page 4

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Table of contents

Preface…………………………………………………………………………………………… 3

Table of contents .……………………………………………………………………………… 4

Survey of standards……………………………………...……………………………………… 5

Survey of standards………………………………………………………………………...…… 5

1. Technical data…..………………..………………………………………………………… 6

2. Description main components stair robot SR 1750 HE

2.1 Drive………………………………………………………………………………… 7

2.2 Transmission and brake………………………………………………………….. 7

2.3 Tracks………………………………………………………………………………. 7

2.4 Controls…………………………………………………………………………….. 8

2.5 Hydraulic levelling platform………………………………………………………. 8

2.6 Descent adjuster ………………………………………………………………….. 9

2.7 Hydraulic motor and Pump

3. Ancillary equipment

3.1 Loading ramp……………………………………………………………………………10

3.2 Turntable…………………………………………………………………………………11

3.3 Winch …………………………………………………………………………………..11

3.4 Dolly .…………………………………………………………………………………….11

4. Safety

4.1 General safety precaution……………………………………………………………...12

5. Operators procedure

5.1 Pre-use inspection…………………………………………………………………….. 14

5.2 Loading…………………………………………………………………………………. 15

5.2.1 The correct position of the load…………………………………………….15

5.2.2 Loading procedure ……………………………………………………… …16

5.3 Ascending………………………………………………………………………………..17

5.4 Descending ……………………………………………………………………………18

5.5 Unloading ………………………………………………………………………………19

6. Trouble shooting chart………………………………………………………………………20

7. Track replacement …………………………………………………………………………22

8. Electrical system chart………………………………………………………………………24

9. Hydraulic system chart …………………………………………………………………… 25

10. Parts………………………………………………………………………………………… 26

10.1 Parts list……………………………………………………………………………… 27

11. CD-rom video……………………………………………………………………………… 28

Page 4 of 28

Page 5

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Survey of standard

We declare that the construction of the stairrobot SR1750HE is according to the provisions of

EC-Directives 89/392/EWG.

Applied harmonized standard:

NEN-EN 60034-5; NEN 10034-6; NEN 10072-2

Applied national standards, directives and technical specifications:

IEC 34-5; IEC 34-7; IEC 72-1

Survey of symbols

Not (or not completely) observing the operating instructions can lead to serious

accidents or damage

Danger as a result of electric tension

Page 5 of 28

Page 6

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

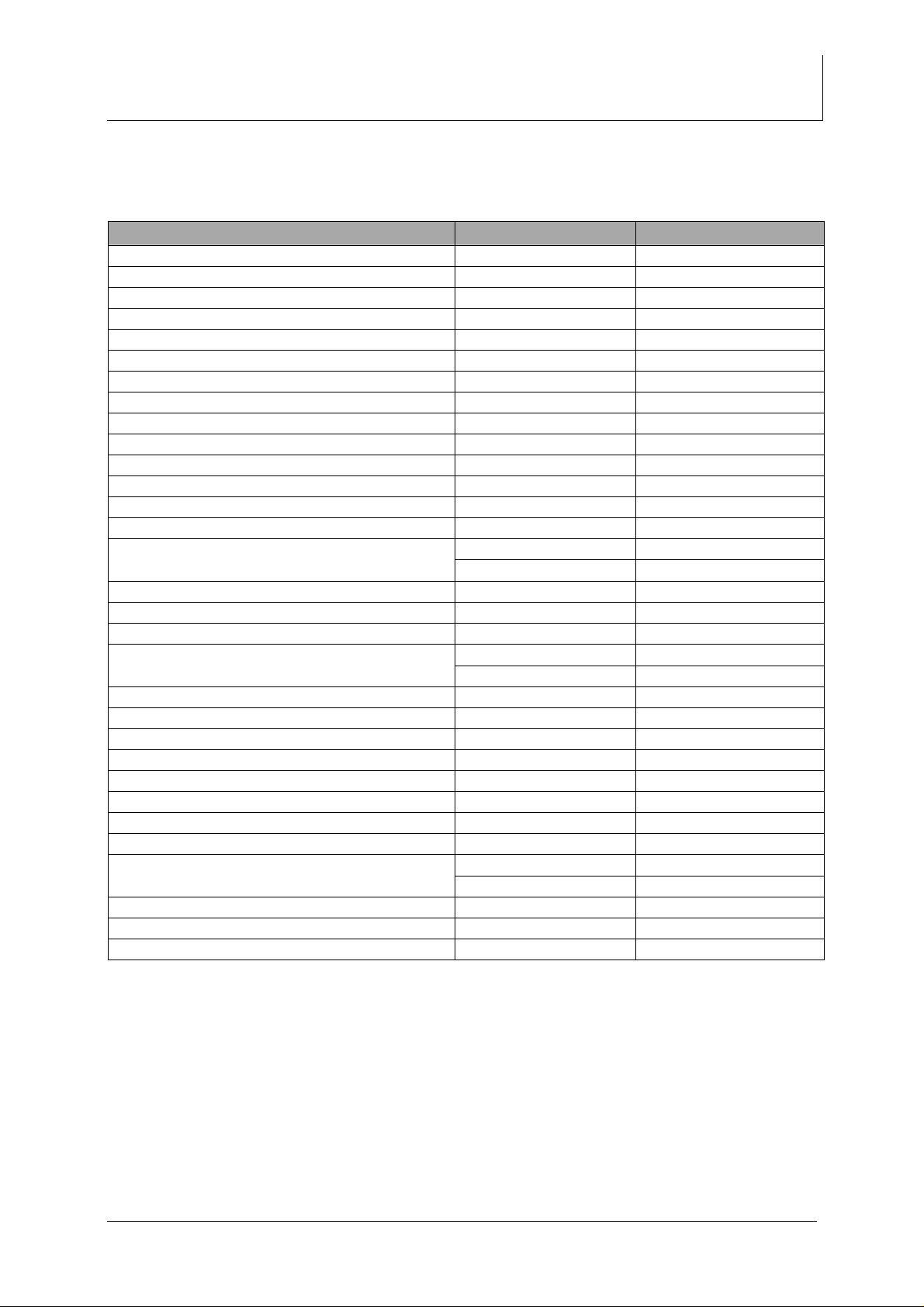

1. Technical data SR 1750 HE

Description Value Units

Speed 3 Metres p/minute

Lifting capacity max. 1000 Kg.

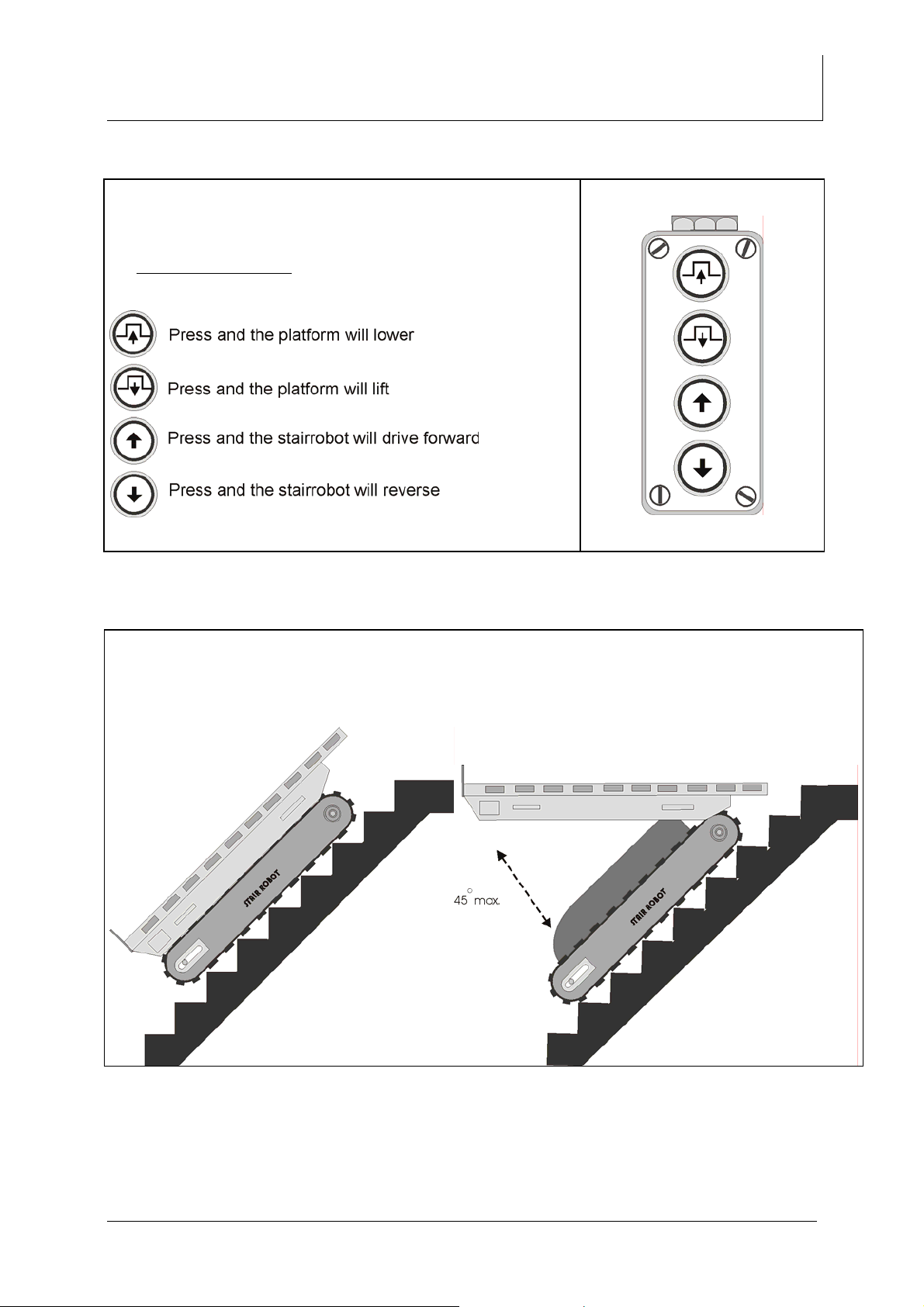

Maximum angle Max. 45 º Degrees

Weight 175 Kg.

Weight including standard accessories 232 Kg.

Colour ~~ ~~

Length 1185 Mm

Width 720 Mm

Height 320 Mm

Length loading ramp 1180 Mm

Width loading ramp 720 Mm

Drive-motor: single phase low noise AC

Thermal cut-out

Drive-motor capacity 0,75 KW

1 Hp

Drive-motor power 220 or 110 V

Hydraulic-motor: single phase low noise AC

with thermal cut out

Hydraulic-motor capacity 0,375 KW

0,5 Hp

Hydraulic-motor power 220 or 110 V

Hydraulic-pump: built directly on the hydraulic

Motor

Hydraulic-pump capacity 0,8 ltr/per minute

Action pressure max. 100 Bar

Capacity oil tank 0,5 Ltr

Control: remote control manually operated

4-button switch 24 V

Mains 220/110 V

50 Hz

Extension cord (cupper wire) 3x2,5 Mm2

Extension cord length 25 Mtr

Page 6 of 28

Page 7

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

2 Description main components stairrobot SR 1750 HE

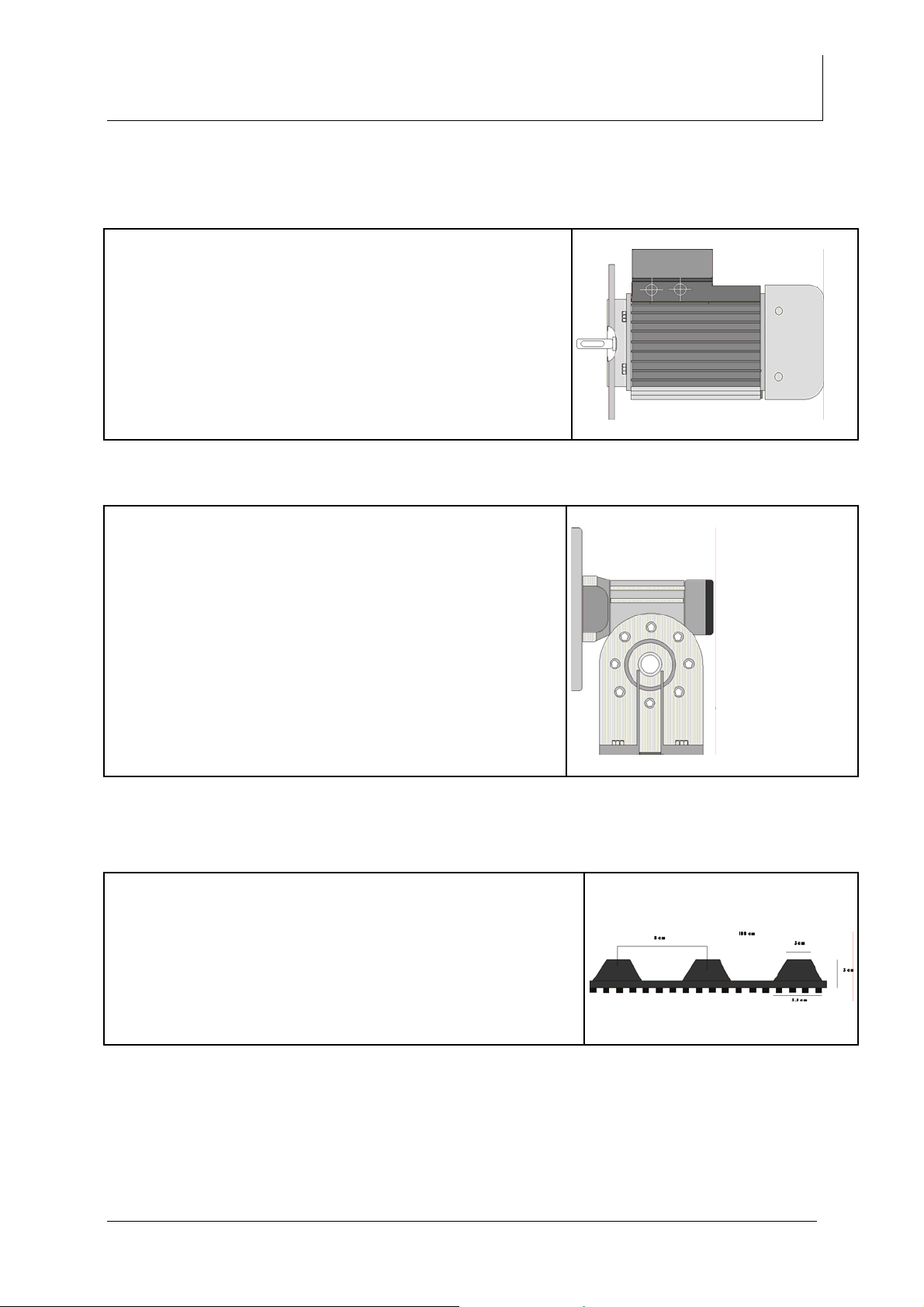

2.1. Drive

Single phase low-noise AC motor

•

with thermal cut-out

2.2. Transmission and brake

• Worm-gearbox built directly onto the

driving motor

• The worm-wheel reduction forms an affective

brake for the (loaded) StairRobot on the staircase

2. 3. Tracks

• Internally and externally toothed caterpillar tracks,

specially designed for smooth stair climbing

Page 7 of 28

Page 8

AATA INTERNATIONAL B.V.

2. 4. Controls

• Remote control (2 metres cable attached) manually

operated 4-button switch

Press a button to drive

Manual Stair Robot SR1750 HE

Publication: 29-07-04

2. 5. Hydraulic-levelling platform

• To increase stability the platform can be adjusted to the angle of the staircase by a

hydraulic cylinder

Page 8 of 28

Page 9

AATA INTERNATIONAL B.V.

2. 6. Descent adjuster

2.7. Hydraulic motor and pump

Manual Stair Robot SR1750 HE

Publication: 29-07-04

The descent adjuster is located at the rear end of

•

the machine and is used to adjust the descent of

the lifting platform depending on the weight of the

load.

Turn maximum clockwise for speed : 0

•

The hydraulic-motor is placed on the drive

•

motor with the pump built directly onto the

motor

3. Ancillary equipment

3.1. Loading ramp

• The loading ramp is designed to fit neatly

into the stairrobots lifting platform. It

provides a safe ridged platform to transport

the load from the floor-surface to the loadposition on the robot.

Page 9 of 28

Page 10

AATA INTERNATIONAL B.V.

3.2. Turntable

•

The turntable is a circular piece of

equipment Ø 610 mm, h. 40 mm.

constructed out-of two disks of

block board with hard-plastic

surface to eliminate friction. It is

used to alter the direction of travel

for the (loaded) StairRobot. There

are finger grips on either side for

easy lifting or carrying.

3.3. Winch

•

The winch is designed to fit into the lifting platform of the stairrobot. With the winch a

load can be pulled onto the platform with a minimum amount of effort

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Page 10 of 28

Page 11

AATA INTERNATIONAL B.V.

3.4. Dolly

•

The dolly is constructed of square steel fittings with four heavy-duty swivel wheels

for easy movements. An extendable frame can be pulled out to increase stability

while driving the StairRobot on the dolly. The lead-off ramp is used to connect the

dolly with the stairway

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Page 11 of 28

Page 12

AATA INTERNATIONAL B.V.

4. Safety

4.1. General safety precaution

Manual Stair Robot SR1750 HE

Publication: 29-07-04

•

It is not permitted to make alterations to the

machine.

•

Everybody who is working with the machine

has to be acquainted with the safety rules and

has to act upon them.

•

Two operators are required to operate the

stairrobot

•

Always check the surroundings where the

stair-robot will be deployed.

•

Assure that the angle of the stairs is not more

than 45 º

• • Make sure that no operator or other person is underneath the (loaded) Stairrobot

during operation

Secure the working area using warning boards or blocking ribbon

Page 12 of 28

Page 13

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

•

To avoid misuse by unauthorised persons,

don’t leave the machine unattended.

•

Within the path of the machine there may be

no obstructions.

•

Make sure the environment of the machine is

dry, clean and illuminated sufficiently.

•

With the machine in operation it is forbidden to

be within the operation area of this apparatus.

•

Before taking the machine into operation the

machine operator has to be certain that

nobody is located within the operating area of

the machine.

•

If the machine is used into the darkness, the

operation position has to be illuminated

sufficiently (about 50 lux).

•

The machine may only be used for the

intended activities.

•

Inspection and maintenance activities have to

be done before operation

•

During inspection and maintenance the

machine may not be used for other purposes

•

The local action and safety rules have to be

acted upon.

•

Make sure you never walk under the robot

during operation.

•

Keep electrical switch boxes closed in order to

prevent contact danger.

•

Never drive the machine over a cable or

extension cord

•

Make sure the mains connection is grounded

properly

•

Make sure that no person stands on a cable

or extension cord

•

Make sure that the extension cord is unrolled

completely

•

Extension cord minimal requirements: 3x 2,5

mm cupper wire properly isolated

•

Extension cord must be no longer than 25

meters.

Page 13 of 28

Page 14

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

5 OPERATORS PROCEDURE

5.1. Pre-use inspection

To ensure proper working and safe operation of the SR 1750 HE StairRobot:

• Check that there are no exposed wires in either the main lead or the pendant control

• Check that both the main plug and the continental 16 amp plug and socket are all

secure

• Check that the pendant cable is secure in the pendant and at the machine end

• Check that no cable has been deformed. If a deformation is found the use of the

machine should be postponed until the cable has been repaired

• If on the dolly; drive the robot of the dolly on a flat surface, listen for excessive or

unusual noises from any part of the machine

• Check that the ramp will raise to it’s full extend and that it’s not leaking oil. When fully

extended the ramp should cause the platform’s front edges to be in firm contact with

the floor and the tracks to be lifted of the floor at the front end about one centimetre

• Irregularities are best noticed by rising the ramp repeatedly to it’s full up position and

then quickly pressing the down button to release the pressure. If, while the ramp is

fully extended the top of the cylinder moves more than 5 mm either towards the front

or the back of the Robot then the machine should not be used

• It is quite usual for some oil to be present around the top of the cylinder, however

with the up-button pressed and the pump running there should be no oil running

down the outside of the cylinder

• Check that the down-button permits the ramp to descend, and in addition check that

the descend adjuster permits the speed of the descend to be altered. From fully

extended to fully closed should take no less than 25 seconds with an applied load of

80 Kilogram with the ascend adjuster turned maximum counter clockwise

• Check that no rubber blocks on the tracks are severely damaged or torn off

• Check the drive-tooth side of the tracks for exposed stringing cords or damage

• Check that nothing has been trapped between the tracks and the robot

• Check that when going from forward to reverse direction on the pendant button the

delay before the tracks start moving in the opposite direction is no longer than one

second. Any longer time indicates sloppiness in the drive chain which should be

investigated

• Check that the platform sits down on the lower base when lowered

• Check that the castors of the dolly can move in all directions and are not jammed

Check that the cable of the winch has not been deformed

•

If there are no defects found the machine is ready for use. If a defect is found do not use the

machine until the Stair-Robot is repaired.

Page 14 of 28

Page 15

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

5.2. Loading

5.2.1 The correct position of the load

• The objective is to create an optimal centre of gravity position for the loaded stairrobot

considering the ‘weight distribution’ of the load

• If the load is not placed in the correct position on the lifting

platform, the Stair robot can get instable during the process of

climbing or descending a staircase. This can cause the robot to

fall down the stairs resulting in serious damage and injuries.

• Before positioning the load on the

lifting platform the centre of gravity of

the load has to be determined

• Position the load on the platform with

the centre of gravity of the load end

forward (in positive area)

• Position the load with the centre of

gravity of the load as low as possible

to the lifting platform.

Page 15 of 28

Page 16

AATA INTERNATIONAL B.V.

5.2.2. Loading procedure

• Start the procedure by securing the area for loading. Move the dolly with the stair

robot into the desired position for loading.

• Always unroll extension power cable and connect with the robot before connecting

to mains

• Reverse the Robot of the dolly, fit the loading-ramp into position at the front of the

robot

• Slot the winch into the lifting platform at the rear of the stairrobot

• Pull the winch-hawser out and connect it with the load. The load can now be

winched into position on the stairrobot, one man operating the winch and one man

guiding the load of the ramp onto the platform. While operating the winch the

lifting platform will rise until the platform has reached the same gradient as the

loading-ramp

• Connect the load secure to the lifting platform. Note: never fit any straps to the

chassis-bracket

• If the load is secured to the stairrobot the winch and loading ramp can be

removed

• Always remove the winch from the stairrobot before ascending the stairway

because it ads length to the dimensions of the stairrobot

• Turn the descent-adjuster maximum clockwise

• Lift the platform +/- 10 cm by pushing the up-button

• Push the down-button to lower the platform and turn the descent adjuster counter

clockwise until the platform starts to descent. Lower the platform

• The stairrobot can now be driven back on the dolly; use the up-button to keep the

‘platform level’ in horizontal position

Manual Stair Robot SR1750 HE

Publication: 29-07-04

• The centre of gravity of the load should

be within the positive area between the

tracks.

Page 16 of 28

Page 17

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

5.3. Ascending

Load level

• Ideal load level is obtained

by adjusting the platform to

the gradient of the stairs or

dolly

• The objective is to maintain

a horizontal level of the

platform during operation.

• Note: do not lower the platform

over its balance point, the Stair

robot will get instable during

the process of climbing or

descending a staircase. This

can cause the robot to fall

down the stairs resulting in

serious damage and injuries.

• Move the loaded stairrobot on the dolly with the forward end towards the bottom of

the stairs

• Fit the lead on ramp between the dolly and second or third step on the stairs.

• Secure a load support strap (6 m) to the reverse end of the stairrobot. Place the strap

across the forward end of the load to be held by one of the operators.

• Both operators should move on to the stairs and make sure that no person is beneath

the stairrobot

• One operator will use the remote control button panel and drive the loaded stairrobot

up the stairs. The other will firmly hold the load support strap; this will enable him to

‘feel’ the balance of the load. He also uses it to restrain the load if necessary and

helps its forward movement at the top of the stairs

• The control operator will press the forward button to drive the stairrobot over the lead

on ramp and up the stairs. He will keep the load level by adjusting the platform

position using the up or down button.

• The up or down button can be pressed simultaneously with either forward or reverse

Press an d the platform will lower

Press an d the platform will lift

Press an d t he stairr obot will driv e forward

Press an d t he stairr obot will rev e rs e

Page 17 of 28

Page 18

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

• The stair robot can be stopped at any stage by just releasing the buttons

• When arriving on top of the stairway; stop the stairrobot on the stairs and place the

dolly in position at the top of the stairs in front of the stairrobot. Pull the extendable

frame out of the dolly to increase stability

• Start the forward movement again

• Note: expect a change of gradient from the level of the stairs to the gradient of the

dolly

• When the stairrobot has reached the ‘point of balance’, the operator holding the load

support strap should assist in the movement by gently pulling the load support strap,

to ease the load downward. The other operator should keep the ideal load level

during this operation. The stairrobot can then be driven forward to settle onto the dolly

• Transport dolly and load to the unloading point or to the next flight of stairs to

continue upwards.

5.4. Descending

• Make sure that the stairway is secured and no person can enter the stairway.

• To descent the stairrobot down the stairway the loaded stairrobot has to be first

driven onto the dolly, as previously described for ascending

• Move the loaded stairrobot on the dolly with the downward end towards the edge of

the top of the step and stop 10 cm away.

• One operator will drive the stairrobot using the control panel while the other operator

will steady the load firmly using a load support strap.

• Press the reverse button to drive the robot from the dolly and down the stairs

• The up and down button is used to maintain ideal load level

• By reversing slowly, 5 cm at a time, and stopping at the ‘point of balance’ the control

operator will be able by pressing the up button gently alter the centre of gravity so as

to lower the reverse end tracks onto the top of the stairs.

• The dolly should be moved aside when the stairrobot is fully on the stairs.

• Drive the robot in reverse down the stairs steadying the movement throughout by

using the a load support strap

• Depending on the gradient, the stair robot will ride on the edge of two or three steps

at once. The rubber tracks pressing firmly onto the stairs

• On some stairs it may be found that occasionally two of the rubber treads ride on the

stair edge and when the third tread releases it’s grip the stairrobot will move down

suddenly about 2,5 cm until all three treads grip once more. This occurrence should

be expected by the operators and the stair robot should be driven on without a pause

• Before arriving at the bottom of the stairs the dolly and the lead on ramp should be

placed in position with the lead on ramp resting on the second or third step.

• Drive the stairrobot of the stairs and onto the dolly keeping the ideal load level by

using the up or down button

• Transport dolly and load to the unloading point or to the next flight of stairs to

continue downwards.

Page 18 of 28

Page 19

AATA INTERNATIONAL B.V.

5.5. Unloading

• Start the procedure by securing the area for unloading. Move the dolly with the

stair robot into the desired position for unloading.

• Reverse the Robot of the dolly, fit the loading-ramp into position at the front of the

robot

• Slot the winch into the lifting platform at the rear of the stairrobot

• Pull the winch-hawser out and connect it with the load. Disconnect the load from

the lifting platform

• The load can now be lowered to floor level, one man operating the winch and one

man guiding the load of the ramp onto the floor. While lowering the load the lifting

platform will rise until the platform has reached the same gradient as the loadingramp

• If the load is on the floor the winch and loading ramp can be removed

l these techniques should be practised with a light load first

• Al

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Page 19 of 28

Page 20

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

6 Trouble shooting chart

The stairrobot SR 1750 HE is designed and built to function for several years with little

maintenance. In case a problem occurs please make the following checks. If the problem

continues to exist please contact your local dealer

Symptom

• Main motor does

not work

Possible course

• No current

Solution

• Check electrical wires

and connections

• Check magneto

switches

• Check capacitors

• Hydraulic pump-

motor does not

work

• Main motor stops

• Hydraulic pump-

motor stops

• Hydraulic platform

does not lift

completely

• Hydraulic platform

does not go down

• No current

• Motor overheated

• Motor overheated

• Possible oil-shortage

• Pressure relieve valve

• Electro-magneto switch

does not work properly

• Check electrical wires

and connections

• Check magneto

switches

• Check capacitors

• Wait several minutes

• Wait several minutes

• Refill oil with spindle oil;

check oil in oil-tank;

should be 5 mm under

the top of the tank

• Open valve by turning it

counter clockwise,

move the platform up

and down a few times;

adjust the valve to the

weight of the load

• Check electrical wiring

and connections

Page 20 of 28

Page 21

AATA INTERNATIONAL B.V.

Symptom

• Oil leaks from

hydraulic ram

• Hydraulic platform

does not move up

Possible course

• Ram packing worn

• Plunger bent

• Under pressure in

hydraulic system

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Solution

• Replace o-ring and

back-up ring with repair

set

• Remove the wood

plate of the lifting

platform and unscrew

the valve on the oiltank pipe; move the

platform in up position

by hand and turn valve

screw tight

Page 21 of 28

Page 22

AATA INTERNATIONAL B.V.

7 Track replacement

• Loosen both bolts a1 and a2

• Turn bolts b1 and b2 counter clockwise until the axle is at point d

• Remove track at point C

• To install the new track, reverse the above procedure

Drawing (1.)

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Drawing (2.)

• After replacing tracks make sure that the > marks on both tracks are in

the in the same direction and position

Page 22 of 28

Page 23

AATA INTERNATIONAL B.V.

Manual Stair Robot SR1750 HE

Publication: 29-07-04

• Proper track tolerance at point F is +/- 10 mm (pulled by hand) drawing (3.)

• Make sure that the distances A1 ….A4 are equal on both sides of the

Stairrobot (drawing 4)

Drawing (3.)

Drawing (4.)

Page 23 of 28

Page 24

AATA INTERNATIONAL B.V.

8 Electrical system

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Page 24 of 28

Page 25

AATA INTERNATIONAL B.V.

9 Hydraulic system

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Page 25 of 28

Page 26

AATA INTERNATIONAL B.V.

10. Parts

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Page 26 of 28

Page 27

AATA INTERNATIONAL B.V.

10.1. Parts list

Art.nr.: Article

175.001A Main motor

175.001B Gearbox

175.002 Hydro-motor

175.003 Hydro-pump

175.003B Oil-seal hydro pump

175.007 4-button switch unit

175.008 Magneto switch

175.009 Transformer 220V/24V

175.011 Oil tank

175.012 Caterpillar wheel Rear

175.013 Caterpillar wheel Front

175.014 Front axle

175.015 Rear axle

175.016 Drive axle

175.017 Gearwheel 11 T

175.018 Gearwheel 38 T

175.019 Gearwheel 20 T

175.020 Bearing axle 30

175.021 Bearing axle 20

175.022 Lock ring

175.023 Teflon 303635

175.024 Teflon304030

175.032 Bearing holder

175.033 Teflon ring 51312

175.040 Top cross beam

175.041 Bottom cross beam

175.042 Hydro-ram

175.043 Filter

175.044 Relief valve

175.045 Main selector valve

175.046 Electro-unit

175.050 Capacitor 8uf

175.051 Capacitor 100 uf

175.077 Hydro-pipe set

175.100 Caterpillar track

175.101 Dolly

175.102 Ramp-board

175.103 Turn disk

175.104 Winch

175.105 Winch-handle

Manual Stair Robot SR1750 HE

Publication: 29-07-04

Page 27 of 28

Page 28

AATA INTERNATIONAL B.V.

11. CD-Rom video

Content:

• Stair robot general promotion video (mpeg1)

• Instruction video SR 1750 HE (mpeg1)

• Instruction video SR 450 (mpeg1)

Manual Stair Robot SR1750 HE

Publication: 29-07-04

cd-rom

Page 28 of 28

Loading...

Loading...