Page 1

PR-G3200M, PR-G5500M AND

PR-G7500M

GENERATORS

Operator’s Manual 1

Page 2

INTRODUCTION

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so

could result in personal injury or equipment damage. This

manual and safety signs on your machine may also be

available in other languages. (See your John Deere dealer

to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your machine and should remain with the machine

when you sell it.

MEASUREMENTS in this manual are given in both metric

and customary U.S. unit equivalents. Use only correct

replacement parts and fasteners. Metric and inch fasteners may require a specic metric or inch wrench.

RIGHT HAND AND LEFT HAND sides are determined by

facing the motor end of the machine.

The SERIAL NUMBER is located in the Specication or

Identication Numbers section. Accurately record all

the numbers to help in tracing the machine should it be

stolen. Your dealer also needs these numbers when you

order parts. File the identication numbers in a secure

place off the machine.

WARRANTY is provided from your John Deere dealer for

customers who operate and maintain their equipment as

described in this manual. The warranty is explained on

the warranty certicate shown in this manual.

This warranty provides you the assurance that your

dealer will back products where defects appear within

the warranty period. Should the equipment be abused,

or modied to change its performance beyond the original factory specications, the warranty will become void.

PROTECT YOUR INVESTMENT......

Use only John Deere Fuel Protect

Fuel Stabilizer with Ethanol Protection

TY27534 or TY27535. Developed to

ensure Optimum Performance and

Protection.

IMPORTANT...Use Year Round!

34-1904 012011

Warning: This product contains lead, a

chemical known to the State of California

to cause birth defects or other reproductive

harm.

Wash your hands after handling this product.

2 Operator’s Manual

Page 3

CONTENTS

Page

Safety ............................................................4

Safety Signs ..................................................5

Controls ......................................................12

Preparing the Generator ..............................11

Operation ..................................................... 16

Troubleshooting ........................................... 19

Service ......................................................... 20

Storage ........................................................25

Specications ..............................................26

Accessoires ................................................... 27

Warranty ....................................................... 28

ALL INFORMATION, ILLUSTRATIONS AND SPECIFICATIONS IN THIS MANUAL ARE BASED

ON THE LATEST INFORMATION AVAILABLE AT THE TIME OF PUBLICATION. THE RIGHT IS

RESERVED TO MAKE CHANGES AT ANY TIME WITHOUT NOTICE.

Operator’s Manual 3

Page 4

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

TH

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

TH

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

SAFETY

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on your machine or in this manual, be alert to the

potential for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word--DANGER, WARNING or CAUTION--is

used with the safety-alert symbol. DANGER identies

the most serious hazards.

DANGER or WARNING safety signs are located near

specic hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and

safety signs on your machine. Keep safety signs in good

condition. Replace missing or damaged safety signs.

Be sure new equipment components and repair parts include the current safety signs. Replacement safety signs

are available from your John Deere Customer Service

Representative.

Learn how to operate the machine and how to use controls properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition. Unauthorized modications to the machine may impair the

function and/or safety and affect machine life.

If you do not understand any part of this manual and

need assistance, contact your John Deere Customer

Service Representative.

4 Operator’s Manual

Page 5

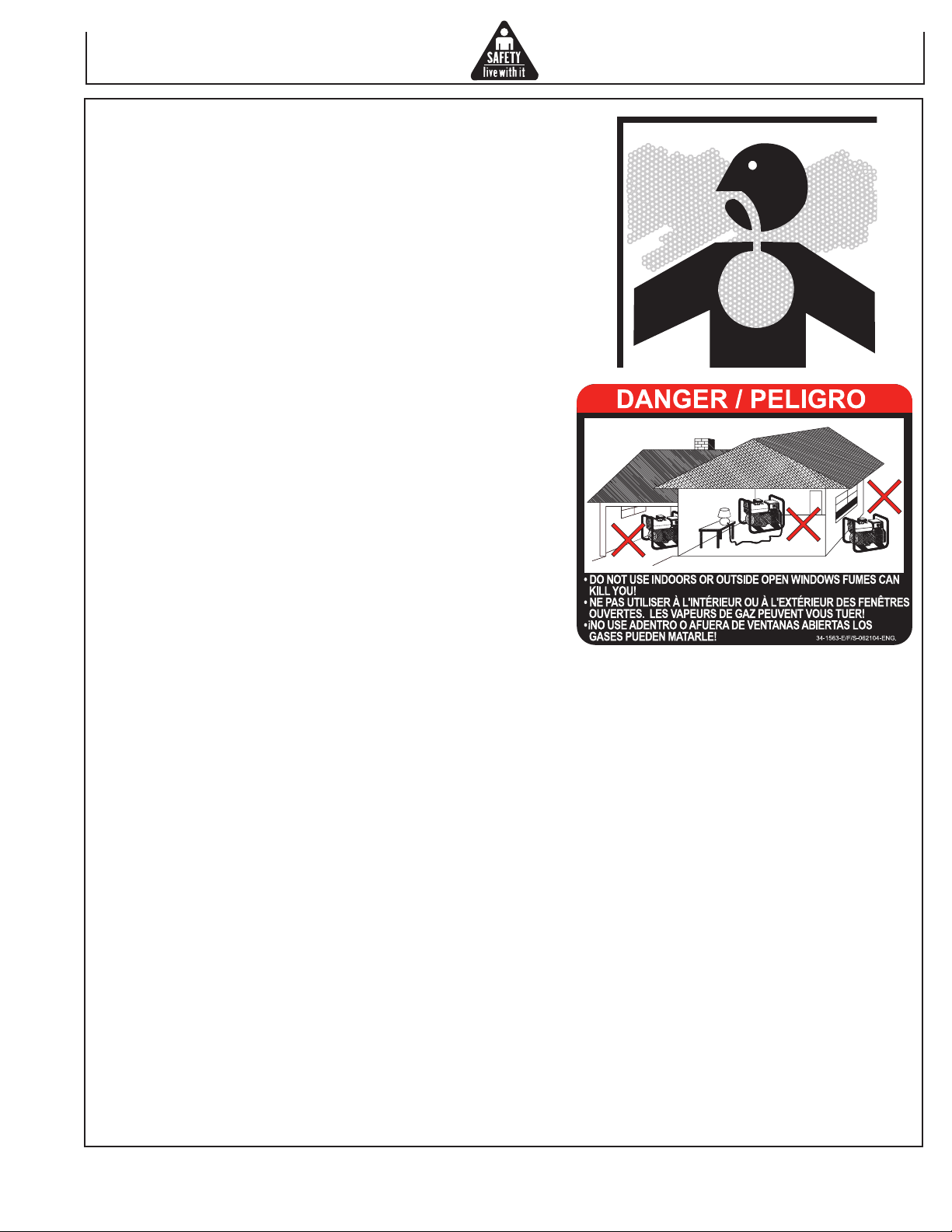

CARBON MONOXIDE - POISONOUS GAS

Use generator outdoors, away from open windows, vents, or

doors.

Generator exhaust contains carbon monoxide - a poisonous gas

that can kill you. You CAN NOT smell or see this gas.

Never use a generator in enclosed or partially-enclosed spaces.

Generators can produce high levels of carbon monoxide very

quickly. When you use a portable generator, remember that you

cannot smell or see carbon monoxide. Even if you can’t smell

exhaust fumes, you may still be exposed to carbon monoxide.

If you start to feel sick, dizzy, or weak while using a generator, get

to fresh air RIGHT AWAY. DO NOT DELAY. The carbon monoxide

from generators can rapidly lead to full incapacitation and death.

If you experience serious symptoms, get medical attention immediately. Inform medical staff that carbon monoxide poisoning

is suspected. If you experienced symptoms while indoors, have

someone call the re department to determine when it is safe to

re-enter the building.

Never operate the generator in an explosive atmosphere, near

combustible materials or where ventilation is not sufcient to carry

away exhaust fumes. Exhaust fumes can cause serious injury or

death.

NEVER use a generator indoors, including in homes, garages,

basements, crawl spaces, and other enclosed or partially-enclosed areas, even with ventilation. Opening doors and windows

or using fans will not prevent carbon monoxide build-up in the

home.

Follow the instructions that come with your generator. Locate

the unit outdoors and away from doors, windows, and vents that

could allow the carbon monoxide gas to come indoors.

ONLY run generator outdoors and away from air intakes.

NEVER run generator inside homes, garages, sheds, or other

semi-enclosed spaces. These spaces can trap poisonous gases

EVEN IF you run a fan or open doors and windows.

If you start to feel sick, dizzy, or weak while using the generator,

shut if off and get fresh air RIGHT AWAY. See a doctor. You may

have carbon monoxide poisoning.

Install battery-operated carbon monoxide alarms or plug-in

carbon monoxide alarms with battery back-up in your home, according to the manufacturer’s installation instructions. The carbon

monoxide alarms should be certied to the requirements of the

latest safety standards for carbon monoxide alarms. (UL 2034,

IAS 6-96, or CSA 6.19.01).

Test your carbon monoxide alarm frequently and replace dead

batteries.

Operator’s Manual 5

Page 6

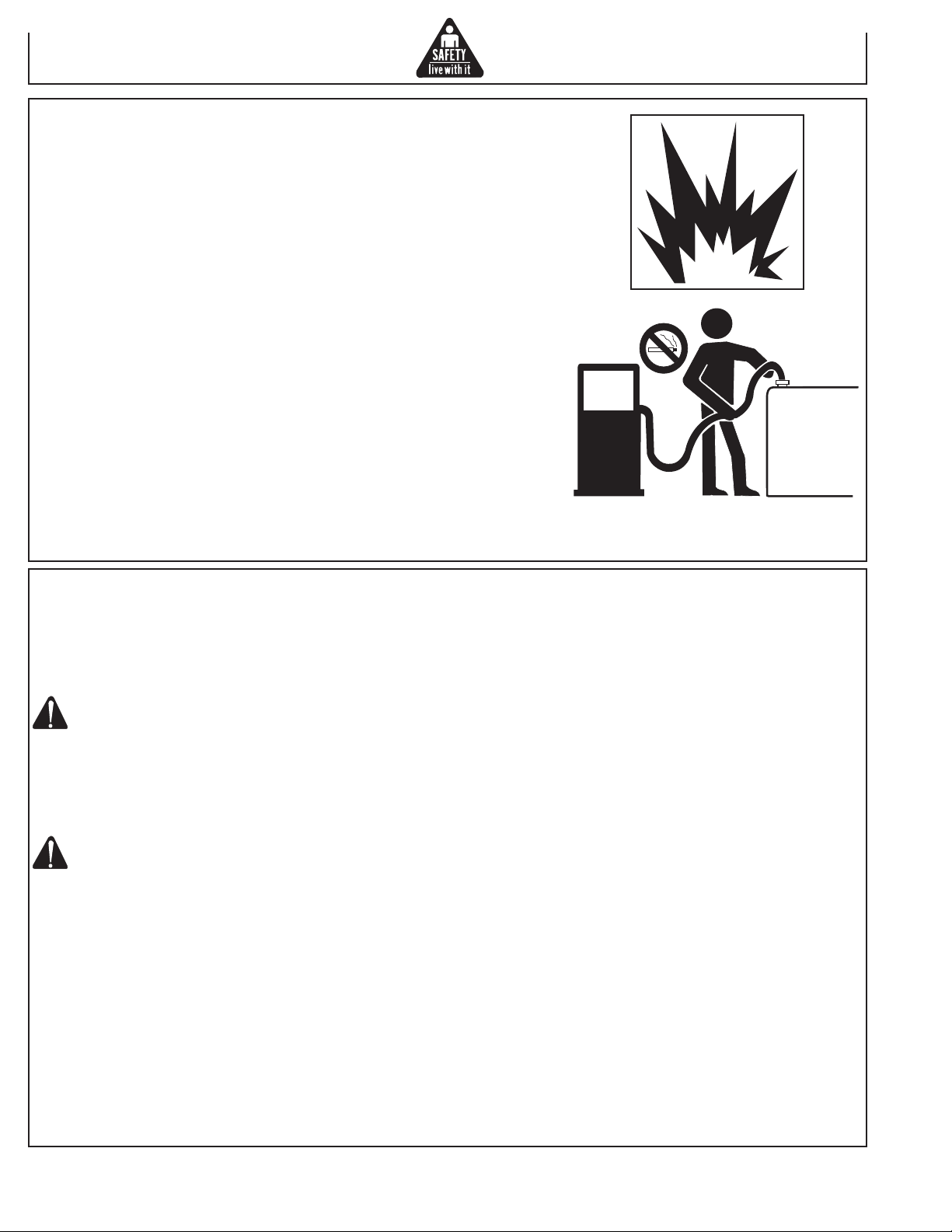

SAFETY WARNING WHEN REFUELING

Gasoline is extremely ammable and its vapors can explode if ignited.

Observe all safety regulations for the safe handling of fuel. Handle fuel

in safety containers. If the container does not have a spout, use a funnel.

Do not overll the fuel tank, leave room for the fuel to expand.

Do not rell fuel tank while the engine is running. Before refueling the

generator, turn it off and let it cool down. Gasoline spilled on hot engine

parts could ignite.

Fill the tank only on an area of bare ground. While fueling the tank, keep

heat, sparks and open ame away. Carefully clean up any spilled fuel

before starting engine.

Always ll fuel tank in an area with plenty of ventilation to avoid inhaling

dangerous fumes.

NEVER store fuel for your generator in the home. Gasoline, propane,

kerosene, and other ammable liquids should be stored outside of living areas in properly-labeled, non-glass safety containers. Do not store

them near a fuel-burning appliance, such as a natural gas water heater

in a garage. If the fuel is spilled or the container is not sealed properly,

invisible vapors from the fuel can travel along the ground and can be

ignited by the appliance’s pilot light or by arcs from electric switches in

the appliance.

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

These generators are equipped with two GFCI (Ground Fault Circuit Interrupters) 120V duplex receptacles for protection against the hazards

of electrical shock from defective attachments such as, tools, cords,

and cables.

WARNING: THE GFCIS MAY NOT FUNCTION UNLESS THE

GENERATOR IS PROPERLY GROUNDED. FOLLOW THE

CORRECT PROCEDURE SPECIFIED IN THE SECTION

LABELED “GROUNDING INSTRUCTIONS”

A GFCI is a device that interrupts electricity from either the utility or

generator by means of a special type of circuit breaker if a fault current

ow to the ground occurs.

WARNING: ONLY THE 120V DUPLEX RECEPTACLES ARE

PROTECTED BY THE GFCI.

A GFCI can be used only with generators that have the neutral wire

internally bonded to the frame, and the frame properly grounded to the

earth. A GFCI will not work on generators that do not have the neutral wire bonded to the frame, or on generators which have not been

properly grounded. All John Deere generators have internally bonded

ground wires. A GFCI will not work if the unit is not properly grounded.

A GFCI may be required by OSHA regulations, the National Electric

Code and/or local and federal codes when operating a generator.

For additional protections against shock hazards due to defective

equipment attached to the twist-lock receptacles, consider the use of

a GFCI on each of these receptacles as well.

GFCIs and GFCI protected cord sets and cables may be purchased

from local electrical supply houses.

6 Operator’s Manual

Page 7

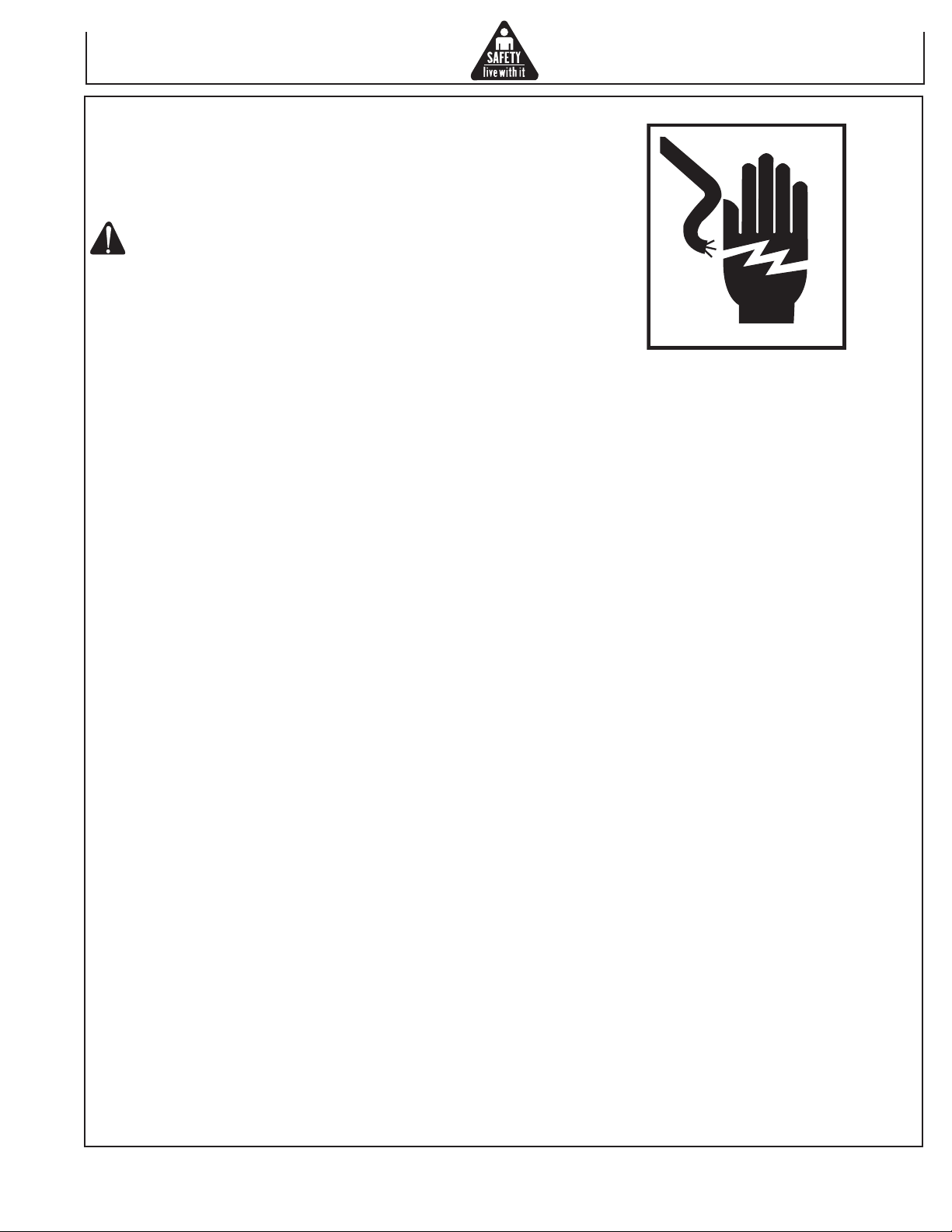

ELECTRICAL HAZARDS

This product must be grounded. It has permanent conductor between

the generator (stator winding) and the frame. If it should malfunction

or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock.

DANGER - IMPROPER CONNECTION OF THE EQUIPMENT-

GROUNDING CONDUCTOR CAN RESULT IN A RISK

OF ELECTROCUTION. CHECK WITH A QUALIFIED

ELECTRICIAN OR SERVICE PERSON IF YOU ARE IN

DOUBT AS TO WHETHER THE UNIT IS PROPERLY

GROUNDED.

This generator is equipped with a grounding terminal for your protection. Always complete the ground path from the generator to an

external ground source as instructed in the section labeled “Grounding Instructions” in the Preparation section of this manual.

The generator is a potential source of electrical shock if not kept dry.

Keep the generator dry and do not use in rain or wet conditions. To

protect from moisture, operate it on a dry surface under an open,

canopy-like structure. Dry your hands if wet before touching the

generator.

Risk of electric shock if you operate this generator with a faulty GFCI

(Ground Fault Circuit Interrupter). Test GFCI before each use, see

Operations Instructions for further information. If GFCI fails test, DO

NOT use your generator. Contact your John Deere customer service

representative.

Plug appliances directly into the generator. Or, use a heavy duty,

outdoor-rated extension cord that is rated (in watts or amps) at least

equal to the sum of the connected appliance loads. Check that the

entire cord is free of cuts or tears and that the plug has all three

prongs, especially a grounding pin.

NEVER try to power the house wiring by plugging the generator into a

wall outlet, a practice known as “back feeding”. This is an extremely

dangerous practice that presents an electrocution risk to utility

workers and neighbors served by the same utility transformer. It also

bypasses some of the built-in household circuit protection devices.

If you must connect the generator to the house wiring to power appliances, have a qualied electrician install the appropriate equipment

in accordance with local electrical codes. Or, check with your utility

company to see if it can install an appropriate power transfer switch.

For power outages, permanently installed stationary generators are

better suited for providing backup power to the home. Even a properly connected portable generator can become overloaded. This may

result in overheating or stressing the generator components, possibly

leading to a generator failure.

Operator’s Manual 7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

TH

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

TH

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

UA

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

UA

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

UA

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

UA

L

S

WARNING: TO REDUCE THE RISK OF INJURY,

READ THIS OPERATOR’S MANUAL COMPLETELY

BEFORE USING. WHEN USING THIS PRODUCT, THE

FOLLOWING BASIC PRECAUTIONS SHOULD ALWAYS

BE FOLLOWED:

1. Read all the instructions before using the product.

2. This product is equipped with a Ground Fault CircuitInterrupter

(GFCI) in the power cord to reduce the risk of electrical shock.

If replacement of the plug or cord is needed, use only identical

replacement parts.

3. Do not allow children or untrained persons to operate the

generator.

4. Do not operate the generator when fatigued or under the inuence

of drugs or chemicals. Stay alert. Watch what you are doing.

5. Follow the maintenance instructions specied in this manual.

6. When starting the generator, using recoil starter grip, be sure

that nothing is in a position to be hit by the operator’s hand or

arm.

7. Be sure the switch on electric power tools is in the “OFF” position

before plugging them into the generator.

8. Keep the immediate area free of all bystanders.

9. Be sure each person who operates this generator is properly

instructed in its safe operation.

10. Do not operate the generator or any electrical tool in any area

where water or similar materials constitute an electrical hazard

to the operator. Do not operate on wet surfaces, in rain or in

snow.

11. Always be sure that the generator is on secure footing so that

it cannot slide or shift around, endangering workers.

12. Avoid contacting the hot exhaust manifold, mufer or cylinder(s).

Keep clear of all rotating parts.

13. Unless the tool or appliance is double insulated, it must

be grounded through a properly grounded receptacle. (See

Preparing the Generator, Grounding Instructions). Tools and

appliances which have 3 prong plugs must be plugged into

extension cords and electrical receptacles with 3 holes. Before

operating any electrical item, be sure it is in good repair.

14. Follow instructions in this manual when testing Ground Fault

Circuit Interrupter to insure reliable operation.

15. Beware of using this equipment in conned spaces. Conned

spaces, without sufcient fresh air ventilation, can contain

dangerous gases. Running gasoline engines in such environments

can lead to deadly explosions and/or asphyxiation.

16. If your generator comes equipped with a transport dolly, make

sure this unit is secure during operation and when transporting

to prevent unexpected movement or rolling.

17. Use extreme caution when lifting this generator. Do not use

dolly handles to lift this generator, use only designated lifting

hook to lift this generator. This generator is heavy so proper

lifting techniques should be used.

8 Operator’s Manual

SAVE THESE INSTRUCTIONS

Page 9

WEAR PROTECTIVE CLOTHING

Wear close tting clothing and safety equipment appropriate to the job.

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones

while operating machine.

PREPARE FOR EMERGENCIES

Keep a rst aid kit and re extinguisher handy.

Keep emergency numbers for doctors, ambulance ser-

vice, hospital and re department near your telephone.

Be prepared if a re starts.

INSPECT GENERATOR

Be sure all covers, guards and shields are tight and in

place.

Locate all operating controls and safety labels.

Inspect power cord for damage before using. There is a

hazard of electrical shock from crushing, cutting or heat

damage.

SERVICE GENERATOR SAFELY

Before servicing the generator, disconnect all equipment and battery (if equipped) and allow unit to cool

down.

Service generator in a clean dry at area.

Operator’s Manual 9

Page 10

SAFETY SIGNS

DANGER DANGER PELIGRO

GND

34-0889

062104-ENG.

34-0889

POISONOUS GAS

This product gives off carbon monoxide, a

poisonous gas that can kill you. You

CANNOT smell it, see it, or taste it.

• ONLY run generator outdoors and away

from air intakes.

• NEVER run generator inside homes,

garages, sheds, or other semi-enclosed

spaces. These spaces can trap poisonous

gases EVEN IF you run a fan or open

doors and windows.

If you start to feel sick, dizzy, or weak while

using the generator, shut it off and get fresh

air RIGHT AWAY. See a doctor. You may

have carbon monoxide poisoning.

OPERATION

Read Operator's Manual carefully

before operating unit. Always make

sure unit is level and properly grounded.

Check engine oil before starting.

START-UP:

1. Open fuel valve.

2. Move choke lever to full choke.

3. Turn engine ignition switch to ON

position.

4. Pull recoil to start engine.

5. Once engine has started, slowly

move choke lever to no choke.

6. Allow unit to run two (2) minutes to

warm-up.

7. Loads can now be applied to unit.

34-1575-E/F/S-120208-ENG.

Read Operator's Manual carefully before operating this unit. Always

make sure unit is level and properly grounded. Check engine oil before

starting.

START-UP:

1. Open fuel valve.

2. Move choke lever to full choke.

3. Turn engine ignition switch to ON

position.

4. Pull recoil to start engine.

5. Once engine has started, slowly

move choke lever to no choke.

6. Allow unit to run two (2) minutes to

warm-up.

7. Loads can now be applied to unit.

WARNING

EXPLOSIVE FUEL

Gasoline is extremely flammable and its

vapors can explode if ignited causing

serious injury or death.

• Store gasoline only in approved

containers, in well-ventilated,

unoccupied areas away from sparks

and flames.

• Always stop unit and allow unit to cool

before refueling.

• Do NOT fill fuel tank while engine is

hot or running.

• Do NOT overfill fuel tank.

• Never use gasoline as a cleaning

agent. Wipe up any spills immediately.

SHUT-DOWN:

1. Remove all load by turning off electrical

applicances and unplugging electric

cords.

2. Allow engine to run at idle speed to cool

for two (2) minutes. Not allowing engine

to cool may result in damage to unit.

3. Turn off engine ignition switch.

4. Close fuel valve.

TEST GFCI RECEPTACLE(S) BEFORE

EACH USE. SEE OPERATORS

MANUAL FOR INSTRUCTIONS.

SHOCK

A generator is a potential shock hazard

which can result in serious injury or death.

• Generator must be kept dry.

• Do NOT operate unit with wet hands.

• Generator MUST be grounded before

use. See operators manual for specific

instructions.

• Use extreme caution when refueling unit.

• GFCI receptacles must be tested before

each use. See operators manual.

• Always keep generator four (4) feet from

any structure.

• Always remove refueling gas can from

generator area.

Lire soigneusement le manuel de l'utilisateur avant

de se servir de l'appareil. S'assurer toujours que

l'appareil est sur une surface plane et qu'il est

correctement relié à la terre. Vérifier le niveau

d'huile du moteur avant le démarrage.

DEMARRAGE:

1. Ouvrir la soupape de carburant.

2. Placer la manette du starter en position

3. Mettre le contact du moteur en position

de marche (ON).

4. Tirer le lanceur à rappel pour démarrer le moteur.

5. Lorsque le moteur a démarré, ramener

6. Permettre à l'appareil de tourner pendant deux (2)

7. L'appareil peut maintenant prendre des charges.

OPERATION

SHUT-DOWN:

1. Remove all load by turning off

electrical applicances and

unplugging electric cords.

2. Allow engine to run at idle speed

to cool two (2) minutes. Not

allowing engine to cool may

result in damage to unit.

3. Turn off engine ignition switch.

4. Close fuel valve.

TEST GFCI RECEPTACLE(S) BEFORE EACH USE.

SEE OPERATORS MANUAL FOR INSTRUCTIONS.

GAZ TOXIQUE

Ce produit émet de l'oxyde de carbone, un gaz

toxique qui peut vous tuer. Vous ne pouvez pas le

sentir, le voir, ou le percevoir au goût.

• N'utiliser le générateur qu'à l'extérieur et loin des

admissions d'air.

• Ne JAMAIS utiliser le générateur à l'intérieur de

maisons, garages, remises, ou autres espaces

partiellement fermés. Ces espaces peuvent retenir

des gaz toxiques même si vous utilisez un

ventilateur ou si vous ouvrez des portes et fenêtres.

Si vous commencez à vous sentir malade, étourdi, ou

faible pendant l'utilisation du générateur, le mettre à

l'arrêt et sortez au grand air immédiatement. Voir un

docteur. Vous souffrez peut être d'une intoxication à

l'oxyde de carbone.

AVERTISSEMENT

CARBURANT EXPLOSIF

L'essence est extrêmement inflammable et ses

vapeurs peuvent exploser si on l'enflamme qui peut

entraîner des blessures graves ou la mort.

• N'entreposer l'essence que dans des conteneurs

homologués, dans des endroits bien aérés et

inoccupés loin de toute étincelle et flamme.

• Arrêter toujours l'appareil et lui permettre de refroidir

avant de le ravitailler en carburant.

• Ne JAMAIS remplir le réservoir d'essence lorsque le

moteur est chaud ou marche.

• Ne PAS trop remplir le réservoir d'essence.

• Ne JAMAIS utiliser l'essence comme nettoyant.

Essuyer immédiatement tout débordement.

DÉCHARGE

Un génerateur pose un danger de décharge électrique qui

peut entraîner des blessures graves ou la mort.

• Le génerateur doit être maintenu au sec.

• Ne PAS utiliser le génerateur avec les mains mouillées.

• Le générateur doit être mis à la terre avant de l'utiliser.

Consulter le manuel de l'utilisateur pour des instructions

spécifiques.

• Soyez extrémement prudent lors du ravitaillement en

carburant de cet appareil.

• Les prises GFCI doivent être testées avant chaque

utilisation. Voir le manuel de l'utilisateur.

• Placer toujours le générateur à une distance d'au moins

quatre pieds (1m 22) de toute structure.

• Enlever toujours le bidon de ravitaillement en essence de

l'endroit où se trouve le générateur.

34-1764 (PR-G3200M)

D'UTILISATION

ARRET:

1. Supprimer les charges en éteignant les appareils

électriques et en débranchant les raccords

électriques.

2. Laisser le moteur tourner au ralenti pendant deux

(2) minutes pour qu'il refroidisse. L'appareil peut

être endommagé si on ne permet pas au moteur de

maximum.

doucement la manette du starter en position

fermée.

minutes pour qu'il se réchauffe.

refroidir.

3. Fermer le contact du moteur.

4. Fermer la soupape de carburant.

TESTER LA (LES) PRISE (S) GFCI AVANT

CHAQUE UTILISATION. VOIR LE MANUEL DE

L'UTILISATEUR POUR LES INSTRUCTIONS À

SUIVRE.

34-1575 (PR-G5500M AND PR-G7500M)

D'UTILISATION

Lire soigneusement le manuel de l'utilisateur avant de se servir de

l'appareil. S'assurer toujours que l'appareil est sur une surface plane et

qu'il est correctement relié à la terre. Vérifier le niveau d'huile du moteur

avant le démarrage.

DEMARRAGE:

1. Ouvrir la soupape de carburant de

l'appareil ou du moteur.

2. Placer la manette du starter en position

maximum.

3. Mettre le contact du moteur en position

de marche (ON).

4. Tirer le lanceur à rappel pour démarrer le

moteur.

5. Lorsque le moteur a démarré, ramener

doucement la manette du starter en

position fermée.

6. Permettre à l'appareil de tourner pendant

deux (2) minutes pour qu'il se

réchauffe.

7. L'appareil peut maintenant prendre des

charges.

TESTER LA (LES) PRISE (S) GFCI AVANT CHAQUE UTILISATION.

VOIR LE MANUEL DE L'UTILISATEUR POUR LES

INSTRUCTIONS À SUIVRE.

ARRET:

1. Supprimer les charges en

éteignant les appareils

électriques et débranchant

les raccords électriques.

2. Laisser le moteur tourner au

ralenti pendant deux (2)

minutes pour qu'il

refroidisse. L'appareil peut

être endommagé si on ne

permet pas au moteur de

refroidir.

3. Fermer le contact du moteur.

4. Fermer la soupape de

carburant sur l'appareil ou le

moteur.

Lea manual de operador antes de operar esta unidad. Siempre

asegúrese que unidad sea plana y conecte a tierra correcto. Revise el

aceite de motor antes de empezando.

OPERACIÓN:

1. Abra válvula de comestible en

2. Mueva palanca de choke a choke

3. Doble interruptor de ignición de

4. Tire retroceso para empezar el

5. Cuando motor empieza, mueva muy

6. Permite la unidad a opere por dos

7. Ahora cargas pueden aplicar a la

EXAMINE GFCI RECIPIENTES ANTES DE CADA USO. VEA MANUAL

34-1762 (PR-G3200M)

GASES VENENOSOS

Este producto despide monóxido de carbono, un

gas venenoso que puede matarle. No puede

olerlo, verlo, o probarlo.

• Sólo opere generador en aire libre y afuera de

entradas de aire.

• NUNCA opere generador adentro de casas,

garajes, cabañas, o otros espacios

parcialamente cerrados. Estos espacios puede

atrapar gases venenosos AUNQUE SI opere

una venilador o abra puertas y ventanas.

Si empieza sentir enfermo, mareo, o débil

cuando usando generador, lo apague y vaya

adentro en aire libre PRONTO. Viste un doctor.

Puede tener venenoso de monóxido de

carbono.

Lea manual de operador antes de operar

esta unidad. Siempre asegúrese que unidad

sea plana y conecte a tierra correcto. Revise

el aceite de motor antes de empezando.

OPERACIÓN:

1. Abra válvula de comestible.

2. Mueva palanca de choke a choke

completo.

3. Doble interruptor de ignición de motor a

posición de ON.

4. Tire retroceso para empezar el motor.

5. Cuando motor empieza, mueva muy

despacio la palanca de choke a no choke.

6. Permite la unidad a opere por dos (2)

minutos para precalentamiento.

7. Ahora cargas pueden aplicar a la unidad.

OPERACIÓN

unidad o motor.

completo.

motor a posición de ON.

motor.

despacio la palanca de choke a no

choke.

(2) minutos para precalentamiento.

unidad.

DE OPERADOR PARA INSTRUCCIONES.

ADVERTENCIA

COMESTIBLE EXPLOSIVO

Gasolina es inflammable sumamente y sus

vapors pueden explotar si inflamarse que

puede resultar en lesiones graves o muerte.

• Mantenga gasoline solo en envases

autorizadors, areas con buen ventilación y

desocupadas afuera de chispas y llamas.

• Siempre pare la unidad y permite enfriarse

de unidad antes de rellenar.

• No llene el tanque de comestible cuando el

motor está calor o funcionando.

• No derrame el tanque de comestible.

• Nunca use gasolina como un agente de

limpiando. Limpie algunas astillas

inmediateamente.

OPERACIÓN

APAGADO:

1. Quite todas cargas como apagadando

aparatos électricos y desconecten cordones

électricos.

2. Permite el motor a operar a velocidad de

flojear para enfriarse por dos (2) minutos.

No permitando enfriarse del motor puede

resultar en daño a la unidad.

3. Apague interruptor de ingnición de motor.

4. Cierre válvula de comestible.

EXAMINE GFCI RECIPIENTES ANTES DE

OPERADOR PARA INSTRUCCIONES.

APAGADO:

1. Quite todas cargas como

apagadando aparatos électricos

y desconecten cordones

électricos.

2. Permite el motor a operar a

velocidad de flojear para

enfriarse por dos (2) minutos.

No permitando enfriarse del

motor puede resultar en daño a

la unidad.

3. Apague interruptor de ingnición

de motor.

4. Cierre válvula de comestible en

unidad o motor.

34-1762-E/F/S-020906-ENG.

DESCARGA

Un generador es un potencial riesgo de descarga

que puede resultar en lesiones graves o muerte.

• Generadores tienen que mantener secos.

• No opere esta unidad con manos mojados.

• Generador TIENE que sea conectado a tierra

antes de uso. Vea manual de operador para

instrcciones especificos.

• Use caución extremo cuando rellenando esta

unidad.

• GFCI recipientes tienen que tener un examen

antes de cada uso. Vea manual de operador.

• Siempre mantenga el generador cuatro (4) pisos

de alga estructura.

• Siempre quite lata de gasolina de rellenando de

area de generador.

34-1764-E/F/S-020906-ENG.

CADA USO. VEA MANUAL DE

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide. This is a

poison you cannot see or smell.

L'utilisation d'un groupe électrogène à

l'intérieur PEUT VOUS TUER EN

QUELQUES MINUTES.

Le gaz d'échappement du groupe

électrogène contient de l'oxyde de

carbone. C'est un gaz toxique que l'on

ne peut pas voir ou sentir.

NEVER use inside a home

or garage, EVEN IF doors

and windows are open.

Only use OUTSIDE and far

away from windows, doors,

and vents.

Ne JAMAIS utiliser à l'intérieur d'une

maison ou d'un garage, MÊME SI les

portes et fenêtres s'ont ouvertes.

N'utiliser qu'à l'EXTÉRIEUR et bien éloigné

des fenêtres, portes, et conduits d'aération.

Utilizando un generador adentro

PUEDE MATARLE EN MINUTOS.

El escape de generador contiene

monóxido de carbono. Este es un

gas tóxico que usted no puede ver ni

puede oler.

Nunca utilice dentro de un hogar ni el

garaje, INCLUSO SI puertas y

ventanas estén abiertas.

Solo utilice AFUERAS y lejos de

ventanas abiertas, las puertas, y

descargas.

34-1916-031607-E-F-S.

34-1916

10 Operator’s Manual

Page 11

34-1590

34-1561 (PR-G7500M)

34-1562 (PR-G5500M)

34-1574 (PR-G5500M)

Operator’s Manual 11

Page 12

CONTROLS FOR

CONTROLS

B

C

A

D

E

B

C

D

B

A -- Control Panel

B -- Fuel Tank

C

D

C -- Fuel Cap

D-- Oil Dipstick

E -- Oil Drain

12 Operator’s Manual

Page 13

PREPARING THE GENERATOR

GROUNDING INSTRUCTIONS

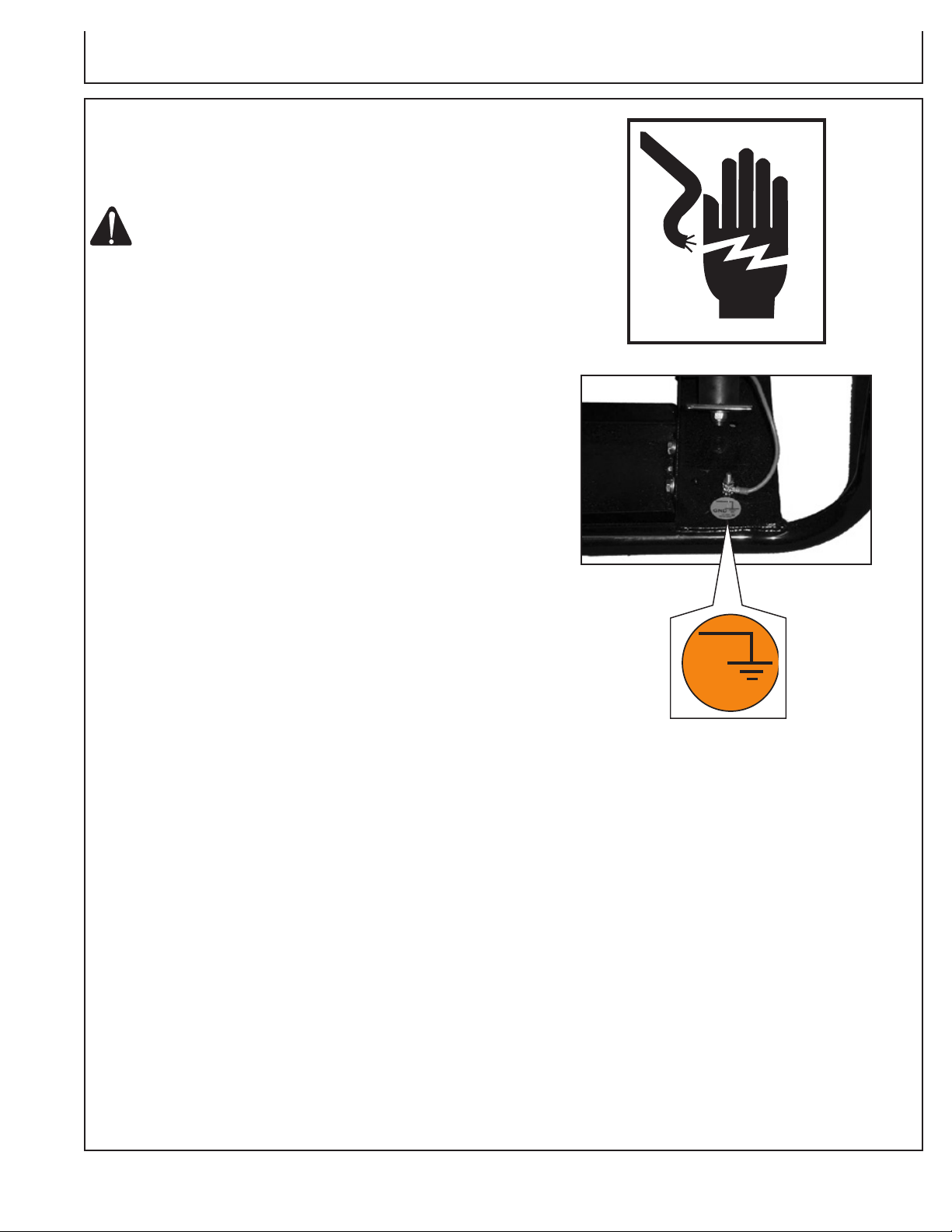

This product must be grounded. If it should malfunction or

breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

DANGER - IMPROPER CONNECTION OF THE

EQUIPMENT-GROUNDING CONDUCTOR CAN

RESULT IN A RISK OF ELECTROCUTION. CHECK

WITH A QUALIFIED ELECTRICIAN OR SERVICE

PERSON IF YOU ARE IN DOUBT AS TO WHETHER

THE UNIT IS PROPERLY GROUNDED.

The wing nut and ground terminal on the frame must always be

used to connect the generator to a suitable ground source. The

ground path should be made with #8 size wire. Connect the

terminal of the ground wire between the two star washers and

wing nut then tighten the wing nut fully. Connect the other end

of the wire securely to a suitable ground source.

The National Electric Code contains several practical ways in

which to establish a good ground source. Examples given below illustrate a few of the ways in which a good ground source

may be established.

A metal underground water pipe in direct contact with the earth

for at least 10 feet can be used as a grounding source. If an

pipe is unavailable, an 8 foot length of pipe or rod may be used

as the ground source. The pipe should be 3/4 inch trade size

or larger and the outer surface must be noncorrosive. If a steel

or iron rod is used it should be at least 5/8 inch diameter and if

a nonferrous rod is used it should be at least 1/2 inch diameter

and be listed as material for grounding. Drive the rod or pipe to

a depth of 8 feet. If a rock bottom is encountered less than 4

feet down, bury the rod or pipe in a trench. All electrical tools

and appliances operated from this generator, must be properly

grounded by use of a third wire or be “Double Insulated”.

It is recommended to:

GND

34-0889

062104-ENG.

1. Use electrical devices with 3 prong power cords.

2. Use an extension cord with a 3 hole receptacle and a 3 prong

plug at the opposite ends to ensure continuity of the ground

protection from the generator to appliance.

We strongly recommend that all applicable federal, state and local regulations relating to grounding specications be checked

and followed.

LINE TRANSFER SWITCH

If this generator is used for standby service, it must have a

transfer switch between the utility power service and the generator. The transfer switch not only prevents the utility power

form feeding into the generator, but is also prevents the generator form feeding out into the utility company’s lines. This is

intended to protect the serviceman who may be working on a

damaged line.

THIS INSTALLATION MUST BE DONE BY A LICENSED

ELECTRICIAN AND ALL LOCAL CODES MUST BE FOLLOWED.

Operator’s Manual 13

Page 14

PREPARING THE GENERATOR

ENGINE OIL

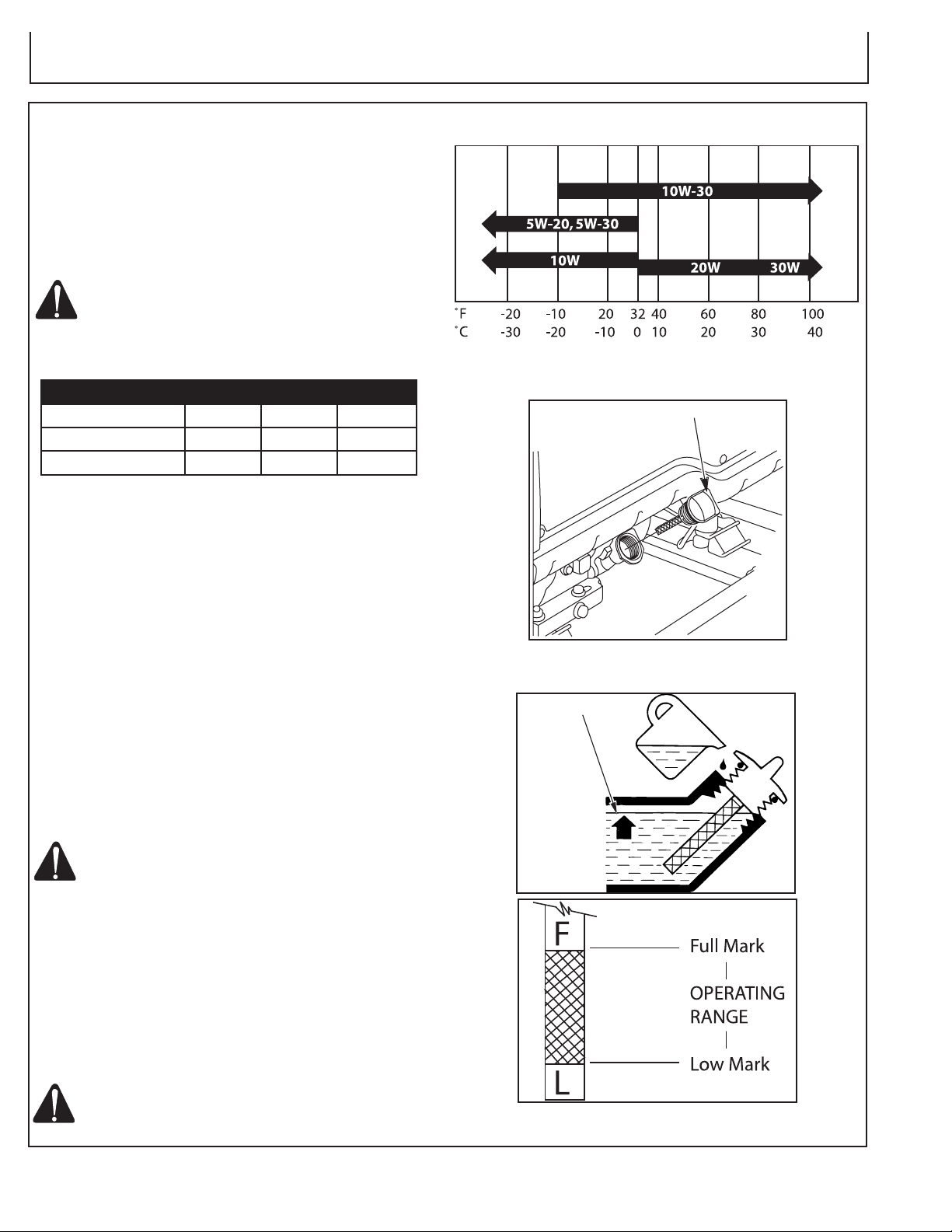

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

Use a high quality detergent oil with API classications of

SJ or higher.

Check oil level before each operation and ensure that it is

maintained.

CAUTION: THIS ENGINE CRANKCASE IS NOT

FILLED WITH OIL AT THE FACTORY, SO BE

SURE TO FILL IT BEFORE OPERATING THE

ENGINE.

ENGINE OIL CAPACITY

MODEL # Liters Quart Ounces

PR-G3200M 0.6 0.63 20.3

PR-G5500M 1.1 1.16 37.2

PR-G7500M 1.1 1.16 37.2

NOTE: These engines are equipped with a “Low Oil” shut-off

system for engine protection. If the engine fails to start, check

engine crankcase for oil.

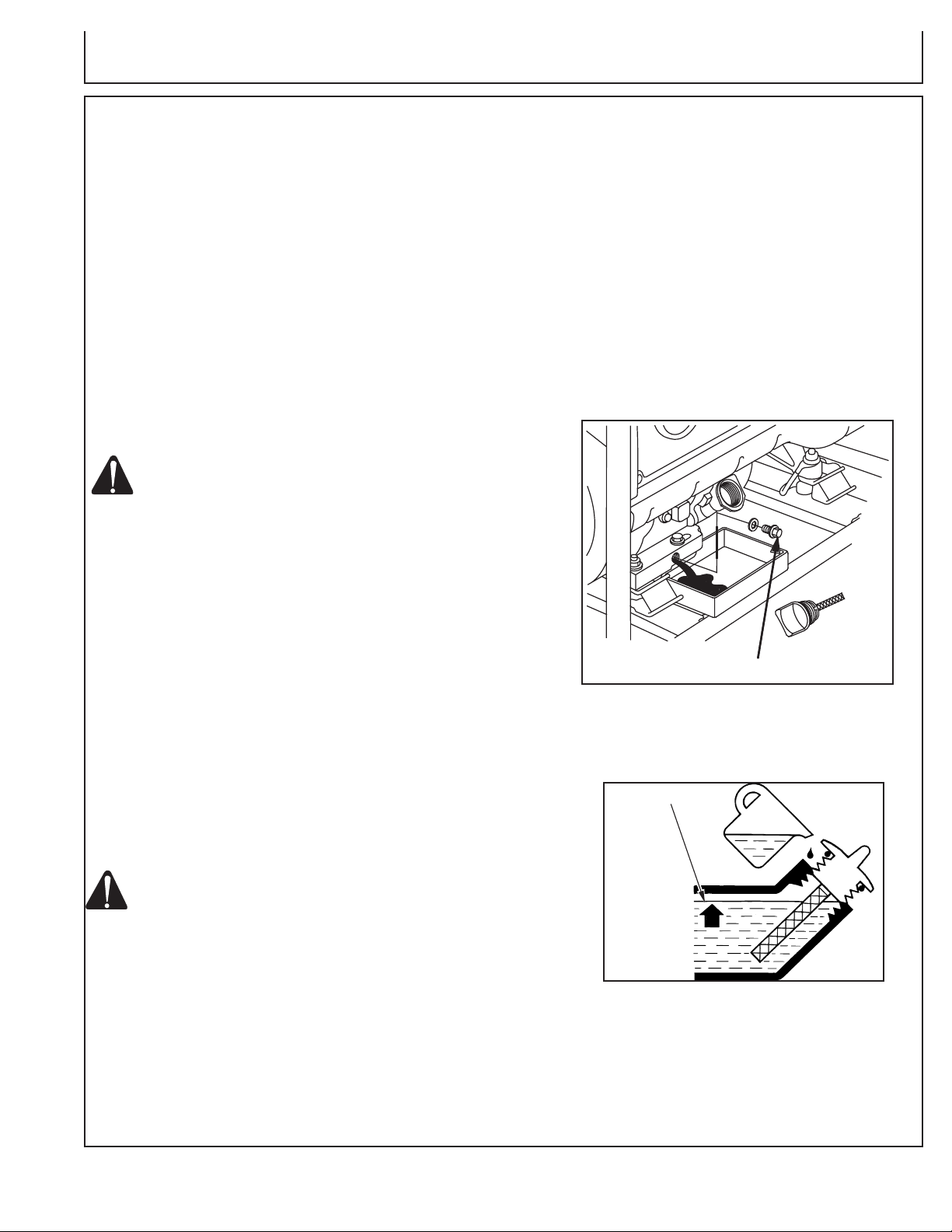

To ll with oil:

TEMPERATURE CHART

OIL GAUGE

1. Level the engine to ensure accurate inspection and to

prevent overlling.

2. Unscrew the oil gauge (Fig. 1), wipe the dipstick dry.

Reinsert the oil gauge back into the oil ll gauge opening.

Remove the oil gauge and check the oil level.

3. The oil level should be between the full and low marks

on the dipstick. (Fig. 2)

NOTE: When checking the oil be sure the engine is level.

4. Fill with oil as required through the oil ll gauge opening.

5. Replace the oil gauge and screw in rmly.

6. Wipe up any spilled oil.

FUELING

WARNING: EXPLOSIVE FUEL! GASOLINE IS

EXTREMELY FLAMMABLE AND ITS VAPORS

CAN EXPLODE IF IGNITED.

STORE GASOLINE ONLY IN APPROVED

CONTAINERS, IN WELL VENTILATED,

UNOCCUPIED BUILDINGS AND AWAY FROM

SPARKS OR FLAMES.

DO NOT FILL THE FUEL TANK WHILE THE ENGINE

IS HOT OR RUNNING, SINCE SPILLED FUEL

COULD IGNITE IF IT COMES IN CONTACT WITH

HOT PARTS OR SPARKS FROM IGNITION. DO

NOT START THE ENGINE NEAR SPILLED FUEL.

NEVER USE GASOLINE AS A CLEANING AGENT.

WARNING: DO NOT OVERFILL THE FUEL TANK,

LEAVE ROOM FOR THE FUEL TO EXPAND.

(Fig. 1)

UPPER LEVEL

(Fig. 2)

14 Operator’s Manual

Page 15

PREPARING THE GENERATOR

GENERAL RECOMMENDATIONS

• Purchase gasoline in small quantities and store in clean,

approved containers.

• To minimize gum deposits in your fuel system and to

insure easy starting, do not use gasoline left over from

the previous season.

• Do not add oil to the gasoline.

FUEL TYPE

• For best results use only clean, fresh, unleaded gasoline

with a pump sticker octane rating of 87 or higher.

• Unleaded gasoline is recommended as it leaves less

combustion chamber deposits.

GASOLINE/ALCOHOL BLENDS:

Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline

by volume) is approved, as a fuel. Other gasoline/alcohol

blends are not approved.

GASOLINE/ETHER BLENDS:

Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline

blends (up to a maximum of 15% MTBE by volume) are

approved as a fuel. Other gasoline/ether blends are not approved.

HIGH ALTITUDE

At high altitude, the standard carburetor air/fuel mixture will

be too rich. Performance will decrease, and fuel consumption will increase. A very rich mixture will also foul the spark

plug and cause hard starting. Operation at an altitude that

differs from that at which this engine was certied, for extended periods of time, may increase emissions.

High altitude performance can be improved by specic

modications to the carburetor. If you always operate your

generator at altitudes above 5,000 feet (1,500 meters),

have your dealer perform this carburetor modication. This

engine, when operated at high altitude with the carburetor

modications for high altitude use, will meet each emission

standard throughout its useful life.

Even with carburetor modication, engine horsepower

will decrease about 3.5% for each 1,000-foot (300-meter)

increase in altitude. The effect of altitude on horsepower will

be greater than this if no carburetor modication is made.

NOTE:When the carburetor has been modied for high altitude opera-

tion, the air/fuel mixture will be too lean for low altitude use.

Operation at altitudes below 5,000 feet (1,500 meters) with a

modied carburetor may cause the engine to overheat and result

in serious engine damage.

For use at low altitudes, have your servicing dealer return the

carburetor to original factory specications.

Operator’s Manual 15

Page 16

OPERATION

OPERATION

RECOIL START

NOTE: Read Operator’s Manual carefully before operating this unit.

Always make sure the unit is level and properly grounded. Check

engine oil before starting.

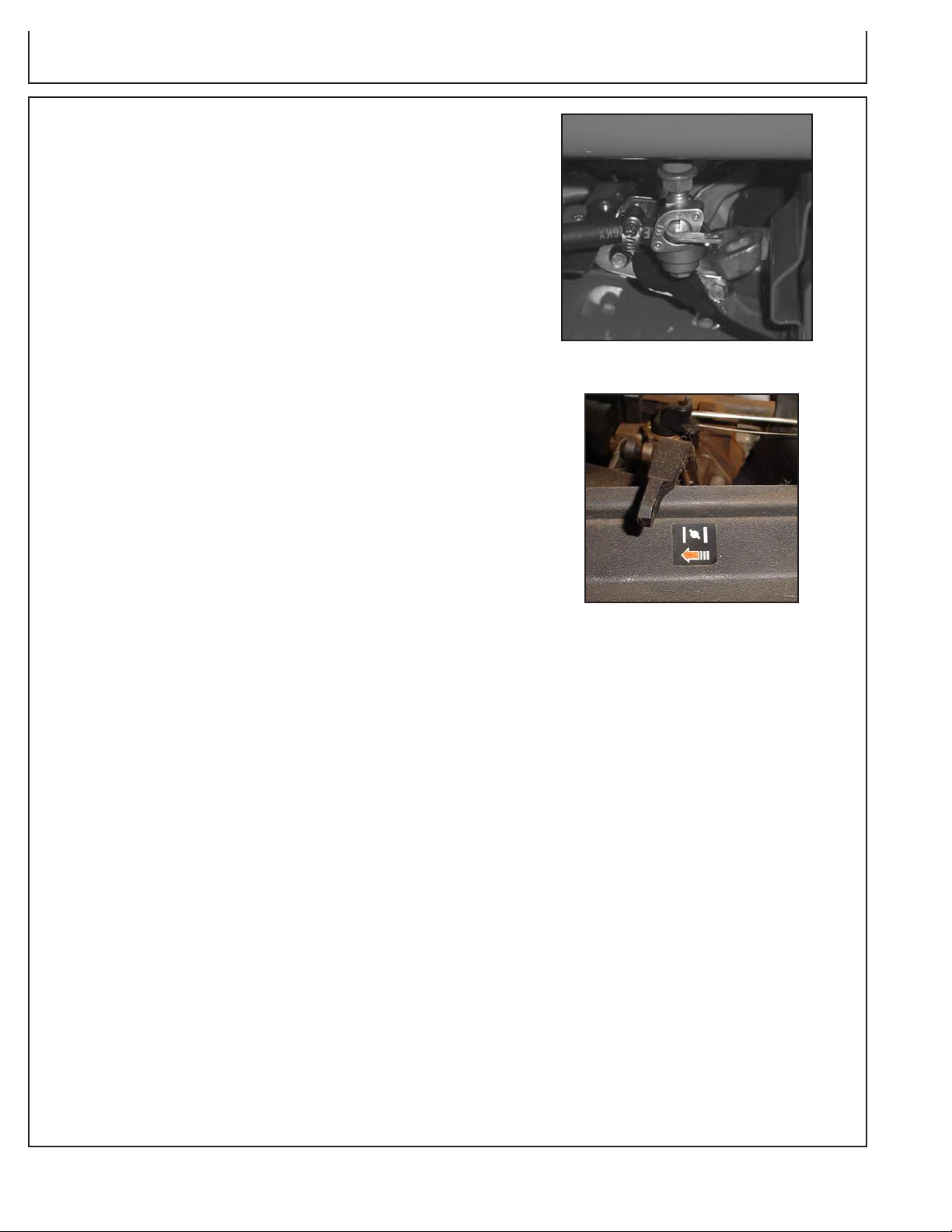

1. Open fuel valve on fuel tank. (See Fig. 3)

2. Move choke lever to full choke. If re-starting a warm engine,

the choke should be left in the off position. (See Fig. 4)

3. Turn the engine ignition switch to the ON position.

4. Pull recoil to start engine.

5. Once engine has started, slowly move choke lever to no

choke.

NOTE: When engine fails to start after several attempts, repeat the

starting procedures mentioned above with the choke lever in the

off position.

6. Allow the unit to run for two (2) minute warm-up.

7. Make sure the generator is grounded. See Preparing the

Generator; Grounding Instructions.

8. Test the GFCI receptacle(s) on the unit. Push the test button.

The reset button should pop out and there should be no

power at the receptacle. Apply a test load or lamp to each

receptacle to verify. IF THE RESET BUTTON DOES NOT POP

OUT, DO NOT USE THE RECEPTACLES(S). SEE DEALER

FOR SERVICE IMMEDIATELY.

9. If GFCI receptacle(s) test correctly, rmly push the reset

button to restore power. A distinctive click should be heard

or felt when this is complete. IF THE RECEPTACLE(S) DO

NOT RESET PROPERLY, DO NOT USE THE RECEPTACLE(S).

SEE DEALER FOR SERVICE IMMEDIATELY.

10. Loads can now be applied to the unit.

(Fig. 3)

(Fig. 4)

NOTE: This engine is equipped with a “Low Oil” shutdown system for

engine protection. The engine stops when the oil level gets too

low. The engine will not restart without adding oil. Refer to Preparing the Generator; Engine Fuel Capacity for instructions on adding

oil.

SHUTDOWN

1. Remove all load by turning off electrical appliances and

unplugging electric cords.

2. Allow engine to run at no load condition to cool for two (2)

minutes.

NOTE: Failure to allow the engine to cool for two (2) minutes may result

in damage to the generator.

3. Close fuel valve on unit or engine.

16 Operator’s Manual

Page 17

OPERATING THE GENERATOR

CONTROLS

CONTROL PANEL:

The generators are equipped with the following items:

PR-G3200M:

• Circuit Breaker

• One 125 Volt, 20 Amp, Duplex (2 outlets), GFCI protected

receptacles.

PR-G5500M:

• Circuit Breakers

• Two 125 Volt, 20 Amp, Duplex (2 outlets), GFCI protected

receptacles.

• One 125/250 Volt, 20 Amp, Locking Type Receptacle.

PR-G7500M:

• Circuit Breakers

• Two 125 Volt, 20 Amp, Duplex (2 outlets), GFCI protected

receptacles.

• One 125/250 Volt, 30 Amp, Locking Type Receptacle.

NOTE: The 125 Volt, 30 Amp locking receptacles ARE NOT GROUND

FAULT PROTECTED. If ground fault protection on these receptacles

is necessary or desired, external protection devices must be used.

Refer to the section on “Ground Fault Interrupter” for more information.

WARNING: NEVER EXCEED THE RATING OF A

RECEPTACLE. THESE RECEPTACLES ARE

PROTECTED AGAINST OVERLOADS BY RESETTING

MAGNETIC TYPE CIRCUIT BREAKERS. IF A

CIRCUIT BREAKER TRIPS, THE CAUSE SHOULD

BE DETERMINED AND CORRECTED PRIOR TO

CONTINUING USE.

CONTROLS

OIL WARNING DEVICE:

NOTE: This engine is equipped with a “Low Oil” shutdown system for

engine protection. The engine stops when the oil level gets too low.

The engine will not restart without adding oil. If the unit is tilted too

much during operation, it may suddenly stop even though the oil

level is not low.

Check the engine oil before restarting the engine. If the unit is

tilted, level the engine, then check the oil before restarting the

engine.

Operator’s Manual 17

Page 18

OPERATING THE GENERATOR

CONTROLS

CABLE SIZE:

Equipment damage can result from low voltage. Therefore, to prevent

excessive voltage drop between the generator and the equipment,

the cable should be of adequate gauge for the length used. The cable

selection chart gives the maximum cable lengths for various gauges of

wire which can adequately carry the loads shown.

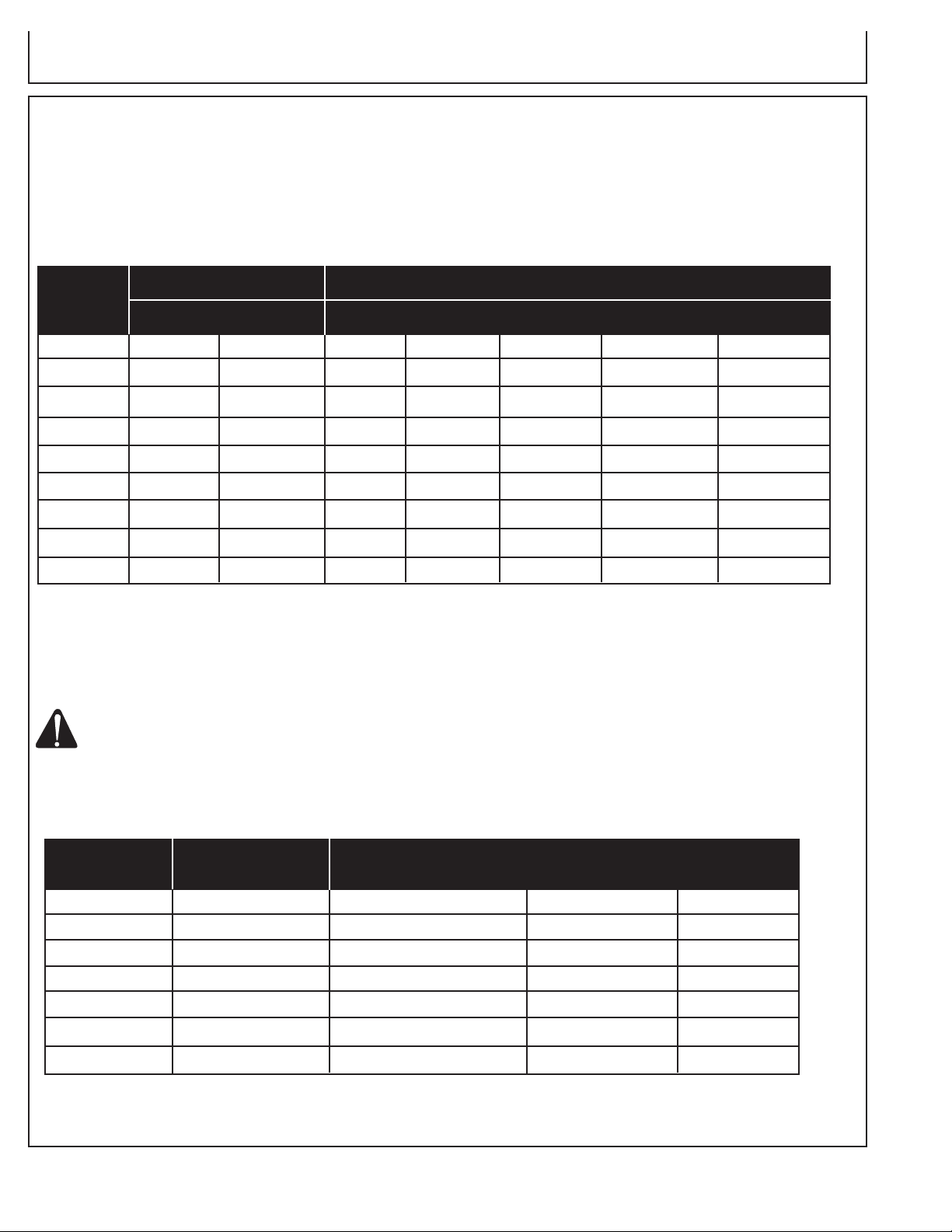

CURRENT LOAD IN WATTS MAXIMUM CABLE LENGTH (FEET)

IN AMPS 120 VOLTS 240 VOLTS #8 WIRE #10 WIRE #12 WIRE #14 WIRE #16 WIRE

2.5 300 600 1000 600 375 250

5 600 1200 500 300 200 125

7.5 900 1800 350 200 125 100

10 1200 2400 250 150 100 50

15 1800 3600 150 100 65

20 2400 4800 175 125 75 50

25 3000 6000 150 100 60

30 3600 7200 125 65

40 4800 9600 90

ELECTRIC MOTOR LOADS:

It is characteristic of common electric motors in normal operation to

draw up to six times their running current while starting. This table

may be used to estimate the watts required to start “CODE G” electric

motors.

CAUTION: IF AN ELECTRIC MOTOR FAILS TO START OR

REACH RUNNING SPEED, TURN OFF THE APPLIANCE OR

TOOL IMMEDIATELY TO AVOID EQUIPMENT DAMAGE.

ALWAYS CHECK THE REQUIREMENTS OF THE TOOL OR

APPLIANCE BEING USED COMPARED TO THE RATED

OUTPUT OF THE GENERATOR.

WATTS REQUIRED TO START MOTOR

MOTOR (H.P.) RUNNING WATTS REPULSION INDUCTION CAPACITOR SPLIT PHASE

1/8 275 600 850 1200

1/6 275 600 850 2050

1/4 400 850 1050 2400

1/3 450 975 1350 2700

1/2 600 1300 1800 3600

3/4 850 1900 2600

1 1100 2500 3300

18 Operator’s Manual

Page 19

TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Engine will not start. Engine switch is off. Turn engine switch to the ON position.

Fuel Tank empty. Fill tank per instructions in this manual.

Fuel Valve is off. Turn Fuel Valve on.

Inadequate engine oil. Check oil level. This engine is

equipped with a low oil sensor. The

engine cannot be started unless the oil

level is above the prescribed lower

limit.

No spark at spark plug. Remove the spark plug cap. Clean any

dirt from around the plug base, then

remove the spark plug. Install the

spark plug in the plug cap. Turn the

engine switch on.

Grounding the electrode to any engine

ground, pull the recoil starter to see if

sparks jump across the gap. If there is

no spark, replace the plug.

Reinstall the plug and start engine

according to instructions in this

manual.

Consult John Deere Customer

Service.

Generator has no output. Circuit breakers tripped. Reset circuit breakers.

Inadequate cord sets or Check cord sets or extension cords

extension cords. capabilities in section Controls;

Cable Size in this manual.

Consult John Deere Customer

Service.

Operator’s Manual 19

Page 20

SERVICE

MAINTENANCE

Keep all air vents clear.

Keep the generator clean. DO NOT spray with water.

Periodically check all fasteners and tighten, see the periodic maintenance chart.

GFCI TEST RECORDS:

As with any other safety devices, the GFCIs supplied with these generators must be checked every month to insure

that they are functioning properly. To test the GFCIs, follow the instructions and then enter the date of the test below.

1. With the generator running and the idle control switch in the “START” position, push the “TEST” button. The

“RESET” button should pop out. This should result in the power being off at both outlets of the duplex receptacle.

Verify this by plugging a test lamp into each outlet.

WARNING: IF THE RESET BUTTON DOES NOT POP OUT, DO NOT USE THE RECEPTACLE(S). SEE

AUTHORIZED JOHN DEERE CUSTOMER SERVICE REPRESENTATIVE FOR SERVICE IMMEDIATELY.

2. If the GFCI test correctly, restore power by FIRMLY pushing the “RESET” button back in until you hear or feel a

distinctive “click”. IF THE GFCI FAILS TO RESET PROPERLY, DO NOT USE EITHER OUTLET OF THE DUPLEX

RECEPTACLE. Have the unit serviced by an authorized John Deere Customer Service Representative immediately.

3. High vibration or severe mechanical shock loads may cause the GFCIs to trip. IF EITHER GFCI TRIPS BY

ITSELF AT ANY TIME, reset it and perform test procedures 1 and 2.

4. Repeat steps 1-3 for the second GFCI.

WARNING: ALTHOUGH THE ABOVE TEST PROCEDURES WILL INDICATE PROPER GFCI OPERATION ON

AN UNGROUNDED OR IMPROPERLY GROUNDED GENERATOR, THE GENERATOR MUST STILL BE

GROUNDED PER THE GROUNDING INSTRUCTIONS LISTED ON PAGE 16 FOR THE GFCI TO FUNCTION

PROPERLY AND PROTECT THE USER FROM ELECTRICAL FAULTS.

Year Jan. Feb. March April May June July Aug. Sept. Oct. Nov. Dec.

NOTE: Situations exist where a GFCI will not afford any protection against the hazards of electrical shock.

Example: if a person touches two or more conductors from a damaged cord set and is not in direct contact with the ground, he or she

may receive a shock. Since there is no path to ground for a ground fault current to ow through, the GFCI will not operate and serious injury may result.

The GFCI are merely an added safety feature. There are no substitutes for good safety precautions, correct electrical practices and proper

maintenance of cords, equipment and connections.

20 Operator’s Manual

Page 21

SERVICE

MAINTENANCE

EVAPORATIVE EMISSION COMPONENTS:

The unit you have purchased includes the following compo-

nents that are in compliance with 2008 California Air Resources

Board Evaporative Emission Standards;

1. Fuel Hose

2. Fuel Hose Fittings

These components should be inspected on a daily basis for

cracks, leaks, and abnormal wear. If cracking, leaks or abnormal wear has occurred, the components should be replaced

immediately.

ENGINE:

The engine for this generator is governed to operate at speeds

close to 3600 RPM (60Hz) throughout the operating load range.

The no load speed (before a load is applied) will be just a bit

higher than the load speed and is normally set to 3750 RPM.

WARNING: DO NOT TAMPER WITH THE GOVERNOR

MECHANISM, CHANGE THE SETTING

EXPERIMENTALLY, OR PUSH THE THROTTLE OPEN

IN AN ATTEMPT TO GENERATE MORE ELECTRICAL

CURRENT; EQUIPMENT DAMAGE OR PERSONAL

INJURY MAY RESULT.

GOVERNOR SPEED ADJUSTMENT SHOULD BE MADE

ONLY BY A JOHN DEERE CUSTOMER SERVICE

REPRESENTATIVE.

CHECKING ENGINE OIL:

Check oil level before each operation and ensure that it is

maintained per Preparing the Generator; Engine Oil Capacity

section.

CHANGING ENGINE OIL:

Change oil after the rst 20 hours of operation. Thereafter it

should be changed every 100 hours.

1. Make sure the unit is on level ground. Run the engine to warm

the oil.

2. Stop the engine.

3. Remove the oil drain plug. (See Fig. 6)

CAUTION: OIL BEING DRAINED MAY BE HOT. TO

REDUCE THE RISK OF BURN INJURY, HANDLE WITH

CARE. DISPOSE OF USED OIL PROPERLY.

4. Drain oil while engine is warm, into a suitable container.

5. Reinstall the oil drain plug.

6. Remove oil gauge and rell with new oil. (Fig. 7)

7. Check the oil level as instructed in Preparing the Generator;

Engine Oil Capacity section.

8. Wipe up any spilled oil.

OIL DRAIN PLUG

(Fig. 6)

UPPER LEVEL

(Fig. 7)

Operator’s Manual 21

Page 22

SERVICE

MAINTENANCE

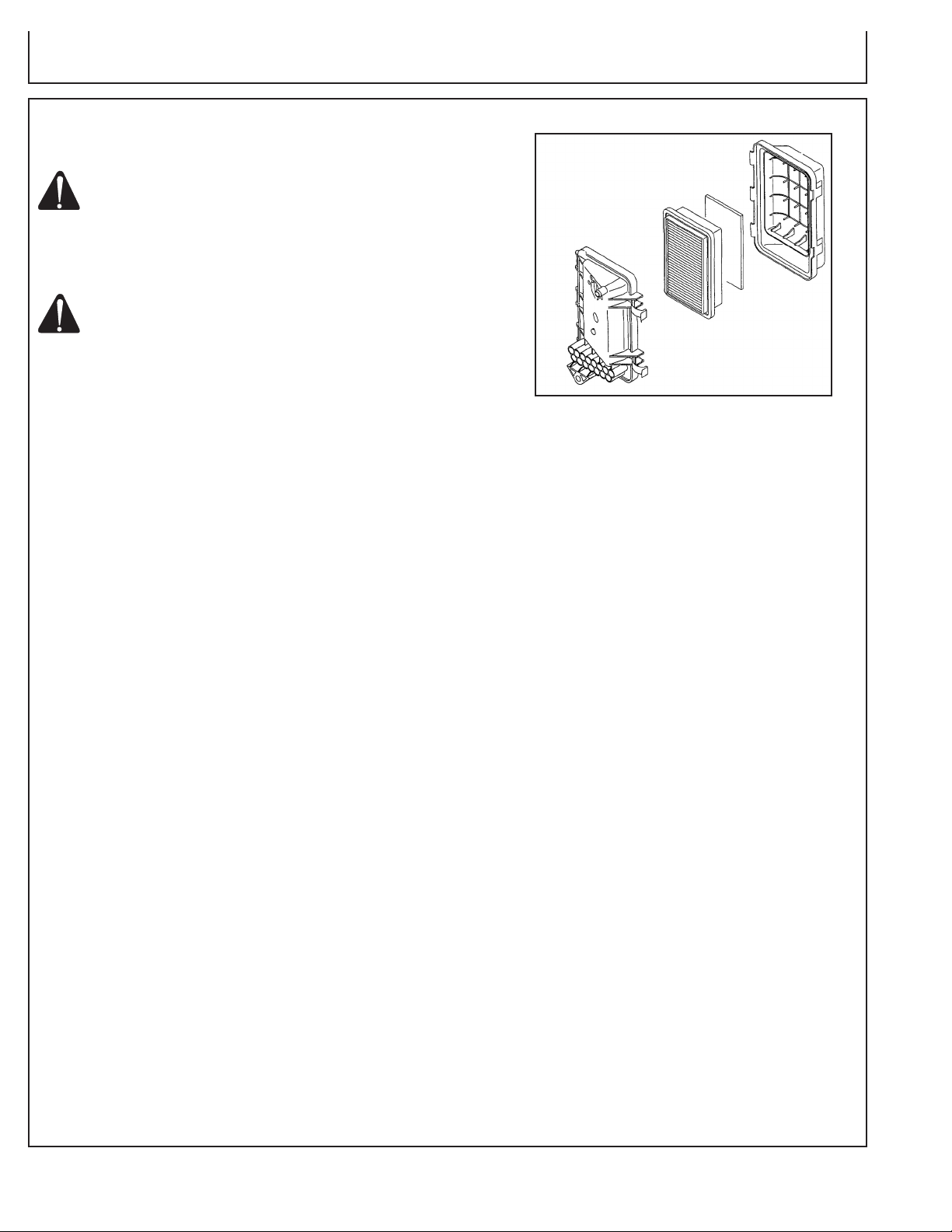

AIR CLEANER:

WARNING: RISK OF FIRE OR EXPLOSION. DO

NOT USE GASOLINE OR LOW FLASH-POINT

SOLVENTS TO CLEAN THE ELEMENT. CLEAN

THE ELEMENT IN A WELL VENTILATED AREA.

ENSURE THAT NO SPARKS OR FLAMES ARE

NEAR THE WORKING AREA, THIS INCLUDES

ANY APPLIANCE WITH A PILOT LIGHT.

CAUTION: NEVER RUN THE ENGINE WITHOUT THE

AIR FILTER, SERIOUS DANGER CAN RESULT.

Check the air cleaner daily or before starting the engine.

Check for and correct heavy buildup of dirt and debris

along with loose or damaged components. (See Fig. 8)

1. Unsnap the air cleaner cover and remove the elements.

2. Clean the elements:

FOAM PRE-CLEANER ELEMENT: Wash the foam precleaner element in warm water with detergent. Rinse the

foam pre-cleaner element thoroughly until all traces of detergent are eliminated. Squeeze out excess water, but do

not wring. Allow the foam pre-cleaner element to air dry.

Saturate the foam pre-cleaner element with new engine oil.

Squeeze out all excess oil. DO NOT put engine oil on the

foam damper.

NOTE: Clean the foam pre-cleaner element every 25 hours of opera-

tion (more often under extremely dusty or dirty condition)

PAPER AIR CLEANER ELEMENT: Do not wash the paper

element or use pressurized air, as this will damage the element. Clean by gently tapping the element to remove dust.

Replace the element if damaged, bent or extremely dirty.

Handle new element carefully; do not use if the sealing

surfaces are bent or damaged.

NOTE: Replace the paper element every 100 hours (more often

under extremely dusty conditions.)

3. Reinstall the foam pre-cleaner element and the paper air

cleaner element. Close air cleaner cover and clasp shut.

(Fig. 8)

22 Operator’s Manual

Page 23

MAINTENANCE

SERVICE

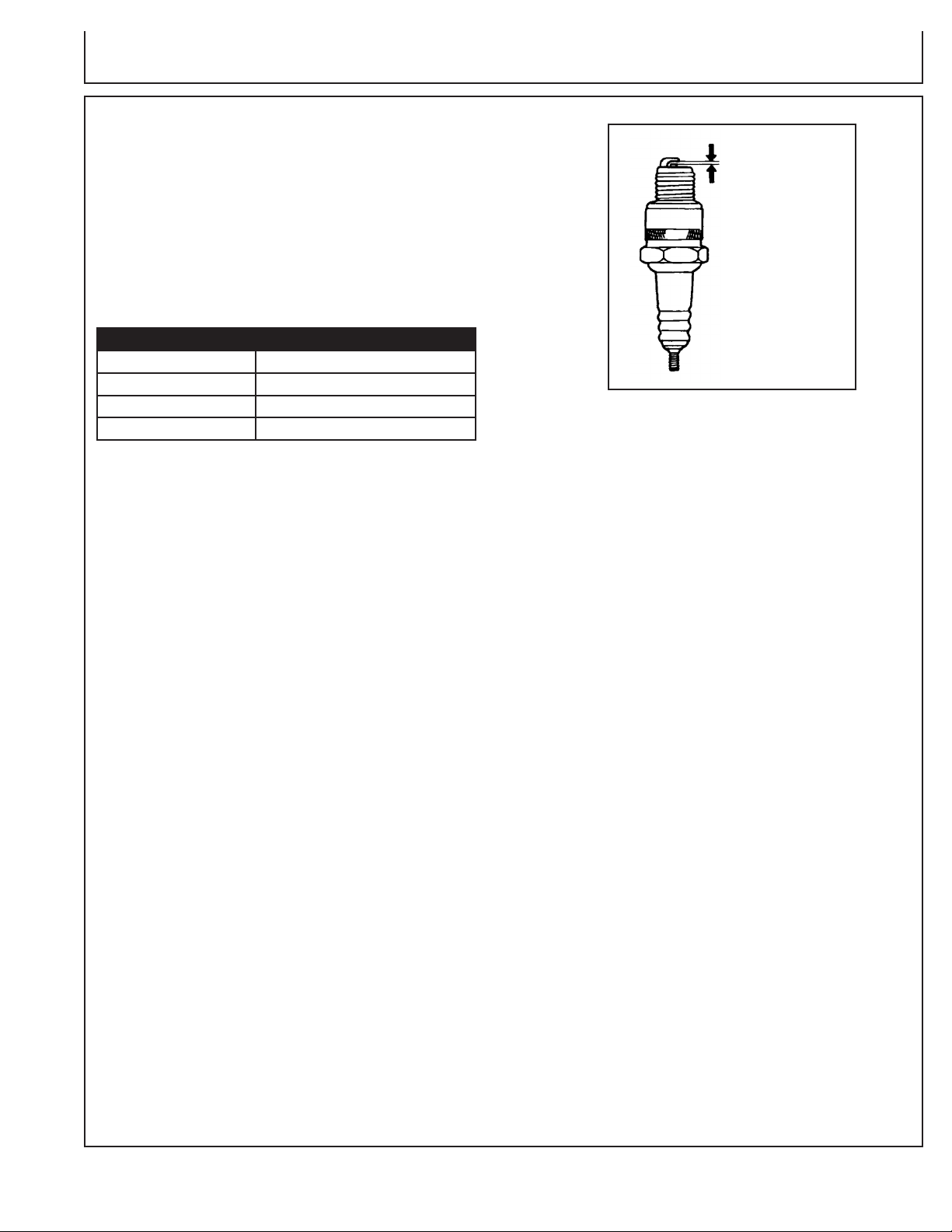

CLEANING AND GAPPING SPARK PLUG:

If the plug is contaminated with carbon, remove it using a

plug cleaner or wire brush.

Check the spark plug gap and reset it if necessary. The

spark plug gaps are listed below. To change the gap, bend

the side-electrode only, using a spark plug tool. (Fig. 9)

Install and tighten the spark plug. Connect the spark plug

lead.

Recommended Spark Plug:

Engine Mi-T-M

Spark Plug NGK BPR6ES

Spark Plug Gap 0.7 - 0.8 mm (0.03 in.)

Torque - New 8.7-10.9 ft-lb

Torque - Retighten 16.6-19.5 ft-lb

SPARK ARRESTOR:

If the generator has been running, the mufer will be very

hot. Allow it to cool before proceeding.

NOTE: Remove and clean spark arrester every 100 hours or as neces-

sary.

NOTE: Product users on United States forest service land, and in

some states, must comply with re prevention regulations.

Clean the spark arrester as follows:

Spark Plug Gap

(See recommendations)

(Fig. 9)

1. Loosen the screw by the exhaust port of the mufer and

remove the spark arrester.

2. Use a brush to remove carbon deposits from the spark

arrester screen. Inspect the screen for breaks or tears and

replace it if necessary.

3. Install the spark arrester in the reverse order of removal.

Spark arrestors are available from your local John Deere

Customer Service. Other user requirements may apply,

check with your Federal, State or local authorities.

Operator’s Manual 23

Page 24

SERVICE

MAINTENANCE

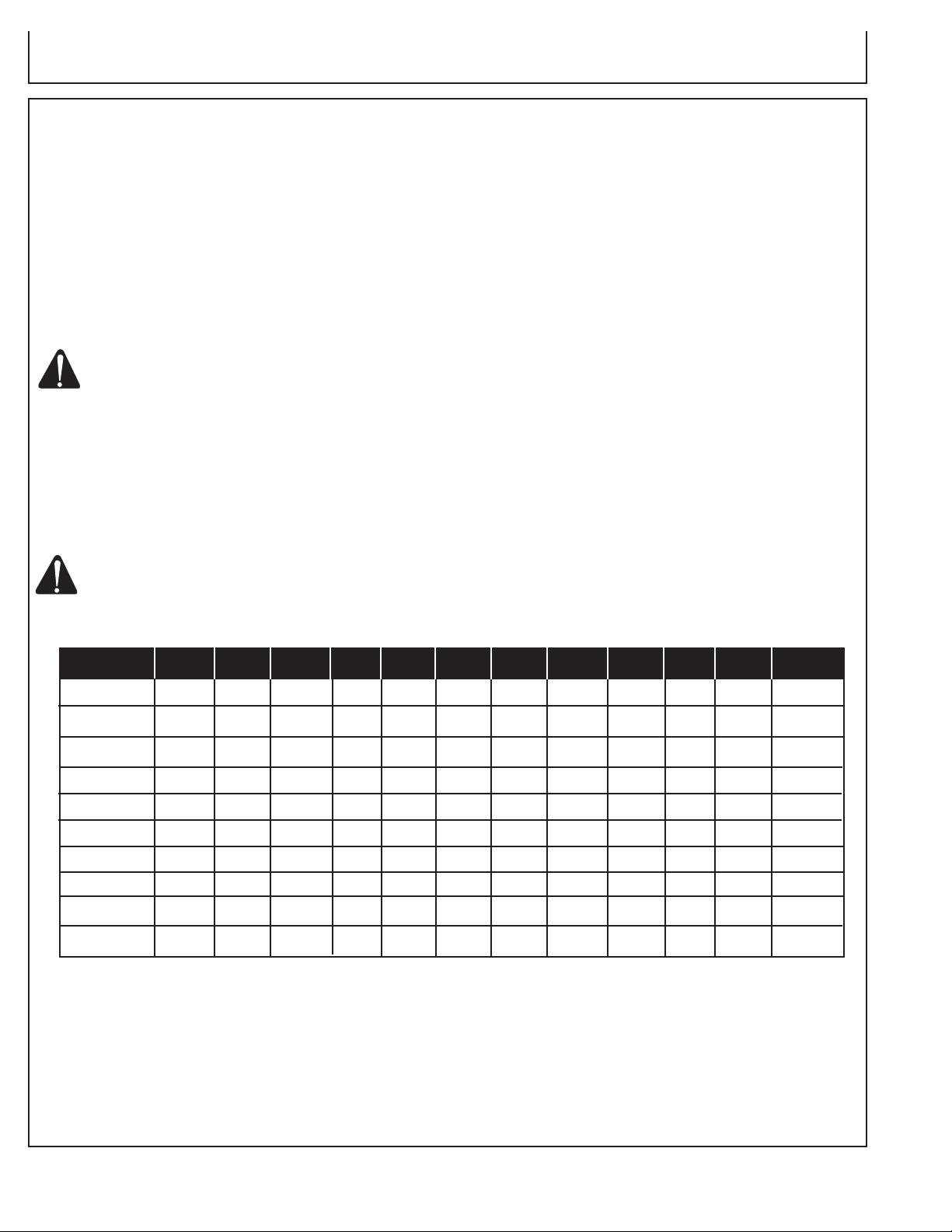

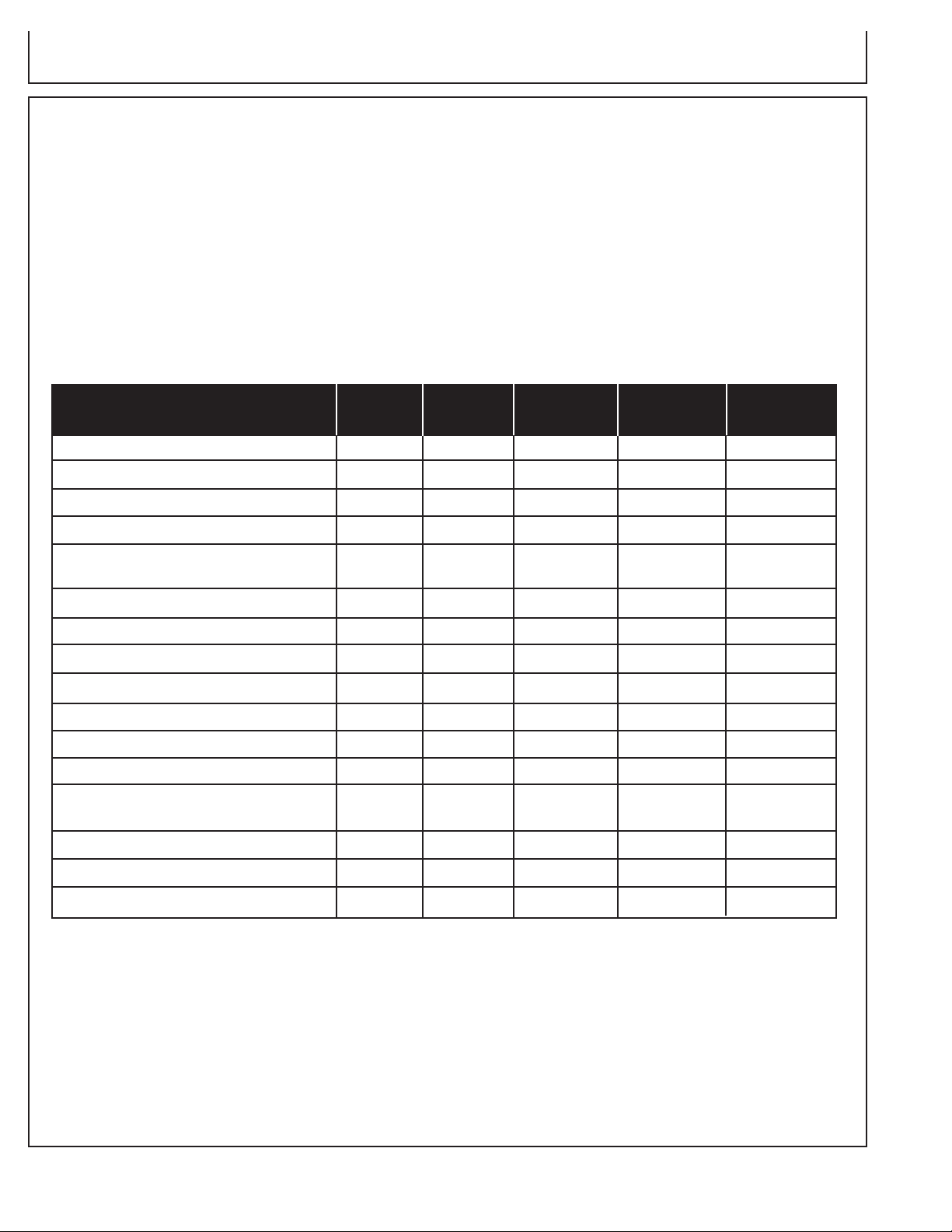

PERIODIC MAINTENANCE CHART:

To ensure satisfactory operation over an extended pe-

riod of time, an engine requires normal maintenance at

regular intervals. The Periodic Maintenance Chart below

shows periodic inspection and maintenance items and

suitable intervals. The bullet mark designates that the

corresponding item should be performed at that interval.

NOTE: Some adjustments require the use of special tools or other

equipment. An electronic tachometer will facilitate setting

idle and running speeds.

Daily Every Every Every Before

25hrs. 100 hrs. 200 hrs. Storage

Check fuel •

Check engine oil •

Check for loose or lost nuts and bolts •

Check for leaks •

Check cylinder and head ns for

dust and dirt •

Check battery electrolyte level •

Check fuel lines (replace if necessary) •

Clean air cleaner foam element (**) •

Tighten nuts and bolts (*) •

Change engine oil (*) •

Clean fuel lter •

Replace air cleaner paper element (**) •

Clean dust and dirt from

cylinder and cylinder head ns (**) •

Clean and regap spark plug •

Add fuel stabilizer •

Run unit dry •

* Perform these operations after the rst 5 hours of use, then at the recommended intervals.

** Service more frequently under dusty conditions.

NOTE: These items must be performed with the proper tools. See your John Deere Customer Service Representative for service, unless

you have the proper equipment and mechanical prociency.

24 Operator’s Manual

Page 25

STORAGE

STORING GENERATOR

SHORT TERM (1-6 MONTHS):

1. Add gasoline conditioner and stabilizer at the specied

concentration.

2. Run the unit for two (2) minutes to ensure the mixed fuel

is in the entire fuel system. Close the fuel valve and run

the unit until it stops.

3. Remove the spark plug, pour 1-2 teaspoons (5-10cc)

of engine oil into the cylinder, slowly pull the starter

handle 2 or 3 times, reinstall the spark plug and tighten

securely.

4. Clean the exterior surface of the generator and apply a

rust inhibitor.

5. Store the generator in a dry, well ventilated place.

LONG TERM (MORE THAN 6 MONTHS):

1. Add gasoline conditioner and stabilizer at the specied

concentration.

2. Run the generator until the fuel tank and carburetor are

dry. As the engine is beginning to die, move the choke

lever to the choke position.

SERVICE

NOTE: Turn off the idle control to decrease the run time.

3. Remove the spark plug, pour 1-2 teaspoons (5-10cc)

of engine oil into the cylinder, slowly pull the starter

handle 2 or 3 times, reinstall the spark plug and tighten

securely.

4. Clean the exterior surface of the generator and apply a

rust inhibitor.

5. Store the generator in a dry, well ventilated place.

WARNING: FUEL SHOULD BE DRAINED IN A

WELL VENTILATED AREA AND STORED IN A

CONTAINER APPROVED FOR GASOLINE.

Operator’s Manual 25

Page 26

SPECIFICATIONS

SPECIFICATIONS

ITEM SPECIFICATION

PR-G3200M PR-G5500M PR-G7500M

Engine Mi-T-M Mi-T-M Mi-T-M

Watts (AC) Rated 2600 watts 4800 watts 6500 watts

Watts (AC) Max. 3200 watts 5500 watts 7500 watts

Max. Amperage 26.7 45.8 62.5

Cont. Amperage 21.67 40.0 54.2

Frequency/Volts 60Hz/120V 60Hz/120V 60Hz/120V

Fuel Tank Capacity 2.7 gal. 5.7 gal. 7.3 gal.

Run Time Hours /

Tank of Fuel* 5.9 hrs. 6.8 hrs. 6.9 hrs.

* Rated at Full Load

NOTE: Unit ratings are established based on operation at standard conditions of 60° F and at sea level. The performance of the generator

must be de-rated for temperature and altitude by 1% for every 10° F above 60° F and 3.5% for every 1000 feet above sea level. Due

to the operational characteristics of the thermal type circuit breaker, the power available from the generator will decrease slightly with

a corresponding increase in ambient temperature.

Due to continuing product improvements, specications are subject to change without notice.

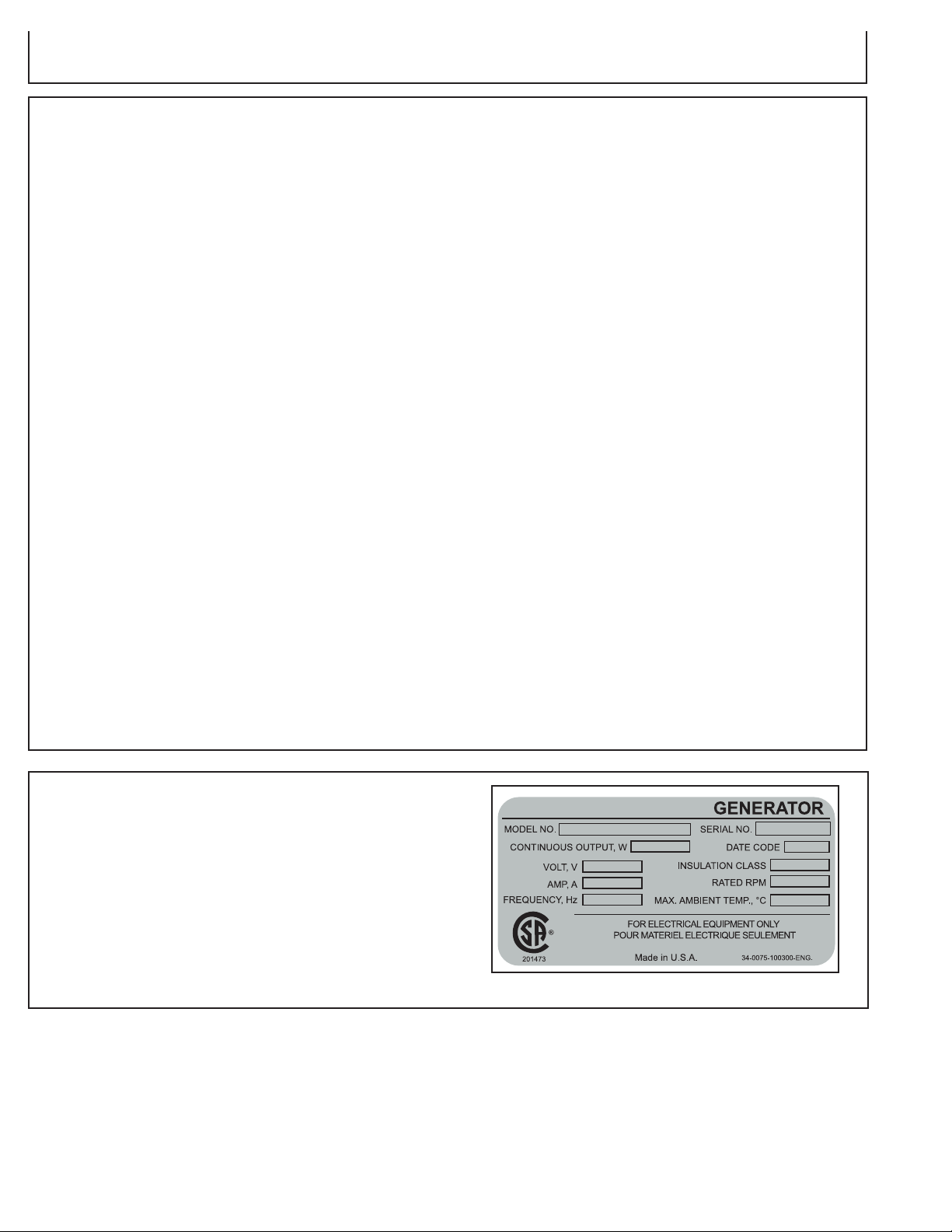

RECORD SERIAL NUMBER

Write you model number, machine serial number and

date of purchase in the spaces provided below. Your

dealer needs this information when ordering parts.

Model No. _________________________________________

Machine Serial No. _________________________________

__________________________________________________

Date of Purchase ___________________________________

(To be lled in by purchaser)

26 Operator’s Manual

Page 27

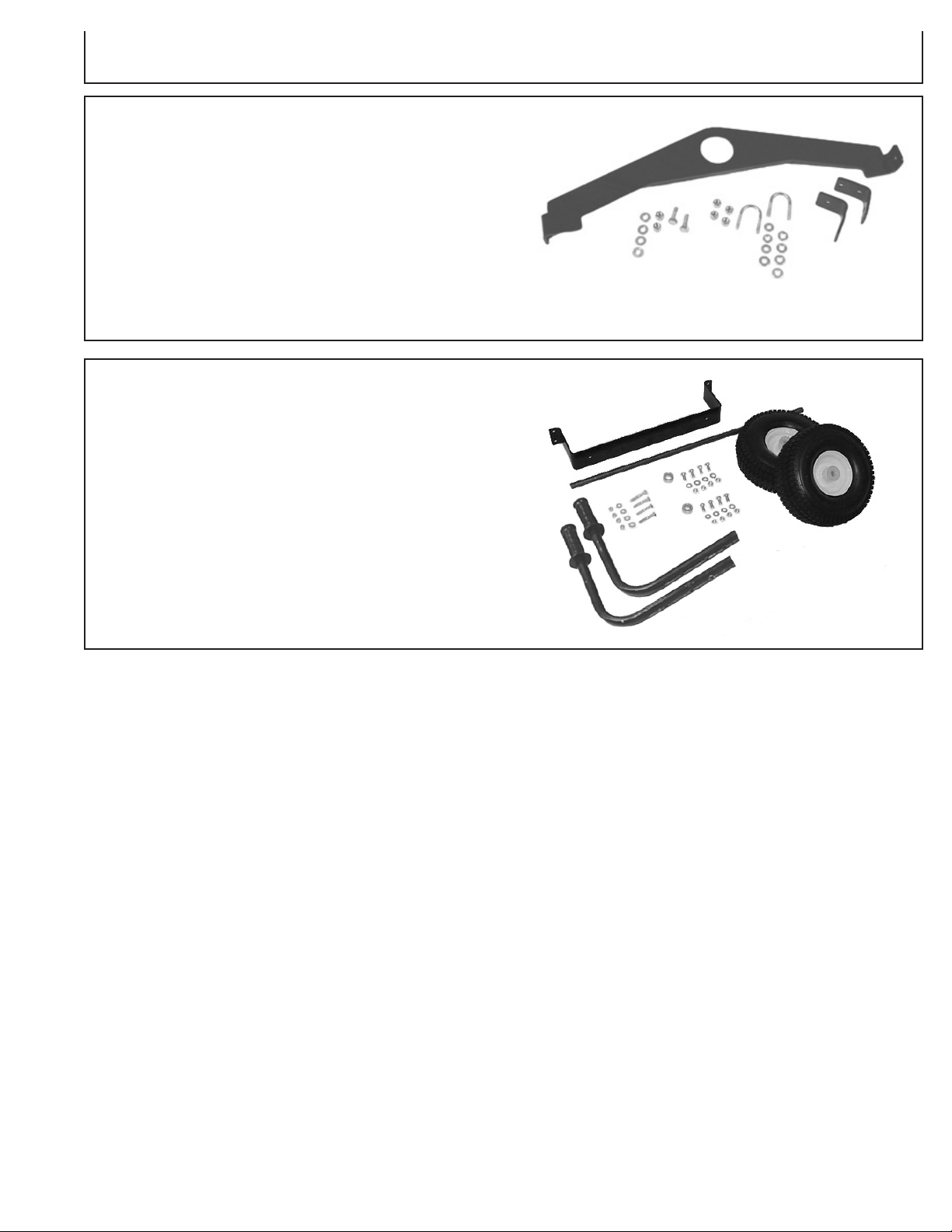

ACCESSORIES

LIFTING HOOK KIT: AW-5090-0001 AND AW-5090-0002

(PR-G5500M AND PR-G7500M)

Used for lifting the generator safely. The Lifting Hook Kit

includes the lifting hook, hardware and instructions needed

to assemble the lifting hook to the generator.

WHEEL AND HANDLE KIT: AW-5740-0001 AND

AW-5740-0002 (PR-G5500M AND PR-G7500M)

Allows easier portability of the generator. The Wheel and

Handle Kit includes the wheels, handles, hardware and

instructions needed to assemble the kit to the generator.

Operator’s Manual 27

Page 28

WARRANTY

STATEMENT OF WARRANTY

John Deere warrants all parts, (except those referred to below), of your new generator

to be free from defects in materials and workmanship during the following periods:

For Two (2) Years from the date of original purchase.

Defective parts not subject to normal wear and tear will be repaired or replaced at

our option during the warranty period. In any event, reimbursement is limited to the

purchase price paid.

EXCLUSIONS

1. Engine/Motor and Generator are covered under separate warranty by its respective

manufacturer and is subject to the terms set forth therein.

2. This warranty does not cover parts damaged due to normal wear, misapplication,

misuse, operation at other than recommended . Failure to follow recommended

operating and maintenance procedures also voids warranty.

3. The use of other than genuine manufacturer repair parts will void warranty.

4. Parts returned, prepaid to our factory or to an Authorized John Deere Service Center

will be inspected and replaced free of charge if found to be defective and subject

to warranty. There are no warranties which extend beyond the description of the

face hereof. Under no circumstances shall the manufacturer bear any responsibility

for loss of use of the unit, loss of time or rental, inconvenience, commercial loss or

consequential damages.

For Service or Warranty Consideration, contact

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

563-556-7484 / 800-553-9053 / Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

28 Operator’s Manual

Page 29

WARRANTY

CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and John Deere are pleased to explain the emissions control system warranty on

your small off-road engine (SORE). In California, new SOREs must be designed, built and equipped to meet the State’s

stringent anti-smog standards. John Deere must warrant the emissions control system on your SOREs for the periods

of time listed below provided there has been no abuse, neglect or improper maintenance of your SOREs.

Your emissions control system may include parts such as the carburetor or fuel-injection system, fuel lines and the

ignition system. Also included may be hoses, clamps , connectors and other associated components.

Where a warrantable condition exist, John Deere will repair your small off-road engine at no cost to you including

diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emissions-related part on your engine is defective, the

part will be repaired or replaced by John Deere.

OWNER’S WARRANTY RESPONSIBILITIES:

-As the SORE owner, you are responsible for performance of the required maintenance listed in your owner’s manual.

John Deere recommends that you retain all receipts covering maintenance on your SORE , but John Deere cannot

deny warranty solely for the lack of receipts.

-As the SORE owner, you should however be aware that John Deere may deny you warranty coverage if your SORE

or a part has failed due to abuse, neglect, or improper maintenance or unapproved modications.

-You are responsible for presenting your SORE to distribution center or service center authorized by John DeereMi-T-M Corporation, 8650 Enterprise Drive, Peosta, IA 52068 (herein John Deere) as soon as the problem exists.

The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have a question regarding your warranty coverage, you should contact John Deere Customer Service Department

at 1-800-JD-KLEEN (1-877-535-5336).

Operator’s Manual 29

Page 30

WARRANTY

GENERAL EMISSIONS WARRANTY COVERAGE

- California Only -

John Deere warrants to the ultimate purchaser and each subsequent purchaser that the SORE (1) has been designed,

built and equipped so as to conform with all applicable regulations; and (2) is free from defects in materials and

workmanship that cause the failure of a warranted part to conform with those regulations as may be applicable to the

terms and conditions stated below.

(a) The warranty period begins on the date the engine is delivered to an ultimate purchaser or rst placed into service.

The warranty period is two years.

(b) Subject to certain conditions and exclusions as stated below, the warranty on emissions related parts is as

follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in your owner’s manual is

warranted for the warranty period stated above. If the part fails during the period of warranty coverage, the

part will be repaired or replaced by John Deere according to subsection (4) below. Any such part repaired or

replaced under warranty will be warranted for the remainder of the period.

(2) Any warranted part that is scheduled only for regular inspection in your owner’s manual is warranted for the

warranty period stated above. Any such part repaired or replaced under warranty will be warranted for the

remaining warranty period.

(3) Any warranted part that is scheduled for replacement as required maintenance in your owner’s manual is

warranted for the period of time before the rst scheduled replacement date for that part. If the part fails before

the rst scheduled replacement, the part will be repaired or replaced by John Deere according to subsection (4)

below. Any such part repaired or replaced under warranty will be warranted for the remainder of the period

prior to the rst scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions herein must be performed at a

warranty station at no charge to the owner.

(5) Notwithstanding the provisions herein, warranty services or repair will be provided at all of our distribution

centers that are franchised to service the subject engines.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is

in fact defective, provided that such diagnostic work is performed at a warranty station.

(7) John Deere is liable for damages to other engine components proximity caused by a failure under warranty of any

warranted part.

(8) Throughout the engine warranty period stated above, John Deere will maintain a supply of warranted parts sufcient

to meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must

be provided without charge to the owner. Such use will not reduce the warranty obligations of John Deere.

(10) Add-on or modied parts that are not exempted by the Air Resources Board may not be used. The use of any

non-exempted add-on or modied parts by the ultimate purchaser will be grounds for disallowing a warranty

claims. John Deere will not be liable to warrant failures of warranted parts caused by the use of a non-exempted

add-on or modied part.

(c) WARRANTED PARTS:

The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from

such warranty coverage if John Deere demonstrates that the engine has been abused, neglected, or improperly

maintained, and that such abuse , neglect ,or improper maintenance was the direct cause of the need for repair

or replacement of the part. That notwithstanding, any adjustment of a component that has a factory installed, and

properly operating, adjustment limiting device is still eligible for warranty coverage. The following emissions warranty

parts list are covered.

(1) Fuel Metering System/

(A) Carburetor and internal parts (and/or pressure regulator or fuel injection system)./

(B) Air/fuel ratio feedback and control system, if applicable./

(C) Cold start enrichment system, if applicable./

(D) Regulator assy (gaseous fuel, if applicable)

(2) Air Induction System/

(A Intake manifold, if applicable/

(B) Air lter.

(3) Ignition System/

(A) Spark plugs. /

(B) Magneto or electronic ignition system. /

(C) Spark advance/retard system, if applicable.

(4) Exhaust manifold, if applicable

(5) Evaporation System /

(A) Fuel line /

(B) Fuel line ttings

30 Operator’s Manual

Page 31

INTRODUCTION

MERCI de la conance témoignée par l’achat d’un

produit John Deere.

LIRE CE MANUEL ATTENTIVEMENT AFIN de pouvoir

utiliser et entretenir correctement votre appareil, sinon

des dommages corporels ou matériels pourraient en

résulter.

CE MANUEL DOIT ÊTRE CONSIDÉRÉ comme faisant

partie intégrante de votre appareil et doit l’accompagner

en cas de revente.

LES MESURES dans ce manuel sont indiquées à la fois

dans leurs équivalents métriques et en unités usuelles

des USA. Utiliser seulement les pièces de rechange et

les éléments de xation corrects. Les éléments de xation métriques et en pouces peuvent nécessiter des clés

spéciques à leurs système d’unités.

LES CÔTÉS DROITS ET GAUCHES de l’appareil sont

déterminés en faisant face au côté moteur de l’appareil.

Le NUMÉRO DE SÉRIE de l’appareil se situe dans la

section Caractéristiques ou Numéros d’Identication.

Noter correctement tous les numéros an de faciliter les

recherches en cas de vol. Les communiquer également

au concessionnaire lors de toute commande de pièces.

Ranger les numéros d’identication dans un endroit sûr

et séparé de l’appareil.

LA GARANTIE fait partie du programme de soutien John

Deere destiné aux clients qui utilisent et entretiennent

leur équipement tel qu’il est décrit dans ce manuel. Les

conditions de garantie dont bénécie cet appareil gurent sur le certicat de garantie dans ce manuel.

Cette garantie vous fournit l’assurance que votre concessionnaire fournira du support pour les produits où des

défauts apparaîtraient au cours de la période de garantie.

Toute utilisation abusive de l’équipement ou modication visant à dépasser les performances spéciées par le

constructeur annuleront la garantie.

AVERTISSEMENT: Ce produit contient

du plomb, un produit chimique qui est

connu par l'état de Californie comme

étant la cause de cancer et de

malformations congénitales ou autres

effets nocifs de reproduction.

Laver vos mains après avoir manipulé ce produit.

Guide d’utilisation 31

Page 32

TABLE DES MATIÈRES

Page

Sécurité ......................................................... 33

Commandes .................................................. 41

Préparation de générateur ........................... 45

Fonctionnement ............................................46

Dépannage .................................................... 50

Entretien ........................................................51

Remisage ......................................................56

Caractéristiques ........................................... 57

Accessories ................................................... 59

Garantie .........................................................60

TOUTES LES INFORMATIONS, ILLUSTRATIONS ET CARACTÉRISTIQUES CONTENUES

DANS LA PRÉSENTE PUBLICATION SONT À JOUR AU MOMENT DE LA PUBLICATION, LE

CONSTRUCTEUR SE RÉSERVANT LE DROIT D’APPORTER SANS NOTIFICATION TOUTE

MODIFICATION JUGÉE APPROPRIÉE.

32 Guide d’utilisation

Page 33

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

TH

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

TH

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

CAU

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

SÉCURITÉ

DANGER

AVERTISSEMENT

ATTENTION

RECONNAITRE LES SYMBOLES DE SÉCURITÉ

Voici le symbole d’alerte de sécurité. Lorsqu’il apparaît

sur votre appareil ou dans ce manuel, rester conscient du

risque potentiel de blessures.

Respecter tous les conseils de sécurité ainsi que les consignes générales de prevention des accidents.

COMPRENDRE LES MOTS D’ALERTE

Un mot d’alerte—DANGER, AVERTISSEMENT ou ATTENTION—est utilisé avec le symbole d’alerte de sécurité. Le terme DANGER identie les dangers les plus

graves.

Les signes de sécurité avec DANGER ou AVERTISSEMENT se trouvent près des dangers spéciques. Les

signes de sécurité avec ATTENTION se réfèrent à des

précautions d’ordre général. Le terme ATTENTION

demande aussi de prêter attention aux messages de

sécurité dans ce manuel.

RESPECTER LES CONSEILS DE SÉCURITÉ

Lire attentivement tous les conseils de sécurité contenus

dans ce manuel et ceux apposés sur l’appareil. Veiller

à ce que les signes de sécurité soient lisibles. Remplacer ceux qui manqueraient ou seraient endommagés.

S’assurer que les nouveaux composants ou pièces de

rechange incluent les signes de sécurité courants. Des

signes de rechange sont disponibles chez votre concessionnaire John Deere.

Apprendre à faire fonctionner l’appareil et à utiliser les

commandes correctement. Ne laisser aucune personne

se servir de l’appareil sans instruction.

Maintenir votre appareil en bonne condition de marche.

Toute modication illicite de votre appareil risque d’en

affecter son fonctionnement et/ou sa sécurité ainsi que

d’en réduire sa durée de vie.

Si vous ne comprenez pas toute partie de ce manuel

et avez besoin d’assistance, prenez contact avec votre

concessionnaire John Deere.

Guide d’utilisation 33

Page 34

OXYDE DE CARBONE – GAZ TOXIQUE

Utiliser le groupe électrogène dehors, loin de fenêtres ouvertes, de

conduits d’aération, ou de portes.

Le gaz d’échappement du groupe électrogène contient de l’oxyde de

carbone – un gaz toxique qui peut vous tuer. Vous NE POUVEZ PAS