Page 1

POWERTECH 8.1 L

Diesel Engines

Base Engine

COMPONENT

TECHNICAL

MANUAL

For complete service information also see:

Deere Power Systems Group

CTM86 (20MAR01)

LITHO IN U.S.A.

ENGLISH

Page 2

Foreword

Introduction

This manual is written for an experienced technician.

Essential tools required in performing certain service

work are identified in this manual and are

recommended for use.

This manual (CTM86) covers only the base engine. It

is one of five volumes on 8.1 L engines. The following

four companion manuals cover fuel system repair and

diagnostics:

• CTM243—Mechanical Fuel Systems

• CTM134—Level 3 Electronic Fuel Systems

• CTM255—Level 9 Electronic Fuel Systems

• CTM68—Electronic Injection Fuel Systems

Other manuals will be added in the future to provide

additional information on electronic fuel systems as

needed.

A set of all manuals covering the 8.1 L engines, except

CTM68, can be obtained by purchasing CTM450

Binder Set.

Live with safety: Read the safety messages in the

introduction of this manual and the cautions presented

throughout the text of the manual.

applicable essential tools, service equipment, and

other materials needed to do the job, service parts kits,

specifications, wear tolerance, and torque values.

Before beginning repair on an engine, clean the engine

and mount on a repair stand. (See CLEAN ENGINE in

Group 010 and see MOUNT ENGINE ON REPAIR

STAND in Group 010..)

This manual contains SI Metric units of measure

followed immediately by the U.S. Customary units of

measure. Most hardware on these engines is metric

sized.

Some components of this engine may be serviced

without removing the engine from the machine. Refer

to the specific machine technical manual for

information on components that can be serviced

without removing the engine from the machine and for

engine removal and installation procedures.

Read each block of material completely before

performing service to check for differences in

procedures that apply to the engine model number you

are working on. If only one procedure is given, that

procedure applies to all the engines in the manual.

This is the safety-alert symbol. When you see this

symbol on the machine or in this manual, be alert to

the potential for personal injury.

Use this component technical manual in conjunction

with the machine technical manual. An application

listing in the introduction identifies

engine-models/applications. See the machine technical

manual for information on engine removal and

installation, and gaining access to engine components.

Information is organized in sections and groups for the

various components requiring service instruction. At

the end of the book are summary listings of all

Component Technical Manuals are concise service

guides for specific components. Component technical

manuals are written as stand-alone manuals covering

multiple machine applications.

Fundamental service information is available from

other sources covering basic theory of operation,

fundamentals of troubleshooting, general maintenance,

and basic types of failures and their causes.

CALIFORNIA PROPOSITION 65 WARNING: Diesel

engine exhaust and some of its constituents are

known to the State of California to cause cancer,

birth defects, and other reproductive harm.

CTM86 (20MAR01) P

OWERTECH

DPSG,OUO1004,912 –19–15JUN99–1/1

8.1 L Diesel Engines — Base Engine

032001

PN=2

Page 3

John Deere Dealers

Introduction

The changes listed below make your CTM obsolete.

Repair, operation, and diagnostics are now covered in

five manuals. Discard CTM86 dated 06JUL99 and

replace with the following new manuals:

• CTM86—Base Engine

• CTM243—Mechanical Fuel Systems

• CTM134—Level 3 Electronic Fuel Systems

• CTM255—Level 9 Electronic Fuel Systems

• CTM68—Electronic Fuel Injection Systems

Also, copy these pages and route through your Service

Department.

SECTION 01, GROUP 001 (Engine Identification)

• Updated engine model designation chart.

• Updated engine application charts.

SECTION 01, GROUP 002 (Fuels, Lubricants, and

Coolants)

• Updated engine oil and coolant application

guidelines.

SECTION 02, GROUP 050 (Camshaft and Timing

Gear Train Repair and Adjustment)

• Eliminated procedure to check valve lift. Use

appropriate procedure from Group 020 or Group

021.

• Revised specifications for installation of crankshaft

gear-driven auxiliary drive.

• Revised procedure for installation of thrust washer

and timing gear cover.

SECTION 02, GROUP 060 (Lubrication System

Repair and Adjustment)

• Added information for top-load oil filter.

SECTION 02, GROUP 070 (Cooling System Repair

and Adjustment)

• Added belt routing diagrams.

• Revised procedure for installation of coolant pump.

SECTION 02, GROUP 080 (Air Intake and Exhaust

System Repair and Adjustments)

SECTION 02, GROUP 010 (Engine Rebuild)

• Updated engine disassembly sequence.

• Updated engine assembly sequence.

• Updated sealant application guidelines.

SECTION 02, GROUP 020 (Cylinder Head and

Valves Repair and Adjustment Serial Number

( —199,999)

• Repair procedures for cylinder head and valves on

engines with serial number ( —199,999) are covered

in this group.

SECTION 02, GROUP 021 (Cylinder Head and

Valves Repair and Adjustment Serial Number

(200,000— )

• Repair procedures for cylinder head and valves on

engines with serial number (200,000— ) are covered

in this group.

• Revised procedure for turbocharger inspection

techniques.

• Eliminated procedure for adjusting turbocharger

wastegate actuator.

• Revised specifications for installing turbocharger.

SECTION 02, GROUP 090 (Fuel System Repair and

Adjustments)

NOTE: Repair procedures for fuel systems have been

have been moved to Section 02, Group 090 in

the three following technical manuals:

•

CTM243—Mechanical Fuel Systems

•

CTM134—Level 3 Electronic Fuel Systems

•

CTM255—Level 9 Electronic Fuel Systems

SECTION 02, GROUP 100 (OEM Starting and

Charging Systems)

CTM86 (20MAR01) P

OWERTECH

DPSG,OUO1004,898 –19–19MAY99–1/2

8.1 L Diesel Engines — Base Engine

032001

PN=3

Page 4

Introduction

• Starting and charging systems are covered in this

new group.

SECTION 03, GROUP 120 (Base Engine Operation)

• Base engine theory of operation is covered in this

new group.

NOTE: Fuel system theory of operation has been

moved to Section 03 in the three following

technical manuals:

•

CTM243—Mechanical Fuel Systems

•

CTM134—Level 3 Electronic Fuel Systems

•

CTM255—Level 9 Electronic Fuel Systems

SECTION 04, GROUP 150 (Observable Diagnostics

and Tests)

• Base engine observable diagnostics and tests are

covered in this new section/group.

NOTE: Fuel system diagnostics and testing has been

moved to Section 04 in the three following

technical manuals:

•

CTM243—Mechanical Fuel Systems

•

CTM134—Level 3 Electronic Fuel Systems

•

CTM255—Level 9 Electronic Fuel Systems

SECTION 05 (Tools and Other Materials)

• All essential tools, service tools, dealer fabricated

tools, and other materials listed throughout this

manual are consolidated in this section for ease of

reference.

SECTION 06 (Specifications)

• All repair, test, and diagnostic specifications listed

throughout this manual are consolidated in this

section for ease of reference.

• Updated bolt and cap screw torque values.

• Updated General OEM specifications.

• Updated dynamometer specifications.

• Updated turbocharger boost specifications

CTM86 (20MAR01) P

OWERTECH

DPSG,OUO1004,898 –19–19MAY99–2/2

8.1 L Diesel Engines — Base Engine

032001

PN=4

Page 5

About this Manual

Introduction

This component technical manual (CTM) covers the base

engine for P

OWERTECH

8.1 L (494 cu. in.) diesel engines

produced in Waterloo, Iowa.

This manual is a complete revision of CTM86

(06JUL99). Replace earlier manual with the following new

manuals:

• CTM86 — P

OWERTECH

8.1 L Diesel Engines—Base

Engine

• CTM243 — P

OWERTECH

8.1 L Diesel Engines—

Mechanical Fuel Systems

• CTM134 — P

OWERTECH

6.8 L & 8.1 L Diesel

Engines—Level 3 Electronic Fuel Systems with Bosch

In-Line Pump

• CTM255 — 8.1 L Diesel Engines—Level 9 Electronic

Fuel Systems with Denso In-Line Pump

• CTM68 —Electronic Fuel Injection Systems

Direction of engine crankshaft rotation in this manual is

referenced facing the flywheel looking toward the fan.

Front of engine is fan drive end.

Read each procedure completely before performing any

service.

IMPORTANT: For repair, diagnostics, and testing

procedures on the fuel system, refer to

the companion manuals:

• CTM243 — P

OWERTECH

8.1 L Diesel

Engines—Mechanical Fuel Systems

• CTM134 — P

OWERTECH

6.8 L & 8.1 L

Diesel Engines—Level 3 Electronic

Fuel Systems with Bosch In-Line

Pump

• CTM255 — 8.1 L Diesel Engines—

Level 9 Electronic Fuel Systems with

Denso In-Line Pump

• CTM68 —Electronic Fuel Injection

Systems

P

OWERTECH

is a registered trademark of Deere & Company

CTM86 (20MAR01) P

OWERTECH

DPSG,OUO1004,913 –19–15JUN99–1/1

8.1 L Diesel Engines — Base Engine

032001

PN=5

Page 6

Introduction

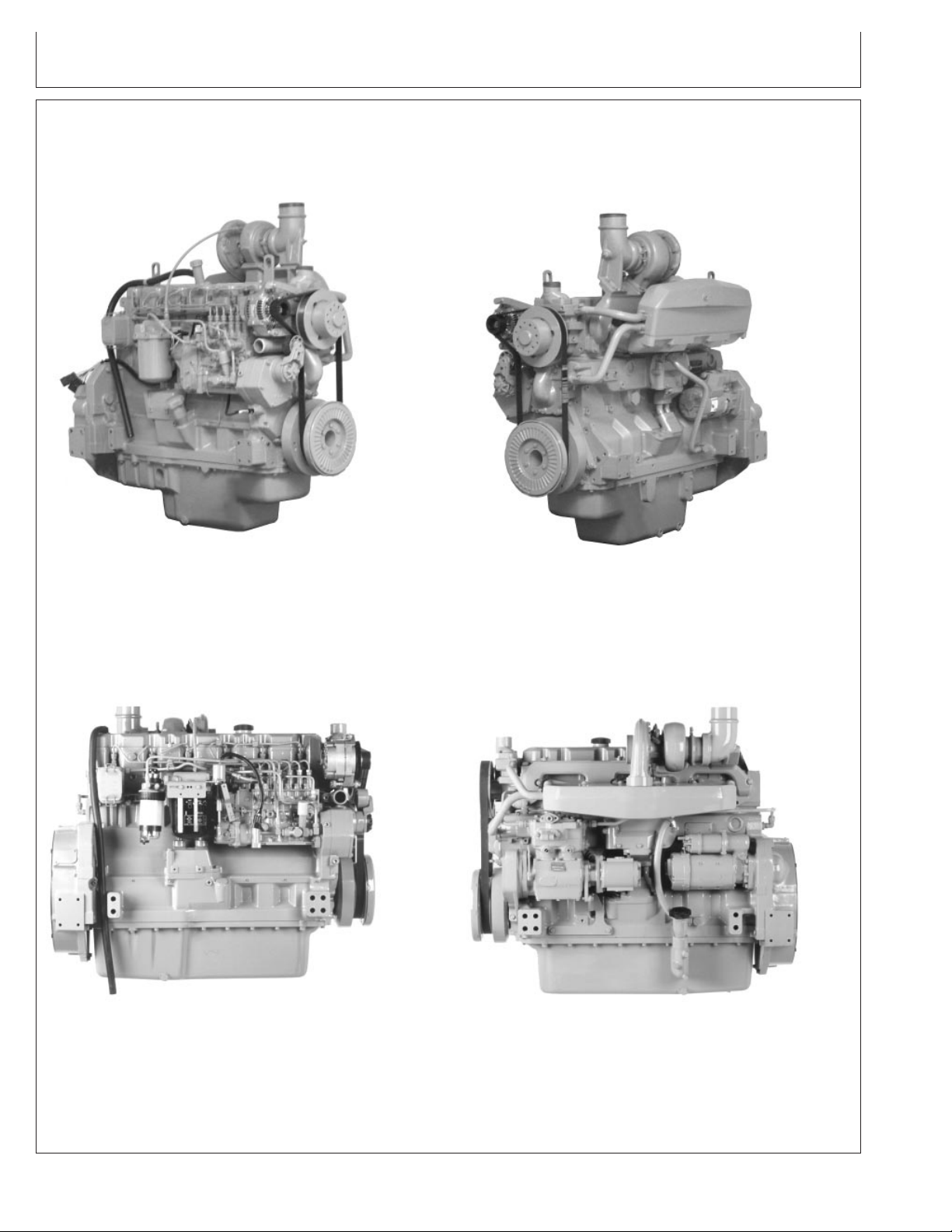

Identification Views Serial Number ( —199,999)

8.1 L Diesel Engine Right Front View (Engines —199,999)

RG7362 –UN–05JAN98

8.1 L Diesel Engines Left Front View (Engines —199,999)

RG7363 –UN–05JAN98

8.1 L Diesel Engines Right Side View (Engines —199,999)

RG7385 –UN–05JAN98

8.1 L Diesel Engines Left Side View (Engines —199,999)

CTM86 (20MAR01) P

OWERTECH

RG7387 –UN–05JAN98

RG,RG34710,4001 –19–14DEC00–1/2

8.1 L Diesel Engines — Base Engine

032001

PN=6

Page 7

Introduction

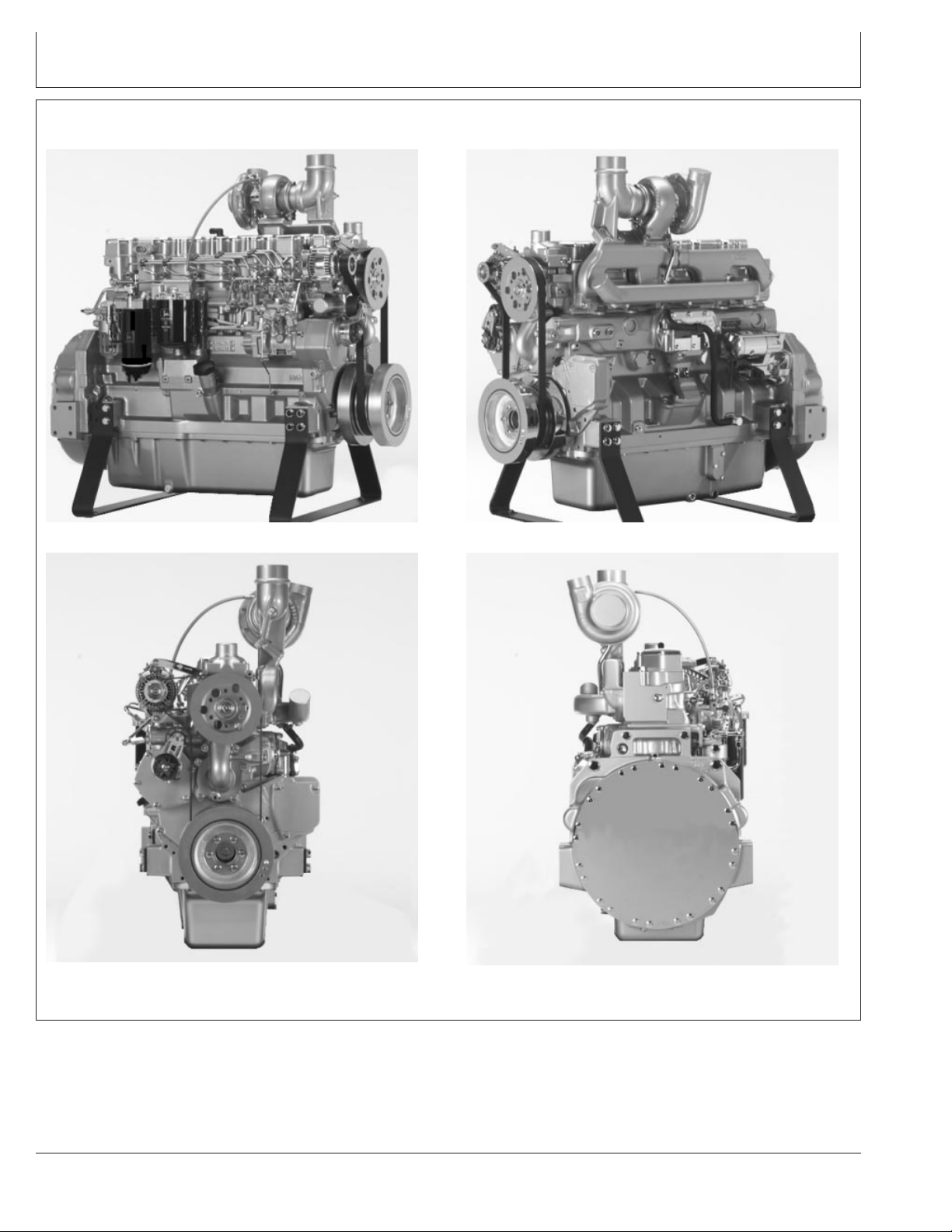

8.1 L Diesel Engine Right Front View (Engines —199,999)

RG7388 –UN–20JUN00

8.1 L Diesel Engine Left Front View (Engines —199,999)

RG7386 –UN–20JUN00

8.1 L Diesel Engine Front View (Engines —199,999)

RG7383 –UN–05JAN98

8.1 L Diesel Engine Rear View (Engines —199,999)

CTM86 (20MAR01) P

OWERTECH

RG7384 –UN–05JAN98

RG,RG34710,4001 –19–14DEC00–2/2

8.1 L Diesel Engines — Base Engine

032001

PN=7

Page 8

Introduction

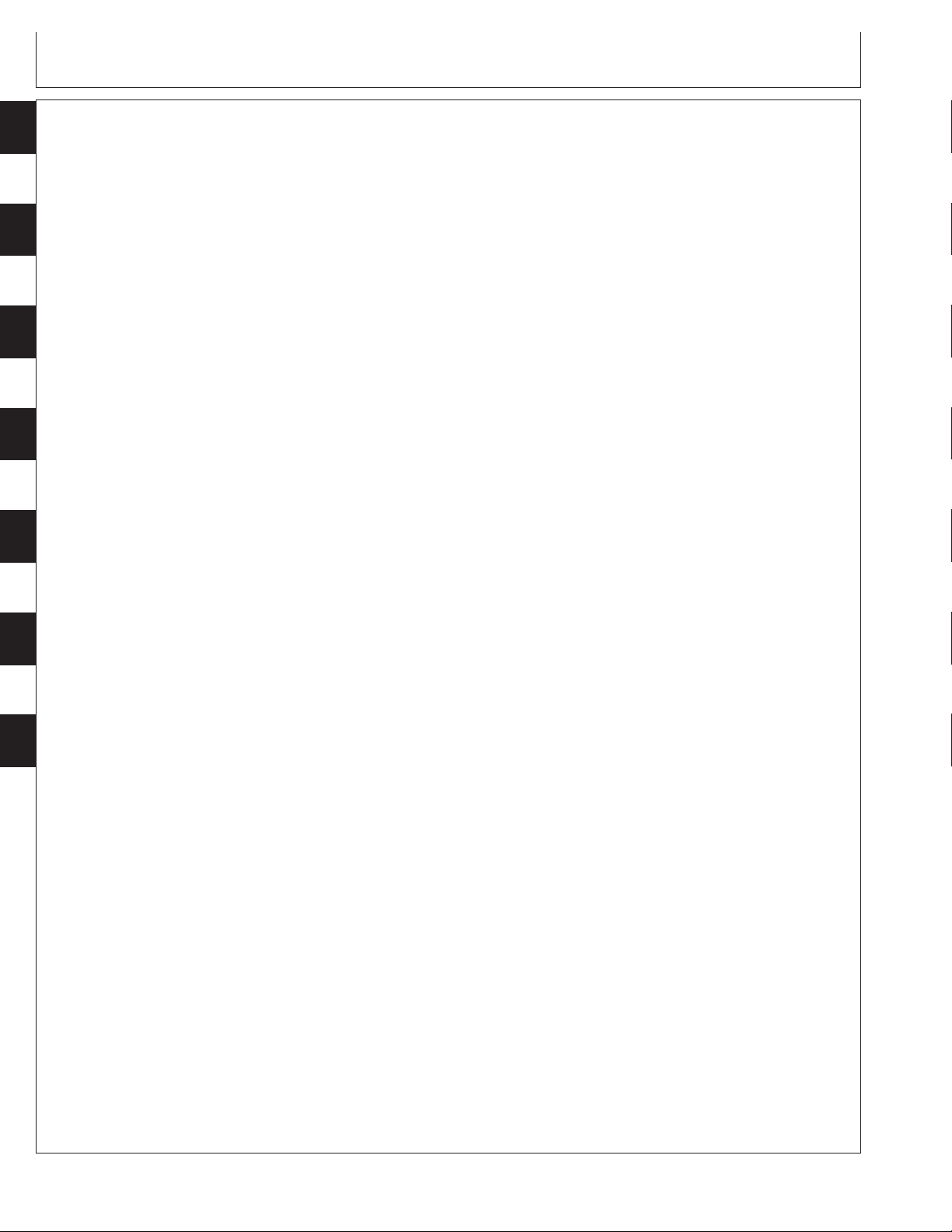

Identification Views Serial Number (200,000— )

8.1 L Diesel Engine Right Front View (Engines 200,000— )

8.1 L Diesel Engine Front View (Engines 200,000— )

RG11511 –UN–13DEC00

RG11513 –UN–31OCT00

8.1 L Diesel Engines Left Front View (Engines 200,000— )

RG11512 –UN–31OCT00

RG11514 –UN–31OCT00

8.1 L Diesel Engine Rear View (Engines 200,000— )

CTM86 (20MAR01) P

OWERTECH

RG,OUOD007,4002 –19–01NOV00–1/1

8.1 L Diesel Engines — Base Engine

032001

PN=8

Page 9

SECTION 01—General

Group 000—Safety

Group 001—Engine Identification

Group 002—Fuels, Lubricants and Coolant

Contents

01

SECTION 02—Repair and Adjustments

Group 010—Engine Rebuild

Group 020—Cylinder Head and Valves Repair and

Adjustment S. N. ( —199,999)

Group 021—Cylinder Head and Valves Repair and

Adjustment S. N. (200,000— )

Group 030—Cylinder Block, Liners, Pistons, and

Rods Repair and Adjustment

Group 040—Crankshaft, Main Bearings and

Flywheel Repair and Adjustment

Group 050—Camshaft and Timing Gear Train

Repair and Adjustment

Group 060—Lubrication System Repair and

Adjustment

Group 070—Cooling System Repair and Adjustment

Group 080—Air Intake and Exhaust System Repair

and Adjustment

Group 100—OEM Starting and Charging Systems

Repair and Adjustment

SECTION 03—Theory of Operation

Group 120—Base Engine Operation

SECTION 04—Diagnostics

Group 150—Observable Diagnostics and Tests

02

03

04

05

06

SECTION 05—Tools and Other Materials

Group 170—Repair Tools and Other Materials

Group 180—Diagnostic Service Tools

Group 190—Dealer Fabricated Service Tools

SECTION 06—Specifications

Group 200—Repair and General OEM

Specifications

Group 210—Diagnostic Specifications

All information, illustrations and specifications in this manual are based on

the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

COPYRIGHT2001

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTIONManual

All rights reserved

Previous Editions

Copyright1994,1997,1999

INDX

CTM86 (20MAR01)

i

P

OWERTECH

8.1 L Diesel Engines — Base Engine

032001

PN=1

Page 10

01

02

03

04

05

Contents

06

INDX

CTM86 (20MAR01)

ii

P

OWERTECH

8.1 L Diesel Engines — Base Engine

032001

PN=2

Page 11

Page

Group 000—Safety ....................01-000-1

Group 001—Engine Identification

Engine Model Designation................01-001-1

Engine Serial Number Plate Information .....01-001-2

Engine Option Code Label ...............01-001-3

Engine Application Chart (John Deere

Agricultural Equipment) ................01-001-4

Engine Application Chart (John Deere

Construction Equipment) ...............01-001-5

Engine Application Chart (OEM) (Outside

Equipment Manufacturers)..............01-001-5

Group 002—Fuels, Lubricants and Coolant

Diesel Fuel ...........................01-002-1

Bio-Diesel Fuel ........................01-002-2

Lubricity of Diesel Fuel ..................01-002-4

Dieselscan Fuel Analysis.................01-002-4

Diesel Engine Break-In Oil ...............01-002-5

Diesel Engine Oil ......................01-002-6

Extended Diesel Engine Oil Service

Intervals............................01-002-6

Alternative and Synthetic Lubricants ........01-002-7

Mixing of Lubricants ....................01-002-7

Oilscan and Coolscan ...................01-002-8

Grease ..............................01-002-9

Diesel Engine Coolant..................01-002-10

Diesel Engine Coolants, Supplemental

Additive Information..................01-002-11

Testing Diesel Engine Coolant ...........01-002-12

Replenishing Supplemental Coolant

Additives (SCAs) Between Coolant

Changes ..........................01-002-13

Operating in Warm Temperature Climates . .01-002-14

Flush and Service Cooling System ........01-002-15

Disposing of Coolant...................01-002-16

01

Section 01

General

Contents

CTM86 (20MAR01)

01-1

P

OWERTECH

8.1 L Diesel Engines — Base Engine

032001

PN=1

Page 12

01

Contents

CTM86 (20MAR01)

01-2

P

OWERTECH

8.1 L Diesel Engines — Base Engine

032001

PN=2

Page 13

Handle Fluids Safely—Avoid Fires

When you work around fuel, do not smoke or work near

heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not

incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn

spontaneously.

Group 000

Safety

01

000

1

TS227 –UN–23AUG88

Avoid Fires

DX,FLAME –19–29SEP98–1/1

Handle Starting Fluid Safely

Starting fluid is highly flammable.

Keep all sparks and flame away when using it. Keep

starting fluid away from batteries and cables.

To prevent accidental discharge when storing the

pressurized can, keep the cap on the container, and store

in a cool, protected location.

Do not incinerate or puncture a starting fluid container.

TS1356 –UN–18MAR92

DX,FIRE3 –19–16APR92–1/1

CTM86 (20MAR01)

01-000-1

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=13

032001

Page 14

01

000

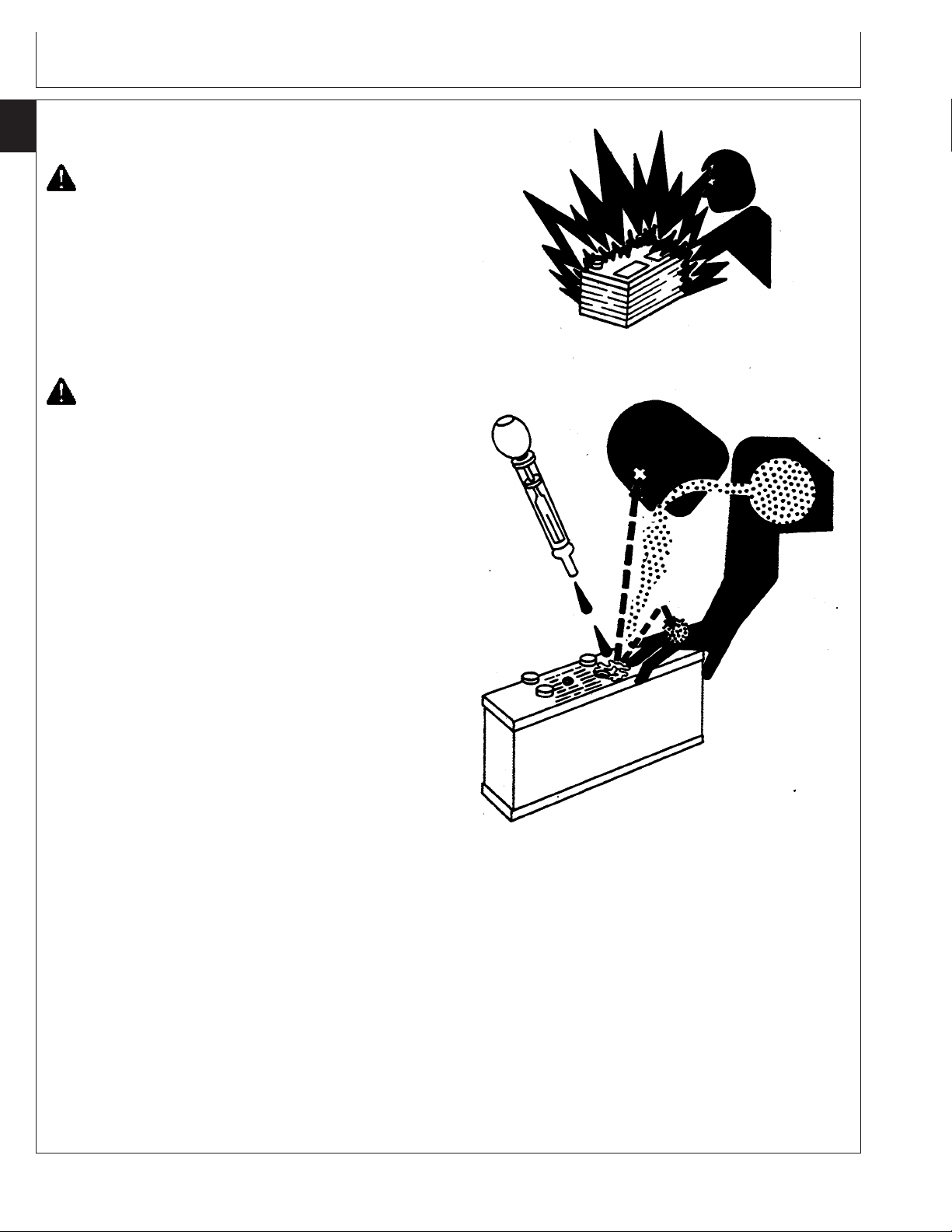

Handling Batteries Safely

2

CAUTION: Battery gas can explode. Keep

sparks and flames away from batteries. Use a

flashlight to check battery electrolyte level.

Never check battery charge by placing a metal

object across the posts. Use a voltmeter or

hydrometer.

Safety

Always remove grounded (-) battery clamp first

and replace it last.

CAUTION: Sulfuric acid in battery electrolyte is

poisonous. It is strong enough to burn skin, eat

holes in clothing, and cause blindness if

splashed into eyes.

Avoid the hazard by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is

added.

4. Avoiding spilling or dripping electrolyte.

5. Use proper jump start procedure.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize

the acid.

3. Flush your eyes with water for 15—30

minutes. Get medical attention immediately.

TS204 –UN–23AUG88TS203 –UN–23AUG88

If acid is swallowed:

1. Do not induce vomiting.

2. Drink large amounts of water or milk, but do

not exceed2L(2quarts).

3. Get medical attention immediately.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

CTM86 (20MAR01)

01-000-2

P

OWERTECH

DPSG,OUO1004,2758 –19–11MAY00–1/1

8.1 L Diesel Engines — Base Engine

PN=14

032001

Page 15

Safety

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

01

000

3

Avoid High-Pressure Fluids

Escaping fluid under pressure can penetrate the skin

causing serious injury.

Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands

and body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid

injected into the skin must be surgically removed within a

few hours or gangrene may result. Doctors unfamiliar with

this type of injury should reference a knowledgeable

medical source. Such information is available from Deere

& Company Medical Department in Moline, Illinois, U.S.A.

First Aid Kit

TS291 –UN–23AUG88

DX,FIRE2 –19–03MAR93–1/1

X9811 –UN–23AUG88

High-Pressure Fluids

CTM86 (20MAR01)

01-000-3

P

OWERTECH

DX,FLUID –19–03MAR93–1/1

8.1 L Diesel Engines — Base Engine

PN=15

032001

Page 16

01

000

Wear Protective Clothing

4

Wear close fitting clothing and safety equipment

appropriate to the job.

Prolonged exposure to loud noise can cause impairment

or loss of hearing.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones

while operating machine.

Service Machines Safely

Safety

TS206 –UN–23AUG88

Protective Clothing

DX,WEAR –19–10SEP90–1/1

Tie long hair behind your head. Do not wear a necktie,

scarf, loose clothing, or necklace when you work near

machine tools or moving parts. If these items were to get

caught, severe injury could result.

Remove rings and other jewelry to prevent electrical

shorts and entanglement in moving parts.

Moving Parts

TS228 –UN–23AUG88

DX,LOOSE –19–04JUN90–1/1

CTM86 (20MAR01)

01-000-4

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=16

032001

Page 17

Safety

Work In Ventilated Area

Engine exhaust fumes can cause sickness or death. If it is

necessary to run an engine in an enclosed area, remove

the exhaust fumes from the area with an exhaust pipe

extension.

If you do not have an exhaust pipe extension, open the

doors and get outside air into the area

01

000

5

Work in Clean Area

Before starting a job:

• Clean work area and machine.

• Make sure you have all necessary tools to do your job.

• Have the right parts on hand.

• Read all instructions thoroughly; do not attempt

shortcuts.

Engine exhaust fumes

TS220 –UN–23AUG88

DX,AIR –19–17FEB99–1/1

T6642EJ –UN–18OCT88

Clean Work Area

CTM86 (20MAR01)

01-000-5

P

OWERTECH

DX,CLEAN –19–04JUN90–1/1

8.1 L Diesel Engines — Base Engine

PN=17

032001

Page 18

01

000

Remove Paint Before Welding or Heating

6

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated

by welding, soldering, or using a torch.

Remove paint before heating:

• Remove paint a minimum of 76 mm (3 in.) from area to

be affected by heating.

• If you sand or grind paint, avoid breathing the dust.

Wear an approved respirator.

• If you use solvent or paint stripper, remove stripper with

soap and water before welding. Remove solvent or

paint stripper containers and other flammable material

from area. Allow fumes to disperse at least 15 minutes

before welding or heating.

Do all work in an area that is ventilated to carry toxic

fumes and dust away.

Safety

TS220 –UN–23AUG88

Dispose of paint and solvent properly.

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near

pressurized fluid lines, resulting in severe burns to

yourself and bystanders. Do not heat by welding,

soldering, or using a torch near pressurized fluid lines or

other flammable materials. Pressurized lines can be

accidentally cut when heat goes beyond the immediate

flame area.

DX,PAINT –19–22OCT99–1/1

TS953 –UN–15MAY90

Flammable Spray

CTM86 (20MAR01)

01-000-6

P

OWERTECH

DX,TORCH –19–03MAR93–1/1

8.1 L Diesel Engines — Base Engine

PN=18

032001

Page 19

Safety

Illuminate Work Area Safely

Illuminate your work area adequately but safely. Use a

portable safety light for working inside or under the

machine. Make sure the bulb is enclosed by a wire cage.

The hot filament of an accidentally broken bulb can ignite

spilled fuel or oil.

01

000

7

Use Proper Lifting Equipment

Lifting heavy components incorrectly can cause severe

injury or machine damage.

Follow recommended procedure for removal and

installation of components in the manual.

Work Area Safely

TS223 –UN–23AUG88

DX,LIGHT –19–04JUN90–1/1

TS226 –UN–23AUG88

Proper Lifting Equipment

CTM86 (20MAR01)

01-000-7

P

OWERTECH

DX,LIFT –19–04JUN90–1/1

8.1 L Diesel Engines — Base Engine

PN=19

032001

Page 20

01

000

Construct Dealer-Made Tools Safely

8

Faulty or broken tools can result in serious injury. When

constructing tools, use proper, quality materials and good

workmanship.

Do not weld tools unless you have the proper equipment

and experience to perform the job.

Safety

Practice Safe Maintenance

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from

power-driven parts. Disengage all power and operate

controls to relieve pressure. Lower equipment to the

ground. Stop the engine. Remove the key. Allow machine

to cool.

Securely support any machine elements that must be

raised for service work.

Construct Dealer-Made Tools Safely

LX1016749 –UN–01JUL97

DPSG,OUO1004,899 –19–19MAY99–1/1

Keep all parts in good condition and properly installed. Fix

damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground

cable (-) before making adjustments on electrical systems

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

CTM86 (20MAR01)

01-000-8

P

OWERTECH

Keep Area Clean

DX,SERV –19–17FEB99–1/1

8.1 L Diesel Engines — Base Engine

PN=20

TS218 –UN–23AUG88

032001

Page 21

Safety

Use Proper Tools

Use tools appropriate to the work. Makeshift tools and

procedures can create safety hazards.

Use power tools only to loosen threaded parts and

fasteners.

For loosening and tightening hardware, use the correct

size tools. DO NOT use U.S. measurement tools on

metric fasteners. Avoid bodily injury caused by slipping

wrenches.

Use only service parts meeting John Deere specifications.

Dispose of Waste Properly

01

000

9

TS779 –UN–08NOV89

Proper Tools

DX,REPAIR –19–17FEB99–1/1

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful waste used

with John Deere equipment include such items as oil, fuel,

coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids. Do not use

food or beverage containers that may mislead someone

into drinking from them.

Do not pour waste onto the ground, down a drain, or into

any water source.

Air conditioning refrigerants escaping into the air can

damage the Earth’s atmosphere. Government regulations

may require a certified air conditioning service center to

recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste

from your local environmental or recycling center, or from

your John Deere dealer.

Recycle Waste

TS1133 –UN–26NOV90

DX,DRAIN –19–03MAR93–1/1

CTM86 (20MAR01)

01-000-9

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=21

032001

Page 22

01

000

Live With Safety

10

Before returning machine to customer, make sure

machine is functioning properly, especially the safety

systems. Install all guards and shields.

Safety

Safety Systems

TS231 –19–07OCT88

DX,LIVE –19–25SEP92–1/1

CTM86 (20MAR01)

01-000-10

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=22

032001

Page 23

Engine Model Designation

JOHN DEERE ENGINE MODEL—6081

John Deere engine model designation includes number of

cylinders, displacement in liters, aspiration, user code, and

application code. For example:

6081 HRW01 Engine

6 ............................................................................ Number of cylinders

8.1 ............................................................................... Liter designation

H .................................................................................... Aspiration code

RW ........................................................................................ User code

01 ............................................................................... Application Code

Aspiration Code

T ............................................................ Turbocharged, no aftercooling

A ...................................... Turbocharged and coolant-to-air aftercooled

H ............................................. Turbocharged and air-to-air aftercooled

User Code

CQ ................................................................ S.L.C. Horizontina (Brazil)

DW ........................................................................................ Davenport

F .................................................................................................... OEM

FF ........................................ Kernersvill Deere-Hitachi (North Carolina)

H ............................................................................................. Harvester

N ......................................................................................... Des Moines

RW ......................................................................... Waterloo (Tractors)

T .............................................................................................. Dubuque

TJ ............................................................................... Ontario (Canada)

........................................................................... Bessemer (Alabama)

Z ........................................................................................ Zweibrucken

Application Code

001, etc. ..... See ENGINE APPLICATION CHART, later in this Group

Group 001

Engine Identification

01

001

1

CTM86 (20MAR01)

01-001-1

P

OWERTECH

RG,RG34710,1021 –19–23OCT97–1/1

8.1 L Diesel Engines — Base Engine

PN=23

032001

Page 24

01

001

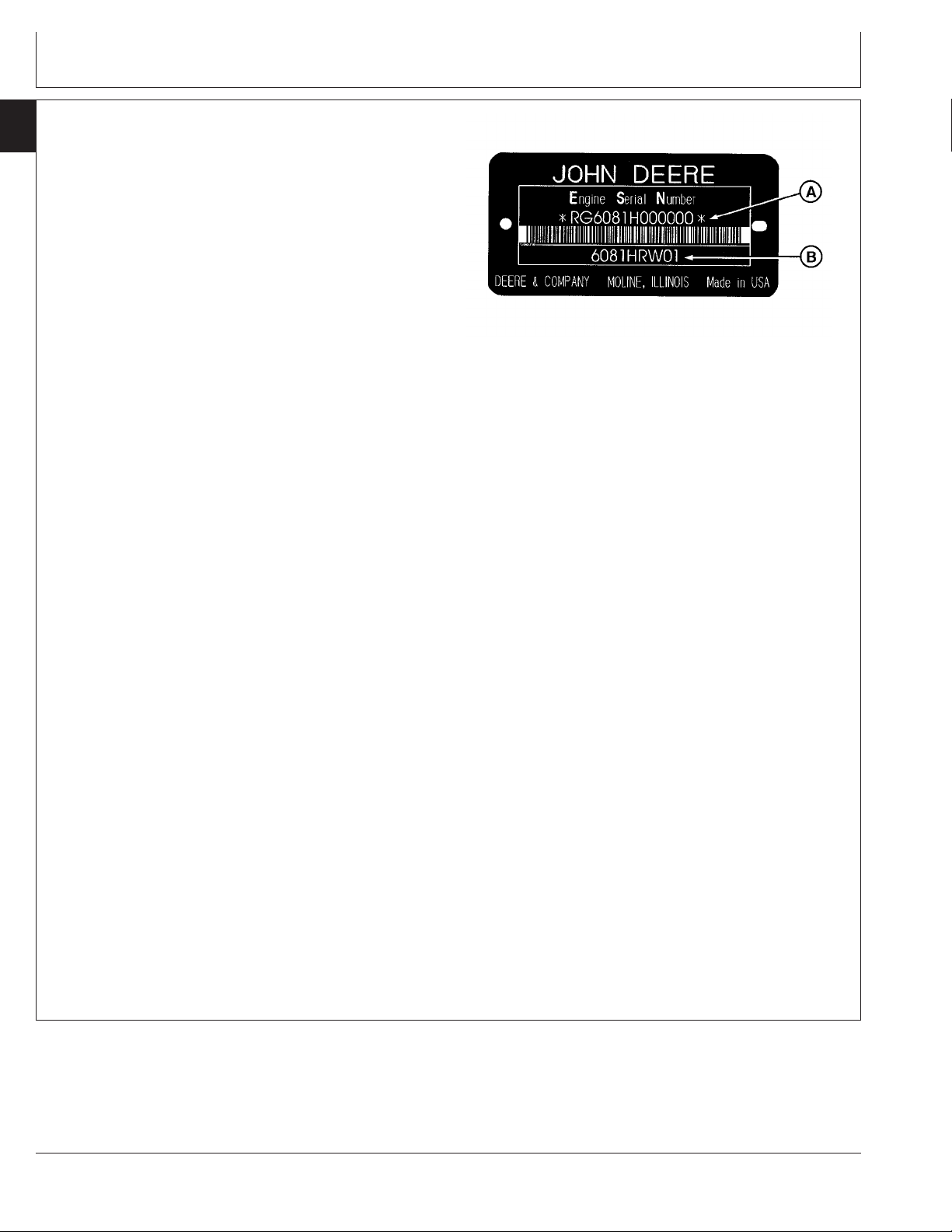

Engine Serial Number Plate Information

2

IMPORTANT: The engine serial number plate can be

easily destroyed. Remove the plate or

record the information elsewhere,

before “hot tank” cleaning the block.

Engine Serial Number (A)

Each engine has a 13-digit John Deere engine serial

number identifying the producing factory, engine model

designation, and a 6-digit sequential number. The

following is an example:

Engine Identification

RG7010 –UN–26NOV97

Engine Serial Number Plate

RG6081H000000

RG ........................................................ Factory code producing engine

6081H ........................................................... Engine model designation

000000 .......................................................... Sequential serial number

Factory Code

RG ............................................................... Waterloo Engine Works

Engine Model Designation

6801H .................................... (See ENGINE MODEL DESIGNATION.)

Sequential Number

000000 .......................................................... 6-digit sequential number

The engine serial number plate is located either on the

right-hand side of engine between the oil filter base and

fuel injection pump (viewed from flywheel end) or on the

left-hand side of the engine directly above the starter

motor.

Engine Application Data (B)

The second line of information on the engine serial

number plate identifies the engine/Deere machine or OEM

relationship. SeeENGINE APPLICATION CHART later in

this group.

A—Engine Serial Number

B—Engine Application Data

CTM86 (20MAR01)

01-001-2

P

OWERTECH

RG,RG34710,1022 –19–19MAY99–1/1

8.1 L Diesel Engines — Base Engine

PN=24

032001

Page 25

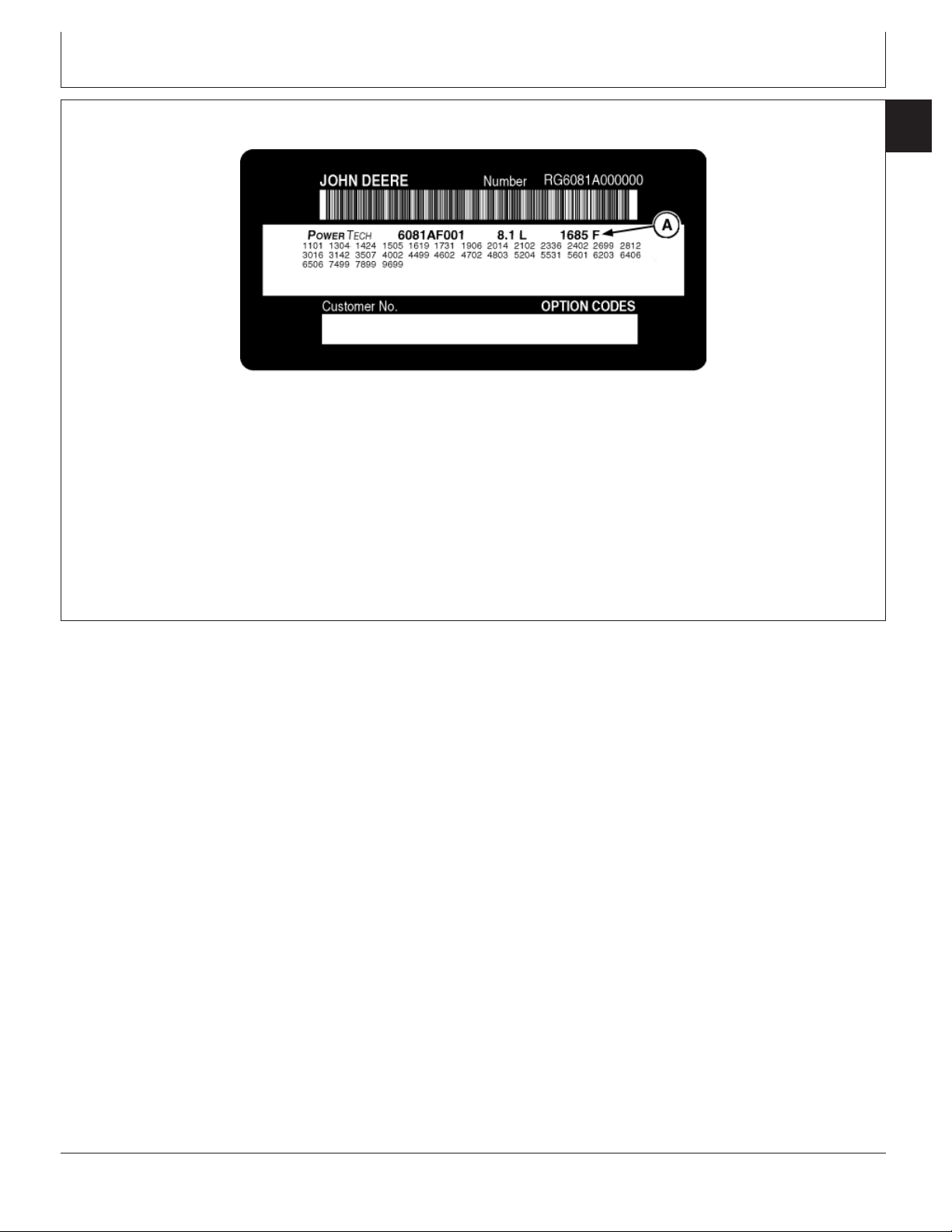

Engine Option Code Label

Engine Identification

01

001

3

Option Code Label

In addition to the serial number plate, later OEM

engines have an engine option code label affixed to

the rocker arm cover. These codes indicate which of

the engine options were installed on your engine at the

RG11074 –UN–14AUG00

factory. When in need of parts or service, furnish your

authorized servicing dealer or engine distributor with

these numbers.

DPSG,OUO1004,900 –19–19MAY99–1/1

CTM86 (20MAR01)

01-001-3

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=25

032001

Page 26

01

001

Engine Application Chart (John Deere

4

Agricultural Equipment)

Machine Model Engine Model

DES MOINES—COTTON PICKERS

9970 Cotton Picker ............................................................. 6081AN001

9976 Cotton Picker .................................................... 6081HN001, 003

HARVESTER—COMBINES

9510 Low Power Combine ................................................. 6081HH001

9510 High Power Combine ................................................ 6081HH002

9550 Low Power Combine ................................................. 6081HH008

9550 High Power Combine ................................................ 6081HH009

9610 Combine .................................................................... 6081HH003

9650 and 9650CTS Combine ............................................ 6081HH010

9650 CTS-(Europe) Combine ............................................ 6081HH011

9650 STS Combine ............................................................ 6081HH006

9750 STS Combine ............................................................ 6081HH005

CTS II Combine (Europe-1998 Model Year ...................... 6081HH003

CTS II Combine (Europe-1999 Model Year) ..................... 6081HH004

CTS II Combine (North America) ....................................... 6081HH003

Amadus Peanut Combine .................................................. 6081HH007

WATERLOO—TRACTORS

7710 Tractor .............................................. 6081TRW01, 03, 05, 07, 09

7810 Tractor ....................................... 6081TRW02, 04, 06, 08, 10, 11

8100 Tractor ...................................................................... 6081HRW06

8200 Tractor ...................................................................... 6081HRW07

8300 Tractor ...................................................................... 6081HRW08

8400 Tractor ................................................................ 6081HRW01, 04

8100T (Tracks) Tractor ..................................................... 6081HRW10

8200T (Tracks) Tractor ..................................................... 6081HRW02

8300T (Tracks) Tractor ..................................................... 6081HRW09

8400T (Tracks) Tractor ..................................................... 6081HRW03

8110 Tractor ...................................................................... 6081HRW11

8210 Tractor ...................................................................... 6081HRW13

8310 Tractor ...................................................................... 6081HRW15

8410 Tractor ...................................................................... 6081HRW17

8110T (Tracks) Tractor ..................................................... 6081HRW12

8210T (Tracks) Tractor ..................................................... 6081HRW14

8310T (Tracks) Tractor ..................................................... 6081HRW16

8410T (Tracks) Tractor ..................................................... 6081HRW18

9100 4-Wheel Drive Tractor .............................................. 6081HRW05

ZWEIBRUCKEN—COMBINES/FORAGE HARVESTERS

2256 Combine ............................................................. 6081HZ003, 007

2258 Combine ............................................................... 6081HZ002, 05

2264 Combine ..................................................................... 6081HZ002

2266 Combine ..................................................................... 6081HZ001

2268 Combine ..................................................................... 6081HZ006

6650 Self-Propelled Forage Harvester ............................... 6081HZ004

S.L.C. HORIZONTINA (BRAZIL)—COMBINES

1185A Combine ................................................................. 6081ACQ01

Engine Identification

CTM86 (20MAR01)

01-001-4

P

OWERTECH

RG,RG34710,1023 –19–23OCT97–1/1

8.1 L Diesel Engines — Base Engine

PN=26

032001

Page 27

Engine Identification

Engine Application Chart (John Deere Construction Equipment)

Machine Model Engine Model

DAVENPORT

644G Loader ..................................................................... 6081HDW04

644H Loader ..................................................................... 6081HDW05

644H-MH Loader ............................................................... 6081HDW06

740G/748G/748G II/748G III Skidder ............................... 6081TDW01

770C (Late)/770CH/772CH Motor Grader ........................ 6081HDW01

770C Motor Grader (Early) ............................................... 6081HDW03

DUBUQUE

762B Series II Scraper ........................................................ 6081AT001

850C Series II Crawler Dozer (822868— ) ........................ 6081AT002

KERNERSVILLE (DEERE-HITACHI)

330LC/370 Excavator .......................................................... 6081HT001

BESSEMER

530B/535 Log Loader ......................................................... 6081ATJ01

WOODSTOCK, ON

660D Skidder ...................................................................... 6081ATJ02

01

001

5

Engine Application Chart (OEM) (Outside Equipment Manufacturers)

Application Engine Model

OEM Engine (Tier I Emissions Certified) ........................ 6081TF001

OEM Engine (Tier I Emissions Certified) ............................ 6081AF001

OEM Engine (Tier I Emissions Certified) ............................ 6081HF001

Marine Engine .................................................................... 6081AFM01

OEM Engine (Tier II Emissions Certified) ........................... 6081HF070

RG41183,0000024 –19–25JAN01–1/1

RG41183,000003A –19–28FEB01–1/1

CTM86 (20MAR01)

01-001-5

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=27

032001

Page 28

01

001

Engine Identification

6

CTM86 (20MAR01)

01-001-6

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=28

032001

Page 29

Diesel Fuel

Consult your local fuel distributor for properties of the

diesel fuel available in your area.

Group 002

Fuels, Lubricants and Coolant

01

002

1

Fuel lubricity should pass a minimum of 3100 gram

load level as measured by the BOCLE scuffing test.

In general, diesel fuels are blended to satisfy the low

temperature requirements of the geographical area in

which they are marketed.

Diesel fuels specified to EN 590 or ASTM D975 are

recommended.

In all cases, the fuel shall meet the following

properties:

Cetane number of 40 minimum. Cetane number

greater than 50 is preferred, especially for

temperatures below -20°C (-4°F) or elevations above

1500 m (5000 ft).

Cold Filter Plugging Point (CFPP) below the

expected low temperature OR Cloud Point at least

5°C(9°F) below the expected low temperature.

Sulfur content:

• Sulfur content should not exceed 0.5%. Sulfur

content less than 0.05% is preferred.

• If diesel fuel with sulfur content greater than 0.5%

sulfur content is used, reduce the service interval for

engine oil and filter by 50%.

• DO NOT use diesel fuel with sulfur content greater

than 1.0%.

DO NOT mix used engine oil or any other type of

lubricant with diesel fuel.

RG41165,0000071 –19–13MAR01–1/1

CTM86 (20MAR01)

01-002-1

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=29

032001

Page 30

Fuels, Lubricants and Coolant

01

002

Bio-Diesel Fuel

2

Bio-diesel fuels may be used ONLY if the fuel

properties meet DIN 51606 or equivalent specification.

It has been shown that bio-diesel fuels have been

found to improve lubricity in concentrations up to 5%

blend in petroleum diesel fuel.

When using a blend of bio-diesel fuel with fuel pumps,

the oil level MUST be checked daily when the air

temperature is -10° C (14° F) or lower. If oil becomes

diluted with fuel, oil change intervals must be

shortened accordingly.

IMPORTANT: Raw pressed vegetable oils are NOT

acceptable for use for fuel in any

concentration in John Deere

engines. These oils do not burn

completely, and will cause engine

failure by leaving deposits on

injectors and in the combustion

chamber.

Users of bio-diesel fuel should always remember that a

major selling merit is its ability to biodegrade, so the

storage and handling of this fuel is very important. This

importance can be seen in the following areas of

concern:

• The quality of the fresh fuel,

• Water content of the fuel,

• Problems due to aging of the fuel.

Potential problems resulting from deficiencies in the

above areas when using bio-diesel fuel in

concentrations above 5% may lead to the following

symptoms:

• Power loss and deterioration of performance,

• Fuel leakage,

• Corrosion of fuel injection equipment,

• Coked/blocked injector nozzles, leading to poor

atomization of fuel,

• Filter plugging,

• Lacquering/seizure of internal components,

• Sludge and sediments,

• Reduced service life.

CTM86 (20MAR01)

Continued on next page

01-002-2

P

OWERTECH

RG41165,0000034 –19–13MAR01–1/2

8.1 L Diesel Engines — Base Engine

PN=30

032001

Page 31

Fuels, Lubricants and Coolant

Bio-Diesel Property List for DIN 51606

Property Unit DIN 51606 Sept 1997

Density at 15° C(59° F) g/cm3(lb/ft3) 0.875—0.900 (55—56)

Viscosity at 40° C(104° F) mm2/s (cST) 3.5—5.0

Flash Point °C(°F) Min. 110 (230)

Cold Filter Plugging Point—Summer °C(°F) Max. 0 (32)

Cold Filter Plugging Point—Winter °C(°F) Max. -20 (-4)

Total Sulfur % Mass 0.01

Conradson (CCR) at 100% % Mass Max. 0.05

Cetane Number — Min. 49

Ash Content % Mass Max. 0.03

Water Content % Mass Max. 0.03

Total Contamination % Mass Max. 0.002

Copper Corrosion (3 hours, 50° C) (3 hours, Degree of Corrosion 1

122° F)

Neutralization Value mg KOH/g Max. 0.5

Methanol Content % Mass Max. 0.3

Monoglycerides % Mass Max. 0.8

Diglycerides % Mass Max. 0.4

Trigycerides % Mass Max. 0.4

Free Glycerine % Mass Max. 0.02

Total Glycerine % Mass Max. 0.25

Iodine Number — Max. 115

Phosphorus % Mass Max. 0.001

Alkali Content (Na + K) % Mass Max. 0.0005

01

002

3

CTM86 (20MAR01)

01-002-3

P

OWERTECH

RG41165,0000034 –19–13MAR01–2/2

8.1 L Diesel Engines — Base Engine

PN=31

032001

Page 32

Fuels, Lubricants and Coolant

01

002

Lubricity of Diesel Fuel

4

Diesel fuel must have adequate lubricity to ensure

proper operation and durability of fuel injection system

components.

Diesel fuels for highway use in the United States and

Canada require sulfur content less than 0.05%.

Diesel fuel in the European Union requires sulfur

content less than 0.05%.

Experience shows that some low sulfur diesel fuels

may have inadequate lubricity and their use may

reduce performance in fuel injection systems due to

inadequate lubrication of injection pump components.

The lower concentration of aromatic compounds in

these fuels also adversely affects injection pump seals

and may result in leaks.

Use of low lubricity diesel fuels may also cause

accelerated wear, injection nozzle erosion or corrosion,

engine speed instability, hard starting, low power, and

engine smoke.

Fuel lubricity should pass a minimum of 3100 gram

load level as measured by the BOCLE scuffing test.

ASTM D975 and EN 590 specifications do not require

fuels to pass a fuel lubricity test.

If fuel of low or unknown lubricity is used, add John

Deere PREMIUM DIESEL FUEL CONDITIONER (or

equivalent) at the specified concentration.

Dieselscan Fuel Analysis

DIESELSCAN is a John Deere fuel sampling program to

help you monitor the quality of your fuel source. It verifies

fuel type, cleanliness, water content, suitability for cold

weather operation, and if fuel is within ASTM

specifications. Check with your John Deere dealer for

availability of DIESELSCAN kits.

DIESELSCAN is a trademark of Deere & Company

DX,FUEL5 –19–24JAN00–1/1

DX,FUEL6 –19–06DEC00–1/1

CTM86 (20MAR01)

01-002-4

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=32

032001

Page 33

Fuels, Lubricants and Coolant

Diesel Engine Break-In Oil

New engines are filled at the factory with John Deere

ENGINE BREAK-IN OIL. During the break-in period,

add John Deere ENGINE BREAK-IN OIL as needed to

maintain the specified oil level.

Change the oil and filter after the first 100 hours of

operation of a new or rebuilt engine.

After engine overhaul, fill the engine with John Deere

ENGINE BREAK-IN OIL.

If John Deere ENGINE BREAK-IN OIL is not available,

use a diesel engine oil meeting one of the following

during the first 100 hours of operation:

• API Service Classification CE

01

002

5

• ACEA Specification E1

After the break-in period, use John Deere PLUS-50or

other diesel engine oil as recommended in this

manual.

IMPORTANT: Do not use PLUS-50 oil or engine

oils meeting API CH-4, API CG4, API

CF4, ACEA E3, or ACEA E2

performance levels during the first

100 hours of operation of a new or

rebuilt engine. These oils will not

allow the engine to break-in

properly.

PLUS-50 is a registered trademark of Deere & Company.

DX,ENOIL4 –19–24JAN00–1/1

CTM86 (20MAR01)

01-002-5

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=33

032001

Page 34

Fuels, Lubricants and Coolant

01

002

Diesel Engine Oil

6

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

The following oil is preferred:

• John Deere PLUS-50

The following oil is also recommended:

• John Deere TORQ-GARD SUPREME

Other oils may be used if they meet one or more of the

following:

• API Service Classification CH-4

• API Service Classification CG-4

• API Service Classification CF-4

• ACEA Specification E3

• ACEA Specification E2

Multi-viscosity diesel engine oils are preferred.

If diesel fuel with sulfur content greater than 0.5% is used,

reduce the service interval by 50%.

Extended service intervals may apply when John Deere

preferred engine oils are used. Consult your John Deere

dealer for more information.

TS1661 –UN–10OCT97

PLUS-50 is a registered trademark of Deere & Company.

TORQ-GARD SUPREME is a registered trademark of Deere & Company

Extended Diesel Engine Oil Service Intervals

When John Deere PLUS-50oil and the specified John

Deere filter are used, the service interval for engine oil

and filter changes may be increased by 50%.

If other than PLUS-50oil and the specified John Deere

filter are used, change the engine oil and filter at the

normal service interval.

PLUS-50 is a trademark of Deere & Company

CTM86 (20MAR01)

01-002-6

P

OWERTECH

DX,ENOIL –19–24JAN00–1/1

DX,ENOIL6 –19–10OCT97–1/1

8.1 L Diesel Engines — Base Engine

PN=34

032001

Page 35

Fuels, Lubricants and Coolant

Alternative and Synthetic Lubricants

Conditions in certain geographical areas may require

lubricant recommendations different from those printed in

this manual.

Some John Deere brand coolants and lubricants may not

be available in your location.

Consult your John Deere dealer to obtain information and

recommendations.

Synthetic lubricants may be used if they meet the

performance requirements as shown in this manual.

The temperature limits and service intervals shown in this

manual apply to both conventional and synthetic oils.

Re-refined base stock products may be used if the

finished lubricant meets the performance requirements.

01

002

7

Mixing of Lubricants

In general, avoid mixing different brands or types of oil.

Oil manufacturers blend additives in their oils to meet

certain specifications and performance requirements.

Mixing different oils can interfere with the proper

functioning of these additives and degrade lubricant

performance.

DX,ALTER –19–15JUN00–1/1

Consult your John Deere dealer to obtain specific

information and recommendations.

DX,LUBMIX –19–18MAR96–1/1

CTM86 (20MAR01)

01-002-7

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=35

032001

Page 36

Fuels, Lubricants and Coolant

01

002

OILSCANand CoolScan

8

OILSCANand CoolScanare John Deere sampling

programs to help you monitor machine performance and

identify potential problems before they cause serious

damage.

Oil and coolant samples should be taken from each

system prior to its recommended change interval.

Check with your John Deere dealer for the availability of

OILSCANand CoolScankits.

T6828AB –UN–15JUN89T6829AB –UN–18OCT88

OILSCAN is a registered trademark of Deere & Company.

CoolScan is a registered trademark of Deere & Company.

DPSG,OUOD002,1824 –19–02AUG00–1/1

CTM86 (20MAR01)

01-002-8

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=36

032001

Page 37

Fuels, Lubricants and Coolant

Grease

Use grease based on NLGI consistency numbers and the

expected air temperature range during the service interval.

The following greases are preferred:

• John Deere SD POLYUREA GREASE

The following greases are also recommended:

• John Deere HD MOLY GREASE

• John Deere HD LITHIUM COMPLEX GREASE

• John Deere HD WATER RESISTANT GREASE

• John Deere GREASE-GARD

Other greases may be used if they meet the following:

• NLGI Performance Classification GC-LB

IMPORTANT: Some types of grease thickener are not

compatible with others. Consult your

grease supplier before mixing different

types of grease.

01

002

9

TS1667 –UN–30JUN99

CTM86 (20MAR01)

01-002-9

P

OWERTECH

DX,GREA1 –19–24JAN00–1/1

8.1 L Diesel Engines — Base Engine

PN=37

032001

Page 38

01

002

Diesel Engine Coolant

10

The engine cooling system is filled to provide

year-round protection against corrosion and cylinder

liner pitting, and winter freeze protection to -37°C

(-34°F).

The following engine coolant is preferred for service:

• John Deere COOL-GARD Prediluted Coolant

The following engine coolant is also recommended:

• John Deere COOL-GARD Coolant Concentrate in a

40 to 60% mixture of concentrate with quality water.

Fuels, Lubricants and Coolant

protection at lower temperatures is required, consult

your John Deere dealer for recommendations.

Water quality is important to the performance of the

cooling system. Distilled, deionized, or demineralized

water is recommended for mixing with ethylene glycol

base engine coolant concentrate.

IMPORTANT: Do not use cooling system sealing

additives or antifreeze that contains

sealing additives.

Coolant Drain Intervals

Other low silicate ethylene glycol base coolants for

heavy-duty engines may be used if they meet one of

the following specifications:

• ASTM D5345 (prediluted coolant)

• ASTM D4985 (coolant concentrate) in a 40 to 60%

mixture of concentrate with quality water

Coolants meeting these specifications require use of

supplemental coolant additives, formulated for

heavy-duty diesel engines, for protection against

corrosion and cylinder liner erosion and pitting.

A 50% mixture of ethylene glycol engine coolant in

water provides freeze protection to -37°C (-34°F). If

Drain the factory fill engine coolant, flush the cooling

system, and refill with new coolant after the first 3

years or 3000 hours of operation. Subsequent drain

intervals are determined by the coolant used for

service. At each interval, drain the coolant, flush the

cooling system, and refill with new coolant.

When John Deere COOL-GARD is used, the drain

interval may be extended to 5 years or 5000 hours of

operation, provided that the coolant is tested annually

AND additives are replenished, as needed, by adding

a supplemental coolant additive.

If COOL-GARD is not used, the drain interval is

reduced to 2 years or 2000 hours of operation.

CTM86 (20MAR01)

01-002-10

P

OWERTECH

DX,COOL3 –19–05FEB99–1/1

8.1 L Diesel Engines — Base Engine

PN=38

032001

Page 39

Fuels, Lubricants and Coolant

Diesel Engine Coolants, Supplemental Additive Information

Engine coolants are a combination of three chemical

components: ethylene glycol (antifreeze), inhibiting

coolant additives, and quality water.

Coolant Specifications

Some products, including John Deere COOL-GARD

Prediluted Coolant, are fully formulated coolants that

contain all three components in their correct

concentrations. Do not add an initial charge of

supplemental coolant additives to these fully

formulated products.

Some coolant concentrates, including John Deere

COOL-GARD Coolant Concentrate, contain both

ethylene glycol antifreeze and inhibiting coolant

additives. Mix these products and quality water, but do

not add an initial charge of supplemental coolant

additives.

Coolants meeting ASTM D5345 (prediluted coolant) or

ASTM D4985 (coolant concentrate) require an initial

charge of supplemental coolant additives.

Replenish Coolant Additives

The concentration of coolant additives is gradually

depleted during engine operation. Periodic

replenishment of inhibitors is required, even when

John Deere COOL-GARD is used. Follow the

recommendations in this manual for the use of

supplemental coolant additives.

Why Use Supplemental Coolant Additives?

Operating without proper coolant additives will result in

increased corrosion, cylinder liner erosion and pitting,

and other damage to the engine and cooling system. A

simple mixture of ethylene glycol and water will not

give adequate protection.

This film acts as a barrier against the harmful effects

of collapsing vapor bubbles.

Avoid Automotive-Type Coolants

Never use automotive-type coolants (such as those

meeting ASTM D3306 or ASTM D4656). These

coolants do not contain the correct additives to protect

heavy-duty diesel engines. They often contain a high

concentration of silicates and may damage the engine

or cooling system.

Non-Aqueous Propylene Glycol

Non-aqueous propylene glycol should not be used with

John Deere diesel engines. This coolant works best

with coolant temperatures above the acceptable

engine operating range. This could decrease engine

life due to lower engine oil viscosity. In addition,

electronically controlled engines could experience

premature power de-rate due to high coolant

temperature.

Water Quality

Water quality is important to the performance of the

cooling system. Distilled, deionized, or demineralized

water is recommended for mixing with ethylene glycol

base engine coolant concentrate. All water used in the

cooling system should meet the following minimum

specifications for quality:

Chlorides 40 mg/L or less

Sulfates 100 mg/L or less

Total Dissolved Solids 340 mg/L or less

Total Hardness 170 mg/L or less

pH Level 5.5 to 9.0

Freeze Protection

01

002

11

Use of supplemental coolant additives reduces

corrosion, erosion, and pitting. These chemicals

reduce the number of vapor bubbles in the coolant and

help form a protective film on cylinder liner surfaces.

CTM86 (20MAR01)

The relative concentrations of ethylene glycol and

water in the engine coolant determine its freeze

protection limit. Refer to the chart on the following

page.

Continued on next page

01-002-11

P

OWERTECH

DPSG,OUOD002,1835 –19–03AUG00–1/2

8.1 L Diesel Engines — Base Engine

PN=39

032001

Page 40

Fuels, Lubricants and Coolant

01

002

12

Ethylene Glycol Freeze Protection Limit

40% -24°C (-12°F)

50% -37°C (-34°F)

60% -52°C (-62°F)

Testing Diesel Engine Coolant

Maintaining adequate concentrations of glycol and

inhibiting additives in the coolant is critical to protect the

engine and cooling system against freezing, corrosion,

and cylinder liner erosion and pitting.

Test the coolant solution at intervals of 12 months or less

and whenever excessive coolant is lost through leaks or

overheating.

Coolant Test Strips

Coolant test strips are available from your John Deere

dealer. These test strips provide a simple, effective

method to check the freeze point and additive levels of

your engine coolant.

DO NOT use a coolant-water mixture greater than

60% ethylene glycol.

DPSG,OUOD002,1835 –19–03AUG00–2/2

Compare the results to the supplemental coolant additive

(SCA) chart to determine the amount of inhibiting

additives in your coolant and whether more John Deere

COOLANT CONDITIONER should be added.

CoolScan

For a more thorough evaluation of your coolant, perform a

CoolScan analysis. See your John Deere dealer for

information about CoolScan.

DPSG,OUOD002,1825 –19–02AUG00–1/1

CTM86 (20MAR01)

01-002-12

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=40

032001

Page 41

Fuels, Lubricants and Coolant

Replenishing Supplemental Coolant Additives (SCAs) Between Coolant Changes

01

002

13

IMPORTANT: Do not add supplemental coolant

additives when the cooling system is

drained and refilled with John Deere

ANTIFREEZE/SUMMER COOLANT or

John Deere COOL-GARD.

NOTE: If a system is to be filled with coolant that does

not contain SCAs, the coolant must be

precharged. Determine the total system

capacity and premix with 3% John Deere

Coolant Conditioner.

Through time and use, the concentration of coolant

additives is gradually depleted during engine operation.

Periodic replenishment of inhibitors is required, even

when John Deere ANTIFREEZE/SUMMER COOLANT

is used. The cooling system must be recharged with

additional supplemental coolant additives available in

the form of liquid coolant conditioner.

RG6261 –UN–08DEC97

Maintaining the correct coolant conditioner

concentration (SCAs) and freeze point is essential in

your cooling system to protect against rust, liner pitting

and corrosion, and freeze-ups due to incorrect coolant

dilution.

John Deere LIQUID COOLANT CONDITIONER is

recommended as a supplemental coolant additive

in John Deere engines.

DO NOT mix one brand of SCA with a different

brand.

Test the coolant solution at 600 hours or 12 months of

operation using either John Deere coolant test strips or

a COOLSCANanalysis. If a COOLSCANanalysis is

not available, recharge system per instructions printed

on label of John Deere Liquid Coolant Conditioner.

RG6262 –UN–05DEC97

COOL-GARD is a registered trademark of Deere & Company

COOLSCAN is a registered trademark of Deere & Company.

CTM86 (20MAR01)

Continued on next page

01-002-13

P

OWERTECH

RG,01,DT7035 –19–14NOV00–1/2

8.1 L Diesel Engines — Base Engine

PN=41

032001

Page 42

Fuels, Lubricants and Coolant

01

002

IMPORTANT: ALWAYS maintain coolant at correct

14

level and concentration. DO NOT

operate engine without coolant for

even a few minutes.

If frequent coolant makeup is

required, the glycol concentration

should be checked with JT07298

Coolant/Battery Tester to ensure that

the desired freeze point is

maintained. Follow manufacturer’s

instructions provided with

Coolant/Battery Tester.

Add the manufacturer’s recommended concentration of

supplemental coolant additive. DO NOT add more than

the recommended amount.

The use of non-recommended supplemental coolant

additives may result in additive drop-out and gelation

of the coolant.

If other coolants are used, consult the coolant supplier

and follow the manufacturer’s recommendation for use

of supplemental coolant additives.

See DIESEL ENGINE COOLANTS, SUPPLEMENTAL

ADDITIVE INFORMATION earlier in this group for

proper mixing of coolant ingredients before adding to

the cooling system.

Operating in Warm Temperature Climates

John Deere engines are designed to operate using glycol

base engine coolants.

Always use a recommended glycol base engine coolant,

even when operating in geographical areas where freeze

protection is not required.

IMPORTANT: Water may be used as coolant

emergency situations only.

Foaming, hot surface aluminum and

iron corrosion, scaling, and cavitation

will occur when water is used as the

coolant, even when coolant

conditioners are added.

Drain cooling system and refill with

recommended glycol base engine

coolant as soon as possible.

in

RG,01,DT7035 –19–14NOV00–2/2

CTM86 (20MAR01)

01-002-14

P

OWERTECH

DX,COOL6 –19–18MAR96–1/1

8.1 L Diesel Engines — Base Engine

PN=42

032001

Page 43

Fuels, Lubricants and Coolant

Flush and Service Cooling System

CAUTION: Explosive release of fluids from

pressurized cooling system can cause serious

burns. Shut off engine. Only remove filler cap

when cool enough to touch with bare hands.

Slowly loosen cap to first stop to relieve

pressure before removing cap completely.

IMPORTANT: Air must be expelled from cooling

system when system is refilled. See

CHECKING COOLING SYSTEM in

operator’s manual.

The ethylene glycol base (antifreeze) can become

depleted of SCAs allowing various acids to form that will

damage engine components. In addition, heavy metals,

such as lead, copper and zinc, accumulate in the ethylene

glycol base. The heavy metals come from corrosion that

occurs to some degree with in a cooling system. When a

coolant is saturated to the point where it can no longer

hold heavy metals and other dissolved solids, they settle

out and act as abrasives on engine parts.

01

002

15

TS281 –UN–23AUG88

NOTE: Refer to your operator’s manual for a specific

service interval. See LUBRICATION AND

MAINTENANCE SERVICE INTERVAL CHART in

operator’s manual.

Flush cooling system as described in your operator’s

manual. See FLUSHING COOLING SYSTEM in

operator’s manual. Clean cooling system with clean water

and TY15979 John Deere Heavy-Duty Cooling System

Cleaner or an equivalent cleaner such as FLEETGUARD

RESTOREor RESTORE PLUS. Follow the instructions

provided with the cleaner. Refill cooling system with the

appropriate coolant solution. See DIESEL ENGINE

COOLANT, earlier in this group.

FLEETGUARD is a registered trademark of the Cummins Engine

Company.

RESTORE is a trademark of FLEETGUARD.

RESTORE PLUS is a trademark of FLEETGUARD.

CTM86 (20MAR01)

Continued on next page

01-002-15

P

OWERTECH

RG,01,DT7033 –19–29OCT97–1/2

8.1 L Diesel Engines — Base Engine

PN=43

032001

Page 44

Fuels, Lubricants and Coolant

01

002

IMPORTANT: NEVER overfill the system. A

16

pressurized system needs space for

heat expansion without overflowing at

the top of the radiator. Coolant level

should be at bottom of radiator filler

neck.

Air must be expelled from cooling

system when system is refilled. Loosen

plug in side of thermostat housing to

allow air to escape when filling system.

Retighten plug when all the air has

been expelled.

After adding new coolant solution, run engine until it

reaches operating temperature. This mixes the coolant

solution uniformly and circulates it through the entire

system. After running engine, check coolant level and

entire cooling system for leaks.

Contact your engine servicing dealer, if there are further

questions.

Disposing of Coolant

Improperly disposing of engine coolant can threaten the

environment and ecology.

Use leakproof containers when draining fluids. Do not use

food or beverage containers that may mislead someone

into drinking from them.

Do not pour waste onto the ground, down a drain, or into

any water source.

Inquire on the proper way to recycle or dispose of waste

from your local environmental or recycling center, or from

your engine servicing dealer.

RG,01,DT7033 –19–29OCT97–2/2

TS1133 –UN–26NOV90

RG,01,DT7032 –19–29OCT97–1/1

CTM86 (20MAR01)

01-002-16

P

OWERTECH

8.1 L Diesel Engines — Base Engine

PN=44

032001

Page 45

Section 02

Repair and Adjustments

Contents

Page Page

Group 010—Engine Rebuild

Engine Overhaul Guidelines ..............02-010-1

Engine Repair Stand....................02-010-1

Safety Precautions .....................02-010-2

Install Adapters on Engine Repair Stand.....02-010-2

Engine Lifting Procedure.................02-010-3

Clean Engine .........................02-010-4

Disconnect Turbocharger Oil Inlet Line ......02-010-5

Mount Engine on Repair Stand ............02-010-6

Engine Disassembly Sequence for

Overhaul ...........................02-010-8

Sealant Application Guidelines ............02-010-9

6081 Engine Assembly Sequence After

Overhaul ..........................02-010-11

Engine Break-In Guidelines..............02-010-13

Perform Engine Break-In................02-010-14

Check Crankcase Ventilation System ......02-010-16

Check Air Intake System................02-010-16

Check Exhaust System.................02-010-17

Check and Service Cooling System .......02-010-17

Check Electrical System ................02-010-19

General Tune-Up Recommendations ......02-010-21

Group 020—Cylinder Head and Valves Repair and

Adjustment S. N. ( —199,999)

Check and Adjust Valve Clearance Serial

Number ( —199,999)..................02-020-1

Check Valve Lift Serial Number

( —199,999) ........................02-020-5

Remove Cylinder Head Serial Number

( —199,999) ........................02-020-6

Head Gasket Inspection and Repair

Sequence Serial Number ( —199,999) ....02-020-9

Disassemble and Inspect Rocker Arm Shaft

Assembly Serial Number

( —199,999) .......................02-020-11

Assemble Rocker Arm Shaft Assembly

Serial Number ( —199,999)............02-020-12

Measure Valve Recess Serial Number

( —199,999) .......................02-020-13

Preliminary Cylinder Head and Valve

Checks Serial Number ( —199,999) .....02-020-14

Remove Valve Assembly Serial Number

( —199,999) .......................02-020-15 ( —199,999) .......................02-020-32

Inspect and Measure Valve Springs Serial

Number ( —199,999).................02-020-16

CTM86 (20MAR01)

Inspect Valve Spring Caps, Wear Caps, and

Retainer Locks Serial Number

( —199,999) .......................02-020-17

Clean Valves Serial Number ( —199,999). . .02-020-17

Inspect and Measure Valves Serial Number

( —199,999) .......................02-020-18

Grind (Reface) Valves Serial Number

( —199,999) .......................02-020-19

Inspect and Clean Cylinder Head Serial

Number ( —199,999).................02-020-19

Check Cylinder Head Combustion Face

Flatness Serial Number ( —199,999).....02-020-20

Measure Cylinder Head Thickness Serial

Number ( —199,999).................02-020-21

Clean Valve Guides Serial Number

( —199,999) .......................02-020-22

Measure Valve Guides Serial Number

( —199,999) .......................02-020-22

Knurl Valve Guides Serial Number

( —199,999) .......................02-020-23

Clean and Inspect Valve Seats Serial

Number ( —199,999).................02-020-23

Measure Valve Sears Serial Number

( —199,999) .......................02-020-24

Grind Valve Seats Serial Number

( —199,999) .......................02-020-25

Remove Valve Seat Inserts Serial Number

( —199,999) .......................02-020-26

Install Valve Seat Inserts Serial Number

( —199,999) .......................02-020-27

Inspect and Clean Cylinder Head Nozzle

Bore Serial Number ( —199,999)........02-020-27

Clean and Inspect Push Rods Serial Number

( —199,999) .......................02-020-29

Inspect and Clean Ventilator Outlet Hose

Serial Number ( —199,999)............02-020-29

Clean and Inspect Top Deck of Cylinder

Block Serial Number ( —199,999) .......02-020-30

Measure Cylinder Liner Standout (Height

Above Block) Serial Number

( —199,999) .......................02-020-31

Assemble Valve Assembly Serial Number

Continued on next page

02-1

P

OWERTECH

8.1 L Diesel Engines — Base Engine

02

032001

PN=1

Page 46

Contents

Page Page

Install Cylinder Head and Cap Screws Grind (Reface) Valves Serial Number

Serial Number ( —199,999)............02-020-33

Torque-to-Yield Flanged-Head Cap Screws—

02

Grade 180 Marked “SPECIAL” Serial

Number ( —199,999).................02-020-35

Install Rocker Arm Assembly Serial Number

( —199,999) .......................02-020-36

Inspect and Clean Ventilator Outlet Hose

Serial Number ( —199,999)............02-020-37

Complete Final Assembly of Injection Pump

Side of Engine Serial Number

( —199,999) .......................02-020-38

Complete Final Assembly on Exhaust

Manifold Side of Engine Serial Number

( —199,999) .......................02-020-39

Perform Engine Break-In Serial Number

( —199,999) .......................02-020-40

(200,000— ) .......................02-021-22

Inspect and Clean Cylinder Head Serial

Number (200,000— ).................02-021-23

Check Cylinder Head Combustion Face

Flatness Serial Number (200,000— ).....02-021-24

Measure Cylinder Head Thickness Serial

Number (200,000— ).................02-021-25

Clean Valve Guides Serial Number

(200,000— ) .......................02-021-26

Measure Valve Guides Serial Number

(200,000— ) .......................02-021-26

Knurl Valve Guides Serial Number

(200,000— ) .......................02-021-27

Clean and Inspect Valve Seats Serial

Number (200,000— ).................02-021-27

Measure Valve Seats Serial Number

(200,000— ) .......................02-021-28

Group 021—Cylinder Head and Valves Repair and

Adjustment S. N. (200,000— )

Check Valve Clearance Serial Number

(200,000— ) ........................02-021-1

Adjust Valve Clearance Serial Number

(200,000— ) ........................02-021-4

Check Valve Lift Serial Number

(200,000— ) ........................02-021-8

Remove Cylinder Head Serial Number

(200,000— ) ........................02-021-9

Diagnosing Head Gasket Joint Failures

Serial Number (200,000— )............02-021-11

Head Gasket Diagnostic Charts Serial

Number (200,000— ).................02-021-13

Head Gasket Inspection and Repair

Sequence Serial Number (200,000— ) . . .02-021-14

Inspect Rocker Arm Assembly Serial Number

(200,000— ) .......................02-021-16

Disassemble and Assemble Rocker Arm

Assembly Serial Number (200,000— )....02-021-17

Measure Valve Recess Serial Number

(200,000— ) .......................02-021-17

Preliminary Cylinder Head and Valve

Checks Serial Number (200,000— ) .....02-021-18

Remove Valve Assembly Serial Number

(200,000— ) .......................02-021-19

Inspect and Measure Valve Springs Serial

Number (200,000— ).................02-021-20

Inspect Valve Spring Caps, Wear Caps, and

Retainer Locks Serial Number

(200,000— ) .......................02-021-20

Clean Valves Serial Number (200,000— ). . .02-021-21

Grind Valve Seats Serial Number

(200,000— ) .......................02-021-29

Remove Valve Seat Inserts and Measure

Bores in Cylinder Head Serial Number

(200,000— ) .......................02-021-30

Install Valve Seat Inserts Serial Number

(200,000— ) .......................02-021-31

Inspect and Clean Cylinder Head Nozzle

Bore Serial Number (200,000— )........02-021-31

Clean and Inspect Push Rods Serial Number

(200,000— ) .......................02-021-32

Clean and Inspect Top Deck of Cylinder

Block Serial Number (200,000— ) .......02-021-32

Measure Cylinder Liner Standout (Height

Above Block) Serial Number

(200,000— ) .......................02-021-33

Assemble Valve Assembly Serial Number

(200,000— ) .......................02-021-34

Install Cylinder Head and Cap Screws

Serial Number (200,000— )............02-021-35

Torque-to-Yield Flanged-Head Cap Screws—

Grade 180 Marked “SPECIAL” Serial

Number (200,000— ).................02-021-37

Install Rocker Arm Assembly Serial Number

(200,000— ) .......................02-021-39

Inspect and Clean Ventilator Outlet Hose

Serial Number (200,000— )............02-021-39

Complete Final Assembly of Fuel Pump Side

of Engine Serial Number

(200,000— ) .......................02-021-40

Complete Final Assembly on Exhaust

Manifold Side of Engine Serial Number