Page 1

Surface Water Pro

OPERATOR’S MANUAL

Surface Water Pro

OMPFP11362 ISSUE F1 (ENGLISH)

DCYOMPFP11362

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

If this product contains a gasoline engine:

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

Additional Proposition 65 Warnings can be found in this manual.

John Deere Ag Management Solutions

North American Edition

LITHO IN U.S.A.

Page 2

Foreword

Introduction

WELCOME TO GREENSTAR™ system offered by John

Deere.

READ THIS MANUAL carefully to learn how to operate

and service your system correctly. Failure to do so could

result in personal injury or equipment damage. This

manual and safety signs on your machine may also be

available in other languages. (See your John Deere

dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your system and should remain with the system

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specific metric or inch wrench.

RIGHTHAND AND LEFTHAND sides are determined by

facing in the direction of forward travel.

WRITE PRODUCT IDENTIFICATION NUMBERS (P.I.N.)

in the Specification or Identification Numbers section.

GREENSTAR is a trademark of Deere & Company

StellarSupport.Deere.com

NOTE: Product functionality may not be fully represented

in this document due to product changes occurring

Accurately record all the numbers to help in tracing

the components should it be stolen. Your dealer also

needs these numbers when you order parts. File the

identification numbers in a secure place off the machine.

WARRANTY is provided as part of John Deere’s support

program for customers who operate and maintain their

equipment as described in this manual. The warranty is

explained on the warranty certificate which you should

have received from your dealer.

This warranty provides you the assurance that John

Deere will back its products where defects appear within

the warranty period. In some circumstances, John Deere

also provides field improvements, often without charge

to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to change

its performance beyond the original factory specifications,

the warranty will become void and field improvements

may be denied.

OUO6050,0000AEC 1931JUL081/1

after the time of printing. For up to date information,

please visit StellarSupport.Deere.com.

OUO6050,0000FA5 1922OCT081/1

061611

PN=2

Page 3

Contents

Page

Safety

Recognize Safety Information ............................051

Understand Signal Words...................................051

Follow Safety Instructions...................................051

Practice Safe Maintenance.................................052

Handle Electronic Components and

Brackets Safely ..............................................052

Operate Guidance Systems Safely ....................053

Use Seat Belt Properly .......................................053

Theory of Operation

Theory of Operation............................................101

Machine and Implement Setup

Setup ..................................................................151

Client, Farm, Field, and Task Setup ................... 152

Machine Setup....................................................153

Machine Offsets..................................................155

Implement Setup ................................................156

Implement Offsets ..............................................158

Machine GPS Receiver Setup.......................... 1511

Implement GPS Receiver Setup.......................1512

Satellite Information

Satellite Information Softkey...............................201

Page

Cut or Clean Ditch Track ..................................4010

Levee

Set Operation to Levee.......................................451

Set to Levee Track .............................................453

Mark Path (Drive Dial) ........................................454

Record a Levee Track ........................................455

Set A B Lines.................................................... 456

Pull Levee...........................................................456

Troubleshooting and Diagnostics

Diagnostic Readings...........................................501

Troubleshooting.................................................. 503

Surface Water Pro Setup

Setup tab ............................................................251

Benchmark Settings ...........................................253

Creating a Benchmark Control Point ..................254

Calibrating to a Control Point..............................254

Boundary and Tracking Setup

Record an External Boundary ............................301

Survey

How to Survey a Field ........................................ 351

Ditch

Setup Operation .................................................401

Set Tracking Mode to Ditch Track ......................403

Recorded Path for Ditching ................................404

Record Ditch Track............................................. 404

Modify Ditch Track.............................................. 406

View Drain Profile ...............................................407

Create Linear Drain Design ................................ 408

Create Best Fit Drain Design ..............................409

Original Instructions. All information, illustrations and specifications in this

manual are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

COPYRIGHT © 2011

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION ® Manual

All rights reserved.

i

061611

PN=1

Page 4

Contents

ii

061611

PN=2

Page 5

Safety

Recognize Safety Information

This is a safetyalert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safetyalert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

T81389 —UN—07DEC88

DX,ALERT 1929SEP981/1

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

There can be additional safety information contained on

parts and components sourced from suppliers that is not

reproduced in this operator’s manual.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

TS187 —19—30SEP88

DX,SIGNAL 1903MAR931/1

TS201 —UN—23AUG88

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

DX,READ 1916JUN091/1

051

061611

PN=5

Page 6

Safety

Practice Safe Maintenance

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from powerdriven

parts. Disengage all power and operate controls to relieve

pressure. Lower equipment to the ground. Stop the

engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On selfpropelled equipment, disconnect battery ground

cable () before making adjustments on electrical systems

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

Handle Electronic Components and Brackets Safely

Falling while installing or removing electronic components

mounted on equipment can cause serious injury. Use a

ladder or platform to easily reach each mounting location.

Use sturdy and secure footholds and handholds. Do not

install or remove components in wet or icy conditions.

If installing or servicing a RTK base station on a tower or

other tall structure, use a certified climber.

If installing or servicing a global positioning receiver mast

used on an implement, use proper lifting techniques and

wear proper protective equipment. The mast is heavy and

can be awkward to handle. Two people are required when

mounting locations are not accessible from the ground

or from a service platform.

TS218 —UN—23AUG88

DX,SERV 1917FEB991/1

TS249 —UN—23AUG88

DX,WW,RECEIVER 1924AUG101/1

052

061611

PN=6

Page 7

Safety

Operate Guidance Systems Safely

Do not use guidance systems on roadways. Always turn

off (disable) guidance systems before entering a roadway.

Do not attempt to turn on (activate) a guidance system

while transporting on a roadway.

Guidance systems are intended to aid the operator in

performing field operations more efficiently. The operator

is always responsible for the machine path.

Guidance Systems include any application that automates

vehicle steering. This includes, but may not be limited to,

AutoTrac, iGuide, iTEC Pro, ATU, and RowSense.

To prevent injury to the operator and bystanders:

Use Seat Belt Properly

Use a seat belt when you operate with a rollover

protective structure (ROPS) or cab to minimize chance of

injury from an accident such as an overturn.

Do not use a seat belt if operating without a ROPS or cab.

Replace entire seat belt if mounting hardware, buckle,

belt, or retractor show signs of damage.

Inspect seat belt and mounting hardware at least

once a year. Look for signs of loose hardware or belt

damage, such as cuts, fraying, extreme or unusual wear,

discoloration, or abrasion. Replace only with replacement

parts approved for your machine. See your John Deere

dealer.

Never get on or off a moving vehicle.

•

Verify the machine, implement, and guidance system

•

are set up correctly. If using iTEC Pro, verify accurate

boundaries have been defined.

Remain alert and pay attention to the surrounding

•

environment.

Take control of the steering wheel, when necessary, to

•

avoid field hazards, bystanders, equipment, or other

obstacles.

Stop operation if poor visibility conditions impair your

•

ability to operate the machine or identify people or

obstacles in the machine path.

Consider field conditions, visibility, and vehicle

•

configuration when selecting vehicle speed.

JS56696,0000970 1910MAY111/1

DX,ROPS1 1929OCT071/1

TS205 —UN—23AUG88

053

061611

PN=7

Page 8

Theory of Operation

Theory of Operation

Surface Water Pro is a two modular program—basic and

advanced. Surface Water Pro (basic program) is designed

for users to create levees and develop basic ditches

in their fields. Surface Water Pro Plus is an advanced

ditching program that generates a “best fit drain”. Surface

Water Pro Plus calculates the most effective drain in a field

while moving the least amount of soil. This information

is generated from vertical GPS signals calculated from

StarFire 3000 or StarFire iTC receivers. Surface Water

Pro Plus requires both a machine and implement receiver

and cannot operate with just an implement receiver.

Levee applications require John Deere RTK, and ditching

requires either SF2 or RTK signal. For greater accuracy,

we highly recommend the RTK solution.

NOTE: For best accuracy, recalibrate benchmark after

power cycling the quick survey and absolute base

station. When starting up the base station, the

point of reference could shift slightly, so for the

highaccuracy user, consider recalibrating.

Operating with an absolute survey base station

reduces the need for benchmarking. In quick

survey mode, anytime the base is moved or

power is cycled, another calibration is required

for high accuracy users.

John Deere implement mounts must be used

because they reduce vibration and minimize

hardware failures. Vibration mounts help

minimize hardware failures over time, especially

in ditching applications.

Record ditches from HIGH TO LOW elevation.

Cut ditches in either direction.

To ensure highest system accuracy, do not operate

Surface Water Pro and Pro Plus outside a ONE

MILE radius of the Base Station.

Surface Water Pro features available on the GS3 display

and our Apex Desktop Software provide value by offering

ways to manage your topographic data better and ensure

optimum water distribution for crop production. Apex

Surface Water Pro features allow you to unload your GS3

survey data to generate Depression, Flow Direction, and

Drainage maps utilizing GSDNet. You can also manage

your Ditch and Levee Tracks from year to year by editing

cut, slope, or drop of fall. Additionally, layering your

ditch or levee tracks over your yield data displays your

results from the work you completed. See your local John

Deere Dealer or visit our website www.StellarSupport.com

to learn more about these additional features for your

Surface Water Pro program.

Reprogram receivers (Surface Water Pro Plus) at the

vehicle receiver location. Each receiver must be updated

individually every time a software update is available

[3.20D or older]. You cannot have both receivers attached

to the wiring harness when reprogramming.

IMPORTANT: A StarFire iTC receiver, or newer, is

required for Surface Water Pro.

Surface Water Pro Plus does not support an

Implement Receiver Only configuration. Do

not run ditching with an implement receiver

only—both a Machine & Implement receiver

must be used to operate that software.

Surface Water Pro and Pro Plus Survey

function is NOT compatible with Swath Control

Pro. Do not use the survey function in

conjunction with Swath Control Pro.

Surface Water Pro and Pro Plus is NOT

compatible with iGuide Do not use in

conjunction with iGuide.

JS56696,00009F3 1901JUN111/1

101

061611

PN=8

Page 9

Setup

Machine and Implement Setup

Machine must be GreenStar Ready.

To run Surface Water Pro, operator needs:

GreenStar Ready Machine

•

Constant Power

•

Front Extension Harness (3 m or 10 m)

•

Implement Application

•

Implement Receiver (if using Surface Water Pro Plus)

•

To make Surface Water Pro function, set up for the

following:

Machine

•

Machine GPS receiver

•

Implement (Optional for some functions)

•

Implement GPS receiver (Optional)

•

Guidance (Optional)

•

Implement Harness (Optional)

•

Turn GS3 system on after connecting all hardware

components.

Receivers are used on both the machine and implement

for some ditching applications. If two receivers are used,

verify both StarFire 3000 receiver softkeys (Machine and

Implement) are shown on the display.

PC8663 —UN—05AUG05

PC12601 —UN—10MAY10

PC13595 —UN—11MAY11

MENU Softkey

StarFire 3000 Machine Softkey

StarFire 3000 Implement Softkey

JS56696,00009D1 1919MAY111/1

151

061611

PN=9

Page 10

Machine and Implement Setup

Client, Farm, Field, and Task Setup

This is a required step for boundaries to run survey mode

or to record ditch and levee tracks.

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

RESOURCES/CONDITIONS softkey >> RESOURCES

tab.

The documentation screen allows the setup of operations

and specific details associated with those operations.

IMPORTANT: When setting up the display with

vehicle key in the accessory position (power

on, engine off), turn key to OFF position for

20 seconds BEFORE starting the vehicle.

This ensures the setup data is saved to the

USB flash drive before operating.

If the vehicle is running during setup and

programming, turn off the vehicle with key

in the OFF position and wait 30 seconds

before restarting. This ensures all data is

saved to the USB flash drive.

DO NOT turn the key to the start position directly

from the accessory position. The reduction

in voltage during the starting phase could

result in a loss of all setup data.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8676 —UN—05AUG05

PC10857BV —UN—15JUL08

RESOURCES/CONDITIONS softkey

MENU softkey

GREENSTAR 3 PRO softkey

Choose the correct information from CLIENT, FARM,

FIELD, and TASK dropdown box or input new information.

Task is required only if Documentation is used. It is not

needed to set or AutoTrac ditch or levee tracks. Always

setting tasks is a good standard practice though.

Resources tab

JS56696,00009D2 1919MAY111/1

152

061611

PN=10

Page 11

Machine and Implement Setup

Machine Setup

Machine and Implement Offsets are critical for Surface

Water Pro to function.

Select MENU softkey >> GREENSTAR 3 PRO softkey

>> EQUIPMENT—allows access to MACHINE and

IMPLEMENT setup screens.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8677 —UN—05AUG05

PC10857BP —UN—15JUL08

MENU Softkey

GREENSTAR 3 PRO softkey

EQUIPMENT Softkey

MACHINE tab

Continued on next page JS56696,00009D3 1901JUN111/3

153

061611

PN=11

Page 12

Machine and Implement Setup

Machine Tab

NOTE: All items and changes will be saved under

the current machine name.

Offsets are provided by some ISO implements

and some John Deere tractors. Some list

boxes may be grayed out when the machine

is automatically recognized.

When setting up Surface Water Pro for the

first time, creating a machine name for the

vehicle is recommended. All dimensions and

parameters set for this vehicle are used for

Surface Water Pro operations.

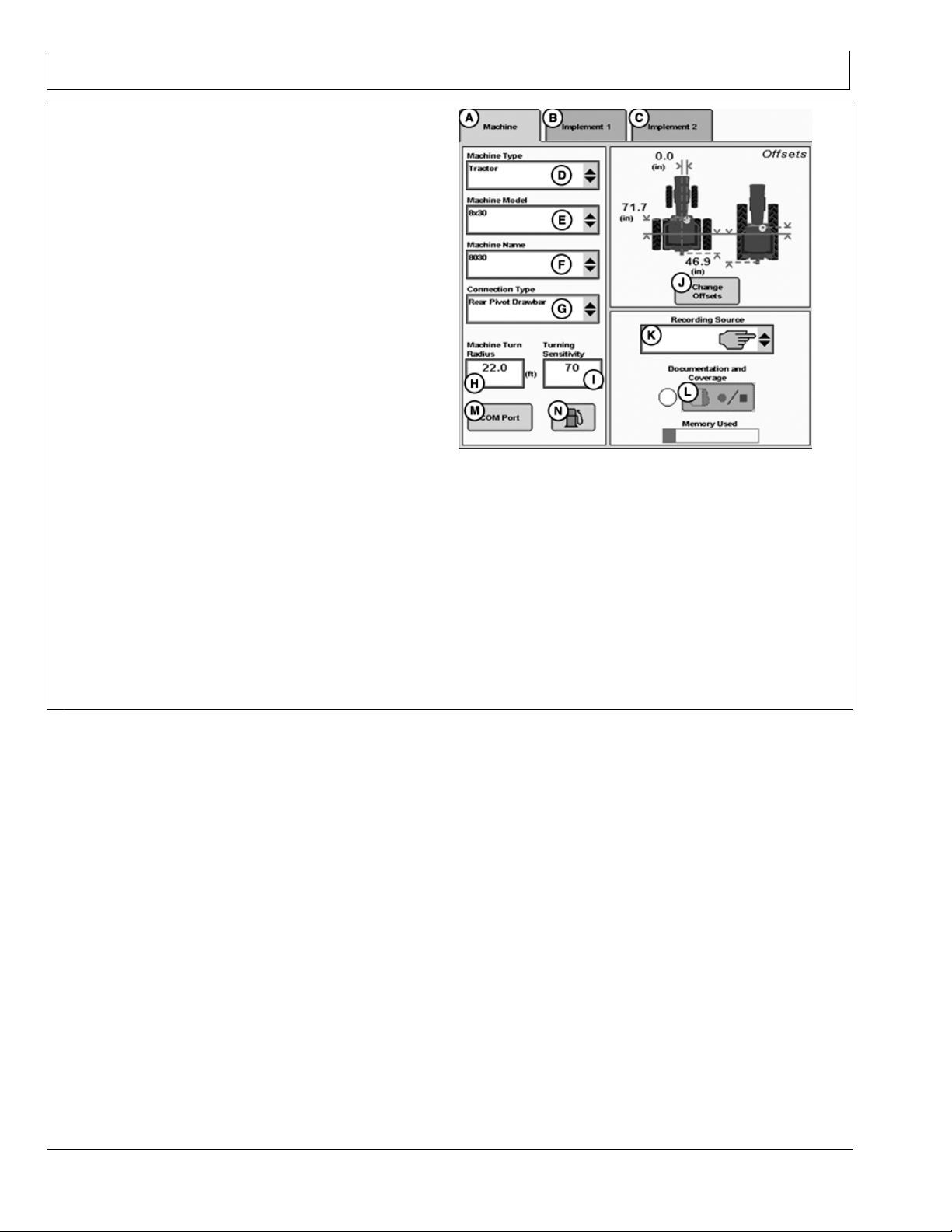

The Machine and Implement tabs are required to be

populated with equipment information such as:

Type

•

Model

•

Name

•

Offsets

•

Machine Type—Vehicle type being used (e.g. Tractor,

Combine, Sprayer).

Machine Model—Model number of the vehicle being

used. For John Deere vehicles, model numbers will be

available from the drop down list.

Machine Name—The name is used to further clarify

which machine is being used. For instance, if there are

two 8430’s in your operation, the machine names may be

“John” and “Deere”, or “84301” and “84302”, or simply

“1” and “2”. However, settings associated to the tractor,

such as turning radius, turn sensitivity, dimensions, etc.,

are stored to the name.

PC13768 —UN—17MAY11

Machine Tab

A—Machine Tab

B—Implement 1 Tab

C—Implement 2 Tab

D—Machine Type dropdown

menu

E—Machine Model dropdown

menu

F— Machine Name dropdown

menu

G—Connection Type

dropdown menu

Continued on next page JS56696,00009D3 1901JUN112/3

H—Machine Turn Radius input

box

I— Turning Sensitivity input

box

J— Change Offsets button

K—Recording Source

dropdown menu

L— Record/Pause button

M—COM Port button

N—Fuel button (Business Pack

/ Europe Only)

154

061611

PN=12

Page 13

Machine and Implement Setup

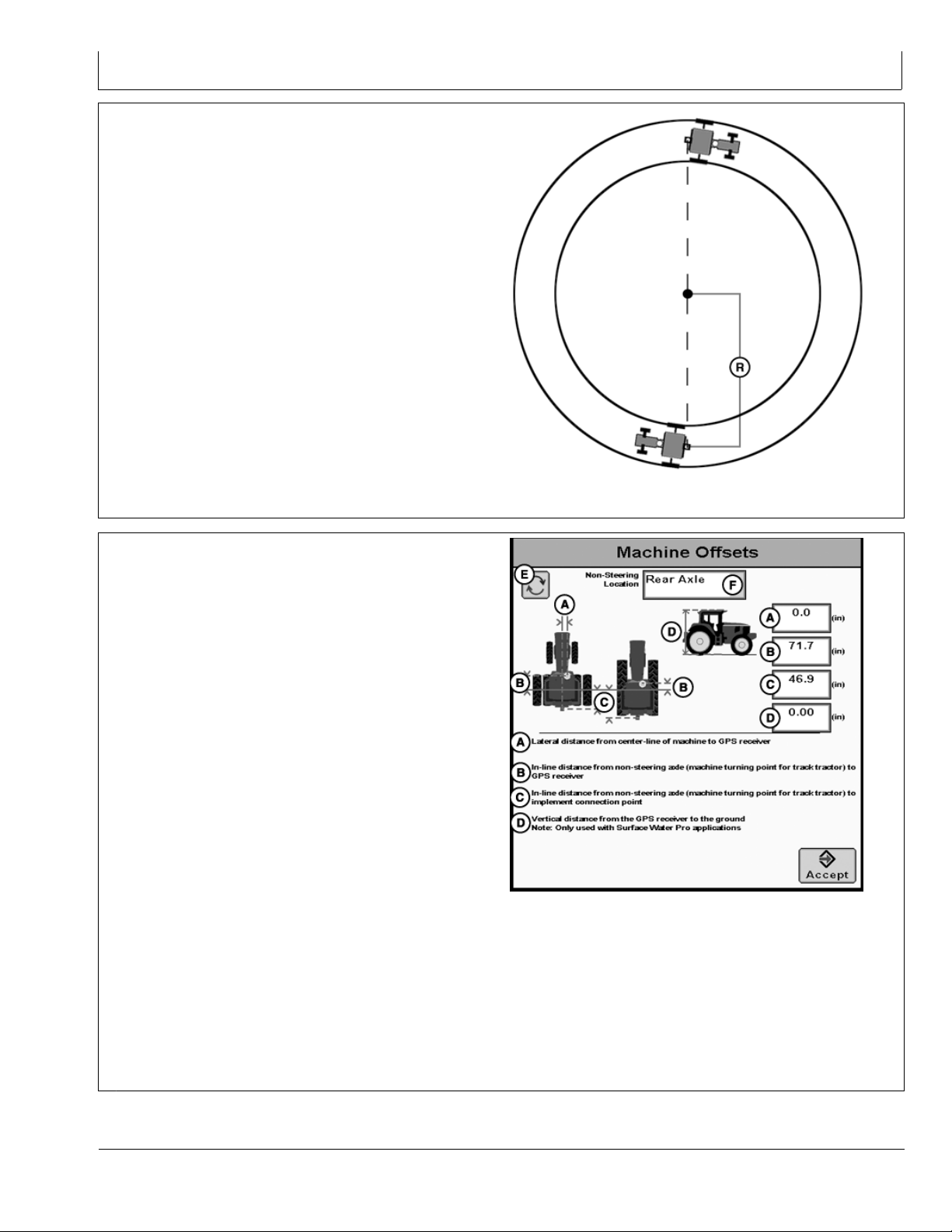

NOTE: Machine Turn Radius and Turning Sensitivity

are for use with iTEC Pro only.

Machine Turn Radius—How sharp the machine can

turn without an implement attached and without applying

brake pressure. The turn radius is half the diameter as

measured at the center of the rear axle of a row crop

tractor, and the pivot point on tracks and 4WD tractors.

Example: 8030 wheel tractors have a minimum turn

radius of 6.1—6.7 m (20—22 ft). Choose a number to

start with and change as needed for accuracy.

Turning Sensitivity—AutoTrac gain setting when the

vehicle is in an automated turn. This is adjustable by the

operator to improve performance (default 70).

Verify proper dimensions correspond to the Machine

selected.

NOTE: Not all recording sources are available

for all machines.

R—Machine Turn Radius

Machine Offsets

Select CHANGE OFFSETS button on Machine Setup

screen.

Offsets are used to eliminate skips or overlaps due to an

offset receiver.

To enter machine offsets:

Select input box.

•

Enter amount of offset in cm (in.) using numeric keypad

•

and select enter button.

Select the receiver toggle button to move the offset to

•

the right or left of cab center.

If no receiver offset is required, RECEIVER OFFSET input

box should read 0.

Machine offsets:

A) Lateral Distance from centerline of machine to GPS

•

receiver.

B) Inline distance from nonsteering axle to GPS

•

Receiver.

C) Inline distance from nonsteering axle to connection

•

point. The connection point is where the tractor

connects to the implement (drawbar, hitch) except

on 2 pt pivoting implements (large planter). In this

case, measure the distance back to the pivot point

immediately behind the hitch.

(D) Vertical distance from GPS receiver to the ground.

•

NOTE: Offset (D) is for use with Surface Water Pro.

Machine Turn Radius

A—Lateral distance from

centerline of machine to

GPS receiver

B—Inline distance from

nonsteering axle to GPS

receiver

C—Inline distance from

nonsteering axle to

connection point

PC9890 —UN—05FEB07

JS56696,00009D3 1901JUN113/3

PC13269 —UN—28APR11

Machine Offsets

D—Vertical distance from GPS

receiver to the ground

E—Offset Toggle button

F— NonSteering Axle Location

dropdown menu

155

JS56696,00009D4 1911MAY111/1

061611

PN=13

Page 14

Machine and Implement Setup

Implement Setup

Implement 1 Tab

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

EQUIPMENT tab >> IMPLEMENT tab.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8677 —UN—05AUG05

Continued on next page JS56696,00009D5 1918MAY111/2

MENU softkey

GREENSTAR 3 PRO softkey

EQUIPMENT softkey

156

061611

PN=14

Page 15

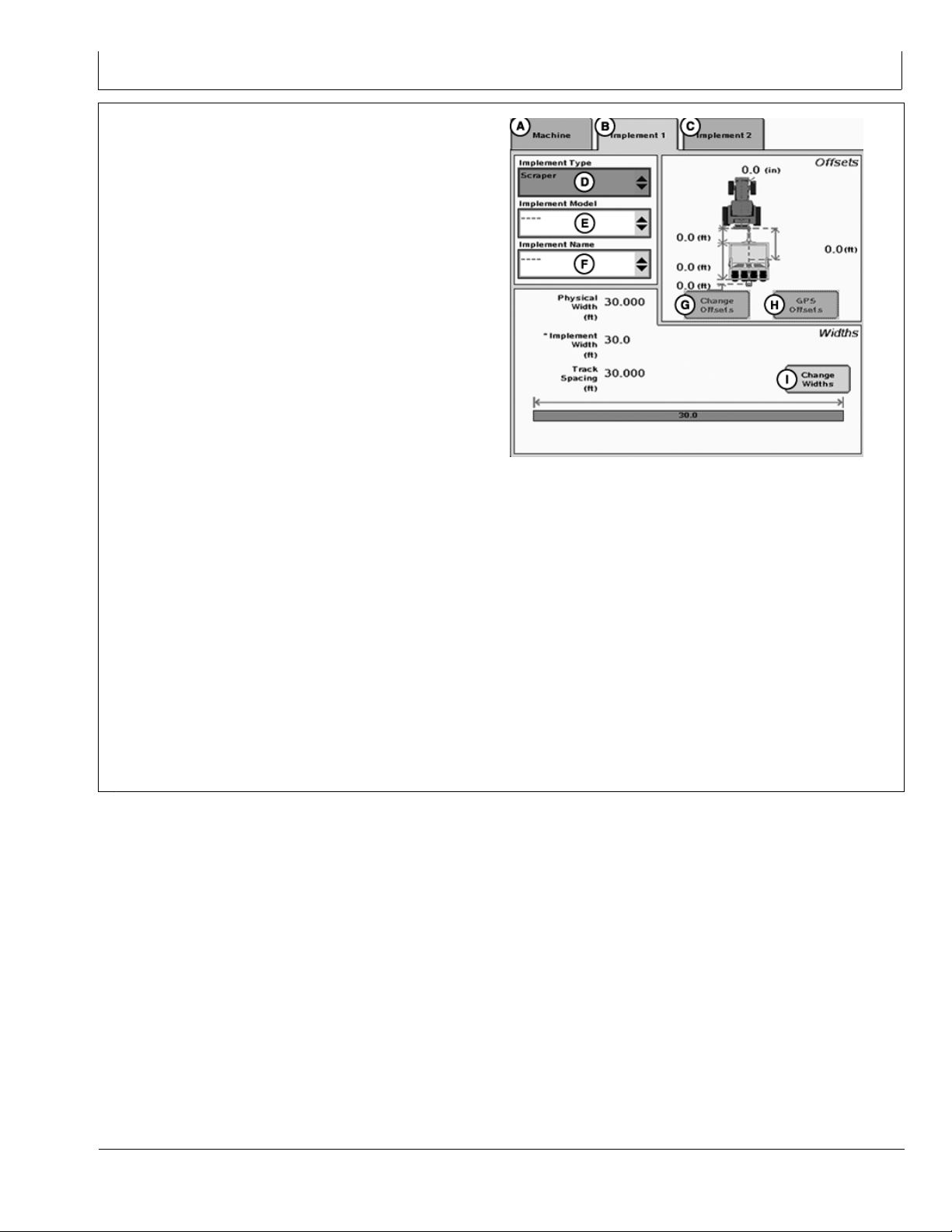

Machine and Implement Setup

Select Change Offsets button (G).

NOTE: All items and changes will be saved under

the current implement name. Implement name

is also the base for transferring data to the

desktop software (if supported).

Verify implement setup before operating Surface

Water Pro Plus. Be sure hydraulic hookups are

in the proper locations and no other changes

to the implement have been made that could

cause unexpected behavior or a change in

vertical receiver position.

When using Surface Water Pro Plus for the

first time, it is necessary to define a name for

the implement being used. All dimensions

and parameters including GPS offsets on the

implement is stored to this name.

For implement setup, the following tabs are required to

be populated:

Implement Type

•

Implement Model

•

Implement Name—information is stored in relation to

•

this name

Verify or Enter implement: Type, Model, and Name in

dropdown boxes.

Implement name allows operator to save implement

dimensions.

NOTE: Select the correct name before changing

any offset dimensions.

Implement Type is required to be selected. Implement

Names are filtered by the type when Implement Model is

selected. For example, scraper or rotary ditcher.

Select CHANGE OFFSET button (G) and proceed to

following Implement Offsets section.

Implement Tab

A—Machine tab

B—Implement 1 tab

C—Implement 2 tab

D—Implement Type dropdown

menu

E—Implement Model

dropdown menu

F— Implement Name

dropdown menu

G—Change Offsets button

H—GPS Offsets button

I— Change Widths button

CHANGE WIDTHS button (I)—IMPLEMENT WIDTHS

are used to calculate CUT VOLUME on the EDIT DRAIN

screen. For example, Implement Width is entered as the

cutting blade width for the scraper.

JS56696,00009D5 1918MAY112/2

PC13799 —UN—02JUN11

157

061611

PN=15

Page 16

Machine and Implement Setup

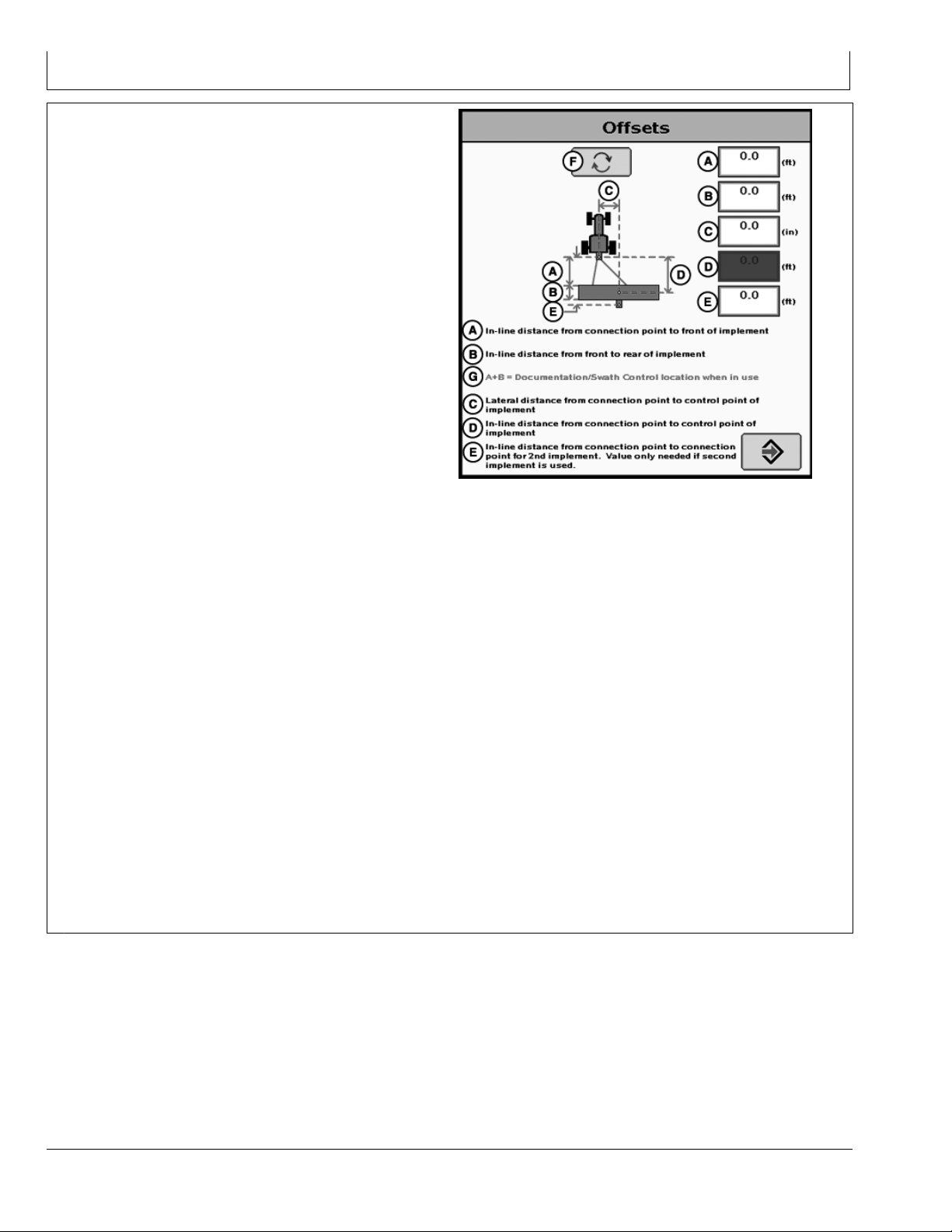

Implement Offsets

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

EQUIPMENT softkey >> IMPLEMENT tab >> CHANGE

OFFSETS button.

IMPORTANT: Distance (D) is measured when the

implement is in the FULLY RAISED position. This

dimension is critical for accurate ditch designs.

Remember: Always measure to the same

place on the receiver when measuring (that

is, top, middle, and others).

Implement Offsets—Used to define the actual implement

position relative to the tractor. This is important for

ensuring the implement is lined up to the field at the end

of turns and in determining where the implement is for

the Minimize Skips and Minimize Overlaps feature (see

Change Settings on Machine tab).

A) Inline distance from connection point to front of

•

implement. On pulltype implements, think of this as the

tongue. For more precision, it is actually the dimension

from the pinbolt to the front side of where the work gets

done (front ranks of field cultivator, seed drop point on a

planter).

B) Working Length of the implement. On ground

•

engagement tools, this is the distance from the front

rank of sweeps or points to the rear rank. Refer to

implement manufacturer’s Operator’s Manual for this

value.

C) Lateral distance from connection point to control point

•

of implement. This is the lateral distance from the center

of the tractor to the center of the implement which will

be 0.0 for most common implements. This dimension is

used to alert the operator to potential collisions. This is

critical for proper endturn performance and may need

to be adjusted.

D) Inline distance from connection point to control

•

point of implement. In many cases, this distance will be

from the connection point to the carrying wheels. For

proper turns, measure this distance with implement at

the height it typically will be at while turning.

NOTE: These dimensions may need to be adjusted

for finetuning performance in the field.

IMPORTANT: Ensure vertical distance (D) is measured

from the GPS receiver to the ground when the

implement is in the FULLY RAISED position.

PC11405 —UN—15OCT08

Implement Offsets

A—Inline distance from

connection point to front of

implement.

B—Inline distance from front

to rear of implement.

C—Lateral distance from

connection point to control

point of implement.

D—Inline distance from

connection point to control

point of implement.

E—Inline distance from

connection point to

connection point for

second implement. Value

only needed if second

implement is used.

F— Offset Toggle button

G—A+B = Documentation /

Swath Control location

when in use.

Remember: Always measure to the exact

same place on the receiver when measuring

(that is, top, middle, and others.).

NOTE: For a rotary ditcher, dimension (C) refers to

the distance from the receiver to the cutting

edge. On a rotary ditcher the cutting edge is the

bottom of the paddle wheel, since this contacts

the soil first. This dimension could be adjusted

depending on individual requirements.

Continued on next page JS56696,00009D6 1911MAY111/4

158

061611

PN=16

Page 17

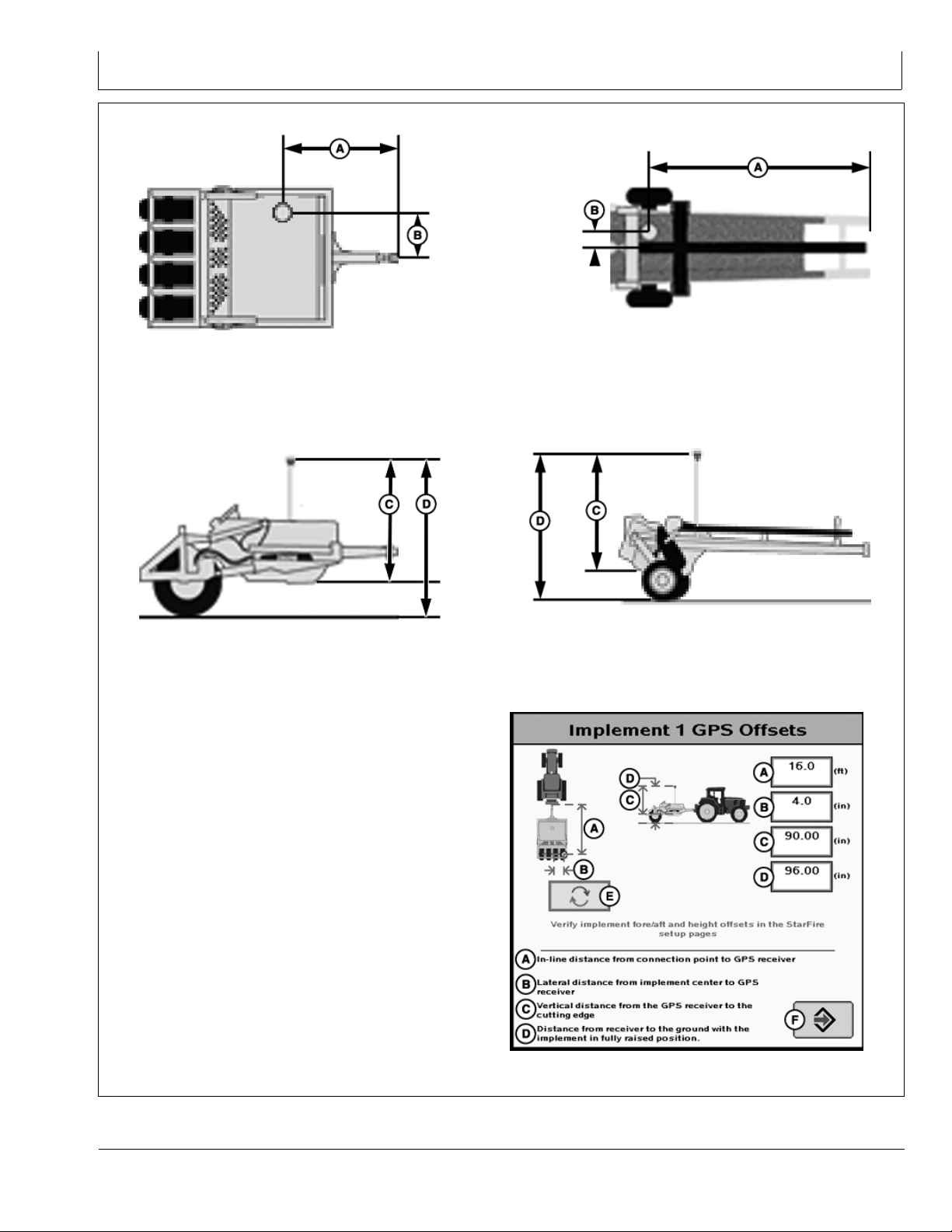

Machine and Implement Setup

Scraper Overhead

Scraper Profile

A—Inline distance from

connection pivot point to

GPS receiver.

B—Lateral distance from

implement center to GPS

receiver.

C—Vertical distance from the

GPS receiver to the cutting

edge.

D—Vertical distance from the

GPS receiver to the ground

in the fully raised position.

E—Offset Toggle button

F— Accept button

PC10376 —UN—13OCT07

PC10375A —UN—14OCT07

PC10378A —UN—14OCT07

Rotary Ditcher Overhead

PC10377 —UN—13OCT07

Pull Type Rotary Ditcher Profile

Implement GPS Offsets

Continued on next page JS56696,00009D6 1911MAY112/4

159

PC13801 —UN—02JUN11

061611

PN=17

Page 18

Machine and Implement Setup

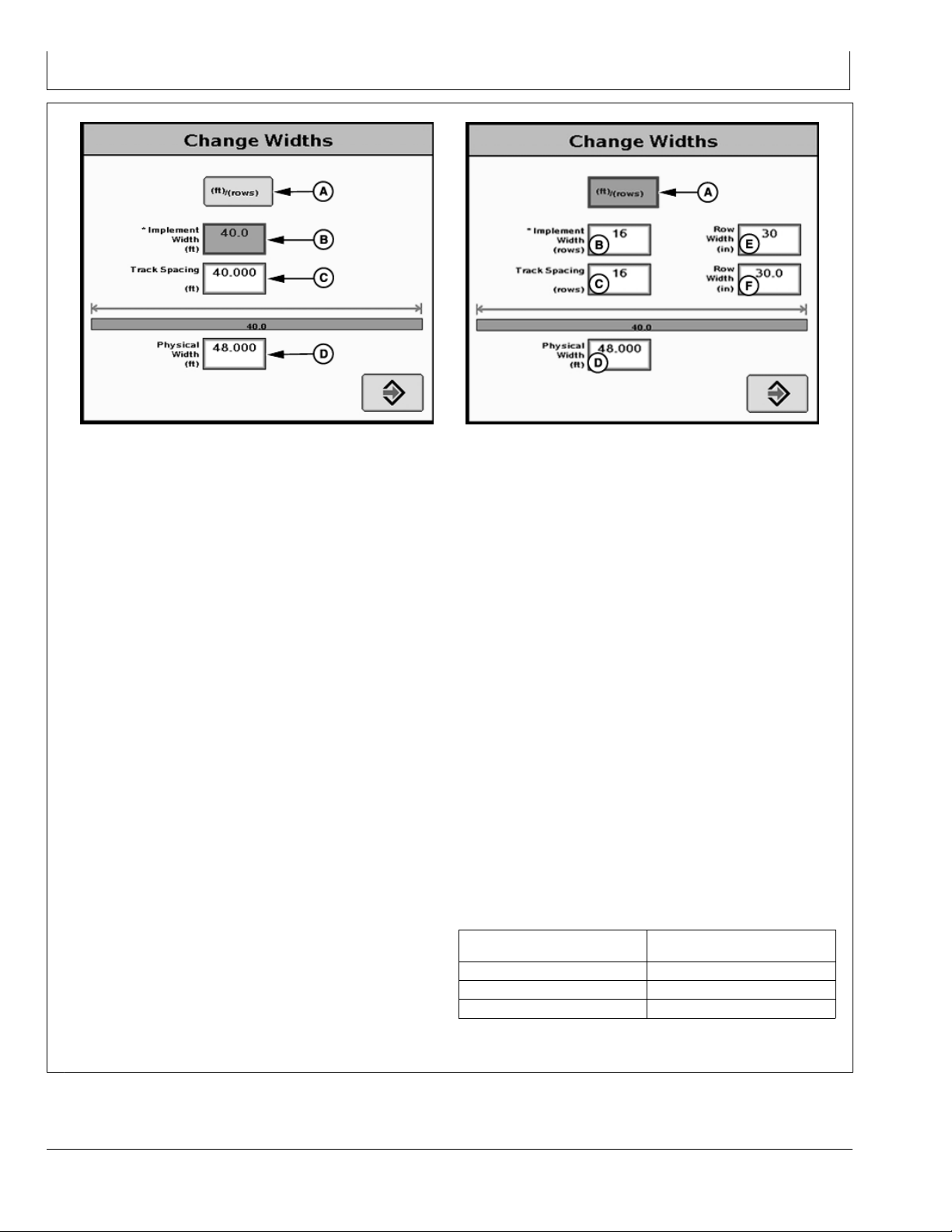

Track Spacing

A—m (ft)/(rows) button

B—Implement Width

C—Track Spacing

D—Physical Width

Implement Widths—Used to enter implement width

and track spacing for guidance. This value is also used

to calculate total area when documenting the operation.

Verify implement type, model, name, implement width and

track spacing when changing implements. Implement

width and track spacing are independent of each other.

NOTE: IMPLEMENT tab will show HEADER for

Combines, ROW UNITS for Cotton Pickers,

and BOOM for Sprayer.

Implement width may come from controller on

select controllers such as SeedStar.

In some cases, a higher degree of precision can be

achieved for track spacing when track spacing is

entered in by rows instead of feet. More decimal

places are used in the track spacing calculation

when entered in by rows versus the three decimal

places allowed when entered by feet.

Defining Implement Width and Track Spacing.

Implement width and track spacing can be defined two

ways: enter the working width of the implement, or enter

the number of rows and the row spacing. To toggle

between these two, select the m (ft)/(rows) button.

Implement Width m (ft)—enter total implement working

•

width

Implement Width rows—enter number of rows and the

•

row spacing in inches

Track Spacing—Used in guidance for how far each pass

is from the last pass. It is entered the same way as

Implement Width. For “perfect” guess rows, this distance

will be the same as Implement Width. To ensure some

PC9902 —UN—09JAN07

Track Spacing

E—Row Width

PC9903 —UN—09JAN07

overlap for tillage or spraying, or to account for some

GPS drift, you may choose to make the Track Spacing

somewhat less than the Implement Width.

Physical Width—The actual width of the entire implement

when being used in the field when the implement is raised.

It is sometimes larger than Implement Width.

Using a planter as an example, the marker arms and

blades are wider than the working width. This width

needs to be entered if markers are not used, or are used

and completely folded on the ends. If markers are only

partially folded during turns, enter this larger dimension.

IMPORTANT: Width measurements are used to help

alert an operator of potential intersections

between the implement and an impassable

boundary. The operator still needs to be aware

of potential collisions if there are times the

implement is wider than the dimension entered

(e.g. marker arm lowered). If markers are used

in the field, add the width of both markers to

give ultimate alarms of possible intersections.

NOTE: As a buffer to avoid obstacles, additional Physical

Width may be added to the implement to compensate

for several things, one of these being GPS drift.

Signal

RTK

SF2 0.9 m (3 ft)

SF1 3.4 m (11 ft)

Physical Width Table

Continued on next page JS56696,00009D6 1911MAY113/4

Approximate Physical Width

added to Implement

0.6 m (2 ft)

1510

061611

PN=18

Page 19

Machine and Implement Setup

NOTE: If the physical width is less than the implement

(working) width, a message will appear as a

reminder that this is not usually correct (A 16R30

planter is physically wider than its 12.2 m (40 ft)

working width). An example where the working

width is wider than the physical width is a dry

fertilizer spreader—it spreads much farther than

the physical width of the buggy.

Confirm Configuration—The

physical width is

smaller than the

implement width which

may not allow detection

of all intersections

with impassable

boundaries.

PC12865 —UN—16SEP10

Confirm Configuration

JS56696,00009D6 1911MAY114/4

Machine GPS Receiver Setup

Select MENU softkey >> STARFIRE 3000 MACHINE

softkey >> SETUP tab.

This screen allows access to StarFire 3000 setup pages.

See the StarFire 3000 operator’s manual to set up the

receiver for the machine.

NOTE: To ensure highest accuracy, do not operate

Surface Water Pro and Pro Plus outside a 1.6 km

(ONE MILE) radius of the Base Station.

If your RTK kit came with a 7.5 cm (3 in.) antenna

extension it is suggested to discard the extension

and use either the 23 or 30 cm (9 or 12 in.)

onepeice antenna. Use of the 7.5 cm (3 in.)

extension on the implement receiver could result

in the loss of the antenna due severe vibration

created by some implements.

PC8663 —UN—05AUG05

PC12042 —UN—08MAY09

PC10857BR —UN—15JUL08

PC13406 —UN—20APR11

StarFire 3000 Receiver

MENU Softkey

StarFire 3000 Machine Softkey

1511

Setup tab

JS56696,00009D7 1919MAY111/1

061611

PN=19

Page 20

Machine and Implement Setup

Implement GPS Receiver Setup

IMPORTANT: Surface Water Pro Plus does not support

an Implement Receiver Only configuration. Do

not run ditching with an implement receiver

only—both a Machine and Implement receiver

must be used to operate ditching software.

Select MENU softkey >> STARFIRE 3000 IMPLEMENT

softkey >> SETUP tab.

This screen allows access to StarFire 3000 setup on the

implement.

NOTE: If using a two receiver solution, Original StarFire

receivers cannot be used on the implement

or the machine. This is due to the address

arbitration between the two at startup.

The number below the text on the StarFire 3000 Softkey

shows the serial number of the receiver.

On the StarFire Main page, the receiver definition

(Machine or Implement) is shown in the headline.

NOTE: Mount the receiver directly over the cutting edge

of the implement or a position with 1:1 vertical

movement of the receiver and cutting edge.

PC8663 —UN—05AUG05

PC13595 —UN—11MAY11

PC10857BR —UN—15JUL08

StarFire 3000 Implement Softkey

MENU Softkey

Setup tab

For future reference, mark the two receivers so it is

clear which receiver is mounted on the machine and

which receiver is mounted on the implement.

JS56696,00009D8 1917MAY111/3

Select the implement receiver softkey and verify its

receiver location is set to implement.

Reconnect the machine receiver if it was disconnected

before continuing. Select Correction Mode (E) to match

the desired correction mode. Ditching requires both

receivers to have the same differential correction level

and subscription.

Select the correct mounting direction (G). The preferred

mounting direction for the implement is forward. Adjust

receiver bracket on implement to match that if possible.

NOTE: Only SF2 and RTK can be used for ditching.

Only RTK can be used for levee work.

Height (I) is the same as machine or

implement D offset.

A—INFO tab

B—SETUP tab

C—ACTIVATIONS tab

D—SERIAL PORT tab

E—CORRECTION MODE

dropdown box

F— DEFAULT check box

G—MOUNT DIRECTION

dropdown box

H—FORE/AFT input box

I— HEIGHT input box

JK—ENABLE QUICKSTART

input box

K—HOURS ON AFTER

SHUTDOWN dropdown

box

L— TCM On

M—TCM OFF

N—TCM On and Off Toggle

button

O—TCM Calibrate button

PC13605 —UN—11MAY11

StarFire 3000 Implement Main, Setup tab

Continued on next page JS56696,00009D8 1917MAY112/3

1512

061611

PN=20

Page 21

Machine and Implement Setup

Enter the correct receiver height above the ground:

Dimension D—fully raise the implement and measure

from the ground to the middle of the receiver (inches).

Dimension C—measure from the middle of the receiver to

the cutting edge.

IMPORTANT: Always measure to the exact same

place on the receiver when measuring.

Enter 0 for the For and Aft dimension for the implement

receiver if the receiver is mounted over the cutting

edge—this space is reserved for future enhancement.

For optimized performance make the Hours On After

Shutdown the same value as on the machine receiver

(24 is recommended).

NOTE: When performing a TCM calibration on the

implement receiver, the wheels of the main frame,

to which the implement receiver is mounted,

need to be in the same location after turning

implement around so the righthand wheels are

in the same place as where the lefthand wheels

were. A smooth level surface is recommended

while performing a TCM calibration.

PC13406 —UN—20APR11

StarFire 3000 Receiver

Perform a TCM calibration each time the receiver

is moved to a different implement or vehicle.

The implement TCM is used for determining

vertical position of the blade.

For more information refer to your StarFire 3000 operators

manual.

JS56696,00009D8 1917MAY113/3

1513

061611

PN=21

Page 22

Satellite Information

Satellite Information Softkey

Select MENU softkey >> STARFIRE 3000 softkey >>

SATELLITE INFORMATION softkey.

The StarFire 3000 Satellite Information screen contains

Sky Plot, Graph, and Predictor tabs.

PC8663 —UN—05AUG05

PC13702 —UN—12MAY11

PC8682 —UN—05AUG05

Continued on next page JS56696,0000A07 1902JUN111/3

SATELLITE INFORMATION softkey

MENU softkey

STARFIRE 3000 softkey

201

061611

PN=22

Page 23

Satellite Information

Sky Plot tab

The Sky Plot tab shows where the satellites are in relation

to the vehicles receiver, allowing the operator to look at

satellite geometry.

Reading Satellite Sky Plot

Sky Plot is fixed so North is always at the top of the

•

screen.

Satellites are displayed as their satellite ID number that

•

corresponds to the Satellite Tracking Chart located to

the right of the Sky Plot.

Red—indicates satellite is in search mode

Blue—indicates satellite is being tracked

Green—indicates satellite is OK (being used for

corrections)

Sky Plot consists of 3 concentric rings depicting 0, 30,

•

and 60 degrees of elevation with directional crossbar

intersection representing 90 degrees of elevation.

Gray radial lines extending from center of Sky Plot

•

represent azimuth. They are spaced 30 degrees apart

and represent 30 and 60 degrees.

Directional crossbar representing North, South, East,

•

and West also represent azimuth at 0, 90, 180, and 270

degrees.

W1 and W2 (WAAS or EGNOS) satellites and inmarsat

•

satellites are not shown in Sky Plot.

A—Sky Plot tab

B—Graph tab

C—Predictor

D—Satellites in Solution

E—Satellites Above Elevation

Mask

F— Satellites Tracked

PC13703 —UN—12MAY11

G—Corrections Age

H—VDOP

I— HDOP

J— PDOP

K—Satellites on Sky Plot

L— Satellite Tracking

Satellite Tracking Chart

SAT ID—(Satellite Identification Number) Identification

•

number for GPS Satellite.

ELV—(Position Elevation) Elevation in degrees above

•

horizon for GPS satellite position.

AZM—(Position Azimuth) Azimuth in degrees from true

•

North for GPS satellite.

L1 SNR—(L1 Signal to Noise Ratio) Signal strength for

•

L1 GPS signal (signal to noise ratio).

L2 SNR—(L2 Signal to Noise Ratio) Signal strength for

•

L2 GPS signal (signal to noise ratio).

Status—(GPS Signal Status) Status of GPS signal.

•

Search—searching for satellite signal.

Track—tracking satellite signal and using it for

positioning.

OK—tracking satellite signal and using it for

positioning.

OK SF1—Tracking satellite signal and using it for

positioning with StarFire single frequency.

OK SF2—Tracking satellite signal and using it for

positioning with StarFire dual frequency.

Satellite Tracking Information

Satellite Tracking information is displayed at bottom of

SKY PLOT and GRAPH tabs.

Satellites in Solution—number of satellites used to

•

compute position.

Satellites Above Elevation Mask—total number of GPS

•

satellites available to receiver that are above seven

degree elevation mask.

Satellites Tracked – total number of GPS satellites

•

tracked by receiver.

Corrections Age (sec.)—age of differential correction

•

signal to GPS (normally less than 10 seconds).

VDOP—Vertical Dilution of Precision.

•

below 2.0 optimal

2.0—2.5 desirable

2.5 or greater can indicate poor vertical accuracy

performance. AMS does not recommend operating

above this value.

HDOP—Horizontal Dilution of Precision.

•

PDOP—Positional Dilution of Precision is an indicator of

•

GPS satellite geometry as viewed by receiver. A lower

PDOP indicates better satellite geometry for calculating

both horizontal and vertical position.

Continued on next page JS56696,0000A07 1902JUN112/3

202

061611

PN=23

Page 24

Satellite Information

Graph

A graph illustrating L1 and L2 SNR values.

Bars are colored to satellites current status.

•

SNR values (colored bar) should be above dashed line

•

that runs horizontally across bar graph.

NOTE: Only GREEN bars are used in calculation of

PDOP, VDOP, AND HDOP. SNR’s are considered

good if above dashed line.

A—SkyPlot tab

B—Graph tab

C—Predictor tab

D—PDOP

PC13704 —UN—12MAY11

JS56696,0000A07 1902JUN113/3

203

061611

PN=24

Page 25

Surface Water Pro Setup

Setup tab

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

Surface Water PRO softkey >> SETUP tab.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC10379 —UN—14OCT07

PC10857BR —UN—15JUL08

MENU softkey

GREENSTAR 3 PRO softkey

Surface Water PRO softkey

Continued on next page JS56696,00009DA 1917MAY111/2

Setup tab

251

061611

PN=25

Page 26

Surface Water Pro Setup

Set SURVEY MODE dropdown box (E) and SURVEY

INTERVAL input box (F).

Distance—feet. Points are determined by feet traveled.

•

This method compensates for speed changes.

Time—seconds. Points are determined every x

•

seconds. This method does not compensate for

changes in vehicle speed.

Set SURVEY RECEIVER SOURCE dropdown box

(G)—Machine or Implement.

BENCHMARK SETTINGS button (H)—the operator can

define a benchmark and calibrate a differential. This is

primarily used in quick survey base setups. A benchmark

is not needed when a permanent base is used.

VERTICAL ACCURACY BAR STEP input box (I) (Surface

Water Pro Plus)—enter the step size for the vertical

accuracy bar. The Vertical Accuracy Bar Step is used

to specify the vertical distance that triggers the vertical

lightbar arrows (the difference between drain design

height and the cutting blade height) For example, if the

Vertical accuracy Step Bar size is set to 2.5 cm (1 in.) and

the cutting edge is 7.6 cm (3 in.) above the desired height,

three arrows are highlighted.

MAP SETTINGS button (J)—selecting this button displays

a MAP SETTINGS screen where the operator can edit

the map settings.

AUTONAME LEVEE TRACKS check box (K)—when

checked, automatically generates levee track names by

numbers, starting at 1 and increment each time a new

levee is created, assuming the next number has not

already been used as a name. When unchecked, the

operator is required to name new ditch tracks.

A—Survey tab

B—Levee tab

C—Ditch tab

D—Setup tab

E—Survey Mode dropdown

box

F— Survey Interval (sec) input

box

G—Receiver Source

dropdown box

H—Benchmark Settings button

I— Vertical Accuracy Bar Step

Size input box

J— Map Settings button

K—AutoName Levee Tracks

check box

L— AutoName Ditch Tracks

check box

AUTONAME DITCH TRACKS check box (L)—when

checked, automatically generates ditch track names

by numbers, starting at 1 and increment each time a

new ditch is created, assuming the next number has not

already been used as a name. When unchecked, the

operator is required to name new ditch tracks.

JS56696,00009DA 1917MAY112/2

PC13606 —UN—12MAY11

252

061611

PN=26

Page 27

Surface Water Pro Setup

Benchmark Settings

Calibrating to a Benchmark Control Point allows the

QuickSurvey user to achieve repeatability accuracy

equivalent to the permanent base station.

Select MENU softkey >> GREENSTAR 3 PRO softkey

>> SURFACE WATER PRO softkey >> SETUP tab >>

BENCHMARK SETTINGS button.

This screen allows the operator to define one control point

and calibrate a differential on a per field basis.

CONTROL POINT dropdown box (A)—shows existing

control point for the field and “New” which allows the

operator to create a control point. Changing the selection

updates the displayed position data:

SET POINT button (B)—sets the position for the selected

control point.

MAST HEIGHT input box (C)—enter the mast height. If

the implement receiver is used to set the control point,

the height dimension on a scraper is equal to Implement

Dimension C.

PC13770 —UN—17MAY11

CALIBRATE button (D)—calculates the difference

between the current GPS reading and the GPS position

of the selected control point and store that value as the

differential for the field.

Enabled only when a valid control point is selected in

•

the CONTROL POINT dropdown box.

Disabled if GPS is not available.

•

Enabled only when the operator has entered a valid

•

mast height.

CLEAR button (E)—clears the differential setting.

ENTER button (F)—save changes and return to the

previous page.

A—CONTROL POINT

dropdown box

B—SET POINT button

C—MAST HEIGHT input box

D—CALIBRATE button

E—CLEAR button

F— ENTER button

NOTE: Place a flag or marker down to identify benchmark

location for later calibration. Do not mark such

places as public roadways or bridges because

it is hazardous to other drivers. Document

Control Point location for later use.

JS56696,00009DB 1912MAY111/1

253

061611

PN=27

Page 28

Surface Water Pro Setup

Creating a Benchmark Control Point

1. Position receiver on the control point.

NOTE: The StarFire 3000 receiver CANNOT be

moved during the creation of a Benchmark

Control Point. Any movement causes the

Benchmark to be inaccurate

2. From CONTROL POINT dropdown box (A), select

NEW.

3. Type in name of control point.

4. Enter mast height in the MAST HEIGHT input box (C).

If the implement receiver is used to set the control

point, the height dimension on a scraper is equal to

Implement Dimension C if blade is lowered to the

ground or Implement Dimension D if blade is fully

raised.

5. Select SET POINT button (B).

6. Select ENTER button (F).

A—CONTROL POINT

dropdown box

B—SET POINT button

C—MAST HEIGHT input box

D—CALIBRATE button

E—CLEAR button

F— ENTER button

Calibrating to a Control Point

1. Position receiver on the control point.

NOTE: The StarFire 3000 receiver CANNOT be

moved during the calibration of a Benchmark

Control Point. Any movement causes the

calibration to be inaccurate.

2. Enter mast height (C) if it is at a different height than

when benchmark was set.

3. Select CALIBRATE button (D).

4. Select ENTER button (F).

A—CONTROL POINT

dropdown box

B—SET POINT button

C—MAST HEIGHT input box

D—CALIBRATE button

E—CLEAR button

F— ENTER button

PC13770 —UN—17MAY11

JS56696,00009DC 1912MAY111/1

254

PC13770 —UN—17MAY11

JS56696,00009DD 1917MAY111/1

061611

PN=28

Page 29

Boundary and Tracking Setup

Record an External Boundary

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

MAPPING softkey >> BOUNDARIES tab.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8672 —UN—05AUG05

PC10632 —UN—15JUL08

MENU softkey

GREENSTAR 3 PRO softkey

MAPPING softkey

Continued on next page JS56696,00009DE 1919MAY111/2

Boundaries tab

301

061611

PN=29

Page 30

Boundary and Tracking Setup

IMPORTANT: Accurate boundaries are necessary

for the system to execute functions

accurately on the ground.

BOUNDARIES tab—allows operator to record exterior

field boundaries. Boundaries are saved on the USB flash

drive.

Client, farm, and field are required before setting up

boundaries.

NOTE: It is highly recommended to have boundaries but

they are not required for ditch or levee tracks.

Survey function on the Surface Water Pro softkey requires

an exterior field boundary. In order to create an elevation

map as a background layer, an exterior field boundary is

required from either the GS3 display or from Apex.

A—MAPS tab

B—BOUNDARIES tab

C—FLAGS tab

D—CLIENT dropdown box

E—FARM dropdown box

F— FIELD dropdown box

G—TYPE dropdown box

H—HEADLAND GROUP

dropdown box

I— DRIVE BOUNDARY check

box

J— HEADLAND INDICATOR

check box

K—BOUNDARY OFFSET input

box

L— BOUNDARY OFFSET toggle

M—RECORD or PAUSE button

N—STOP RECORDING button

PC13701 —UN—12MAY11

Boundaries with Driven Exterior Headland Boundary

JS56696,00009DE 1919MAY112/2

302

061611

PN=30

Page 31

Survey

How to Survey a Field

Surface Water Pro provides a Survey tab for the purpose

of performing a field survey. When a survey is performed,

the RCD (GS3) creates a survey file for the field that

contains a collection of data points. Each point represents

a specific latitude and longitude position within the field for

which an elevation value is stored.

The data collected can be valuable to create informational

maps. Any maps created from this data is only as good

as the quality of the data that creates it. In order to create

quality maps from your field survey data, be sure to

perform your field survey to the highest quality. As a start,

please observe the following guidelines as a minimum for

performing a field survey.

1. Use the correct differential correction for your

application. It is recommended an RTK correction

be used for the highest accuracy and quality survey

data. An SF2 correction is allowed for surveying your

fields, but only after consulting your dealer to see if

it is right for your application. An RTK correction is

always utilized for flat to rolling field terrain. Using

an inappropriate differential correction for collecting

elevation data leads to inaccurate maps.

2. Make the first pass very close to the exterior field

boundary, when collecting survey data, to ensure

sufficient data around the perimeter of the field. Make

the second pass around the field boundary but slightly

offset inward from the first pass. Offset the second

pass approximately 15 m (50 ft.).

3. Conducting a thorough survey can be done by

setting up straight track lines and parallel tracking

off them through the field. Set up straight track

lines with intervals depending on the field being

surveyed.

Fields with significant elevation changes and slopes

•

— track spacing of 7.5—15 m (25—50 ft.) is

recommended.

Flatter fields — a track spacing of 15 m (50 ft.) is

•

recommended.

Flat to precision leveled ground — a track spacing of

•

15—30 m (50—100 ft.).

Do not exceed 50 m (164 ft.) track spacing for

surveying purposes.

4. Two forms of Survey recording types are available:

Distance Base—ideal for low speed surveys and

•

consistently spaced at userdefined distances.

Time Based—suited to higher speed surveying and

•

the distance between the points varies with the

speed at which the survey is recorded.

5. Ensure that the entire field has been covered. Do not

skip parts of the field because they are inaccessible

due to wet or muddy conditions; you are in a hurry;

you think you do not have time to finish properly. This

has a negative impact on the quality of your maps

generated from your collected data. It is important to

cover the entire field.

6. It is also a good idea to survey the bottom of existing

ditches within the field, and at a minimum ditches with

measurable width and depth. Utilizing parallel tracking

with straight track can cause the user to miss areas

of interest for surveying, for example the bottom of

a main ditch which can have measurable width and

depth.

Survey Mode is designed to allow an operator to collect

elevation and position data as a separate operation. From

this data, topographical information can be created and

displayed. The accuracy level while surveying determines

the accuracy of the topographical maps. Elevation

data points can also be obtained for log files created

while performing field operations such as planting and

combining.

NOTE: Survey Mode is not allowed with Swath Control Pro.

Continued on next page JS56696,00009E0 1918MAY111/3

351

061611

PN=31

Page 32

Survey

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

SURFACE WATER PRO softkey >> SURVEY tab.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC10379 —UN—14OCT07

PC10857BW —UN—15JUL08

SURFACE WATER PRO softkey

MENU softkey

GREENSTAR 3 PRO softkey

1. Record an external boundary for the field (Required).

2. Set up straight track for your survey pattern (optional).

Set survey mode and interval on Setup tab (D).

3. Select Record button (E) (Located on Survey tab (A)).

NOTE: Light (F) begins blinking red to signify

recording status as ON.

4. To stop surveying, select the Record button (E) again.

NOTE: Light (F) blinks rapidly until all data is saved

to the storage device.

Background layer cannot be changed during

survey recording. To change the background

layer, stop survey recording, change background

layer, and restart survey recording.

A—Survey tab

B—Levee tab

C—Ditch tab

D—Setup tab

E—Record button

F— Indicator Light

Survey tab

JS56696,00009E0 1918MAY112/3

PC13705 —UN—17MAY11

GreenStar 3 Pro—Water Management, SURVEY tab

JS56696,00009E0 1918MAY113/3

352

061611

PN=32

Page 33

Ditch

Setup Operation

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

DOCUMENTATION softkey >> NEW tab.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8678 —UN—05AUG05

PC10857BT —UN—15JUL08

MENU softkey

GREENSTAR 3 PRO softkey

DOCUMENTATION softkey

Continued on next page JS56696,00009E1 1912MAY111/2

New tab

401

061611

PN=33

Page 34

Ditch

GreenStar 3 Pro—Documentation, New tab

A—New tab

B—Tillage button

C—Planting/Seeding button

D—Product Application button

E—Harvest button

F— Water Management button

Select Water Management button (F) and type (I).

IMPORTANT: Surface Water Pro Plus does not support

an Implement Receiver Only configuration. Do

not run ditching with an implement receiver

PC13740 —UN—16MAY11

GreenStar 3 Pro—Documentation, Water Management tab

G—Other button

H—Water Management tab

I— Type dropdown menu

J— Remove button

only. AMachine and Implement receiver must

be used to operate ditching software.

PC13707 —UN—17MAY11

JS56696,00009E1 1912MAY112/2

402

061611

PN=34

Page 35

Ditch

Set Tracking Mode to Ditch Track

NOTE: Ditches must be recorded from high to low, but can

be cut in either direction. If the track is not recorded

from high to low, the drain design software in

Surface Water Pro Plus does not function correctly.

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

GUIDANCE softkey >> GUIDANCE SETTINGS tab.

Select DITCH TRACK in TRACKING MODE dropdown

box (A).

NOTE: Selecting Ditch Mode can be found in the GS3

Guidance area, not in the Surface Water Pro area.

A—Guidance Settings tab

B—Tracking Mode dropdown

box

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8673 —UN—14OCT07

PC10857BU —UN—15JUL08

MENU softkey

GREENSTAR 3 PRO softkey

GUIDANCE softkey

PC13728 —UN—17MAY11

Guidance Settings tab

JS56696,00009E2 1912MAY111/1

403

061611

PN=35

Page 36

Recorded Path for Ditching

Ditch

PC10857DW —UN—07OCT08

A—Path Recorded by Tractor for

AutoTrac

B—Path Recorded by Implement

for Ditch Track

C—Start of recorded Tractor Path

D—End of recorded Tractor Path

If an implement receiver is used to record elevation data

for ditch track, the resulting path differs from the AutoTrac

path. AutoTrac is always based off of the receiver on the

tractor. AutoTrac and Ditch Track paths have different

starting and stopping points. Although the tractor may

Record Ditch Track

Select MENU softkey >> GREENSTAR 3 PRO softkey

>> SURFACE WATER PRO softkey >> DITCH tab >>

OVERHEAD VIEW button.

E—Start of recorded Implement

Path

F— End of recorded Implement

Path

be driving on the Ditch path, ditching guidance does not

become active until the implement receiver is on the cut

line path. The cut line is updated when the implement

receiver is over the recorded ditch.

JS56696,00009E3 1916MAY111/1

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC10379 —UN—14OCT07

MENU softkey

GREENSTAR 3 PRO softkey

PC10857BS —UN—15JUL08

Continued on next page JS56696,00009E4 1918MAY111/2

SURFACE WATER PRO softkey

Ditch tab

404

061611

PN=36

Page 37

1. Drive to the HIGH POINT of the desired area for the

Ditch Track.

2. Place selected survey receiver on beginning position

for Ditch Track A (see SETUP tab for SURVEY

RECEIVER SOURCE).

3. Select NEW button (B).

4. Enter desired name for ditch track, and select Accept

button, unless AutoName has been selected.

5. Select SET A to begin recording ditch track.

6. Drive the ditch track.

7. Stop the survey receiver in the position where drain

water exits.

8. Select B to stop recording the ditch track.

Ditch

A—DITCH tab

B—NEW button

PC13748 —UN—16MAY11

PC13749 —UN—16MAY11

PC13729 —UN—17MAY11

Overhead View

Set A button

Set B button

JS56696,00009E4 1918MAY112/2

405

061611

PN=37

Page 38

Modify Ditch Track

Cancel button—allows operator to return to the previous

•

page without an action being taken.

REPLACE button—existing ditch track is removed and

•

a new ditch track with the same name can be recorded

immediately to that track.

REMOVE button—Existing ditch track is removed.

•

If Remove button is selected, the operator must verify

removal of the existing ditch track. If a track is removed

and AutoName is selected on the SETUP page, the

numbered track names are not adjusted down. For

example, if ditch tracks 1, 2, 3, 4, and 5 have been

created, and track 3 is removed, the remaining tracks are:

1, 2, 4, and 5. The tracks do NOT adjust to: 1, 2 ,3 , and 4.

Cancel button—ditch track is not deleted.

•

Enter button—ditch track is deleted.

•

Ditch

PC10312 —UN—29AUG07

Modify Ditch Track

PC10313 —UN—29AUG07

Remove Ditch Track

JS56696,00009E5 1916MAY111/1

406

061611

PN=38

Page 39

Ditch

View Drain Profile

NOTE: The Edit Drain button is not available until a valid

Surface Water Pro Plus activation number is entered.

Select MENU softkey >> GREENSTAR 3 PRO softkey

>> SURFACE WATER PRO softkey >> DITCH tab >>

PROFILE VIEW button.

View the recorded drain profile of the drain by utilizing the

zoom functions (A, B). This view is a side “cutaway” view

of the drain itself (existing topography).

A—Ditch tab

B—Zoom Out button

C—Zoom In button

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC10379 —UN—14OCT07

PC10857BS —UN—15JUL08

SURFACE WATER PRO softkey

MENU softkey

GREENSTAR 3 PRO softkey

Ditch tab

Profile View

PC13730 —UN—17MAY11

JS56696,00009E6 1916MAY111/1

407

061611

PN=39

Page 40

Create Linear Drain Design

Surface Water Pro Plus

Select MENU softkey >> GREENSTAR 3 PRO softkey

>> SURFACE WATER PRO softkey >> DITCH tab >>

PROFILE VIEW button >> EDIT DRAIN button.

The CREATE/EDIT DRAIN screen provides the ability for

an operator to create or edit a drain design associated

with a ditch track.

The map shows the portion of the survey elevation that

is highlighted on the FullView Map.

The Edit and FullView Map is updated to reflect the new

design of the Linear Drain.

NOTE: The drain design generated is a black line.

Cut Volume is calculated based on Implement

Width. Check before designing drains.

Ditch

1. Select Drain Type (A)—Linear.

2. Select GENERATE DRAIN button (H). A black line is

displayed. Zoom out to see the entire drain or select

Accept to return to profile view.

3. Adjust the slope of the linear design by using the Slope

or + buttons (B, D) or by selecting the slope input box

(C) and entering the desired slope. Each increase or

decrease adjusts the up or down by + or 0.01%.

4. Select GENERATE DRAIN button (H) again, if

necessary, or adjust offset.

5. Adjust offset up or down by selecting the Offset or +

buttons (E, G) or by selecting the offset input box (F)

and entering the desired offset.

6. Select GENERATE DRAIN (H) again to view updated

design (black line).

Create or Edit Drain

A—Drain Type dropdown

menu

B—Slope Decrease button

C—Slope input box

D—Slope Increase button

E—Offset Decrease button

F— Offset input box

G—Offset Increase button

H—Generate Drain button

I— Cancel button

J— Accept button

7. Cut volume is updated after each time GENERATE

DRAIN button is selected.

JS56696,00009E7 1916MAY111/1

PC13732 —UN—17MAY11

408

061611

PN=40

Page 41

Create Best Fit Drain Design

Surface Water Pro Plus

Select MENU softkey >> GREENSTAR 3 PRO softkey

>> SURFACE WATER PRO softkey >> DITCH tab >>

PROFILE VIEW button >> EDIT DRAIN button.

The CREATE/EDIT DRAIN screen provides the ability to

create or edit a drain design associated with a ditch track.

The map shows the portion of the survey elevation that

is highlighted on the FullView Map.

NOTE: The drain generated is a black line.

Cut Volume is calculated based on Implement

Width. Check before designing drains.

Best fit drain provides the operator with the ability to create

a drain design that utilizes existing ditch track vertical

profile while minimizing the amount of soil moved. This

is dependent upon the input parameters. It is possible

to get a NO SOLUTION with this feature. If software

fails to create a drain design, update image and adjust

parameters in Step 2 to produce a valid drain design.

1. Select drain type (A)—Best Fit.

2. Input: MIN Slope (%) (B), MAX Slope (%) (C), MIN

Cut (in.) (D), MAX Cut (in.) (E).

3. Select GENERATE DRAIN button (F). A black line is

displayed.

4. Drain design, visible by black line, is updated.

Ditch

A—Drain Type dropdown

menu

B—Minimum Slope input box

C—Maximum Slope input box

D—Minimum Cut input box

E—Maximum Cut input box

F— Generate Drain button

G—Cancel button

H—Accept button

6. Repeat steps 2 and 3 until desired drain is created.

PC13733 —UN—17MAY11

5. Cut Volume is updated.

JS56696,00009E8 1916MAY111/1

409

061611

PN=41

Page 42

Ditch

Cut or Clean Ditch Track

Select MENU softkey >> GREENSTAR 3 PRO softkey

>> SURFACE WATER PRO softkey >> DITCH tab >>

OVERHEAD VIEW button.

1. Turn machine and scraper around and return to the

ditch and begin cutting.

2. Acquire Ditch Track with AutoTrac guidance system.

3. Engage AutoTrac system (Resume button).

NOTE: At times, it is necessary to toggle

between overhead and profile view during

reacquisition of the track.

A—DITCH tab

B—NEW button

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC10379 —UN—14OCT07

PC10857BS —UN—15JUL08

SURFACE WATER PRO softkey

MENU softkey

GREENSTAR 3 PRO softkey

Ditch tab

PC13729 —UN—17MAY11

Overhead View

Continued on next page JS56696,00009E9 1916MAY111/2

4010

061611

PN=42

Page 43

Ditch

4. Select MENU softkey >> GREENSTAR 3 PRO softkey

>> SURFACE WATER PRO softkey >> DITCH tab

>> PROFILE VIEW button.

5. Begin ditching operation by manipulating cutting blade

with hydraulic controls.

NOTE: If there is a second receiver on the implement,

the system displays the current blade position

by drawing a red profile on the screen. The

blue and optional black drain design line is not

removed, as they are there for reference.

(A) Red line—the actual location of the blade after

making the cut. Ideally the red line follows the black

line when ditching is complete.

(B) Black line—the desired location of the cut created

by pressing "Generate Drain" button on Edit Drain

screen.

(C) Blue line—the existing drain profile saved at the

time of track recording.

(D) Green Triangle—lower point references the blade

of the scraper. As you raise and lower the scraper, this

triangle moves up and down appropriately.

NOTE: Zoom levels and view can be adjusted

for optimal cutting.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC10379 —UN—14OCT07

PC10857BS —UN—15JUL08

SURFACE WATER PRO softkey

MENU softkey

GREENSTAR 3 PRO softkey

A—Location of Blade after

making Cut (red)

B—Desired Location of Cut

(black)

C—Drain Profile Recorded

(blue)

D—Blade of Scraper

E—Ditch tab

F— View button

Ditch tab

PC13739 —UN—16MAY11

JS56696,00009E9 1916MAY112/2

4011

061611

PN=43

Page 44

Levee

Set Operation to Levee

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

DOCUMENTATION softkey >> NEW tab.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8678 —UN—05AUG05

PC10857BT —UN—15JUL08

MENU softkey

GREENSTAR 3 PRO softkey

DOCUMENTATION softkey

Continued on next page JS56696,00009EA 1916MAY111/2

New tab

451

061611

PN=44

Page 45

Levee

GreenStar 3 Pro—Documentation

A—New tab

B—Tillage button

C—Planting/Seeding button

D—Product Application button

E—Harvest button

F— Water Management button

Select Water Management button (F).

PC13740 —UN—16MAY11

GreenStar 3 Pro—Documentation

G—Other button

J— Remove button

H—Water Management tab

I— Type dropdown menu

Select LEVEE from Type dropdowm menu (I).

JS56696,00009EA 1916MAY112/2

PC13741 —UN—16MAY11

452

061611

PN=45

Page 46

Levee

Set to Levee Track

Select MENU softkey >> GREENSTAR 3 PRO softkey >>

GUIDANCE softkey >> GUIDANCE SETTINGS tab.

Select LEVEE TRACK in TRACKING MODE dropdown

box (B).

NOTE: Selecting Levee Mode can be found in the GS3

Guidance area, not in the Surface Water Pro area.

A—GUIDANCE SETTINGS tab B—TRACKING MODE

dropdown

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC8673 —UN—14OCT07

PC10857BU —UN—15JUL08

MENU softkey

GREENSTAR 3 PRO softkey

GUIDANCE softkey

PC13742 —UN—16MAY11

Guidance Settings tab

JS56696,00009EB 1916MAY111/1

453

061611

PN=46

Page 47

Mark Path (Drive Dial)

1. Set desired elevation drop between levees in the

ELEVATION DROP input box (D). A keypad appears

to enter elevation amount.

2. Drive to the starting location for marking levees or the

high point to SET ELEVATION.

If operator is continuing to mark levees from a

•

previously known elevation, such as a prior levee,

proceed to the next step.

If operator is beginning a new field and needs

•

to mark the high point or beginning elevation

from which levees are marked off of, select SET

ELEVATION button (B) to begin.

3. Increase (C) or decrease (E) ELEVATION DROP to

adjust target elevation.

4. Proceed up or down slope to the target elevation. Be

careful driving down headlands. Avoid driving on large

obstacles.

5. Target elevation is been reached when the vertical dial

is centered on the 0 (zero).

6. Proceed to mark the levee location by traversing

through the field at a constant elevation. Keep the

dial at the zero position as much as possible for that

particular levee.

NOTE: If returning to field to mark more levees and

using a quickstart base (no permanent base),

set receiver on previous levee and set elevation

button before setting next target elevation.

Levee

GreenStar 3 Pro—Water Management

A—Levee tab

B—Set Elevation button

C—Increase Elevation button

D—Elevation Drop input box

E—Decrease Elevation button

Continued on next page JS56696,00009EC 1916MAY111/2

F— AutoTrac Enable button

G—Levee Track Name

dropdown

H—New Levee Track Name

button

I— Modify Levee Track Name

button

PC13743 —UN—16MAY11

454

061611

PN=47

Page 48

Levee

Home Page set up to show Dial and Map view

A—Set Elevation button

B—Increase Elevation button

C—Decrease Elevation button

D—Elevation Drop input box

CAUTION: While using elevation dial, remain alert

and pay attention to surrounding environment.

Drive along and mark a constant elevation line using

elevation dial (Driving the Dial).

Record a Levee Track

After making the levee with the dial, turn the vehicle

around.

1. Select NEW button. The system autoincrements the

names by numbers beginning at 1.

2. Set A.

E—Levee Track Name dropdown

F— New Levee Track Name

button

G—Modify Levee Track Name

button

H—Record button

After the levee has been marked for that elevation, select

either up (B) or down (C) arrow to set target elevation for

the next levee at either a higher (up arrow) or lower (down

arrow) elevation.

JS56696,00009EC 1916MAY112/2

3. Record the levee track by driving back over your wheel

tracks in the soil that you created with the dial.

4. At the end of the track, select B.

5. The name appears in the list.

JS56696,00009ED 1916MAY111/1

PC13745 —UN—16MAY11

455

061611

PN=48

Page 49

Set A B Lines

1. Select New button (A) at the bottom of the page.

NOTE: Levee tracks are automatically named. If a track

is deleted, the other tracks retain the number

that was given to them for a name.

2. Select Set A button at the bottom of the page and

drive path currently marked out.

3. Select Set B button at the bottom of the page when at

the end of the path.

IMPORTANT: The path cannot intersect or

cross over itself.

A—New Levee Track Name

button

Levee

PC13747 —UN—16MAY11

PC13748 —UN—16MAY11

Pull Levee

Use AutoTrac to retrace levee line and pull up levee.

PC13749 —UN—16MAY11

Set A button

Set B button

JS56696,00009EE 1916MAY111/1

456

PC13750 —UN—16MAY11

GreenStar 3 Pro—Water Management

JS56696,00009EF 1916MAY111/1

061611

PN=49

Page 50

Troubleshooting and Diagnostics

Diagnostic Readings

Select MENU softkey >> GREENSTAR 3 PRO softkey