Page 1

John Deere AutoTrac™

Controller—Raven™

OPERATOR'S MANUAL

John Deere AutoTrac™

Controller—Raven™

OMPFP11320 ISSUE H1 (ENGLISH)

DCYOMPFP11320

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

If this product contains a gasoline engine:

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

Additional Proposition 65 Warnings can be found in this manual.

John Deere Ag Management Solutions

Worldwide Edition

PRINTED IN U.S.A.

Page 2

Introduction

www.StellarSupport.com

NOTE: Product functionality may not be fully represented in this document due to product changes occurring after the time of printing. Read the

latest Operator's Manual and Quick Reference Guide prior to operation. To obtain a copy, see your dealer or visit www.StellarSupport.com

OUO6050,0000FB1 -19-10AUG10-1/1

Foreword

This AutoTrac Controller Operator's Manual is to be used

with the Guidance Operator's Manual.

READ BOTH MANUALS carefully to learn how to operate

and service your system correctly. Failure to do so could

result in personal injury or equipment damage. These

manuals may also be available in other languages. (See

your John Deere dealer to order.)

JS56696,0000A39 -19-14JUN11-1/1

090811

PN=2

Page 3

Contents

Page

Safety

Recognize Safety Information ............................ 05-1

Understand Signal Words...................................05-1

Follow Safety Instructions...................................05-1

Practice Safe Maintenance.................................05-2

Handle Electronic Components and

Brackets Safely .............................................. 05-2

Use Seat Belt Properly .......................................05-3

Operate Guidance Systems Safely ....................05-3

Use AutoTrac Controller on Approved Vehicles ..05-3

Safety Signs

Automatic Guidance System Detected...............10-1

AutoTrac Controller

AutoTrac Accuracy .............................................15-1

General Information............................................15-1

AutoTrac Settings ............................................... 15-2

Activity Monitor ...................................................15-2

AutoTrac Controller Troubleshooting

AutoTrac Controller ............................................20-1

Diagnostic Readings...........................................20-2

Stop Codes.........................................................20-3

AutoTrac Controller—Raven

AutoTrac Controller— Raven Calibration ...........25-1

Failed Calibrations..............................................25-8

Necessary Conditions for Activating AutoTrac ...25-9

AutoTrac Controller—Raven

Diagnostic Addresses .................................. 25-10

AutoTrac Controller—Raven

Diagnostic Trouble Codes ............................25-12

Page

Troubleshooting—GS2 Display 1800

Trouble Codes .................................................... 35-1

Diagnostic Addresses.........................................35-1

Guidance Alarms ................................................ 35-3

AutoTrac Deactivation Message.........................35-4

Diagnostic Addresses.........................................35-5

GS3 2630 Display

Automatic Guidance System Detected...............40-1

Enabling System.................................................40-2

Activating System ............................................... 40-3

Deactivating System...........................................40-3

Setup ..................................................................40-4

StarFire ..............................................................40-5

GS3 2630 Advanced Settings

Tuning Recommendations..................................45-1

Recommended Tuning Settings .........................45-3

Optimizing AutoTrac Controller Performance.....45-4

Tuning Tips, Tricks, and Precautions.................. 45-9

Troubleshooting.................................................. 45-9

Specications

Unied Inch Bolt and Screw Torque Values........50-1

Metric Bolt and Screw Torque Values ................. 50-2

EC Declaration of Conformity ............................. 50-3

GS2 Display 1800

Automatic Guidance System Detected...............30-1

Enabling System.................................................30-1

Activating System ............................................... 30-1

GreenStar Run Page..........................................30-2

Enabling AutoTrac .............................................. 30-6

AutoTrac Status Pie............................................30-7

Reactivating AutoTrac on Next Pass ..................30-8

Deactivating AutoTrac ........................................30-8

Guidance Settings ..............................................30-9

AutoTrac Settings ............................................. 30-10

Advanced AutoTrac Settings ............................30-13

StarFire ............................................................30-16

Original Instructions. All information, illustrations and specications in this

manual are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

COPYRIGHT © 2011

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION ® Manual

i

All rights reserved.

090811

PN=1

Page 4

Contents

ii

090811

PN=2

Page 5

Safety

Recognize Safety Information

This is a safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safety-alert symbol. DANGER identies the

most serious hazards.

DANGER or WARNING safety signs are located near

specic hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

T81389 —UN—07DEC88

DX,ALERT -19-29SEP98-1/1

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

There can be additional safety information contained on

parts and components sourced from suppliers that is not

reproduced in this operator's manual.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modications to the machine may impair the

function and/or safety and affect machine life.

TS187 —19—30SEP88

DX,SIGNAL -19-03MAR93-1/1

TS201 —UN—23AUG88

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

DX,READ -19-16JUN09-1/1

05-1

090811

PN=5

Page 6

Safety

Practice Safe Maintenance

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from power-driven

parts. Disengage all power and operate controls to relieve

pressure. Lower equipment to the ground. Stop the

engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground

cable (-) before making adjustments on electrical systems

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

Handle Electronic Components and Brackets Safely

Falling while installing or removing electronic components

mounted on equipment can cause serious injury. Use a

ladder or platform to easily reach each mounting location.

Use sturdy and secure footholds and handholds. Do not

install or remove components in wet or icy conditions.

If installing or servicing a RTK base station on a tower or

other tall structure, use a certied climber.

If installing or servicing a global positioning receiver mast

used on an implement, use proper lifting techniques and

wear proper protective equipment. The mast is heavy and

can be awkward to handle. Two people are required when

mounting locations are not accessible from the ground

or from a service platform.

TS218 —UN—23AUG88

DX,SERV -19-17FEB99-1/1

TS249 —UN—23AUG88

DX,WW,RECEIVER -19-24AUG10-1/1

05-2

090811

PN=6

Page 7

Use Seat Belt Properly

Use a seat belt when you operate with a roll-over

protective structure (ROPS) or cab to minimize chance of

injury from an accident such as an overturn.

Do not use a seat belt if operating without a ROPS or cab.

Replace entire seat belt if mounting hardware, buckle,

belt, or retractor show signs of damage.

Inspect seat belt and mounting hardware at least

once a year. Look for signs of loose hardware or belt

damage, such as cuts, fraying, extreme or unusual wear,

discoloration, or abrasion. Replace only with replacement

parts approved for your machine. See your John Deere

dealer.

Safety

TS205 —UN—23AUG88

DX,ROPS1 -19-29OCT07-1/1

Operate Guidance Systems Safely

Do not use guidance systems on roadways. Always turn

off (disable) guidance systems before entering a roadway.

Do not attempt to turn on (activate) a guidance system

while transporting on a roadway.

Guidance systems are intended to aid the operator in

performing eld operations more efciently. The operator

is always responsible for the machine path.

Guidance Systems include any application that automates

vehicle steering. This includes, but may not be limited to,

AutoTrac, iGuide, iTEC Pro, ATU, and RowSense.

To prevent injury to the operator and bystanders:

Use AutoTrac Controller on Approved Vehicles

Use AutoTrac Controller only on Approved Vehicles—see

StellarSupport.Deere.com for list of approved vehicles

When activity monitor is selected, AutoTrac Controller

looks for operator activity every seven minutes. Operator

Never get on or off a moving vehicle.

•

Verify the machine, implement, and guidance system

•

are set up correctly. If using iTEC Pro, verify accurate

boundaries have been dened.

Remain alert and pay attention to the surrounding

•

environment.

Take control of the steering wheel, when necessary, to

•

avoid eld hazards, bystanders, equipment, or other

obstacles.

Stop operation if poor visibility conditions impair your

•

ability to operate the machine or identify people or

obstacles in the machine path.

Consider eld conditions, visibility, and vehicle

•

conguration when selecting vehicle speed.

JS56696,0000970 -19-10MAY11-1/1

will receive a time-out warning 15 seconds before

AutoTrac deactivates. Pressing the resume will reset

activity monitor timer.

JS56696,0000615 -19-14JUN11-1/1

05-3

090811

PN=7

Page 8

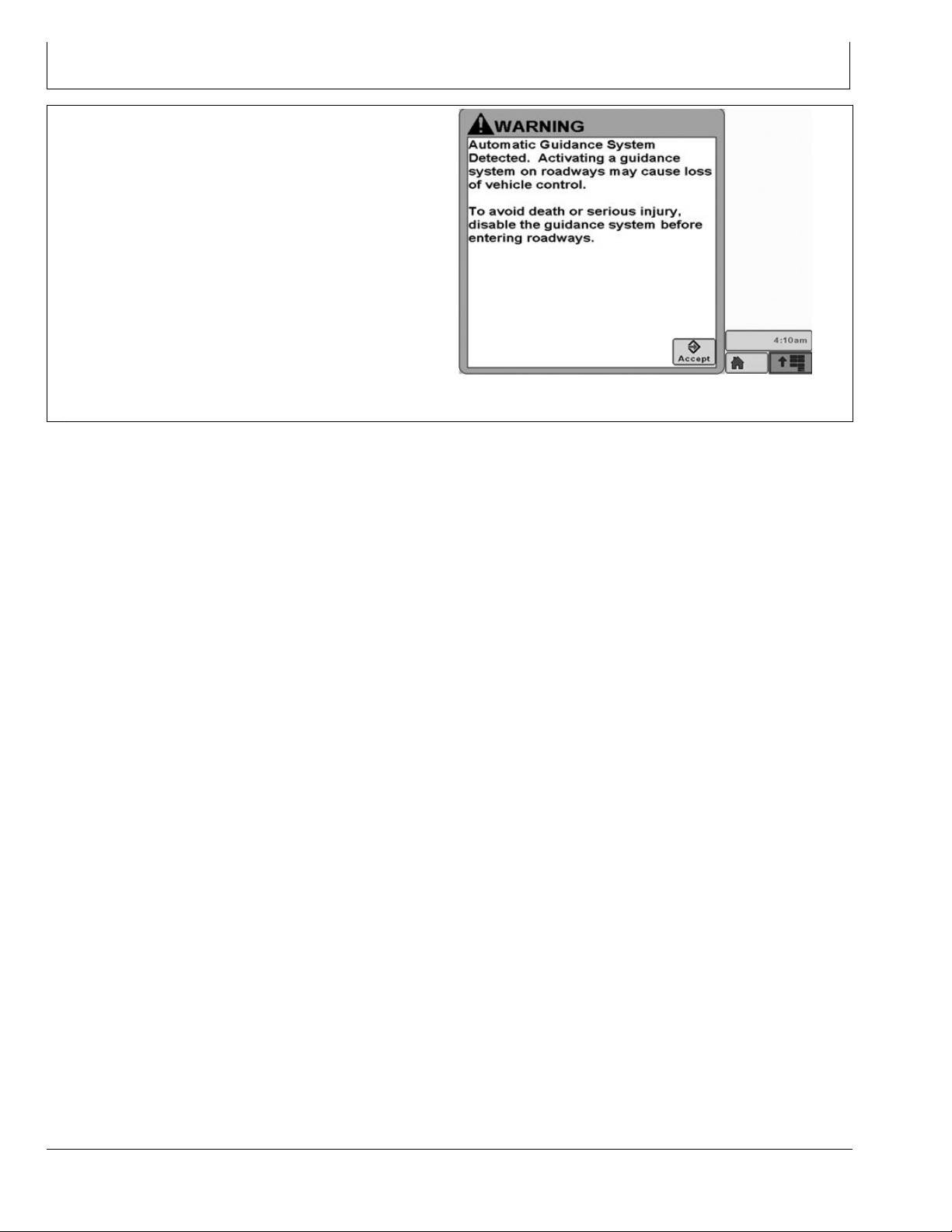

Safety Signs

Automatic Guidance System Detected

This message occurs during startup on vehicles with

AutoTrac installed.

The master switch removes power from the EH Valve to

prevent AutoTrac from being unintentionally activated. The

master switch is intended for use on roadways or when

the operator does not want AutoTrac able to be activated.

Ensure AutoTrac is disabled by turning the Master Switch

to the OFF position.

PC13157 —19—17FEB11

Automatic Guidance

JS56696,0000A3B -19-14JUN11-1/1

10-1

090811

PN=8

Page 9

AutoTrac Controller

AutoTrac Accuracy

IMPORTANT: The John Deere AutoTrac system relies

on the GPS system operated by the government

of the United States, which is solely responsible

for its accuracy and maintenance. The system

is subject to changes that could affect accuracy

and performance of all GPS equipment.

The overall AutoTrac system accuracy is dependent upon

many variables. The equation looks like:

AutoTrac System Accuracy = Signal accuracy + Vehicle

Setup + Implement Setup + Field/Soil Conditions.

It is very important to remember:

Receiver has to go through a warm-up period after

•

starting.

Vehicle is setup properly (ballasted according to vehicle

•

operator manual, etc.)

General Information

All operators must be familiar with AutoTrac system and

operating characteristics prior to operation. Operator must

know the make of the AutoTrac controller installed on their

machine prior to operation.The following is a suggested

procedure for operator to become familiar with system:

1. Read and understand Operators Manual for GreenStar

Guidance—Parallel Tracking and AutoTrac Assisted

Steering Systems.

2. Choose an open area free of hazards (ditches,

buildings, etc.).

3. Set Track Spacing to 92.0 meters (300 ft).

4. Set a Track 0 (A—B Line).

NOTE: Operate vehicle at a speed you are comfortable,

recommend less than 8 km/h (5 mph).

5. Enable AutoTrac on display by turning Steer ON.

6. Press Resume switch to activate AutoTrac. (See

Activating system later in this section).

7. After driving a short distance, then turn steering wheel

to turn vehicle off track to deactivate AutoTrac. (See

Deactivating System later in this section).

8. Practice Activating AutoTrac at different distances

before and after crossing track and at different angles.

Increase and decrease speeds to simulate different

operating conditions.

9. Reduce Track Spacing to acquire multiple tracks and

continue practicing activating AutoTrac at different

angles and varying speeds to understand how

AutoTrac behaves under different conditions.

Implement is setup to run properly (wear parts such

•

as shanks, shovels, and sweeps are in good working

condition and correctly spaced).

Understand how eld/soil conditions affect system

•

(loose soil requires more steering than rm soil, but rm

soil can cause uneven draft loads).

IMPORTANT: Although AutoTrac system can be

activated when SF2 (or SF1 if using AutoTrac

SF1 activation) correction signal is conrmed,

system accuracy may continue to increase

after powering up system.

AutoTrac SF2 activation will operate on a SF1, SF2, or

RTK signal.

AutoTrac SF1 activation will operate on a SF1 signal only.

CF86321,00002B7 -19-05AUG11-1/1

Always be prepared to resume manual control if AutoTrac

does not perform expected maneuvers or machine course

must be changed to avoid injury or property damage.

Operator can regain manual steering by turning steering

wheel or Disabling AutoTrac by turning Steer off on

display. It is recommended practice to be as close as

possible to desired track prior to activating AutoTrac. This

will ensure correct track and direction are acquired.

The AutoTrac basic system is intended to be used as

an assistance tool to mechanical markers on planters.

Operator must evaluate overall system accuracy to

determine specic eld operations where assisted

steering may be used. This evaluation is necessary

because accuracy required for various eld operations

may differ depending on farming operation. Because

AutoTrac uses StarFire differential correction network

along with Global Positioning System (GPS), slight shifts

in position may occur over time.

To operate AutoTrac operator must set track 0 (similar to

parallel tracking) and all tracks are drawn parallel to track

0 using track spacing.

The AutoTrac system operating status can exist at four

levels: INSTALLED, CONFIGURED, ENABLED, and

ACTIVATED.

After enabling AutoTrac (see Enabling AutoTrac),

AutoTrac is activated by pressing resume switch

on armrest (see Activating AutoTrac). To return to

manual steering, operator must deactivate system (see

Deactivating System).

If required track can be shifted left, right or centered using

shift track feature on display. (See Shift Track).

CF86321,00002B8 -19-17MAY11-1/1

15-1

090811

PN=9

Page 10

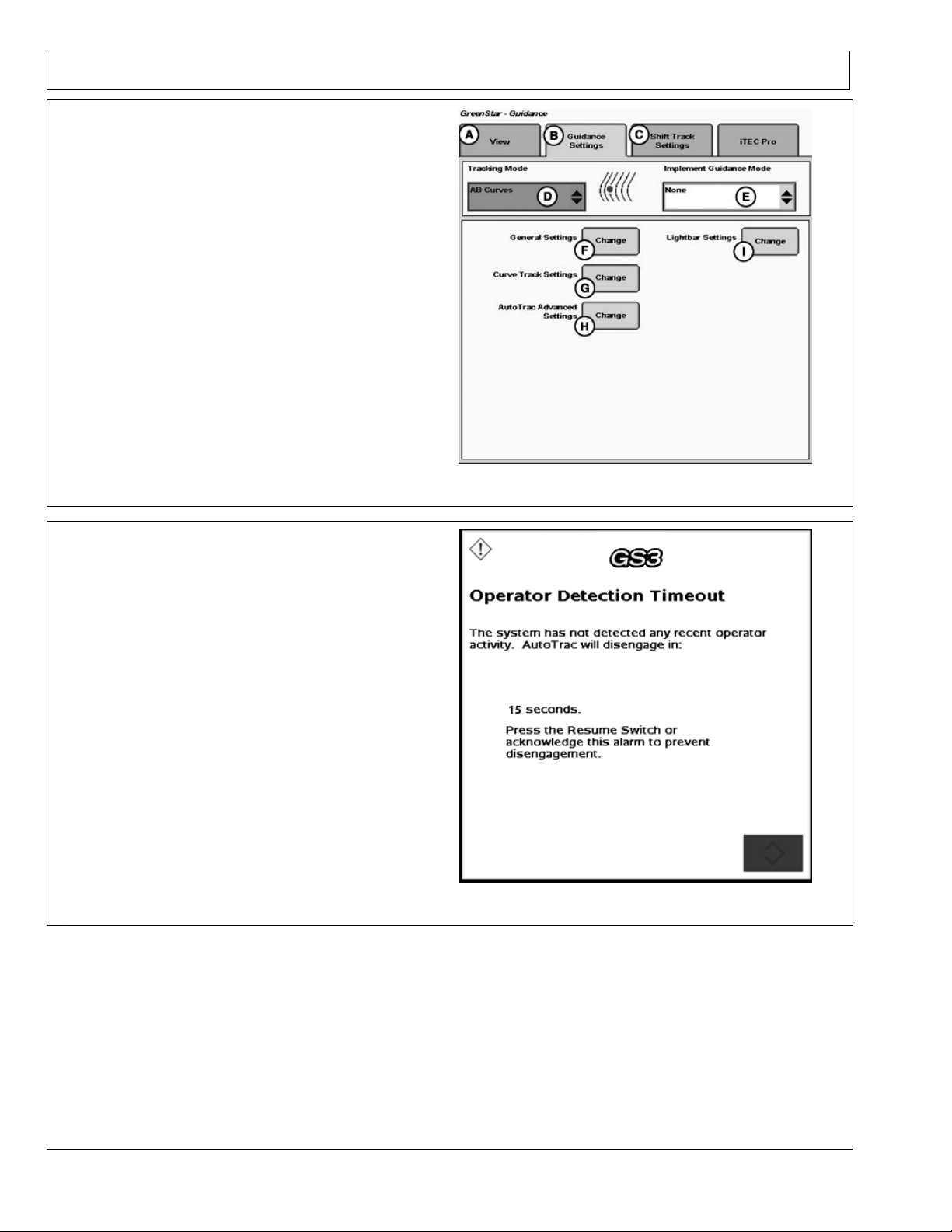

AutoTrac Settings

AutoTrac Controller

A—View Tab

B—Guidance Settings Tab

C—Shift Track Settings

D—Tracking Mode

E—Implement Guidance Mode

F— General Settings

G—Curve Track Settings

H—AutoTrac Advanced

Settings

I— Lightbar Settings

Activity Monitor

NOTE: Activity Monitor will only operate if the seat switch

is not operational or not installed on the machine.

PC13709 —UN—13MAY11

Guidance Settings

CF86321,00002B9 -19-17MAY11-1/1

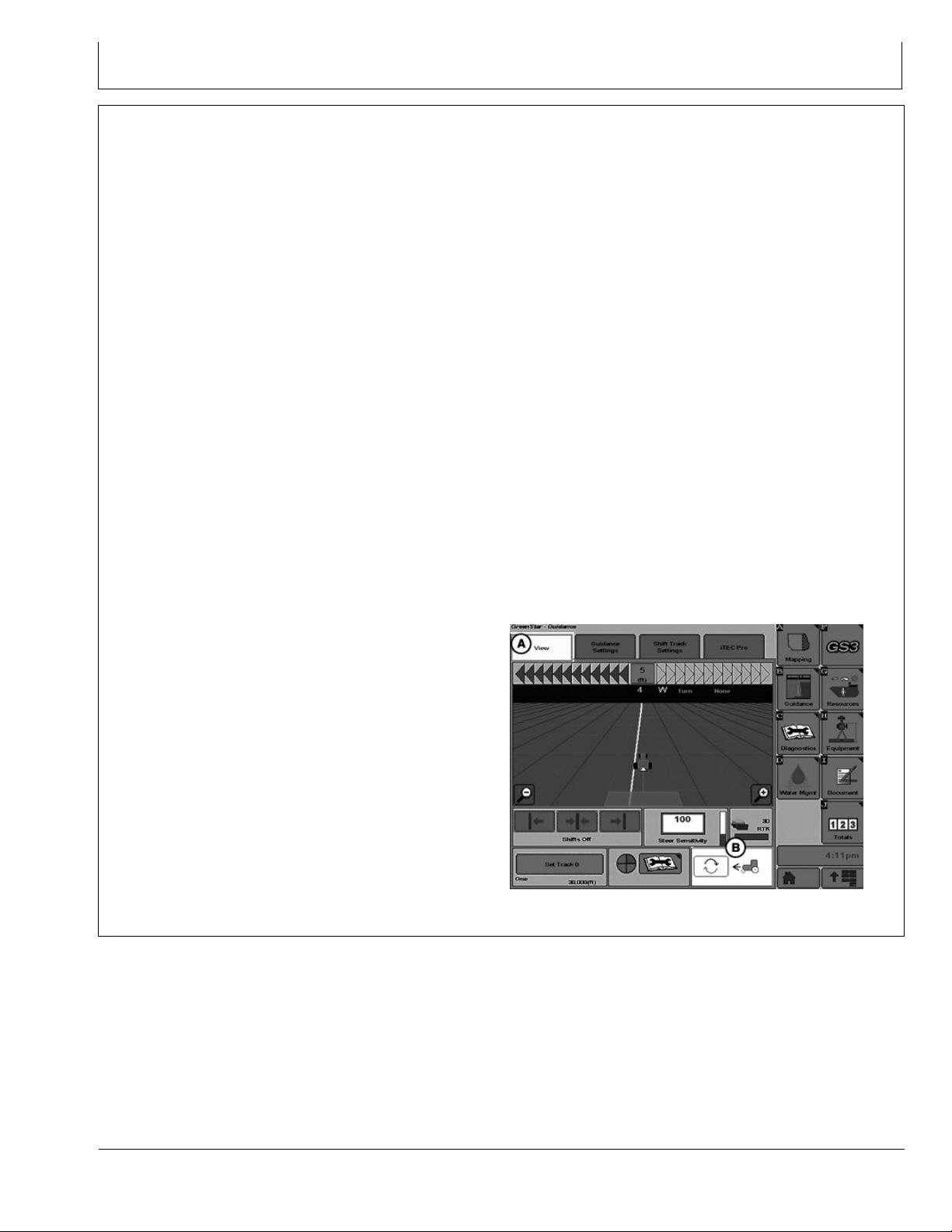

Operator Detection Timeout

The system has not detected any recent operator activity.

AutoTrac will deactivate in: 15 seconds.

Press the Resume Switch or acknowledge this alarm to

prevent deactivation.

The Activity Monitor will monitor the status of the operator

by requiring the operator to provide input to the display

every 7 minutes.

To reset the Activity Monitor, push the resume switch or

click the Enter button on the pop-up screen.

PC13872 —UN—20JUL11

Operator Detection Timeout

BA31779,0000232 -19-20JUL11-1/1

15-2

090811

PN=10

Page 11

AutoTrac Controller Troubleshooting

AutoTrac Controller

Symptom Problem Solution

AutoTrac Controller won’t activate.

AutoTrac will not resume.

AutoTrac Controller does not

appear on INFO or SETUP screens

Direction can not be determined

Tractor acquires guidance line but

tracks 25 to 518 cm (10 to 204 in.)

to right or left of line.

Stop Code encountered See list of stop codes to nd issue

System not recognizing AutoTrac

Controller on CAN bus line

Ensure AutoTrac Controller is

connected to GreenStar Harness and

receiving power

Check for blown fuses in AutoTrac

Controller wiring harness

Old TCM Software Update TCM Software to newest

software (Version 1.08 or greater)

No differential Correction Establish differential correction

No GPS

AutoTrac Controller did not establish

direction correctly

Establish signal

Drive forward at a speed greater than

1.6 km/h (1 mph) and turn steering

wheel greater than 45 degrees in one

direction

AutoTrac Controller has encountered

a bad wheel angle sensor calibration

and has an incorrect wheel angle

Recalibrate wheel angle sensor and

reacquire line to ensure problem is

corrected.

sensor bias.

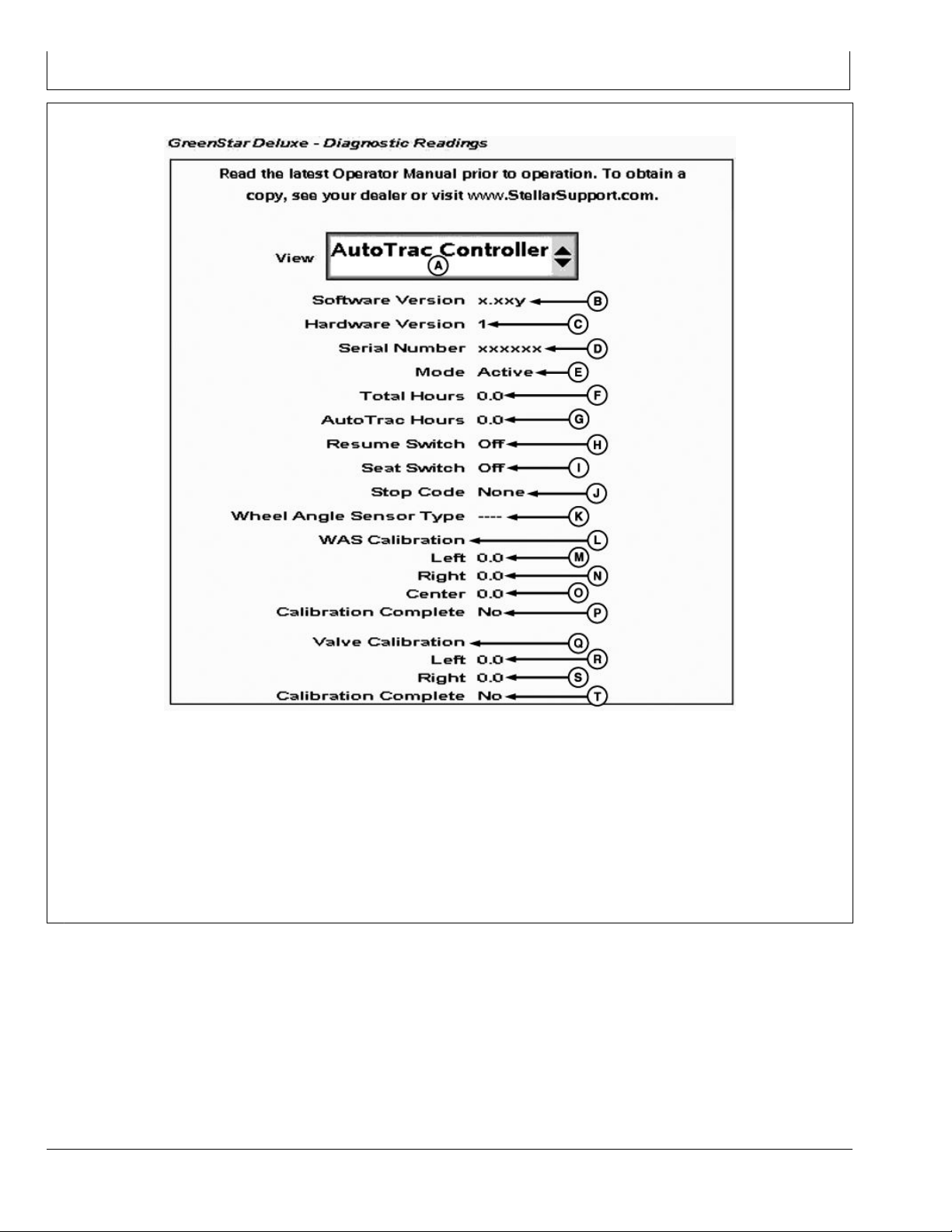

Direction Change Toggle

If the direction of travel is determined to be incorrect, Select

the View Tab (A) then select Direction Change Toggle

Button (B) to change the displayed direction of travel.

A—View Tab

B—Direction Change Toggle

Button

PC13566 —UN—04MAY11

Home Screen

CF86321,000035D -19-23MAY11-1/1

20-1

090811

PN=11

Page 12

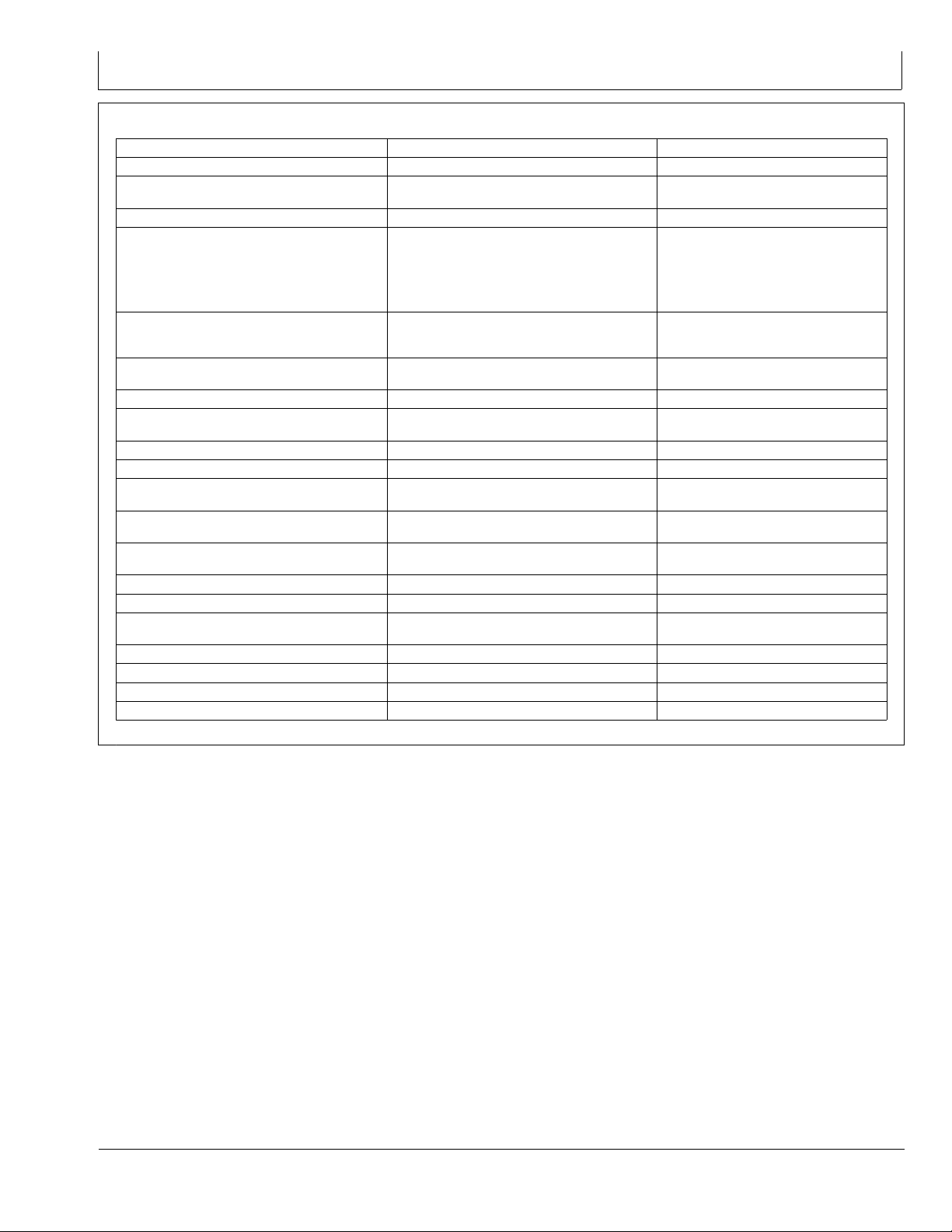

Diagnostic Readings

AutoTrac Controller Troubleshooting

GreenStar Diagnostic Readings

A—View Drop-Down Menu

B—Software Version

C—Hardware Part Number

D—Serial Number

E—Mode Status

F— Total Hours

G—AutoTrac Hours

H—Resume Switch Status

I— Seat Switch Status

J— Stop Code

Read the latest Operator Manual prior to operation.

To obtain a copy, see your dealer or visit

www.StellarSupport.com.

K—Wheel Angle Sensor Type

L— WAS Calibration

M—Left WAS Calibration Number

N—Right WAS Calibration

Number

O—Center WAS Calibration

Number

PC13826 —UN—28JUN11

P—WAS Calibration Complete

Status

Q—Valve Calibration

R—Left Valve Calibration Number

S—Right Valve Calibration

Number

T— Valve Calibration Complete

Status

CF86321,000035E -19-28JUN11-1/1

20-2

090811

PN=12

Page 13

AutoTrac Controller Troubleshooting

Stop Codes

Stop Code

None Nothing has been checked yet

Steering Wheel Steering wheel has moved to deactivate AutoTrac

Too Slow

Too Fast

Unknown Direction Unknown direction

Track Changed

Lost Dual GPS SF1, SF2, or RTK signal was lost

Steer Control Fault A steering control fault severe enough to disable

OK Last state upgrade was successful

PT Turned Off

Heading Error

Lateral Error

No Operator Operator presence switch is open. Operator in seat or press resume for

No TCM Either no TCM present or TCM is turned off. Turn TCM on, or install TCM

Voltage Unstable Voltage Too Low

Reverse Timeout

0 Speed Timeout 0 Speed Timeout Increase speed over 0.5 km/h (0.3 mph)

Curvature Curve Track radius tighter than AutoTrac will allow

Tracking on Line Vehicle is driving on line

Acquiring Line Vehicle is acquiring line

Vehicle speed too slow to use AutoTrac

Vehicle Speed too high to use AutoTrac Reduce Speed below platform limit

Track number changed Align vehicle on desired track and press

AutoTrac

Tracking not turned on.

Heading error is out of range. Align tractor within heading limit (80° of

Lateral error is out of range. Align tractor within lateral limit (40% of

Reverse Timeout (greater than 45 seconds) Cycle direction forward before resuming

Description

Solution

Press resume switch to re-activate

AutoTrac

Increase speed over 0.5 km/h (0.3 mph)

Tractor - 30 km/h (18.6 mph)

Sprayer - 37 km/h (23 mph)

Harvester - 22 km/h (13.7 mph)

Reverse speed on all machines – 10 km/h

(6 mph)

Drive forward greater than 1.6 km/h (1

mph) and turn steering wheel greater than

45°

resume

Establish signal

Cycle tractor power

Turn tracking on in Setup - Tracking

track)

track spacing)

activity monitor to reset time

Check harnessing

in reverse

Manually drive through tight radius curves

CF86321,000035F -19-28JUN11-1/1

20-3

090811

PN=13

Page 14

AutoTrac Controller—Raven

AutoTrac Controller— Raven Calibration

IMPORTANT: John Deere 2600 Display will not operate

with AutoTrac Controller—Raven™

NOTE: Calibration procedure must be completed with a

passing status prior to using AutoTrac.

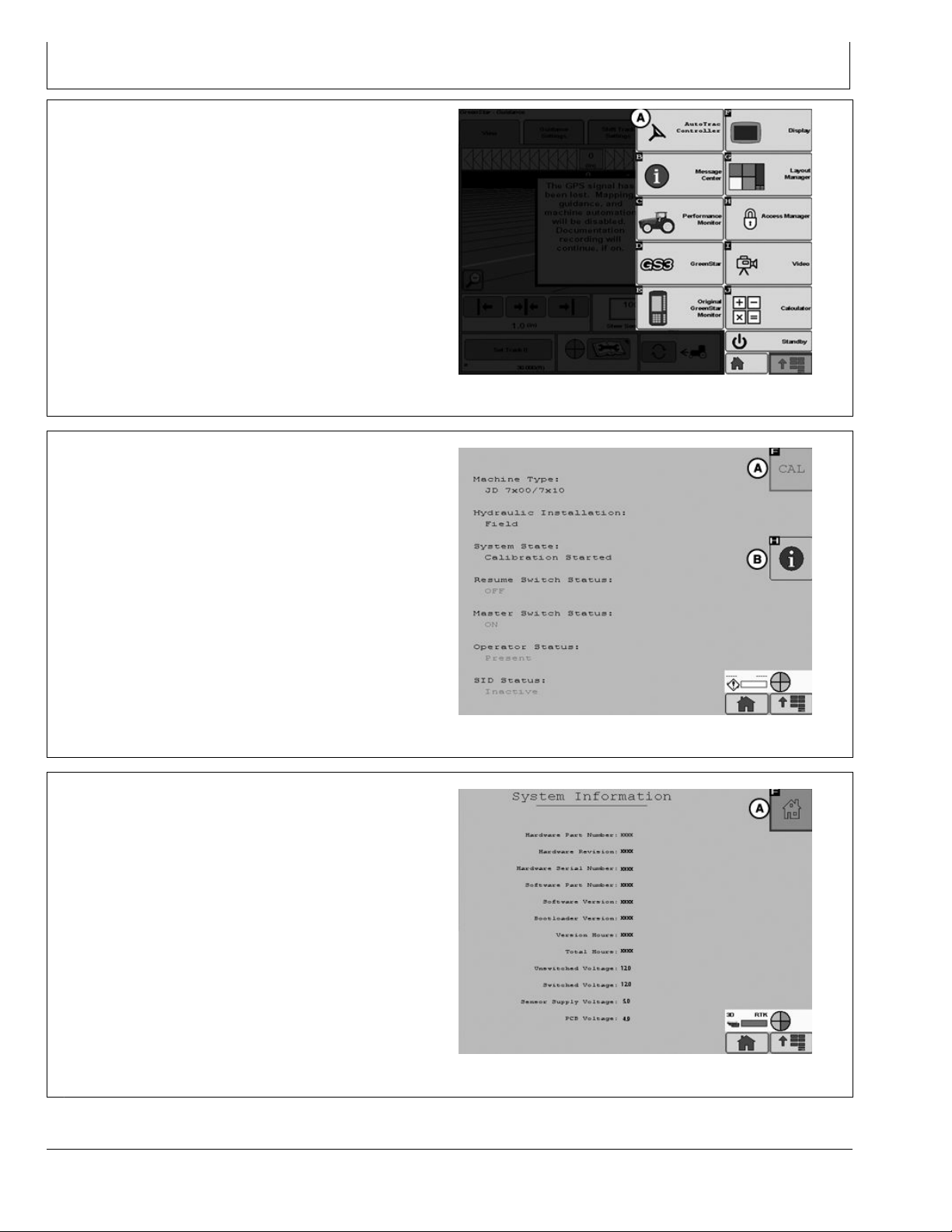

From the Main Menu select AutoTrac Controller.

A—AutoTrac Controller

AutoTrac Main Screen will appear.

In the AutoTrac main screen select the CAL button (A).

The Calibration Assistant main screen will appear.

PC13382 —UN—20JUL11

AutoTrac Button

BA31779,0000223 -19-04AUG11-1/21

A—Calibration Button B—Information Button

Select the System Information button (B). This will display

information to inform the operator that AutoTrac is ready

for calibration. Some information is software version and

operating voltages. If there are no voltages make sure to

check all connections.

After all information is veried select the AutoTrac home

button (A) in the upper right of the screen. This will

navigate back to the AutoTrac main screen.

A—Home Button

PC13383 —UN—20APR11

AutoTrac Main Screen

BA31779,0000223 -19-04AUG11-2/21

System Information

Continued on next page BA31779,0000223 -19-04AUG11-3/21

25-1

PC13384 —UN—19MAY11

090811

PN=14

Page 15

AutoTrac Controller—Raven

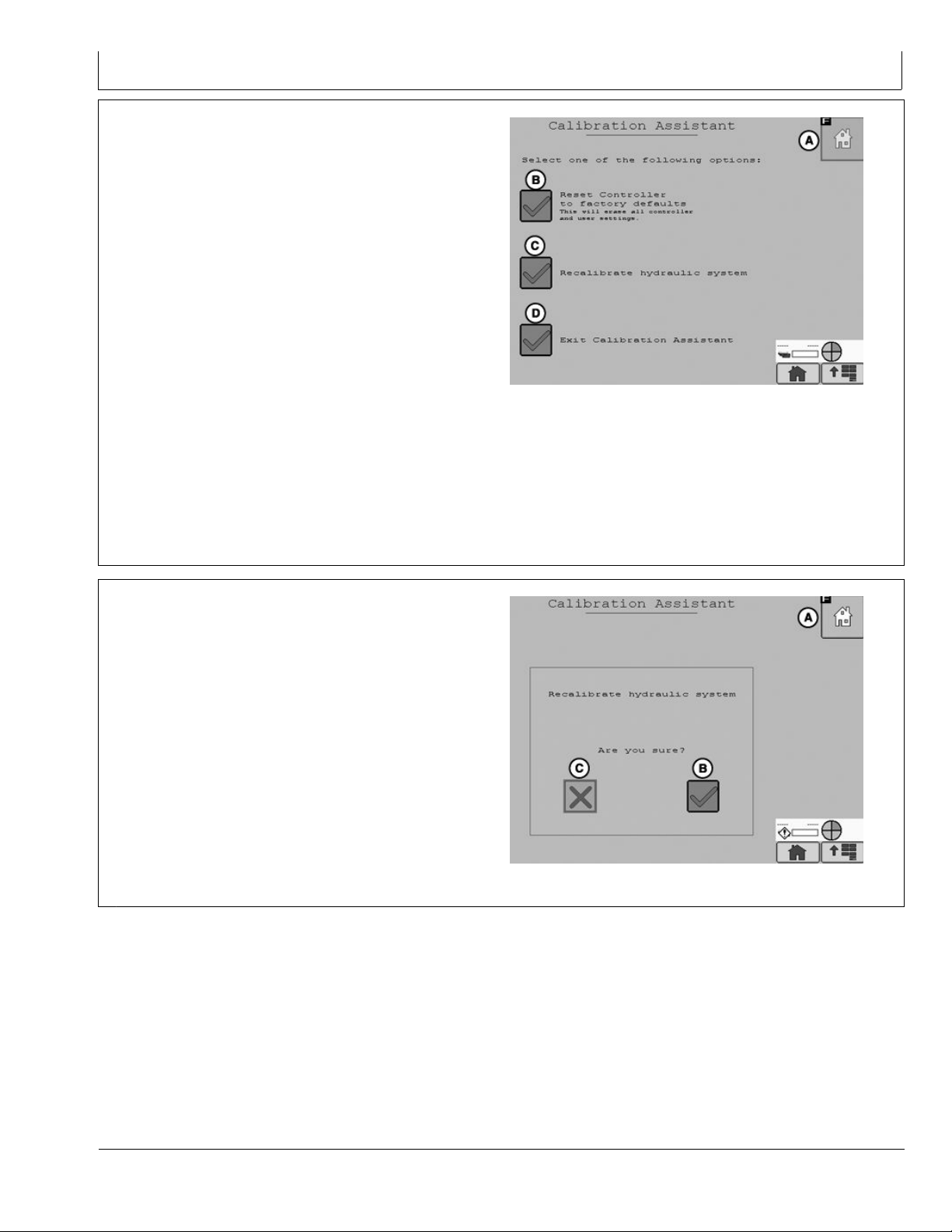

IMPORTANT: Read all instructions before calibrating

the AutoTrac Controller

AutoTrac calibration should completed without

an implement connected to the tractor to avoid

damage to the tractor or implement.

Drive tractor slowly at full throttle for approximately

•

2 to 5 minutes to bring hydraulic uid to operating

temperature before beginning calibration procedure.

Calibration procedure will require a large, open, level

•

surface to complete the required steps.

Calibration procedure must be completed prior to using

•

AutoTrac for the rst time.

Calibration procedure must be complete with a passing

•

status prior to using AutoTrac. If a passing status is not

achieved then AutoTrac will not work.

NOTE: At any time during calibration, the operator

may take control of the system by grabbing the

steering wheel or stopping the machine.

To begin calibration select Recalibrate Hydraulic System

button (C) form the Calibration Assistant Main screen.

Calibration Assistant Main Screen

A—Home

B—Reset controller to Factory

Defaults

PC13385 —UN—20APR11

C—Recalibrate Hydraulic

System

D—Exit Calibration Assistant

BA31779,0000223 -19-04AUG11-4/21

To proceed with the calibration process select yes (B) to

proceed or select no (C) to cancel.

A—Home

B—Yes

C—No

PC13387 —UN—20APR11

Recalibrate Hydraulic System

Continued on next page BA31779,0000223 -19-04AUG11-5/21

25-2

090811

PN=15

Page 16

AutoTrac Controller—Raven

Select the machine type from the drop down menu (A)

then select the Next Button (B).

A—Drop Down Menu B—Next

Select Kit type from the drop down menu (A). If the Kit was

installed by the factory select Factory, if it was not installed

at the factory select Field. Select Next (B) to proceed,

select previous (C) to return to the Machine Type screen.

PC13388 —UN—20APR11

Machine Type

BA31779,0000223 -19-04AUG11-6/21

A—Drop Down Menu

B—Next

C—Previous

Select Start (B) to calibrate the SID (steering input device).

Select Previous to return to the Kit Type screen.

A—Previous

B—Start

PC13389 —UN—20APR11

Kit Type

BA31779,0000223 -19-04AUG11-7/21

SID Calibration

Continued on next page BA31779,0000223 -19-04AUG11-8/21

25-3

PC13390 —UN—28JUL11

090811

PN=16

Page 17

AutoTrac Controller—Raven

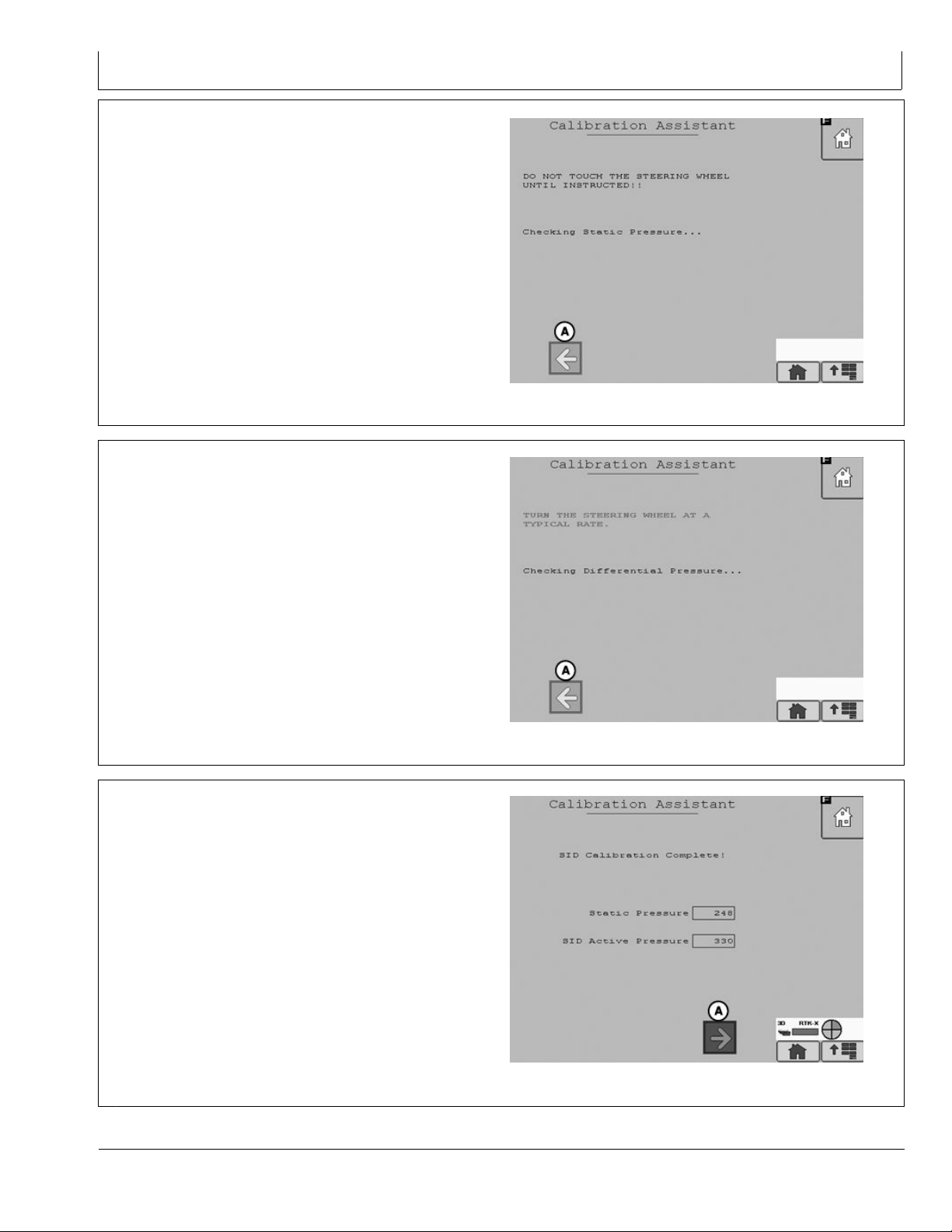

SID will start calibration. Do not touch the steering wheel

until instructed. AutoTrac will perform a static pressure

test .

A—Previous

When instructed turn the steering wheel at a normal rate.

AutoTrac will perform a Active Pressure test.

NOTE: Turning the steering wheel too fast or too slow

will cause an inaccurate calibration and may cause

undesired AutoTrac performance.

PC13391 —UN—20APR11

SID Calibration

BA31779,0000223 -19-04AUG11-9/21

When the Active pressure test is complete the SID

Calibration Complete screen will appear. Select Next (A)

to proceed to the Resume Switch Status screen.

A—Next

25-4

PC13394 —UN—20APR11

Differential Pressure Test

BA31779,0000223 -19-04AUG11-10/21

PC13395 —UN—20APR11

SID Calibration Complete

Continued on next page BA31779,0000223 -19-04AUG11-11/21

090811

PN=17

Page 18

AutoTrac Controller—Raven

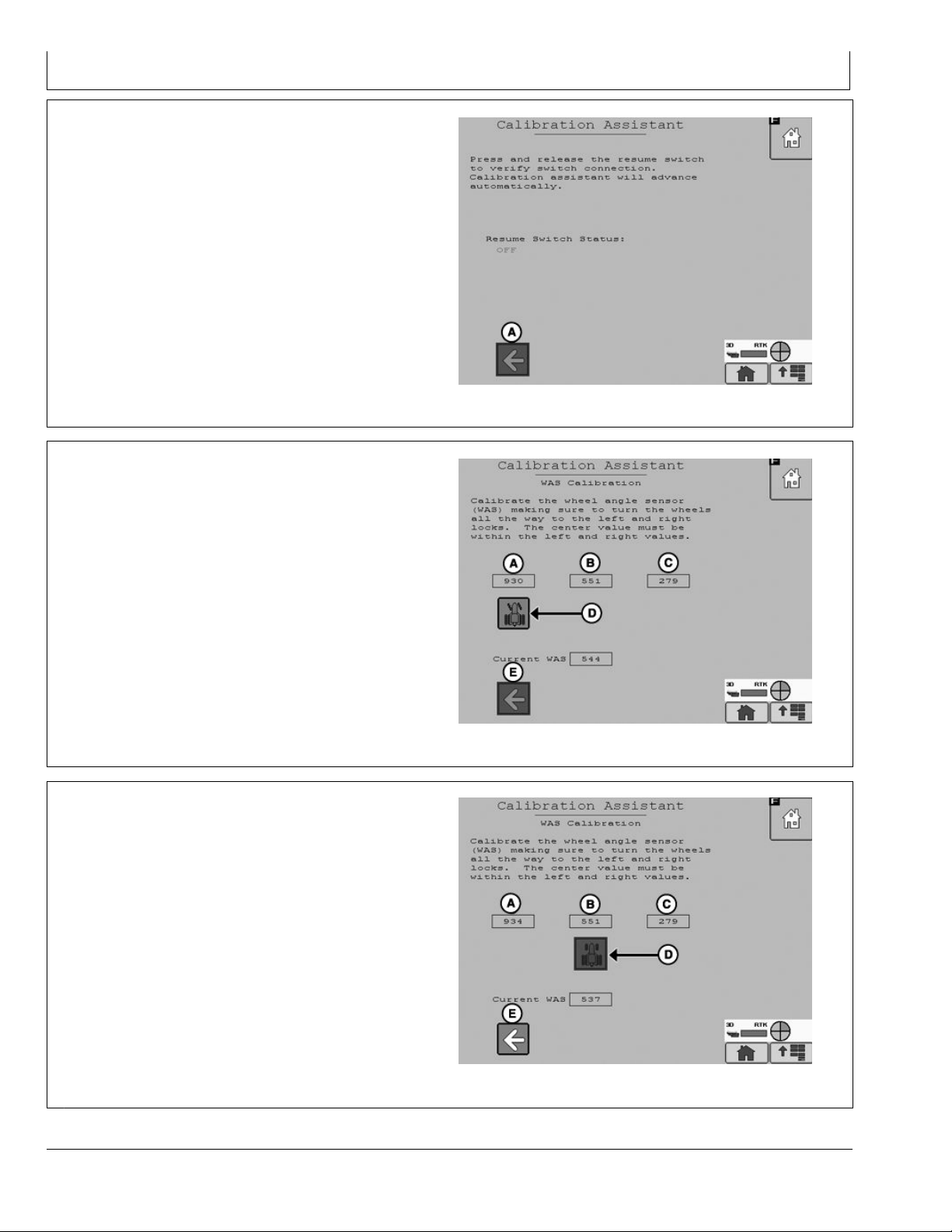

Press and release the resume switch. The red “OFF” text

will change to green “ON” text when the button is pressed

and back to red “OFF” text when the button is released.

When successful the screen will change to the WAS

(Wheel Angle Sensor) Calibration screen.

Select previous to return to SID calibration.

A—Previous

NOTE: It is important that the wheels are turned all of the

way to the left and right during the WAS Calibration

or undesired AutoTrac operation may occur.

PC13396 —UN—20APR11

Resume Switch Status

BA31779,0000223 -19-04AUG11-12/21

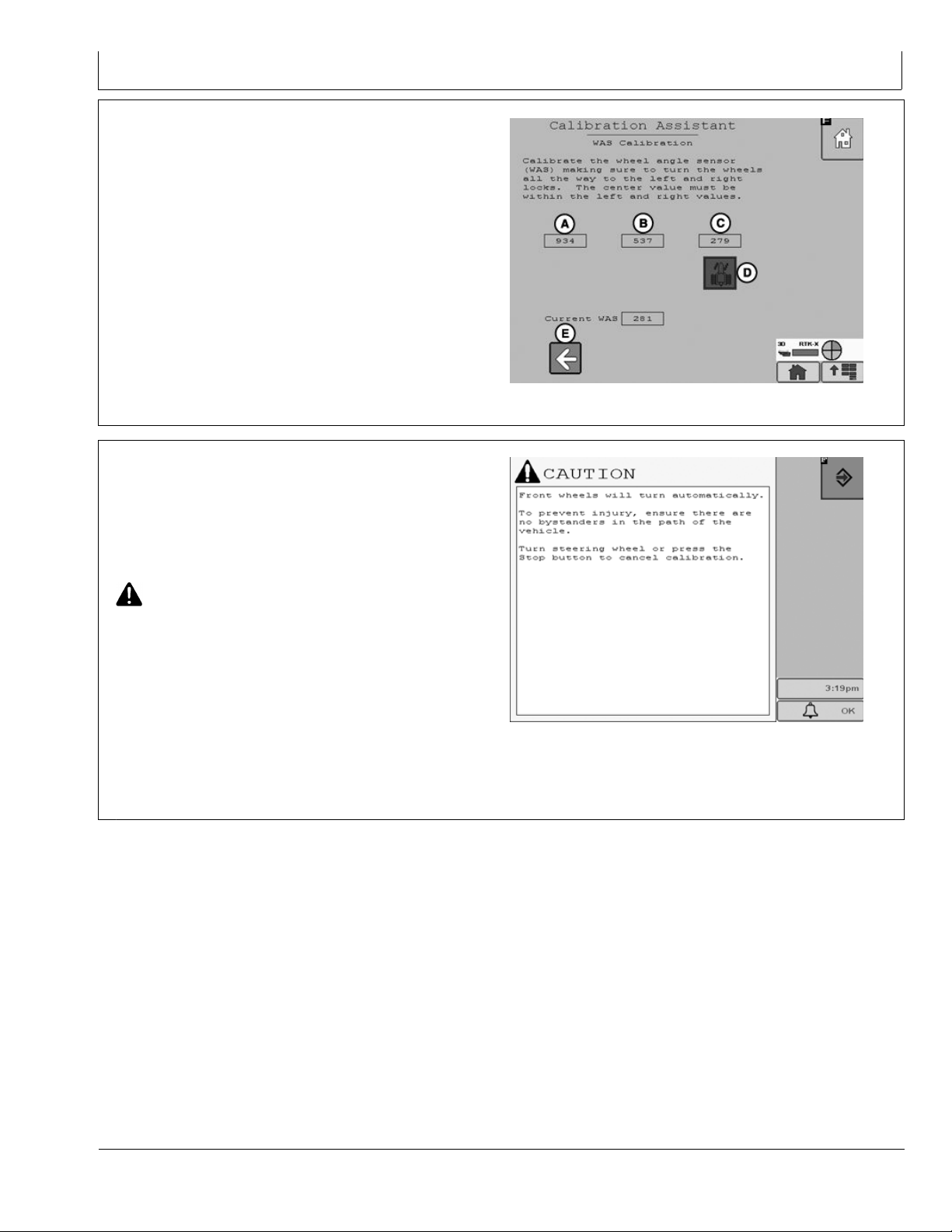

Turn the steering wheel left all the way to the wheels stops

and select the tractor icon (D). Selecting the tractor icon

will make the icon move under the WAS Center Value (B).

A—WAS Left Value

B—WAS Center Value

C—WAS Right Value

D—Tractor Icon

E—Previous

NOTE: An accurate center WAS calibration is critical to

have desired AutoTrac operation. Driving a short

distance looking down the center of the hood and

turning your wheels so that you drive straight to a

xed point on the horizon maybe required.

Turn the steering wheel so the wheels are pointing straight

forward and select the tractor icon (D). Selecting the

tractor icon will make the icon move under the WAS Right

Value (C). Selecting previous will make the tractor icon

move under the WAS Left Value (A) allowing the operator

to change the WAS Left Value.

PC13397 —UN—20APR11

WAS Calibration Left

BA31779,0000223 -19-04AUG11-13/21

A—WAS Left Value

B—WAS Center Value

C—WAS Right Value

D—Tractor Icon

E—Previous

WAS Calibration Center

Continued on next page BA31779,0000223 -19-04AUG11-14/21

25-5

PC13398 —UN—20APR11

090811

PN=18

Page 19

AutoTrac Controller—Raven

Turn the steering wheel all the way to the right wheel stops

and select the tractor icon (D). Selecting the tractor icon

will complete the WAS Calibration process and navigate

to the Valve Autocalibration screen.

Selecting Previous will make the tractor icon move under

the WAS Center Value (B) allowing the operator to change

the WAS Center Value.

NOTE: The WAS Center Value must be between the

WAS Left Value and the WAS Right Value for

the WAS Calibration to be valid.

A—WAS Left Value

B—WAS Center Value

C—WAS Right Value

D—Tractor Icon

E—Previous

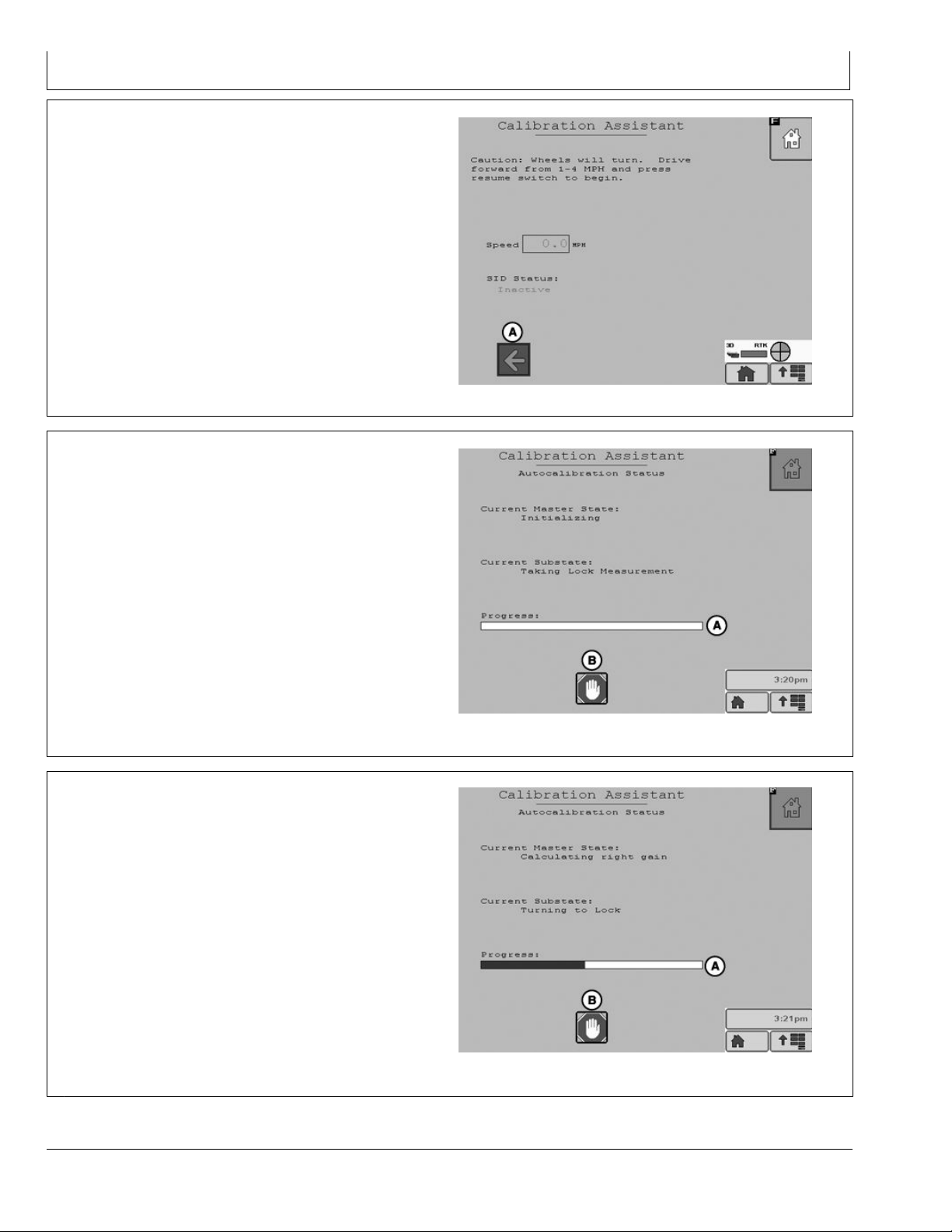

Front wheels will turn automatically.

To prevent injury, ensure there are no bystanders in the

path of the vehicle.

Turn steering wheel or press the Stop button to cancel

calibration.

CAUTION: Calibration procedure will require

a large, open, level surface to complete

the required steps.

Check for bystanders or obstacles before starting

the autocalibration process. Failure to do so

may cause injury to yourself, or others. Severe

damage to the machine could also occur.

NOTE: You can abort the autocalibration procedure and

take over control at any time by manually turning

the steering wheel. This will result in a failed

calibration. When you restart the autocalibration

it will begin where it left off.

PC13399 —UN—20APR11

WAS Calibration Right

BA31779,0000223 -19-04AUG11-15/21

PC13874 —UN—28JUL11

Continued on next page BA31779,0000223 -19-04AUG11-16/21

25-6

090811

PN=19

Page 20

AutoTrac Controller—Raven

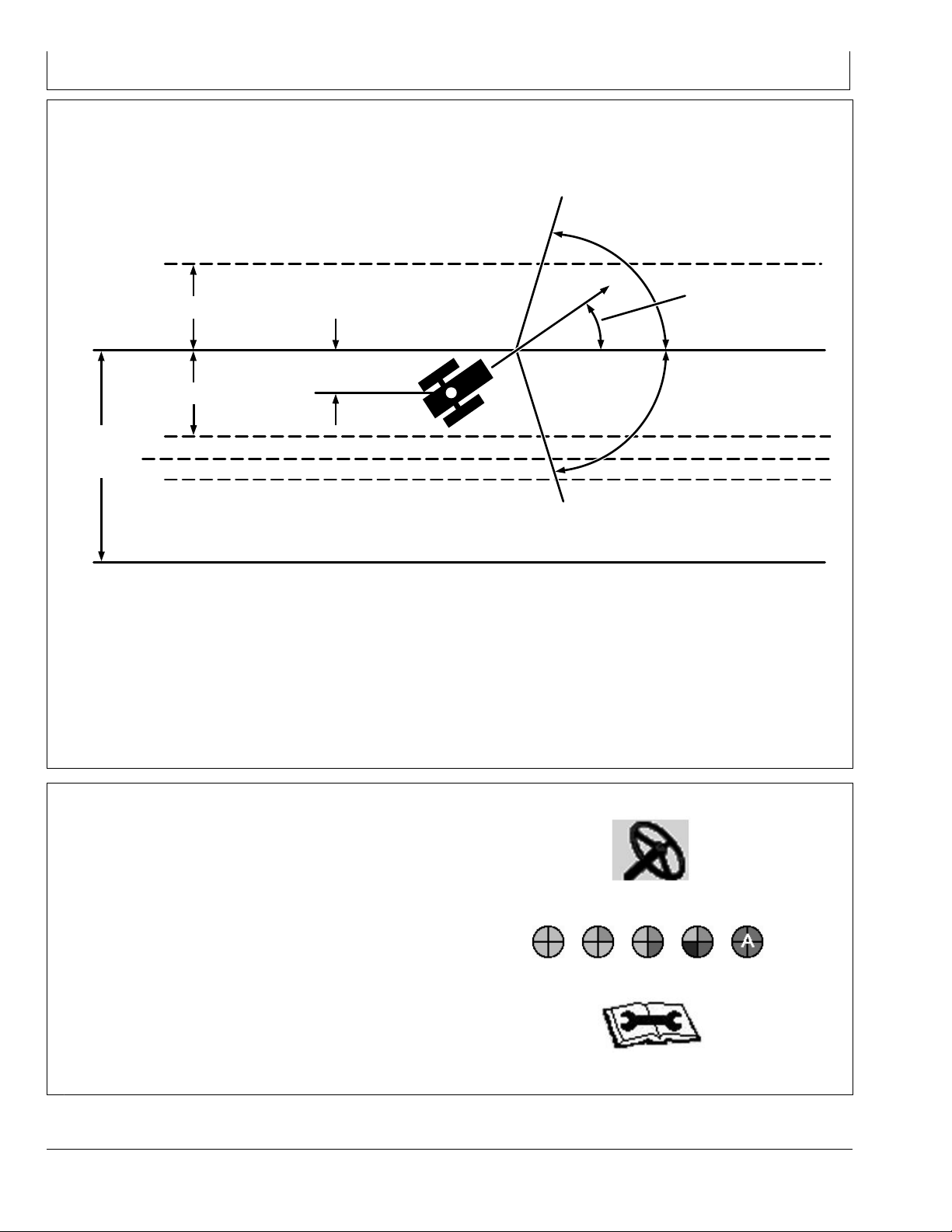

To start the Valve autocalibration process the machine

must be moving forward at 1 to 4 mph. When the machine

is moving at 1 to 4 mph press the resume switch to start

the autocalibration process.

Select previous (A) to navigate back to WAS Calibration.

A—Previous

The autocalibration screen will display when the resume

button is pressed. The progress bar (A) will start to ll

during the autocalibration process.

To stop autocalibration select Stop (B) at any time. The

operator can also turn the steering wheel at anytime to stop

autocalibration. If the autocalibration is stopped at any

time it must be completed before AutoTrac will operate.

PC13400 —UN—20APR11

BA31779,0000223 -19-04AUG11-17/21

NOTE: Do not turn the steering wheel during the

autocalibration process unless it is an emergency.

Turning the steering wheel will cause the test to

stop. If the test is stopped it must be completed

before AutoTrac will operate.

A—Progress Bar

B—Stop

Autocalibration process will go through several steps. The

last step is calculating right min. The Progress bar will ll

completely indicating the autocalibration is nished.

A—Progress Bar

PC13401 —UN—28JUL11

Autocalibration Status

BA31779,0000223 -19-04AUG11-18/21

PC13402 —UN—28JUL11

Calculating right min

Continued on next page BA31779,0000223 -19-04AUG11-19/21

25-7

090811

PN=20

Page 21

AutoTrac Controller—Raven

During the valve calibration if the Stop button is pressed

or the steering wheel is moved the user is given the option

to continue (A) the calibration or cancel (B).

A—Continue B—Cancel

When autocalibration is complete the main screen will

appear. If the calibration completed successfully then

system state (A) will read “READY”. If the calibration

failed system state (A) will read “FAULT”. If calibration

failed select CAL (B) to start the calibration process over.

PC13964 —UN—03AUG11

BA31779,0000223 -19-04AUG11-20/21

If the calibration process was aborted or not completed

the system state (A) will read “Calibration Started”.

If the calibration is successful then the Tool Box (C) will

appear on the screen. Tool Box gives access to vehicle

health test.

NOTE: Vehicle health test should only be completed

by a dealer.

Selecting system information (D) will display information

about the AutoTrac system.

A—System State Ready

B—CAL

C—Tool Box

D—Information

Failed Calibrations

If calibration failure persists, check the Message Center

and/or contact your John Deere dealer.

A failed calibration may be the result of:

Incorrect inputs provided by the operator

•

System State

BA31779,0000223 -19-04AUG11-21/21

Not enough area to complete calibration without

•

stopping during the calibration step

Grabbing the steering wheel to avoid obstacles

•

Wheel angle sensor not responding

•

Valve not responding.

•

Machine hardware failure

•

CF86321,0000337 -19-23MAY11-1/1

PC13403 —UN—20APR11

25-8

090811

PN=21

Page 22

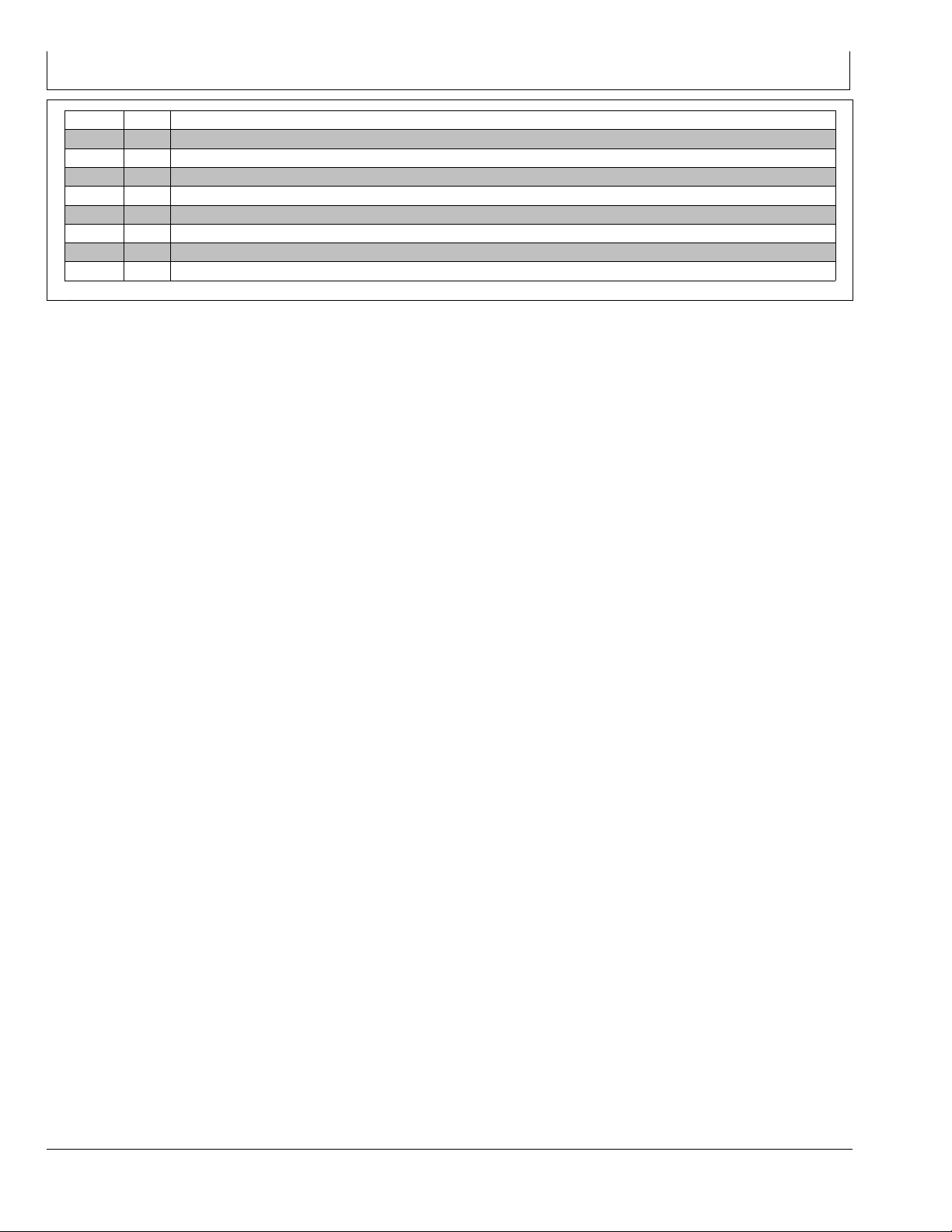

AutoTrac Controller—Raven

80˚

80˚

40%

40%

Track

Spacing

Track No. 0

Off-Track

Lateral Error

Track No. changes at 50%

Track Heading

Error

Track No. 1-S

Necessary Conditions for Activating

AutoTrac

Once tractor is at end of row operator must turn system

to next pass. By turning steering wheel, AutoTrac is

deactivated. Operator must turn onto next track.

AutoTrac can be activated by pressing resume switch only

after following conditions are met:

NOTE: Calibration procedure must be complete with a

Once two pieces of the PIE are achieved, the operator

can enable AutoTrac by selecting the Steer On icon.

If two pieces of the PIE can not be achieved, the operator

The Diagnostics page will indicate what is needed for each

of the four PIE pieces and the status of all requirements.

AutoTrac may not become available until hydraulic

temperature has reached pre set level (1 PIE piece only

until warm). This issue will not provide any diagnostic

code or show in the status menu.

passing status prior to using AutoTrac.

will not be able to activate AutoTrac.

A diagnostic button is located next to the PIE icon.

•

If two pieces of the PIE can not be achieved, select

•

wrench icon to view AutoTrac Diagnostics.

1. System is enabled (steering ON on RUN screen).

2. The machine is within 40% of track spacing.

3. Track heading is within 80° of track.

CF86321,0000338 -19-23MAY11-1/2

PC11972 —UN—09APR09

PC11971 —UN—09APR09

Steer On icon

PC11973 —UN—09APR09

AutoTrac Diagnostics Wrench

Pie Pieces

CF86321,0000338 -19-23MAY11-2/2

PC7051 —19—04FEB02

25-9

090811

PN=22

Page 23

AutoTrac Controller—Raven

AutoTrac Controller—Raven Diagnostic

PC8663 —UN—05AUG05

Addresses

Diagnostic Adresses

Select Diagnostic Address button and a list of controllers

will appear and controllers with diagnostic codes are

indicated.

Individual controllers can be accessed by pressing

ENTER button to view codes for that controller.

To view the AutoTrac Controller Raven select ACI.001

Implement form the device drop down menu.

Codes can also be displayed for all controllers by

selecting SHOW ALL button and pressing ENTER button.

Codes can be relayed to a John Deere dealer to assist in

diagnosing machine problems.

All diagnostic codes below are specic to AutoTrac

Controller—Raven.

Diagnostic Address Description

001

003 ELX Voltage

004 Battery voltage

005 5V Regulator Voltage at the Regulator

008

009

010

013

014

015

016

019

023 Max Flow Rate Test

025

031 Adjustable Parameter-Heading Lead

037 AutoTrac Aggressiveness

048

051

052

053

054

056 Auto Trac Hours

060

061

062

063

065 Lateral Error

067 Heading Error

071 Lateral Error Accumulator

076

Recall Trouble Codes

LS pressure Sensor Voltage

LS Pressure Sensor-Measured pressure in kpa

WAS/Gyro Sensor Voltage

WAS Calibrated Center Voltage

WAS Calibrated Full-Left Voltage

WAS Calibrated Full-Right Voltage

WAS Actual Wheel Angle

GPS Speed kph

Closed-loop Step Response Test

Adjustable Parameter-Inner-Loop Gain

Adjustable Parameter-Heading Gain

Adjustable Parameter-Curvature Sensitivity

Adjustable Parameter-Acquisition Sensitivity

Adjustable Parameter-Lateral Gain

Auto Trac Exit Code

Steer Switch-Resume Switch-Auto Trac State

Parallel Tracking-Keycard Present-TCM State

Seat/Track Number/GPS Status

Engineering Diognostics Enable/Disable

PC8655 —UN—05AUG05

PC8668 —UN—05AUG05

MENU button

MESSAGE CENTER button (With Info Icon)

Diagnostic Addresses

Continued on next page CF86321,0000339 -19-28JUN11-1/2

25-10

090811

PN=23

Page 24

AutoTrac Controller—Raven

Diagnostic Address Description

077

078

079 Yaw-Rate

080

081

082

083

084

085

086

087

088

089

090

091

092

093

110

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

200 Password

219

220

Actual Curvature

Target Curvature

Inner loop Gain Proportional

Inner Loop Gain Integral

Inner Loop Gain Derivative

Inner Loop Filtered Constant 1

Inner Loop Filtered Constant 2

Valve Left Gain

Valve Right Gain

Valve Left Deadband (%)

Valve Right Deadband (%)

Signal to valve (%)

Current draw from valve (Power line) (mA)

Pressure Sensor 2 Voltage

Pressure Transducer 2 (kPa)

Pressure Differential (kPa)

Steering Override Setting - SID Disengage Pressure Setting (kPa)

Valve Left Gain 1

Valve Left Gain 2

Valve Left Gain 3

Valve Left Gain 4

Valve Left Gain 5

Valve Left Gain 6

Valve Left Gain 7

Valve Left Gain 8

Valve Left Gain 9

Valve Left Gain 10

Valve Right Gain 1

Valve Right Gain 2

Valve Right Gain 3

Valve Right Gain 4

Valve Right Gain 5

Valve Right Gain 6

Valve Right Gain7

Valve Right Gain 8

Valve Right Gain 9

Valve Right Gain 10

Controller Conguration Data Part Number

Controller Conguration Data Version Number

CF86321,0000339 -19-28JUN11-2/2

25-11

090811

PN=24

Page 25

AutoTrac Controller—Raven

AutoTrac Controller—Raven Diagnostic

Trouble Codes

Select TROUBLE CODES button, a list of controllers will

appear and controllers with diagnostic codes are indicated.

Individual controllers can be accessed by pressing

ENTER button to view codes for that controller.

Codes can also be displayed for all controllers by

selecting SHOW ALL button and pressing ENTER button.

Codes can be relayed to a John Deere dealer to assist in

diagnosing machine problems.

SPN

168 3

168 4

232 9

517 9

628 12

630 13

1504 9

1504 14

1504 31

3509 3

3509 4

3509

3509 6

1807

1807 6

520431

520431 6

522385 1

522387

522390 9 Abnormal Update Rate

522394 9

523698 9

523767 2

523795 2

523795 11 Indicates steering valve deadbands inconsistent

523795 13

523795 12

523824

FMI Description

Steering Controller unswitched supply voltage (cc# 182) out of range high

Steering Controller unswitched supply voltage (cc# 182) out of range low

Loss of StarFire Differential Status Message (PGN 65535/0x53)

GPS Speed Message Missing

Indicates control unit Steering Controllerbeing reprogrammed (boot block generated). Reprogram control unit Steering

Controller. Replace control unit Steering Controller if condition persists.

Indicates incomplete calibration of steering valve. Wheel Angle Sensor calibration incomplete. AutoTrac will remain disabled

until successful calibration of system.

Operator out of seat during AutoTrac

Operator out of seat during AutoTrac

Operator out of seat during AutoTrac - within 2 to 7s

Indicates sensor supply voltage (cc# 733) for steering wheel pressure sensor and/or wheel angle position sensor out

of range high.

Indicates sensor supply voltage (cc# 733) for steering wheel pressure sensor and/or wheel angle position sensor out

of range low.

5

Steering Wheel Position Sensor 1 Circuit Current Low

Steering Wheel Position Sensor 1 Circuit Current High

5

Steering Wheel Angle

Steering Wheel Angle

5

Isolation Shutoff Valve Circuit Current Low

Isolation Shutoff Valve Circuit Current Current High

Indicates that the AutoTrac Controller ON/OFF switch on vehicle is not ON. Switch AutoTrac master switch to ON position.

7

Indicates control unit Steering Controller not receiving wheel angle position sensor signal.

TCM Messages Missing

IVS Display Message Missing

AutoTrac Resume Switch Circuits Conict

Indicates steering valve orientation incorrect. Check steering valve right/left circuit codes switched.

The deadband is out of range.

EH Valve or harness fault

5

Controller - Not in FMEA

PC8663 —UN—05AUG05

PC8655 —UN—05AUG05

PC8669 —UN—05AUG05

MESSAGE CENTER button (With Info Icon)

MENU button

TROUBLE CODES softkey

Continued on next page CF86321,000033A -19-28JUN11-1/2

25-12

090811

PN=25

Page 26

AutoTrac Controller—Raven

SPN

523824 6

523826 0

523826 1

523826 2

523826

523826 10

523826 14

FMI Description

Controller - Not in FMEA

Wheel Angle Sensor Primary Signal High

Wheel Angle Sensor Primary Signal Low

Steering Controller Calibration / Wheel Angle Sensor Polarity

7

Wheel Angle Sensor Primary Fault/No Motion

Wheel Angle Sensor Fault/No SID Motion

Primary and Secondary Wheel Angle Sensor Conict

524221 9 Vehicle Yaw Rate Message Missing

CF86321,000033A -19-28JUN11-2/2

25-13

090811

PN=26

Page 27

GS2 Display 1800

Automatic Guidance System Detected

Each time a machine equipped with AutoTrac is started,

this screen will appear as a reminder of operator

responsibilities when using AutoTrac steering system.

Enabling System

PC13157 —19—17FEB11

Automatic Guidance

CF86321,000038D -19-01JUN11-1/1

Press STEER ON/OFF button to toggle between

enable/disable AutoTrac.

To enable system, all of the following criteria must be met:

AutoTrac activation is detected.

•

Activating System

CAUTION: While AutoTrac is activated, operator

is responsible for steering at end of path

and collision avoidance.

Do not attempt to turn on (Activate) AutoTrac

system while transporting on a roadway.

After system has been ENABLED, operator must manually

change system to ACTIVATED status when steering

assistance is desired.

Press resume switch. This will initiate assisted steering.

Track 0 has been setup.

•

Tracking mode selected.

•

Proper operator presence mode selected.

•

TCM must be installed and turned on.

•

AutoTrac Controller Steering Kit is plugged in.

•

CF86321,000038E -19-01JUN11-1/1

In order to activate system following criteria must be met:

Vehicle speed is greater than 0.5 km/h (0.3 mph).

•

Forward vehicle speed is less than 30 km/h (18.6 mph)

•

Reverse vehicle speed is less than 10 km/h (6.0 mph).

•

Vehicle within 45 degrees of desired track.

•

Operator is seated.

•

TCM is on.

•

In reverse AutoTrac will remain activated for 45

•

seconds. After 45 seconds the machine must be put in

a forward gear before reverse will activate again.

CF86321,000038F -19-01JUN11-1/1

30-1

090811

PN=27

Page 28

GS2 Display 1800

GreenStar Run Page

Path Accuracy Indicator - Is a visual indicator of off-track

error. The indicator consists of eight boxes on each side

of the off-track error box. The boxes will light up indicating

the direction the vehicle must be steered to get back on

the AB line. Each arrow represents a distance (default is

10 cm (4 in.)). This distance and the steering direction

may be dened on the Lightbar Settings Page:

GreenStar Main Page -> Settings -> Guidance Settings

-> Lightbar Settings

Off Track Error (A)– Off Track error is numerically displayed

in the box. Off Track error will be displayed in cm (inches)

up to 99 cm (35 in.). If Off Track error exceeds 99 cm (35

in.), the distance displayed will change to meters (feet).

Track number (B)– Represents the track number the

vehicle is guiding on. It also shows the direction that the

track is located from the original Track 0 for the eld.

PC13962 —UN—01AUG11

PC10857JN —UN—13APR09

Guidance Icon (C)– The icon represents the machine and

implement in relative dimensions. The triangle on the

machine represents the control point, which as used for

guiding the machine and is dened by the machine offset

measurements.

GPS Indicator (D)— Indicates what level of accuracy the

StarFire receiver is currently operating at (3D, SF2, SF1,

RTK). If using a GPS receiver other than a StarFire, the text

3D GPS will be displayed but the indicator bar will not ll.

AutoTrac Status Pie (E)(See AutoTrac section)

NOTE: Some softkeys only appear when the

hardware or functions associated with those

buttons are connected or available, such as

the AutoTrac controls.

AutoTrac Steer On/Off – Enables and disables AutoTrac

PC10857JF —UN—13APR09

PC10857KZ —UN—14APR09

A—Off Track Error

B—Track number

C—Guidance Icon

PC13711 —UN—16MAY11

Continued on next page BA31779,000024B -19-01AUG11-2/23

GreenStar Main Page

Settings Button

Guidance Settings

D—GPS Indicator

E—AutoTrac Status Pie

BA31779,000024B -19-01AUG11-1/23

Auto Steer On/Off

30-2

090811

PN=28

Page 29

GS2 Display 1800

Select the Settings button. This will give the operator the

option to increase or decrease the steering sensitivity and

Direction Toggle button.

Direction Toggle button can be used to change the

direction of the vehicle on the map if it is different than the

direction the machine is traveling.

Recording ON/OFF – Turns coverage recording ON and

OFF when Manual recording source is selected.

PC13959 —UN—01AUG11

PC10857LB —UN—14APR09

PC10857LC —UN—14APR09

PC13960 —UN—01AUG11

PC10857LD —UN—14APR09

Increase AutoTrac Steering Sensitivity

Decrease AutoTrac Steering Sensitivity

Settings

Direction Toggle

BA31779,000024B -19-01AUG11-3/23

ShiftTrack – Go to the following Shift Track Controls.

Shift Track is used to adjust position of machine left,

center, or right of the set track. Shift track can be used to

compensate for GPS drift. Drift is inherent to any satellite

based, differentially corrected GPS system.

Shift Track Left

Shift Track Right

Recording ON/OFF

BA31779,000024B -19-01AUG11-4/23

PC10857NC —UN—24SEP09

ShiftTrack

BA31779,000024B -19-01AUG11-5/23

PC10857LE —UN—14APR09

Shift Track Left

BA31779,000024B -19-01AUG11-6/23

PC10857LF —UN—14APR09

Shift Track Right

Continued on next page BA31779,000024B -19-01AUG11-7/23

30-3

090811

PN=29

Page 30

GS2 Display 1800

Shift Track Center

Clear Shifts

Back to Run Page Softkeys

Map Controls – Go to the following Map Controls

PC10857LG —UN—14APR09

Shift Track Center

BA31779,000024B -19-01AUG11-8/23

PC10857LH —UN—14APR09

Clear Shifts

BA31779,000024B -19-01AUG11-9/23

PC10857LI —UN—14APR09

Back button

BA31779,000024B -19-01AUG11-10/23

PC10857LJ —UN—14APR09

Toggle Mapping Mode

Pan Map Up

Map Controls

BA31779,000024B -19-01AUG11-11/23

PC10857LK —UN—14APR09

Toggle Mapping Mode

BA31779,000024B -19-01AUG11-12/23

PC10857LM —UN—14APR09

Pan Map Up

Continued on next page BA31779,000024B -19-01AUG11-13/23

30-4

090811

PN=30

Page 31

GS2 Display 1800

Pan Map Left

Pan Map Right

Pan Map Down

Toggle Map Size – Selecting this button increases the

map to full screen, hiding the softkeys. Select the button

again to decrease the maps size and show the softkeys.

PC10857LN —UN—14APR09

Pan Map Left

BA31779,000024B -19-01AUG11-14/23

PC10857LO —UN—14APR09

Pan Map Right

BA31779,000024B -19-01AUG11-15/23

PC10857LP —UN—14APR09

Pan Map Down

BA31779,000024B -19-01AUG11-16/23

PC10857LQ —UN—14APR09

Zoom Out

Zoom In

Toggle Map Size

BA31779,000024B -19-01AUG11-17/23

PC10857LR —UN—14APR09

Zoom Out

BA31779,000024B -19-01AUG11-18/23

PC10857LR —UN—14APR09

Zoom In

Continued on next page BA31779,000024B -19-01AUG11-19/23

30-5

090811

PN=31

Page 32

GS2 Display 1800

Center Map – Centers the map on the vehicle.

Back to Run Page Softkeys

Swath Control ON/OFF Toggle

GreenStar – Go to GreenStar Main Page

PC10857LT —UN—14APR09

Center Map

BA31779,000024B -19-01AUG11-20/23

PC10857LI —UN—14APR09

Back Button

BA31779,000024B -19-01AUG11-21/23

PC10857LU —UN—14APR09

Swath Control ON/OFF Toggle

BA31779,000024B -19-01AUG11-22/23

PC10857JN —UN—13APR09

Enabling AutoTrac

The following criteria must be met for AutoTrac to be

enabled:

Vehicle has an AutoTrac capable steering controller

•

(ACI)

Valid AutoTrac Activation (26 digit Activation Code)

•

Setup Wizard is complete and a guidance track has

•

been created. See the GETTING STARTED section

earlier in this manual for Setup Wizard information

and see the sections on each Guidance Mode for

information on creating guidance tracks.

Correct StarFire signal level for AutoTrac Activation is

•

selected (SF1, SF2, or RTK) and a valid GPS signal

is acquired.

TCM turned on and TCM message is valid

•

GreenStar Main Page

BA31779,000024B -19-01AUG11-23/23

PC13711 —UN—16MAY11

AutoTrac On/Off

ACI has no active faults pertaining to the steering

•

function.

Hydraulic oil warmer than minimum temperature

•

Tractors - above 20°C (68°F)

•

Forward vehicle speed is less than 30 km/h (18.6 mph)

•

Reverse speed is less than 10 km/h (6 mph)

•

To Enable AutoTrac, select the Steer On/Off softkey

located on the Run Page. This softkey will disable

AutoTrac if selected again.

CF86321,0000391 -19-01JUN11-1/1

30-6

090811

PN=32

Page 33

GS2 Display 1800

AutoTrac Status Pie

The AutoTrac Status Pie is shown at the bottom of the

Run Page as a quick diagnostic indicator.

INSTALLED (1/4 of pie)—AutoTrac Steering Controller

and all other necessary hardware are installed.

CONFIGURED (2/4 of pie)—Valid AutoTrac Activation,

Tracking Mode has been determined and a valid Track

0 has been established. Correct StarFire signal level

for AutoTrac Activation is selected (SF1, SF2, or RTK).

Vehicle conditions met.

ENABLED (3/4 of pie)—Steer On/Off softkey has been

selected.

PC8832 —UN—25OCT05

Installed

CF86321,0000392 -19-01JUN11-1/4

PC8833 —UN—25OCT05

Congured

CF86321,0000392 -19-01JUN11-2/4

PC8834 —UN—25OCT05

Enabled

CF86321,0000392 -19-01JUN11-3/4

ACTIVATED (4/4 of pie with “A”)—Resume switch is

pressed and AutoTrac is steering the vehicle.

PC8835 —UN—25OCT05

Activated

CF86321,0000392 -19-01JUN11-4/4

30-7

090811

PN=33

Page 34

Reactivating AutoTrac on Next Pass

A—Track 0

B—Track 1 South

C—Track Spacing

D—Off-Track Lateral Error

GS2 Display 1800

PC8866 —UN—02NOV05

Tracking

E—Track Heading Error

Once the end of the row is reached, the operator must

turn system to next pass. By turning steering wheel,

AutoTrac is deactivated.

AutoTrac can be activated again by pressing Resume

Switch only after following conditions are met:

Forward vehicle speed is less than 30 km/h (18.6 mph)

•

Reverse speed is less than 10 km/h (6 mph).

•

In reverse AutoTrac will remain activated for 45

•

seconds. After 45 seconds the machine must be put in

a forward gear before reverse will activate again.

Deactivating AutoTrac

CAUTION: Always turn off (Deactivate and Disable)

AutoTrac system before entering a roadway.

To turn off AutoTrac, turn the Master Switch

to the OFF position.

AutoTrac system can be made DEACTIVE by the

following methods:

Turning Master Switch to the OFF position.

•

Turning steering wheel.

•

Exceeding speed of 30 km/h (18.6 mph).

•

Degradation of differential correction signal from SF2 or

•

RTK to WAAS/ EGNOS for longer than 3 minutes.

Selecting the STEER ON/OFF button.

•

Vehicle heading is within 80° of desired track.

•

The machine is within 40% of track spacing

•

Operator is seated.

•

TCM is on.

•

NOTE: The Track Number that is displayed at the top

of the RUN PAGE changes at half the distance

between two guidance tracks.

CF86321,0000393 -19-01JUN11-1/1

PC10857LA —UN—14APR09

Steer On/Off Softkey

Operator out of seat for more than 7 seconds.

•

Machine traveling less than 0.5 kph (0.3 mph) for 30

•

seconds.

In reverse for longer than 45 seconds.

•

Reverse speed exceeds 9.6 km/h (6 mph).

•

The master switch removes power from the EH Valve to

prevent AutoTrac from being unintentionally activated. The

master switch is intended for use on roadways or when

the operator does not want AutoTrac able to be activated.

BA31779,0000240 -19-26JUL11-1/1

30-8

090811

PN=34

Page 35

GS2 Display 1800

Guidance Settings

Optimal performance of the GreenStar system usually

requires adjustment of settings. Access Guidance settings

to customize your user experience and optimize the

system performance.

General Settings

Turning View - assists the operator view the next track

when turning around. To turn ON/OFF, select / unselect

check box.

Turn Predictor - alerts operator by predicting the end of

pass. To turn ON/ OFF, select / unselect check box.

Tracking Tones – provide an audible indication off-track

error. To turn ON/ OFF, select / unselect check box. To

change distance at which tracking tones make a sound,

select input eld, scroll the thumb wheel to the desired

value, and press Enter. Values between 10—60 cm

(4—24 in.) may be entered.

Lead Compensation – shows how far down current track

guidance looks to for such things as turns. It is used with

Shift Track – is used to adjust the position of guidance

tracks left or right to compensate for GPS drift. This

setting will turn shifts ON/OFF, select small shifts or large

shifts, and change the distance of each shift.

PC10857JN —UN—13APR09

PC10857JF —UN—13APR09

PC10857NG —UN—27APR09

GreenStar Main Page

Settings

Guidance Settings

Parallel Tracking only. To turn ON/OFF, select / unselect

check box.

CF86321,0000395 -19-01JUN11-1/2

Shifts Off – Check the box to turn shifts OFF.

Small Shifts – Select Small Shifts to use a Shift Size of

1—30 cm (0.4—12 in.).

Large Shifts – Select Large Shifts to use a Shift Size of

1— 410cm (12-161.5 in.). Large Shifts are disabled when

AutoTrac is active or when operating in Adaptive Curve

Track mode.

Shift Size – Distance that tracks shift when SHIFT LEFT

or SHIFT RIGHT buttons are selected.

PC10857NH —UN—27APR09

CF86321,0000395 -19-01JUN11-2/2

30-9

090811

PN=35

Page 36

GS2 Display 1800

AutoTrac Settings

NOTE: AutoTrac Settings only appear on the display

in machines that are AutoTrac capable.

Steering Sensitivity—Allows AutoTrac users to adjust

the vehicle’s steering sensitivity. To adjust steering

sensitivity select the input box and enter the desired

steering sensitivity value via numeric keypad and select

the enter button. The sensitivity can also be adjusted up

or down by selecting the Increase Steering Sensitivity and

Decrease Steering Sensitivity softkeys on the Run Page.

NOTE: Valid range for steer sensitivity is 50 - 200 with

200 being the most aggressive setting.

Direction Toggle

To be able to select the Direction Toggle Button the left

region of the home page must be setup correctly. Setting

up the left hand region will also allow the user to perform

other operations.

1. Select the Layout Manager Button from the main menu

PC10857LB —UN—14APR09

PC10857LC —UN—14APR09

PC13727 —UN—16MAY11

Continued on next page BA31779,000024C -19-01AUG11-2/5

Increase Steering Sensitivity

Decrease Steering Sensitivity

BA31779,000024C -19-01AUG11-1/5

Layout Manager Button

30-10

090811

PN=36

Page 37

GS2 Display 1800

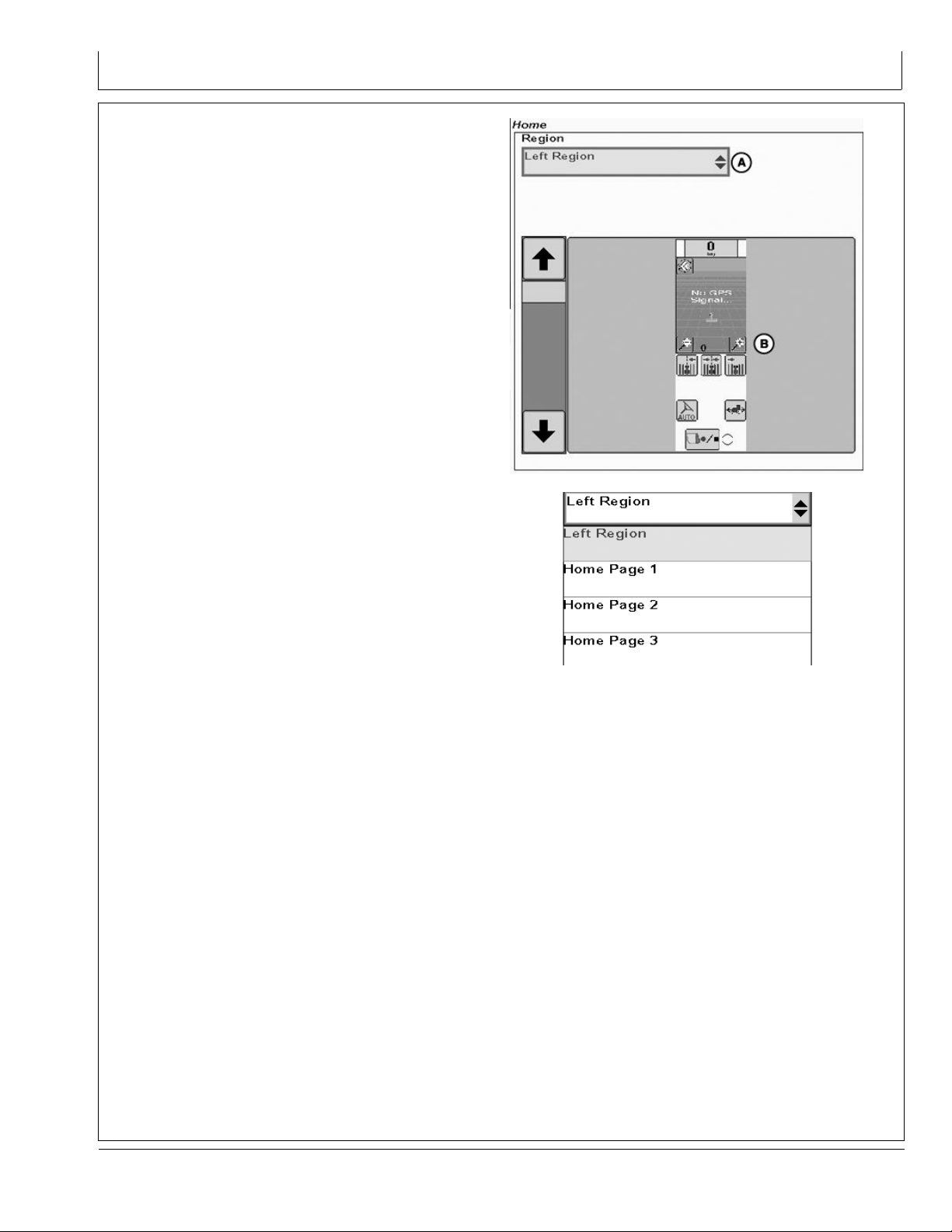

2. In the layout manager home page select left region

from the drop down menu (A).

PC13735 —UN—16MAY11

Layout Manager Home

Region Select

PC13734 —UN—16MAY11

Continued on next page BA31779,000024C -19-01AUG11-3/5

30-11

090811

PN=37

Page 38

GS2 Display 1800

3. In the setup selection (B) of the layout manager home

screen select the left region that displays the Direction

Toggle button (C).

A—Drop Down Menu

B—Setup Selection

C—Direction Toggle

D—AutoTrac On/Off

E—Recording

F— Shift Track Left

G—Center Track

H—Shift Track Right

I— Zoom Page Out

J— Zoom Page IN

K—Toggle Mapping Mode

The Direction toggle button can also be displayed on the

right hand side of the Run Page by selecting the Settings

Button on the run page.

PC13736 —UN—16MAY11

Left Region

BA31779,000024C -19-01AUG11-4/5

30-12

PC13959 —UN—01AUG11

PC13963 —UN—01AUG11

Run Page

Settings

BA31779,000024C -19-01AUG11-5/5

090811

PN=38

Page 39

GS2 Display 1800

Advanced AutoTrac Settings

To access the Advanced AutoTrac settings select the

GreenStar button, select Settings Button, then select

AutoTrac Settings from the Settings home page.

PC10857JN —UN—13APR09

PC10857JF —UN—13APR09

PC13713 —UN—16MAY11

Continued on next page CF86321,0000397 -19-01JUN11-1/4

GreenStar

Settings

AutoTrac Settings

30-13

090811

PN=39

Page 40

GS2 Display 1800

The AutoTrac Settings button will only be visible under

Guidance Settings when an Steering Controller that

supports advanced AutoTrac Integrated settings is

detected.

The Accept button (K) saves and applies the current

settings and returns the user to the previous page. The

Restore Default Settings button (I) will set all settings to

the factory default value. See each setting for its default

value. Next page (J ) will take the user to page 2 of the

Advanced AutoTrac Settings. Selecting Previous page (L)

will take the user to page 1 of the Advanced AutoTrac

Settings The ‘?’ button (A) will display a popup with help

text for the specic setting.

A—Help

B—Steer Sensitivity

C—Line Sensitivity Heading

D—Line Sensitivity Tracking

E—Heading Lead

F— Steering Response Rate

G—Curve Sensitivity

H—Acquire Sensitivity

I— Restore Default Settings

J— Next Page

K—Accept

L— Previous Page

PC13714 —UN—16MAY11

Advanced Settings

Advanced Settings

Continued on next page CF86321,0000397 -19-01JUN11-2/4

30-14

PC13715 —UN—16MAY11

090811

PN=40

Page 41

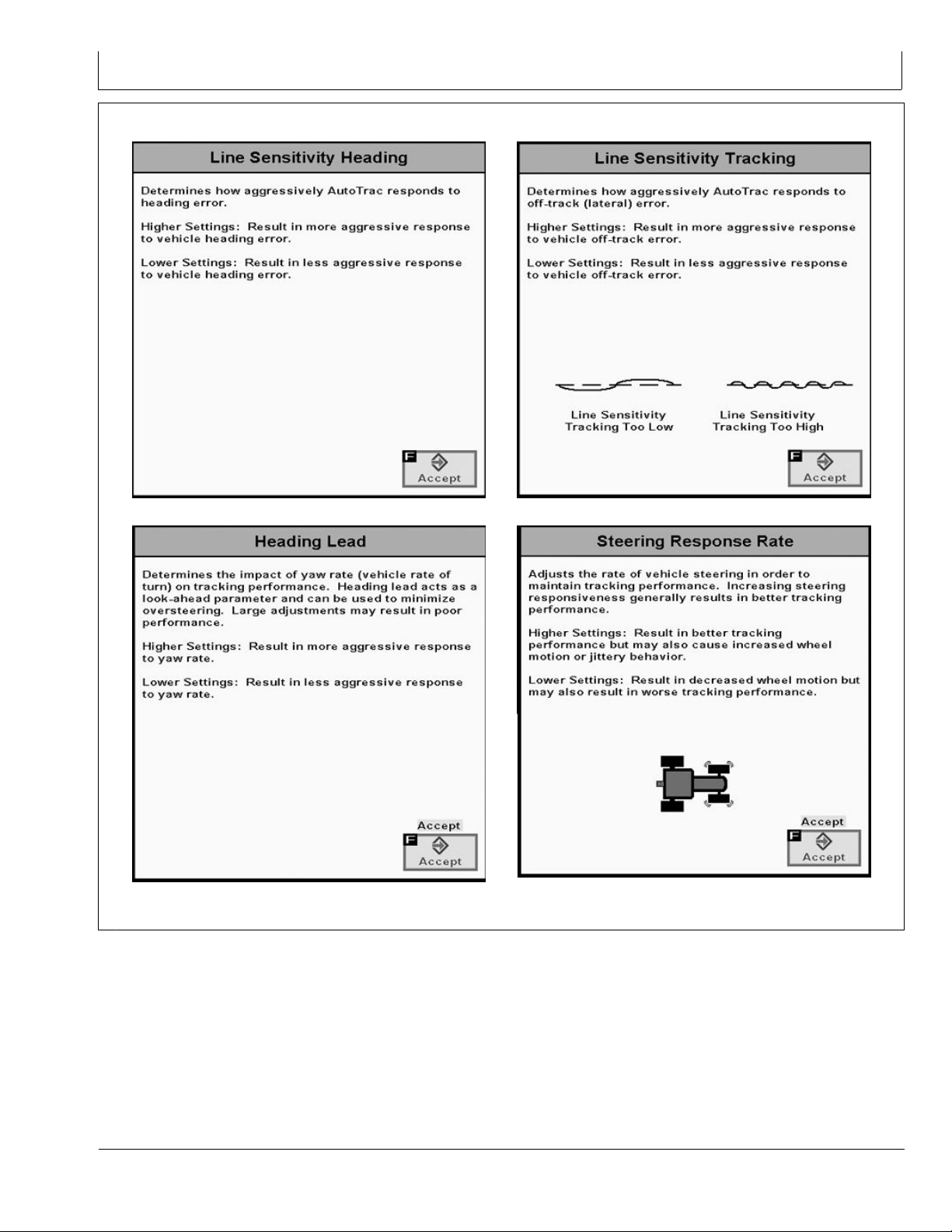

Advanced Settings Help Information

GS2 Display 1800

Line Sensitivity Heading

Heading Lead

PC13716 —UN—16MAY11

PC13717 —UN—16MAY11

Line Sensitivity Tracking

PC13718 —UN—16MAY11

PC13723 —UN—16MAY11

Steering Response Rate

Continued on next page CF86321,0000397 -19-01JUN11-3/4

30-15

090811

PN=41

Page 42

GS2 Display 1800

Curve Sensitivity

StarFire

AutroTrac controller takes its StarFire Height and Fore-Aft

measurements from the StarFire setup. To change

this information select the menu button then select the

StarFire button. The StarFire main page will appear.

Select the Setup tab (A) at the top of the screen.

PC13724 —UN—16MAY11

Acquire Sensitivity

CF86321,0000397 -19-01JUN11-4/4

PC8663 —UN—05AUG05

PC13738 —UN—17MAY11

Continued on next page BA31779,0000225 -19-08JUL11-1/2

Menu Button

SF3000 Button

PC13725 —UN—16MAY11

30-16

090811

PN=42

Page 43

GS2 Display 1800

StarFire Height (in.) Enter the height of the StarFire

receiver into the Height box (C) of the StarFire Setup

screen. Height is measured from the ground to the center

(where the green and yellow meet) of the dome.

StarFire Fore-Aft (in.) Enter the Fore-Aft measurement

into the Fore/Aft box (B) of the StarFire Setup screen.

This is the distance from the xed axle of the machine to

the receiver. The xed axle is the rear axle on a row crop

tractor. The xed axle is the front axle on an articulated

tractor

NOTE: For more information on StarFire setup

see the StarFire operators manual that

matches your equipment.

PC13726 —UN—19MAY11

StarFire Setup Screen

BA31779,0000225 -19-08JUL11-2/2

30-17

090811

PN=43

Page 44

Troubleshooting—GS2 Display 1800

Trouble Codes

Select TROUBLE CODES button, a list of controllers will

appear and controllers with diagnostic codes are indicated.

Individual controllers can be accessed by navigating with

rotary thumb wheel and selected by pressing ENTER

button, to view codes for that controller.

Codes can also be displayed for all controllers by selecting

SHOW ALL button with rotary thumb wheel and pressing

ENTER button. Codes can be relayed to a John Deere

dealer to assist in diagnosing machine problems.

Diagnostic Addresses

PC8663 —UN—05AUG05

PC8655 —UN—05AUG05

PC8669 —UN—05AUG05

MESSAGE CENTER button (With Info Icon)

MENU button

TROUBLE CODES softkey

CF86321,0000331 -19-23MAY11-1/1

MESSAGE CENTER button >> DIAGNOSTIC

ADDRESSES softkey >> DEVICE drop down box >>

“VT;.001 Implement”

PC8655 —UN—05AUG05

PC8668 —UN—05AUG05

Continued on next page CF86321,0000332 -19-23MAY11-1/2

MESSAGE CENTER button

DIAGNOSTIC ADDRESSES softkey

35-1

090811

PN=44

Page 45

Troubleshooting—GS2 Display 1800

COMPONENTS AND SOFTWARE VERSIONS softkey

MESSAGES softkey

TROUBLE CODES softkey

BUS INFORMATION softkey

PC8665 —UN—05AUG05

PC8667 —UN—05AUG05

PC8669 —UN—05AUG05

PC8671 —UN—05AUG05

PC8666 —UN—05AUG05

SOFTWARE INFORMATION softkey

PC8668 —UN—05AUG05

DIAGNOSTIC ADDRESSES softkey

PC8670 —UN—05AUG05

Electronic CONTROL UNIT INFORMATION softkey

Message center will display all active alarm messages.

35-2

CF86321,0000332 -19-23MAY11-2/2

090811

PN=45

Page 46

Troubleshooting—GS2 Display 1800

Guidance Alarms

ACI Communication Error No communication with vehicle steering controller (Steering Controller). Check vehicle for diagnostic codes

Turn Predictor Turned On Turn predictor is turned ON. Use the check box to turn it OFF

AutoTrac Deactivated

AutoTrac

Data Card Problem! A data card must be inserted in the compact ash drive with the door closed to use the GreenStar2 Pro

No Setup Data! Setup data for the GreenStar2 Pro application could not be found on the data card. The GreenStar2 Pro

AutoTrac Steering Controller

Software Incompatible

Communication Error Communication problem with controller. Check connections to controller.

Mobile Processor Detected

GPS Communication Problem No communication with GPS receiver. Check connections at GPS receiver.

Tracking Inaccurate

Invalid Boundary An invalid boundary has been recorded. You may continue recording or clear the current boundary and start

Activation Error Invalid activation code. Please reenter activation code.

Invalid Filter

Flags of Same Selection Selected the Flags of same name and mode.

Name Already Exists The name you have entered already exists in this list. Please enter a new name.

GPS Communication Problem No communication with GPS receiver. Check connection at GPS receiver and perform operation again.

Curve Track Memory Full Internal memory available for Curve Track is full. Data must be cleared to continue Curve Track Operation.

AutoTrac Disabled

AutoTrac Disabled

License Problem

Duplicate Name

Curve Track Recording Curve Track recording in progress. Cannot perform operation until recording is turned off.

Circle Denition Problem There was an internal error during Circle denition. Redene the circle.

Circle Denition Problem Communication with GPS receiver was lost during circle denition. Redene the circle once communication

Circle Denition Problem Center point is too far. Select another center point.

A-B Line Denition Problem There was an internal error during A-B line denition. Redene the A-B line.

A-B Line Denition Problem A timeout occurred during A-B line denition. Redene the A-B line.

A-B Line Denition Problem A and B points of the A-B line are too close. Perform operation again.

Loss of GPS While Recording

Boundary

Data Card Full

Data Card 90% Full

No Memory

Low Memory

No Memory

No Memory

Circle Denition Problem The distance from the vehicle to the center point is greater than 1 mile. Select another center point or drive

Zero All Totals

Incorrect RS232 Controller Model

Selected

Prescription Error

and contact your John Deere Dealer.

AutoTrac system deactivates when operator is out of seat for more than 5 seconds

The operator is responsible for collision avoidance. Turn AutoTrac OFF before entering roadways.

application.

application will not be available until a data card with setup data is inserted

See your John Deere Dealer for Steering Controller update.

Mobile Processor Detected on CAN Bus. GreenStar Application is disabled. Remove mobile processor

and cycle power to enable GreenStar application.

The GPS receiver must be set to report at the 5Hz message output rate. Conrm settings on GPS receiver

and change output to 5Hz,

recording again.

All the elds that are required to be lled out based on the Totals Type Selected have not been lled out.

Alarms

Clear curved track data from system

AutoTrac SF1 license cannot operate with current StarFire software. Update StarFire software to operate

AutoTrac.

AutoTrac SF1 license cannot operate while SF2 corrections are turned on. Turn SF2 corrections off to

operate AutoTrac.

No license available for the selected tracking mode. Previous tracking mode will be selected.

Name already exists. Select another name.

has been re-established.

GPS has been lost while recording the boundary. Point logging will resume when the GPS signal returns. This

may result in an inaccurate boundary.

Unload and cleanup data card or insert new data card.

Unload and cleanup data card or insert new data card.

No Memory available for Curve Track. Unload and cleanup data card or insert new data card.

Low Memory available for Curve Track. Unload and cleanup data card or insert new data card.

No Memory available for Straight Track. Unload and cleanup data card or insert new data card.

No Memory available for Circle Track. Unload and cleanup data card or insert new data card.

another circle.

You have decided to zero all totals for the selected lter.

The RS232 controller model selected is incorrect. Please verify and reenter manufacturer and model number.

Controller is not setup to accept prescriptions.

Continued on next page CF86321,0000333 -19-23MAY11-1/2

35-3

090811

PN=46

Page 47

Troubleshooting—GS2 Display 1800

Prescription Error

Prescription Error

Controller Unit of Measure Error Controller will only operate when using metric units.

Controller Unit of Measure Error Controller will only operate when using English (US) units.

Controller Unit of Measure Error Controller will only operate when using metric or English (US) units.

Controller Operation Error Invalid operation selected for controller.

Prescription Warning

Prescription Warning

Prescription Warning

AutoTrac Deactivation Message

AutoTrac deactivation message–Each time AutoTrac

is deactivated text is displayed indicating the reason

Deactivation Message Description

Steering wheel moved Operator turned steering wheel

Speed too slow

Speed too fast

Invalid gear Vehicle operating in an invalid gear

Track number changed Track number changed

Invalid GPS signal SF1, SF2, or RTK signal was lost

Steering Controller fault See John Deere dealer

Invalid display messages

Invalid display settings

No AutoTrac Activation

Heading error too large

Offtrack error too large Vehicle not within 40% of track spacing

Out of seat Out of seat too long

Oil temp too cold

No TCM corrections Make sure TCM is turned on

Invalid Steering Controller activation Need Steering Controller activation code.

FICA in diagnostic mode Fuse is in diagnostic slot in vehicle fuse box. remove fuse.

Header off Header was turned off

Road mode In transport gear

Invalid Steering Controller voltage See John Deere dealer

Reverse timeout

Vehicle too slow AutoTrac below minimum speed

Curve too sharp

Vehicle not moving in a forward direction Vehicle must be in forward gear to activate

Vehicle shutting down Vehicle is shutting down

Gear data error See John Deere dealer

Resume switch error

Keyswitch error

SPFH AutoTrac switch is not on Make sure SPFH AutoTrac switch is turned on

SPFH Quick Stop switch is on Make sure SPFH Quick Stop switch is turned off

Controller is setup to accept prescriptions. No controller prescription has been selected.

Prescription rate is out of controller range.

Out of eld prescription rate is now being applied.

Loss of GPS signal has occurred. Loss of GPS prescription rate is now being applied.

Controller does not support selected prescription.

INFO

CF86321,0000333 -19-23MAY11-2/2

why AutoTrac deactivated. Messages are also displayed

as to why AutoTrac did not activate. The deactivation

messages display for 3 seconds and then disappear.

AutoTrac Deactivation Message

Vehicle speed is below minimum required speed

Vehicle speed is above maximum allowed speed

Check display settings

Check guidance settings and Track 0 setup

No AutoTrac Activation on GS2

Vehicle is at an angle greater than 45 degrees from track

Hydraulic oil not above minimum required temperature

See John Deere dealer.

In reverse gear for more than 45 seconds

Maximum curvature has been exceeded

See John Deere dealer

See John Deere dealer

CF86321,0000334 -19-23MAY11-1/1

35-4

090811

PN=47

Page 48

Diagnostic Addresses

Troubleshooting—GS2 Display 1800

Diagnostic Addresses

NOTE: Diagnostic addresses are available to access

specic diagnostic information. This information

can assist the John Deere Dealer in diagnosing

problems. Different device controllers can be

selected from drop-down box, as shown.

Select DIAGNOSTIC ADDRESSES button. The

number of devices available will depend upon machine

conguration. The list of addresses can be scrolled up or

down with rotary thumb wheel. Selecting an address will

show data for that address.

Address Number Address Name

008

009

010 Unit Internal Temperature

011

012

013

015

016

017

018

019

020

021

022

023

024

025 External Analog Input Voltage

026

028

029

030

031

032

033

038

039 Daytime Luminance

040 Daytime Luminance Balance Ratio

041 Nighttime Luminance

042 Nighttime Luminance Balance Ratio